Page 1

User's

Manual

USB Compliance

Test Fixture

Safety Precautions

To ensure safe and correct operation of the fixture, you must take the safety precautions given below.

The fixture’s protective functions may not work if used in a manner not described in this manual. The

test fixture is a dedicated instrument for the DL9240/DL9240L. Yokogawa bears no responsibility for,

nor implies any warranty against damages occurring as a result of failure to take these precautions.

The following safety symbols and wording are used on the test fixture.

Warning: handle with care. Refer to the user’s manual or service manual. This symbol

appears on dangerous locations on the instrument which require special instructions for

proper handling or use. The same symbol appears in the corresponding place in the manual

to identify those instructions.

Hot surface

Make sure to comply with the following safety precautions in order to prevent accidents

such as an electric shock which impose serious health risks to the user and damage to the

instrument.

WARNING

• To prevent shock or fires, only use the AC adapter and power cable supplied by

Yokogawa specifically for the test fixture. Also, connect a power supply that meets the

specifications of the AC adapter.

Insert the power cable securely into the plug inlet on the AC adapter, and connect the

output cable securely to the test fixture’s power connector.

AC adapter

Test fixture

Output cable

Power connector

Input terminal

Power cable

Never use an AC adapter or power cable other than the dedicated ones supplied by

Yokogawa. Using the wrong adapter or cable can result in damage or injury.

Also, never use the AC adapter that came with the test fixture for any other device.

• Do not allow any electrically conductive objects to come into contact with the bottom

surface of the test fixture.

• Beware of exposed circuits

Due to the structure of the test fixture, certain components may be exposed. To prevent

injury, remove all jewelry such as rings and wristwatches. Also, make sure not to touch

any exposed connectors or components.

• Never insert your fingers between the metal plates in the center of the test fixture and the

solder-side of the PCB.

CAUTION

• Do not inadvertently twist or pull the USB cable. The wires inside the cable can break,

causing malfunction.

• When shipping or handling, support the test fixture by the center metal plates and avoid

vibration and shock. Take extra care not to drop the test fixture. Also, never carry the test

fixture by the USB cable.

• Due to the structure of the test fixture, certain components may be exposed. Take

precautions against static electricity when handling.

[

INRUSH TEST

]

[

INIT

]

LED2

CN35

[

DEVICE SQ TEST

]

DEVICE RECEIVER

SENSITIVITY TEST

CN14

VBUS

GND

GND

VBUS

CN19

CN20

[

TRIGGER

]

VBUS

CN32

(

OFF

)

(

500 mA

)

SW4

(

500 mA

)

SW3

BACKDRIVE

VOL TAGE TE

ST

[

HOST SQ TEST

]

(

100mA

)

CN11

CN28

CN30

CN29

CN34

CN25

G

D-

D+

G

GND

CN31

LED1

F1

CN100

G

D-

D+

G

CN4

CN2

AVERAGE

CURRENT

DRAW TEST

TP4

TP3

VBUS

VBUS

VBUS

D-

D+

G

CN5

DROOP

TEST

LOAD

TEST

(

3

)

CN9

(

OFF

)

SW1

LOAD

TEST

(

1

)

CN7

LOAD

TEST

(

4

)

CN10

(

100mA

)

SW2

LOAD

TEST

(

2

)

CN8

G

D-

D+

G

G

D+

D-

G

D-

G

CN16

Metal plate

Hold at the locations

of the arrows.

Operating environment limitations

See below for operating environment limitations.

CAUTION

This product is a Class A (for industrial environments) product. Operation of this product in

a residential area may cause radio interference in which case the user will be required to

correct the interference.

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment (WEEE), Directive 2002/96/EC

(This directive is only valid in the EU.)

This product complies with the WEEE Directive (2002/96/EC) marking requirement.

This marking indicates that you must not discard this electrical/electronic product in

domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive Annex 1, this product is

classified as a “Monitoring and Control instrumentation” product.

Do not dispose in domestic household waste. When disposing products in the EU,

contact your local Yokogawa Europe B. V. office.

The Following Symbols are Used in this Manual.

Improper handling or use can lead to injury to the user or damage to the instrument.

This symbol appears on the instrument to indicate that the user must refer to the

user’s manual for special instructions. The same symbol appears in the corresponding

place in the user’s manual to identify those instructions. In the manual, the symbol is

used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

Calls attention to actions or conditions that could cause serious or fatal injury to the

user, and precautions that can be taken to prevent such occurrences.

CAUTION

Calls attentions to actions or conditions that could cause light injury to the user or

damage to the instrument or the user’s data, and precautions that can be taken to

prevent such occurrences.

Note

Calls attention to information that is important for proper operation of the instrument.

This user’s manual describes handling of the test fixture used for USB compliance tests. For USB

compliance test procedures, software operating instructions, and other information, please refer to the

following manuals.

Manual Name Manual No.

USB Compliance Test Software (busXplorer-USB) User’s Manual IM701985-61E

Universal Serial Bus 2.0 Device Compliance Test Procedure (CD-ROM) IM701985-62E

Universal Serial Bus 2.0 Host Compliance Test Procedure (CD-ROM) IM701985-63E

Universal Serial Bus 2.0 Hub Compliance Test Procedure (CD-ROM) IM701985-64E

For inquiries, please see PIM112-01E (attached).

IM 701985-01E

3rd Edition

1. Checking the Product

A name plate with the model name is located on the bottom surface (back side) of the test fixture.

Confirm that the model on the name plate matches that of your order.

MODEL

Model Suffix Code Specification

701985 USB Compliance test fixture

Power cord -D UL/CSA Standard power cord (Part No.:A1068WD)

-F VDE Standard power cord (Part No.:A1071WD)

-Q BS Standard power cord (Part No.:A1069WD)

-R AS Standard power cord (Part No.:A1070WD)

Options /F30 USB compliance software

/MN1* Mini B connector type test fixture

* When the /MN1 option is selected, cable CN25 of the DEVICE RECEIVER SENSITIVITY TEST

block and cable CN31 of the DEVICE SQ TEST BLOCK will have mini b type connectors.

NO. (Instrument Number)

Please have this number ready when contacting your Yokogawa representative.

Note

For PC system requirements and other specifications, see “USB Compliance Test Software User’s

Manual” (IM701985-61E).

2. Product Overview

The test fixture is used together with the USB compliance test software to perform tests conforming

to the USB 2.0 compliance test procedures. The fixture consists of separate test blocks for the

following nine tests: DEVICE SQ TEST, HOST SQ TEST, DEVICE RECEIVER SENSITIVITY TEST,

TRIGGER, INRUSH TEST, LOAD TEST, DROOP TEST, BACKDRIVE VOLTAGE TEST, AVERAGE

CURRENT DRAW TEST. The test block used differs depending on the test.

Waveforms can be observed by probing the measurement pins and waveform measurement

connectors on the test fixture.

3. Names of Parts

CAUTION

• Take care when handling USB cables and the current measurement loop attached to the

test fixture. Pulling strongly on cables can cause them to become detached from the test

fixture.

• Do not forcefully press the measurement pins and waveform measurement connectors

on the test fixture.

CN2

CN4

CN11

CN25

CN31

LOAD

TEST(4)

LOAD

TEST(3)

TRIGGER

INRUSH

TEST

LOAD

TEST(2)

LOAD

TEST(1)

HOST SQ

TEST

BACKDRIVE

VOLTAGE TEST

AVERAGE

CURRENT

DRAW TEST

DROOP

TEST

DEVICE SQ TEST

DEVICE

RECEIVER

SENSITIVITY

TEST

SW8

LED2

LED3

SW3

SW4

SW5

CN16

SW2

SW1

POWER

LED3

LED1

F1

[

POWER

]

CN100

G D- D+ G

CN4

CN1

CN2

[

HOST SQ TEST

]

AVERAGE

CURRENT

DRAW TEST

TP4

TP3

VBUS

VBUS

VBUS

D- D+

G

BACKDRIVE

VOLTAGE TEST

CN13

CN20

TP2

TP1

SW5

[

DISCHARGE

]

[

OFF

]

[

TEST ON

]

G D-D+ G

CN17

CN19

VBUS

GND

[

INRUSH TEST

]

GN16

G

D-D+

G

[

TRIGGER

]

CN11

CN12

CN14

VBUS

GND

CN26

GD-D+

G

CN15

1

CN28

CN30

D-

CN29

D+

RL1

1

1

1

CN34

RL2

SW8

[

TEST

]

DEVICE RECEIVER

SENSITIVITY TEST

CN25

GD-D+

G

[

IN IT

]

CN32

LED2

CN35

GND

VBUS

[

DEVICE SQ TEST

]

CN31

Receptacle A

Receptacle B

Cable A

Cable B

Power LED

Current measurement loop

4. Usage Precautions

Safety Precautions

• Do not remove the case

Do not remove the cover from the top of the test fixture or the case on the bottom. Load resistors

inside the cover and adjacent components become dangerously hot.

• In case of abnormalities

If there are any symptoms of trouble such as strange smells or smoke coming from the test

fixture or AC adapter, remove the power cord from the outlet immediately.

If abnormalities occur, please contact your nearest Yokogawa dealer or representative.

• AC adapter and power cord

Nothing should be placed on top of the AC adapter or power cord. The AC adapter and power

cord should also be kept away from heat sources. When removing the power cord plug from the

outlet, always pull by the plug, never pull by the cord. When removing the AC adapter output

cable from the test fixture, hold by the plug and pull straight out. Do not pull by the cord. If the

cord is damaged, contact your dealer for replacement.

General Handling Precautions

• Do not place anything on top of the test fixture

Never place other instruments or objects containing water on top of the test fixture.

Doing so can lead to malfunction.

• Do not apply shock to the test fixture

Never apply physical shocks to the connectors, switches, or other components.

• Take proper care when carrying

Do not hold by the USB cable. Also, hold the test fixture firmly by the center metal plates, and do

not drop the fixture.

• Extended periods of non-use

Remove the power cord from the outlet.

• Cleaning

When cleaning, remove the power cord from the outlet, then wipe gently with a soft, dry cloth.

Also, never immerse the test fixture in liquid, nor use any detergents or abrasives. Do not use

any volatile solvents such as benzine.

Installation Conditions

Install the fixture so that the following conditions are met.

• Flat horizontal location

• Well ventilated location

• Place the test fixture on a stable, horizontal surface. Also, always orient the fixture with the

component side up.

• Maintain a gap of 10 cm or more on all sides of the test fixture.

VBUS

VBUS

10 cm or more

10 cm or more

10 cm

or

more

10 cm

or

more

Do Not Install the Fixture in the Following Places

• In direct sunlight or near heat sources

• Where an excessive amount of soot, steam, dust, or corrosive gas is present

• Near strong magnetic field sources

• Near high voltages or power lines

• Location where mechanical vibration is high

• In an unstable place

• On an unleveled surface

3rd Edition : December 2008 (YK)

All Rights Reserved, Copyright © 2006, Yokogawa Electric Corporation

IM 701985-01E 3rd Edition 1/2

Page 2

5. Test Blocks

WARNING

• If you set SW1 to SW4 to 500 mA when Vbus is supplying the LOAD TEST connectors

(CN7 to CN9), the load resistors will become extremely hot. Make sure you do not touch

the load resistors.

• Since the load resistors of the LOAD TEST blocks get hot during the Droop and Drop

tests, after finishing these tests, immediately remove the USB cables connected to

connectors CN7–CN10 and disconnect the Vbus power supply from the upstream port, or

turn OFF SW1–SW4.

LOAD TEST

Four blocks (1 to 4) are available for the LOAD test. You can switch the load current between 100

mA, OFF, and 500 mA using the switch for each of the blocks (SW1 to SW4).

Block Name Connector Used Switch Used

LOAD TEST[1] CN7 (receptacle B) SW1 (100 mA/OFF/500 mA)

LOAD TEST[2] CN8 (receptacle B) SW2 (100 mA/OFF/500 mA)

LOAD TEST[3] CN9 (receptacle B) SW3 (100 mA/OFF/500 mA)

LOAD TEST[4] CN10 (receptacle B) SW4 (100 mA/OFF/500 mA)

Note

Supply a voltage of 5 V ±5% to Vbus.

DROOP TEST

Switches the load current between 0 mA and 100 mA at cycles of approximately 2 Hz.

Connector used: CN5 (receptacle B)

INRUSH TEST

SW5 switches between TEST ON, OFF, and DISCHARGE.

When measuring the inrush current, attach a current probe to the current measurement loop.

Cable and connector used: CN16 (cable A) and CN20 (receptacle A)

Note

Do not apply a current of 1 Arms or greater to Vbus.

TRIGGER

Cable and connector used: CN11 (cable A) and CN15 (receptacle A)

HOST SQ TEST

Cable used: CN2 (cable A)

DEVICE RECEIVER SENSITIVITY TEST

SW8 switches RL1(RL2) between INIT and TEST.

• When Set to INIT

TheD+andD−signalsareroutedbetweenCN30andCN25.

• When Set to TEST

TheD+signalisroutedbetweenCN29andCN25,andtheD−signalisroutedbetweenCN28

and CN25.

Vbus is always connected between CN25 and CN30 regardless of the SW8 setting.

Cable and connector used: CN25 (cable B, or mini B cable with the /MN1 option) and CN30

(receptacle B)

DEVICE SQ TEST

SW8 switches RL2 (RL1) between INIT and TEST.

• When Set to INIT

The D+ and D– signals are routed between CN34 and CN31.

• When Set to TEST

TheD+andD–signalsareroutedbetweenCN31andthe45Ωterminator.

Vbus is always connected between CN31 and CN34 regardless of the SW8 setting.

Cable and connector used: CN31 (cable B, or mini B cable with the /MN1 option) and CN34

(receptacle B)

BACKDRIVE VOLTAGE TEST

MeasureD+,D−,andVbusvoltageatCN18.

Connector used: CN13 (receptacle A)

AVERAGE CURRENT DRAW TEST

This test block is used for “Device Framework Testing.” Measure the Vbus current between TP3 and

TP4.

For testing methods, see “C. Device Framework Testing” in the Universal Serial Bus Implementers

Forum Full and Low Speed Electrical And Interoperability Compliance Test Procedure.

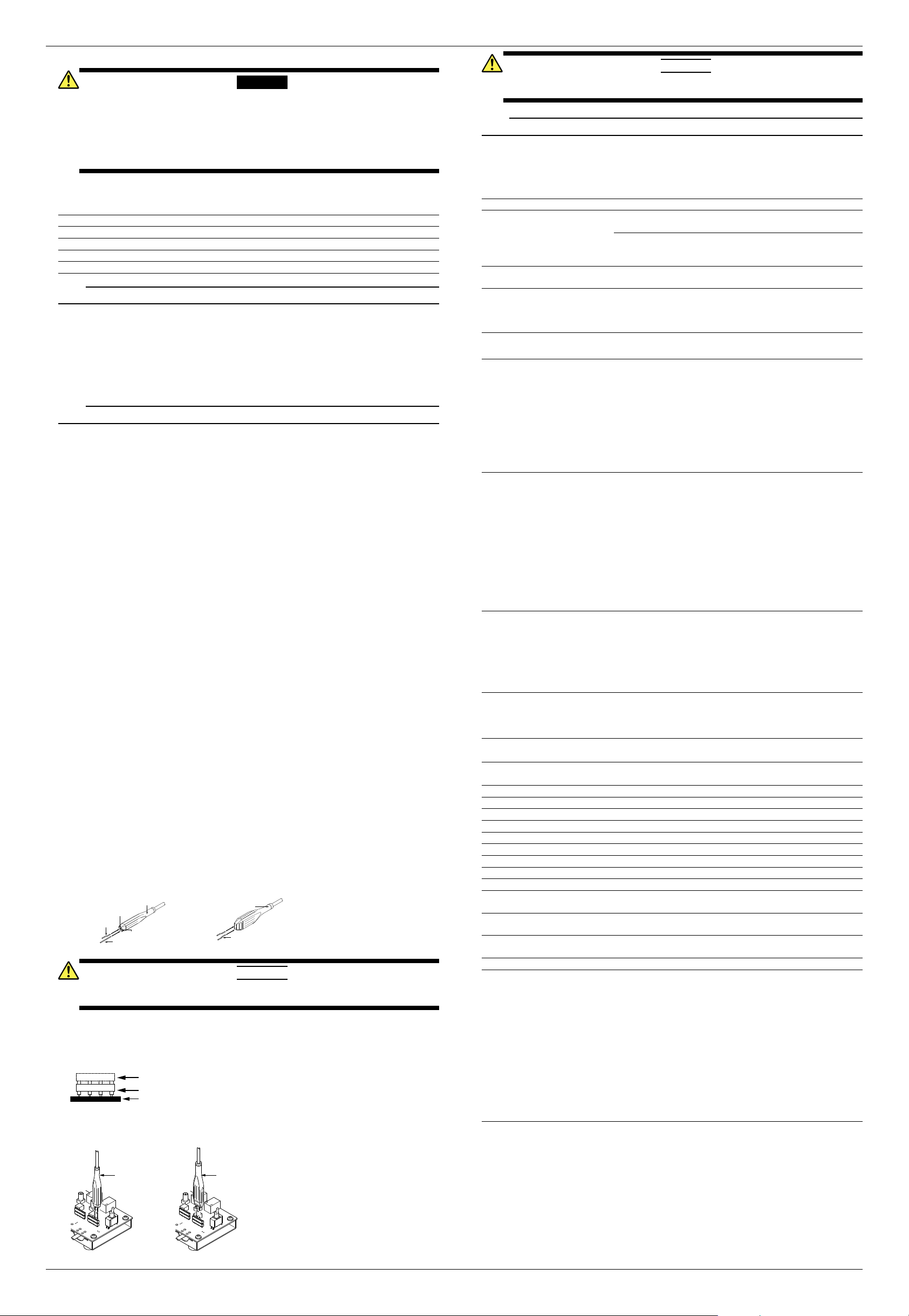

6. Preparing for Waveform Measurement

Affixing the Probe Attachment

• PBA2500 Active Probe (Model 701913, Sold Separately)

Affix the attachment (model B8080JP or B8080JQ) that came with the probe as shown in the

diagram below.

• PBD2000 Active Probe (Model 701923, Sold Separately)

Affix the attachments (model B8080JP, 2 pcs.) that came with the probe as shown in the diagram

below.

B8080JP

B8080JQ

PBA2500

Active Probe

Signal input terminal

GND terminal

+

-

B8080JP

PBD2000

Differential Probe

CAUTION

When inserting a probe with the attachment affixed into the waveform measurement

connector, do not apply vibration or shock to the probe.

Waveform Measurement Connector

• As for the waveform measurement connectors (CN3, CN12, CN17, CN18, CN26, and CN32),

insert the accessory connectors into the connectors already installed on the test fixture in a twolayer configuration. The connectors come in two layers upon shipment.

Fixture

Waveform measurement connectors

Accessory connectors stacked

in two layers

• Affix the dedicated attachments to the PBA2500 and PBD2000 probes, then insert into the

specified pins of the second layer of connectors. For the locations and numbers of pins, see the

procedure manuals for the individual tests.

LED3

[

TEST

]

CN34

RL2

[

INIT

]

LED2

CN32

CN35

GND

[

DEVICE SQ TEST

]

CN31

CN30

CN29

RL1

CN28

CN26

E RECEIVER

IVITY TEST

1

1

CN25

G

D-

D+

G

G

D-

D+

G

D-

VBUS

LED3

[

TEST

]

CN34

RL2

[

INIT

]

LED2

CN32

CN35

GND

[

DEVICE SQ TEST

]

CN31

CN30

CN29

RL1

CN28

CN26

E RECEIVER

IVITY TEST

1

1

CN25

G

D-

D+

G

G

D-

D+

G

D-

VBUS

+

-

PBA2500

Active Probe

PBD2000

Differential Probe

CAUTION

Do not insert anything into the waveform measurement connectors other than the PBA2500

or PBD2000 with dedicated attachments affixed, or the accessory sockets.

Note

Never pull out the top layer of connectors except when changing them.

7. Troubleshooting

Troubleshooting

If servicing is necessary, or if the fixture is not operating correctly after performing the corrective

actions below, contact your nearest YOKOGAWA dealer.

Description Possible Problem Corrective Action

LED1, 2, or 3 does not turn ON. Using an AC adapter of a

voltage outside the rated range.

Use the AC adapter that came

with the fixture.

Faulty connection between the

AC adapter and the CN100

connector of the test fixture.

Check the connection between

the AC adapter and connector

CN100 of the test fixture.

Trigger does not activate on the

inrush current waveform.

SW5 not set to TEST ON. Set SW5 to TEST ON when

measuring.

The VID, PID, connected

address, and port of the DUT

(host/hub) are not displayed in

the HS Electrical Test Tool.

SW8 not set to INIT. Set SW8 to INIT.

8. Specification

Safety Standards

Conforming standards EN61010-1

Overvoltage category (installation category) II*

Pollution degree 2**

* Overvoltage category (installation category) is a number that defines excessive voltage, and

includes regulations for impulse withstand voltage. II applies to electrical equipment that is

powered by a fixed installation such as a distribution board.

** Pollution degree refers to the degree of adherence by a solid, liquid, or vapor that reduces

the withstand voltage or surface resistance factor. Pollution degree 2 applies to normal indoor

atmospheres (with non-conductive pollution) only.

Emmisions

Conforming standards EN61326-1 Class A

EN61326-2-1

EN55011 Class A, Group 1

C-tick EN55011 Class A, Group 1

This product is a Class A (for industrial environment) product. Operation of this product in a

residential area may cause radio interference in which case the user is required to correct the

interference.

Cable conditions

• Use a 5 m USB cable at CN20 (receptacle A) on the INRUSH TEST block.

• Use a 5 m USB cable at CN34 (receptacle B) on the DEVICE SQ TEST block.

• Use a 1 m USB cable at the A and B receptacles on the other TEST blocks.

Immunity

Conforming standards EN61326-1 Table 2 (for use in industrial locations)

EN61326-2-1

Cable conditions

• Use a 5 m USB cable at CN20 (receptacle A) on the INRUSH TEST block.

• Use a 5 m USB cable at CN34 (receptacle B) on the DEVICE SQ TEST block.

• Use a 1 m USB cable at the A and B receptacles on the other TEST blocks.

Reference operating

conditions

Ambient temperature 23˚C±5˚C

Ambient humidity 55 ± 10% RH

Error in supply voltage

and frequency

Within 1% of rating

Storage Environment Temperature –20˚Cto60˚C

Humidity 20% to 80% RH (no condensation)

Operating environment Temperature 5˚Cto40˚C

Humidity 20% to 80% RH (no condensation)

Storage altitude 3000 m or less

Operating altitude 2000 m or less, indoors

Rated supply voltage 100 to 240 VAC

Permitted supply voltage range 90 to 264 VAC

Rated supply frequency 50/60 Hz

Permitted supply frequency range 45 to 66 Hz

Test fixture input voltage 5 V ± 5%

Test fixture power fuse 1.1 A time lag, UL/CSA compliant

Maximum power consumption Approximately 7 VA

Withstand voltage (AC adapter, between input

terminal and output terminal)

3.0 kVAC for one minute

Insulation resistance (AC adapter, between input

terminal and output terminal)

500 VDC, 100 MΩ or more

External dimensions Approximately 317 (W) x 31 (H) x 75 (D) mm,

excluding projections

Weight Approximately 430 g, excluding AC adapter

Standard Accessories

AC adapter (A1626UP) 1

Power cord 1

Waveform Measurement Connector (B8080YH) 6

PBD2000 probe pin, B8080JP (variable type) 6

PBA2500 probe pin, B8080JP (variable type)

B8080JQ (straight type)

4

4

Carrying case (B8080JL) 1

User's manuals (this manual) 1

• Only with the /F30 option

Software (CD-ROM) 1

Software user’s manual (IM701985-61E) 1

The procedures for device, host, and hub are included in PDF format on the software CD-ROM.

IM 701985-01E 3rd Edition 2/2

Loading...

Loading...