Page 1

User ’s

Manual

AQ2200 Series

Multi Application Test System

Startup Guide

IM 735101-01EN

13th Edition

Page 2

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services.

Please allow us to serve you best by completing the product registration form

accessible from our website.

http://tmi.yokogawa.com/

PIM 103-04E

Page 3

List of Manual

Thank you for purchasing this AQ2200 Series Multi Application Test System. The AQ2200

Series Multi Application Test System consists of the AQ2211/AQ2212 Frame Controller

and multiple measurement modules. The frame controllers are capable of holding and

controlling measurement modules.

This user’s manual explains the features, operating procedures, and handling precautions

of the AQ2200 Series. To ensure correct use, please read this manual thoroughly before

operation. Keep this manual in a safe place for quick reference in the event a question

arises.

The following manuals, including this one, are provided as manuals for the AQ2200

Series. Please read all manuals.

Manual Title Manual No. Description

AQ2200 Series

Multi Application Test System

User’s Manual Startup Guide

AQ2200 Series

Multi Application Test System

Frame and Module Operation

User’s Manual

AQ2200 Series

Multi Application Test System

Application Operation

User’s Manual

AQ2200 Series

Multi Application Test System

Communication Interface

User’s Manual

64 Mbit Program Pattern Option

User’s Manual

SDH/SONET Frame Option

User’s Manual

AQ2200 Series Modules

Checking the Contents of

the Package and Handling

Precautions of the Modules

Connector Adapter

for Multi-Fiber Cable

User’s Manual

IM 735101-01EN This manual. The supplied CD contains

the PDF file of this manual. This manual

describes the handling precautions for, the

names and functions of all parts of, and the

firmware upgrade procedure for the AQ2200

Series.

IM 735101-03EN The supplied CD contains the PDF file of

this manual. This manual describes all the

features of the AQ2200 Series and how to

use them, with the exception of some of the

application and communication features.

IM 735101-04EN The supplied CD contains the PDF file of

this manual. This manual describes the

AQ2200 Series application features and

how to use them.

IM735101-17EN The supplied CD contains the PDF file of

this manual. This manual describes the

AQ2200 Series communication interface

features and how to use them.

IM 810518801-61E This manual describes how to create

program patterns for the AQ2200-601

10 Gbit/s BERT module with the /M option.

IM 810518801-62E This manual describes how to create SDH/

SONET patterns for the AQ2200-601

10 Gbit/s BERT module with the /P1 option.

IM 810518901-04E This is included with AQ2200 Series

modules. It explains the handling

precautions of the module and lists the

package contents.

IM AQ9340-01EN This manual explains the handling

precautions of the connector adapters and

how to use them.

The “EN” and “E” in the manual numbers are the language codes.

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Manual No. Description

PIM 113-01Z2 List of worldwide contacts

13th Edition: February 2019 (YMI)

All Rights Reserved, Copyright ©2009, Yokogawa Electric Corporation

All Rights Reserved, Copyright ©2012, Yokogawa Test & Measurement Corporation

IM 735101-01EN

i

Page 4

Notes

Trademarks

Revisions

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions.

The figures given in this manual may differ from those that actually appear on your

screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

• Adobe and Acrobat are registered trademarks or trademarks of Adobe Systems

Incorporated.

• Microsoft and Windows are registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

• In this manual, the ® and TM symbols do not accompany their respective registered

trademark or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective holders.

• 1st Edition: August 2009

• 2nd Edition: November 2009

• 3rd Edition: January 2010

• 4th Edition: March 2010

• 5th Edition: November 2012

• 6th Edition: September 2014

• 7th Edition: May 2015

• 8th Edition: November 2015

• 9th Edition: May 2017

• 10th Edition: October 2017

• 11th Edition: February 2018

• 12th Edition: September 2018

• 13th Edition: February 2019

ii

IM 735101-01EN

Page 5

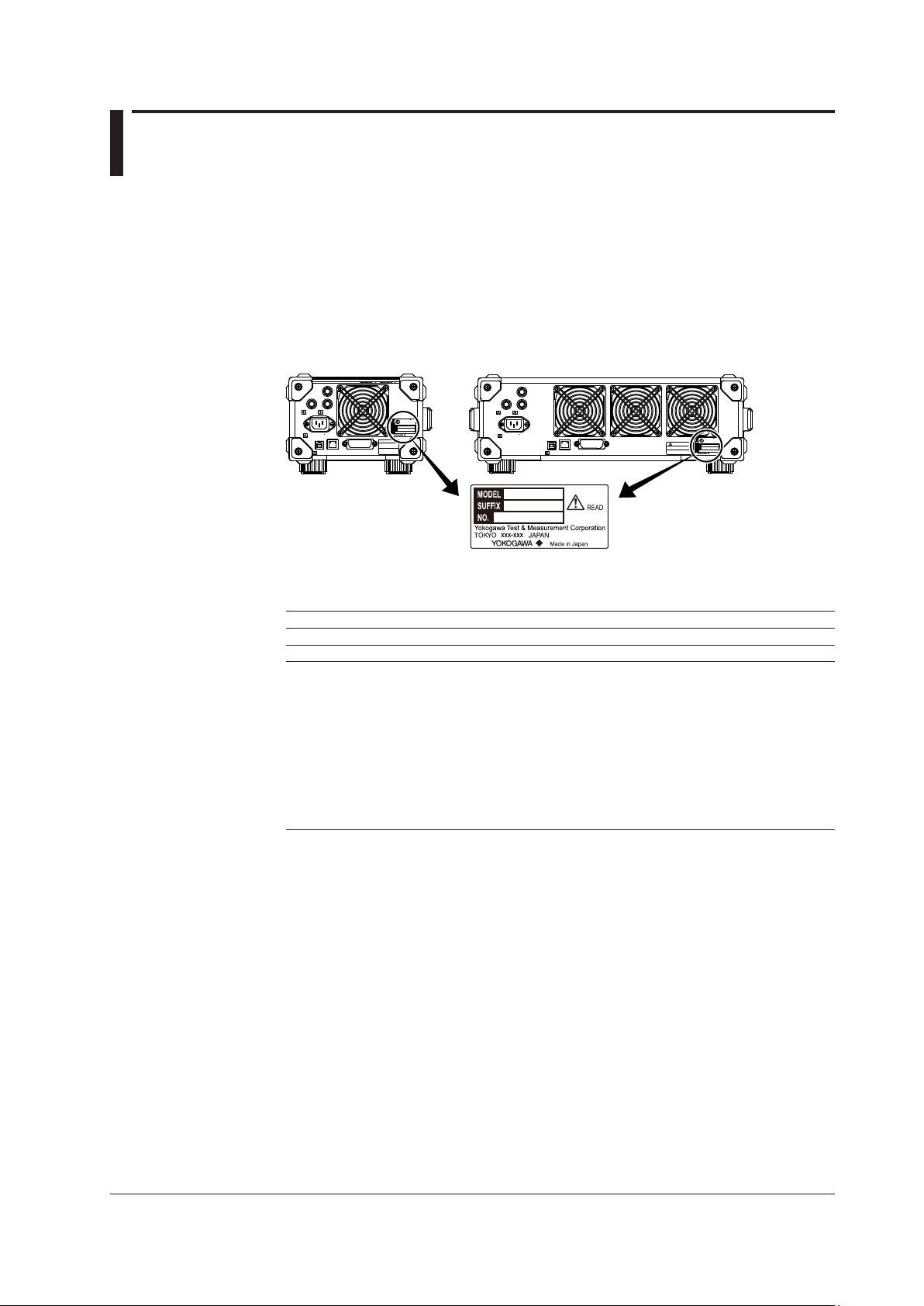

Checking the Package Contents

AQ2211 Frame Controller

AQ2212 Frame Controller

After receiving the product and opening the package, check the items described below.

If the wrong items have been delivered, if items are missing, or if there is a problem with

the appearance of the items, contact your nearest YOKOGAWA dealer. When contacting

the dealer from which you purchased the instrument, please give them the instrument

number.

Also, check that the model name and suffix code given on the name plate on the side

panel of the module are the same as those on your order.

REMOTE

INTERLOCK

170 VA MAX 50/60 Hz

100-240 V AC

TRIGGER

LINK/ACT

USB ETHERNET

IN

OUT

100 LINK

GP-IB

(IEEE488)

WARNING

Do not operate without reading

the safety precautions in the

user's manual.

DATE OF

MANUFACTURE

—

—

□□□□ □□ □□

MODEL

SUFFIX

NO

Made in Japan

REMOTE

INTERLOCK

100-240 V AC

580 VA MAX 50/60 Hz

IN

OUT

TRIGGER

LINK/ACT

100 LINK

ETHERNET

GP-IB

USB

(IEEE488)

AQ2211/AQ2212 Frame Controller

MODEL SUFFIX1Description

735101 AQ2211 Frame Controller (Three slots)

735102 AQ2212 Frame Controller (Nine slots)

Power cord

2

-D UL/CSA standard and PSE compliant, Maximum rated voltage: 125 V

-F VDE/Korean standard, Maximum rated voltage: 250 V

-R Australian standard, Maximum rated voltage: 250 V

-Q British standard, Maximum rated voltage: 250V

-H Chinese standard, Maximum rated voltage: 250 V

-N Brazilian standard, Maximum rated voltage: 250 V

-T Taiwanese standard, Maximum rated voltage: 125 V

-B Indian standard, Maximum rated voltage: 250 V

-U IEC Plug Type B, Maximum rated voltage: 250 V

-Y No power cord included.

3

WARNING

Do not operate without reading the

safety precautions in the user's manual.

DATE OF

MANUFACTURE

—

—

□□□□ □□ □□

MODEL

SUFFIX

NO

Made in Japan

IM 735101-01EN

1 For products whose suffix code contains “Z,” an exclusive manual may be included.

Please read it along with the standard manual.

2 Make sure that the attached power cord meets the designated standards of the country and area

that you are using it in.

3 Prepare a power cord that complies with the standard specified by the country or region that the

instrument will be used in.

No. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please give them

the instrument number.

iii

Page 6

UL/CSA standard

A1006WD

Chinese standard

Brazilian standard

A1088WD

Power cord (one cord that matches the suffix code is included)

Checking the Package Contents

Standard Accessories

The standard accessories below are supplied with the instrument. Check that all contents

are present and that they are undamaged.

1

VDE/Korian standard

A1009WD

D

Taiwanese standard

A1100WD

N

Interlock connector plug

A1288JA 1 piece

F R

T

Rubber feet

A9088ZM 1 set

Australian standard

A1024WD

Indian standard

A1101WD

B

Manuals

• Printed manuals

British standard

A1054WD

Q

IEC Plug Type B

A1102WD

U

2

A1064WD

H

• Manual CD

Standard accessories are not covered by warranty of this instrument.

1 Make sure that the attached power cord meets the designated standards of the country and area

that you are using it in. If the suffix code is -Y, a power cord is not included.

2 Manuals

Item Model or Part No. Quantity Specifications and Notes

Printed manuals IM 735101-01EN 1 Startup Guide (this guide)

PIM 113-01Z2 1 List of worldwide contacts

IM 810518801-61E 1 For the AQ2200-601 10 Gbit/s BERT module

with the /M option

IM 810518801-62E 1 For the AQ2200-601 10 Gbit/s BERT module

with the /P1 option

IM 810518901-04E 1 For the AQ2200 series modules.

Manual CD B8085NZ 1 Contains PDFs of the user’s manuals

(For the types of manuals that CD contains,

see the next page.)

Printed manuals can be purchased separately.

Contact your nearest YOKOGAWA dealer to

purchase a copy.

iv

Optional Accessories (Sold separately)

The optional accessories below are available for purchase separately. For information

about ordering accessories, contact your nearest YOKOGAWA dealer.

Item Model or Part No. Specifications

AQ2200-901 blank panel 810518926 1-slot size

AQ2211 rack mount kit 735182-03 For mounting one AQ2211 to the left side of an EIA-

AQ2212 rack mount kit 735182-09 For mounting one AQ2212 to an EIA-standard rack.

Optional accesories(sold separately) are not covered by warranty of this instrument.

standard rack.

IM 735101-01EN

Page 7

Manual CD

The English folder in the manual CD contains the PDF files shown below. The CD also

contains Japanese manuals.

Manual Title Manual No.

AQ2200 Series Multi Application Test System

User’s Manual Startup Guide

AQ2200 Series Multi Application Test System

Frame and Module Operation User’s Manual

AQ2200 Series Multi Application Test System

Application Operation User’s Manual

AQ2200 Series Multi Application Test System

Communication Interface User’s Manual

To view the manuals above, you need Adobe Reader.

WARNING

Never play this manual CD in an audio CD player.

Doing so may cause loss of hearing or speaker damage due to the high-volume

sound that may be produced.

French

Checking the Package Contents

IM 735101-01EN

IM 735101-03EN

IM 735101-04EN

IM 735101-17EN

AVERTISSEMENT

Ce CD contient les manuels d’utilisation. Ne jamais insérer ce CD dans un lecteur

de CD audio. Cela pourrait entraîner une perte d’audition ou l’endommagement

des enceintes en raison du volume potentiellement élevé des sons produits.

IM 735101-01EN

v

Page 8

Safety Precautions

This product is designed to be used by a person with specialized knowledge.

This instrument is an IEC safety class I instrument (provided with a terminal for protective

earth grounding).

The general safety precautions described herein must be observed during all phases

of operation. If the instrument is used in a manner not specified in this manual, the

protection provided by the instrument may be impaired. This manual is part of the

product and contains important information. Store this manual in a safe place close to the

instrument so that you can refer to it immediately. Keep this manual until you dispose of

the instrument.

YOKOGAWA assumes no liability for the customer’s failure to comply with these

requirements.

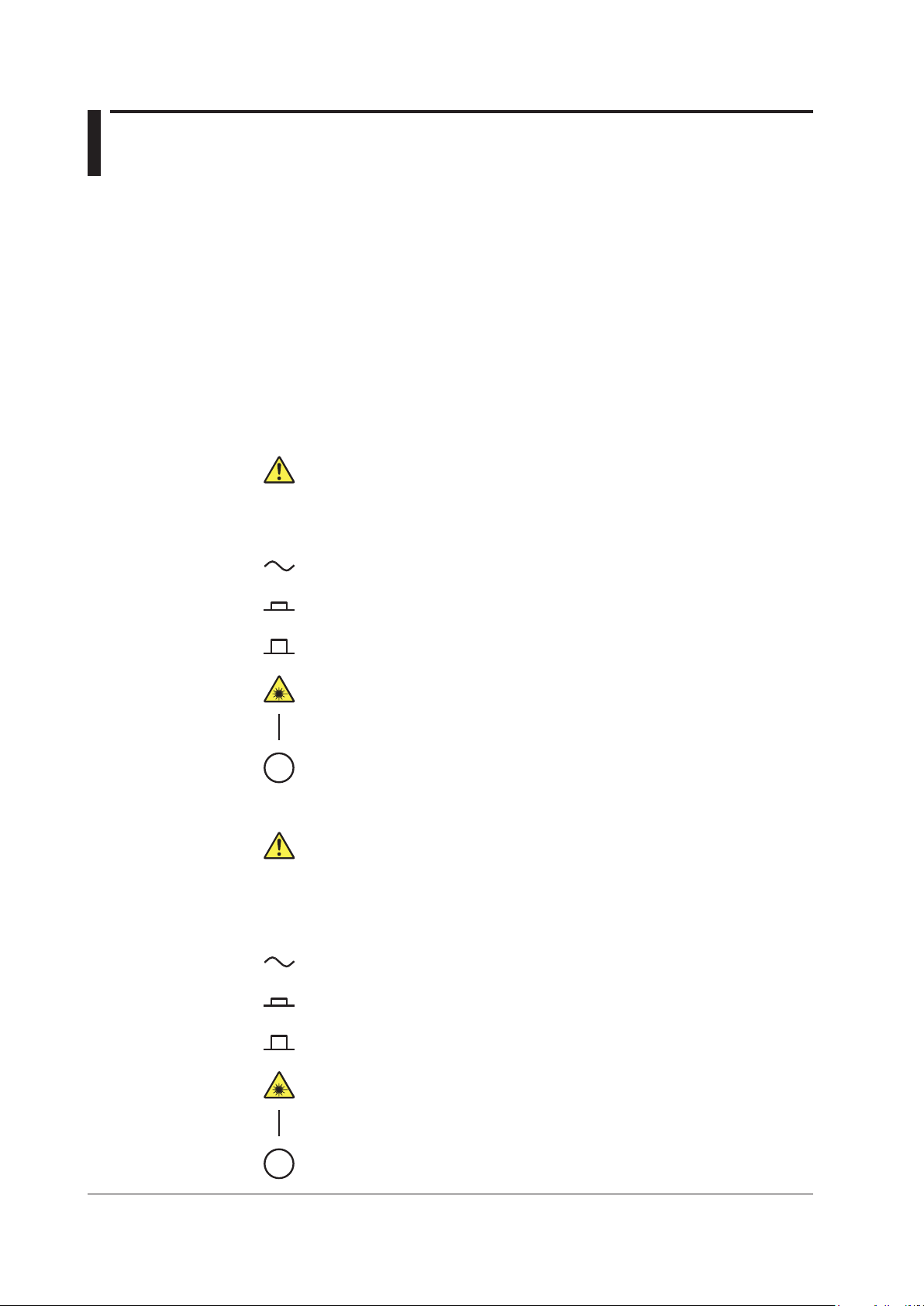

The following symbols are used on this instrument.

Handle with care. Refer to the user’s manual or service manual. This symbol

appears on dangerous locations on the instrument which require special

instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.

Alternating current

Power-on state

Power-off state

Laser radiation hazard

Power on

Power off

French

À manipuler délicatement. Toujours se reporter aux manuels d’utilisation et

d’entretien. Ce symbole a été apposé aux endroits dangereux de l’instrument pour

lesquels des consignes spéciales d’utilisation ou de manipulation ont été émises.

Le même symbole apparaît à l’endroit correspondant du manuel pour identifier les

consignes qui s’y rapportent.

Courant alternatif

Marche

Arrêt

Danger : Appareil laser à rayonnement.

Marche (alimentation)

Arrêt (alimentation)

vi

IM 735101-01EN

Page 9

Safety Precautions

Failure to comply with the precautions below could lead to injury or death or

damage to the instrument.

WARNING

Use the Instrument Only for Its Intended Purpose

This optical measuring instrument is designed to measure the optical characteristics

of light sources and evaluate their performance. Do not use this instrument for

anything other than as an optical measuring instrument.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

Use the Correct Power Supply

Make sure that the power supply voltage matches the instrument’s rated supply

voltage and that it does not exceed the maximum voltage range of the power cord

to use.

Use the Correct Power Cord and Plug

To prevent electric shock or fire, be sure to use the power cord for the instrument.

The main power plug must be plugged into an outlet with a protective earth terminal.

Do not invalidate this protection by using an extension cord without protective earth

grounding. Further, do not use this power cord with other instruments.

Connect to a Protective Earth Terminal

To prevent electric shock, be sure to connect to a protective earth terminal before

turning on the frame controller’s power. The power cord to use is a three-prong

cord. Connect the power cord to a properly grounded three-prong outlet.

Do Not Impair the Protective Grounding

Never cut off the frame controller’s internal or external protective earth wire or

disconnect the wiring to the protective earth terminal. Doing so may result in

electric shock or damage to the instrument.

Do Not Operate with Defective Protective Grounding or Fuses

Do not operate the frame controller if its protective grounding or one of its fuses

might be defective. Check the grounding and the fuses before operating the frame

controller.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or vapors.

Doing so is extremely dangerous.

Do Not Remove the Covers or Disassemble or Alter the Instrument

Only qualified YOKOGAWA personnel may remove the covers and disassemble or

alter the instrument. The inside of the frame controller is dangerous because parts

of it have high voltages.

IM 735101-01EN

Ground the Instrument before Making External Connections

Securely connect the protective grounding before connecting to the item under

measurement or to an external control unit. Before touching a circuit, turn off its

power and check that it has no voltage.

vii

Page 10

Safety Precautions

Avoid Electric Shock When Using the Modules

Do not apply an input voltage that exceeds the maximum input voltage, withstand

voltage, or allowable surge voltage.

To prevent the possibility of electric shock, be sure to fasten the screws that are at

the bottom of the front panel of 2-slot and 3-slot modules. Otherwise, the electrical

and mechanical protection functions will not be activated.

Do not leave the modules connected to the instrument in environments in which a

voltage equal to or greater than the allowable surge voltage may occur.

Dispose the Instrument Properly

Do not throw this instrument into a fire to dispose of it. Doing so may cause the

instrument to explode, resulting in fire or personal injury.

The devices used in this instrument contain gallium arsenide (GaAs) and indium

phosphide (InP). When you dispose this instrument, you must separate it from

general industrial waste and household garbage, and dispose of it according to

local regulations.

Additionally, gallium arsenide powder and vapor are dangerous substances. Do not

burn, cut, crush, chemically disassemble, or otherwise destroy this instrument.

Install or Use the Instrument in Appropriate Locations

• Do not install or use the instrument outdoors or in locations subject to rain or

water.

• Install the instrument so that you can immediately remove the power cord if an

abnormal or dangerous condition occurs.

CAUTION

Operating Environment Limitations

This is a class A instrument designed for an industrial environment. Operation of

this equipment in a residential area can cause radio interference, in which case

users will be required to correct the interference.

French

AVERTISSEMENT

Utiliser l’instrument aux seules fins prévues

Cet instrument de mesure optique est prévu pour mesurer les caractéristiques

optiques des sources lumineuses et évaluer leur performance. Ne pas utiliser cet

instrument à d’autres fins que celles de mesure optique.

Inspecter l’apparence physique

Ne pas utiliser l’instrument si son intégrité physique semble être compromise.

Vérifier l’alimentation

Assurez-vous que la tension d’alimentation correspond à la tension d’alimentation

nominale de l’appareil et qu’elle ne dépasse pas la plage de tension maximale du

cordon d’alimentation à utiliser.

viii

Utiliser le cordon d’alimentation et la fiche adaptés

Pour éviter tout risque de choc électrique, utiliser exclusivement le cordon

d’alimentation prévu pour cet instrument. La fiche doit être branchée sur une prise

secteur raccordée à la terre. En cas d’utilisation d’une rallonge, celle-ci doit être

impérativement reliée à la terre. Par ailleurs, ne pas utiliser ce cordon d’alimentation

avec d’autres instruments.

IM 735101-01EN

Page 11

Safety Precautions

Brancher la prise de terre

Avant de mettre l’instrument sous tension, penser à brancher la prise de terre

pour éviter tout choc électrique. Le cordon d’alimentation à utiliser est un cordon

d’alimentation à trois broches. Brancher le cordon d’alimentation sur une prise de

courant à trois plots et mise à la terre.

Ne pas entraver la mise à la terre de protection

Ne jamais neutraliser le fil de terre interne ou externe, ni débrancher la borne

de mise à la terre. Cela pourrait entraîner un choc électrique ou endommager

l’instrument.

Ne pas utiliser avec un conducteur de terre ou un fusible défectueux

Ne pas utiliser l’instrument si le conducteur de terre ou le fusible est défectueux.

Vérifier le conducteur de terre et le fusible avant d’utiliser l’instrument.

Ne pas utiliser dans un environnement explosif

Ne pas utiliser l’instrument en présence de gaz ou de vapeurs inflammables.

Cela pourrait être extrêmement dangereux.

Ne pas retirer le capot, ni démonter ou modifier l’instrument

Seul le personnel YOKOGAWA qualifié est habilité à retirer le capot et à démonter

ou modifier l’instrument. Certains composants à l’intérieur de l’instrument sont à

haute tension et par conséquent, représentent un danger.

Relier l’instrument à la terre avant de le brancher sur des connexions

externes

Toujours relier l’instrument à la terre avant de le brancher aux appareils à mesurer

ou à une commande externe. Avant de toucher un circuit, mettre l’instrument hors

tension et vérifier l’absence de tension.

Éviter les chocs électriques lors de l’utilisation des modules.

Ne pas dépasser les valeurs maximales de tension d'entrée, de tension de

maintien ou de surtension admissible.

Pour éviter tout risque de choc électrique, veiller à serrer les vis situées au bas du

panneau avant des modules à 2 et 3 emplacements, à défaut de quoi les fonctions

de protection électrique et mécanique ne seront pas activées.

Ne pas laisser les modules branchés à l'instrument dans des environnements dans

lesquels la tension pourrait être égale ou supérieure à la surtension admissible.

Mettre l’instrument au rebut de manière adéquate.

Ne pas mettre l’instrument au rebut en le jetant au feu. Il risquerait d’exploser et de

provoquer un incendie ou de blesser quelqu’un.

Les dispositifs utilisés avec cet instrument contiennent de l’arséniure de gallium

(AsGa) et du phosphure d’indium (InP). Lors de la mise au rebut de l’instrument,

vous ne devez pas l’associer aux déchets industriels généraux ni aux déchets

domestiques, mais l’éliminer conformément aux réglementations locales.

De plus, la poudre et les vapeurs d’arséniure de gallium sont des substances

dangereuses. Ne pas brûler, couper, écraser, démonter chimiquement ou détruire

cet instrument.

IM 735101-01EN

ix

Page 12

Safety Precautions

Installer et utiliser l’instrument aux emplacements appropriés

• Ne pas installer, ni utiliser l’instrument à l’extérieur ou dans des lieux exposés à

la pluie ou à l’eau.

• Installer l’instrument de manière à pourvoir immédiatement le débrancher du

secteur en cas de fonctionnement anormal ou dangereux.

ATTENTION

Limitations relatives à l’environnement opérationnel

Ce produit est un produit de classe A (pour environnements industriels).

L’utilisation de ce produit dans un zone résidentielle peut entraîner une interférence

radio que l’utilisateur sera tenu de rectifier.

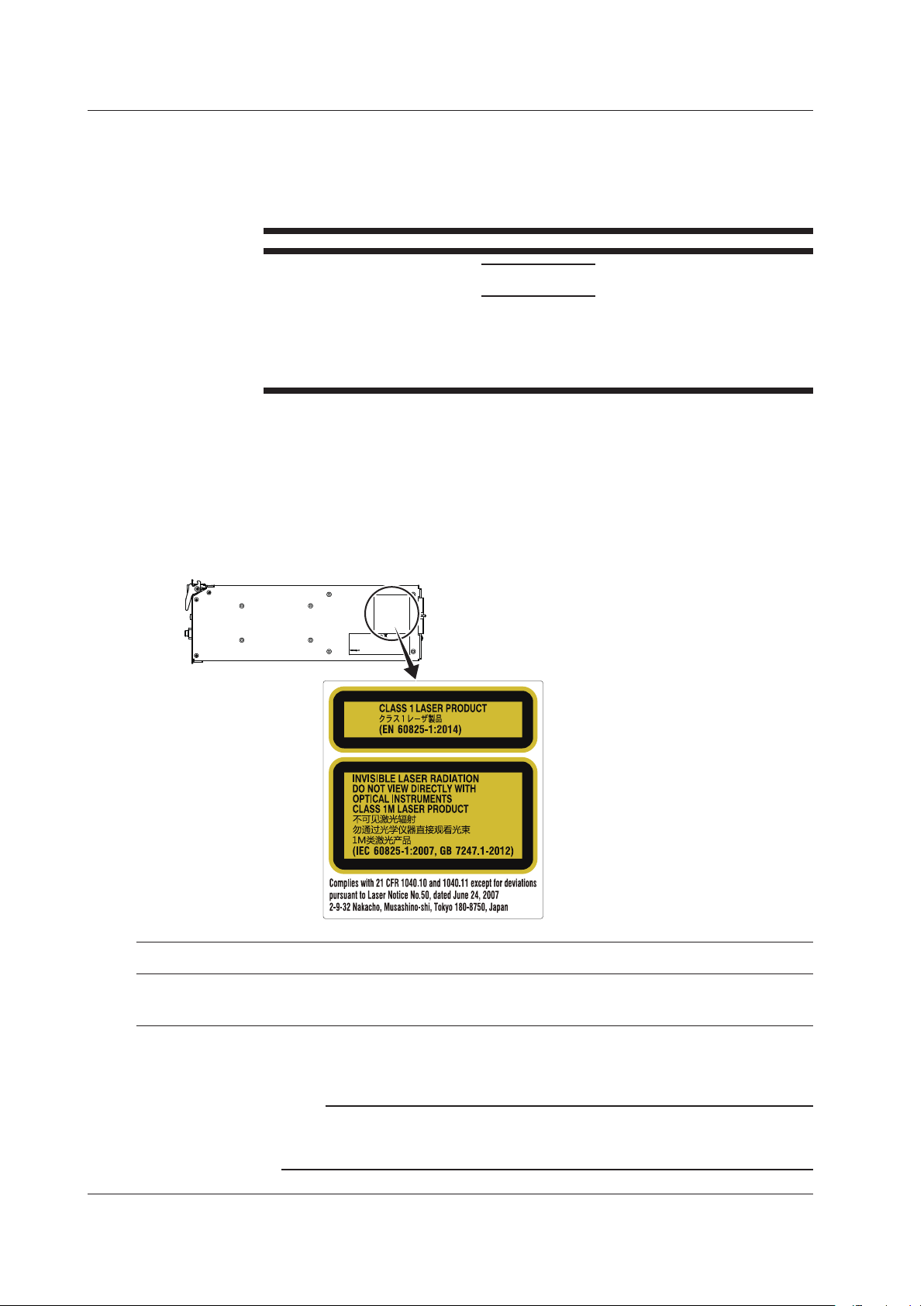

Safety Precautions for Laser Products

This instrument uses a laser light source. This instrument is a Class 1M laser product as

defined by IEC 60825-1:2007 Safety of Laser Products—Part1: Equipment Classification

and Requirements. In addition, this instrument complies with 21 CFR 1040.10 and

1040.11 except for deviations pursuant to Laser Notice No. 50, dated June 24, 2007.

AQ2200-112, AQ2200-131, and AQ2200-132 Modules

Laser Class 1 Label

Laser Class 1M Label

Using an optical instrument, such as a

loupe, magnifying glass, or microscope,

when observing the laser beam from a

distance of less than 100 mm may cause

eye injury.

Do not expose users of binoculars or

telescopes.

Skin exposure near aperture may cause

burns.

Model Class Laser Type 1Center Wavelength

AQ2200112 1, 1M DFB-Laser 1310 to 1650 nm 40 mW 9 μm 11.5 degree CW

AQ2200131 1, 1M ITLA 1527.60 to 1608.76 nm 63 mW 9 µm 11.5 degree CW

AQ2200132 1, 1M ITLA 1527.60 to 1608.76 nm 63 mW 9 µm 11.5 degree CW

1 Class 1: EN 60825-1:2014

Class 1M: IEC 60825-1:2007, GB 7247.1-2012

2 Under single fault conditions.

Maximum

Output Power

Mode Field

2

Diameter

Beam Divergence

(full angle at 1/e2)

Pulse Duration and

Repetition Rate

Note

Laser classes differ depending on the standard number and the year of the standard.

Take safety measures according to the laser class corresponding to the standard of the country

or region that the instrument will be used in.

x

IM 735101-01EN

Page 13

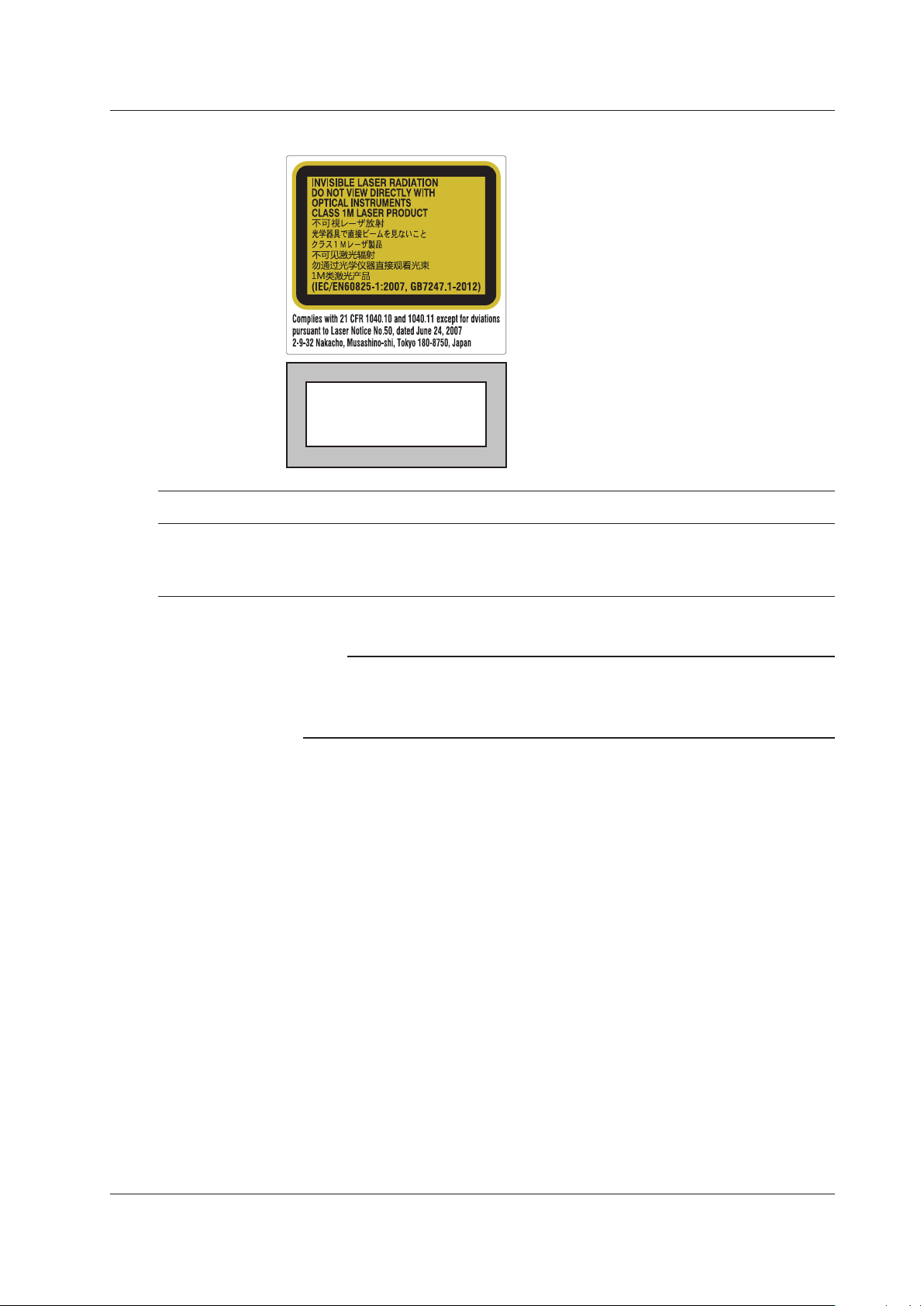

AQ2200-111, AQ2200-141, AQ2200-142, and AQ2200-136 Modules

Laser Class 1M Label

Using an optical instrument, such as a loupe,

CLASS 1 LASER PRODUCT

(IEC 60825-1:2007)

Safety Precautions

magnifying glass, or microscope, when

observing the laser beam from a distance of

less than 100 mm may cause eye injury.

Do not expose users of binoculars or

telescopes.

Skin exposure near aperture may cause

burns.

Laser Class 1 Label

Model Class Laser Type Center Wavelength

810518901 1M DFB-Laser 1310 to 1650 nm 40 mW

810518902 1 FP-Laser 1310/1550 nm 10 mW

810518903 1 FP-Laser 1310/1550 nm 10 mW

810518904 1M EC-Laser 1440 to 1640 nm 50.2 mW

1 Under single fault conditions.

Maximum

Output Power

Note

• Commercially available XFP transceivers installed in the AQ2200-641 XFP Interface Module

are not covered under warranty.

• For save handling of the laser, consult the user’s manual that came with the XFP

transceiver.

Mode Field

1

Diameter

9

m

μ

9

m

μ

9

m

μ

9

m

μ

Beam Divergence

(full angle at 1/e2)

11.5 degree CW

11.5 degree CW

11.5 degree CW

11.5 degree CW

Pulse Duration and

Repetition Rate

IM 735101-01EN

xi

Page 14

Sales in Each Country or Region

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive

(This directive is valid only in the EU.)

This product complies with the WEEE directive marking requirement. This marking

indicates that you must not discard this electrical/electronic product in domestic

household waste.

Product Category

With reference to the equipment types in the WEEE directive, this product is

classified as a “Monitoring and control instruments” product.

When disposing of products in the EU, contact your local Yokogawa Europe B.V.

office. Do not dispose in domestic household waste.

EU Battery Directive

EU Battery Directive

(This directive is valid only in the EU.)

Batteries are included in this product. This marking indicates they shall be sorted

out and collected as ordained in the EU battery directive.

Battery type: Lithium battery

You cannot replace batteries by yourself. When you need to replace batteries,

contact your local Yokogawa Europe B.V. office.

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test & Measurement

Corporation for this product in the EEA. To contact Yokogawa Europe B.V., see the

separate list of worldwide contacts, PIM 113-01Z2

About Environmental Standard

This instrument complies with environmental standard EN50581, but it will not comply

with the standard if an incompliant module is installed.

For details on compliant modules, see section 5.1.

關於在台灣銷售

This section is valid only in Taiwan.

關於在台灣所販賣的符合其相關規定的電源線

的網址進行查詢

https://tmi.yokogawa.com/support/service-warranty-quality/product-compliance/

A1100WD

的限用物質含量信息,請至下麵

xii

IM 735101-01EN

Page 15

Symbols and Notation Used in This Manual

Notes and Cautions

The notes and cautions in this manual are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage

to the instrument. This symbol appears on the instrument to indicate

that the user must refer to the user’s manual for special instructions.

The same symbol appears in the corresponding place in the user’s

manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

CAUTION

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

Calls attentions to actions or conditions that could cause light injury to

the user or damage to the instrument or user’s data, and precautions

that can be taken to prevent such occurrences.

French

AVERTISSEMENT

ATTENTION

Calls attention to information that is important for proper operation of

Note

Attire l’attention sur des gestes ou des conditions

Attire l’attention sur des gestes ou des conditions

susceptibles de provoquer des blessures graves (voire

mortelles), et sur les précautions de sécurité pouvant

prévenir de tels accidents.

susceptibles de provoquer des blessures légères ou

d’endommager l’instrument ou les données de l’utilisateur,

et sur les précautions de sécurité susceptibles de prévenir

de tels accidents.

the instrument.

IM 735101-01EN

Character Notations

Bold characters in procedural explanations are used to indicate panel keys and soft keys

that are used in the procedure and menu items that appear on the screen.

xiii

Page 16

Contents

List of Manual.....................................................................................................................................i

Checking the Package Contents...................................................................................................... iii

Safety Precautions ........................................................................................................................... vi

Sales in Each Country or Region .................................................................................................... xii

Symbols and Notation Used in This Manual .................................................................................. xiii

Module Model Name, Sux Code, and Accessories ..................................................................... xvi

Chapter 1 Component Names and Functions

1.1 Frame Controller .............................................................................................................. 1-1

1.2 Light Source Modules ....................................................................................................... 1-5

1.3 Optical Sensor Modules ................................................................................................. 1-10

1.4 ORL Module ................................................................................................................... 1-14

1.5 Attenuator Modules ........................................................................................................ 1-15

1.6 Optical Switch Modules .................................................................................................. 1-18

1.7 BERT Module ................................................................................................................. 1-21

1.8 Optical Modulator Modules ............................................................................................. 1-22

1.9 Optical Receiver Module ................................................................................................ 1-23

1.10 XFP Interface Module ..................................................................................................... 1-24

1.11 Transceiver I/F Module ................................................................................................... 1-25

1.12 SG Module ..................................................................................................................... 1-26

Chapter 2 Making Preparations for Measurements

2.1 Handling Precautions ....................................................................................................... 2-1

2.2 Installing the Instrument ................................................................................................... 2-3

2.3 Attaching and Removing Blank Panels ............................................................................ 2-7

2.4 Installing and Uninstalling Modules .................................................................................. 2-9

2.5 Connecting Cables ......................................................................................................... 2-12

2.6 Connecting and Disconnecting Connector Adapters ...................................................... 2-21

2.7 Connecting Optical Fiber Cables .................................................................................... 2-24

2.8 Connecting to the Power Supply .................................................................................... 2-25

Chapter 3 External Input and Output

3.1 Frame Controller .............................................................................................................. 3-1

3.2 Optical Sensor Modules ................................................................................................... 3-3

3.3 BERT Module ................................................................................................................... 3-4

3.4 Optical Modulator Module ................................................................................................ 3-8

3.5 Optical Receiver Module .................................................................................................. 3-9

3.6 XFP Interface Module ..................................................................................................... 3-10

3.7 Transceiver I/F Module ................................................................................................... 3-12

3.8 SG Module ..................................................................................................................... 3-15

xiv

IM 735101-01EN

Page 17

Contents

Chapter 4 Troubleshooting, Maintenance, and Inspection

4.1 Troubleshooting ................................................................................................................ 4-1

4.2 Error Messages ................................................................................................................ 4-6

4.3 Changing Modules ......................................................................................................... 4-16

4.4 Updating the Firmware ................................................................................................... 4-19

4.5 Routine Maintenance ..................................................................................................... 4-27

4.6 Recommended Replacement Parts ............................................................................... 4-34

4.7 Calibration ...................................................................................................................... 4-35

4.8 Disposing of the Instrument ............................................................................................ 4-35

Chapter 5 Specications

5.1 AQ2211/AQ2212 Frame Controller .................................................................................. 5-1

5.2 AQ2200-111 DFB-LD Module ........................................................................................... 5-4

5.3 AQ2200-112 LS Module ................................................................................................... 5-7

5.4 AQ2200-141/142 FP-LD Module ...................................................................................... 5-8

5.5 AQ2200-131/132 Grid TLS Module .................................................................................. 5-9

5.6 AQ2200-136 TLS Module ................................................................................................5-11

5.7 AQ2200-201 Interface Module ....................................................................................... 5-12

5.8 AQ2200-202 Interface Module ....................................................................................... 5-13

5.9 AQ2200-231/241 Optical Sensor Head .......................................................................... 5-14

5.10 AQ2200-232/242 Optical Sensor Head .......................................................................... 5-16

5.11 AQ2200-211 Sensor Module .......................................................................................... 5-18

5.12 AQ2200-215 Sensor Module .......................................................................................... 5-20

5.13 AQ2200-221 Sensor Module .......................................................................................... 5-22

5.14 AQ2200-271 ORL Module .............................................................................................. 5-24

5.15 AQ2200-311 ATTN Module ............................................................................................. 5-25

5.16 AQ2200-311A/312 ATTN Module ................................................................................... 5-26

5.17 AQ2200-331/332 ATTN Module ..................................................................................... 5-27

5.18 AQ2200-342 DUAL ATTN Module .................................................................................. 5-28

5.19 AQ2200-411/412 OSW Module ...................................................................................... 5-29

5.20 AQ2200-421 OSW Module ............................................................................................. 5-30

5.21 AQ2200-601 10 Gbit/s BERT Module ............................................................................ 5-31

5.22 AQ2200-621/622 10 Gbit/s Optical Modulator ............................................................... 5-34

5.23 AQ2200-631 10 Gbit/s Optical Receiver ........................................................................ 5-35

5.24 AQ2200-641 XFP Interface Module ............................................................................... 5-36

5.25 AQ2200-642 Transceiver I/F Module ............................................................................. 5-37

5.26 AQ2200-651 SG Module ................................................................................................ 5-39

5.27 External Dimensions ...................................................................................................... 5-40

1

2

3

4

5

Index

Index

IM 735101-01EN

xv

Page 18

Module Model Name, Suffix Code, and Accessories

AQ2200-111 DFB-LD Module

Model Suffix Code Description

810518901 —

Wavelength -Mxxxx See section 5.2 for the list of supported

wavelengths

-W1310 1310 nm

-W1490 1490 nm

Optical connector -FCA FC/Angled PC connector

Optical output level -P10 10 mW optical output

-P20 20 mW optical output

Optical fiber -SMF SM fiber

-PMF PM fiber

External modulation -MODN No external modulation

-MODS External modulation (sine)

-MODC External modulation (chop)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1 Green

Protective cap* — 1 White (for use with the external

modulation option)

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-112 LS Module

Model Suffix Code Description

AQ2200112 —

Wavelength -D300 DFB-LD, 1310 nm

-D500 DFB-LD, 1550 nm

-D600 DFB-LD, 1625 nm

-D700 DFB-LD, 1650 nm

-D3D3 DFB-LD, Ch1: 1310 nm, Ch2: 1310 nm

-D3D5 DFB-LD, Ch1: 1310 nm, Ch2: 1550 nm

-D3D6 DFB-LD, Ch1: 1310 nm, Ch2: 1625 nm

-D3D7 DFB-LD, Ch1: 1310 nm, Ch2: 1650 nm

-D5D5 DFB-LD, Ch1: 1550 nm, Ch2: 1550 nm

-D5D6 DFB-LD, Ch1: 1550 nm, Ch2: 1625 nm

-D5D7 DFB-LD, Ch1: 1550 nm, Ch2: 1650 nm

-D6D6 DFB-LD, Ch1: 1625 nm, Ch2: 1625 nm

-D6D7 DFB-LD, Ch1: 1625 nm, Ch2: 1650 nm

-D7D7 DFB-LD, Ch1: 1650 nm, Ch2: 1650 nm

(Firmware version 3.08 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1 1-channel model (-D300, -D500,

-D600, -D700)

2 2-channel model (-D3D3, -D3D5,

-D3D6, -D3D7, -D5D5, -D5D6,

-D5D7, -D6D6, -D6D7, -D7D7)

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

xvi

IM 735101-01EN

Page 19

Module Model Name, Suffix Code, and Accessories

AQ2200-141 FP-LD Module

Model Suffix Code Description

810518902 —

Wavelength -W1310 1310 nm

-W1550 1550 nm

Optical connector /FCC AQ9441 (FC) universal adapter

/SCC AQ9441 (SC) universal adapter

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model Notes

AQ9441 (FC) universal adapter 813917321-FCC FC connector

AQ9441 (SC) universal adapter 813917321-SCC SC connector

AQ2200-142 DUAL FP-LD Module

Model Suffix Code Description

810518903 —

Wavelength -W135D 1310/1550 nm

Optical connector /FCC AQ9441 (FC) universal adapter

/SCC AQ9441 (SC) universal adapter

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model Notes

AQ9441 (FC) universal adapter 813917321-FCC FC connector

AQ9441 (SC) universal adapter 813917321-SCC SC connector

IM 735101-01EN

xvii

Page 20

Module Model Name, Suffix Code, and Accessories

AQ2200-131 Grid TLS Module

Model Suffix Code Description

AQ2200131 —

Wavelength -C C-band

-L L-band

LD type -T4 Standard type

-T2 Advanced type (Fine tuning)

-T6 Advanced type (Fine tuning)

Optical fiber -PA PM fiber

Optical connector -FCC FC/PC connector

-FCA FC/Angled PC connector

(-T2 and -T4:Firmware version 3.00 and later)

(-T6:Firmware version 3.05 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-132 Grid TLS Module

Model Suffix Code Description

AQ2200132 —

Wavelength -CC CH1: C-band, CH2: C-band

-LL CH1: L-band, CH2: L-band

-CL CH1: C-band, CH2: L-band

LD type -T4 Standard type

-T2 Advanced type (Fine tuning)

-T6 Advanced type (Fine tuning)

Optical fiber -PA PM fiber

Optical connector -FCC FC/PC connector

-FCA FC/Angled PC connector

(-T2 and -T4:Firmware version 3.00 and later)

(-T6:Firmware version 3.05 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-136 TLS Module

Model Suffix Code Description

810518904 —

Optical connector -FCA FC/Angled PC connector

Optical fiber -SMF SM fiber

Wavelength -WLSTD Changeable

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap (small)* — 2 Green

Protective cap (large)* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

xviii

IM 735101-01EN

Page 21

AQ2200-201 Interface Module

Optical sensor head

Analog out plug

955-230002662

Model Suffix Code Description

810518905 —

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Analog out plug 955-230002662 1

Optical sensor head

connector cable

User’s manual IM 810518901-04E 1 Read before using the instrument

Optional Accessory

The following optional accessory is available for purchase separately.

Item Part No. Notes

Analog out plug 955-230002662

Module Model Name, Suffix Code, and Accessories

955-850002026 1

connector cable

955-850002026

AQ2200-202 Interface Module

Model Suffix Code Description

AQ2200202 —

(Firmware version 3.05 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

User’s manual IM 810518901-04E 1 Read before using the instrument

IM 735101-01EN

xix

Page 22

Module Model Name, Suffix Code, and Accessories

AQ2200-231 Optical Sensor Head

Model Suffix Code Description

810518906 Large-aperture, long-wavelength sensor

Connector adapter /FCC AQ9355C (FC) connector adapter with a light shielding cap

/SCC AQ9335C (SC) connector adapter with a light shielding cap

/STC AQ9335C (ST) connector adapter with a light shielding cap

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Ring* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9335C (FC) connector adapter 810518909-FCC FC connector

AQ9335C (SC) connector adapter 810518910-SCC SC connector

AQ9335C (ST) connector adapter 810518911-STC ST connector

AQ9335C (LC) connector adapter M3407JD LC connector with a dust protection cap

AQ9335C (MU) connector adapter M3407JE MU connector with a dust protection cap

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Light shielding cap (ST) 810518914-STC Light shielding cap for an ST connector

AQ9346 tape fiber adapter 810517917

AQ9302 (125) bare fiber adapter 819705500-0125

AQ9440B MT connector 810517921-B 2, 4, 8, and 12 cores

Dust protection cap (LC) M3407HD Dust protection cap for an LC connector

Dust protection cap (MU) M3407HE Dust protection cap for an MU connector

xx

IM 735101-01EN

Page 23

Module Model Name, Suffix Code, and Accessories

AQ2200-232 Optical Sensor Head

Model Suffix Code Description

AQ2200232 Large-aperture, long-wavelength sensor

Connection cable -L1 Length: 1 m

-L4 Length: 4 m

Connector adapter /FCC AQ9355C (FC) connector adapter with a light shielding cap

/SCC AQ9335C (SC) connector adapter with a light shielding cap

/LCC AQ9335C (LC) connector adapter with a dust protection cap

/MUC AQ9335C (MU) connector adapter with a dust protection cap

(Firmware version 3.05 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Ring* — 1

Connection cable A1638WL 1 For -L1 model (cable length: 1 m)

A1639WL 1 For -L4 model (cable length: 4 m)

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9335C (FC) connector adapter 810518909-FCC FC connector

AQ9335C (SC) connector adapter 810518910-SCC SC connector

AQ9335C (LC) connector adapter M3407JD LC connector with a dust protection cap

AQ9335C (MU) connector adapter M3407JE MU connector with a dust protection cap

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Connection cable A1638WL Cable le ght: 1 m

Connection cable A1639WL Cable le ght: 4 m

Dust protection cap (LC) M3407HD Dust protection cap for an LC connector

Dust protection cap (MU) M3407HE Dust protection cap for an MU connector

IM 735101-01EN

xxi

Page 24

Module Model Name, Suffix Code, and Accessories

AQ2200-241 Optical Sensor Head

Model Suffix Code Description

810518907 Large-aperture, short-wavelength sensor

Connector adapter /FCC AQ9355C (FC) connector adapter with a light shielding cap

/SCC AQ9335C (SC) connector adapter with a light shielding cap

/STC AQ9335C (ST) connector adapter with a light shielding cap

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Ring* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9335C (FC) connector adapter 810518909-FCC FC connector

AQ9335C (SC) connector adapter 810518910-SCC SC connector

AQ9335C (ST) connector adapter 810518911-STC ST connector

AQ9335C (LC) connector adapter M3407JD LC connector with a dust protection cap

AQ9335C (MU) connector adapter M3407JE MU connector with a dust protection cap

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Light shielding cap (ST) 810518914-STC Light shielding cap for an ST connector

AQ9346 tape fiber adapter 810517917

AQ9302 (125) bare fiber adapter 819705500-0125

AQ9440B MT connector 810517921-B 2, 4, 8, and 12 cores

Dust protection cap (LC) M3407HD Dust protection cap for an LC connector

Dust protection cap (MU) M3407HE Dust protection cap for an MU connector

xxii

IM 735101-01EN

Page 25

Module Model Name, Suffix Code, and Accessories

AQ2200-242 Optical Sensor Head

Model Suffix Code Description

AQ2200242 Large-aperture, short-wavelength sensor

Connection cable -L1 Length: 1 m

-L4 Length: 4 m

Connector adapter /FCC AQ9355C (FC) connector adapter with a light shielding cap

/SCC AQ9335C (SC) connector adapter with a light shielding cap

/LCC AQ9335C (LC) connector adapter with a dust protection cap

/MUC AQ9335C (MU) connector adapter with a dust protection cap

(Firmware version 3.06 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Ring* — 1

Connection cable A1638WL 1 For -L1 model (cable length: 1 m)

A1639WL 1 For -L4 model (cable length: 4 m)

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9335C (FC) connector adapter 810518909-FCC FC connector

AQ9335C (SC) connector adapter 810518910-SCC SC connector

AQ9335C (LC) connector adapter M3407JD LC connector with a dust protection cap

AQ9335C (MU) connector adapter M3407JE MU connector with a dust protection cap

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Connection cable A1638WL Cable le ght: 1 m

Connection cable A1639WL Cable le ght: 4 m

Dust protection cap (LC) M3407HD Dust protection cap for an LC connector

Dust protection cap (MU) M3407HE Dust protection cap for an MU connector

IM 735101-01EN

xxiii

Page 26

Analog out plug

955-230002662

Module Model Name, Suffix Code, and Accessories

AQ2200-211 Sensor Module

Model Suffix Code Description

810518908 Highly sensitive, long-wavelength sensor

Connector adapter /FCC AQ9447 (FC) connector adapter with a light shielding cap

/SCC AQ9447 (SC) connector adapter with a light shielding cap

/STC AQ9447 (ST) connector adapter with a light shielding cap

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Analog out plug 955-230002662 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9447 (FC) connector adapter 810804602-FCC FC connector

AQ9447 (SC) connector adapter 810804602-SCC SC connector

AQ9447 (ST) connector adapter 810804602-STC ST connector

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Light shielding cap (ST) 810518914-STC Light shielding cap for an ST connector

AQ9346 tape fiber adapter 810517917

AQ9302 (125) bare fiber adapter 819705500-0125

AQ9440B MT connector 810517921-B 2, 4, 8, and 12 cores

Analog out plug 955-230002662

xxiv

IM 735101-01EN

Page 27

Module Model Name, Suffix Code, and Accessories

AQ2200-215 Sensor Module

Model Suffix Code Description

735125 High power sensor

Connector adapter -NON No connector adapter

-FCC AQ9335C (FC) connector adapter with a light shielding cap

-SCC AQ9335C (SC) connector adapter with a light shielding cap

-STC AQ9335C (ST) connector adapter with a light shielding cap

-LCC AQ9335C (LC) connector adapter with a dust protection cap

-MUC AQ9335C (MU) connector adapter with a dust protection cap

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Ring* — 1

Protective cover* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9335C (FC) connector adapter 810518909-FCC FC connector

AQ9335C (SC) connector adapter 810518910-SCC SC connector

AQ9335C (ST) connector adapter 810518911-STC ST connector

AQ9335C (LC) connector adapter M3407JD LC connector with a dust protection cap

AQ9335C (MU) connector adapter M3407JE MU connector with a dust protection cap

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Light shielding cap (ST) 810518914-STC Light shielding cap for an ST connector

Dust protection cap (LC) M3407HD Dust protection cap for an LC connector

Dust protection cap (MU) M3407HE Dust protection cap for an MU connector

IM 735101-01EN

xxv

Page 28

Module Model Name, Suffix Code, and Accessories

AQ2200-221 Sensor Module

Model Suffix Code Description

735122 Two-channel, long-wavelength sensor

Connector adapter -NON No connector adapter

-FCC AQ9335C (FC) connector adapter with a light shielding cap

-SCC AQ9335C (SC) connector adapter with a light shielding cap

-STC AQ9335C (ST) connector adapter with a light shielding cap

-LCC AQ9335C (LC) connector adapter with a dust protection cap

-MUC AQ9335C (MU) connector adapter with a dust protection cap

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Ring* — 2

Protective cover* — 2

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Model or Part No. Notes

AQ9335C (FC) connector adapter 810518909-FCC FC connector

AQ9335C (SC) connector adapter 810518910-SCC SC connector

AQ9335C (ST) connector adapter 810518911-STC ST connector

AQ9335C (LC) connector adapter M3407JD LC connector with a dust protection cap

AQ9335C (MU) connector adapter M3407JE MU connector with a dust protection cap

Light shielding cap (FC) 810518912-FCC Light shielding cap for an FC connector

Light shielding cap (SC) 810518913-SCC Light shielding cap for an SC connector

Light shielding cap (ST) 810518914-STC Light shielding cap for an ST connector

Dust protection cap (LC) M3407HD Dust protection cap for an LC connector

Dust protection cap (MU) M3407HE Dust protection cap for an MU connector

AQ2200-271 ORL Module

Model Suffix Code Description

735185 —

Optical fiber -SA SMF (10/125)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 3

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

Optional Accessories

The optional accessories below are available for purchase separately.

Item Part No. Notes

ORL master cord 955-300001169 FC connector

ORL master cord 955-300001170 SC connector

ORL master cord 955-300900506 Open

xxvi

IM 735101-01EN

Page 29

Module Model Name, Suffix Code, and Accessories

AQ2200-311 ATTN Module

Model Suffix Code Description

810518915 —

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

-FCA FC/Angled PC connector

-SCA SC/Angled PC connector

Monitor port option /MON Monitor port included

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

— 3 When the monitor port (/MON) is

available

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-311A ATTN Module

Model Suffix Code Description

735131 —

Optical fiber -SA SMF (10/125)

-G5 MMF (50/125)

-G6 MMF (62.5/125)

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

Monitor port option /MON Monitor port included

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

— 3 When the monitor port (/MON) is

available

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-312 ATTN Module

Model Suffix Code Description

AQ2200312 —

Optical fiber -SA SMF (10/125)

-G5 MMF (50/125)

-G6 MMF (62.5/125)

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

Monitor port option /MON Monitor port included

(Firmware version 3.04 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

— 3 When the monitor port (/MON) is

available

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

IM 735101-01EN

xxvii

Page 30

Module Model Name, Suffix Code, and Accessories

AQ2200-331 ATTN Module

Model Suffix Code Description

735133 Built-in monitor power meter

Optical fiber -SA SMF

Optical connector -FCC FC/PC connector

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

-G5 MMF (GI 50/125)

-G6 MMF (GI 62.5/125)

-SCC SC/PC connector

AQ2200-332 ATTN Module

Model Suffix Code Description

AQ2200332 Built-in monitor power meter

Optical fiber -SA SMF

-G5 MMF (GI 50/125)

-G6 MMF (GI 62.5/125)

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

(Firmware version 3.04 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-342 DUAL ATTN Module

Model Suffix Code Description

AQ2200342 Built-in monitor power meters

Optical fiber -SA SMF

Optical connector -FCC FC/PC connector

-FCA FC/Angled PC connector

(Firmware version 3.01 and later)

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

xxviii

IM 735101-01EN

Page 31

Module Model Name, Suffix Code, and Accessories

AQ2200-411 OSW Module

Model Suffix Code Description

735141 1×4 or 1×8

Port configuration -04 1×4

-08 1×8

Optical fiber -SA SMF

-G5 MMF (GI 50/125)

-G6 MMF (GI 62.5/125)

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 5 When the port configuration is 1×4

— 9 When the port configuration is 1×8

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-412 OSW Module

Model Suffix Code Description

735143 1×16

Port configuration -16 1×16

Optical fiber -SA SMF

-G5 MMF (GI 50/125)

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 17

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-421 OSW Module

Model Suffix Code Description

735142 1×2 or 2×2

Port configuration -21 1×2

-22 2×2

Optical fiber -SA SMF

-G5 MMF (GI 50/125)

-G6 MMF (GI 62.5/125)

Optical connector -FCC FC/PC connector

-SCC SC/PC connector

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 6 When the port configuration is 1×2

— 8 When the port configuration is 2×2

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

IM 735101-01EN

xxix

Page 32

Module Model Name, Suffix Code, and Accessories

AQ2200-601 10 Gbit/s BERT Module

Model Suffix Code Description

810518801 —

Options /M PC software for creating 64 Mbit program patterns

/P1 PC software for creating SDH/SONET frame patterns

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 5

Terminator for circuit

protection*

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

AQ2200-621 10 Gbit/s Optical Modulator

Model Suffix Code Description

810518802

Crystal orientation of

the LN modulator

Optical connector -S SC connector

Cable /P

— 6

1.55

-A X-cut

-B Z-cut

-F FC connector

PMF (FC-SC) for 1.5

/U U-link coaxial cable

m

μ

m

μ

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

Terminator for circuit

protection*

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

— 1

AQ2200-622 10 Gbit/s Optical Modulator

Model Suffix Code Description

810518804

Crystal orientation of

the LN modulator

Optical connector -S SC connector

Cable /P

-A X-cut

-B Z-cut

-F FC connector

/U U-link coaxial cable

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 2

Terminator for circuit

protection*

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

— 1

1.31

m

μ

PMF (FC-SC) for 1.3

m

μ

xxx

IM 735101-01EN

Page 33

Module Model Name, Suffix Code, and Accessories

AQ2200-631 10 Gbit/s Optical Receiver

Model Suffix Code Description

810518803

Optical connector -S SC connector

-F FC connector

Cable /U U-link coaxial cable

1.31/1.55

m

μ

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Terminator for circuit

protection*

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

— 1

AQ2200-641 XFP Interface Module

Model Suffix Code Description

735161 —

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 3

Terminator for circuit

protection*

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

— 2

AQ2200-642 Transceiver I/F Module

Model Suffix Code Description

735162 —

Standard Accessory

The standard accessory below is supplied with the instrument.

Item Model or Part No. Quantity Notes

User’s manual IM 810518901-04E 1 Read before using the instrument

AQ2200-651 SG Module

Model Suffix Code Description

735163 —

Standard Accessories

The standard accessories below are supplied with the instrument.

Item Model or Part No. Quantity Notes

Protective cap* — 1

Terminator for circuit

protection*

User’s manual IM 810518901-04E 1 Read before using the instrument

*: Already attached to the module

— 6

IM 735101-01EN

xxxi

Page 34

Display screen

Hard keys

Power switch

Used when you connect a USB

Used to remotely control the instrument.

Power inlet

Used to remotely control the instrument.

Chapter 1 Component Names and Functions

1.1 Frame Controller

Three-Slot Type

Front

Module installation slots

Hold AQ2200 series modules.

1 2 3

DETAIL

SUMMARY

FILE

PRTSC

7

4

1

0

Displays settings and measured results.

Soft keys

Used when you control the

frame controller or a module.

FRAME CONTROLLER

AQ2211

8

SLOT SLOT

5

HOLD

2

MACRO

PRESET

9

6

APPLI

3

SYSTEM

SHIFT

CANCEL

POWER

ENTER

USB Port (type A)

memory device.

USB

1

Component Names and Functions

Back

This is the connector for the power source.

REMOTE INTERLOCK connector

(For details, see section 3.1.)

TRIGGER-OUT connector

(For details, see section 3.1.)

TRIGGER-IN connector

IN

OUT

REMOTE

TRIGGER

INTERLOCK

100-240 V AC

170 VA MAX 50/60 Hz

LINK/ACT

100 LINK

USB ETHERNET

(

IEEE488

GP-IB

)

(For details, see section 3.1.)

Xxxxxxx xxxx xxxxx xxxx

xxxx xxxxx xxxx xxxx xxx

xxxxx xxxxxx xxx xxxx

xxxxxxx xxxxx xxxxxxx

Xxxx XX, XXXX

X-X-XX Xxxxxxxx,

Xxxxxxx-xxx, Xxxxxx,

XXX-XXXX, Xxxxx

DATE OF

MANUFACTURE

MODEL

SUFFIX

NO

WARNING

Do not operate without reading

the safety precautions in the

user` s manual.

GP-IB connector

IM 735101-01EN

Ethernet port

Used to remotely control the instrument.

USB port (type B)

1-1

Page 35

Soft keys

Used when you connect a USB memory device.

Used to remotely control the instrument.

REMOTE INTERLOCK connector

1.1 Frame Controller

Nine-Slot Type

Front

Used when you control the frame controller or a module.

Display screen

Displays settings and measured results.

Module installation slots

Hold AQ2200 series modules.

1 2 3 4 5 6 7 8 9

USB port (type A)

AQ2212

8

7

SLOT SLOT

DETAIL

4

5

SUMMARY

HOLD

2

1

FILE

MACRO

0

PRTSC

PRESET

Hard keys

Power switch

FRAME CONTROLLER

9

6

APPLI

3

CANCEL

CANCEL

SYSTEM

SHIFT

POWER

ENTER

ENTER

USB

Back

(For details, see section 3.1.)

REMOTE

INTERLOCK

100-240 V AC

580 VA MAX 50/60 Hz

Power inlet

This is the connector

for the power source.

TRIGGER-OUT connector

(For details, see section 3.1.)

TRIGGER-IN connector

(For details, see section 3.1.)

IN

OUT

TRIGGER

LINK/ACT

100 LINK

ETHERNET

USB

WARNING

Do not operate without reading the

Xxxxxxxx xxxx XX XXX XXXX.XX xx XXXX.XX xxxx xxx xxxxxxxx

GP-IB

xxxxxxxx xx Xxxx Xxxxx Xx.XX, xxxxx Xxxx XX, XXXX

(

)

IEEE488

X-X-XX Xxxxxx, Xxxxxxxx-xxx, Xxxxx,XXX-XXXX, Xxxxx

safety precautions in the user` s manual.

GP-IB connector

Used to remotely control the instrument.

Ethernet port

Used to remotely control the instrument.

USB port (type B)

DATE OF

MANUFACTURE

1-2

IM 735101-01EN

Page 36

Display

This key is used to cancel operations.

This key is used to set selected items

1.1 Frame Controller

Display and Key Operation Console

1

Component Names and Functions

Displays information such as measured

FRAME CONTROLLER

AQ2211

7

DETAIL

4

SUMMARY

1

FILE

0

PRTSC

8

SLOT SLOT

5

HOLD

2

MACRO

PRESET

9

6

APPLI

3

SYSTEM

SHIFT

values, settings, and status.

CANCEL

POWER

ENTER

USB

Soft keys

The soft keys are used to select and

execute the items that are shown on

the display.

Arrow keys

◄ and ► are used to change the

selected digit during the input of

numeric values and to input

backspaces and the minus symbol in

keypad mode.

▲ and ▼ are used to change the

module to control, move the cursor,

and change numeric values.

ENTER key

and entered values.

USB port (type A)

Used when you connect a USB

memory device.

Hard keys

Power switch

This switch is used when you turn the instrument on and off.

CANCEL key

Hard Keys

Key Name Description

DETAIL Switches the displayed screen to the DETAIL screen.

This hard key is “7” in keypad mode.

SLOT

◄

SLOT

►

SUMMARY Switches the displayed screen to the SUMMARY screen.

HOLD Stops updating the screen display. If you press this hard key again or if you press

APPLI Displays the APPLICATION screen. This hard key is “6” in keypad mode.

FILE Displays the FILE LIST screen. This hard key is “1” in keypad mode.

MACRO Displays the MACRO screen. This hard key is “2” in keypad mode.

SYSTEM Displays the SYSTEM screen. This hard key is “3” in keypad mode.

PRTSC Saves a capture of the displayed screen to a file. This hard key is “0” in keypad

PRESET Initializes the parameters of the frame and the installed modules.

SHIFT Extension key. This hard key is “-” in keypad mode.

Switches the module to control. Each time you press this hard key, you switch the

module that is being controlled to the module in the previous slot. This hard key is “8”

in keypad mode.

Switches the module to control. Each time you press this hard key, you switch the

module that is being controlled to the module in the next slot. This hard key is “9” in

keypad mode.

This hard key is “4” in keypad mode.

another hard key, the screen display will start updating again.

This hard key is “5” in keypad mode.

mode.

This hard key is “.” in keypad mode.

IM 735101-01EN

1-3

Page 37

for any slots that do not have

a module installed in them.

The tab for the slot that contains the current module is shown on top.

1.1 Frame Controller

SUMMARY Screen

The SUMMARY screen displays the information from all the installed modules at once.

You can view the main parameters, and confirm and change all the parameters.

• Current module: Module with a blue background.

You can change this module’s parameters. The parameters that

you can change are displayed as soft keys.

• Current parameter: Parameter with a light blue background.

Current module

Current parameter

“NO MODULE” is displayed

DETAIL Screen

Note

Error No. 1014 may appear on this screen immediately after unit start up.

This error shows that, due to a discrepancy between the release version of the firmware

installed in the frame controller and the firmware installed in the module, there is a possibility

that some operations may not work properly.

Please update the firmware if this error appears.

The DETAIL screen displays the detailed information about the selected module (the

current module).

You can view, confirm, and change all the current-module parameters.

1-4

IM 735101-01EN

Page 38

1.2 Light Source Modules

terminal. (On models with the /MODS

Lock lever release button

Modulation indication lamp

CW/CHOP key

AQ2200-111 DFB-LD Module

Releases the lock lever.

AQ2200-111

DFB-LD

MODULE

1

Component Names and Functions

Lock lever

Used when installing and

uninstalling the module.

The lamp is lit when the laser output

modulation is set to CHOP.

Switches the laser output modulation.

When set to CHOP, modulation is

performed at the current frequency.

Laser output

Transmits the laser beam.

CHOP

CW

CW

CHOP

ANGLED

PC ONLY

PMF+13dBm

ON

OFF

OPT

EXT-CHOP

(TTL)

Laser output indication lamp

The lamp is lit when the laser output

is on.

OPT key

Turns the laser output on and off.

External modulation terminal

A modulation signal is applied to this

or /MODC option.)

IM 735101-01EN

1-5

Page 39

1.2 Light Source Modules

OUTPUT1 key

Lock lever release button

Laser output (OUTPUT1)

OUTPUT1 key

Lock lever release button

Laser output (OUTPUT1)

AQ2200-112 LS Module