Page 1

Operation

Yokogawa Electric Corporation

Guide

Model 436101/436102/436103/436104/436106

µR10000 Recorder

IM 04P01B01-02E

12th Edition

Page 2

Page 3

User Registration Request

Thank you for purchasing YOKOGAWA products.

Please register to the following Partner Portal Member Site.

You can use various services such as confirmation of purchased product information,

download of related materials, and newsletter.

https://partner.yokogawa.com/global/

PRS 108-02E

Page 4

Page 5

Contents

Introduction ................................................................................................................................................................4

Safety Precautions .....................................................................................................................................................4

Handling Precautions .................................................................................................................................................5

SD Memory Card Handling Precautions ....................................................................................................................5

How to Use This Manual ............................................................................................................................................6

Checking the Contents of the Package .....................................................................................................................6

Recorder Style Number, Release Number, and Firmware Version Number ..............................................................7

Removing the Packing Materials ...............................................................................................................................7

Recorder’s Version and Functions Described in This Manual ...................................................................................8

Protection of Environment .........................................................................................................................................9

Function Introduction/Names of Parts ......................................................................................................................10

Function Introduction ...............................................................................................................................................10

Names of Parts ........................................................................................................................................................11

Display and Key Panel .............................................................................................................................................12

Installing/Wiring the Recorder ...................................................................................................................................13

Installation Location .................................................................................................................................................13

Installation Procedure ..............................................................................................................................................13

Input Signal Wiring ...................................................................................................................................................16

Optional Terminal Wiring ..........................................................................................................................................18

Power Supply Wiring ...............................................................................................................................................20

Common Operations and Menu Structure ................................................................................................................22

Execution Modes .....................................................................................................................................................22

Operation Sequence ................................................................................................................................................22

Key Operation ..........................................................................................................................................................23

Menu Structure of Setting Mode ..............................................................................................................................26

Menu Structure of Basic Setting Mode ....................................................................................................................27

Preparing to Record ....................................................................................................................................................28

Loading or Replacing the Chart Paper ....................................................................................................................28

Installing/Replacing Felt Pens (Pen Model) .............................................................................................................30

Installing/Replacing the Plotter Pen (Pen Model) ....................................................................................................31

Installing/Replacing the Ribbon Cassette (Dot Model) ............................................................................................31

Checking or Setting the Date/Time ..........................................................................................................................33

Setting the Input Range and Alarm on Measurement Channels .............................................................................34

Setup Example (1) of Thermocouple Input ..............................................................................................................34

Setup Example (2) of 1-5V Input and unit ................................................................................................................35

Setup Example (3) of 0 to 10 V Input .......................................................................................................................37

Setting the Alarm .....................................................................................................................................................40

Recording/Displaying Data .........................................................................................................................................42

Starting the Recording .............................................................................................................................................42

Stopping the Recording ...........................................................................................................................................42

Feeding the Chart Paper Manually ..........................................................................................................................42

Changing the Chart Speed ......................................................................................................................................43

Viewing the Recorded Results .................................................................................................................................43

Description of the Printout Contents ........................................................................................................................44

Switching the Display Screen ..................................................................................................................................46

Changing the Displayed Information ........................................................................................................................47

FUNC Key Operations in Operation Mode ..............................................................................................................48

Printing Measured Values (Manual Printout) ...........................................................................................................48

Printing the Recorder Settings .................................................................................................................................49

Clearing the Alarm Printout Buer ...........................................................................................................................50

Printing a Message ..................................................................................................................................................50

Releasing the Alarm Output (Alarm ACK Operation) ...............................................................................................51

Activating/Releasing the Key Lock ..........................................................................................................................51

Setup Items and Default Values .................................................................................................................................52

Setup Items in Setting Mode and Their Default Values ...........................................................................................52

Setup Items in Basic Setting Mode and Their Default Values ..................................................................................54

Recommended Replacement Periods for Worn Parts .............................................................................................57

For detailed explanation of functions and the operating procedures of the recorder, see the µR10000 Recorder

User’s Manual (IM 04P01B01-01E).

IM 04P01B01-02E

3

Page 6

Introduction

Thank you for purchasing the YOKOGAWA µR10000 Recorder.

This manual describes concisely the operating procedures of the

µR10000 Recorder. To ensure correct use, please read this manual

and the following manuals thoroughly before beginning operation.

For the product specifications, see the general specifications.

• PaperManuals

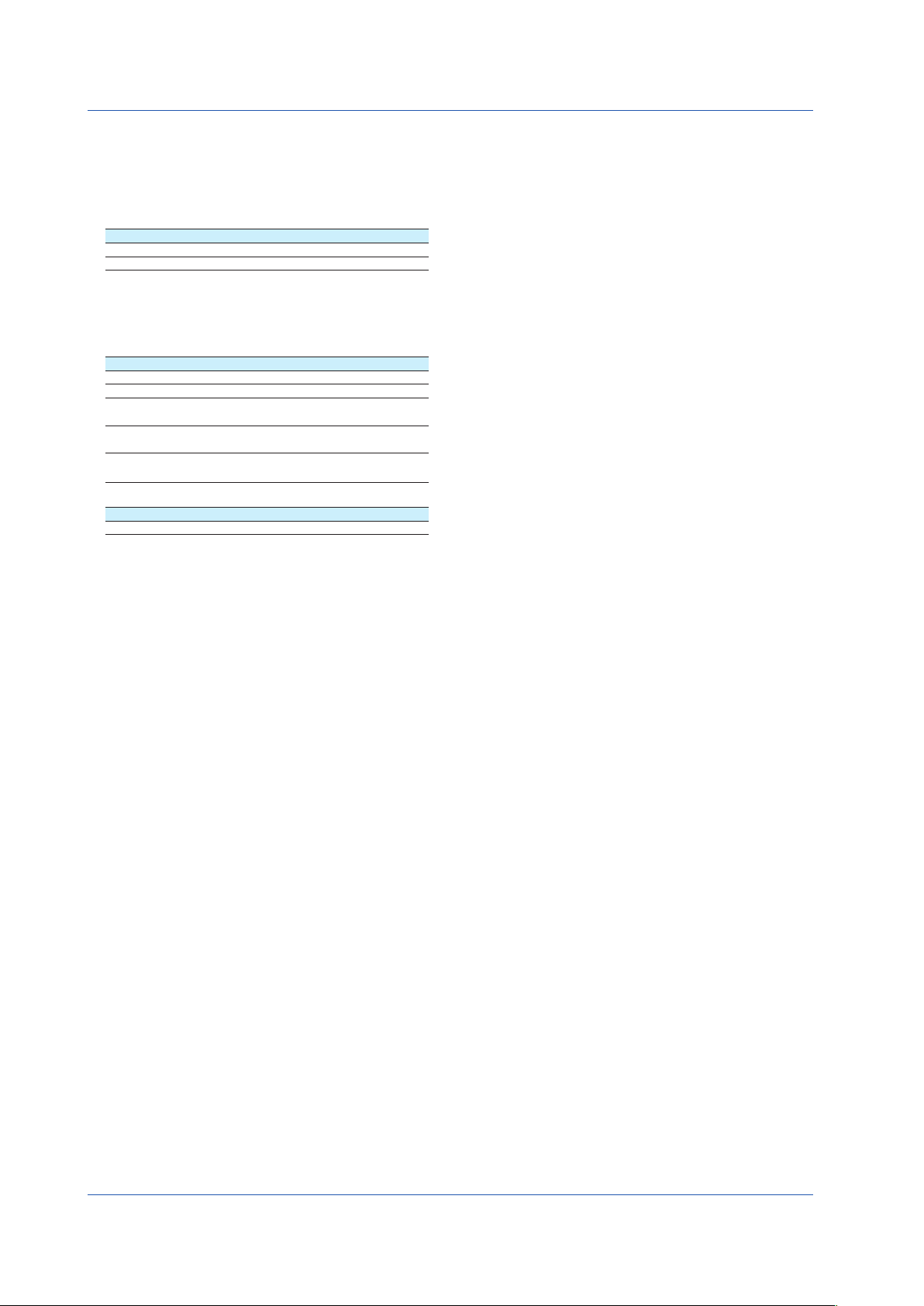

Manual Title Manual No.

μR10000 Recorder Operation Guide IM 04P01B01-02E (this manual)

μR10000 /μR20000 Usage Precautions

1 Only delivered when the Operation Guide is not included.

1

IM 04P01B01-93E

*

• ElectronicManuals

You can download these manuals from the following web page. You

will need Adobe Reader 7 or later (latest version recommended) by

Adobe Systems.

http://www.yokogawa.com/ns/mr/im/

Manual Title Manual No.

μR10000 Recorder Operation Guide IM 04P01B01-02E

μR10000 Recorder User’s Manual IM 04P01B01-01E

μR10000/μR20000 Communication Interface

User’s Manual

μR10000/μR20000 SD Memory Card (/EM1

option) User’s Manual

RXA10-01 and RXA10-02 Configuration

Software User’s Manual (sold separately)

IM 04P01B01-17E

IM 04P01B01-03E

IM 04P01B01-61E

*

• GeneralSpecifications(GS)

GeneralSpecificationsName GeneralSpecificationsNo.

μR10000 Recorder GS04P01B01-01E

* The last character of the manual number and general specifi-

cations number indicates the language in which the manual is

written.

Notes

• The contents of this manual are subject to change without prior

notice as a result of continuing improvements to the instrument’s

performance and functions.

• Every effort has been made in the preparation of this manual to

ensure the accuracy of its contents. However, should you have

any questions or find any errors, please contact your nearest

YOKOGAWA dealer as listed on the back cover of this manual.

• Copying or reproducing all or any part of the contents of this

manual without the permission of Yokogawa Electric Corporation

is strictly prohibited.

• The TCP/IP software of this product and the document con-

cerning the TCP/IP software have been developed/created by

YOKOGAWA based on the BSD Networking Software, Release

1 that has been licensed from the University of California.

QR Code

The product has a QR Code pasted for efficient plant maintenance

work and asset information management.

It enables confirming the specifications of purchased products and

user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

About the Usage of Open Source Software

MD5

The following products uses MD5 source code.

In accordance with the MD5 license agreement, the copyright

notice, redistribution conditions, and license are listed below.

436101, 436102, 436103, 436104, 436106

• RSA Data Security’s MD5 License

RSA Data Security, Inc., MD5 message-digest algorithm

Copyright (C) 1991-2, RSA Data Security, Inc. Created 1991. All

rights reserved.

12th Edition: February 2021 (YK)

All Rights Reserved, Copyright © 2004, Yokogawa Electric Corporation

4

License to copy and use this software is granted provided that it is identified as the “RSA Data Security, Inc. MD5 Message-Digest Algorithm” in

all material mentioning or referencing this software or this function.

License is also granted to make and use derivative works provided

that such works are identified as “derived from the RSA Data Security, Inc. MD5 Message-Digest Algorithm” in all material mentioning

or referencing the derived work.

RSA Data Security, Inc. makes no representations concerning

either the merchantability of this software or the suitability of this

software for any particular purpose. It is provided “as is” without

express or implied warranty of any kind.

These notices must be retained in any copies of any part of this

documentation and/or software.

Trademarks

• All the brands or names of Yokogawa Electric’s products used

in this manual are either trademarks or registered trademarks of

Yokogawa Electric Corporation.

• Microsoft and Windows are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or

other countries.

• Adobe, Acrobat, and PostScript are trademarks of Adobe Sys-

tems Incorporated.

• The SD logo is a registered trademark of the SD association.

• For purposes of this manual, the TM and ® symbols do not

accompany their respective trademark names or registered

trademark names.

• Company and product names that appear in this manual are

trademarks or registered trademarks of their respective holders.

*

Revisions

1st Edition December 10th Edition February 2020

2nd Edition March 2005 11th Edition June 2020

3rd Edition August 2005 12th Edition February 2021

4th Edition September 2006

5th Edition April 2011

6th Edition March 2015

7th Edition July 2017

8th Edition June 2018

9th Edition September 2018

Authorised Representative in the EEA

The Authorised Representative for this product in the EEA is:

Yokogawa Europe B.V.

Euroweg 2, 3825 HD Amersfoort,The Netherlands

Safety Precautions

The general safety precautions described here must be observed

during all phases of operation.

• SafetyStandardsandEMCStandards

This recorder conforms to IEC safety class I (provided with terminal

for protective grounding), Overvoltage Category II or I

Degree 2, Measurement Category II (CAT II)

(EMC standard) class A (use in a commercial, industrial, or busi-

ness environment). The influence rate (judgment condition A) in the

immunity test environment is within ±10 % of the range.

This recorder is designed for indoor use.

*1 II : Applied to standard power supply (100-240 VAC), I: Applied

to /P1 option (24 VDC/AC)

*2 Measurement Category II (CAT II) applies to measuring circuits

connected to low voltage installation, and electrical instruments

supplied with power from fixed equipment such as electric

switchboards.

• AboutThisManual

• This manual should be read by the end user.

• Read this manual thoroughly and have a clear understanding of

the product before operation.

• This manual explains the functions of the product. YOKOGAWA does

not guarantee that the product will suit a particular purpose of the user.

• Under absolutely no circumstances may the contents of this manual

be transcribed or copied, in part or in whole, without permission.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made in the preparation of this manual to

ensure the accuracy of its contents. However, should you have

any questions or find any errors or omissions, please contact

your nearest YOKOGAWA dealer.

• PrecautionsRelatedtotheProtection,Safety,andAlterationof

the Product

*1

*2

, Pollution

, and EN61326-1

IM 04P01B01-02E

Page 7

“High temperature.” To avoid injury caused by hot

appears.

“Handle with care.” To avoid injury and damage

• The following safety symbols are used on the product and in this

manual.

to the instrument, the operator must refer to the

explanation in the manual.

Protective ground terminal

AC

DC

surface, do not touch locations where this symbol

• For the protection and safe use of the product and the system

controlled by it, be sure to follow the instructions and precautions

on safety that are stated in this manual whenever you handle

the product. Take special note that if you handle the product in a

manner that violate these instructions, the protection functionality of the product may be damaged or impaired. In such cases,

YOKOGAWA does not guarantee the quality, performance, function, and safety of the product.

• When installing protection and/or safety circuits such as lightning

protection devices and equipment for the product and control

system or designing or installing separate protection and/or

safety circuits for fool-proof design and fail-safe design of the

processes and lines that use the product and the control system,

the user should implement these using additional devices and

equipment.

• If you are replacing parts or consumable items of the product,

make sure to use parts specified by YOKOGAWA.

• This product is not designed or manufactured to be used in criti-

cal applications that directly affect or threaten human lives. Such

applications include nuclear power equipment, devices using

radioactivity, railway facilities, aviation equipment, air navigation

facilities, aviation facilities, and medical equipment. If so used,

it is the user’s responsibility to include in the system additional

equipment and devices that ensure personnel safety.

• Do not modify this product.

WARNING

• UsetheCorrectPowerSupply

Ensure that the source voltage matches the voltage of the power

supply before turning ON the power.

• ProtectiveGrounding

Make sure to connect the protective grounding to prevent electric shock before turning ON the power.

• NecessityofProtectiveGrounding

Never cut off the internal or external protective earth wire or

disconnect the wiring of the protective earth terminal. Doing so

invalidates the protective functions of the instrument and poses

a potential shock hazard.

• DefectofProtectiveGrounding

Do not operate the instrument if the protective earth or fuse

might be defective. Make sure to check them before operation.

• DoNotOperateinanExplosiveAtmosphere

Do not operate the instrument in the presence of flammable

liquids or vapors. Operation in such environments constitutes a

safety hazard.

• DoNotRemoveCovers

The cover should be removed by YOKOGAWA’s qualified

personnel only. Opening the cover is dangerous, because some

areas inside the instrument have high voltages.

• ExternalConnection

Connect the protective grounding before connecting to the item

under measurement or to an external control unit.

• DamagetotheProtectiveStructure

Operating the recorder in a manner not described in this manual

may damage its protective structure.

IM 04P01B01-02E

Portable Type (/H5x Option)

• UsetheCorrectPowerSupply

Ensure that the power supply is within the maximum rated voltage range of the provided power cord before connecting the

power cord.

• UsetheCorrectPowerCordandPlug

To prevent electric shock or fire, be sure to use the power cord

supplied by YOKOGAWA. The main power plug must be plugged

into an outlet with a protective earth terminal. Do not disable this

protection by using an extension cord without protective earth

grounding. The power cord is designed for use with this instrument. Do not use the power cord with other instruments.

• ConnecttheProtectiveGroundingTerminal

The power cord for the µR10000 is a three-prong type power

cord. Connect the power cord to a properly grounded threeprong outlet.

CAUTION

This instrument is a Class A product. Operation of this instrument in a residential area may cause radio interference, in which

case the user is required to take appropriate measures to correct the interference.

• ExemptionfromResponsibility

• YOKOGAWA makes no warranties regarding the product except

those stated in the WARRANTY that is provided separately.

• YOKOGAWA assumes no liability to any party for any loss or

damage, direct or indirect, caused by the user or any unpredictable defect of the product.

• HandlingPrecautionsoftheSoftware

• YOKOGAWA makes no warranties regarding the software ac-

companying this product except those stated in the WARRANTY

that is provided separately.

• Use the software on a single PC.

• You must purchase another copy of the software, if you are to

use the software on another PC.

• Copying the software for any purposes other than backup is

strictly prohibited.

• Please store the original media containing the software in a safe

place.

• Reverse engineering, such as decompiling of the software, is

strictly prohibited.

• No portion of the software supplied by YOKOGAWA may be

transferred, exchanged, sublet, or leased for use by any third

party without prior permission by YOKOGAWA.

Handling Precautions

• Use care when cleaning the recorder, especially any plastic

parts. When cleaning, wipe using a dry soft cloth. Do not use

chemicals such as benzene or thinner, since these may cause

discoloring and deformation.

• Keep electrically charged objects away from the signal terminals.

This may damage the recorder.

• Do not apply volatile chemicals to the door glass, display, panel

keys, etc. Do not allow rubber and vinyl products to remain in

contact with the recorder for long periods of time. This may damage the recorder.

• When not in use, make sure to turn OFF the power switch.

• If there are any symptoms of trouble such as strange odors or

smoke coming from the recorder, immediately turn OFF the

power switch and the power supply source. Then, contact your

nearest YOKOGAWA dealer.

SD Memory Card Handling Precautions

• SD memory cards are delicate and should be handled with cau-

tion.

• Yokogawa provides no warranty for damage to, or loss of data

recorded on the SD memory card, regardless of the cause of

such damage or loss. Please always make backup copies of

your data.

5

Page 8

Unit: mm

• Do not store or use the SD memory card in places with static

electricity, near electrically charged objects, or where electrical

noise is present. Doing so can result in shock or damage.

• Do not disassemble or modify the SD memory card. Doing so

can result in damage.

• Do not physically shock, bend, or pinch the SD memory card.

Doing so can lead to malfunction.

• During reading/writing of data, do not turn OFF the power, apply

vibration or shock, or pull out the card. Data can become corrupt or permanently lost.

• Only use Yokogawa SD memory cards. Operation cannot be

guaranteed with other brands of card.

• When inserting the SD memory card into the instrument, make

sure you orient the card correctly (face up or down) and that you

insert it securely. If not inserted correctly, the card will not be

recognized by the instrument.

• Never touch the SD memory card with wet hands. Doing so can

lead to shock or malfunction.

• Never use the SD memory card if it is dusty or dirty. Doing so

can lead to shock or malfunction.

• The SD memory card comes formatted.

SD memory cards must be formatted according to the standard

established by the SD Association (https://www.sdcard.org/

home). If you want to format the SD memory card, use the instrument’s Format function. If using a PC to perform the formatting, use the SD memory card formatter software available from

the above SD Association.

• You can use SD/SDHC cards (up to 32 GB) on the µR10000.

SD Memory Card Specifications

Electrical specifications Operating voltage: 2.7 V to 3.6 V

(memory operation)

Operating temperature/

humidity

Storage temperature/

humidity

–25 to 85°C/20 to 85%RH

(no condensation)

–40 to 85°C/5 to 85%RH

(no condensation)

24±0.1

Writable

WP

SD

32±0.1

Write-protected

How to Use This Manual

This manual covers information regarding the recorders with English as the display/printing language (suffix code “2”).

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or damage to the instrument. This symbol appears on the instrument to

indicate that the user must refer to the user’s manual for special

instructions. The same symbol appears in the corresponding place

in the user’s manual to identify those instructions. In the manual,

the symbol is used in conjunction with the word “WARNING” or

“CAUTION.”

WARNING

Calls attention to actions or conditions that could cause serious or

fatal injury to the user, and precautions that can be taken to prevent

such occurrences.

CAUTION

Calls attentions to actions or conditions that could cause light injury

to the user or damage to the instrument or user’s data, and precautions that can be taken to prevent such occurrences.

6

Note

Calls attention to information that is important for proper operation

of the instrument.

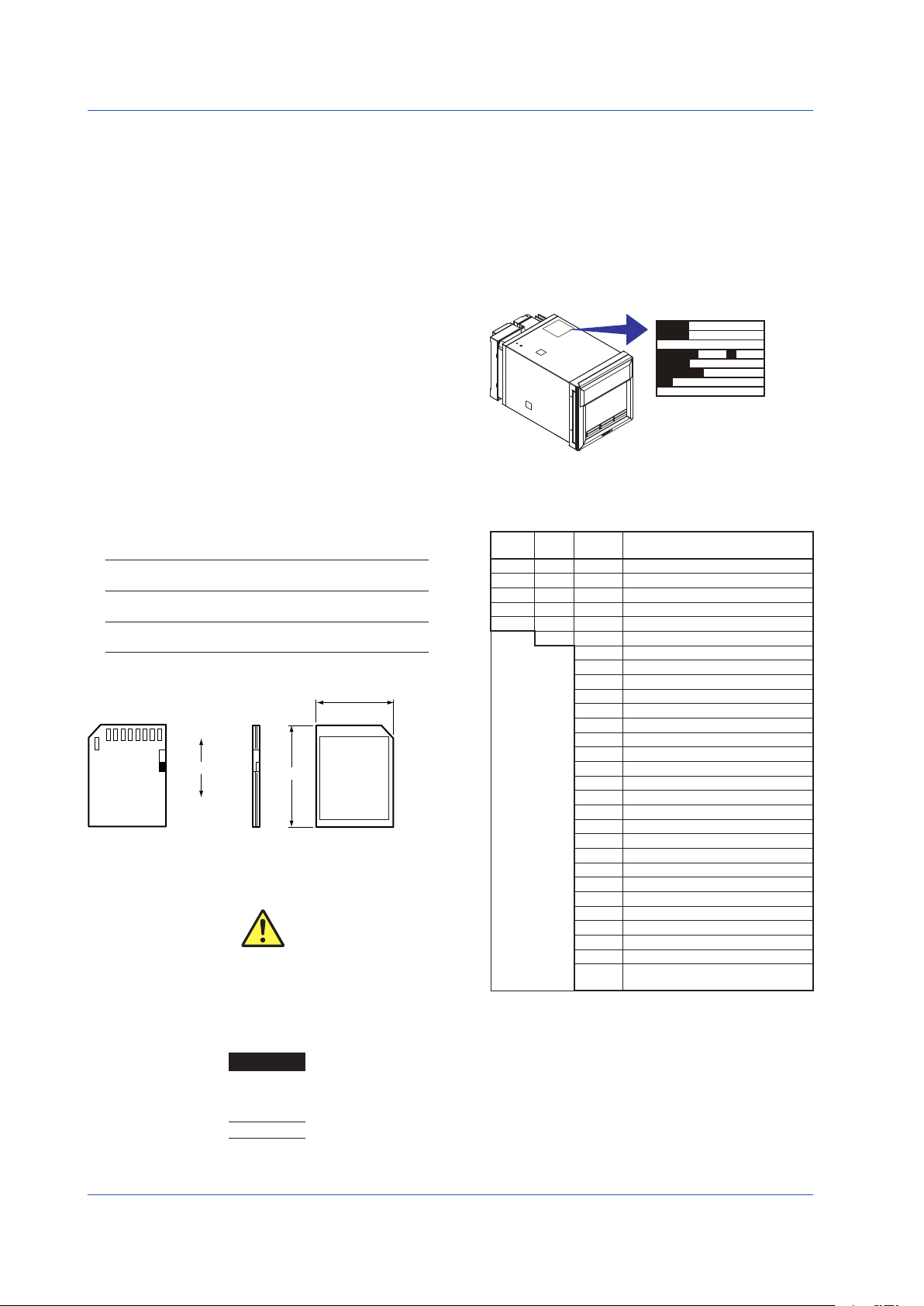

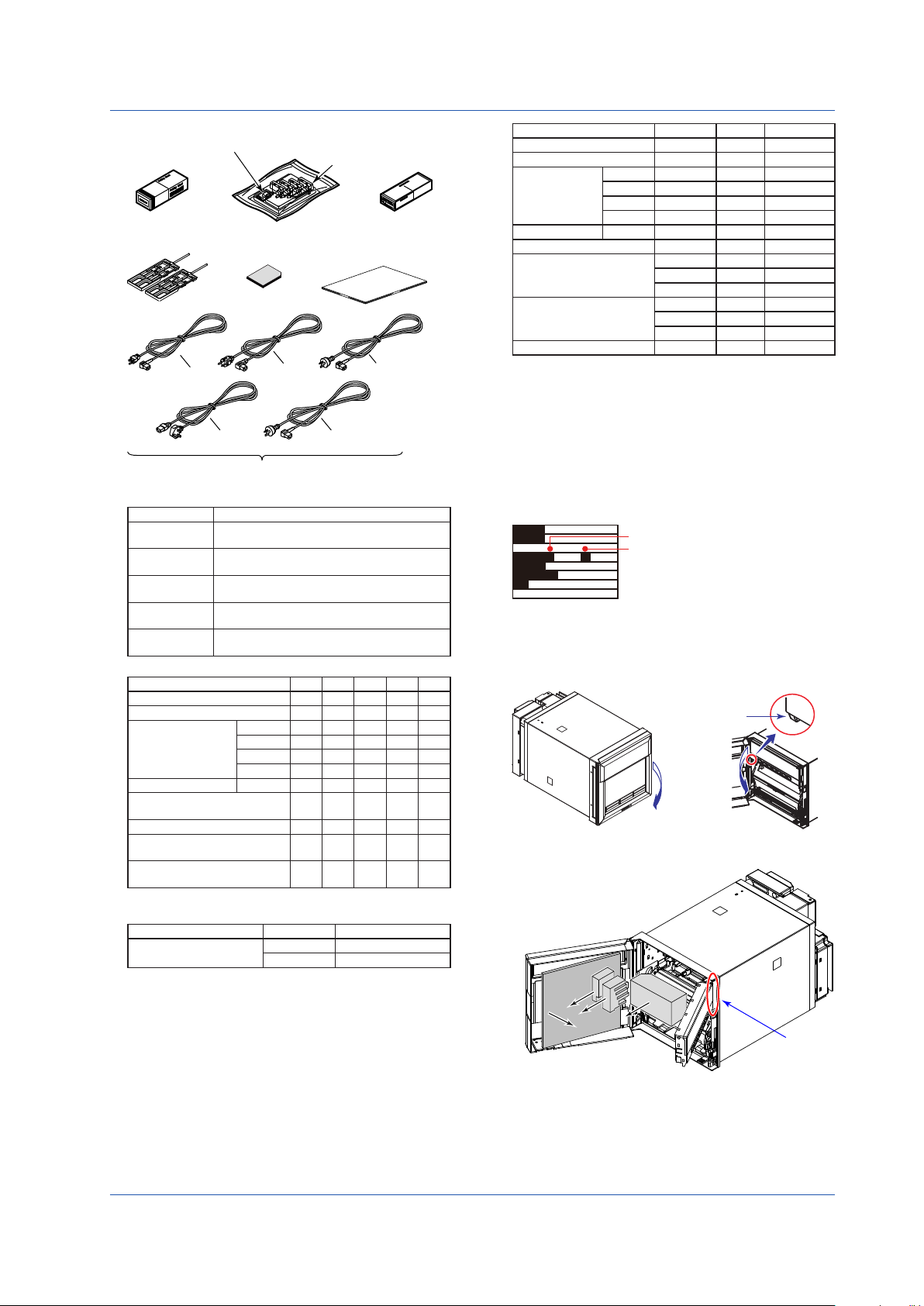

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. If some of the contents are not correct or missing or if there

is physical damage, contact the dealer from which you purchased

them.

µR10000 Recorder

A name plate is affixed to the case. Check that the model name

and suffix code given on the name plate on the rear panel match

those on your order.

MODEL

SUFFIX

STYLE

SUPPLY

FREQUENCY

NO.

NO. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please give them the instrument number.

MODEL and SUFFIX Code

Suffix

Model

436101 µR10000 1 pen recorder

436102 µR10000 2 pen recorder

436103 µR10000 3 pen recorder

436104 µR10000 4 pen recorder

436106 µR10000 6 dot recorder

Optional

Code

Code

-2 English/German/French & deg F/DST

/A1 Alarm output relay 2 points

/A2 Alarm output relay 4 points

/A3 Alarm output relay 6 points

/C3 RS-422A/485 interface

/C7 Ethernet (10BASE-T) interface

/F1 Fail/Chart end detection and output

/H2 Clamped input terminal

/H3 Non-glare door glass

/H5D Portable type Power cord UL, CSA st’d

/H5F Portable type Power cord VDE st’d

/H5R Portable type Power cord AS st’d

/H5J Portable type Power cord BS st’d

/H5H Portable type Power cord GB st’d

/M1 Mathematical function

/N1 Cu10, Cu25 RTD input

/N2 3 legs isolated RTD

/N3 Expansion inputs

/P1 24 VDC/AC power supply

/R1 Remote control 5 points

/CC1 Calibration Correction

/BT1 Header printout

/EM1 SD memory card

/S#

Description

Customized Product; for more detail,

please see IM 4361-S# or IM 4371-S#

1 /A1, /A2, and /A3 cannot be specified simultaneously.

2 /A3 and /F1 cannot be specified simultaneously.

3 /C3 and /C7 cannot be specified simultaneously.

4 /H2 and /N2 cannot be specified simultaneously.

5 Valid only on the model 436106.

6 14 types of input including Pt50 RTD, PR40-20, and Platinel TC.

7 /H5x and /P1 cannot be specified simultaneously.

8 /C3 and /EM1 cannot be specified simultaneously.

9 For customized product, the product is identified by the option

code of /S# (where ‘#’ is a number). Contact your supplier in

case your instrument has option /S#, and you are not in the possession of IM 4361-S# or IM 4371-S#.

SH

1

1

1, 2

3

3

4

4, 5

6

7

8

IM 04P01B01-02E

2

7

7

7

7

7

9

Page 9

Z-fold chart

Ribbon

Disposable

Plotter pen

according to the instrument’s suffix code

MODEL

Release number

Tab on the display

Standard Accessories

paper

Mounting

bracket

SD memory card

/H5D

felt pen

µR10000 Recorder

Operation Guide

IM 04P01B01-02E

/H5F

/H5H/H5J

One of these power cord types is supplied

Part Number Note

A1006WD

A1009WD

A1024WD

A1023WD

A1064WD

Z-fold chart paper 1 1 1 1 1

Ribbon cassette - - - - 1

Disposable felt pen

Plotter pen Purple 1 1 1 1 Mounting bracket (included with

models without /H5x)

Power cord (included with /H5x) 1 1 1 1 1

SD memory card 1 GB (included

with /EM1)

µR10000 Recorder Operation

Guide IM 04P01B01-02E

Provided when optional code /H5D is specified.

Maximum rated power voltage: 125 V

Provided when optional code /H5F is specified.

Maximum rated power voltage: 250 V

Provided when optional code /H5R is specified.

Maximum rated power voltage: 250 V

Provided when optional code /H5J is specified.

Maximum rated power voltage: 250 V

Provided when optional code /H5H is specified.

Maximum rated power voltage: 250 V

Item 1-Pen 2-Pen 3-Pen 4-Pen Dot

Red 1 1 1 1 Green - 1 1 1 Blue - - 1 1 Violet - - - 1 -

2 2 2 2 2

1 1 1 1 1

1 1 1 1 1

cassette

/H5R

Z-fold chart paper B9565AW 1 10 pieces.

Ribbon cassette B9901AX 1

Disposable felt

pen

Plotter pen Purple B9902AR 1 3 pieces.

Mounting bracket B9900BX 2

Shunt resistor for the screw

terminal (standard)

Shunt resistor for the

clamped input terminal (/H2)

SD memory card 773001 1 1 GB

Item Model Quantity Note

Red B9902AM 1 3 pieces.

Green B9902AN 1 3 pieces.

Blue B9902AP 1 3 pieces.

Violet B9902AQ 1 3 pieces.

415920 1 250 Ω ±0.1%

415921 1 100 Ω ±0.1%

415922 1 10 Ω ±0.1%

438920 1 250 Ω ±0.1%

438921 1 100 Ω ±0.1%

438922 1 10 Ω ±0.1%

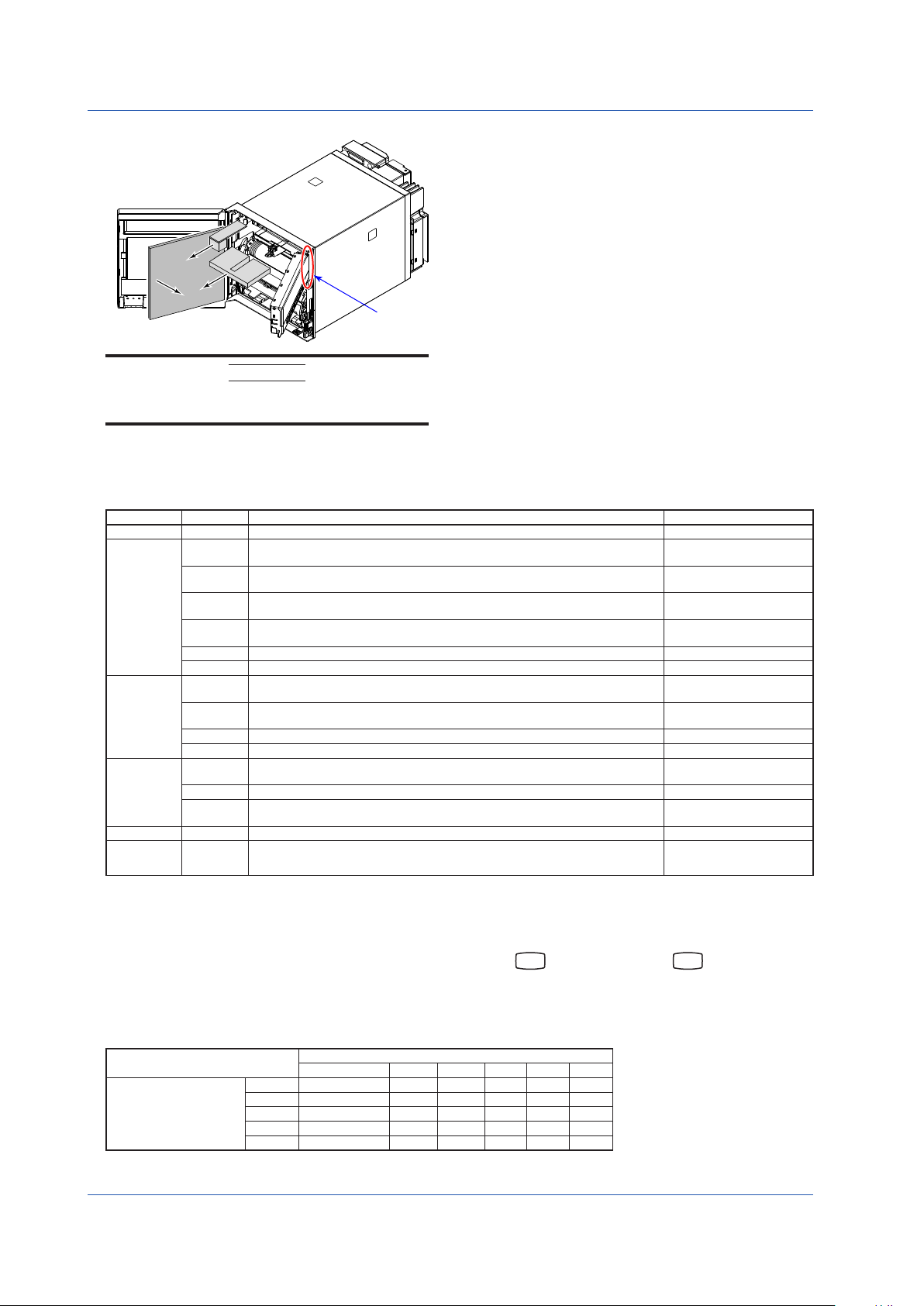

Recorder Style Number, Release Number, and Firmware Version Number

Style number: The recorder hardware ID number.

This number is written on the name plate.

Release number: The recorder firmware ID number. This number

is written on the name plate. This number matches with the integer

part of the firmware version number.

Example: If the firmware version number is 2.01, the release number is 2.

Firmware version number: See “Checking the Version Number.”

SUFFIX

STYLE

SUPPLY

FREQUENCY

NO.

SH

Style number

Removing the Packing Materials

Open the door, put your finger on the tab at the lower left of the

display and key panel section, and open the display and key panel

section.

key panel section

Remove all packing materials.

• PenModel

Open

Open

Software (Sold Separately, see page 8)

Configuration software

* You can use the Configuration Software if you install the in-

terface unit to a recorder does not include the communication

function. An interface unit cannot be installed in a recorder with

an SD memory card function (/EM1 option).

The optional accessories below are available for purchase separately. If you make an order, make sure that all contents are present

and undamaged.

For information about ordering accessories, contact the dealer from

which you purchased the recorder.

IM 04P01B01-02E

Item Model Note

RXA10-01

RXA10-02 With interface unit*

Hinge

7

Page 10

DISP

DISP

• DotModel

Hinge

CAUTION

To protect the hinges, do not apply vertical force on the display

and key panel section.

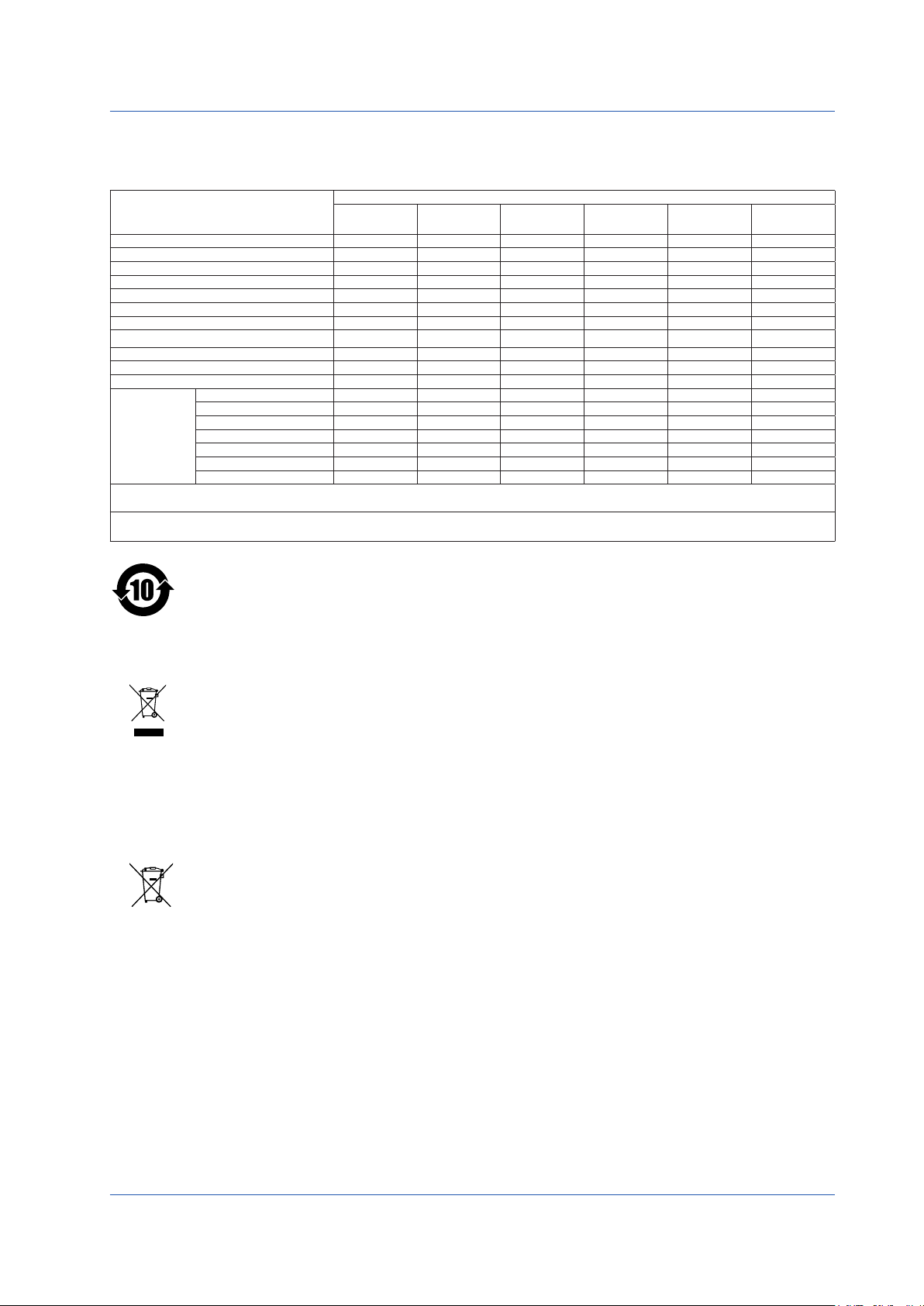

Recorder’s Version and Functions Described in This Manual

The contents of this manual corresponds to the recorder with version 1.5x.

µR10000 Versions and Functions

Version Suffix Code Added or Modified Functions Reference

1.02 or earlier – – –

1.1x – (Added) The printout/display format of the date can be changed. Sec. 7.19 in the User’s Manual

– (Added) Key operation to move the printer carriage near the center position so that the

– (Changed) Selectable range of alarm values during linear scaling (including 1-5V and

– (Changed) The procedure to set the start/end date and time of Daylight Saving Time (DST)

/C3 (Added) Modbus/RTU slave protocol, two-wire system Communication manual

/C7 (Changed) Users with the same user name cannot be registered. Communication manual

1.2x -2 (Added) Language support (German and French) Sec. 1.9 in the User’s Manual

/CC1 (Added) Calibration Correction Sec. 1.2 in the User’s Manual

/H5x (Added) Portable type Pages 15 and 20 in this manual

/P1 (Added) 24 VDC/AC power supply operation Pages 20 and 21 in this manual

1.3x – (Added) Customized menu Sec. 1.9 in the User’s Manual

– (Added) Modbus register (40301 to 40348) Communication manual

/BT1 (Added) Header printout Sec. 1.4 in the User’s Manual

1.4x /EM1 (Added) SD memory card IM 04P01B01-03E

1.5x – (Changed)

ribbon cassette can be replaced with the recorder turned ON (dot model)

SQRT) to -5% to 105% of the scale span.

has been changed.

Styel (H): 4*

* Style (H) 4 supports firmware version 1.5x or later.

• Checking the Version Number

You can check the version number on the System display.

The System display cannot be shown at the factory default condition.

First, register the System display to the display screen.

• Procedure of registering the System display to the display screen: See Changing the Displayed Information on Page 47.

• Procedure of displaying the System display: The screen switches each time the

System display is shown. The displayed contents on the System display switches every 3 seconds. Check the number shown by the “Version:”

item.

key is pressed. Press the

(IM 04P01B01-01E)

Sec. 3.4 in the User’s Manual

(IM 04P01B01-01E)

Sec. 5.2 in the User’s Manual

(IM 04P01B01-01E)

Sec. 6.16 in the User’s Manual

(IM 04P01B01-01E)

(IM 04P01B01-01E)

(IM 04P01B01-01E)

(IM 04P01B01-01E)

(IM 04P01B01-01E)

–

key repeatedly until

Software (Sold Separately)

The table below shows the relationship between the RXA10 Configuration Software revisions and the µR10000 recorder versions.

Recorder version

RXA10 Configuration Software revision

R1.01 Ye s Limited

1.02 or earlier 1.1x 1.2x 1.3x 1.4x 1.5x

R2.01 Ye s Ye s Ye s Limited

R3.01 Ye s Ye s Ye s Yes Limited

R3.05 Ye s Ye s Ye s Yes Yes Limited

R3.06 Ye s Ye s Ye s Yes Yes Ye s

Yes: Compatible

Limited: The new functions of the recorder cannot be configured from the RXA10.

8

IM 04P01B01-02E

Page 11

Protection of Environment

Control of Pollution Caused by the Product

This is an explanation for the product based on “Control of pollution caused by Electronic Information Products” in the People’s Republic of China.

产品中含有的有毒有害物质或元素的名称和含量

印制电路板组件 × × × ○ ○ ○

显示器 × × × ○ ○ ○

箱体 × × × ○ ○ ○

前盖 × × × ○ ○ ○

内部单元底座 ○ ○ ○ ○ ○ ○

电源 × × × ○ ○ ○

操作键 × × × ○ ○ ○

打印单元 × × × ○ ○ ○

制动器 ( 电机、螺线管 ) × × × ○ ○ ○

输入端子和可选端子 × × × ○ ○ ○

电缆 × ○ ○ ○ ○ ○

附件 / 可选项 6 色盒式色带 ○ ○ ○ ○ ○ ○

○ :表示该部件所有基材中所含的有毒有害物质含量均未超过 GB/T26572 标准中规定的限量要求。

× :表示该部件中至少有一种基材中所含的有毒有害物质含量超过 GB/T26572 标准所规定的限量要求。

本产品的部分部件包含 RoHS 指令中的限用物质,但是其使用方法不受该指令限制。

Some parts of this product include the restricted substances of RoHS Directive, but their applications are under the exemption of the directive.

环境保护使用期限

部件名称 有毒有害物质或元素

铅 (Pb) 汞 (Hg) 镉 (Cd) 六价铬 (Cr6+) 多溴联苯

(PBB)

可拆卸式毡笔 ○ ○ ○ ○ ○ ○

绘图笔 ○ ○ ○ ○ ○ ○

安装支架 × × × ○ ○ ○

电源线 × × × ○ ○ ○

分流电阻 × × × ○ ○ ○

SD 存储卡 × × × ○ ○ ○

该标志为环境保护使用期限,根据 SJ/T11364,适用于在中国 ( 台湾、香港、澳门除外 ) 销售的电子电气产品。

只要遵守该产品的安全及使用注意事项,从产品生产之日起至该标志所示年限内,不会因为产品中的有害物质

外泄或突变而导致环境污染或对人身财产产生重大影响。

注释 ) 该标志所示年限为“环境保护使用期限”,并非产品的保质期。另外,关于更换部件的推荐更换周期,请参阅使用说明书。

多溴二苯醚

(PBDB)

Waste Electrical and Electronic Equipment (WEEE), Directive

This is an explanation of how to dispose of this product based on Waste Electrical and Electronic Equipment (WEEE), Directive. This directive is only valid

in the EU.

• Marking

This product complies with the WEEE Directive marking requirement. This marking indicates that you must not discard this electrical/electronic product

in domestic household waste.

• Product Category

With reference to the equipment types in the WEEE directive, this product is classified as a “Small equipment” product.

Do not dispose in domestic household waste.

When disposing products in the EU, contact your local Yokogawa Europe B.V. office.

How to Dispose the Batteries

This is an explanation about the new EU Battery Directive (DIRECTIVE 2006/66/EC). This directive is only valid in the EU.

Batteries are included in this product. Batteries incorporated into this product cannot be removed by yourself. Dispose them together with this product.

When you dispose this product in the EU, contact your local Yokogawa Europe B.V.office. Do not dispose them as domestic household waste.

Battery type: Lithium battery

Notice: The symbol (see above) means they shall be sorted out and collected as ordained in ANNEX II in DIRECTIVE 2006/66/EC.

IM 04P01B01-02E

9

Page 12

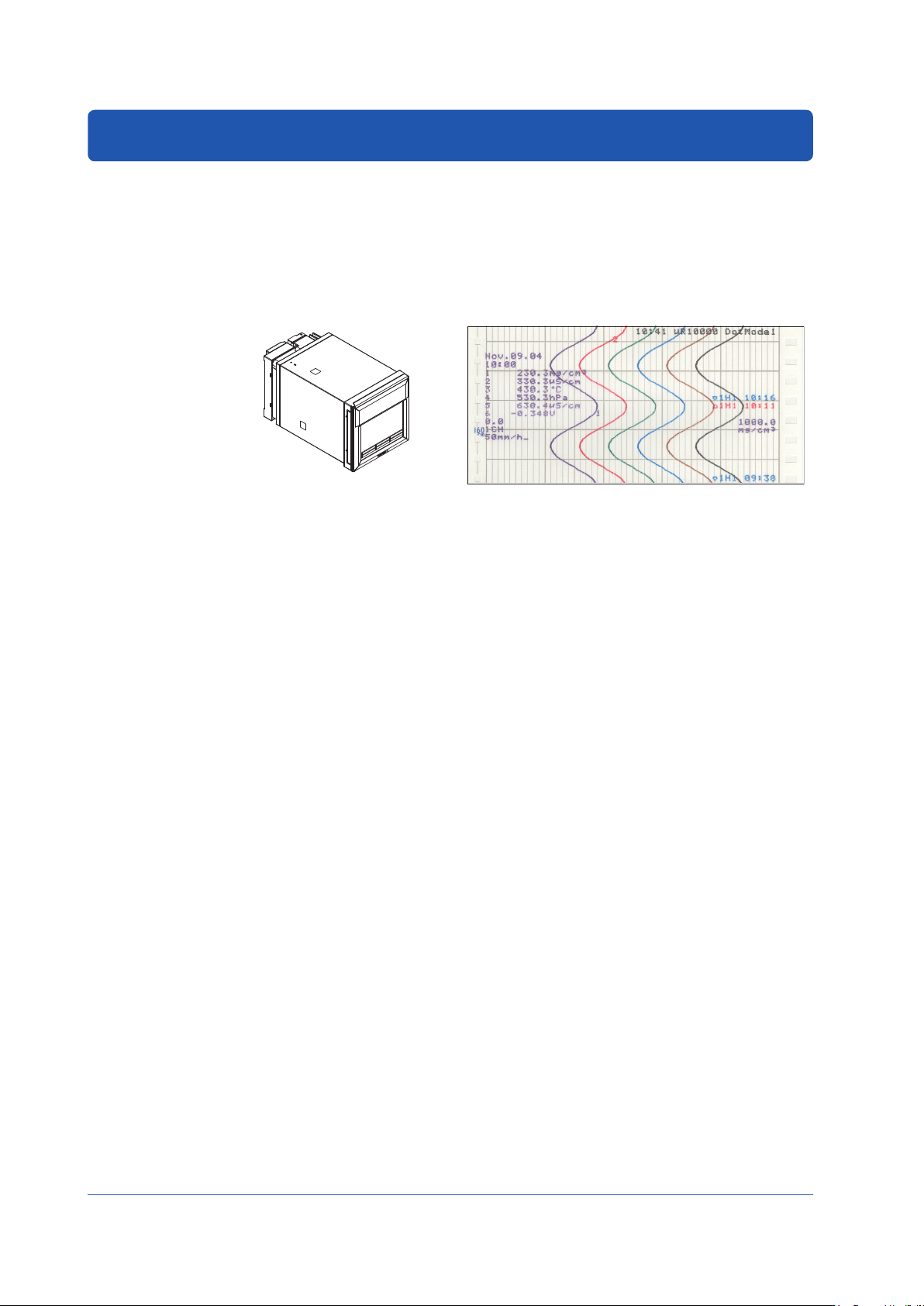

Function Introduction/Names of Parts

µR10000 Recorder Recording example (dot model)

Function Introduction

The µR10000 Recorder (hereafter referred to as the recorder) can be used to assign DC

voltage, 1-5V, thermocouple, RTD, and contact or voltage ON/OFF signal to channels

for measurement. The measured results are recorded with pens or dots on a chart paper

that is fed at a constant speed. The pen model can record up to 4 channels; the dot

model can record up to 6 channels.

Alarms

For each channel, various alarms such as high limit alarm and low limit alarm can be

assigned to monitor the measured values. Alarm output relays can be used to output

contact signals when alarms occur (/A1, /A2, and /A3 options).

Recording

The measured results are recorded with pens or dots on a chart paper (trend recording).

The chart speed can be selected from 5 to 12000 mm/h on the pen model and 1 to 1500

mm/h on the dot model.

In addition to trend recording, various types of information can be printed on the chart

paper such as numeric measured values, alarm occurrence/release, and predefined

messages.

Also, the recorder settings can be printed.

Internal Light

A light is provided for easier viewing of the recording area of the chart paper.

Display

Measured values can be displayed numerically or using bar graphs on the large display.

Also, alarm status and chart speed can be displayed.

Communication Functions

Using the Ethernet communication interface (/C7 option) or the RS-422A/485

communication interface (/C3 option), the measured values on the recorder can be

output to a computer or a computer can be used to control the recorder.

For information about the communication functions, see the μR10000/μR20000

Communication Interface User’s Manual, IM 04P01B01-17E.

Other Main Functions

The computation function (/M1 option) can be used to perform various computations from

four arithmetic operations to statistical calculations on 8 and 12 computation channels on

the pen model and dot model, respectively. The computed results can be recorded.

The remote control function (/R1 option) can be used to control the recording start/

stop and other operations of the recorder by applying contact signals to the dedicated

terminals.

The FAIL/chart end detection and output function (/F1 option) can be used to output

contact signals when errors are detected on the recorder or when the chart paper runs out.

10

IM 04P01B01-02E

Page 13

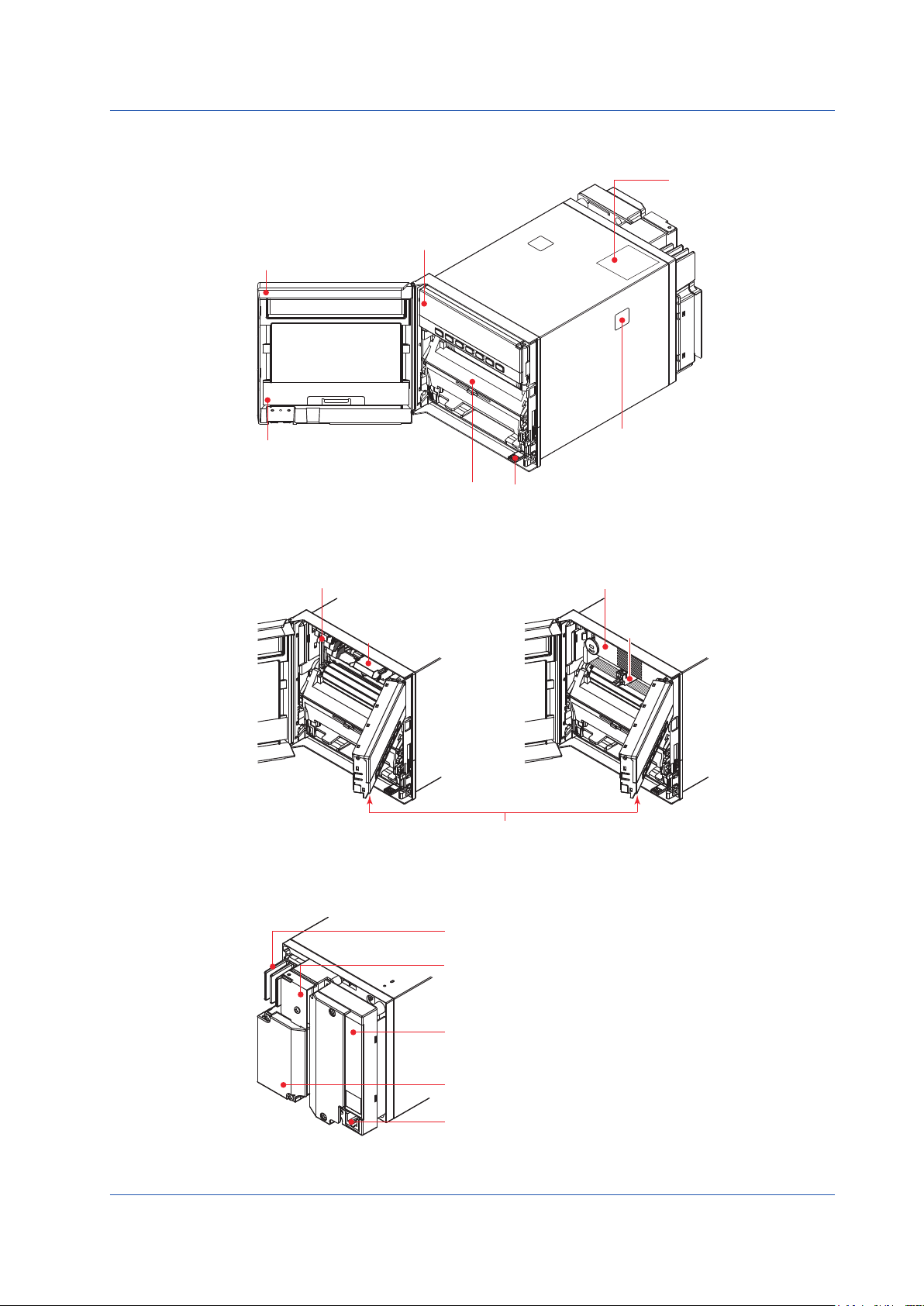

Names of Parts

Door

Name plate

The model name is written

time the switch is pressed.

Pen model Dot model

recording area of the chart paper.

prints various types of information.

This is where terminals or ports used by options such

Front

Function Introduction/Names of Parts

Tag plate

Used to write

channel names.

Display and key panel

Hold the tab at the lower

left and pull to open.

Chart cassette

Holds the chart paper.

Recording pen

Records the measured value.

Plotter pen

Prints various types

of information.

on the name plate.

Mounting hole

There is one hole on each of the

top, bottom, left, and right panels.

The hole is covered with a seal.

Power switch

Turns ON/OFF the power each

Ink ribbon

Six-color ink.

Printer carriage

Records measured values and

Rear Panel

IM 04P01B01-02E

The portable type (/H5x option) comes with a handle, feet, and dedicated power supply

connector.

Display and key panel (see the next page)

There is an internal light on the bottom section

of the display and key panel. It lights up the

Heatsink

Dissipates the internal heat.

Power terminal block

The power terminal and protective ground terminal.

Optional terminal block

as alarm output relays and communication interface

are installed.

Measuring input terminal block

Measuring input terminals.

Ethernet port (/C7 option)

11

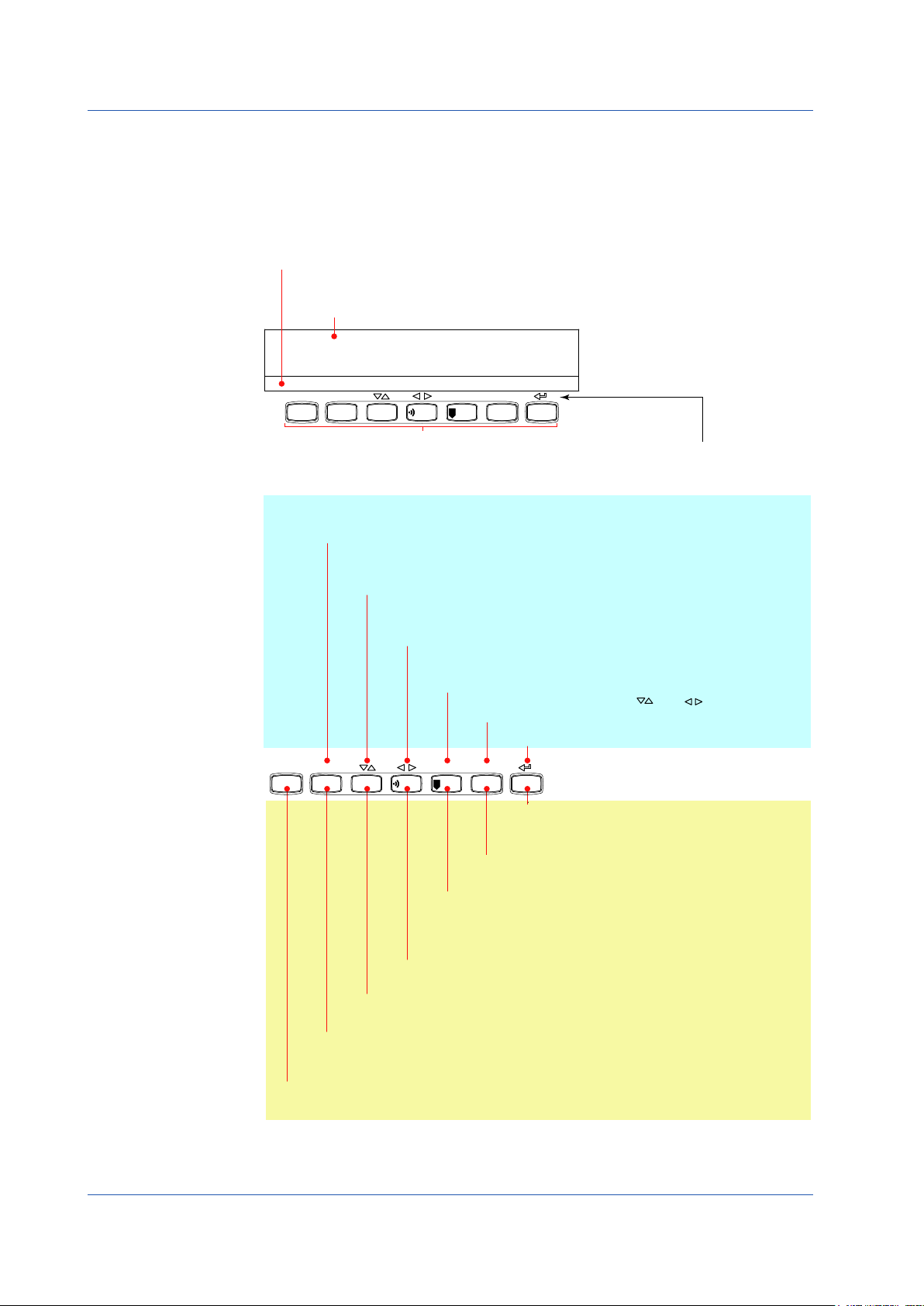

Page 14

Status display

Function Introduction/Names of Parts

Display and Key Panel

Displays the following information.

RECORD Illuminates while recording measured values.

KEY LOCK Illuminates when key lock is enabled.

MATH Illuminates when computation on the computation function (/M1 option)

is in progress.

CHART END Illuminates when the chart paper is out (/F1 option).

ALARM 1 to 6 Illuminates when an alarm is occurring on channels 1 to 6.

Main display

Displays the measured values. Also, displays the setup screen when

setting functions.

RECORD MATH CHART END ALARM

CHARACTER

RCD

MENU FEED

DISP

FUNC

ESC/? SHIFT

1

MENU

1 2 3 4 5 6KEY LOCK

CH UP

Seven keys are available.

For all keys except RCD, functions marked above the keys are enabled when

setting functions or when the FUNC key or the DISP MENU key is pressed.

<While setting functions, when the FUNC key/DISP MENU key is pressed>

CHARACTER Key: Changes the character type when entering a character. Press

this key while holding down the SHIFT key to switch the character type in reverse

order.

UP/DOWN Key: Switches the setup item or the value.

Press this key while holding down the SHIFT key to switch the setup item

or the value in reverse order.

LEFT/RIGHT Key: Moves the cursor to the right when entering a value

or character. Press this key while holding down the SHIFT key to move

the cursor to the left.

ESC Key: Cancels the operation.

When pressed with the SHIFT key, the display of the comment

on the setting turns ON/OFF.

SHIFT Key: Used with the key, key,

the CHARACTER key, or the ESC key.

ENTER Key: Confirms the setup item or value.

CHARACTER ESC/? SHIFT

RCD

MENU FEED

DISP

FUNC

1

MENU

CH UP

<During normal operation>

CH UP key

Switches the displayed channel.

(when manual switching is specified)

FEED key

Feeds the chart paper.

DISP MENU key

Hold this key down for 3 seconds to switch to the data display

setup screen. Hold this key down for 3 seconds also to exit

from the data display setup screen.

FUNC key

Used when executing manual printout, message printout, etc.

DISP key

Switches the screen in the main display.

MENU key

Hold this key down for 3 seconds to enter Setting mode. Hold this key down for

3 seconds also to exit from Setting mode.

RCD key

Starts/stops recording.

12

IM 04P01B01-02E

Page 15

Installing/Wiring the Recorder

Installation Location

Install the recorder indoors in a location that meets the following conditions.

• InstrumentPanel

The recorder is designed for panel mounting. The portable type (/H5x option) is

designed to be used on the desktop.

• Well-VentilatedLocation

To prevent overheating, install the recorder in a well-ventilated location.

For the panel cut dimensions when arranging multiple recorders, see page 15. Follow

the panel cut dimensions providing adequate space between instruments when other

instruments are arranged on the panel.

We recommend that you secure at least 50 mm of space from the left, right, top, and

rear panels on the portable type (/H5x option).

• MinimumMechanicalVibrations

Choose an installation location with the minimum mechanical vibration.

Installing the recorder in a location with large mechanical vibration not only causes

adverse eects on the mechanism but also may hinder normal recording.

• Horizontal

Install the recorder horizontally (However, the recorder can be inclined up to 30

degrees backwards for panel mounting).

• Ambienttemperaturerangebetween0to50°C

• Ambienthumiditybetween20to80%RH(at5to40°C)or30to50%RH(at

0to5,40to50°C),Nocondensationshouldbepresent.

• Altitude2000morless

Note

Do not install the recorder in the following places.

• Outdoors

• InDirectSunlightorNearHeatSources

Install the recorder in a place with small temperature uctuations near room

temperature (23°C). Placing the recorder in direct sunlight or near heat appliances can

cause adverse eects on the internal circuitry.

• WhereanExcessiveAmountofSoot,Steam,Moisture,Dust,or

CorrosiveGasesArePresent

Soot, steam, moisture, dust, and corrosive gases will adversely aect the recorder.

Avoid such locations.

• NearStrongMagneticFieldSources

Do not bring magnets or instruments that produce electromagnetic elds close to the

recorder. Strong magnetic elds can cause errors in the measurements.

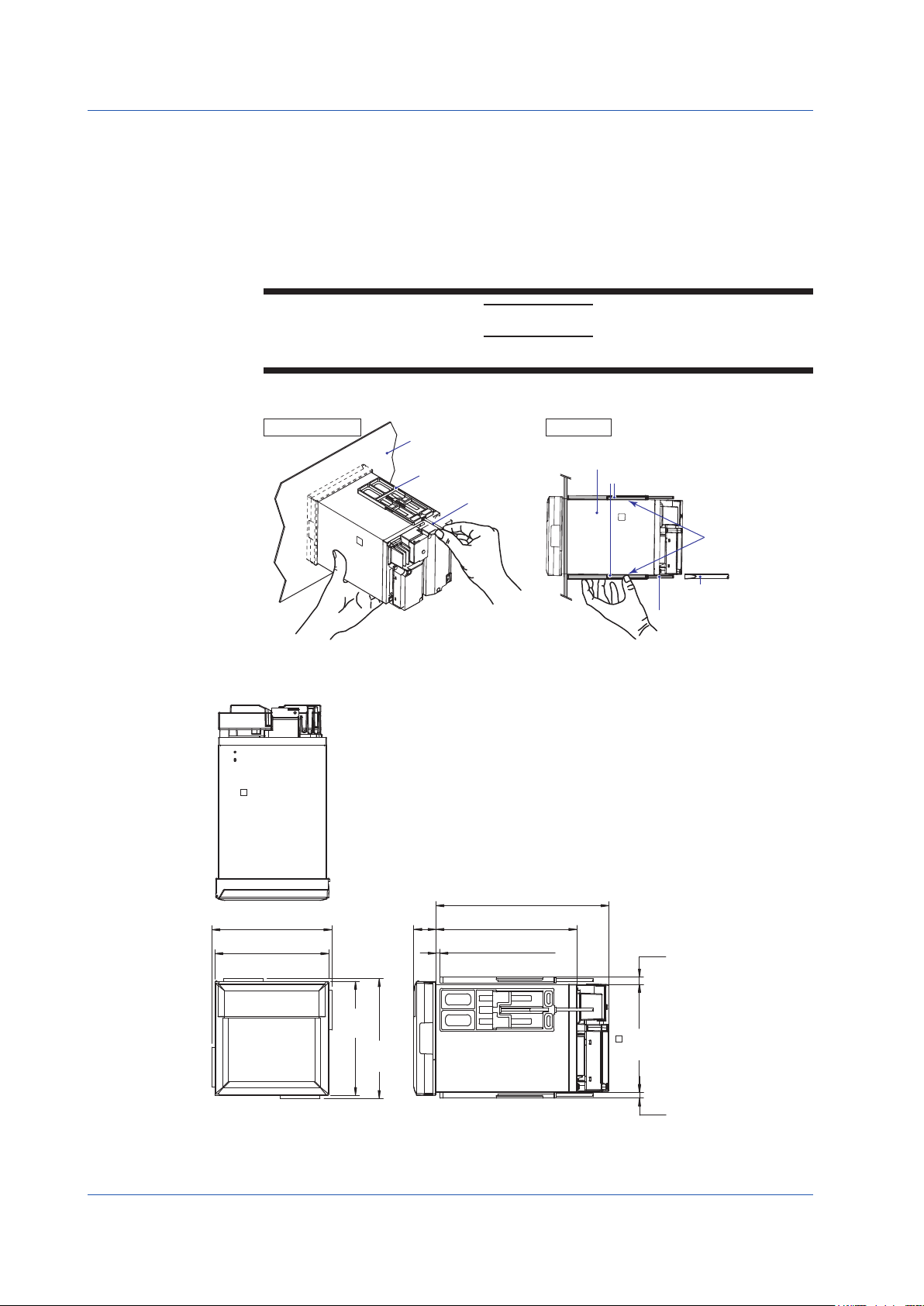

Installation Procedure

The recorder should be mounted on a steel panel of thickness 2 mm to 26 mm.

1.

2.

• Condensation may occur if the recorder is moved to another place where both the ambient

temperature and humidity are higher, or if the temperature changes rapidly. In addition,

measurement errors will result when using thermocouples. In this case, let the recorder

adjust to the new environment for at least one hour before using it.

• The chart paper may be adversely affected by a rapid change in the ambient temperature

and humidity.

Insert the recorder from the front of the panel (see the diagram on the next page).

Mount the recorder to the panel using the mounting brackets provided.

• Use two brackets to support the top and bottom or the left and right sides of the case

(remove the seal that is covering the holes for the mounting brackets beforehand).

IM 04P01B01-02E

13

Page 16

Installing/Wiring the Recorder

with each other

brackets are used on the top and bottom of the case.)

(Dimensions before attaching

(0.30)

Panel Mounting Diagram

Screw temporarily

• Thepropertorquefortighteningthemountingscrewsis0.7to0.9N•m.

• Mounttherecordertothepanelaccordingtotheprocedurebelow.

• First,attachthetwomountingbracketsandtemporarilyfastentheattachment

screws.

• Next,xtherecorderinplacebytighteningtheattachmentscrewswiththe

appropriatetorque.Whentherecorderisapproximatelyperpendiculartothe

panelasyoufastenthescrews,pressthemountingbracketagainstthecase

sothattheyareincontactwitheachother.

CAUTION

Tighteningthescrewstoomuchcandeformthecaseordamagethebracket.

Panel

Mounting bracket

Attachment

screw

Fix in place

Case

Panel

Mounting bracket

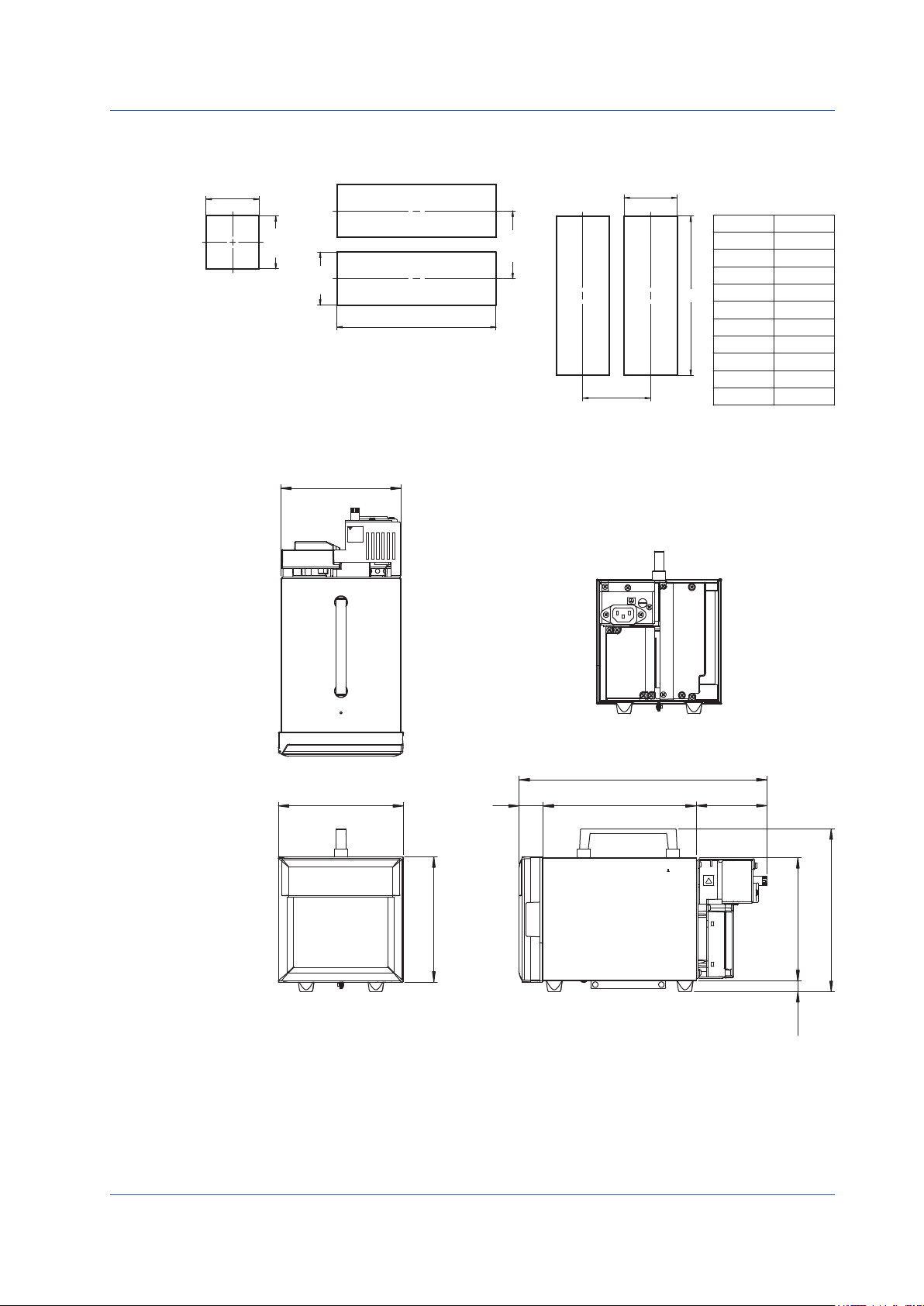

External Dimensions

151.5 (5.96)

144 (5.67)

Front

(The figure shows the case when the mounting

Unit: mm (approx. inch)

Unless otherwise specified, tolerance is ± 3%

(however, tolerance is ± 0.3 mm when below 10 mm).

220 (8.66)

(1.08) 27.5

178 (7.01)

Mounting panel

thickness

2 to 26

In contact

Torque driver

(flat blade)

Attachment screw

9.4

the mounting bracket)

(0.37)

144

(5.67)

14

151.5

(5.96)

136.5

(5.37)

(Dimensions after attaching

7.5

the mounting bracket)

IM 04P01B01-02E

Page 17

Panel Cutout

Unit: mm

Unless otherwise specified, tolerance is ± 3%

(however, tolerance is ± 0.3 mm when below 10 mm).

Attach the mounting brackets to the top and bottom when

mounting the recorders side-by-side horizontally or right and

left when mounting the recorders side-by-side vertically.

Side-by-Side Mounting

Side-by-Side Mounting

Single-Unit Mounting

138.5 (5.45)

Installing/Wiring the Recorder

(vertically, max. 3 units)

137

+2

0

(horizontally)

(5.39)

+2

137

0

(5.39)

137

(5.39)

(approx. inch)

+2

0

+2

0

L

175 min.

(6.89)

175 min.

(6.89)

External Dimensions of the Portable Type (/H5x Option)

Unit: mm (approx. inch)

Unless otherwise specified, tolerance is ± 3%

(however, tolerance is ± 0.3 mm when below 10 mm).

40VA MAX

50/60Hz

100-240V~

137

(5.39)

+2

0

Units

L (mm)

2 282

3

4

+2

5

0

L

6

7

8

9

10

n

426

570

714

858

1002

1146

1290

1434

(144xn)-6

144 (5.67)

27.5

(1.08)

144 (5.67)

285 (11.2)

176 (6.93)

81.5 (3.21)

187 (7.36)

141.5 (5.57)

12.4

(0.49)

IM 04P01B01-02E

15

Page 18

Installing/Wiring the Recorder

Crimp-on lug with insulation sleeves (for 4-mm screws)

Input Signal Wiring

WARNING

Precautions to Be Taken While Wiring

Take the following precautions when wring the input signal cables.

It is recommended that crimp-on lug with insulation sleeves (designed for 4-mm screws)

be used when connecting the input/output signal wires to the terminals. However, this

does not apply clamped terminals (/H2).

For clamped terminals (/H2), the following wire is recommended.

• Conductive cross-sectional area for single wire: 0.14 mm2 to 1.5 mm2, stranded wire:

• Length of the stripped section of the wire: Approx. 5 mm

Take measures to prevent noise from entering the measurement circuit.

• Move the measurement circuit away from the power cable (power circuit) and ground circuit.

• It is desirable that the object being measured does not generate noise. However, if

• Shielded wires should be used to minimize noise caused by electrostatic induction.

• To minimize noise caused by electromagnetic induction, twist the measurement circuit

• Make sure to earth ground the protective ground terminal through minimum resistance.

Do not allow static electricity to be applied to the terminals.

• When wiring the terminals, remove static electricity so that static electricity is not applied.

• If static electricity or similar high-voltage transient noise is applied to the signal line,

When using internal reference junction compensation on the thermocouple

input,takemeasurestostabilizethetemperatureattheinputterminal.

• Always use the terminal cover.

• Do not use thick wires which may cause large heat dissipation (cross sectional area of

• Make sure that the ambient temperature remains reasonably stable. Large

Connecting the input wires in parallel with other devices can cause signal

degradation, affecting all connected devices.

If you need to make a parallel connection, then

• Turn the burnout detection function OFF.

• Ground the instruments to the same point.

• Do not turn ON or OFF another instrument during operation. This can have adverse

• RTDs cannot be wired in parallel.

• To prevent electric shock while wiring, ensure that the power supply source is turned OFF.

CAUTION

• The input terminals of this instrument are specific to this instrument. Do

not connect the input terminals of the µR1000, µR1800 or other models, as

malfunction may result.

• If a strong tension is applied to the cable wired to the recorder, the terminals of the recorder

and/or the cable can be damaged. In order to prevent tension from being applied directly

on the terminals, fasten all wiring cables to the rear of the mounting panel.

• Do not apply a voltage exceeding the following value to the input terminals as

this may damage the recorder.

• Maximum input voltage

Voltage range less than or equal to 200 mVDC, TC, RTD, and DI: ±10 VDC

Ranges other than those listed above: ±60 VDC

• Maximum common-mode voltage

±60 VDC (under measurement category II conditions)

0.14 mm

this is unavoidable, isolate the measurement circuit from the object. Also, ground the

object being measured.

Connect the shield to the ground terminal of the recorder as necessary (make sure

you are not grounding at two points).

wires at short, equal intervals.

the system may break.

0.5 mm

temperature uctuations can occur if a nearby fan turns ON or OFF.

eects on the other instruments.

2

to 1.0 mm

2

or less recommended).

2

16

IM 04P01B01-02E

Page 19

Installing/Wiring the Recorder

Terminal cover

attachment screws

Measuring input

+/A

b

Channel 1

Channel 3

Screw input terminal

(/H2 option)

+/A

b

Channel 1

Channel 3

Channel 5

Screw input terminal

(/H2 option)

DC voltage, 1-5V, ON/OFF

Extension leadwire

DC current

Thermocouple input Resistance temperature detector input

Wiring Procedure

A terminal cover is screwed in place on the

terminal block

measuring input terminal block on the rear panel.

A label indicating the terminal arrangement is

affixed to the cover.

Turn OFF the recorder and remove the

1.

terminal cover.

Connect the signal wires to the terminals.

2.

Note

Input signal wires of diameter less than or equal to 0.3 mm may not be secured firmly for

clamped terminals (/H2). Fold over the conducting section of the wire, for example, to make

sure that the wire is securely connected to the clamped terminal.

Replace the terminal cover and fasten it with screws.

3.

The proper torque for tightening the screws is 0.6 N•m.

Pen Model

–/B

Channel 1

Channel 2

Channel 3

Channel 4

Channel 2

Channel 4

+/A

b

Clamped input terminal

+/A

-/B–/B

b

Dot Model

–/B

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Measuring Input Wiring

–/Bb +/A

DC voltage input, 1-5V input,

and ON/OFF input

–/Bb +/A –/Bb +/A

+

–

Note

IM 04P01B01-02E

RTD input terminals A and B on the dot model are isolated on each channel. Terminal b is

shorted internally across all channels. However, for 3 legs isolated RTDs (/N2 option), input b is

also isolated for each channel.

Channel 2

Channel 4

Channel 6

+/A

–/B

b

+/A

–/B

b

Clamped input terminal

Leadwire resistance:

10 Ω max./wire. The resistance

of the three wires should be

equal.

DC current input

Shunt resistor

Example:

For a 4 to 20 mA input,

a shunt resistor of

250 Ω ± 0.1% can be used

to convert to 1-5V input

–/Bb +/A

b

A

–

B

+

17

Page 20

Installing/Wiring the Recorder

Optional

terminal block

Terminal cover

attachment screws

Optional Terminal Wiring

WARNING

• To prevent electric shock while wiring, ensure that the power supply source is

• If a voltage of more than 30 VAC or 60 VDC is to be applied to the output

• The option terminals of this instrument are specific to this instrument. Do

• To prevent fire, use signal wires having a temperature rating of 70°C or more.

• If a strong tension is applied to the cable wired to the recorder, the terminals of

• Use the following circuit voltage for the connection to the alarm/FAIL/status

turned OFF.

terminals, use ring-tongue crimp-on lugs with insulation sleeves on all terminals

to prevent the wires from slipping out when the screws become loose.

Furthermore, use double-insulated wires (dielectric strength of 3000 VAC or

more) for the signal wires on which a voltage of more than 30 VAC or 60 VDC is

to be applied. For all other wires, use basic insulated wires (dielectric strength of

1500 VAC). To prevent electric shock, attach the terminal cover after wiring and

make sure not to touch the terminals.

CAUTION

not connect the option terminals of the µR1000, µR1800 or other models, as

malfunction may result.

the recorder and/or the cable can be damaged. In order to prevent tension from

being applied directly on the terminals, fasten all wiring cables to the rear of the

mounting panel.

output terminal.

• When the connection is to Mains Circuits (primary AC power source circuits):

150 V or less

• When the connection is to circuits derived from Mains Circuits (secondary

circuits): 250 V or less

(Mains Circuits voltage is less than 300 V, and connection must be used by

isolation transformer.)

Wiring Procedure

As shown in the figure below, the optional terminal

block is located on the rear panel. The optional

terminal block is provided on the recorder when an

option that requires input/output is installed such as

the alarm output relay (/A1, /A2, or /A3 option),

FAIL/chart end output (/F1 option), remote control

function (/R1 option), RS-422A/485 interface (/C3

*

option)

option)

the measuring input terminal block. A label indicating the terminal arrangement is affixed

to the terminal block.

, and Ethernet (10BASE-T) interface (/C7

*

. A terminal cover is screwed in place on

* For details on terminal and connector arrangement and wiring, see the µR10000 /µR20000

Communication Interface User’s Manual (IM 04P01B01-17E).

Turn OFF the recorder and remove the terminal cover.

1.

Connect the input signal wires to the terminals.

2.

Replace the terminal cover and fasten it with screws.

3.

The proper torque for tightening the screws is 0.6 N•m.

Note

To reduce noise, use a shielded cable for the wiring of the remote control input terminals.

Connect the shield to the ground terminal of the recorder.

18

IM 04P01B01-02E

Page 21

Installing/Wiring the Recorder

/A2

/A3

communication interface (/C3 or /C7 option)

/A1

/A1/F1 /A1/R1

/A1/F1/R1

NO

Output: Relay contact

250 VAC (50/60 Hz) /3 A, 250 VDC/0.1 A (for resistor load)

NO(Normally Opened), C(Common), NC(Normally Closed)

terminals and the ground terminal)

Allowable input voltage:

• Relay contact input

(Voltage-free contact)

• Transistor input (Open collector)

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

I01

I02

(/F1)

NO C NC

NO C NC

NO C NC

NO C NC

I01

I02

NO C NC

NO C NC

I01

I02

CE

FAIL

1 2 3

(/R1) (/R1)

4 5 C

/A2/F1 /A2/R1

I01

I02

I03

I04

(/F1)

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

I01

I02

I03

I04

NO C NC

NO C NC

NO C NC

NO C NC

I01

I02

I03

I04

CE

FAIL

1 2 3

(/R1) (/R1)

4 5 C

/A3/R1 /F1

I01

I02

I03

I04

I05

I06

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

1 2 3

(/R1) (/R1)

4 5 C

I01

I02

I03

I04

I05

I06

(/F1)

NO C NC

NO C NC

CE

FAIL

(/F1)

(/F1)

NO C NC

NO C NC

NO C NC

NO C NC

1 2 3

4 5 C

/A2/F1/R1

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

NO C NC

1 2 3

4 5 C

/R1

1 2 3

4 5 C

CE: Chart end

I01

Shaded: Arrangement of the

I02

terminals or connectors. For details on

wiring, see the μR10000 /μR20000

CE

Communication Interface User’s Manual

FAIL

(IM 04P01B01-17E).

I01

I02

I03

I04

CE

FAIL

/F1/R1

(/F1)

(/R1)

NO C NC

NO C NC

1 2 3

4 5 C

CE

FAIL

IM 04P01B01-02E

Alarm Output Relay Terminals and FAIL/Chart End Output Relay Terminals

Alarm output terminals 01 to 06 are expressed as I01 to I06 in the alarm output relay

settings.

Remote Control Input Terminals

Remote control input terminals 1 to 5 are expressed as numbers 1 to 5 in the remote

control input settings.

Contact closed at 200 Ω or less

Contact open at 100 kΩ or greater

1 2 3

4 5

C

Contact rating:

Dielectric strength: 1500 VAC at 50/60 Hz for one minute

(between output terminals and the ground terminal)

C

NC

ON voltage: 0.5 V or less (30 mADC)

Leakage current when turned OFF: 0.25 mA or less

1 2 3

4 5

C

1 to 5 (Remote control input terminals), C (Common)

Dielectric strength: 500 VDC for one minute (between input

Internal circuit

5V

Input format:

Photocoupler isolation

Shared common (C)

1 to 5

C

5 VDC

C: Negative side of the power supply

19

Page 22

Installing/Wiring the Recorder

Power Supply Wiring

WARNING

Panel Mount Type

• To prevent electric shock when wiring, ensure the main power supply is turned

OFF.

• To prevent the possibility of fire, use 600 V PVC insulated wire (AWG20 to 16) or

an equivalent wire for power wiring.

• Make sure to earth ground the protective earth terminal through a minimum

grounding resistance before turning ON the power.

• Use crimp-on lugs (designed for 4-mm screws) for power and ground wiring

termination.

• To prevent electric shock, make sure to close the transparent cover for the

power supply wires.

• Make sure to provide a power switch (double-pole type) on the power supply line

in order to separate the recorder from the main power supply. Put an indication

on this switch as the breaker on the power supply line for the recorder and

indications of ON and OFF.

Switch specifications

Rated power current: 1 A or more (other than /P1), 3 A or more (/P1 option)

Rated rush current: 60 A or more (other than /P1), 70 A or more (/P1 option)

Complies with IEC 60947-1, 3.

• Connect a fuse in the power supply line.

2 A to 15 A (other than /P1), 4 A to 15 A (/P1 option)

• Do not add a switch or fuse to the ground line.

Portable Type (/H5x Option)

• Ensure that the source voltage matches the rated power supply voltage of the

instrument before connecting the power cord.

• Connect the power cord after checking that the power switch of the portable type

is turned OFF.

• To prevent electric shock or fire, be sure to use the power cord for the portable

type supplied by YOKOGAWA.

• Make sure to connect protective earth grounding to prevent electric shock.

Connect the power cord of the portable type to a three-prong power outlet

equipped with a protective earth terminal.

• Do not use an extension cord that does not have a protective grounding wire.

The protective features of the instrument will be rendered ineffective.

Use a power supply that meets the following conditions:

Item Power Supply Specifications

(Options Other Than /P1) (/P1 Option)

Rated supply voltage 100 to 240 VAC 24V DC/AC

Allowable power supply voltage range 90 to 264 VAC 21.6 V to 26.4 VDC/AC

Rated power supply frequency 50/60 Hz 50/60 Hz (for AC)

Allowable power supply frequency range 50/60 Hz ±2% 50/60 Hz ±2% (for AC)

Maximum power consumption 40 VA 25 VA (for DC) or 35 VA (for AC)

Note

Do not use a supply voltage in the range 132 to 180 VAC, as this may have adverse effects on

the measurement accuracy.

20

IM 04P01B01-02E

Page 23

Wiring Procedure (Panel Mount Type)

Screw for fixing

the power terminal

cover in place

Power

terminal block

Power

terminal cover

screwdriver

cord

• Other than /P1 • /P1

(24 VDC/AC power supply)

The power supply terminals and protective ground terminals are located on the rear

panel.

Turn OFF the power switch on the recorder and open the power terminal cover.

1.

Wire the power cord and the protective ground cord to the power supply terminals.

2.

Use ring-tongue crimp-on lugs (designed for 4-mm screws).

Close the power supply terminal cover and secure it with the screw.

3.

The proper torque for tightening the screws is 0.6 N•m.

Open

Crimp-on lug

with insulation

sleeves

Power cord

Installing/Wiring the Recorder

L

N

DC/AC24V

L

+

N

-

IM 04P01B01-02E

Philips

Protective ground

Wiring Procedure (Portable Type (/H5x Option))

Check that the power switch to the instrument is turned OFF.

1.

Connect the plug on the accessory power cord to the power supply connector on

2.

the rear panel.

100-240V~

50/60Hz

40VA MAX

Ensure that the power outlet to be used meets the conditions on the previous

3.

page and that the voltage of the power supply is within the maximum voltage

rating of the power cord, then connect the other end of the power cord to the

power supply outlet.

The AC outlet must be of a three-prong type with a protective earth ground terminal.

Turning ON/OFF the Power Switch

The power switch is located inside the door at the lower right. The power switch is a push

button.

Press once to turn it ON and press again to turn it OFF. When the power switch is turned

ON, a self-diagnosis program runs for a few seconds, and the recorder is ready for

operation.

21

Page 24

Common Operations and Menu Structure

Power ON

Execution Modes

The recorder has three execution modes.

Operation Mode

This mode is used for normal recording operation. The recorder enters this mode when

the power is turned ON.

Setting Mode

This mode is used to set the input range, alarms, chart speed, and other parameters.

These settings can be changed while recording is in progress. However, the input

range of measurement channels and the computing equation, unit, constant, and TLOG

setting of computation channels cannot be changed while computation (/M1 option) is in

progress.

Basic Setting mode

This mode is used to set the basic specifications of the recorder such as the

thermocouple burnout detection function and the alarm output relay operation. This mode

cannot be entered while the recorder is recording or while computation is in progress

on the computation function (/M1 option). Measurement, recording, and alarm detection

cannot be carried out in this mode.

Operation Sequence

Display “End=Store” and press

Operation mode

Data display screen

1

Hold down

Data display setup screen

MENU

for 3 s

Hold down

for 3 s

MENU

Setting mode

Basic Setting mode

Hold down

+

for 3 s

This section explains the operations that need to be carried out when using the recorder

for the first time.

• PreparingtoRecord

Load the chart paper and pens (pen model) or ribbon cassette (dot model). Change

the date/time if necessary.

For the operating procedure, see page 28.

• SettingtheChannelInputRangeandOtherParameters

Set the measurement conditions suitable for the object being measured.

This manual explains the following operations.

• Setting the input range and alarm (see page 34 for the procedure)

• Changing the chart speed (see page 43 for the procedure)

• Recording/DisplayingData

Start/Stop the recording operation and carry out various types of printouts. Also,

switch the display screen and change the displayed contents.

For the operating procedure, see page 42.

22

IM 04P01B01-02E

Page 25

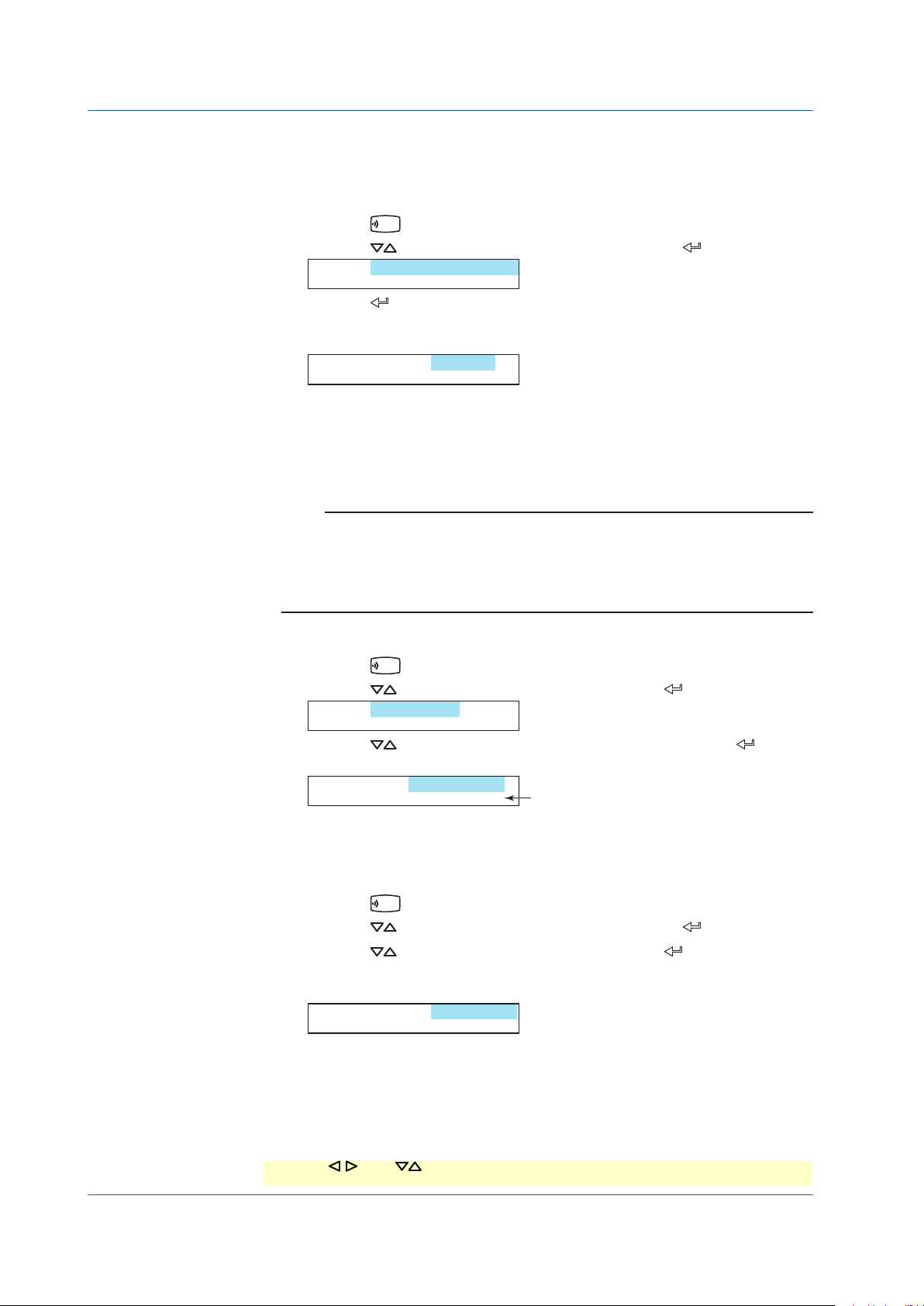

Key Operation

MENU

The item to be controlled blinks.

Setup item

Comment

Set=Range

Input range and

MENU

DISP

FUNC

The item to be controlled blinks.

Setup item

Comment

Basic=Alarm

Auxiliary alarm

Basic=End

Save Settings

DISP

CH UP

CH UP

End=Store

Save settings and

Entering Setting Mode

Exiting from Setting Mode (Returning to Operation Mode)

Entering Basic Setting Mode

Common Operations and Menu Structure

Hold down the

key for 3 seconds.

The Setting mode display appears. The top and bottom lines are the setup item and

comment, respectively.

The section that is blinking is the setup item that you change. In this manual, the section

that you change appears shaded.

In Setting mode, the panel keys are set to the functions marked above the keys.

CHARACTER ESC/? SHIFT

RCD

MENU FEED

DISP

Hold down the

MENU

1

FUNC

MENU

key for 3 seconds.

CH UP

The recorder returns to operation mode.

Hold down the

(

) key and the (

key for 3 seconds to enter Setting mode. Next, hold down both the

) key for 3 seconds.

The Basic Setting mode display appears. The top and bottom lines are the setup item

and comment, respectively.

The section that is blinking in the setup item that you change.

Exiting from Basic Setting Mode (Returning to Operation Mode)

1

Press the ESC (

Press the

MENU

) key several times to return to the Basic= screen.

DISP

(

) key to select End and then press the (

) key. The setup

CH UP

save screen appears.

Press the (

) key to select Store and then press the (

) key. The setting

is applied, and the screen returns to Operation mode. If you select Abort and press the

(

) key, the setting is discarded, and the screen returns to Operation mode.

IM 04P01B01-02E

23

Page 26

Common Operations and Menu Structure

SHIFT key + key

key

Possible choices

CH UP

01-01 Channel

Setting complete

FUNC

FEED

FUNC

DISP

FEED

DISP

SHIFT key + key

8

2

FUNC

SHIFT key + key

Cursor

Changing the Settings

Note

The comment line shows useful information such as a description of the setup item and the

range of selectable values. Read the comment and change the items as necessary.

Using the ESC Key

The selected item change each time you press the (

change in reverse order if you press the

FEED

) key.

(

Skip

Mode=TC

Volt

RTD

1-5V

(

DISP

DISP

) key. The selected item

) while holding down the SHIFT

This manual denotes the operation of pressing a key while holding down the SHIFT

FEED

(

) key as SHIFT + the other key (for example: SHIFT + key).

After you make a selection, press the

(

) key. The next screen appears.

When the Setting complete screen is displayed, the changed item is applied.

1

If you press the ESC (

MENU

) key, the operation is cancelled, and the display returns to a

higher level menu. In other words, if you do not show the Setting complete screen, the

changes you made up to that point are discarded.

Press the ESC (

1

MENU

) key while holding down the SHIFT (

FEED

) key to show or hide the

comment that is displayed at the bottom half of the screen.

24

Entering Values

Press the (

(

) to move the cursor to the left.

Press the

key to decrement the value.

You repeat these steps to enter the value.

Span_L= -2.000

-2.000/ 2.000V

When you press the (

displayed.

Entering Characters

Press the (

FUNC

(

) to move the cursor to the left.

Unit=ppm

CHR:a-z

) key to move the cursor to the right. Press the SHIFT (

(

) key to increment the value. Press the SHIFT (

key

Span_L= -1.500

-2.000/

Cursor

) key, the change is applied and the next screen is

CH UP

) key to move the cursor to the right. Press the SHIFT (

key

) + (

7

6

4

3

key

SHIFT key + key

FEED

IM 04P01B01-02E

) +

)

) +

Page 27

Common Operations and Menu Structure

DISP

FEED

DISP

p

j

FUNC

DISP

DISP

Position to insert the character

CHR:Ins DISP

DISP

FUNC

DISP

The character type changes each time you press the CHARACTER (

character type changes in reverse order each time you press the SHIFT (

CHARACTER (

MENU

) key.