Page 1

User’s

Manual

DPharp

Differential Pressure and

Pressure Transmitters

Manual Change No. 12-021-2

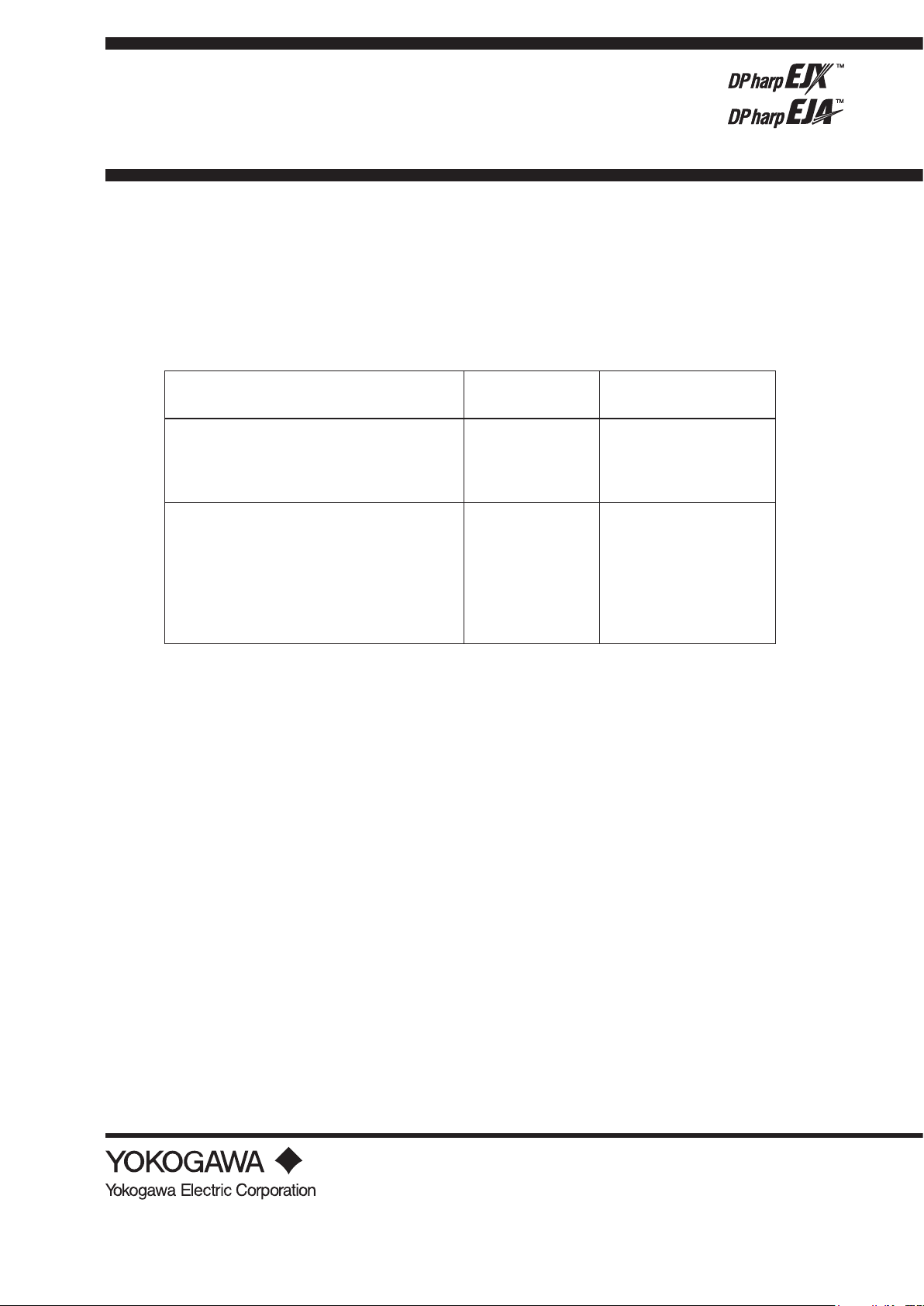

For the products of EJX and EJA-E series with any of the following option codes, please refer to

this manual change for handling cautions of ATEX approval.

Model Option code

EJX110A, EJX115A, EJX118A, EJX120A,

EJX130A, EJX210A, EJX310A, EJX430A,

EJX438A, EJX440A, EJX510A, EJX530A,

EJX610A, EJX630A

EJX110A, EJX115A, EJX118A, EJX120A,

EJX130A, EJX210A, EJX310A, EJX430A,

EJX438A, EJX440A, EJX510A, EJX530A,

EJX610A, EJX630A,

EJA110E, EJA115E, EJA118E, EJA120E,

EJA130E, EJA210E, EJA310E, EJA430E,

EJA438E, EJA440E, EJA510E, EJA530E

Applicable part of this

manual change

/KF21, /KS2

( I )

/KS26

( II )

Oct. 15, 2012

Page 2

<2.HandlingCautions>

(I)

ATEXCertication

(1) TechnicalData

a. ATEXIntrinsicallySafeType

Caution for ATEX Intrinsically safe type.

Note 1. Model EJX Series pressure transmitters

with optional code /KS2 for potentially

explosive atmospheres:

• No. KEMA 03ATEX1544 X

• Applicable Standard:

EN 50014:1997, EN 50020:2002,

EN 50284:1999, EN 50281-1-1:1998

• Type of Protection and Marking code:

EEx ia IIC T4

• Group: II

• Category: 1G, 1D

• Ambient Temperature for gas-proof:

–50 to 60°C

• Process Temperature (Tp.): 120°C max.

• Maximum Surface Temperature for dustproof:

T85°C (Tamb.: –40* to 60°C, Tp.: 80°C)

T100°C (Tamb.: –40* to 60°C, Tp.: 100°C)

T120°C (Tamb.: –40* to 60°C, Tp.: 120°C)

* –15°C when /HE is specied.

• Enclosure: IP66 and IP67

Note 2. Electrical Data

• In type of explosion protection intrinsic

safety EEx ia IIC only for connection to a

certied intrinsically safe circuit with following

maximum values:

Ui = 30 V, Ii = 200 mA, Pi = 0.9 W,

Effective internal capacitance; Ci = 10 nF,

Effective internal inductance; Li = 0 mH

Note 3. Installation

• All wiring shall comply with local installation

requirements. (Refer to the installation

diagram)

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void KEMA

Intrinsically safe Certication.

Note 5. Special Conditions for Safe Use

• In the case where the enclosure of the

Pressure Transmitter is made of aluminium,

if it is mounted in an area where the use of

category 1 G apparatus is required, it must

be installed such, that, even in the event of

rare incidents, ignition sources due to impact

and friction sparks are excluded.

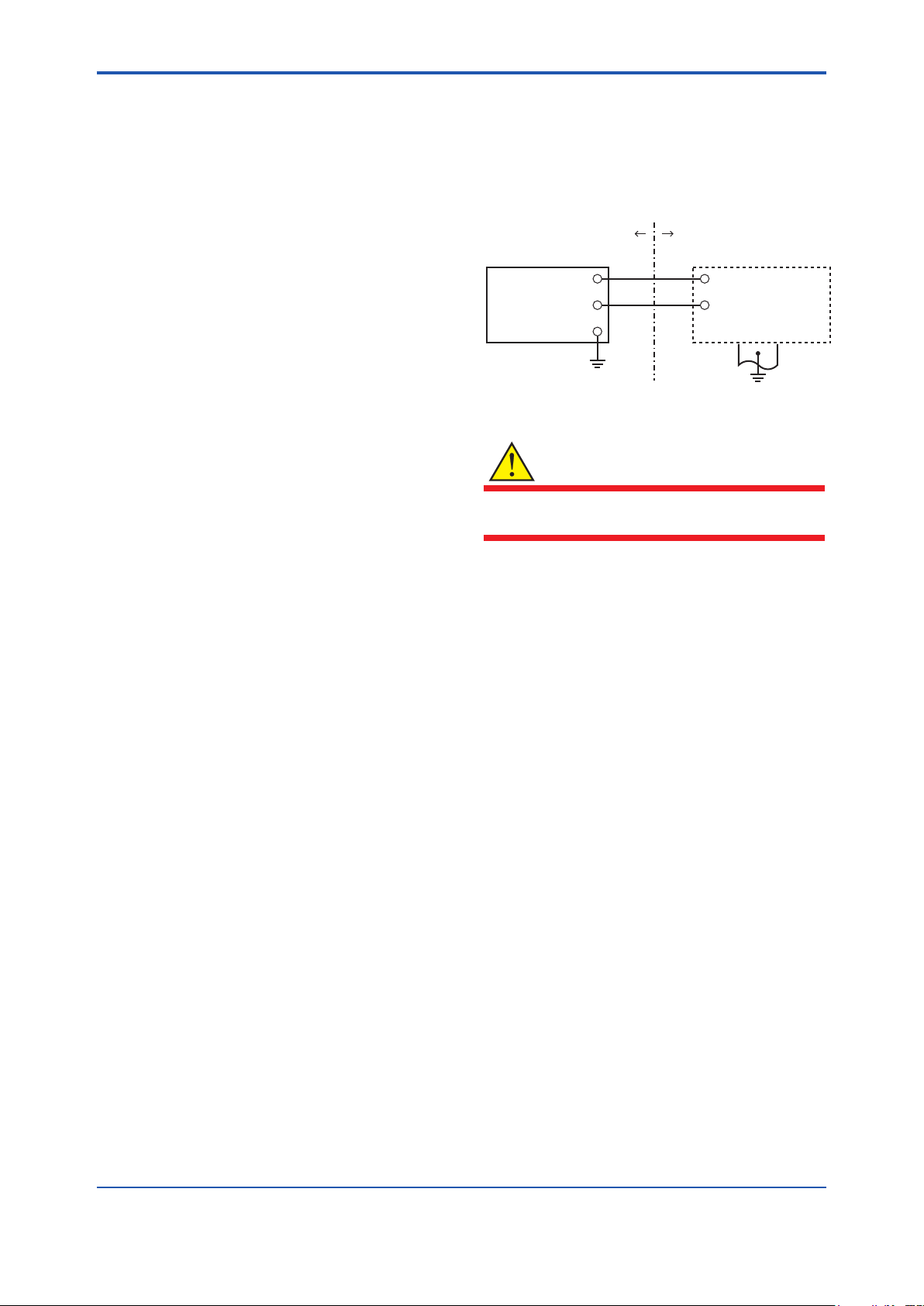

[Installation Diagram]

Hazardous Location

Transmitter

+

Supply

–

*1: In any safety barriers used the output current must be

limited by a resistor “R” such that Imaxout-Uz/R.

WARNING

Nonhazardous Location

+

Safety Barrier

–

F0206.ai

To satisfy IP66 or IP67, apply waterproof glands

to the electrical connection port.

b. ATEXFlameproofType

Caution for ATEX ameproof type.

Note 1. Model EJX Series pressure transmitters

with optional code /KF21 for potentially

explosive atmospheres:

• No. KEMA 07ATEX0109

• Applicable Standard: EN 60079-0:2006,

EN 60079-1:2004, EN 61241-0:2006,

EN 61241-1:2004

• Type of Protection and Marking Code: Ex d

IIC T6...T4, Ex tD A21 IP6x T85, T100, T120

• Group: II

• Category: 2G, 2D

• Enclosure: IP66 and IP67

• Temperature Class for gas-poof:

T6, T5, and T4

• Ambient Temperature for gas-proof:

–50 to 75°C (T6), –50 to 80°C (T5), and

–50 to 75°C (T4)

• Maximum Process Temperature (Tp.) for

gas-proof:

85°C (T6), 100°C (T5), and 120°C (T4)

• Maximum Surface Temperature for dustproof:

T85°C (Tamb.: –40* to 40°C, Tp.: 80°C)

T100°C (Tamb.: –40* to 60°C, Tp.: 100°C)

T120°C (Tamb.: –40* to 80°C, Tp.: 120°C)

* –15°C when /HE is specied.

*1

Page 3

<2.HandlingCautions>

Note 2. Electrical Data

• Supply voltage: 42 V dc max.

• Output signal: 4 to 20 mA

Note 3. Installation

• All wiring shall comply with local installation

requirement.

• The cable entry devices shall be of a certied

ameproof type, suitable for the conditions of

use.

Note 4. Operation

• Keep the “WARNING” label attached to the

transmitter.

WARNING: AFTER DE-ENERGIZING,

DELAY 5 MINUTES BEFORE OPENING.

WHEN THE AMBIENT TEMP.≥65°C, USE

HEAT-RESISTING CABLES≥90°C.

• Take care not to generate mechanical

sparking when accessing to the instrument

and peripheral devices in a hazardous

location.

Note 5. Maintenance and Repair

• The instrument modication or part

replacement by other than an authorized

representative of Yokogawa Electric

Corporation is prohibited and will void KEMA

Flameproof Certication.

WARNING

(3) Installation

WARNING

• All wiring shall comply with local installation

requirements and the local electrical code.

• There is no need for conduit seal in Division

1 and Division 2 hazardous locations

because this product is sealed at the factory.

(4) Operation

WARNING

• OPEN CIRCUIT BEFORE REMOVING

COVER. INSTALL IN ACCORDANCE WITH

THIS USER’S MANUAL

• Take care not to generate mechanical

sparking when access to the instrument and

peripheral devices in a hazardous location.

(5) MaintenanceandRepair

WARNING

The instrument modication or parts replacement

by other than an authorized Representative of

Yokogawa Electric Corporation is prohibited and

will void the certication.

To satisfy IP66 or IP67, apply waterproof glands

to the electrical connection port.

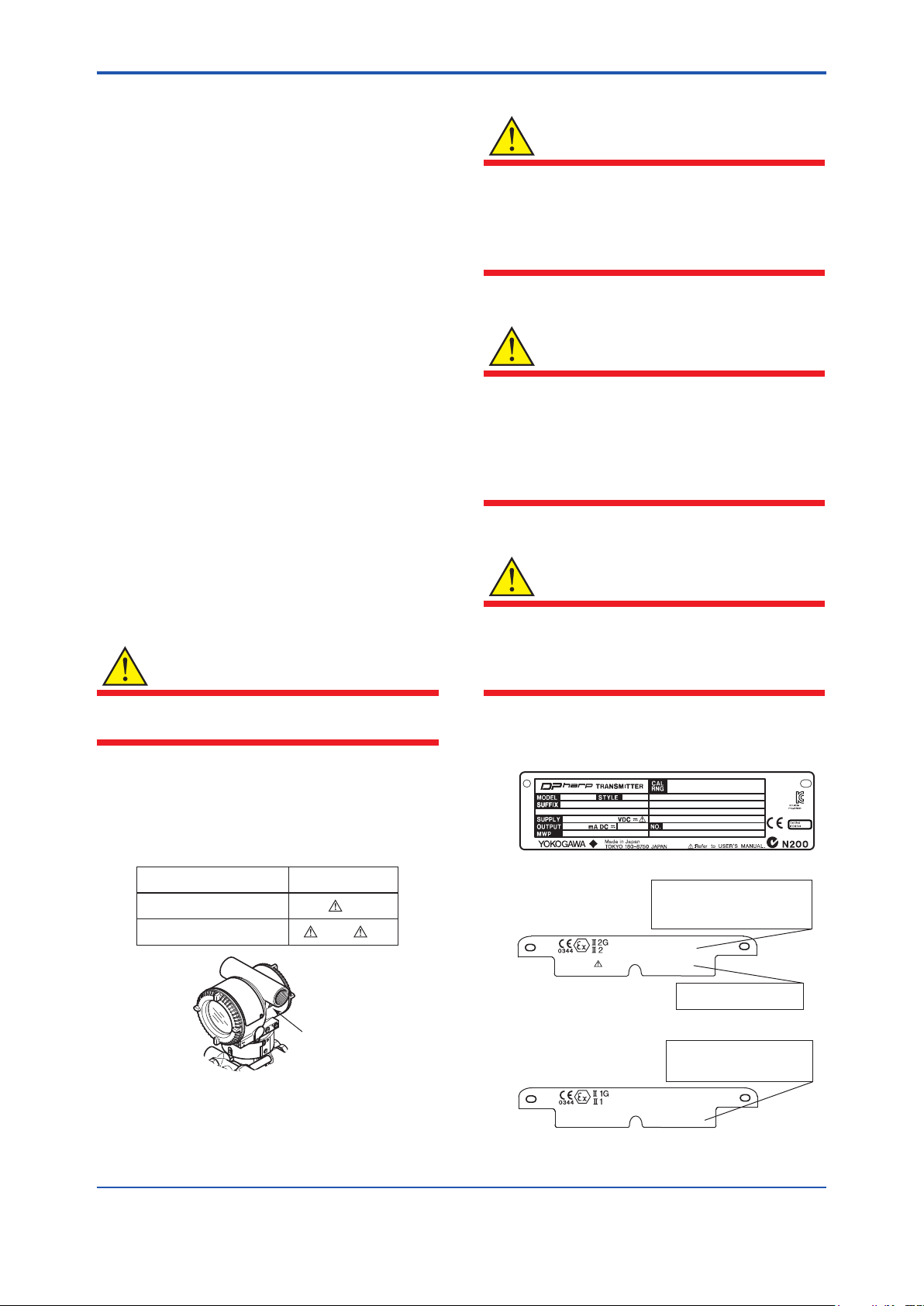

(2) ElectricalConnection

A mark indicating the electrical connection type is

stamped near the electrical connection port. These

marks are as followed.

Screw Size Marking

ISO M20 × 1.5 female

ANSI 1/2 NPT female

M

A or W

Location of the mark

F0208.ai

(6) NamePlate

● Name plate

● Tag plate for flameproof type

No. KEMA 07ATEX0109

Ex d IIC T6...T4, Ex tD A21, IP6X

Enlcosure : IP66, IP67

TEMP. CLASS T6 T5 T4

MAX PROCESS TEMP.(Tp.) 85 100 120 °C

Tamb. -50 to 75 80 75 °C

T85°C(Tamb.:40°C, Tp.:80°C),T100°C(Tamb.:60°C, Tp.:100°C),

T120°C(Tamb.:80°C, Tp.:120°C) Min.Tamb.:-40(-15)°C(for Dust)

D

WARNING

AFTER DE-ENERGIZING, DELAY 5 MINUTES

BEFORE OPENING.

WHEN THE AMBIENT TEMP. ≥ 65°C,

USE THE HEAT-RESISTING CABLES ≥ 90°C

● Tag plate for intrinsically safe type

No. KEMA 03ATEX1544 X

EEx ia IIC T4

IP66 and IP67

Tamb. -50 to 60°C MIN. Tamb.:-40(-15)°C(for DUST)

MAX. PROCESS TEMP.(Tp.) 120°C

T85°C(Tp.:80°C), T100°C(Tp.:100°C), T120°C(Tp.:120°C)

Ui=30V, Ii=200mA , Pi=0.9W, Ci=10nF, Li=0

D

F0209.ai

Page 4

<2.HandlingCautions>

91K819857 032

MODEL: Specied model code.

STYLE: Style code.

SUFFIX: Specied sufx code.

SUPPLY: Supply voltage.

OUTPUT: Output signal.

MWP: Maximum working pressure.

CAL RNG: Specied calibration range.

NO.: Serial number and year of production*1.

TOKYO 180-8750 JAPAN:

The manufacturer name and the address*2.

*1: The rst digit in the nal three numbers of the serial

number appearing after “NO.” on the nameplate

indicates the year of production. The following is an

example of a serial number for a product that was

produced in 2010:

The year 2010

*2: “180-8750” is a zip code which represents the

following address.

2-9-32 Nakacho, Musashino-shi, Tokyo Japan

(II)

ATEXCertication

(1) TechnicalData

a. ATEXIntrinsicallySafeType

Caution for ATEX Intrinsically safe type.

Note 1. EJX/EJA-E series pressure transmitters

with optional code /KS26 for potentially

explosive atmospheres:

• No. KEMA 04ATEX1116 X

• Applicable Standard: EN 60079-0:2009,

EN 60079-11:2007/EN 60079-11:2012,

EN 60079-26:2007, EN 60079-27:2008,

EN 61241-11:2006

Note 2. Ratings

Type of Protection and Marking Code:

Ex ia IIC/IIB T4 Ga

Ex ia IIIC T85°C T100°C T120°C Db

Group: II

Category: 1G, 2D

Ambient Temperature for EPL Ga: –40 to 60°C

Ambient Temperature for EPL Db: –30* to 60°C

* –15°C when /HE is specied.

Maximum Process Temperature (Tp.): 120°C

Maximum Surface Temperature for EPL Db.

T85°C (Tp.: 80°C)

T100°C (Tp.: 100°C)

T120°C (Tp.: 120°C)

Ambient Humidity:

0 to 100% (No condensation)

Degree of Protection of the Enclosure:

IP66 / IP67

Electrical Data

• When combined with Trapezoidal and

Rectangular output characteristic FISCO

model IIC barrier

Ui = 17.5 V, Ii = 380 mA, Pi = 5.32 W,

Ci = 3.52 nF, Li = 0 μH

• When combined with Linear characteristic

barrier

Ui = 24 V, Ii = 250 mA, Pi = 1.2 W,

Ci = 3.52 nF, Li = 0 μH

• When combined with Trapezoidal or

Rectangular output characteristic FISCO

model IIB barrier

Ui = 17.5 V, Ii = 460 mA, Pi = 5.32 W,

Ci = 3.52 nF, Li = 0 μH

Page 5

<2.HandlingCautions>

Note 3. Installation

• All wiring shall comply with local installation

requirements. (Refer to the installation

diagram)

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void

DEKRA Intrinsically safe Certication.

Note 5. Special Conditions for Safe Use

WARNING

• In the case where the enclosure of the

Pressure Transmitter is made of aluminium,

if it is mounted in an area where the use of

category 1 G apparatus is required, it must

be installed such, that even in the event of

rare incidents, ignition sources due to impact

and friction sparks are excluded.

• Electrostatic charge may cause an explosion

hazard. Avoid any actions that cause the

generation of electrostatic charge, such as

rubbing with a dry cloth on coating face of

the product.

• In the case where the enclosure of the

Pressure Transmitter is made of aluminum,

if it is mounted in an area where the use of

category 2D apparatus is required, it shall

be installed in such a way that the risk from

electrostatic discharges and propagating

brush discharges caused by rapid ow of

dust is avoided.

• To satisfy IP66 or IP67, apply waterproof

glands to the electrical connection port.

• When the lightning protector option is

specied, the apparatus is not capable

of withstanding the 500V insulation test

required by EN60079-11.

This must be taken into account when

installing the apparatus.

Note 6. Installation Instructions

[Installation Diagram]

Terminator

Terminator

+

Safety Barrier

+

−

−

+

SUPPLY

−

+

−

+

−

Hazardous Location

Non-Hazardous Location

Pressure

Transmitter

Transmitter

Transmitter

• In the rating 1(*1), the output current of the

barrier must be limited by a resistor ‘Ra’ such

that Io = Uo/Ra.

• In the rating 2(*2), the output of the barrier

must be the characteristics of the trapezoid

or the rectangle and this transmitter can be

connected to Fieldbus equipment which are

in according to the FISCO model.

• The terminators may be built in by a barrier.

• More than one transmitter may be connected

to the power supply line.

• The terminator and the safety barrier shall be

certied.

Electrical data:

Maximum Input Voltage Ui: 24 V

Maximum Input Current Ii: 250 mA

Maximum Input Power Pi: 1.2 W

Maximum Internal Capacitance Ci: 3.52 nF

Maximum Internal Inductance Li: 0 μH

or

Maximum Input Voltage Ui: 17.5 V

Maximum Input Current Ii: 380 mA

Maximum Input Power Pi: 5.32 W

Maximum Internal Capacitance Ci: 3.52 nF

Maximum Internal Inductance Li: 0 μH

or

Maximum Input Voltage Ui: 17.5 V

Maximum Input Current Ii: 460 mA

Maximum Input Power Pi: 5.32 W

Maximum Internal Capacitance Ci: 3.52 nF

Maximum Internal Inductance Li: 0 μH

F0212.ai

*1:

Rating 1

*2:

Rating 2

Page 6

<2.HandlingCautions>

(2) ElectricalConnection

A mark indicating the electrical connection type is

stamped near the electrical connection port. These

marks are as follows.

Screw Size Marking

ISO M20 × 1.5 female

ANSI 1/2 NPT female

M

N or W

Location of the mark

F0214.ai

(3) Installation

WARNING

• All wiring shall comply with local installation

requirements and the local electrical code.

• There is no need for a conduit seal in

Division 1 and Division 2 hazardous

locations because this product is sealed at

the factory.

(4) Operation

WARNING

(6) NamePlate

Name plate

CAL

MODEL

SUFFIX

SUPPLY

OUTPUT

MWP

STYLE

mA DC

RNG

V DC

NO.

Made in Japan

TOKYO 180-8750 JAPAN

: Refer to USER'S MANUAL.

Tag plate for intrinsically safe type

No. KEMA 04ATEX1116 X

Ex ia IIC/IIB T4 Ga Ta:-40 to 60°C

Ex ia IIIC T85°C T100°C T120°C Db Ta:-30(-15) to 60°C

MAX PROCESS TEMP.(Tp.):120°C

T85°C(Tp.:80°C), T100°C(Tp.:100°C), T120°C(Tp.:120°C)

Enclosure: IP66/IP67

FISCO field device(IIC/IIB)

Entity parameters Ui=24V, Ii=250mA, Pi=1.2W, Ci=3.52nF, Li=0μH

D

WARNING

POTENTIAL ELECTROSTATIC CHARTGING HAZARD - SEE USER'S MANUAL.

F0213.ai

STYLE: Style code.

SUFFIX: Specied sufx code.

SUPPLY: Supply voltage.

OUTPUT: Output signal.

MWP: Maximum working pressure.

CAL RNG: Specied calibration range.

NO.: Serial number and year of production*1.

TOKYO 180-8750 JAPAN:

The manufacturer name and the address*2.

*1: The rst digit in the nal three numbers of the serial

number appearing after “NO.” on the name plate

indicates the year of production. The following is an

example of a serial number for a product that was

produced in 2010:

91K819857 032

• OPEN CIRCUIT BEFORE REMOVING

COVER. INSTALL IN ACCORDANCE WITH

THIS USER’S MANUAL

• Take care not to generate mechanical

sparking when accessing the instrument and

peripheral devices in a hazardous location.

(5) MaintenanceandRepair

WARNING

The instrument modication or part replacement

by other than an authorized Representative of

Yokogawa Electric Corporation is prohibited and

will void the certication.

The year 2010

*2: “180-8750” is the Zip code for the following address.

2-9-32 Nakacho, Musashino-shi, Tokyo Japan

Page 7

User’s

Manual

DPharp

Differential Pressure and

Pressure Transmitters

Manual Change No. 12-026

Please use this manual change for the manuals listed below.

For following models, the contents in the attached sheet should be used to replace the original contents.

1. Applicable manuals, sections, and corresponding items

IM No. and Edition Model

IM 01C25A01-01E (6th) EJX series and EJA-E series 3.3 (I)

IM 01C25H01-01E (8th) EJX118A, EJX438A, EJA118E, and EJA438E

IM 01C25T01-06E (3rd)

IM 01C25T03-01E (4th)

IM 01C25F01-01E (9th)

EJX series and EJA-E series

for HART communication protocol

EJX series and EJA-E series

for BRAIN communication protocol

EJX510A, EJX530A, EJX610A, EJX630A,

EJA510E, and EJA530E

Applicable Sections

of Each Manual

4.3 (I)

8.1 to 8.3 (III)

3.3.14 (II)

3.2.3 (20) (II)

9.4 (IV)

Corresponding

Items in the

Attached Section 2

Nov. 30, 2012

Page 8

2. Contents of change

(I) Transmitter Mounting (for EJA118E, EJX118A,

EJA438E, and EJX438A)

Please replace the original contents as follows when

the transmitter cannot be installed at least 600 mm

below the HP process connection.

IMPORTANT

The transmitter should be installed at least 600 mm below

the high pressure (HP) process connection to ensure a

positive head pressure of ll uid. Pay special attention to

vacuum applications.

If it can not be installed at least 600 mm below the HP

process connection, please use the equation below:

(P–P0)

h= × 0.102 [mm]

ds

h: Vertical height between the HP process connection

and the transmitter (mm)

h≤0: Install the transmitter at least h (mm) below the

HP process connection

h>0: Install the transmitter at most h (mm) above the

HP process connection

P: Pressure in the tank (Pa abs)

P0: Minimum working pressure limit of the transmitter (Pa

abs). See below table.

[For ll uid code A, B, C, D, E]

Wetted parts

material code

SW

SE

SY

HW

TW

UW

[For ll uid code 1, 2, 4]

Wetted parts

material code

SW

SE

SY

HW

TW

ds: Specic gravity of ll uid (at 25°C). See below table.

Fill uid code A, 1, 4 B C, 2 D E

ds: Specic

gravity

Capillary

length

1 to 5m 6790 3190

6 to 10m 10030 3520

1 to 5m 6790 3190

6 to 10m 10030 3520

1 to 5m 3190

6 to 10m 3520

1 to 5m 19150 6140

6 to 10m 8290

1 to 5m 9620 3620

6 to 10m 4210

1 to 5m 9540 4750

6 to 10m 6050

Capillary

length

1 to 5m 2570 320

6 to 10m 4680 530

1 to 5m 2570 320

6 to 10m 4680 530

1 to 5m 320

6 to 10m 530

1 to 5m 10220 2050

6 to 10m 3450

1 to 5m 4270 570

6 to 10m 960

1.07 0.94 1.09

Process connection size

code

2, 8 3 4,W

Process connection size

code

2, 8 3 4,W

1.90 to

1.92

1.09

(II) Capillary Fill Fluid Density Compensation (for

EJA118E, EJX118A, EJA438E, and EJX438A)

Please use the following constant value [B] of ll uid

for the capillary ll uid density compensation when ll

uid code 1, 2, or 4 is specied.

Table A. Constant value [B] of ll uid

Fill uid code 1, 2, 4

Constant value [B] mmH2O 0.75

2

Kgf/cm

kPa 0.00745

mbar 0.07453

atm 0.000074

inH2O 0.02992

psi 0.00108

mmHg 0.05592

0.0000745

Page 9

(III) Specications regarding ll uid code 1, 2, and 4 (for EJA118E, EJX118A, EJA438E, and EJX438A)

Please use the following additional contents for each item on the section 10, when ll uid code 1, 2, or 4 is specied.

8.1 Standard Specications (for EJA118E, EJX118A, EJA438E, and EJX438A)

Working Pressure Limits (Page 8-2): See below table.

Fill uid Working pressure

High temp. and high vacuum use

High vacuum use

0.013 kPa abs (0.0019 psi abs) to ange rating pressure

For atmospheric pressure or below, see gure 8.a, 8.b, and 8.c.

Transmitter ambient

temperature range

(for fill fluid code 1)

100(14.5)

Working

pressure

kPa abs

(psi abs)

10(1.4)

Process temperature

for fill fluid code 1

*1

Transmitter ambient

temperature range

(for fill fluid code 2)

Flange max.

working

pressure

Atmospheric

pressure

Working

pressure

kPa abs

(psi abs)

100(14.5)

10(1.4)

Process temperature

for fill fluid code 2

*1

Transmitter ambient

temperature range

(for fill fluid code 4)

Flange max.

working

pressure

Atmospheric

pressure

Working

pressure

kPa abs

(psi abs)

100(14.5)

10(1.4)

*1

Process temperature

for fill fluid code 4

Flange max.

working

pressure

Atmospheric

pressure

2.7(0.38)

1(0.14)

0.1(0.014)

0.013(0.0019)

0.01(0.0014)

-50 0 50 100 150 200 250 300 350

Temperature (°C)

Figure 8.a. Working Pressure and

Process Temperature

(Fill uid: silicone oil for high

temp. and high vacuum use)

2.7(0.38)

1(0.14)

0.1(0.014)

0.013(0.0019)

0.01(0.0014)

-50 0 50 100 150 200 250 300 350

Temperature (°C)

Figure 8.b. Working Pressure and

Process Temperature

(Fill uid: silicone oil for high

temp. and high vacuum use)

2.7(0.38)

1(0.14)

0.1(0.014)

0.013(0.0019)

0.01(0.0014)

-50 0 50 100 150 200 250 300 350

Figure 8.c Working Pressure and

*1: The upper ambient temperature limit is 50°(122°F) in the following combinations.

Process Temperature Limits (Page 8-2): See below table.

Code Process temperature Ambient temperature Working pressure Specic gravity

Silicone oil

(high temp. and

1

high vacuum use)

Silicone oil

(high temp. and

2

high vacuum use)

Silicone oil

(high vacuum use)

*1: In case of wetted parts material code TW (Tantalum), process temperature limit is up to 200°C (392°F).

*2: The upper ambient temperature limit is 50°C(122°F) in the following combinations.

4

–10 to 250°C*1

(14 to 482°F)

10 to 310°C

(50 to 590°F)

–10 to 100°C

(14 to 212°F)

–10 to 60°C*2

(14 to 140°F)

10 to 60°C*2

(50 to 140°F)

–10 to 60°C*2

(14 to 140°F)

0.013 kPa abs

(0.0019 psi abs)

to ange rating

pressure

Process connection style code Process connection size code

W (Flush type) 2 (2-inch) or 8 (1 1/2-inch)

E (Extension type) 3 (3-inch)

Temperature (°C)

Process Temperature

(Fill uid: silicone oil for high

vacuum use)

1.07

1.09

1.07

Page 10

8.2 Model and Sufx Codes (for EJA118E, EJX118A, EJA438E, and EJX438A)

Fill uid

-1……

-2……

-4……

*1: In case of wetted parts material code TW (Tantalum), process temperature limit is up to 200°C (392°F)

*2: Not applicable for wetted parts material code TW (Tantalum).

*3: Not applicable for process connection size code 8 (1 1/2-inch).

*4: Not applicable for ashing connection ring code 1, 2, A, and B.

*5: Not applicable for wetted parts material code UW (Titanium).

*6: The upper ambient temperature limit is 50°C (122°F) in the following combinations.

[Process temperature] [Ambient temperature]

High temp. and high vacuum use (Silicone oil) *1 –10 to 250°C –10 to 60°C

High temp. and high vacuum use (Silicone oil) *2 10 to 310°C 10 to 60°C

High vacuum use (Silicone oil) –10 to 100°C –10 to 60°C

Process connection style code Process connection size code

W (Flush type) 2 (2-inch) or 8 (1 1/2-inch)

E (Extension type) 3 (3-inch)

8.3 Optional Specications (for EJA118E, EJX118A, EJA438E, and EJX438A)

Teon lm* Diaphragm protection from sticky process uid by FEP Teon lm attached with

uorinated oil.

TF1

Operation range: 20 to 150°C, 0 to 2 MPa (Not applicable for vacuum service).

*: Applicable for the combination of ush type (process connection style code W) and ushing connection ring code 0.

Not applicable for Fill uid code 1, 2, or 4.

(IV) Dimensions for Process connection code 8 and 9 (for EJA510E, EJX510A, EJX610A, EJA530E, EJX530A, and

EJX630A)

9.4 Dimensions

With Process connections code 8 and 9

Regarding process connection code 8 and 9, the appearance of process connection part has been changed in

January, 2013.

The difference can be distinguished by the 3-digit marking engraved on the side of hexagonal nut part.

Marking (3 digits):

=Numerical character such as `3´: See figure (a).

=Alphabet such as `N´: See figure (b).

(a) (b)

24(0.94)

172

(6.77)

ø6

(0.24)

5(0.20) 20(0.78)

172

ø6

(0.24)

(6.77)

5(0.20)

Loading...

Loading...