Page 1

User ’s

Manual

CA500, CA550

Multifunction Process

Calibrator

IM CA500-01EN

1st Edition

Page 2

Thank you for purchasing the CA500/CA550 Multifunction Process Calibrator. This user’s manual

explains the features, operating procedures, and handling precautions of the CA500 and CA550. To

ensure correct use, please read this manual thoroughly before operation.

After reading this manual, keep it in a safe place. The following manuals, including this one, are

provided as manuals for the CA500 and CA550. Please read all manuals.

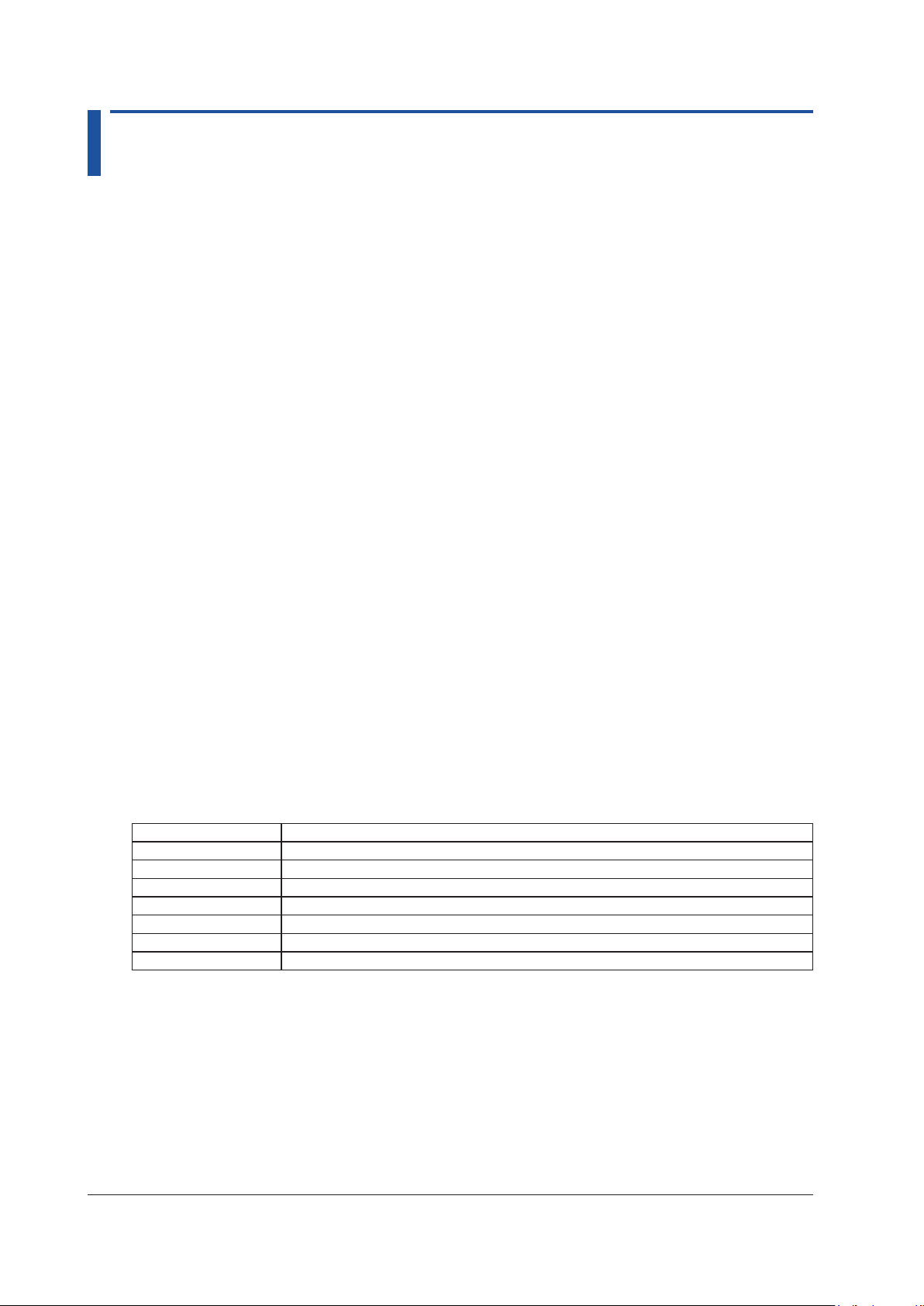

Manual Title Manual No. Description

CA500, CA550

Multifunction Process Calibrator

User’s Manual

CA500, CA550

Multifunction Process Calibrator

Getting Started Guide

CA500 Multifunction Process Calibrator

Userʼs Manual

“전기용품 및 생활용품 안전관리법”

관련일차전지에 대한 대응

IM CA500-01EN This document. The manual explains all

the instrument features.

It is included in the accompanying CD.

IM CA500-02EN Provided as a printed manual. This

guide explains the handling precautions,

basic operations, and specifications of

the instrument.

IM CA500-92Z1 Document for China.

PIM 902-01KO Document for Korea.

The “EN”, “Z1”, and “KO” in the manual numbers are the language codes.

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document No. Description

PIM 113-01Z2 List of worldwide contacts

Notes

• The contents of this manual are subject to change without prior notice as a result of continuing

improvements to the instrument’s performance and functions. The figures given in this manual

may differ from those that actually appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the permission of

YOKOGAWA is strictly prohibited.

Trademarks

• Microsoft, Internet Explorer, Windows, Windows 8, and Windows 10 are registered trademarks

or trademarks of Microsoft Corporation in the United States and/or other countries.

• Adobe and Acrobat are either registered trademarks or trademarks of Adobe Systems

Incorporated.

• HART is a registered trademark of FieldComm Group.

• In this manual, the TM and ® symbols do not accompany their respective registered trademark

or trademark names.

• Other company and product names are trademarks or registered trademarks of their respective

holders.

1st Edition: October 2019 (YMI)

All Rights Reserved, Copyright © 2019 Yokogawa Test & Measurement Corporation

IM CA500-01EN

i

Page 3

Revisions

• October, 2019 1st Edition

ii

IM CA500-01EN

Page 4

Conventions Used in This Manual

Prefixes k and K

This manual distinguishes prefixes k and K used before units as follows:

k: Denotes 1000. Example: 100 kS/s (sample rate)

K: Denotes 1024. Example: 720 KB (file size)

Displayed Characters

Bold characters in procedural explanations are used to indicate panel keys and soft keys that

are used in the procedure and menu items that appear on the screen.

Notes and Cautions

The notes and cautions in this manual are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage to the

instrument. This symbol appears on the instrument to indicate that the

user must refer to the user’s manual for special instructions. The same

symbol appears in the corresponding place in the user’s manual to identify

those instructions. In the manual, the symbol is used in conjunction with

the word “WARNING” or “CAUTION.”

WARNING

CAUTION

Note

Calls attention to actions or conditions that could cause serious or fatal

injury to the user, and precautions that can be taken to prevent such

occurrences.

Calls attention to actions or conditions that could cause light injury to the

user or damage to the instrument or user’s data, and precautions that

can be taken to prevent such occurrences.

Calls attention to information that is important for the proper operation of the

instrument.

IM CA500-01EN

iii

Page 5

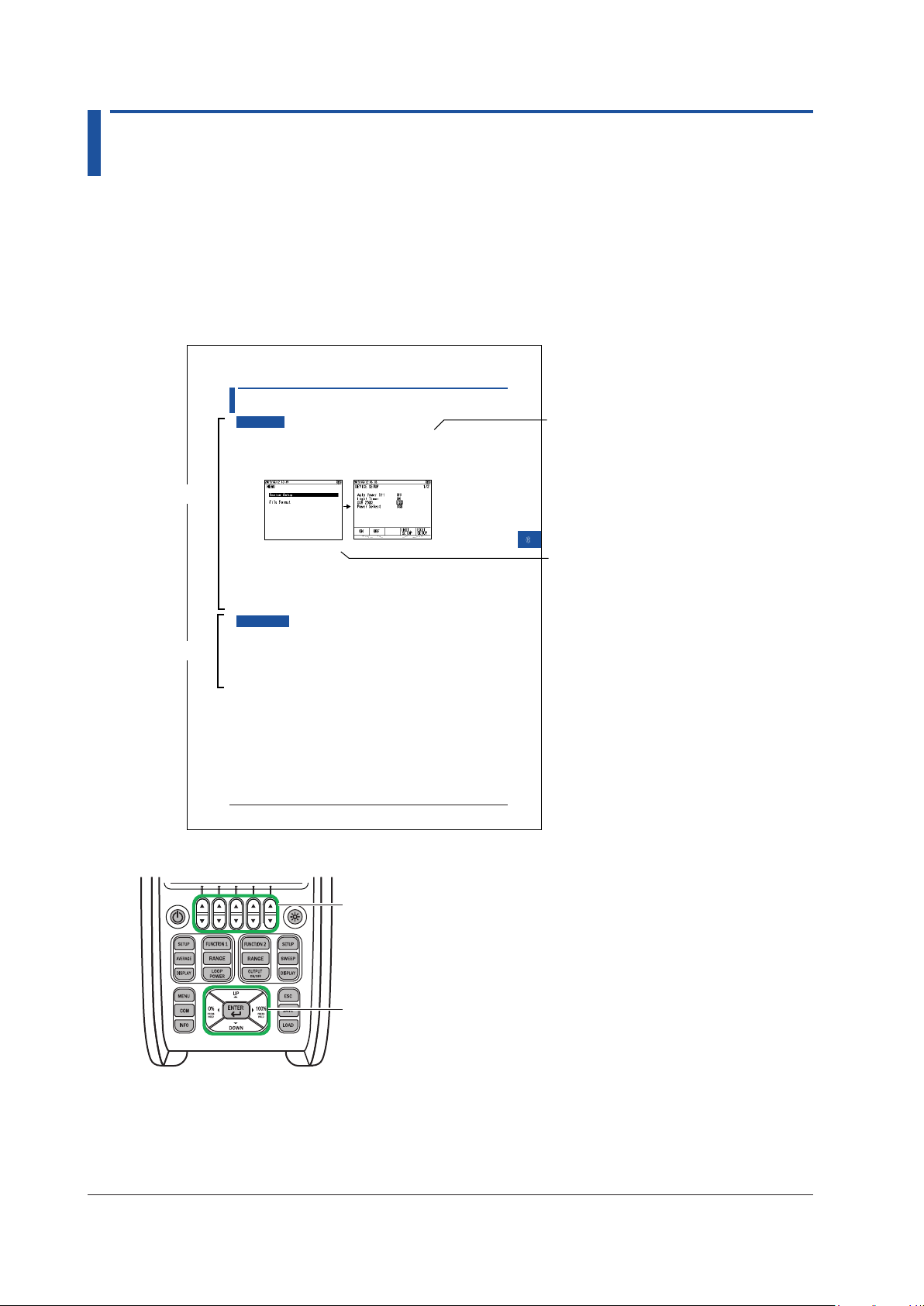

How to Read This Manual

1

2

3

4

5

This document provides descriptions with the procedure first followed by the explanation.

In the procedure section, steps for configuring the settings are provided.

In the explanation section, the details of the configure functions are provided.

How the Procedure Is Described

In the procedure section, the panel keys and the names on the menus that are used in the steps

are indicated in bold text.

6.2 Turning Communication Resistance On or Off

Panel key

Procedure

Procedure

1.

With the source value and measurement value displayed, press MENU. A menu screen

appears.

2.

Use the cursor keys to select Device Setup, and then press ENTER. A Device Setup screen

appears.

3.

Use the cursor keys to select &20ȍ. ON and OFF appear in the selection menu.

6

Other Settings

Menu display

6-3

Explanation

4.

Use the arrow keys to select ON or OFF

Confirming the Settings

5.

Press the arrow key corresponding to EXIT SETUP. The settings are confirmed, and a screen

appears showing the source value and measurement value.

Pressing ESC causes the instrument to discard the settings and return to the menu screen.

To initialize the settings, pressing the arrow key corresponding to INIT SETUP.

Description

:KHQWKHFRPPXQLFDWLRQUHVLVWDQFHLVWXUQHGRQDȍUHVLVWRULVFRQQHFWHGWRWKH9ORRS

power output inside the instrument. The communication resistance is used to provide amplitude

to the HART communication signals or BRAIN communication signals superimposed in the

transmission line.

Set this to off when communication signals are not superimposed in the transmission line.

IM CA500-01EN

In addition, “arrow keys” and “cursor keys” indicate the following keys.

Arrow keys

Cursor keys

iv

IM CA500-01EN

Page 6

Contents

Conventions Used in This Manual ................................................................................................... iii

How to Read This Manual ................................................................................................................iv

Chapter 1 Features

1.1 System Configuration and Block Diagram ..................................................................... 1-1

1.2 Source Function ............................................................................................................. 1-2

1.3 Sweep function ............................................................................................................... 1-8

1.4 Measurement Function ................................................................................................ 1-12

1.5 Calibration Function for Field Instruments ................................................................... 1-17

1.6 Saving and Loading CA500 Data ................................................................................. 1-18

1.7 Saving and Loading CA550 Data ................................................................................. 1-20

1.8 Other Features ............................................................................................................. 1-24

Chapter 2 Source

2.1 DC Voltage Source ......................................................................................................... 2-1

2.2 DC Current Source ......................................................................................................... 2-3

2.3 Resistance Source ......................................................................................................... 2-5

2.4 Voltage Source Corresponding to TC Thermoelectromotive Force ............................... 2-7

2.5 Resistance Source Corresponding to the RTD Temperature ....................................... 2-10

2.6 Frequency and Pulse Source ....................................................................................... 2-12

2.7 Setting the 0% and 100% Values ................................................................................. 2-16

2.8 Dividing and Generating the Source Values ................................................................ 2-18

2.9 Sweep Source .............................................................................................................. 2-20

Chapter 3 Measurement

3.1 DC Voltage Measurement .............................................................................................. 3-1

3.2 DC Current Measurement .............................................................................................. 3-3

3.3 Resistance Measurement .............................................................................................. 3-5

3.4 Temperature Measurement Using Thermocouples ........................................................ 3-7

3.5 Temperature Measurement Using RTDs ...................................................................... 3-10

3.6 Frequency and Pulse Measurement ............................................................................ 3-12

3.7 Setting the 0% and 100% Values ................................................................................. 3-14

3.8 Setting the Tolerance (CA550) ..................................................................................... 3-16

3.9 Average Value Display ................................................................................................. 3-17

1

2

3

4

5

6

7

Index

Chapter 4 Calibrating Field Instruments (CA550)

4.1 Calibration Procedure .................................................................................................... 4-1

4.2 Setting Calibration Conditions ........................................................................................ 4-2

4.3 Saving Calibration Results ............................................................................................. 4-5

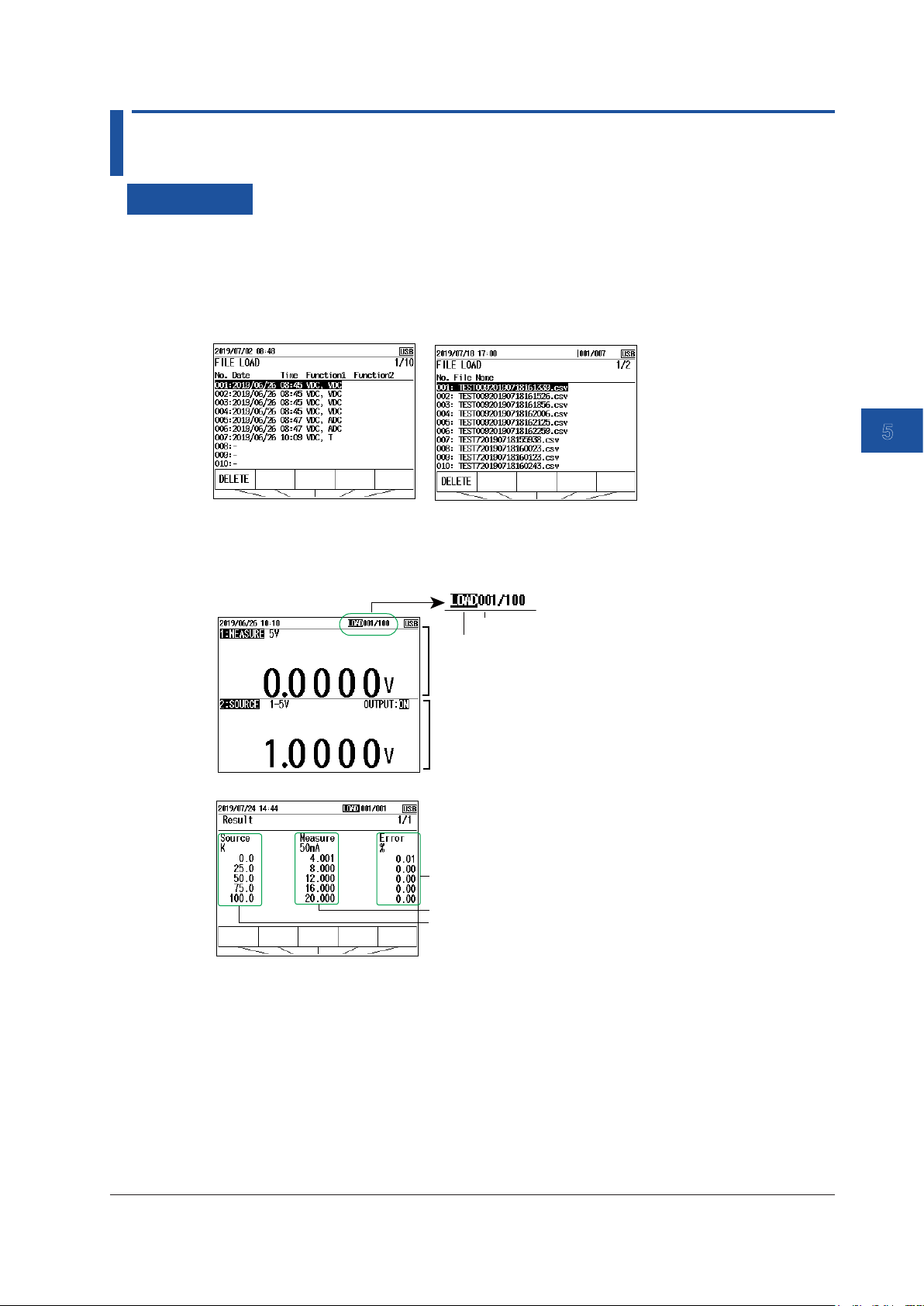

Chapter 5 Saving Data

5.1 Saving Data Manually .................................................................................................... 5-1

5.2 Saving Sweeps .............................................................................................................. 5-4

5.3 Loading and Deleting Saved Data ................................................................................. 5-7

5.4 Copying Saved Data to a PC (CA550) ........................................................................... 5-9

5.5 Saved Data Format (CA550) ........................................................................................ 5-10

IM CA500-01EN

v

Page 7

Contents

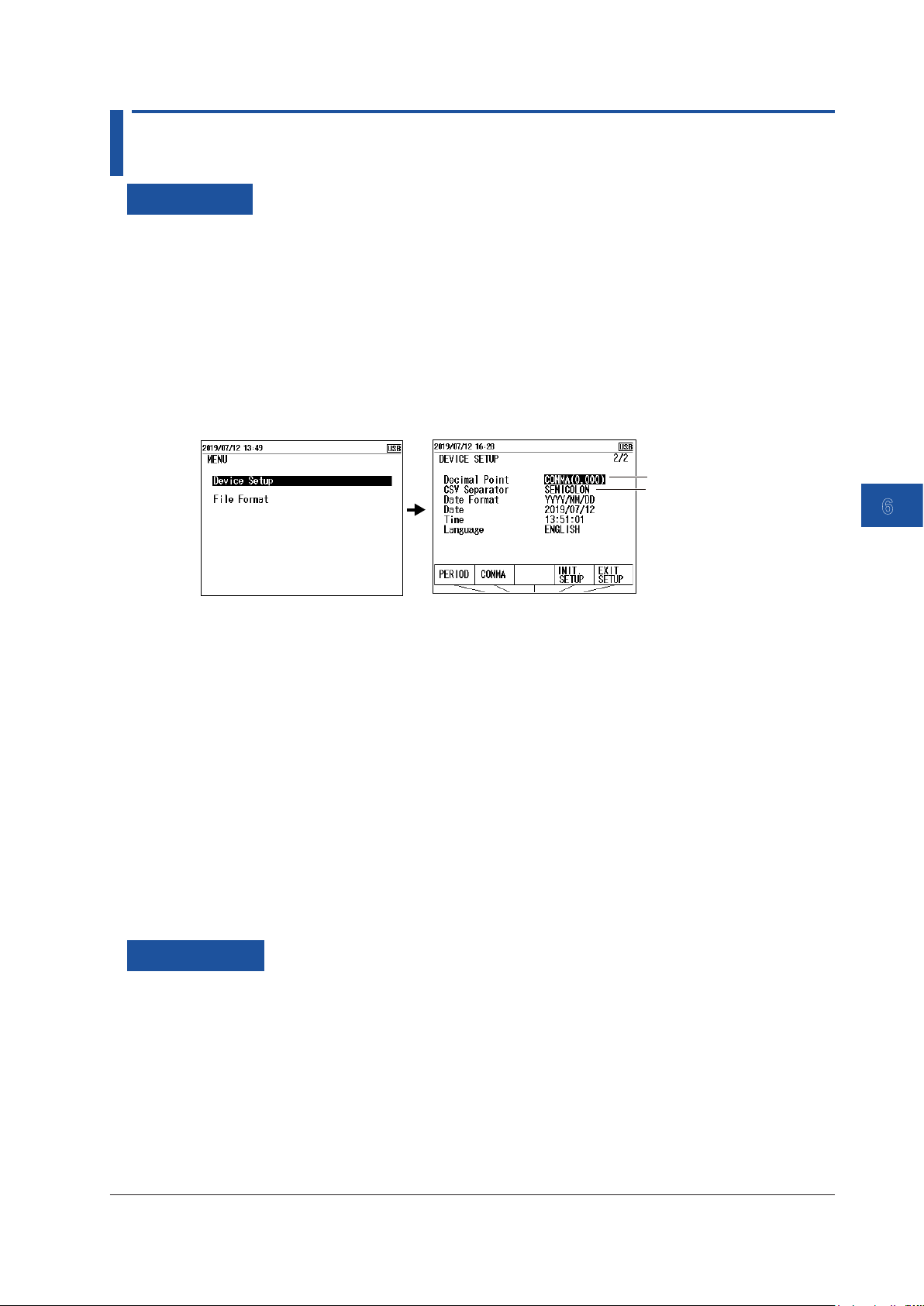

Chapter 6 Other Features

6.1 Auto Power-off, Turning the Light Timer On and Off, and Turning the Light On and Off 6-1

6.2 Turning Communication Resistance On or Off ............................................................... 6-3

6.3 Setting the Priority Power Supply ................................................................................... 6-4

6.4 Setting the Decimal Symbol and CSV Separator ........................................................... 6-5

6.5 Setting the Date Display Format .................................................................................... 6-6

6.6 Setting the Language ..................................................................................................... 6-7

6.7 Formatting (Initializing) the Internal Memory .................................................................. 6-8

Chapter 7 USB Function

7.1 USB Interface Features and Specifications ................................................................... 7-1

7.2 Connecting through the USB Interface .......................................................................... 7-2

7.3 List of Commands .......................................................................................................... 7-3

7.4 Commands ..................................................................................................................... 7-5

7.5 Error Codes .................................................................................................................. 7-19

7.6 Status Byte Format ...................................................................................................... 7-20

Index

vi

IM CA500-01EN

Page 8

Chapter 1 Features

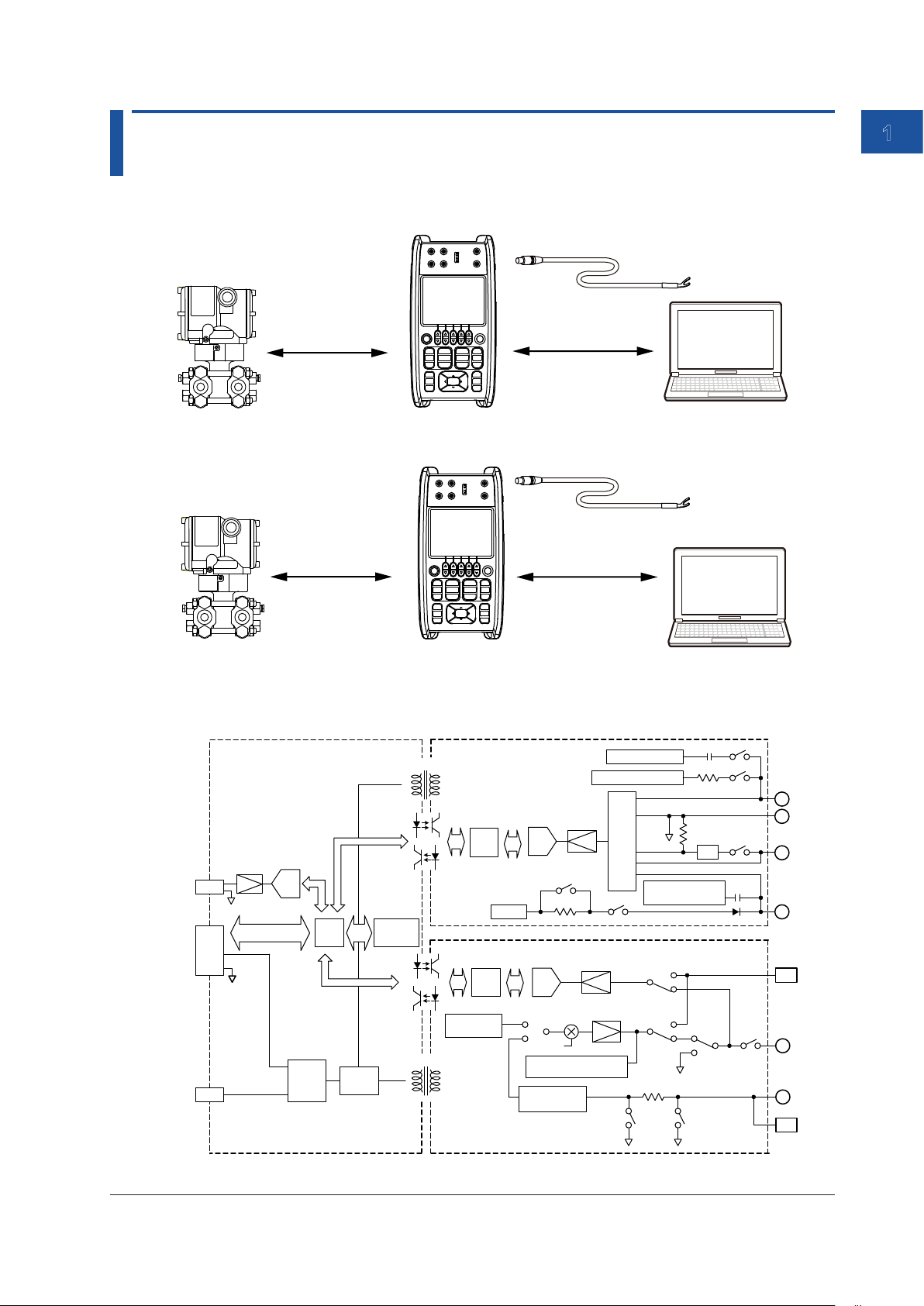

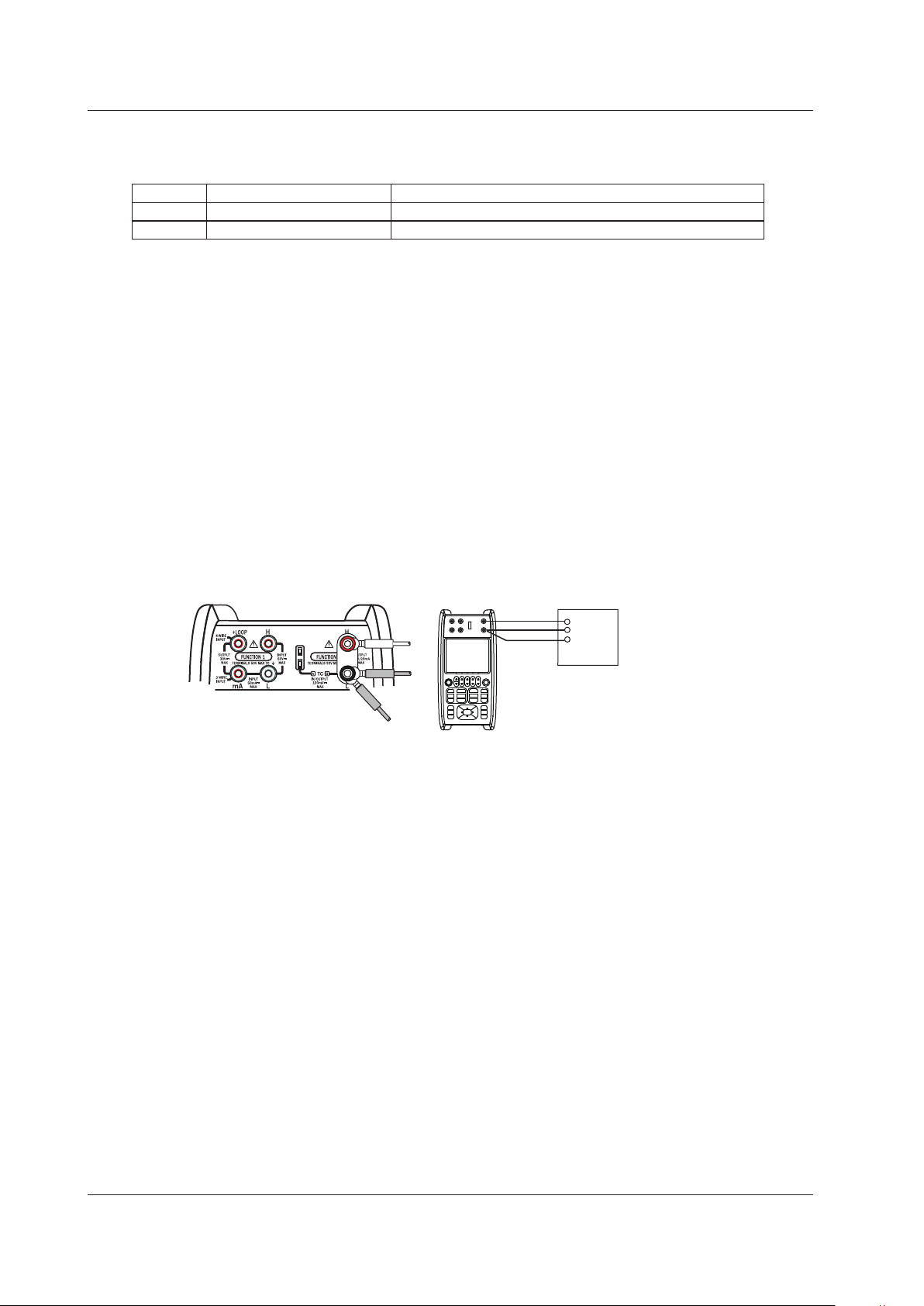

1.1 System Configuration and Block Diagram

System Configuration

RJ sensor (sold separately)

DC voltage, DC

current, resistance,

TC, RTD, pulse

CA500

DC voltage, DC

current, resistance,

TC, RTD, pulse

USB interface

(communication)

PCField instrument

RJ sensor (sold separately)

USB interface

(communication/mass

storage)

1

Features

HART/BRAIN

communication

Field instrument

Block Diagram

Power Source/Communication Port

R.J.

INPUT

USB B

BATT.

ADC

Power

source

control

CPU

DC/DC

Display

CA550

DC/DC

DC/DC

FUNCTION 1 part

CPU

DC/DC

FUNCTION 2 part

CPU

Reference

voltage source

USB interface

(HART/BRAIN modem)

Frequency counter

Constant voltage source

ADC

250Ω

ADC

DCV

DCA

Setting

OHM

Excess volatge / excess

current protection

Current voltage

conversion

OUTPUT

Power AMP

Input

circuit

Current detection

Shunt resistance

Communication

modem

TC-A

TC-A

DCVDCA

PTC

FRQ

PC

FRQ

OHM

DCA

OUTPUT

H

L

mA

+LOOP

+TC-A

H

L

-TC-A

IM CA500-01EN

1-1

Page 9

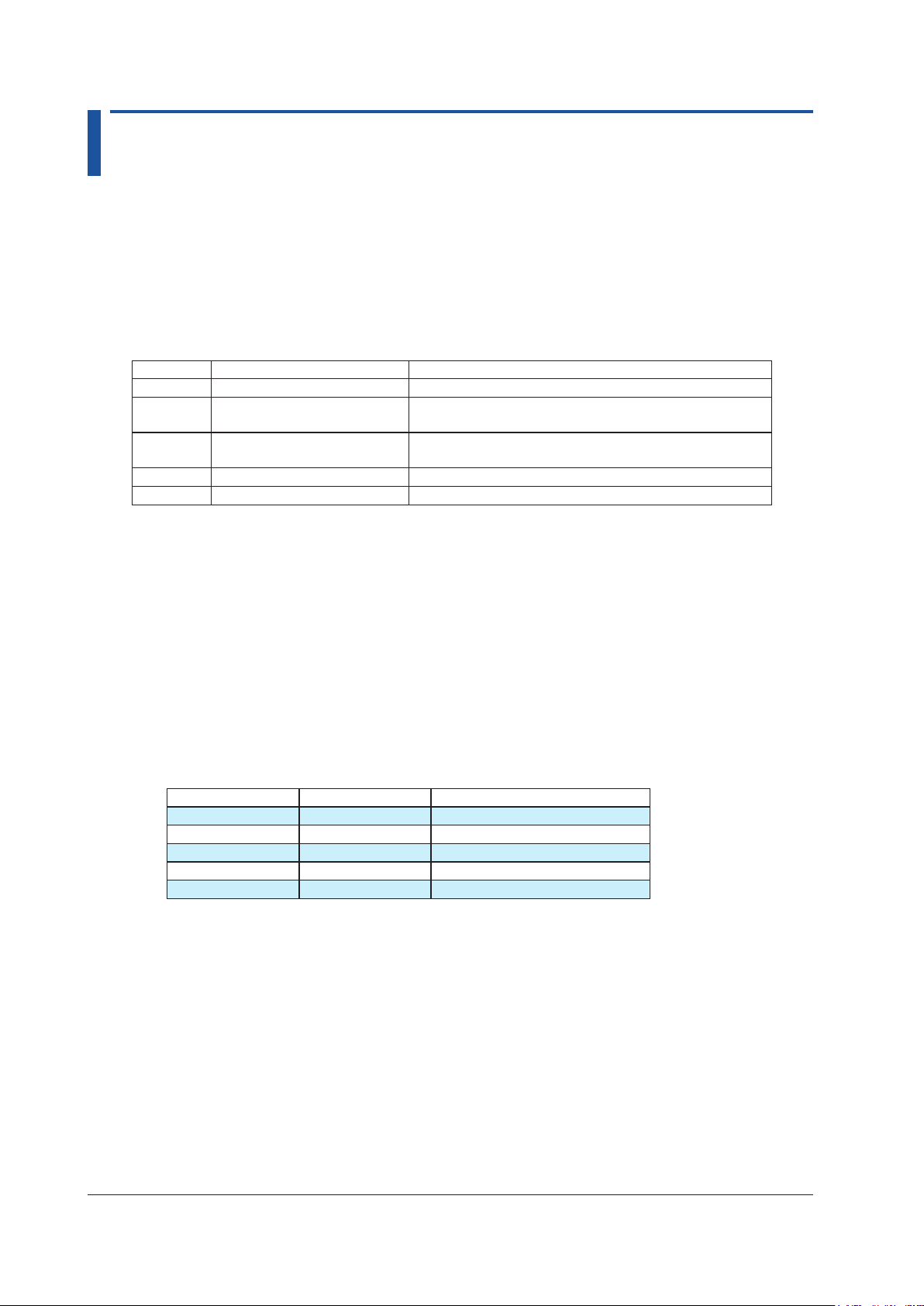

1.2 Source Function

The source function generates DC voltage, DC current, resistance, voltage corresponding to the

electromotive force of thermocouples, voltage corresponding to the resistance of RTDs (pseudo-

resistance), and pulse signals.

It can be used simultaneously with measurement functions other than temperature measurement

using thermocouples.

DC Voltage

This function generates the following DC voltages.

Range Source Range Notes

100 mV ±110.000 mV Maximum output current: 10 mA

1-5 V 0.0000 V to +6.0000 V Maximum output current: 10 mA

Can be used as calibration signals for 1, 2, 3, 4, 5 V.

(1-5 V√) 0.0000 V to +6.0000 V Maximum output current: 10 mA

Values for square root operation

5 V ±6.0000 V Maximum output current: 10 mA

30 V ±33.000 V Maximum output current: 1 mA

1-5 V Range

The interval between 0% and 100% is equally divided by four, and the 0%, 25%, 50%, 75%,

and 100% values are output.

With the default settings, you can change the output between 1 V, 2 V, 3 V, 4 V, and 5 V in 1

V steps by pressing the UP or DOWN key. This is convenient when calibrating the five points

from 1 to 5 V.

Square Root Output Function (1-5 V√)

Values corresponding to the square root of 0%, 25%, 50%, 75% and 100% values are

generated. You can change the output using the UP or DOWN key. This can be used as

calibration signals for the square root output of differential pressure transmitters.

Percentage and source value

Percentage 1-5 V source value Square root output (1-5V√)

0% 1.0000 V 1.0000 V

25% 2.0000 V 1.2500 V

50% 3.0000 V 2.0000 V

75% 4.0000 V 3.2500 V

100% 5.0000 V 5.0000 V

1-2

IM CA500-01EN

Page 10

1.2 Source Function

DC Current

This function generates the following DC currents.

Range Source Range Notes

20 mA ±24.000 mA Output voltage: 0 to 20 V

4-20 mA 0.000 mA to 24.00 mA Output voltage: 0 to 20 V

Can be used as calibration signals for 4, 8, 12, 16, 20 mA.

(4-20 mA√) 0.000 mA to 24.00 mA Output voltage: 0 to 20 V

Values for square root operation

4-20 mA

Simulate

4-20 mA Range

The interval between 0% and 100% is equally divided by four, and the 0%, 25%, 50%, 75%,

and 100% values are output.

With the default settings, you can change the output between 4 mA, 8 mA, 12 mA, 16 mA, and

20 mA in 4 mA steps by pressing the UP or DOWN key. This is convenient when calibrating

the five points from 4 to 20 mA.

Square Root Output Function (4-20 mA√)

Values corresponding to the square root of 0%, 25%, 50%, 75% and 100% values are

generated. You can change the output using the UP or DOWN key. This can be used as

calibration signals for the square root output of differential pressure transmitters.

Percentage and source value

Percentage 4-20 mA source value Square root output (4-20 mA√)

0% 4.000 mA 4.000 mA

25% 8.000 mA 5.000 mA

50% 12.000 mA 8.000 mA

75% 16.000 mA 13.000 mA

100% 20.000 mA 20.000 mA

0.000 mA to 24.000 mA External power supply 5 V to 28 V

1

Features

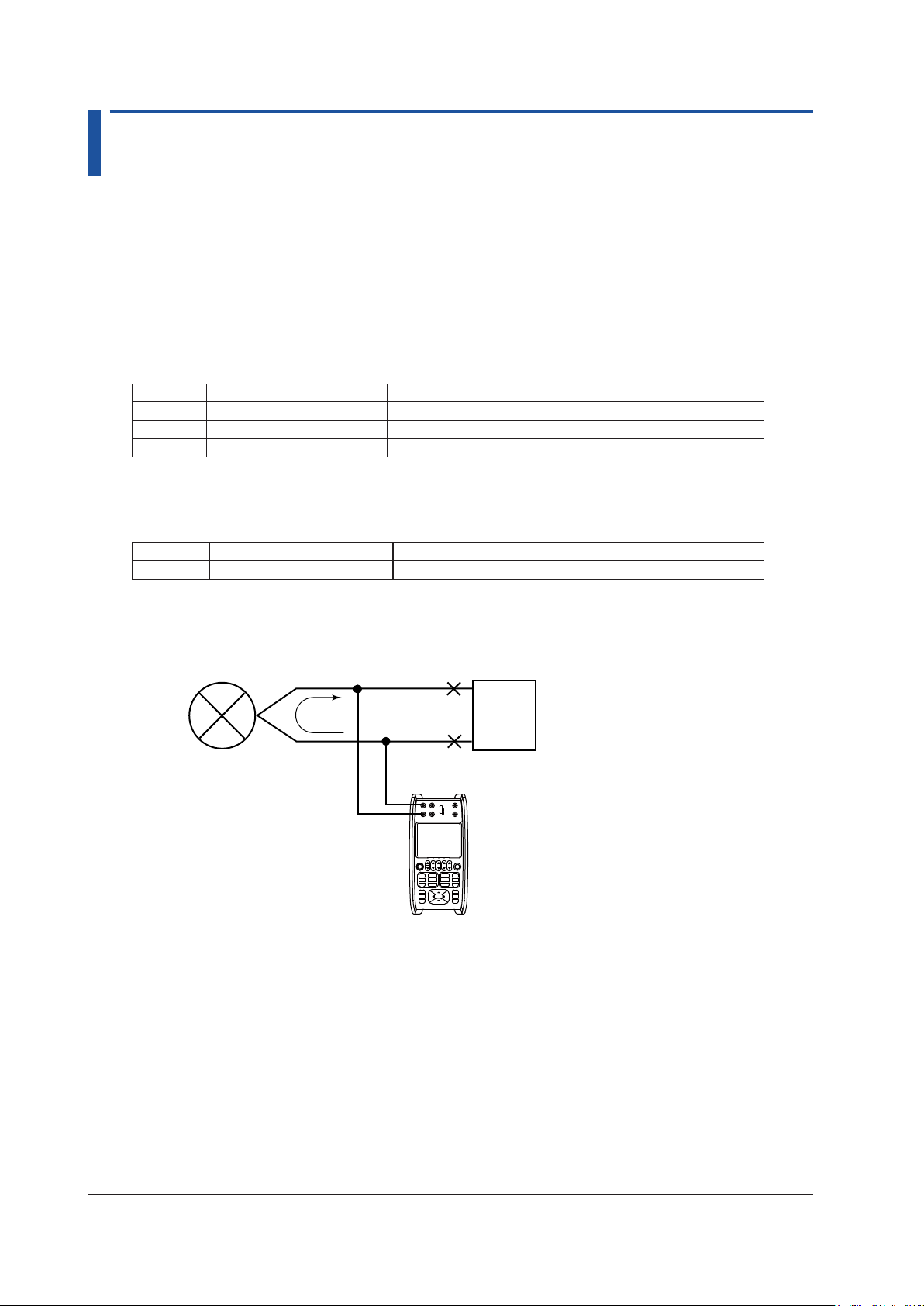

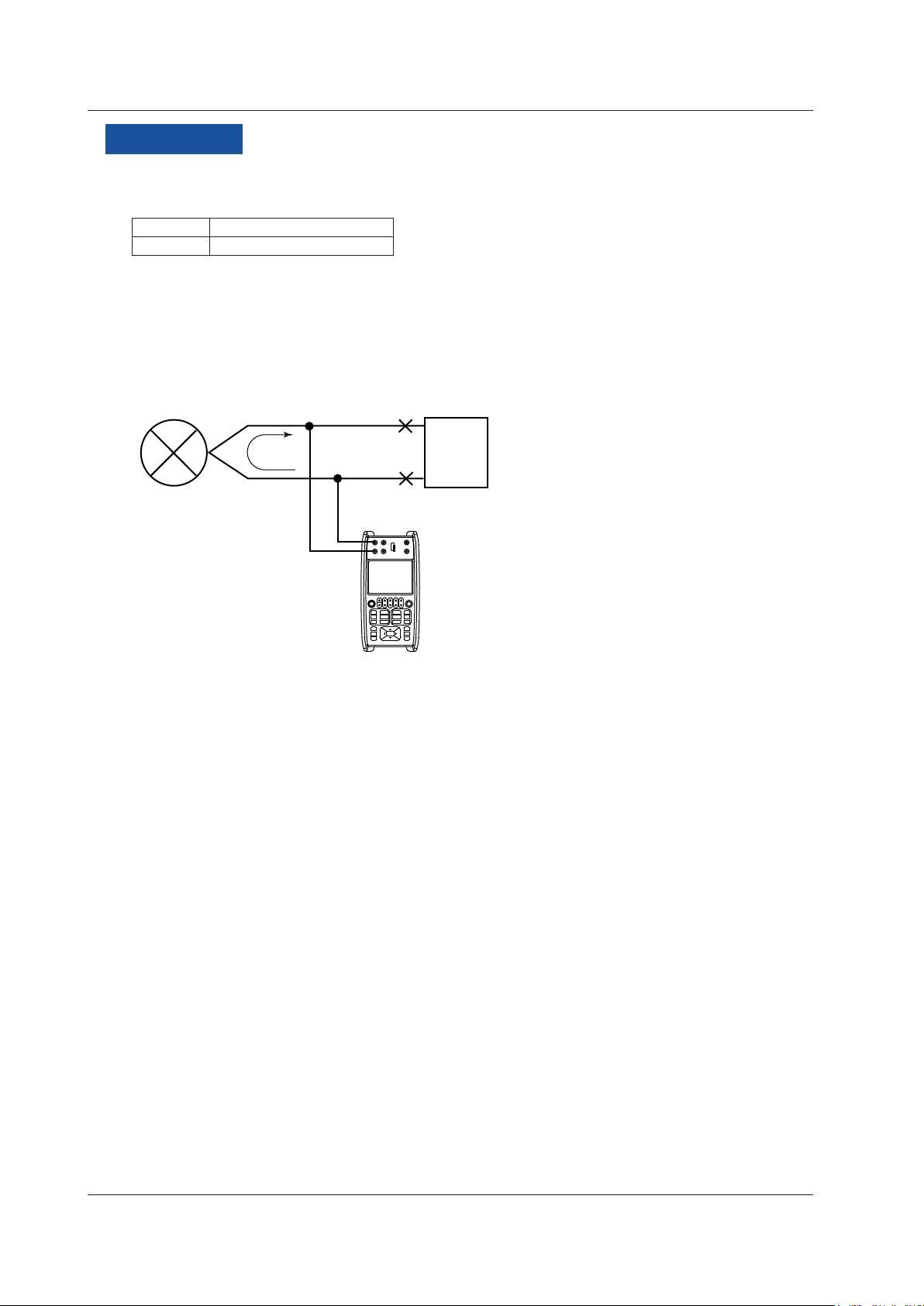

Simulate (20 mA Simulate) Function

You can connect this instrument to a distributor and simulate a two-wire transmitter. This is

valid when the range is set to 4-20 mA Simulate.

CA500/CA550

H

L

4-20mA

+

Distributor

—

IM CA500-01EN

1-3

Page 11

1.2 Source Function

Resistance

This function generates the following resistances.

Range Source Range Notes

400Ω 0.00 Ω ~ 440.00 Ω Allowable measurement current: 0.1 mA to 3 mA

4000Ω 0.0 Ω ~ 4400.0 Ω Allowable measurement current: 0.05 mA to 0.6 mA

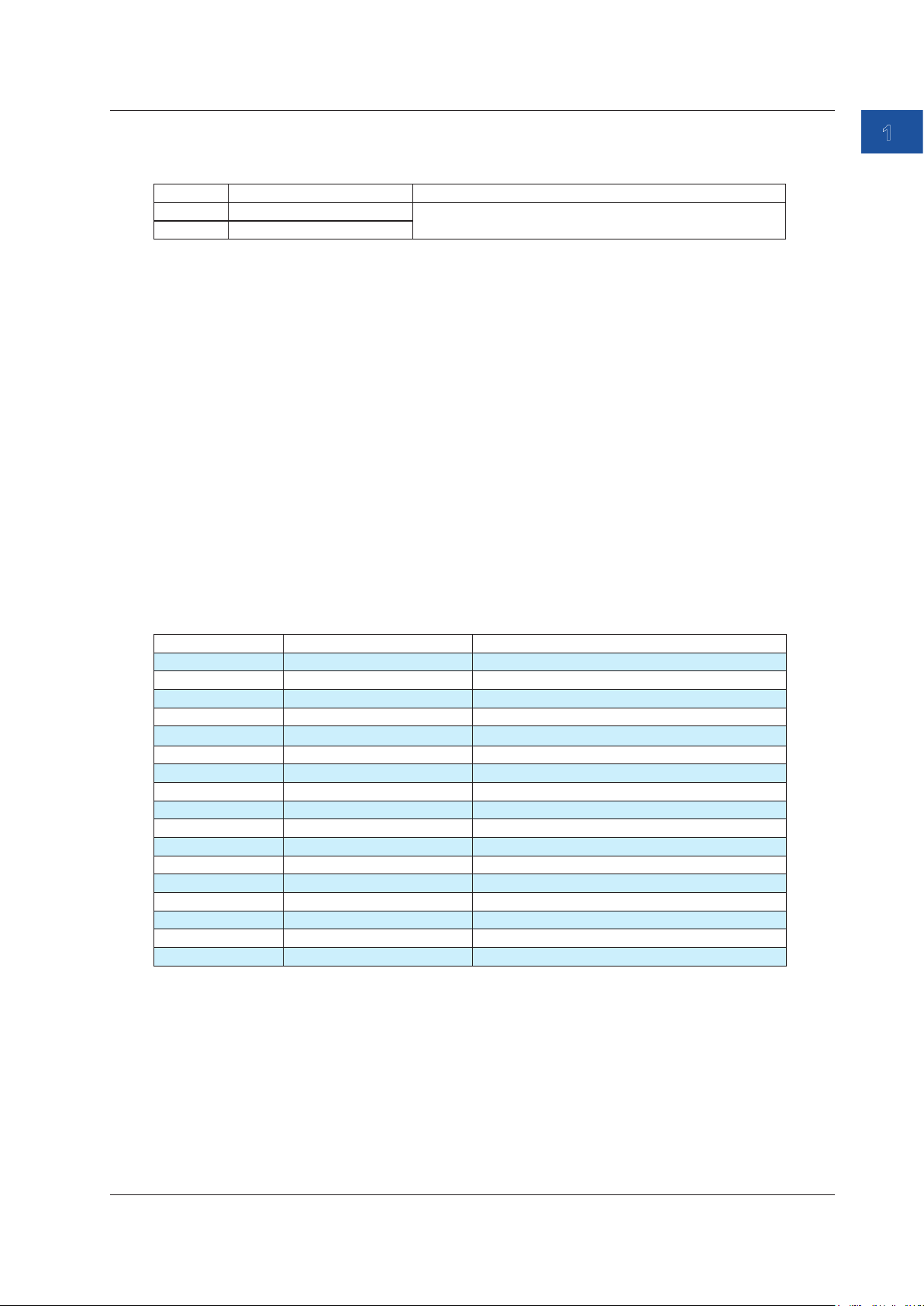

Resistance Source Method

A pseudo-resistance (R=V/I) is sourced by generating a voltage (V=R×I) corresponding to the

resistance [R] set on the instrument across the output terminals for the current for measuring

resistance [I] supplied to the device to be calibrated such as a resistance measuring

instrument and RTD thermometer.

Therefore, this instrument can be used only for instruments that measure pseudo-resistance

using a current for measuring resistance.

How to Source Accurately

• When measuring resistance using a two-wire system, use lead cables with low resistance.

Because the source resistance is calibrated without including the voltage drop of the

leaked cables, the lead cable resistance will result in error.

• To source the resistance accurately, use of the three-wire system or four-wire system.

Calibration target

CA500/CA550

Red

Black

(three-wire

measuring instrument)

H

L

L’

1-4

IM CA500-01EN

Page 12

1.2 Source Function

Thermoelectromotive Force of a Thermocouple

Thermoelectromotive force corresponding to the following temperatures is generated for each

thermocouple type.

Thermocouple Source Range Notes

K -200.0°C to +1372.0°C IEC 60584-1

E -250.0°C to +1000.0°C IEC 60584-1

J -210.0°C to +1200.0°C IEC 60584-1

T -250.0°C to +400.0°C IEC 60584-1

N -200.0°C to +1300.0°C IEC 60584-1

L -200.0°C to +900.0°C DIN 43710

U -200.0°C to +600.0°C DIN 43710

R -20.0°C to +1767.0°C IEC 60584-1

S -20.0°C to +1768.0°C IEC 60584-1

B +600.0°C to +1820.0°C IEC 60584-1

C 0.0°C to +2315.0°C IEC 60584-1

XK -200.0°C to +800.0°C GOST R 8.585-2001

A 0.0°C to +2500.0°C IEC 60584-1

D (W3Re/W25Re) 0.0°C to +2315.0°C ASTM E1751/E1751M-09e1

G (W/W26Re) +100.0°C to +2315.0°C ASTM E1751/E1751M-09e1

PLATINEL II 0.0°C to +1395.0°C ASTM E1751/E1751M-09e1

PR20-40 0.0°C to +1888.0°C ASTM E1751/E1751M-09e1

*: Complies also with JIS C 1602

**: The setting can be changed to comply with IPTS-68 (JIS C 1602 1981).

*, **

*, **

*, **

*, **

*

*, **

*, **

*, **

*

1

Features

Temperature Scale

This instrument complies with ITS-90 and IPTS-68.

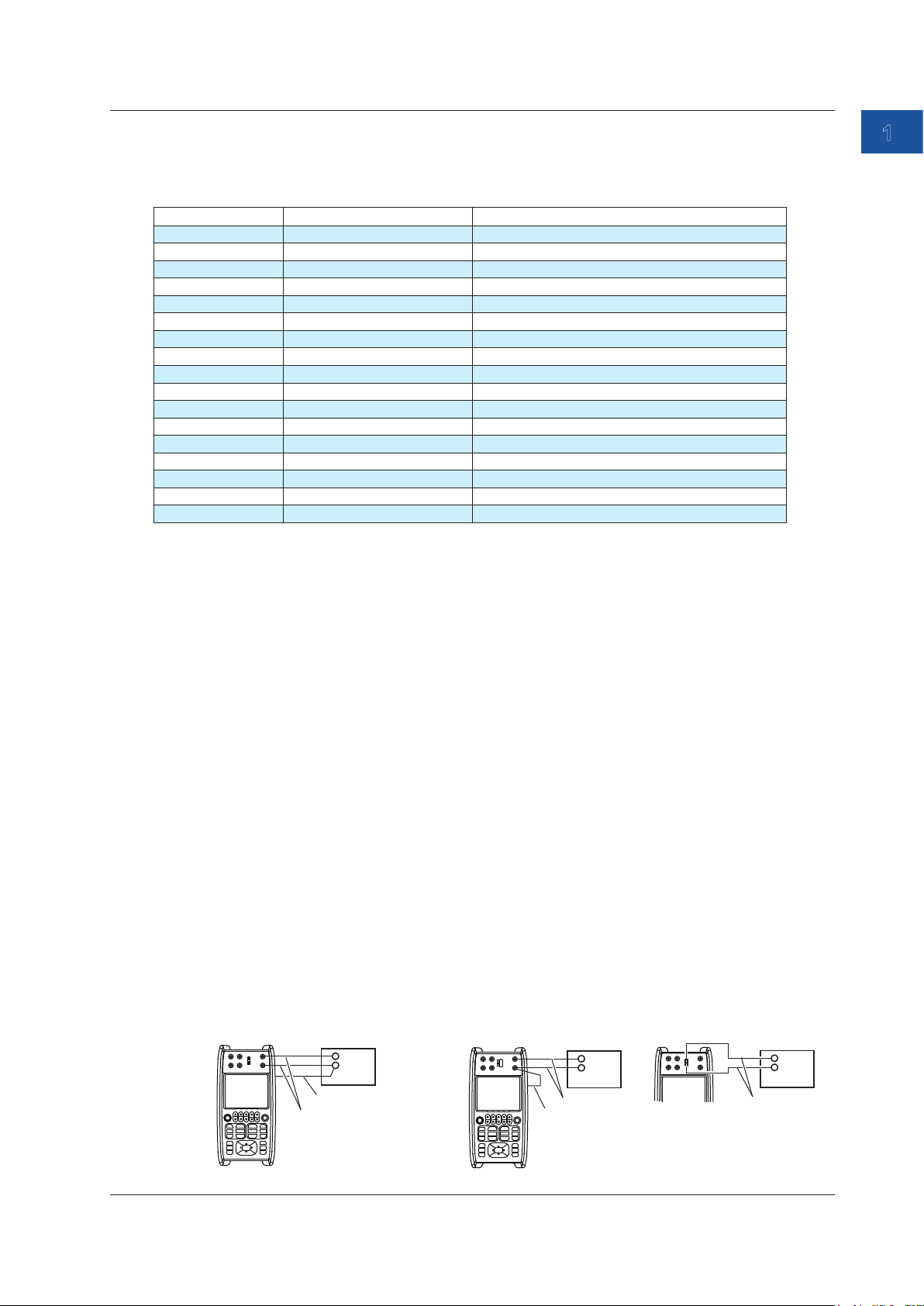

Connection Terminals

This instrument is equipped with the following two types of terminals.

TC-A (TC mini plug)

A thermocouple is connected to the instrument using a thermocouple mini plug set,

sold separately. Reference junction compensation using an external RJ sensor (sold

separately) is not possible.

TC-B (banana plug)

Reference junction compensation using the internal RJ sensor or an external RJ sensor is

possible.

Reference Junction Compensation

The instrument measures the temperature of the contact using an RJ sensor and generates a

voltage based on the temperature component. This instrument can perform reference junction

compensation using the internal RJ sensor or an external RJ sensor.

When an instrument with a built-in reference junction temperature compensation is to be

calibrated, the reference junction temperature of the device to be calibrated is measured using

an external RJ sensor.

Calibrating only the thermometer

CA500/CA550

H

L

Calibration target

H

L

Calibrating including the thermocouple

CA500/CA550

Calibration target

H

L

H

L

H

L

H

L

IM CA500-01EN

External RJ sensor

Source/measurement

lead cable

Thermocouple

Internal RJ sensor or

external RJ sensor

Internal RJ sensor

Thermocouple

1-5

Page 13

1.2 Source Function

Resistance of an RTD

Resistance corresponding to the following temperatures is generated for each RTD type.

RTD Source Range Notes

PT100 (PT100 (3851)) -200.0°C to 800.0°C EC 60751

JPT100 (PT100 (3916)) -200.0°C to 510.0°C JIS C 1604 1989 (JPt100)

PT100 (3850) -200.0°C to 630.0°C JIS C 1604 1989 (Pt100)

PT100 (3926) -200.0°C to 630.0°C Minco Application Aid #18

PT200 -200.0°C to 630.0°C IEC 60751

PT500 -200.0°C to 630.0°C IEC 60751

PT1000 -200.0°C to 630.0°C IEC 60751

Cu10 -100.0°C to 260.0°C Minco Application Aid #18

Ni120 -80.0°C to 260.0°C Minco Application Aid #18

PT50 -200.0°C to 630.0°C IEC 60751

PT50G -200.0°C to 800.0°C GOST R 8.625-2006

PT100G -200.0°C to 630.0°C GOST R 8.625-2006

Cu50M -180.0°C to 200.0°C GOST R 8.625-2006

Cu100M -180.0°C to 200.0°C GOST R 8.625-2006

*

*

*

*

*

*: Complies also with JIS C 1604

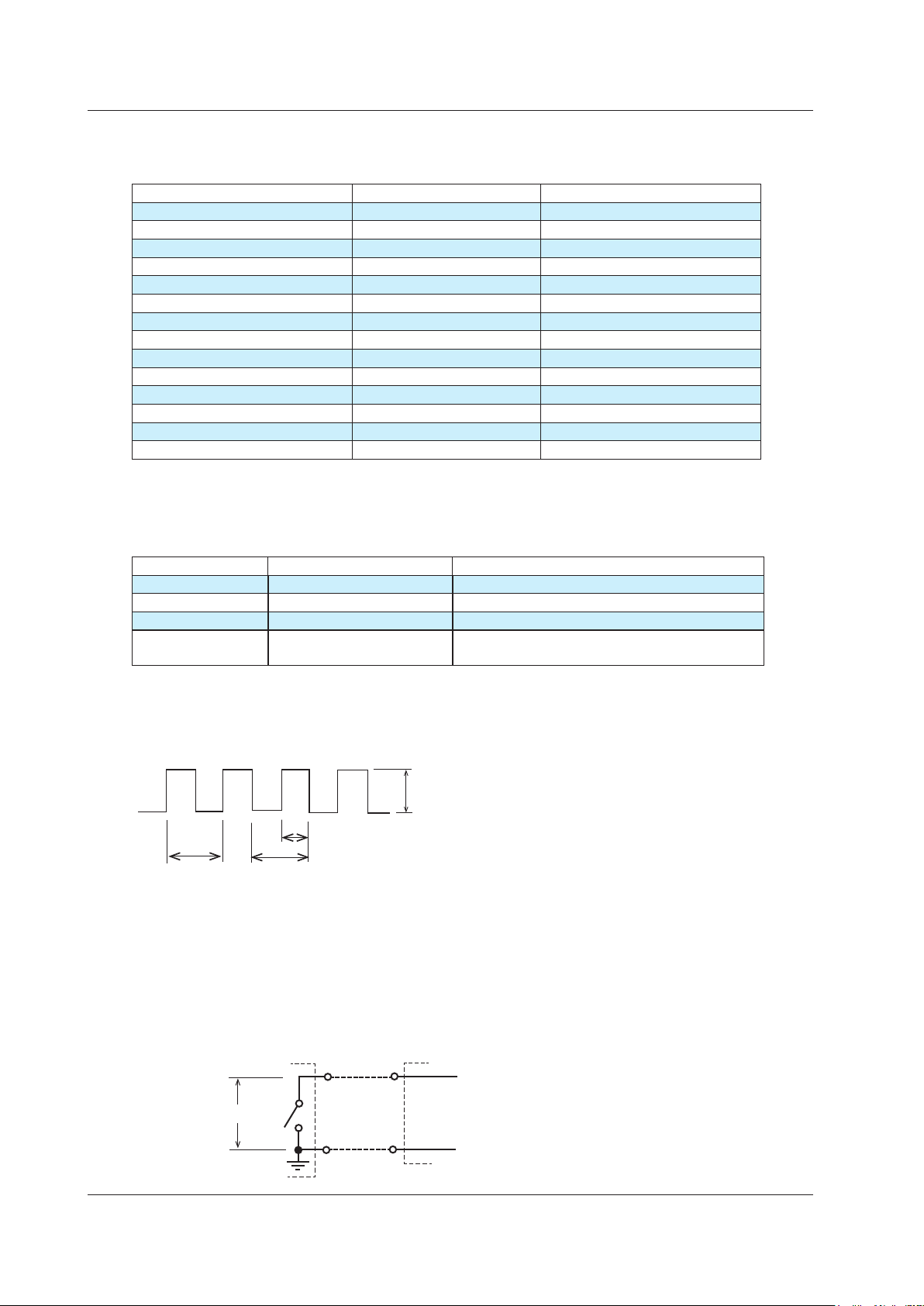

Frequency

Pulse signals are generated at the following frequencies.

Range Source Range Notes

500 Hz 1.00 Hz to 550.00 Hz

5000 Hz 1.0 Hz to 5500.0 Hz

50 kHz 0.001 kHz to 50.000 kHz

CPM 1.0 to 1100.0/min Generates a signal with a specified number of

pulses per minute

The sweep function cannot be used.

For source range CPM, you can set the frequency using the number of pulses to generate per

minute.

This instrument outputs waveforms at 50% duty cycle.

1-6

Amplitude

h

1 pulse

Frequency = pulse count/s, CPM = pulse count/min

Duty: (h/t)×100%

t

Contact Output

If the contact output is set on during frequency output, a contact signal can be output with the

specified frequency or number of pulses.

The instrument’s

output terminal

H

0.5 to 30 VDC

L

Input terminal of the

output destination device

H

L

IM CA500-01EN

Page 14

1.2 Source Function

0% and 100% Values

These values become references for the source values when dividing or sweeping the source

values.

When the source is to be generated in divisions, the interval between 0% and 100% is divided

equally by a specified number, and the source value is changed stepwise through key operation.

In a linear sweep, the source value is varied linearly from 0% to 100% or from 100% to 0% over a

specified time period.

In a step sweep, the interval from 0% to 100% is divided equally by a specified number, and the

source value is automatically varied stepwise.

Number of Divisions

The interval between 0% and 100% is divided equally by a specified number, and the source value

is changed stepwise by operating the cursor keys (UP and DOWN keys).

For example, if 0% is set to 50 mV, 100% is set to 100 mV, and the number division is set to 4,

each time you press UP, the source value changes as follows: 0% (50 mV), 25% (62.5 mV), 50% (75

mV), 75% (87.5 mV), 100% (100 mV).

When the source range is 1-5V, 1-5V√, 4-20mA, 4-20mA√, or 4-20mA Simulate, the number

divisions is fixed to 4.

1

Features

Display Switching

You can select the value to show on the main display of the function 2 display area between a

physical value such as a voltage or a percentage.

In the case of a temperature measurement using a thermocouple or RTD, the thermal electromotive

force or resistance can be shown in sub display 2. Moreover, in the case of a temperature

measurement using a thermocouple, the reference junction temperature can also be shown.

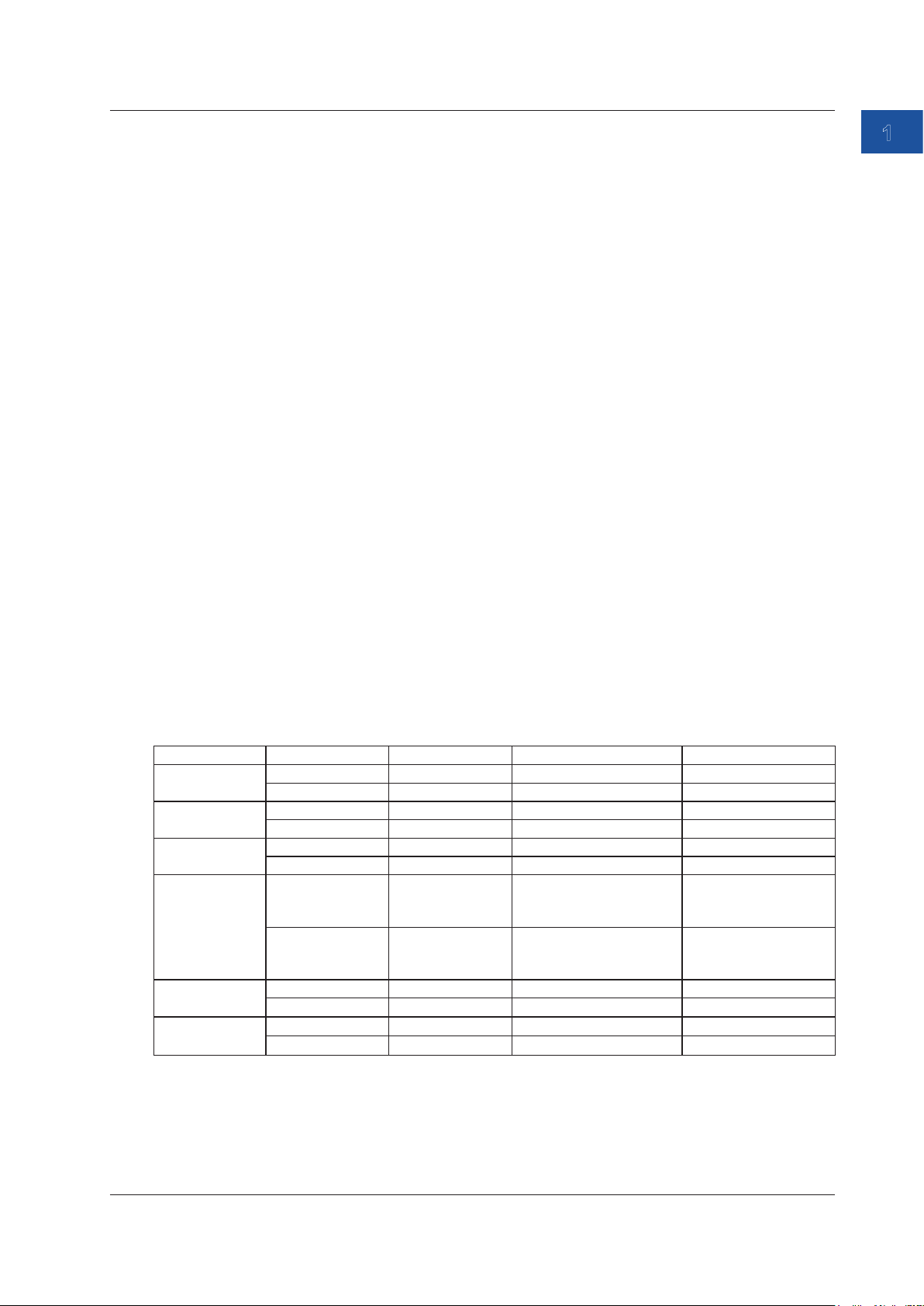

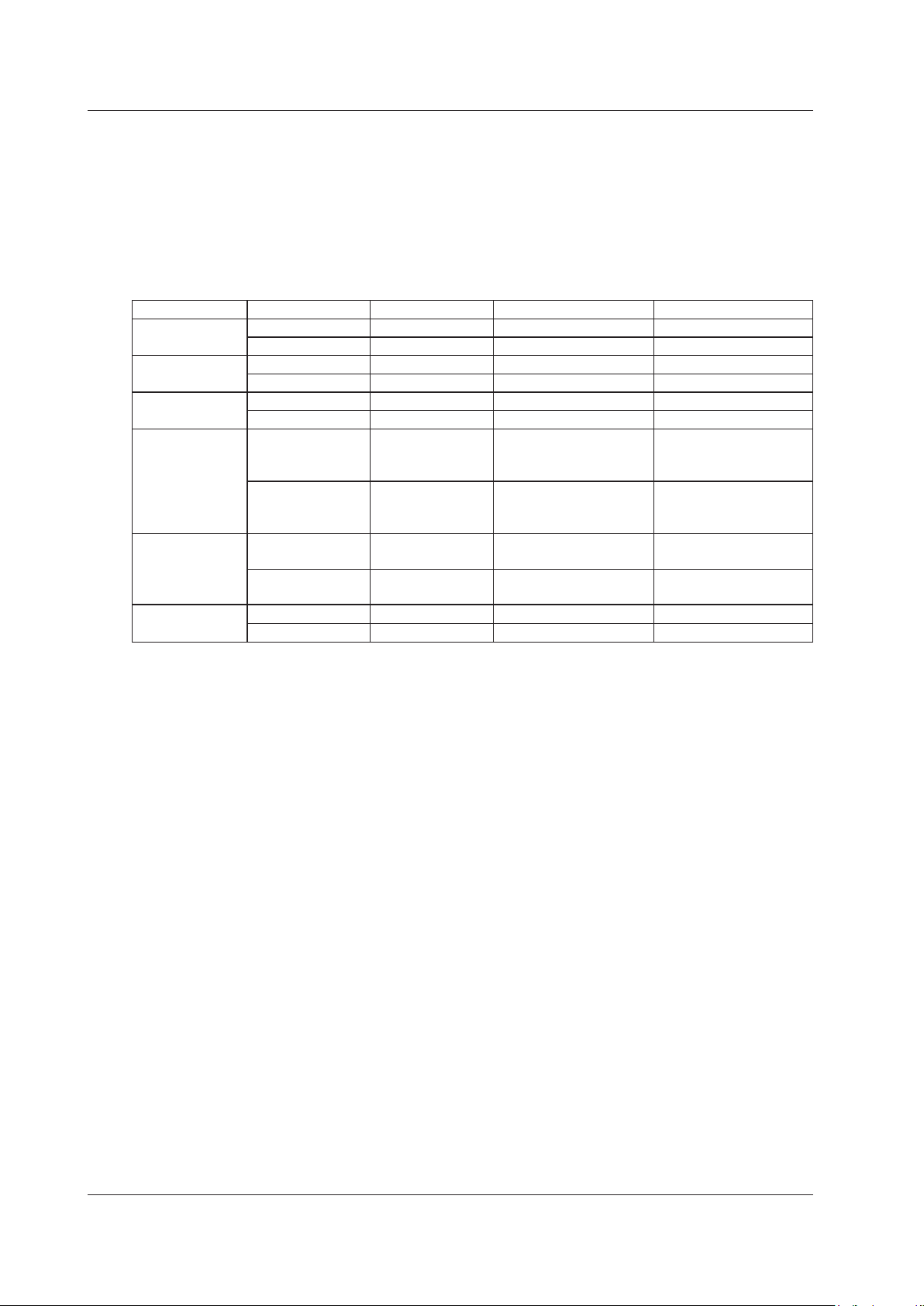

Function Main display Sub display 1 Sub display 2 Sub display 3

DC voltage Source value Percentage — —

Percentage Source value — —

DC Current Source value Percentage — —

Percentage Source value — —

Resistance Source value Percentage — —

Percentage Source value — —

Thermocouple Source value (°C) Percentage Source value(voltage) Temperature monitor

(reference junction

temperature)

Percentage Source value (°C) Source value(voltage) Temperature monitor

(reference junction

temperature)

RTD Source value (°C) Percentage Source value (resistance ) —

Percentage Source value (°C) Source value (resistance ) —

Frequency Source value Percentage — —

Percentage Source value — —

The source value or percentage shown in the main display area can also be changed directly using

arrow keys.

IM CA500-01EN

1-7

Page 15

1.3 Sweep function

The source value can be varied according to a process set in advance.

There are three types: linear sweep, step sweep, and program sweep.

This cannot be used when the source function is set the frequency.

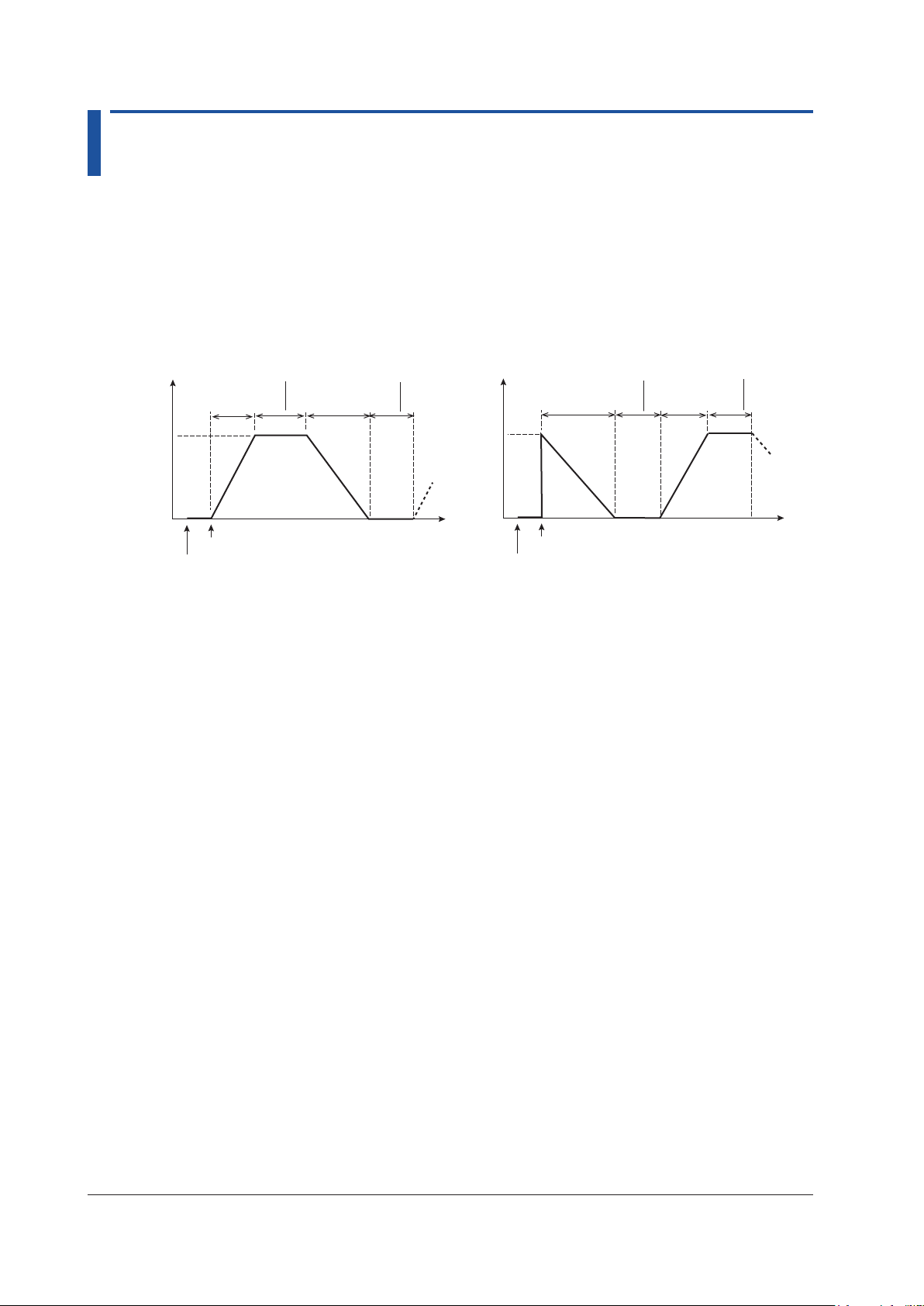

Linear Sweep

The source value is varied linearly from 0% to 100% (sweep up) or from 100% to 0% (sweep

down).

Source

value

100%

0%

Interval

Sweep time

(rise time)

Sweep start (UP key)

Output on

time

Sweep time

(fall time)

Interval

time

Source

value

Time

100%

0%

Interval

time

Sweep time

(fall time)

Sweep start (DOWN key)

Output on

Sweep time

(rise time)

Interval

time

Time

Sweep Time

The time period during which the source value is varied. You can set the rise time and fall time

separately.

Interval Time

The time period during which the source value is held when the source value reaches 0% or

100% after sweeping.

1-8

IM CA500-01EN

Page 16

Output on (OUTPUT key)

1.3 Sweep Function

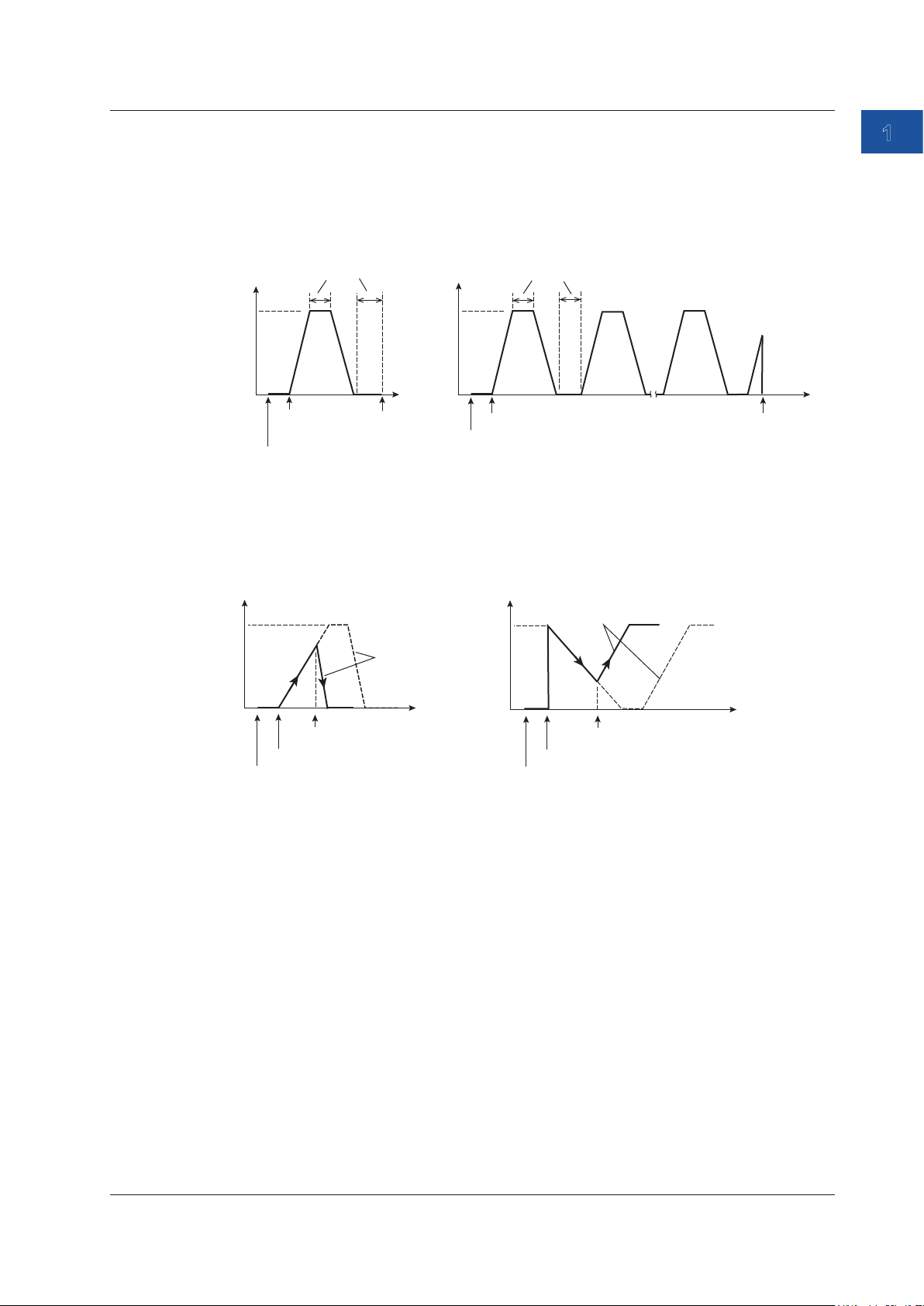

Repetition

Sweeping is repeated until the source is turned off. If sweeping is performed for one iteration,

sweeping stops automatically when the interval time elapses after sweeping.

Repetition: Off

Source

value

100%

0%

Sweep start

(UP key)

Interval

time

Repetition: On

Source

value

100%

0%

Time

Sweep stop

Interval time

Sweep start (UP key)

Output on (OUTPUT key)

Output off

(OUTPUT key)

Time

Operation While Sweeping Is in Progress

If you press UP or DOWN while sweeping is in progress (including the interval time) the suite

direction changes.

1

Features

Sweep up->Sweep down

100%

Same slope

0%

DOWN key

Sweep start (UP key)

Output on (OUTPUT key)

Sweep down->Sweep up

100%

0%

Output on (OUTPUT key)

Same slope

UP key

Sweep start

(DOWN key)

If you press OUTPUT while sweeping is in progress, the source turns off.

IM CA500-01EN

1-9

Page 17

1.3 Sweep Function

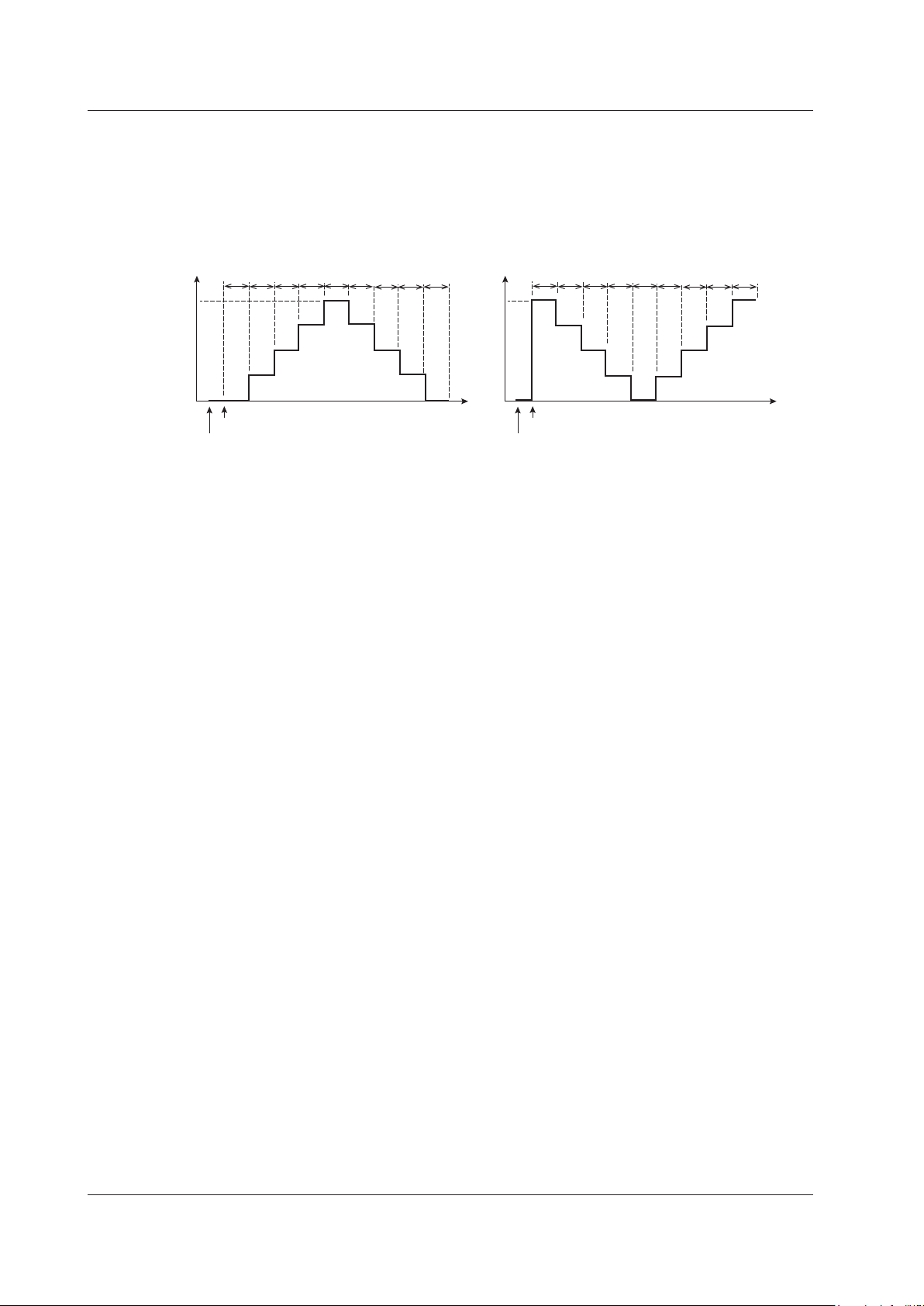

Step Sweep

The source value interval from 0% to 100% is divided equally by a specified number, and the

source value is varied stepwise.

The source time of each step is set with interval time.

Source

value

100%

0%

t

Sweep start (UP key)

Output on

t

t

t: Interval time

t

t

t

Source

t

Time

value

100%

0%

t

t

t

Sweep start (DOWN key)

Output on

t t

t

t: Interval time

t t t

t

t

Number of Divisions

The source value interval from 0% to 100% is divided by the specified number. The variation

of each step is given by

Variation = (100% source value - 0% source value)/number of divisions.

Given 0% source value = 1 V, 100% source value = 5 V, number of divisions = 4,

(5 V-1 V)/4 = 1 V.

The source value is stepped up or down by 1 V.

Interval Time

The time period during which the source value of each step is held.

Time

Repetition

Sweep up->Sweep down or Sweep down->Sweep up can be performed once to complete the

sweep, or this cycle can be repeated until the output is turned off.

Saving Data

After sweeping, source values, measure values, and other data can be saved to files.

For details, see section 1.6, “Saving and Loading CA500 Data”, or section 1.7, “Saving and

Loading CA550 Data”.

1-10

IM CA500-01EN

Page 18

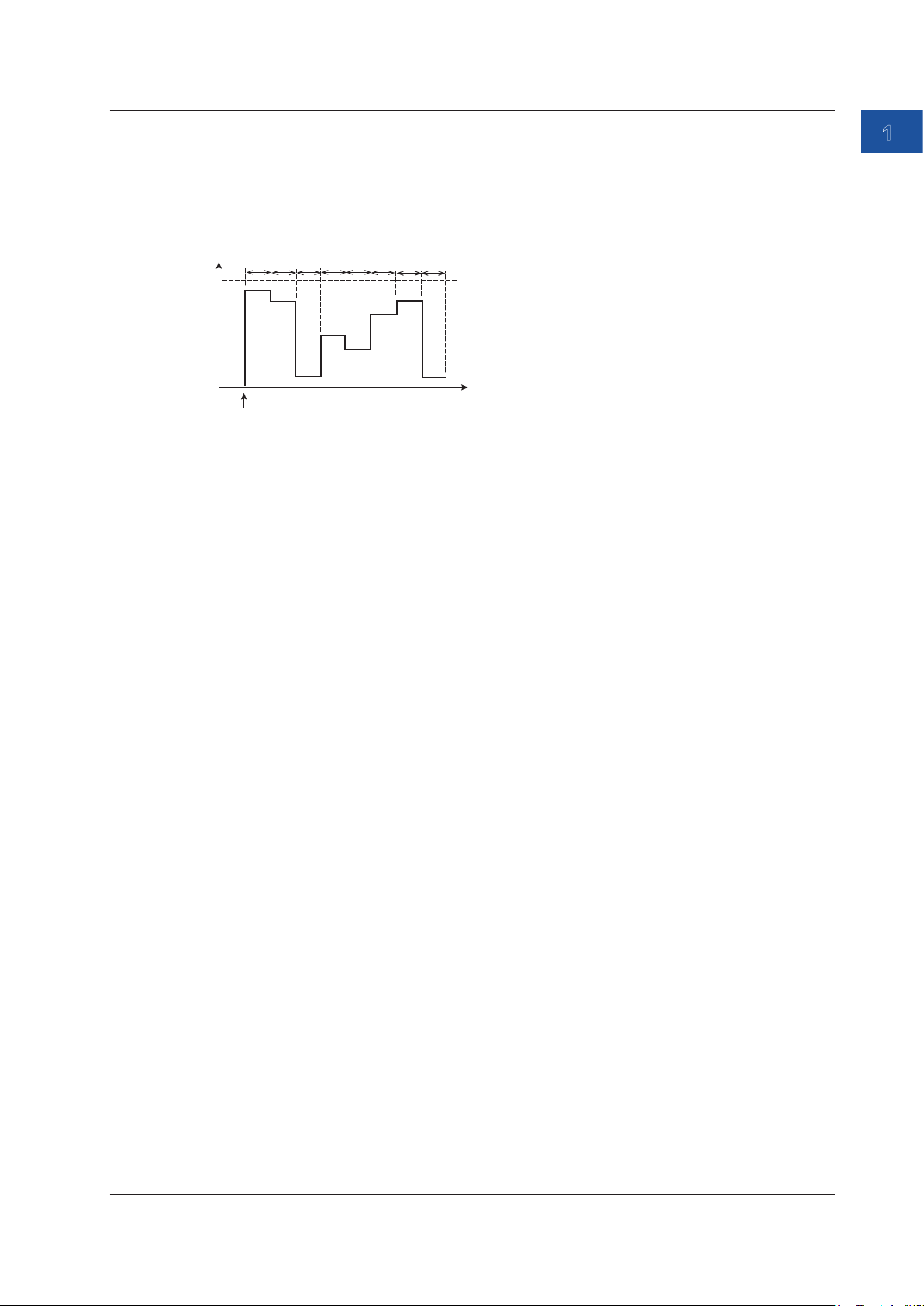

1.3 Sweep Function

Program Sweep

The CA500 and CA550 generate up to 10 and 20 specified values, respectively, in order by

switching.

You can set source values to match specific calibration points.

2

Source

value

100%

0%

1

t

Output on

t

Interval Time

The time period during which each source value is held.

Source Number

You can assign source values to each number from 1 to 10 on the CA500 and 1 to 20 on the

CA550.

When the output is turned on, the specified source values are generated in order from source

number 1.

The source time of each source number is the interval time.

4

3

t

5

t

t

7

6

t

t

Source number

8

t

Interval time

Time

1

Features

Saving Data

After sweeping, source values, measure values, and other data can be saved to files.

For details, see section 1.6, “Saving and Loading CA500 Data”, or section 1.7, “Saving and

Loading CA550 Data”.

Calibration Target Information (CA550)

On the CA550, you can set the model number, serial number, tag number, and loop name of

the device to be calibrated and include them in the saved data.

IM CA500-01EN

1-11

Page 19

1.4 Measurement Function

The measurement function measures DC voltage, DC current, resistance, temperature, and pulse

signals.

It can be used simultaneously with source functions other than temperature measurement using

thermocouples.

Temperature measurement using thermocouples can be performed simultaneously with another

measurement.

DC voltage

This function measures the following DC voltages.

Range Measurement Range Notes

100 mV ±110.000 mV Input resistance: 1 GΩ or more

5 V ±6.0000 V Input resistance: Approx.1 MΩ

50 V ±55.000 V Input resistance: Approx.1 MΩ

DC Current

This function measures the following DC currents.

Range Measurement Range Notes

50 mA ±60.000 mA Input resistance: 10 Ω or less

Loop Power

A loop test can be performed by applying a constant voltage of 24 VDC to a two-wire

transmitter and measuring the transfer signal.

—

H

L

Distributor

+

Two-wire transmitter

4-20mA

24VDC

CA500/CA550

1-12

IM CA500-01EN

Page 20

1.4 Measurement Function

Resistance

This function measures the following resistances.

Range Measurement Range Notes

400Ω 0.00 Ω ~ 440.00 Ω

4000Ω 0.0 Ω ~ 4400.0 Ω

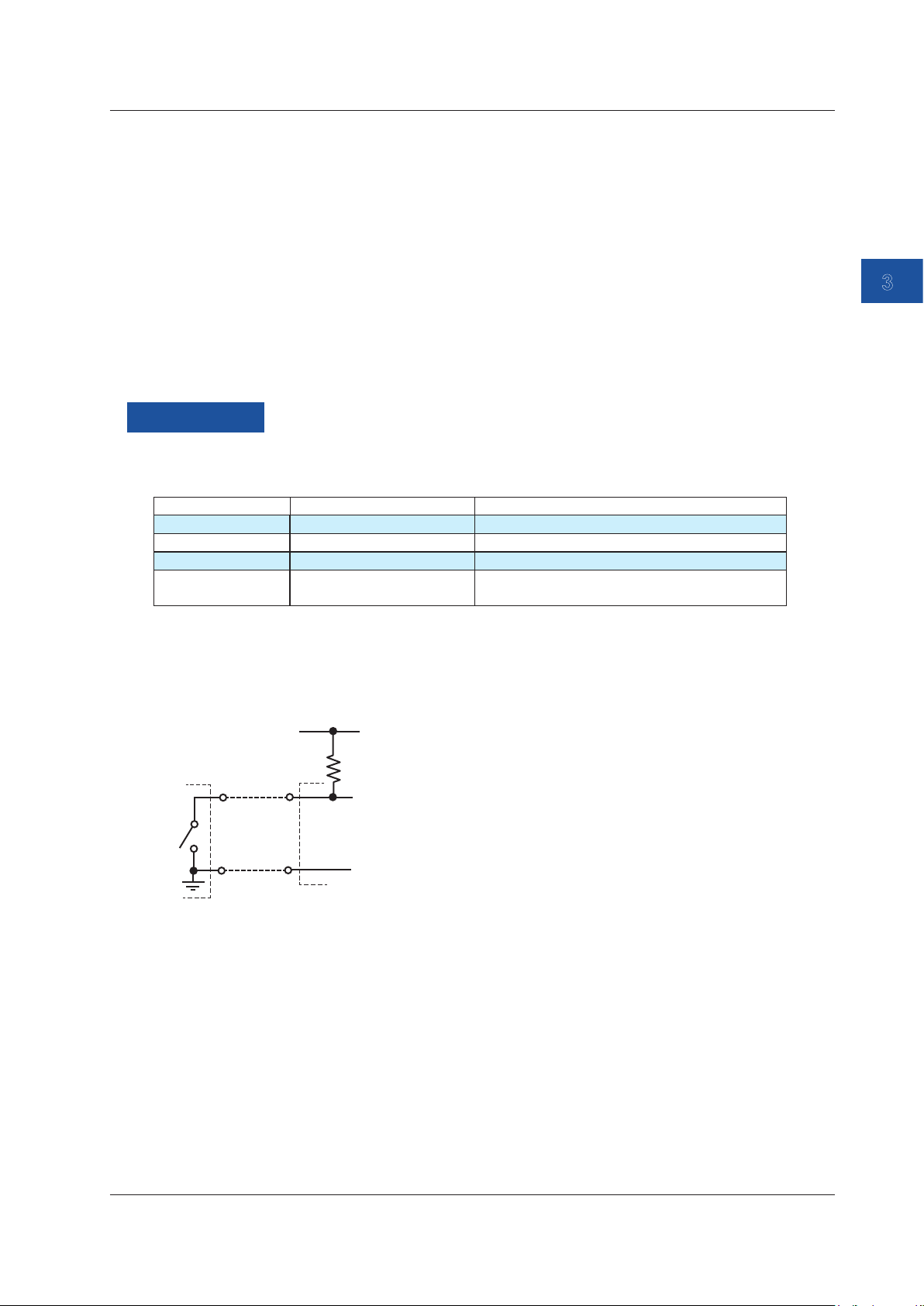

Wiring Systems

The following wiring systems are available: two-wire, three-wire, and four-wire.

Two-wire system: Because measurements include the resistance of measurement lead

cables and contact resistance, errors become large. Use this when the

resistance of the DUT is sufficiently larger then the resistance of the

measurement lead cables and contact resistance.

Three-wire system: By making the length of the three measurement lead cables the same,

measurements can be made without hardly being affected by the

resistance of the lead cables.

Four-wire system: Measurements can be made by eliminating the resistance of measurement

lead cables and contact resistance. Use this when you want to make

accurate measurements.

Voltage applied current measurement method

Typical values: 1 mA@0 Ω, 781 μA@400 Ω, 240 μA@4 kΩ

1

Features

Temperature Measurement Using Thermocouples

Temperature is measured using the following thermocouples.

Thermocouple Measurement Range Notes

K -200.0°C to +1372.0°C IEC 60584-1

E -250.0°C to +1000.0°C IEC 60584-1

J -210.0°C to +1200.0°C IEC 60584-1

T -250.0°C to +400.0°C IEC 60584-1

N -200.0°C to +1300.0°C IEC 60584-1

L -200.0°C to +900.0°C DIN 43710

U -200.0°C to +600.0°C DIN 43710

R -20.0°C to +1767.0°C IEC 60584-1

S -20.0°C to +1768.0°C IEC 60584-1

B +600.0°C to +1820.0°C IEC 60584-1

C 0.0°C to +2315.0°C IEC 60584-1

XK -200.0°C to +800.0°C GOST R 8.585-2001

A 0.0°C to +2500.0°C IEC 60584-1

D (W3Re/W25Re) 0.0°C to +2315.0°C ASTM E1751/E1751M

G (W/W26Re) +100.0°C to +2315.0°C ASTM E1751/E1751M

PLATINEL II 0.0°C to +1395.0°C ASTM E1751/E1751M

PR20-40 0.0°C to +1888.0°C ASTM E1751/E1751M

*: Complies also with JIS C 1602

**: The setting can be changed to comply with IPTS-68 (JIS C 1602 1981).

Temperature Scale

This instrument complies with ITS-90 and IPTS-68.

*, **

*, **

*, **

*, **

*

*, **

*, **

*, **

*

IM CA500-01EN

1-13

Page 21

1.4 Measurement Function

Connection Terminals

This instrument is equipped with the following two types of terminals.

TC-A terminal (TC mini plug)

A thermocouple is connected to the instrument using a thermocouple mini plug set, sold

separately. Reference junction compensation using an external RJ sensor (sold separately) is

not possible.

TC-B terminal (banana plug)

Reference junction compensation using the internal RJ sensor or an external RJ sensor is

possible.

Reference Junction Compensation

The instrument measures the temperature of the reference contact using an RJ sensor and

makes measurements based on that temperature.

This instrument can perform reference junction compensation using the internal temperature

sensor or an external RJ sensor.

When using the TC-A mini plug terminal, you cannot use an external RJ sensor.

Burnout

Thermocouple burnout is detected. When a burnout is detected, this instrument displays “B

OUT” on the screen.

Temperature Measurement Using RTDs

Temperature is measured using the following RTDs.

RTD Measurement range Notes

PT100 (PT100 (3851)) -200.0°C to 800.0°C EC 60751

JPT100 (PT100 (3916)) -200.0°C to 510.0°C JIS C 1604 1989 (JPt100)

PT100 (3850) -200.0°C to 630.0°C JIS C 1604 1989 (Pt100)

PT100 (3926) -200.0°C to 630.0°C Minco Application Aid #18

PT200 -200.0°C to 630.0°C IEC 60751

PT500 -200.0°C to 630.0°C IEC 60751

PT1000 -200.0°C to 630.0°C IEC 60751

Cu10 -100.0°C to 260.0°C Minco Application Aid #18

Ni120 -80.0°C to 260.0°C Minco Application Aid #18

PT50 -200.0°C to 630.0°C IEC 60751

PT50G -200.0°C to 800.0°C GOST R 8.625-2006

PT100G -200.0°C to 630.0°C GOST R 8.625-2006

Cu50M -180.0°C to 200.0°C GOST R 8.625-2006

Cu100M -180.0°C to 200.0°C GOST R 8.625-2006

*: Complies also with JIS C 1604

Wiring Systems

The following RTD wiring systems are available: two-wire, three-wire, and four-wire.

Two-wire system: Because the resistance in the lead wires connecting the RTD and the

instrument is included in the measurement, errors become large. Use this when

the RTD and the instrument are close.

Three-wire system: By making the length of the three measurement lead wires connecting the

RTD and the instrument the same, measurements can be made without hardly

being affected by the resistance of the lead cables.

Four-wire system: Measurements can be made without being affected by the resistance in

the lead wires connecting the RTD and the instrument.

1-14

*

*

*

*

*

IM CA500-01EN

Page 22

1.4 Measurement Function

Frequency

This function measures the following frequencies.

Range Measurement range Notes

500 Hz 1.00 Hz to 550.0 Hz

5000 Hz 1.0 Hz to 5500.0 Hz

50 kHz 0.001 kHz to 50.000 kHz

Pulse count 0 to 99999 The number of pulses is counted within a unit

time period.

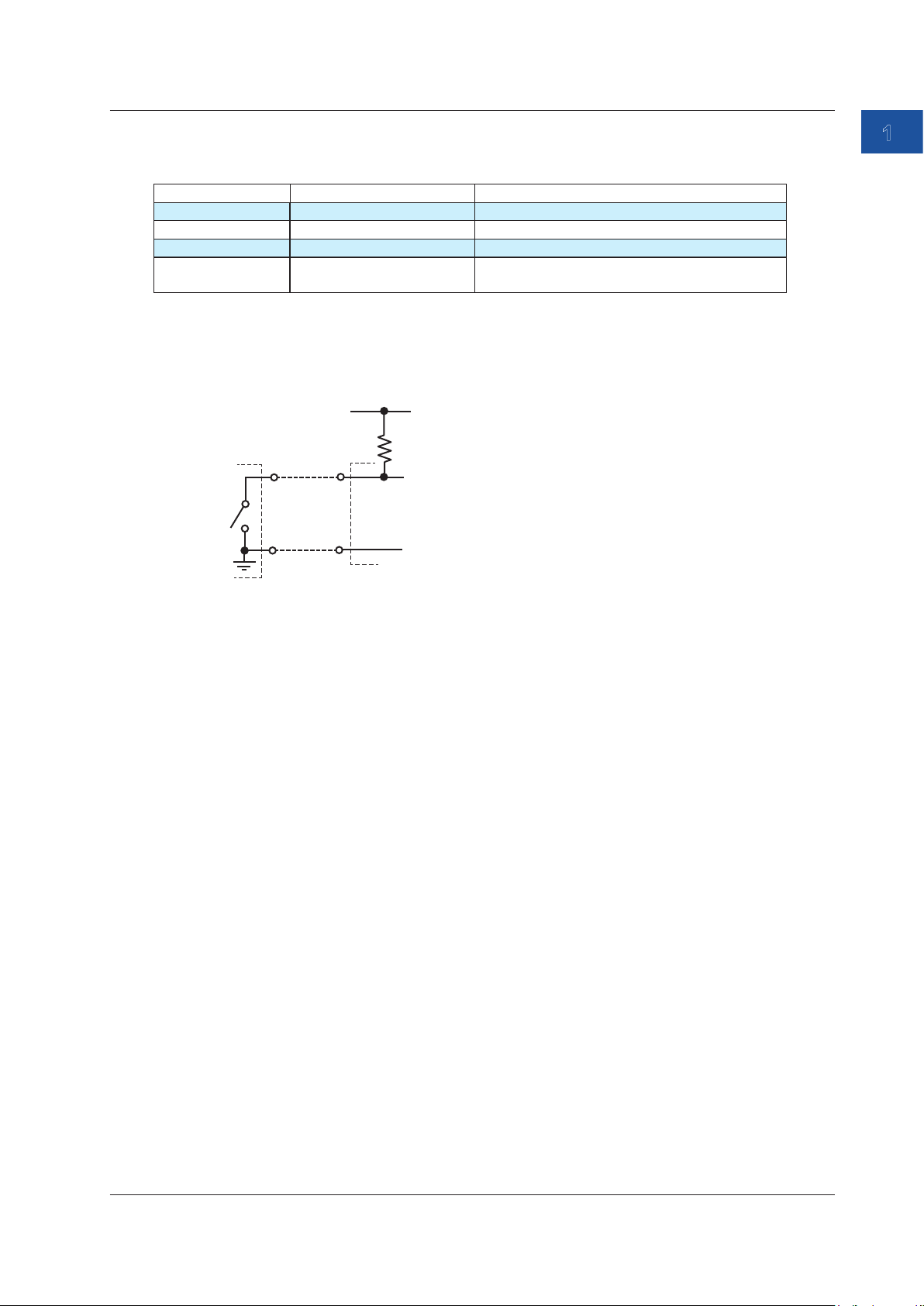

Contact Input

The frequency or the number of signals per minute can be measured through a contact input

using a non-voltage contact.

Vcc (approx. 5 V)

H

L

H

L

Approx. 100 kΩ

1

Features

Measurement

signal

The instrument’s

input terminal

Averaging

Moving average values for every five measured values and the maximum value (MAX) and

minimum value (MIN) of the moving average values are displayed on the screen.

0% and 100% Values

By mapping the output value (specified according to the specifications of the device to be

calibrated) to the 0% or 100% source value of this instrument, you can determine the output value

of the device to be calibrated for the source value.

For example, if the source value of 0% is 1 V and that of 100% is 5 V and the output values are

4 mA and 20 mA when 1 V and 5 V are input to the device be calibrated, assign 4 mA to the

measured value of 0% and 20 mA to that of 100%.

In this situation, the output value (specified according to the specifications of the device to be

calibrated) is 8 mA for a source value of 2 V of this instrument.

4 mA + (20 mA - 4 mA)×(2 V - 1 V)/(5 V - 1 V) = 8 mA

The CA550 calculates the error in the actual output value relative to the output value (specified

according to the specifications of the device to be calibrated) that is mapped to the source value.

Furthermore, this instrument calculates the measurement value percentages relative to the

specified 0% value and 100% value.

IM CA500-01EN

1-15

Page 23

1.4 Measurement Function

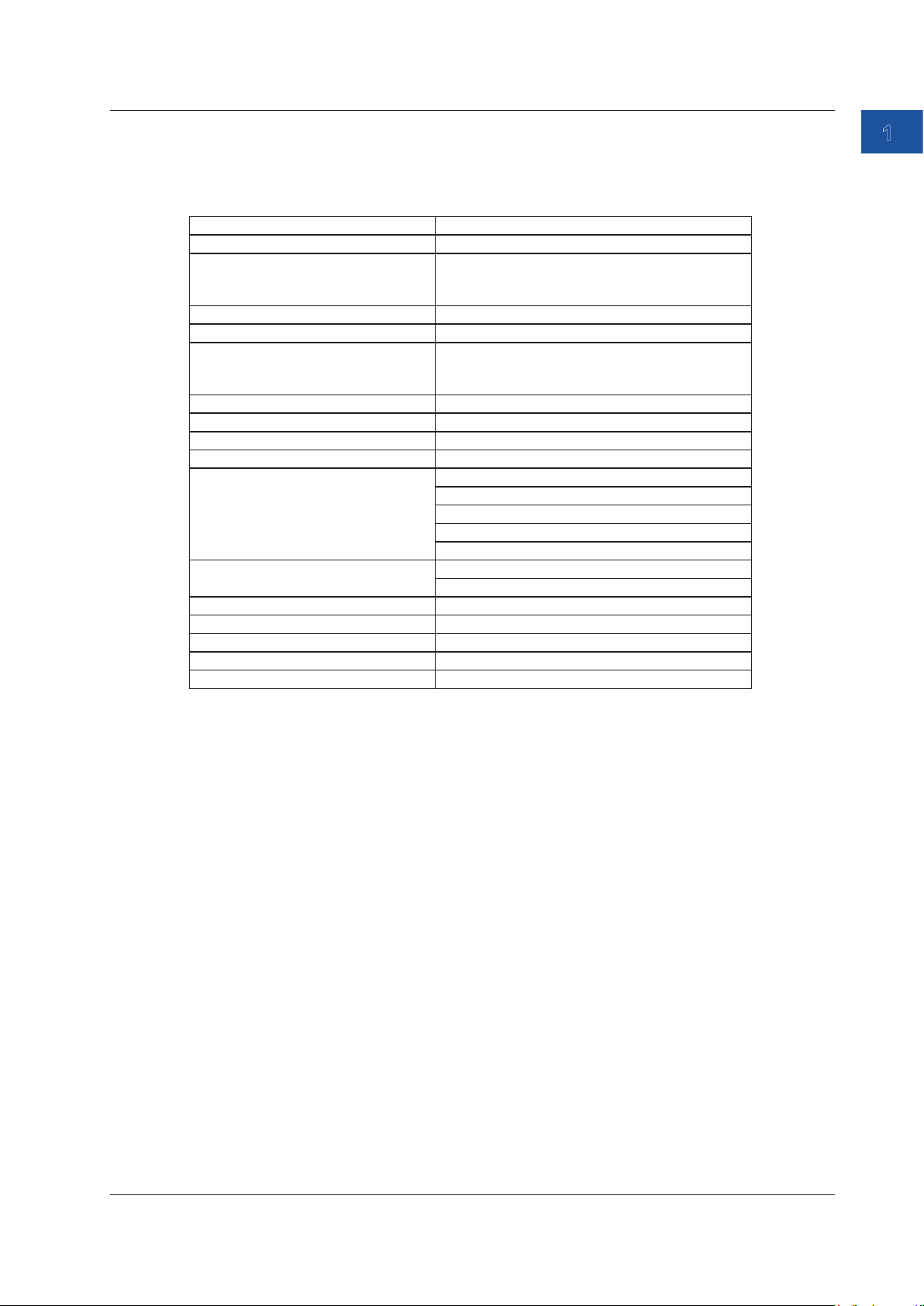

Display Switching

You can select the value to show on the main display of the function 1 display area (function 2

display area for temperature measurements using a thermocouple) between a physical value such

as a voltage or a percentage.

In the case of a temperature measurement using a thermocouple or RTD, the thermal electromotive

force or resistance can be shown in sub display 2. Moreover, in the case of a temperature

measurement using a thermocouple, the reference junction temperature can also be shown.

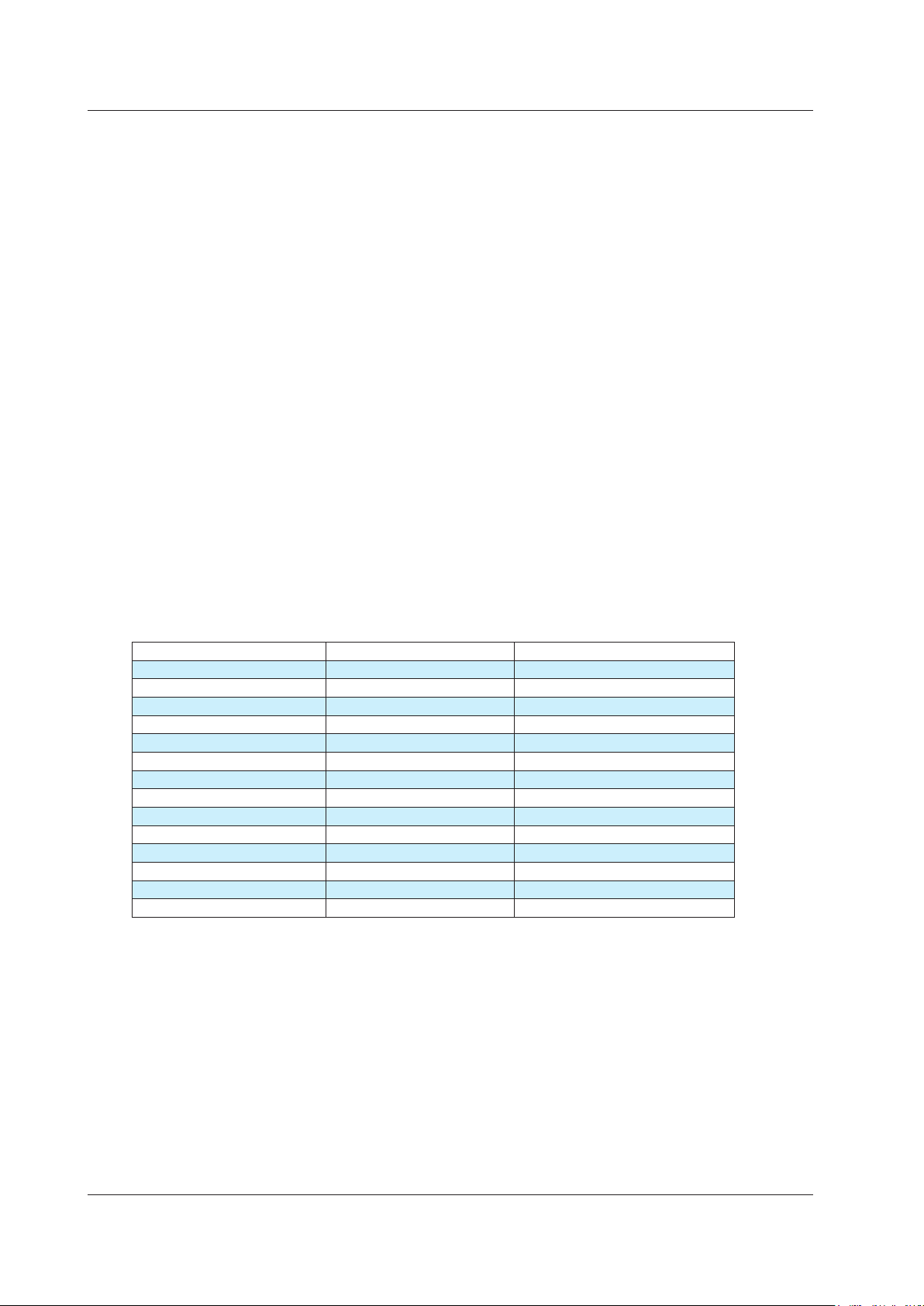

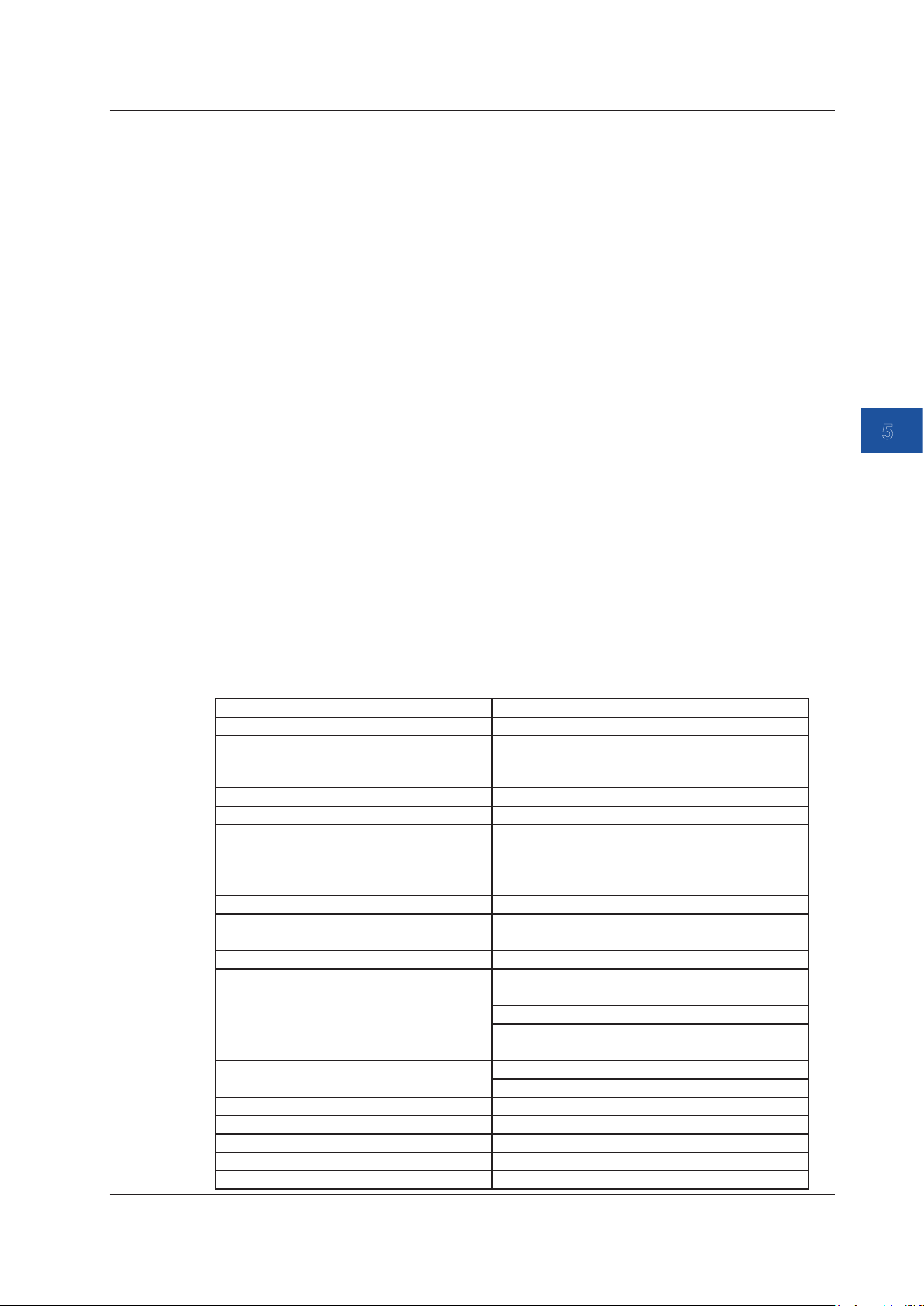

Function Main display Sub display 1 Sub display 2 Sub display 3

DC voltage Measured value Percentage — —

Percentage Measured value — —

DC Current Measured value Percentage — —

Percentage Measured value — —

Resistance Measured value Percentage — —

Percentage Measured value — —

Thermocouple Measured value

(°C)

Percentage Measured value

RTD Measured value

(°C)

Percentage Measured value

Frequency Measured value Percentage — —

Percentage Measured value — —

Percentage Measured value (voltage) Temperature monitor

(reference junction

temperature)

Measured value (voltage) Temperature monitor

(°C)

Percentage Measured value

(resistance)

Measured value

(°C)

(resistance)

(reference junction

temperature)

—

—

1-16

IM CA500-01EN

Page 24

1.5 Calibration Function for Field Instruments

The following functions are available to efficiently calibrate field instruments.

1-5V Range

DC voltages from 1 to 5 V, which are common instrumentation signals, are generated in 1 V steps.

This is useful when calibrating the five input signals: 1 V, 2 V, 3 V, 4 V, and 5 V.

4-20 mA Range

DC currents from 4 to 20 mA, which are common instrumentation signals, are generated in 4 mA

steps.

This is useful when calibrating the five input signals: 4 mA, 8 mA, 12 mA, 16 mA, and 20 mA.

Program Sweep (CA550)

By using the CA550 program sweep function, you can assign instrument information such as the

calibration target model number, serial number, and tag number. The assigned information can be

saved as CSV data along with source values, measured values, and errors.

Because measured values, source values, errors, pass/fail judgment results, and the like can be

saved to a file automatically after a program sweep is completed, this is useful for recording data

before adjustment or data after adjustment.

1

Features

Errors and Pass/Fail Judgment (CA550)

The instrument determines the error in the actual output value of the device to be calibrated relative

to the output value (specified according to the specifications of the device to be calibrated) that is

mapped to the source value.

Moreover, the instrument indicates pass or fail depending on whether the measured value is within

the tolerance set in advance.

You can view the errors and pass/fail judgments in the files saved automatically by the program

sweep function.

IM CA500-01EN

1-17

Page 25

1.6 Saving and Loading CA500 Data

For details on the CA550, see section 1.7.

Saving Data

The following three methods are available to save data.

• Save data by pressing the SAVE key

• Save data automatically after the completion of a step sweep

• Save data automatically after the completion of a program sweep

A total of 100 data entries (memory numbers 1 to 100) can be saved using the above three

methods.

Saving Data Using the SAVE Key

The date and time, information such as the specified function and range, and the measured

value and source value when the SAVE key is pressed are saved.

Auto Save in Step Sweeps or Program Sweeps

The date and time, information such as the specified function and range, the source value and

measured value of each sweep step, and sweep conditions are saved.

Data is saved in a dedicated format of this instrument. Data can be transmitted to a PC using

communication commands.

Memory Number

Saved data is automatically assigned a memory number from 01 to 100.

This also applies when data is saved automatically in a step sweep or program sweep. The data of

each step is assigned a memory number.

Saved Information

The following information is saved.

Function1 Information

Saved data Notes

Measured value

Function

Range

0% value

100% value

Contact input setting

Count time

1-18

IM CA500-01EN

Page 26

1.6 Saving and Loading CA500 Data

Function2 Information

Saved Data Notes

Source value

Function

Range

0% value

100% value

Sweep setting* Interval time

Repeat

Saving Data ON/OFF

Temperature

setting

Frequency setting Amplitude voltage setting

TC measurement

settings

Contact output setting ON/OFF

Thermocouple terminal TC-A/TC-B

TC-B RJC setting ON/OFF

Burnout setting ON/OFF

TC scale standard setting IPTS-68/ITS-90

Temperature unit °C

Pulse count setting

0% value

100% value

* Not saved when using the SAVE key.

Loading Data

Specify the memory number containing the saved data to load the information. The instrument

settings are changed to the loaded settings.

Measured value and source value are shown in the Function1 and Function2 display positions.

1

Features

IM CA500-01EN

1-19

Page 27

1.7 Saving and Loading CA550 Data

For details on the CA500, see section 1.6.

Saving Data

The following three methods are available to save data.

• Save data by pressing the SAVE key

• Save data automatically after the completion of a step sweep

• Save data automatically after the completion of a program sweep

Saving Data Using the SAVE Key

Information such as the specified function and range, and the date and time, measured value,

and source value when the SAVE key is pressed are saved. Each time you press SAVE, the

measurement data is added to the same file. However, a new file is created in the following

cases.

• When a setting is changed on the Device Setup screen

• When the function or range is changed

• When the number of save data points exceeds 2000

• When the power is turned off

Auto Save in Step Sweeps

Information such as the specified function and range, the date and time, source value, and

measured value at the completion of each sweep step, and sweep conditions are saved.

Auto Save in Program Sweeps

Calibration target information, information such as the specified function and range, the date

and time, source value, and measured value at the completion of each sweep step, and

sweep conditions are saved as calibration data of field instruments.

The data format is CSV. You can select a comma, semicolon, or tab for the data separator.

In addition, you can select the measured value to be saved, the decimal symbol of the source

value, and the date and time format.

1-20

IM CA500-01EN

Page 28

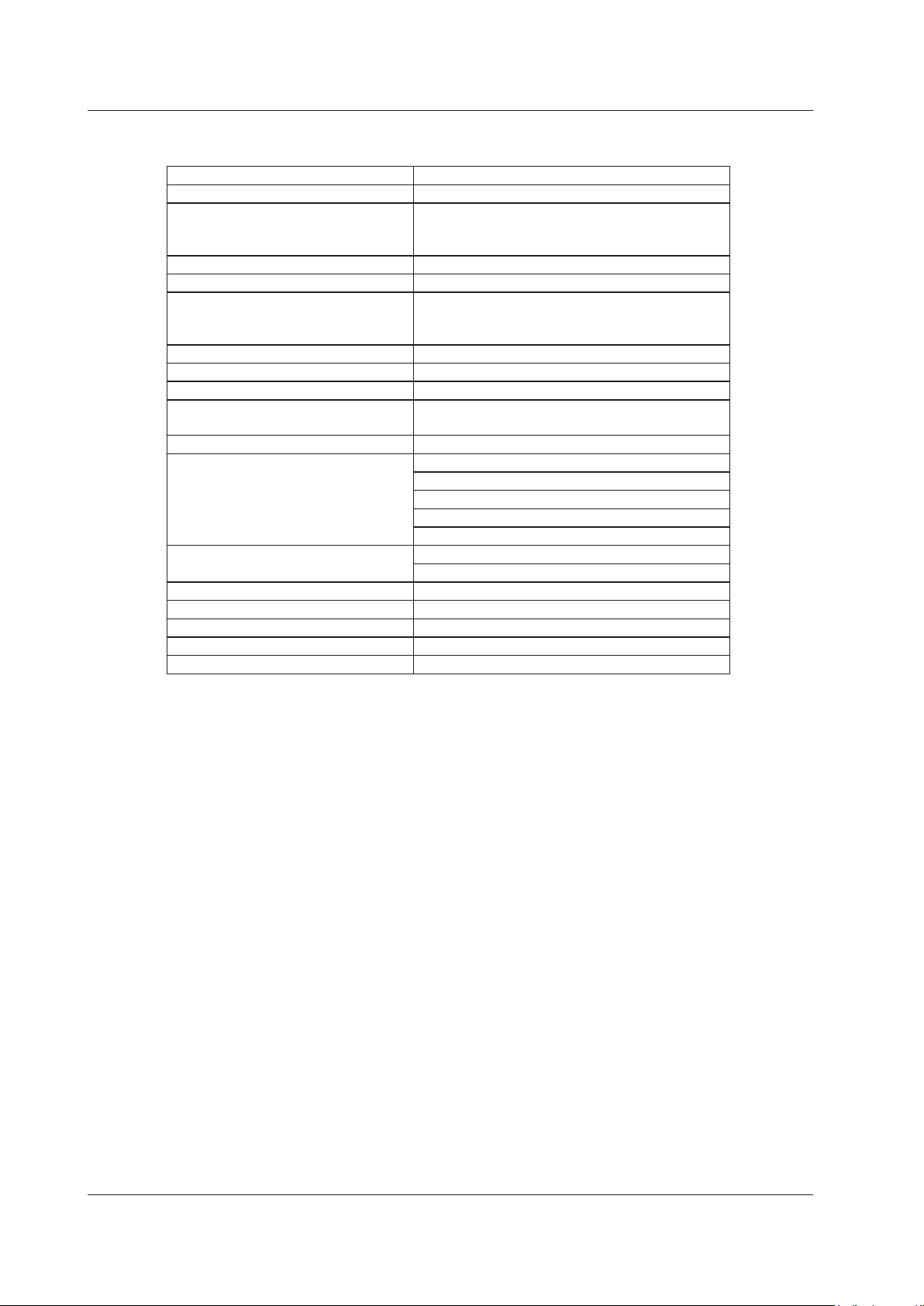

1.7 Saving and Loading CA550 Data

Saved Information

The following information is saved.

Saving Data Using the SAVE Key

Saved Data Notes

MODEL CA550

FILE TYPE 0: Manually saved data using the SAVE key

1: Automatically saved data by a step sweep

2: Calibration data by a program sweep

CSV SEPARATOR 0: Comma, 1: Semicolon, 2: Tab

DECIMAL POINT 0: Period, 1: Comma

DATE FORMAT 0: YYYY/MM/DD

1: DD/MM/YYYY

2: MM/DD/YYYY

Range Measurement range, source range

0% VALUE

100% VALUE

CONTACT (contact I/O) 0: OFF, 1:ON

TC SETTING

(temperature setting)

FREQUENCY SETTING

(frequency setting)

No. Number

DATE Measurement date YYYY/MM/DD

TIME Measurement time hh:mm:ss

MEASURE Measured value

SOURCE Source value

Thermocouple terminal setting. 0: TC-A, 1: TC-B

TC-B RJC setting. 0: OFF, 1:ON

Burnout setting. 0: OFF, 1:ON

TC scale standard setting. 0: ITS-90, 1:IPTS-68

Temperature unit. 0: °C

Amplitude voltage setting

Pulse count setting

1

Features

IM CA500-01EN

1-21

Page 29

1.7 Saving and Loading CA550 Data

Saving Data Using Step Sweep

Saved data Notes

MODEL CA550

FILE TYPE 0: Manually saved data using the SAVE key

CSV SEPARATOR 0: Comma, 1: Semicolon, 2: Tab

DECIMAL POINT 0: Period, 1: Comma

DATE FORMAT 0: YYYY/MM/DD

Range Measurement range, source range

0% VALUE

100% VALUE

DIVISION NUMBER (number of

divisions)

CONTACT (contact I/O) 0: OFF, 1:ON

TC SETTING

(temperature setting)

FREQUENCY SETTING

(frequency setting)

No. Number

DATE Measurement date YYYY/MM/DD

TIME Measurement time hh:mm:ss

MEASURE Measured value

SOURCE Source value

1: Automatically saved data by a step sweep

2: Calibration data by a program sweep

1: DD/MM/YYYY

2: MM/DD/YYYY

Thermocouple terminal setting. 0: TC-A, 1: TC-B

TC-B RJC setting. 0: OFF, 1:ON

Burnout setting. 0: OFF, 1:ON

TC scale standard setting. 0: ITS-90, 1:IPTS-68

Temperature unit. 0: °C

Amplitude voltage setting

Pulse count setting

1-22

IM CA500-01EN

Page 30

1.7 Saving and Loading CA550 Data

Saving Data Using Program Sweep

Saved data Notes

MODEL CA550

FILE TYPE 0: Manually saved data using the SAVE key

1: Automatically saved data by a step sweep

2: Calibration data by a program sweep

CSV SEPARATOR 0: Comma, 1: Semicolon, 2: Tab

DECIMAL POINT 0: Period, 1: Comma

DATE FORMAT 0: YYYY/MM/DD

1: DD/MM/YYYY

2: MM/DD/YYYY

Range Measurement range, source range

0% VALUE

100% VALUE

CONTACT (contact I/O) 0: OFF, 1:ON

TC SETTING

(temperature setting)

FREQUENCY SETTING

(frequency setting)

MODEL NO. Model number

TAG NO. Tag number

SERIAL NO. Serial number

CALIBRATION DATE Calibration date

CALIBRATOR S/N CA550 serial number

No. Calibration point number

DATE Calibration date YYYY/MM/DD

TIME Calibration time of the calibration point hh:mm:ss

MEASURE Measured value

SOURCE Source value

ERROR% Error

PASS/FAIL Pass/fail

Thermocouple terminal setting. 0: TC-A, 1: TC-B

TC-B RJC setting. 0: OFF, 1:ON

Burnout setting. 0: OFF, 1:ON

TC scale standard setting. 0: ITS-90, 1:IPTS-68

Temperature unit. 0: °C

Amplitude voltage setting

Pulse count setting

YYYY/MM/DD

1

Features

Loading Data

Only the data saved using program sweep can be loaded.

Folder Structure

The following figure shows the CA550 folder structure.

Data saved with the SAVE key is saved.

Measurement/source data (.csv) of step

sweeps is saved.

Measurement/source data (.csv) of program

sweeps is saved.

IM CA500-01EN

Root

SaveData

SweepData

CalibrationData

1-23

Page 31

1.8 Other Features

Communication Function

You can connect the instrument to a PC through the USB port. You can remotely control the

instrument from a PC or use the instrument as a USB device on the PC.

Remote Control

You can use dedicated communication commands to remotely control the instrument from a

PC. The following operations can be controlled remotely.

• CA500/CA550 configuration (limited features)

• CA500/CA550 configuration retrieval (limited features)

• Measured data retrieval

USB Mass Storage (CA550)

You can use the instrument as a PC’s USB mass storage device.

From a PC, you can access the instrument’s internal memory and read the data.

Data cannot be written to the instrument’s internal memory from a PC.

Auto Power-off

When the auto power-off feature is enabled, the instrument automatically turns off if there is no user

interaction for about 30 minutes. Auto power-off is automatically disabled (the icon also disappears)

in the following situations.

• Pulse count is in progress.

• The output is on.

• Sweeping is in progress.

• Power is being supplied through USB.

Turning the Screen Light On and Off

To reduce battery consumption, you can turn off the screen light or adjust the brightness between

two levels.

Further, the screen light can be turned off automatically when there is no user interaction with the

instrument for a given period.

Note

If the screen light is turned on in a dark location, white spots may appear on the screen.

This is due to the material characteristics of the light guide of the screen and has no effect on the

performance of the instrument.

Communication Resistance

This instrument has an built-in 250 Ω communication resistor. When communicating with a

transmitter, you do not need to prepare a separate external resistor.

Power Supply Priority

When both batteries and USB power supply are available, priority can be given to either source.

When the priority power supply cannot be used, a switch is made to the other part supply.

1-24

IM CA500-01EN

Page 32

1.8 Other Features

CSV Separator

The CSV separator can be set to a comma, semicolon, or tab.

Decimal Point

The decimal point can be set to a period or comma.

Date Display Format

You can select the date display format from the following:

YYYY/MM/DD

DD/MM/YYYY

MM/DD/YYYY

YYYY: year (Gregorian), MM: month, DD: day

The format is applied to the date and time displayed in the upper left of the screen, the date and

time on the LOAD screen, and the date and time saved in CSV files from the CA550.

Language

You can select the language used on the screen from the following:

English, Japanese, Chinese, Korean, Russian

1

Features

Formatting the Internal Memory

You can format the internal memory.

The format type is quick format (logical format).

Instrument Information

You can view the model (CA500/CA550), serial number, firmware version, and most recent

inspection date or calibration date.

A simple wiring diagram is displayed according to the Function 1 and Function 2 settings.

IM CA500-01EN

1-25

Page 33

Chapter 2 Source

1

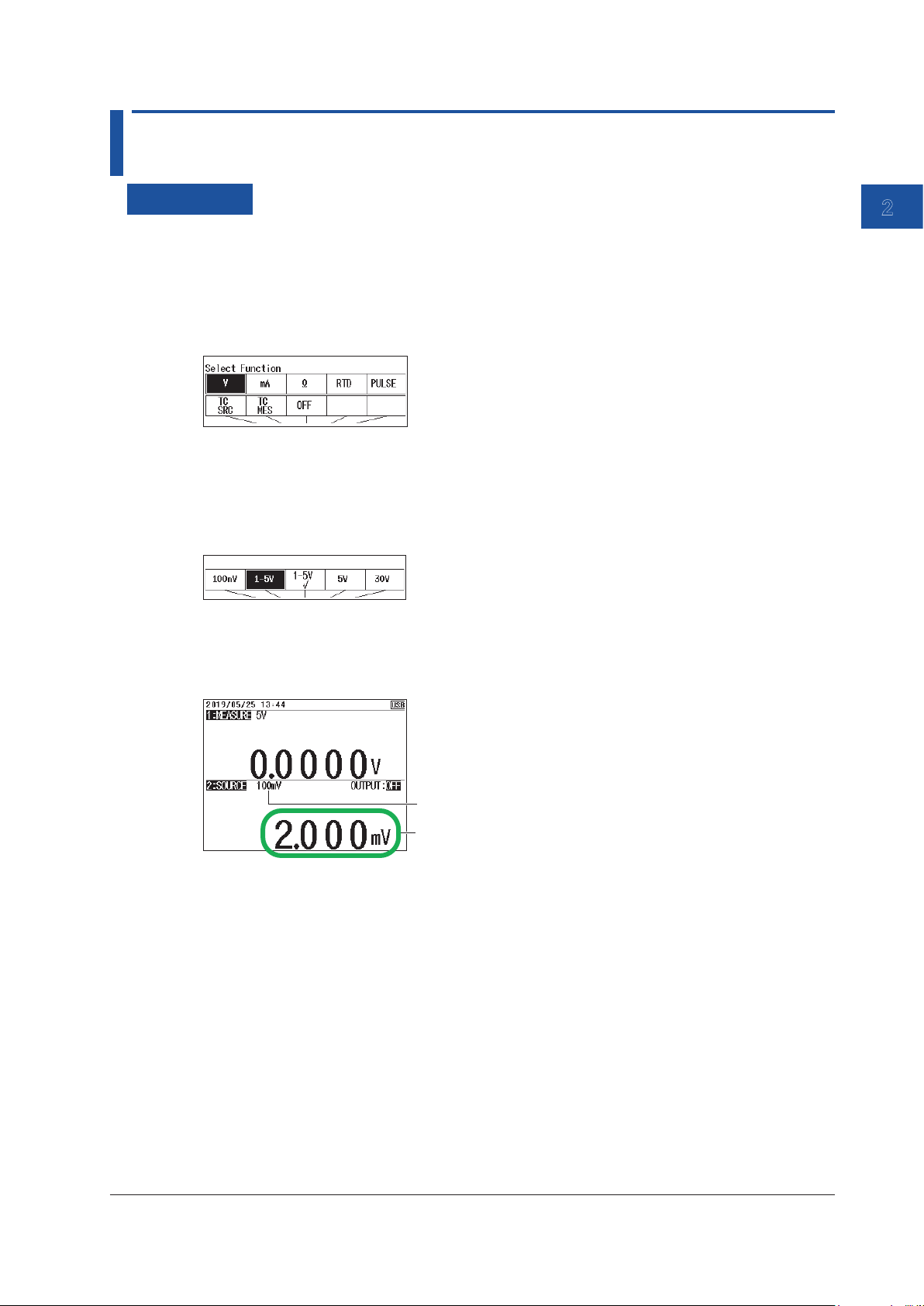

2.1 DC Voltage Source

Procedure

Setting the Function

1.

With the source value and measurement value displayed, press FUNCTION 2. The function

options are displayed.

2.

Use the arrow keys to select V. The display returns to the source and measurement value

display.

Setting the Source Range

3.

Under Function 2, press RANGE.

4.

Use the arrow keys to set the source range. The display returns to the source and measurement

value display.

Setting the Source Value

2

Source

5.

With the source value and measurement value displayed, use the arrow keys to set the source

value.

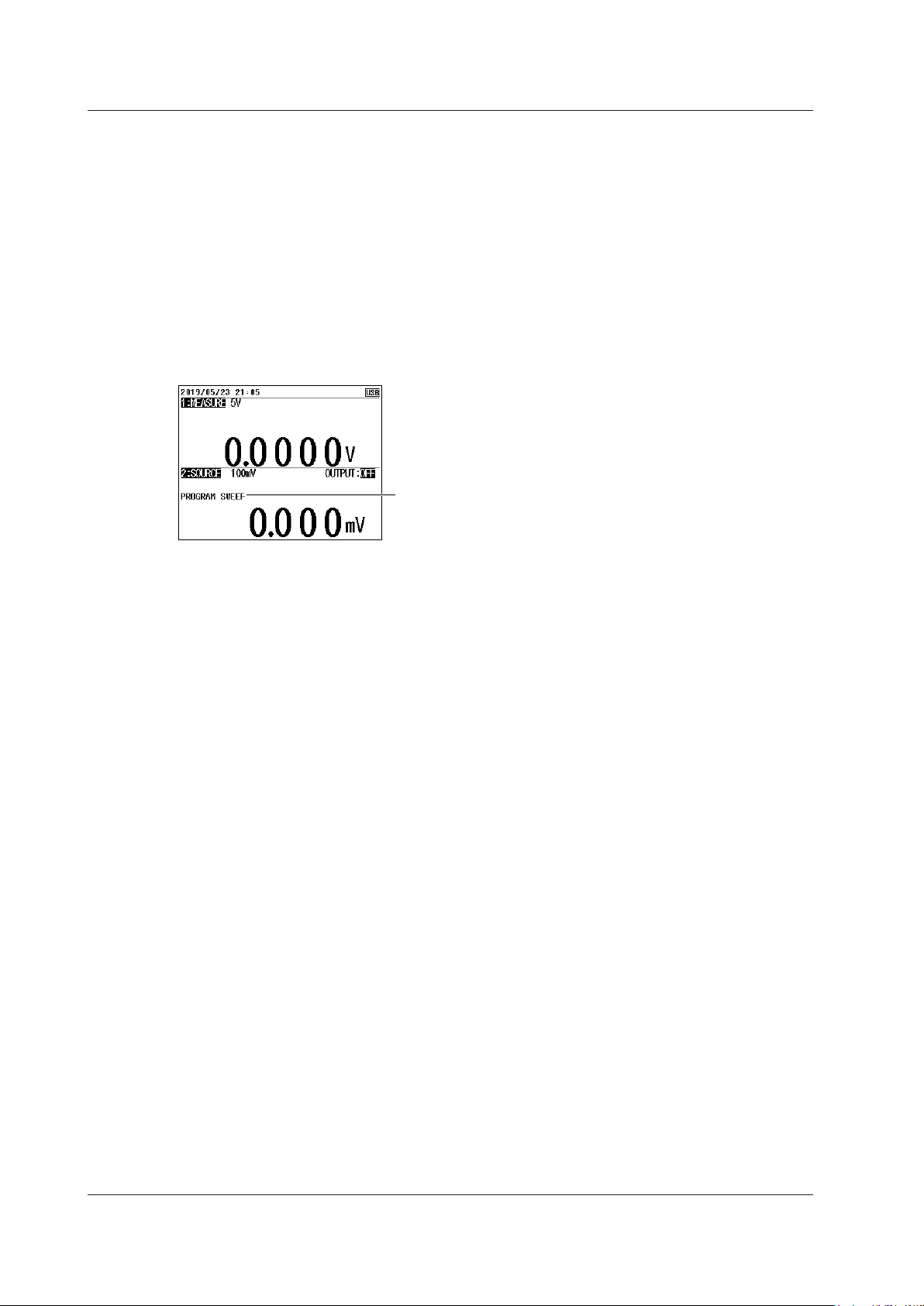

Source range

Source value

When the source range is 1-5V or 1-5V√, pressing UP or DOWN changes the source value at a

given interval.

Turning the Source On and Off

6.

With the source value and measurement value displayed, press OUTPUT ON/OFF.

The displayed voltage is generated. OUTPUT:OFF on the screen changes to OUTPUT:ON.

To turn off the source, press OUTPUT ON/OFF again.

7.

When the source range is 1-5V or 1-5V√, press UP or DOWN to change the source value.

Divided Source

See section 2.8, “Dividing and Generating the Source Values”.

Sourcing with the Sweep Function

See section 2.9, “Sweep Source”.

IM CA500-01EN

2-1

Page 34

2.1 DC Voltage Source

Description

Source Range

You can select from the following five source ranges.

Range Source Range

100 mV ±110.000 mV

1-5 V 0.0000 V to +6.0000 V

1-5 V√ 0.0000 V to +6.0000 V

Values for square root operation

5 V ±6.0000 V

30 V ±33.000 V

1-5V

The interval between 0% and 100% is equally divided by four, and the 0%, 25%, 50%,

75%, and 100% values are output. By default, because the 0% value is assigned to 1.0000

V and the 100% value is assigned to 5.0000 V, this can be used as a calibration signal for

instruments that use 1 to 5 V as input signals.

Square Root Commendation Function (1-5V√)

This can be used as a calibration signal for instruments that output the square root of input

signals.

Values for square root operation are generated.

Source Value

Voltages within each source range are generated.

In the default setting of the 1-5V range, 1 V to 5 V are divided into four, and 1 V, 2 V, 3 V, 4 V, and 5

V are generated.

In the default setting of the 1-5V√ range, 1 V to 5 V are divided into four, and values corresponding

to the square root of 1 V, 2 V, 3 V, 4 V, and 5 V are generated.

Source value = (%/100)×(%/100)×(100% value - 0% value) + 0%

In the default setting of the 1-5V√ range, 0% = 1 V and 100% = 5 V, so for 25% = 2 V,

Source value = (25/100)×(25/100)×(5 V - 1 V) + 1 V = 1.25 V.

Notes about Sourcing

Be careful not to short the output terminals.

When the output terminals are shorted, the output is automatically turned off by the protection

function.

2-2

IM CA500-01EN

Page 35

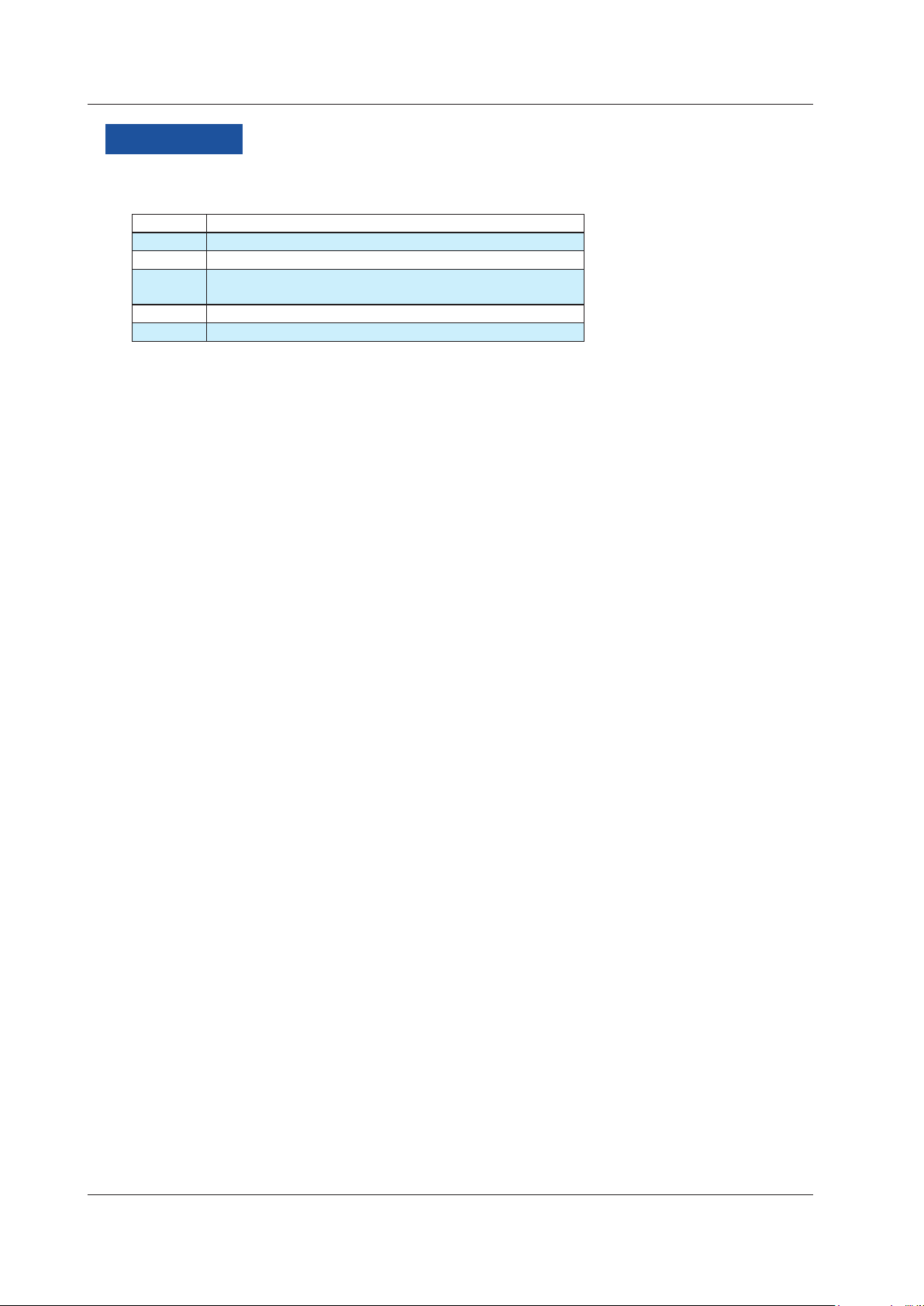

1

2.2 DC Current Source

Procedure

Setting the Function

1.

With the source value and measurement value displayed, press FUNCTION 2. The function

options are displayed.

2.

Use the arrow keys to select mA. The display returns to the source and measurement value

display.

Setting the Source Range

3.

Under Function 2, press RANGE.

4.

Use the arrow keys to set the source range. The display returns to the source and measurement

value display.

Setting the Source Value

5.

With the source value and measurement value displayed, use the arrow keys to set the source

value.

2

Source

Source range

Source value

When the source range is 4-20mA, 4-20mA√ or 4-20mA Simulate, pressing UP or DOWN

changes the source value at a given interval.

Turning the Source On and Off

6.

With the source value and measurement value displayed, press OUTPUT ON/OFF.

The source value set in step five is output, and OUTPUT:OFF on the screen changes to

OUTPUT:ON.

To turn off the source, press OUTPUT ON/OFF again.

7.

When the source range is 4-20mA, 4-20mA√ or 4-20mA Simulate, press UP or DOWN to

change the source value.

Divided Source

See section 2.8, “Dividing and Generating the Source Values”.

Sourcing with the Sweep Function

See section 2.9, “Sweep Source”.

IM CA500-01EN

2-3

Page 36

2.2 DC Current Source

Description

Source Range

You can select from the following four source ranges.

Range Source Range

20 mA ±24.000 mA

4-20 mA 0.000 mA to 24.000 mA

4-20 mA√ 0.000 mA to 24.000 mA

4-20 mA Sim 0.000 mA to 24.000 mA

4-20mA

The interval between 0% and 100% is equally divided by four, and the 0%, 25%, 50%, 75%,

and 100% values are output. By default, because the 0% value is assigned to 4.000 mA

and the 100% value is assigned to 20.000 mA, this can be used as a calibration signal for

instruments that use 4 to 20 mA as input signals.

Square Root Computation Function (4-20 mA√)

This can be used as a calibration signal for instruments that output the square root of input

signals.

DC currents corresponding to the square root of 4 mA, 8 mA, 12 mA, 16 mA, and 20 mA are

generated.

4-20 mA Simulate

Currents ranging from 0 to 20 mA that simulate transfer signals are generated. This can be

used to perform a loop check on the source value by connecting to a distributor or the like.

CA500/CA550

H

L

4-20mA

+

Distributor

—

Output 1 to 5 V

Source Value

Currents within each source range are generated.

In the default setting of the 4-20mA and 4-20mA Simulate ranges, 4 mA to 20 mA are divided into

four, and 4 mA, 8 mA, 12 mA, 16 mA, and 20 mA are generated.

In the default setting of the 4-20mA√ range, 4 mA to 20 mA are divided into four, and values

corresponding to the square root of 4 mA, 8 mA, 12 mA, 16 mA, and 20 mA are generated.

Source value = (%/100)×(%/100)×(100% value - 0% value) + 0% value

In the 4-20mA√ range, 0% = 4 mA and 100% = 20 mA, so for 25% = 8 mA,

Source value = (25/100)×(25/100)×(20 mA - 4 mA) + 4 mA = 5 mA.

Notes about Sourcing

Be careful not to open the output terminals.

When the output terminals are opened, the output is automatically turned off by the protection

function.

2-4

IM CA500-01EN

Page 37

1

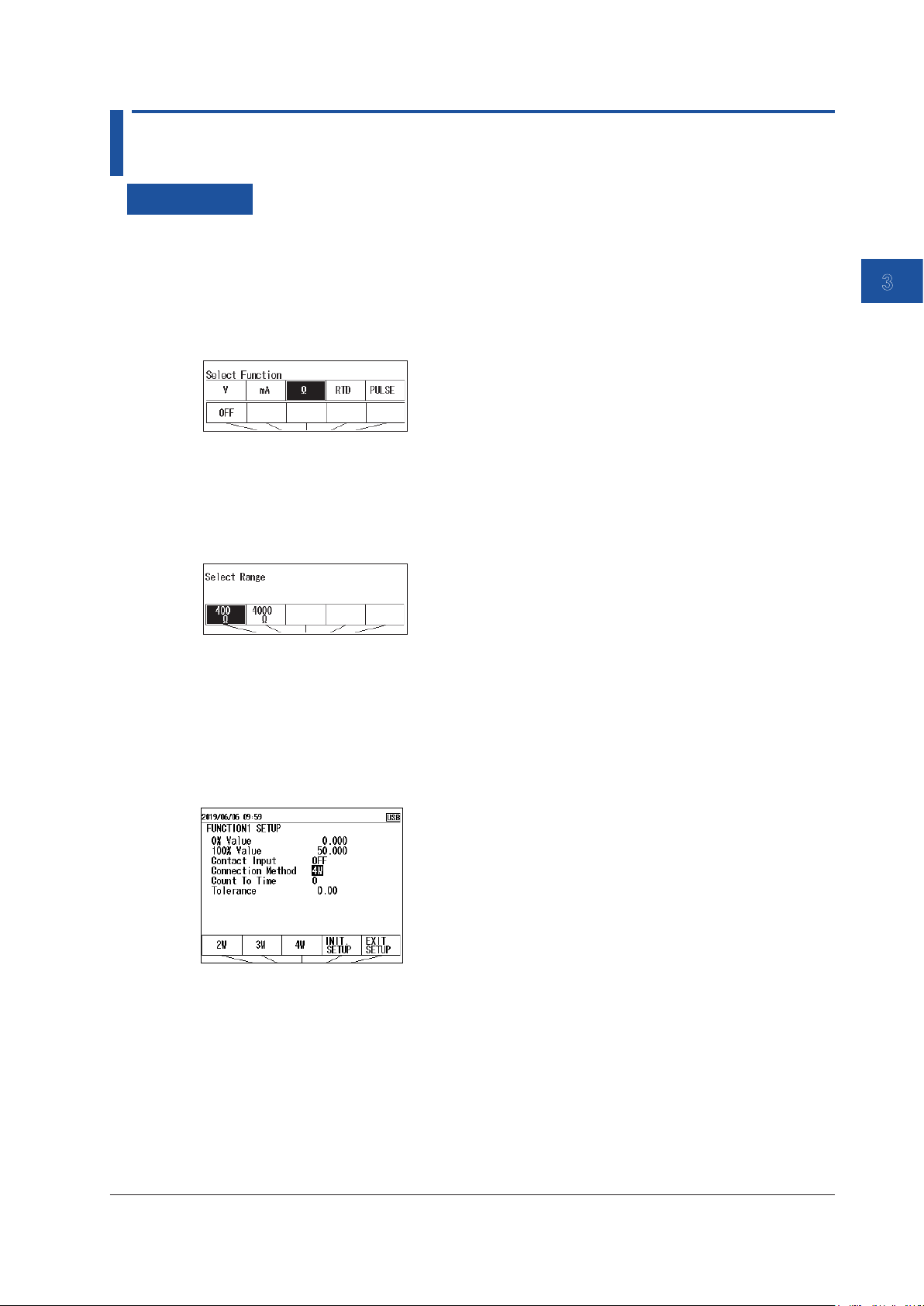

2.3 Resistance Source

Procedure

Setting the Function

1.

With the source value and measurement value displayed, press FUNCTION 2. The function

options are displayed.

2.

Use the arrow keys to select Ω. The display returns to the source and measurement value

display.

Setting the Source Range

3.

Under Function 2, press RANGE.

4.

Use the arrow keys to set the source range. The display returns to the source and measurement

value display.

Setting the Source Value

2

Source

5.

With the source value and measurement value displayed, use the arrow keys to set the source

value.

Source range

Source value

Turning the Source On and Off

6.

With the source value and measurement value displayed, press OUTPUT ON/OFF.

The source value set in step five is output, and OUTPUT:OFF on the screen changes to

OUTPUT:ON.

To turn off the source, press OUTPUT ON/OFF again.

Divided Source

See section 2.8, “Dividing and Generating the Source Values”.

Sourcing with the Sweep Function

See section 2.9, “Sweep Source”.

IM CA500-01EN

2-5

Page 38

2.3 Resistance Source

Description

Source Range

You can select from the following two source ranges.

Range Source Range

400 Ω 0.00 Ω ~ 440.00 Ω

4000 Ω 0.0 Ω ~ 4400.0 Ω

Note

If the allowable measurement current exceeds the upper limit, the source value display blinks.

2-6

IM CA500-01EN

Page 39

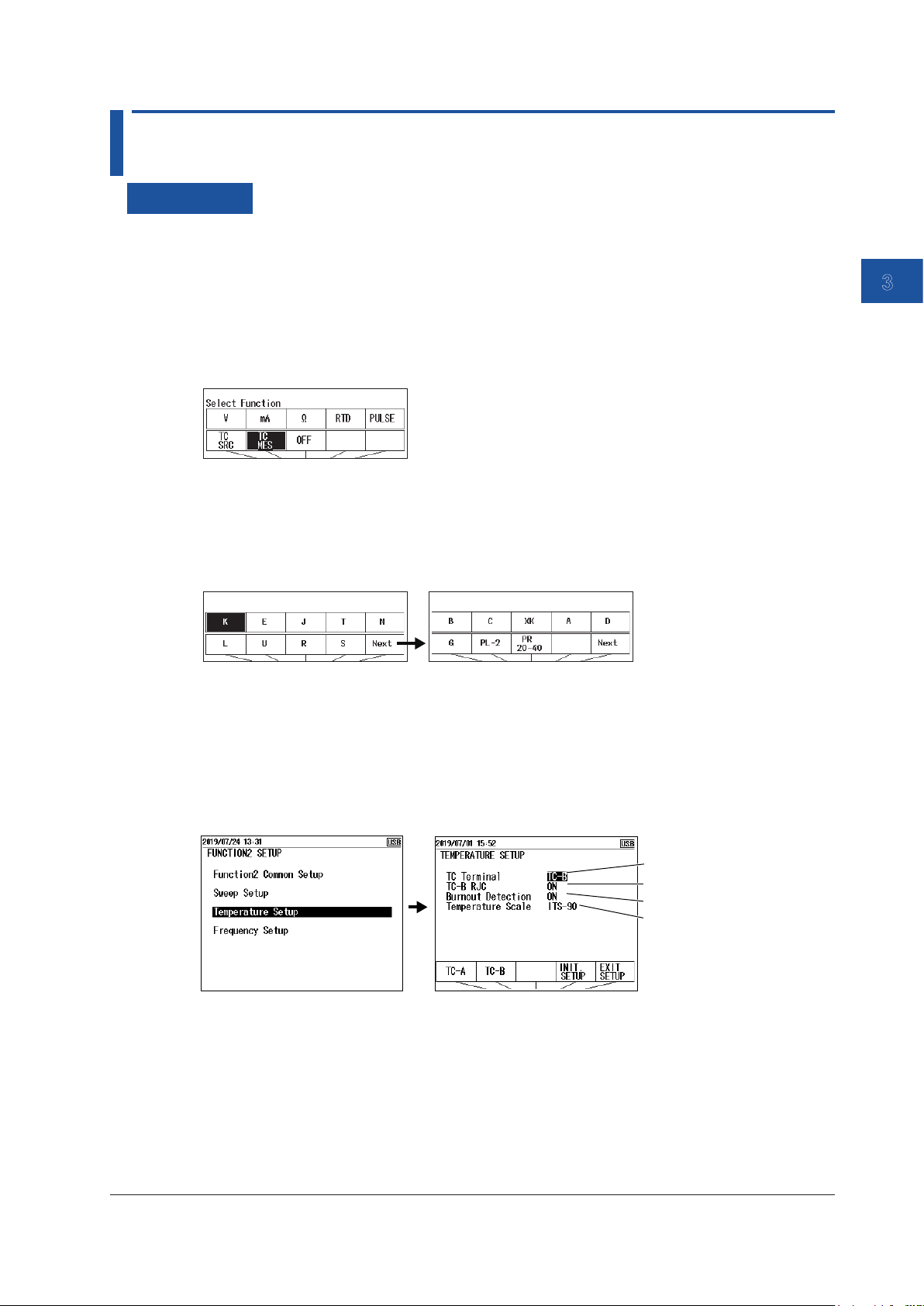

1

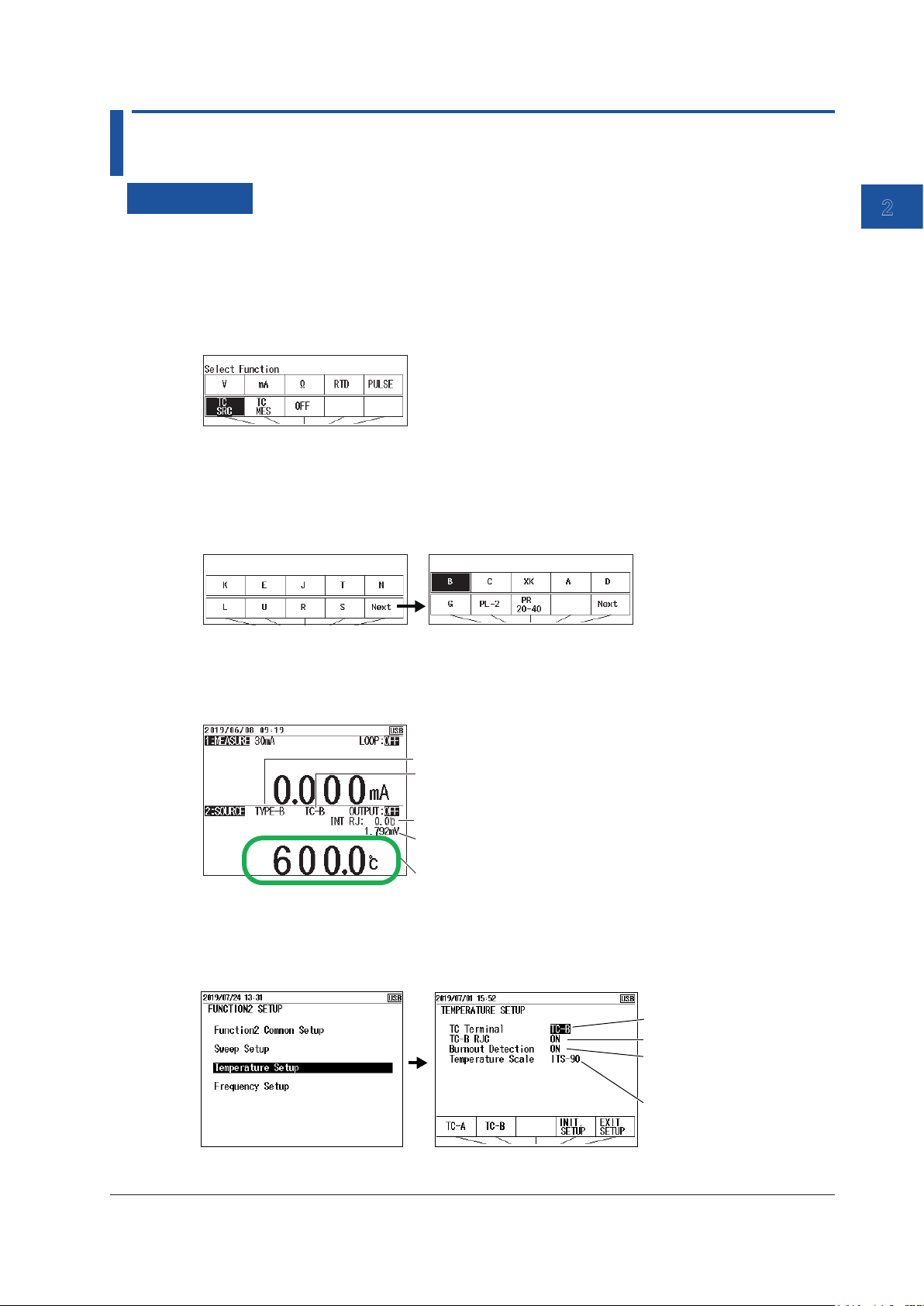

2.4 Voltage Source Corresponding to TC Thermoelectromotive Force

Procedure

Setting the Function

1.

With the source value and measurement value displayed, press FUNCTION 2. The function

options are displayed.

2.

Use the arrow keys to select TC SRC (source). The display returns to the source and

measurement value display.

Setting the Source Range (TC Type)

3.

Under Function 2, press RANGE.

4.

Use the arrow keys to set the TC type. The display returns to the source and measurement

value display.

2

Source

Setting the Source Value

5.

With the source value and measurement value displayed, use the arrow keys to set the source

value.

Source range

Terminal to use

Reference junction temperature

Thermoelectromotive force corresponding

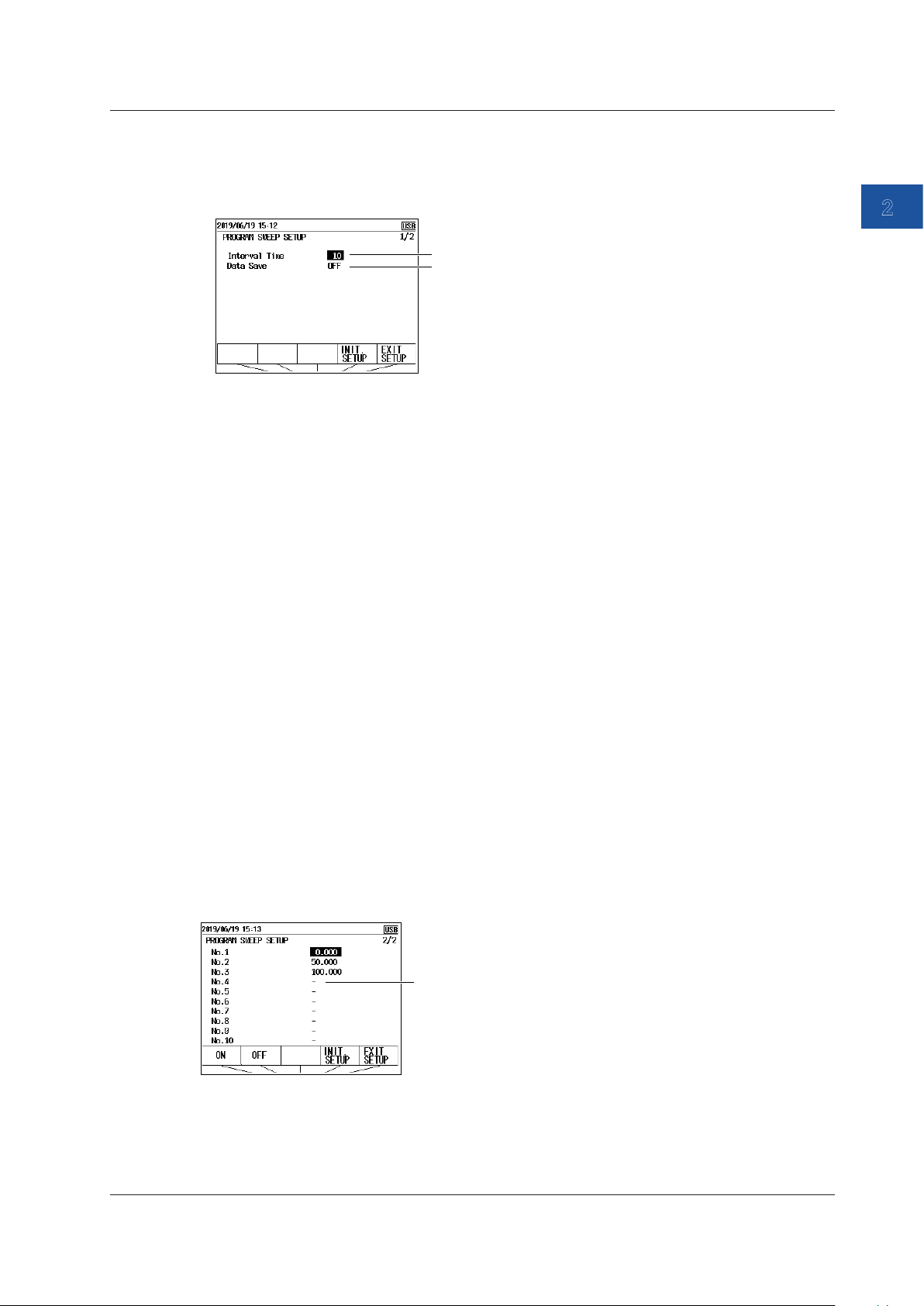

to the set temperature

Source value

Selecting the Terminal

6.

With the source value and measurement value displayed, press SETUP under Function 2.

7.

Select Temperature Setup, and press ENTER. A Temperature Setup setup screen appears.

Set the terminal.

Set the RJC sensor.

Turn burnout on or off.

(measurement setting

see section 3.4)

Set the temperature

scale.

8.

Select TC Terminal. TC-A and TC-B appear in the selection menu.

IM CA500-01EN

2-7

Page 40

2.4 Voltage Source Corresponding to TC Thermoelectromotive Force

9.

Using the arrow keys, select TC-A to use the TC-A terminal (thermocouple mini plug) or TC-B

to use TC-B.

To finish entering the settings here, proceed to step 14.

Setting the Reference Junction Compensation (RJC) (when using the TC-B

terminal)

10.

Select TC-B RJC. ON and OFF appear in the selection menu.

11.

Use the arrow keys to set RJC to ON or OFF.

To finish entering the settings here, proceed to step 14.

Setting the Temperature Scale

12.

Select Temperature Scale. Options appear in the selection menu.

13.

Use the arrow keys to set the temperature scale.

Confirming the Settings

14.

Press the arrow key corresponding to EXIT SETUP. The settings are confirmed, and a screen

appears showing the source value and measurement value.

The cancel the settings, press ESC to return to the screen in step 6.

To initialize the settings, pressing the arrow key corresponding to INIT SETUP.

Turning the Source On and Off

15.

With the source value and measurement value displayed, press OUTPUT ON/OFF.

The source value set in step five is output, and OUTPUT:OFF on the screen changes to

OUTPUT:ON.

To turn off the source, press OUTPUT ON/OFF again.

Divided Source

See section 2.8, “Dividing and Generating the Source Values”.

Sourcing with the Sweep Function

See section 2.9, “Sweep Source”.

2-8

IM CA500-01EN

Page 41

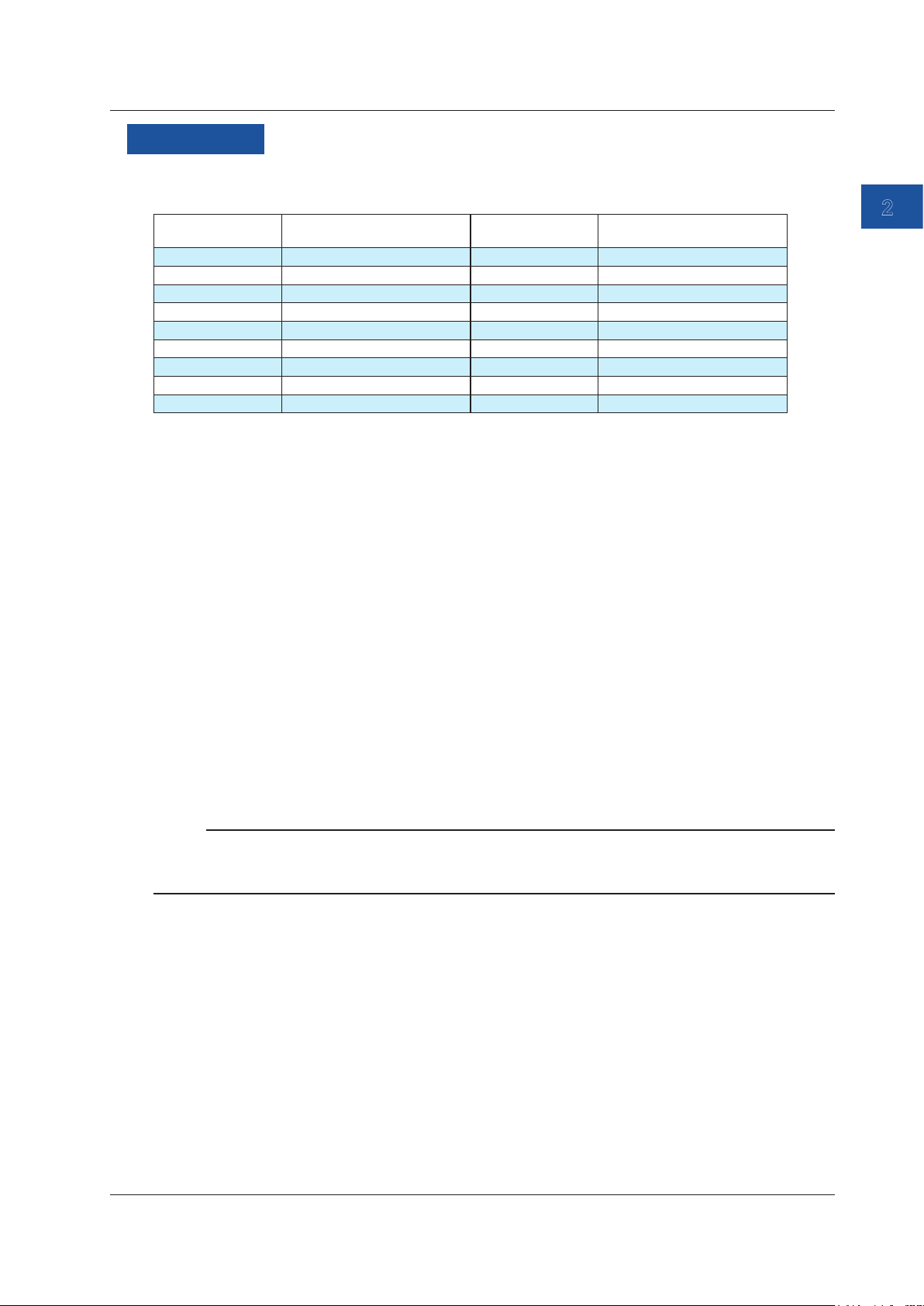

2.4 Voltage Source Corresponding to TC Thermoelectromotive Force

1

Description

Source Range (TC Type)

You can select from the following 17 TC types.

TC type

(thermocouple)

K -200.0°C to +1372.0°C B +600.0°C to +1820.0°C

E -250.0°C to +1000.0°C C 0.0°C to +2315.0°C

J -210.0°C to +1200.0°C XK -200.0°C to +800.0°C

T -250.0°C to +400.0°C A 0.0°C to +2500.0°C

N -200.0°C to +1300.0°C D (W3Re/W25Re) 0.0°C to +2315.0°C

L -200.0°C to +900.0°C G (W/W26Re) +100.0°C to +2315.0°C

U -200.0°C to +600.0°C PLATINEL II 0.0°C to +1395.0°C

R -20.0°C to +1767.0°C PR20-40 0.0°C to +1888.0°C

S -20.0°C to +1768.0°C - -

Match the TC type of this instrument to that of the measuring instrument.

Source range TC type

(thermocouple)

Source range

Output Terminal

Set whether to use the TC-A terminal (dedicated thermocouple mini plug) or TC-B terminal (banana

terminal).

If you select TC-A terminal, you cannot use an external RJ sensor (sold separately).

When using the TC-B terminal, we recommend that you use the included binding post (99045).

2

Source

Turning Reference Junction Compensation (RJC) On and Off

When using the TC-B terminal, set whether to perform RJC (ON/OFF).

ON: If an external RJ sensor is connected, the external RJ sensor is used to perform

reference junction compensation.

If an external RJ sensor is not connected, the internal RJ sensor is used to perform

reference junction compensation.

OFF: Reference junction compensation is not performed.

When the TC-A terminal is used, the internal RJ sensor is always used to perform reference

junction compensation.

Note

• The internal RJ sensor measures the temperature of the instrument’s terminal.

• When the temperature inside the instrument is high, wait for the temperature to decrease before use.

• For the external RJ sensor, use the 90080 RJ sensor, sold separately.

Temperature Scale

TC types K, E, J, T, R, S, and B can also handle the IPTS-68 temperature scale..

IPTS-68: The international temperature scale standard of 1968

ITS-90: The international temperature scale standard of 1990

Notes about Sourcing

If you perform a temperature measurement or temperature source using an RJC immediately after

using loop power or simulating 20 mA, the measured value or source value may be affected by the

temperature rise inside the instrument. Wait for the temperature inside instrument to stabilize before

using it.

IM CA500-01EN

2-9

Page 42

2.5 Resistance Source Corresponding to the RTD Temperature

Procedure

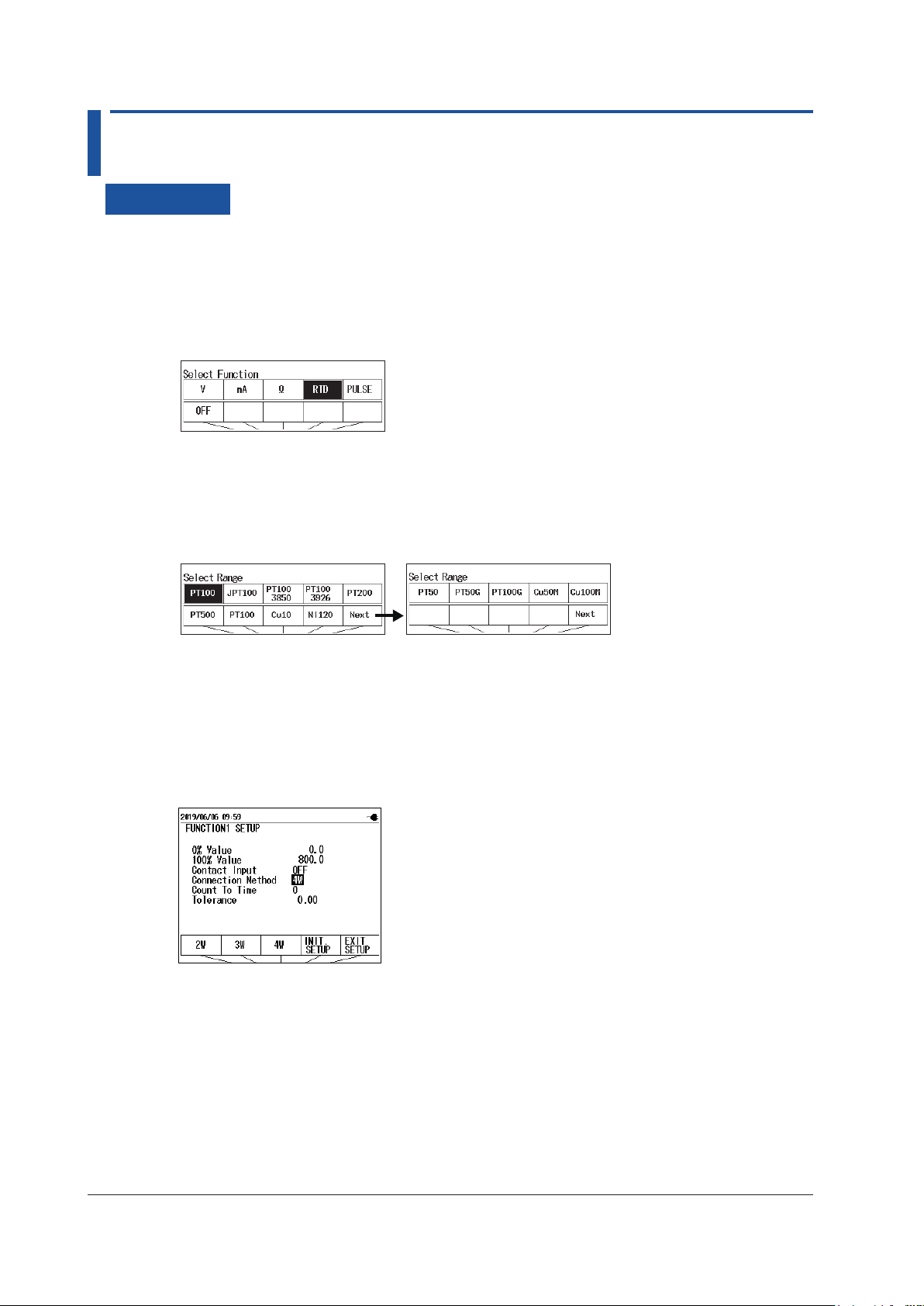

Setting the Function

1.

With the source value and measurement value displayed, press FUNCTION 2. The function

options are displayed.

2.

Use the arrow keys to select RTD. The display returns to the source and measurement value

display.

Setting the Source Range (RTD Type)

3.

Under Function 2, press RANGE.

4.

Use the arrow keys to set the RTD type. The display returns to the source and measurement

value display.

Setting the Source Value

5.

With the source value and measurement value displayed, use the arrow keys to set the source

value.

RTD type

Source value

Turning the Source On and Off

6.

With the source value and measurement value displayed, press OUTPUT ON/OFF.

The source value set in step five is output, and OUTPUT:OFF on the screen changes to

OUTPUT:ON.

To turn off the source, press OUTPUT ON/OFF again.

Divided Source

See section 2.8, “Dividing and Generating the Source Values”.

Sourcing with the Sweep Function

See section 2.9, “Sweep Source”.

2-10

IM CA500-01EN

Page 43

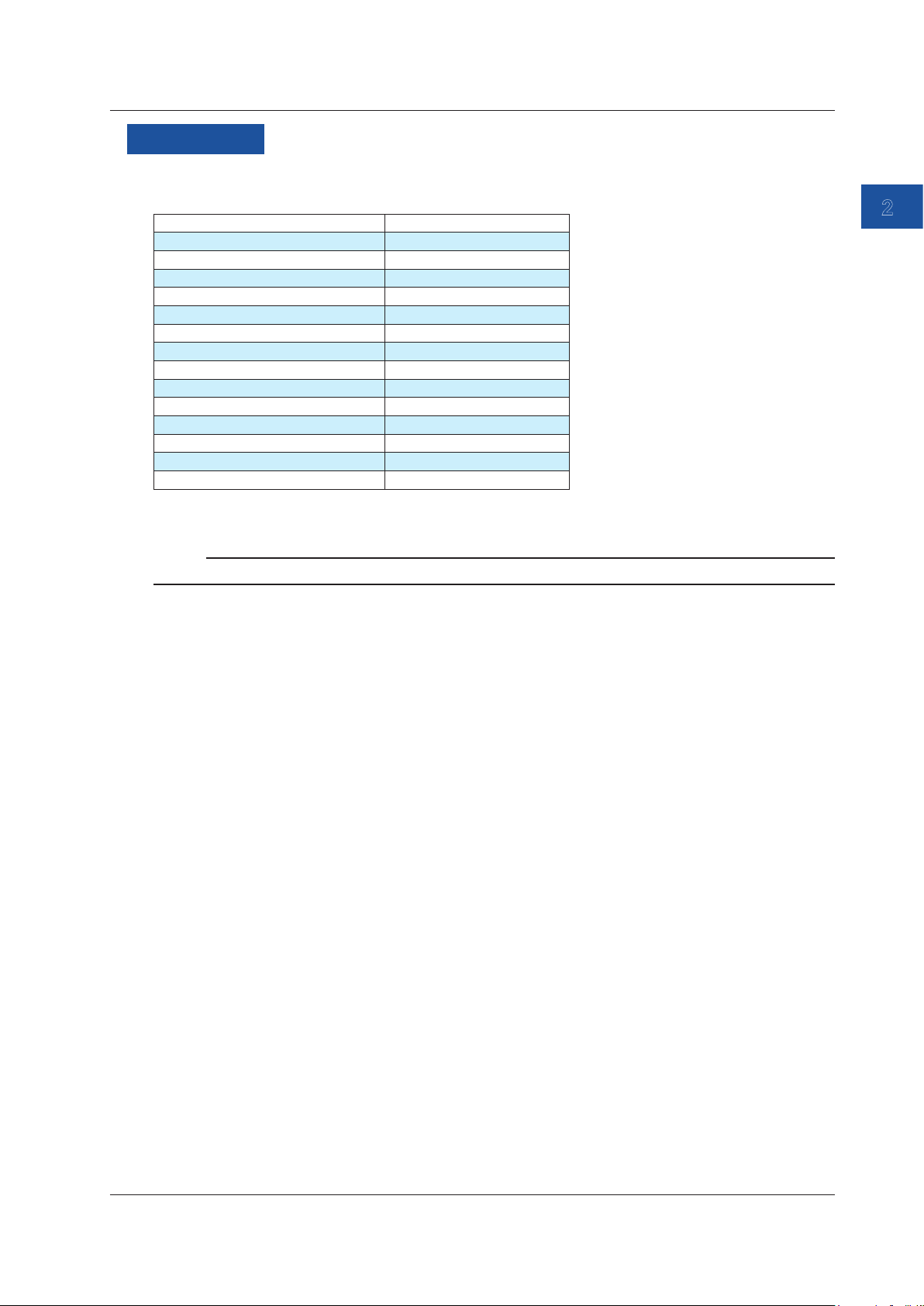

2.5 Resistance Source Corresponding to the RTD Temperature

1

Description

Source Range (RTD Type)

You can select from the following 14 RTD types.

RTD Measurement range

PT100 (PT100 JIS (3851)) -200.0°C to 800.0°C

JPT100 (PT100 former JIS (3916)) -200.0°C to 510.0°C

PT100 (3850) -200.0°C to 630.0°C

PT100 (3926) -200.0°C to 630.0°C

PT200 -200.0°C to 630.0°C

PT500 -200.0°C to 630.0°C

PT1000 -200.0°C to 630.0°C

Cu10 -100.0°C to 260.0°C

Ni120 -80.0°C to 260.0°C

PT50 -200.0°C to 630.0°C

PT50G -200.0°C to 800.0°C

PT100G -200.0°C to 630.0°C

Cu50M -180.0°C to 200.0°C

Cu100M -180.0°C to 200.0°C

Match the RTD type of this instrument to that of the measuring instrument.

2

Source

Note

If the excitation current exceeds the upper limit, the source value display blinks.

IM CA500-01EN

2-11

Page 44

2.6 Frequency and Pulse Source

Procedure

Setting the Function

1.

With the source value and measurement value displayed, press FUNCTION 2. The function

options are displayed.

2.

Use the arrow keys to select PULSE. The display returns to the source and measurement value

display.

Setting the Source Range

3.

Under Function 2, press RANGE.

4.

Use the arrow keys to set the source range. The display returns to the source and measurement

value display.

Setting the Source Value

5.

With the source value and measurement value displayed, use the arrow keys to set the source

value.

Source range

Source value

2-12

IM CA500-01EN

Page 45

2.6 Frequency and Pulse Source

1

Setting the Pulse Signal Amplitude

6.

With the source value and measurement value displayed, press SETUP under Function 2.

7.

Select Frequency Setup, and press ENTER. A Frequency Setup setup screen appears.

Set the amplitude.

Set the pulse count.

8.

Select Amplitude Voltage, and press ENTER. The settings are displayed at the bottom of the

screen.

9.

Use the arrow keys to select the amplitude, and then press ENTER.

To finish entering the settings here, proceed to step 12.

Setting the Number of Pulses to Source

10.

Select Pulse Count, and press ENTER. The settings are displayed at the bottom of the screen.

2

Source

11.

Use the arrow keys to select the number of pulses to source, and then press ENTER.

If you set the number to 0, Continue will be selected.

Setting the Amplitude and the Number of Pulses

12.

Press the arrow key corresponding to EXIT SETUP. The settings are confirmed, and the screen

reverts to show the source value and measurement value.

The cancel the settings, press ESC to return to the screen and step 6.

To initialize the settings, pressing the arrow key corresponding to INIT SETUP.

Turning the Contact Output On and Off

13.

With the source value and measurement value displayed, press SETUP under Function 2.

14.

Select Frequency Setup, and press ENTER. A Frequency Setup setup screen appears.

Turn the contact

output on or off.

15.

Select Contact Output. ON and OFF appear in the selection menu.

16.

Use the arrow keys to set the contact output to ON or OFF. To generate contact signals, select

ON.

IM CA500-01EN

2-13

Page 46

2.6 Frequency and Pulse Source

Confirming the Contact Output

17.

Press the arrow key corresponding to EXIT SETUP. The settings are confirmed, and the screen

reverts to show the source value and measurement value.

The cancel the settings, press ESC to return to the screen and step 14.

To initialize the settings, pressing the arrow key corresponding to INIT SETUP.

Turning the Source On and Off

18.

With the source value and measurement value displayed, press OUTPUT ON/OFF.

The source value set in step 5 is output. The signal is generated according to the specified

pulse count.

To turn off the source, press OUTPUT ON/OFF again.

Divided Source

See section 2.8, “Dividing and Generating the Source Values”.

2-14

IM CA500-01EN

Page 47

Description

1

Source Range

You can select from the following four source ranges.

Range Source Range

500 Hz 1.00 Hz to 550.00 Hz

5000 Hz 1.0 Hz to 5500.0 Hz

50 kHz 0.001 kHz to 50.000 kHz

CPM 1.0 to 1100.0/min

If you select CPM, set the number of pulses to generate per minute.

Bandwidth

Set the voltage of the high side of the pulse signal. The low side is 0 V.

Set the voltage in the range of 0.1 V to 15.0 V.

The default setting is 0.1 V.

Duty Cycle

The duty cycle of the pulse signals that this instrument generates is 50%.

2.6 Frequency and Pulse Source

2

Source

Pulse Count

Set the number of pulses to generate.

If you set the number to 0, the instrument continuously generates pulse signals at the specify

frequency.

Contact Output

If you turn on the contact output, the non-voltage contact is turned on then off at the specify

frequency or the number of pulses/min.

Be careful not to apply a voltage exceeding 30 VDC to the source terminal of this instrument.

The instrument’s

output terminal

H

0.5 to 30 VDC

L

When you turn on the contact output, the amplitude setting is ignored.

Input terminal of the

output destination device

H

L

IM CA500-01EN

2-15

Page 48

2.7 Setting the 0% and 100% Values

Procedure

Setting Values Using the 0% and 100% Keys

1.

With the source value and measurement value displayed, use the arrow keys to set the 0%

source value.

2.

Hold down the 0% cursor key. The specified source value is assigned to the 0% value.

3.

Use the arrow keys to set the 100% source value.

4.

Hold down the 100% cursor key. The specified source value is assigned to the 100% value.

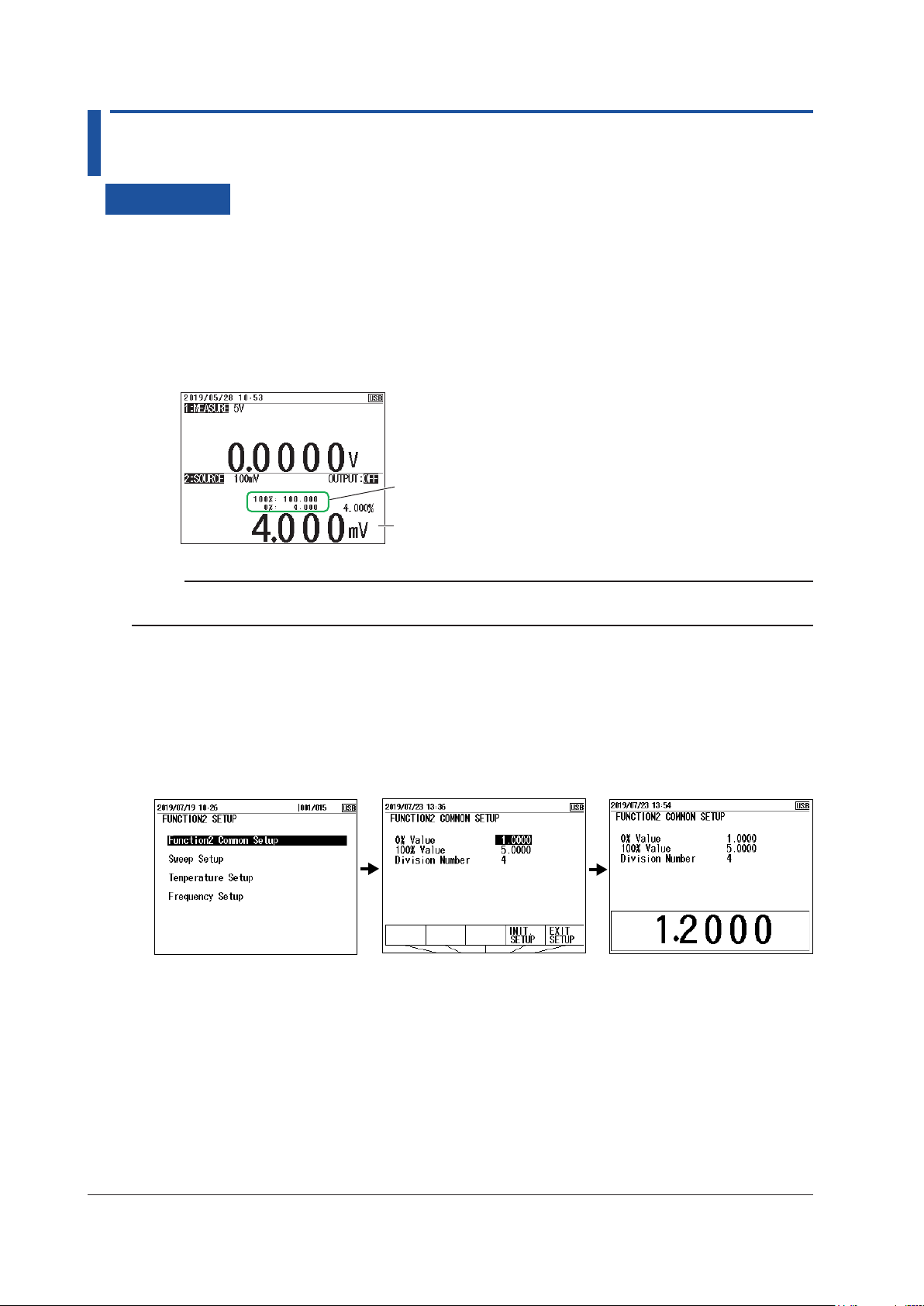

When you display the percentage value,

you can check the 0% or 100% values.

When you hold down the 0% or 100% key,

this value is assigned to 0% or 100%.

Note

If you display the percentage on the screen using the DISPLAY key, you can view the assigned 0% and

100% values.

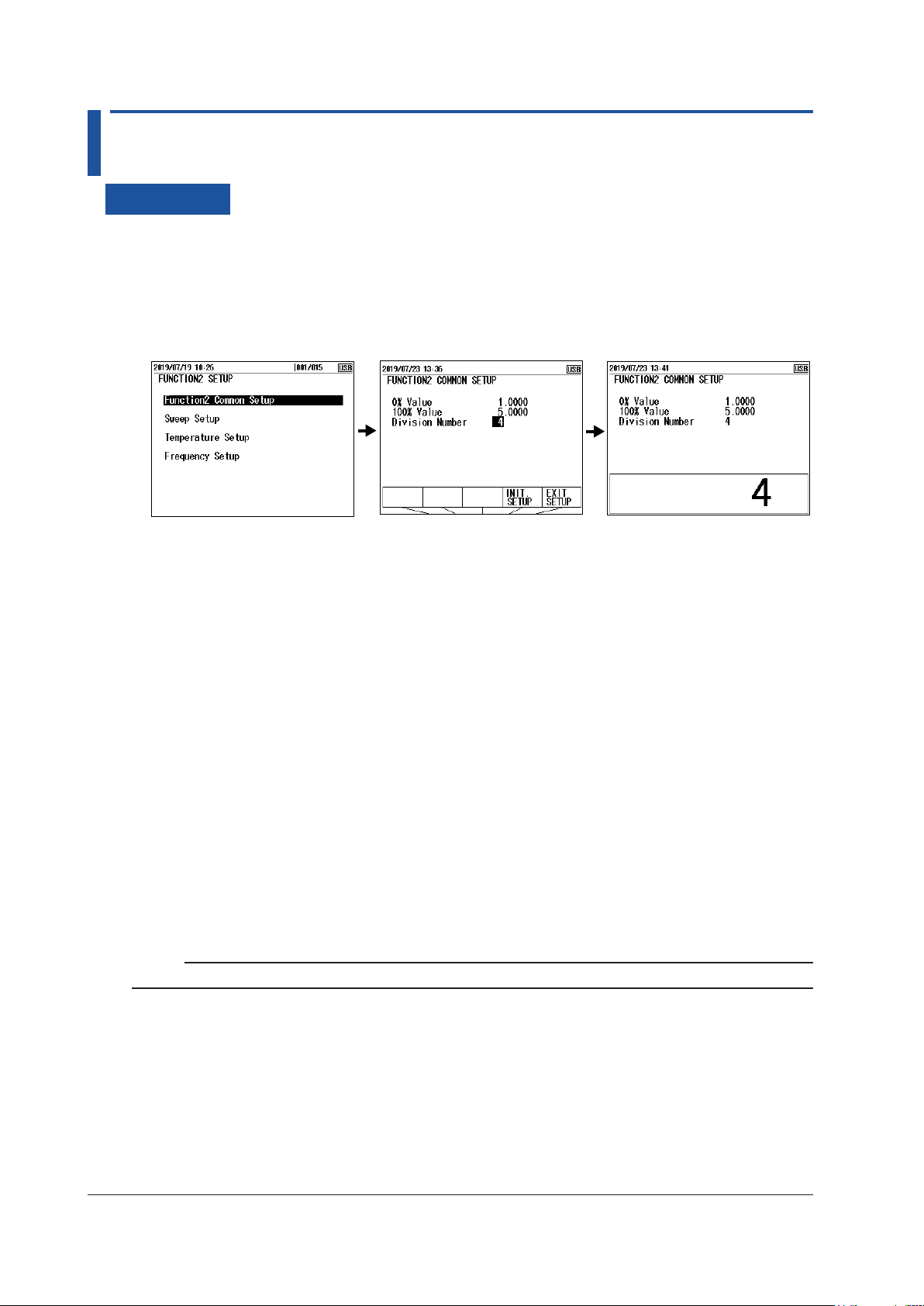

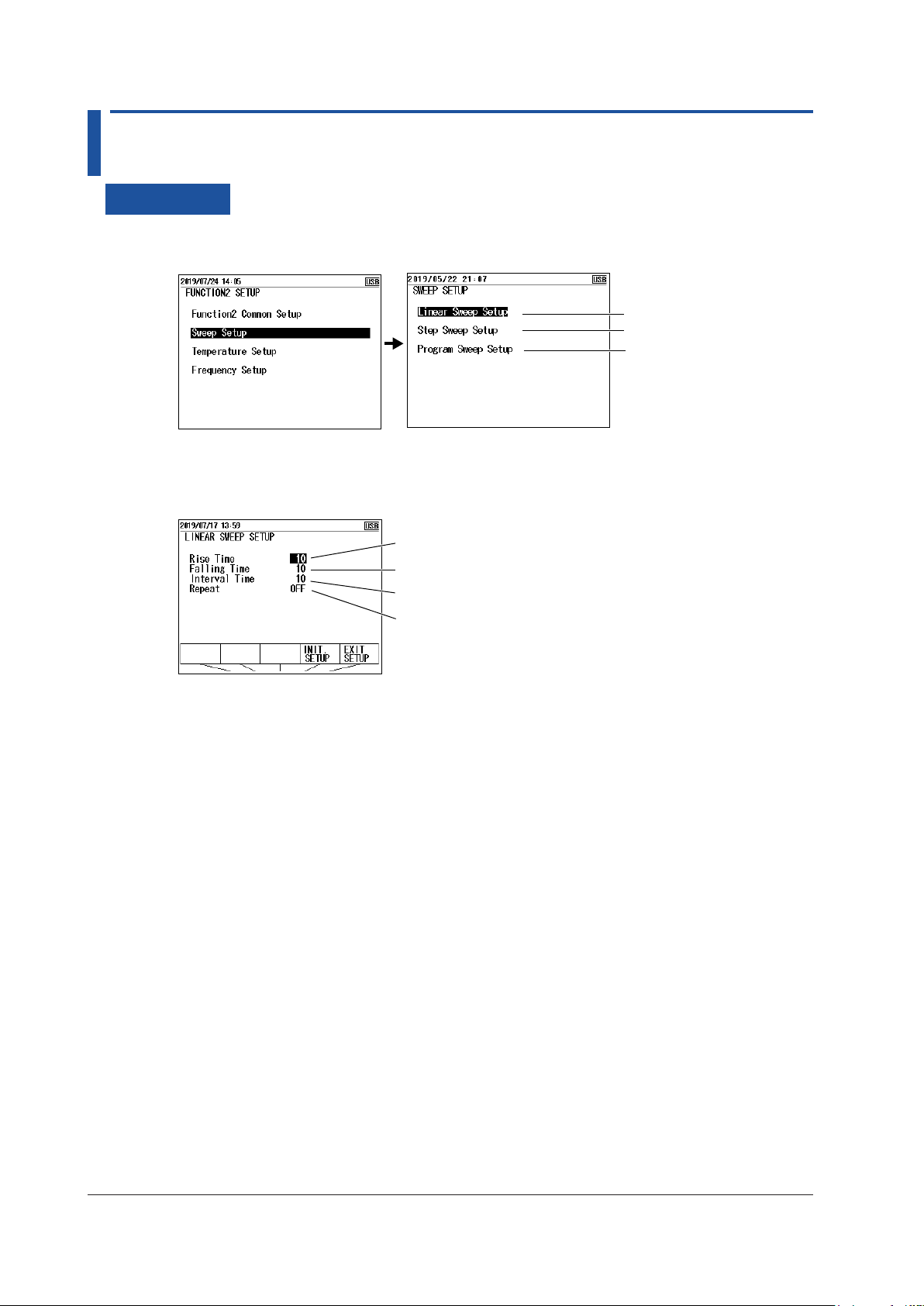

Setting Values Using the Setup Menu

1.

With the source value and measurement value displayed, press SETUP under Function 2.

2.

Use the arrow keys to select Function2 Common Setup, and then press ENTER.

3.

Use the arrow keys to select the 0% Value value, and then press ENTER. The settings are

displayed at the bottom of the screen.

4.

Use the arrow keys to set the 0% value, and then press ENTER.

5.

Likewise, set the 100% value.

6.

Press the arrow key corresponding to EXIT SETUP. The settings are confirmed, and a screen

appears showing the source value and measurement value.

The cancel the settings, press ESC to return to the screen in step 2.

To initialize the settings, press the arrow key corresponding to INIT SETUP.

2-16

IM CA500-01EN

Page 49