Page 1

User ’s

Manual

CA500, CA550

Multifunction Process

Calibrator

Getting Started Guide

IM CA500-02EN

1st Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and

services.

Please allow us to serve you best by completing the product registration

form accessible from our homepage.

http://tmi.yokogawa.com/

Page 3

Page 4

Thank you for purchasing the CA500/CA550 Multifunction Process Calibrator. This

Getting Started Guide focuses on the handling precautions, basic operations, and

specifications of the CA500 and CA550.

To ensure correct use, please read this manual thoroughly before operation. Keep

this manual in a safe place for quick reference.

List of Manuals

The following three manuals, including this one, are provided as manuals for the

CA500 and CA550.

Please read all manuals.

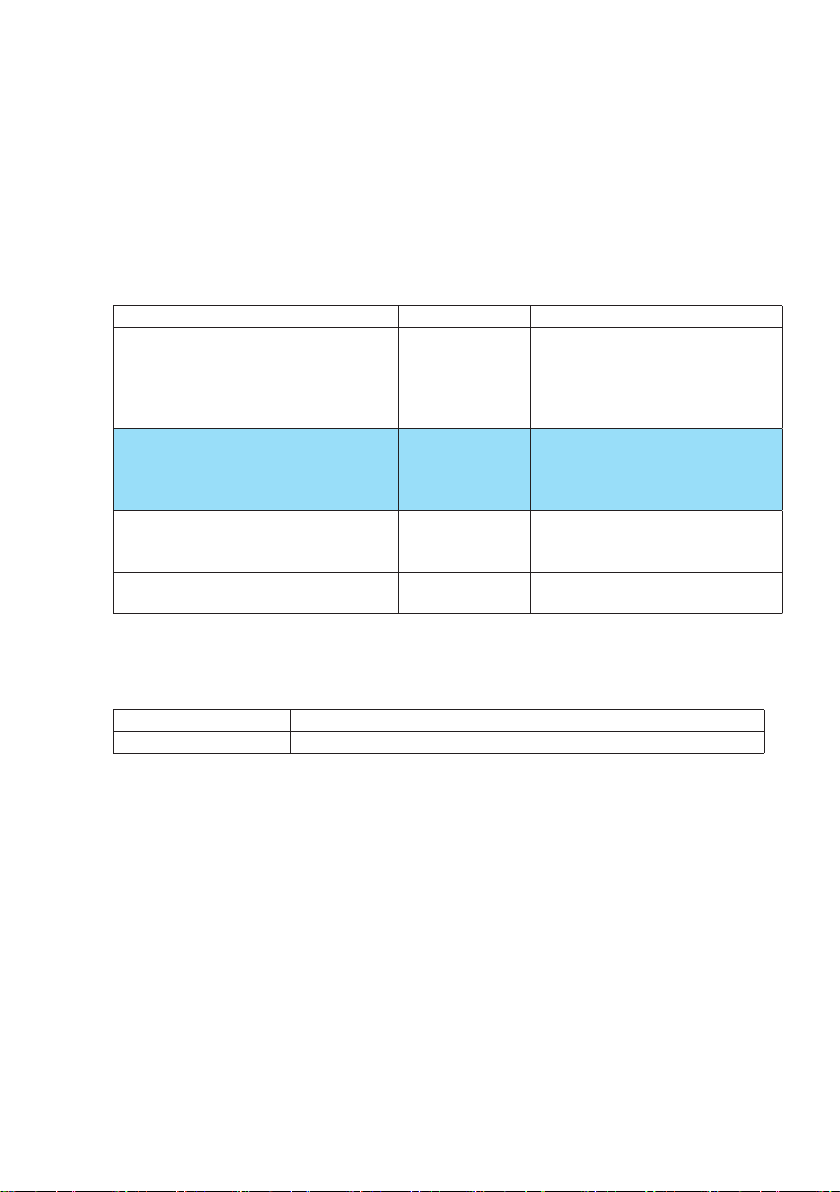

Manual Title Manual No. Description

CA500, CA550 Multifunction Process

Calibrator

User’s Manual

CA500, CA550 Multifunction Process

Calibrator

Getting Started Guide

CA500, CA550 Multifunction Process

Calibrator

User’s Manual

“전기용품 및 생활용품 안전관리법”

관련일차전지에 대한 대응

The “-EN”, “-Z1”, and “KO” in the manual number are the language code.

Contact information of Yokogawa offices worldwide is provided on the following

sheet.

Manual No. Description

PIM113-01Z2 List of worldwide contacts

IM CA500-01EN The supplied CD contains the PDF

file of this manual. This manual

explains the instrument’s standard

features and how to use these

features.

IM CA500-02EN This document. This guide explains

the handling precautions, basic

operations, and specifications of

this instrument.

IM CA500-92Z1 A manual for China.

PIM 902-01KO A manual for Korea.

1st Edition: October 2019 (YMI)

All Rights Reserved, Copyright © 2019, Yokogawa Test & Measurement Corporation

Printed in Japan

IM CA500-02EN

1

Page 5

Notes

• The contents of this manual are subject to change without prior notice as a result

of continuing improvements to the instrument’s performance and functions. The

figures given in this manual may differ from those that actually appear on your

screen.

• Every effort has been made in the preparation of this manual to ensure the

accuracy of its contents. However, should you have any questions or find any

errors, please contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

Trademarks

• Adobe and Acrobat are either registered trademarks or trademarks of Adobe

Systems Incorporated.

• HART is a registered trademark of FieldComm Group.

• In this manual, the ® and TM symbols do not accompany their respective

registered trademark or trademark names.

• Company and product names are trademarks or registered trademarks of their

respective holders.

Revisions

1st Edition: October 2019

2

IM CA500-02EN

Page 6

Checking the Contents of the Package

To prevent condensation, before opening the package, allow it to adjust to the

ambient temperature. In particular, if you move the package from a cool location to a

hot location, allow it to adjust to the ambient temperature for at least an hour before

opening the package.

Unpack the box, and check the following before operating the instrument. If the

wrong items have been delivered, if items are missing, or if there is a problem with

the appearance of the items, contact your nearest YOKOGAWA dealer.

CA500/CA550

Check that the product that you received is what you ordered by referring to the

model name on the name plate on the rear panel of the main unit. For reference, the

model name and specifications of the products are listed below.

MODEL Suffix Code* Description

CA500 -F1

CA550

* For products whose suffix code contains “Z,” an exclusive manual may be

included. Please read it along with the standard manual.

** A model without either the HART or BRAIN communication function. This suffix

code is always added for the CA500.

*** Either F2 or F3 is always added for the CA550.

Please contact your dealer for sales area.

HART/BRAIN communication function will be supported in the near future.

-F2

-F3

**

***

***

Multifunction process calibrator

Multifunction process calibrator (with HART

communication function)

HART/BRAIN (CA550 only)

HART (CA550 only)

No. (Instrument number)

When contacting the dealer from which you purchased the instrument, please give

them the instrument number.

IM CA500-02EN

3

Page 7

Standard Accessories

The following accessories are included. Check that all contents are present and

undamaged.

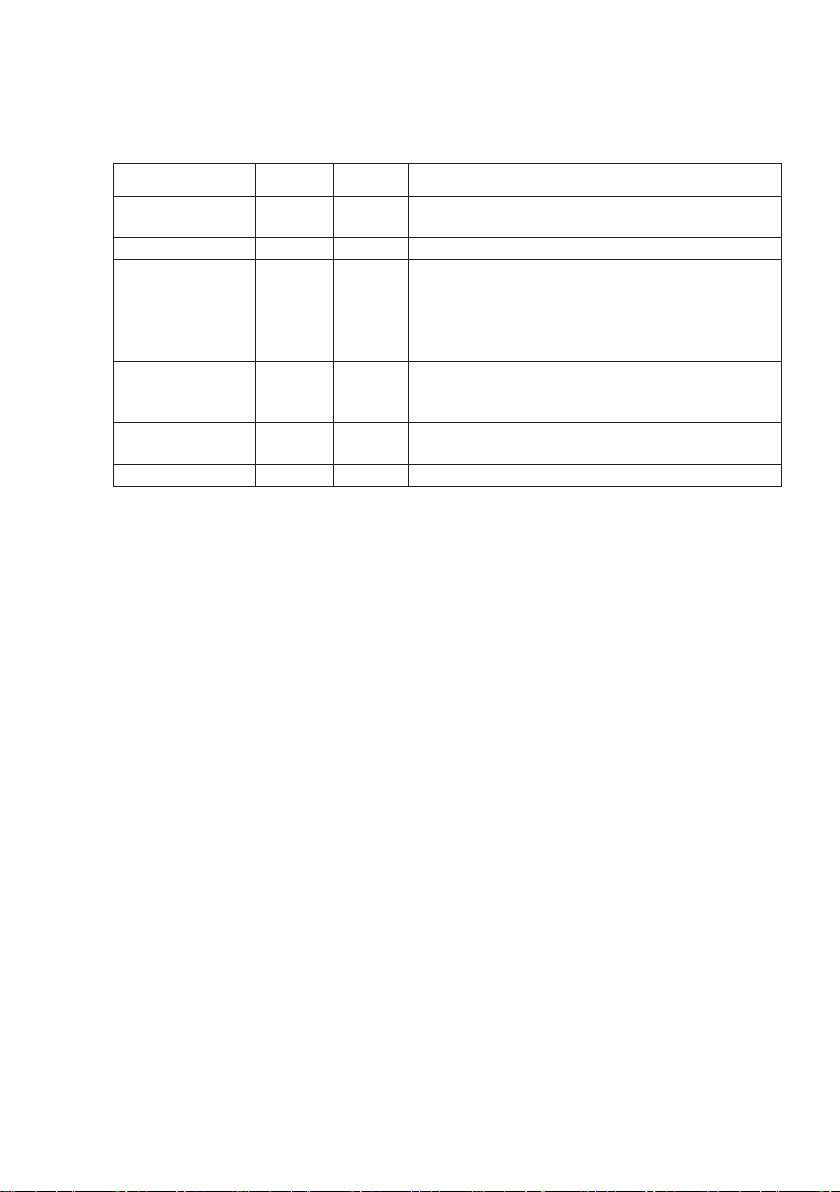

No Name Model or

Part No.

1 Lead cable for source 98020 1 set 1 red, 2 black, 1.7 m

2 Source/measurement

lead cable

3 Binding post (red-black

pair)*

4 Binding post (red-red

pair)*

5 USB cable A1421WL 1 pc. USB Type A to Type B, 2 m

6 Shoulder strap B8070CY 1 pc.

7 Soft case B8080FQ 1 pc. For accessories

8 Batteries - 4 pcs. AA alkaline batteries (LR6)

9 CD A1031US 1 copy User’s Manual (PDF)

10 Manuals IM CA500-02EN

98035 1 pc. 3 red, 1 black, 1.7 m

99045 1 set One short plate included

99046 1 set One short plate included

IM CA500-92Z1

PIM 902-01KO

PIM 113-01Z2

* Before using the included binding post, remove the short plate attached to the

binding post.

Standard accessories are not covered by warranty.

Quantity Notes

7 mm fork terminal to alligator clip

L plug terminal to alligator clip

1 copy

each

This manual.

A manual for China.

A manual for Korea.

Not Included depending on the

specifications.

List of contacts

Manual CD

The English folder in the CD contains the PDF files shown below. The CD also

contains Japanese manuals.

File Name Manual Title Manual No.

CA500,CA550 Users_manual.pdf CA500, CA550 Multifunction

Process Calibrator User’s

Manual

IM CA500-01EN

To view the above PDF data, you need Acrobat Reader or a software application

that can open PDF.

4

IM CA500-02EN

Page 8

Optional Accessories (Sold separately)

The optional accessories below are available for purchase separately. For

information about ordering accessories, contact your nearest YOKOGAWA dealer.

Item Model Min. Q’ty Specifications

Lead cable 98064 1 1 red, 1 black, 1.7 m

L plug terminal to alligator clip

Grabber clip 98026 1 1 red-black pair, 2 m, separate type

RJ sensor 90080 1 Pt100 JIS AA class or equivalent,

Thermometer operating temperature range: -10°C

to +55°C

8-polar miniDin connector, 1.5 m shielded cable

Fork terminal (M3 terminal block compatible)

Thermocouple Mini

Plug Set 1

Thermocouple Mini

Plug Set 2

Soft Carrying Case SU2006A 1

* Accessories (sold separately) are not covered by warranty.

90040 1 K (yellow)/ E (violet)/ J (black)/ T (blue)/R•S (green)/

B•U (white)/ G (red, green)/D (red, white)/ C (red)/

N (orange)

90045 1 K (yellow)/ E (violet)/ J (black)/ T (blue)

IM CA500-02EN

5

Page 9

Conventions Used in This Guide

Prefixes k and K

This manual distinguishes prefixes k and K used before units as follows:

k: Denotes 1000. Example: 100 kS/s (sample rate)

K: Denotes 1024. Example: 720 KB (file size)

Displayed Characters

Bold characters in procedural explanations are used to indicate panel keys and soft

keys that are used in the procedure and menu items that appear on the screen.

Notes and Cautions

The notes and cautions in this guide are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage to the

instrument. This symbol appears on the instrument to indicate that the user

must refer to the user’s manual for special instructions. The same symbol

appears in the corresponding place in the user’s manual to identify those

instructions. In the manual, the symbol is used in conjunction with the word

“WARNING” or “CAUTION.”

WARNING

CAUTION

Note

French

Une manipulation ou une utilisation incorrectes risquent de blesser

AVERTISSEMENT

6

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and precautions that can be taken to

prevent such occurrences.

Calls attention to actions or conditions that could cause light

injury to the user or damage to the instrument or user’s data,

and precautions that can be taken to prevent such occurrences.

Calls attention to information that is important for the proper operation of the

instrument.

l’utilisateur ou d’endommager l’instrument. Ce symbole apparaît sur

l’instrument pour indiquer à l’utilisateur qu’il doit se reporter au manuel

de l’utilisateur afin d’y lire les instructions spécifiques correspondantes.

Ce même symbole apparaît à la section correspondante du manuel de

l’utilisateur pour signaler lesdites instructions. Dans le manuel de l’utilisateur,

ce symbole est accompagné des termes AVERTISSEMENT et ATTENTION.

Attire l’attention sur des gestes ou des conditions

susceptibles de provoquer des blessures graves (voire

mortelles), et sur les précautions de sécurité pouvant

prévenir de tels accidents.

IM CA500-02EN

Page 10

ATTENTION

Attire l’attention sur des gestes ou des conditions

susceptibles de provoquer des blessures légères

ou d’endommager l’instrument ou les données

de l’utilisateur, et sur les précautions de sécurité

susceptibles de prévenir de tels accidents.

IM CA500-02EN

7

Page 11

Safety Precautions

This product is designed to be used by a person with specialized knowledge. The

general safety precautions described herein must be observed during all phases

of operation. If the product is used in a manner not specified in this guide, the

protection provided by the product may be impaired. YOKOGAWA assumes no

liability for the customer’s failure to comply with these requirements.

This manual is part of the product and contains important information. Store

this manual in a safe place close to the instrument so that you can refer to it

immediately. Keep this manual until you dispose of the instrument.

The following symbols are used on this instrument.

Handle with care. Refer to the user’s manual or service manual. This symbol

appears on dangerous locations on the instrument which require special

instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.

Direct current Functional ground

French

À manipuler délicatement. Toujours se reporter aux manuels d’utilisation et

d’entretien. Ce symbole a été apposé aux endroits dangereux de l’instrument

pour lesquels des consignes spéciales d’utilisation ou de manipulation ont

été émises. Le même symbole apparaît à l’endroit correspondant du manuel

pour identifier les consignes qui s’y rapportent.

Courant direct Borne de terre fonctionnelle

Failure to comply with the precautions below could lead to injury

or death or damage to the instrument.

WARNING

Use the Instrument Only for Its Intended Purpose

This instrument sources and measures DC voltage and DC

current. Use this instrument only for these purposes.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical

appearance.

Batteries

• Do not mix new and old batteries or mix different brands or types

of batteries. The batteries may leak, heat up, or burst due to their

characteristic differences.

• Never replace the batteries with the main unit turned on.

8

IM CA500-02EN

Page 12

Do Not Operate in an Explosive Atmosphere

Do not use this instrument in the presence of flammable gases or

vapors. Doing so is extremely dangerous.

Do Not Remove the Covers or Disassemble or Alter the

Instrument

Only qualified YOKOGAWA personnel may remove the covers and

disassemble or alter the instrument.

The inside of the instrument is dangerous because parts of it have

high voltages.

Measurement Category

The measurement category of this instrument’s signal input

terminals is Other (O). Do not use it to measure the main power

supply or for Measurement Categories II, III, and IV.

Install or Use the Instrument in Appropriate Locations

• This instrument is not dust-proof or water-proof. Do not install or

use this instrument outdoors, in a location subject to rain or water,

or a location full of dust.

• Install the instrument so that you can immediately turn off the

power if an abnormal or dangerous condition occurs.

External Connections

Before connecting the instrument to the DUT or external control

circuit or before touching a circuit, turn off its power and check

that it has no voltage. To prevent electric shock and accidents,

connect the ground of the probes or input connectors to the ground

potential of the device under measurement.

IM CA500-02EN

Handling

• Never use the instrument if the instrument or your hand is wet or

when condensation or other water droplets are on the instrument.

• Never open the battery cover while a measurement is in progress.

Signal Input

Do not apply signals that exceed the measurement range.

Lead cable

• Use the probes supplied by Yokogawa for this instrument.

• Do not use deteriorated or damaged lead cables.

• Check the conduction of the lead cable before using it.

• Do not use the lead cable for source (98020) to make

measurements.

When making a measurement, be sure to use the source/

measurement lead cable (98035).

9

Page 13

Accessories

• Use the accessories specified in this manual. Moreover, use the

accessories of this product only with Yokogawa products that

specify them as accessories.

• Use the accessories of this product within the rated range of each

accessory. When using several accessories together, use them

within the specification range of the accessory with the lowest

rating.

• Do not use faulty accessories.

Damaged Cable

If the cable is torn and the inner metal is exposed or if a color

different from the outer sheath appears, stop using the cable

immediately.

CD

Never play this CD, which contains the user’s manuals, in an audio

CD player. Doing so may cause loss of hearing or speaker damage

due to the high-volume sound that may be produced.

CAUTION

Operating Environment Limitations

This product is classified as Class A (for use in industrial

environments). Operation of this product in a residential area may

cause radio interference, in which case the user will be required to

correct the interference.

10

Operating Environment

This instrument is not dust-proof or water-proof.

French

AVERTISSEMENT

Ne faites de cet équipement que l’utilisation pour laquelle il a

été conçu

Cet équipement est un calibreur pour l’équipement de mesure de

tension/courant, pour l’équipement de termocouple/mesure et pour

l’équipement de RTD/mesure. Utilisez cet équipement à des fins de

calibrage uniquement.

Inspecter l’apparence physique

Ne pas utiliser l’instrument si son intégrité physique semble être

compromise.

IM CA500-02EN

Page 14

Batteries

• Ne pas mélanger des batteries neuves et des batteries usagées,

ni des batteries de marques ou de types différents. Les batteries

risquent de fuir, de chauffer ou d’éclater en raison de leurs

différentes caractéristiques.

• Ne jamais remplacer les batteries lorsque la mesure est en cours.

Ne pas utiliser dans un environnement explosif

Ne pas utiliser l’instrument en présence de gaz ou de vapeurs

inflammables. Cela pourrait être extrêmement dangereux.

Ne pas retirer le capot, ni démonter ou modifier l’instrument

Seul le personnel YOKOGAWA qualifié est habilité à retirer le capot

et à démonter ou modifier l’instrument. Certains composants à

l’intérieur de l’instrument sont à haute tension et par conséquent,

représentent un danger.

Catégorie de mesure

La catégorie de mesure des terminaux d’entrée de signal de ce

produit est Autre(O). Ne pas l’utiliser pour mesurer l’alimentation

électrique, ni pour les catégories de mesureII, III et IV.

Installer et utiliser l’instrument aux emplacements appropriés

• Cet instrument n’est pas étanche à la poussière ni à l’eau. Ne pas

installer, ni utiliser cet instrument à l’extérieur, dans un endroit

exposé à la pluie ou à l’eau, ou dans un endroit poussiéreux.

• Installer l’instrument de manière à pourvoir immédiatement le

débrancher du secteur en cas de fonctionnement anormal ou

dangereux

IM CA500-02EN

Connexions Externes

Avant de brancher cet instrument au dispositif en essai (DUT) ou au

circuit de commande externe, ou avant de toucher un circuit, mettre

l’instrument hors tension et vérifier l’absence de tension. Pour éviter

un choc électrique ou des accidents, brancher la terre des sondes

ou les connecteurs d’entrée au potentiel de terre de l’appareil faisant

l’objet de la mesure.

Manipulation

• Ne jamais utiliser cet instrument si l’instrument ou votre main est

mouillé, ou la condensation ou la goutte d’eau sont adhérées à

l’instrument.

• Ne jamais ouvrir le couvercle de batterie pendant la mesure est en

cours.

Signal d’Entrée

Ne pas appliquer de signaux qui dépassent la plage de mesure.

11

Page 15

Câble de Raccordement

• Utiliser les sondes fournies par Yokogawa pour cet instrument.

• Ne pas utiliser des câbles de raccordement détériorés ou

endommagés.

• Vérifier la conduction de câble de raccordement avant l’utiliser.

• Ne pas utiliser le câble de raccordement pour la source (98020)

pour faire des mesures.

Lors de la mesure, veiller à utiliser le câble de raccordement de la

source/mesure (98035).

Accessoires

• Utiliser les accessoires spécifiés dans ce manuel. En outre, utiliser

les accessoires de ce produit uniquement avec des produits

Yokogawa pour lesquels ils sont spécifiés comme accessoires.

• Utiliser les accessoires de ce produit dans la plage nominale de

chaque accessoire. Lors de l’utilisation de plusieurs accessoires

ensemble, les utiliser dans la plage spécifiée de l’accessoire avec

la tension nominale la plus basse.

• Ne pas utiliser d’accessoires défectueux.

Câble de signal endommagé

Si le câble de signal est déchiré et que le métal intérieur est exposé

ou si une couleur différente de la gaine externe est visible, arrêter

immédiatement d’utiliser ce câble.

CD

Ce CD contient les manuels d’utilisation. Ne jamais insérer ce CD

dans un lecteur de CD audio. Cela pourrait entraîner une perte

d’audition ou l’endommagement des enceintes en raison du volume

potentiellement élevé des sons produits.

ATTENTION

Limitations relatives à l’environnement opérationnel

Ce produit est un produit de classe A (pour environnements

industriels). L’utilisation de ce produit dans un zone résidentielle peut

entraîner une interférence radio que l’utilisateur sera tenu de rectifier.

Environnement Opérationnel

Cet instrument n’est pas étanche à la poussière ni à l’eau.

12

IM CA500-02EN

Page 16

Regulations and Sales in Each Country or Region

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive

(This directive is valid only in the EU.)

This product complies with the WEEE directive marking

requirement. This marking indicates that you must not discard this

electrical/electronic product in domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive, this

product is classified as a “Monitoring and control instruments”

product.

When disposing products in the EU, contact your local Yokogawa

Europe B.V. office.

Do not dispose in domestic household waste.

EU Battery Directive

(This directive is valid only in the EU.)

Batteries are included in this product. This marking indicates

they shall be sorted out and collected as ordained in EU Battery

Directive.

Battery type:

1. Lithium battery

You cannot replace batteries by yourself. When you need to

replace batteries, contact your local Yokogawa Europe B.V.office.

2. Alkaline battery

When disposing of alkaline batteries, follow the domestic law

concerning disposal. Take the proper action to dispose batteries

in accordance with the established collection system in the

European Economic Area. For the battery removal procedure,

see page 31.

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test &

Measurement Corporation for this product in the EEA. To contact Yokogawa Europe

B.V., see the separate list of worldwide contacts, PIM 113-01Z2.

Disposing of the Instrument

When disposing of the instrument, follow the laws and ordinances of your country or

region.

IM CA500-02EN

13

Page 17

Contents

Product Registration .............................................................................................................. i

Checking the Contents of the Package ................................................................................ 3

Conventions Used in This Guide ..........................................................................................6

Safety Precautions ............................................................................................................... 8

Regulations and Sales in Each Country or Region ............................................................ 13

1 Component Names and Functions

1.1 Front Panel ..............................................................................................................15

1.2 Side Panel and Rear Panel......................................................................................17

1.3 Display ..................................................................................................................... 18

2 Preparation before Use

2.1 Handling Precautions ............................................................................................... 21

2.2 Installing the Instrument ........................................................................................... 23

2.3 Connecting Cables ...................................................................................................26

2.4 Loading and Removing Batteries ............................................................................. 31

2.5 Supplying Power through the USB Terminal ............................................................ 33

2.6 Turning the Power On and Off .................................................................................34

2.7 Setting the Date and Time .......................................................................................35

3 Common Operations

3.1 Opening and Closing Setup Screens ....................................................................... 37

3.2 Setup Screen Operation ..........................................................................................37

3.3 Selection Menu Operation .......................................................................................38

3.4 Specifying Values .....................................................................................................38

3.5 Setting Alphanumeric Characters ............................................................................ 39

4 Troubleshooting, Maintenance, and Inspection

4.1 Troubleshooting .......................................................................................................40

4.2 Error Codes, Error Messages, and Corrective Actions ............................................41

4.3 Displaying Instrument Information ...........................................................................42

4.4 Recommended Replacement Parts, Consumable Parts, and Calibration ............... 42

5. Specifications

5.1 DC Voltage, DC Current, Resistance and Pulse Source ........................................43

5.2 DC Voltage, DC Current, Resistance and Pulse Measurement ..............................45

5.3 Temperature Measurement (TC) and Thermocouple Calibration Voltage Source ...47

5.4 Temperature Measurement (RTD) and Resistance Source for RTD Calibration ..... 60

5.5 Common Specifications ........................................................................................... 63

5.6 General Specifications ............................................................................................. 64

14

IM CA500-02EN

Page 18

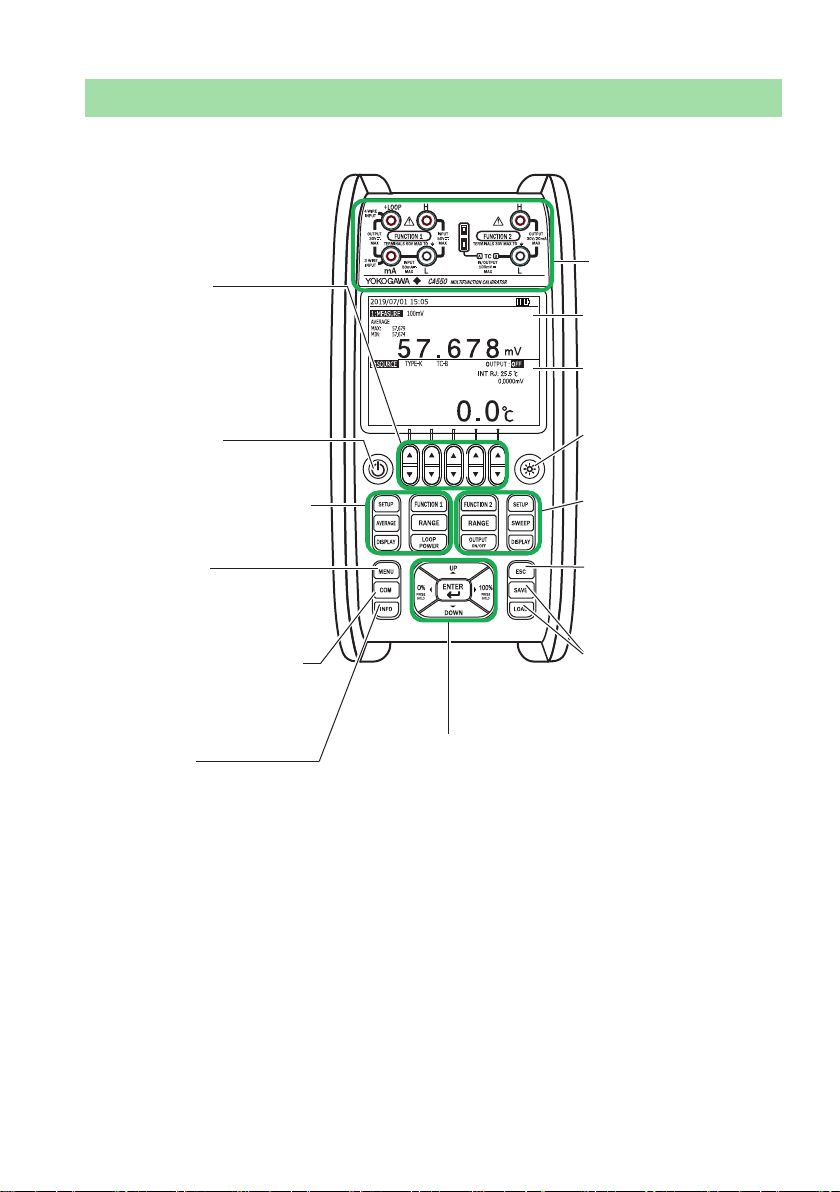

1 Component Names and Functions

1.1 Front Panel

I/O terminals

Arrow keys

Increases or decreases the

number at the

corresponding digit or

selects the corresponding

item from the selection

menu

POWER key

Turns the power on and off

Function 1 setup keys

(see page 16)

MENU key

Displays an

instrument setup

menu

COM key (CA550 only)

Performs HART/BRAIN

(to be supported in the

near future)

INFO key

Displays information about the

instrument and the wiring

diagram of the specified

function

Cursor keys and ENTER key

(see page 16)

Display area

(Function 1)

Display area

(Function 2)

Light key

Turns on the display

light

Function 2 setup

keys

(see page 16)

ESC key

Cancels settings or

returns to the previous

screen

File key

Saves and loads

measured values

IM CA500-02EN

15

Page 19

1 Component Names and Functions

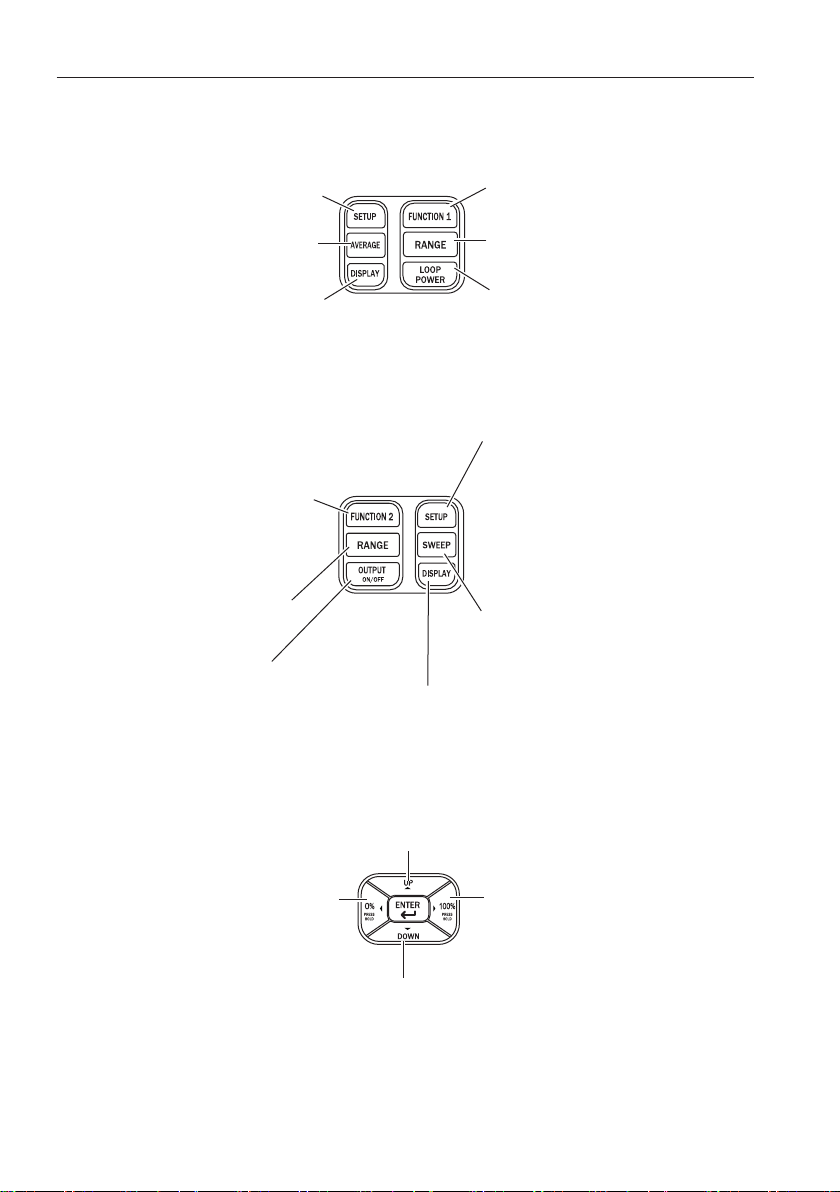

Function Set Keys

Function 1 setup keys

Sets the 0 and 100% value

and the pulse contact input

on/off

Turns on/off the moving

average function and the

max/min display

Turns on/off the 0 and 100%

value displays and selects

whether to show the

measured value or percentage

on the main display

Function 2 setup keys

Selects thermocouple

measurement and source

function (voltage, current,

resistance, RTD, pulse,

thermocouple, off)

Selects the source

range

Turns the source

on or off

Selects the measurement

function (voltage, current,

resistance, RTD, pulse, off)

Selects the measurement

range

Turns on and off the loop

power supply (when current is

being measured)

Sets the 0 and 100% value,

number of divisions, sweep

settings, temperature

measurement/source items

(thermocouple terminal

selection, burnout, etc.), and

pulse source items (amplitude,

pulse count, pulse contact

output on/off)

Selects the sweep to be

executed (linear, step,

program)

Turns on and off the 0 and 100% value displays

and selects whether to show the source value

or percentage on the main display

Cursor Keys and ENTER Key

On screens displaying the source value, the following functions can be executed.

Steps up the source value according to the specified number of divisions

Sets the source value to the

0% value. To set the 0%

value, hold down the key. The

displayed source value is set

to 0%.

Steps down the source value according to the specified

number of divisions

On various setup menus, use the cursor keys to select settings and the ENTER key

to confirm the settings.

16

Sets the source value to the

100% value. To set the 100%

value, hold down the key. The

displayed source value is set to

100%.

IM CA500-02EN

Page 20

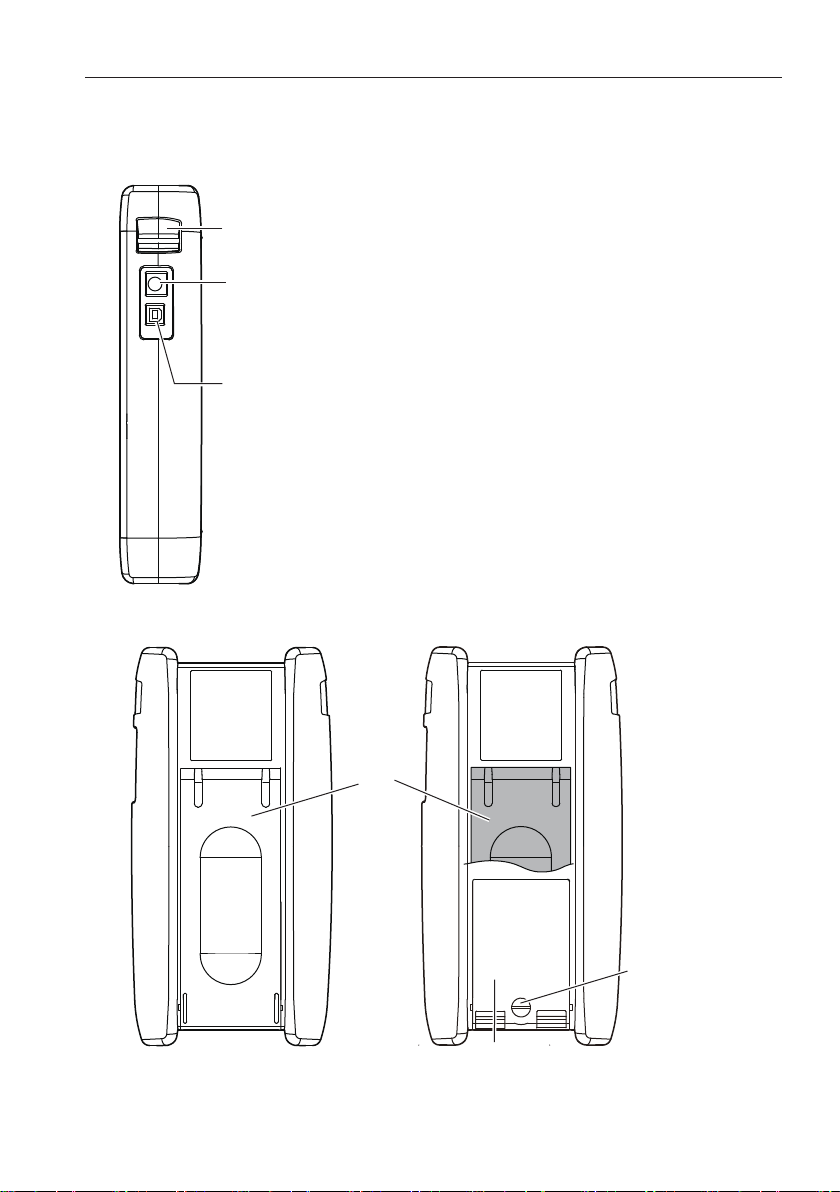

1.2 Side Panel and Rear Panel

Side panel

Shoulder strap fastening area (see page 25)

RJ sensor connector

Connect an external RJ sensor(sold

separately).

USB port (type B)

Can be used to control the instrument remotely

from a PC and supply power to the instrument.

On the CA550, data control can be performed

according to the USB mass storage class.

Rear Panel

1 Component Names and Functions

IM CA500-02EN

Stand

Battery cover

lock key

Battery cover

17

Page 21

1 Component Names and Functions

1.3 Display

Displayed when pulse contact input is on and

function is set to PULSE

Average display

Displayed when auto power-off is on

Measurement

range

Date/time

Function 1

display

Function 2

display

Source/measurement range

Displayed when pulse contact output is on and

function is set to PULSE

Sweep mode

State of sweep

0, 100% value

Displayed when display

light is on

Displayed when

communication

resistance is on

0, 100% value

Thermocouple type

Power supply state

USB:

Battery:

Source state

Sub display 3

Sub display 2

Sub display 1

Main display

(source value

and unit)

USB

(level)

LOOP POWER

output state

Sub display 3

Sub display 2

Sub display 1

Main display

(measured value

and unit)

Function 1 and 2 Displays

The top area of the screen shows the function 1 information and the bottom area

the function 2 information.

18

IM CA500-02EN

Page 22

1 Component Names and Functions

Main Displays and Sub Displays

Each time you press the DISPLAY key of function 1 or 2, the main display switches

between showing the physical value and percentage. When the main display is

showing the physical value, sub display 1 shows the percentage, and vice versa.

Sub display 2 shows the thermoelectromotive force of a thermocouple, the

resistance of an RTD.

Sub display 3 shows the temperature of a reference junction or the amplitude

voltage.

The 0% and 100% values can be shown or hidden using DISPLAY.

Function Main display Sub display 1 Sub display 2 Sub display 3

DC voltage Measure value/

source value

Percentage Measure value/

DC current Measure value/

source value

Percentage Measure value/

Resistance Measure value/

source value

Percentage Measure value/

Thermocouple Measure value/

source value

temperature

(

Percentage Measure value/

RTD Measure value/

source value

temperature

(

Percentage Measure value/

Frequency Measure value/

source value

Percentage Measure value/

Percentage — —

— —

source value

Percentage — —

— —

source value

Percentage — —

— —

source value

Percentage Measure value/

source value

)

source value

temperature

(

Percentage Measure value/

)

source value

temperature

(

Percentage — —

source value

voltage

(

)

Measure value/

source value

voltage

)

(

)

source value

(resistance )

Measure value/

source value

(resistance )

)

— —

Temperature monitor

(reference junction

temperature)

Temperature monitor

(reference junction

temperature)

—

—

IM CA500-02EN

19

Page 23

1 Component Names and Functions

Select Menu

When setting a function, available options are displayed at the bottom of the screen.

Press the arrow key corresponding to the option you want to select.

For two-row selection menus, the up arrow key corresponds to the top area and the

down arrow key to the bottom area.

Select menu

Initializes the settings

Confirms the settings and

closes the setup screen

20

IM CA500-02EN

Page 24

2 Preparation before Use

2.1 Handling Precautions

Safety Precautions

If you are using this instrument for the first time, make sure to thoroughly read the

safety precautions given on pages 8 to 12.

Unplug If Abnormal Behavior Occurs

If you notice smoke or unusual odors coming from the instrument, immediately

turn off the power, remove the batteries if possible, and contact your nearest

YOKOGAWA dealer. Also, turn off the power to source/measurement targets that

are connected to the input terminals.

Do Not Remove the Case

Do not remove the case from the instrument. Some parts of the instrument

use high voltages and are extremely dangerous. For internal inspection and

adjustment, contact your nearest YOKOGAWA dealer.

Operating Environment and Conditions

This instrument complies with the EMC standard under specific operating

environment and operating conditions. If the installation, wiring, and so on are

not appropriate, the compliance conditions of the EMC standard may not be met.

In such cases, the user will be required to take appropriate measures.

General Handling Precautions

Do Not Place Objects on Top of the Instrument

Never place other instruments or objects containing water on top of the

instrument, otherwise a breakdown may occur.

Do Not Subject the Inputs and Outputs to Mechanical Shock

If the input connectors or adapters are subjected to mechanical shock, they may

be damaged. The instrument may not perform measurements correctly due to

damage or deformation that is not visible to the naked eye.

Do Not Damage the LCD

Because the LCD can be easily scratched, do not allow any sharp objects near

it. In addition, observe the following:

• Do not apply vibration or shock.

• Do not apply strong shock to the LCD.

• Do not place objects on the LCD.

IM CA500-02EN

21

Page 25

2 Preparation before Use

Remove the Batteries during Extended Non-Use

Remove the batteries from the main unit.

When Carrying the Instrument

First, turn off the device under measurement. Next, turn off the instrument.

When USB power supply is in use, remove the USB cable. Then, remove all the

cables.

Attaching the Shoulder Strap

Attach the shoulder belt to prevent dropping the instrument. For instructions on

how to attach the shoulder strap, see page 25.

When Cleaning the Instrument

When cleaning the case or the operation panel, gently wipe the outer surface

using a damp, well-wrung, soft, clean cloth. The instrument can malfunction if

water enters inside the instrument.

Do not use chemicals such as benzene or thinner. These can cause discoloring

and deformation.

Other Precautions

• Keep electrically charged objects away from the input terminals. They may

damage the internal circuitry.

• Do not cover the case or operation panel with a volatile material or leave

rubber or vinyl products in contact with the case or operation panel for a long

time.

Notes on generating accurate source

In a small output range, the error in the source value may become large due to

changes in the temperature of the output terminals caused by (1) the conductor

making contact when wiring, (2) changes in the temperature inside the instrument

due to 4-20mA simulation or loop power, or (3) the movement of the surrounding air.

In such situations, wait until the output stabilizes.

In addition, while the instrument is generating output, be careful to keep the output

terminal temperature from changing due to the effects air conditioning, other heat

sources, and the like.

Storage Precautions

Avoid the following kinds of places for storing the instrument:

• Where the temperature falls outside the storage temperature and humidity ranges

• In direct sunlight or near heat sources

• Where an excessive amount of soot, steam, dust, or corrosive gas is present

• Where the level of mechanical vibration is high

• On an unstable surface

• Where an excessive amount of soot, dust, salt, or iron is present

22

IM CA500-02EN

Page 26

2.2 Installing the Instrument

WARNING

• Install the instrument so that you can immediately turn off the

power if an abnormal or dangerous condition occurs.

• Do not use the instrument to measure locations that fall under

Measurement Categories II, III, and IV.

CAUTION

This instrument is equipped with voltage and current source and

measurement features. Do not use the instrument when it is wet.

Doing so may damage the instrument.

French

AVERTISSEMENT

• Installer l’instrument de manière à pourvoir immédiatement le

débrancher du secteur en cas de fonctionnement anormal ou

dangereux.

• N’utilisez pas cet équipement pour mesurer des points tombant

sous les catégories de mesure II, III et IV.

2 Preparation before Use

ATTENTION

• Cet équipement est doté de fonctions de mesure et de source

de courant et de tension. N’utilisez pas l’équipement lorsqu’il est

mouillé. Le cas échéant, un endommagement de l’équipement

risquerait de se produire.

IM CA500-02EN

23

Page 27

2 Preparation before Use

Installation Conditions

Install the instrument in a place that meets the following conditions.

• Operating Altitude and Ambient Temperature and Humidity

• Use the instrument in the following environment.

• Ambient temperature -10°C to 50°C

• Ambient humidity 80% RH or less for -10°C to 40°C, 50% RH or less

for over 40°C

No condensation

• Operating altitude Up to 2000 m

Note

• To ensure high accuracy, operate the instrument within 23°C ± 5°C.

• When using the instrument in a place where the ambient humidity is 30% or less, take

measures to prevent static electricity such as using an anti-static mat.

• Condensation may occur if the instrument is moved to another place where the ambient

temperature or humidity is higher, or if the temperature changes rapidly.

In such cases, allow the instrument adjust to the new environment for at least an hour

before using the instrument.

Install the instrument in a proper location by referring to “Safety Precautions” on

page 8.

Do not install the instrument in the following places, as it can cause incorrect

measurements or damage the instrument.

• In direct sunlight or near heat sources

• In an environment with excessive amounts of soot, steam, dust, or corrosive gas

• Near strong magnetic field sources

• Near noise sources, such as high-voltage equipment or power lines

• Where the level of mechanical vibration is high

• On an unstable surface

• Outdoors or in locations subject to rain or water

24

IM CA500-02EN

Page 28

2 Preparation before Use

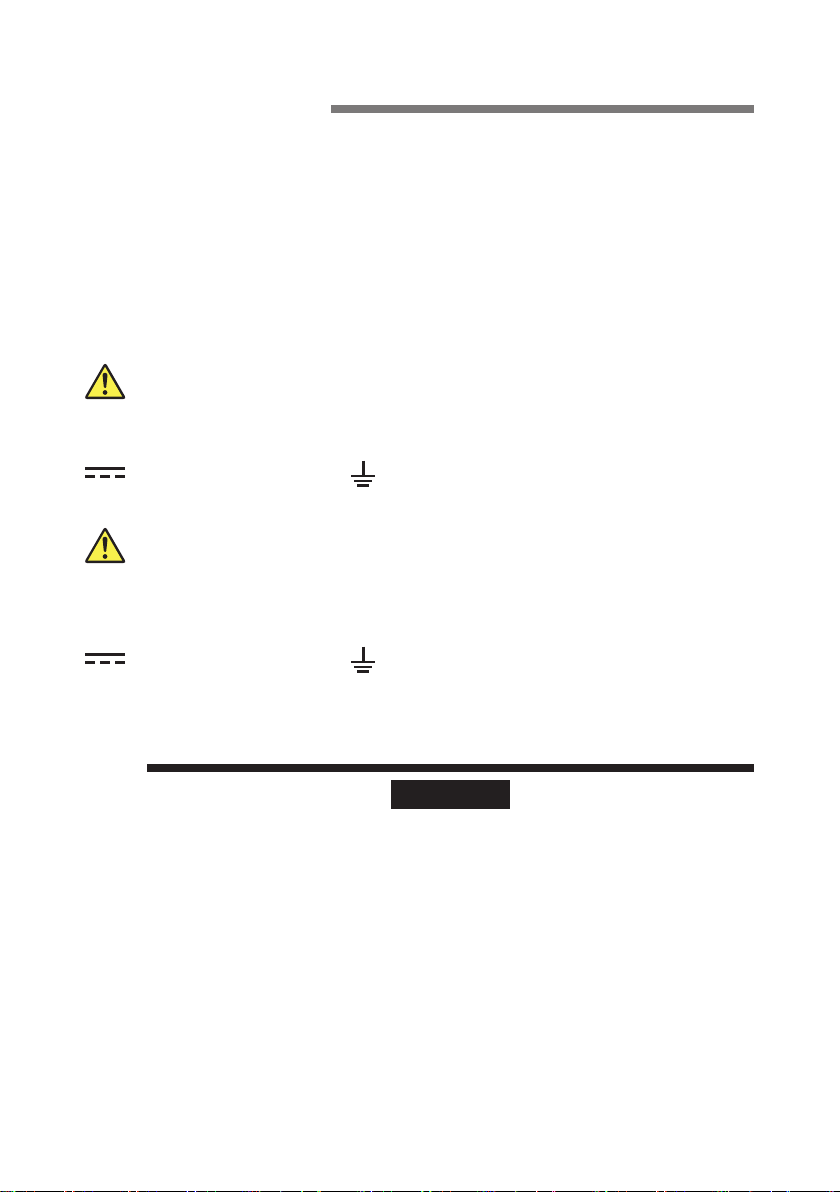

Measurement Category

The measurement category of this instrument is Other (O).

Measurement

Category

O(None, Other) Other circuits that are not directly

CAT II For measurements performed on circuits

CAT III For measuring facility circuits Distribution boards, circuit

CAT IV For measurements performed on power

Description Notes

Circuits that are not powered

connected to the mains.

that are connected to low-voltage

installations

source circuits

from the mains

Household appliances,

portable tools, etc.

breakers, etc.

Entrance cables, cable

systems, etc.

The estimated transient overvoltage that may appear at the CA500 and CA550

signal input terminals is 500 V.

Fastening the Shoulder Strap

Fasten the shoulder strap to the strap fastening area at the top section on each side

of the instrument.

Pass the shoulder strap through the fastening area and then the buckle as shown in

the figure. Attach the left and right sides in the same manner.

Pass the belt back

through the buckle again

and tighten it.

Buckle

IM CA500-02EN

25

Page 29

2 Preparation before Use

2.3 Connecting Cables

WARNING

Maximum Voltage Application Between Terminals And Earth

The maximum voltage application between measurement terminals

and earth is 50 VDC, and that of the source terminals is 30 VDC. To

prevent electric shock, do not exceed these voltages.

Source Terminals

To prevent electric shock, observe the following:

• Be careful not apply voltages exceeding the ratings of each

terminal.

• Be sure to use the included source lead cables.

Measurement Terminals

• Be careful not apply voltages exceeding the ratings of each

terminal.

• Before connecting or disconnecting measurement/source lead

cables from the device under measurement, turn off the device

under measurement. Connecting or disconnecting measurement/

source lead cables with the device under measurement turned on

is extremely dangerous.

• If you connect the H voltage input terminal and mA current

input terminal incorrectly, the device under measurement or this

instrument may break.

Be sure to check that the measurement function setting and the

terminal connection are correct.

26

CAUTION

• Do not apply a voltage to the output terminal for measurements

other than temperature measurements using a thermal couple.

If you apply a voltage by mistake, the internal circuit may break.

French

AVERTISSEMENT

Application de la Tension Maximale Entre les Bornes et la Terre

L’application de la tension maximale entre les bornes et la terre est

50 VDC, et celle des bornes de source est 30 VDC. Pour éviter le

choc électrique, ne pas dépasser ces tensions.

IM CA500-02EN

Page 30

2 Preparation before Use

Bornes de Source

Pour éviter le choc électrique, observer les points suivants:

• Veiller à ne pas appliquer les tensions dépassant les tensions

nominales de chaque borne.

• Veiller à utiliser les câbles de raccordement de la source fournis.

Bornes de Mesure

• Veiller à ne pas appliquer les tensions dépassant les tensions

nominales de chaque borne.

• Avant de brancher ou débrancher des câbles de raccordement de

la mesure/source de l’appareil faisant l’objet de la mesure, mettre

l’appareil hors tension. Il est extrêmement dangereux de brancher

ou débrancher des câbles de raccordement de la mesure/source

pendant que l’appareil faisant l’objet de la mesure est en cours.

• Si vous branchez incorrectement le borne de la tension d’entrée “H”

et le borne du courant d’entrée “mA”, l’appareil faisant l’objet de la

mesure ou cet instrument pourrait casser.

Veiller à vérifier que le réglage de la fonction de mesure et le

branchement de la borne sont corrects.

ATTENTION

• Ne pas appliquer de tension sur la borne de sortie pour les

mesures autres que les mesures de la température qui utilisent

une sonde thermocouple.

Si vous appliquez la tension par erreur, le circuit d’interne pourrait

casser..

Note

Pressing INFO displays a wiring diagram of the selected function.

Before Using the Binding Post

Before using the included binding post, remove the short plate attached to the

binding post.

Inserting or Removing Lead Cables

Insert or remove lead cables straight from the instrument’s terminals.

Do not apply force at an angle.

IM CA500-02EN

27

Page 31

HART Communicator

(BRAIN Terminal)

transmitter

2 Preparation before Use

DC Voltage Source

DC Voltage Measurement

+

−

20 mA simulate

DC current source

4

+

V

−

L

+

30V/

A

−

DC Current Measurement

+

+

4-20 mA

Distributor

−

−

Loop Power

28

+

Two-wire

−

IM CA500-02EN

Page 32

Thermocouple Source

When using the TC-A mini plug terminal

−

2 Preparation before Use

Thermocouple measurement

When using the TC-A mini plug terminal

V

+

−

+

When using the banana plug*

Resistance/RTD Source*

Resistance/RTD Measurement (3W)

Pulse Source

+

V

−

−

When using the banana plug*

Resistance/RTD Measurement (4W)

Ω

Resistance/RTD Measurement (2W)

Pulse Measurement (4W)

−

+

+

−

+

Hz

−

*: Example of using a binding post

Attach according to the terminal color.

Before using the included binding post, remove the short plate attached to the binding

post.

IM CA500-02EN

29

Page 33

2 Preparation before Use

Using Thermocouple Mini Plugs

The TC-A terminal is a dedicated thermocouple mini plug terminal.

Using the thermocouple mini plug results in more stable reference junction

compensation then using a banana terminal.

Use the same type of thermocouple mini plug as the plug on the item to be

calibrated (thermocouple or range of the device to be calibrated).

(Use the thermocouple mini plug set 90040 or 90045 or a thermocouple mini plug

that you prepared.)

To connect the plug and the item to be calibrated, use the same type of

thermocouple or compensating lead wire as that used on the item to be calibrated.

(Prepare your own thermocouple or compensating lead wires.)

30

IM CA500-02EN

Page 34

2.4 Loading and Removing Batteries

WARNING

• Never replace the batteries with the main unit turned on.

• Insert batteries with the correct polarity as shown inside the battery

holder. Otherwise, the batteries may leak, heat up, or burst.

• Do not mix new and old batteries or mix different brands or types

of batteries. The batteries may leak, heat up, or burst due to their

characteristic differences.

• When replacing batteries, be sure to remove the lead cables.

French

AVERTISSEMENT

• Ne retirez pas les piles lorsque le boîtier principal est en marche.

• Inserer les batteries en observant la polarite correcte. A defaut, les

batteries risquent de fuir, de chauffer ou d’eclater.

• Ne pas mélanger des batteries neuves et des batteries usagées,

ni des batteries de marques ou de types différents. Les batteries

risquent de fuir, de chauffer ou d’éclater en raison de leurs

différentes caractéristiques.

• Lors du remplacement des batteries, veillez a retirer les cables de

plomb.

2 Preparation before Use

1.

2.

3.

IM CA500-02EN

Turn the power off.

Lift the rear panel stand.

Using a coin or the like, turn the battery cover lock key to the left

(counterclockwise) by 90°.

Turn the lock key to the

left (counterclockwise).

Locked

Unlocked

Lock key

Stand

Battery cover

31

Page 35

2 Preparation before Use

Remove the battery cover.

4.

Insert new batteries into the battery holder. Insert the batteries in the correct

5.

orientation according to the polarity markings in the battery holder.

Attach the battery cover. Insert the battery cover tab into the battery holder

6.

hole, and close the battery cover.

+

-

+

+

-

+

-

Turn the lock key to the right (clockwise) by 90°.

7.

Battery Life

The battery life after replacing with new batteries is about 16 hours (at 5 V range,

10 kΩ load) at an ambient temperature of 23±5°C. Due to the characteristics

of batteries, the battery life is typically reduced as the ambient temperature is

decreased.

Battery level

The remaining battery power is displayed with an indicator as shown below.

Low

32

Level High

+5.3 V or more

*: The voltage indicates the remaining battery power.

Less than +5.3 V

+4.7 V or more

Less than +4.7 V

+4.1 V or more

Less than +4.1 V

IM CA500-02EN

Page 36

2 Preparation before Use

2.5 Supplying Power through the USB Terminal

WARNING

• Use a USB power supply that can supply stable power and that

complies with the specifications of this instrument

• For details on handling the USB power supply, follow the

instruction manual of the power supply.

French

AVERTISSEMENT

• Utilisez une alimentation USB pouvant fournir une alimentation

stable et conforme aux spécifications de cet instrument.

• Pour les détails de la manipulation de l’adaptateur d’alimentation

USB, suivez le manuel d’instruction de l’adaptateur.

Using the included USB cable, connect the USB power supply to the USB

1.

port on the side panel of this instrument.

Note

• If both the batteries and USB power supply are available and the preferred power supply

is set to batteries, the battery level is displayed instead of “USB”. The batteries argues for

the power supply. For instructions on how to change the preferred power supply setting,

see the “Other Functions” in the Users Manual (IM CA500-01EN) in the CD.

• Please use the USB power supply that can supply a current of 500 mA or more.

IM CA500-02EN

33

Page 37

2 Preparation before Use

2.6 Turning the Power On and Off

Before Turning On the Power, Check That:

• The instrument is installed properly. See section 2.2, “Installation.”

• The batteries are inserted properly. See section 2.4, “Loading and Removing

Batteries.”

• The USB power supply is connected properly. See section 2.5, “Supplying Power

through the USB Terminal.”

Turning the Power On

Press (POWER key) on the front panel.

1.

When the self-test is completed, measurement value and output value are

displayed.

If an error occurs during a self-test, an error code and “Push Any Key” are

displayed. Check the details of the error in “Self-Test Errors” on page 41, and

press any key. The measured value and source value are displayed.

If the symptom persists even after you turn the power off and then back on

again, contact your nearest YOKOGAWA dealer.

Power-On Operation

When the power is turned on, a self-test starts automatically.

If the instrument does not power on properly, turn the power off, and check that:

• The dry cells are inserted properly.

• The USB power supply is connected properly.

• New and old dry cells are not being used together.

• Batteries of different types or different brands are being used together.

• Check whether the power supply that you are using can supply a current of

500 mA or more.

If the instrument still does not work properly, contact your nearest YOKOGAWA

dealer for repairs.

34

IM CA500-02EN

Page 38

Turning the Power Off

CAUTION

• Do not turn off the instrument when the instrument’s output is turned

on. Doing so can damage the instrument. It can also cause damage

to the devices connected to the instrument. Turn off the output first

and then the instrument.

French

ATTENTION

• Ne mettez pas l’instrument hors tension lorsque sa sortie

est activée. Cela pourrait endommager l’instrument ou les

périphériques connectés à l’instrument. Eteignez d’abord la sortie,

puis l’instrument.

2 Preparation before Use

Press

1.

.

2.7 Setting the Date and Time

This section explains how to set the date and time.

For details on the operation, see chapter 3, “Common Operations.”

Press MENU.

1.

Press the cursor keys to select Device Setup.

2.

Press ENTER. A Device Setup screen appears.

3.

Press the cursor keys several times to display Device Setup 2/2.

4.

Press the cursor keys to select Date Format.

5.

Set the date display format.

Set the date.

Press ENTER. A setup screen appears for the date display format.

6.

Use the cursor keys to select the date display format, and then press

7.

ENTER.

YYYY: year (Gregorian), MM: month, DD: day

Set the time.

Initializes the settings

Confirms the settings and

closes the setup screen

IM CA500-02EN

35

Page 39

2 Preparation before Use

Use the cursor keys to select Date, and then press ENTER. The date is

8.

displayed at the bottom of the screen.

Using the arrow keys corresponding to the digits you want to set, set the

9.

year, month, and day.

Press ENTER. The date is set.

10.

Use the cursor keys to select Time, and then press ENTER. The time is

11.

displayed at the bottom of the screen.

Using the arrow keys for the digits you want to set, set the hour, minute, and

12.

second.

Press ENTER. The time is set.

13.

From the selection menu, EXIT SETUP. The settings are confirmed, and the

14.

setup screen closes.

36

IM CA500-02EN

Page 40

3 Common Operations

closes the setup screen

Use the cursor keys (UP and DOWN key) to select an item.

3.1 Opening and Closing Setup Screens

To open a setup screen, press the appropriate key on a screen showing the

measured value or source value.

After entering the settings, to confirm the settings and close the screen, select Exit

Setup from the selection menu.

When you press the ESC key to close the screen, the changes are not applied.

Initializes the settings

Confirms the settings and

3.2 Setup Screen Operation

On the setup screen, the highlighted item is selected.

To open the next menu, press ENTER.

To change the selected item, press the cursor keys (UP/DOWN key).

ENTER key

Selected item

The operation varies depending on the item you are setting.

Items selected from a list of options:

When you select an item, the available options are displayed in the selection

menu (see section 3.3).

Items that require a value to be set:

Select an item, and then press ENTER. The value appears at the bottom of

the screen (see section 3.4).

Items that require alphanumeric characters to be set:

Select an item, and then press ENTER. A window appears for entering

alphanumeric characters (see section 3.5).

IM CA500-02EN

37

Page 41

3 Common Operations

3.3 Selection Menu Operation

When a selection menu appears at the bottom of the screen, use the arrow keys to

make selections.

When the setup menu has one row

Select items

When the setup menu has two rows

Select items in the top row

Select items in the bottom row

3.4 Specifying Values

Select the item you want to set the value of and press ENTER to display the value

at the bottom of the screen. If the source value is displayed, you can change it

directly.

Using the arrow keys corresponding to the digits you want to set, set the value.

After setting the value using the arrow keys, press ENTER to confirm the value.

When setting the source value, you do not need to press ENTER.

38

Increases or decreases the number (with

carrying and borrowing).

IM CA500-02EN

Page 42

to select the character

3 Common Operations

3.5 Setting Alphanumeric Characters

Select an item you want to set alphanumeric characters for and press ENTER to

display a window for entering alphanumeric characters.

Character input position

Use the cursor keys

and the ENTER key to input the character.

Switches the selected character to

“number + uppercase character” or

“symbol + lowercase character”

Confirms the character string and

closes the set up screen

IM CA500-02EN

39

Page 43

4 Troubleshooting, Maintenance, and

Inspection

4.1 Troubleshooting

Faults and Corrective Actions

If servicing is necessary, or if the instrument does not operate properly even after

you have attempted to deal with the problem according to the instructions in this

section, contact your nearest YOKOGAWA dealer.

Problems and Solutions Reference Page

The instrument

does not turn on.

The power turns

off.

The screen is dark. Increase the display light setting. IM CA500-01EN

The screen turns

off.

The display is odd. Confirm that the ambient temperature and humidity

The measured or

source value is

odd.

A self-test error

appears at poweron.

* User’s manual in the CD

Check the battery level. 32

Check that the batteries are inserted correctly.

Or, check that the USB power supply adapter is

connected properly.

Check the battery level. 32

Check whether the power supply that you are using

can supply a current of 500 mA or more.

Set auto power-off to OFF. IM CA500-01EN

are within their specified ranges.

Confirm that the display is not being affected by

noise.

Restart the instrument. 34

Check the battery level. 32

Check whether the power supply that you are using

can supply a current of 500 mA or more.

Check that connections are correct. 26

Confirm that the ambient temperature and humidity

are within their specified ranges.

When using the included binding post for sourcing

thermoelectromotive force of a thermocouple, check

that the short bar has been removed.

This indicates that the settings have been initialized

due to an error in the setting information stored in

the instrument.

If the error appears every time at power-on, repair is

necessary.

There is an error in the calibration data stored in the

instrument.

If the error appears every time at power-on, repair is

necessary.

31 to 33

33

24

24

33

24

–

–

–

*

*

40

IM CA500-02EN

Page 44

4 Troubleshooting, Maintenance, and Inspection

4.2 Error Codes, Error Messages, and Corrective Actions

Information and Warning Messages

No. Message Cause Corrective Action

01 Memory error Insufficient free internal

memory space

02 Low power error Low battery level

Low USB power

Error Messages

No. Message Cause Corrective Action

31 Memory error The measurement adjustment data saved

in EEPROM is inappropriate.

32 Memory error The source adjustment data saved in

EEPROM is inappropriate.

Communication Errors

No. Message Cause Corrective Action

11 Communication

Errors

12 Communication

Errors

13 Communication

Errors

Received an undefined

command

Incorrect command

parameter

Received a command that

cannot be executed in the

instrument’s current condition

Delete unneeded data.

Replace the batteries, or switch to

a USB power supply that meets the

power supply specifications.

Servicing is required.

Servicing is required.

Send a correct command.

Specify the parameter correctly.

Check the instrument condition, and

send the command again.

Self-Test Errors

No. Message Cause Corrective Action

53 RTC error RTC backup power supply

error

Initialize the date and time.

81 CPU board error Measurement CPU error Servicing is required.

83 CPU board error Source CPU error Servicing is required.

IM CA500-02EN

Servicing is required

41

Page 45

Wiring diagram corresponding to

4 Troubleshooting, Maintenance, and Inspection

4.3 Displaying Instrument Information

The instrument information can be displayed.

Press INFO.

1.

the range setting of Function 1

and Function 2

Model

Recent inspection date or calibration date

Inspection Date (performed at YOKOGAWA)

Factory Calibration Date (performed at YOKOGAWA)

Serial number

Firmware version

4.4 Recommended Replacement Parts, Consumable Parts, and Calibration

Recommended Replacement Parts and Consumable Parts

YOKOGAWA guarantees the instrument for the period and under the conditions of

the product warranty.

Calibration

To ensure accuracy, we recommend periodic calibration.

Recommended calibration period: 1 year

42

IM CA500-02EN

Page 46

5. Specifications

5.1 DC Voltage, DC Current, Resistance and Pulse Source

DC Voltage Source

Accuracy (1 year)

Range Resolution Source Range

100 mV 1 μV ±110.000 mV 0.015% + 10 μV 0.015% + 5 μV Maximum output

1-5V 0.1 mV 0.0000 to

6.0000 V

5 V 0.1 mV ±6.0000 V 0.015% + 0.5 mV Maximum output

30 V 1 mV ±33.000 V 0.015% + 5 mV Maximum output

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

The source accuracy is defined for the following conditions.

• The specified cable is used to source the signal.

• The effect of the voltage drop in the cable is excluded.

• The effect of the aging of the instrument is excluded.

±(% of setting + offset)

CA500 CA550

0.015% + 0.5 mV Maximum output

Notes

current: 10 mA

current: 10 mA

Value output function

supporting square

root computation is

available.

current: 10 mA

current: 1 mA

DC Current Source

Accuracy (1 year)

Range Resolution Source Range

20 mA 1

4-20 mA 1

20 mA

SIMULATE

1

μA

μA

μA

±24.000 mA

0.000 to

24.000 mA

(4.000 mA steps)

0.000 to

+24.000 mA

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

IM CA500-02EN

±(% of setting + offset)

CA500 CA550

0.015% + 3 μA 0.010% + 2 μA

0.015% + 3 μA 0.010% + 2 μA

0.015% + 3 μA 0.010% + 2 μA

Notes

Source voltage: 0 to

+20 V

Source voltage: 0 to

+20 V

Value output function

supporting square

root computation is

available.

External power

supply +5 to +28 V

43

Page 47

5. Specifications

The source accuracy is defined for the following conditions.

• The specified cable is used to source the signal.

• The effect of the voltage drop in the cable is excluded.

• The effect of the aging of the instrument is excluded.

Resistance Source

Range

Resolution

400 Ω 10 mΩ

4000 Ω 100 mΩ

Source Range Accuracy (1 year)

±(% of setting + offset)

CA500 CA550

0.00 to 440.00 Ω

0.0 to 4400.0 Ω

0.020% + 0.1 Ω

0.020% + 0.5 Ω 0.015% + 0.2 Ω Allowable

0.015% + 0.05 Ω

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

The source accuracy is defined for the following conditions.

• The specified cable is used to source the signal.

• The effect of the voltage drop in the cable is excluded.

• The effect of the aging of the instrument is excluded.

1: Accuracy when using the included binding post (99045).

1

Allowable

measurement current:

0.1 to 3 mA

measurement current:

0.05 to 0.6 mA

Notes

Frequency/Pulse Source

Range

Resolution

500Hz

0.01 Hz

5000Hz

0.1 Hz

50kHz

0.001 kHz

CPM 0.1 /min

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

The source accuracy is defined for the following conditions.

• The specified cable is used to source the signal.

• The effect of the voltage drop in the cable is excluded.

• The effect of the aging of the instrument is excluded.

Source Range

1.00 to 550.00 Hz

1.0 to 5500.0 Hz

0.001 to 50.000 kHz

1.0 to 1100.0 /min

1-Year Accuracy

±(% of setting + offset)

CA500 CA550

0.005% + 0.01 Hz

0.005% + 0.1 Hz

+0.005% + 0.001 kHz

0.5 /min

Notes

Square wave, 50% Duty Cycle,

+0.1 to +15 V

Pulse count: Continuous, 1 to

999999 cycles

Maximum load current: 10 mA

Non-voltage contact compatible

44

IM CA500-02EN

Page 48

5. Specifications

5.2 DC Voltage, DC Current, Resistance and Pulse Measurement

DC Voltage Measurement

Range Resolution

100 mV 1 μV ±110.000 mV 0.015% + 10 μV 0.015% + 5 μV Input resistance:

5 V 0.1 mV ±6.0000 V 0.015% + 0.5 mV Input resistance:

50 V 1 mV ±55.000 V 0.015% + 5 mV Input resistance:

Measurement

Range

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

DC Current Measurement

Range Resolution

50 mA 1 μA ±60.000 mA 0.015% + 3 μA 0.010% + 2 μA Input resistance:

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

Measurement

Range

Accuracy (1 year)

±(% of reading + offset)

CA500 CA550

Accuracy (1 year)

±(% of reading + offset)

CA500 CA550

Notes

1 GΩ or more

Approx.1 MΩ

Approx.1 MΩ

Notes

10 Ω or less

IM CA500-02EN

45

Page 49

5. Specifications

Resistance Measurement

Range

400 Ω

4000 Ω

Resolution

10 mΩ

100 MΩ

Measurement

Range

0.00 to 440.00 Ω

0.0 to 4400.0 Ω

Accuracy (1 year)

±(% of setting + offset)

CA500 CA550

0.020% + 0.1 Ω

0.020% + 0.5 Ω 0.015% +0.2 Ω

0.015% +0.05 Ω

Notes

Voltage applied current

measurement method

Typical value:

1 mA(0 Ω)

781

240

μA(400 Ω)

μA(4 kΩ)

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

Accuracies through four-wire system measurement

For accuracies through three-wire system measurement, add 0.05

0.2

Ω

for 4000

Ω range

. However, this assumes that the resistances of all cables are

Ω

for 400

the same.

Assume the accuracies through two-wire system measurement to be the same as

those through three-wire system measurement. However, cable resistance are not

taken into consideration.

Pulse Measurement

Range

500Hz 0.01 Hz 1.00 to 550.00 Hz 0.005% +0.01 Hz Measurement time: 1.0 s

5000Hz 0.1 Hz 1.0 to 5500.0 Hz 0.005% +0.1 Hz

50kHz 0.001 kHz 0.001 to 50.000 kHz 0.005% +0.001 kHz

PULSE

COUNT

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.005% of Range/°C for -10°C to +18°C and +28°C

to +50°C.

Resolution

1 0 to 99999 2 Maximum integration time:

Measurement

Range

1-Year Accuracy

±(% of setting + offset)

CA500 CA550

Notes

0.5 V to 30 Vpp

Non-voltage contact

compatible

60 min, 0.5 V to 30 Vpp

Non-voltage contact

compatible

Ω range

,

Loop Power Supply

Supply voltage Notes

24 V ±2 V

46

Communication resistance: OFF

Maximum load current: 24 mA

IM CA500-02EN

Page 50

5. Specifications

5.3 Temperature Measurement (TC) and Thermocouple Calibration Voltage Source

When the TC-A terminal (thermocouple plug terminal)

and reference junction compensation using the internal

temperature sensor are in use

Source Accuracy (common to CA500 and CA550 )

Accuracy (1 year, t: source temperature)

Thermocouple

K

E

J

T

N

L

U

R

S

B

C

XK

A

Temperature Range Source Accuracy

[°C]

±

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.30% IEC60584-1

0.0°C ≤ t < +500.0°C 0.5

+500.0°C ≤ t ≤ +1372.0°C 0.5+(t-500) x 0.03%

-250.0°C ≤ t < -200.0°C 1.1+(|t|-200) x 2.00% IEC60584-1

-200.0°C ≤ t <0.0°C 0.5+|t| x 0.30%

0.0°C ≤ t < +500.0°C 0.5

+500.0°C ≤ t ≤ +1000.0°C 0.5+(t-500) x 0.02%

-210.0°C ≤ t < 0.0°C 0.5+|t| x 0.30% IEC60584-1

0.0°C ≤ t≤ +1200.0°C 0.5+t x 0.02%

-250.0°C ≤ t < -200.0°C 1.1+(|t|-200) x 2.50% IEC60584-1

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.30%

0.0°C ≤ t ≤ +400.0°C 0.5

-200.0°C ≤ t < 0.0°C 0.6+|t| x 0.40% IEC60584-1

0.0°C ≤ t ≤ +1300.0°C 0.6

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.15% DIN 43710

0.0°C ≤ t≤ +900.0°C 0.5

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.20% DIN 43710

0.0°C ≤ t≤ +600.0°C 0.5

-20.0°C ≤ t < 0.0°C 2.0 IEC60584-1

0.0°C ≤ t < +100.0°C 2.0

+100.0°C ≤ t ≤ +1767.0°C 1.4

-20.0°C ≤ t < 0.0°C 2.0 IEC60584-1

0.0°C ≤ t < +100.0°C 2.0

+100.0°C ≤ t ≤ +1768.0°C 1.4

+600.0°C ≤ t < +800.0°C 1.2 IEC60584-1

+800.0°C ≤ t < +1000.0°C 1.0

+1000.0°C ≤ t ≤ +1820.0 °C 1.0

0.0°C ≤ t < +1000.0°C 0.8 IEC60584-1

+1000.0°C ≤ t ≤ +2315.0°C 0.8+(t-1000) x 0.06%

-200.0°C ≤ t < 0.0°C 0.4+|t| x 0.20% GOST R

0.0°C ≤ t < +300.0°C 0.4

+300.0°C ≤ t ≤ +800.0°C 0.5

0.0°C ≤ t < +1000.0°C 1.0 IEC60584-1

+1000.0°C ≤ t ≤ +2500.0°C 1.0+(t-1000) x 0.06%

Specification

1985

1985

8.585-2001

1, 2

1, 2

1, 2

1, 2

1

1, 2

1, 2

1, 2

1

IM CA500-02EN

47

Page 51

5. Specifications

Accuracy (1 year, t: source temperature)

Thermocouple

D

(W3Re/W25Re)

G

(W/W26Re)

Temperature Range Source Accuracy

[°C]

±

0.0°C ≤ t < +300.0°C 1.4 ASTM E1751/

+300.0°C ≤ t < +1500.0°C 1.2

+1500.0°C ≤ t ≤ +2315.0°C 1.8

+100.0°C ≤ t < +300.0°C 1.4 ASTM E1751/

+300.0°C ≤ t < +1500.0°C 1.2

+1500.0°C ≤ t ≤ +2315.0°C 1.8

0.0°C ≤ t < +100.0°C 0.6 ASTM E1751/

PLATINEL II

+100.0°C ≤ t < +1000.0°C 0.8

+1000.0°C ≤ t ≤ +1395.0°C 1.0

0.0°C ≤ t < +500.0°C 10.0 ASTM E1751

PR20-40

+500.0°C ≤ t < +1000.0°C 3.0

+1000.0°C ≤ t ≤ +1888.0°C 2.0

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.05°C/°C for -10°C to +18°C and +28°C to

+50°C.

Display resolution of source/measured values: 0.1°C

1 Complies also with JIS C 1602

2 The setting can be changed to comply with IPTS-68 (JIS C 1602 1981).

Measurement Accuracy (common to CA500 and CA550 )

Accuracy (1 year, t: measurement temperature)

Thermocouple

K

E

J

T

N

L

U

Temperature Range Measurement

Accuracy

±

[°C]

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.30% IEC60584-1

0.0°C ≤ t < +500.0°C 0.5

+500.0°C ≤ t ≤ +1372.0°C 0.5+(t-500) x 0.02%

-250.0°C ≤ t < -200.0°C 1.1+(|t|-200) x 2.00% IEC60584-1

-200.0°C ≤ t <0.0°C 0.5+|t| x 0.30%

0.0°C ≤ t < +500.0°C 0.5

+500.0°C ≤ t ≤ +1000.0°C 0.5+(t-500) x 0.02%

-210.0°C ≤ t < 0.0°C 0.5+|t| x 0.30% IEC60584-1

0.0°C ≤ t≤ +1200.0°C 0.5+|t| x 0.02%

-250.0°C ≤ t < -200.0°C 1.1+(|t|-200) x 2.50% IEC60584-1

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.30%

0.0°C ≤ t ≤ +400.0°C 0.5

-200.0°C ≤ t < 0.0°C 0.6+|t| x 0.30% IEC60584-1

0.0°C ≤ t ≤ +1300.0°C 0.6

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.15% DIN 43710

0.0°C ≤ t≤ +900.0°C 0.5

-200.0°C ≤ t < 0.0°C 0.5+|t| x 0.20% DIN 43710

0.0°C ≤ t≤ +600.0°C 0.5

Specification

E1751M

E1751M

E1751M

Specification

1985

1985

1, 2

1, 2

1, 2

1, 2

1,

48

IM CA500-02EN

Page 52

5. Specifications

Accuracy (1 year, t: measurement temperature)

Thermocouple

R

S

B

C

XK

A

D

(W3Re/W25Re)

G

(W/W26Re)

PLATINEL II

PR20-40

Temperature Range Measurement

Accuracy

-20.0°C ≤ t < 0.0°C 2.0 IEC60584-1

0.0°C ≤ t < +100.0°C 1.4

+100.0°C ≤ t ≤ +1767.0°C 1.4

-20.0°C ≤ t < 0.0°C 2.0 IEC60584-1

0.0°C ≤ t < +100.0°C 1.4

+100.0°C ≤ t ≤ +1768.0°C 1.4

+600.0°C ≤ t < +800.0°C 1.5 IEC60584-1

+800.0°C ≤ t < +1000.0°C 1.2

+1000.0°C ≤ t ≤ +1820.0 °C 1.1

0.0°C ≤ t < +1000.0°C 0.8 IEC60584-1

+1000.0°C ≤ t ≤ +2315.0°C 0.8+(t-1000) x 0.06%

-200.0°C ≤ t < 0.0°C 0.4+|t| x 0.20% GOST R

0.0°C ≤ t < +300.0°C 0.4

+300.0°C ≤ t ≤ +800.0°C 0.5

0.0°C ≤ t < +1000.0°C 1.0 IEC60584-1

+1000.0°C ≤ t ≤ +2500.0°C 1.0+(t-1000) x 0.06%

0.0°C ≤ t < +300.0°C 1.8 ASTM E1751/

+300.0°C ≤ t < +1500.0°C 1.2

+1500.0°C ≤ t ≤ +2315.0°C 2.2

+100.0°C ≤ t < +300.0°C 1.8 ASTM E1751/

+300.0°C ≤ t < +1500.0°C 1.2

+1500.0°C ≤ t ≤ +2315.0°C 2.2

0.0°C ≤ t < +100.0°C 1.8 ASTM E1751/

+100.0°C ≤ t < +1000.0°C 1.8

+1000.0°C ≤ t ≤ +1395.0°C 2.2

0.0°C ≤ t < +500.0°C 11.0 ASTM E1751

+500.0°C ≤ t < +1000.0°C 4.0

+1000.0°C ≤ t ≤ +1888.0°C 2.0

±

Specification

[°C]

8.585-2001

E1751M

E1751M

E1751M

Accuracy guaranteed under +23°C±5°C, 20 to 80%RH

Add a temperature coefficient of 0.05°C/°C for -10°C to +18°C and +28°C to

+50°C.

Display resolution of source/measured values: 0.1°C

1 Complies also with JIS C 1602

2 The setting can be changed to comply with IPTS-68 (JIS C 1602 1981).

Accuracy with respect to the measurement or source temperature (t) is

expressed as constant or a linear equation of t.

Example: Accuracy for Thermocouple K (terminal A) measurement value of

1000.0°C = ±(0.5 + (1000.0-500)×0.02%)°C = ±0.6°C

1, 2

1, 2

1, 2

1

IM CA500-02EN

49

Page 53

5. Specifications

When terminal B (banana terminal) and reference junction

compensation using the internal temperature sensor are

in use

Source Accuracy (common to CA500 and CA550 )

Accuracy (1 year, t: source temperature)

Thermocouple

K

E

J

T

N

L

U

R

S

B

C

XK

A

D

(W3Re/W25Re)

Temperature Range Source Accuracy

[°C]

±

-200.0°C ≤ t < 0.0°C 1.0+|t| x 0.75% IEC60584-1

0.0°C ≤ t < +500.0°C 1.0

+500.0°C ≤ t ≤ +1372.0°C 1.0+(t-500) x 0.04%

-250.0°C ≤ t < -200.0°C 2.0+(|t|-200) x 7.00% IEC60584-1

-200.0°C ≤ t < 0.0°C 1.0+|t| x 0.50%

0.0°C ≤ t < +500.0°C 1.0

+500.0°C ≤ t ≤ +1000.0°C 1.0

-210.0°C ≤ t < 0.0°C 1.0+|t| x 0.50% IEC60584-1

0.0°C ≤ t ≤ +1200.0°C 1.0+t x 0.02%