Page 1

User’s

Manual

Absolute Pressure and

Gauge Pressure Transmitters

EJ510, EJ530,

EJX610A and EJX630A

IM 01C25F01-01E

IM 01C25F01-01E

10th Edition

Page 2

Absolute Pressure and Gauge Pressure Transmitters

EJ510, EJ530, EJX610A and EJX630A

IM 01C25F01-01E 10th Edition

Contents

1. Introduction ............................................................................................... 1-1

Regarding This Manual ................................................................................................1-1

1.1 Safe Use of This Product .................................................................................1-2

1.2 Warranty .............................................................................................................1-3

1.3 ATEX Documentation .......................................................................................1-4

2. Handling Cautions .................................................................................... 2-1

2.1 Model and Specications Check .....................................................................2-1

2.2 Unpacking ..........................................................................................................2-1

2.3 Storage ...............................................................................................................2-1

2.4 Selecting the Installation Location ................................................................2-1

2.5 Pressure Connection ........................................................................................2-2

2.6 Waterproong of Cable Conduit Connections ..............................................2-2

2.7 Restrictions on Use of Radio Transceivers ...................................................2-2

2.8 Insulation Resistance and Dielectric Strength Test ...................................... 2-2

2.9 Installation of an Explosion-Protected Instrument .......................................2-3

2.9.1 FM Approval .......................................................................................2-4

2.9.2 CSA Certication ................................................................................2-6

2.9.3 ATEX Certication ..............................................................................2-8

2.9.4 IECEx Certication ........................................................................... 2-11

2.10 EMC Conformity Standards ...........................................................................2-12

2.11 Pressure Equipment Directive (PED) ...........................................................2-13

2.12 Low Voltage Directive .....................................................................................2-13

i

3. Component Names .................................................................................. 3-1

4. Installation ................................................................................................. 4-1

4.1 Precautions .......................................................................................................4-1

4.2 Mounting ...........................................................................................................4-1

4.3 Rotating Transmitter Section ...........................................................................4-2

4.4 Changing the Direction of Integral Indicator .................................................4-2

5. Installing Impulse Piping ......................................................................... 5-1

5.1 Impulse Piping Installation Precautions ........................................................5-1

5.1.1 Connecting Impulse Piping to a Transmitter ......................................5-1

5.1.2 Routing the Impulse Piping ................................................................5-1

5.2 Impulse Piping Connection Examples ........................................................... 5-2

10th Edition: June 2013(YK)

All Rights Reserved, Copyright © 2004, Yokogawa Electric Corporation

IM 01C25F01-01E

Page 3

6. Wiring ......................................................................................................... 6-1

6.1 Wiring Precautions ...........................................................................................6-1

6.2 Selecting the Wiring Materials .........................................................................6-1

6.3 Connections of External Wiring to Terminal Box .......................................... 6-1

6.3.1 Power Supply Wiring Connection ......................................................6-1

6.3.2 External Indicator Connection............................................................6-1

6.3.3 Communicator Connection ................................................................6-1

6.3.4 Check Meter Connection ...................................................................6-2

6.3.5 Status Output Connection ..................................................................6-2

6.4 Wiring .................................................................................................................6-2

6.4.1 Loop Conguration ............................................................................6-2

6.4.2 Wiring Installation ...............................................................................6-2

6.5 Grounding ..........................................................................................................6-3

6.6 Power Supply Voltage and Load Resistance .................................................6-3

7. Operation ................................................................................................... 7-1

7.1 Preparation for Starting Operation .................................................................7-1

7.2 Zero Point Adjustment ..................................................................................... 7-2

7.3 Starting Operation ............................................................................................ 7-3

7.4 Shutting Down the Transmitter ....................................................................... 7-3

7.5 Setting the Range Using the Range-setting Switch ......................................7-4

ii

8. Maintenance .............................................................................................. 8-1

8.1 Overview ............................................................................................................8-1

8.2 Calibration Instruments Selection ..................................................................8-1

8.3 Calibration .........................................................................................................8-1

8.4 Disassembly and Reassembly ........................................................................8-3

8.4.1 Replacing the Integral Indicator .........................................................8-3

8.4.2 Replacing the CPU Board Assembly .................................................8-4

8.4.3 Cleaning and Replacing the Capsule Assembly ..........................8-4

8.5 Troubleshooting ................................................................................................8-5

8.5.1 Basic Troubleshooting .......................................................................8-6

8.5.2 Troubleshooting Flowcharts ...............................................................8-6

8.5.3 Alarms and Countermeasures ...........................................................8-8

9. General Specications ............................................................................ 9-1

9.1 Standard Specications ................................................................................... 9-1

9.2 Model and Sufx Codes ...................................................................................9-5

9.3 Optional Specications “◊” .............................................................................9-8

9.4 Dimensions ......................................................................................................9-10

Revision Information

When using the Transmitters in a Safety Instrumented Systems(SIS)

application, refer to Appendix A in either IM 01C25T01-06EN for the

HART protocol or IM 01C25T03-01E for the BRAIN protocol.

IM 01C25F01-01E

Page 4

<1. Introduction>

1. Introduction

Thank you for purchasing the DPharp EJX and EJA

Differential Pressure and pressure transmitter.

NOTE

1-1

Your transmitter was precisely calibrated at the

factory before shipment. To ensure both safety and

efciency, please read this manual carefully before

you operate the instrument.

NOTE

This manual describes the hardware

congurations of the transmitters listed in below.

For information on the software conguration

and operation, please refer to either

IM 01C25T03-01E for the BRAIN communication

type, or IM 01C25T01-06EN for the HART

communication type.

For FOUNDATION Fieldbus protocol type,

please refer to IM 01C25T02-01E.

For PROFIBUS PA protocol type, please refer to

IM 01C25T04-01EN.

Model Style code

EJX510A S2

EJX530A S2

EJX610A S1

EJX630A S1

EJA510E S1

EJA530E S1

To ensure correct use of this instrument, read

both the hardware and software manuals

thoroughly before use.

WARNING

When using the transmitters in a Safety

Instrumented Systems (SIS) application, refer

to Appendix 1 in either IM 01C25T01-06EN for

the HART protocol or IM 01C25T03-01E for the

BRAIN protocol. The instructions and procedures

in this section must be strictly followed in order to

maintain the transmitter for this safety level.

Unless otherwise stated, the illustrations in this

manual are of the EJ530 gauge pressure

transmitter.

Users of the EJ510, EJX610A and EJX630A

should bear in mind that certain features of their

instrument will differ from those shown in the

illustrations of the EJ530.

Regarding This Manual

• This manual should be provided to the end

user.

• The contents of this manual are subject to

change without prior notice.

• All rights reserved. No part of this manual may

be reproduced in any form without Yokogawa’s

written permission.

• Yokogawa makes no warranty of any kind with

regard to this manual, including, but not limited

to, implied warranty of merchantability and

tness for a particular purpose.

• If any question arises or errors are found, or if

any information is missing from this manual,

please inform the nearest Yokogawa sales

ofce.

• The specications covered by this manual are

limited to those for the standard type under the

specied model number break-down and do not

cover custom-made instruments.

• Please note that changes in the specications,

construction, or component parts of the

instrument may not immediately be reected

in this manual at the time of change, provided

that postponement of revisions will not cause

difculty to the user from a functional or

performance standpoint.

• Yokogawa assumes no responsibility for this

product except as stated in the warranty.

NOTE

When describing the model name like EJ510

or EJ530, it shows the applicability for

both EJX510A and EJA510E or EJX530A and

EJA530E.

• If the customer or any third party is harmed by

the use of this product, Yokogawa assumes

no responsibility for any such harm owing to

any defects in the product which were not

predictable, or for any indirect damages.

IM 01C25F01-01E

Page 5

<1. Introduction>

1-2

• The following safety symbols are used in this

manual:

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

IMPORTANT

Indicates that operating the hardware or software

in this manner may damage it or lead to system

failure.

1.1 Safe Use of This Product

For the safety of the operator and to protect the

instrument and the system, please be sure to follow

this manual’s safety instructions when handling this

instrument. If these instructions are not heeded,

the protection provided by this instrument may be

impaired. In this case, Yokogawa cannot guarantee

that the instrument can be safely operated. Please

pay special attention to the following points:

(a) Installation

• This instrument may only be installed by an

engineer or technician who has an expert

knowledge of this device. Operators are not

allowed to carry out installation unless they

meet this condition.

• With high process temperatures, care must

be taken not to burn yourself by touching the

instrument or its casing.

• Never loosen the process connector nuts when

the instrument is installed in a process. This can

lead to a sudden, explosive release of process

uids.

NOTE

Draws attention to information essential for

understanding the operation and features.

Direct current

• When draining condensate from the pressure

detector section, take appropriate precautions

to prevent the inhalation of harmful vapors and

the contact of toxic process uids with the skin

or eyes.

• When removing the instrument from a

hazardous process, avoid contact with the uid

and the interior of the meter.

• All installation shall comply with local installation

requirements and the local electrical code.

(b) Wiring

• The instrument must be installed by an

engineer or technician who has an expert

knowledge of this instrument. Operators are not

permitted to carry out wiring unless they meet

this condition.

• Before connecting the power cables, please

conrm that there is no current owing through

the cables and that the power supply to the

instrument is switched off.

IM 01C25F01-01E

Page 6

<1. Introduction>

1-3

(c) Operation

• Wait 5 min. after the power is turned off, before

opening the covers.

(d) Maintenance

• Please carry out only the maintenance

procedures described in this manual. If you

require further assistance, please contact the

nearest Yokogawa ofce.

• Care should be taken to prevent the build up of

dust or other materials on the display glass and

the name plate. To clean these surfaces, use a

soft, dry cloth.

(e) Explosion Protected Type Instrument

• Users of explosion proof instruments should

refer rst to section 2.9 (Installation of an

Explosion Protected Instrument) of this manual.

• The use of this instrument is restricted to those

who have received appropriate training in the

device.

• Take care not to create sparks when accessing

the instrument or peripheral devices in a

hazardous location.

(f) Modication

1.2 Warranty

• The warranty shall cover the period noted on

the quotation presented to the purchaser at the

time of purchase. Problems occurring during

the warranty period shall basically be repaired

free of charge.

• If any problems are experienced with this

instrument, the customer should contact the

Yokogawa representative from which this

instrument was purchased or the nearest

Yokogawa ofce.

• If a problem arises with this instrument,

please inform us of the nature of the problem

and the circumstances under which it

developed, including the model specication

and serial number. Any diagrams, data and

other information you can include in your

communication will also be helpful.

• The party responsible for the cost of xing the

problem shall be determined by Yokogawa

following an investigation conducted by

Yokogawa.

• The purchaser shall bear the responsibility for

repair costs, even during the warranty period, if

the malfunction is due to:

• Yokogawa will not be liable for malfunctions or

damage resulting from any modication made

to this instrument by the customer.

- Improper and/or inadequate maintenance by

the purchaser.

- Malfunction or damage due to a failure

to handle, use, or store the instrument in

accordance with the design specications.

- Use of the product in question in a location

not conforming to the standards specied by

Yokogawa, or due to improper maintenance

of the installation location.

- Failure or damage due to modication or

repair by any party except Yokogawa or an

approved representative of Yokogawa.

- Malfunction or damage from improper

relocation of the product in question after

delivery.

- Reason of force majeure such as res,

earthquakes, storms/oods, thunder/

lightening, or other natural disasters, or

disturbances, riots, warfare, or radioactive

contamination.

IM 01C25F01-01E

Page 7

<1. Introduction>

1.3 ATEX Documentation

This is only applicable to the countries in European Union.

1-4

GB

DK

E

NL

SK

CZ

I

LT

LV

EST

PL

SF

P

F

D

S

SLO

H

BG

RO

M

GR

IM 01C25F01-01E

Page 8

<2. Handling Cautions>

2. Handling Cautions

2-1

This chapter provides important information on how

to handle the transmitter. Read this carefully before

using the transmitter.

The transmitters are thoroughly tested at the

factory before shipment. When taking delivery of an

instrument, visually check them to make sure that

no damage occurred during shipment.

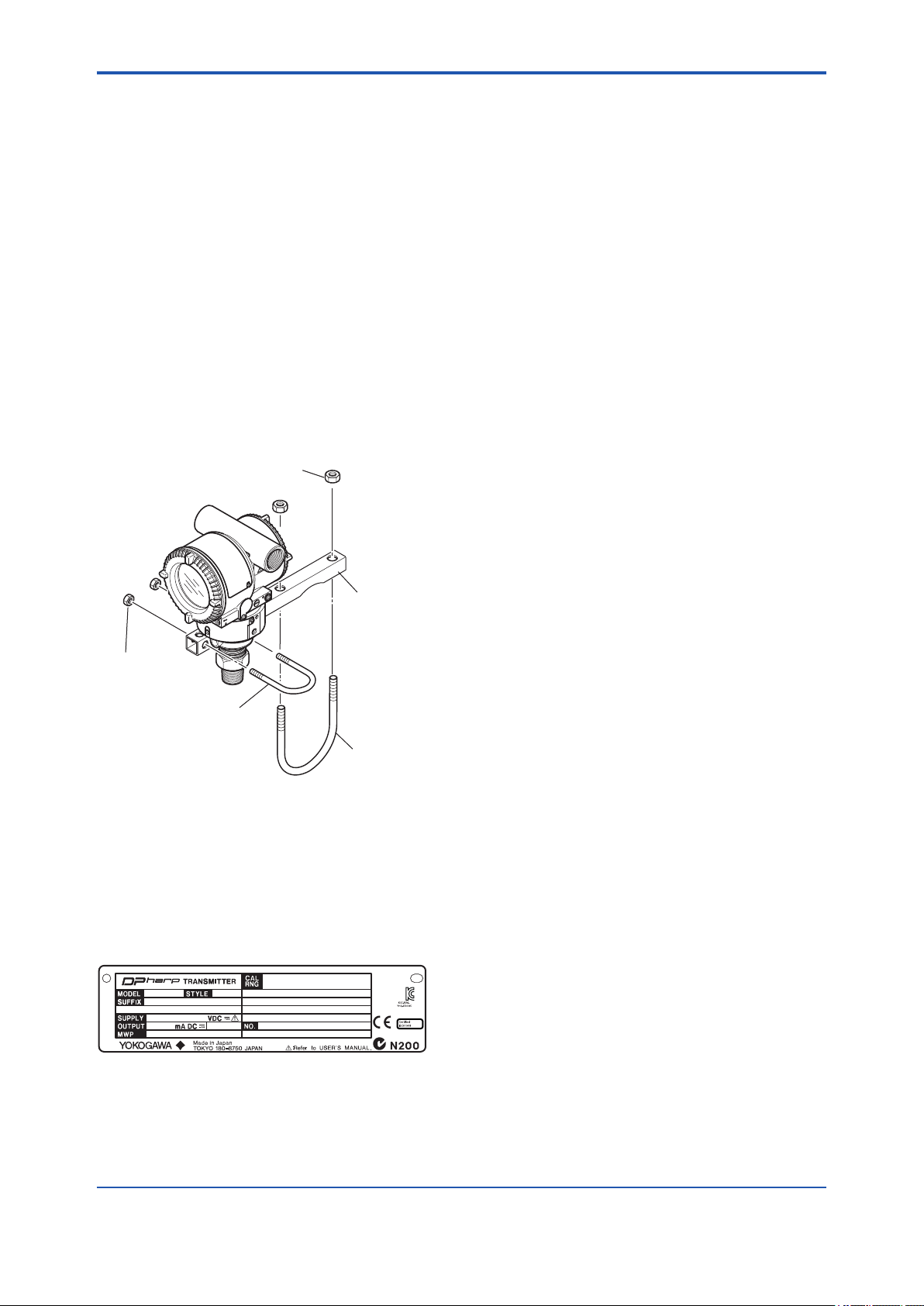

Also check that all transmitter mounting hardware

shown in gure 2.1 is included. If the transmitter

is ordered without the mounting bracket and the

process connector, the transmitter mounting

hardware will not be included. After checking the

transmitter, carefully repack it in its box and keep it

there until you are ready to install it.

U-bolt nut (L)

Mounting bracket

U-bolt nut (S)

2.2 Unpacking

Keep the transmitter in its original packaging to

prevent it from being damaged during shipment.

Do not unpack the transmitter until it reaches the

installation site.

2.3 Storage

The following precautions must be observed when

storing the instrument, especially for a long period.

(a) Select a storage area which meets the following

conditions:

• It is not exposed to rain or subject to water

seepage/leaks.

• Vibration and shock are kept to a minimum.

• It has an ambient temperature and relative

humidity within the following ranges.

Ambient temperature:

–40* to 85°C without integral indicator

–30* to 80°C with integral indicator

* –15°C when /HE is specied.

Relative humidity:

0% to 100% R.H.

Preferred temperature and humidity:

approx. 25°C and 65% R.H.

U-bolt (S)

U-bolt (L)

F0201.ai

Figure 2.1 Transmitter Mounting Hardware

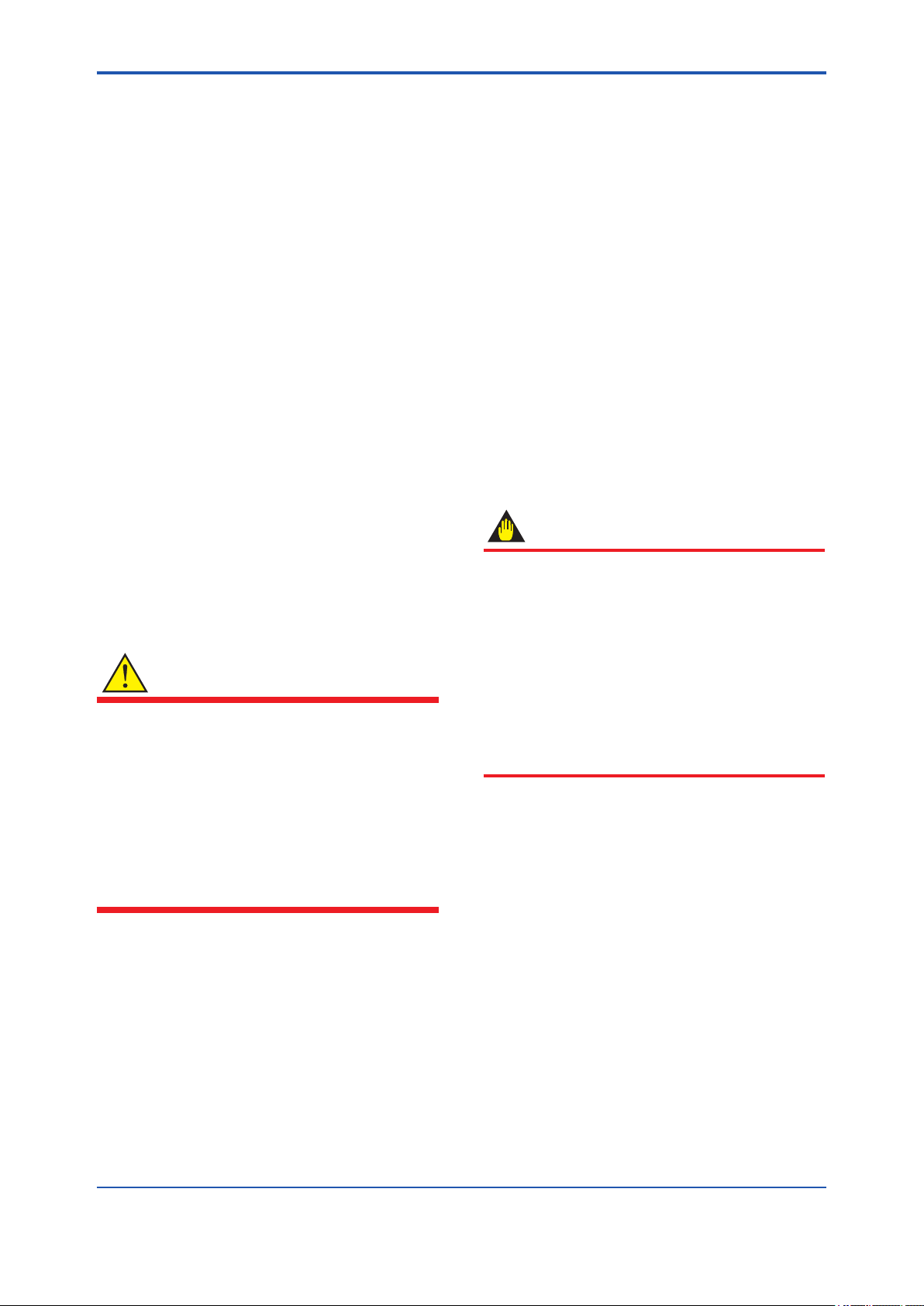

2.1 Model and Specications

Check

The model name and specications are written on

the name plate attached to the case.

F0202.ai

Figure 2.2 Name Plate

(b) When storing the transmitter, repack it carefully

in the packaging that it was originally shipped

with.

(c) If the transmitter has been used, thoroughly

clean the chambers inside the cover anges, so

that there is no process uid remaining inside.

Before placing it in storage, also make sure that

the pressure-detector is securely connected to

the transmitter section.

2.4 Selecting the Installation Location

The transmitter is designed to withstand severe

environmental conditions. However, to ensure

that it will provide years of stable and accurate

performance, take the following precautions when

selecting the installation location.

IM 01C25F01-01E

Page 9

<2. Handling Cautions>

2-2

(a) Ambient Temperature

Avoid locations subject to wide temperature

variations or a signicant temperature gradient.

If the location is exposed to radiant heat from

plant equipment, provide adequate thermal

insulation and/or ventilation.

(b) Ambient Atmosphere

Do not install the transmitter in a corrosive

atmosphere. If this cannot be avoided, there

must be adequate ventilation as well as

measures to prevent the leaking of rain water

and the presence of standing water in the

conduits.

(c) Shock and Vibration

Although the transmitter is designed to be

relatively resistant to shock and vibration, an

installation site should be selected where this is

kept to a minimum.

(d) Installation of Explosion-protected Transmitters

An explosion-protected transmitters is

certied for installation in a hazardous area

containing specic gas types. See subsection

2.9 “Installation of an Explosion-Protected

Transmitters.”

2.5 Pressure Connection

WARNING

• Never loosen the process connector bolts

when an instrument is installed in a process.

The device is under pressure, and a loss of

seal can result in a sudden and uncontrolled

release of process uid.

• When draining toxic process uids that have

condensed inside the pressure detector,

take appropriate steps to prevent the contact

of such uids with the skin or eyes and the

inhalation of vapors from these uids.

The following precautions must be observed

in order to safely operate the transmitter under

pressure.

(a) Make sure that all the process connector bolts

are tightened rmly.

(b) Make sure that there are no leaks in the impulse

piping.

(c) Never apply a pressure higher than the

specied maximum working pressure.

2.6 Waterproong of Cable

Conduit Connections

Apply a non-hardening sealant to the threads

to waterproof the transmitter cable conduit

connections. (See gure 6.8, 6.9 and 6.10.)

2.7 Restrictions on Use of Radio Transceivers

IMPORTANT

Although the transmitter has been designed to

resist high frequency electrical noise, if a radio

transceiver is used near the transmitter or its

external wiring, the transmitter may be affected

by high frequency noise pickup. To test this, start

out from a distance of several meters and slowly

approach the transmitter with the transceiver

while observing the measurement loop for noise

effects. Thereafter use the transceiver outside

the range where the noise effects were rst

observed.

2.8 Insulation Resistance and Dielectric Strength Test

Since the transmitter has undergone insulation

resistance and dielectric strength tests at the factory

before shipment, normally these tests are not

required. If the need arises to conduct these tests,

heed the following:

(a) Do not perform such tests more frequently than

is absolutely necessary. Even test voltages that

do not cause visible damage to the insulation

may degrade the insulation and reduce safety

margins.

IM 01C25F01-01E

Page 10

<2. Handling Cautions>

2-3

(b) Never apply a voltage exceeding 500 V DC

(100 V DC with an internal lightning protector)

for the insulation resistance test, nor a voltage

exceeding 500 V AC (100 V AC with an internal

lightning protector) for the dielectric strength

test.

(c) Before conducting these tests, disconnect

all signal lines from the transmitter terminals.

The procedure for conducting these tests is as

follows:

• Insulation Resistance Test

1) Short-circuit the + and – SUPPLY terminals in

the terminal box.

2) Turn OFF the insulation tester. Then connect

the insulation tester plus (+) lead wire to the

shorted SUPPLY terminals and the minus (–)

leadwire to the grounding terminal.

3) Turn ON the insulation tester power and

measure the insulation resistance. The voltage

should be applied as briey as possible to verify

that the insulation resistance is at least 20 MΩ.

4) After completing the test and being very careful

not to touch exposed conductors disconnect the

insulation tester and connect a 100 kΩ resistor

between the grounding terminal and the shortcircuiting SUPPLY terminals. Leave this resistor

connected at least one second to discharge any

static potential. Do not touch the terminals while

it is discharging.

2.9 Installation of an ExplosionProtected Instrument

NOTE

For FOUNDATION Fieldbus explosion protected

type, please refer to IM 01C22T02-01E.

For PROFIBUS PA explosion protected type,

please refer to IM 01C25T04-01EN.

If a customer makes a repair or modication to

an intrinsically safe or explosionproof instrument

and the instrument is not restored to its original

condition, its intrinsically safe or explosionproof

construction may be compromised and the

instrument may be hazardous to operate. Please

contact Yokogawa before making any repair or

modication to an instrument.

CAUTION

This instrument has been tested and certied

as being intrinsically safe or explosionproof.

Please note that severe restrictions apply to this

instrument’s construction, installation, external

wiring, maintenance and repair. A failure to abide

by these restrictions could make the instrument a

hazard to operate.

• Dielectric Strength Test

1) Short-circuit the + and – SUPPLY terminals in

the terminal box.

2) Turn OFF the dielectric strength tester. Then

connect the tester between the shorted

SUPPLY terminals and the grounding terminal.

Be sure to connect the grounding lead of the

dielectric strength tester to the ground terminal.

3) Set the current limit on the dielectric strength

tester to 10 mA, then turn ON the power and

gradually increase the test voltage from ‘0’ to

the specied voltage.

4) When the specied voltage is reached, hold it

for one minute.

5) After completing this test, slowly decrease the

voltage to avoid any voltage surges.

WARNING

Maintaining the safety of explosionproof

equipment requires great care during mounting,

wiring, and piping. Safety requirements also

place restrictions on maintenance and repair.

Please read the following sections very carefully.

WARNING

The range setting switch must not be used in a

hazardous area.

IM 01C25F01-01E

Page 11

<2. Handling Cautions>

2-4

IMPORTANT

For combined approval types

Once a device of multiple approval type is

installed, it should not be re-installed using any

other approval types. Apply a permanent mark

in the check box of the selected approval type

on the certication label on the transmitter to

distinguish it from unused approval types.

IMPORTANT

All the blind plugs which accompany the EJX/

EJA-E transmitters upon shipment from the

factory are certied by the applicable agency

in combination with the transmitters. The plugs

which are marked with the symbols “◊ Ex” on

their surfaces are certied only in combination

with the EJX/EJA-E series transmitters.

2.9.1 FM Approval

Note 2. Entity Parameters

• Intrinsically Safe Apparatus Parameters

[Groups A, B, C, D, E, F and G]

Vmax = 30 V Ci = 6 nF

Imax = 200 mA Li = 0 µH

Pmax = 1 W

* Associated Apparatus Parameters

(FM approved barriers)

Voc ≤ 30 V Ca > 6 nF

Isc ≤ 200 mA La > 0 µH

Pmax ≤ 1W

• Intrinsically Safe Apparatus Parameters

[Groups C, D, E, F and G]

Vmax = 30 V Ci = 6 nF

Imax = 225 mA Li = 0 µH

Pmax = 1 W

* Associated Apparatus Parameters

(FM approved barriers)

Voc ≤ 30 V Ca > 6 nF

Isc ≤ 225 mA La > 0 µH

Pmax ≤ 1 W

a. FM Intrinsically Safe Type

Caution for FM intrinsically safe type. (Following

contents refer “DOC. No. IFM022-A12”)

Note 1. Model EJX/EJA-E Series Differential,

gauge and absolute pressure transmitters

with optional code /FS1 are applicable for

use in hazardous locations.

• Applicable Standard: FM3600, FM3610,

FM3611, FM3810

• Intrinsically Safe for Class I, Division 1,

Groups A, B, C & D. Class II, Division 1,

Groups E, F & G and Class III, Division 1,

Class I, Zone 0 in Hazardous Locations, AEx

ia IIC

• Nonincendive for Class I, Division 2, Groups

A, B, C & D. Class II, Division 2, Groups F &

G, Class I, Zone 2, Groups IIC, in Hazardous

Locations.

• Outdoor hazardous locations, NEMA TYPE

4X.

• Temperature Class: T4

• Ambient temperature: –60 to 60°C

• Entity Installation Requirements

Vmax ≥ Voc or Uo or Vt, Imax ≥ Isc or Io or It,

Pmax (or Po) ≤ Pi, Ca or Co ≥ Ci + Ccable,

La or Lo ≥ Li + Lcable

Note 3. Installation

• Barrier must be installed in an enclosure that

meets the requirements of ANSI/ISA S82.01.

• Control equipment connected to barrier must

not use or generate more than 250 V rms or

V dc.

• Installation should be in accordance with

ANSI/ISA RP12.6 “Installation of Intrinsically

Safe Systems for Hazardous (Classied)

Locations” and the National Electric Code

(ANSI/NFPA 70).

• The conguration of associated apparatus

must be FMRC Approved.

• Dust-tight conduit seal must be used when

installed in a Class II, III, Group E, F and G

environments.

• Associated apparatus manufacturer’s

installation drawing must be followed when

installing this apparatus.

• The maximum power delivered from the

barrier must not exceed 1 W.

• Note a warning label worded

“SUBSTITUTION OF COMPONENTS MAY

IMPAIR INTRINSIC SAFETY,” and “INSTALL

IN ACCORDANCE WITH DOC. No. IFM022A12”

IM 01C25F01-01E

Page 12

<2. Handling Cautions>

2-5

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void

Factory Mutual Intrinsically safe and

Nonincendive Approval.

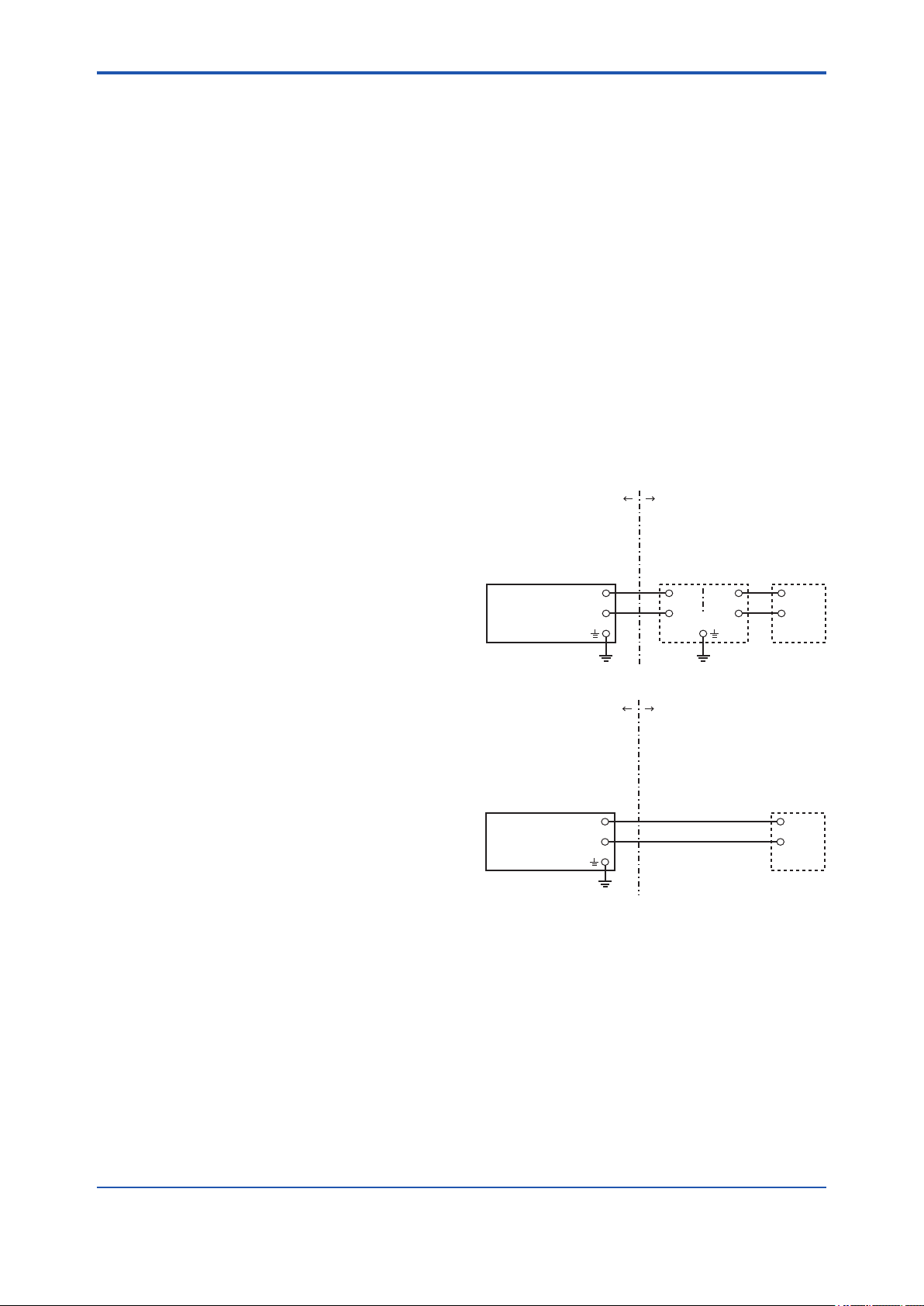

[Intrinsically Safe]

Hazardous Location Nonhazardous Location

Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G

Class 1, Zone 0 in

Hazardous (Classified)

Locations AEx ia IIC

Pressure Transmitters

+

Supply

Hazardous Location Nonhazardous Location

Class I, II, Division 2,

Groups A, B, C, D, F, G

Class 1, Zone 2, Group IIC,

in Hazardous (Classified)

Locations

Pressure Transmitters

Supply

–

[Nonincendive]

+

–

Safety Barrier

+

+

–

–

Not Use

Safety Barrier

b. FM Explosionproof Type

Caution for FM explosionproof type.

Note 1. Model EJX/EJA-E Series pressure

transmitters with optional code /FF1 are

applicable for use in hazardous locations.

• Applicable Standard: FM3600, FM3615,

FM3810, ANSI/NEMA 250

• Explosionproof for Class I, Division 1,

Groups B, C and D.

• Dust-ignitionproof for Class II/III, Division 1,

Groups E, F and G.

• Enclosure rating: NEMA TYPE 4X.

• Temperature Class: T6

• Ambient Temperature: –40 to 60°C

• Supply Voltage: 42 V dc max.

• Output signal: 4 to 20 mA

General

Purpose

Equipment

+

–

F0203-1.ai

General

Purpose

Equipment

+

–

F0203-2.ai

Note 2. Wiring

• All wiring shall comply with National Electrical

Code ANSI/NFPA70 and Local Electrical

Codes.

• When installed in Division 1, “FACTORY

SEALED, CONDUIT SEAL NOT

REQUIRED.”

Note 3. Operation

• Keep the “WARNING” nameplate attached to

the transmitter.

WARNING: OPEN CIRCUIT BEFORE

REMOVING COVER. FACTORY SEALED,

CONDUIT SEAL NOT REQUIRED.

INSTALL IN ACCORDANCE WITH THE

USERS MANUAL IM 01C25.

• Take care not to generate mechanical

sparking when accessing to the instrument

and peripheral devices in a hazardous

location.

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void

Factory Mutual Explosionproof Approval.

c. FM Intrinsically Safe Type/FM

Explosionproof Type

Model EJX/EJA-E Series pressure transmitters

with optional code /FU1 or /V1U1 can be

selected the type of protection (FM Intrinsically

Safe or FM Explosionproof) for use in

hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be in

accordance with the description about the

type of protection in this instruction manual.

Note 2. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

the transmitter is installed.

IM 01C25F01-01E

Page 13

<2. Handling Cautions>

2-6

2.9.2 CSA Certication

a. CSA Intrinsically Safe Type

Caution for CSA Intrinsically safe and

nonincendive type. (Following contents refer to

“DOC No. ICS013-A13”)

Note 1. Model EJX/EJA-E Series differential,

gauge, and absolute pressure transmitters

with optional code /CS1 are applicable for

use in hazardous locations

Certicate: 1606623

[For CSA C22.2]

• Applicable Standard: C22.2 No.0, C22.2

No.0.4, C22.2 No.25, C22.2 No.94, C22.2

No.157, C22.2 No.213, C22.2 No.61010-1,

C22.2 No.60079-0

• Intrinsically Safe for Class I, Division 1,

Groups A, B, C & D, Class II, Division 1,

Groups E, F & G, Class III, Division 1

• Nonincendive for Class I, Division 2, Groups

A, B, C & D, Class II, Division 2, Groups E, F

& G, Class III, Division 1

• Enclosure: NEMA TYPE 4X

• Temp. Code: T4

• Amb. Temp.: –50* to 60°C

* –15°C when /HE is specied.

• Process Temperature: 120°C max.

[For CSA E60079]

• Applicable Standard: CAN/CSA E60079-11,

CAN/CSA E60079-15, IEC 60529:2001

• Ex ia IIC T4, Ex nL IIC T4

• Ambient Temperature: –50* to 60°C

* –15°C when /HE is specied.

• Max. Process Temp.: 120°C

• Enclosure: IP66/IP67

Note 2. Entity Parameters

• Intrinsically safe ratings are as follows:

Maximum Input Voltage (Vmax/Ui) = 30 V

Maximum Input Current (Imax/Ii) = 200 mA

Maximum Input Power (Pmax/Pi) = 0.9 W

Maximum Internal Capacitance (Ci) = 10 nF

Maximum Internal Inductance (Li) = 0 µH

• Type "n" or Nonincendive ratings are as

follows:

Maximum Input Voltage (Vmax/Ui) = 30 V

Maximum Internal Capacitance (Ci) = 10 nF

Maximum Internal Inductance (Li) = 0 µH

• Installation Requirements

Uo ≤ Ui, Io ≤ Ii, Po ≤ Pi,

Co ≥ Ci + Ccable, Lo ≥ Li + Lcable

Voc ≤ Vmax, Isc ≤ Imax,

Ca ≥ Ci + Ccable, La ≥ Li + Lcable

Uo, Io, Po, Co, Lo, Voc, Isc, Ca and La are

parameters of barrier.

Note 3. Installation

• In any safety barreir used output current

must be limited by a resistor 'R' such that

Io=Uo/R or Isc=Voc/R.

• The safety barrier must be CSA certied.

• Input voltage of the safety barrier must be

less than 250 Vrms/Vdc.

• Installation should be in accordance with

Canadian Electrical Code Part I and Local

Electrical Code.

• Dust-tight conduit seal must be used when

installed in Class II and III environments.

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation and Yokogawa Corporation

of America is prohibited and will void

Canadian Standards Intrinsically safe and

nonincendive Certication.

[Intrinsically Safe]

Hazardous Location Nonhazardous Location

Group IIC, Zone 0

Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G

Pressure Transmitters

+

Supply

Hazardous Location Nonhazardous Location

Group IIC, Zone 2

Class I, II, Division 2,

Groups A, B, C, D, F, G

Class III, Division 1.

Pressure Transmitters

Supply

–

[Nonincendive]

+

–

Safety Barrier

+

+

–

–

Not Use

Safety Barrier

CSA Certified

Equipment

([nL] or

nonincendive)

b. CSA Explosionproof Type

Caution for CSA explosionproof type.

Note 1. Model EJX/EJA-E Series pressure

transmitters with optional code /CF1 are

applicable for use in hazardous locations:

• Certicate: 2014354

• Applicable Standard: C22.2 No.0,

C22.2 No.0.4, C22.2 No.0.5, C22.2 No.25,

C22.2 No.30, C22.2 No.94,

C22.2 No.61010-1, C22.2 No.60079-0,

C22.2 No.60079-1

General

Purpose

Equipment

+

–

F0204-1.ai

+

–

F0204-2.ai

IM 01C25F01-01E

Page 14

<2. Handling Cautions>

2-7

• Explosion-proof for Class I, Groups B, C and

D.

• Dustignition-proof for Class II/III, Groups E, F

and G.

• Enclosure: NEMA TYPE 4X

• Temperature Code: T6...T4

• Ex d IIC T6...T4

• Enclosure: IP66/IP67

• Maximum Process Temperature: 120°C (T4),

100°C (T5), 85°C (T6)

• Ambient Temperature: –50* to 75°C (T4),

–50* to 80°C (T5), –50* to 75°C (T6)

* –15°C when /HE is specied.

• Supply Voltage: 42 V dc max.

• Output Signal: 4 to 20 mA dc

Note 2. Wiring

• All wiring shall comply with Canadian

Electrical Code Part I and Local Electrical

Codes.

• In hazardous location, wiring shall be in

conduit as shown in the gure.

• WARNING:

A SEAL SHALL BE INSTALLED WITHIN

50cm OF THE ENCLOSURE.

UN SCELLEMENT DOIT ÊTRE INSTALLÉ À

MOINS DE 50cm DU BOÎTIER.

• WARNING:

WHEN INSTALLED IN CL.I, DIV 2, SEAL

NOT REQUIRED.

UNE FOIS INSTALLÉ DANS CL I, DIV 2,

AUCUN JOINT N'EST REQUIS.

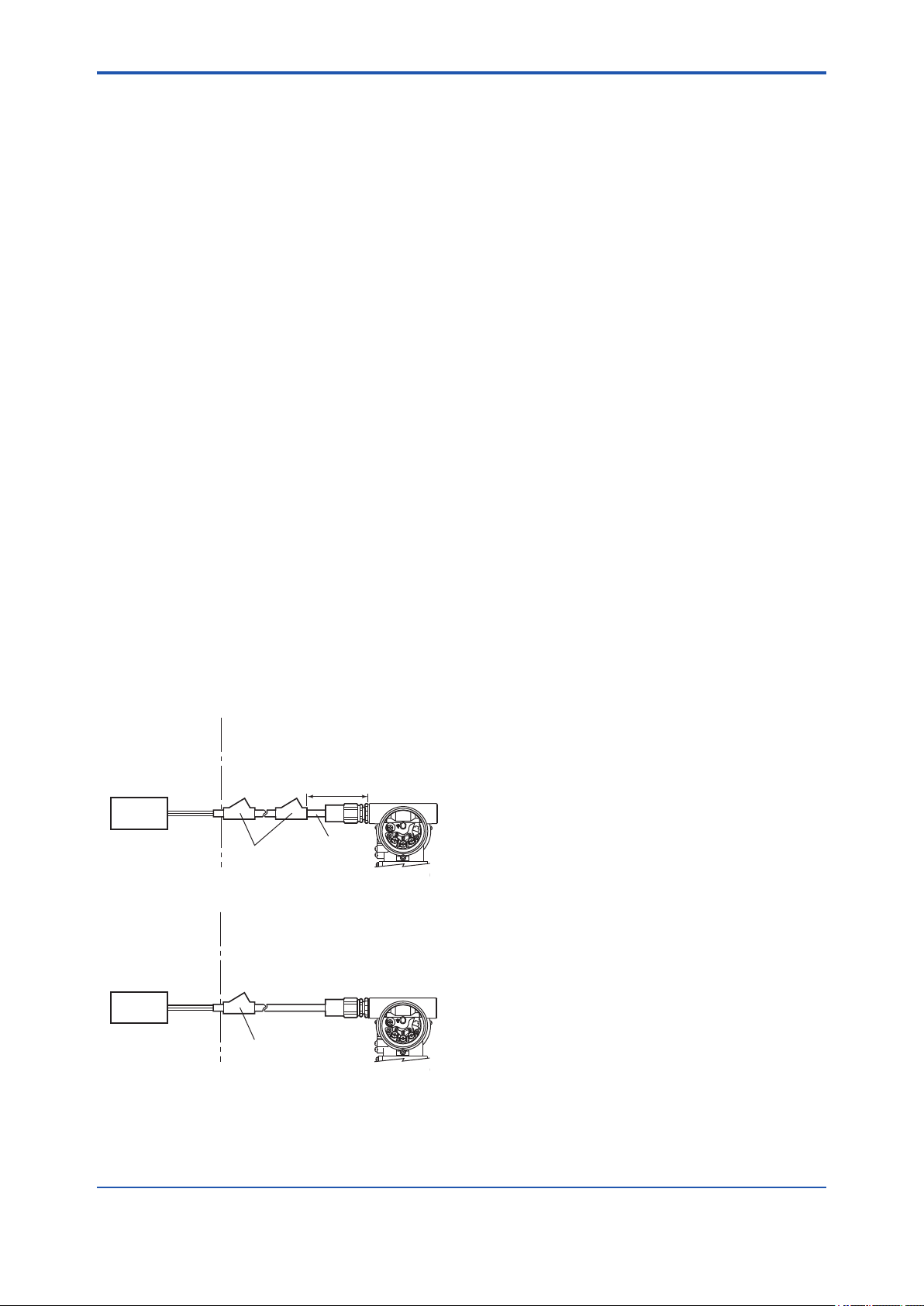

Non-Hazardous

Locations

Non-hazardous

Location

Equipment

42 V DC Max.

4 to 20 mA DC

Signal

Non-Hazardous

Locations

Non-hazardous

Location

Equipment

42 V DC Max.

4 to 20 mA DC

Signal

Hazardous Locations Division 1

50 cm Max.

Sealing Fitting

Hazardous Locations Division 2

Sealing Fitting

Conduit

Transmitter

Transmitter

PULSE

SUPPLY

CHECK

ALARM

F0205-1.ai

PULSE

SUPPLY

CHECK

ALARM

F0205-2.ai

• All wiring shall comply with local installation

requirements and local electrical code.

• In hazardous locations, the cable entry

devices shall be of a certied ameproof

type, suitable for the conditions of use and

correctly installed.

• Unused apertures shall be closed with

suitable ameproof certied blanking

elements. (The plug attached is ameproof

certied.)

Note 3. Operation

• WARNING:

AFTER DE-ENERGIZING, DELAY 5

MINUTES BEFORE OPENING.

APRÉS POWER-OFF, ATTENDRE 5

MINUTES AVANT D'OUVRIR.

• WARNING:

WHEN AMBIENT TEMPERATURE ≥ 65°C,

USE THE HEAT-RESISTING CABLES ≥

90°C.

QUAND LA TEMPÉRATURE AMBIANTE

≥ 65°C, UTILISEZ DES CÂBLES

RÉSISTANTES Á LA CHALEUR ≥ 90°C.

• Take care not to generate mechanical

sparking when accessing to the instrument

and peripheral devices in a hazardous

location.

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation and Yokogawa Corporation of

America is prohibited and will void Canadian

Standards Explosionproof Certication.

c CSA Intrinsically Safe Type/CSA

Explosionproof Type

Model EJX/EJA-E Series pressure transmitters

with optional code /CU1 or /V1U1 can be

selected the type of protection (CSA Intrinsically

Safe or CSA Explosionproof) for use in

hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be in

accordance with the description about the

type of protection in this instruction manual.

Note 2. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

the transmitter is installed.

IM 01C25F01-01E

Page 15

<2. Handling Cautions>

2-8

2.9.3 ATEX Certication

(1) Technical Data

a. ATEX Intrinsically Safe Ex ia

Caution for ATEX Intrinsically safe type.

Note 1. Model EJX/EJA-E Series pressure

transmitters with optional code /KS21 for

potentially explosive atmospheres:

• No. DEKRA 11ATEX0228 X

• Applicable Standard:

EN 60079-0:2009, EN 60079-11:2007,

EN 60079-26:2007, EN 61241-11:2006

• Type of Protection and Marking code:

Ex ia IIC T4 Ga

Ex ia IIIC T85 ºC T100 ºC T120 ºC Db

• Group: II

• Category: 1G, 2D

• Ambient Temperature for EPL Ga:

–50 to 60°C

• Ambient Temperature for EPL Db:

–30* to 60°C

* –15°C when /HE is specied.

• Process Temperature (Tp.): 120°C max.

• Maximum Surface Temperature for EPL Db:

T85°C (Tp.: 80°C)

T100°C (Tp.: 100°C)

T120°C (Tp.: 120°C)

• Enclosure: IP66 / IP67

Note 2 Electrical Data

• In type of explosion protection intrinsic safety

Ex ia IIC or Ex ia IIIC, only for connection to a

certied intrinsically safe circuit with following

maximum values:

Ui = 30 V

Ii = 200 mA

Pi = 0.9 W

(Linear Source)

Maximum internal capacitance; Ci = 27.6 nF

Maximum internal inductance; Li = 0 µH

Note 3. Installation

• Refer to the control drawing. All wiring shall

comply with local installation requirements.

[Control Drawing]

Hazardous Location

Transmitter

+

Supply

–

*1: In any safety barriers used the output current must be

limited by a resistor “R” such that Io=Uz/R.

Nonhazardous Location

+

Safety Barrier

–

F0206.ai

*1

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void

DEKRA Intrinsically safe Certication.

Note 5. Special Conditions for Safe Use

WARNING

• In the case where the enclosure of the

Pressure Transmitter is made of aluminium,

if it is mounted in an area where the use of

category 1 G apparatus is required, it must

be installed such, that, even in the event of

rare incidents, ignition sources due to impact

and friction sparks are excluded.

• Electrostatic charge may cause an exlosion

hazard. Avoid any actions that cause the

gerenation of eletrostatic charge, such as

rubbing with a dry cloth on coating face of

the product.

• In case of the enclosure of the Pressure

Transmitter with paint layers, if it is mounted

in an area where the use of category 2D

apparatus is required, it shall be installed in

such a way that the risk from electrostatic

discharges and propagating brush

discharges caused by rapid ow of dust is

avoided.

• To satisfy IP66 or IP67, apply waterproof

glands to the electrical connection port.

• When the lightning protector option is

specied, the apparatus is not capable

of withstanding the 500V insulation test

required by EN60079-11. This must be taken

into account when installing the apparatus.

IM 01C25F01-01E

Page 16

<2. Handling Cautions>

2-9

b. ATEX Flameproof Type

Caution for ATEX ameproof type.

Note 1. Model EJX/EJA-E Series pressure

transmitters with optional code /KF22 for

potentially explosive atmospheres:

• No. KEMA 07ATEX0109 X

• Applicable Standard: EN 60079-0:2009,

EN 60079-1:2007, EN 60079-31:2009

• Type of Protection and Marking Code:

Ex d IIC T6...T4 Gb, Ex tb IIIC T85°C Db

• Group: II

• Category: 2G, 2D

• Enclosure: IP66/IP67

• Temperature Class for gas-poof:

T6, T5, and T4

• Ambient Temperature for gas-proof:

–50 to 75°C (T6), –50 to 80°C (T5), and

–50 to 75°C (T4)

• Maximum Process Temperature (Tp.) for

gas-proof:

85°C (T6), 100°C (T5), and 120°C (T4)

• Maximum Surface Temperature for dustproof:

T85°C (Tamb.: –30* to 75°C, Tp.: 85°C)

* –15°C when /HE is specied.

Note 2. Electrical Data

• Supply voltage: 42 V dc max.

• Output signal: 4 to 20 mA

Note 3. Installation

• All wiring shall comply with local installation

requirement.

• The cable entry devices shall be of a certied

ameproof type, suitable for the conditions of

use.

Note 4. Operation

• Keep the “WARNING” label attached to the

transmitter.

WARNING: AFTER DE-ENERGIZING,

DELAY 5 MINUTES BEFORE OPENING.

WHEN THE AMBIENT TEMP.≥65°C, USE

HEAT-RESISTING CABLE AND CABLE

GLAND ≥90°C.

• Take care not to generate mechanical

sparking when accessing to the instrument

and peripheral devices in a hazardous

location.

Note 5. Special Conditions for Safe Use

WARNING

• Electrostatic charge may cause an exlosion

hazard. Avoid any actions that cause the

gerenation of eletrostatic charge, such as

rubbing with a dry cloth on coating face of the

product.

• In the case where the enclosure of the

Pressure Transmitter is made of aluminium,

if it is mounted in an area where the use of

category 2D apparatus is required, it shall

be installed in such a way that the risk from

electrostatic discharges and propagating

brush discharges caused by rapid ow of

dust is avoided.

• The instrument modication or parts

replacement by other than an authorized

Representative of Yokogawa Electric

Corporation is prohibited and will void the

certication.

• To satisfy IP66 or IP67, apply waterproof

glands to the electrical connection port.

c. ATEX Intrinsically Safe Type/ATEX

Flameproof Type

Model EJX/EJA-E Series pressure transmitters

with optional code /KU22 or /V1U1 can

be selected the type of protection ATEX

Flameproof, Intrinsically Safe. Ex ia, or Ex ic for

use in hazardous area.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be in

accordance with the description about the

type of protection in this user’s manual.

Note 2. For combined approval types Once a

device of multiple approval type is installed,

it should not be re-installed using any

other approval types. Apply a permanent

mark in the check box of the selected

approval type on the certication label on

the transmitter to distinguish it from unused

approval types.

IM 01C25F01-01E

Page 17

<2. Handling Cautions>

● ATEX Intrinsically Safe Ex ic

Caution for ATEX intrinsically safe Ex ic

• Applicable Standard:

EN 60079-0:2009/EN 60079-0:2012,

EN 60079-11:2012

• Type of Protection and Marking Code:

II 3G Ex ic IIC T4 Gc

• Ambient Temperature: –30* to +60°C

* –15°C when /HE is specied.

• Ambient Humidity:

0 to 100% (No condensation)

• Maximum Process Temperature: 120°C

• IP Code: IP66

WARNING

• Electrostatic charge may cause an explosion

hazard. Avoid any actions that cause the

gerenation of eletrostatic charge, such as

rubbing with a dry cloth on coating face of

the product.

• When the lightning protector option is

specied, the apparatus is not capable

of withstanding the 500V insulation test

required by EN60079-11. This must be taken

into account when installing the apparatus.

• Ambient pollution degree: 2

• Overvoltage category: I

Note 1. Electrical Data

Ui = 30 V

Ci = 27.6 nF

Li = 0 µH

(2) Electrical Connection

A mark indicating the electrical connection type

is stamped near the electrical connection port.

These marks are as followed.

Screw Size Marking

Note 2. Installation

• All wiring shall comply with local installation

requirements. (refer to the control drawing)

ISO M20 × 1.5 female

ANSI 1/2 NPT female

• Cable glands, adapters and/or blanking

elements shall be of Ex “n”, Ex “e” or Ex “d”

and shall be installed so as to maintain the

specied degree of protection (IP Code) of

the transmitters.

Location of the mark

Note 3. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

(3) Installation

Corporation is prohibited and will void ATEX

intrinsically safe.

Hazardous Area

Transmitter

[Control drawing]

+

–

Nonhazardous Area

Associated

Apparatus

WARNING

• All wiring shall comply with local installation

requirements and the local electrical code.

• There is no need for conduit seal in Division

1 and Division 2 hazardous locations

because this product is sealed at the factory.

2-10

M

N or W

F0208.ai

Note 4. Specic Conditions of Use

F0207.ai

(4) Operation

WARNING

• OPEN CIRCUIT BEFORE REMOVING

COVER. INSTALL IN ACCORDANCE WITH

THIS USER’S MANUAL

• Take care not to generate mechanical

sparking when access to the instrument and

peripheral devices in a hazardous location.

IM 01C25F01-01E

Page 18

<2. Handling Cautions>

2-11

(5) Maintenance and Repair

WARNING

The instrument modication or parts replacement

by other than an authorized Representative of

Yokogawa Electric Corporation is prohibited and

will void the certication.

(6) Name Plate

Name plate

Tag plate for flameproof type

No. KEMA 07ATEX0109 X

Ex d IIC T6...T4 Gb, Ex tb IIIC T85°C Db

Enlcosure : IP66/IP67

TEMP. CLASS T6 T5 T4

MAX PROCESS TEMP.(Tp.) 85 100 120 °C

Tamb. -50 to 75 80 75 °C

T85°C(Tamb.:-30(-15) to 75°C, Tp.:85°C)(for Dust)

*3

WARNING

Tag plate for intrinsically safe type

D

AFTER DE-ENERGIZING, DELAY 5 MINUTES BEFORE

OPENING.

WHEN THE AMBIENT TEMP. ≥ 65°C, USE THE

HEAT-RESISTING CABLE & CABLE GLAND ≥ 90°C

POTENTIAL ELECTROSTATIC CHARGING HAZARD

No. DEKRA 11ATEX 0228 X

Ex ia IIC T4 Ga Ta: -50 TO 60°C

Ex ia IIIC T85°C T100°C T120°C Db Ta:-30(-15) TO 60°C

IP66/IP67

MAX. PROCESS TEMP.(Tp.) 120°C

T85°C(Tp.:80°C), T100°C(Tp.:100°C), T120°C(Tp.:120°C)

Ui=30V, Ii=200mA , Pi=0.9W, Ci=27.6nF, Li=0µH

*1: The rst digit in the three numbers next to the nine

letters of the serial number appearing after “NO.”

on the nameplate indicates the year of production.

The following is an example of a serial number for a

product that was produced in 2010:

91K819857 032

The year 2010

*2: “180-8750” is a zip code which represents the

following address.

2-9-32 Nakacho, Musashino-shi, Tokyo Japan

*3: The identication number of Notied Body.

2.9.4 IECEx Certication

Model EJX Series pressure transmitters with

optional code /SU2 can be selected the type of

protection (IECEx Intrinsically Safe/type n or

ameproof) for use in hazardous locations.

Note 1. For the installation of this transmitter,

once a particular type of protection is

selected, any other type of protection

cannot be used. The installation must be in

accordance with the description about the

type of protection in this instruction manual.

Note 2. In order to avoid confusion, unnecessary

marking is crossed out on the label other

than the selected type of protection when

the transmitter is installed.

a. IECEx Intrinsically Safe Type / type n

Caution for IECEx Intrinsically safe and type n.

*3

WARNING

D

POTENTIAL ELECTROSTATIC

CHARGING HAZARD

- SEE USER’S MANUAL

Tag plate for intrinsically safe Ex ic

Ex ic IIC T4 Gc

IP66

Tamb -30(-15) TO 60°C

MAX. PROCESS TEMP. 120°C

Ui=30V, Ci=27.6nF, Li=0µH

WARNING

POTENTIAL ELECTROSTATIC

CHARGING HAZARD

- SEE USER’S MANUAL

MODEL: Specied model code.

STYLE: Style code.

SUFFIX: Specied sufx code.

SUPPLY: Supply voltage.

OUTPUT: Output signal.

MWP: Maximum working pressure.

CAL RNG: Specied calibration range.

NO.: Serial number and year of production*1.

TOKYO 180-8750 JAPAN:

The manufacturer name and the address*2.

F0209.ai

Note 1. Model EJX Series differential, gauge,

and absolute pressure transmitters with

optional code /SU2 are applicable for use

in hazardous locations

• No. IECEx CSA 05.0005

• Applicable Standard: IEC 60079-0:2000,

IEC 60079-11:1999, IEC 60079-15:2001

• Ex ia IIC T4, Ex nL IIC T4

• Ambient Temperature: –50 to 60°C

• Max. Process Temp.: 120°C

• Enclosure: IP66/IP67

Note 2. Entity Parameters

• Intrinsically safe ratings are as follows:

Maximum Input Voltage (Vmax/Ui) = 30 V

Maximum Input Current (Imax/Ii) = 200 mA

Maximum Input Power (Pmax/Pi) = 0.9 W

Maximum Internal Capacitance (Ci) = 10 nF

Maximum Internal Inductance (Li) = 0 µH

• Type "n" ratings are as follows:

Maximum Input Voltage (Vmax/Ui) = 30 V

Maximum Internal Capacitance (Ci) = 10 nF

Maximum Internal Inductance (Li) = 0 µH

IM 01C25F01-01E

Page 19

<2. Handling Cautions>

2-12

• Installation Requirements

Uo ≤ Ui, Io ≤ Ii, Po ≤ Pi,

Co ≥ Ci + Ccable, Lo ≥ Li + Lcable

Voc ≤ Vmax, Isc ≤ Imax,

Ca ≥ Ci + Ccable, La ≥ Li + Lcable

Uo, Io, Po, Co, Lo, Voc, Isc, Ca and La are

parameters of barrier.

Note 3. Installation

• In any safety barrier used output current

must be limited by a resistor 'R' such that

Io=Uo/R.

• The safety barrier must be IECEx certied.

• Input voltage of the safety barrier must be

less than 250 Vrms/Vdc.

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation and will void IECEx Intrinsically

safe and type n certication.

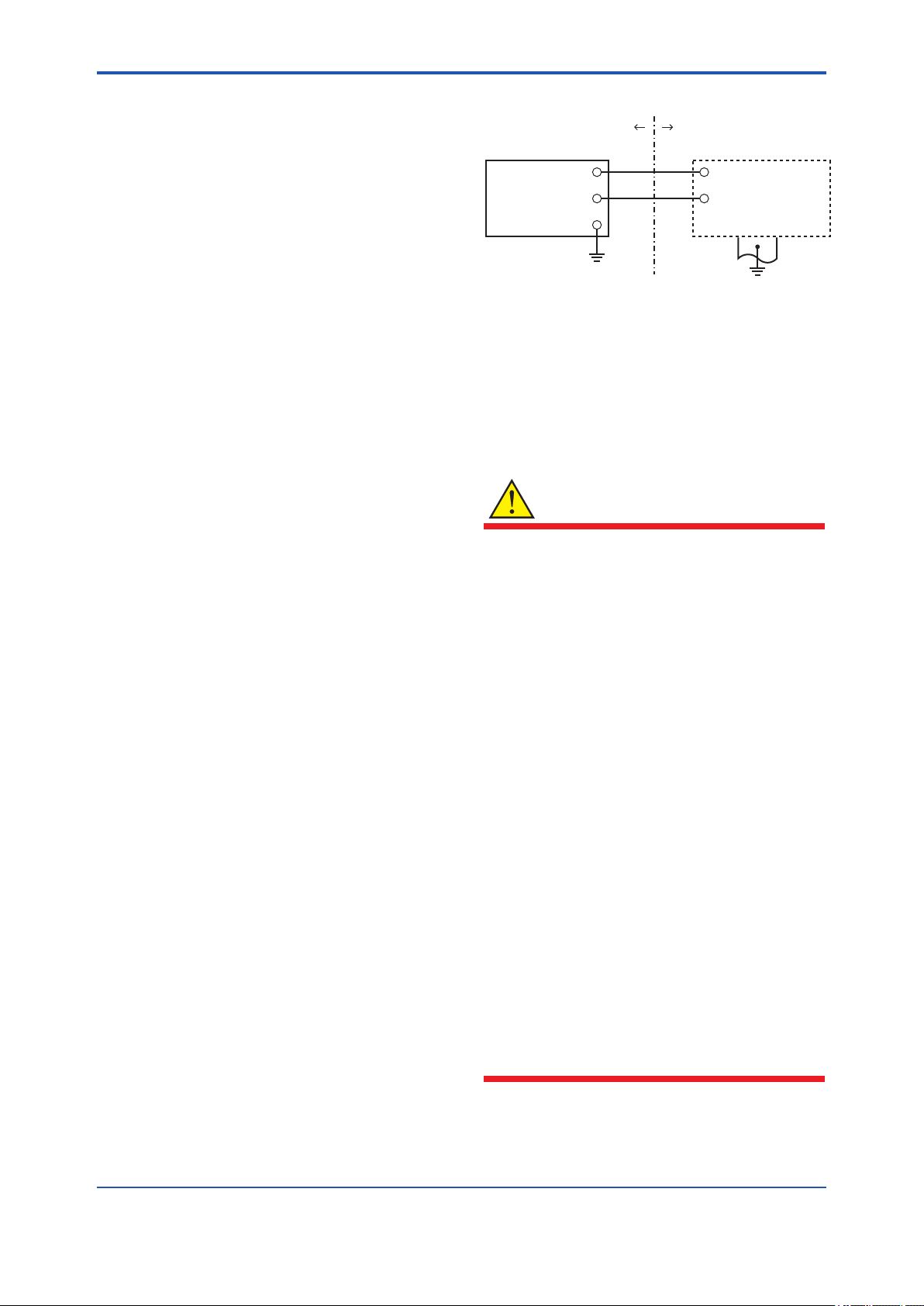

[Intrinsically Safe]

Hazardous Location Nonhazardous Location

Group IIC, Zone 0

[type n]

IECEx certified

Safety Barrier

+

+

–

–

Not Use

Safety Barrier

IECEx Certified

Equipment [nL]

Pressure Transmitters

+

Supply

Hazardous Location Nonhazardous Location

Group IIC, Zone 2

Pressure Transmitters

Supply

–

+

–

b. IECEx Flameproof Type

Caution for IECEx ameproof type.

General

Purpose

Equipment

+

–

F0210-1.ai

+

–

F0210-2.ai

• Maximum Process Temperature: 120°C (T4),

100°C (T5), 85°C (T6)

• Ambient Temperature: –50 to 75°C (T4),

–50 to 80°C (T5), –50 to 75°C (T6)

• Supply Voltage: 42 V dc max.

• Output Signal: 4 to 20 mA dc

Note 2. Wiring

• In hazardous locations, the cable entry

devices shall be of a certied ameproof

type, suitable for the conditions of use and

correctly installed.

• Unused apertures shall be closed with

suitable ameproof certied blanking

elements.

Note 3. Operation

• WARNING:

AFTER DE-ENERGIZING, DELAY 5

MINUTES BEFORE OPENING.

• WARNING:

WHEN AMBIENT TEMPERATURE ≥ 65°C,

USE THE HEAT-RESISTING CABLES ≥

90°C.

• Take care not to generate mechanical

sparking when accessing to the instrument

and peripheral devices in a hazardous

location.

Note 4. Maintenance and Repair

• The instrument modication or parts

replacement by other than authorized

representative of Yokogawa Electric

Corporation is prohibited and will void IECEx

Certication.

2.10 EMC Conformity Standards

EN61326-1 Class A, Table2 (For use in industrial

locations)

EN61326-2-3

CAUTION

Note 1. Model EJX/EJA-E Series pressure

transmitters with optional code /SF2 or

/SU2 are applicable for use in hazardous

locations:

• No. IECEx CSA 07.0008

• Applicable Standard: IEC60079-0:2004,

IEC60079-1:2003

• Flameproof for Zone 1, Ex d IIC T6...T4

• Enclosure: IP66/IP67

To meet EMC regulations, Yokogawa

recommends that customers run signal wiring

through metal conduits or use shielded twistedpair cabling when installing EJX/EJA-E series

transmitters in a plant.

IM 01C25F01-01E

Page 20

<2. Handling Cautions>

2-13

2.11 Pressure Equipment Directive (PED)

(1) General

• EJX/EJA-E Series pressure transmitters are

categorized as piping under the pressure

accessories section of directive 97/23/EC,

which corresponds to Article 3, Paragraph 3 of

PED, denoted as Sound Engineering Practice

(SEP).

• EJ510-D, EJ530-D, EJX610A-D,

and EJX630A-D can be used above 200

bar and therefore considered as a part of a

pressure retaining vessel where category III,

Module H applies. These models with option

code /PE3 conform to that category.

(2) Technical Data

• Models without /PE3

Article 3, Paragraph 3 of PED, denoted as

Sound Engineering Practice (SEP).

• Models with /PE3

Module: H

Type of Equipment: Pressure Accessory-Vessel

Type of uid: Liquid and Gas

Group of uid: 1 and 2

Model

EJ510

EJX610A

EJ510,

EJX610A

with code /

PE3

EJ530,

EJX630A

EJ530,

EJX630A

with code /

PE3

*1: PS is maximum pressure for vessel itself based on

*2: Referred to Table 1 covered by ANNEX II of EC Directive

Capsule

code

A, B, C 100 0.1 10

D 700 0.1 70

D 700 0.1 70 III

A, B, C 100 0.1 10

D 700 0.1 70

D 700 0.1 70 III

Pressure Equipment Directive 97/23/EC. Refer to

General Specication for maximum working pressure of a

transmitter.

on Pressure Equipment Directive 97/23/EC

PS*

(bar)

1

V(L)

PS.V

(bar.L)

Category*

Article 3,

Paragraph 3

(SEP)

Article 3,

Paragraph 3

(SEP)

(3) Operation

CAUTION

• The temperature and pressure of uid should

be maintained at levels that are consistent

with normal operating conditions.

• The ambient temperature should be

maintained at a level that is consistent with

normal operating conditions.

• Please take care to prevent water hammer

and the like from inducing excessive

pressures in pipes and valves. If phenomena

are likely, install a safety valve or take

some other appropriate measure to prevent

pressure from exceeding PS.

• Take appropriate measures at the device or

system level to protect transmitters if they

are to be operated near an external heat

source.

2.12 Low Voltage Directive

Applicable standard: EN61010-1

(1) Pollution Degree 2

"Pollution degree" describes the degree to

2

which a solid, liquid, or gas which deteriorates

dielectric strength or surface resistivity is

adhering. " 2 " applies to normal indoor

atmosphere. Normally, only non-conductive

pollution occurs. Occasionally, however,

temporary conductivity caused by condensation

must be expected.

(2) Installation Category I

"Overvoltage category (Installation category)"

describes a number which denes a transient

overvoltage condition. It implies the regulattion

for impulse withstand voltage. " I " applies to

electrical equipment which is supplied from the

circuit when appropriate transient overvoltage

control means (interfaces) are provided.

IM 01C25F01-01E

Page 21

<3. Component Names>

3. Component Names

3-1

Integral

indicator

Mounting screw

Amplifier Cover

(Note 1)

(Note 2)

Slide switch

Range-setting

(Note 1)

switch

(See section 7.5)

Transmitter section

External indicator

conduit connection

CPU assembly

Burnout direction switch

BO H L

WR E D

Write protection switch

(Note 1)

Conduit

connection

Zeroadjustment

screw

Burnout direction switch (BO)

Burnout Direction

Switch Position

Burnout Direction

Note 1: See subsection 9.2, “Model and Sufx Codes,” for details.

Note 2: Applicable for BRAIN/HART communication type. Set the switches as shown in the gure above to set the burn-out direction

and write protection. The Burnout switch is set to the H side for delivery (unless option code /C1 or /C2 is specied in the order),

and the hardware write protection switch is set to E side.The setting of the switches can be conrmed via communication. An

external zero adjustment screw can only be disabled by communication. To disable the screw, set a parameter before activating

the hardware write protect function. See each communication manual.

H L H L

HIGH LOW

Write Protection

Switch Position

Write Protection

Hardware write protection switch (WR)

H L

E D

NO

(Write enabled)

H L

E D

YES

(Write disabled)

Figure 3.1 Component Names

Table 3.1 Display Symbol

Display Symbol Meaning of Display Symbol

The output signal being zero-adjusted is increasing.

The output signal being zero-adjusted is decreasing.

Write protect function is enabled.

F0301.ai

F0302.ai

IM 01C25F01-01E

Page 22

<4. Installation>

4. Installation

4-1

4.1 Precautions

Before installing the transmitter, read the cautionary

notes in section 2.4, “Selecting the Installation

Location.” For additional information on the ambient

conditions allowed at the installation location, refer

to section 9.1 “Standard Specications.”

IMPORTANT

• When welding piping during construction,

take care not to allow welding currents to

ow through the transmitter.

• Do not step on this instrument after

installation.

• For the EJ530 and EJX630A whose

capsule code is A, B or C, the pipe of the

atmospheric opening is located on the

pressure detecting section. The opening

must not face upward. See subsection 5.1.1.

• D capsule of EJ530 and EJX630A is

of sealed gauge reference and the change

in atomospheric pressure may affect the

measurement.

Vertical pipe mounting

U-bolt nut (L)

U-bolt nut (S)

Mounting bracket

U-bolt (S)

Horizontal pipe mounting

50 mm (2-inch) pipe

U-bolt (L)

U-bolt nut (L)

Mounting bracket

50 mm (2-inch) pipe

4.2 Mounting

■ The impulse piping connection port of the

transmitter is covered with a plastic cap to

protect against dust. This cap must be removed

before connecting the piping. (Be careful not

to damage the threads when removing these

caps. Do not insert a screw driver or other

tool between the cap and the port threads to

remove the cap.)

■ The transmitter can be mounted on a nominal

50 mm (2-inch) pipe using the mounting bracket

supplied, as shown in Figure 4.1.

■ The user should prepare the mating gasket for

the transmitters with Process connection code

8 and 9. See Figure 4.2.

U-bolt nut (S)

U-bolt (S)

U-bolt (L)

Figure 4.1 Transmitter Mounting

Gasket

Figure 4.2 Gasketing

F0401.ai

F0402.ai

IM 01C25F01-01E

Page 23

<4. Installation>

4-2

IMPORTANT

Tighten the hexagonal nut part of the capsule

assembly. See Figure 4.3.

Capsule assembly

F0403.ai

Figure 4.3 Tightening Transmitter

4.3 Rotating Transmitter Section

The transmitter section can be rotated

approximately 360° (180° to either direction or

between -90° and +270° from the original position

at shipment, depending on the conguration of

the instrument.) It can be xed at any angle within

above range.

Transmitter section

Setscrew

Pressure-detector section

Stopper

Figure 4.4 Rotating Transmitter Section

4.4 Changing the Direction of Integral Indicator

IMPORTANT

Always turn OFF power, release pressure and

remove a transmitter to non-hazardous area

before disassembling and reassmbling an

indicator.

F0404.ai

1) Remove the two setscrews that fasten the

transmitter section and capsule assembly,

using the Allen wrench.

2) Rotate the transmitter section slowly and stop it

at designated position. For the EJ530 and

EJX630A whose capsule code is A, B or C, the

pipe of the atmospheric opening may interfere

with the stopper and disturb further rotation.

In that case, screw off the pipe rst, rotate the

housing, and then screw in the pipe by hand

again.

3) Tighten the two setscrews to a torque of

1.5 N·m.

IMPORTANT

Do not rotate the transmitter section more than

the above limit.

An integral indicator can be installed in the

following three directions. Follow the instructions in

section 8.4 for removing and attaching the integral

indicator.

F0405.ai

Figure 4.5 Integral Indicator Direction

IM 01C25F01-01E

Page 24

<5. Installing Impulse Piping>

5. Installing Impulse Piping

5-1

5.1 Impulse Piping Installation Precautions

The impulse piping that connects the process

outputs to the transmitter must convey the process

pressure accurately. If, for example, gas collects in

a liquidlled impulse line, or the drain for a gas-lled

impulse line becomes plugged, it will not convey the

pressure accurately. Since this will cause errors in

the measurement output, select the proper piping

method for the process uid (gas, liquid, or steam).

Pay careful attention to the following points when

routing the impulse piping and connecting the

impulse piping to a transmitter.

5.1.1 Connecting Impulse Piping to a Transmitter

IMPORTANT

The transmitter can be installed in horizontal

impulse piping conguration, tilting the

transmitter's position up to 90°. When tilting,

observe that the pipe (for Model EJ530 and

EJX630A with measurement span code A, B,

and C) is positioned horizontal downwards, or

any place between them, as shown in Figure 5.1

The zero-adjustment screw must be positioned

downwards for all the models.

The pipe (open to atmosphere) is positioned horizontal.

5.1.2 Routing the Impulse Piping

(1) Process Pressure Tap Angles

If condensate, gas, sediment or other extraneous

material in the process piping gets into the impulse

piping, pressure measurement errors may result. To

prevent such problems, the process pressure taps

must be angled as shown in gure 5.2 according to

the kind of uid being measured.

NOTE

• If the process uid is a gas, the taps must be

vertical or within 45° either side of vertical.

• If the process uid is a liquid, the taps must

be horizontal or below horizontal, but not

more than 45° below horizontal.

• If the process uid is steam or other

condensing vapor, the taps must be

horizontal or above horizontal, but not more

than 45° above horizontal.

[Gas]

45°

Pressure

taps

Process

piping

Figure 5.2 Process Pressure Tap Angle

45°

45° 45°

(For Horizontal Piping)

(2) Position of Process Pressure Taps and

Transmitter

45°

[Steam][Liquid]

45°

F0502.ai

Pipe

(backside of the instrument)

Zero-adjustment screw

If the zero-adjustment screw is positioned other than

donwards after installation, rotate the housing unitl it is

positioned downwards.

F0501.ai

Figure 5.1 Horizontal Impulse Piping Connection

If condensate (or gas) accumulates in the impulse

piping, it should be removed periodically by

opening the drain (or vent) plugs. However, this will

generate a transient disturbance in the pressure

measurement, and therefore it is necessary to

position the taps and route the impulse piping so

that any extraneous liquid or gas generated in the

leadlines returns naturally to the process piping.

• If the process uid is a gas, then as a rule the

transmitter must be located higher than the

process pressure taps.

• If the process uid is a liquid or steam, then as a

rule the transmitter must be located lower than

the process pressure taps.

IM 01C25F01-01E

Page 25

<5. Installing Impulse Piping>

5-2

(3) Impulse Piping Slope

The impulse piping must be routed with only an

upward or downward slope. Even for horizontal

routing, the impulse piping should have a slope of

at least 1/10 to prevent condensate (or gases) from

accumulating in the pipes.

(4) Preventing Freezing

If there is any risk that the process uid in the

impulse piping or transmitter could freeze, use a

steam jacket or heater to maintain the temperature

of the uid.

NOTE

After completing the connections, close the

valves on the process pressure taps (main

valves), the valves at the transmitter (stop

valves), and the impulse piping drain valves,

so that condensate, sediment, dust and other

extraneous material cannot enter the impulse

piping.

Tap valve

Union or flange

Stop valve

Tee

Union or flange

Drain valve

Drain plug

Figure 5.3 Impulse Piping Connection Examples

Stop valve

F0503.ai

5.2 Impulse Piping Connection Examples

Figure 5.3 shows examples of typical impulse

piping connections. Before connecting the

transmitter to the process, study the transmitter

installation location, the process piping layout,

and the characteristics of the process uid

(corrosiveness, toxicity, ammability, etc.), in order

to make appropriate changes and additions to the

connection congurations.

Note the following points when referring to these

piping examples.

• If the impulse line is long, bracing or supports

should be provided to prevent vibration.

• The impulse piping material used must

be compatible with the process pressure,

temperature, and other conditions.

• A variety of process pressure tap valves (main

valves) are available according to the type

of connection (anged, screwed, welded),

construction (globe, gate, or ball valve),

temperature and pressure. Select the type of

valve most appropriate for the application.

IM 01C25F01-01E

Page 26

<6. Wiring>

6. Wiring

6-1

6.1 Wiring Precautions

IMPORTANT

• Lay wiring as far as possible from electrical

noise sources such as large capacity

transformers, motors, and power supplies.

• Remove the electrical connection dust cap

before wiring.

• All threaded parts must be treated with

waterproong sealant. (A non-hardening

silicone group sealant is recommended.)

• To prevent noise pickup, do not pass signal

and power cables through the same ducts.

• Explosion-protected instruments must

be wired in accordance with specic

requirements (and, in certain countries,

legal regulations) in order to preserve the

effectiveness of their explosion-protected

features.

• The terminal box cover is locked by an

Allen head bolt (a shrouding bolt) on ATEX

ameproof type transmitters. When the

shrouding bolt is driven clockwise using

an Allen wrench, it goes in. The cover lock

can then be released and the cover can

be opened by hand. See subsection 8.4

“Disassembly and Reassembly” for details.

• Plug and seal an unused conduit connection.

6.2 Selecting the Wiring

6.3 Connections of External Wiring to Terminal Box

6.3.1 Power Supply Wiring Connection

Connect the power supply wiring to the SUPPLY +

and – terminals. When /AL is specied, also refer to

subsection 6.3.5.

Power supply

+

–

Figure 6.1 Power Supply Wiring Connection

6.3.2 External Indicator Connection

Available only when /AL is not specied.

Connect wiring for external indicators to the CHECK

+ and – terminals.

(Note) Use a external indicator whose internal resistance is 10 Ω

or less.

Power supply

+

–

Transmitter terminal box

Figure 6.2 External Indicator Connection

Transmitter terminal box

External indicator

PULSE

SUPPLY

CHECK

ALARM

PULSE

SUPPLY

CHECK

ALARM

F0601.ai

F0602.ai

Materials

(a) Use stranded leadwires or cables which are

the same as or better than 600 V grade PVC

insulated wire (JIS C3307) or its equivalent.

(b) Use shielded wires in areas that are susceptible

to electrical noise.

(c) In areas with higher or lower ambient

temperatures, use appropriate wires or cables.

(d) In environment where oils, solvents, corrosive

gases or liquids may be present, use wires or

cables that are resistant to such substances.

(e) It is recommended that crimp-on solderless

terminal lugs (for 4 mm screws) with insulating

sleeves be used for leadwire ends.

6.3.3 Communicator Connection

Connect the BT200 or HART Communicator to the

SUPPLY + and – terminals. (Use hooks.)

Transmitter terminal box

PULSE

SUPPLY

CHECK

ALARM

Ignore the polarity since the

BT200 is AC-coupled to the

terminal box.

BT200

Figure 6.3 BT200 Connection

Power supply

+

–

F0603.ai

IM 01C25F01-01E

Page 27

<6. Wiring>

6-2

6.3.4 Check Meter Connection

Available only when /AL is not specied.

Connect the check meter to the CHECK + and

– terminals. (Use hooks.)

• A 4 to 20 mA DC output signal from the CHECK

+ and – terminals.

(Note) Use a check meter whose internal resistance is 10 Ω or