Page 1

FIELD MOUNTED

RATE TOTALISER

MODEL 202A

2 August 1999

Page 2

Page 3

CONTENTS

1. Introduction 3

1.1 Model Number Designation 4

1.2 Operation 6

1.3 Intrinsic Safety Considerations 7

2. Specification 8

3. Programming 10

3.1 Program Steps 11

3.2 Calculation of Rate and Total 14

3.3 Total Conversion 16

3.4 Filtering 17

3.5 Example 19

4. Signal Input 20

5. Alarm & Pulse Outputs 21

6. Intrinsic Safety Connections 23

7. Installation 25

7.1 Wall Mounting 25

7.2 Panel Mount Version 26

7.3 Removing the Front Panel 27

7.4 The Main Electronics 29

7.5 Wiring 30

7.6 Terminal Designations 31

Index 32

Page 4

Page 5

Introduction 3

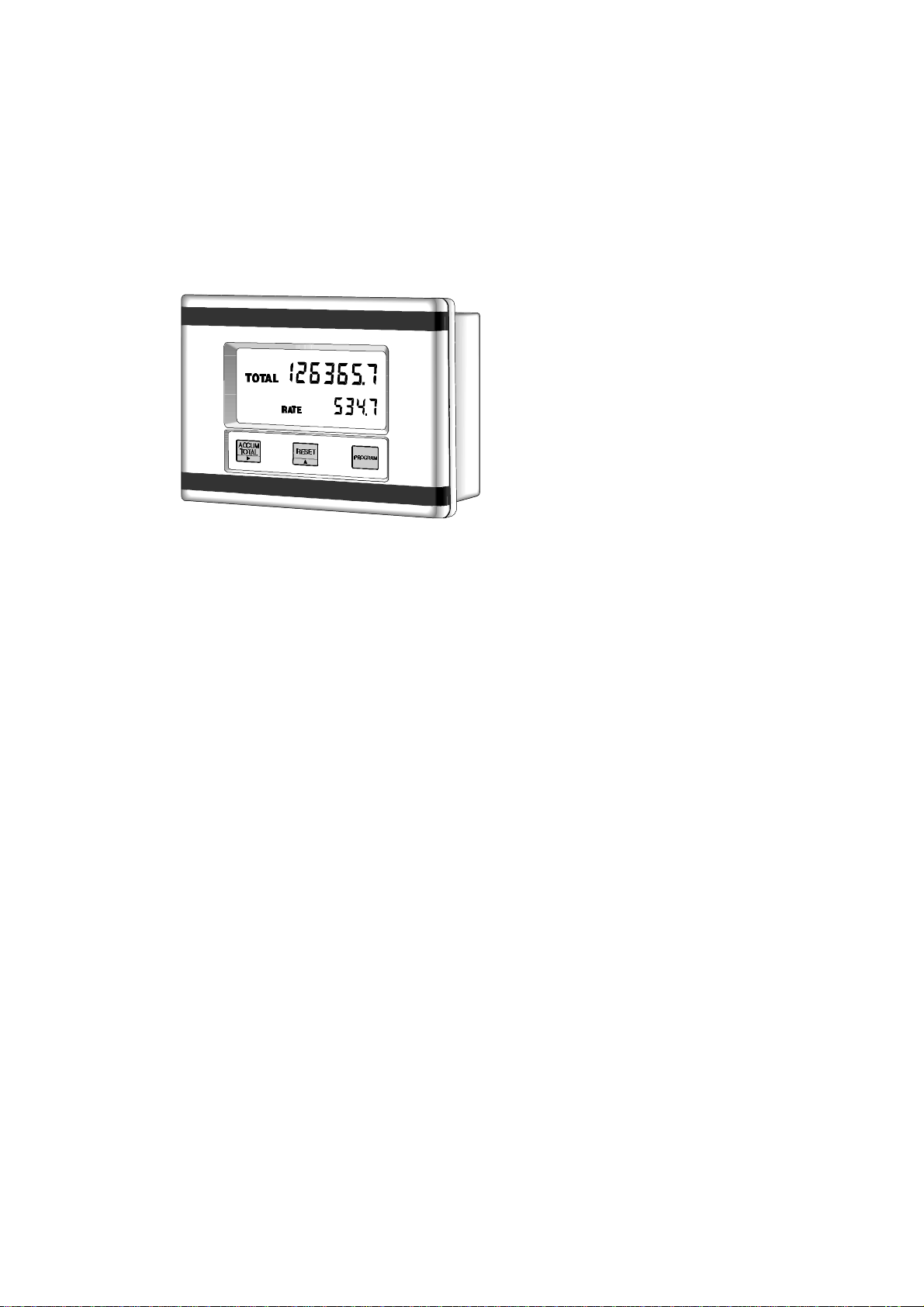

1. INTRODUCTION

The Model 202A Rate-Totaliser is a microprocessor based instrument designed to

measure a 4-20mA signal from flowmeters and pressure transducers. The

instrument can be programmed to display directly in engineering units and

includes features such as linear or square law calculation, integration and digital

filtering.

Rate, Total and Accumulated Total can be displayed in engineering units on the

large LCD display. A front panel switch selects the function for display and a

Reset button allows the Total to be reset to zero.

The instrument is fully programmable, with all calculation constants set via the

front panel switches and stored in a non-volatile memory which will retain data

indefinitely. The user can program span, filtering levels, display resolution and

cutoff point.

The instrument is powered from a 4-20mA input signal and therefore, requires

no external power.

This instrument conforms to the EMC-Directive of the Council of European

Communities 89/336/EEC and the following standards:

Generic Emission Standard EN 50081-1 Residential, Commercial & Light

Industry Environment.

Generic Emission Standard EN 50081-2 Industrial Environment.

Generic Immunity Standard EN 50082-1 Residential, Commercial & Light

Industry Environment.

Generic Immunity Standard EN 50082-2 Industrial Environment.

In order to comply with these standards, the wiring instructions in Section 7.5

must be followed.

Page 6

4 Introduction

1.1 MODEL NUMBER DESIGNATION

The Model Number of an instrument describes which input and output options

are installed.

Model 202 A. 1 0

Input Options

A for 4-20mA no options available at this

time

Mounting

1 for panel mounting

2 for field mounting

6 for pipe mounting

Page 7

Introduction 5

The Model 202A

Page 8

6 Introduction

1.2 OPERATION

The Model 202A Rate Totaliser will display:

Rate

Resettable Total

Accumulated Total.

Both the Rate and Resettable Total are continuously displayed while the

Accumulated Total is only displayed when the ACCUM TOTAL key is pressed.

The Resettable Total can be reset at any time by pressing the RESET key.

The instrument also has a test mode which can be entered by simultaneously

pressing all three front panel keys. The tests are as follows:

Lo Test By pressing the ACCUM TOTAL key, the low alarm output

will go low.

Hi Test By pressing the RESET key, the high alarm output:

a. will go low if CAL00 = 0 (high alarm output),

b. will output 100ms pulses every 0.5sec if CAL00 = 1 (scaled

pulse output).

Display Test By pressing the PROGRAM key, all segments of the display

will show.

To exit the test mode, simultaneously press all three front panel keys.

Note that when the input signal drops below 3.75mA (4-20mA input), a signal

error will occur. The display will alternate between the current total and the

word "SIGNAL". When the input signal drops below ≈3.5mA the Model 202A

shuts down saving totals in the non-volatile memory.

Page 9

Introduction 7

1.3 INTRINSIC SAFETY CONSIDERATIONS

The Model 202A is certified for use in hazardous areas and has both CENELEC

and CSA NRTL/C approvals.

The Model 202A certification details are:

CENELEC Approval: Kema 98.E.1873.

Type of Protection: Ex ia.

Group: IIB.

Temperature Class: T4 at ambient temperature of 60°C.

CSA NRTL/C Approval

File Number: LR 104 840-5.

Type: Class 1, Groups C and D.

When installing in hazardous areas, the instrument will have to be installed

according to the guidelines given in section 6 and in accordance with standards

for wiring and installation in hazardous areas.

4-20mA Input

The input can be connected to IS circuits with the following maximum

values:

Ui = 28V

Ii = 93mA

Pi = 653mW.

Relay Outputs

The outputs can be connected to IS circuits with the following maximum

values:

Ui = 28V

Ii = 93mA

Pi = 653mW.

Page 10

8 Specification

2. SPECIFICATION

General

Display: LCD, which is continuously powered.

Resettable Total: 7 digits with 10mm (0.4") high digits.

Resettable from front panel.

Accumulated Total: Displayed when the Accumulated Total button is

pressed.

Rate/Display: 5 digits with 8.5mm (0.33") high digits.

Span: The units of measure per timebase (eg. gallons/sec) is

programmable in the range 0.000001 to 999,999.

Decimal Points: Decimal Point positions are fully programmable for

both rate and total.

Timebase: Span can be programmed in units per second, minute,

hour or day.

Signal Type: 4-20mA.

4-20mA Input

Resolution and

Linearity: 0.05% of span.

Accuracy: 0.05% of span @ 25°C.

0.1% (typ) of span, full temperature range.

Update Time: 0.5 seconds.

Connection: Two wire.

Voltage Drop: 2.5 volts maximum.

Page 11

Specification 9

Outputs

Type: Two open collector outputs suitable for driving DC

solenoids or external relays. The outputs provide high

and low flow alarms or pulse output and low flow

alarm.

Switching Power: 200mA. 30VDC maximum.

Saturation Voltage: 0.8VDC typical across the output in the "on" state.

Isolation: Both outputs are separately opto-isolated.

Pulse Duration: If CAL00 = 1 (scaled pulse output):

(for pulse output) a. 1ms if output frequency > 50Hz,

b. 10ms if output frequency is 5 ... 50Hz,

c. 100ms if output frequency is < 5Hz.

Physical

Temperature: Operating Temperature: -20°C to 60°C.

Dimensions: 97mm (3.8") high x 150mm (5.9") wide x 41mm

(1.6") deep (cable glands not included).

Protection: Sealed to Nema 4x or IP67 standards.

Cable Entry: By cable glands.

Wall Mounting: Universal Mounting Bracket supplied as standard.

Pipe Mounting: A galvanised metal bracket is available which enables

the Model 202A to be attached to a 2" vertical or

horizontal pipe.

Panel Mounting: Supplied with mounting brackets.

Terminals accessible from rear (Note that the panel

mount version is not watertight).

Cutout: 141mm (5.6") wide x 87mm (3.4") high.

Page 12

10 Programming

3. PROGRAMMING

The Model 202A is fully programmable, with all parameters being stored in

non-volatile memory.

The Program Mode can be entered in the following way:

By removing the lower cover strip (ie. the dark grey strip along the

bottom of the enclosure) and replacing it the wrong side up. This brings

a small magnet on the inside of the cover strip in contact with a reed

switch inside the instrument.

The PROGRAM switch is used to step through the program (CAL sequences)

and the and keys on the front panel are used to change and increment the

flashing digits.

The CAL number is displayed on the lower display and the parameter is

displayed on the upper display.

Page 13

3.1 PROGRAM STEPS

Step Comment

Programming 11

CAL 00

CAL 01

CAL 02

CAL 03

CAL 04

Pulse Output

0 = No pulse output, low and high alarms

1 = Scaled pulse output and low alarm

Span - whole numbers.

Span - digits after the decimal point.

The Span is the number of units of measure per

timebase (eg. litres/sec, Gal/min). The Span can be

programmed in the range of 0.000001 - 999,999.

See section 3.2.

Cutoff Point.

This determines the cutoff point as a fraction of Span.

See section 3.2.2.

Decimal Point for Rate Display.

The flowrate can be displayed with 0, 1, 2 or 3 decimal

point places.

CAL 05

Timebase for Rate.

The Rate can be displayed in units per second, minute,

hour or day.

0 = second

See section 3.2.

1 = minute

2 = hour

3 = day.

Page 14

12 Programming

Step Comment

CAL 06

CAL 07

CAL 08

CAL 09

Filter.

Fluctuations in the flowrate can be filtered out so that

the Rate is held steady. The filter value is programmed

between 1 - 99 where "1" represents no filtering and 99

is maximum.

See section 3.4.

Decimal Point for Total Display.

The totals can be displayed with 0, 1, 2 or 3 decimal

points.

Total Conversion Factor - whole numbers.

Total Conversion Factor - digits after the decimal point.

The Total Conversion Factor enables the Rate to be

displayed in one engineering unit and the Totals to be

displayed in another engineering unit. The Total

Conversion Factor can be programmed in the range of

0.000001 - 999,999.

Set to 1.000 if totals and rate are in the same unit eg.

litres.

See section 3.3.

CAL 10

Low Alarm - whole numbers.

Page 15

Step Comment

Programming 13

CAL 11

CAL 12

CAL 13

CAL 14

Low Alarm - digits after the decimal point.

CAL 10 & 11 program the flowrate below which the

low alarm relay will close. The value can be

programmed in the range 0 to 999,999.

High Alarm or Pulse Output Factor - whole numbers.

High Alarm or Pulse Output Factor - digits after the

decimal point.

CAL 12 & 13 program the flowrate above which the

high alarm relay will close. The value can be

programmed in the range 0 to 999,999.

If the pulse output is selected (see CAL 00), the value will

represent the total per pulse. eg. 5 litres per pulse.

Input Flow Relationship.

0 = Linear Input

1 = Square Root Input.

CAL 15

SOFT

Accumulated Total Reset.

CAL 15 displays the accumulated total which can be

reset by pressing and holding the RESET key for about

5 seconds.

Software Version.

Page 16

14 Programming

3.2 CALCULATION OF RATE AND TOTAL

3.2.1 Analog Input

The flowrate, R, is calculated as follows:

R = SA if the linear relationship is selected

or R = S if a square law relationship is selected.A

where A = the input value.

S = the span.

At the minimum input (ie. 4mA), A = 0, and at the maximum input (ie. 20mA),

A = 1.

The Span, S, can be set during calibration anywhere in the range of 0.000001 to

999,999.

The Span, S, is programmed in units of volume per timebase (ie. litres/minute or

kilograms/hour). This also means that the Total will be displayed with the same

unit of volume, ie. litres or kilograms.

Page 17

Programming 15

3.2.2 The Cutoff Point

Because many transducers do not always exactly transmit 4mA when they are at

zero rate, it is often necessary to define a rate below which no integration takes

place. This is termed the cutoff point and is programmed as a percentage of the

Span, S.

For example, if S = 2200 kg/min in a square law system, and the cutoff point is

set at 20.0%, the actual cutoff rate Rc can be determined as follows:

The cutoff rate is defined as:

Rc = 2200 A

At 20% cutoff,

Rc = 2200 x 0.2

= 440 kg/min

The value of A which would produce this cutoff is:

A = 0.04 (since = 0.2)0.04

and the input signal would be:

I = 16mA x 0.04 + 4mA

= 4.64mA

Page 18

16 Programming

3.3 TOTAL CONVERSION

The Total Conversion feature enables the rate to be displayed in one engineering

unit (eg. gallons/minute) and the totals to be displayed in another engineering

unit (eg. barrels).

The Span is always programmed in the unit relating to Rate, and the Total

Conversion constant is a division factor which can be used to convert the totals to

the different unit. The Total Conversion factor affects the resettable and

accumulated totals.

For Example.

If the Rate is required in gallons per minute:

1. The Span would be programmed as gallons per minute

2. The timebase would be programmed as minutes

If the Totals are required in barrels:

3. The Total Conversion factor is programmed as 42 (there are 42

gallons in a barrel). All totals will now totalise in barrels.

Some common units are given below together with the Total Conversion constant

which should be programmed.

Rate* Totals TOTCON

Gallons (US)/ Barrels (oil) 42.000

Litres/ Kilolitres 1000

ml/ Litres 1000

Mgallons/ Acre-feet 0.32587

* Units per second, minute, hour or day. The timebase is programmed

separately during Programming.

Page 19

Programming 17

3.4 FILTERING

Frequency fluctuations caused by pulsating flow through a flowmeter, often

makes the Rate impossible to read with any precision.

The Model 202A has a digital filter which will average out these fluctuations and

enable the Rate to be read to four digit accuracy. The ability to select a suitable

filtering level means that highly accurate and stable readings can be obtained

without excessive lag.

The diagram below shows a pulsating signal input together with the effect of

filtering.

Rate

Filtered Response

Unfiltered Response

Time

As a guideline to the degree of filtering to be used, the following table shows the

response to a step change in input. The value, CAL 06, is the filter constant

which is programmed during the Programming routine. The times for the

display value to reach 90% and 99% of full swing are given in seconds, for

different values of CAL 06.

Page 20

18 Programming

A 90% 99%

1 0 0

2 1 2

4 2 4

6 3 6

10 5 11

15 8 17

20 11 22

25 14 28

35 20 40

45 25 51

60 34 69

75 43 86

90 52 103

99 57 113

Table 1 - Response to a step Input (in seconds).

Note that if CAL 06 is set to 01 there is no filtering of the input signal.

Page 21

Programming 19

3.5 EXAMPLE

A vortex flowmeter has a maximum output of 20.538 litres/min at 20mA. It is

required to display the flowrate in litres/min with 1 decimal point and the total in

litres with no decimals. High and low alarms are required at 18 l/m and 2 l/m

respectively. The instrument is then programmed as follows.

CAL00 0 No Pulse Output

CAL01 00020 Span (Whole Numbers)

CAL02 5380 Span (Decimals)

03 0.05 Cutoff Point as a fraction of Span

04 1 Rate decimal position

05 1 Timebase

06 01 Filter disabled

07 0 Total decimal position

08 0001 Total Conversion (set to 1.0000)

09 0000 Total Conversion (decimals)

10 00002 Low Alarm

11 0000 Low Alarm

12 00018 High Alarm

13 0000 High Alarm

14 0 Linear Input

15 xxxx Accumulated Totals

SOFT 202A1.11 Software Version

Page 22

20 Signal Input

4. SIGNAL INPUT

The signal input is on terminals 3 and 4 and can be connected as follows:

Page 23

Alarm & Pulse Outputs 21

5. ALARM & PULSE

OUTPUTS

Open collector outputs are provided for high and low flowrate alarms. The

output can sink up to 200mA and can be used to power external relays, lights or

audible alarms. The outputs are internally protected against voltage spikes

caused by relays and coils.

Both outputs are separately isolated via opto isolators.

As an alternative to a high flowrate alarm, the output on terminals 7 and 8 can be

programmed to output a scaled pulse output.

The switching points can be programmed during the setup mode and the low

flow alarm will switch on whenever the flowrate drops below the programmed

flowrate. Similarly, the high alarm switches on whenever the flow exceeds the

high setpoint.

If a Scaled Pulse Output is programmed, a pulse will be output every preset value

of the total. For example, if the total is in litres, then programming 5 will output

one pulse every 5 litres. The duration of pulses is adjusted automatically to the

output frequency.

Specification for Alarm Outputs

Maximum Current (sink): 200mA.

Maximum Voltage: 30VDC.

Saturation Voltage: 0.8VDC across Outputs when in the "on"

state.

Isolation: Both outputs are separately isolated.

Pulse Frequency: 500Hz maximum.

Pulse Duration: 1ms if output frequency > 50Hz.

10ms if output frequency = 5 ... 50Hz.

100ms if output frequency < 5Hz.

Page 24

22 Alarm & Pulse Outputs

Connections

Page 25

Intrinsic Safety Connections 23

6. INTRINSIC SAFETY

CONNECTIONS

When installing the Model 202A in hazardous areas, the wiring and installation

must comply with appropriate installation standards.

The approval uses entity parameters and an associated apparatus type approval

on the input/output connections to the 4-20mA current loop and alarms. The

4-20mA input and alarm outputs must, therefore, only be connected as shown on

the following page, to barriers with the specified parameters.

The Model 202A will connect directly to a 4-20mA current loop and alarms,

provided they do not exceed the following input parameters:

Ui = 28V

Ii = 93mA

Pi = 653mW

The internal capacitance seen on the input (terminals 3 & 4) is 0.02uF while the

internal capacitance seen on the output (terminals 5-8) is 0.1uF maximum.

Inductance is negligibly small on both the input and output.

Outputs

The two open collector outputs must only be connected to certified IS equipment

via barriers as shown on the following page. Only certified intrinsically safe

solenoids may be used for IS applications.

Page 26

24 Intrinsic Safety Connections

Page 27

Installation 25

7. INSTALLATION

7.1 WALL MOUNTING

A wall mounting bracket is supplied with each instrument. The bracket should

be attached to the wall using round head screws (do not use counter sunk screws).

The bracket is mounted with the "tray" section at the bottom. The instrument is

then attached to the bracket at the bottom with two screws (see diagram below).

Page 28

26 Installation

7.2 PANEL MOUNT VERSION

The panel mount version of the Model 202A is supplied with two panel mount

brackets and plug-in terminals which are accessible from the rear of the

instrument.

A diagram of the rear panel is shown below.

The cutout for the panel mount version is 141mm (5.55") wide x 87mm (3.43")

high.

Page 29

Installation 27

7.3 REMOVING THE FRONT PANEL

The front of the instrument is removed as follows:

1. Remove both the top and bottom cover strips (ie. the dark plastic strips on

the front) by levering a screwdriver under one end.

2. Undo the seven screws retaining the front. Note that the screws should

not be removed from the front panel as they are retained by O-rings.

3. Pull the front panel free from the housing.

Replacing the front panel of the instrument is the reverse procedure. However,

ensure that the front panel is aligned at both connector points before tightening

the screws.

Page 30

28 Installation

Page 31

Installation 29

7.4 THE MAIN ELECTRONICS

The front section of the housing contains the microprocessor and display.

It is also possible to adjust the display contrast via a small potentiometer on the

board. The DISPLAY CONTRAST control is shown below and this can be

adjusted for optimum contrast.

Adjacent to this control is a RESET switch which can be used to reset the

microprocessor. Note that pressing this button will Set all totals to zero and

calibration parameters to default values.

The Main Electronics

Page 32

30 Installation

7.5 WIRING

When connecting the Model 202A, it is goods practice to use shielded cable.

In order to comply with the requirements for Electromagnetic Compatibility, as

per EMC-Directive 89/336/EEC of the Council of the European Community, this

wiring practice is mandatory.

Page 33

7.6 TERMINAL DESIGNATIONS

4-20mA Input

3 4-20mA (-)

4 4-20mA (+)

Outputs

5 Low Alarm (-)

6 Low Alarm (+)

7 High Alarm (-) or Pulse Output (-)

8 High Alarm (+) or Pulse Output (+)

Installation 31

Page 34

32 Index

Index

A

Accumulated Total, 6

C

CAL Sequences, 10

Cutoff Point, 11

D

Decimal Point, 11

Display, 8

Display Test, 6

F

Filtering, 17

H

Hi Test, 6

High Alarm, 13

I

Installation, 25

Intrinsic Safety, 7

L

Lo Test, 6

Low Alarm, 12

O

Operating

Temperature, 9

Operation, 6

P

Panel Mount, 26

Programming, 10

Protection, 9

Pulsating Signal, 17

Pulse Output, 21

R

Rate, 6

Removing the Front

Panel, 27

Resettable Total, 6

Response, 18

S

Span, 11

Specification, 8

T

Temperature, 9

Terminal

Designations, 31

Test Mode, 6

Timebase, 11

Total Conversion, 16

M

Model Number, 4

W

Wall Mounting, 25

Loading...

Loading...