Page 1

User’s

Manual

EJX Series

Fieldbus Communication Type

IM 01C25T02-01E

Yokogawa Electric Corporation

IM 01C25T02-01E

4th Edition

Page 2

CONTENTS

CONTENTS

1. INTRODUCTION............................................................................................ 1-1

Regarding This Manual ................................................................................. 1-1

1.1 Safe Use of This Product.................................................................... 1-2

1.2 Warranty.............................................................................................. 1-3

1.3 ATEX Documentation.......................................................................... 1-3

2. HANDLING CAUTIONS ................................................................................ 2-1

2.1 Installation of an Explosion-Protected Instrument .............................. 2-1

2.1.1 FM approval ................................................................................. 2-1

2.1.2 CSA Certification .......................................................................... 2-3

2.1.3 CENELEC ATEX Certification...................................................... 2-4

3. ABOUT FIELDBUS ....................................................................................... 3-1

3.1 Outline ................................................................................................. 3-1

3.2 Internal Structure of EJX..................................................................... 3-1

3.2.1 System/network Management VFD ............................................. 3-1

3.2.2 Function Block VFD ..................................................................... 3-1

3.3 Logical Structure of Each Block.......................................................... 3-1

3.4 Wiring System Configuration .............................................................. 3-1

4. GETTING STARTED .....................................................................................4-1

4.1 Connection of Devices ........................................................................ 4-1

4.2 Host Setting......................................................................................... 4-2

4.3 Bus Power ON .................................................................................... 4-3

4.4 Integration of DD................................................................................. 4-3

4.5 Reading the Parameters ..................................................................... 4-3

4.6 Continuous Record of Values ............................................................. 4-4

4.7 Generation of Alarm............................................................................ 4-4

5. CONFIGURATION......................................................................................... 5-1

5.1 Network Design................................................................................... 5-1

5.2 Network Definition ............................................................................... 5-1

5.3 Definition of Combining Function Blocks ............................................ 5-2

5.4 Setting of Tags and Addresses .......................................................... 5-3

5.5 Communication Setting ....................................................................... 5-4

5.5.1 VCR Setting .................................................................................. 5-4

5.5.2 Function Block Execution Control ................................................ 5-5

5.6 Block Setting ....................................................................................... 5-5

5.6.1 Link Object ................................................................................... 5-5

5.6.2 Trend Object ................................................................................. 5-6

5.6.3 View Object .................................................................................. 5-6

5.6.4 Function Block Parameters ........................................................ 5-10

FD No. IM 01C25T02-01E

4th Edition: Apr. 2006(KP)

All Rights Reserved, Copyright © 2004, Yokogawa Electric Corporation

i

IM 01C25T02-01E

Page 3

CONTENTS

6. EXPLANATION OF BASIC ITEMS ............................................................... 6-1

6.1 Outline ................................................................................................. 6-1

6.2 Setting and Changing Parameters for the Whole Process ................ 6-1

6.3 SENSOR Transducer Block................................................................ 6-1

6.3.1 Functional block ........................................................................... 6-1

6.3.2 Block Mode ................................................................................... 6-1

6.3.3 Functions Relating to Pressure/Differential Pressure .................. 6-2

6.3.4 Functions Relating to Static Pressure .......................................... 6-3

6.3.5 Functions Relating to Capsule and Amplifier Temperature......... 6-4

6.3.6 BLOCK_ERR................................................................................ 6-4

6.3.7 XD_ERROR.................................................................................. 6-4

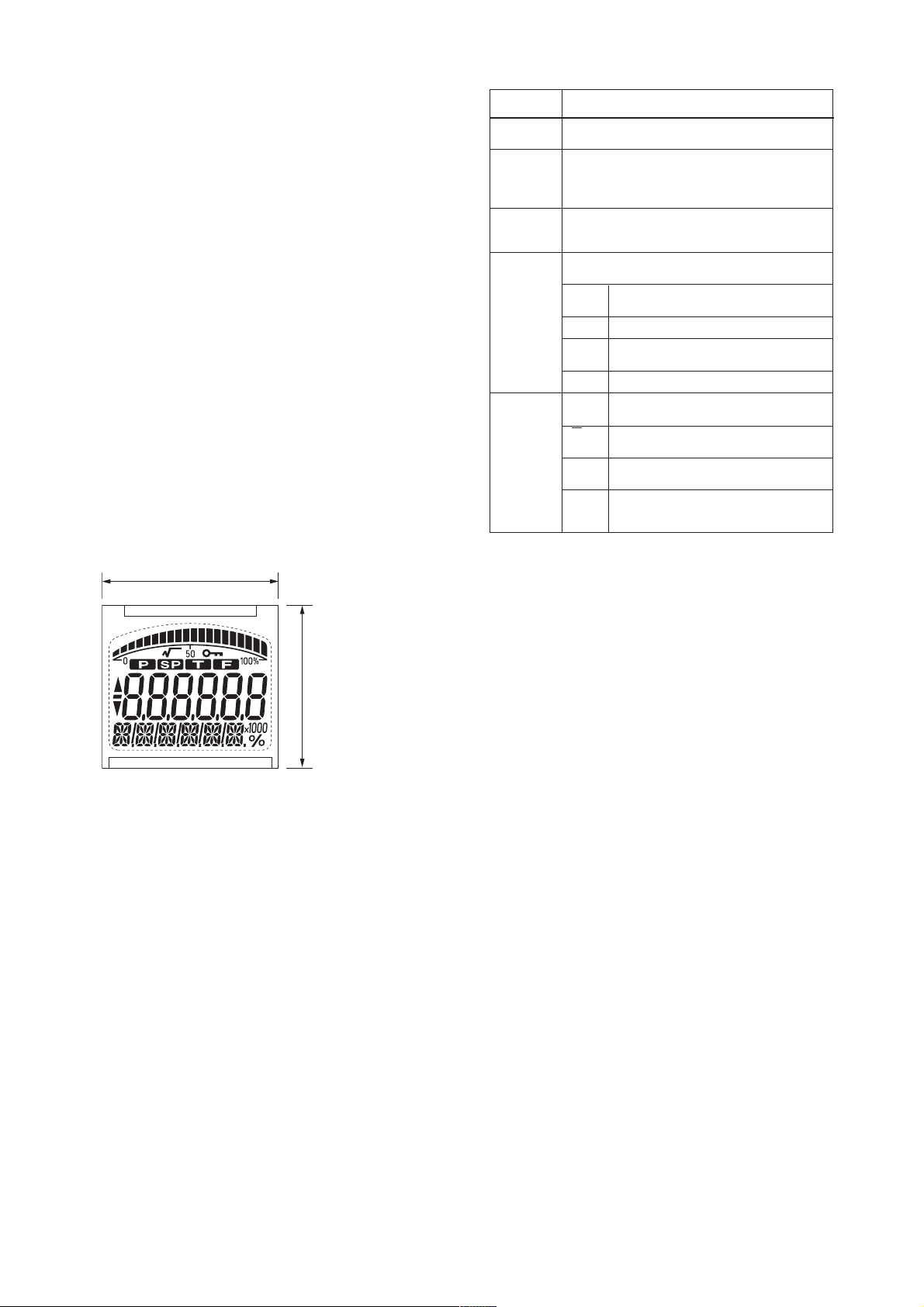

6.4 LCD Transducer Block........................................................................ 6-5

6.4.1 Outline of the Functions ............................................................... 6-5

6.4.2 Block Mode ................................................................................... 6-5

6.4.3 Display Contents of the integral indicator .................................... 6-5

6.4.4 Example Displays of the integral indicator ................................... 6-6

6.4.5 Procedure to Set the Built-in Display........................................... 6-7

6.4.6 Units That Can Be Displayed on the LCD by the Automatic Link

Function........................................................................................ 6-9

6.5 AI Function Block .............................................................................. 6-10

6.5.1 Function Blocks .......................................................................... 6-10

6.5.2 Block Mode ................................................................................. 6-10

6.5.3 IO_OPTS .................................................................................... 6-10

6.5.4 STATUS_OPT ............................................................................ 6-10

6.5.5 OUT_D ....................................................................................... 6-11

6.5.6 Basic Parameters of the AI Block. ............................................. 6-11

7. IN-PROCESS OPERATION .......................................................................... 7-1

7.1 Mode Transition .................................................................................. 7-1

7.2 Generation of Alarm............................................................................ 7-1

7.2.1 Indication of Alarm ....................................................................... 7-1

7.2.2 Alarms and Events ....................................................................... 7-1

7.3 Simulation Function............................................................................. 7-2

8. DEVICE INFORMATION ............................................................................... 8-1

8.1 DEVICE STATUS................................................................................ 8-1

8.2 Status of each parameter in failure mode .......................................... 8-4

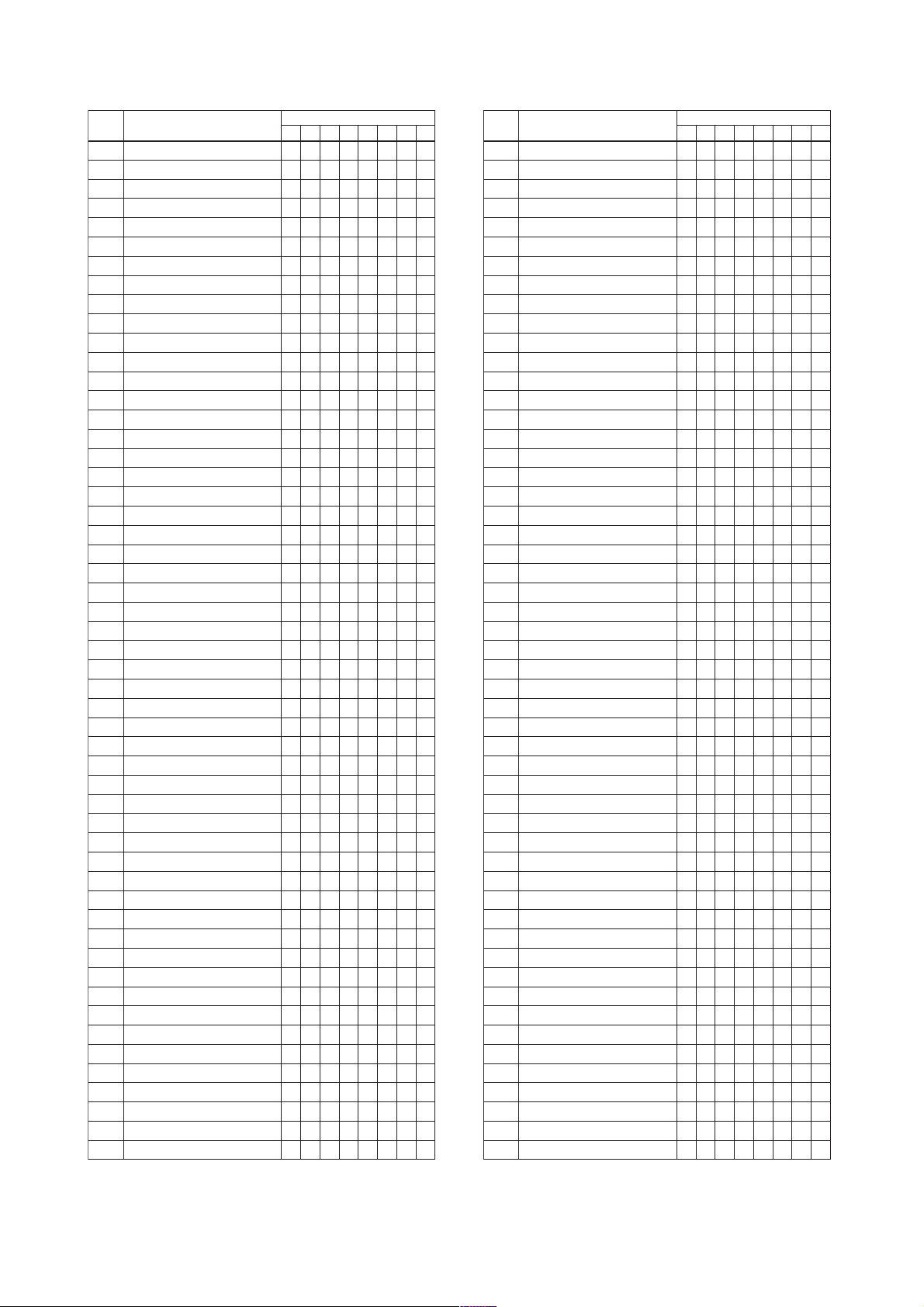

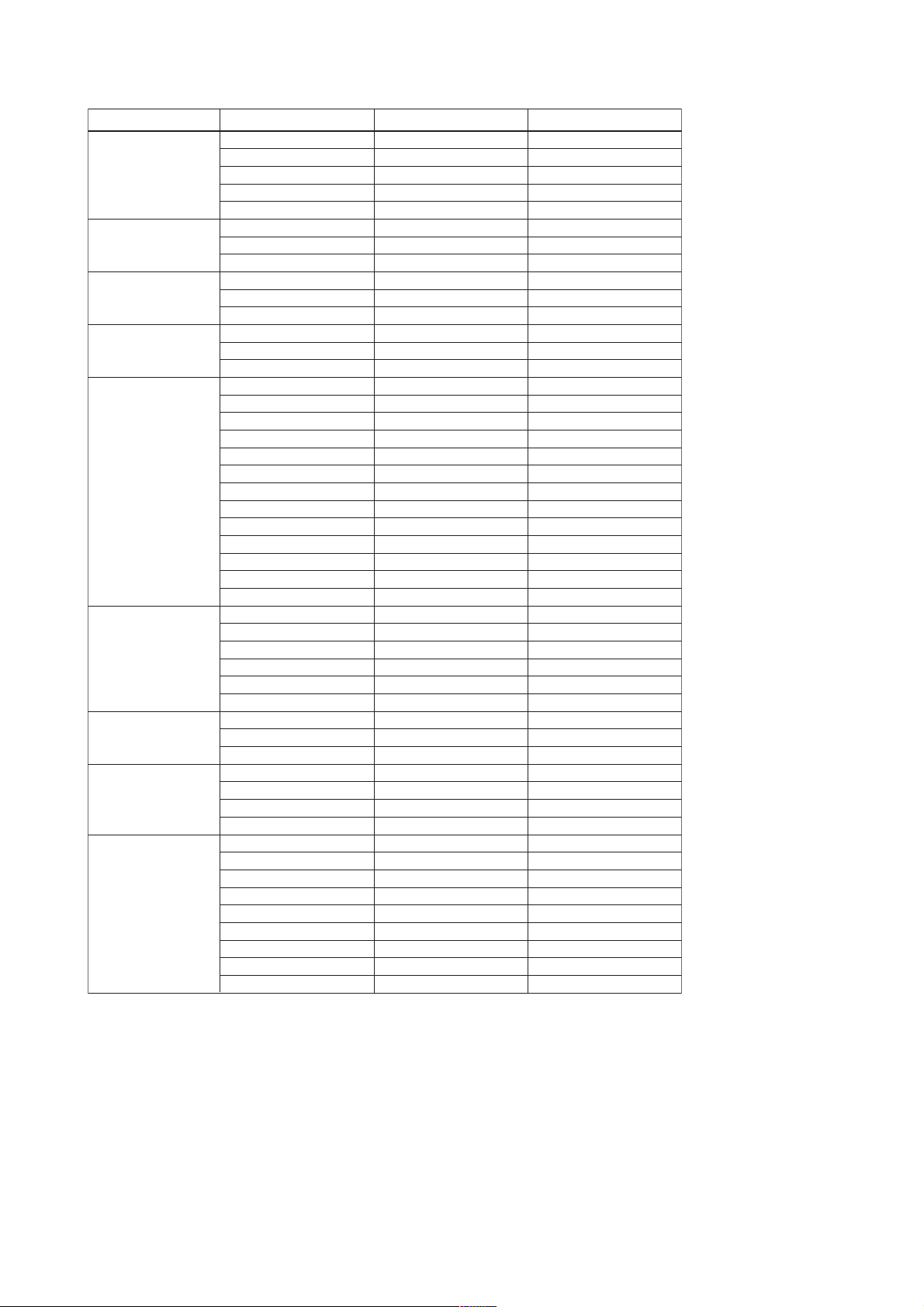

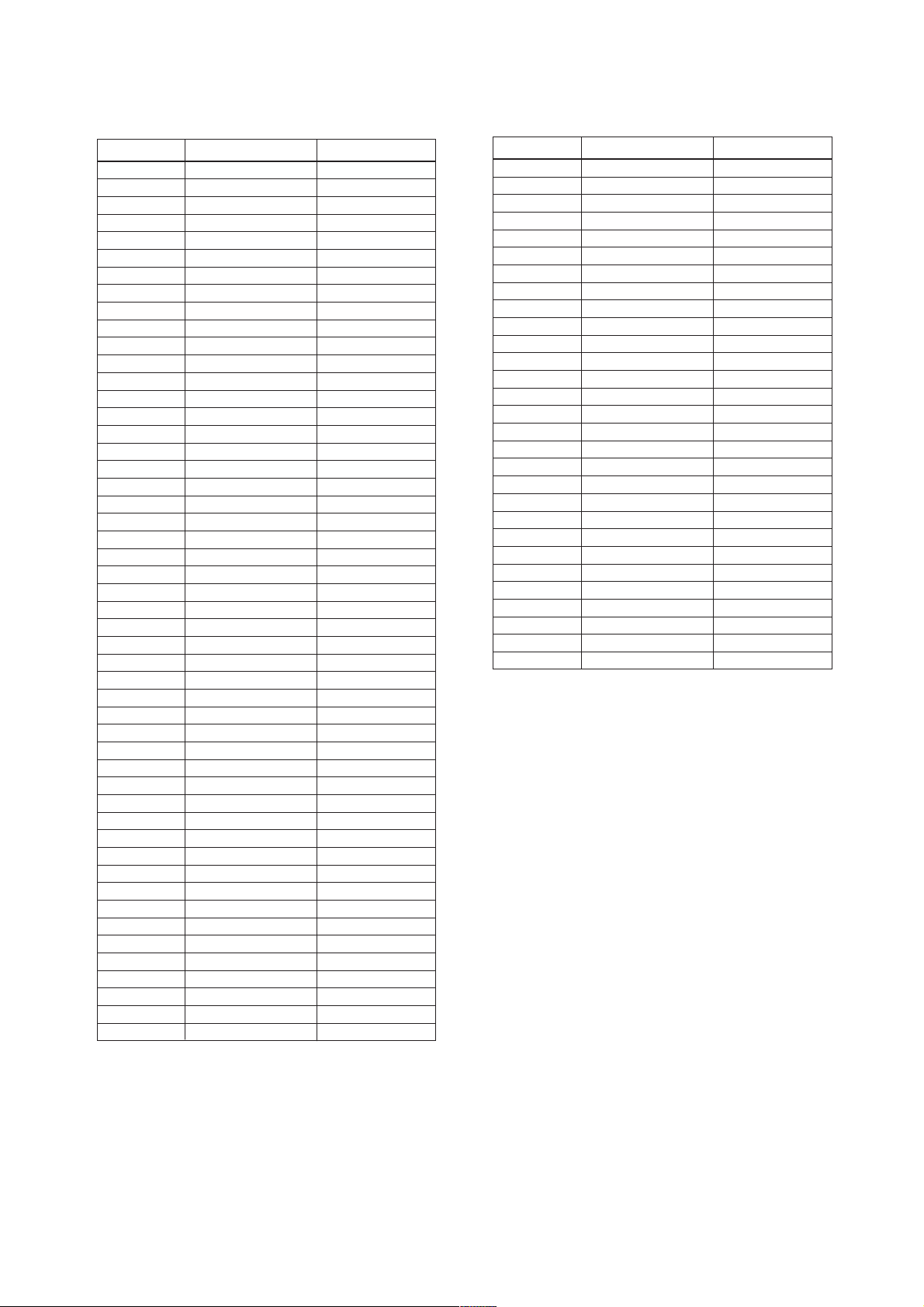

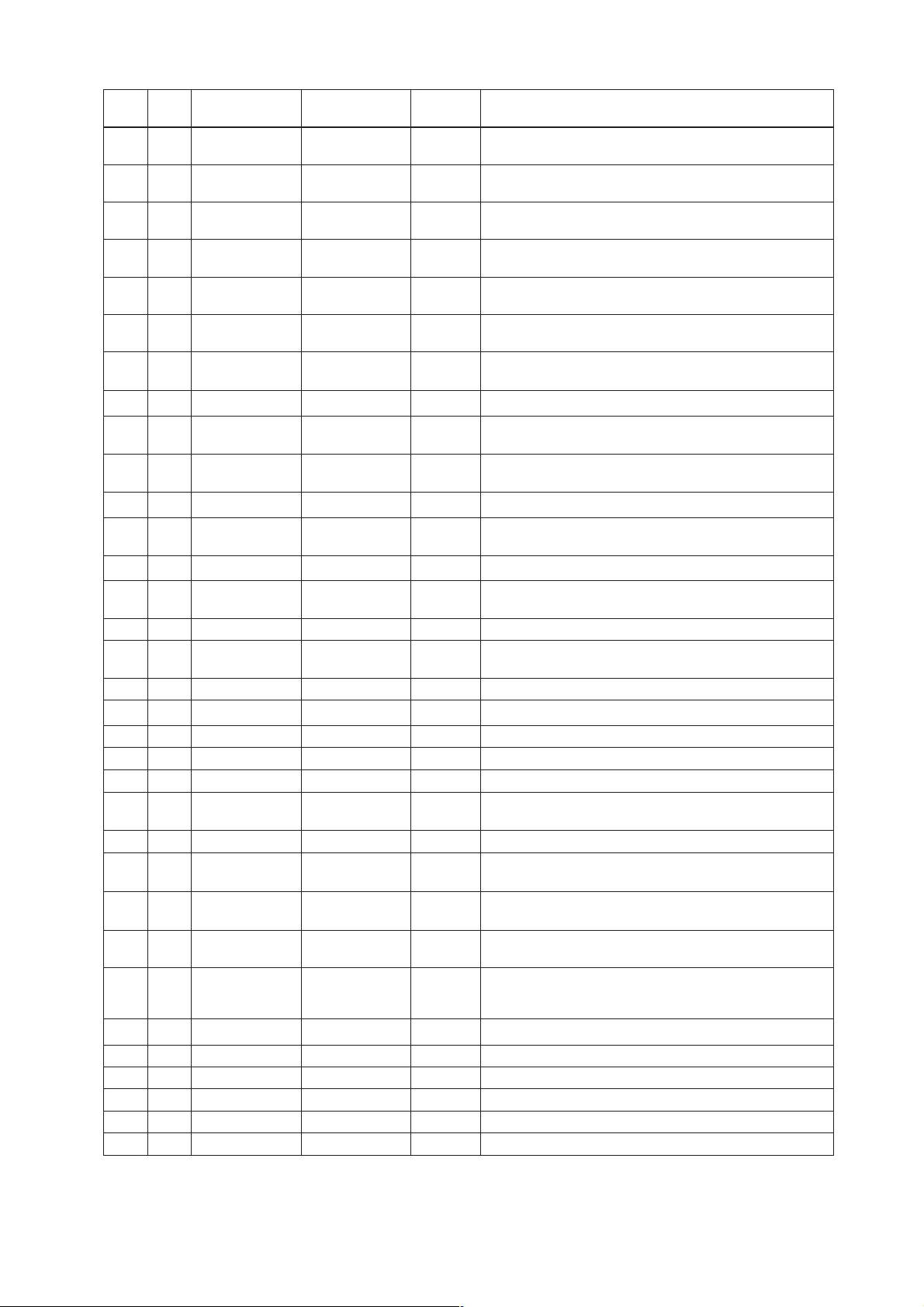

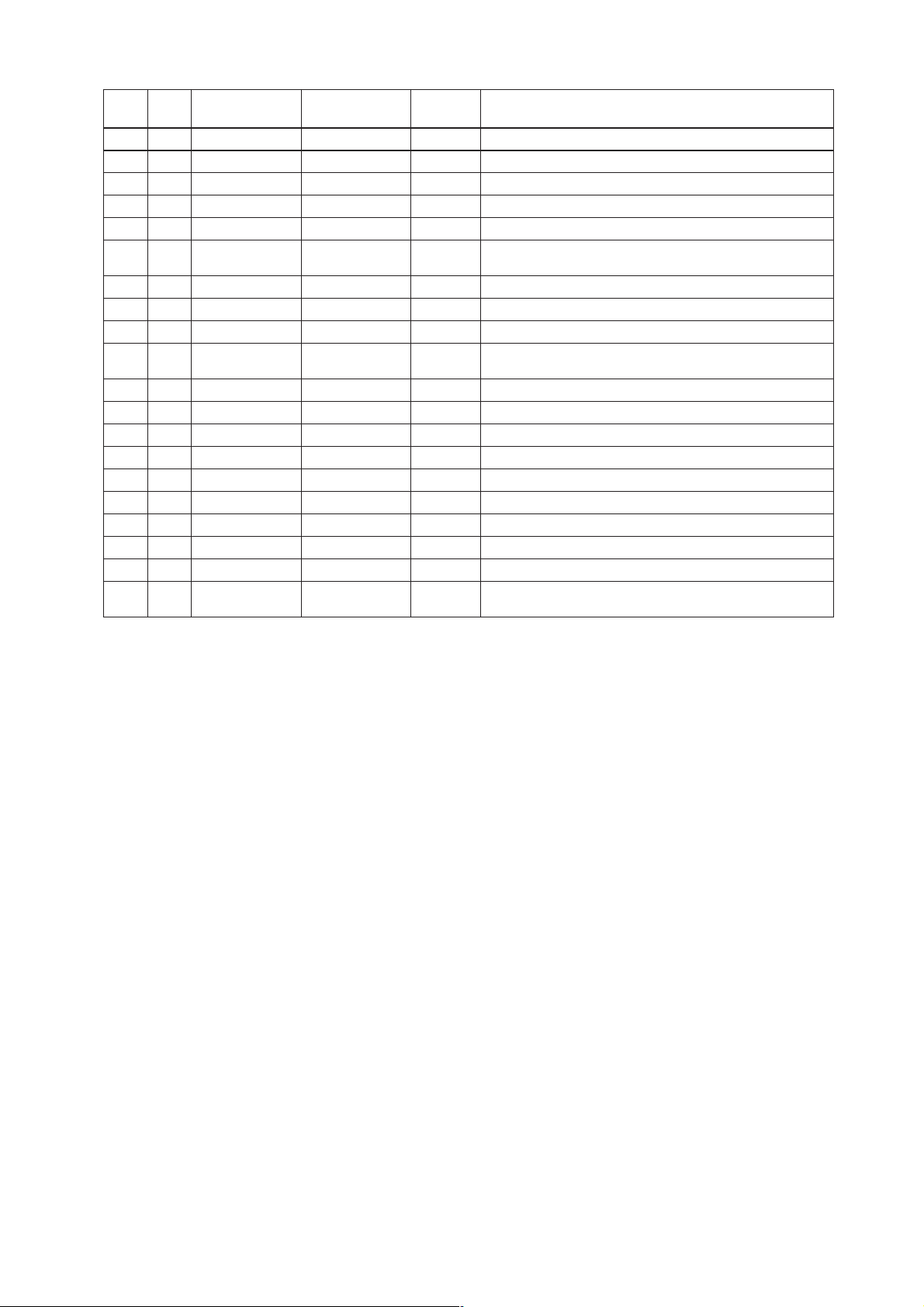

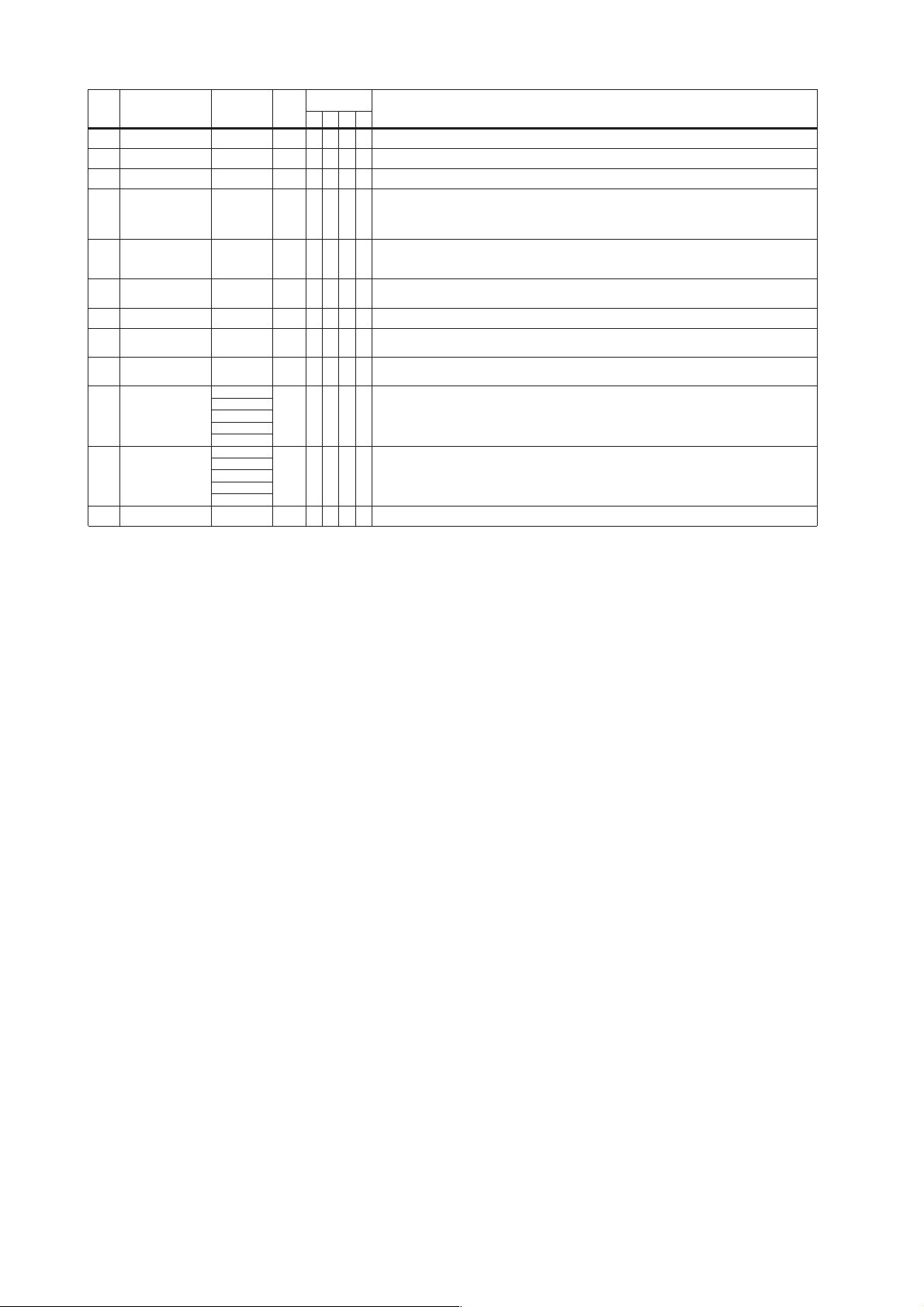

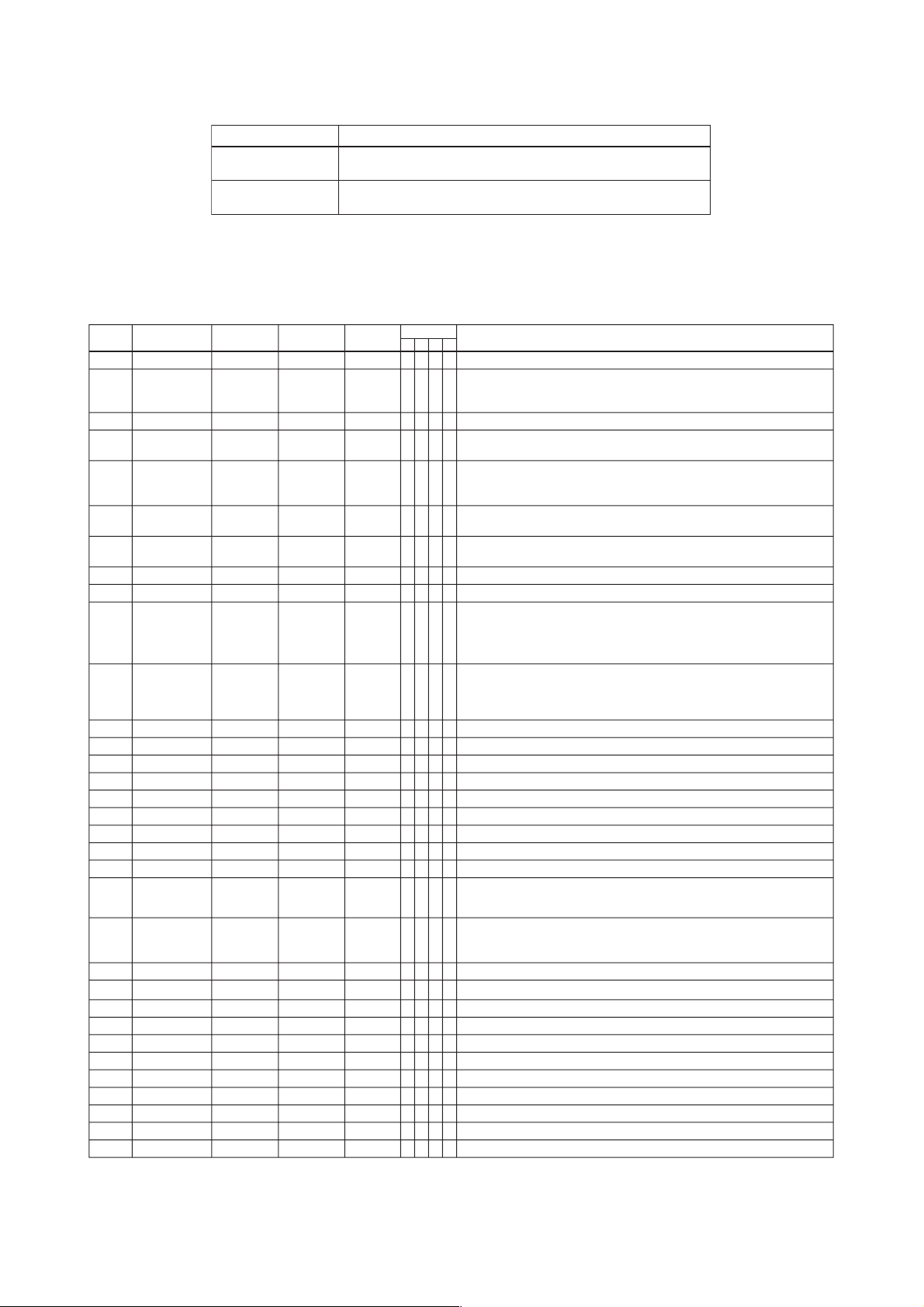

9. PARAMETER LISTS .....................................................................................9-1

9.1 Resource Block ................................................................................... 9-1

9.2 SENSOR Transducer Block................................................................ 9-3

9.3 LCD Transducer Block........................................................................ 9-7

9.4 Al Function Block ................................................................................ 9-9

10. GENERAL SPECIFICATIONS .................................................................... 10-1

10.1 STANDARD SPECIFICATIONS ....................................................... 10-1

10.2 OPTIONAL SPECIFICATIONS ......................................................... 10-1

10.3 OPTIONAL SPECIFICATIONS (For Explosion Protected type)....... 10-2

ii

IM 01C25T02-01E

Page 4

CONTENTS

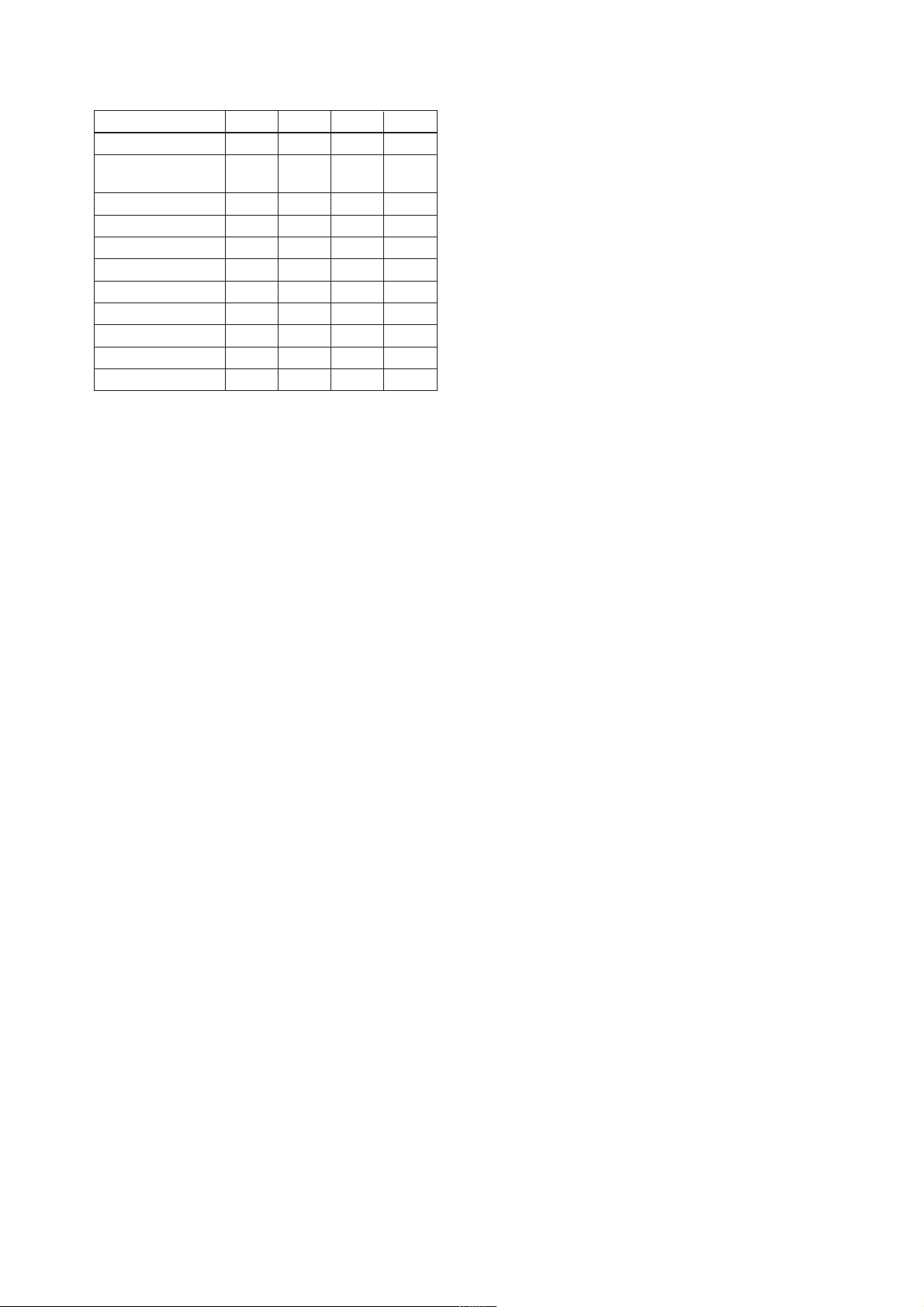

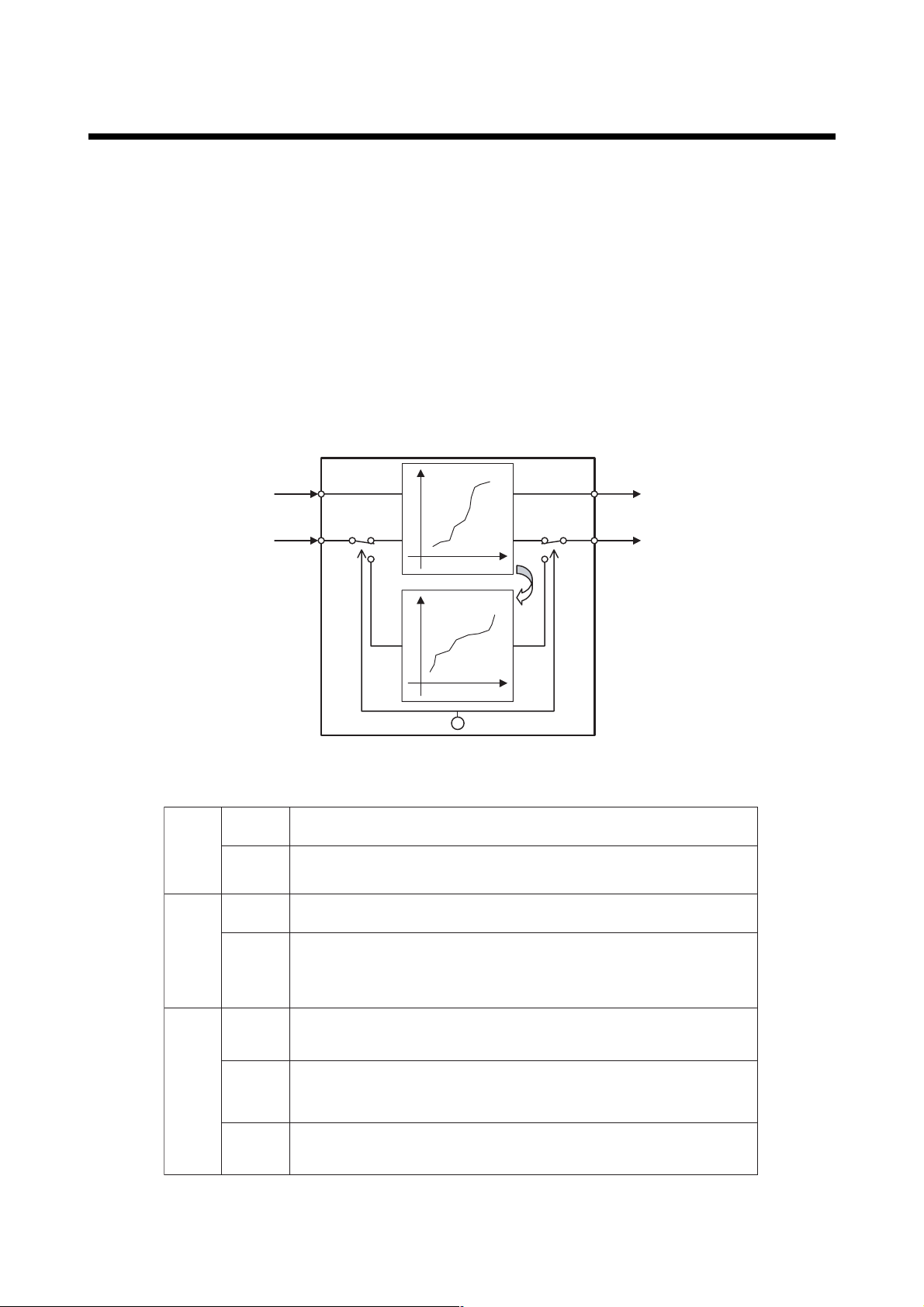

Appendix 1. Signal Characterizer (SC) Block ............................................... A-1

A1.1 Schematic Diagram of Signal Characterizer Block.............................A-1

Input/Output Parameters.....................................................................A-1

A1.2 Input Section ....................................................................................... A-3

A1.2.1 Determining the Mode..................................................................A-3

A1.2.2 Judging BLOCK_ERR.................................................................. A-3

A1.3 Line-segment Factor Determination Section ....................................... A-4

A1.3.1 Conditions for Configuring Valid Coefficients

(CURVE_X, CURVE_Y) ...............................................................A-4

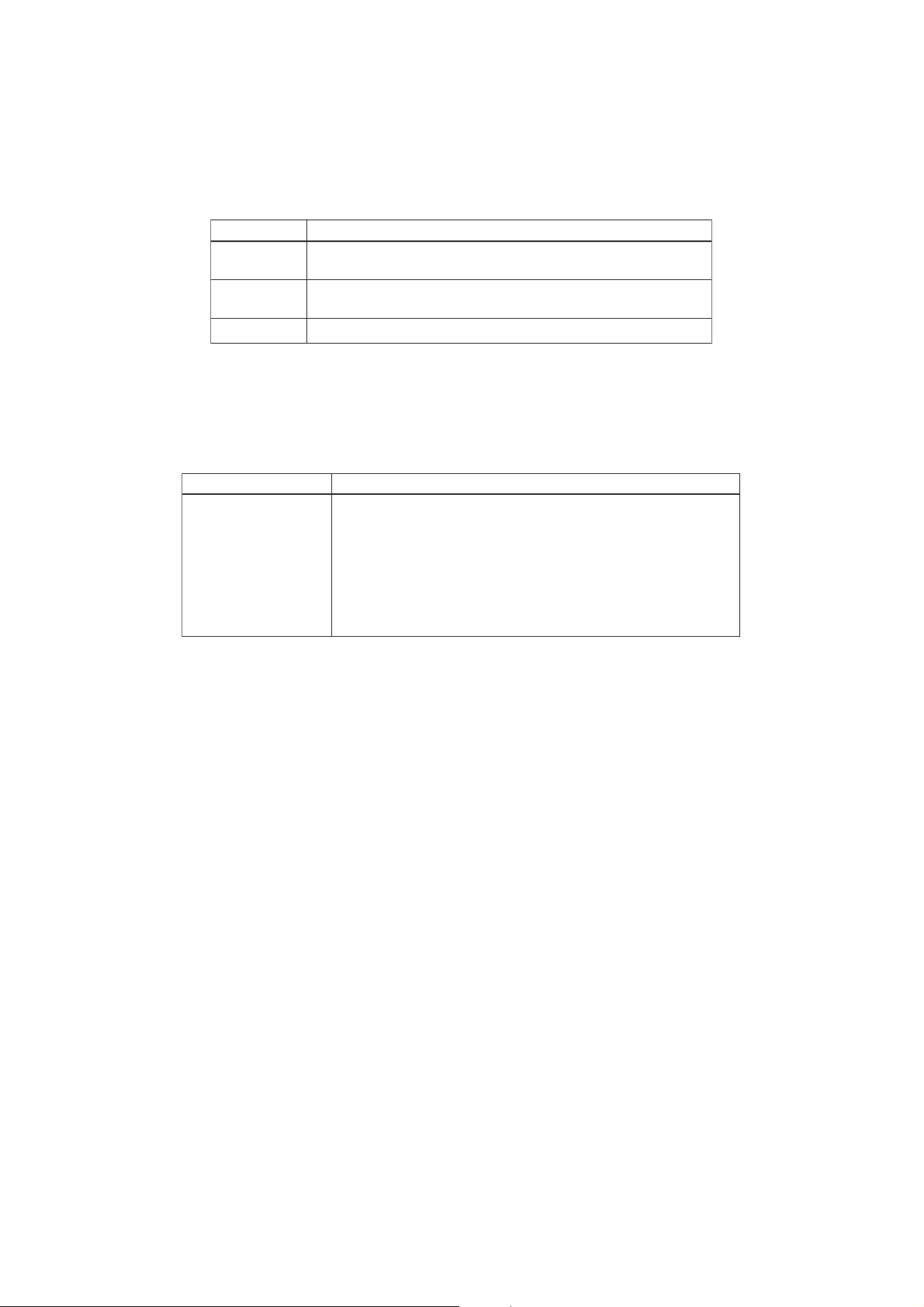

A1.4 List of Signal Characterizer Block Parameters ...................................A-6

A1.5 Application Example............................................................................A-7

A1.5.1 Input Compensation .....................................................................A-7

A1.5.2 Calorie Flow Compensation......................................................... A-7

A1.5.3 Backward Control......................................................................... A-7

Appendix 2. Integrator (IT) Block ................................................................... A-9

A2.1 Schematic Diagram of Integrator Block ..............................................A-9

A2.2 Input Process Section .......................................................................A-10

A2.2.1 Determining Input Value Statuses ............................................. A-10

A2.2.2 Converting the Rate ...................................................................A-10

A2.2.3 Converting Accumulation ........................................................... A-11

A2.2.4 Determining the Input Flow Direction .........................................A-11

A2.3 Adder................................................................................................. A-12

A2.3.1 Status of Value after Addition ....................................................A-12

A2.3.2 Addition.......................................................................................A-12

A2.4 Integrator ...........................................................................................A-13

A2.5 Output Process .................................................................................A-14

A2.5.1 Status Determination..................................................................A-14

A2.5.2 Determining the Output Value ....................................................A-15

A2.5.3 Mode Handling ...........................................................................A-16

A2.6 Reset .................................................................................................A-17

A2.6.1 Reset Trigger ..............................................................................A-17

A2.6.2 Reset Timing ..............................................................................A-17

A2.6.3 Reset Process............................................................................ A-18

A2.7 List of Integrator Block Parameters .................................................. A-19

Appendix 3. Input Selector (IS) Block.......................................................... A-21

A3.1 Input Selector Function Block Schematic .........................................A-21

A3.2 Input Section ..................................................................................... A-23

A3.2.1 Mode Handling ...........................................................................A-23

A3.2.2 MIN_GOOD Handling .................................................................A-23

A3.3 Selection............................................................................................A-24

A3.3.1 OP_SELECT Handling............................................................... A-24

A3.3.2 SELECTION Handling................................................................A-25

A3.4 Output Processing.............................................................................A-31

A3.4.1 Handling of SELECTED............................................................. A-31

A3.4.2 OUT Processing......................................................................... A-32

A3.4.3 STATUS_OPTS..........................................................................A-33

A3.5 List of Input Selector Block Parameters ........................................... A-33

A3.6 Application Example..........................................................................A-34

iii

IM 01C25T02-01E

Page 5

CONTENTS

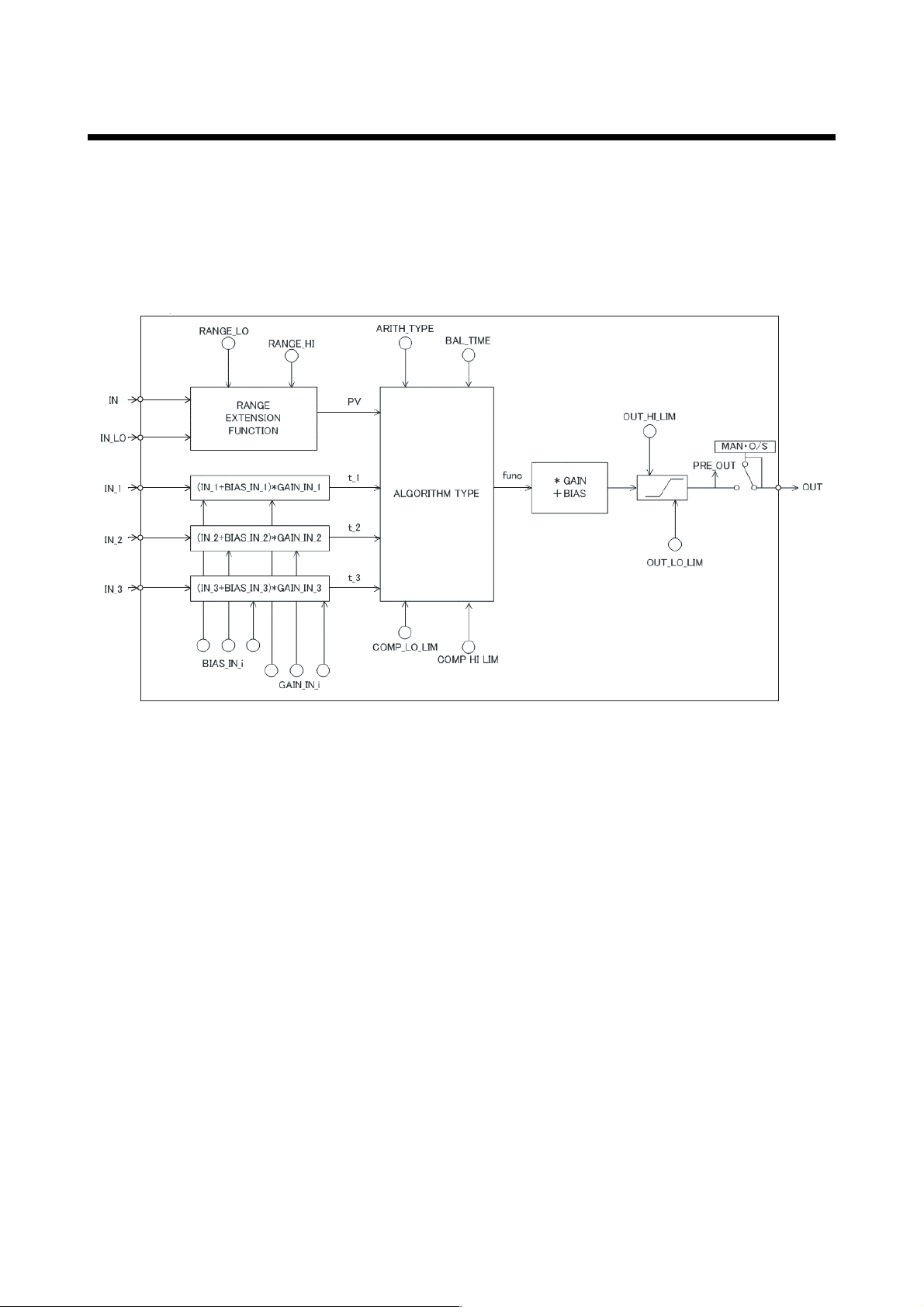

Appendix 4. Arithmetic (AR) Block .............................................................. A-35

A4.1 Arithmetic Function Block Schematic ...............................................A-35

A4.2 Input Section ..................................................................................... A-36

A4.2.1 Main Inputs.................................................................................A-36

A4.2.2 Auxiliary Inputs........................................................................... A-36

A4.2.3 INPUT_OPTS............................................................................. A-37

A4.2.4 Relationship between the Main Inputs and PV ..........................A-37

A4.3 Computation Section......................................................................... A-38

A4.3.1 Computing Equations................................................................. A-38

A4.3.2 Compensated Values................................................................. A-38

A4.3.3 Average Calculation ...................................................................A-38

A4.4 Output Section ..................................................................................A-38

A4.4.1 Mode Handling ...........................................................................A-39

A4.4.2 Status Handling.......................................................................... A-39

A4.5 List of the Arithmetic Block Parameters ...........................................A-40

APPENDIX 5. PID BLOCK .............................................................................. A-42

A5.1 Function Diagram.............................................................................. A-42

A5.2 Functions of PID Block .....................................................................A-42

A5.3 Parameters of PID Block ..................................................................A-43

A5.4 PID Computation Details...................................................................A-45

A5.4.1 PV-proportional and -derivative Type PID (I-PD) Control

Algorithm ....................................................................................A-45

A5.4.2 PID Control Parameters............................................................. A-45

A5.5 Control Output................................................................................... A-45

A5.5.1 Velocity Type Output Action .......................................................A-45

A5.6 Direction of Control Action ................................................................A-45

A5.7 Control Action Bypass.......................................................................A-45

A5.8 Feed-forward .....................................................................................A-46

A5.9 Block Modes......................................................................................A-46

A5.9.1 Mode Transitions........................................................................A-46

A5.10Bumpless Transfer ............................................................................ A-47

A5.11Setpoint Limiters ............................................................................... A-47

A5.11.1 When PID Block Is in Auto Mode ............................................ A-47

A5.11.2 When PID Block Is in Cas or RCas Mode...............................A-47

A5.12External-output Tracking ................................................................... A-47

A5.13Measured-value Tracking.................................................................. A-47

A5.14Initialization and Manual Fallback (IMan) .........................................A-48

A5.15Manual Fallback ................................................................................ A-48

A5.16Auto Fallback .................................................................................... A-48

A5.17Mode Shedding upon Computer Failure........................................... A-49

A5.17.1 SHED_OPT .............................................................................. A-49

A5.18Alarms ...............................................................................................A-49

A5.18.1 Block Alarm (BLOCK_ALM) .....................................................A-49

A5.18.2 Process Alarms ........................................................................ A-49

A5.19Example of Block Connections ......................................................... A-50

A5.20View Object for PID Function Block ................................................. A-50

iv

IM 01C25T02-01E

Page 6

CONTENTS

APPENDIX 6. LINK MASTER FUNCTIONS ................................................... A-52

A6.1 Link Active Scheduler .......................................................................A-52

A6.2 Link Master........................................................................................A-52

A6.3 Transfer of LAS................................................................................. A-53

A6.4 LM Functions.....................................................................................A-54

A6.5 LM Parameters..................................................................................A-55

A6.5.1 LM Parameter List...................................................................... A-55

A6.5.2 Descriptions for LM Parameters ................................................A-57

A6.6 FAQs ................................................................................................. A-59

APPENDIX 7. SOFTWARE DOWNLOAD ....................................................... A-60

A7.1 Benefits of Software Download.........................................................A-60

A7.2 Specifications .................................................................................... A-60

A7.3 Preparations for Software Downloading ........................................... A-60

A7.4 Software Download Sequence..........................................................A-61

A7.5 Download Files..................................................................................A-61

A7.6 Steps after Activating a Field Device................................................A-62

A7.7 Troubleshooting.................................................................................A-63

A7.8 Resource Block’s Parameters Relating to Software Download .......A-63

A7.9 System/Network Management VFD Parameters Relating to Software

Download ..........................................................................................A-65

A7.10Comments on System/Network Management VFD Parameters

Relating to Software Download ........................................................A-66

REVISION RECORD

v

IM 01C25T02-01E

Page 7

1. INTRODUCTION

1. INTRODUCTION

This manual is for the DPharp EJX Series Differential

Pressure/Pressure Transmitter Fieldbus Communication

Type. The Fieldbus communication type is based on

the same silicon resonant sensing technology used in

the BRAIN/HART communication type, and is similar

to the communication types in terms of basic performance and operation. This manual describes only those

topics that are required for operation of the Fieldbus

communication type. For information on the installation, wiring, and maintenance of EJX series pressure

transmitters, refer to the user’s manual for each model.

Also note that the contents of this manual are applicable for device revision 3 of EJX series pressure

transmitters. See a device information sheet attached to

the instrument to check the device revision.

Regarding This Manual

•This manual should be passed on to the end user.

• The contents of this manual are subject to change

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without Yokogawa’s written

permission.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury. It may also be used to alert against

unsafe practices.

IMPORTANT

Indicates that operating the hardware or software

in this manner may damage it or lead to system

failure.

• Yokogawa makes no warranty of any kind with

regard to this manual, including, but not limited to,

implied warranty of merchantability and fitness for a

particular purpose.

• If any question arises or errors are found, or if any

information is missing from this manual, please

inform the nearest Yokogawa sales office.

• The specifications covered by this manual are

limited to those for the standard type under the

specified model number break-down and do not

cover custom-made instruments.

• Please note that changes in the specifications,

construction, or component parts of the instrument

may not immediately be reflected in this manual at

the time of change, provided that postponement of

revisions will not cause difficulty to the user from a

functional or performance standpoint.

• The following safety symbols are used in this

manual:

NOTE

Draws attention to information essential for

understanding the operation and features.

1-1

IM 01C25T02-01E

Page 8

1. INTRODUCTION

1.1 Safe Use of This Product

For the safety of the operator and to protect the

instrument and the system, please be sure to follow this

manual’s safety instructions when handling this

instrument. If these instructions are not heeded, the

protection provided by this instrument may be impaired. In this case, Yokogawa cannot guarantee that

the instrument can be safely operated. Please pay

special attention to the following points:

(a) Installation

• This instrument may only be installed by an engineer or technician who has an expert knowledge of

this device. Operators are not allowed to carry out

installation unless they meet this condition.

•With high process temperatures, care must be taken

not to burn yourself by touching the instrument or

its casing.

• Never loosen the process connector nuts when the

instrument is installed in a process. This can lead to

a sudden, explosive release of process fluids.

•When draining condensate from the pressure

detector section, take appropriate precautions to

prevent the inhalation of harmful vapors and the

contact of toxic process fluids with the skin or eyes.

• When removing the instrument from a hazardous

process, avoid contact with the fluid and the interior

of the meter.

(c) Operation

•Wait 5 min. after the power is turned off, before

opening the covers.

(d) Maintenance

• Please carry out only the maintenance procedures

described in this manual. If you require further

assistance, please contact the nearest Yokogawa

office.

•Care should be taken to prevent the build up of dust

or other materials on the display glass and the name

plate. To clean these surfaces, use a soft, dry cloth.

(e) Explosion Protected Type Instrument

•Users of explosion proof instruments should refer

first to section 2.1 (Installation of an Explosion

Protected Instrument) of this manual.

• The use of this instrument is restricted to those who

have received appropriate training in the device.

• Take care not to create sparks when accessing the

instrument or peripheral devices in a hazardous

location.

(f) Modification

• Yokogawa will not be liable for malfunctions or

damage resulting from any modification made to this

instrument by the customer.

•All installation work shall comply with local

installation requirements and the local electrical

code.

(b) Wiring

• The instrument must be installed by an engineer or

technician who has an expert knowledge of this

instrument. Operators are not permitted to carry out

wiring unless they meet this condition.

• Before connecting the power cables, please confirm

that there is no current flowing through the cables

and that the power supply to the instrument is

switched off.

1-2

IM 01C25T02-01E

Page 9

1. INTRODUCTION

1.2 Warranty

•The warranty shall cover the period noted on the

quotation presented to the purchaser at the time of

purchase. Problems occurring during the warranty

period shall basically be repaired free of charge.

• If any problems are experienced with this instrument, the customer should contact the Yokogawa

representative from which this instrument was

purchased or the nearest Yokogawa office.

• If a problem arises with this instrument, please

inform us of the nature of the problem and the

circumstances under which it developed, including

the model specification and serial number. Any

diagrams, data and other information you can

include in your communication will also be helpful.

• The party responsible for the cost of fixing the

problem shall be determined by Yokogawa following an investigation conducted by Yokogawa.

1.3 ATEX Documentation

This is only applicable to the countries in European

Union.

GB

All instruction manuals for ATEX Ex related products

are available in English, German and French. Should

you require Ex related instructions in your local

language, you are to contact your nearest Yokogawa

office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og fransk.

Skulle De ønske yderligere oplysninger om håndtering

af Ex produkter på eget sprog, kan De rette

henvendelse herom til den nærmeste Yokogawa

afdeling eller forhandler.

• The purchaser shall bear the responsibility for repair

costs, even during the warranty period, if the

malfunction is due to:

- Improper and/or inadequate maintenance by the

purchaser.

- Malfunction or damage due to a failure to handle,

use, or store the instrument in accordance with the

design specifications.

- Use of the product in question in a location not

conforming to the standards specified by

Yokogawa, or due to improper maintenance of the

installation location.

- Failure or damage due to modification or repair by

any party except Yokogawa or an approved

representative of Yokogawa.

- Malfunction or damage from improper relocation

of the product in question after delivery.

- Reason of force majeure such as fires, earthquakes,

storms/floods, thunder/lightening, or other natural

disasters, or disturbances, riots, warfare, or

radioactive contamination.

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i manuali

operativi di prodotti Ex in lingua locale, mettersi in

contatto con l’ufficio Yokogawa più vicino o con un

rappresentante.

E

Todos los manuales de instrucciones para los productos

antiexplosivos de ATEX están disponibles en inglés,

alemán y francés. Si desea solicitar las instrucciones de

estos artículos antiexplosivos en su idioma local,

deberá ponerse en contacto con la oficina o el

representante de Yokogawa más cercano.

NL

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal, contact

op met de dichtstbijzijnde vestiging van Yokogawa of

met een vertegenwoordiger.

1-3

IM 01C25T02-01E

Page 10

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyttöhjeet

ovat saatavilla englannin-, saksan- ja ranskankielisinä.

Mikäli tarvitsette Ex -tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa yhteyttä

lähimpään Yokogawa-toimistoon tai -edustajaan.

P

Todos os manuais de instruções referentes aos

produtos Ex da ATEX estão disponíveis em Inglês,

Alemão e Francês. Se necessitar de instruções na sua

língua relacionadas com produtos Ex, deverá entrar em

contacto com a delegação mais próxima ou com um

representante da Yokogawa.

F

1. INTRODUCTION

Tous les manuels d’instruction des produits ATEX Ex

sont disponibles en langue anglaise, allemande et

française. Si vous nécessitez des instructions relatives

aux produits Ex dans votre langue, veuillez bien

contacter votre représentant Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch, Deutsch

und Französisch zur Verfügung. Sollten Sie die

Betriebsanleitungen für Ex-Produkte in Ihrer

Landessprache benötigen, setzen Sie sich bitte mit

Ihrem örtlichen Yokogawa-Vertreter in Verbindung.

S

Alla instruktionsböcker för ATEX Ex

(explosionssäkra) produkter är tillgängliga på

engelska, tyska och franska. Om Ni behöver

instruktioner för dessa explosionssäkra produkter på

annat språk, skall Ni kontakta närmaste

Yokogawakontor eller representant.

GR

ATEX Ex

, .

Ex

Yokogawa .

1-4

IM 01C25T02-01E

Page 11

2. HANDLING CAUTIONS

2. HANDLING CAUTIONS

2.1 Installation of an Explosion-

Protected Instrument

If a customer makes a repair or modification to an

intrinsically safe or explosionproof instrument and the

instrument is not restored to its original condition, its

intrinsically safe or explosionproof construction may

be compromised and the instrument may be hazardous

to operate. Please contact Yokogawa before making

any repair or modification to an instrument.

CAUTION

This instrument has been tested and certified as

being intrinsically safe or explosionproof. Please

note that severe restrictions apply to this

instrument’s construction, installation, external

wiring, maintenance and repair. A failure to

abide by these restrictions could make the

instrument a hazard to operate.

WARNING

Maintaining the safety of explosionproof equipment requires great care during mounting,

wiring, and piping. Safety requirements also

place restrictions on maintenance and repair.

Please read the following sections very carefully.

WARNING

The range setting switch must not be used in a

hazardous area.

2.1.1 FM approval

a. FM Explosionproof Type

Caution for FM Explosionproof type

Note 1. EJX Series differential gauge, and absolute

pressure transmitters with optional code /FF1

are applicable for use in hazardous locations:

• Applicable Standard: FM3600, FM3615,

FM3810, ANSI/NEMA 250

• Explosionproof for Class I, Division 1,

Groups B, C and D.

•Dust-ignitionproof for Class II/III, Division

1, Groups E, F and G.

• Enclosure rating: NEMA 4X.

• Temperature Class: T6

• Ambient Temperature: –40 to 60°C

• Supply Voltage: 32V dc max.

• Current Draw: 15 mA dc

Note 2. Wiring

• All wiring shall comply with National

Electrical Code ANSI/NFPA70 and Local

Electrical Codes.

•When installed in Division 1, “FACTORY

SEALED, CONDUIT SEAL NOT REQUIRED.”

Note 3. Operation

•Keep the “WARNING” nameplate attached

to the transmitter.

WARNING: OPEN CIRCUIT BEFORE

REMOVING COVER.

FACTORY SEALED, CONDUIT

SEAL NOT REQUIRED.

INSTALL IN ACCORDANCE

WITH THE USERS MANUAL IM

01C25.

• Take care not to generate mechanical

sparking when accessing the instrument and

peripheral devices in a hazardous location.

Note 4. Maintenance and Repair

• The instrument modification or parts

replacement by other than authorized

representative of Yokogawa Electric Corporation is prohibited and will void Factory

Mutual Explosionproof Approval.

2-1

IM 01C25T02-01E

Page 12

2. HANDLING CAUTIONS

b. FM Nonincendive Type

EJX Series differential, gauge, and absolute

pressure transmitters with optional code /FN15.

• Applicable Standard: Class 3600, Class 3611,

Class 3810,ANSI/NEMA250

• Class I, Division 2, Groups A, B, C & D

Temperature Class T4 Ta=60°C, Type 4X and

Class II, Division 2, Groups F & G Temperature

Class T4 Ta=60°C, Type 4X and Class III,

Division 1, Temperature Class T4 Ta=60°C,

Type 4X and Class I, Zone 2, Group IIC,

Temperature Class T4 Ta=60°C, Type 4X

• Electrical Connection: 1/2 NPT female and M20

female

• Caution for FM Nonincendive type. (Following

contents refer to “DOC. No. IFM024-A12 p.3,

p.4-1, and p.4-2.”)

IFM024-A12

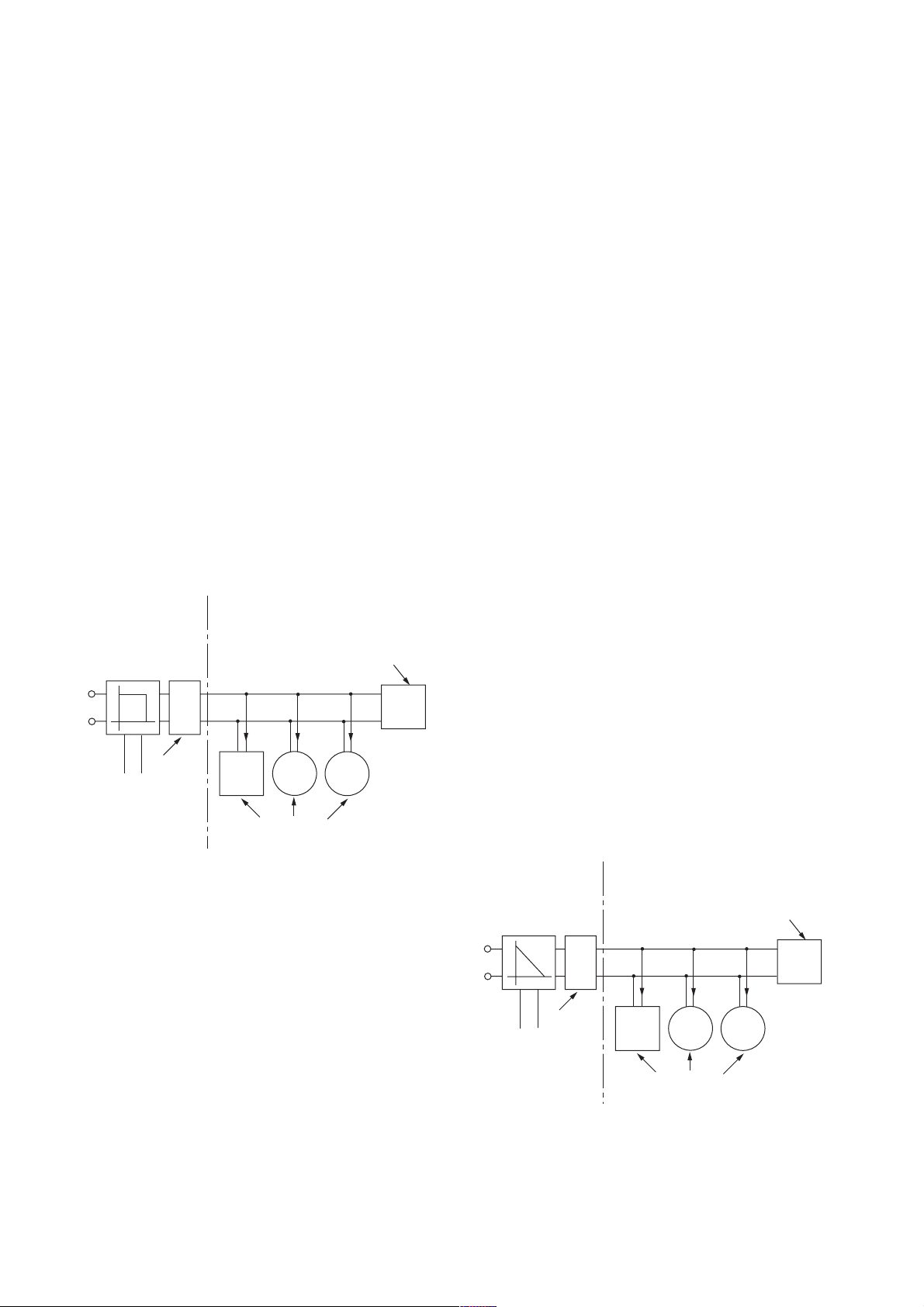

Installation Diagram for Nonincendive

(Division 2 Installation)

Terminator

Pressure

Transmitter

SUPPLY

Transmitter

Transmitter

Hazardous location

Note 1. Installation should be in accordance with the

National Electrical Code ® (ANSI/NFPA 70)

Article 500.

Note 2. The configuration of Associated Nonincendive

Field Wiring Apparatus must be FM

Approved.

Note 3. Approved under FNICO Concept.

Note 4. Dust-tight conduit seal must be used when

installed in Class II and Class III environ-

ments.

Note 5. Associated Apparatus manufacturer’s installa-

tion drawing must be followed when installing

this apparatus.

Note 6. No revision to drawing without prior FM

Approvals.

Note 7. Terminator must be FM Approved.

Note 8. The nonincendive field wiring circuit concept

allows interconection of nonincendive field

wiring apparatus with associated nonincendive

field wiring apparatus, using any of the wiring

methods permitted for unclassified locations.

Note 9. Installation requirements;

Vmax Voc or Vt

Imax = see note 10.

Ca Ci + Ccable

La Li + Lcable

Note 10. For this current controlled circuit, the param-

eter (Imax 3) is not required and need not be

aligned with parameter (Isc 3) of the barrier

or associated nonincendive field wiring

apparatus.

Note 11. If ordinary location wiring methods are used,

the transmitter shall be connected to FM

Approved associated non-incendive field

wiring apparatus.

Electrical data:

Vmax: 32V

Ci:1.76 nF

Li: 0 H

Terminator

General Purpose

Equipment

Non-Hazardous location

FM Approved

Associated Nonincendive Field

Wiring Apparatus

Vt or Voc

It or Isc

Ca

La

F0204.EPS

2-2

IM 01C25T02-01E

Page 13

2. HANDLING CAUTIONS

FNICO Rules

The FNICO Concept allows the interconnection of

nonincendive field wiring apparatus to associated

nonincendive field wiring apparatus not specifically

examined in such combination. The criterion for such

interconnection is that the voltage (Vmax), the current

(Imax) and the power (Pmax) which nonincendive field

wiring apparatus can receive and remain nonincendive,

considering faults, must be equal or greater than the

voltage (Uo, Voc or Vt), the current (Io, Isc or It) and

the power (Po) which can be provided by the associated nonincendive field wiring apparatus (supply unit).

In addition the maximum unprotected residual capacitance (Ci) and inductance (Li) of each apparatus (other

than terminators) connected to the Fieldbus must be

less than or equal to 5nF and 10uH respectively.

In each N.I. Fieldbus segment only one active source,

normally the associated nonincendive field wiring

apparatus, is allowed to provide the necessary power

for the Fieldbus system. The allowed voltage (Uo, Voc

or Vt) of the associated nonincendive field wiring

apparatus used to supply the bus cable must be limited

to the range 14Vdc to 17.5Vdc. All other equipment

connected to the bus cable has to be passive, meaning

that the apparatus is not allowed to provide energy to

the system, except a leakage current of 50É A for each

connected device. Separately powered equipment needs

galvanic isolation to ensure the nonincendive field

wiring Fieldbus circuit remains passive.

Cable

The cable used to interconnect the devices needs to

comply with the following parameters:

Loop resistance R': 15...150 Ω/km

Inductance per unit length L': 0.4...1 mH/km

Capacitance per unit length C': 80....200 nF/km

C' =C' line/line+0.5 C' line/screen, if both lines are

floating or C' = C' line/line + C'line/screen, if

thescreen is connected to one line.

Length of spur cable: max. 30 m

Length of trunk cable: max. 1 km

Length of splice: max = 1 m

Terminators

At the end of each trunk cable an FM Approved line

terminator with the following parameters is suitable:

R= 90...100 Ω

C = 0 ....2.2 uF

2.1.2 CSA Certification

a. CSA Explosionproof Type

Caution for CSA explosionproof type.

Note 1. Model EJX Series differential, gauge, and

absolute pressure transmitters with

optional code /CF1 are applicable for use

in hazardous locations:

Certificate: 1589701

[For CSA C22.2]

• Applicable Standard: C22.2 No.0, C22.2 No.0.4,

C22.2 No.0.5, C22.2 No.25, C22.2 No.30,

C22.2 No.94, C22.2 No.61010.1-01

• Explosion-proof for Class I, Groups B, C and D.

• Dustignition-proof for Class II/III, Groups E, F and

G.

• Enclosure: TYPE 4X

• Temperature Code: T6...T4

[For CSA E60079]

• Applicable Standard: CAN/CSA E60079-0,

CAN/CSA E60079-1

• Flameproof for Zone 1, Ex d IIC T6...T4

• Enclosure: IP66 and IP67

• Maximum Process Temperature: 120°C (T4),

100°C (T5), 85°C (T6)

• Ambient Temperature: –50 to 75°C (T4), –50 to

80°C (T5), –50 to 72 õ (T6)

• Supply Voltage: 32 V dc max.

• Output Signal: 15 mA dc

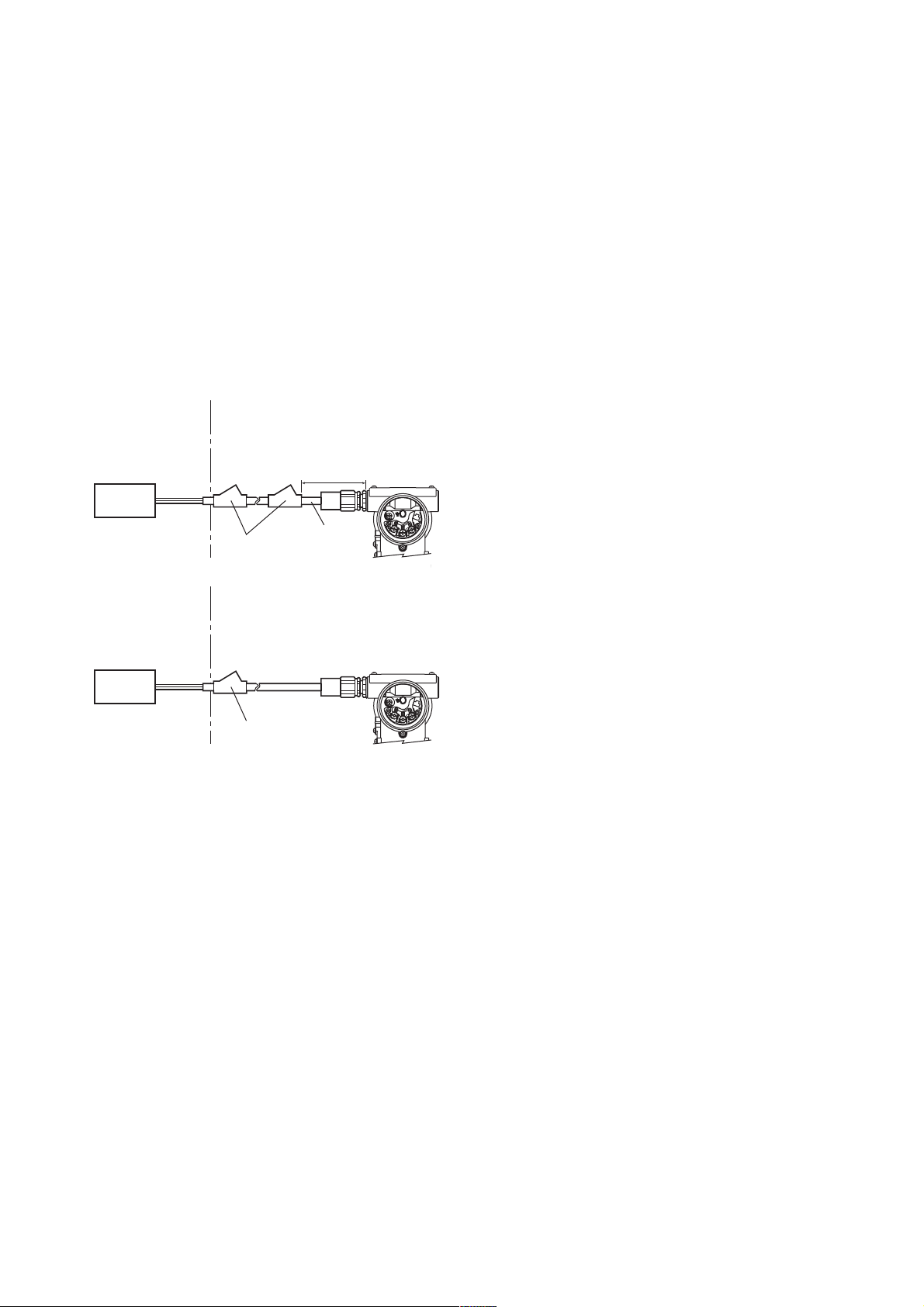

Note 2. Wiring

• All wiring shall comply with Canadian Electrical

Code Part I and Local Electrical Codes.

• In hazardous location, wiring shall be in conduit as

shown in the figure.

• WARNING:

A SEAL SHALL BE INSTALLED WITHIN 50cm

OF THE ENCLOSURE.

UN SCELLEMENT DOIT ÊTRE INSTALLÉ À

MOINS DE 50cm DU BOÎTIER.

• WARNING:

WHEN INSTALLED IN CL.I, DIV 2, SEAL NOT

REQUIRED.

UNE FOIS INSTALLÉ DANS CL I, DIV 2,

AUCUN JOINT N'EST REQUIS.

Note 3. Operation

• WARNING:

AFTER DE-ENERGIZING, DELAY 5 MINUTES

BEFORE OPENING.

APRÉS POWER-OFF, ATTENDRE 5 MINUTES

AVANT D'OUVRIR.

2-3

IM 01C25T02-01E

Page 14

2. HANDLING CAUTIONS

• WARNING:

WHEN AMBIENT TEMPERATURE ≥ 65°C,

USE THE HEAT-RESISTING CABLES ≥ 90°C.

QUAND LA TEMPÉRATURE AMBIANTE ≥

65°C, UTILISEZ DES CÂBLES RÉSISTANTES Á

LA CHALEUR ≥ 90°C.

• Take care not to generate mechanical sparking

when accessing to the instrument and peripheral

devices in a hazardous location.

Note 4. Maintenance and Repair

• The instrument modification or parts replacement

by other than authorized representative of

Yokogawa Electric Corporation and Yokogawa

Corporation of America is prohibited and will void

Canadian Standards Explosionproof Certification.

Non-Hazardous

Locations

Non-hazardous

Location

Equipment

32 V DC Max.

15 mA DC

Signal

Non-Hazardous

Locations

Non-hazardous

Location

Equipment

32 V DC Max.

15 mA DC

Signal

Hazardous Locations Division 1

50 cm Max.

Sealing Fitting

Conduit

EJX Series

Hazardous Locations Division 2

Sealing Fitting

EJX Series

S

U

P

PL

Y

CHECK

RM

A

L

A

S

U

P

P

L

Y

K

C

E

H

C

M

R

A

L

A

F0205.EPS

2.1.3 CENELEC ATEX Certification

(1) Technical Data

a. CENELEC ATEX (KEMA) Intrinsically Safe

Type

Caution for CENELEC ATEX (KEMA) Intrinsically

safe type.

Note 1. EJX Series differential, gauge, and absolute

pressure transmitters with optional code /KS25

for potentially explosive atmospheres:

• No. KEMA 04ATEX1116 X

• Applicable Standard: EN 50014, EN 50020,

EN 50284, EN50281-1-1

Note 2. Ratings

[EEx ia IIC T4]

Type of Protection and Marking Code:

EEx ia IIC T4

Group: II

Category: 1GD

Ambient Temperature: –40 to 60°C

Maximum Process Temperature (Tp.): 120°C

Maximum Surface Temperature for dust

proof.

T85°C (Tamb.: –40°C to 60°C, Tp.: 80°C)

T100°C (Tamb.: –40°C to 60°C, Tp.: 100°C)

T120°C (Tamb.: –40°C to 60°C, Tp.: 120°C)

Degree of Protection of the Enclosure: IP66

and IP67

Electrical Data

• When combined with Trapezoidal and

Rectangular output characteristic FISCO

model IIC barrier

Ui = 17.5 V, Ii = 380 mA, Pi = 5.32 W,

Ci = 1.76 nF, Li = 0 H

SE

PUL

• When combined with Linear characteristic

barrier

Ui = 24.0 V, Ii = 250 mA, Pi = 1.2 W,

Ci = 1.76 nF, Li = 0 H

[EEx ia IIB T4]

Type of Protection and Marking Code:

EEx ia IIB T4

Group: II

Category: 1GD

E

S

UL

P

Ambient Temperature: –40 to 60°C

Maximum Process Temperature (Tp.): 120°C

Maximum Surface Temperature for dust

proof.

T85°C (Tamb.: –40°C to 60°C, Tp.: 80°C)

T100°C (Tamb.: –40°C to 60°C, Tp.: 100°C)

T120°C (Tamb.: –40°C to 60°C, Tp.: 120°C)

Degree of Protection of the Enclosure: IP66

and IP67 Electrical Data

• When combined with Trapezoidal or

Rectangular output characteristic FISCO

model IIB barrier

Ui = 17.5 V, Ii = 460 mA, Pi = 5.32 W,

Ci = 1.76 nF, Li = 0 H

Note 3. Installation

• All wiring shall comply with local installation requirements. (Refer to the installation

diagram)

Note 4. Maintenance and Repair

• The instrument modification or parts

replacement by other than authorized

representative of Yokogawa Electric Corporation is prohibited and will void KEMA

Intrinsically safe Certification.

2-4

IM 01C25T02-01E

Page 15

2. HANDLING CAUTIONS

Note 5. Special Conditions for Safe Use

• In the case where the enclosure of the

Pressure Transmitter is made of aluminium,

if it is mounted in an area where the use of

category 1 G apparatus is required, it must

be installed such, that even in the event of

rare incidents, ignition sources due to impact

and friction sparks are excluded.

Note 6. Installation instructions

• From the safety point of view the circuit

shall be considered to be connected to earth.

As this deviates from the FISCO system in

acordance with IEC TS 60079-27 care has to

be taken that the (local) installation requirements are taken into account as well.

When used in a potentially explosive

atmosphere, requiring the use of apparatus of

equipment category 1D or 2D, certified

cable entry devices shall be used that are

suitable for the application and correctly

installed.

FISCO Model

Supply unit

The supply unit must be certified by a Notified body as

FISCO model and following trapezoidal or rectangular

output characteristic is used.

Uo = 14...17.5 V (I.S. maximum value)

Io based on spark test result or other assessment,

No specification of Lo and Co is required on the

certificate or label.

Cable

The cable used to interconnect the devices needs to

comply with the following parameters:

Loop resistance Rc: 15...150 Ω/km

Inductance per unit length Lc: 0.4...1 mH/km

Capacitance per unit length Cc: 80...200 nF/km

Length of spur cable: max. 30 m (IIC and IIB)

Length of trunk cable: max. 1 km (IIC) or 5 km

(IIB)

Terminators

The terminator must be certified by a Notified body as

FISCO model and at each end of the trunk cable an

approved line terminator with the following parameters

is suitable:

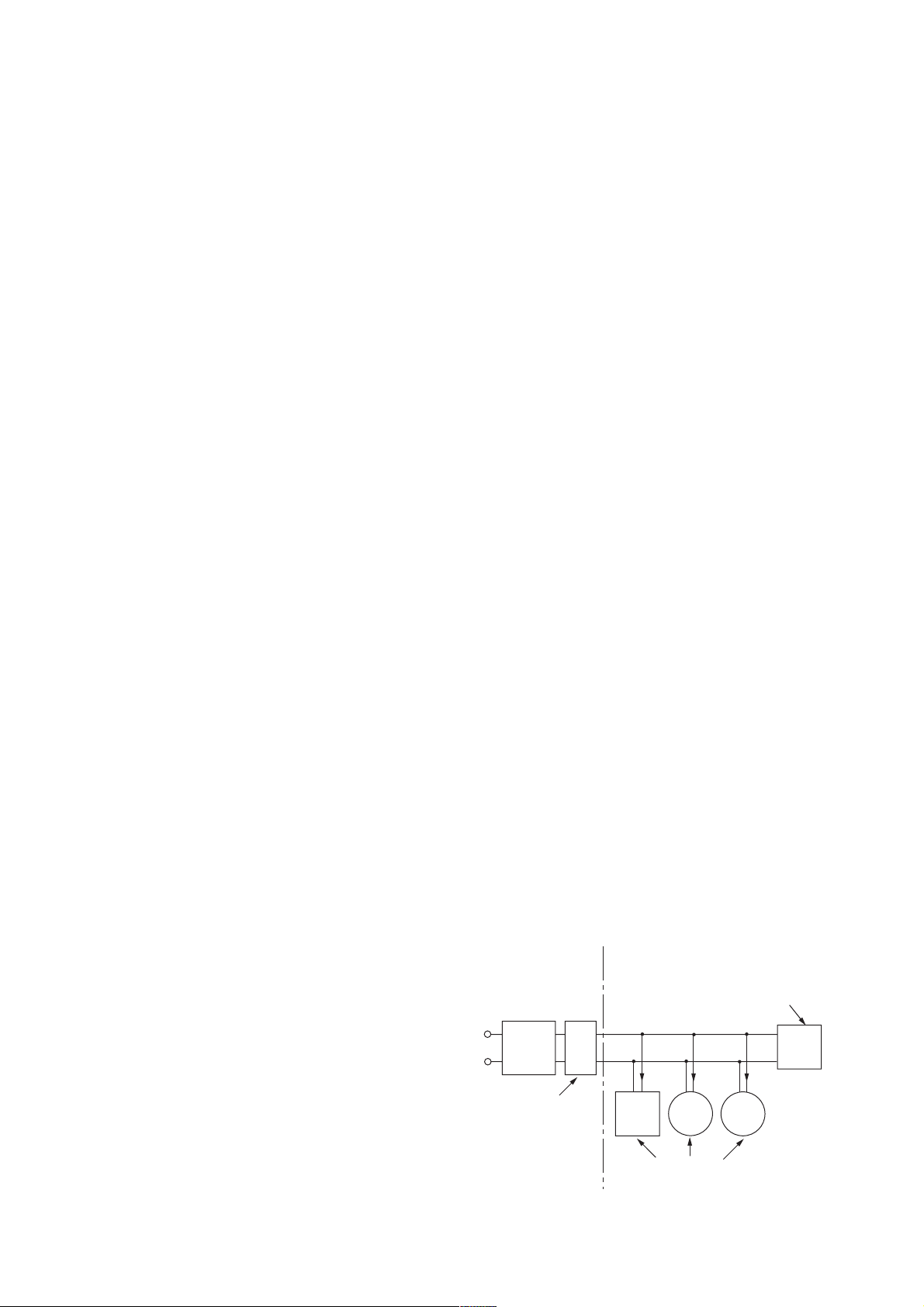

Non-Hazardous

Locations

Supply Unit and

Safety Barrier

(FISCO Model)

U

U

I

Terminator

Data

I.S. fieldbus system complying with FISCO

Hazardous Locations

Ex i

Hand-

held-

Terminal

Field Instruments

(Passive)

Terminator

(FISCO Model)

F0201-1.EPS

The criterion for such interconnection is that the

voltage (Ui), the current (Ii) and the power (Pi), which

intrinsically safe apparatus can receive, must be equal

or greater than the voltage (Uo), the current (Io) and the

power (Po) which can be provided by the associated

apparatus (supply unit).

Po Pi, Uo Ui, Io Ii

In addition, the maximum unprotected residual capaci-

tance (Ci) and inductance (Li) of each apparatus (other

than the terminators) connected to the fieldbus line

must be equal or less than 5 nF and 10 H respectively.

Ci 5 nF, Li 10H

R = 90 . . . 102 Ω

C = 0 . . . 2.2 F. (0.8...1.2 F is required in

operation)

The resistor must be infallible according to IEC 60079-

11.

Number of Devices

The number of devices (max. 32) possible on a

fieldbus link depends on factors such as the power

consumption of each device, the type of cable used,

use of repeaters, etc.

Entity Model

Non-Hazardous

Locations

Supply Unit and

Safety Barrier

U

U

I

Terminator

Data

I.S. fieldbus system complying with Entity model

Hazardous Locations

Ex i

Hand-

held-

Terminal

Field Instruments

(Passive)

Terminator

F0202-1.EPS

2-5

IM 01C25T02-01E

Page 16

2. HANDLING CAUTIONS

I.S. values Power supply-field device:

Po Pi, Uo Ui, Io Ii

Calculation of max. allowed cable length:

Ccable Co - ∑Ci - ∑Ci (Terminator)

Lcable Lo - ∑Li

Number of Devices

The number of devices (max. 32) possible on a

fieldbus link depends on factors such as the power

consumption of each device, the type of cable used,

use of repeaters, etc.

b. CENELEC ATEX (KEMA) Flameproof Type

Caution for CENELEC ATEX (KEMA) flameproof

type

Note 1. EJX Series differential, gauge, and absolute

pressure transmitters with optional code /KF2

for potentially explosive atmospheres:

• No. KEMA 03ATEX2570

• Applicable Standard: EN 50014, EN 50018,

EN 50281-1-1

• Type of Protection and Marking Code: EEx

d IIC T6...T4

• Group: II

• Category: 2G, 1D

• Temperature Class: T6, T5, and T4

• Enclosure: IP66 and IP67

• Ambient Temperature for gas-proof:

–50 to 70°C (T6), –50 to 80°C (T5), and

–50 to 75°C (T4)

• Maximum Process Temperature (Tp.) for

gas-proof:

85°C (T6), 100°C (T5), and 120°C (T4)

• Maximum Surface Temperature for dust-

proof:

T80°C (Tamb.: –40 to 40°C, Tp.: 80°C)

T100°C (Tamb.: –40 to 60°C, Tp.: 100°C)

T120°C (Tamb.: –40 to 80°C, Tp.: 120°C)

Note 2. Electrical Data

• Supply voltage: 32 V dc max.

Output current: 15 mA dc

Note 3. Installation

• All wiring shall comply with local installation requirements.

•The cable entry devices shall be of a

certified flameproof type, suitable for the

conditions of use.

Note 4. Operation

• Keep the “WARNING” label attached to the

transmitter.

WARNING: AFTER DE-ENERGIZING,

DELAY 5 MINUTES BEFORE

OPENING. WHEN THE AMBIENT

TEMP.65°C, USE HEAT-RESISTING

CABLES90°C.

• Take care not to generate mechanical

sparking when accessing the instrument and

peripheral devices in hazardous location.

Note 5. Maintenance and Repair

• The instrument modification or part replacement by other than an authorized representative of Yokogawa Electric Corporation is

prohibited and will void KEMA Flameproof

Certification.

c. CENELEC ATEX Type of Protection “n”

Caution for CENELEC ATEX Type of Protection “n”

type

Note 1. EJX Series differential, gauge, and absolute

pressure transmitters with option code /KN25

for potentially explosive atmospheres:

• Applicable standard: EN 50021, EN 60529

• Type of Protection and Marking Code:

EEx nL IIC T4

• Group: II

• Category: 3G

• Ambient Temperature: –50 to 60°C

• Ambient humidity: 0 to 100%RH

(No condensation)

• Maximum Process Temperature : 120°C

• Enclosure: IP66 and IP67

Note 2. Electrical Data

Ui = 32 Vdc

Ci = 1.76 nF

Li = 0 µH

Note 3. Installation

• All wiring shall comply with local installation requirements. (refer to the installation

diagram)

Note 4. Maintenance and Repair

• The instrument modification or parts

replacement by other than authorized

representative of Yokogawa Electric Corporation is prohibited and will void Type of

Protection “n”.

[Installation Diagram]

U

2-6

Non-Hazardous

Locations

(Zone2)

Power

Supply

[EEx nL]

Terminator

Hazardous Locations

Terminator

Hand-

held-

Terminal

Field Instruments

(Passive)

IM 01C25T02-01E

F0202-2.EPS

Page 17

2. HANDLING CAUTIONS

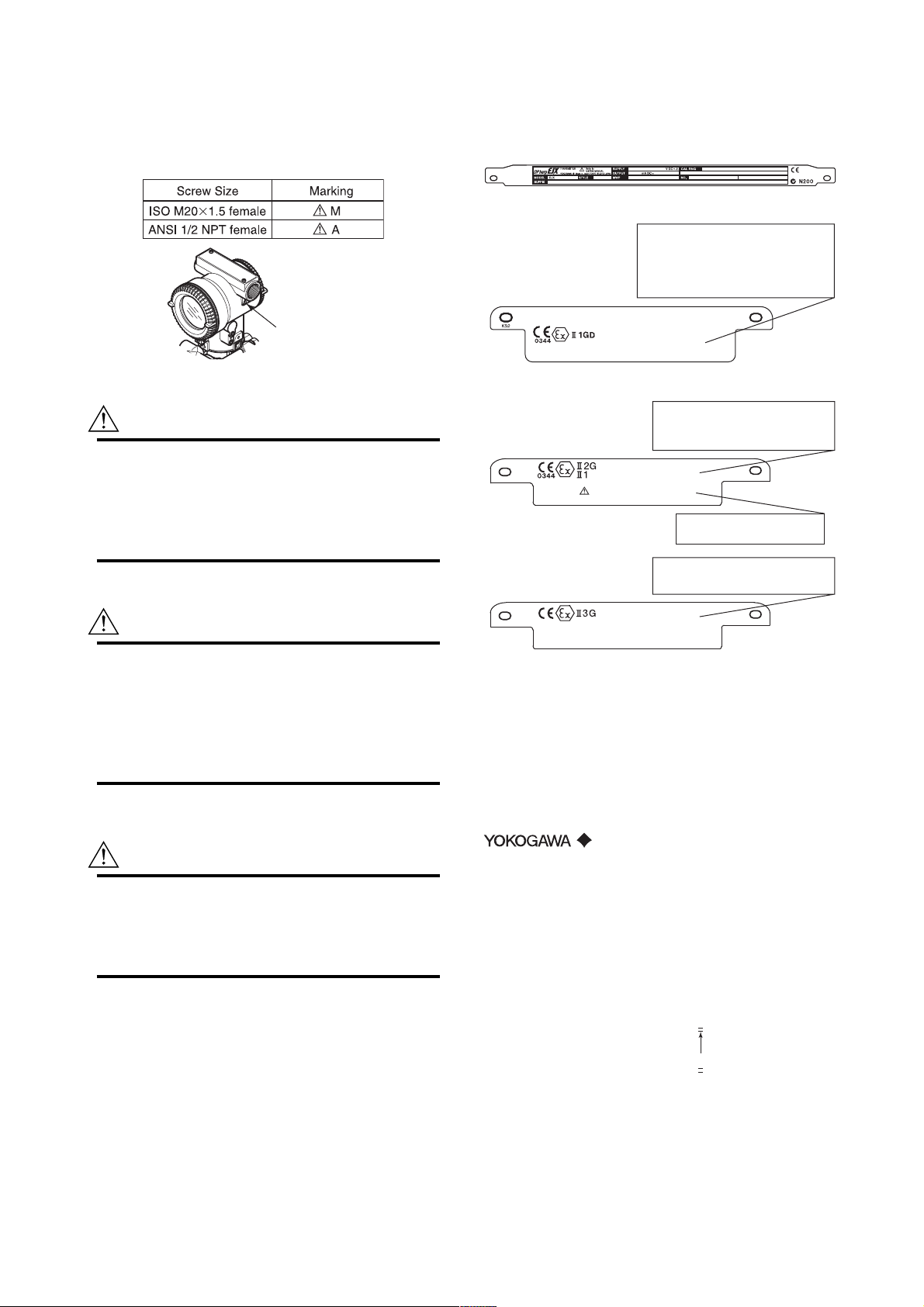

(2) Electrical Connection

A mark indicating the electrical connection type is

stamped near the electrical connection port. These

marks are as follows.

T0201.EPS

Location of the mark

F0201.EPS

(3) Installation

WARNING

•All wiring shall comply with local installation

requirements and the local electrical code.

• There is no need for a conduit seal in Division

1 and Division 2 hazardous locations because

this product is sealed at the factory.

(4) Operation

(6) Name Plate

Name plate

Tag plate for intrinsically safe type

No. KEMA 04ATEX1116 X

EEx ia IIB/IIC T4 Tamb.:-40 to 60°C

MAX PROCESS TEMP.(Tp.):120°C

T85°C(Tp.:80°C), T100°C(Tp.:100°C), T120°C(Tp.:120°C)

Enclosure: IP66 and IP67

FISCO Field device(IIC) FISCO Field device(IIB) Entity Parameters

Ui=17.5V Ui=17.5V Ui=24V

Ii=380mA Ii=460mA Ii=250mA

Pi=5.32W Pi=5.32W Pi=1.2W

Ci=1.76nF Ci=1.76nF Ci=1.76nF

Li=0µH Li=0µH Li=0µH

Tag plate for flameproof type

No. KEMA 03ATEX2570

EEx d IIC T6...T4 IP66 andIP67

TEMP. CLASS T6 T5 T4

MAX PROCESS TEMP.(Tp.) 85 100 120 °C

Tam b. -50 to 70 80 75 °C

T80°C(Tamb.:40°C, Tp.:80°C),T100°C(Tamb.:60°C, Tp.:100°C),

T120°C(Tamb.:80°C, Tp.:120°C) Min.Tamb.:-40°C(for DUST)

D

WARNING

EEx nL IIC T4

IP66 and IP67

Tam b. -5 0 to 60°C

MAX PROCESS TEMP. 120°C

Ui=32V Ci=1.76nF Li=0µH

AFTER DE-ENERGIZING, DELAY 5 MINUTES

BEFORE OPENING.

WHEN THE AMBIENT TEMP. 65°C,

USE THE HEAT-RESISTING CABLES 90°C

WARNING

• OPEN CIRCUIT BEFORE REMOVING

COVER. INSTALL IN ACCORDANCE WITH

THIS USER’S MANUAL

• Take care not to generate mechanical sparking

when accessing the instrument and peripheral

devices in a hazardous location.

(5) Maintenance and Repair

WARNING

The instrument modification or part replacement

by other than an authorized Representative of

Yokogawa Electric Corporation is prohibited and

will void the certification.

F0202.EPS

MODEL: Specified model code.

STYLE: Style code.

SUFFIX: Specified suffix code.

SUPPLY: Supply voltage.

OUTPUT: Output signal.

MWP: Maximum working pressure.

CAL RNG: Specified calibration range.

NO.: Serial number and year of production*1.

TOKYO 180-8750 JAPAN:

The manufacturer name and the address*2.

*1: The first digit in the final three numbers of the

serial number appearing after “NO.” on the name

plate indicates the year of production. The following is an example of a serial number for a product

that was produced in 2004:

12A819857 432

The year 2004

*2: “180-8750” is the Zip code for the following

address.

2-9-32 Nakacho, Musashino-shi, Tokyo Japan

2-7

IM 01C25T02-01E

Page 18

3. ABOUT FIELDBUS

3. ABOUT FIELDBUS

3.1 Outline

Fieldbus is a wide l y u se d bi-directional digital communication protocol for field devices that enable the simultaneous output to many types of data to the process

control system.

The EJX Series Fieldbus communication type employs

the specification standardized by The Fieldbus Foundation, and provides interoperability between Yokogawa

devices and those produced by other manufacturers.

Fieldbus comes with software consisting of three AI

function blocks that enable the flexible implementation

of systems.

For information on other features, engineering, design,

construction work, startup and maintenance of

Fieldbus, refer to “Fieldbus Technical Information” (TI

38K03A01-01E).

3.2 Internal Structure of EJX

The EJX contains two virtual field devices (VFD) that

share the following functions.

3.2.1 System/network Management VFD

• Sets node addresses and Physical Device tags (PD

Tag) necessary for communication.

• Controls the execution of function blocks.

•Manages operation parameters and communication

resources (Virtual Communication Relationship:

VCR).

• Carry out scaling, damping and square root extraction.

(5)PID function block

• Performs the PID control computation based on the

deviation of the measured value from the setpoint.

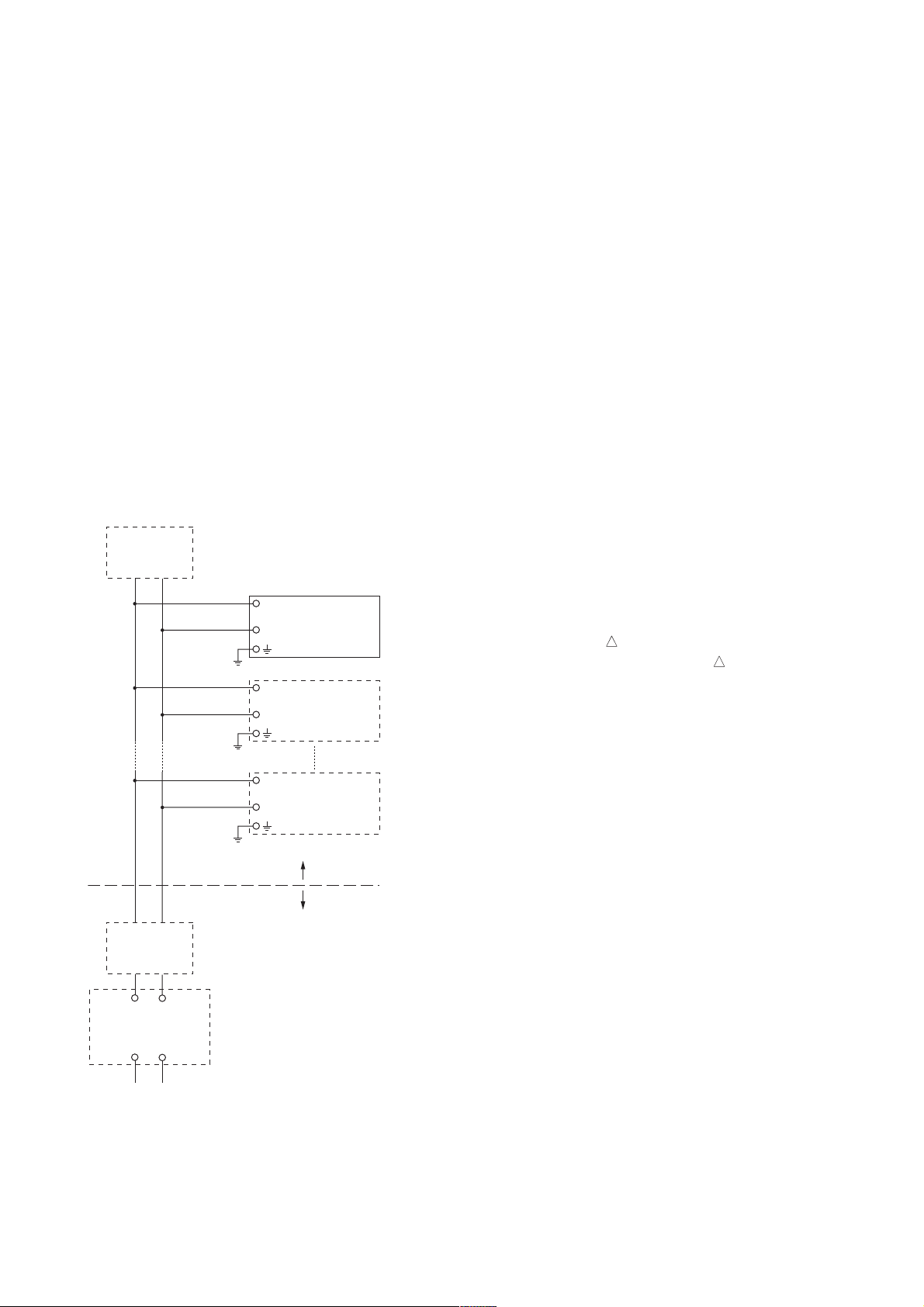

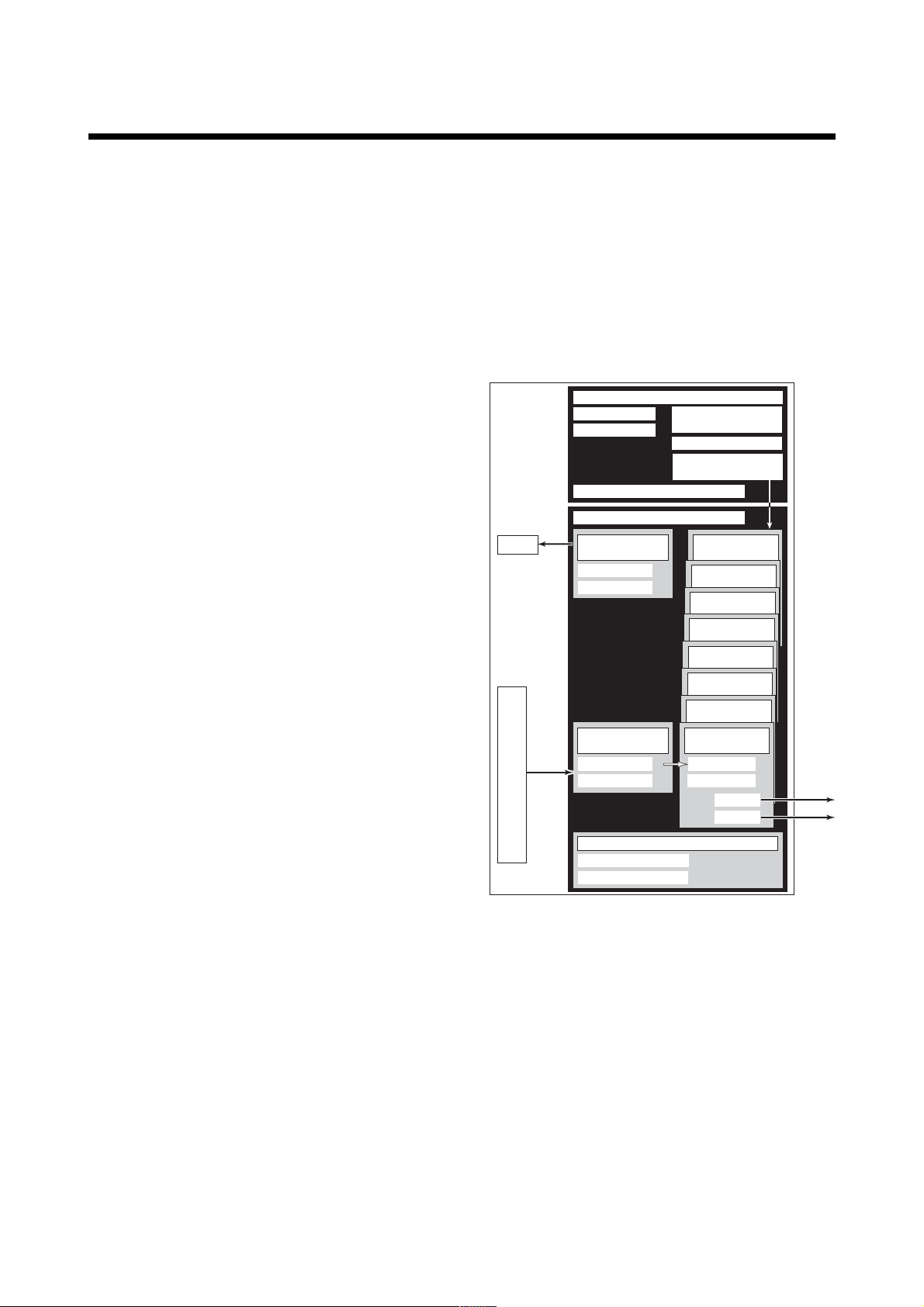

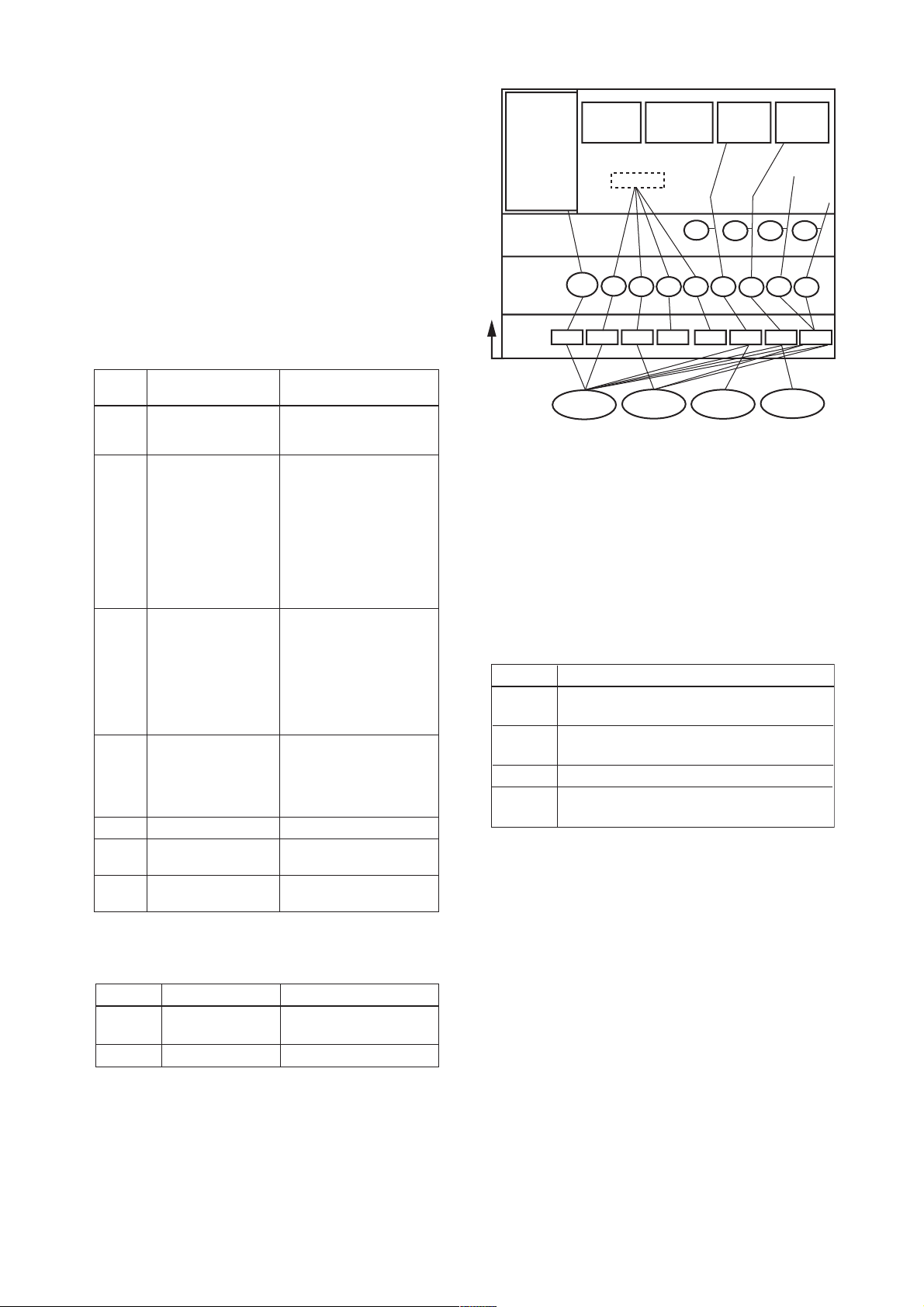

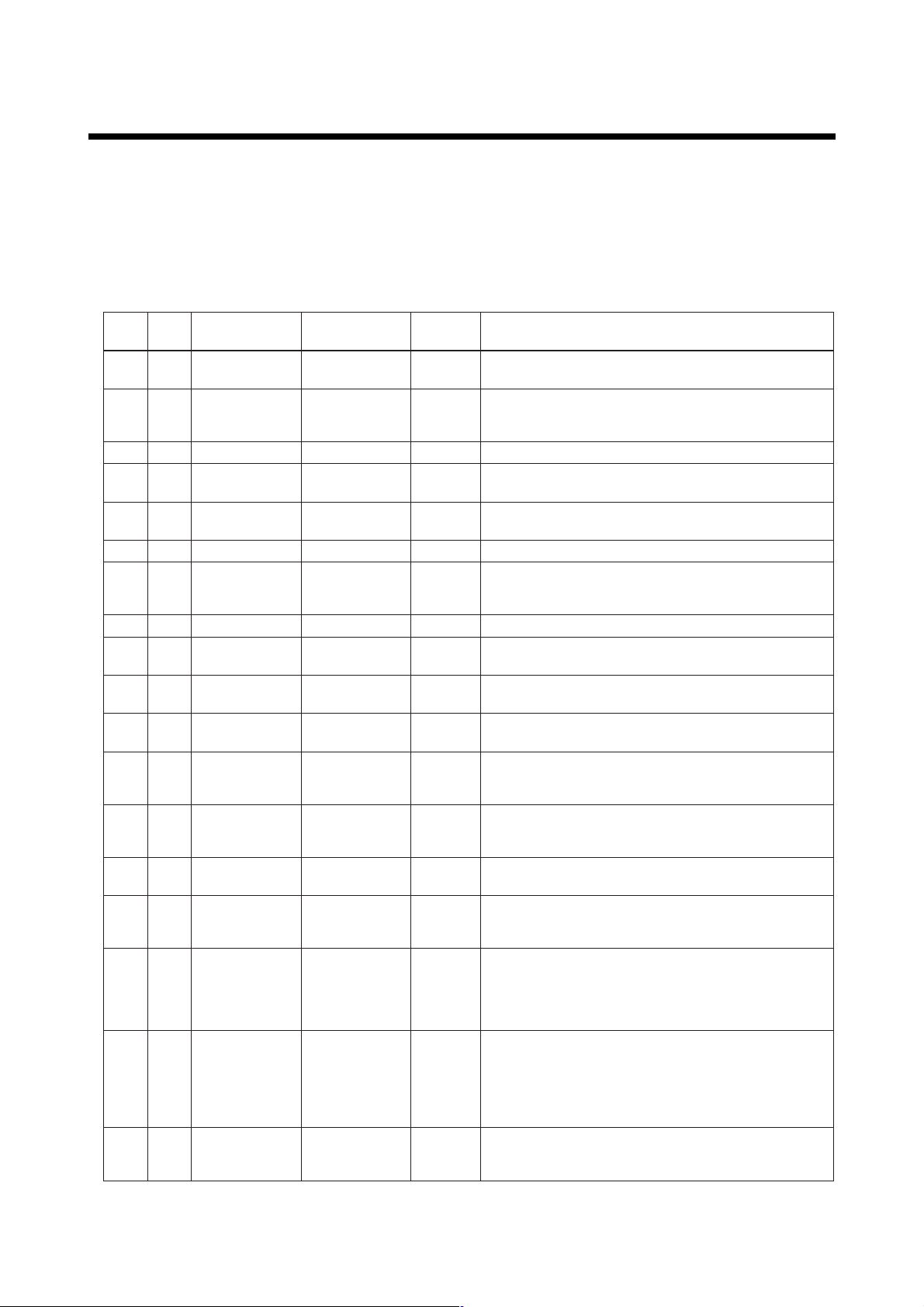

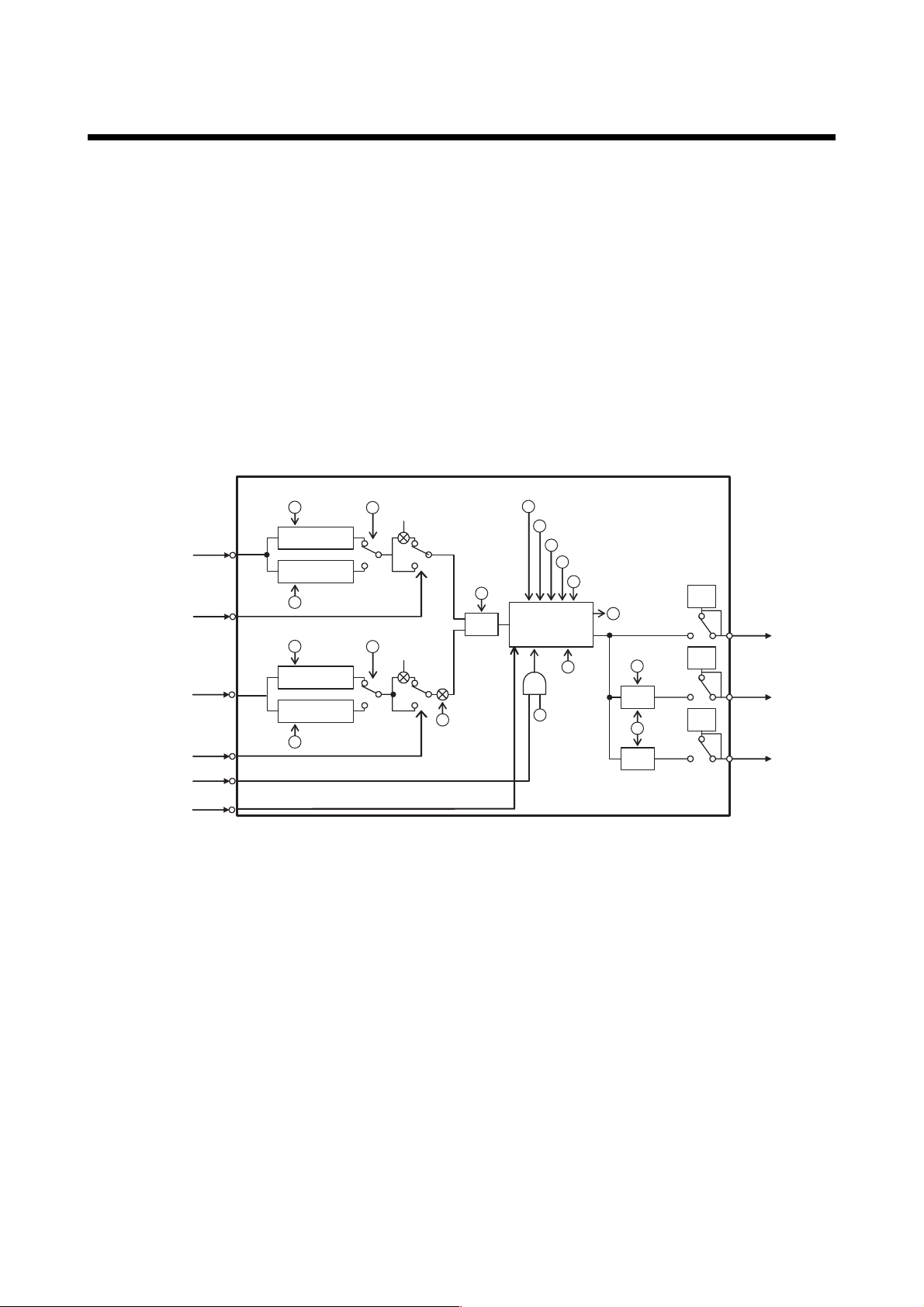

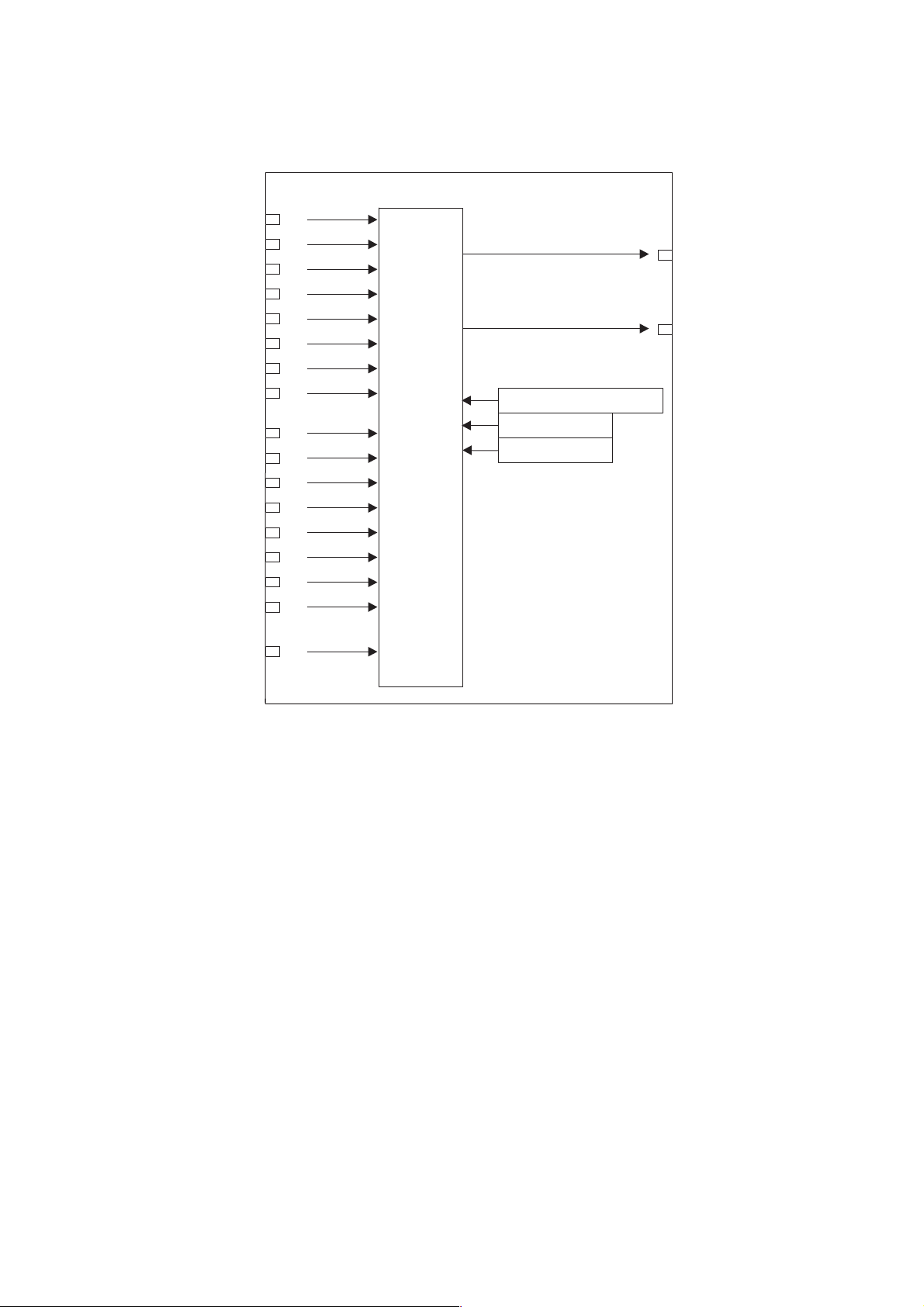

3.3 Logical Structure of Each

Block

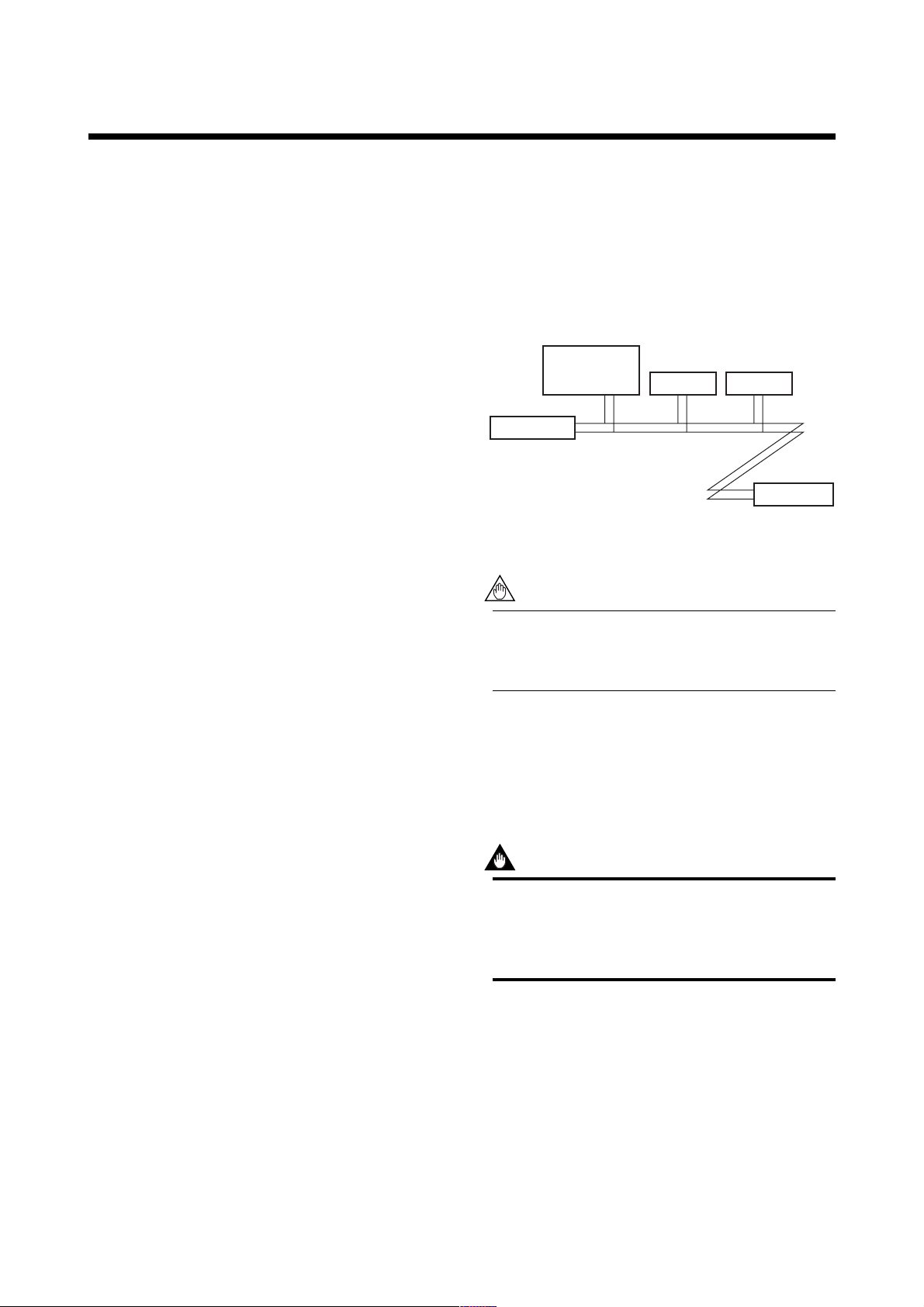

EJX

Fieldbus

LCD

Sensor

input

Sensor

System/network management VFD

PD Tag

Node address

Link Master

Function block VFD

LCD

Transducer block

Block tag

Parameters

SENSOR

Transducer block

Block tag

Parameters

Communication

parameters

VCR

Function block

execution schedule

PID function

block (option)

AR function

block

IS function

block

IT function

block

SC function

block

AI function

block

AI function

block

AI function

block

Block tag

Parameters

OUT

OUT_D

Output

3.2.2 Function Block VFD

(1)Resource block

•Manages the status of EJX hardware.

•Automatically informs the host of any detected

faults or other problems.

(2)SENSOR Transducer block

• Converts sensor output to pressure, static pressure,

and capsule temperature signals, and transfers to the

AI function blocks.

(3)LCD Transducer block

• Controls the display of the integral indicator.

(4)AI1 function block

• Condition raw data from the Transducer block.

• Output differential pressure, static pressure and

capsule temperature signals.

Resource block

Block tag

Parameters

Figure 3.1 Logical Structure of Each Block

Setting of various parameters, node addresses, and PD

Tags shown in Figure 3.1 is required before starting

operation.

3.4 Wiring System Configuration

The number of devices that can be connected to a

single bus and the cable length vary depending on

system design. When constructing systems, both the

basic and overall design must be carefully considered

to achieve optimal performance.

3-1

IM 01C25T02-01E

F0301.EPS

Page 19

4. GETTING STARTED

4. GETTING STARTED

Fieldbus is fully dependent upon digital communication protocol and differs in operation from conventional 4 to 20 mA transmission and the BRAIN

communication protocol. It is recommended that

novice users use field devices in accordance with the

procedures described in this section. The procedures

assume that field devices will be set up on a bench or

in an instrument shop.

4.1 Connection of Devices

The following are required for use with Fieldbus

devices:

• Power supply:

Fieldbus requires a dedicated power supply. It is

recommended that current capacity be well over the

total value of the maximum current consumed by all

devices (including the host). Conventional DC

current cannot be used as is.

• Terminator:

Fieldbus requires two terminators. Refer to the

supplier for details of terminators that are attached

to the host.

•Field devices:

Connect Fieldbus communication type EJX. Two or

more EJX devices or other devices can be connected.

• Host:

Used for accessing field devices. A dedicated host

(such as DCS) is used for an instrumentation line

while dedicated communication tools are used for

experimental purposes. For operation of the host,

refer to the instruction manual for each host. No

other details on the host are given in this manual.

•Cable:

Used for connecting devices. Refer to “Fieldbus

Technical Information” (TI 38K03A01-01E) for

details of instrumentation cabling. For laboratory or

other experimental use, a twisted pair cable two to

three meters in length with a cross section of

0.9 mm2 or more and a cycle period of within 5 cm

(2 inches) may be used. Termination processing

depends on the type of device being deployed. For

EJX, use an M4 screw terminal claw. Some hosts

require a connector.

Refer to Yokogawa when making arrangements to

purchase the recommended equipment.

Connect the devices as shown in Figure 4.1. Connect

the terminators at both ends of the trunk, with a

minimum length of the spur laid for connection.

The polarity of signal and power must be maintained.

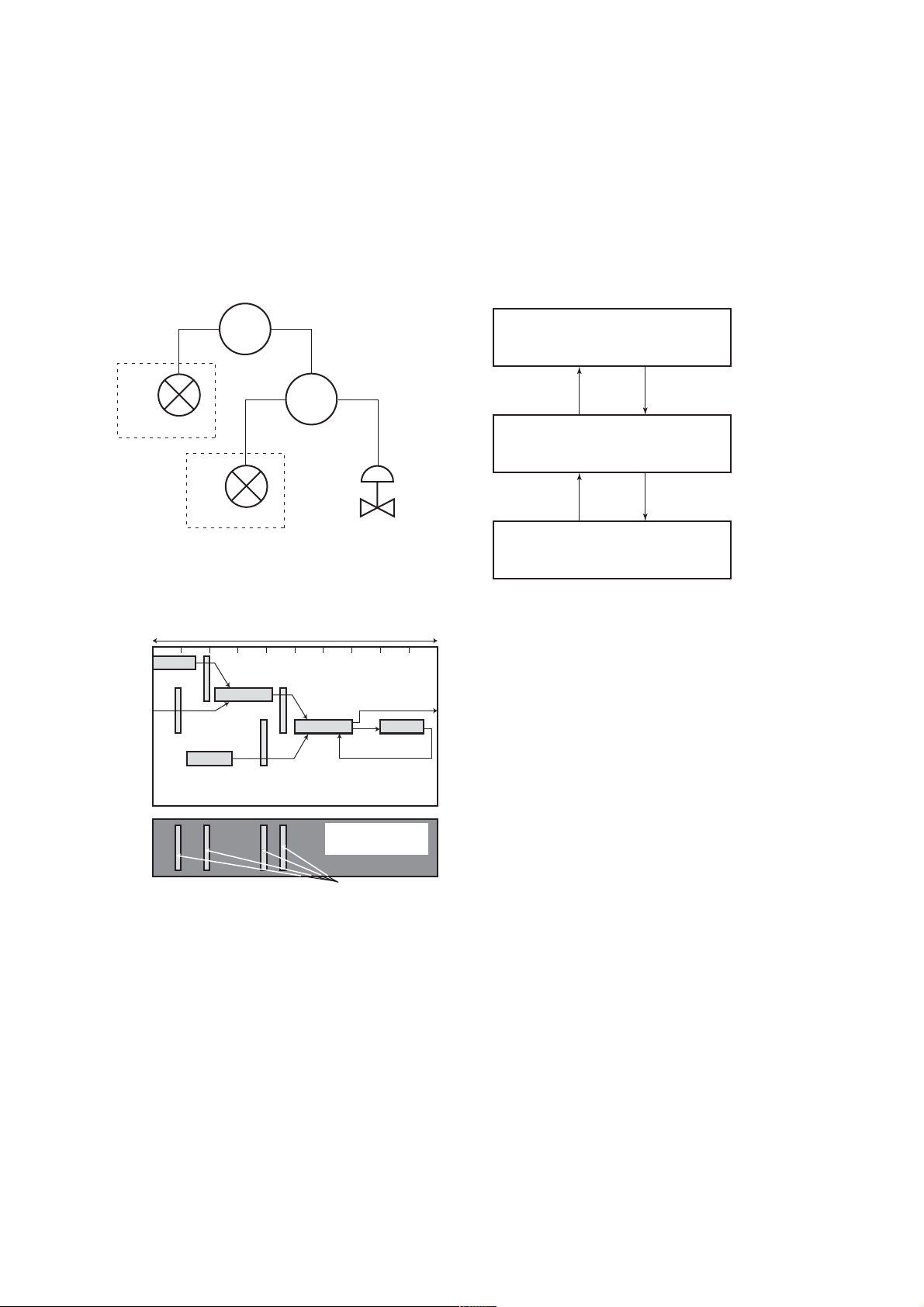

Fieldbus power

supply

Terminator

Figure 4.1 Cabling

EJX

HOST

Terminator

F0401.EPS

NOTE

No CHECK terminal is used for Fieldbus communication EJX. Do not connect the field indicator and check meter.

Before using a Fieldbus configuration tool other than

the existing host, confirm it does not affect the loop

functionality in which all devices are already installed

in operation. Disconnect the relevant control loop from

the bus if necessary.

IMPORTANT

Connecting a Fieldbus configuration tool to a

loop with its existing host may cause communication data scrambling resulting in a functional

disorder or a system failure.

4-1

IM 01C25T02-01E

Page 20

4. GETTING STARTED

4.2 Host Setting

To activate Fieldbus, the following settings are

required for the host.

IMPORTANT

Do not turn off the power immediately after

setting. When the parameters are saved to the

EEPROM, the redundant processing is executed

for an improvement of reliability. If the power is

turned off within 60 seconds after setting is

made, the modified parameters are not saved

and the settings may return to the original

values.

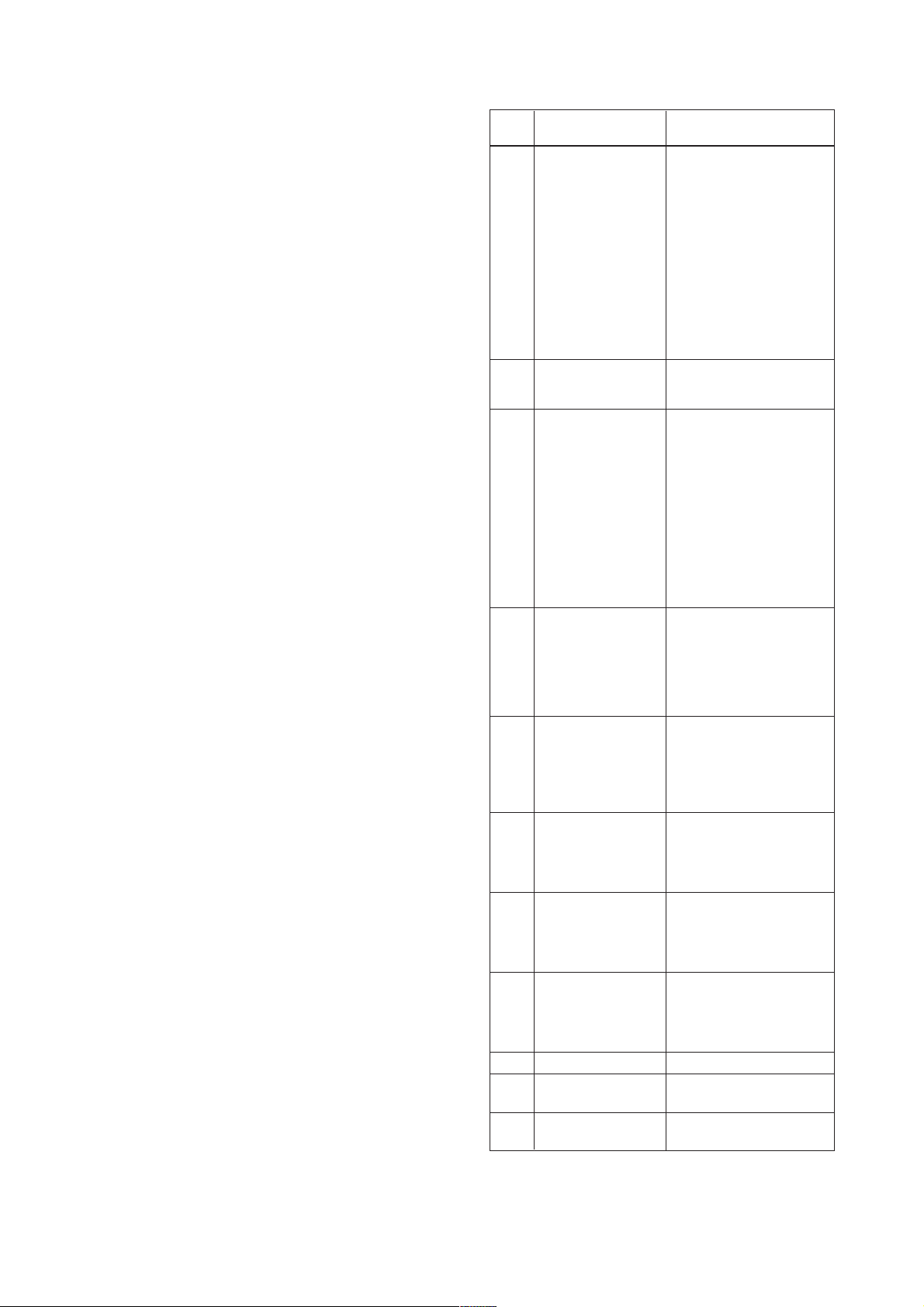

Table 4.1 Operation Parameters

Symbol Parameter Description and Settings

V (ST)

V (MID)

V (MRD)

V (FUN)

V (NUN)

Slot-Time

Minimum-Inter-PDUDelay

Maximum-ReplyDelay

First-Unpolled-Node

Number-ofconsecutiveUnpolled-Node

Indicates the time

necessary for immediate

reply of the device. Unit of

time is in octets (256 µs).

Set maximum specification

for all devices. For EJX,

set a value of 4 or greater.

Minimum value of

communication data

intervals. Unit of time is in

octets (256 µs). Set the

maximum specification for

all devices. For EJX, set a

value of 4 or greater.

The worst case time

elapsed until a reply is

recorded. The unit is Slottime; set the value so that

V (MRD) V (ST) is the

maximum value of the

specification for all

devices. For EJX, the

setting must be a value of

12 or greater.

Indicate the address next

to the address range used

by the host. Set 015 or

greater.

Unused address range.

T0401.EPS

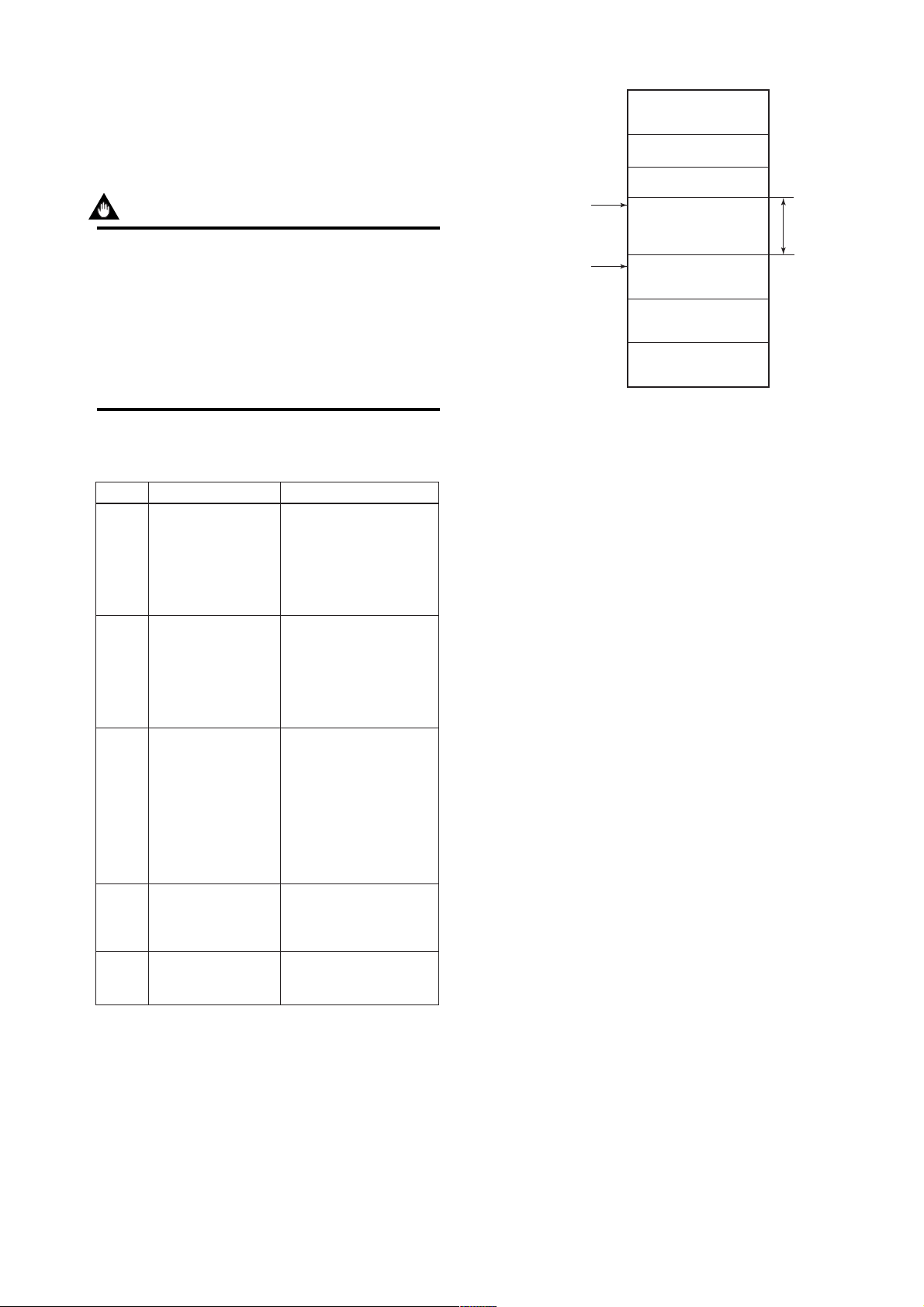

0x00

Not used

0x0F

0x10

0x13

0x14

V(FUN)

V(FUN)V(NUN)

0xF7

0xF8

0xFB

0xFC

0xFF

Note 1: Bridge device: A linking device which brings data from one

or more H1 networks.

Note 2: LM device: with bus control function (Link Master function)

Note 3: BASIC device: without bus control function

Figure 4.2 Available Address Range

Bridge device

LM device

Unused V(NUN)

BASIC device

Default address

Portable device address

F0402.EPS

4-2

IM 01C25T02-01E

Page 21

4. GETTING STARTED

4.3 Bus Power ON

Turn on the power of the host and the bus. Where the

EJX is equipped with an LCD indicator, first all

segments are lit, then the display begins to operate. If

the indicator is not lit, check the polarity of the power

supply.

Using the host device display function, check that the

EJX is in operation on the bus.

The device information, including PD tag, Node

address, and Device ID, is described on the sheet

attached to the EJX. The device information is given in

duplicate on this sheet.

Device ID : 594543000CXXXXXXXX

PD Tag : PT2001

Device Revision : 3

Node Address : 0xf3

Serial No. : XXXXXXXXXXXXXXXXX

Physical Location :

Note:

Our Device Description Files and Capabilities Files available at

http://www.yokogawa.com/fld (English) or

http://www.yokogawa.co.jp/Sensor/fieldbus/fieldbus.htm (Japanese)

DEVICE INFORMATION

4.4 Integration of DD

If the host supports DD (Device Description), the DD

of the EJX needs to be installed. Check if host has the

following directory under its default DD directory.

594543\000C

(594543 is the manufacturer number of Yokogawa

Electric Corporation, and 000C is the EJX device

number, respectively.)

If this directory is not found, the DD of the EJX has

not been included. Create the above directory and copy

the DD file (0m0n.ffo, 0m0n.sym) (m, n is a numeral)

into the directory. ‘0m’ in the file name shows the

device revision, and ‘0n’ shows the DD revision. If

you do not have the DD or capabilities files, you can

download them from our web site:

http://www.yokogawa.com/fld

Once the DD is installed in the directory, the name and

attribute of all parameters of the EJX are displayed.

Off-line configuration is possible by using capabilities

files.

EJX has two capabilities levels, “1” and “2”.

Device ID : 594543000CXXXXXXXX

PD Tag : PT2001

Device Revision : 3

Node Address : 0xf3

Serial No. : XXXXXXXXXXXXXXXXX

Physical Location :

Note:

Our Device Description Files and Capabilities Files available at

http://www.yokogawa.com/fld (English) or

http://www.yokogawa.co.jp/Sensor/fieldbus/fieldbus.htm (Japanese)

Figure 4.3 Device Information Sheet Attached to EJX

DEVICE INFORMATION

F0403.EPS

If no EJX is detected, check the available address

range and the polarity of the power supply. If the node

address and PD tag are not specified when ordering,

default value is factory set. If two or more EJXs are

connected at a time with default value, only one EJX

will be detected from the host as EJXs have the same

initial address. Separately connect each EJX and set a

different address for each.

Select “Capabilities level = 1” when the EJX don’t

have LC1(PID function) option.

Select “Capabilities level = 2” when the EJX has

LC1(PID function) option.

The capabilities level defines the kind and the number

of function blocks that can be used.

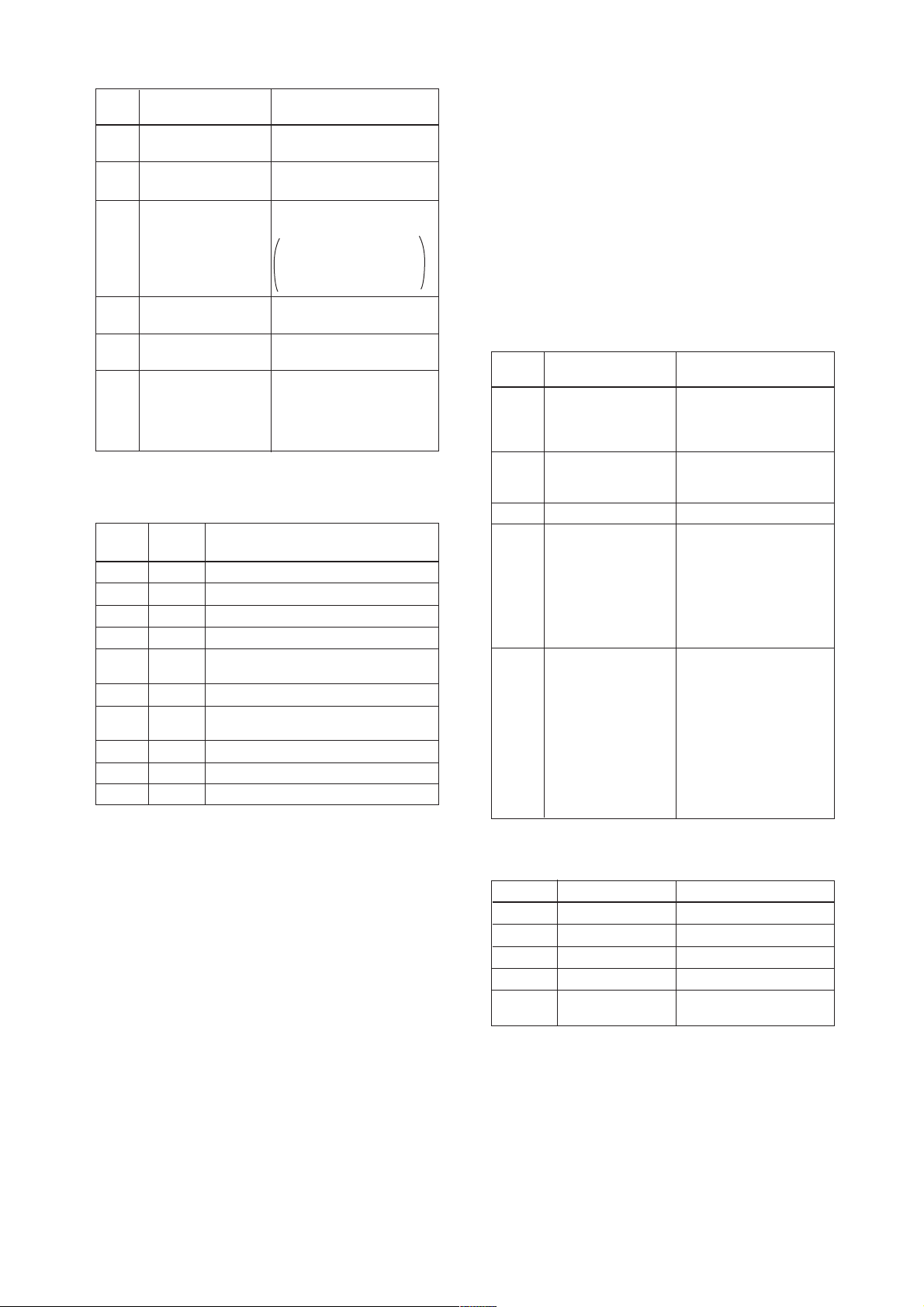

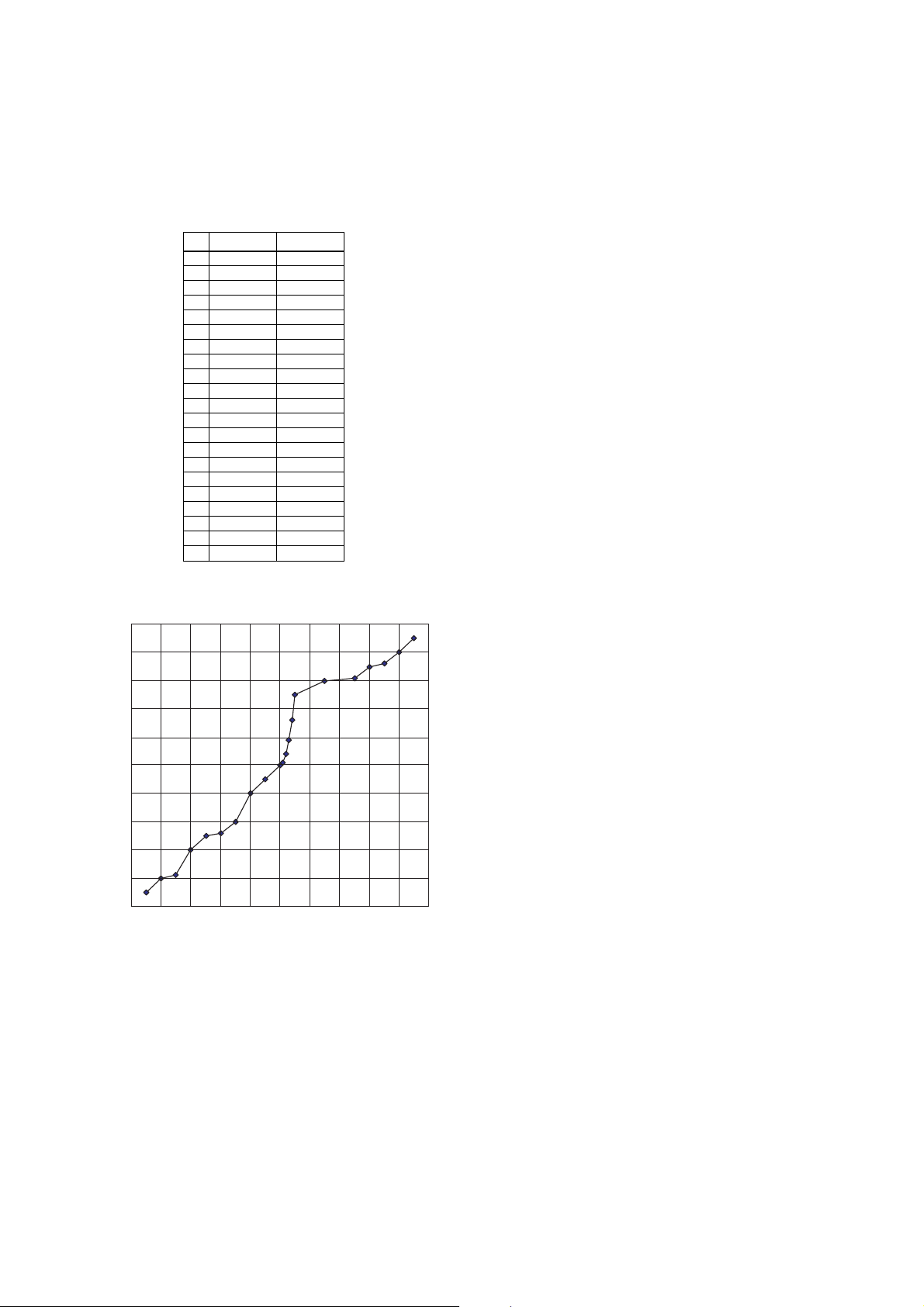

The table below shows the relation.

The relation between and function blocks that can be used

Capabilities

Level

1

2

AI SC IT IS AR PID

3

11110

311111

T0402.EPS

4.5 Reading the Parameters

To read EJX parameters, select the AI1 block of the

EJX from the host screen and read the OUT parameter.

The current selected signal is displayed. Check that

MODE_BLOCK of the function block and resource

block is set to AUTO, and change the signal input and

read the parameter again. A new designated value

should be displayed.

4-3

IM 01C25T02-01E

Page 22

4.6 Continuous Record of Values

If the host has a function that continuously records the

indications, use this function to list the indications

(values). Depending on the host being used, it may be

necessary to set the schedule of Publish (the function

that transmits the indication on a periodic basis).

4.7 Generation of Alarm

Generation of an alarm can be attempted from EJX.

Block alarm, Output limit alarm, and Update alarm are

informed to the host. When generating alarm, a Link

Object and a VCR Static Entry need to be set. For

details of Link Object and VCR Static Entry, refer to

section 5.6.1 Link object and section 5.5.1 VCR

Setting.

4. GETTING STARTED

4-4

IM 01C25T02-01E

Page 23

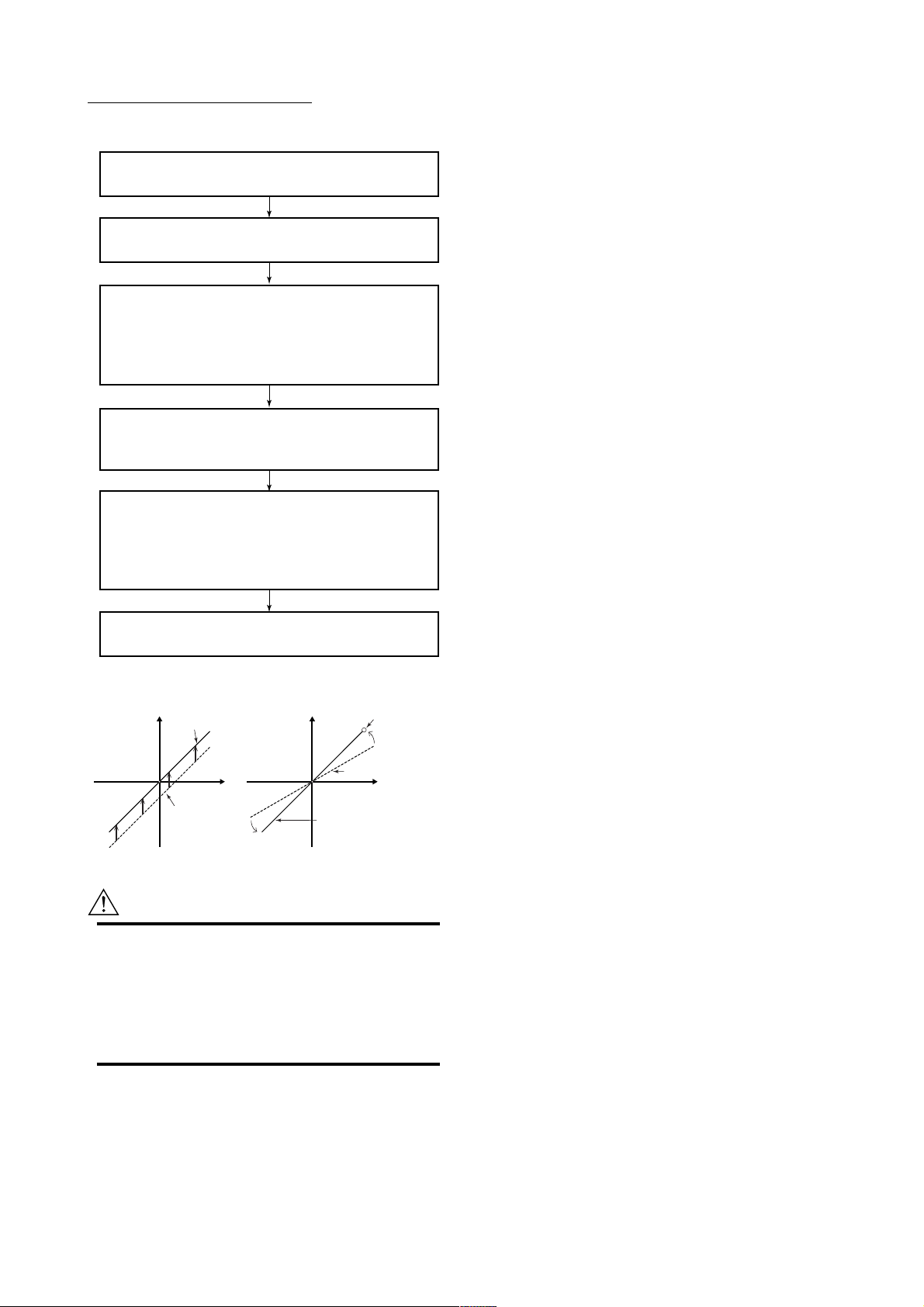

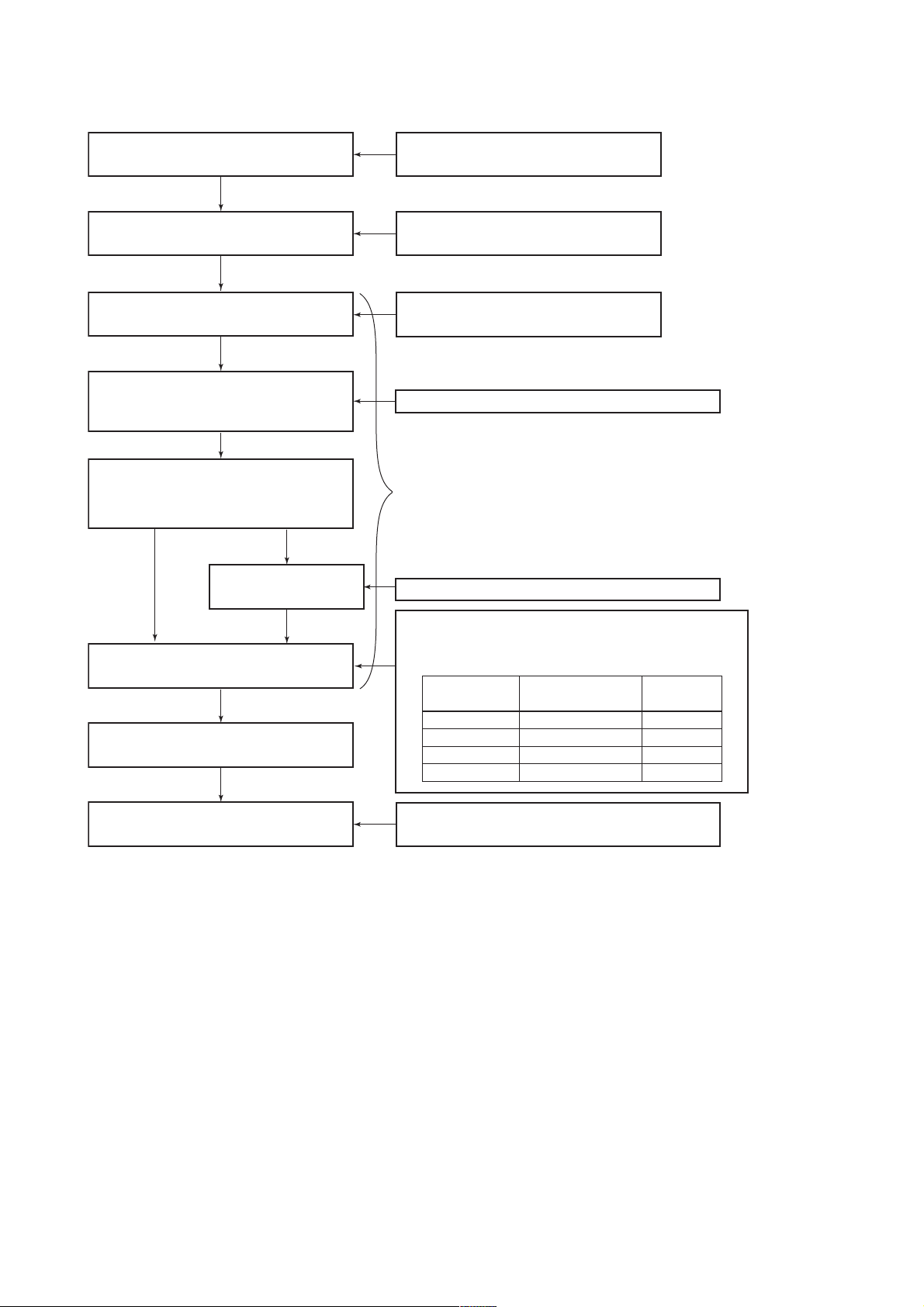

5. CONFIGURATION

5. CONFIGURATION

This chapter describes how to adapt the function and

performance of the EJX to suit specific applications.

Because multiple devices are connected to Fieldbus, it

is important to carefully consider the device requirements and settings when configuring the system. The

following steps must be taken.

(1)Network design

Determines the devices to be connected to Fieldbus

and checks the capacity of the power supply.

(2)Network definition

Determines the tag and node addresses for all

devices.

(3)Definition of combining function blocks

Determines how function blocks are combined.

(4)Setting tags and addresses

Sets the PD Tag and node addresses for each device.

(5)Communication setting

Sets the link between communication parameters

and function blocks.

(6)Block setting

Sets the parameters for function blocks.

The following section describes in sequence each step

of this procedure. The use of a dedicated configuration

tool significantly simplifies this procedure. Refer to

Appendix 6 when the EJX is used as Link Master.

• Terminator

Fieldbus requires two terminators. Refer to the

supplier for details of terminators that are attached

to the host.

•Field devices

Connect the field devices necessary for instrumenta-

tion. The EJX has passed the interoperability test

conducted by The Fieldbus Foundation. In order to

properly start Fieldbus, it is recommended that the

devices used satisfy the requirements of the above

test.

• Host

Used for accessing field devices. A minimum of one

device with the bus control function is needed.

• Cable

Used for connecting devices. Refer to “Fieldbus

Technical Information” for details of instrumenta-

tion cabling. Provide a cable sufficiently long to

connect all devices. For field branch cabling, use

terminal boards or a connection box as required.

First, check the capacity of the power supply. The

power supply capacity must be greater than the sum of

the maximum current consumed by all devices to be

connected to Fieldbus. The maximum current consumed (power supply voltage 9 V to 32 V) for the EJX

is 15 mA (24 mA in Software download operation).

The cable used for the spur must be of the minimum

possible length.

5.1 Network Design

Select the devices to be connected to the Fieldbus

network. The following are essential for the operation

of Fieldbus.

• Power supply

Fieldbus requires a dedicated power supply. It is

recommended that current capacity be well over the

total value of the maximum current consumed by all

devices (including the host). Conventional DC

current cannot be used as is.

5.2 Network Definition

Before connection of devices with Fieldbus, define the

Fieldbus network. Allocate PD Tag and node addresses

to all devices (excluding such passive devices as

terminators).

The PD Tag is the same as the conventional one used

for the device. Up to 32 alphanumeric characters may

be used for definition. Use a hyphen as a delimiter as

required.

The node address is used to specify devices for

communication purposes. Because this data is too long

for a PD Tag, the host uses the node address in place

of the PD Tag for communication. A range of 20 to

247 (or hexadecimal 14 to F7) can be set. The device

5-1

IM 01C25T02-01E

Page 24

5. CONFIGURATION

(LM device) with bus control function (Link Master

function) is allocated from a smaller address number

(20) side, and other devices (BASIC device) without

bus control function allocated from a larger address

number (247) side respectively. Place the EJX in the

range of the BASIC device. When the EJX is used as

Link Master, place the EJX in the range of the LM

device. Set the range of addresses to be used to the LM

device. Set the following parameters.

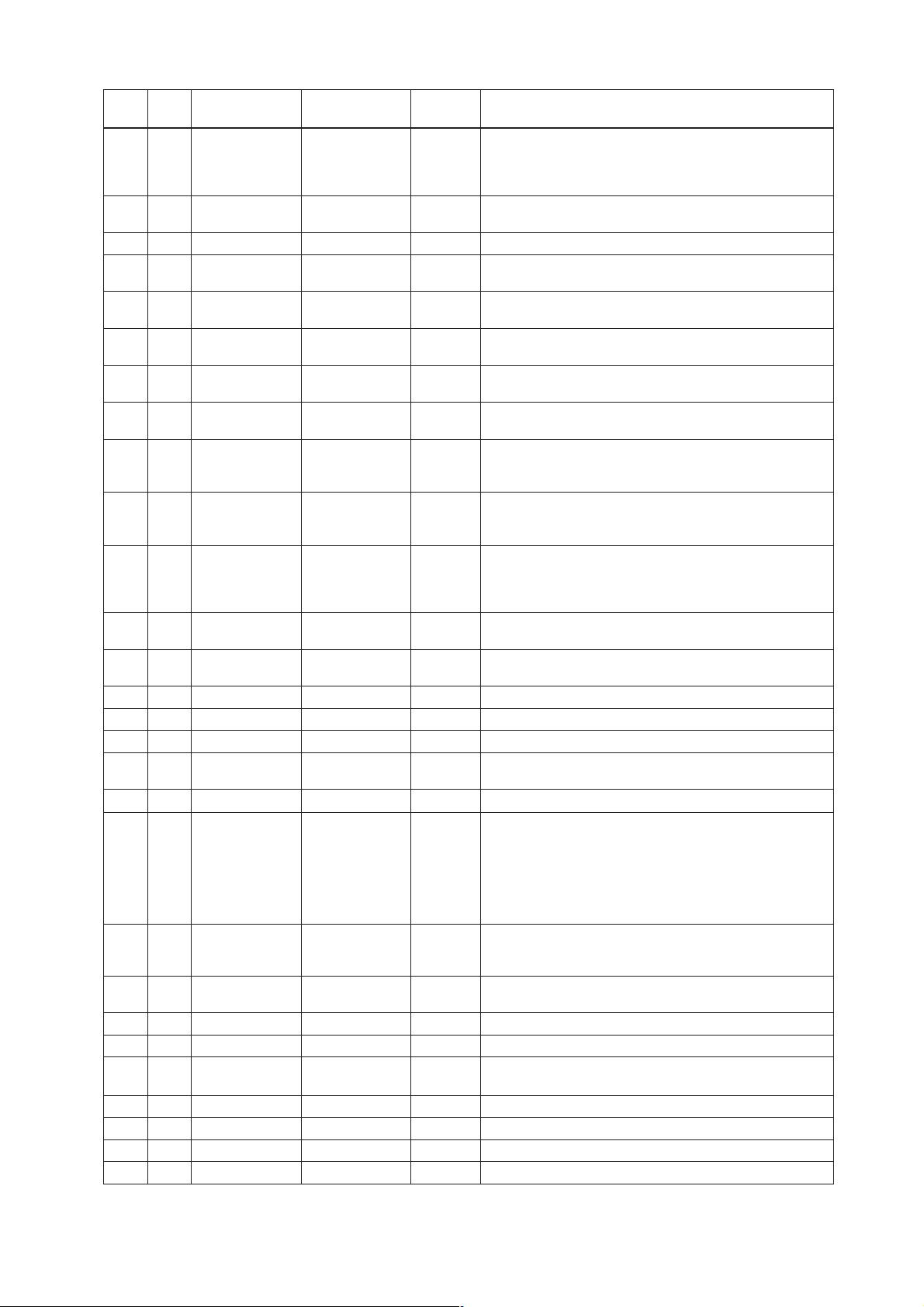

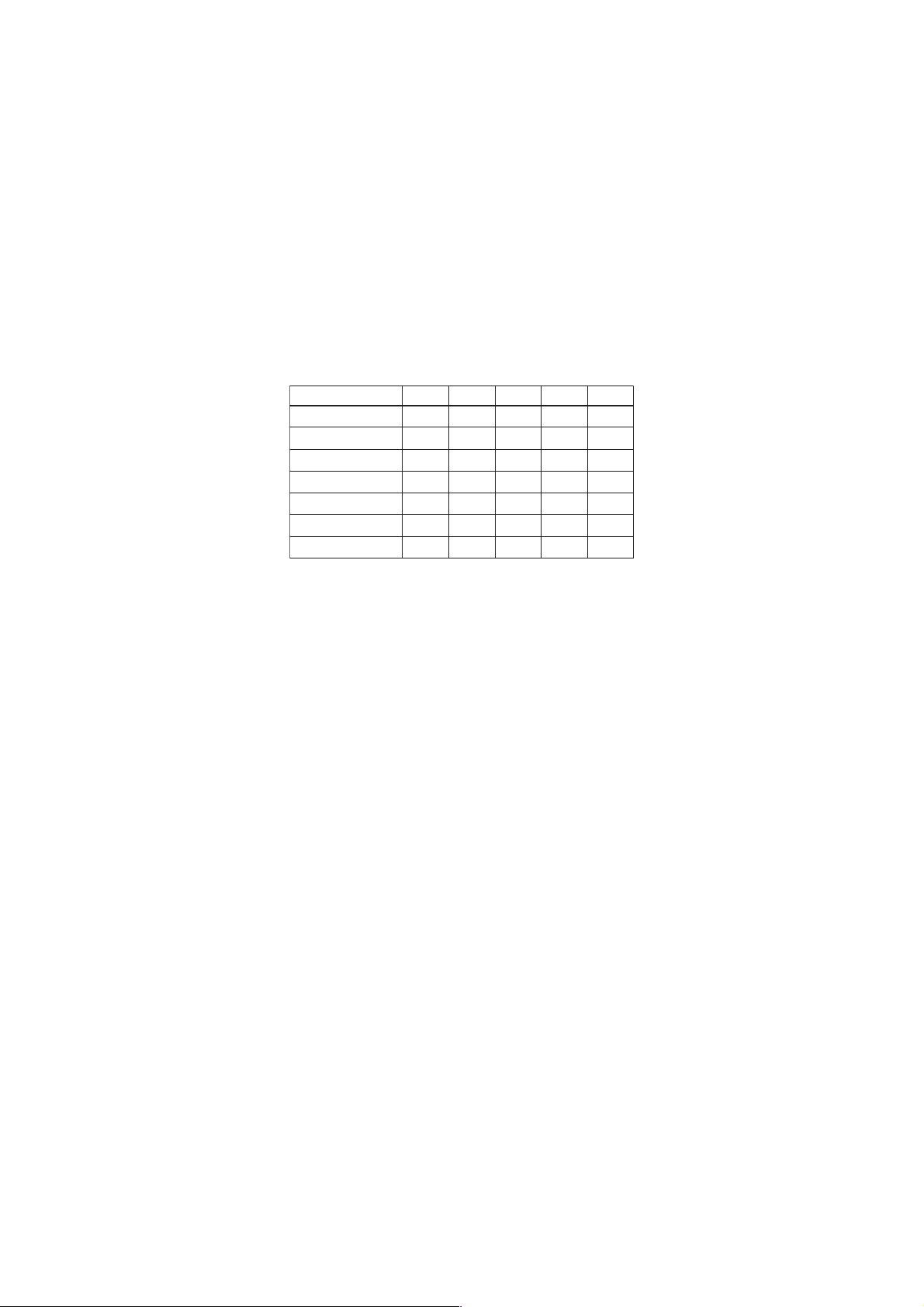

Table 5.1 Parameters for Setting Address Range

Symbol

V (FUN) First-Unpolled-Node

V (NUN) Number-of-

Parameters Description

Indicates the address next

to the address range used

for the host or other LM

device.

Unused address range

consecutiveUnpolled-Node

T0501.EPS

The devices within the address range written as

“Unused” in Figure 5.1 cannot be used on a Fieldbus.

For other address ranges, the range is periodically

checked to identify when a new device is mounted.

Care must be taken to keep the unused device range as

narrow as possible so as to lessen the load on the

Fieldbus.

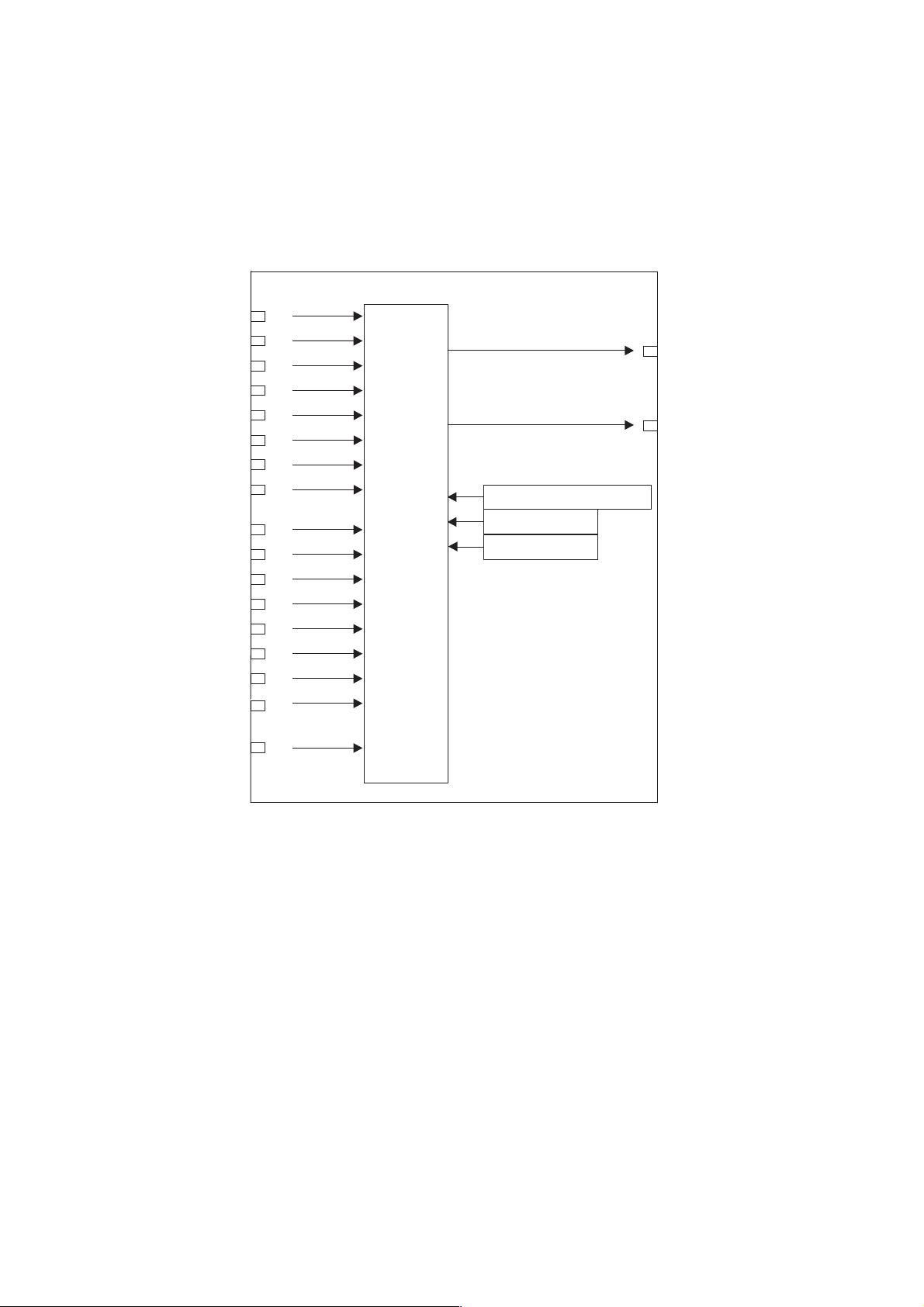

0x00

0x0F

0x10

0x13

0x14

V(FUN)

V(FUN)V(NUN)

0xF7

0xF8

0xFB

0xFC

0xFF

Figure 5.1 Available Range of Node Addresses

Not used

Bridge device

LM device

Unused V(NUN)

BASIC device

Default address

Portable device address

F0501.EPS

To ensure stable operation of Fieldbus, determine the

operation parameters and set them to the LM devices.

While the parameters in Table 5.2 are to be set, the

worst-case value of all the devices to be connected to

the same Fieldbus must be used. Refer to the specification of each device for details. Table 5.2 lists EJX

specification values.

Table 5.2 Operation Parameter Values of the EJX to be

Set to LM Devices

Symbol Parameters Description and Settings

V (ST) Slot-Time

V (MID) Minimum-Inter-PDU-

Delay

V (MRD) Maximum-Reply-Delay

Indicates the time

necessary for immediate

reply of the device. Unit of

time is in octets (256 µs).

Set maximum specification

for all devices. For EJX,

set a value of 4 or greater.

Minimum value of

communication data

intervals. Unit of time is in

octets (256 µs). Set the

maximum specification for

all devices. For EJX, set a

value of 4 or greater.

The worst case time

elapsed until a reply is

recorded. The unit is Slottime; set the value so that

V (MRD) V (ST) is the

maximum value of the

specification for all

devices. For EJX, the

setting must be a value of

12 or greater.

T0502.EPS

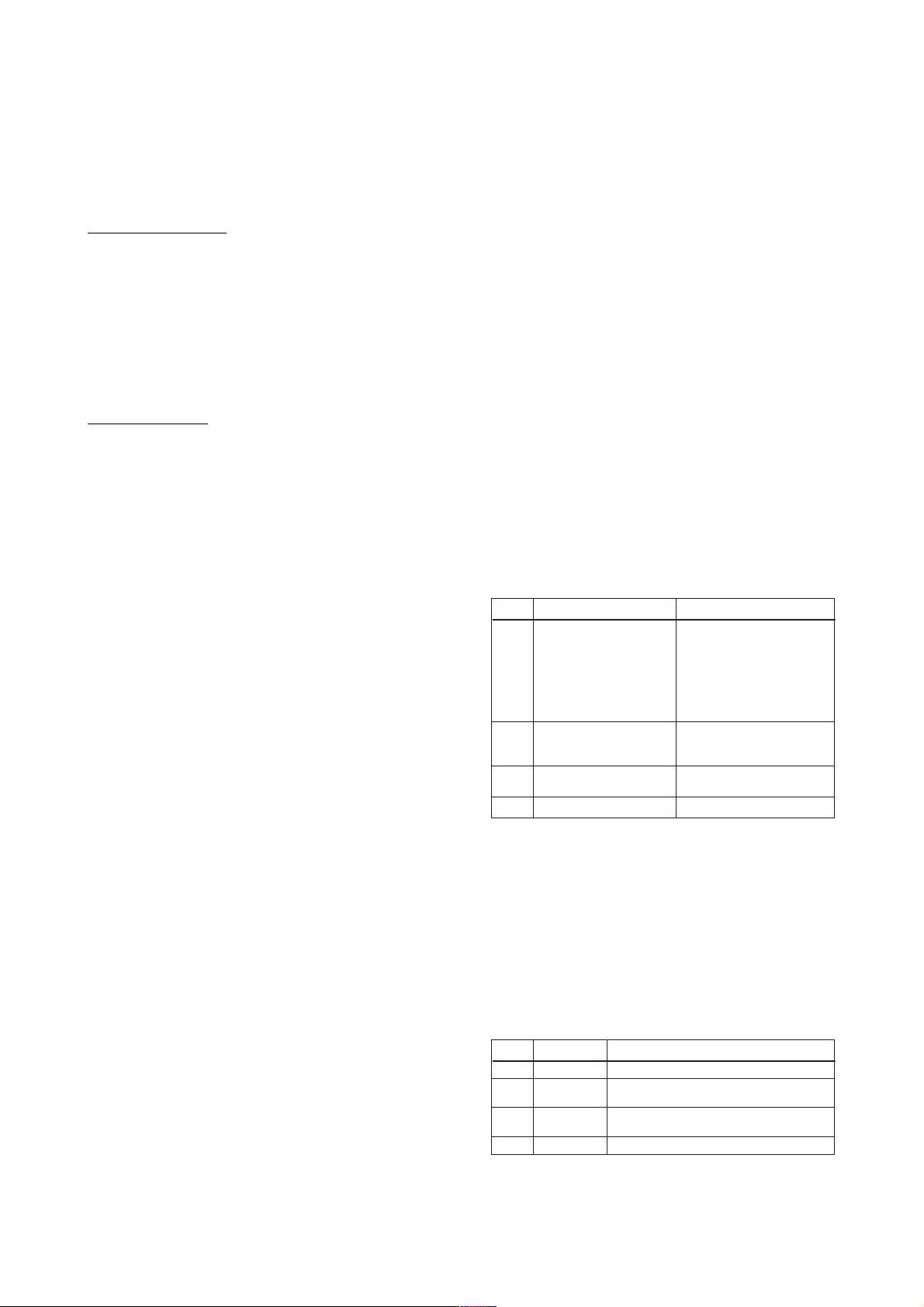

5.3 Definition of Combining Function Blocks

The input/output parameters for function blocks are

combined. As required, they can be combined with the

input of the control block. The setting is written to the

EJX link object. See “Block setting” in Section 5.6 for

the details. It is also possible to read values from the

host at proper intervals instead of connecting the EJX

block output to other blocks.

The combined blocks need to be executed synchronously with other blocks on the communications

schedule. In this case, change the EJX schedule

according to the following table. The values in the

table are factory-settings.

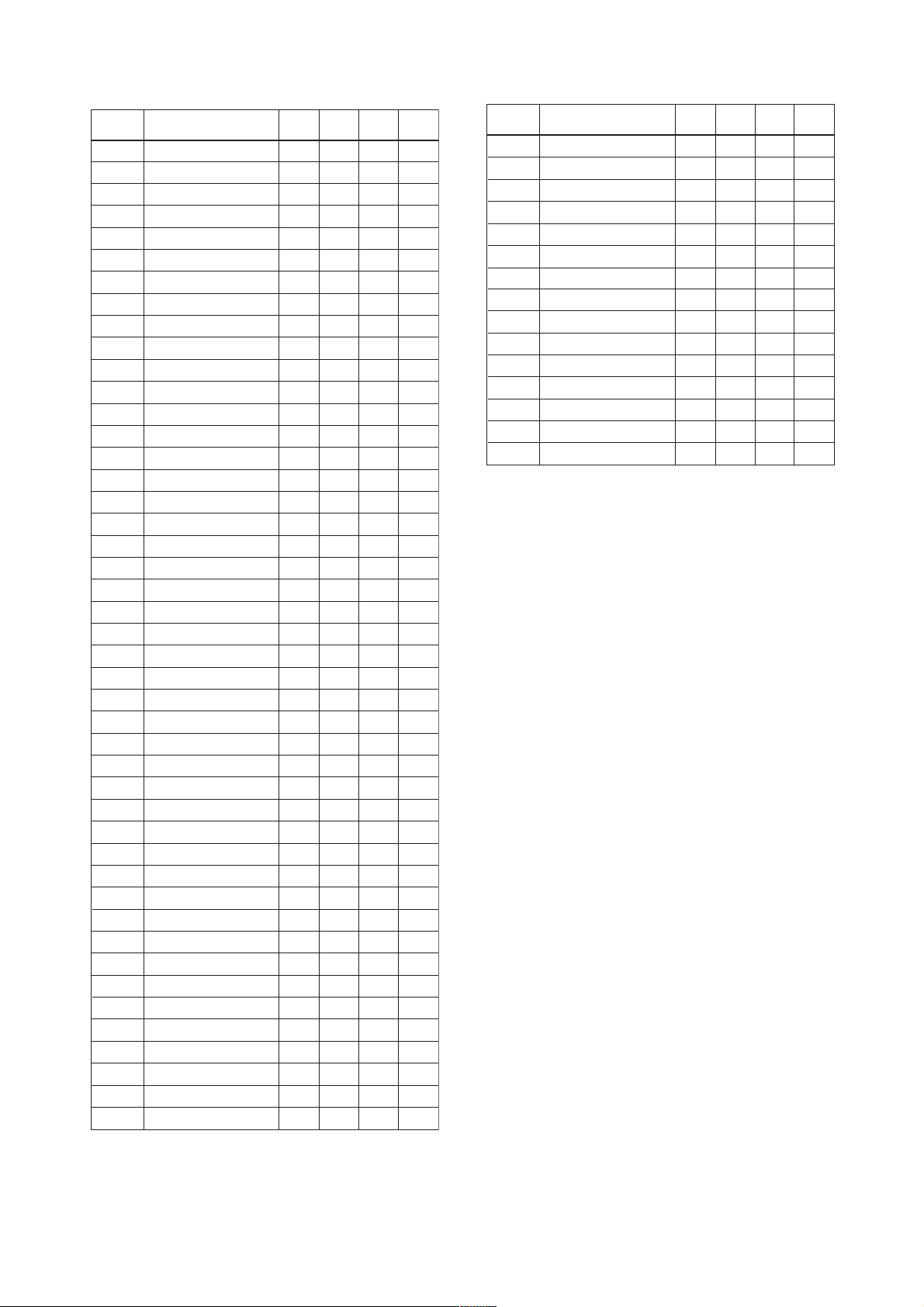

Table 5.3 Execution Schedule of the EJX Function Blocks

Index Parameters

269

MACROCYCLE_

(SM)

DURATION

276

FB_START_ENTRY.1

(SM)

277 to

FB_START_ENTRY.2

289

FB_START_ENTRY.14

(SM)

to

Setting (Enclosed is

factory-setting)

Cycle (MACROCYCLE)

period of control or

measurement. Unit is 1/32

ms. (16000 = 0.5 s)

AI1 block startup time.

Elapsed time from the start

of MACROCYCLE specified

in 1/32 ms. (0 = 0 s)

Not used.

T0503.EPS

5-2

IM 01C25T02-01E

Page 25

5. CONFIGURATION

A maximum of 30 ms is taken for execution of AI

block. For scheduling of communications for combination with the next function block, the execution is so

arranged as to start after a lapse of longer than 30 ms.

In no case should function blocks of the EJX be

executed at the same time (execution time is overlapped).

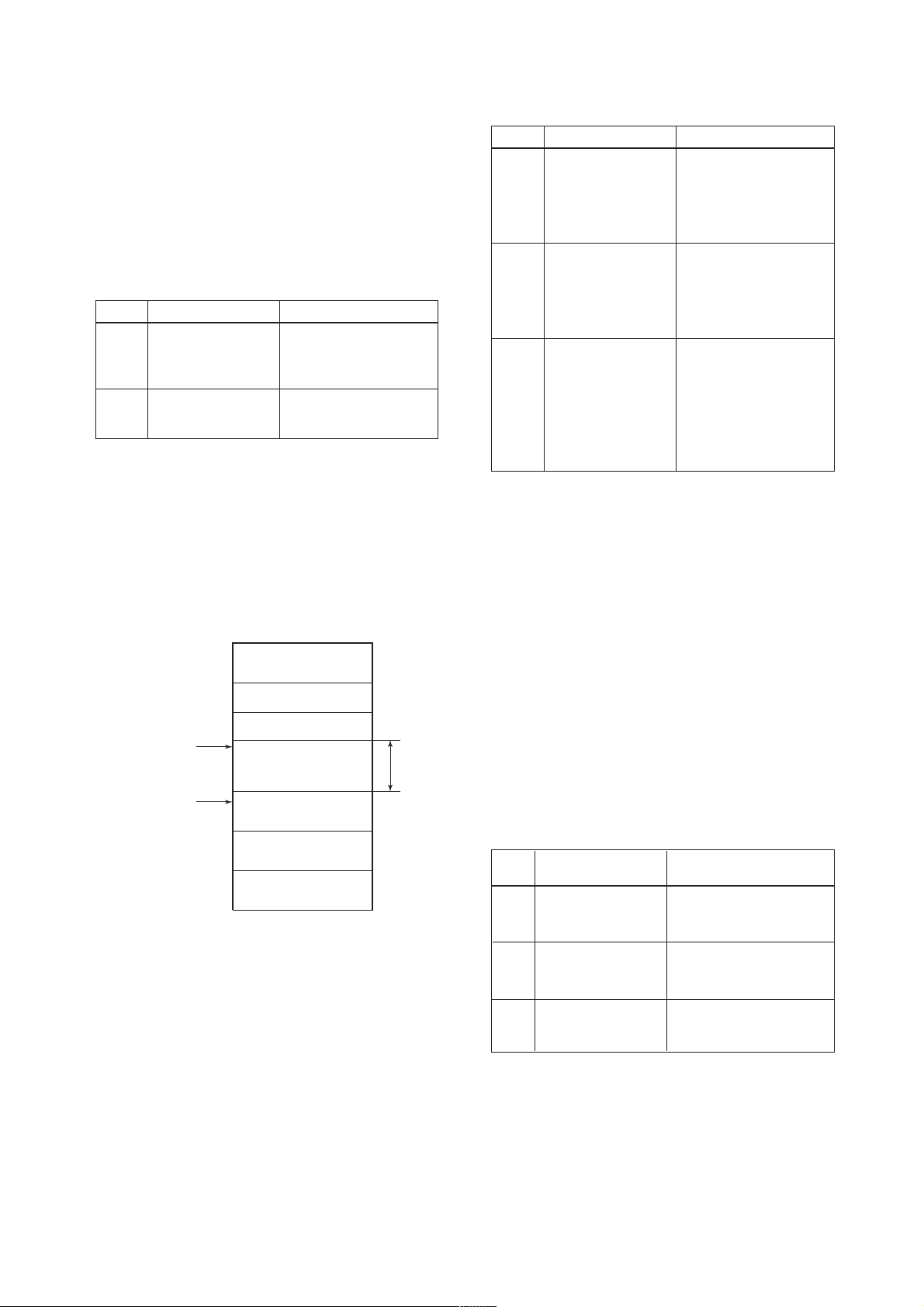

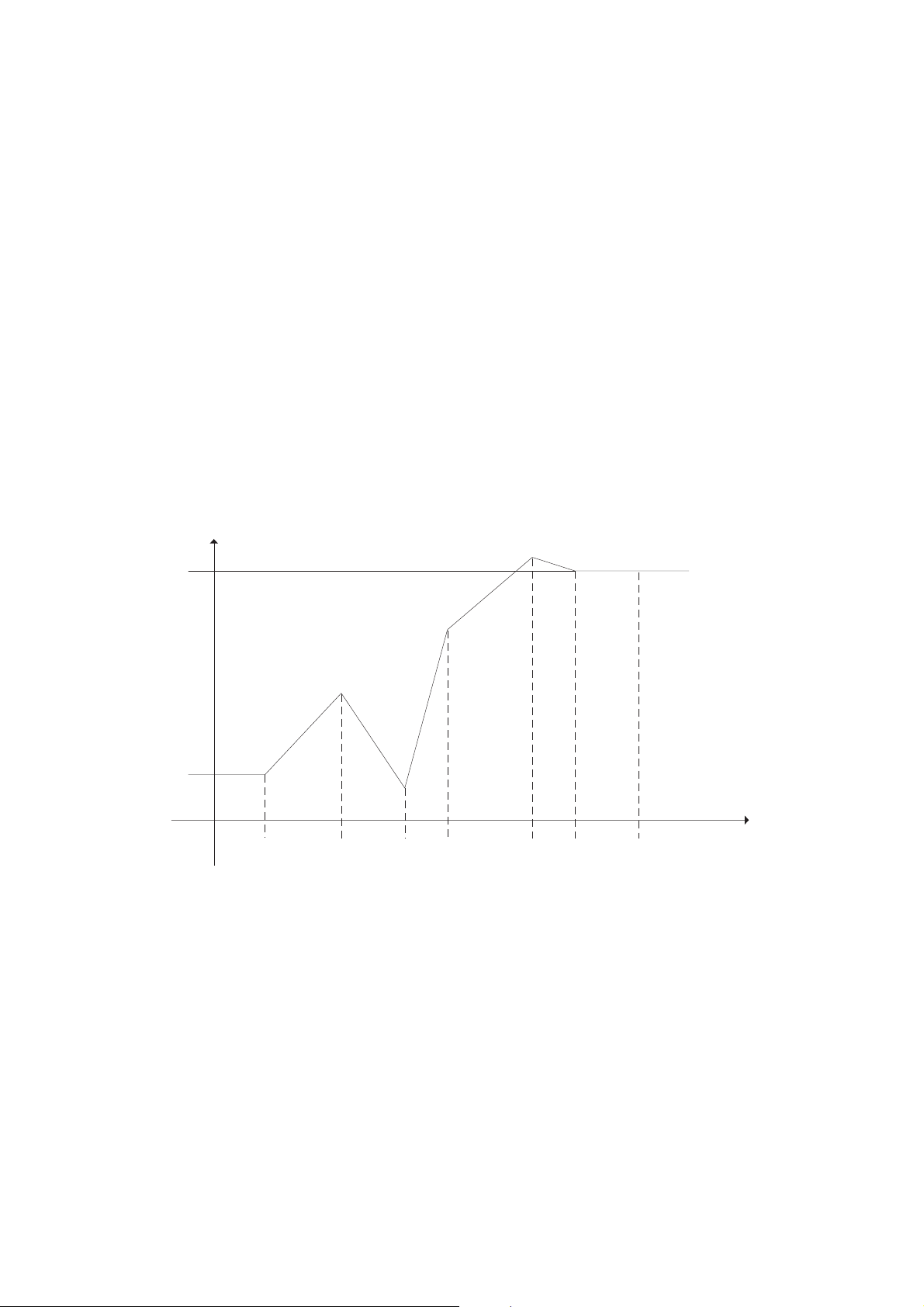

Figure 5.3 shows an example of schedule based on the

loop shown in Figure 5.2.

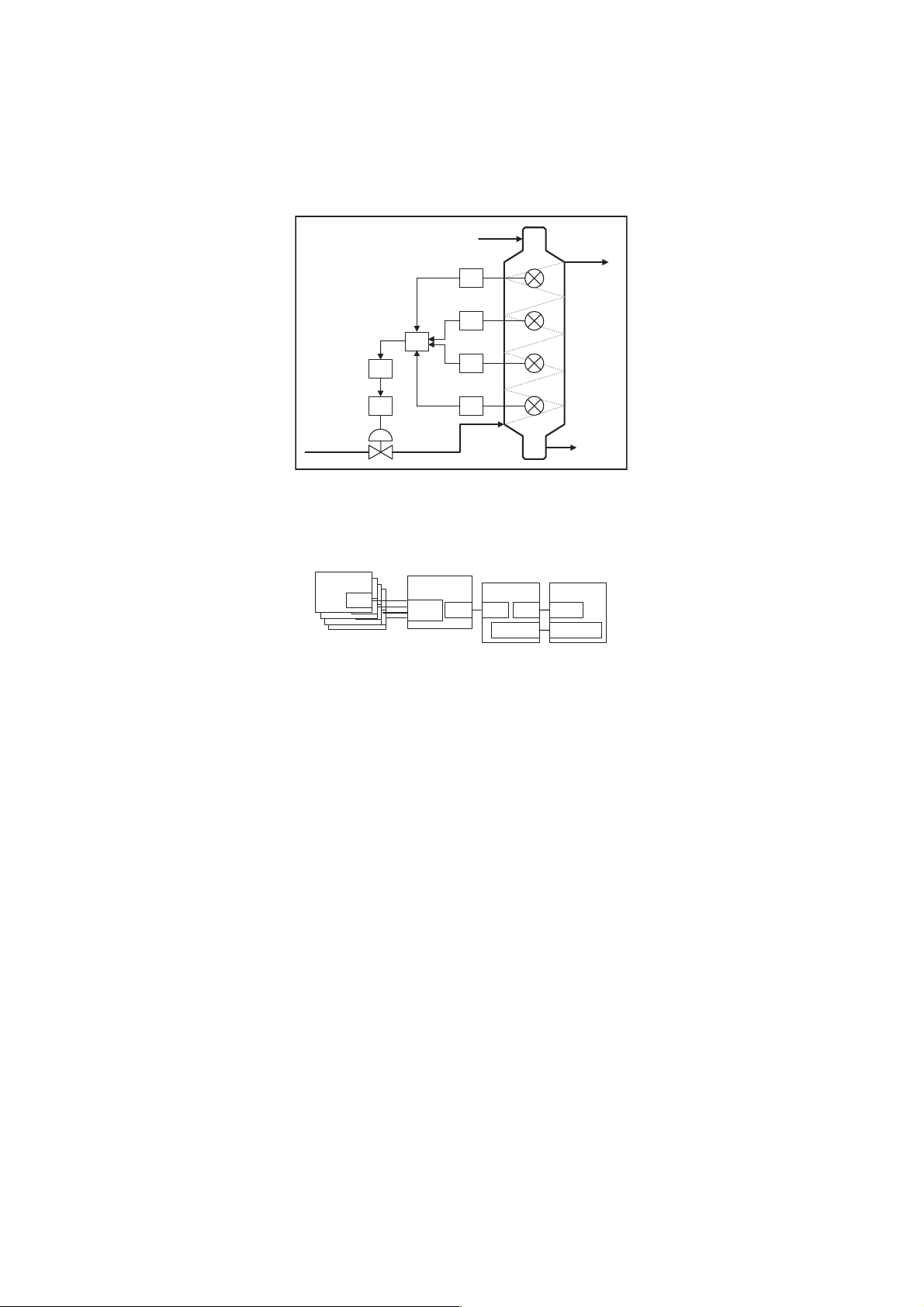

LIC100

EJX

#1

LI100

EJX

#2

FI100

Figure 5.2 Example of Loop Connecting Function Block of

Two EJX with Other Instruments

Macrocycle (Control Period)

FIC100

FC100

F0502.EPS

5.4 Setting of Tags and Addresses

This section describes the steps in the procedure to set