Page 1

User’s

Manual

Model SIND (Style R)

Integrator

IM 01B04M01-02E

IM 01B04M01-02E

9th Edition

Page 2

Page 3

Model SIND (Style R)

Integrator

Contents

1. INTRODUCTION........................................................................................... 1-1

1.1 Inspection.................................................................................................................1-2

1.2 Documentation Conventions.................................................................................. 1-3

1.3 Notice........................................................................................................................1-3

1.4 About Compatibility with the Conventional Model (Style A)............................... 1-5

2. GENERAL..................................................................................................... 2-1

2.1 Standard Specifications..........................................................................................2-2

2.2 Model and Suffix Codes.......................................................................................... 2-3

2.3 Accessory................................................................................................................. 2-3

3. INSTALLATION............................................................................................ 3-1

3.1 External Wiring......................................................................................................... 3-1

3.2 Connecting the SICD Counter................................................................................ 3-2

3.3 Connector a Third-party Counter...........................................................................3-3

3.3.1 Attaching an external power supply........................................................ 3-3

3.3.2 Transistor input electronic counter..........................................................3-4

4. PRINCIPLES OF OPERATION..................................................................... 4-1

4.1 Principle of Operation ............................................................................................. 4-1

5. SETTING....................................................................................................... 5-1

5.1 Names of Components............................................................................................ 5-2

5.2 Setting Jumper......................................................................................................... 5-3

5.2.1 Check of Setting Jumper and Location................................................... 5-3

5.3 Setting of Parameters.............................................................................................. 5-4

5.3.1 Parameter Change Disable Function......................................................5-4

5.3.2 Setting Parameters Using Display Setter (SIND-x04)............................. 5-4

5.3.3 Setting Parameters Using Handy Terminal............................................. 5-8

5.4 Parameter List..........................................................................................................5-9

6. MAINTENANCE............................................................................................ 6-1

6.1 Test Equipments......................................................................................................6-1

6.2 Check of I/O.............................................................................................................. 6-1

6.2.1 Wiring ......................................................................................................6-2

6.2.2 Checking procedure................................................................................ 6-2

6.3 Replacement of Fuse............................................................................................... 6-3

6.4 Replacement of Capacitor ...................................................................................... 6-3

7. TROUBLESHOOTING.................................................................................. 7-1

7.1 Troubleshooting Flowchart .................................................................................... 7-1

7.2 Action in Fault Condition........................................................................................ 7-2

7.3 Replacement of Parts.............................................................................................. 7-3

7.3.1 Replacement Procedure ......................................................................... 7-3

7.3.2 Replacement of Power Supply Unit ........................................................7-4

7.3.3 Replacement of Main Board.................................................................... 7-4

7.3.4 Replacement of Display (SIND-x04 only) ...............................................7-4

Toc-1

IM 01B04M01-02E 9th Edition

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 4

Toc-2

Appendix /TB Power Supply Terminal Connections (Option) ................App.-1

Appendix-1 GENERAL............................................................................................ App.-1

Appendix-2 APPLICABLE INSTRUMENTS ........................................................... App.-1

Appendix-3 NAMES OF PARTS & POWER TERMINAL SYMBOLS .................... App.-1

Appendix-4 POWER SUPPLY AND GROUND WIRING........................................ App.-2

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 5

<Toc> <1. INTRODUCTION>

1. INTRODUCTION

This manual describes the functions and operations of the SIND Integrator.

Intended Readers

This manual is intended for personnel in charge of:

z Installation and wiring

z Instrumentation and setup of functions

z Operation and monitoring of the controller

z Maintenance of equipment

Related Documents

The following documents all relate to the SIND Integrator. Read them as necessary. The

codes enclosed in parentheses are the document numbers.

z Rack-Mounted Instruments (IM 1B4F2-01E)

Describes mounting and wiring for YS80 rack-mounted instruments.

z Model JHT200 Handy Terminal (IM JF81-02E)

Describes operation of JHT200.

z YEWSERIES 80 Installation Manual (TI 1B4A9-01E)

Describes the installation conditions of YS80 instruments.

1-1

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 6

<Toc> <1. INTRODUCTION>

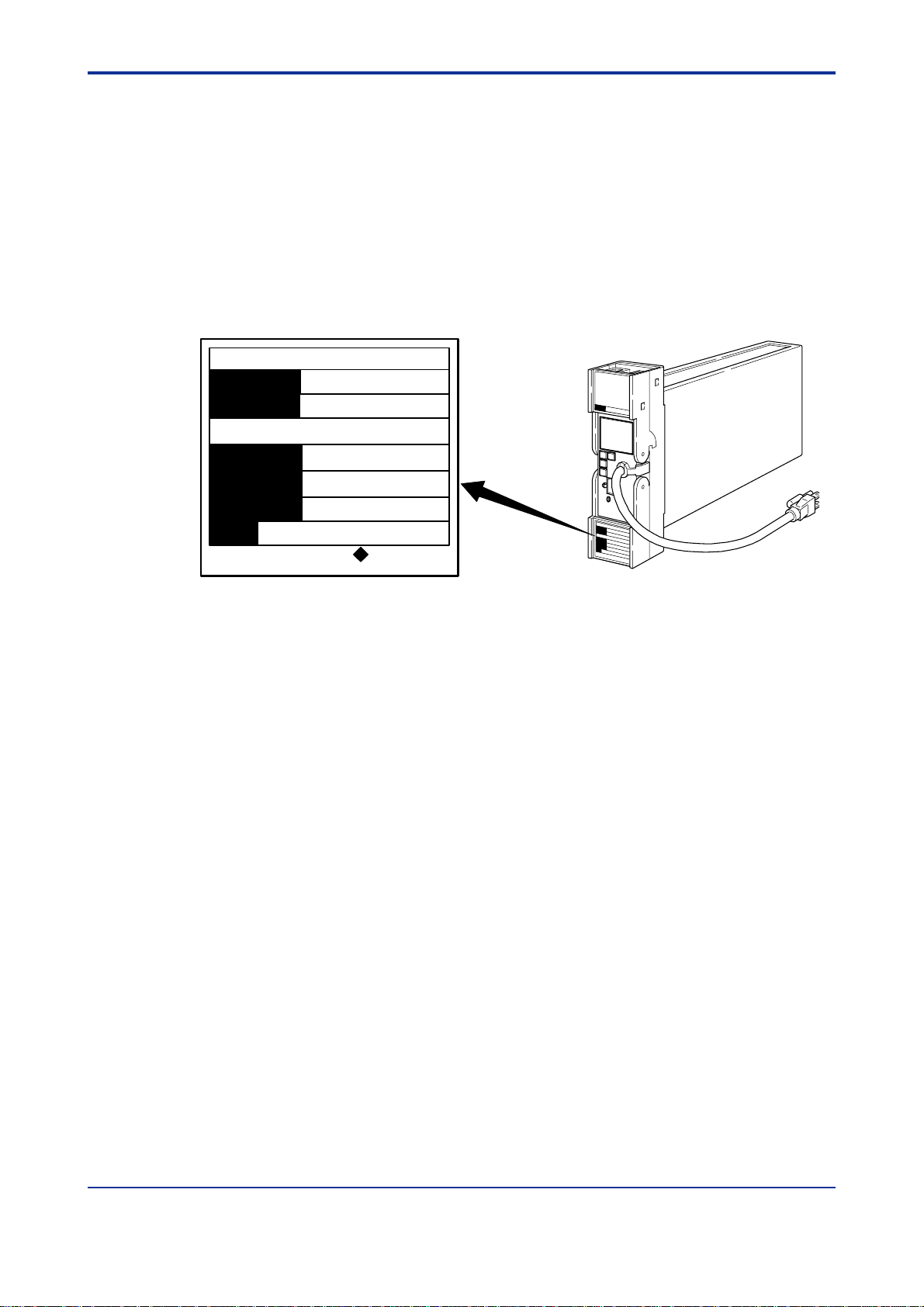

1.1 Inspection

The SIND integrator is shipped only after stringent inspection at the factory. Visually inspect the product upon delivery to make sure it is not damaged in any way.

Store the box and inner packing material of the package in a safe place / they may be

needed if there is a problem with the product and it needs to be sent back for repair.

Check of Model and Suffix Codes

The model and suffix codes are indicated on the Name plate attached to the front cover

of the instrument. Crosscheck this information with the model and suffix codes of Section 2.2 to ensure that the product is as specified in the order.

INTEGRATOR

MODEL

SUFFIX

SIND

-104*R

1-2

SUPPLY

INPUT

MODEL

80-138VAC 47-63 Hz

/20-130VDC 250mA AT 20VDC

1〜5 VDC

TypeK

NO.

YOKOGAWA

Yokogawa Electric Corporation

Figure 1-1 Name Plate

Confirmation of the Package Contents

Check the package contents against the list below. If anything is missing or damaged,

immediately contact the sales office from which you purchased the product or your

nearest Yokogawa representative.

z SIND Integrator............................................................................................... 1

z Integrating ratio label (Parts No.:L4040JA)..................................................... 1 sheet

z Fuse (Parts No.: S9510VK)............................................................................ 1

z User’s Manual (This manual).......................................................................... 1

Made in Korea

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 7

<Toc> <1. INTRODUCTION>

1.2 Documentation Conventions

This manual uses the following notational conventions.

Symbols

The following symbols are used in this manual.

WARNING

Indicates that operating the hardware or software in a particular manner may damage it

or result in a system failure.

NOTE

Draws attention to information that is essential for understanding the operation and/or

features of the product.

TIP

Gives additional information to complement the present topic and/or describes terms

specific to this document.

See Also

Gives reference locations for further information on the topic.

Description of Displays

Some of the representations of product displays shown in this manual may be exaggerated, simplified, or partially omitted for reasons of convenience when explaining them.

1-3

1.3 Notice

This User’s Manual

z This manual should be passed on to the end user. Keep at least one extra copy of

the manual in a safe place.

z Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

z This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that

these functions are suited to the particular purpose of the user.

z Under absolutely no circumstances may the contents of this manual, in part or in

whole, be transcribed or copied without permission.

z The contents of this manual are subject to change without prior notice.

z Every effort has been made to ensure accuracy in the preparation of this manual.

Should any errors or omissions come to your attention however, please contact your

nearest Yokogawa representative or sales office.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 8

<Toc> <1. INTRODUCTION>

Protection, Safety, and Prohibition against Unauthorized Modification

z In order to protect the product and the system controlled by it against damage and

ensure its safe use, make certain that all of the instructions and precautions relating

to safety contained in this document are strictly adhered to. Yokogawa does not

guarantee safety if products are not handled according to these instructions.

z The following safety symbols are used on the product and in this manual.

If this symbol is indicated on the product, the operator should refer to the explanation

given in the user’s manual in order to avoid personal injury or death to either themselves or other personnel, and/or damage to the instrument. The manual describes

that the operator should exercise special care to avoid shock or other dangers that

may result in injury or loss of life.

Protective ground terminal:

This symbol indicates that the terminal must be connected to ground prior to operating the equipment.

1-4

Function ground terminal:

This symbol indicates that the terminal must be connected to ground prior to operating the equipment.

AC voltage:

This symbol indicates that AC voltage is present.

DC voltage:

This symbol indicates that DC voltage is present.

z Do not turn off the power of the product during adjustment.

z Be sure to confirm the parameters referring to ''5.4 Parameter List'' before installing

the product in a system or plant. After confirming them, install the product in a system

or plant and turn on the power.

z If protection/safety circuits are to be used for the product or the system controlled by

it, they should be externally installed on the product.

z When you replace the parts or consumables of the product, only use those specified

by Yokogawa.

z Do not modify the product.

Force Majeure

z Yokogawa does not make any warranties regarding the product except those men-

tioned in the WARRANTY that is provided separately.

z Yokogawa assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 9

<Toc> <1. INTRODUCTION>

1-5

1.4 About Compatibility with the Conventional Model (Style A)

z The operation and function differ from the conventional model.

Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

z Be sure to confirm the parameters such as integrating ratio set point and setting

jumper referring to ''5. Setting'' before installing the product in a system or plant. After

confirming them, install the product in a system or plant and turn on the power.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 10

<Toc> <1. INTRODUCTION>

Blank Page

1-6

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 11

<Toc> <2. GENERAL>

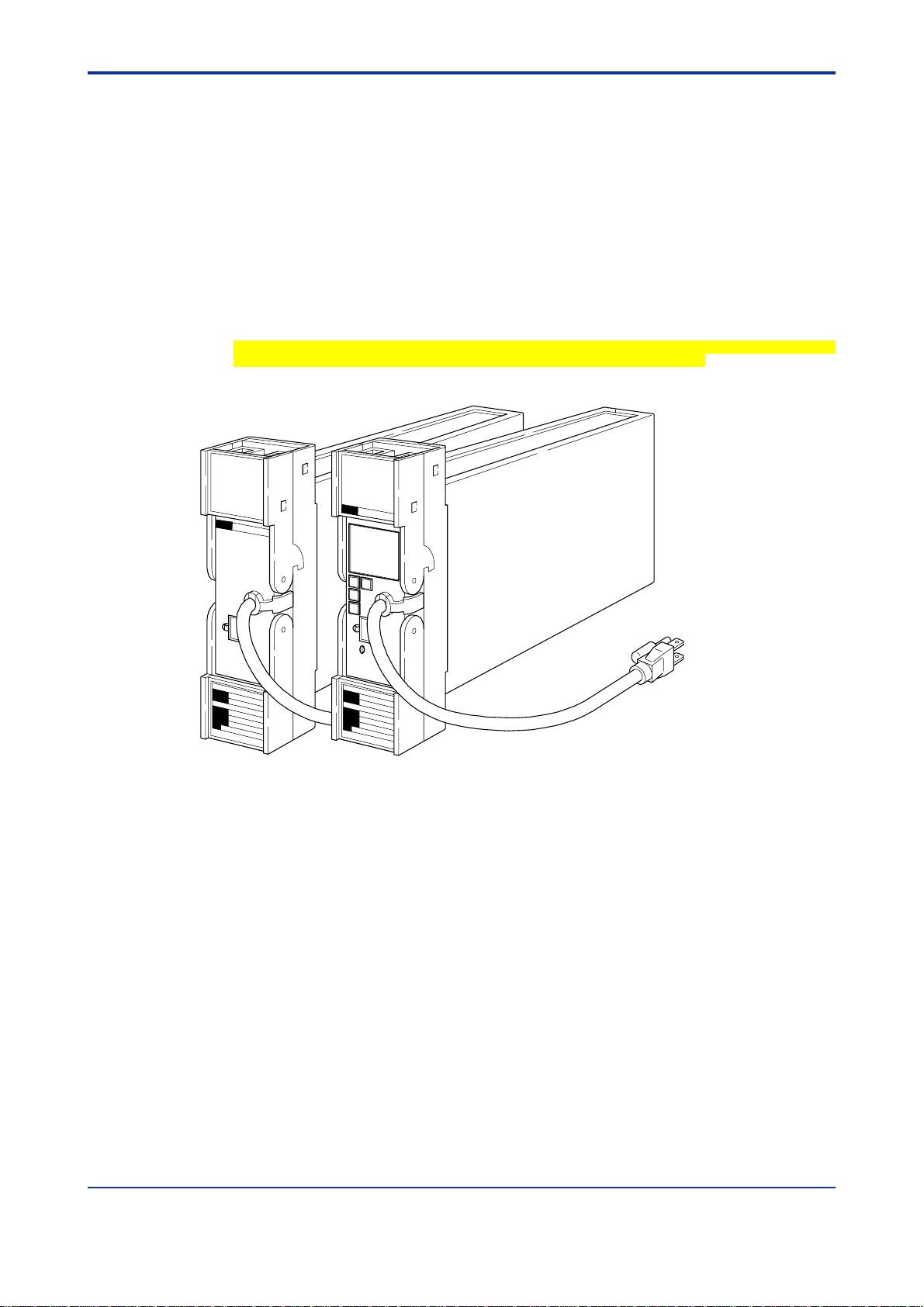

2. GENERAL

The SIND Integrator is a voltage-to-pulse converter that converts 1 to 5 V DC inputs to

corresponding pulse frequency output. It can be used with a YS80 series SICD counter

to totalize flow quantity.

Two integrating modes are available: proportional integration that directly totalizes the

input, and square root integration that totalizes square-root values.

The JHT200 Handy Terminal

On the SIND model with display setter (SIND-x04), input indication can be displayed and

integrating ratio and low input cut off can be displayed / set on the front panel.

*1: The modular jack conversion adapter (E9786WH) is required for connecting the JHT200 Handy Terminal to the

Integrator.

The 5 pin-connector type communication cable (F9182EE) and modular jack conversion adapter (E9786WH) is

required for connecting the BT200 BRAIN Terminal of YOKOGAWA ELECTRIC Corporation

(*1)

is used for setting the SIND parameters.

2-1

Figure 2-1 External View

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 12

<Toc> <2. GENERAL>

2.1 Standard Specifications

The following table shows the SIND standard specifications.

Table 2-1 Standard Specifications

Item Description

Input Signal 1 to 5 V DC Input resistance: 1MΩ 1 point

Output Signal SICD counter drive pulse (24 V DC) or transistor contact 2 points (*1)

• Pulse ON time: 30 ms or 60 ms (*1)

• Load: SICD counter drive pulse 150 mA or less

Transistor contact pulse 30 V DC 150 mA or less

Integrating Ratio (*2) 1 to 10,000 pph/full scale

Integration Method Proportional integration or square root integration

Low Input Cutoff (*2) Proportional integrating type: Cut-off point can be set within 0 to 10% of

input signal.

Square root integrating type: Cut-off point can be set within 0.3 to 10% of

input signal.

Accuracy ±0.5% of span (at output 10% or more on a square root integrating type)

Power Voltage

For both DC/AC

Current/Power

Consumption

Ambient Temperature

and Ambient Humidity

Mounting and Wiring Mounting: Indoor, rack mounting

Weight Approx. 1.7 kg (including rack and case)

*1: The time becomes 60 ms by shorting the A and C terminals. The number of outputs at this time is one.

*2: Can be set and changed on the JHT200 Handy Terminal.

On the SIND-x04, can be set and changed on the display setter.

100 V version: With DC drive, 20 to 130 V (no polarity)

With AC drive, 80 to 138 V, 47 to 63 Hz

220 V version: With DC drive, 120 to 340 V (no polarity)

With AC drive, 138 to 264 V, 47 to 63 Hz

Integrating ratio at 1000 pph: 100 mA at 24 V DC, 7.3 VA at 100 V AC,

10.2 VA at 220 V AC

Integrating ratio at 10000 pph: 190 mA at 24 V DC, 10.8 VA at 100 V AC,

13.7 VA at 220 V AC

0 to 50°C, 5 to 90%RH (non-condensing)

Signal connection: M4 screw terminal connection

Power supply connection: Power plug or M4 screw terminal connection

2-2

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 13

<Toc> <2. GENERAL>

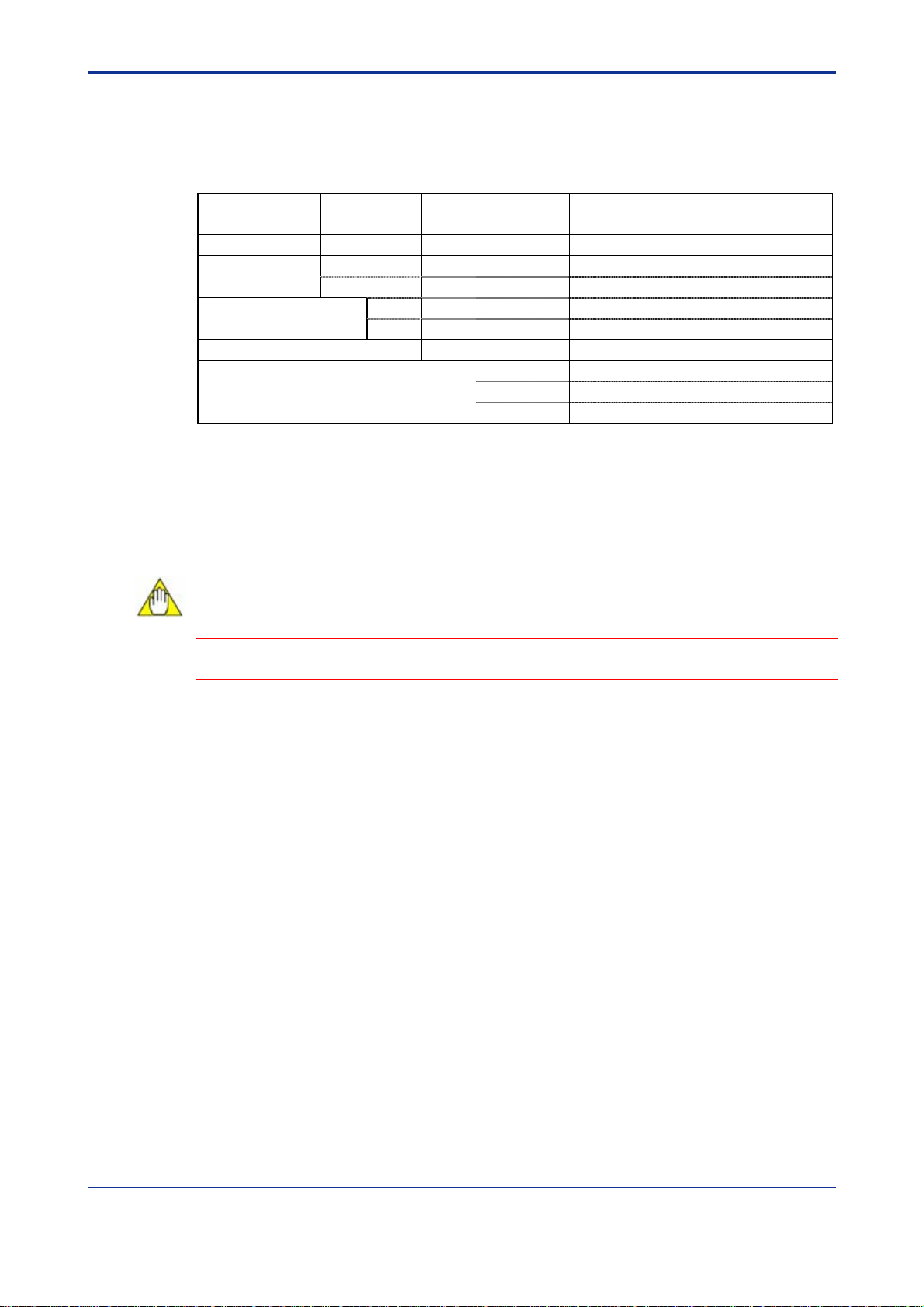

2.2 Model and Suffix Codes

The following table shows the SIND model and suffix codes.

Table 2-2 Model and Suffix Codes

Model Suffix Codes Sytle

SIND Integrator

-1 Not proviced (proportional output) Square-root

integration mode

Style Code *R Style R

Option

*1: When the square-root integration mode is provided, SIND is shipped as a square-root integrating model. This model

can be changed to a proportional output type using the JHT200 Handy Terminal.

-2 Provided (square-root output)

00 Not provided Display setter

04 Provided

Optional

Suffix Codes

/A2ER 220 V power supply

/NHR Without case

/TB Power supply terminal type

Description

2.3 Accessory

2-3

(*1)

Fuse 1 A: 1

Integrating ratio label: 1 sheet

NOTE

The fuse (S9510VK) is the dedicated fuse, Do not use it for other products.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 14

<Toc> <2. GENERAL>

Blank Page

2-4

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 15

<Toc> <3. INSTALLATION>

3. INSTALLATION

For details of the installation procedure and wiring precautions, refer to the

technical information “YEWSERIES 80 Installation Manual” (TI 1B4A9-01E) or the

instruction manual “Installation of Rack-Mounted Instruments” (IM 1B4F2-01E).

3.1 External Wiring

(a) All cable ends must furnished with crimp-on type solderless lugs (for 4mm screws).

(b) Draw out the internal unit from the rack case.

(c) Connect the cables to the correct terminals referring to Figure 3-1.

(d) Return the internal unit into the rack case after completing the wiring.

(e) Always return the terminal block cover to its original position after completing the

wiring.

NOTE

• Contacts have positive/negative minus polarity. Take care not to confuse the

polarity when wiring.

• Connect a surge absorber (protective diode, CR circuit, etc.) in parallel to the load.

• Do not connect loads exceeding the rated load.

• The terminal block cover cannot be returned to its original position if the internal

unit is not installed correctly inside the rack case.

Securely return the terminal block cover because it also functions as lock for the

internal unit.

3-1

J K

B

A

Front view

may differ

according to

device.

1

2

C

H

D

F

5

3

4

6

7 8

*1: Pulse signals can also be used to drive an electromagnetic counter of rating (24 V DC, 150mA or less).

*2: Transistor contact output can be used to provide a pulse output signal to a computer or used to drive another

counter when combined with an external power supply

*3 If a pulse ON time of 60 ms is required, short terminals A and C. This generates a pulse signal having an ON time of

60 ms across the A/C and F terminals and across the A/C and B terminals.

*4: When a counter other than SICD is used, connect a surge voltage protective diode in parallel with the counter coil.

Figure 3-1 Terminal Layout and Terminal Wiring

Terminal

Designation

A - SICD drive+Transistor contact-1

B pulse-1 (*1, 3) COM (*2, 3)

C - SICD drive + Transistor contact-2

D pulse-2 (*1, 3) (*2, 3)

F +

H

J

K

1 +

2 3

4

5

6

7

8

Input (1 to 5 V DC)

Description

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 16

<Toc> <3. INSTALLATION>

3.2 Connecting the SICD Counter

Up to two SICD counters can be connected. (See Figure 3-2.) If the input pulse

specifications are the same as the SICD, a third-party electromagnetic counter (24 V DC,

150 mA or less) can also be connected. When a counter other than a SICD is used,

connect a diode in parallel with the counter coil to prevent surge voltage.

SIND integrator

3-2

24VD C

Q2

Q1

F

A

C

B

1

2

SICD

counter

1

2

counter

F

A

Short across

terminals A

SICD

C

Wiring for outputting a

pulse of width 60 ms

and C.

1

2

SICD

counter

Figure 3-2 Connecting the SICD Counter

If a pulse ON time of 60 ms is required, short terminals A and C. This generates a pulse

signal having an ON time of 60 ms across the A/C and F terminals (see Figure 3-2) and

across the A/C and B terminals (see Figures 3-4 and 3-5).

The number of pulse outputs becomes one when the A and C terminals are shorted.

No.1 integrating pulse output

Pulse width=30 ms

No.2 integrating pulse output

Pulse width=30 ms

Combined integrating pulse output

Pulse width=60 ms

Figure 3-3 SIND Pulse Output

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 17

<Toc> <3. INSTALLATION>

3.3 Connecting a Third-party Counter

A third-party counter can be driven by an external power supply, and pulse signals can

be generated for output to a computer, for example.

3.3.1 Attaching an External Power Supply

Specifications of connectable counter

Applied voltage: 30 V DC or less

Minimum pulse ON/OFF time: 30 ms(*) each or less

*: Long response time (60 ms or less) counters can also be connected by shorting the A and C terminals.

When a counter other than a SICD is used, connect a diode in parallel with the counter

coil to prevent surge voltage.

SIND integrator

3-3

24VD C

Q1

Q2

F

A

C

B

Counter

Figure 3-4 Connecting a Counter

30V DC

200 mA

Counter

30V DC

200 m A

A

C

Short across A

and C terminals.

B

Wiring for outputting a pulse of

width 60 ms

Counter

30V DC

200 mA

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 18

<Toc> <3. INSTALLATION>

3.3.2 Transistor input electronic counter

Electronic counters that take the open collector contact of a transistor input as their input

also can be connected. (See Figure 3-5.) The number of counters that can be connected

and the specifications are the same as those indicated at 3.3.1.

SIND integrator

3-4

24VDC

Q1

Q2

Figure 3-5 Connecting a Third-party Counter

Applicable Cables

(1) Signal circuit wiring

• Cross-sectional area of the cable conductor: 0.5 to 1.25 mm

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires

PVC insulated cable for electrical apparatus

Heat-resistant vinyl-insulated cable (UL style

(2) Power supply wiring

• Cross-sectional area of the cable conductor: 1.25 to 2.00 mm

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires

F

A

C

B

Counter

Counter

A

C

Short across A

and C terminals.

B

Wiring for outputting a pulse of

width 60 ms

Counter

2

(JIS C 3307);

(KIV) stranded wires (JIS C 3316);

1007)

2

(JIS C 3307)

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 19

<Toc> <4. PRINCIPLES OF OPERATION>

4. PRINCIPLES OF OPERATION

4.1 Principle of Operation

Input signals are converted to digital data by the A/D conversion circuit after passing

through the input processing circuit. The resulting digital data is processed (square root

calculation, input scaling, integrating pulse calculation, etc.) by the microcomputer, and

turns the output transistor N/OFF by the pulse output circuit.

4-1

1

Handy

Terminal

Input

processing

circuit

2

Display setter (*1)

*1: SIND-x04 only

SET

A/D

conversion

circuit

Figure 4-1 Hardware Function Block Diagram

Input signal

Micro-

computer

24V DC

output 1

Pulse

output 2

Power

supply

circuit

Pulse

A

B

C

F

L+

Power supply

N−

GND

A/D conversion

INPUT1

Square root

calculation (*1)

*1: SIND-2xx only

Low input cutoff

processing

Scaling (*1)

LOW CUT1

SCH1

SCL1

DP1

PV1

Integrating pulse

calculation

Relay output 1 Relay output 2

INTEG.R

Figure 4-2 Software Function Block Diagram

The alphabet symbols in the figure are the names of parameters displayed on the Handy

Terminal.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 20

<Toc> <4. PRINCIPLES OF OPERATION>

Input signals undergo A/D conversion and compensation before being converted to data

at INPUT1.

On the SIND-20x, input signals also undergo square root calculation.

The low input cutoff function is provided for both square root calculation and proportional

calculation (w/out square root calculation). When the input signal is at the low-cut point

(LOW CUT1) or less, output of this function is 0%.

Hysteresis of the low-cut point is equivalent to 0.2% input.

Proportional calculation (SIND-10x)

Output

Square root calculation (SIND-20x)

Output

4-2

Low-cut point (LOW CUT1)

Figure 4-3 Low-cut Point

Input

Low-cut point (LOW CUT1)

Input

z Scaling (SCH1, SCL1, DP1):

Set three parameters (SCH1, SCL1, DP1) for displaying the signal after input calculation

processing in engineering units on the display setter.

Decimal Point Position (DP1) This is the decimal point position. At default "####.#",

one digit past the decimal point is displayed.

Input Scale L (SCL1) This is the value indicated when the input signal is 0%.

(default: 0.0)

Input Scale H (SCH1) This is the value indicated when the input signal is

100%. (default: 100.0)

For example, to display input signals 1 to 5 V as 0.00 to 30.00 (kl/h), set as follows:

DP1=”###.##”, SCH1=30.00, SCL1=0.00

NOTE

Reverse scaling (SCH1 < SCL1) is also possible.

A setting error occurs when SCH1 is set to equal SCL1.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 21

<Toc> <4. PRINCIPLES OF OPERATION>

z Integrating pulse calculation (INTEG.R):

Converts signals that have undergone input calculation processing (square root

calculation, input low cut processing) to an integrating pulse.

The integrating ratio (1 to 10000 pulses/hour) can be specified.

The number of pulses per unit hour at 100% input (continuous) are displayed as the

integrating ratio.

3750 pulses/hour are output when the integrating ratio is set to "5000" and input is 75%

(input=4 V DC).

NOTE

The integrating calculation function does not work for 3 seconds after power ON.

4-3

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 22

Blank Page

Page 23

<Toc> <5. SETTING>

5. SETTING

Items to Confirm before Start of Operation

Before you start operation, inspect and confirm the following items:

(1) Draw out the internal unit from the rack case, and make sure that the specified fuses

are properly mounted in the fuse holders at the rear of the internal unit.

(2) When inserting the internal unit into the rack case, firmly connect the multi-pin

connectors for connecting the internal unit and the case.

(3) Make sure that power plugs are properly connected to the power outlet.

(4) Make sure that external wiring to the terminal block is properly connected.

5-1

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 24

<Toc> <5. SETTING>

5.1 Names of Components

The following shows the names of SIND components.

Integrating ratio indicator lamp (PPH)

AL M S P

1

2

PPH LCT

Low input cutoff indicator lamp (LCT)

Display setter

Data digit feed key

Parameter selection key

5-2

Tag plate

BRAIN connector

(w / cover)

Key setting enable switch

(ENBL switch)

Name plate

SIN D- 00

x

SIN D - 04

x

Output terminal block

SET

Main board

Terminal block cover/handle for

drawing out internal unit

Data change key

SET

Data setting fix key

Rack case

Input terminal block

Multi-pin connector

Power plug

Figure 5-1 Names of Components

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 25

<Toc> <5. SETTING>

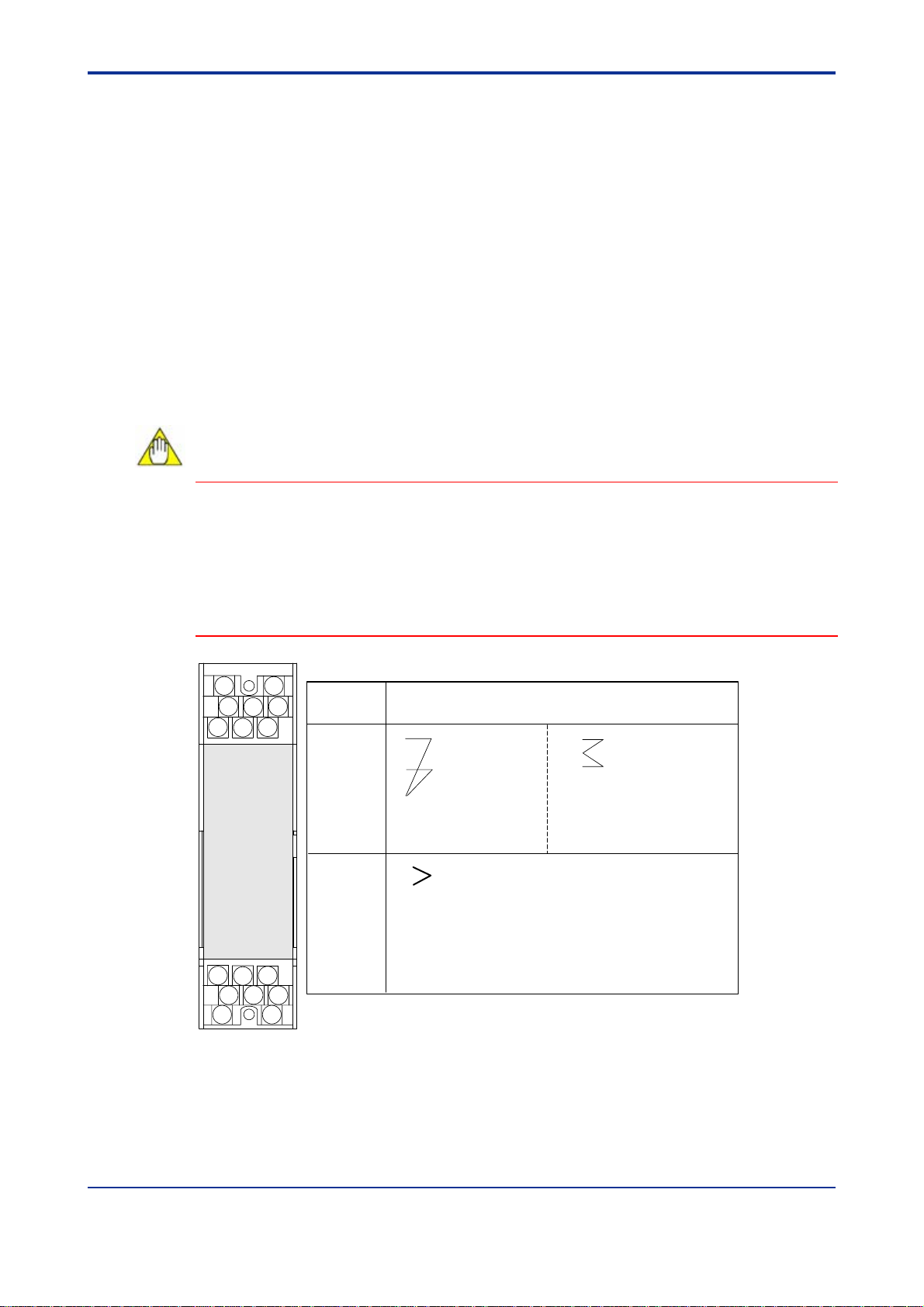

5.2 Setting Jumper

SIND is provided with a Parameter Write Protect (W.P.) jumper.

When this jumper is set to ON, changing of parameters by the key switches and Handy

Terminal is disabled. “LOC” will be displayed on the display setter if the “” switch is

pressed with the PPH or LCT parameter displayed on the display setter. To cancel the

“LOC” display and return to the previous display, press any key.

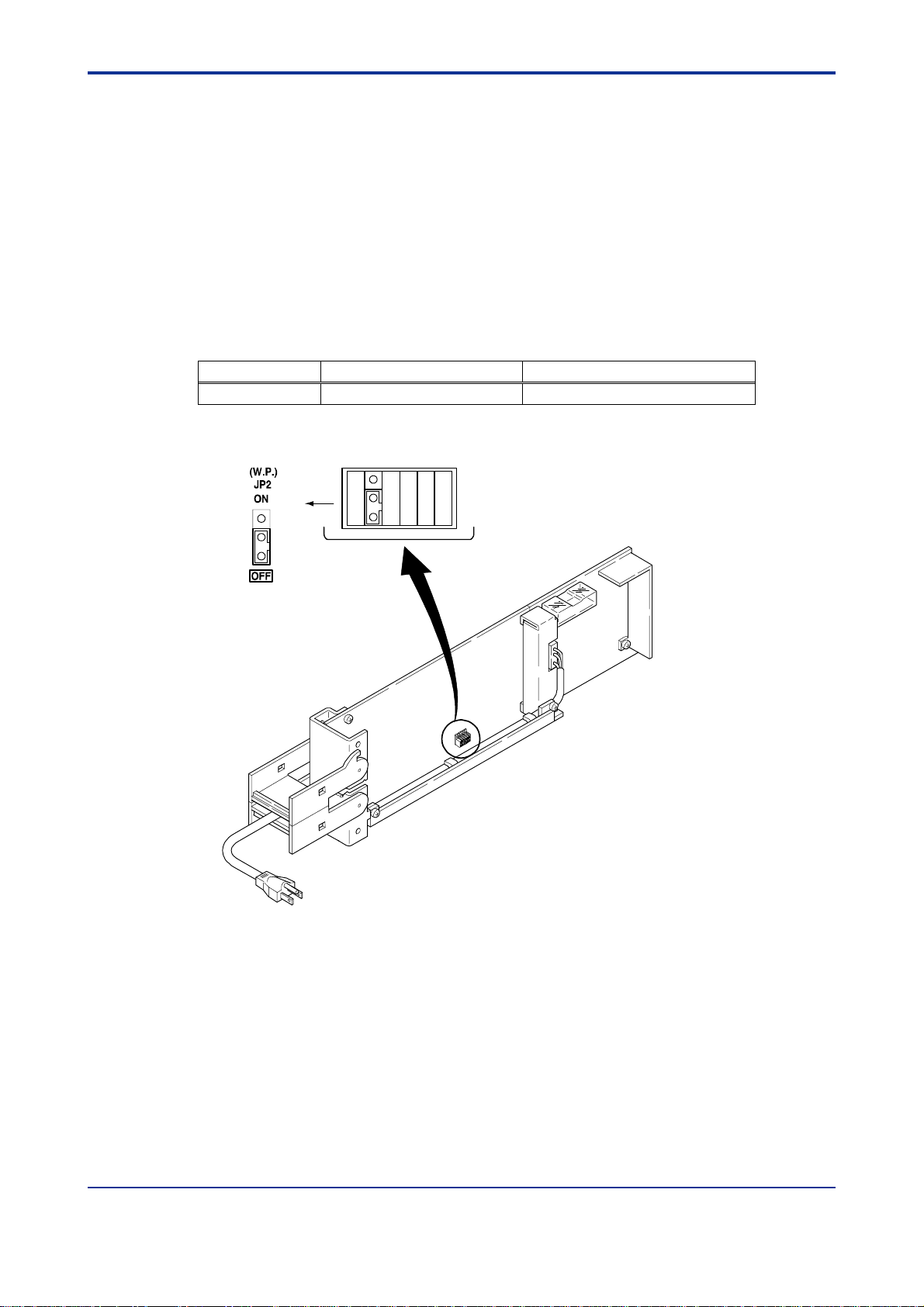

5.2.1 Check of Setting Jumper and Location

The Parameter Write Protect jumper is located on the main board of the internal unit.

Draw out the internal unit, and check the current jumper settings. Current jumper

settings can also be checked on the JHT200 Handy Terminal.

Jumper Code Jumper Name Parameter Name

W.P. Parameter Write Protect

Parameter

Write Protect

Setting jumper (factory-set default)

A55:WRT PROTECT

5-3

ON disables changing

of parameters.

Figure 5-2 Parameter Write Protect Jumper

Change of Setting Jumper

Follow the procedure below to change the setting jumpers:

(a) Pull the terminal block cover toward you to draw out the internal unit from the rack

case.

(b) Check the jumpers on the main board of the internal unit, and change their settings

as desired. Use tweezers or another fine-tipped object to change the setting jumpers.

(c) Return the internal unit to the rack case.

(d) Return the terminal block cover to its original position.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 26

<Toc> <5. SETTING>

5.3 Setting of Parameters

5-4

This instrument has BRAIN communication parameters for specifying functions and

adjusting input. Connect JHT200 Handy Terminal

(*1)

to the instrument to display or set

parameters (modular jack conversion adapter (E9786WH) is required )

On the SIND model with display setter (SIND-x04), input indication can be displayed,

and integrating ratio and low input cutoff can be set / displayed and changed on the

display setter.

For details on parameters, refer to the Parameter List.

*1: BT200 BRAIN Terminal of YOKOGAWA ELECTRIC Corporation can also be used.

5.3.1 Parameter Change Disable Function

The SIND is provided with a parameter change disable function for preventing

parameter settings from being changed by operator error.

Table 5-1 Parameter Change Disable Function

Disable Setting Method Disable Cancel

Method

Parameter Write

Protect jumper

Enable switch

(SIND-x04 only)

Set W.P. jumper on main board to

"ON".

Changes cannot be made if no

settings are made for 30 minutes after

operating any key switch on the front

panel in a setting change enable

state.

Set W.P.

jumper on main

board to

"OFF".

Press the

Enable switch.

Description of Disable Operation

y Changing of parameter setting

by key switches.

y Changing of parameter setting

by Handy Terminal.

y Changing of parameter setting

by key switches.

5.3.2 Setting of Parameters Using Display Setter (SIND-x04)

On the SIND-x04, you can set change only the integrating ratio and using the display

setter on the front panel.

Other parameters are changed using the JHT200 Handy Terminal.

The table below describes the relationship between key switch operations and migration

of display states.

Table 5-2 Relationship between Key Switch Operations and Migration of Display States

Key

Cancels the newly

changed values, returns

to the display mode, and

displays the next

parameter.

Returns to the setting

change mode, and

moves to the next digit.

Fixes the set point, and

advances to the display

mode.

This mode is

entered if no key

switches are

operated for 30

minutes when the

display mode

parameter is set to

"OFF".

The display mode is

returned to if any

key switch is

pressed in the

indicator out mode.

Switch

Display Mode Setting Change Mode Setting Fix Mode Indicator Out Mode

△

→

↑

SET No operation

ENBL

Displays the next

parameter.

Advances to the setting

change mode when a

settable or changeable

parameter is displayed in

the setting change enabled

state.

Displays the next

parameter.

Enters setting change enable state.

Enable switch is disabled if the Parameter Write Protect jumper is set to "ON".

*1: When the Parameter Write Protect jumper on the main board is set to "ON", the SIND will not advance to the setting

(* 1)

change mode. In this state, "LOC" is displayed on the display setter.

Display Function

Cancels the newly

changed values,

returns to the display

mode, and displays

the next parameter.

Moves setting digit.

Changes the set point. No operation

Advances to setting fix

mode.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 27

<Toc> <5. SETTING>

Indicator out mode is

entered if no key switch is

operated for 30 minutes

when display mode

parameter is "OFF".

Indicator out mode Display mode

Display mode is returned to

when any key switch is

pressed.

Cancels new set point,

returns to display mode,

and displays next

parameter.

Setting fix mode Setting change mode

(all digits flashing)

△

SET

Fixes set point, and moves

to display mode.

Moves to setting fix

mode.

Returns to setting change

→

mode, and moves to next digit.

↑

Displays previous parameter.

△

Displays next parameter.

→

Moves to setting

change mode.

SET

△

(1digitflashing)

→

Feeds digit.

↑

Increments value.

Cancels new set point,

returns to display mode,

and displays next

parameter.

Figure 5-3 Key Switch Operations and Migration of Display States

5-5

Switching the Display

Each press of the △ key switches the display data.

Power on

Input value (PV1) is

displayed.

PPH/LCT lamps out

In this example,

"400.00 (m

Figure 5-4 Progression of Display Screen

PPH

Press △

key.

3

/h)"

LCT

PPH

LCT

Press △

key.

Integrating ratio set point

(PPH) is displayed.

PPH lamp lit

In this example, "5000

pulses/hour"

PPH

LCT

Press △

key.

Low-cut point (LCT) is

displayed.

LCT lamp lit

In this example, "3.0%"

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 28

<Toc> <5. SETTING>

Setting Parameters

Display the desired parameter (integrating ratio or low-cut point), and follow the

procedure below to change its setting.

AL M SP

1

2

PPH LCT

(1) Input value (60.00) is dis played at power ON.

SET

AL M SP

1

2

SET

Press the key.

PPH LCT

(2) The integrating ratio (8000) is displayed.

Press the key.

→ The PPH lamp lights, and the integrating rat io is

displayed.

The LCT lamp lights, and the low-cut point is displayed.

→

AL M S P

1

2 PPH LCT

The low-cut point (3.00) is

displayed.

5-6

(3)Press the ENBL switch to enter setting change enable state.

(4)Set the integrating ratio. (Change the integrating ratio to "7000" from

"8000".) Make sure that the PPH lamp is lit.

Press the key.

Press the key.

Press the key.

Figure 5-5 Setting Parameters

NOTE

SET

The uppermost digit on the display f lashes.

Hold down the key to move the flashing

→

section to the digit on the right.

→

This increments the value at the flashing digit.

Hold down the key to feed the value to "7".

All parameter digits flash.

→

Pressing the SET key again causes "7000" to light.

(This fixes the new parameter settings.)

When the Parameter Write Protect jumper on the main board is set to "ON", the SIND

will not advance to the setting change mode. In this state, "LOC" is displayed on the

display setter.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 29

<Toc> <5. SETTING>

Display at Power ON

The model with display setter displays REV NO. (revision number of software for SIND

for about 3 seconds after power ON.

Example of display (REV NO.2)

LOC Display

When "LOC" is displayed, this indicates that parameter settings cannot be changed.

(The Parameter Write Protect jumper on the main board is set to "ON".)

To cancel the "LOC" display and return to the previous display, press any key.

Indicator Out Mode Display

In this mode, only the decimal point is displayed on the display setter.

When the display mode parameter (DSP MODE) is set to "OFF", and no key operation is

performed for 30 minutes, the SIND moves to the indicator out mode.

To cancel this mode and return to the display mode, press any key switch.

I/O signal processing and calculations are performed as usual even in the indicator out

mode.

If the self check discovers an error (A/D conversion error, EEPROM error,

EEPROMSUM error) in the indicator out mode, this mode is canceled, and the error is

displayed. Also, the SIND does not move to the indicator out mode when an error (A/D

conversion error, EEPROM error, EEPROMSUM error) occurs.

5-7

PPH

LCT

Moves to indicator out

mode if no key is

Indicator out mode

Only decimal point is lit.

Figure 5-6 Indicator Out Mode

operated for 30

minutes.

Press any key.

PPH LCT

Normal operation mode

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 30

<Toc> <5. SETTING>

5.3.3 Setting Parameters Using Handy Terminal

NOTE

For details of operation and adjusting procedures of JHT200 Handy Terminal, refer to

the instruction manual “JHT200 Handy Terminal” (IM JF81-02E).

5-8

<Connection>

JHT200

Handy Terminal

Figure 5-7 Connecting the Handy Terminal

Cable of 5-pin

connector type

(F9182EE))

BRAIN

connector

Modular jack conversion

adapter (E9786WH)

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 31

<Toc> <5. SETTING>

5.4 Parameter List

BRAIN communication parameters for SIND are as follows.

On the SIND-x04, only the input value can be displayed, and integrating ratio and low-

cut point can be displayed and set on the display setter on the front panel. Other,

parameters are displayed and set using the Handy Terminal.

No. Parameter Name Symbol Description Display

01 Model Name MODEL Displays the model name.

02 Tag Number TAG NO

03 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

A Display 1 DISPLAY1

A01 Analog Input 1 INPUT1 Input value before input processing (square root or scaling)

A03 PV1 PV1 Input value (engineering unit) after input processing (square

A54 Status Display STATUS Displays the value added to the value (Hex) indicating the

A55 Parameter Write

Protect

A56 Rev No. REV NO. Displays the device software revision No.

A58 MENU REV MENU REV Displays the revision No. of the parameter groups displayed

A60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

B Display 2 DISPLAY2

B01 Analog Input 1

B03 PV1

B60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

WRT PROTECT Displays the state of the Parameter Write Protect jumper.

Same as A01 and A03, respectively. Note, however, that display values are

updated periodically.

Displays the tag number that is set.

(unit: V)

root or scaling)

self check result.

0000: Normal

0001: EEPROM error

0002: EEPROMSUM error

0004: Low input cut state

0008: Input range exceeded

0010: Setting error

0040: Power interruption during operation

1000: A/D conversion error

OFF: Setting of parameters enabled

ON: Setting of parameters disabled

on the Handy Terminal.

5-9

Conditions

Displayed on all

Displayed on all

Displayed on all

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 32

<Toc> <5. SETTING>

No. Parameter Name Symbol Description Setting Range Default

D Setting

Parameters (I/O)

D01 Tag Number 1 TAG NO.1 8 alphanumerics can be entered.

D02 Tag Number 2 TAG NO.2 8 alphanumerics can be entered.

D03 Comment 1 COMMENT1 8 alphanumerics can be entered.

D04 Comment 2 COMMENT2 8 alphanumerics can be entered.

D17 Input 2 Square

Root Linearization

D19 Low Cut LOW CUT1 Specifies low-cut point during

D40 Decimal Point

Position

D41 Input Scale L SCL1 Display value at 0% input value -9999 to 9999

D42 Input Scale H SCH1 Display value at 100% input value -9999 to 9999

D50 Integrating Ratio INTEG.R Sets the number of output pulses per

D51 Display Mode DSP MODE Selects the display state after 30

D60 Self Check

*:Initialized when LINEARIZE1 is changed.

SET(I/O)

LINEARIZE1 Specifies square root calculation

ON/OFF.

integration of input 1.

(*)

DP1 Sets the position of the decimal point for

the input scale (SCH1, SCL1).

hour.

minutes without key operation has

elapsed.

OFF: Only the decimal point is displayed

(indicator OUT mode)

ON: Regular data display

SELF CHK Displays the result (GOOD/ERROR) of

the self check.

OFF

SQR

Proportion:

0.0 to 10.0%

Square root: 0.3

to 10.0%

#####.

####.#

###.##

##.###

(engineering unit)

(engineering unit)

1 to 10000 pph 9990

OFF

ON

Displayed on

OFF Displayed on

Proportion:

0.0

Square root:

1.0

####.#

0.0

100.0

ON Displayed on

No. Parameter Name Symbol Description Setting Range Default

P Adjustment

Parameters

P03 Zero Adjustment

(Input 1)

P04 Span Adjustment

(Input 1)

P60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the

Q Test Parameters TEST

Q08 Output 1 Forced

Output

Q60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

ADJUST

ZERO ADJ1 Performs zero adjustment (0% side) on input 1.

n.nnn V RST

n.nnn V INC

n.nnn V HINC

n.nnn V HDEC

n.nnn V DEC

n.nnn indicates the current input value.

Increase or decrease “n.nnn” until the target value is reached.

INC/DEC : Increase/decrease “n.nnn.”

HINC/HDEC : Increase/decrease “n.nnn” more rapidly than INC/DEC.

RST : When a reset is made, the adjustment values return to their factory

settings.

SPAN ADJ1 Performs span adjustment (100% side) on

input 1.

The adjustment method is the same as ZERO

ADJ1.

self check.

OUT1 TEST Forcibly outputs the pulse of the preset value

regardless of the input signal.

Pressing the OK key cancels forced output.

0.0 to 125.0

5-10

Display

Conditions

Displayed on

all

SIND-2xx

Displayed on

all

SIND-x04

all

Display

Conditions

Displayed on

all

Displayed on

all

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 33

<Toc> <6. MAINTENANCE>

6. MAINTENANCE

This chapter describes the simple maintenance procedures and fuse

replacements that can be done in the instrument room or service shop.

6.1 Test Equipments

For efficient maintenance of this integrator, it is recommended that the user have the

following test equipment manufactured by Yokogawa or their equivalent.

Device Model Name Number of Units Remarks

DC voltage/current Standard 7651 1

Counter YS80 SICD 1

Handy Terminal JHT200 (BT200) 1

Modular jack conversion adapter Part No. E9786WH 1

6.2 Check of I/O

The JHT200 Handy Terminal is required for checking I/O.

6-1

NOTE

• For details of operation and adjusting procedures of JHT200 Handy Terminal, refer

to the instruction manual ‘‘JHT200 Handy Terminal’’ (IM JF81-02E).

• Do not turn off the power of the instrument during adjustment.

<Connection>

JHT200

Handy Terminal

Figure 6-1 Connecting the Handy Terminal

Cable of 5-pin

connector type

(F9182EE))

BRAIN

connector

Modular jack conversion

adapter (E9786WH)

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 34

<Toc> <6. MAINTENANCE>

6.2.1 Wiring

(a) Set the Parameter Write Protect (W.P.) jumper to "OFF".

(b) Connect each device referring to Figure 6-2 below.

(c) Turn on SIND with a devices connected, and allow 5 minutes for the system to warm

up.

JK

H

DB

001234

SICD Counter

2

1

F

CA

6-2

Voltage/Current

Standard

YOKOGAWA Type 7651

or equivalent

Figure 6-2 Wiring Diagram

+

−

531

246

87

6.2.2 Checking Procedure

(a) Set the integrating ratio (PPH) on the SIND integrator to 9000 pph.

(b) Apply a voltage of 0 V DC to the input, and reset the integration value on the SICD

counter.

(c) Apply the input signal in a stepped manner for 400 seconds while monitoring the

time, and integrate to 5 V DC.

(d) Make sure that the integration value on the SICD counter after 400 seconds is 995

or more or 1005 or less.

(e) If the integration value exceeds these permissible errors, call up and adjust

parameters P03 and P04 (Input 1 Zero and Span Adjustments) so that the

integration value on the SICD counter is within these errors.

Power

Supply

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 35

<Toc> <6. MAINTENANCE>

6.3 Replacement of Fuse

When the fuse has blown or requires replacement, replace it according to the following

procedure. Recommended replacement interval: About 3 years.

Before replacing a fuse, turn off the power to the instrument.

NOTE

• When a fuse has blown, check for the cause first because a fuse itself may not be

responsible for the problem. Then replace the fuse.

• Use the dedicated fuse (S9510VK). Do not use a fuse for other products.

(a) Remove the fuse holder cap, then pull the fuse out in the direction shown in Figure

6-3.

(b) When installing a new fuse, use a fuse with the correct rating. Fasten the cap

securely.

6-3

Figure 6-3 Replacement of Fuse

6.4 Replacement of Capacitor

Degradation of the aluminum electrolytic capacitor used in the power supply unit

depends on operating temperature condition or operating environment.

Recommended replacement interval: 5 to 10 years.

NOTE

• Ask your nearest Yokogawa sales staff to replace the capacitor.

• Do not replace the capacitor by yourself, because the parts number of power

supply unit (refer to CMPL 01B04M01-02E) and capacitor to be used are different

according to the power supply specifications.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 36

<Toc> <6. MAINTENANCE>

Blank Page

6-4

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 37

<Toc> <7. TROUBLESHOOTING>

7. TROUBLESHOOTING

If any fault occurs in the instrument, note down the symptoms, and follow Section

7.1, “Troubleshooting Flowchart.”

To find the fault, first wire the instruments according to the maintenance w iring

diagram, apply an input signal, and note down the symptoms.

If the fault also requires replacement of the power supply unit, main board or

display, or is difficult to find, contact your nearest Yokogawa sales staff.

7.1 Troubleshooting Flowchart

Instrument operates

abnormally.

7-1

Pulse output

absent?

NO

Abnormal setting

operation?

NO

Display error?

NO

NO

Recheck instrument

abnormality.

YES

YES

YES

Replace and check

display again.

Is fuse down?

AD.ER, EEP.ER,

Normal?

No

YES

Replace main board

and recheck.

Replace power supply unit

and recheck.

NO

SU.ER?

Normal?

NO

YES

Replace fuse and

recheck.

(See section 6.3)

Power voltage normal?

End

(See

subsection

7.3.3)

YES

End

(See

subsection

7.3.2)

Turn on again at

rated power voltage

and recheck.

Normal?

NO

Recheck instrument

abnormality.

YES

End

Figure 7-1 Troubleshooting Flowchart

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 38

<Toc> <7. TROUBLESHOOTING>

7.2 Action in Fault Condition

The SIND has a self check function for detecting device errors on the actual SIND itself.

Details of SIND errors can be confirmed on the display setter on the front panel and in

the STATUS parameter using the JHT200 Handy Terminal.

The blinking error display means failure.

7-2

Indication

on Display

Setter (*1)

Out Hardware error

Out

Out

(AD.ER)

Blinking

(EEP.ER)

Blinking

(SU.ER)

Blinking

0008 ERROR

0010 ERROR

0004 GOOD LOW_CUT

0040 GOOD None

0000 GOOD - - - -

Indication on Handy Terminal

STATU

S

(*2)

1000 ERROR

0001 ERROR

0002 ERROR

SELF

CHK

Note 1: On the SIND-x04, the error details are indicated in alphabet characters.

When two or more errors occur, high priority errors are displayed.

The table shows the errors in order of priority.

Note 2: STATUS error code is to be the addition display (hexadecimal number) when two errors or more occur.

Error

Information

AD

ERROR

EEPROM

ERROR

EEPROM

SUM

ERROR

INPUT

OVER

RANGE

RANGE

SET

ERROR

Device Operation Cause of Error Remedy

Same state as power OFF

Pulse output: OFF

Key switch: Disabled

Communications: Stopped

Lamp: All out

Pulse output: Normal

Key switch: Disabled

Communications: Normal

action

Lamp: All out

Pulse output: OFF

Key switch: Disabled

Communications:

Unstable

Lamp: All out

Pulse output: OFF

Key switch: Disabled

Communications:

Unstable

Lamp: Normal action

Pulse output: Normal

Key switch: Enabled

Communications: Normal

action

Lamp: Normal action

Pulse output: Normal

Key switch: Enabled

Communications: Normal

action

Power supply error,

broken fuse

Display malfunction

A/D conversion

error

EEPROM error

EEPROMSUM

error

(Parameter error)

Out of input range 25 to +125%

SCH1 and SCL1

are same values.

Input at low-cut

point or less

Power interruption

during operation

Replace the main

board.

Replace power

board.

Replace fuse.

Replace the

display.

Replace the main

board.

Replace the main

board.

Set SCH1 or SCL1

again.

Write "0000" at the

STATUS display on

the Handy

Terminal.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 39

<Toc> <7. TROUBLESHOOTING>

7.3 Replacement of Parts

WARNING

Replacement of parts must be performed by Yokogawa service personnel. If customer

service personnel are to replace parts, first thoroughly read this user’s manual to

familiarize yourself with the procedure.

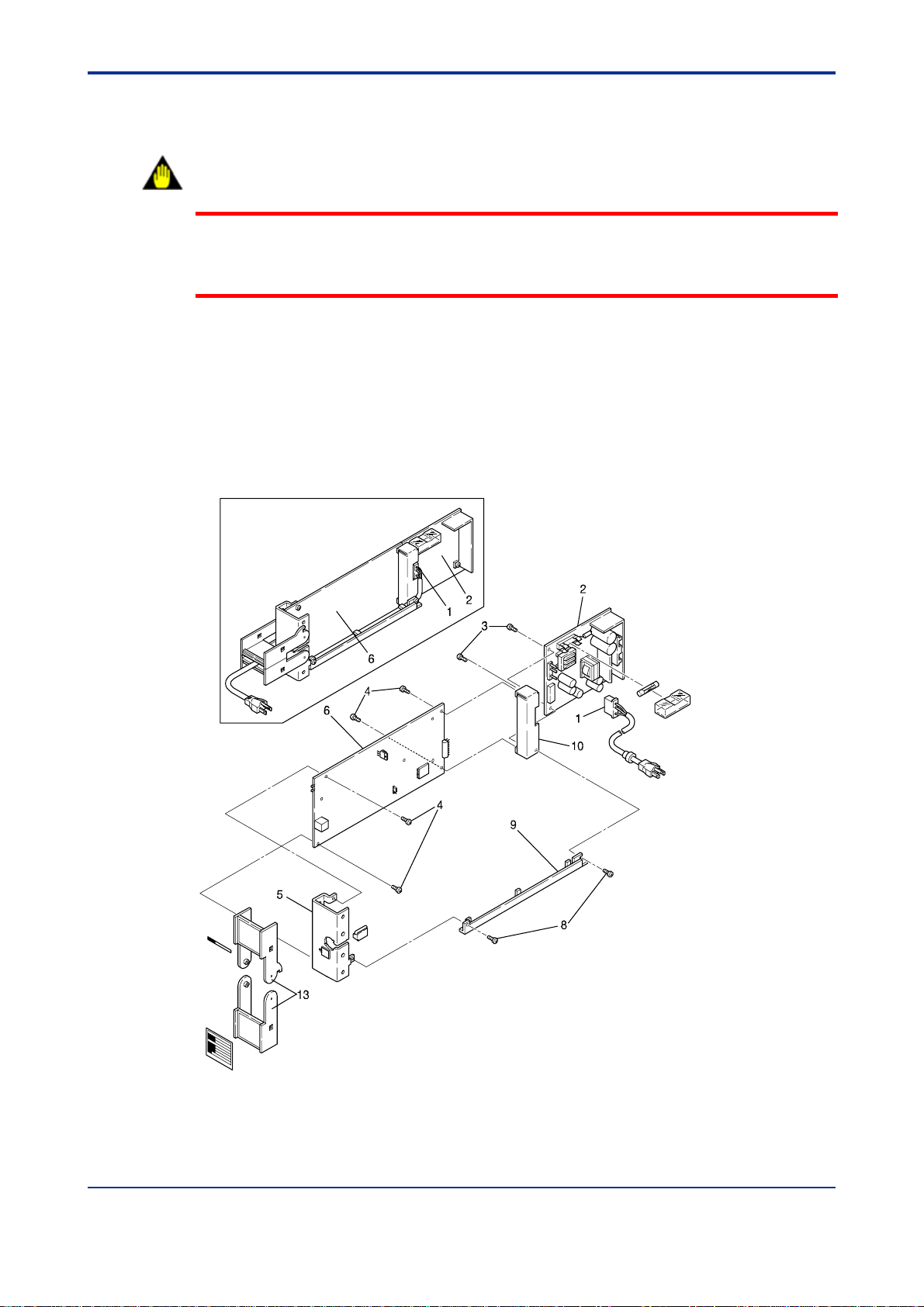

7.3.1 Replacement Procedure

The following replacement procedures are described:

• Replacement of Power Supply Unit

• Replacement of Main Board

• Replacement of Display

7-3

Internal Unit

Figure 7-2 Disassembled View

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 40

<Toc> <7. TROUBLESHOOTING>

NOTE

• Limit the number of disassembled parts to a minimum when disassembling the

SIND during replacement of parts.

• Perform disassembly and assembly carefully.

7.3.2 Replacement of Power Supply Unit

(a) Pull the terminal cover (13) toward you to draw out the internal unit from the rack

case.

(b) Unplug the connector (1) from the power supply unit (2).

(c) Remove two screws (3) to separate the power supply unit (2) from the bracket (10).

(d) Assemble the new power supply unit following steps (c) through (a).

7-4

NOTE

• Use the power supply unit for style R for replacement (refer to CMPL).

• The power supply unit of former style without compatibility cannot be used.

7.3.3 Replacement of Main Board

(a) Remove the power supply unit (2).

(Refer to Subsection 7.3.2 for operating procedure.)

(b) Remove two screws (8) to separate the bracket (9).

(c) Remove four screws (4) to separate the bracket (10) and the front bracket (5) from

the main board (6).

(d) Assemble the new main board following steps (c) through (a).

7.3.4 Replacement of Display (SIND-x04 only)

(a) Remove the connector (1) from the power supply unit (2).

(b) Remove two screws (8) to separate the bracket (9).

(c) Remove two screws (4) to separate the front bracket (5) from the main board (6).

(d) Assemble the new front bracket following steps (c) through (a).

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 41

<Toc> <Appendix /TB POWER SUPPLY TERMINAL CONNECTIONS (Option)>

App.-1

Appendix /TB Power Supply Terminal

Connections (Option)

Appendix-1 GENERAL

If you specify the optional terminal block (optional suffix code /TB), the power supply is

connected directly to the terminal block. So, drawing out of the internal unit requires

turning off the power supply and disconnecting the wiring from the terminal block.

Appendix-2 APPLICABLE INSTRUMENTS

Model Description

STED

SKYD

SALD

SDAU

SPLR

SIND

SISD

SDBT

SDBS

SDBU-21

mV, Temperature and Potentiometer/Voltage Converters

Alarm Unit

mV and Temperature Alarm Unit

Digital Alarm Unit

Programmable Computing Unit

Integrator

Isolator

Distributor (for 1 point)

Distributor (for 4 points)

Distributor (for 1 point)

Appendix-3 NAMES OF COMPONENTS AND

POWER TERMINAL SYMBOLS

Figure 1 Names of Parts and Power Terminal

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 42

<Toc> <Appendix /TB POWER SUPPLY TERMINAL CONNECTIONS (Option)>

App.-2

Appendix-4 POWER SUPPLY AND GROUND

WIRING

(1) All cable ends must be furnished with crimp-on type solderless lugs (for 4 mm

screws).

(2) Examples of applicable cables:

Cross-sectional area of the cable conductor: 2.0 mm

For the power supply, use cable having a cross-sectional area of at least 1.25 mm

Applicable cable: 600 V PVC insulated cable (IV) stranded wires, conforming to JIS

C3307.

PVC insulated cables for electric appliances (KIV) stranded wires,

conforming to JIS C3316.

Note *: Power supply cables should be determined from the instrument power consumption. They must have

conductors with cross-sectional area of at least 1.25mm2.

(3) Wirings to power supply and ground terminals should be made after completion of

signal terminal wirings.

(When signal terminal wirings are made after completion of power supply wiring, pull

the internal unit approximately half way out of the housing. Do not remove the power

terminal block.)

(4) After completing the power supply and ground wiring, mount the power terminal

cover.

2

*

2

.

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 43

Customer

Maintenance

Parts List

Model SIND (Style R)

Integrator

4

15

20

20

1

2

20

20

16

7

3

6

11

20

5

12

10

All Right Reserved, Copyright © 2002, Yokogawa Electric Corporation.

Subject to change without notice. Printed in Japan.

CMPL 01B04M01-02E

7th Edition: May 2004

Page 44

Qty

Model

SIND-100

SIND-200

SIND-104

Item Part No. Description

1 L3040DG 1 1 Main Board Assembly

L3040DH 1 1 Main Board Assembly

2 A1211JS 1 1 1 1 Socket & Holder

3 L4040EA 1 1 1 1 Cap

SIND-204

2

4 L3040YB 1 1 1 1 Power Supply Unit (for 100V Version)

L3040YS 1 1 1 1 Power Supply Unit (for 220V Version)

5 S9510VK 1 1 1 1 Fuse(1A)

6 E9713CA 1 1 1 1 Cover

7 E9713CK 1 1 1 1 Cover

10 E9713EG 1 1 1 1 Cable Assembly(for 100V Version)

E9713FS 1 1 1 1 Cable Assembly(for 220V Version)

11 E9713CE 1 1 1 1 Cover

12 S9079PB 1 1 1 1 Bushing

15 Y9422NP 1 1 1 1 Tag No. Label (blank)

16 L4040JA 1 1 1 1 Label (blank)

20 Y9306JB 8 8 8 8 Pan H. Screw, M3x6

CMPL 01B04M01-02E 7th Edition : 2004.05.01-00

Page 45

Customer

4

8

76

3

1

2

5

Maintenance

Parts List

/TB

Power Supply Terminals

For Rack-Mounted Instruments

(Option)

All Right Reserved, Copyright © 1984, Yokogawa Electric Corporation.

Subject to change without notice. Printed in Japan.

CMPL 01B04F02-11E

8th Edition: May 2004

Page 46

Part No. Qty Descripion

Item

1

−−−

2

E9713CJ

3

−−−

4

E9713ET

5

S9510VK

6

E9713CV

7

Y9306JB

8

E9714DM

Table 1. Power Supply Unit Part Number.

Model

SPLR

STED, SISD, SDBT

SALD, SKYD, SIND, SDAU

SDBS, SDBU-21

SPCM

1

Power Supply Unit (see Table 1)

1

Cover

1

Bracket (see Table 2)

1

Terminal Assembly

1

Fuse (1A)

1

Cover

2

Pan H. Screw, M3 × 6

1

Label (1A/250V)

Power Supply Unit Part No.Applicable Instruments

100 V Version 200 V Version

E9715YH

L3040YH

L3040YJ

E9715YK

E9715YL

Table 2. Bracket Part Number.

Applicable Instruments

Model

STED-110/310/410

STED-210

STED-710

SISD,SIND-100/200, SDBT-21

SKYD-200/201/302

SKYD-100/101,SALD-110/310

SKYD-204/304

SKYD-104

SALD-210/710

SALD-724

SALD-214/714

SIND-104/204

SDBS

SDBT-11

SDAU-xxx/TB

SDAU-100/RLY4/TB

SDAU-270/RLY4/TB

SDAU-xxx/TB/COM

SDAU-100/RLY4/TB/COM

SDAU-270/RLY4/TB/COM

Bracket Part No.

L4040CA

L4040CB

L4040CC

L4040CE

L4040CG

L4040CH

L4040CL

L4040CM

L4040CQ

L4040CS

L4040CT

L4040CX

E9713DR

E9713DL

L4040DA

L4040DB

L4040DE

L4040DF

Page 47

<Toc>

Revision Information

Title :Model SIND (Style R) Integrator

Manual No. :IM 01B04M01-02E

Jul. 2002/7th

Renewal

Mar. 2003/8th

Correct

May 2004/9th

Change of the company name.

i

Written by Yokogawa Electric Corporation

Published by Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, JAPN

IM 01B04M01-02E 9th Edition : 2004.05.01-00

Page 48

Blank Page

Page 49

Page 50

YOKOGAWA ELECTRIC CORPORATION

Network Solutions Business Div.

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 JAPAN

Phone: +81-422-52-7179 Facsimile: +81-422-52-6793

Sales Branch Offices

Tokyo, Nagoya, Osaka, Hiroshima, Fukuoka

YOKOGAWA CORPORATION OF AMERICA

Headquaters

2 Dart Road, Newnan, GA. 30265-1094 U.S.A.

Phone: +1-770-253-7000 Facsimile: +1-770-251-0928

Sales Branch Offices / Texas, Chicago, Detroit, San Jose

YOKOGAWA EUROPE B. V.

Headquaters

Databankweg 20, 3821 AL Amersfoort THE NETHERLANDS

Phone: +31-334-64-1611 Facsimile: +31-334-64-1610

Sales Branch Offices / Houten (The Netherlands), Wien (Austria), Zaventem

(Belgium), Ratingen (Germany), Madrid (Spain), Bratislava (Slovakia), Runcorn

(United Kingdom), Milano (Italy), Velizy villacoublay(France), Johannesburg(Republic

of South Africa)

YOKOGAWA AMERICA DO SUL S.A.

Headquarters & Plant

Praca Acapulco, 31-Santo Amaro, Sao Paulo/SP, BRAZIL CEP-04675-190

Phone: +55-11-5681-2400 Facsimile: +55-11-5681-4434

YOKOGAWA ENGINEERING ASIA PTE. LTD.

Head office

5 Bedok South Road, Singapore 469270 SINGAPORE

Phone: +65-6241-9933 Facsimile: +65-6241-2606

YOKOGAWA ELECTRIC KOREA CO., LTD.

Seoul Sales office

395-70, Shindaebang-dong, Dongjak-gu, Seoul,156-010, KOREA

Phone: +82-2-3284-3000 Facsimile: +82-2-3284-3019

YOKOGAWA TAIWAN CORPORATION

Head office

17F, No.39, Sec. 1, Chung Hwa Road Taipei, 100 TAIWAN

Phone: +886-2-2314-9166 Facsimile: +886-2-2314-9918

YOKOGAWA AUSTRALIA PTY. LTD.

Head office

Centrecourt D1, 25-27 Paul Street North, North Ryde, N. S. W. 2113, AUSTRALIA

Phone: +61-2-9805-0699 Facsimile: +61-2-9888-1844

YOKOGAWA INDIA LTD.

Head office

40/4 Lavelle Road, Bangalore, 560 001, INDIA

Phone: +91-80-227-1513 Facsimile: +91-80-227-4270

LTD. YOKOGAWA ELECTRIC

Grokholskiy per. 13, Build. 2, 4th Floor, 129010, Moscow, RUSSIA FEDERATION

Phone: +7-095-737-7868 Facsimile: +7-095-737-7869

Loading...

Loading...