Page 1

HEAT CALCULATOR

MODEL 212

July 1998

Page 2

Page 3

CONTENTS

1. Overview 3

1.1 Model Number Designation 5

1.2 Conversion Factors 6

2. Specification 7

3. Operation 11

3.1 Display Operation 13

3.1.1 Normal Operation 13

3.1.2 Charge/Discharge Operation 17

3.1.3 Peak and Off-Peak Operation 18

3.2 Checking Set-up Parameters 19

3.3 Units of Measurement 24

3.4 Frequency Cut-off 25

3.5 Offset Functions 26

3.6 Operating Modes 27

3.6.1 Heating 27

3.6.2 Cooling 27

3.6.3 Heating/Cooling 27

3.6.4 Charge/Discharge 28

3.7 Peak and Off-Peak 29

3.8 Logging 30

4. Communications 31

4.1 Meter-bus 32

4.2 Infra-red Communications Link 34

4.3 RS485 with Modbus RTU Protocol 35

4.3.1 Hardware 35

4.3.2 Protocol 35

4.3.3 Bus Address 36

4.3.4 Function Codes 37

4.3.5 Exception Response 37

4.3.6 List of Data Registers 38

Page 4

5. Set-up Mode 44

6. Input & Output Connections 50

6.1 Flowmeter Input 50

6.2 RTD Input 53

6.3 Power Supply 54

6.4 Pulse Output 55

6.5 Alarm Relay Outputs 57

6.6 4-20mA Output Option 59

7. Installation 61

7.1 Wall Mounting 61

7.2 Panel Mount Version 63

7.3 Removing the Front Panel 64

7.4 Verification Seal 66

7.5 Wiring Practices 67

7.6 Terminal Designations 69

Index 70

Page 5

)

Overview 3

1. OVERVIEW

The Model 212 Heat Calculator is designed to measure the energy consumed in

both heating and cooling (air conditioning) systems. The instrument is normally

supplied complete with temperature probes and power supply, and will interface

to a wide variety of flowmeters, including positive displacement and inferential

water meters, magnetic flowmeters with pulse outputs, turbine flowmeters &

paddlewheel flowmeters.

The Model 212 measures the temperature in the feed and return flow lines and

uses this information to calculate the density and enthalpy of water. By also

measuring the volume of water flowing in the system, the Model 212 will then

determine the energy used. Power is calculated as:

P=Vxρ x(h

TV-hTR

where P = Power (W)

3

V = Volumetric Flow rate (m

!

= density (kg/m

= Specific Enthalpy (J/kg) at Feed Temperature

h

TV

= Specific Enthalpy (J/kg) at Return Temperature

h

TR

3

)

/sec)

The Model 212 is designed to be used in typical water heating or cooling systems

where pressures do not exceed 16 bars.

The temperature in both the feed and return lines is measured via two PT100

resistance temperature devices (RTDs). For maximum accuracy, four wire RTD

measurement is used and internally corrected for non-linearities which are

inherent to an RTD.

The Model 212 complies with OIML R75 and EN1434 standards and includes

Meter-bus and an infra-red data transfer option.

The Model 212 includes separate peak and off-peak registers as well as the ability

to compute charge and discharge energy in systems where heat may be stored in

underground tanks. The Model 212 also includes an RS485 communications link

with Modbus RTU protocol.

Page 6

4 Overview

The Model 212 has a highly accurate built-in real time clock (2ppm typ) to keep

track of logging, peak-on/peak-off points, etc. In case of a power failure, the

real-time clock is able to keep running for two days with a ± 1 minute accuracy,

typically.

This instrument conforms to the EMC-Directive of the Council of European

Communities 89/336/EEC and the following standards:

Generic Emission Standard EN 50081-1 Residential, Commercial & Light

Industry Environment.

Generic Emission Standard EN 50081-2 Industrial Environment.

Generic Immunity Standard EN 50082-1 Residential, Commercial & Light

Industry Environment.

Generic Immunity Standard EN 50082-2 Industrial Environment.

In order to comply with these standards, the wiring instructions in Section 7.5

must be followed.

Page 7

1.1 MODEL NUMBER DESIGNATION

Model 212 . 2 0 E 8 S

Mounting

Panel Mount 1

Wall Mount 2

Options

No Options 0

4-20mA Output 1

Power

12VDC Power N

European Adapter

(220 VAC) E

UK Adapter

(220 VAC) U

USA Adapter

(110 VAC) A

Australian Adapter

(240 VAC) H

Overview 5

Temperature Sensor

None 0

85mm pipe 8

120mm pipe 1

210mm pipe 2

Compliance

EN1434 S

Page 8

6 Overview

1.2 CONVERSION FACTORS

1 kWh = 3.600 MJ

1 MJ = 0.27778 kWh

3

1 m

1 US gal = 3.785 litres

3

1 ft

1 kBTU = 1.0551 MJ

1 Ton x Hour (Refrigeration) = 12,000 BTU

1 therm = 100,000 BTU

Note: kBTU are used on the Model 212 display and mean BTU x 1000.

= 1000 litres

= 7.4805 US gal

Page 9

Specification 7

2. SPECIFICATION

General

Energy Display units: kWh, MWh, MJ, GJ, therm, BTU x 1000,

tons x hours (refrigeration).

Maximum Thermal

Power: 3000 MW.

Accuracy Class: OIML R75 Class 4,

EN1434.

Measurement Time: 0.5 sec time interval.

Environmental Class: EN1434 Classes A & C.

Ambient Temp Range: 0°C to 60°C.

Storage Temp Range: -20°C to 70°C.

Temperature Measurement

Type of Sensor: Pt100 to IEC751.

Temperature Range: -10°C to 220°C

Temperature Difference: 1K to 200K.

Approved Temp Range: 1°C to 200°C.

Approved Temp Difference: 3K to 199K.

Measurement Time: 3 sec time interval.

Display

Type: LCD with 7 digit numeric display and 11

character display.

Digits: 15.5mm (0.6") high.

Characters: 6mm (0.24") high.

Page 10

8 Specification

Flowmeter Input

Type: Frequency or Pulse between 0.01Hz to 20kHz.

Default low frequency cut-off is 0.25Hz.

Signal Type: Pulse, open collector, reed switch, proximity

switch or coil.

K-factor range: Programmable between 0.001 to 999,999.9 pulse

3

per litre, m

, US gallon or ft3.

Location: In either the feed or return lines.

Temperature Sensor (RTD) Input

Sensor Type: Pt100 to IEC 751.

Connection Type: Four wire.

Location: Two RTD inputs, one for the feed and a second

for the return lines.

Linearisation: Built in RTD linearisation.

Temperature Range: -10°C to 220°C.

RTD Cable Length: < 50m.

Pulse Out

Pulse Width: 10ms.

Type: Open collector will sink up to 100mA.

30Vdc Maximum.

Function: Volume or Energy (scaled).

Frequency: 1 pulse every preset number of units of energy or

volume total.

Power Requirements

dc Power: 12 to 24V dc @ 100mA maximum.

ac Power: Supplied via a power adapter.

Page 11

Specification 9

Construction

Enclosure Material: ABS/Polycarbonate.

Colour: Light beige.

Protection: Sealed to IP67 (Nema 4X).

Mounting: Wall mounting or panel mounting.

Dimensions: 152mm (6.0") wide x 98mm (3.9") high x 43mm

(1.7") deep.

Alarm Output (not available if 4-20mA Output Option is installed)

Type: Two solid state opto-isolated relays which will

sink up to 250mA. 30V dc maximum.

Function: High and low alarms individually programmable

as unsigned values, for volumetric flow rate,

energy flow rate, feed temperature, return

temperature or temperature difference.

4-20mA Output Option

Function: Volumetric flowrate, energy flowrate, feed

temperature, return temperature or temperature

difference.

Output Range: 2.0mA to 22.0mA.

Linearity: 0.02% of span.

Accuracy: 0.1% of span.

Response Time: 0.5 seconds to 99%.

Maximum Output: Vdc -6V.

Page 12

10 Specification

RS485 Option

Data Transmitted: Volume and energy totals, peak power,

temperatures.

Baud rate: 300 - 9600 baud.

Parity: Odd, even or none.

Stop bits: One or two stop bits.

Bus Address: Programmable for multiple instruments on the

same bus.

Protocol: Modbus RTU.

Meter-Bus

Type: Conforms to CEN/TC176 Meter-bus standard.

Protocol: IEC 870-5.

Page 13

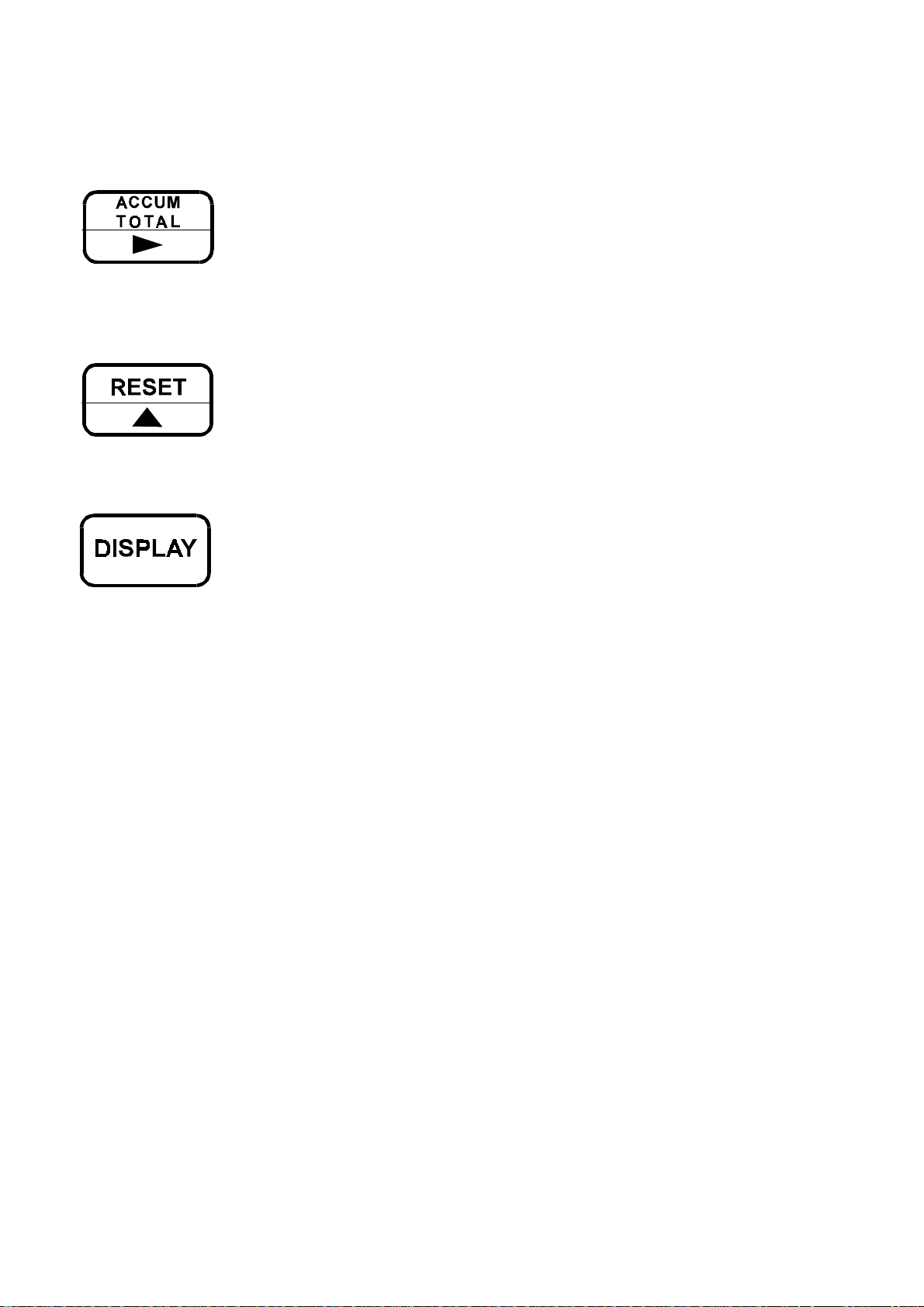

3. OPERATION

The Model 212 has three display modes:

1. Display of normal energy and flow information.

This information is available by pressing the DISPLAY key. Where

appropriate Accumulated Totals can be displayed by pressing the

ACCUM TOTAL key.

2. Checking Set-up Parameters.

By pressing and holding the DISPLAY key for about 5 seconds, the

instrument will enter the parameter set-up routine and allow all set-up

parameters to be checked but not changed. The DISPLAY key is used

to step through the parameter list.

3. Set-up Parameters.

By removing the bottom cover strip of the instrument (see Section 7),

the set-up switch becomes visible. Pressing this switch will put the

instrument into the set-up mode, whereby all parameters can be

programmed using the DISPLAY, and switches.

Operation 11

The LCD display has 7 numeric digits with 11 alphanumeric characters along the

bottom. The alphanumeric characters are used to display the parameter and

units.

Page 14

12 Operation

Three key switches provide the following functions:

Displays the accumulated (non-resettable) totals

for Energy, Volume, operating time (elapsed time)

and Energy total for log entries.

Also changes digits, decimal point or units when

entering the set-up parameters. A flashing digit,

decimal point or unit will indicate that the

parameter can be changed.

If the Reset function is enabled during set-up, the

RESET key, when held for 5 seconds, will reset

all totals and the operating time.

Also increments the digit, changes decimal point

position, steps through units when entering set-up

parameters and steps through individual log

entries.

Used to change the display to the next parameter.

Also steps through display modes when held for 5

seconds.

Page 15

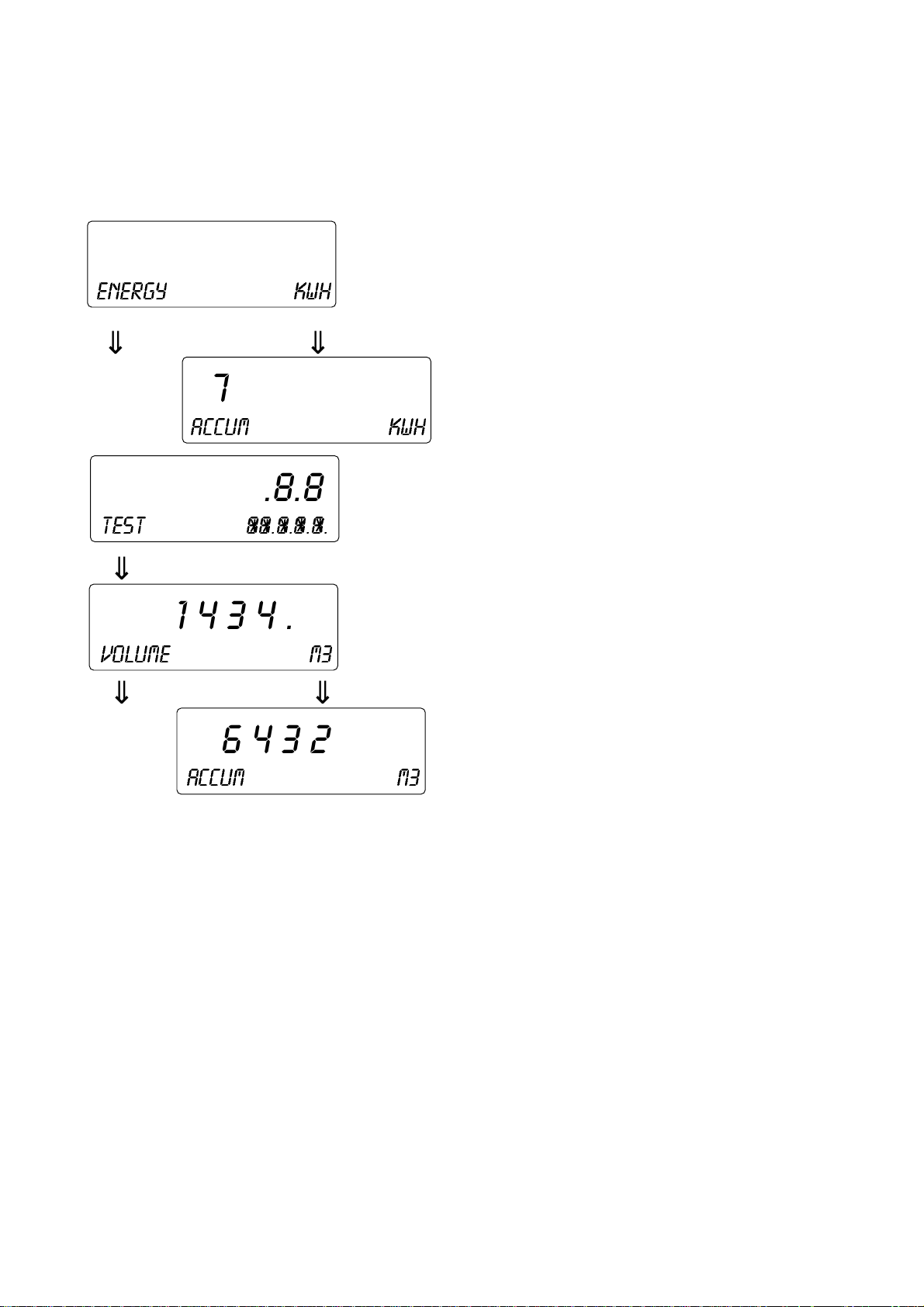

Operation 13

3.1 DISPLAY OPERATION

3.1.1 Normal Operation

Data which can be displayed by pressing the DISPLAY key is as follows:

Default display - Energy measured

since the last reset.

(1(5*< .:K

Press DISPLAY Press ACCUM TOTAL

⇓⇓

Accumulated Energy

Total (non-resettable).

$&&80 .:K

7(67

Press DISPLAY

⇓

92/80( 0

Press DISPLAY Press ACCUM TOTAL

⇓⇓

Display segments test. Segments are

flashing.

Volume of water measured through

the system since the last reset.

Accumulated Volume

Total (non-resettable).

$&&80 0

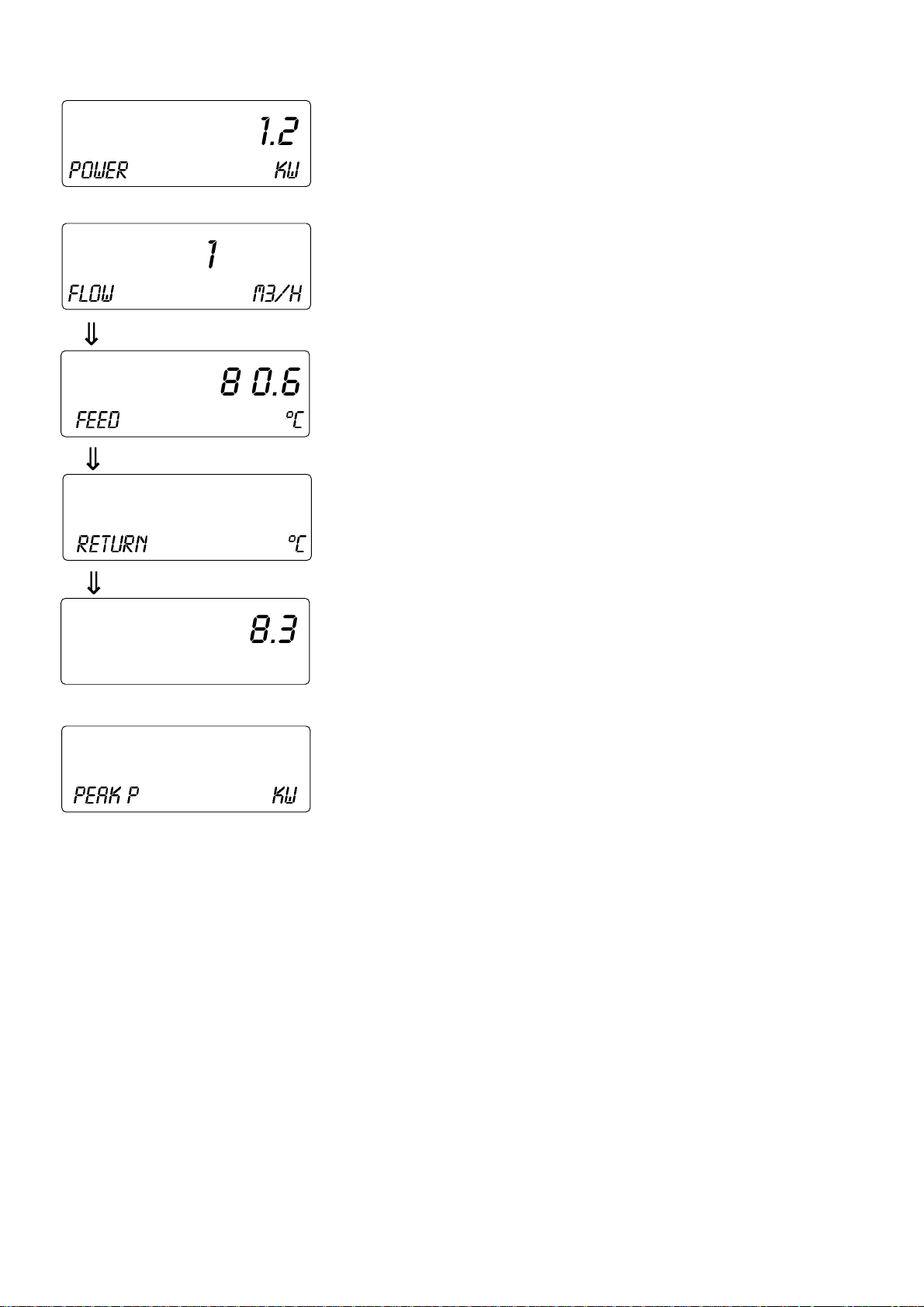

Page 16

14 Operation

32:(5 .:

Press DISPLAY

⇓

Energy flow rate

)/2: 0+

Press DISPLAY

⇓

)((' &

Press DISPLAY

⇓

5(7851 &

Press DISPLAY

⇓

Volume flow rate

Temperature in the feed line.

Temperature in the return line.

Difference in temperature between

the feed and return lines.

Press DISPLAY

⇓

3($. 3 .:

Peak power averaged over a 15

minute period.

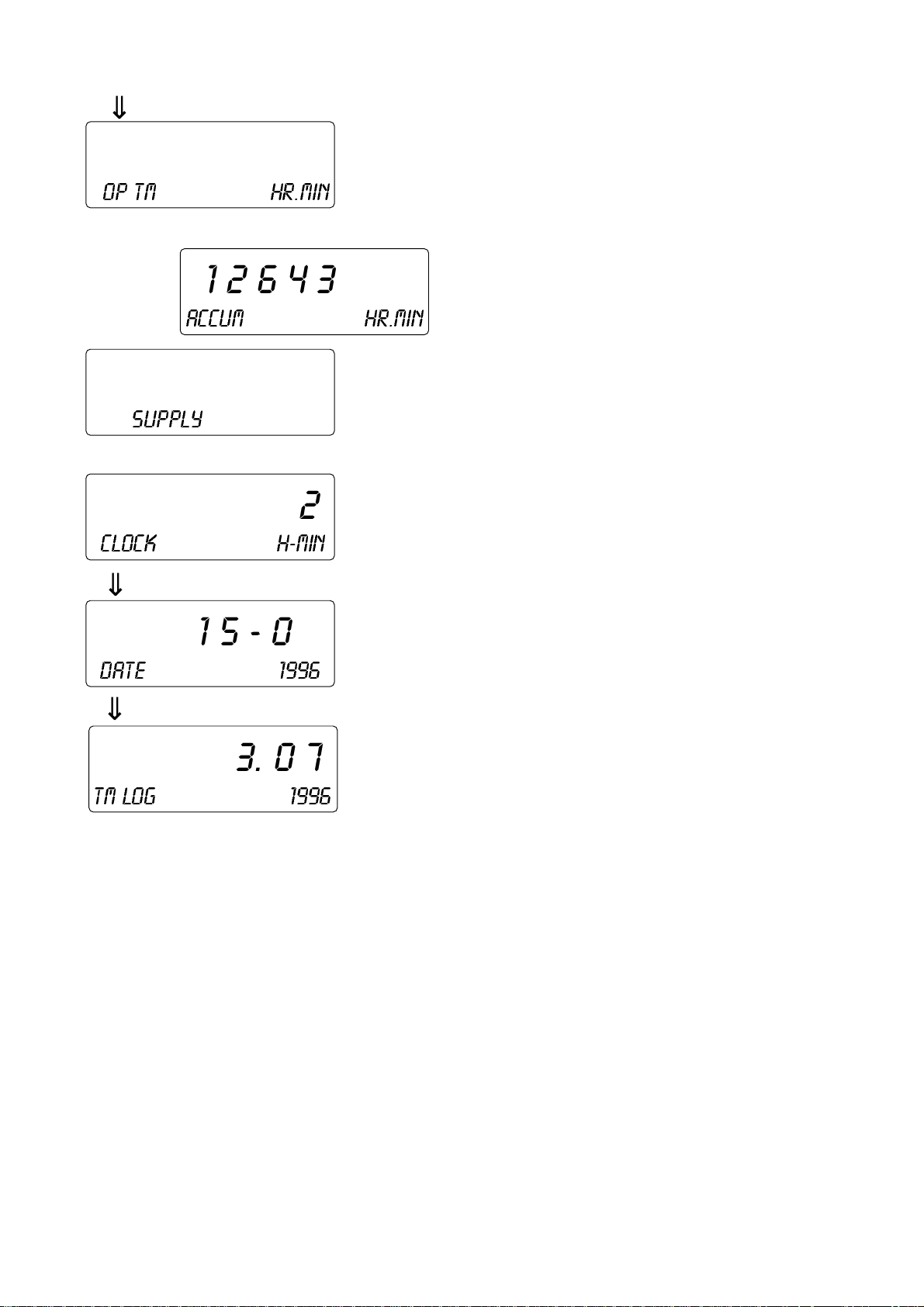

Page 17

Press DISPLAY

⇓

Operating time elapsed since the last

reset.

23 70 +50,1

Press DISPLAY Press ACCUM TOTAL

⇓⇓

Operation 15

$&&80 +50,1

6833/<

Press DISPLAY

⇓

&/2&. +0,1

Press DISPLAY

⇓

'$7(

Press DISPLAY*

⇓

Accumulated operating

time (non-resettable).

Number of times the power has failed

or has been switched off to the unit

since the last reset.

Time of day (24 hour clock).

Date - Day - Month (SI Units)

Month - Day (US Units)

70 /2*

Time and date of the last logged

entry. Pressing the RESET key will

display the previous logged entries.

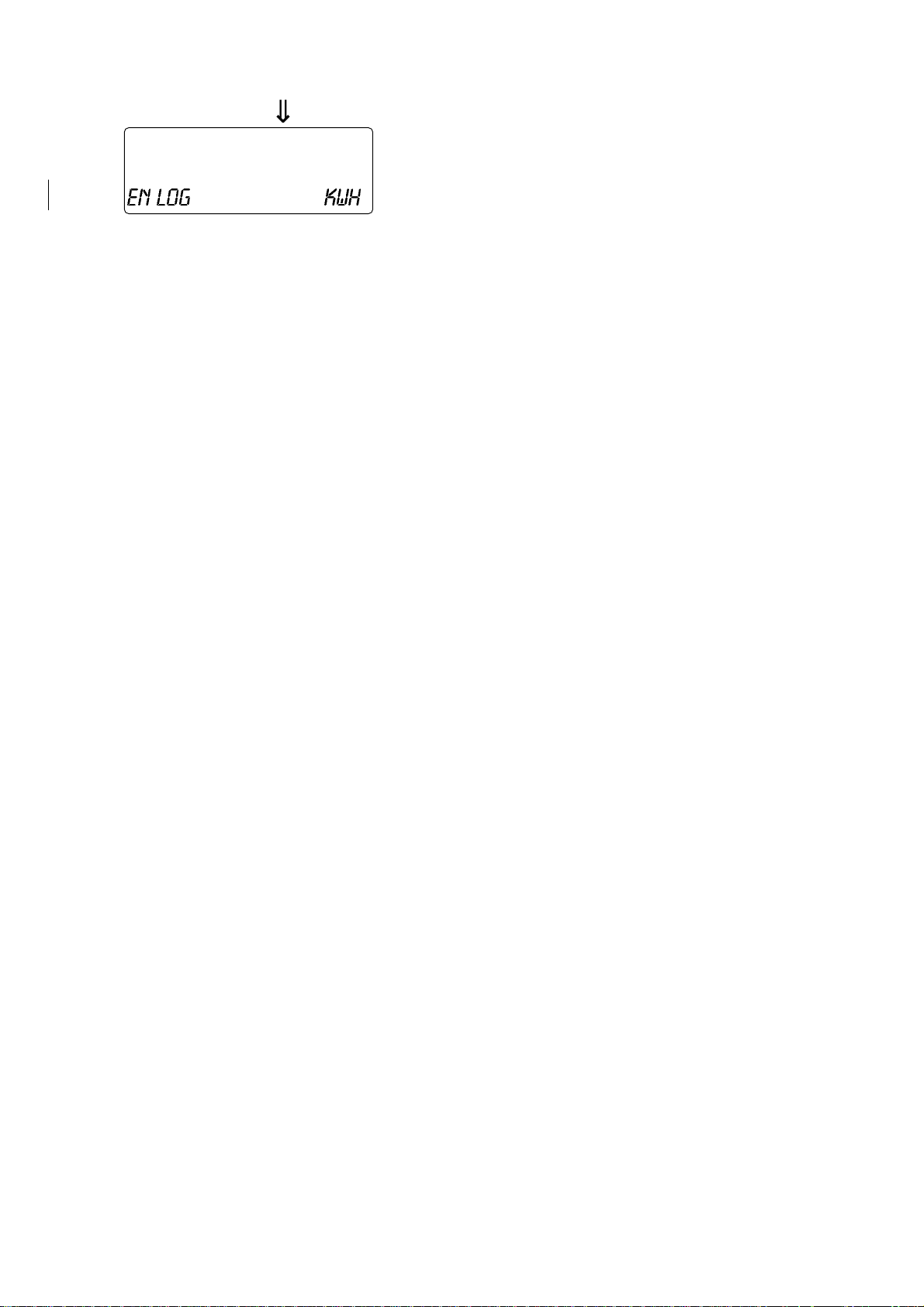

Page 18

16 Operation

Press ACCUM TOTAL

⇓

Energy Total of selected

log entry.

(1 /2* .:+

* If logging is not used, pressing the DISPLAY key will return to the Energy

display.

Page 19

Operation 17

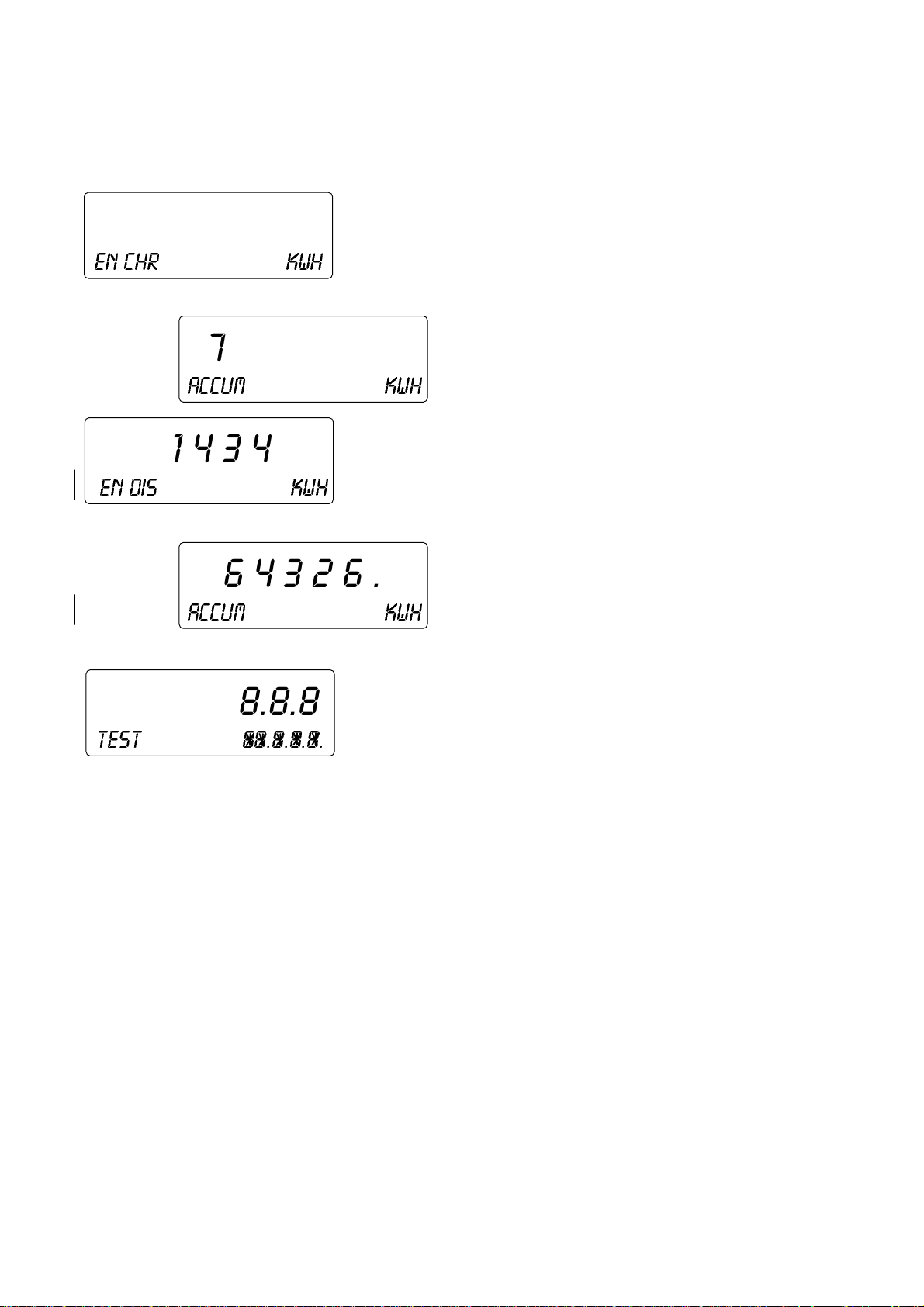

3.1.2 Charge/Discharge Operation

If Charge/Discharge operation is programmed, the following display formats will

be apparent in place of the normal ENERGY display:

(1 &+5 .:K

Press DISPLAY Press ACCUM TOTAL

⇓⇓

$&&80 .:K

Charge Energy default display Charge Energy measured since the

last reset.

Accumulated Charge

Energy Total

(non-resettable).

Discharge Energy measured since the

last reset.

(1 ',6 .:+

Press DISPLAY Press ACCUM TOTAL

⇓⇓

Accumulated Discharge

Energy (non-resettable).

$&&80 .:+

Press DISPLAY Press ACCUM TOTAL

⇓⇓

Display segments test. Segments are

7(67

⇓

Press DISPLAY

For continuation of displays refer to Section 3.1.1 Normal Operation.

flashing.

Page 20

18 Operation

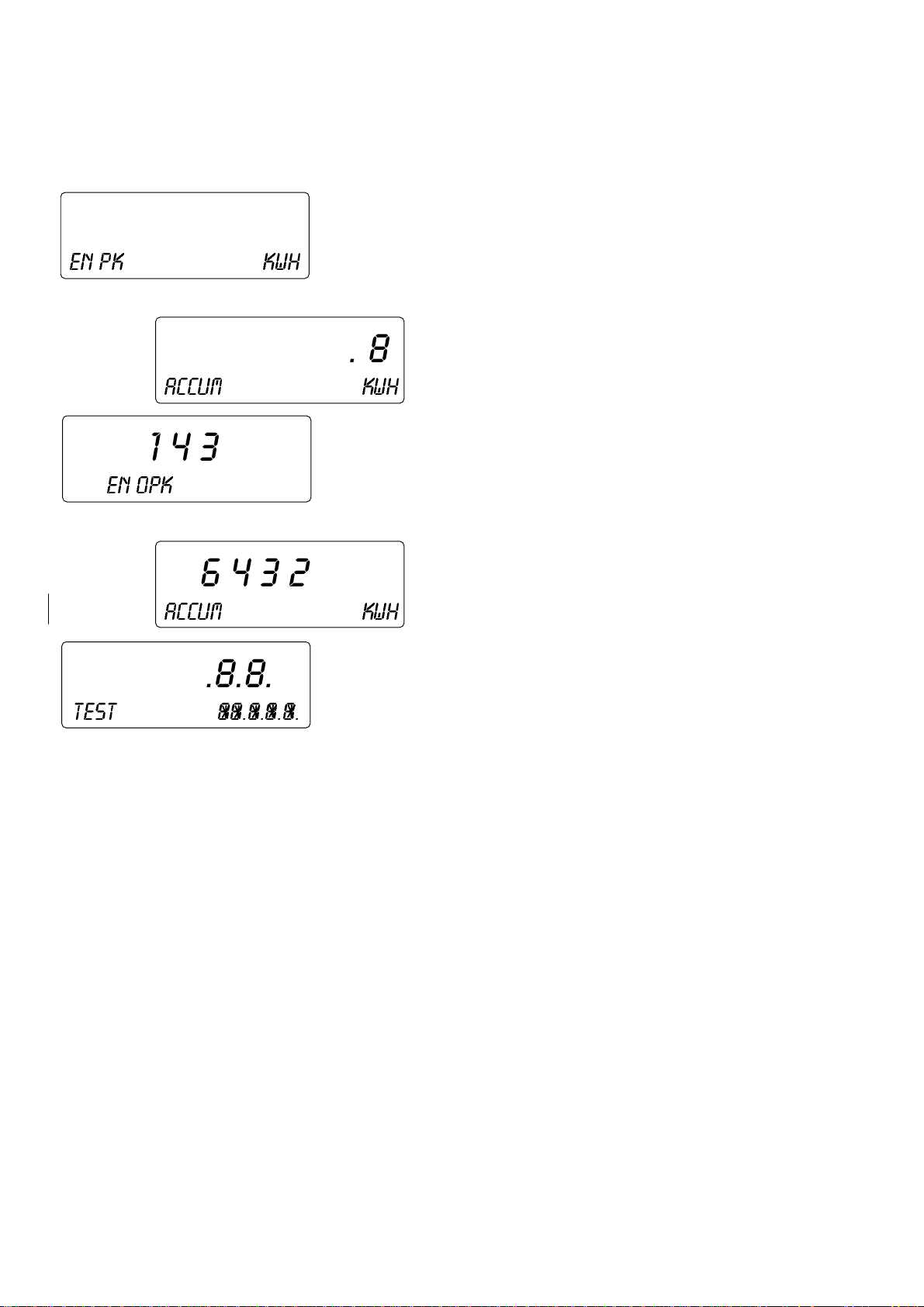

3.1.3 Peak and Off-Peak Operation

If Peak and Off-Peak operation is programmed, the following display formats will

be apparent in place of the normal ENERGY display:

(1 3. .:K

Press DISPLAY Press ACCUM TOTAL

⇓⇓

$&&80 .:K

Peak Energy default display - Peak

Energy measured since the last reset.

Accumulated Peak

Energy Total

(non-resettable).

Off-Peak Energy measured since the

last reset.

(1 23.

Press DISPLAY Press ACCUM TOTAL

⇓⇓

Accumulated Off-Peak

Energy (non-resettable).

$&&80 .:+

Display segments test. Segments are

flashing.

7(67

⇓

Press DISPLAY

For continuation of displays refer to Section 3.1.1 Normal Operation.

Page 21

Operation 19

3.2 CHECKING SET-UP PARAMETERS

By pressing the DISPLAY key for 5 seconds, the program will enter the Check

Set-up Parameters mode. Various set-up parameters can be checked, but not

changed, by using the DISPLAY key.

Set-up Mode may be exited by either moving to the last set-up item, QUIT, and

selecting YES, or the DISPLAY key may be pressed and held for 5 seconds.

After this time, the Model 212 will return to normal operation.

The readout will display the following:

Parameter Value Description

1. LANG ENGL

GERM

Current language.

2. MODE HEAT

COOL

HT/CL

CHAR

3. UNITS SI

US

4. FACTOR xxx.x p/ltr The K-factor of the flowmeter which has

5. CUTOFF x.xx Hz Low frequency cut-off of the flowmeter

Current mode of operation.

Metric units.

US units.

been programmed.

expressed in Hz. The Model 212 will not

register flow if the input frequency is

below this value. (Default is 0.25Hz).

See Section 3.4.

Page 22

20 Operation

Parameter Value Description

6. OFFSET x.x

YES

The offset between temperature sensors

(see Section 3.5).

0.0

NO

7. FM LOC Feed

Ret

If High and Low alarms are installed

8. REL0 Flw H

Flw L

Pwr H

Pwr L

∆t° H

∆t° L

Ft° H

Ft° L

Rt° H

Rt° L

9. REL0 xxxx.xxx Set point for parameters set in step 8

The offset function is disabled.

Location of the flowmeter in either the

feed or return line.

Defines the parameter for Relay 0 output

as being high or low alarm for flow,

power, temperature difference, feed or

return temperatures.

above. For low alarms the relay will

close if the parameter is below the set

point. For high alarms it will close if the

parameter is above the set point.

10 REL1 ... Defines the parameter for Relay 1 as in

step 8 above.

11. REL1 xxxx.xxx Set point for parameter for Relay 1 as in

step 9 above.

Page 23

Operation 21

Parameter Value Description

If 4-20mA Output is installed

8. 4-20mA Flow

Pwr

∆t°

Ft°

Rt°

9. 4mA xxxx.xxx Flowrate or temperature which

10. 20mA xxxx.xxx Flowrate or temperature which

Defines the parameter to be output as a

4-20mA signal.

corresponds to 4mA.

corresponds to 20mA.

12. PULSE Ener

Volu

13. PULSE xxx.x kWh Defines how often a pulse is output

14. COMMS NONE

M-BUS

RS485

15. BAUD xxxx Communications baud rate between 300

16. PARITY Even/Odd/None Communications parity.

17. BUS xx ADDR Bus address for the communications link.

Defines whether the pulse output is for

the energy or volume total.

(maximum frequency = 49Hz).

No Communications.

Meter-bus (see Section 4).

Modbus RTU.

and 9600.

Page 24

22 Operation

Parameter Value Description

18. Df DIS YES

Display will revert to Energy Total if no

key has been pressed for 10 seconds.

NO

19. Fr RES YES

NO

20. PK/OPK OFF

ON

21. PK ON xx

hour

22. PK OFF xx

hour

Display will stay on the last displayed

parameter.

Enable RESET key on front panel.

Disable RESET key.

Indicates whether Energy will be

totalised in separate Peak and Off-Peak

registers.

(Only displayed if mode is set to Heat,

Cool or Heating/Cooling.)

Sets the hour at which energy totalisation

will commence in the PEAK register.

(Only displayed if mode is set to Heat,

Cool or Heating/Cooling and PK/OPK is

set to ON.)

Sets the hour at which energy totalisation

will commence in the OFF PEAK

register. (Only displayed if mode is set

to Heat, Cool or Heating/Cooling and

PK/OPK is set to ON.)

23. LOG OFF

MONTH

WEEK

DAY

HOUR

Selects the interval at which Logging

will take place.

Page 25

Parameter Value Description

24. RESOL NORM

Operation 23

Display Energy, Volume and

Temperatures with normal resolution.

HIGH

Display Energy, Volume and

Temperatures with high resolution for

testing purposes (EN1434-2). Energy

and Volume will be displayed as floating

point values in Joule and m

respectively. Temperatures will be

displayed with two decimal places.

25. S/WARE x.xx Software revision number.

26. QUIT YES

Return to normal operation upon

pressing the DISPLAY key.

NO

Continue in the Check Set-up mode. To

continue use the key to select NO

and then press the DISPLAY key.

3

units

Page 26

24 Operation

3.3 UNITS OF MEASUREMENT

The Model 212 can be programmed to operate in both metric and US units. The

units which are displayed are fully programmable during the Set-up routine.

Metric

Energy kWh MWh MJ GJ

Power kW MW MJ/hour GJ/hour

Volume litres m

Flow l/min m3/min m3/hour

Temperature °C

US Units

Energy kBTU ton x hour therm

Power KBTU/min KBTU/hour ton therm/min therm/hour

Volume gallon ft

Flow gal/min ft3/min ft3/hour

Temperature °F

3

3

Note: Gallons are US Gallons.

Page 27

Operation 25

3.4 FREQUENCY CUT-OFF

A frequency cut-off can be programmed to prevent registering very low flow

signals which may be the result of spurious pulses or a drift in the zero point of a

flowmeter, such as magnetic flowmeter.

Input frequencies at or below the cut-off are not registered and no flow is

totalised.

The relationship between the flow rate at cut-off and the frequency is:

frequency (Hz) =

flow rate x K-factor

time base

where time base = 60 if the flow rate is in units/min and 3600

if the flow rate is in units/hour.

flow rate = flow rate at the cut-off.

K-factor = pulses per unit for the flowmeter.

For example, if the required cut-off is 50 l/h and the K-factor for the flowmeter is

63, then the cut-off frequency:

50x63

f=

3600

= 0.88Hz.

Generally, at frequencies above 0.25Hz, the cut-off is left at the default value of

0.25Hz. However, some water meters produce relatively low frequencies and the

cut-off may need to be programmed to a frequency less than 0.25Hz.

Note: Be careful when setting low cut-off values below 0.25Hz, since the

display update time on the flow rate and power will become long. For

example, if the cut-off is set to 0.01Hz, the instrument will continue to

display the flow rate for 100 seconds, if the signal stops. This is

because the time interval between the signal at 0.01Hz is 100 seconds

and the Model 212 must wait this long before it can determine that the

flow has actually stopped.

Page 28

26 Operation

3.5 OFFSET FUNCTIONS

The offset function is designed for air conditioning systems with a very low ∆t.

Often, in these systems, a bypass valve is installed to enable any differences in

the feed and return temperature to be zeroed out.

To compensate for any offset in the temperature sensors the Model 212 must be

put into the Set-up Program mode. The bypass valve "A" is then opened and the

valves "B" and "C" are closed.

With offset selected, the user then enters YES to zero the offset between the feed

and return lines. The measured offset will then be displayed on the Model 212,

the value of which will be stored when the Set-up Mode is exited.

The system is then returned to normal by closing valve "A" and opening valves

"B" and "C".

Page 29

Operation 27

3.6 OPERATING MODES

The Model 212 may be programmed to operate in either of four modes, as

follows:

1. Heating

2. Cooling

3. Heating/Cooling

4. Charge/Discharge.

3.6.1 Heating

Heating mode is used when the application is for Heating only and assumes that

the Feed Temperature will always be higher than the Return Temperature

(positive ∆t). If the Feed Temperature is lower than the Return Temperature

(negative ∆t), then no Energy is totalised, but Volumetric Flow is still totalised.

3.6.2 Cooling

Cooling mode is used when the application is for Cooling only and assumes that

the Feed Temperature will always be lower than the Return Temperature

(negative ∆t). If the Feed Temperature is higher than the Return Temperature

(positive ∆t), then no Energy is totalised, but Volumetric Flow is still totalised.

3.6.3 Heating/Cooling

Heating/Cooling mode is used where the flow of Energy may be for Heating or

Cooling. In this mode Energy is increased regardless of whether ∆t is positive or

negative.

Page 30

28 Operation

3.6.4 Charge/Discharge

Charge/Discharge mode is used when it is necessary to maintain two Energy

totals. One for when ∆t is positive and one for when ∆t is negative. Only one

total at a time is used.

Page 31

Operation 29

3.7 PEAK AND OFF-PEAK

When the Model 212 is programmed for either Heating, Cooling or Heating and

Cooling, it is possible to program Peak and Off-Peak times. This enables the

Model 212 to record Energy totals in two separate registers, depending on the

time of day.

A 24 hour period can be programmed as having one peak period and one off-peak

period. For example, if "PEAK ON" is programmed as 09 and "PEAK OFF" is

programmed as 18, then between 9.00am and 6.00pm totalisation would occur in

the Peak register and between 6.00pm and 9.00am, totalisation would occur in

the Off-Peak register.

Page 32

30 Operation

3.8 LOGGING

The Model 212 has the facility to log the current Energy total at fixed intervals

which can be programmed to hour, day, week or month.

HOUR A log entry will occur at 00 minutes each hour.

DAY A log entry will occur at 00 hours 00 minutes each day.

WEEK A log entry will occur at 00 hours 00 minutes each Monday.

MONTH A log entry will occur at 00 hours 00 minutes on the 1st of the

month.

A total of 31 log entries can be stored and viewed by the Model 212.

After 31 entries have been completed, the oldest logged entry is overwritten by

the newest logged entry, therefore only the 31 most current logged entries are

kept.

Logging facilities are only available if the mode of operation is set to Heating,

Cooling or Heating/Cooling without Peak/Off-Peak Energy registers.

Page 33

Communications 31

4. COMMUNICATIONS

Three modes of communications are provided:

1. Meter-bus.

2. Infra-red Communications link using M-Bus protocol.

3. RS485 with Modbus RTU protocol.

Terminals 24 and 25 provide a connection for both the Meter-bus and the RS485.

Links on the main board determine which interface is selected as follows:

BA

Link 4

Meter-bus

Link 5

Link 4

RS485

Link 5

These links are accessible by removing the front panel as detailed in section 7.2

and the link positions are as shown in the drawing in section 7.3. Links are

made via small black caps which fit over the connecting posts, thereby creating a

link.

Page 34

32 Communications

4.1 METER-BUS

The Model 212 serves as a secondary station in communications and includes the

Meter-bus hardware and protocol according to IEC 870-5 and as detailed in

EN 1434-3 with variable data format for reading out all parameters.

Hardware

The Meter-bus connection is available through galvanically isolated terminals

24/25 (irrespective of polarity) or optical interface (optional). The levels of input

voltage/output current are as detailed in EN 1434-3.

Bus Address

The bus address of the Model 212 is programmable in range between 0 to 250.

Some addresses are reserved according to EN 1434-3 and have a special

meaning:

0 default address for unconfigured meter

251...253 reserved

254 answer regardless of own address

255 broadcast, no response.

Protocol

The protocol uses asynchronous serial bit transmission in half-duplex mode with

1 start bit, 8 data bits, 1 even parity bit, 1 stop bit and programmable baud rate

(300 to 9600 baud). Link service classes S2 (SEND/CONFIRM) and S3

(REQUEST/RESPOND) are provided utilising frame format class FT1.2

according to IEC 870-5.

This protocol incorporates a frame counter bit (FCB) which has to be toggled by

primary station if the last communication was undisturbed. The Model 212 keeps

a copy of the last transmitted CONFIRM or RESPOND frame in order to

retransmit it if the next FCB has not been toggled.

Page 35

Communications 33

Reception Frames*

SEND (normalise):

10 40 ADR CS 16

REQUEST (data):

10 5B/7B ADR CS 16

SEND (data):

68 LEN LEN 68 53/73 ADR 51/55 DATA... CS 16

Transmission Frames*

CONFIRM (acknowledgment of NORMALISE):

E5

CONFIRM (acknowledgment):

10 00 ADR CS 16

CONFIRM (no acknowledgment, link busy):

10 01 ADR CS 16

RESPOND (no acknowledgment, data is not available):

10 09 ADR CS 16

RESPOND (data)

68 LEN LEN 68 08 ADR 72 DATA... CS 16

* byte values are represented in the hexadecimal format.

Page 36

34 Communications

4.2 INFRA-RED COMMUNICATIONS LINK

The infra-red communication option uses the Meter-bus protocol as defined in

IEC 870-5 and as detailed in EN 1434-3.

This function is not implemented at this time.

Page 37

Communications 35

4.3 RS485 WITH MODBUS RTU PROTOCOL

Modbus RTU is an industry standard protocol which allows the Model 212 to be

easily interfaced to DCS or PLC, or to computers running supervisor software

systems.

The Model 212 serves as a slave station in communications and includes the

RS485 hardware and implementation of the standard protocol according to

Modicon Modbus Protocol (RTU-mode) and as detailed in PI-MBUS-300 Rev F.

Implementation specific details are as follows.

4.3.1 Hardware

The Modbus connection is available on terminals 24/25 and links 4 and 5 must

be connected as described at the beginning of this chapter.

4.3.2 Protocol

The protocol uses asynchronous serial bit transmission in half duplex mode with

1 start bit, 8 data bits and (1 parity bit + 1 stop bit) or 2 stop bits depending on

whether the parity check has been programmed to "NONE" or not. The baud rate

is programmable in range from 300 to 9600 Baud. The parity check can be

programmed to Even, Odd or None. Link service classes SEND/CONFIRM and

REQUEST/RESPOND are provided utilising frame formats according to

PI-MBUS-300.

In RTU mode, messages start with a silent interval of at least 3.5 character time.

Following the last transmitted character, a similar interval of at least 3.5

character times marks the end of the message. A new message can begin after

this interval. The entire message frame must be transmitted as a continuous

stream. A typical message frame is shown below:

ADDRESS FUNCTION DATA CRC CHECK

1 byte 1 byte N bytes 2 bytes

Page 38

36 Communications

Except for broadcast messages, when a master device sends a query to a slave

device it expects a normal response. One of four possible events can occur from

the master's query:

1. If the slave device receives the query without a communication error,

and can handle the query normally, it returns a normal response.

2. If the slave does not receive the query due to a communication error,

no response is returned. The master program has to process a timeout

condition for the query.

3. If the slave receives the query, but detects a communications error

(parity or CRC), no response is returned. The master program has to

process a timeout condition for the query.

4. If the slave receives the query without a communication error, but

cannot handle it (for example, if the request is to read a nonexistent

register), the slave will return an exception response informing the

master of the nature of the error.

4.3.3 Bus Address

The bus address of the Model 212 is programmable in range between 1 to 247.

Some addresses are reserved according to PI-MBUS-300 and have a special

meaning:

0 Broadcast, no response

247...255 Reserved

Page 39

Communications 37

4.3.4 Function Codes

The Model 212 accepts the following function codes:

Code Name Description

03 Read data register(s) Obtain the content of one or

more 2 byte data registers.

06 Preset data register Preset one 2 byte data register.

07 Read status register Obtain the content of 1 byte

status register.

16 Preset data register(s) Preset one or more 2 byte data

registers.

4.3.5 Exception Response

The Model 212 forms an exception response by adding 80H to the function code

and using an exception code as the 1 byte data field in the returned frame.

Implemented exception codes are as follows:

Code Name Description

01 Illegal function The function code is not a

legal action for the slave.

02 Illegal data address The data address is not a legal

address for the slave.

03 Illegal data value The data value is not a legal

value for the slave.

Page 40

38 Communications

Code Name Description

05 Acknowledge The slave has accepted the

request and is processing it,

but a long duration of time will

be required to do so.

06 Slave device busy The slave is engaged in

processing a long duration

program command. The

master should re-transmit the

message later when the slave is

free.

4.3.6 List of Data Registers

The following list describes addresses and meaning of data registers for the

Model 212. Engineering units programmed during setup are used for floating

point values. Conventional numbering of registers often starts from 1, therefore

be aware that "register 1" in this case has an "address 0" and so on.

Read and Write Registers

Address Name Value Note

00 Heating mode 00 - heat

01 - cool

02 - heat/cool

03 - charge/discharge

01 Total reset 00 - no action

01 - reset totals

02 Flowmeter location 00 - feed line

01 - return line

Page 41

Communications 39

Address Name Value Note

If High and Low Alarms are installed:

03 Relay 0 mode 00 - flow high

01 - flow low

02 - power high

03 - power low

04 - ∆t° high

05 - ∆t° low

06 - feed t° high

07 - feed t° low

08 - return t° high

09 - return t° low

04 Relay 1 mode 00 - flow high

01 - flow low

02 - power high

03 - power low

04 - ∆t° high

05 - ∆t° low

06 - feed t° high

07 - feed t° low

08 - return t° high

09 - return t° low

If 4-20mA Output is installed:

03 4-20mA mode 00 - flow

01 - power

02 - ∆t°

03 - feed t°

04 - return t°

05 Pulse out mode 00 - volume

01 - energy

06 Year 00...99 (when writing)

07 Month 01...12

08 Day 01...31

09 Hour 00...23

10 Minute 00...59

Page 42

40 Communications

Address Name Value Note

11 Peak mode 00 - off

01 - on

12 Peak on setpoint 00...23

13 Peak off setpoint 00...23

14 Logging mode 00 - off

01 - month

02 - week

03 - day

04 - hour

15 K-factor 0.001...999,999.9 FP

17 Cutoff frequency 0.01...0.99 FP

If High and Low Alarms are installed:

19 Relay 0 setpoint 0.000...999,999.9 FP

21 Relay 1 setpoint 0.000...999,999.9 FP

If 4-20mA Output is installed:

19 4mA setpoint 0.000...999,999.9 FP

21 20mA setpoint 0.000...999,999.9 FP

23 Pulse out setpoint 0.000...999,999.9 FP

Read Only Registers

Address Name Value Note

25 Energy 0 FP

27 Energy 1 FP

29 Accumulated energy 0 FP

31 Accumulated energy 1 FP

33 Volume FP

35 Accumulated volume FP

37 Not Used FP

39 Not Used FP

Page 43

Communications 41

Address Name Value Note

41 Elapsed time FP

43 Accumulated elapsed time FP

45 Power FP

47 Peak power FP

49 Volume flow FP

51 Not Used FP

53 Flow temperature FP

55 Return temperature FP

57 Temperature difference FP

59 Supply failures

60 Exception register 00 - no failure

01 - RTD failure

61 Logging point 1 - energy FP

63 Logging point 1 - time (seconds) since 01.01.1996 LI

...

...

...

181 Logging point 31 - energy FP

183 Logging point 31 - time (seconds) since 01.01.1996 LI

185 K-factor unit SI: 00 - pulse/ltr

01 - pulse/m

3

US: 00 - pulse/gallon

01 - pulse/ft

3

186 Energy unit SI: 00 - MJ

01 - GJ

02 - kWh

03 - MWh

US: 00 - kBTU

01 - ton x hour

02 - therm

Page 44

42 Communications

Address Name Value Note

187 Volume unit SI: 00 - ltr

3

01 - m

US: 00 - gallon

3

01 - ft

188 Power unit SI: 00 - MJ/hour

01 - GJ/hour

02 - kW

03 - MW

US: 00 - kBTU/min

01 - kBTU/hour

02 - ton

03 - therm/min

04 - therm/hour

189 Volume flow unit SI: 00 - ltr/min

3

/min

01 - m

3

/hour

02 - m

US: 00 - gallon/min

3

/min

01 - ft

3

/hour

02 - ft

Page 45

Communications 43

Notes:

FP This variable is represented in IEEE-754 Floating Point 4 byte

format and requires two 2 byte data registers used as Modicon's

floats:

IEEE-754 Modicon Registers

1st byte low byte (register X)

2nd byte high byte (register X)

3rd byte low byte (register X+1)

4th byte high byte (register X+1)

This means that two data registers must be read/written to

obtain/preset one data value.

LI This variable is represented as a long integer in 4 byte format and

requires two 2 byte data registers:

Long Integer Modicon Registers

1st byte (MSB) high byte (register X)

2nd byte low byte (register X)

3rd byte high byte (register X+1)

4th byte (LSB) low byte (register X+1)

This means that two data registers must be read/written to

obtain/preset one data value.

Page 46

44 Set-Up Mode

5. SET-UP MODE

The Set-up Mode can only be entered by removing the lower cover strip (see

Section 7). Usually this will mean breaking a seal which prevents the strip being

removed without tampering.

Once the strip is removed, a small hole provides access to a pushbutton. By

inserting a pen tip or similar item into the hole and pressing the pushbutton, the

instrument will enter the Set-up mode whereby the parameters can be entered or

changed.

The DISPLAY key is used to step through each parameter and the and

keys are used to step through and change items (digits, decimal points or units).

The item which can be changed flashes. Thus the instrument can be fully

programmed on-site without having to purchase a separate programmer.

If the Set-up access pushbutton is pressed while the Model 212 is in Set-up Mode,

the display will return to step 1.

Set-up Mode may be exited by either moving to the last set-up item, QUIT, and

selecting YES, or the DISPLAY key may be pressed and held for 5 seconds.

After this time, the Model 212 will return to normal operation.

Parameter Value Description

1. LANG ENGL

GERM

2. MODE HEAT

COOL

HT/CL

CHAR

3. RESET NO

YES Resets totals upon exiting the Set-up

Select language.

Selects the mode of operation between

Heating, Cooling, Heating and Cooling

or Charge/Discharge.

Mode.

Page 47

Set-up Mode 45

Parameter Value Description

4. UNITS SI

US

5. ENERGY Set energy units for display.

6. VOLUM Set volume units for display.

7. POWER Set power units for display.

8. FLOW Set flow rate units for display.

9. FACTOR xxx.x p/ltr The K-factor of the flowmeter which has

10. CUTOFF x.xx Hz Low frequency cut-off of the flowmeter,

Metric units.

US units.

been programmed. (See flowmeter

manufacturers data.)

expressed in Hz. The Model 212 will

not register flow if the input frequency is

below this value. Note that the default is

0.25Hz and it is recommended to not

change this value unless the flowmeter

produces very low frequencies. (See

Section 3.4.)

11. OFFSET x.x

YES

0.0

NO

12. FM LOC Feed

Ret

The offset between temperature sensors.

(See Section 3.5).

The offset function is disabled.

Location of the flowmeter as being in

either the feed or return line.

Page 48

46 Set-up Mode

Parameter Value Description

If High and Low alarms are installed.

13. REL0 Flw H

Flw L

Pwr H

Pwr L

∆t° H

∆t° L

Ft° H

Ft° L

Rt° H

Rt° L

14. REL0 xxxx.xxx Set point for parameters set in step 13

15. REL1 ... Defines the parameter for Relay 1 as in

Defines the parameter for Relay 0 output

as being high or low alarm for flow,

power, temperature difference, feed or

return temperatures.

above. For low alarms the relay will

close if the parameter is below the set

point. For high alarms it will close if the

parameter is above the set point.

step 13 above.

16. REL1 xxxx.xxx Set point for parameter for Relay 1 as in

step 14 above.

If 4-20mA Output is installed.

13 4-20mA Flow

Pwr

∆t°

Ft°

Rt°

14 4mA xxxx.xxx Flowrate or temperature which

Defines the parameter to be output as a

4-20mA signal.

corresponds to 4mA.

Page 49

Set-up Mode 47

Parameter Value Description

15. 20mA xxxx.xxx Flowrate or temperature which

corresponds to 20mA.

17. PULSE Ener

Volu

18. PULSE xxx.x kWh Defines how often a pulse is output

19. CLOCK xx

Hour/Min

20. DATE xxxx

Year/Month/Day

21. COMMS NONE

M-BUS

RS485

22. BAUD xxxx Communications baud rate between 300

23. PARITY Even/Odd/None Communications parity (with Meter-bus

Defines whether the pulse output is for

the energy or volume total.

(maximum frequency = 49Hz).

Set time in hours and minutes.

Real time clock is able to run without

power for two days typically.

Set date in year, month and day.

Real time clock is able to run without

power for two days typically.

If no communications are to be used,

Set-up Mode continues at step 25.

Meter-bus (see Section 4).

Modbus RTU.

and 9600.

the parity is not changeable and is set to

even parity).

24. BUS xx ADDR Bus address for the communications

link.

Page 50

48 Set-up Mode

Parameter Value Description

25. Df DIS YES

Display will revert to Energy Total if no

key has been pressed for 10 seconds.

NO

26. Fr RES YES

NO

27. PK/OPK OFF

ON

28. PK ON xx

hour

29. PK OFF xx

hour

30. LOG OFF

MONTH

WEEK

DAY

HOUR

Display will stay on the last displayed

parameter.

Enable RESET key on front panel.

Disable RESET key.

Selects whether Energy will be totalised

in separate Peak and Off-Peak registers.

If set to OFF, Set-up continues at step

30.

Sets the hour at which energy totalisation

will commence in the PEAK register.

(Only available if mode is set to Heat,

Cool or Heating/Cooling.)

Sets the hour at which energy totalisation

will commence in the OFF PEAK

register. (Only available if mode is set to

Heat, Cool or Heating/Cooling.)

Selects the interval at which Logging

will take place.

Logging is only available if the mode

(step 2) is set to Heating, Cooling or

Heating/Cooling and the Peak/Off-Peak

(step 27) is set to OFF. If logging is not

available, this step will not be displayed.

Page 51

Parameter Value Description

31. RESOL NORM

Set-up Mode 49

Display Energy, Volume and

Temperatures with normal resolution.

HIGH

32. QUIT YES

NO

Display energy, Volume and

Temperatures with high resolution for

testing purposes (EN1434-2). Energy

and Volume will be displayed as floating

3

point values in Joule and m

units

respectively. Temperatures will be

displayed with two decimal places.

Return to normal operation upon

pressing the DISPLAY key.

Continue in the Set-up mode. To

continue use the key to select NO

and then press the DISPLAY key.

Page 52

50 Input & Output Connections

6. INPUT & OUTPUT

CONNECTIONS

6.1 FLOWMETER INPUT

The instrument will accept frequency or pulse inputs from a wide range of

flowmeters.

Examples of connection diagrams are shown on the following pages.

Note that it may be necessary to change the position of the links as shown. These

links are accessible by removing the front panel as detailed in section 7.2 and the

link positions are shown in the drawing in section 7.3.

Link 1 Links in an input filter for a reed switch. The

maximum input frequency is approximately 500Hz

with this filter.

Link 2 Link for coils (eg. turbine or paddlewheel flow

sensors).

Link 3 Not connected. This position is selected if links 1 or 2

are not required.

Link 6 Selects a two wire proximity switch when in position

B.

Link 7 Selects a coil input when in position B.

The links are made via small black caps which fit over the two connecting posts

thereby creating the link.

The input on terminals 10 or 11 is limited to 30 volts maximum.

Note: After connecting the flowmeter, it is also necessary to program the

flowmeter factor. This is supplied by the flowmeter manufacturer and

represents the number of pulses per litre, m3, gallon or ft3 that the

flowmeter outputs for each unit of volume. It is often referred to as the

K-factor.

Page 53

1. Pulse

2. Reed Switch

Input & Output Connections 51

3. Coils eg. mV signals from turbine flowmeters or paddlewheels.

Page 54

52 Input & Output Connections

4. Opto-Sensors

5. Namur Switch

Page 55

Input & Output Connections 53

6.2 RTD INPUT

The Model 212 uses four wire RTDs to provide optimum accuracy and stability.

The RTDs are high grade 100 ohm platinum types manufactured to BS1094

standards.

It is not necessary with four wire RTDs to have equal lead lengths, but cables

should not be longer than 50 meters (150 feet). They should be shielded twisted

pairs connected as follows:

Note: Care must be taken to ensure the (+) of the current terminal is

connected to the same side of the RTD as the (+) of the input terminal.

The RTD, itself, has no polarity.

Page 56

54 Input & Output Connections

6.3 POWER SUPPLY

The Model 212 will operate from a central 12-24 Volts dc source and typically

draws around 60mA.

A power adapter is supplied as standard and this supply can also be used to power

the flowmeter, alarms and peripheral items.

The flexible power supply system allows:

1. The Model 212 to be operated from a low cost power adapter.

2. Multiple units to be powered from a single power source.

3. Mains powered systems with battery backup to be easily implemented

using standard sealed lead acid batteries.

By separating the ac power from the main Model 212, the system is completely

safe to install and reduces the need for qualified electricians to complete the

wiring.

Page 57

Input & Output Connections 55

6.4 PULSE OUTPUT

A pulse output is available on terminals 16 and 17. The output is an open

collector transistor suitable for external counters.

† Linked internally

Page 58

56 Input & Output Connections

The output on terminal 16 is capable of sinking up to 100mA maximum and can

withstand external voltages of 30 Volts. Reverse polarity and inductive load

protection is provided.

Two connection examples are provided. If a voltage pulse output is required, an

external load resistor must be used as shown on the second diagram.

The pulse output can be programmed during Set-up as an energy or volumetric

flow output. The pulse rate is also programmable, so that a pulse can, for

3

example, be programmed to occur every .001m

.

Duration of the pulse is around 10ms thus the maximum pulse output frequency

is 49Hz. Hence, in the above example, if the volumetric flow rate was 60

3

/hour, then this is equivalent to 0.0167 m3/sec. If a pulse occurs every 0.001

m

3

then the output frequency would be 16.7 Hz.

m

Page 59

Input & Output Connections 57

6.5 ALARM RELAY OUTPUTS

Note that the High/Low alarms are not available when the 4-20mA output option

is installed.

Two Solid State dc relays are provided as alarm outputs. These relays are fully

isolated and can be used to drive external relays, lamps, audible alarms, etc.

Output characteristics for Relay 0 and Relay 1 are:

Maximum Voltage 30 Volts dc

Maximum Current 250mA dc

Off State Leakage Current 5uA maximum

On State Resistance 6 ohms maximum

The relays can be individually programmed during Set-up to alarm on:

Flow rate Low or High

Power Low or High

Feed Temperature Low or High

Return Temperature Low or High

Temperature Difference Low or High

Page 60

58 Input & Output Connections

For example, Relay 0 can be programmed to alarm if the flow rate is below a

certain value, while Relay 1 can be programmed to alarm if the power

consumption exceeds a preset value.

In the alarm condition the relays are closed, and are open in the non-alarm

condition or when the instrument is unpowered.

Page 61

Input & Output Connections 59

6.6 4-20mA OUTPUT OPTION

A 4-20mA Output Option is available and can be used to retransmit the

volumetric flowrate, energy flowrate, temperature difference, feed temperature

and return temperature.

The maximum output voltage is the supply voltage less 6 volts. Therefore the

maximum load resistance can be calculated as:

Maximum Load =

Supply - 6

0.02

At 24 volts, Rmax = 900 ohms and at 12 volts, Rmax = 300 ohms.

Page 62

60 Input & Output Connections

The output specifications are:

Current Range: 2.0mA to 22.0mA.

Linearity & Resolution: 0.02% of span.

Accuracy: 0.1% of span.

Response Time: 0.5 seconds to 99% of step.

The output can be programmed to output the following:

Volumetric Flowrate

Energy Flowrate (power)

Feed Temperature

Return Temperature

Temperature Difference

The 4mA point and 20mA point can be individually programmed during setup.

Page 63

Installation 61

7. INSTALLATION

7.1 WALL MOUNTING

A wall mounting bracket is supplied with each instrument. A drilling diagram is

outlined on the following page.

Page 64

62 Input & Output Connections

Page 65

Installation 63

7.2 PANEL MOUNT VERSION

The panel mount version of the Model 212 is supplied with two panel mount

brackets and plug-in terminals which are accessible from the rear of the

instrument.

A diagram of the rear panel is shown below. Note that access to the Input Circuit

Links 1-3 and Communication Links 4-7 can only be obtained by opening the

instrument. Access is not available via the rear panel.

The cutout for the panel mount version is 141mm (5.55") wide x 87mm (3.43")

high.

Page 66

64 Installation

7.3 REMOVING THE FRONT PANEL

The front of the instrument is removed as follows:

1. Remove both the top and bottom cover strips (ie. the dark plastic strips on

the front) by using a screwdriver to lever up one end.

2. Undo the seven screws retaining the front. Note: The screws should not

be removed from the front panel as they are retained by O-rings.

3. Pull the front panel free from the housing.

Replacing the front panel of the instrument is the reverse procedure. However,

ensure that the front panel is aligned at both connector points before tightening

the screws.

Page 67

Installation 65

Page 68

66 Installation

7.4 VERIFICATION SEAL

A Verification Seal is supplied with the instrument and can be placed across the

calibration switch to prevent unauthorised tampering. The seal is made from a

self adhesive material which is destroyed if the seal is broken.

Page 69

Installation 67

7.5 WIRING PRACTICES

Three of the terminals are marked and must be connected to a good earth,

using a multi-stranded, braided wire.

It is good wiring practice to use shielded cables for all connections to the Model

212. Care must be taken to separate signal cables from power cables and relay

cables, so as to minimise interference.

Overall shields should be connected at the instrument side only and to the

terminals marked . These connections should be as short as possible.

In order to comply with the requirements for Electromagnetic Compatibility as

per EMC Directive 89/336/EEC of the Council of the European Community, this

wiring practice is mandatory.

Although it is possible to connect shields to the (-) volt supply terminal (51 -),

this practice is not in accordance with the EMC Directive.

Page 70

68 Installation

Termination Board

Page 71

Installation 69

7.6 TERMINAL DESIGNATIONS

Terminal numbering is in accordance with international standards.

Terminal Description

1 + Feed line RTD0 Current (+)

2 - Feed line RTD0 Current (-)

3 + Return line RTD1 Current (+)

4 - Return line RTD1 Current (-)

5 + Feed line RTD0 Input (+)

6 - Feed line RTD0 Input (-)

7 + Return line RTD1 Input (+)

8 - Return line RTD1 Input (-)

10 Flow Signal Input

11 Flow Signal Reference

16 + Pulse Output (+)

17 - Pulse Output (-)

24 Meter-bus or RS485 (-)

25 Meter-bus or RS485 (+)

50 + 12 Volts Supply (+)

51 - 12 Volts Supply (-)

52 + Relay 0 (+) dc Voltage Only or 4-20mA (+)

53 - Relay 0 (-) dc Voltage Only or 4-20mA (-)

54 + Relay 1 (+) dc Voltage Only

55 - Relay 1 (-) dc Voltage Only

58 Shields

Page 72

70 Index

Index

A

ACCUM TOTAL

Key, 12

Accuracy Class, 7

Alarm Relay Outputs, 57

B

Batteries, 54

BTU, 6

Bus Address, 21

Bus Hardware, 21

C

Cable Length, 8

Charge/Discharge, 28

Check Set-up

Parameters, 19

Coils, 51

Communications, 31

Connections, 50

Construction, 9

Conversion Factors, 6

Cooling, 27

Cover Strips, 64

Cut-off, 25

D

DISPLAY Key, 12

Display Mode, 11

E

EMC, 4

EMC Directive, 67

Emission, 4

EN1434, 3

Energy

Measured, 13, 17, 18

Enthalpy, 3

F

Flowmeter Input, 50

Frequency

Cut-off, 19, 25

H

Heating, 27

Heating/Cooling

Mode, 27

High Alarms, 20

I

IEC 870-5, 32

IEC751, 7

Infra-red

Communication, 34

Input Connections, 50

Installation, 61

K

K-factor, 19

K-factor Range, 8

kBTU, 6

Key Switches, 12

L

Language, 19

Lead Lengths, 53

Links, 50

Location, 20

Logging, 30

Low Alarms, 20

M

M-bus

(refer Meter-bus), 32

Mains Powered, 54

Meter-bus, 32

Metric, 19

Modbus RTU, 35

Model Number, 5

Mounting, 61

N

Namur Switch, 52

O

Off-Peak and Peak, 29

Offset Function, 20, 26

OIML, 3

Operating Modes, 27

Operating Time, 15

Operation, 11

Opto-Sensors, 52

Output Connections, 50

P

Panel Mount, 63

Parity, 21

Peak and Off-Peak, 29

Peak Power, 14

Platinum, 53

Power, 3

Power Adapter, 54

Power Requirements, 8

Power Supply, 54

Pressures, 3

Protocol, 32

Pulse Inputs, 50

Page 73

Pulse Output, 21, 55

R

Reed Switch, 51

Relay, 20

Relays, 57

RESET Key, 12

Reverse Polarity, 56

RS485, 35

RTD Input, 53

S

Sensor Type, 8

Set-up Mode, 44

Set point, 20

Shielded Cables, 67

Shields, 67

Software Revision, 23

Solid State dc Relays, 57

Specification, 7

Index 71

W

Wall Mounting, 61

Wiring Practices, 67

Z

Zero, 26

T

Temperature

Difference, 7

Temperature Range, 7

Terminal

Designations, 69

Termination Board, 68

Ton, 6

U

Units of

Measurement, 24

V

Verification Seal, 66

Loading...

Loading...