Page 1

GAS & STEAM

FLOW COMPUTER

MODEL 415

6 December 1999

Page 2

Page 3

CONTENTS

List of Symbols

1. Introduction 7

1.1 Model Number Designation 9

2. Specification 10

3. Operation 14

3.1 Front Panel Operation 14

3.2 Flow Equations for Gases 16

3.2.1 Ideal Gas Law 22

3.2.2 General Gas 24

3.2.3 Natural Gas 25

3.3 Steam Measurement 26

3.4 Filtering 31

3.5 Non-Linearity Correction 33

3.5.1 Digital Input Linearity Correction 33

3.5.2 Analog Input Linearity Correction 35

3.6 The Output Pulse 37

4. Options 39

4.1 The 4-20mA Output Option 39

4.1.1 Load Specification 40

4.1.2 Calculation 40

4.2 The RS232/422/485 Interface Option 43

4.2.1 Hardware 43

4.2.2 Multipoint Communication 44

4.2.3 Communication Protocol 46

4.3 Data Logging 48

4.4 The Relay Output Option 49

Page 4

5. Calibration 50

5.1 Programming Chart 52

5.2 Definitions 59

6. Input Circuits 62

6.1 Frequency Flow Input 62

6.2 Analog Inputs 67

6.3 Remote Switches (Model 415A Only) 70

7. Installation 71

7.1 General 71

7.2 Wiring Designations for the Mode 415 73

Appendix 75

Properties of Selected Gases 75

Index 77

Page 5

List of Symbols Used in this Manual

Symbol Description SI Units US Units

A Normalised signal from the

flowmeter which will be 0 at 4mA

and 1 at 20mA.

G Specific Gravity for Gas.

Specific Enthalpy at Reference

h

B

kJ/kg kJ/kg

Conditions.

Specific Enthalpy at Flow

h

F

kJ/kg kJ/kg

Conditions.

K-factor (pulses/unit) for a

K

F

pulses/m

3

frequency flowmeter.

N Timebase Constant with which the

flowrate is displayed and is:

1 for units/second

60 for units/minute

3600 for units/hour

86400 for units/day

Density at base conditions. kg/m

ρ

B

Density at flow conditions. kg/m

ρ

F

P

Pressure at base conditions. kPa (abs) psia

B

3

3

pulses/ft

lbs/ft

lbs/ft

3

3

3

Critical pressure of gas. kPa (abs) psia

P

C

Page 6

Symbol Description SI Units US Units

Pressure at flow conditions. kPa (abs) psia

P

F

Energy value of steam. MJ/day

Q

E

BTU x 1000/day

MJ/hr

MJ/min

BTU x 1000/min

MJ/sec

Mass Flowrate. kg/day

Q

M

kg/hr

kg/min

kg/sec

Volume Corrected Flowrate. m3/day

Q

VB

3

/hr

m

3

/min

m

3

/sec

m

Note: If the corrected flowrate is at standard base conditions, then the

flow will be in scm or scf (ie. standard cubic meters or feet).

If the corrected flowrate is at normalised base conditions, then the

3

flow will be in Nm

Span (Mass Flowrate at 20mA). kg/day

S

M

(ie. Normalised cubic meters).

kg/hr

kg/min

kg/sec

BTU x 1000/hr

BTU x 1000/sec

lbs/day

lbs/hr

lbs/min

lbs/sec

3

/day

ft

3

/hr

ft

3

/min

ft

3

/sec

ft

lbs/day

lbs/hr

lbs/min

lbs/sec

Span for a volumetric flowmeter (eg

S

V

vortex).

m3/day

3

/hr

m

3

/min

m

3

/sec

m

ft

ft

ft

3

ft

3

/day

3

/hr

/min

3

/sec

Page 7

Symbol Description SI Units US Units

Span (Volumetric Flowrate at

S

VB

20mA) and at base conditions.

Temperature at base conditions. °K

T

B

m3/day

3

/hr

m

3

/min

m

3

/sec

m

(Kelvin)

Critical temperature of gas. °K °R

T

C

Temperature at flow conditions. °K °R

T

F

Specific Weight of Steam at

ν

B

Reference Conditions.

Specific Weight of Steam at Flow

ν

F

Conditions.

Compressibility at base conditions.

Z

b

Z

Compressibility at flow conditions.

F

dm3/kg dm3/kg

dm3/kg dm3/kg

3

/day

ft

3

/hr

ft

3

/min

ft

3

/sec

ft

°R

(Rankin)

Page 8

Page 9

Introduction 7

1. INTRODUCTION

The Model 415 Gas Flow Computer incorporates compensation for gas and

vapours to the following equations:

1. Ideal Gas Law using temperature & pressure correction, but where

compressibility is ignored.

2. General Gases where compressibility is calculated using the

1

Redlich-Kwong

3. Natural Gas using NX-19

equation.

2

equation for supercompressibility.

4. Steam Equations for both saturated and superheated steam. Mass and

energy flowrates are calculated using standard equations to determine

the specific weight and enthalpy of steam.

Inputs from a wide range of flowmeters are handled including vortex, turbine,

orifice plate, averaging pitot tubes, wedges, V-Cones and target flowmeters. In

addition, where two differential pressure transmitters are used across an orifice

(or similar device) to increase the measured flowrange, both D.P. transmitter

inputs can be accepted into the Flow Computer and scaled separately with

automatic crossover.

Options include a 4-20mA re-transmission, high and low flow alarms and an

RS232/422/485 output. A unique feature available with the RS232/422/485

output is the ability to print flowrates and totals at programmable time intervals.

This enables the instrument to function as a data logger when used in conjunction

with a printer, or other storage device.

Two versions of the instrument are available, the Model 415R with direct RTD

input, and the 415A with a 4-20mA temperature input. Both accept a 4-20mA

pressure input.

The Model 415 is designed to supersede the Models 405GS and 405ST.

1

Redlich & Kwong. "An equation of State". Chem Rev, vol 44, p233, 1949.

2

Par Research Project NX-19. "Extension of Range of Supercompressibility

Tables", American Gas Association, 1962.

Page 10

8 Introduction

This instrument conforms to the EMC-Directive of the Council of European

Communities 89/336/EEC and the following standards:

Generic Emission Standard EN 50081-1 Residential, Commercial & Light

Industry Environment.

Generic Emission Standard EN 50081-2 Industrial Environment.

Generic Immunity Standard EN 50082-1 Residential, Commercial & Light

Industry Environment.

Generic Immunity Standard EN 50082-2 Industrial Environment.

In order to comply with these standards, the wiring instructions in Section 7.1

must be followed.

Page 11

Introduction 9

1.1 MODEL NUMBER DESIGNATION

The Model number of an instrument describes which input and output options are

installed and the AC mains voltage rating.

Model 415 R. 1 0 E C

C for Conformal Coating

E for 220/240 VAC

A for 110/120 VAC

D for DC Power Only

Temperature Options

R for RTD input 0 for no option

A for 4-20mA 1 for 4-20mA output

2 for RS232/422/485

3 for Relay option

4 for 4-20mA and relays

5 for RS232/422/485 and relays

Mounting

1 for panel mounting

2 for field mounting

3 for explosionproof

The Model number of the instrument is displayed on first entering the

Calibration Mode (see Section 5).

Page 12

10 Specification

2. SPECIFICATION

General

Display: Alphanumeric LCD display with

backlighting and 2 lines x 20 characters/line.

Each character 5.5mm high.

Keyboard: Sealed membrane keyboard with four keys.

Transducer Supply: 8-24VDC field adjustable, 65mA maximum.

Power Requirements: 14 to 28.0 VDC, 300mA typical.

AC mains - Set internally to 95 - 135 VAC

or 190 - 260 VAC.

Operating Temperature: 0 to 55°C.

Facia: Watertight to IP65 or Nema 3S.

Dimensions: 144mm (5.7") wide x 72mm (2.8") high x

188mm (7.4") deep.

Depth behind Panel: 139mm (5.5") x 67mm (2.6").

Frequency Input

Frequency Range: Minimum: 0.25Hz on Rate.

0Hz on Total.

Maximum: 10KHz.

Input Circuits: Will accept most sine logic and proximity

switch inputs (see section 6.1).

K-factor Range: 0.1000 to 999,999.

Non-Linear Correction: Up to 10 correction points.

Page 13

Specification 11

4-20mA Inputs

Inputs: Flow (2), pressure & temperature.

Input Impedance: 250 ohms.

Measurement Ranges: Pressure: 0kPa (abs) (0 psia) to 100,000 kPa

(10,000 psia).

Temp:-273°C (-459.4°F) to 1200°C (2192°F).

Accuracy: 0.05%

Circuit: The 250 ohm resistors are connected to a

common signal ground (current sinking).

Span (Flow): 999,999.

RTD Input (Model 415R)

Temperature

Measurement Range: -100°C (-148°F) to 200°C (392°F),

Note: a wider temperature range can be

handled via a 4-20mA input.

Accuracy: 0.1°C

RTD Type: Platinum PT100.

Linearity: The non-linearity of the RTD is internally

compensated for.

Pressure Input

Type: Absolute or Gauge.

Span: The absolute or gauge pressure at both 4mA

and 20mA is programmable.

Atmospheric: If a gauge pressure sensor is used the

atmospheric pressure can be programmed.

4-20mA Output

Function: The flowrate selected as the Default display

is output on the 4-20mA output.

Resolution: 10 bits.

Accuracy: Better than 0.1%.

Maximum Load: 500 ohms internally powered.

950 ohms from 24 VDC.

Isolation: Output is isolated.

Page 14

12 Specification

Relay Output

Function: High and low flowrate alarms based on the

flowrate selected as the default display.

Maximum Switching Power: 1250VA.

Maximum Switching Voltage: 250 VAC, 30VDC.

Maximum Switching Current: 5 Amps.

RS232/422/485 Option

Type: Both RS232 & RS422/485 are provided.

Function: Printer and computer protocols are

programmable.

Output: Output is on request or at a programmable

time interval.

Baudrate: 300 to 9600.

Data Bits: 7 or 8.

Parity: None, Odd, Even.

Pulse Output

Function: The pulse output is scaled and outputs one

pulse each time the Default total increments

by one digit.

Pulse Width: 10mSec (negative going pulse).

Duty Cycle: Maximum of 49 pulses per second.

Output: An open collector transistor will sink 100mA

maximum.

Ideal Gas

3

Display: Corrected Volume (m

or ft3).

Mass (kg or lbs).

Temperature Range: -273°C (-450°F) to 800°C (1472°F).

(RTD has a more limited range.)

Pressure Range: 0 kPa abs (0 psia) to 100,000 kPa (10,000

psia).

Page 15

Specification 13

General Gas

Gases: Handles most gases for which the critical

temperature, pressure and SG are known.

Compressibility: Calculated using Redlich-Kwong equation.

3

Display: Corrected Volume (m

or ft3).

Mass (kg or lbs).

Temperature Range: -273°C (-450°F) to 800°C (1472°F).

(RTD has a more limited range.)

Pressure Range: 0 kPa abs (0 psia) to 100,000 kPa (10,000

psia).

Natural Gas

Calculations: Uses NX-19 equation to calculate

supercompressibility Fpv.

3

Displays: Corrected Volume (m

or ft3).

Mass (kg or lbs).

Temperature Range: -40°C (-40°F) to 115°C (240°F).

Pressure Range: 101.325 kPa (14.69 psia) to 34,380 kPa (4985

psia).

SG Range: 0.554 to 1.000.

Carbon Dioxide: 0 to 15% mole.

Nitrogen: 0 to 15% mole.

Steam

Displays; Mass (kg or lbs)

Energy (MJ or BTU x 1000).

Calculations: Uses 1967 IFC Formulation equations to

calculate specific weight and enthalpy of

steam.

Steam Type: Saturated and Superheated.

Temperature Range: 20°C (68°F) to 800°C (1472°F).

(RTD has a more limited range.)

Pressure Range: 1 kPa (abs) (1 psia) to 100,000 kPa (10,000

psia).

Page 16

14 Operation

3. OPERATION

The Model 415 uses a low power CMOS microprocessor to perform all

measurement and control functions.

The instrument is fully programmable with all operating parameters and

calculation constants user programmable (see Section 5 entitled Calibration for

information on programming). All parameters and constants are stored in a

non-volatile memory which retains data without battery backup for a minimum of

10 years.

3.1 FRONT PANEL OPERATION

The alphanumeric display provides a clear indication of which parameter is

displayed and the engineering units.

During Calibration, the value which is to be normally displayed can be

programmed as the DEFAULT display. For example, if Mass is required and is

programmed as the DEFAULT display, then pressing the RATE key will show

the Mass flowrate, and pressing the TOTAL key will show the Mass total.

The scaled pulse out, 4-20mA output option and high/low alarm option are also

based on the DEFAULT display selection. For example, the 4-20mA output

would be a re-transmission of the Mass flowrate, if the DEFAULT display is set

to Mass.

The DISPLAY key can be used to step through the data which can be displayed,

as follows:

Gas Flow

Corrected Volume (Rate & Total)

Mass (Rate & Total)

Temperature & Pressure

Page 17

Operation 15

Steam

Mass (Rate & Total)

Energy (Rate & Total)

Temperature & Pressure

Specific Weight & Enthalpy

If any value other than the default display values are selected, they will remain

displayed for 5 seconds, after which the display will automatically revert to the

default values.

Totals are displayed with a maximum of 8 digits, including decimals. For

example, if two decimals are programmed, the maximum total is 999,999.99,

after which the totals roll over to zero and continue counting.

For large flowrates, totals can be integrated at 1/1000 of the flowrate by

programming the Total Units function at x 1000. The units of measure will then

be displayed as follows:

SI Units

Rate Total

cm/h kcm

scm/h kscm

Nm

3

kNm

3

kg/h tonne

MJ/h GJ

US Units

Rate Total

cft/h kcft

scft/h kscft

lbs/h klbs

BTU x 1000/h MBTU

(Note: k = x 1000, M = x 1,000,000, G = x 1,000,000,000).

The RESET key can be used to reset the totals whenever one of the totals is

displayed. Both totals will be reset at the same time. The RESET switch can be

disabled during calibration to prevent front panel resetting.

Page 18

16 Operation

3.2 FLOW EQUATIONS FOR GASES

This section applies only to gas flow measurement and, if the Model 415 is to be

used for steam measurement, the reader can skip this section and go to section

3.3.

The Model 415 will accept inputs from a wide range of flowmeters with the

flowrate calculated by the equations defined below. Both mass flow and volume

corrected flow to a base temperature and pressure are calculated and displayed in

either SI (metric) or US units. For an explanation of the symbols used in the

equations see the list at the beginning of this manual.

Two basic formulae are common to all equations:

1. Specific Gravity, G =

2. Density of a Gas,

MolecularWeight ofGas

MolecularWeight ofAir

MolecularWeight ofGas

.....(1)=

ρ

at base conditions:

,

In SI Units

3.4834 G P

=

ρ

kg/m

B

In US Units

2.6988 G P

=

ρ

B

ZBT

Standard Conditions

Standard conditions are defined as:

15°C (288.15°K) and 101.325 kPa

or 59°F (518.67°R) and 14.69595 psia.

ZBT

28.9625

B

B

B

B

lbs/ft

3

3

.....(2)

.....(3)

Page 19

Normalised Conditions (SI Units only)

A

Normalised conditions are defined as:

0°C (273.15°K) and 101.325 kPa.

A. Volumetric Flowmeters With Frequency Output.

eg. Vortex, turbine or positive displacement flowmeters.

Operation 17

VB

=

N. frequency(Hz)

K

F

VB

P

T

F

.

P

B

Z

B

B

.

.

T

Z

F

F

......(4)Q

......(5)QM= ρB.Q

B. Volumetric Flowmeters With 4-20mA Output.

eg. Vortex, turbine or positive displacement flowmeters with frequency to

current convertors.

P

T

Q

VB=SV

.

QM= ρB.Q

F

P

B

VB

Z

B

B

.

.

T

.

Z

F

F

......(6)

C. Differential Pressure Flowmeters With 4-20mA Output And A Square

Law Relationship.

eg. Orifice Plates, Averaging Pitot Tubes, Target Flowmeters, etc.

P

T

VB=SVB

QM= ρB.Q

F

.

.

P

B

VB

Z

B

B

.

Z

F

.A

T

F

......(7) Q

Page 20

A

18 Operation

D. Differential Pressure Flowmeters With 4-20mA Output And With A

Linear Flow Relationship.

eg. D.P. transmitters with a square root extractor or VA meters.

P

T

VB=SVB

F

.

.

P

B

Z

B

B

.

T

F

.

Z

F

......(8)Q

QM= ρB.Q

VB

Note that the pressure and temperature are still square rooted, even though

the flow signal A is not. This is because the output from the D. P.

transmitter is not truly volumetric, but will be affected by a change in

density of the gas being measured. Therefore, the equations relating to

differential pressure will apply.

E. Dual Differential Pressure Flowmeters With 4-20mA Output.

To increase the range over which flow can be measured, two D. P.

transmitters with different spans can be connected across a common

orifice or other differential pressure device.

Equations 5 & 6 or 7 & 8 above would be used depending upon whether

the D. P. transmitters have square root extractors. Separate scaling using

these equations is then programmed for each transmitter.

At lower flowrates, transmitter 2 will be used as a basis of measurement

and at higher flowrates, transmitter 1 will be used. The crossover point

will occur when the input on transmitter 2 exceeds 20mA.

Page 21

Operation 19

Example 1

Flow is to be measured across an orifice in the range of 0 - 2000

scm/hr. Because flow needs to be measured over a 10:1 range, two

transmitters are spanned as follows:

Transmitter 2 0 - 600 scm/hr

Transmitter 1 0 - 2000 scm/hr

Hence, above 600 scm/hr, transmitter 2 is used and below 600

scm/hr, transmitter 1 is used. Since D. P. transmitters are accurate

over a 3:1 range, then the system will provide reliable readings

between 200 to 2000 scm/hr, which is a 10:1 turndown.

Both transmitters will be individually scaled to equations 5 & 6 or

7 & 8, as appropriate.

PROGRAMMING THE FLOW COMPUTER

For equations 4 to 8 to work correctly, a number of parameters need to

be programmed:

K-factor (for frequency producing flowmeters)

K

F

(or SM) Span (for analog flowmeters)

S

VB

T

B

P

B

Base temperature

Base pressure

G Specific Gravity of Gas

The flow computer will measure the flow input A (normalised between

0 and 1), the temperature, T

, and pressure, PB. Depending on the gas

F

equation selected, the compressibility factors and density are then

calculated. Other parameters must also be programmed and these are

fully detailed in section 5.

Page 22

ρ

20 Operation

PROGRAMMING THE SPAN AS MASS

It is also possible to enter the span of an analog flowmeter in mass

(instead of volume) at a nominal flowrate. The flow computer will

then automatically calculate the Span, S

as:

=

S

VB

Example 2

If a flowmeter produces 1000 kg/h at 30°C and 220 kPa, and the

specific gravity is 1.52 then from equation (2)

3.4834 x 1.52 x 220

ρ =

1x(30 + 273.2

, for corrected volume flow

VB

S

M

B

)

......(9)

(assuming ZB = 1)

= 3.84 kg/m

3

Therefore, from equation (9)

1000

=

S

VB

3.84

= 260 m

3

/hr

If the span is programmed as mass SM = 1000 kg/hr, with the base

temperature programmed to 30°C and the base pressure

programmed to 220 kPa, then the flow computer will display both

mass (kg/hr) and volume (m

3

/hr) corrected to a base condition of

30°C and 220 kPa.

Page 23

and

Operation 21

Example 3

If the mass flow is defined at non- standard base conditions and it

is required to display the corrected volume at standard conditions,

then it is first necessary to convert the mass to an equivalent mass

at standard conditions.

Using example 2 for a differential pressure device, the

corresponding mass at 15°C and 101.325 kPa can be determined

from equation 7 as:

P

T

S

M1=SMB

1

.

.

P

B

Z

B

B

.

T

Z

1

1

where SM1 = the new span at 15°C and 101.325 kPa

with the input A = 1

Therefore, the new span S

= 1000 x

S

M1

, with ZB = Z1= 1, is:

M1

101.325

220

x

30 + 273.2

15 + 273.2

= 696.1 kg/hr

Hence, the span would be programmed as 696.1 kg/hr, the base

temperature as 15°C and the base pressure as 101.325 kPa. The

corrected volume will now be displayed at standard conditions.

Page 24

22 Operation

3.2.1 Ideal Gas Law

If the effects of compressibility on a gas can be ignored, then Z

and ZF can be set

B

to 1.00 in equations 1 to 8. This can make calculations much simpler,

particularly when the properties of a gas are not known or, over small ranges of

pressure and temperature, where the effects of compressibility are often

negligible.

Example 4

A vortex meter is used to measure oxygen in a 2" pipe at 25° C and

200 kPa (abs). The flowmeter produces 9500 pulses/m

flowrange is 100 to 1000 m

3

/h. Determine the flow parameters

3

and the

which need to be programmed into the instrument for it to display

the flowrate and total flow as both mass and corrected volume to

Standard Conditions.

From the table, the Molecular Weight of oxygen is 31.9988. From

equation (1)

31.9988

28.9625

= 1.105

G=

According to ISO5024, Standard Conditions are 15° C (59° F) and

101.325 kPa (14.69595 psia). Hence, the following are

programmed into the instrument:

Scaling Factor (K-factor) = 9500 pulse/m

3

Specific Gravity G = 1.105

Base Temperature = 15 °C

Base Pressure = 101.325 kPa

Timebase of Rate = Hours

Other parameters can be programmed as required.

The instrument will now display the corrected volume and mass

flowrates of the gas.

Page 25

Example 5

Operation 23

The same vortex meter installation, as detailed in Example 4, also

has a 4-20mA output. The meter produces 20mA at 1000 m

4mA at 0 m

3

/h. Determine the flow parameters which need to be

3

/h and

programmed for mass flow and corrected volume to standard

conditions.

With the instrument set for a linear 4-20mA input signal, the

following parameters are programmed:

Span (S

) = 1000 m3/h

V

Specific Gravity G = 1.105

Base Temperature = 15 °C

Base Pressure = 101.325 kPa

Timebase of Rate = Hours

Page 26

24 Operation

3.2.2 General Gas

For general gases, the compressibility is calculated using the Redlich-Kwong

equation. In order to calculate the compressibility of a gas, it is necessary to

know the critical temperature and pressure. From these parameters, the

compressibility factors Z

and ZF are calculated for a gas.

B

A list of common gases with specific gravity and critical temperatures &

pressures is given in the appendix to this manual.

The equations 1 to 9 are then used to calculate both corrected volume and mass

flow.

Example 6

It is required to measure Hydrogen via an orifice plate using

compressibility. Find the critical temperature and pressure which

need to be programmed and the specific weight.

From the table, in the appendix,

= -239.9 C

T

C

= 1296.9 kPa

P

c

G = 0.0696

Page 27

3.2.3 Natural Gas

Operation 25

In the gas industry, compressibility is referred to by a factor, F

, termed the

PV

supercompressibility factor where:

Z

B

=

PV

Z

F

FPV is calculated in the flow computer using the NX-19 equation for natural gas

and (F

In order to calculate F

2

)

is substituted into equations 4 to 8 in place of .

PV

, the following must be programmed within the following

PV

Z

B

Z

F

......(10)F

ranges:

Specific Gravity G: 0.554 to 1.000

Carbon Dioxide mol%: 0 to 15%

Nitrogen mol%: 0 to 15%

Also, the temperature and pressure must be within the following ranges:

Temperature -40 to 115°C

(-40 to 240°F)

Pressure 0 to 34,372 kPa

(0 to 5000 psia)

Page 28

26 Operation

3.3 STEAM MEASUREMENT

The Model 415 incorporates equations to handle both saturated and superheated

steam over the following range:

Pressure 0 kPa abs (0 psia) to 100,000 kPa abs (10,000 psia)

Temperature 100°C (212°F) to 800°C (1472°F).

When measuring saturated steam, it is possible to delete either the pressure or

temperature sensor since, on the saturation line, there is a corresponding pressure

for all temperatures. For superheated steam, it is necessary to use both the

pressure and temperature sensors.

Both the mass flow (in kg/hr or lbs/hr) and the heat content (enthalpy) are

calculated internally based on the 1967 IFC Formulation (ASME) Equations.

The equations use the pressure and temperature readings to determine:

ν

, the specific volume of steam in dm3/kg or,

-

- h, the specific enthalpy of steam in kJ/kg.

A. Volumetric Flowmeters With Frequency Output.

eg. Vortex, Steam turbines, etc.

Mass Flow

US Units : Q

M(SI)

M(US)

=1000.

= 62.435 .

N. frequency (Hz)

K

F

N. frequency

K

1

.

ν

F

1

.

ν

F

F

(Note: for US units KF is in pulses/ft3.)

......(11)SI Units : Q

......(12)

Page 29

Energy Flow

A

Q

xh

M(SI)

=

E(SI)

E(US)

1000

= 0.42992

Q

M(US)

1000

xh

B. Volumetric Flowmeters With 4-20mA Output.

eg. Vortex or Steam turbines with frequency to current convertors.

Mass Flow

S

V

x

ν

F

S

V

xA

ν

F

US Units : Q

M(SI)

M(US)

= 1000 x

= 62.447 x

Energy Flow

Operation 27

......(13)SI Units : Q

......(14)US Units : Q

......(15)SI Units : Q

......(16)

Equations 13 & 14 are used.

C. Differential Pressure Flowmeters With 4-20mA Output And A Square

Law Relationship.

eg. Orifice Plates, Averaging Pitot tubes, target flowmeters, etc.

Mass Flow

M=SM

ν

F

.A

......(17)Q

ν

B

.

Energy Flow

Equations 13 & 14 are used.

Page 30

A

28 Operation

D. Differential Pressure Flowmeters With 4-20mA Output And With A

Linear Flow Relationship.

eg. D. P. transmitters with a square root extractor or VA meters.

Mass Flow

ν

B

.

Q

M=SM

.

ν

F

......(18)

Energy Flow

Equations 13 & 14 are used.

Note that the Specific Weight (density) is still square rooted even though

the flow signal A is not. This is because the output from the D. P.

transmitter is not truly volumetric, but will be affected by a change in the

steam density. Therefore, the gas equations relating to differential

pressure must apply.

E. Dual Differential Pressure Flowmeters With 4-20mA Output.

To increase the range over which flow can be measured, two D. P.

transmitters with different spans can be connected across a common

orifice or other differential pressure flowmeter.

Equations 17 or 18 would be used depending on whether the D. P.

transmitters have square root extractors. Separate spans are then

programmed for each transmitter and at lower flowrates transmitter 2 will

be used. At higher flowrates, where the output of transmitter 2 exceeds

20mA, transmitter 1 will be used.

Page 31

Operation 29

PROGRAMMING THE FLOW COMPUTER

For equations 11 to 18 to work, a number of parameters need to be

programmed. These include:

K

S

M

ν

K-factor (for frequency producing flowmeters).

F

Span (for analog flowmeters).

Base specific weight at which the span is determined.

B

The flowmeter will measure the flow input A (normalised between 0

and 1) and the temperature T

pressure are used to calculate the specific weight,

and pressure PF. The temperature and

F

ν

, and enthalpy, h,

from internal equations. Other parameters must also be programmed

and these are fully detailed in section 5.

Example 7

A vortex flowmeter has a K-factor of 68.32 pulses/ft

3

, and it is

required to measure saturated steam in lbs/hour. What are the

main parameters to be programmed?

The instrument should be programmed for steam measurement

from a frequency meter. Because the steam is saturated, it is only

necessary to use either a temperature or pressure sensor. Because

of cost, a temperature probe is used. The main parameters to

program are simply:

Units US Units

K-factor = 68.32

Timebase hours

Page 32

30 Operation

Example 8

A differential pressure transmitter across an orifice is designed to

output 20mA at 10,000 kgs/hour at a reference pressure of 1300

kPa (abs) and specific weight of 216.05 dm

required in kg/hour and the calorific value in MJ/hour. What are

the main parameters to be programmed?

3

/kg. The flowrate is

From the steam tables at 1300 kPa (abs) and a specific weight of

216.05 dm

3

/kg, the temperature can be calculated as 350°C, and is

in a superheated state. Hence, steam measurement via a 4-20mA

input with square law relationship is selected and the following key

parameters are programmed:

Units SI Units

Span 10,000

Base Temperature 350°C

Base Pressure 1300 kPa

Timebase hours

Steam Superheated

Page 33

Operation 31

3.4 FILTERING

Frequency fluctuations caused by pulsating flow through a flowmeter, often make

the Rate impossible to read with any precision.

The Flow Computer `as a digital filter which will average out these fluctuations

and enable the Rate to be read to four digit accuracy. The ability to select a

suitable filtering level means that highly accurate and stable readings can be

obtained without excessive lag. When the Rate is retransmitted via the 4-20mA

output, the filtering will also average out any fluctuations on the output.

The diagram below shows a pulsating signal input together with the effect of

filtering.

Rate

Filtered Response

Unfiltered Response

Time

As a guideline to the degree of filtering to be used, the following table shows the

response to a step change in input. The value, A, is the filter constant which is

programmed during the Calibration routine. The times for the display value to

reach 90% and 99% of full swing are given in seconds, for different values of A.

Page 34

32 Operation

A 90% 99%

100

212

424

636

10 5 11

15 8 17

20 11 22

25 14 28

35 20 40

45 25 51

60 34 69

75 43 86

90 52 103

99 57 113

Table 1 - Response to a step Input (in seconds).

Note that if A is set to 1 there is no filtering of the input signal.

Page 35

Operation 33

3.5 NON-LINEARITY CORRECTION

3.5.1 Digital Input Linearity Correction

Non-linearity correction enables the instrument to correct for known

non-linearities if the flowmeter. This feature is not selectable for analog flow

inputs.

Up to 10 frequencies and scaling factors can be programmed. Data on the

flowmeter non-linearity can usually be supplied by the flowmeter manufacturer in

the form of a Calibration Certificate, and is the result of individual tests on a

flowmeter over a range of flowrates. The Certificate will list a number of

flowrates or frequencies with the measured K-factor (eg. pulses per gallon or

litre) at each flowrate.

The following diagram graphs the change in scaling factor with frequency for a

hypothetical flowmeter. The heavy black line represents the actual scaling factor

of the flowmeter, while the light black line is the approximation used in the

instrument.

Scaling Factor

Fact 4

Fact 6

Freq

6

Fact 5

Freq

5

Freq

4

Freq

3

Fac t 3

Fact 2

Freq

2

Freq

1

Fact 1

Frequency

Max

Frequency

Linear Interpolation is used between points on the curve, except for Factor 1

which maintains a constant value between Frequency 1 and the maximum input

frequency.

Page 36

34 Operation

During Calibration, the program requires the user to input a frequency and the

Scaling Factor (K-factor of the flowmeter) at up to 10 points on the curve.

Generally these points will correspond to those shown on the Certificate.

If any frequency is set to 0Hz (Frequency 6 in the preceding example), then the

program will require no further correction points to be programmed. Hence, the

user can program any number of correction points up to a maximum of 10. Note

that if all 10 correction points are required, then Frequency 10 will automatically

be assigned the value of 0Hz.

Page 37

Operation 35

3.5.2 Analog Input Linearity Correction

For single analog flow inputs, an input table can be programmed to correct for

any non-linearities between the flow signal and the actual flowrate. This feature

is very useful when using the flow computer with some types of VA flowmeters

or laminar flow tubes which may exhibit slight non-linear characteristics.

Up to 20 points can be programmed, and linear interpolation is then used

between points in the curve. The table works by inputting a normalised flow

input signal A, into the table and produces a corrected output A

ranges between 0 and 1.0000 so that, at a 4mA input, both A and A

. The table

C

equal 0 and

C

at 20mA both values must also equal 1.0000.

The user programs the table starting with 1.0000 and programs corresponding

values of A and A

. As soon as A is programmed as 0.0000, no further input to

C

the table is possible and the program will correct over the number points that

were programmed. A maximum of 20 points can be programmed.

At the base temperature and pressure, the flow equation, with non-linearity

correction is defined as:

Q=Span.A

C

Note: The square root relationship for conventional differential pressure

flow devices is handled separately and not by the linearity

correction described in this section.

Page 38

36 Operation

Example

A flowmeter has been tested and the following relationship between

the input and the flowrate has been determined at the nominal

temperature & pressure as follows:

Input Flowrate Normalised Inputs for

table

IncheswgD.P. OutputmAlbs/hr Input (A)

Output (A

)

C

52.2007 20.000 7075.89 1.0000 1.0000

39.3894 5306.92 0.7546 0.7500

33.3231 4422.43 0.6384 0.6250

26.7444 3537.94 0.5123 0.5000

20.1656 2653.45 0.3863 0.3750

12.9913 1768.97 0.2489 0.2500

5.5400 884.48 0.1061 0.1250

1.0388 269.06 0.0199 0.0380

0.0000 4.0000 0 0.0000 0.0000

where A =

AC=

Inches wg

Inches wg at 20mA

flowrate

flowrate at 20mA

Inches wg

=

flowrate

=

7075.85

52.2007

The values of A and AC are input into the table during Calibration

and the span would be programmed as 7075.89 such that

Q = 7075.89 x A

C

Page 39

Operation 37

3.6 THE OUTPUT PULSE

An OUTPUT PULSE is available on terminal 10 for driving remote counters

and produces a pulse each time the Total of the Default display increments by

one digit. For example, if the Default Total has a resolution of 0.01 kilograms, a

pulse is produced each 0.01 kilograms.

The pulse is a current sinking pulse of approximately 10mSec produced by an

open collector transistor and can sink up to 100mA. The maximum pulse rate is

limited to 49 pulses per second and the resolution on the accumulated total must

be set so that the accumulated total increments at less than 49 counts per second.

Note that due to the uneven pulse output spacing on this output, the pulse output

cannot be used to drive rate indicators.

Page 40

38 Operation

Connection of Output Pulse is as follows:

Model 415

5.6 ohms

33V

Zener

Relay or

Impulse Counter

10

12

DC Supply

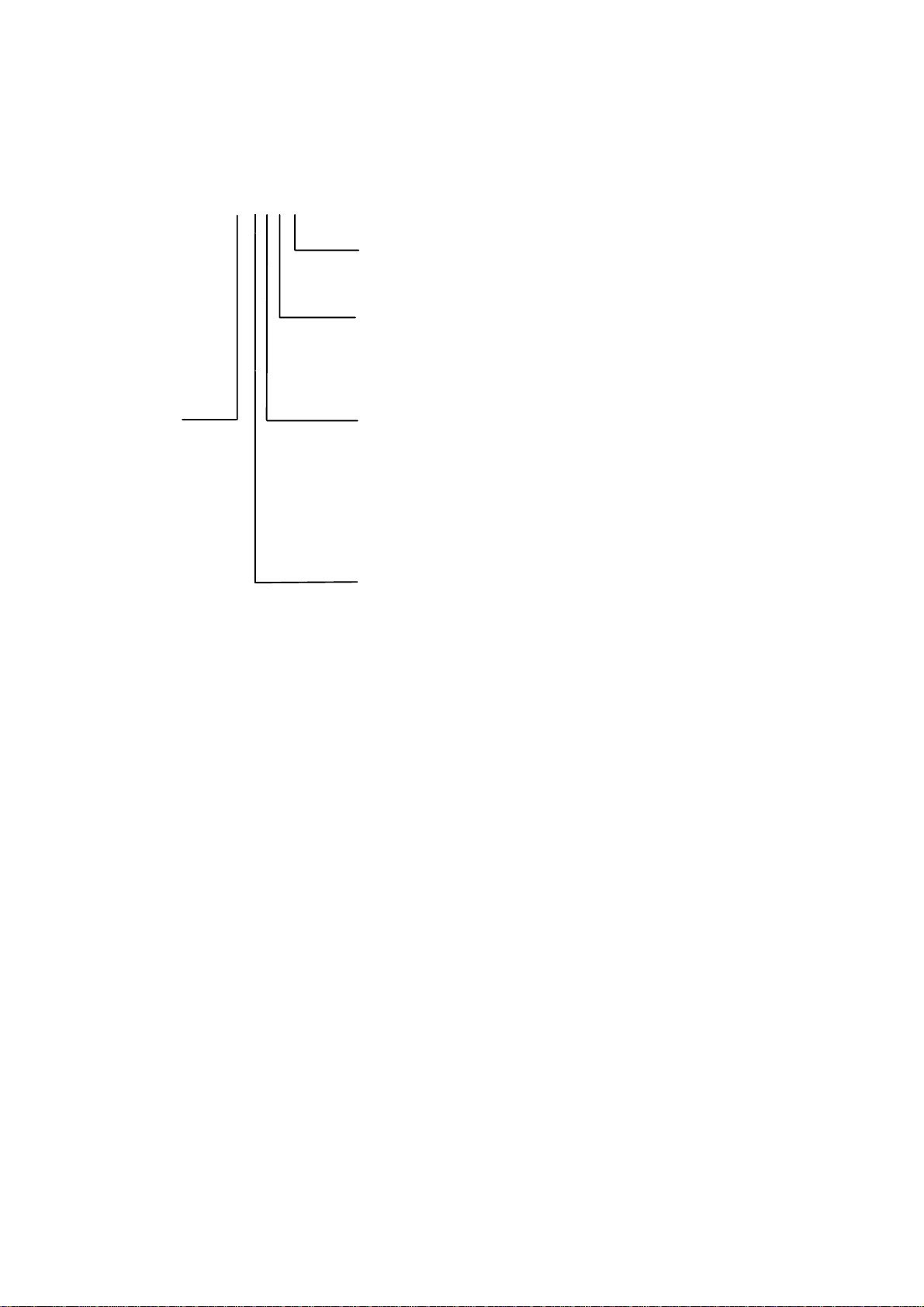

Driving an External Relay or Impulse Counter

Model 415

DC Supply

Out (8-24V)

5.6 ohms

33V

Zener

11

External Load

Resistor 10K

10

2

Driving a Logic Input such as a PLC or Electronic Counter

Logic Input

Page 41

Options 39

4. OPTIONS

4.1 THE 4-20mA OUTPUT OPTION

The 4-20mA output option provides an analog output of the Default flowrate as

either a 4-20mA current or a 0-10 Volt level. The output will be the corrected

volume, mass or energy, depending on which parameter is programmed as the

default displayed. All output signals are electrically isolated from the instrument

power supply and signal inputs to ensure minimum interference.

Either 2 wire current transmission is available with the loop powered internally,

or 3 wire transmission from an external loop supply.

A block diagram of the output is shown below and various methods of

interconnection are outlined on the following pages.

DC to DC

Convertor

Digital to

Analog

Convertor

Opto-Isolation Amplifiers

+15V

0-10V Out

0V

-12V

Terminal

26

25

24

22

21

23

Page 42

40 Options

4.1.1 Load Specification

Maximum load which the output can drive:

Internally powered loop: 500 ohms

Externally powered: R = (V-5)/.02

where V is the external loop voltage

R is the maximum load in ohms.

Output impedance of 0-10 Volt source: 100 ohms

4.1.2 Calculation

Parameters relating to this option are programmed when calibrating the

instrument (see section 5) and provide for:

Defining the rate which is equivalent to 4mA or 0 volts.

Defining the rate which is equivalent to 20mA or 10 volts.

Selecting the output range as 4-20mA (which also gives 2-10 volts on

the voltage output circuit) or as 0-10 volts (which gives 0-20mA on the

current output circuit).

By being independently able to set the output range, the instrument can

effectively be programmed to amplify the input signal. In driving chart

recorders, for example, this enables the output to zoom in on a particular

operating area, instead of having to display the full operating range of the

transducer.

For example, 4mA may be set as 0 kg/min and 20mA as 200 kg/min. However,

the user could set 4mA as representing 100 kg/min and 20mA as representing

120 litres/min.

For rates or displayed values above and below the maximum and minimum

values the output will remain at its 20mA or 4mA level respectively.

It should be noted that the output will be updated every 0.5 seconds in unison

with the display and, between updates, the output value is constant.

Page 43

Amplifiers

Amplifiers

Terminal

+15V

0-10V Out

0V

-12V

26

25

I(+)

I(-)

24

22

21

23

Voltage Output Configurations

Terminal

+15V

0-10 V Out

I(+)

I(-)

26

25

24

22

21

Link

23

Link

LOAD

LOAD

500 ohm

maximum

Options 41

Two Wire Transmission (Internal Supply)

Page 44

42 Options

+15V

I(+)

I(-)

Terminal

26

25

24

Amplifiers

0-10 V Out

0V

-12V

22

21

23

LOAD

Three Wire Transmission (External Supply)

Page 45

Options 43

4.2 THE RS232/422/485 INTERFACE OPTION

With this option installed, the circuits for both the RS232 and RS422/485 are

provided as standard. They can be used to interface to both printers and

computers, and a number of standard protocols are built into the instrument.

4.2.1 Hardware

The following diagram provides an overview of the RS232/RS422/RS485

communications hardware. All three interfaces are available on the rear terminal

strips and the user can select either one by making the appropriate connections.

The RS232 interface is primarily used with printers or for simple communication

with a computer over a short distance. The RS422 and RS485 interfaces are used

for communication over a long distance or in applications requiring multipoint

communication.

(+)

24

23

RS422 Out

(-)

(+)

26

(-)

25

Data In

21

Data Out

22

27 CTS

20

Ground

RS422 I n

RS232

Page 46

44 Options

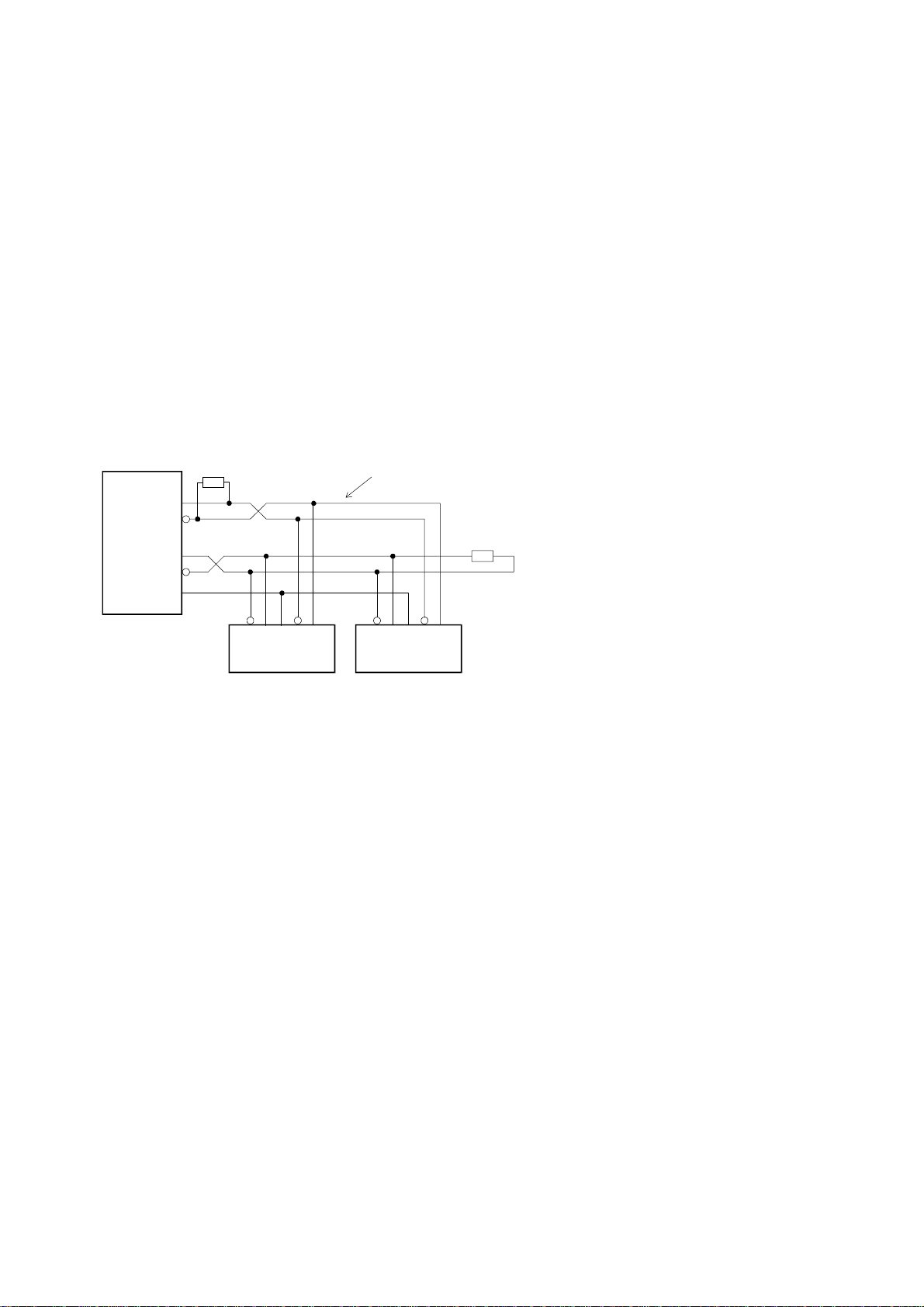

4.2.2 Multipoint Communication

Multipoint Communication is a system whereby a number of instruments can be

addressed over a dual twisted pair interface. Up to 32 instruments can be

connected to a common bus using the RS422 and RS485 interfaces as shown

below.

To covert the RS422 interface to an RS485 interface, the RS422 (-) Data In

Terminal must be connected to the RS422 (-) Data Out Terminal and the RS422

(+) Data In Terminal must be connected to the RS422 (+) Data Out Terminal.

These connections will convert the RS422 4 wire interface to the RS485 2 wire

interface, as shown in figure 2.

Each instrument can be programmed with a unique address which is used by the

Master Controller (ie IBM/PC) to identify each instrument. The Controller will

send the address down the line and will alert the relevant instrument.

Subsequent software protocol will control the flow of data between the Controller

and the Instrument.

Host

Compu ter

Load

120 ohms

400 Series

Instrument

Twisted Pair

Figure 1 RS422 Interface

Load

120 ohms

400 Series

Instrument

Page 47

Twisted Pair

Options 45

Host

Compu ter

Gnd

+

Load

120 ohms

-

+-

-

Gnd

In

400 Series

Instrument

Out

+

-

+--+

Gnd

In

Out

400 Series

Instrument

Figure 2 RS485 Interface

Page 48

46 Options

4.2.3 Communication Protocol

The Model 415 has a real time clock and enables the time and date to be set and

printed on tickets. The date format can be European (days/months/years) or USA

(months/days/hours), while the time is on a 24 hour clock.

Note that the clock will only retain its time for 3 days minimum if there is no

power connected to the instrument. After this period, the clock may need to be

reset.

The baudrate, parity and wordlength can be programmed during calibration and

the user must ensure that these correspond to the setting on the printer or

computer with which the Model 415 is communicating.

The software protocols can be selected during Calibration to provide standard

interfaces to a number of printers and computers. Since other interfaces will

continue to be added, the user should consult the manual "The RS232/422/485

Communications Option for the 400 Series, Version 2", for the latest protocols

and printer drivers.

Printer

A ticket is printed each time the RESET key is pressed or at defined time

intervals (see Data Logging). If the Reset key is used, the instrument prints the

ticket before resetting the totals.

Protocols are provided to drive the following printers:

1 Standard Computer Printer (Note that the printer must have an

RS232 Serial Interface).

2 EPSON CTM290 Slip Printer.

3 Contrec Model 624.

4 EPSON TM290-2 Slip Printer.

5 Contrec Model 632-2 Printer.

6 Syntest SP-210 Printer.

Page 49

Options 47

A CTS input is provided, and will prevent the instrument from transmitting any

further characters to a printer if the printer buffer is full. The CTS input is

usually connected to the "Data Buffer Full" output from the printer.

If the printer buffer is large enough to handle the messages output from the

instrument, then this input need not be used and should be left unconnected.

Computer

The instrument receives and transmits messages in ASCII, with all command

strings to the instrument terminated by a carriage return. While replies from the

instrument are terminated with a carriage return and a line feed.

Xon/Xoff protocol is also supported, and the instrument will automatically

determine if the message sent by the host computer is preceded by an Xoff

character. If it does recognise an Xoff as the first character of a command string,

the instrument will automatically switch to Xoff/Xon protocol, and begin & end

all messages with Xoff and Xon characters respectively. Xoff/Xon protocol is

only available when the RS232 interface is selected.

During Calibration, the instrument can be programmed to operate in a full

duplex or half duplex transmission mode. In full duplex mode, all commands

sent to the instrument will be echoed back to the host computer. In half duplex,

the commands are not echoed.

For more information on the computer interface please consult the manual "The

RS232/422/485 Communications Option for the 400 Series, Version 2".

Page 50

48 Options

4.3 DATA LOGGING

The Model 415 can be programmed to output data to a printer, computer or other

storage device at the following intervals:

1 minute (Every minute on the minute)

10 minutes (On the hour, at 10 past...etc)

30 minutes (On the hour and half hour)

1 hour (On the hour)

6 hours (At 6:00, 12:00, 18:00 and 24:00)

12 hours (At 12:00 and 24:00)

24 hours (At 24:00)

The totals can be programmed to reset manually via the front panel, or

automatically after each print is initiated, or at 24:00 after the print is initiated.

Note that if manual reset is selected, it is still possible to prevent front panel reset

by inhibiting this function in General Setup (in Calibration).

Page 51

Options 49

4.4 THE RELAY OUTPUT OPTION

The Relay output option consists of two Form C relays which can be preset

during calibration to energise when the Default flowrate exceeds or drops below

the preset values.

The "low" relay is energised whenever the rate is below the preset value, and the

"high" relay is energised whenever the rate exceeds the preset value. The preset

values are programmed during calibration as described in section 5.

Normally Open

34

Relay 1

Low Alarm

Relay 2

High Alarm

35

Normally Closed

36

Common

Normally Open

31

Normally Closed

32

Common

33

Page 52

50 Calibration

5. CALIBRATION

The Calibration routine enables the Setup Parameters to be programmed, as well

as enabling the input signals to be checked.

The calibration routine can be entered in two ways:

1 By connecting a wire link (or switch) to the rear terminal strip

across terminals 1 and 2 or,

2 By pressing the TOTAL key and, while still holding, pressing the

DISPLAY key. Both keys must then be held for approximately 6

seconds. This second method of access can be disabled during the

calibration so that it is only possible to enter the calibration routine

via the link across terminals 1 and 2.

The key switch actions during Calibration are as follows:

RATE will change a flashing digit, to the next digit.

TOTAL will increment a flashing digit or change a

parameter selection.

RESET will reset a flashing digit to zero.

DISPLAY (Program) will step through the program sequences.

Note that the arrows in the Rate and Total key switches indicate that these

switches can be used to change and increment digits respectively.

In stepping through the program sequence, the Parameter Description is always

shown. When a value or parameter can be changed, it is always shown as

flashing, and the LED's in the switch panels are lit if that key switch can be used

to change a value.

Page 53

Calibration 51

On first entering the Calibration routine, the display will show the Model number

followed by:

SELECT

(GENERAL SETUP)

There are six main menu items as follows:

1. GENERAL SETUP

2. GAS PARAMETERS

3. FLOW PARAMETERS

4. OPTIONS

5. TEST

6. EXIT

The user can toggle between these menus using the " " key. To enter a menu,

the DISPLAY key is then pressed.

In the following flowcharts, the options which can be selected using the or

keys are shown in brackets ( ), and values to be entered are shown as xxxx's. The

flowcharts show the program flow during the Calibration and a List of

Definitions is given immediately after the flowchart. This list covers those terms

which are not explained elsewhere in the text.

To exit Calibration, step through the Setup program until the end, and press the

DISPLAY switch when Exit is displayed, (ensure the calibration link is

removed).

Floating Point Numbers

Values such as the SPAN or Pressure are programmed in floating point format.

This enables numbers as low as 0.00001 and as high as 999999 to be

programmed with 6 digit accuracy.

To enter a value of, say, 101.325 when the display shows 0.0000, the key

would be pressed 9 times until 000.000 is displayed. Once the correct position is

reached, the and keys can then be used as normal to enter data.

Page 54

52 Calibration

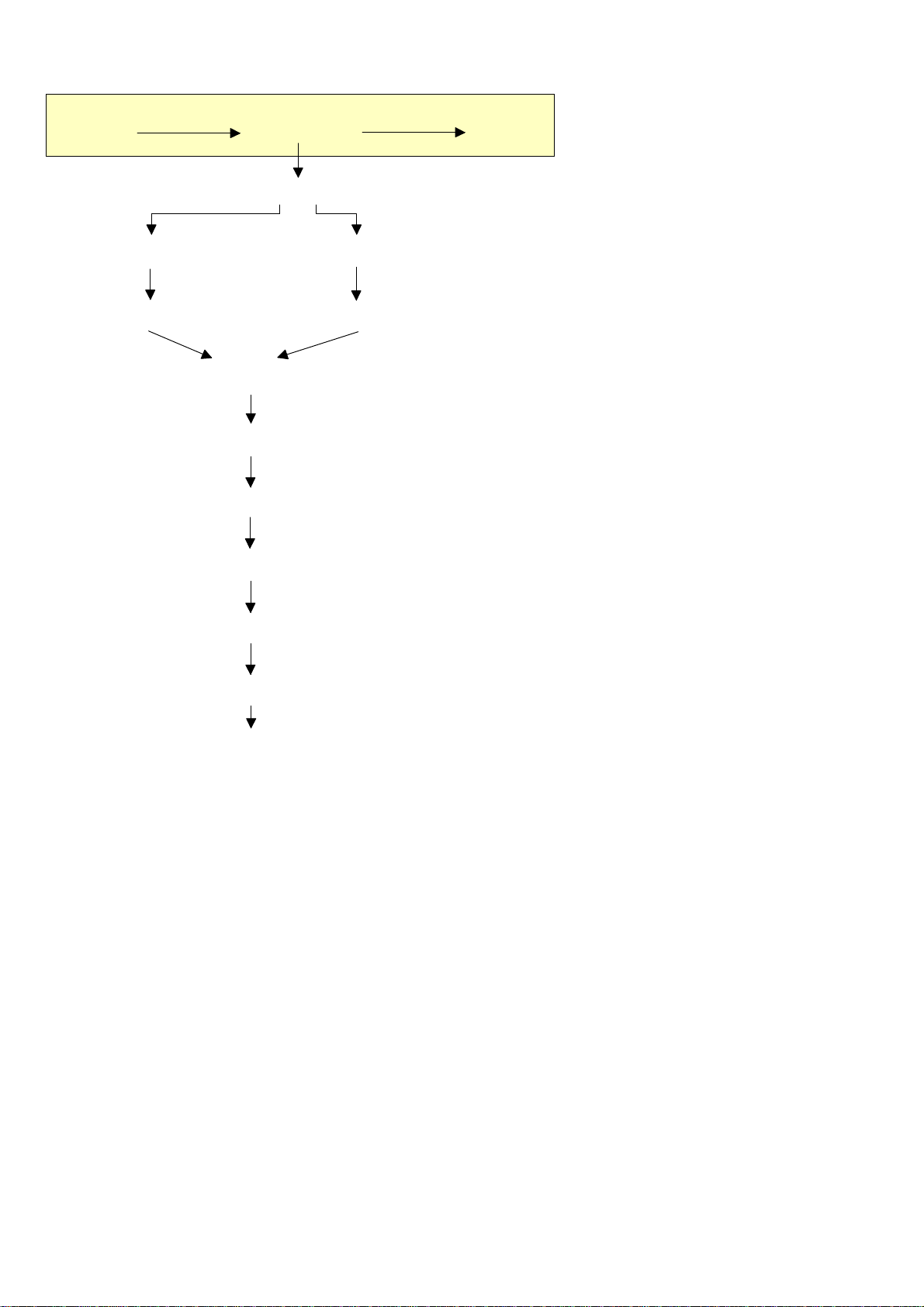

5.1 PROGRAMMING CHART

CALIBRATION

SELECT

(GENERAL SETUP)

DISPLAY CONTRAST

ADJUST

FLOW UNITS

(SI UNITS, US UNITS)

TOTAL UNITS

(UNITS X 1000

X 1)

FLOW TIMEBASE

(DAYS, HOURS, MINUTES, SECONDS)

FRONT ACCESS

(ENABLE, DISABLE)

FRONT RESET

(ENABLE, DISABLE)

RESET TOTALS NOW?

(PRESS RESET)

SELECT

(EXIT)

Page 55

SELECT

(GAS PARAMETERS)

Calibration 53

(STEAM, IDEAL GAS, GENERAL GAS, NATURAL GAS)

STEAM TYPE

(SATURATED, SUPERHEATED)

SAT STEAM INPUT

(PRESSURE,

TEMPERATURE)

DEFAULT DISPLAY

(MASS, ENERGY)

BASE TEMP

+XXX.XX

BASE PRESSURE

1

1

XXXXX

SELECT

(EXIT)

GAS EQUATION

BASE TEMP

±XXX.XX

BASE PRESSURE

XXXXX

SPECIFIC GRAVITY

X.XXX

DEFAULT DISPLAY

(CORRECTED

VOLUME, MASS)

SELECT

(EXIT)

CRITICAL TEMP

±XXX.XX

CRITICAL

PRESSURE

XXXXX

BASE TEMP

±XXX.XX

BASE PRESSURE

XXXXX

SPECIFIC

GRAVITY

X.XXX

BASE

TEMPERATURE

±XXX.XX

BASE PRESSURE

XXXXX

SPECIFIC GRAVITY

X.XXX

MOLE % N2

XX.XX

MOLE % CO2

XX.XX

DEFAULT DISPLAY

(CORRECTED

VOLUME, MASS)

SELECT

1

Only required for differential pressure flowmeters. With volumetric flowmeters, there is no need to enter

base temperature & pressure and these values can be left at the default values.

Temperatures are entered as °C or °F rather than °K or °R.

(EXIT)

DEFAULT DISPLAY

(CORRECTED

VOLUME, MASS)

SELECT

(EXIT)

Page 56

54 Calibration

SELECT

(FLOW PARAMETERS)

FLOW INPUT TYPE

(FREQUENCY, ANALOG)

FLOW SIGNAL TYPE

(LINEAR, NON-LINEAR)

K-FACTOR

XXXXX.XXX

UP TO 10

FREQUENCIES &

K-FACTORS

CAN BE

ENTERED

FLOW SIGNAL TYPE

(DIFFERENTIAL, VOLUMETRIC)

(LINEAR, SQUARE ROOT, NON-LINEAR)

FLOW SPAN

(MASS, VOLUME)

LOW SPAN (at 20mA)

XXXX

CUTOFF (Low)

XX.X%

HIGH SPAN (at 20mA)

XXXX

FLOW CORRECTION

NO SENSORS

(2, 1)

1

(MASS, VOLUME)

FLOW SPAN

SPAN (at 20mA)

XXXX

FLOW CUTOFF

XX.X%

UP TO 20 INPUT

& OUTPUT

POINTS CAN BE

PROGRAMMED

1

SPAN (at 20mA)

XXXX

FLOW CUTOFF

XX.X%

1

For Steam measurement, the Span defaults to mass.

Page 57

FILTER FACTOR

XX

FLOWRATE DECIMAL

XXX.XX

TOTAL DECIMAL

XXX.XX

Calibration 55

PRESSURE INPUT

(ABSOLUTE, GAUGE)

PRESSURE at 4mA

XXXXX

PRESSURE at 20mA

XXXXX

TEMP at 4mA

±XXX.XX

TEMP at 20mA

±XXX.XX

TEMP OFFSET

±X.XX

ATMOSPHERIC PRESSURE

SELECT

(EXIT)

XXXXX

PRESSURE at 4mA

PRESSURE at 20mA

415A ONLY

415A ONLY

415R ONLY

XXXX

XXXX

Page 58

56 Calibration

SELECT

(OPTIONS)

OUTPUT TYPE

(4-20mA, 0-10V)

OUTPUT at 4mA

XXXXX

OUTPUT at 20mA

XXXXX

DATE FORMAT

(dd/mm/yy), mm/dd/yy)

DATE XX/XX/XX

TIME XX:XX

BAUDRATE

(300 - 9600)

WORD LENGTH

(7, 8)

PARITY

(NONE, ODD, EVEN)

SIGNAL TYPE

(RS232, RS422, RS485)

OUTPUT at 0V

XXXXX

OUTPUT at 10V

XXXXX

IF

4-20mA

OUTPUT OPTION

IS INSTALLED

IF

RS232/RS422/RS485

OPTION IS

INSTALLED

Page 59

IDENTIFICATION NO

XX

TYPE OF COMMS

(PRINTER, COMPUTER)

Calibration 57

PRINTER

(STANDARD 80 COLUMN)

(EPSON CTM 290)

(MODEL 624)

PRINT METHOD

(ON RESET, TIME INTERVAL)

(FULL DUPLEX, HALF DUPLEX)

ECHO

PRINT INTERVAL

(1, 10, 30 MINUTES,

1, 6, 12, 24 HOURS)

RESET TYPE

(FRONT PANEL RESET)

(RESET AT 24:00 HOURS)

(RESET EACH PRINT)

HIGH ALARM SETPOINT

XXXXX

LOW ALARM SETPOINT

XXXXX

SELECT

(EXIT)

IF

RS232/RS422/RS485

OPTION IS

INSTALLED

IF

ALARM OPTION

IS INSTALLED

Page 60

58 Calibration

SELECT

(TEST)

FREQUENCY INPUT

XXX.X Hz

LOW FLOW

XXX.X mA

HIGH FLOW

XX.X mA

PRESSURE INPUT

XX.X mA

TEMPERATURE INPUT

±XXX.XX

TEMPERATURE INPUT

XX.XmA

DATE: XX/XX/XX

TIME: XX:XX

SELECT

(EXIT)

IF FREQUENCY INPUT

IS SELECTED

IF TWO 4-20mA FLOW

INPUTS

IF ONE OR TWO

4-20mA FLOW INPUTS

IF MODEL 415R, THE

RTD TEMPERATURE IS

DISPLAYED

IF MODEL 415A

Page 61

5.2 DEFINITIONS

GENERAL SETUP

Display Contrast It is possible to adjust the contrast of the

Total Units Enables totals to be integrated at 1/1000 of the

Timebase Timebase selection will determine whether the

Front Access If enabled, access to the Calibration routine is

Calibration 59

display using the key to give optimum

viewability.

flowrate by programming x 1000. For

example, if the flowrate is in scm/h the total

will be kscm/h (scm x 1000).

rate of flow is displayed in kg/day,

kg/hour...etc.

possible via the front panel (via the Total and

Display keys). If disabled, access to the

Calibration routine is only possible by

connecting a link between terminals 1 and 2.

Front Reset If disabled, the front panel reset key becomes

inoperable during normal operation.

GAS PARAMETERS

Default Display The flowrate and total which is normally

displayed (eg. Mass or Corrected Volume).

Page 62

60 Calibration

Sat Steam Input With saturated steam it is only necessary to use

FLOW PARAMETERS

either a pressure or temperature sensor, but not

both. The user can program which sensor is to

be used in the system.

K-factor

The pulses/m

3

or pulses/ft3 produced by a

frequency type flowmeter.

Flow Signal Type

(Analog Input)

Differential refers to all devices where the

signal is pressure related, such as orifice, pitot

tubes, wedges or target flowmeters.

Volumetric refers to flowmeters producing a

truly volumetric signal such as vortex, turbine

or positive displacement meters.

Flow Correction Square root applies to most standard

differential pressure devices where there is a

square law relationship between flow and the

output signal.

Linear applies to D. P. transmitters with square

root extractors or to meters which produce a

linear flow signal, such as laminar flow tubes

or Gilflo meters.

Non-Linear applies if a custom non-linearity

correction curve is to be programmed.

Flow Cutoff The flowrate, as a percentage of the SPAN

below which the flow is not displayed or

integrated.

Page 63

Calibration 61

Flowrate Decimal The number of decimal points with which the

flowrate is displayed.

Total Decimal The number of decimal points with which the

total is displayed.

Temperature Offset This allows a small offset to be programmed to

correct for any offset error in the RTD. For

example, if during "TEST" the temperature was

read at 125.3°C when it was known that the

actual temperature was really 124.8°C, then an

offset of -0.7°C could be programmed to correct

for the error in the RTD.

Pressure Input Both absolute and gauge pressure systems can

be used with the Model 415.

Atmospheric Pressure If a gauge pressure sensor is used, the

atmospheric pressure must be programmed

since this will vary with the altitude of the

installation.

Note that the Absolute Pressure = Atmospheric

Pressure + Gauge Pressure. The atmospheric

pressure will default to 101.325 kPa (14.696

psia) which is the standard value at sea level.

Page 64

62 Input Circuits

6. INPUT CIRCUITS

The Model 415 has a regulated output which can be used to power sensors. A

trimpot on the rear of the instrument allows the voltage to be adjusted in the

range of 8-24 Volts and the output can supply a maximum of 50mA.

6.1 FREQUENCY FLOW INPUT

The Model 415 has an input conditioning card which will accept signals from

most pulse or frequency producing flowmeters. An 8 position DIL switch on the

rear panel enables the input circuit to be configured for different signal types:

The input will interface directly to:

- Turbine Flowmeters

- Open Collector Outputs

- Reed Switches

- Logic Signals

- Two Wire Proximity Switches.

The following pages give examples of interconnections to various signal outputs,

and a circuit diagram of the input is also provided.

Page 65

Input Circuits 63

Switch Settings

The following switch settings are recommended for different input signal types.

Input Signal Type Input Terminals Switch Settings

+-12345678

a. Logic Signal CMOS,

TTL, Pulse

b. Open Collector or Reed

switch

c. Naeur Proximity (set

DC out to 8 volts)

d. Switch or Reed Switch

with debounce circuit

(200Hz max)

e. Coil (20mV P-P

minimum)

f. Coil (low Impedance)

22mV pp minimum

9 8 off off off off on off off off

9 8 off off off off on off on off

11 9 on off on on on off off off

9 8 off off off off on off on on

9 8 off on off off off off off off

9 8 on on off off off off off off

General Specification

Switching Threshold: 2.5 Volts (except for input type c, e and f)

Maximum Input Voltage: 50V peak

Input Impedance

Input type a: 100K

Input types b & d: 10K

Input type c: 1K

Input type e: 100K

Input type f: 2.4K

Page 66

64 Input Circuits

+5V

10K

Pulse Input

Common

(9)

(8)

S7

S1

2K4

1K

S3

100R

100K

.01

S5

The Frequency Input Circuits

INPUT C OMPARATOR

S8

+

1uF

S2

33K

33K

S4

1K2

22K

+5V

S6

Page 67

1. Squarewave, CMOS or TTL

Common

2. Open-Collector

9

on

8

1

eg. vortex, pre-amplifiers

or magnetic flowmeters

Input Circuits 65

Model 415

8

Model 415

3. Reed Switch

Common

9

8

9

8

1

eg. hal l effe ct

sensors

1

eg. pos itive di spla ceme nt

flow me te rs w i th r ee d sw it ch

on

8

Model 415

on

8

Page 68

66 Input Circuits

4. Coils

Use shielded

cable

5. Namur Proximity Switch

+8V

6. Opto-Sensors

9

8

to case earth

11

9

on

1

eg. millivolt signal

from a turbine flowmeter

(singl e input only)

on

1

eg. pos itive di spla ceme nt

flowm eters with 2 wire

proximity switch outputs

Model 415

8

Model 415

8

Resistor

Common

11

18

9

eg. pre-amplifiers

and op to- sen s ors .

8

Note that the curren t

limiting resistor may be

required. See the flowmeter

manufacturer's data.

on

Model 415

Page 69

Input Circuits 67

6.2 ANALOG INPUTS

The Flow Computer can be supplied as:

* Model 415R Direct 4 wire Platinum RTD (PT100) for temperature

* Model 415A 4-20mA input for temperature.

Both versions have a 4-20mA pressure input.

THE RTD INPUT

Four wire RTD measurement is the most accurate form of measurement and can

be used for measurements with the RTD up to 100 meters from the instrument. It

is recommended to use shielded cable when interfacing to RTD's.

Two or three wire RTD's can be used in place of 4 wire RTD's, but 4 wires must

be taken to the RTD and the signal and current wires joined as close to the RTD

as possible.

With direct RTD measurement, the program automatically corrects for the

non-linearity in the RTD.

RTD

Temperature Sensor

Twisted P air

Cable

Shield

4

I (-)

14

5

Signal (+ )

Signal (-)

6

2

I (+)

MODEL 415R

Page 70

68 Input Circuits

When wiring the RTD, care must be taken to ensure the (+) of the Current on

terminal 4 is connected to the same side of the RTD as the (+) of the signal on

terminal 5. The RTD has no polarity and can be connected in either direction.

4-20mA Inputs

Each 4-20mA has a 250 ohm input connected to the signal ground as shown

below. When the instrument is AC powered, there is sufficient current from the

DC output to power up to three current loops. If more loops are to be powered,

an external DC power source is required.

Powering from the Internal DC Supply

MODEL 415

Set Supply to 24V out

11

+

+

P

-

∆

P

-

3

7

12

When using only one 4-20mA flow input, the signal must be connected to

terminal 3 as shown above

Shielding: When shielding the input signals, the shield should be connected to

the case earth and not connected at the transmitter end (ie. ground

at one end only).

Page 71

Powering from an External Supply

12-24 VDC

+

-

Flow 1 (CH3)

+

-

∆

P

High Flow

Input Circuits 69

MODEL 415A

3

P

∆

T

P

Flow 2 (CH1)

-

Low Flow

Temperature

-

(CH0)

Pressure

-

(CH2)

14

4

250

7

ohm

250

ohm

+

+

+

250

ohm

250

ohm

2

Signal Ground

The above diagram shows an installation with dual D. P. transmitters to measure

flow. When using only one 4-20mA flow input, the signal must be connected to

terminal 3 only.

Page 72

70 Input Circuits

6.3 REMOTE SWITCHES (Model 415A Only)

Remote push-buttons can be connected to the Model 415A to duplicate the

switches on the front panel.

The switches are wired as follows:

2

RESET

5

DISPLAY

6

Page 73

Installation 71

7. INSTALLATION

7.1 GENERAL

Terminal designations for the Model 415 Flow Computer are given on the

following pages. The cutout hole in the panel should be 5.5" (139mm) wide x

2.6" (67mm) high. Two side clips are supplied to secure the instrument into the

panel.

A case earthing point is provided via an earth lug on the side of the case. Note

that this earthing point is for the case only and there is complete electrical

isolation between this point and all electronic circuits. For EMC purposes, or

when the instrument is connected to mains, this point must be connected to a

good earth using a multi-stranded, braided wire or strap. All relay outputs are

totally isolated from the case and from the internal circuitry.

A Supply Output voltage is provided to power sensors. This output will provide a

regulated voltage of 8 to 24 volts and the voltage is adjustable by means of the

potentiometer on the rear panel. Maximum current is 65mA and the instrument

comes with the voltage factory set at 24 Volts. When the instrument is powered

from a DC power source, the maximum output voltage on the Supply Output is

the DC Input Voltage less 3.5 volts.

The instrument will operate from either 14 - 28 volts DC or from the mains. The

mains voltage is factory set to either 95 - 135 VAC (110 VAC nominal) or 190 260 VAC (220 VAC nominal). An internal mains transformer provides full

isolation between the mains and the electronic circuits.

The DC Ground terminal 12 provides a common ground for the 14 - 28 Volt

power input, the 8 - 24 Volt output and the pulse output.

It is good practice to use shielded cables for all signal connections to the Model

415. Care must be taken to separate signal cables from power cables so as to

minimise interference.

Overall shields should be connected to the case earth at the instrument end only.

This connection should be as short as possible and connected to the earthing lug

on the side of the case.

Page 74

72 Installation

In order to comply with the requirements for Electromagnetic Compatibility as

per EMC-Directive 89/336/EEC of the Council of European Community, this

wiring practice is mandatory.

Although it is also possible to connect shields to the signal ground (terminal 2)

this practice is not in accordance with EMC directives.

RC Networks for Interference Suppression

When driving highly inductive loads with the relay outputs, it is recommended

that RC suppression networks (often called "Snubbers") are used for two reasons:

To limit the amount of electrical noise caused by arcing across the

contacts which may, in extreme cases, cause the microprocessor to act

erratically.

To protect the relay contacts against premature wear through pitting.

RC suppression networks consist of a capacitor and series resistor and are

commonly available in the electrical industry. The values of R and C are

dependant entirely on the load. However, if the user is unsure of the type of

snubber to use, values of 0.25uF and 100 ohms will usually suffice. Note that

only mains approved RC suppression networks should be used.

The basic principle of operation is that the capacitor prevent a series of sparks

arcing across the contact as the contact breaks. The series resistor limits the

current through the contact when the contact first makes.

Page 75

Installation 73

7.2 WIRING DESIGNATIONS FOR THE MODEL 415

Terminal Model 415R Model 415A

1 Calibration Link Calibration Link

2 Signal Ground Signal Ground

3 Flow 1 (4-20mA) Flow 1 (4-20mA)

4 PT100 I (+) Temperature (4-20mA)

5 PT100 Signal (+) Reset Switch

6 PT100 Signal (-) Display Switch

7 Pressure (4-20mA) Pressure (4-20mA)

8 Flow Common (-) Flow Common (-)

9 Flow Pulse Input (+) Flow Pulse Input (+)

10 Pulse Out Pulse Out

11 DC Power Out (8-24V) DC Power Out (8-24V)

12 DC Ground DC Ground

13 DC Power Input DC Power Input

14 PT100 I (-) Flow 2 (4-20mA)

Note: When using a single 4-20mA flowmeter, it is connected to

terminal 3. The second 4-20mA flow input on terminal 14 is only

used when there are dual 4-20mA inputs. In this case, terminal 3

becomes the High Flow input and terminal 14 is used for the low

flow.

Terminal Analog Flow Output (4-20mA) RS232/422/485

20 Not To Be Used RS232 Signal Ground

21 0 Volts RS232 Data In

22 0-10 Volts RS232 Data Out

23 -12 Volts RS422/485 (-) Data Out

24 I(-) RS422/485 (+) Data Out

25 I(+) RS422/485 (-) Data In

26 +15 Volts RS422/485 (+) Data In

27 Not To Be Used RS232 CTS

Page 76

74 Installation

Terminal Relay Option

31 High - Normally Open

32 High - Normally Closed

33 High - Common

34 Low - Normally Open

35 Low - Normally Closed

36 Low - Common

Page 77

Appendix 75

APPENDIX

PROPERTIES OF SELECTED GASES

Sp. Gravity Critical Temperature Critical Pressure

G °C °F kPa psia

Acetylene 0.8990 35.17 95.3 6140 890.6

Air 1.0000 -140.4 -220.8 3769 546.7

Ammonia 0.5880 -168.0 -270.4 11277 1637.7

Argon 1.3793 -122.3 -188.2 4873 706.9

Butane 2.0054 153.0 307.4 3648 529.1

Carbon Dioxide 1.5196 31.06 87.9 7376 1069.9

Carbon Monoxide 0.9671 -140.3 -220.5 3496 507.0

Chlorine 2.4482 143.8 290.9 7701 1116.9

Ethane 1.0382 32.28 90.1 4884 708.4

Ethylene 0.9686 9.28 48.7 5036 730.4

Helium 0.1381 -267.9 -450.2 228.99 33.21

Helium-4 0.1382 -267.9 -450.3 226.8 32.9

Hydrogen 0.0696 -239.9 -399.9 1296.9 188.1

Hydrogen Chloride 1.1898 51.44 124.6 8313 1205.7

Hydrogen Sulfide 1.1767 100.1 212.1 8751 1269.2

Methane 0.5539 -82.56 -116.6 4600 667.2

Neon 0.6969 -228.8 -379.8 2756 399.7

Nitrogen 0.9672 -146.9 -232.5 3394 492.3

Nitrous Oxide 1.5199 36.5 97.7 7265 1053.7

Oxygen 1.1048 -118.6 -181.4 5046 731.9

Propane 1.5226 96.67 206.0 4246 615.8

Page 78

76 Appendix

Propylene 1.4529 91.83 197.3 4620 670.1

Sulphur Dioxide 2.2119 157.7 315.8 7883 1143.4

Xenon 4.5334 16.56 61.8 5836 846.5

Page 79

Index 77

Index

4-20mA Inputs, 68

4-20mA Output, 39

405GS, 7

405ST, 7

A

Analog Inputs, 67

ASME, 26

Atmospheric

Pressure, 61

C

Calibration

Certificate, 33

Calibration Routine, 50

Coils, 66

Compressibility, 24

Computer, 47

Cutoff, 60

D

Data Logging, 48

Date Format, 46

Decimal Points, 60

Default Display, 14, 59

Density, 16

DIL Switch, 62

Dimensions, 10

Display, 10

Display Contrast, 59

Dual Differential

Pressure, 18, 28

E

Earthing Point, 71

External Supply, 69

F

Filtering, 31

Floating Point

Numbers, 51

Flow Correction, 60

Flow Equations, 16

Flow Input, 62

Flow Parameters, 51

Flow Signal Type, 60

Fluctuations, 31

Front Access, 59

Front Reset, 59

G

Gas Parameters, 51

Gases, 75

General Gas, 24

General Setup, 51

Ground Terminal, 71

I

Ideal Gas Law, 22

IFC Formulation, 26

Impulse Counter, 38

Input Circuits, 62

Installation, 71

Interference

Suppression, 72

Isolation, 39, 71

K

K-factor Range, 10

L

Laminar Flow Tubes, 35

Linear Interpolation, 33

Logic Signals, 62

M

Mass, 20

Model Number, 9

Molecular Weight, 16

Multipoint

Communication, 44

N

Natural Gas, 25

Non-Linearity

Correction, 33

NX-19, 7

O

Offset, 61

Open Collector, 62

Options, 51

Orifice Plates, 17, 27

Output Pulse, 37

Output Voltage, 71

P

Pitot Tubes, 17, 27

Power Requirements, 10

Pressure Input, 11, 61

Printer, 46

Properties, 75

Protocol, 46

Protocols, 43

Proximity Switches, 62

Pulse Output, 12

Page 80

78 Index

R

Transducer Supply, 10

Turbine, 17

Redlich-Kwong, 7

Reed Switches, 62

Relay Output, 49

Remote Switches, 70

RS232, 43

RS232/422/485

Interface Option, 43

RS422, 43

RTD Input, 67

S

Saturated, 26

Setup Parameters, 50

Shielding, 68

Snubbers, 72

Span, 19

Specific Enthalpy, 26

Specific Gravity, 16

Specific Volume, 26

Specification, 10

Standard Conditions, 16

Steam Measurement, 26

Steam Turbines, 27

Supercompressibility

Factor, 25

Superheated, 26

Symbols, 5

V

VA Flowmeters, 35

Vortex, 17, 27

W

Wiring Designations, 73

T

Target

Flowmeters, 17, 27

Temperature

Measurement Range, 11

Temperature Offset, 61

Test, 51

Timebase, 59

Loading...

Loading...