Page 1

BATCH CONTROLLERS

MODEL 414A

November 1995

Page 2

Page 3

CONTENTS

1. Introduction 3

1.1 Model Number Designation 4

2. Specification 5

3. Operation 7

3.1 Front Panel Operation 8

3.2 Batch Operations 11

3.2.1 Control Relay Outputs 13

3.2.2 Signal Timeout 14

3.2.3 End of Batch 15

3.2.4 Auto Restart 16

3.2.5 Automatic Overrun Compensation 17

3.3 Calculation of Rate and Total 18

3.3.1 Analog Input 18

3.3.2 The Cutoff Point 19

3.3.3 Filtering 20

3.4 Total Conversion 22

3.5 The Output Pulse and Flow Alarm 23

4. Options 25

4.1 The RS232/422/485 Interface Option 25

4.1.1 Hardware 25

4.1.2 Multipoint Communication 26

4.1.3 Communication Protocol 28

5. Calibration 30

5.1 Programming the Setup Parameters 32

5.2 Entering the Batch Parameters 34

5.3 Programming Options 36

5.4 Checking the Input Signal 38

Page 4

6. Input Circuits 39

6.1 The Signal Input 39

6.2 Remote Switch Inputs 41

7. Installation 42

7.1 General 42

7.2 Wiring Designations for the Model 414A 44

8. Trouble Shooting 45

8.1 Error Codes 47

Index 48

Page 5

Introduction 3

1. INTRODUCTION

The Model 414A Batch Controller accepts analog flow signals and automatically

controls the batching of fluids via a one or two stage control valve.

The instrument is extremely flexible and easy to operate, with a four key, front

panel operation that enables the batch quantity to be set, and batches to be

started or stopped.

The Batch Controller is a microprocessor based instrument which measures

4-20mA, 0-20mA, 1-5 Volt or 0-10 Volt signals from flowmeters and pressure

transducers. The instrument can be programmed to display directly in

engineering units and includes such features as linear or square law calculation,

integration and digital filtering.

The 4-20mA, 0-20mA, 1-5 Volt and 0-10 Volt input signals are isolated from the

supply rails and outputs, and may therefore float independently. This ensures

that the input will be compatible with all transmitters and can be used in current

loops which have more than one receiver.

The instrument is fully programmable, with all calculation constants set via the

front panel switches and stored in a non-volatile memory which will retain data

indefinitely. The user can program such parameters as span, zero, filtering

levels, display resolution and cutoff points.

This instrument conforms to the EMC-Directive of the Council of European

Communities 89/336/EEC and the following standards:

Generic Emission Standard EN 50081-1 Residential, Commercial & Light

Industry Environment.

Generic Emission Standard EN 50081-2 Industrial Environment.

Generic Immunity Standard EN 50082-1 Residential, Commercial & Light

Industry Environment.

Generic Immunity Standard EN 50082-2 Industrial Environment.

In order to comply with these standards, the wiring instructions in Section 8.1

must be followed.

Page 6

4 Introduction

1.1 MODEL NUMBER DESIGNATION

The Model number of an instrument describes which input and output options

are installed and the AC mains voltage rating.

Model 414 A. 1 0 E B

B for Backlite

C for Conformal Coating

E for 220/240 VAC

A for 110/120 VAC

D for DC Power Only

Options

0 for no option

2 for RS232/422/485

Mounting

1 for panel mounting

2 for field mounting

3 for explosionproof

The Model Number of the instrument is displayed on first entering the

Calibration Mode (see Section 5).

Page 7

Specification 5

2. SPECIFICATION

General

Display: 6 digit LCD. 0.7" (17.8mm) high digits.

Display Update Rate: 0.25 seconds.

Transducer Supply: 8-24VDC field adjustable.

50mA maximum.

Power Requirements: 11.5 to 28.5 volts DC.

130 mA typical current (no options).

AC Mains: Set internally to 95-135 VAC or

190-260 VAC.

Operating Temperature: 0 to 55°C standard.

Dimensions: 5.7" (144mm) wide x 2.8" (72mm) high x

7.0" (178mm) deep.

Cutout: 5.5" (139mm) wide x 2.6" (67mm) high.

Analog Input

Input: 4-20mA, 0-20mA, 1-5 Volt or 0-10 Volt.

The input circuit is floating and isolated from

the power supply and outputs.

Span: 0.1000 to 50000.0000.

Zone: 0.0000 to 50000.0000.

Accuracy: 0.075% of full scale.

Self-Calibrating: An internal reference is sampled every 10

minutes. Temp Co-efficient is 40ppm/C.

Aging is 20ppm/1000 hrs.

Integration: The rate is integrated with a timebase

selectable to be in days, hours, minutes or

seconds.

Cut-off: A cut-off point can be set below which the

rate is not integrated.

Page 8

6 Specification

Relay Outputs

Maximum Switching Power: 1250VA.

Maximum Switching Voltage: 250VAC, 30VDC.

Maximum Switching Current: 5 Amps.

Pulse Output

Pulse Width: 10mSec (negative going pulse).

Maximum Duty Cycle: 49 pulses per second.

Output: An open collector transistor will sink

100mA.

Scaling: The pulse output is scaled and outputs one

pulse each time the accumulated total

increments.

Page 9

Operation 7

3. OPERATION

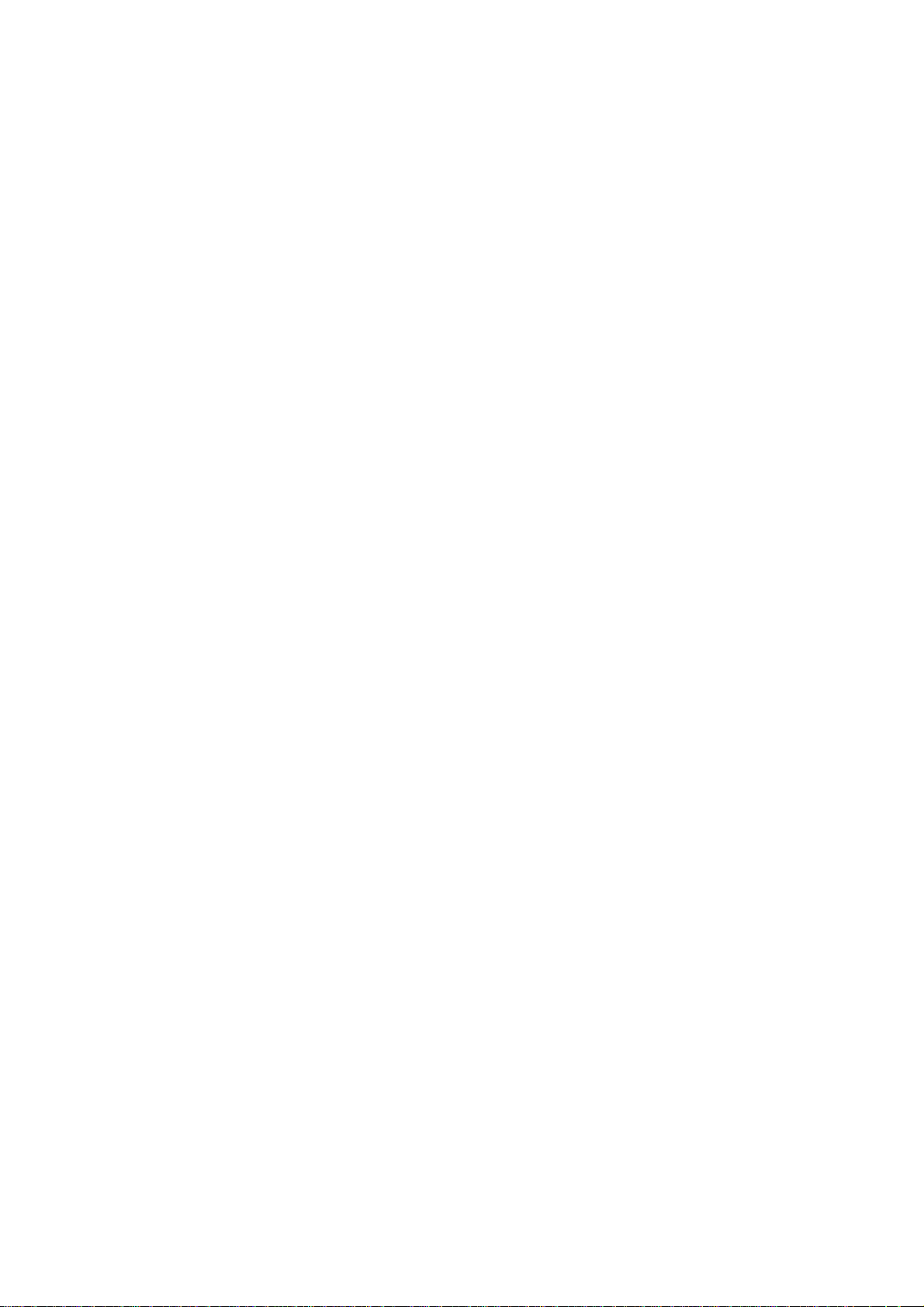

The Model 414A Batch Controller uses a low power CMOS microprocessor to

perform all control functions and calculations.

The instrument is fully programmable with all operating parameters and

calculation constants user programmable. (See Section 5 entitled "Calibration"

for information on programming.) All parameters and constants are stored in a

non-volatile memory which retains data without battery backup for a minimum

of 10 years.

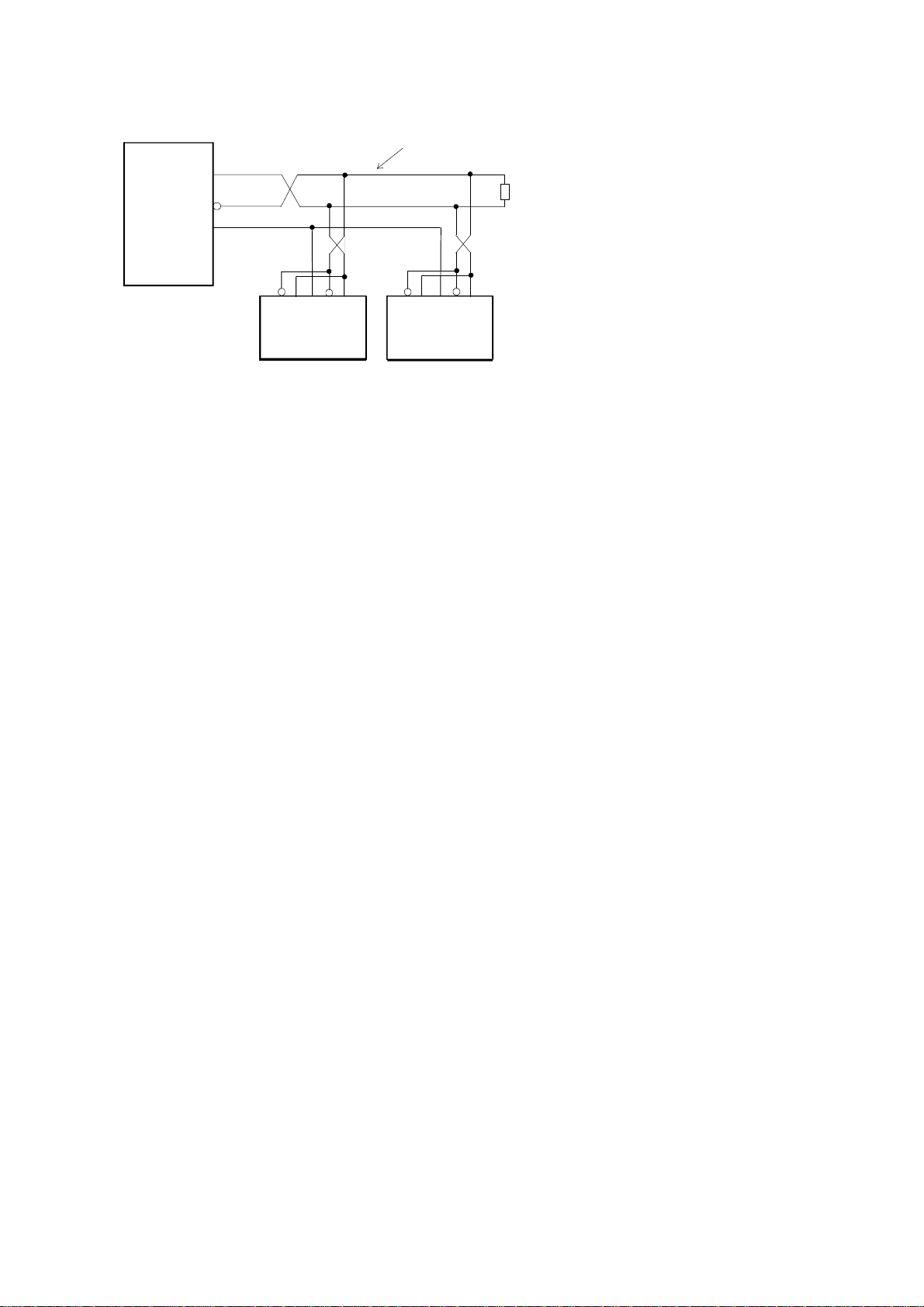

A block diagram of the instrument is shown below.

4-20mA

(0-20mA)

Signal

Common

0-10 V

1-5 V

Model 414A

110/220V

AC Main s

RS232/422

Option

Relays

RS232/422

Output

EOB

Control

Relay Outputs (2)

Pulse

Output

Flow Alarm

DC Input Power

DC Power Ground

DC Power Output to Sensors

Page 10

8 Operation

3.1 FRONT PANEL OPERATION

The four key operation of the Batch Controller is straight forward.

SETTING THE BATCH QUANTITY

The Batch quantity is programmed as follows:

Switch Action Display Comments

Press BATCH SET Batch "Batch" is displayed for one second

followed by the batch quantity last

entered. The Batch Set LED lights.

"1" 2345 The most significant digit flashes

indicating that it can be changed.

Press "2" 2345 Pressing the DISPLAY key will

increment the digit. (The up arrow on

the Display key indicates to increment

digit.)

Press 2 "2" 345 Pressing the RUN key will change digit

and enables the next digit to be

incremented. (The right arrow on the

RUN key indicates to change digit.)

Press BATCH SET Set Once the desired number is entered,

press the BATCH SET key to return to

the Run mode. The Batch Set LED will

extinguish.

Once programmed, the Batch quantity will be retained in the non-volatile

memory and will not alter until changed by the user.

Page 11

Operation 9

The Batch quantity can only be set while the instrument is in non-operational

state such as when the batch is complete, or if the batch process has been

interrupted. However, the Batch key can be pressed while in the run state and

the Batch quantity checked. All digits will flash to signal the quantity cannot be

changed.

STARTING A BATCH

To start the process the RUN key is pressed. The Run LED will light and the

instrument will begin to totalise from zero or, if programmed for the count down

mode, the display will decrement from the batch quantity.

The batcher has two output relays and these are energised and de-energised as

described in section 3.2.

STOPPING

The process can be stopped at any time by pressing the STOP switch. Once the

process has been interrupted in this way it can be continued by pressing the RUN

switch or the process can be aborted and the instrument reset by pressing the

STOP switch a second time.

When the process is interrupted, the STOP LED will flash to prompt the

operator to either restart or abort the batch.

RESETTING

The instrument can be programmed to reset in one of two ways.

At the end of a batch, the STOP key must be pressed to reset the Batch

Total. If the instrument is programmed to count down, the Batch

Total will then revert to the preset quantity. If it is programmed to

count up, the Batch Total will clear to zero.

If Auto Reset is programmed, the Batch Total will automatically reset

when the RUN key is pressed and then commence the next batch.

Page 12

10 Operation

DISPLAYED INFORMATION

The display will normally show the Batch Total, which is the total count for the

current batch and is reset on each new batch.

The DISPLAY key can be used to display the following additional information:

Rate

On the first press of the DISPLAY key, the display shows RATE for

one second followed by the flowrate.

Accumulated Total

On the next press of the DISPLAY key, the display shows ACC for

one second followed by the actual total. The Accumulated Total

cannot be reset during normal operation.

LIMIT ON BATCH SIZE

To prevent accidental entry of large batch quantities, a maximum batch limit can

be programmed during calibration. The operator is then prevented from entering

a batch quantity which exceeds this value.

Page 13

Operation 11

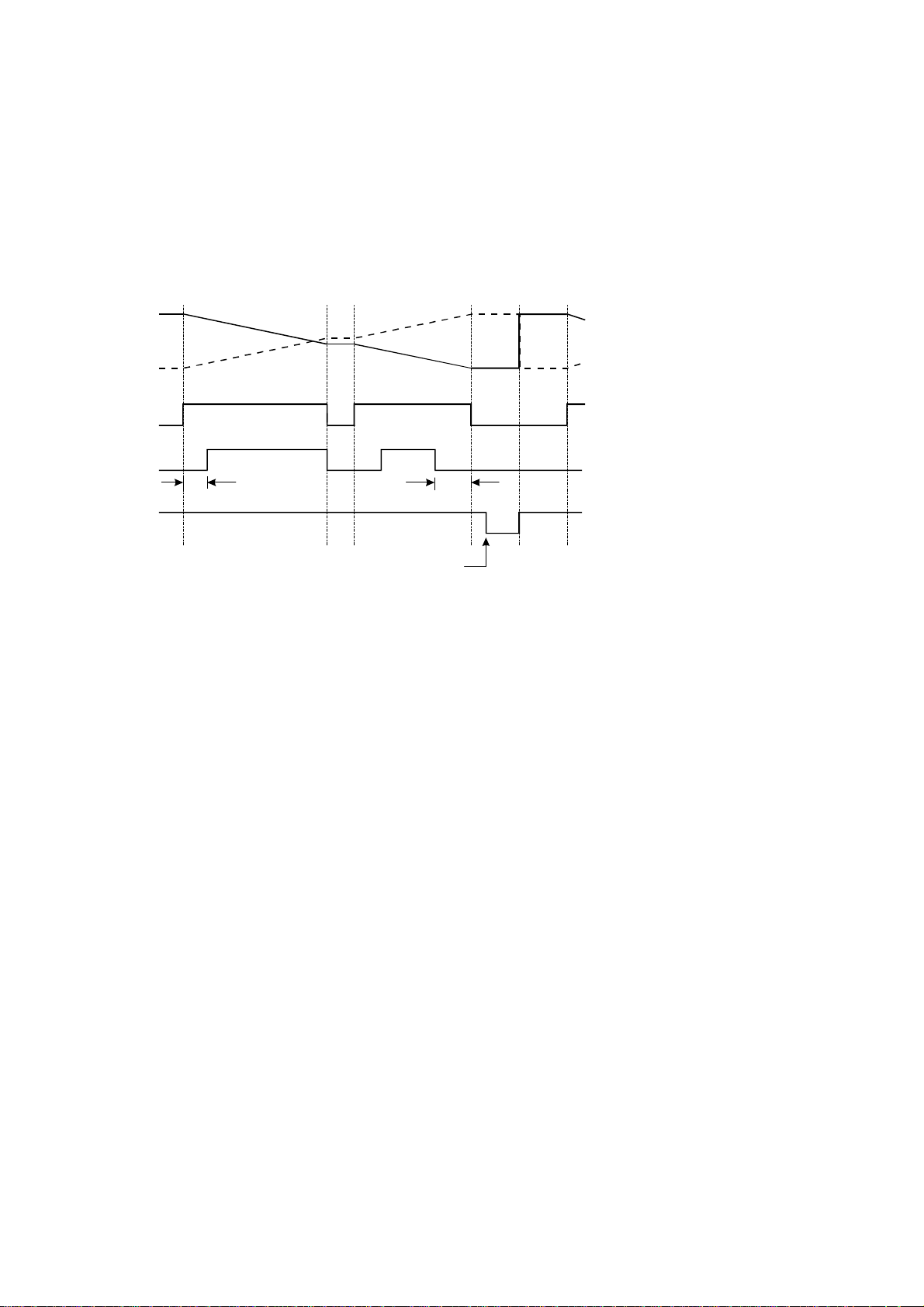

3.2 BATCH OPERATIONS

The Batch Control functions can be programmed, during Calibration, to operate

in one of two ways.

1. At the end of the batch, the STOP key must be pressed to reset the Batch

Total. (This must be done before another batch can be started.)

Run Stop Run

Count Down

Count Up

Relay 1

Relay 2

Start Time

End of

Batch

PAUSE

Presto p

Quantity

End of Batch

Batch

Quantity

Reached

Stop Run

Page 14

12 Operation

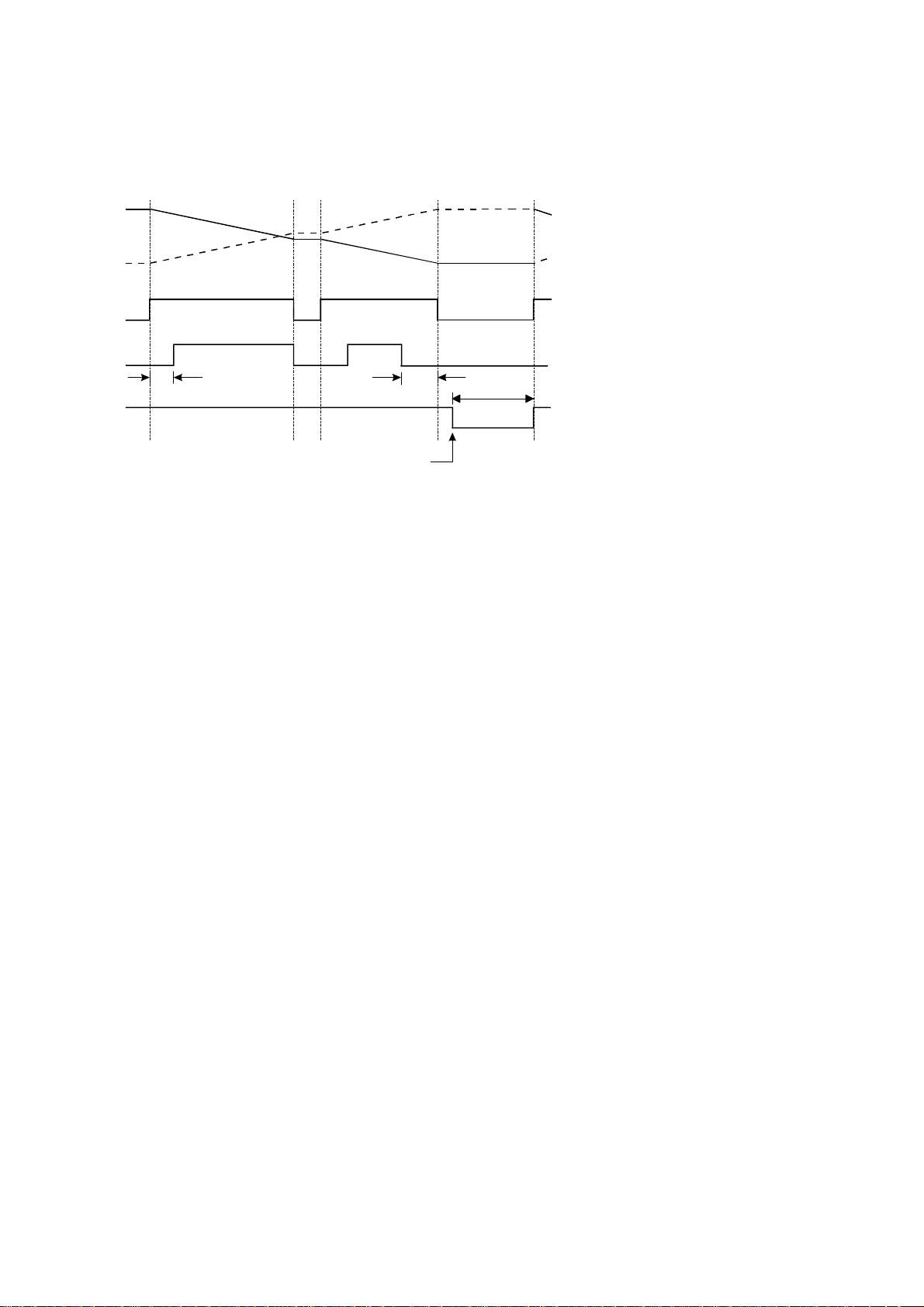

2. If Automatic Reset is programmed, a new batch is commenced each time the

RUN key is pressed.

Batch

Quantity

Reached

Run

Auto Restart

Time

Run Stop Run

Count Down

Count Up

Relay 1

Relay 2

Start Time

End of

Batch

PAUSE

Presto p

Quantity

End of Batch

The Batch Controller can also be programmed, during Calibration, to either

count up from zero on each batch, or to count down from the preset batch

quantity.

Page 15

Operation 13

3.2.1 Control Relay Outputs

The two output relays can be set up to control a single valve or a dual valve with

slow stop and/or slow start. Alternatively, the second relay can be used to

control a pump.

The relay operation is shown on the previous two pages.

A time delay between the Start and the time when relay 2 energises can be

programmed to provide a soft startup. The delay can range from 0 (no delay) to

79 minutes and 59 seconds.

A Prestop quantity (ie. the quantity to the end of the batch) can also be

programmed to provide a slowdown of flow at the end of the batch, thereby

enabling precise quantities to be batched.

The process can be stopped at any time by pressing the STOP key, whereby both

relays will immediately de-energise. The process can then be aborted and the

batcher reset by pressing the STOP key again, or the process continued by

pressing the RUN key.

If the process is continued and the instrument was previously in the slow start or

main control phases (ie. not the prestop phase), the timer will be reset and a slow

start will occur with a full time delay to ensure a correct start up. The totals will

not be reset and the batch quantity will remain unchanged.

Page 16

14 Operation

3.2.2 Signal Timeout

The Signal Timeout period defines a time interval which is used to detect if the

flow has stopped. If there is no signal input for a time greater than the Signal

Timeout period, the flow is deemed to have stopped. A Signal Timeout period

has two functions:

To detect the loss of signal midway through a batch when the relays

are energised. In this case, the Batcher will enter a Flow Alarm

condition and de-energise the relays.

After the preset batch quantity has been reached and the relays

de-energised, some overrun of flow may occur due to slow valve

closure, etc. In this case, the Signal Timeout is used to determine

when the flow has ceased and thereby accurately determine the

amount of overrun.

The instrument enables the user to program a time interval of up to 99 seconds to

detect an absence of signal input. If the Signal Timeout is set to 0, this

function is disabled.

Flow Alarm

If the Signal Timeout is set at greater than 0, and loss of signal is detected

midway through a batch, a Flow Alarm signal is output on terminal 7. In

addition, both relays are de-energised. The Flow Alarm output and condition is

maintained until acknowledged by pressing the STOP switch. The alarm

condition is also signalled to the operator by the flashing STOP LED. Once

acknowledged, process can then be reset via the STOP switch or continued by

pressing the RUN key.

Page 17

Operation 15

3.2.3 End of Batch

An End of Batch is defined as being when the Batch Quantity is reached, the

flow has stopped and the Signal Timeout period has expired.

If the Signal Timeout is set to zero, the End of Batch is defined as being when

the Batch Quantity is reached, regardless of whether the flow has stopped.

The Batch Controller cannot be reset or restarted until the End of Batch and

similarly, for an RS232/422/485 interface, data will not be output until the End

of Batch has been determined. Consequently, it is strongly recommended that

the Signal Timeout period be kept fairly short.

Signal

End of

Batch

End of

Batch

(Timeout = 0)

Batch Quantity

Reached

4mA (0V)

Signal Timeout

Reset

End of Batch Signal

An End of Batch signal from an open collector transistor is output on terminal 30

and the output is identical to the Output Pulse circuit as shown in section 3.5.

When reaching the End of Batch, the output transistor is switched on, and will

remain in the "on" state until the instrument is reset.

Page 18

16 Operation

3.2.4 Auto Restart

The Batch Controller can be programmed to continually repeat the batch

process. This mode of operation is selected during the programming procedure.

The process is started by pressing the RUN key whereby the normal batch

operation is commenced. After reaching the End of Batch (see section 3.2.3),

the Batch Controller will then wait for a pre-programmed period before

automatically resetting and starting the batch process once again.

The STOP button can be pressed at any time to interrupt the batching process

and continued using the RUN key. If, however, the process is to be aborted, the

STOP key is again pressed. The Batch Controller is reset and to restart the auto

batching process the RUN key is pressed.

Page 19

Operation 17

3.2.5 Automatic Overrun Compensation

The Batch Controller can be programmed to automatically compensate for any

overrun at the end of a batch.

Typically, this could be due to the slowness of a valve to close or a pump to stop

pumping on receiving a signal from the Batch Controller. The result is that the

batch quantity will always read higher than the batch quantity set.

The Automatic Overrun Compensation can be enabled or disabled during the

Calibration routine and this feature should only be used if the overrun is

repeatable. The user is cautioned against using Automatic Overrun

Compensation if the overrun is erratic, such as may occur with changing back

pressures or sticking valves.

In calculating the amount of overrun to be compensated for, the Batch Controller

uses the average overrun on the last three batches.

The overrun is defined as the difference between the batch quantity set by the

user and the batch total once the flow has stopped.

With Automatic Overrun Compensation, the Signal Timeout must be set to a

value greater than zero.

Once the Batch Controller de-energises both relays, the instrument looks for a

Signal Timeout, indicating that the flow must, therefore, have stopped. It then

uses the overrun quantity measured during this period and averages this together

with the overrun on the last two batches. The resulting value is then subtracted

from the next batch.

Page 20

R

R

R

18 Operation

3.3 CALCULATION OF RATE AND TOTAL

3.3.1 Analog Input

The flowrate, R, is calculated as follows:

= SA + C

= SA+C

or if an open channel relationship is selected.

At the minimum input (ie. 4mA, 0mA, 1 Volt or 0 Volts), A = 0, and at the

maximum input (ie. 20mA, 5 Volts or 10 Volts), A = 1.

The Span, S, can be set during calibration anywhere in the range of 0.1000 to

50000.0000 and the Zero value, C, set in the range 0.0000 to 50000.0000.

The Span, S, can be selected to display rate in any units desired, such as

litres/minute or kilograms/hour. This also means that the Total will be displayed

with the same unit of volume, ie. litres or kilograms.

= SAn+C

where A= the input value.

S= the span.

C= the zero.

n = a variable power which can be programmed between 0 and

9.999.

if the linear relationship is selected.

if a square law relationship is selected.

Page 21

R

R

A

I

Operation 19

3.3.2 The Cutoff Point

Because many transducers do not always exactly transmit 4mA (0mA, 1V or 0V)

when they are at zero rate, it is often necessary to define a rate below which no

integration takes place. This is termed the cutoff point and is programmed as a

percentage of the Span, S.

For example, if S = 2200 kg/min with an offset of 100 kg/min in a square law

system, and the cutoff point is set at 20.0%, the actual cutoff rate Rc can be

determined as follows:

The cutoff rate is defined as:

At 20% cutoff:

c =

2200

A + 100

c = 2200 x 0.2 + 100

= 540 kg/min

The value of A which would produce this cutoff is:

= 0.04

and the input signal would be:

= 16mA x 0.04 +4mA

= 4.64mA

(since 0.04 = 0.2)

Page 22

20 Operation

3.3.3 Filtering

Frequency fluctuations caused by pulsating flow through a flowmeter, often

makes the Rate impossible to read with any precision. The Batch Controller has

a digital filter which will average out these fluctuations and enable the Rate to be

read to four digit accuracy. The ability to select a suitable filtering level means

that highly accurate and stable readings can be obtained without excessive lag.

The diagram below shows a pulsating signal input together with the effect of

filtering.

Rate

Filtered Response

Unfiltered Response

Time

As a guideline to the degree of filtering to be used, the following table shows the

response to a step change in input. The value, A, is the filter constant which is

programmed during the Calibration routine. The times for the display value to

reach 90% and 99% of full swing are given in seconds, for different values of A.

Page 23

Operation 21

A 90% 99%

100

212

424

636

10 5 11

15 8 17

20 11 22

25 14 28

35 20 40

45 25 51

60 34 69

75 43 86

90 52 103

99 57 113

Table 1 - Response to a step Input (in seconds).

Note that if A is set to 1 there is no filtering of the input signal.

Page 24

22 Operation

3.4 TOTAL CONVERSION

The Total Conversion feature enables the rate to be displayed in one engineering

unit (eg. gallons/minute) and the totals to be displayed in another engineering

unit (eg. barrels).

The Scaling Factor is always programmed in the unit relating to Rate

Total Conversion constant is a division factor which can be used to convert the

totals to the different unit. The Total Conversion factor affects the net,

accumulated and gross totals and is limited between 0.01 and 2000.

For Example.

If the Rate is required in gallons per minute:

1. The Scaling Factor would be programmed as pulses per gallon.

2. The timebase would be programmed as minutes.

If the Totals are required in barrels:

3. The Total Conversion factor is programmed as 42 (there are 42 gallons in a

barrel). All totals, including the Batch Quantity and Batch Total, will now be

in barrels.

Some common units are given below together with the Total Conversion

constant (TOTCON) which should be programmed.

Rate*

Gallons (US)/ Barrels (oil) 42.000

Litres/ Kilolitres 1000

ml/ Litres 1000

Mgallons/ Acre-feet 0.32587

Totals TOTCON

, and the

* Units per second, minute, hour or day. The timebase is programmed

separately during Calibration.

Page 25

Operation 23

3.5 THE OUTPUT PULSE AND FLOW ALARM

An OUTPUT PULSE is available on terminal 10 for driving remote counters

and produces a pulse each time the Accumulated Total increments by one digit.

For example, if the Accumulated Total has a resolution of 0.01 litres, a pulse is

produced each 0.01 litres.

The pulse is a current sinking pulse of approximately 10mSec produced by an

open collector transistor. The maximum pulse rate is limited to 49 pulses per

second and the resolution on the accumulated total must be set so that the

accumulated total increments at less than 49 counts per second.

Note that due to the uneven pulse output spacing on this output, the pulse output

cannot be used to drive rate indicators.

The FLOW ALARM uses an identical circuit to the Output Pulse, and is on

terminal 7.

The Flow Alarm will output an alarm condition if the flow times out during a

batch (ie. there is no flow registered for a time greater than the Signal Timeout

period, providing the Signal Timeout is greater than 0).

The Flow Alarm output will switch "on" (ie the signal goes low) whenever an

alarm condition exists. The Alarm will switch "off" (ie the signal goes high)

when the alarm is reset by pressing the STOP key.

Page 26

24 Operation

Connection of Output Pulse and Flow Alarm are as follows:

Relay or

Impulse Counter

5.6 ohms

33V

Zener

12

DC Supply

Driving an External Relay or Impulse Counter

DC Supply

Out (8-24V)

5.6 ohms

33V

Zener

11

External Load

Resistor 10K

Logic Input

2

Driving a Logic Input such as a PLC or Electronic Counter

Page 27

Options 25

4. OPTIONS

4.1 THE RS232/422/485 INTERFACE OPTION

With this option installed, the circuits for both the RS232 and RS422/485 are

provided as standard. They can be used to interface to both printers and

computers and a number of standard protocols are built into the instrument.

4.1.1 Hardware

The following diagram provides an overview of the RS232/RS422/485

communications hardware. All three interfaces are available on the rear terminal

strips and the user can select either one by making the appropriate connections.

The RS232 interface is primarily used with printers or for simple communication

with a computer over a short distance. The RS422 and RS485 interfaces are

used for communication over a long distance or in applications requiring

multipoint communication.

(+)

24

(-)

23

(+)

26

(-)

25

Data In

21

Data Out

22

27 CTS

20

Ground

RS422 Out

RS422 In

RS232

Page 28

26 Options

4.1.2 Multipoint Communication

Multipoint Communication is a system whereby a number of instruments can be

addressed over a dual twisted pair interface. Up to 32 instruments can be

connected to a common bus using the RS422 and RS485 interfaces as shown

below.

To convert the RS422 interface to an RS485 interface, the RS422 (-) Data In

Terminal must be connected to the RS422 (-) Data Out Terminal and the RS422

(+) Data In Terminal must be connected to the RS422 (+) Data Out Terminal.

These connections will convert the RS422 4 wire interface to the RS485 2 wire

interface, as shown in figure 2.

Each instrument can be programmed with a unique address which is used by the

Master Controller (ie IBM/PC) to identify each instrument. The Controller will

send the address down the line and will alert the relevant instrument.

Subsequent software protocol will control the flow of data between the

Controller and the Instrument.

Host

Compu ter

Load

120 ohms

400 Series

Instrument

Twisted Pair

Figure 1 RS422 Interface

Load

120 ohms

400 Series

Instrument

Page 29

Twisted Pair

Options 27

Host

Compu ter

Gnd

+

Load

120 ohms

-

+-

-

Gnd

In

400 Series

Instrument

Out

+

-

+--+

Gnd

In

Out

400 Series

Instrument

Figure 2 RS485 Interface

Page 30

28 Options

4.1.3 Communication Protocol

The Model 414A has a real time clock and enables the time and date to be set

and printed on tickets. The date format can be European (days/months/years) or

USA (months/days/years), while the time is on a 24 hour clock.

Note that the clock will only retain its time for 3 days minimum if there is no

power connected to the instrument. After this period, the clock may need to be

reset.

The baudrate, parity and word length can be programmed during calibration and

the user must ensure that these correspond to the setting on the printer or

computer with which the 414 is communicating.

The software protocols can be selected during Calibration to provide standard

interfaces to a number of printers and computers. Since other interfaces will

continue to be added, the user should consult the manual "The RS232/422/485

Communications Option for the 400 Series, Version 2", for the latest protocols

and printer drivers.

Printer

A ticket is printed at the end of each batch. Protocols are provided to drive the

following printers:

1 Standard Computer Printer (Note that the printer must have an

RS232 Serial Interface).

2 EPSON CTM290 Slip Printer.

3 Contrec Model 624.

4 EPSON TM290-2 Slip Printer

5 Contrec Model 632-2.

6 Syntest SP-210.

The tickets can also be printed with a number of different units, including litres

and gallons. The units are selectable from a pre-programmed list.

Page 31

Options 29

A CTS input is provided, and will prevent the instrument from transmitting any

further characters to a printer if the printer buffer is full. The CTS input is

usually connected to the "Data Buffer Full" output from the printer.

If the printer buffer is large enough to handle the messages output from the

Batch Controller, then this input need not be used and can be left unconnected.

Computer

The instrument receives and transmits messages in ASCII, with all command

strings to the instrument terminated by a carriage return. While replies from the

instrument are terminated with a carriage return and a line feed.

Xon/Xoff protocol is also supported, and the instrument will automatically

determine if the message sent by the host computer is preceded by an Xoff

character. If it does recognise an Xoff as the first character of a command string,

the instrument will automatically switch to Xoff/Xon protocol, and begin & end

all messages with Xoff and Xon characters respectively. Xoff/Xon protocol is

only available when the RS232 interface is selected.

During Calibration, the instrument can be programmed to operate in a full

duplex or half duplex transmission mode. In full duplex mode, all commands

sent to the instrument will be echoed back to the host computer. In half duplex,

the commands are not echoed.

For more information on the computer interface please consult the manual "The

RS232/422/485 Communications Option for the 400 Series, Version 2".

Page 32

30 Calibration

5. CALIBRATION

The Calibration routine enables the Setup Parameters to be programmed, as well

as enabling the input signals to be checked.

The calibration routine can be entered in two ways:

1 By connecting a wire link (or switch) to the rear terminal strip

across terminals 1 and 2 or,

2 By pressing the STOP key and while still holding, press the

DISPLAY key. Both keys must then be held for approximately 6

seconds. This second method of access can be disabled during the

calibration so that it is only possible to enter the calibration routine

via the link across terminals 1 and 2.

The key switch actions during Calibration are as follows:

RUN will change a flashing digit, to the next digit.

DISPLAY will increment a flashing digit or change a parameter

selection.

BATCH SET will reset a flashing digit to zero.

STOP will step through the program sequences.

Note that the arrows in the RUN and DISPLAY key switches indicate that these

switches can be used to change and increment digits respectively.

In stepping through the program sequence, the Parameter Description is always

displayed first, followed by actual value or parameter. When a value or

parameter can be changed, it is always shown as flashing, and the LED's in the

switch panels are lit if that key switch can be used to change a value.

Page 33

Calibration 31

On first entering the Calibration routine, the display will show:

CAL Setup Program parameters (see section 5.1).

Batch Enter Batch parameters (see section 5.2)

Option Option - if installed (see Section 5.3).

Test Check Input Signals (see section 5.4)

End Exit to Normal Operation.

The user can toggle between these modes using the DISPLAY switch and by

using the STOP switch, select the appropriate mode.

To exit Calibration, step through the Setup program, Batch program or Test

program until the end, and press the STOP switch when End is displayed,

(ensure the calibration link is not connected).

Page 34

32 Calibration

5.1 PROGRAMMING THE SETUP PARAMETERS

Step Display Description Text

Ref

1 CAL

BATCH

OPTION

TEST

END

The following steps are displayed if CAL

2 RESTOT Reset all totals

3 INPUT

4-20

0-20

1-5

0-10

4 SPAN

xxx.xx

5 RBASE

xxx

6 PO. n

Lin

Sq. rt.

Op. Ch.

If Open Channel is selected Steps 7 and 8 are displayed, otherwise the program

goes to Step 9.

7 POL

Pos

Neg

8 N

x.xxx

Select the Calibrate mode to setup program

parameters.

Select Batch to enter Batch Setup parameters.

Option (if installed).

Select the test mode to check input signals.

Exit to normal operation.

is selected.

to zero.

To reset all totals (resettable and accumulated)

press the BATCH SET key once.

Select Input

for 4-20mA.

for 0-20mA.

for 1-5 V.

for 0-10 V.

The Span.

Enter the Span.

The Zero value.

Enter the Zero base value.

(Normally 0 for most flow applications).

The power of A

Select for linear input (n=1).

Select for square law (n=½).

Select for Open Channel.

Polarity.

Flow increases as the input increases.

Flow decreases as the input increases.

Value of exponent, n.

Program between 0 and 9.999.

n.

5.2

5.3

5.4

3.3.1

3.3.1

3.3.1

Page 35

Calibration 33

Step Display Description Text

Ref

9 CUTOFF

xx.x

10 F dPt Number of decimal points with which the Rate

11 t.base The Timebase

60secs

hours

days

secs

12 FILTER The filter constant

1

to

99

13 TOTCON A division factor

1 Rate and totals have the same engineering units.

x.xxxx Other factors can be programmed between 0.01

14 t.dPt Number of decimal points with which the

15 A.dPt Number of decimal points with which the

16 ACCESS

Front

No Acc

The signal Cutoff.

Enter as a % of the Span.

to be displayed between 0 to 0.00000.

with which the Span is entered

must be programmed.

units/min

units/hour

units/day

units/second

for filtering the rate display. 3.2.2

No filtering.

Very heavy filtering

to convert the totals to different

units from those used for rate (ie gallons/min and

barrels).

and 2000.

resettable total is displayed between 0 to 0.000.

Accumulated

between 0 to 0.000.

Enable access to calibration routine via the front

keyboard only.

Enable access via front keyboard.

Disable access via front keyboard.

(non resettable) total is displayed

3.3.2

is

3.2.1

3.4

Page 36

34 Calibration

5.2 ENTERING THE BATCH PARAMETERS

Step Display Description Text

1 BATCH

OPTION

TEST

END

CAL

The following steps are displayed if BATCH is selected.

2 BATCH L

xxxxxx

3 AUTO S

Off

On

xx:xx

Enter Batch Parameters.

Option (if installed)

Check Input Signals.

Exit to normal operation.

Program Setup Parameters.

Maximum Batch Size which can be

entered.

Set to 0 if no limit on batch size.

Automatic restart

Disable.

Enable.

If enabled, automatically restarts the

batch xx:xx (mins:sec) after the end of

the last batch.

feature.

Ref

5.3

5.4

5.1

3.2

3.2.4

4 START. T

xx:xx

5 PREST

xxxx

Slow start

Time, in (minutes:seconds), when

Relay 2 will energise once the batch

has started.

Prestop Quantity.

Quantity at which Relay 2 will

de-energise before the end of the batch.

(Eg. If the batch quantity is 100 litres

and Prest is 2 litres, relay 2 will

de-energise after 98 litres.)

time.

3.2

3.2

Page 37

Calibration 35

Step Display Description Text

Ref

6 COUNT

dn

up

The Batch Total

Count down from the batch quantity.

Count up from zero.

counts Up or Down.

3.2

7 T OUT The Signal Timeout

(Setting to 00 disables this feature.) 3.2.2

8 AOC

En

Dis

9 AUTO R

Off

On

Automatic Overrun Compensation.

Note that the Signal Timeout must be

greater than 0 (ie enabled) for this

feature to work.

Enable.

Disable.

Auto Reset

Restart is programmed - Step 3 above).

Batch Total must be manually reset

before starting the next batch.

The Batch can be automatically reset

and started by pressing only the RUN

key.

(not displayed if Auto

in seconds.

3.2.5

3.2

Page 38

36 Calibration

5.3 PROGRAMMING OPTIONS

Step Display Description Text

Ref

1 OPTIONS

Test

End

CAL

Batch

If the RS232/422/485 option is installed, the following will be

displayed:

2 DF

Eur

USA

Options (if installed).

Check the Input Signals.

Exit to normal operation.

Program Setup Parameters.

Set Batch Parameters.

Date Format.

European (ie. days/months/years).

USA (ie. months/days/years).

5.4

5.1

5.2

4.1

3 Date

xx:xx:xx

4 HOUR

xx:xx

5 BAUD

xxx

6 DATA

7

8

7 PARITY

NP

OP

EP

Enter date as:

Years:Months:Days.

Enter time as a 24 hour clock.

Hours:Minutes.

Baudrate

300, 600, 1200, 2400, 4800 and 9600.

Word length.

7 bits.

8 bits.

Parity.

No Parity.

Odd Parity.

Even Parity.

4.1

Page 39

Calibration 37

Step Display Description Text

Ref

8 SIGNAL

rs232

rs422

9 ID NO

0

1 - 99

10 P TYPE xx

Signal Type.

RS232.

RS422/RS485.

Unit Identification Number.

None.

Id number.

Printer/Computer Type.

00

01

02

03

04

05

20

If a Printer Protocol is selected, the following message is displayed:

10 UNIT xx

00

01

02

03

04

05

06

07

If a Computer Protocol is selected, the following message is displayed:

10 ECHO

On

Off

Standard Computer Printer.

EPSON CTM 290 Slip Printer.

Model 624 Roll Printer.

EPSON TM290-2 Slip Printer.

Contrec Model 632-2 Printer.

Syntest SP-210 Printer.

Computer.

Units of measurement printed.

None.

Litres (Ltrs).

Gallons (Gals).

Barrels (bbls).

Pounds (lbs).

Grams (gms).

Kilograms (kgs).

Tons (tons).

ECHO Command.

Echo (Full Duplex).

No Echo (Half Duplex).

Page 40

38 Calibration

5.4 CHECKING THE INPUT SIGNAL

Step Display Description Text

1 TEST

OPTIONS

CAL

BATCH

END

The following steps are displayed if TEST is selected.

2 Sr x.xx Software revision number.

Depending on the input selected, the input current or voltage will be

displayed.

Check the Input Signals.

Options (if installed).

Program Setup Parameters.

Set Batch Parameters.

Exit to normal operation.

Ref

5.3

5.1

5.2

3 4-20mA

xx.xx

0-20mA

xx.xx

1-5 Volt

xx.xx

0-10 Volt

xx.xx

If the RS232/422485 option is installed, the display will then show:

4 CLOC

xx:xx:xx

Displayed for 1 second followed by the actual

current.

Displayed for 1 second followed by the actual

current.

Displayed for 1 second followed by the actual

voltage.

Displayed for 1 second followed by the actual

voltage.

Clock.

Time in Hours:Mins:Sec.

Page 41

Input Circuits 39

6. INPUT CIRCUITS

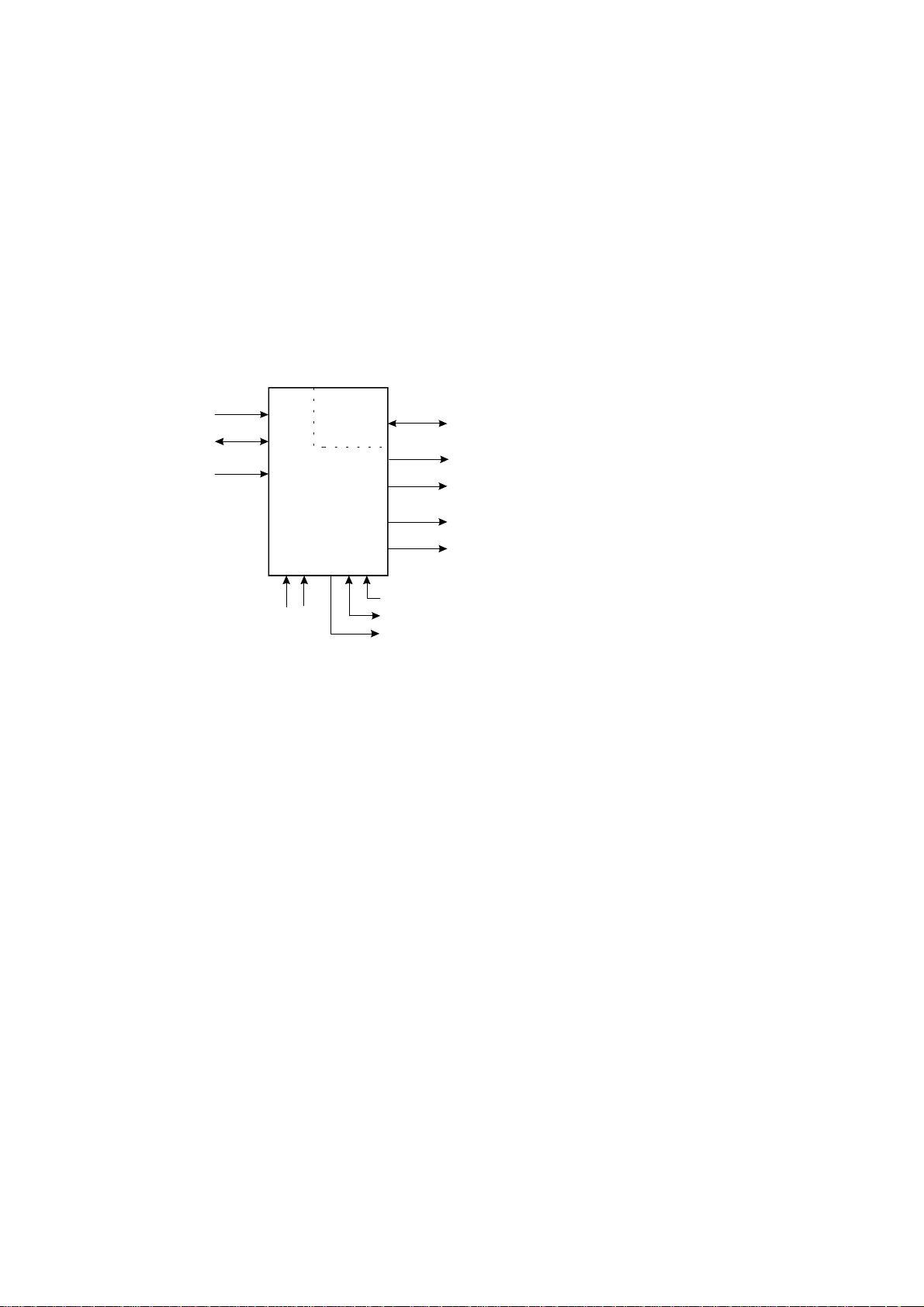

6.1 THE SIGNAL INPUT

The basic circuit of the input is shown below. Both the current and voltage

signals are fed to a data selector but only one signal is processed, depending

upon whether a current (4-20mA or 0-20mA) or a voltage (1-5 V or 0-10 V)

input configuration is selected. The signal is fed to a voltage to frequency

convertor and transmitted to the microprocessor via an opto-coupler.

The microprocessor uses a crystal reference to provide an accurate measurement

of the incoming frequency. Once every 10 minutes a stable and accurate internal

reference is sampled and used to compensate the input. This technique ensures a

highly accurate measurement and makes periodic calibration unnecessary.

14

9

250

Ohm

8

Current

Voltage

10K

Reference

DC to DC

Convertor

Voltage to

Frequency

Microprocessor

Regulator

Isolation

Page 42

40 Input Circuits

Model 414 Batch Controller

11

9

8

2

Transmitter

+

-

4-20mA

Transmitter Powered by the Flow Computer

External Loop Power

+

Transmitter

4-20mA

-

8-24 VDC

250 ohms

Ground

Batch Control ler

9

250 ohms

8

4-20mA Loop with External Power Supply

INPUT CONNECTIONS

+

Chart Recorder

-

Page 43

Input Circuits 41

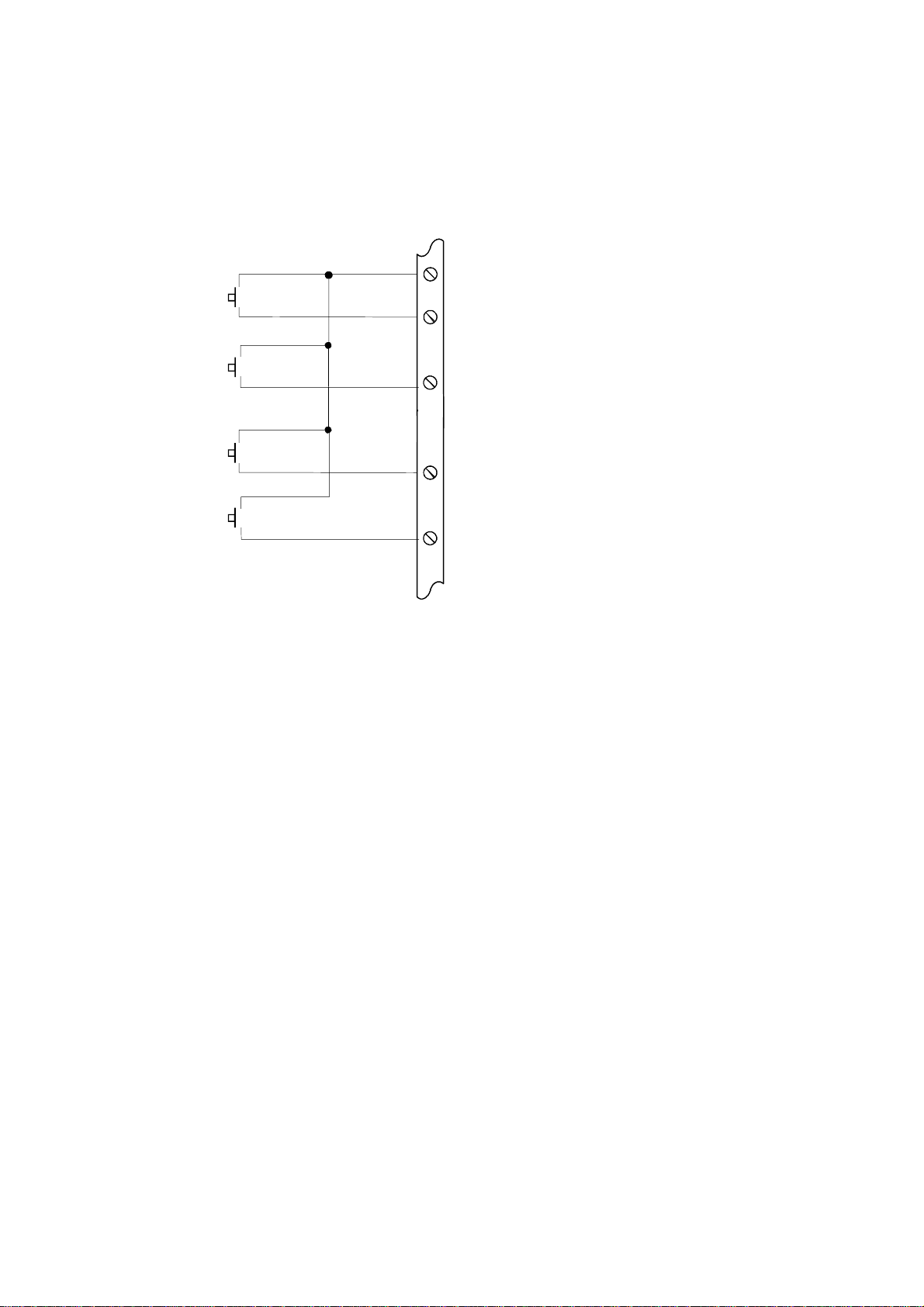

6.3 REMOTE SWITCH INPUTS

Remote push-buttons can be connected to the Model 414A to duplicate the

switches on the front panel.

The switches are wired as follows:

2

RUN

28

DISPLAY

BATCH

SET

STOP

4

5

29

Page 44

42 Installation

7. INSTALLATION

7.1 GENERAL

The terminal designations for the Model 414A Batch Controller are given on the

following pages. The cutout hole in the panel should be 5.5" (139mm) wide x

2.6" (67mm) high. Two side clips are supplied to secure the instruments into

panel.

A case earthing point is provided via an earth lug on the side of the case. Note

that this earthing point is for the case only and there is complete electrical

isolation between this point and all electronic circuits. For EMC purposes, or

when the instrument is connected to mains, this point must be connected to a

good earth using a multi-stranded, braided wire or strap. All relay outputs are

totally isolated from the case and from the internal circuitry.

The two output relays are changeover relays and both the "normally open" and

the "normally closed" terminals are available on the rear terminal strips. All

relay outputs are totally isolated from the case and from the internal circuitry.

A Supply Output voltage is provided to power sensors. This output will provide

a regulated voltage of 8 to 24 volts and the voltage is adjustable by means of the

potentiometer on the rear panel. Maximum current is 50mA and the instrument

comes with the voltage factory set at 24 Volts. When the instrument is powered

from a DC power source, the maximum output voltage on the Supply Output is

the DC Input Voltage less 3.5 volts.

The instrument will operate from either 12 - 28 volts DC or from the mains. The

mains voltage is factory set to either 95 - 135 VAC (110 VAC nominal) or 190 260 VAC (220 VAC nominal). An internal mains transformer provides full

isolation between the mains and the electronic circuits.

The DC Ground terminal 12 provides a common ground for the 12 - 28 Volt

power input, the 8 - 24 Volt output, pulse output and End of Batch output.

It is good practice to use shielded cables for all signal connections to the Model

414. Care must be taken to separate signal cables from power cables so as to

minimise interference.

Page 45

Installation 43

Overall shields should be connected to the case earth at the instrument end only.

This connection should be as short as possible and connected to the earthing lug

on the side of the case.

In order to comply with the requirements for Electromagnetic Compatibility as

per EMC-Directive 89/336/EEC of the Council of European Community, this

wiring practice is mandatory.

Although it is also possible to connect shields to the signal ground (terminal 2)

this practice is not in accordance with EMC directives.

RC Networks for Interference Suppression

When driving highly inductive loads with the relay outputs, it is recommended

that RC suppression networks (often called "Snubbers") are used for two reasons:

To limit the amount of electrical noise caused by arcing across the

contacts which may, in extreme cases, cause the microprocessor to act

erratically.

To protect the relay contacts against premature wear through pitting.

RC suppression networks consist of a capacitor and series resistor and are

commonly available in the electrical industry. The values of R and C are

dependent entirely on the load. However, if the user is unsure of the type of

snubber to use, values of 0.25uF and 100ohms will usually suffice. Note that

only mains approved RC suppression networks should be used.

The basic principle of operation is that the capacitor prevent a series of sparks

arcing across the contact as the contact breaks. The series resistor limits the

current through the contact when the contact first makes.

Page 46

44 Installation

7.2 WIRING DESIGNATIONS FOR THE MODEL 414A

Terminal Model 414A

1 Calibration Link

2 Signal Ground

3 Not To Be Used

4 Remote Display Switch

5 Remote Batch Set Switch

6 Not To Be Used

7 Flow Alarm

8 Flow Common (-)

9 Flow 4-20mA In (+)or 0-20mA In (+)

10 Pulse Out

11 DC Power Out (8-24 VDC)

12 DC Ground

13 DC Power Input

14 Flow 1-5V In (+) or 0-10V In (+)

Terminal RS232/422/485 Option

20 RS232 Signal Ground

21 RS232 Data In

22 RS232 Data Out

23 RS422/485 (-) Data Out

24 RS422/485 (+) Data Out

25 RS422/485 (-) Data In

26 RS422/485 (+) Data In

27 RS232 CTS

Terminal Relay Output Switches

28 Remote RUN Switch

29 Remote STOP Switch

30 End of Batch

31 Relay 2 - Normally Open

32 Relay 2 - Normally Closed

33 Relay 2 - Common

34 Relay 1 - Normally Open

35 Relay 1 - Normally Closed

36 Relay 1 - Common

Page 47

Trouble Shooting 45

8. TROUBLE SHOOTING

Batcher does not reset.

The Signal Timeout has been set to an excessively long period

and has not timed out at the end of the last batch.

Batch will not start or relay 1 will not close.

Ensure that the instrument has not timed out as controlled by

the Signal Timeout and that a Flow Alarm condition does not

prevail. Pressing the Stop switch will cancel this condition.

Check for a fault on the flow input before restarting.

Batcher stops midway through a batch.

This could be due to the Signal Timeout having timed out.

Check for a fault in the system.

No display.

Check power to the instrument.

All 88888888 displayed.

The Batcher will display all eights on power up for 4 seconds

as a display test. If it continues to display all eights after this

period, this is symptomatic of the power supply voltage being

low. Check the power input voltage.

Not counting.

If the Batcher does not count with the flowmeter connected and

flow passing through it, first check the connections on the rear

of the instrument are set as per section 6.

Page 48

46 Trouble Shooting

Counting erratically

This can be caused by lack of shielding on the input.

Shield the input signal with the shield earthed at the Batch

Controller only.

Instrument acting erratically

Erratic operation can be the result of severe electrical

interference. Considerable attention has been given to

designing the Batch Controller to withstand electrical

interference.

However, in extreme cases, loads may be encountered which

are exceptionally inductive and may require additional

protection. One measure is to use an RC Suppression Network

as described in Section 7.

Another remedy for this problem is to use an isolating relay to

switch the load, and use the Batcher to drive the isolating relay.

The isolating relay should be mounted away from the Batcher

and from signal wiring.

No end of batch, pulse output or flow alarm.

This fault is usually caused by lack of a pullup resistor or load

on the output. The outputs themselves have no internal pullups

and rely on an external load.

Page 49

Trouble Shooting 47

8.1 ERROR CODES

The instrument has extensive self test facilities and will display an error code if

it detects an invalid condition. If the instrument displays an error code other

than those listed below, please contact the factory.

Error codes are displayed as "Err 12" and a list of commonly encountered codes

are given below:

Error Codes

Input Errors

11 Invalid input configuration programmed.

13 Signal less than 3.5mA.

14 Communications Input error (RS232/422/485 Interface).

Output Errors

21 Invalid output configuration.

22 Communications error - Baud rate not set.

23 Communications error - Printer fault.

Calibration Errors

30 Zero Value not Allowed.

33 Invalid Printer Type.

34 Invalid Volume Units selected.

Page 50

48 Index

Index

$

Access, 33

Accumulated Total, 10

Auto Reset, 9

Auto Restart, 16

Automatic Overrun

Compensation, 17

%

Backlite, 4

Batch Limit, 10

Batch Set, 8

Battery Backup, 7

Baudrate, 28

&

Calibration, 30

Check the Input, 38

Communication

Protocol, 28

Computer, 29

Conformal Coating, 4

Control Functions, 11

Control Relay, 13

Count Down, 9

Count Up, 9

Cutout, 5

'

Displayed

Information, 10

(

Earth Lug, 42

Earthing Point, 42

End of Batch, 15

Error Codes, 47

)

Filtering, 20

Flow Alarm, 14

Frequency Input, 18

Frequency Range, 5

Front Panel Operation, 8

*

Ground, 42

,

Installation, 42

Interference, 43

Introduction, 3

Isolation, 42

.

Key Operation, 8

/

Limit on Batch, 10

Loss of Signal, 14

Multipoint

Communication, 26

1

Non-volatile Memory, 7

2

Operating

Temperature, 5

Operation, 7

Options, 25

Output Pulse, 23

Output Relays, 13

Overrun, 17

3

Parity, 28

Power Requirements, 5

Prestop, 13

Printer, 28

Pulse Output, 6, 23

Pulse Width, 6

5

Rate, 10

Remote Counters, 23

Remote Push-buttons, 41

Resetting, 9

Response, 20

RS232/422/485

Interface, 25

Run Key, 8

Date, 28

DC Input Voltage, 42

Decimal Points, 32

Dimensions, 5

Display Key, 10

0

Mains, 42

Mains Voltage, 42

Model Number, 4

6

Setting the Batch, 8

Setup Parameters, 30

Signal Timeout, 14

Page 51

Slow Start, 13

Slow Stop, 13

Specification, 5

Starting, 9

Stop Key, 13

Stopping, 9

Switching Current, 6

Switching Power, 6

7

Terminal, 44

Ticket, 28

Time Clock, 28

Time Delay, 13

Total Conversion, 22

Transducer Supply, 5

Trouble Shooting, 45

:

Wiring Designations, 44

Index 49

Loading...

Loading...