Yellow Jacket 40812 Operating Manual

YELLOW JACKET

Refrigeration System Analyzer

Users Manual

UPC# 40812, 40813 and 40815

(Versions 1.06 and higher)

Note: These instructions do not cover the manifold

attached to the instrument.

®

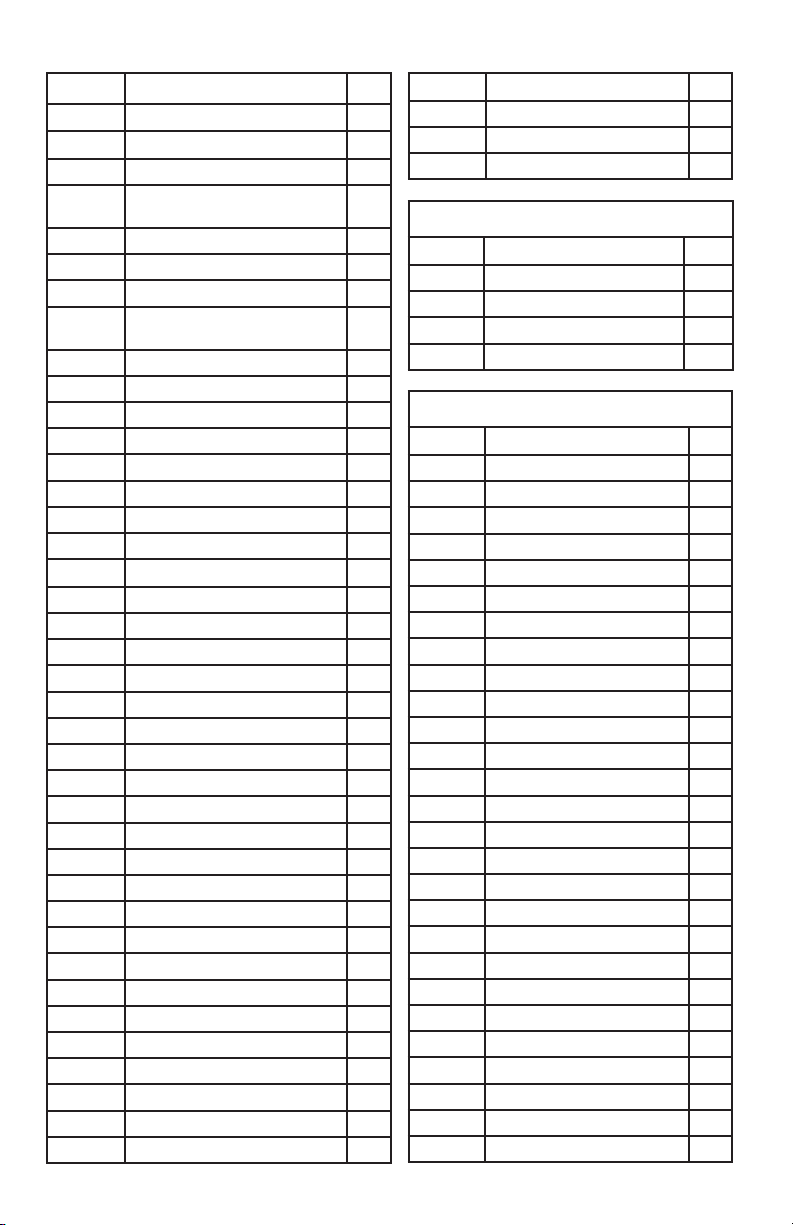

Table of Contents

Chapter Title Pg.

1 Before You Start

Contact and Safety Information

2 Getting Acquainted

Turning the Instrument On

and Off

Battery Considerations

Keyboard Keys

Understanding the Displays

Using the Temperature and

Vacuum Sensors

3 Getting the Job Done

Temperature and Pressure Mode

Vacuum Mode

Vacuum Sensor Calibration

4 Data Logging

Begin Logging

Playback and USB Functionality

Erase Files

5 Settings

Refrigerant Type

Temperature Unit

Elevation

Auto Vacuum Gauge

Power Saving Mode

Auto Power Off

Battery Type

Graph Type

Time Format

Time and Date

Refrigerant Favorites

Zero Pressure

Exiting the Set-Up Display

Settings Shortcut

6 Maintenance

General Maintenance

Replacing the Batteries

Spare Parts

Software Updates

Further Assistance

7 Specications

Safety

2

Chapter Title Pg.

3

3

4

4

Features and Specications 15

Instrumentation Specications 16

Warranty Policy

List of Tables

4

5

6

7

7

7

9

10

10

10

11

11

11

11

12

12

12

12

12

12

12

12

12

12

13

13

13

13

13

14

14

14

15

15

15

Table Title Pg.

1-1 Safety Information

1-2 Symbols

2-1 Key Functions

6-1 Spare Parts

List of Figures

Table Title Pg.

2-1 Menu Display

2-2 Battery Power Symbol

2-3 Low Battery Pop-up Message

2-4 Menu Display

2-5 System Analyzer Display

2-6 P/T Chart Display

2-7 Vacuum Gauge Display

2-8 Data Logging Start-up Display

2-9 Set-Up Display

2-10 Sensor Connections

2-11 Sensors without Boots

2-12 Sensors with Boots

3-1 First System Analyzer Display

3-2 2nd System Analyzer Display

3-3 3rd System Analyzer Display

3-4 Vacuum Gauge Display

3-5 Sensor Calibration Number

4-1 Data Logging Menu

4-2 Data Logging Start-Up Screen

4-3 Data Log Files

5-1 (a, b) Set-up Displays

5-2 Time & Date Setting Screen

5-3 Refrigerant Favorites Set-up

5-4 Refrigerant Favorites Screen

5-5 Settings Shortcut

5-6 Battery Access

5-7 Battery Servicing

16

3

4

5

14

4

5

5

6

6

6

6

6

6

7

7

7

8

8

9

9

10

10

10

11

11

12

12

13

13

14

14

Chapter 1

Before You Start

Contacting Ritchie

To order accessories, receive assistance, or

locate the nearest YELLOW JACKET distributor.

Corporate Ofce and Mailing Address:

Ritchie Engineering Co, Inc.

YELLOW JACKET Products Division

10950 Hampshire Avenue South

Bloomington, MN 55438-2623 U.S.A.

Phone: (952) 943-1300 or (800) 769-8370

Fax: (800) 769-8370

E-mail: custserv@yellowjacket.com

www.yellowjacket.com

Safety Information

Use the instrument only as specied in this

manual. Otherwise, the protection provided by

the instrument may be impaired. Refer to safety

information in Table 1-1.

A Warning identies conditions and actions that

pose hazards to the user. A Caution identies

conditions and actions that may damage the

instrument or the equipment under test.

Table 1-1. Safety Information

Warning

To avoid personal injury or death, follow these

guidelines:

●

Most governments and legal authorities require that HVAC technicians be trained and

certied in the safe and proper operation of

HVAC tools, such as this instrument. Since

this tool may be connected to many types of

equipment through a limitless combination

of hoses and ttings, proper training is the

most important element of using this tool

safely.

●

Read the entire Users Manual before using

the instrument.

●

Use the instrument only as described in the

Users Manual, otherwise the protection provided by the equipment may be impaired.

Do not use the instrument if it is damaged.

●

Before you use the instrument, inspect the

case. Look for cracks or loose components.

Table 1-1. Safety Information

Warning

●

The instrument contains no internal userserviceable parts other than batteries that

may be accessed through the battery door.

Do not open the instrument other than opening the battery door. Have the instrument

serviced only by Ritchie Engineering Co. or

authorized service centers.

●

Do not use the instrument if it operates abnormally. Protection may be impaired. When

in doubt, have the instrument serviced.

●

Refer to warnings supplied with batteries

acquired for use in this instrument. If the batteries are not supplied with warnings, obtain

them from the manufacturer or supplier.

Do not operate the instrument or service bat-

●

teries around explosive gas, vapor, or dust.

●

Various refrigerants have been intentionally

excluded for very signicant safety reasons.

Never use refrigerants in this instrument that

are not listed in the Set-up menu.

●

The refrigerant database in this unit may

include refrigerants classied as ammable.

If such refrigerants are selected, the operator

may need additional certications and/or

training. Consult your government and legal

authority and comply fully with all requirements.

●

Always wear eye and skin protection when

working with refrigerants. Escaping refrigerant vapors will present a freezing danger.

Do not direct refrigerant vapors venting from

hoses towards the skin.

Maximum Working Pressure: High Side: 700

●

psia (4.83 MPa)

Maximum Working Pressure: Low Side: 350

●

psia (2.41 MPa)

●

Because this instrument allows for various

inputs including electrical and mechanical,

care must be taken to observe any ways that

an electrical shock hazard could develop.

Example: Wet or humid conditions, along

with a damaged thermocouple or vacuum

sensor, could allow an electrical path across

the instrument and over wet hoses. Keep all

interconnected equipment clean, organized,

and in proper condition. Do not use the in-

strument if you are not qualied to recognize

potential electrical faults.

cont. next page.......

3

Table 1-1. Safety Information

Caution

To avoid damage to equipment, follow these

guidelines:

Do not allow pressures beyond the speci-

●

cations listed in this manual.

●

Be aware that internal pressures can

change unintentionally when equipment is

stored with pressure in the system during

temperature changes. If sub-cooled liquid

refrigerant is trapped in a hose or manifold

with no room for expansion, it may result in

dramatic pressure variations with seemingly

small temperature changes. Pressures can

reach high enough levels to cause damage to the instrument’s internal pressure

transducers. Release liquid refrigerant from

the hoses and manifold when disconnecting

from a system.

Refer to cautions supplied with batteries

●

acquired for use in this instrument.

Do not attempt to introduce liquid or

●

samples heavily laden with oil into the

instrument.

●

Read and observe instructions and speci-

cations related to the batteries used in this

instrument that may cause damage to it.

Do not use this instrument on systems

●

containing leak sealing chemicals. These

leak sealants can collect and harden in the

instrument, causing permanent damage.

Chapter 2

Getting Acquainted

Introduction

This instrument will clearly and accurately report

critical information needed to properly service refrigeration and air-conditioning equipment. With its

many features, time can be saved and the quality

of service can be veried through data reports for

customer satisfaction. Some of the most signi-

cant features include:

●

High accuracy and resolution

●

Very fast and sensitive leak detection

●

Robust temperature compensation with fault

detection

●

Data logging and downloading for reporting and

analysis

●

High durability and weather-resistance

Note that these instructions do not cover the

manifold attached to the instrument.

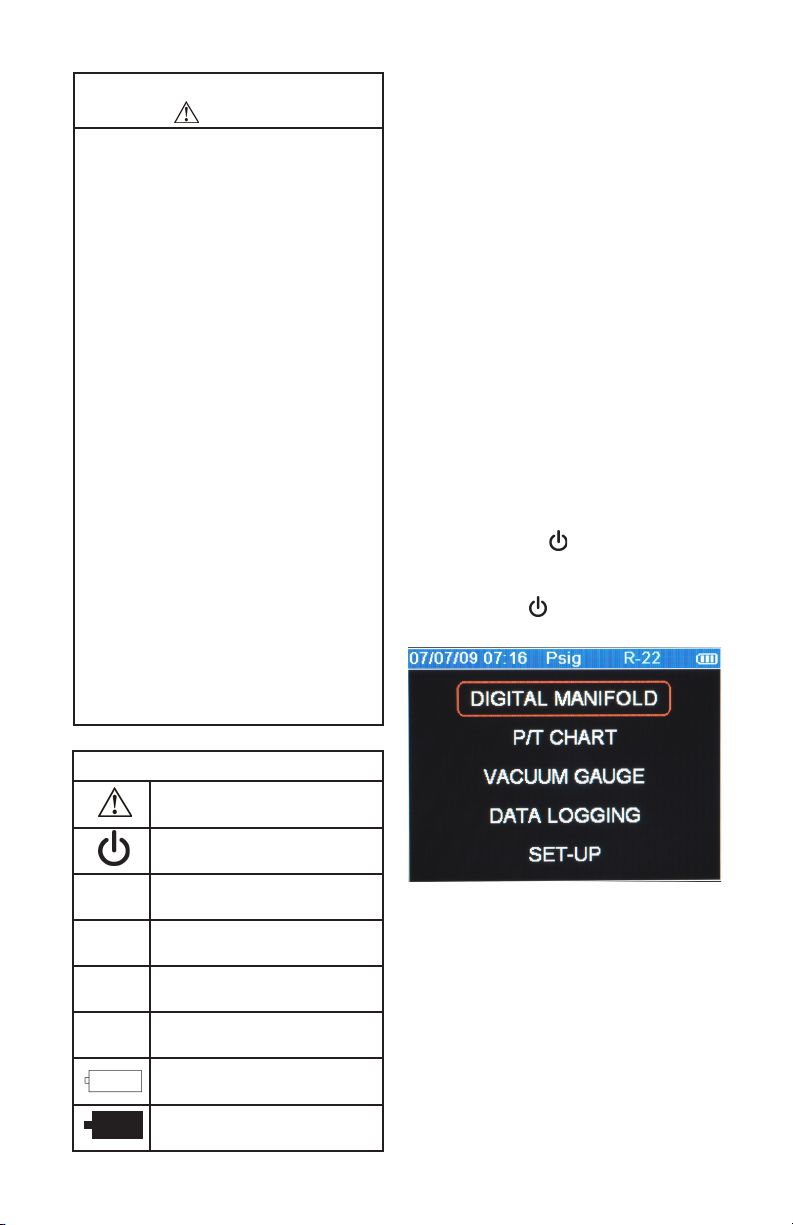

Turning the Instrument On

and Off

Press and release the key to turn unit on. After

the logo appears briey, the instrument will present the main menu.

Press and hold the key (~two seconds) to turn

unit off.

4

T1

T2

REC

||><||

Table 1-2 Symbols

Important information

Power On/Off

Temperature 1

Temperature 2

Indicates that the instrument is

recording readings (data logging)

Indicates page-by-page scrolling

mode (during data log playback)

Battery

Battery connector orientation

Figure 2-1. Menu Display

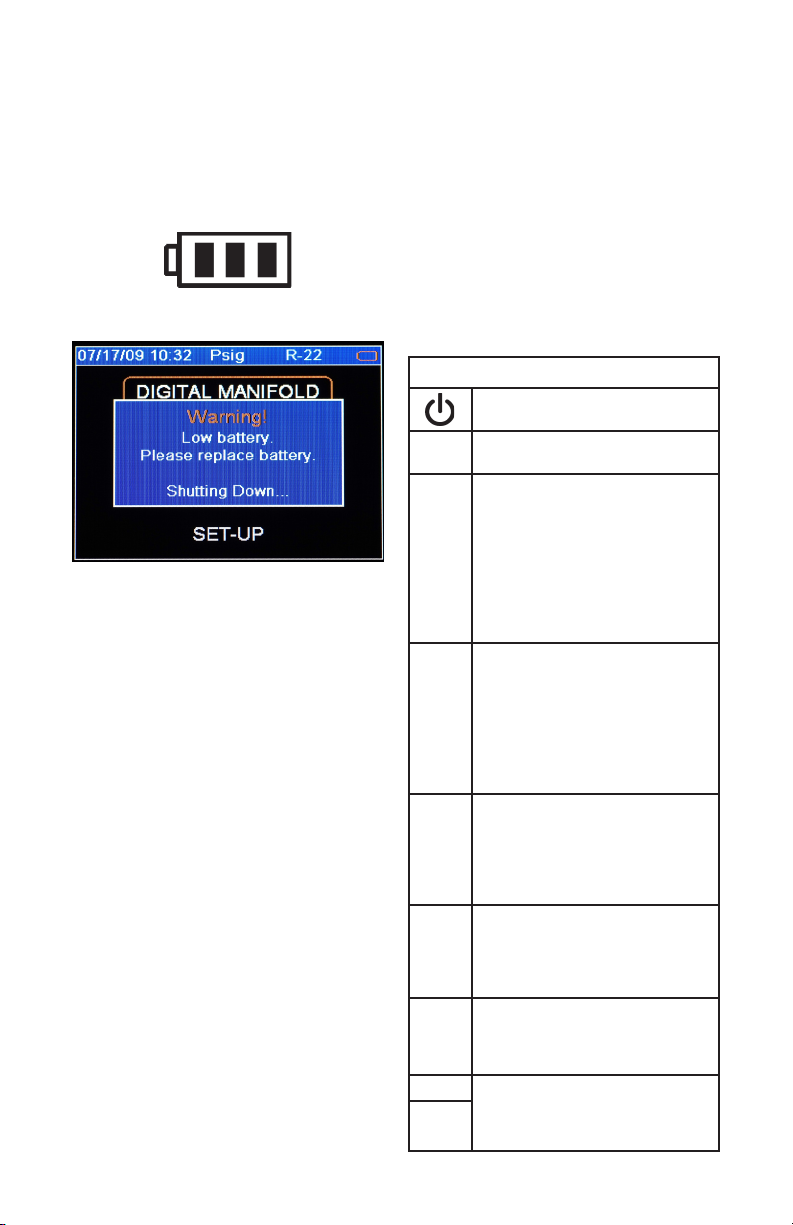

Battery Considerations

The instrument uses eight AA batteries. The

user may select batteries of the following types:

Alkaline, AA-Lithium, Ni-MH, Ni-Cd, Li-Pol, Li-Ion

from the Setup menu (see Chapter 5). Do not mix

battery types, including rating (i.e., do not mix four

Ni-MH rated at 1600mAh with four Ni-MH rated

at 1800mAh). Also, each battery in a set of eight

must be at the same power state, preferably fully

charged. The battery life indicator is only accurate

when the correct battery type is selected in the

SET-UP menu.

The illustration below shows three bars that indicate a fresh or well-charged battery pack. When

the battery weakens, the bars will disappear oneby-one as the battery power decays. When one

bar remains, the symbol will turn yellow. When all

bars are gone, the batteries are nearly dead and

the symbol will turn red. The unit will briey show

a pop-up message just before the unit stores all

data and then automatically shuts off.

Figure 2-2. Battery Power Symbol

Figure 2-3. Low Battery Pop-Up Message

Automatic Power Off

The instrument may automatically turn off after

a period of time. The default is one hour. The

user may select other settings from ten minutes

to four hours from the Setup menu (see Chapter

5). The user may also disable this feature. The

Auto Power Off time limit is automatically disabled

during data logging and is automatically restored

once data logging has terminated.

Power Saving Mode

The display backlight will fade, darkening the

display to save battery life if a key has not been

pressed for a set period of time. While in Power

Saving Mode, pressing any key turns the display

backlight back to full brightness. Note that

backlighting is independent from the display

brightness and contrast settings (see Chapter 5)

which do not affect battery life.

The Power Saving Mode is preset to 10 minutes.

From the Setup menu (see Chapter 5), you can

specify settings from 30 seconds to 60 minutes.

Low Battery Conditions

The unit will attempt to store all logged data if

low battery power is detected. Once the data is

stored, unit will turn off.

Maximizing Battery Life

Battery life decays fastest when the DIGITAL

MANIFOLD display is selected, the vacuum sensor is attached, and the backlight is on. Battery

life during data logging is maximized by using

high-performance batteries, detaching the vacuum

sensor (if not in use), and a short Power Saving

Mode time setting is selected.

Keyboard Keys

Note that pressing a key that has not been

assigned to a function will result in three, short

beeps.

Table 2-1. Key Functions

Power On/Off (see Chapter 2, Turning the Instrument On and Off).

Menu Accesses menu of instrument

functions.

Enter Accepts selected functions and

values.

This key will also toggle the instrument data display modes. See

Chapter 3.

During playback of logged data,

toggles between point-by-point and

page-by-page scrolling.

Clear A single press clears the chart set

point. (See Figure 3-1, item 11)

Press and hold to clear ‘Min.’ and

‘Max.’ values. (See Figure 3-1,

item 5)

Resets vacuum timer to 0:00:00.

(See Chapter 3)

Hold Freezes the data display at the

moment the key is depressed when

data is being displayed. A second

key press will return the display to

the normal, dynamic mode (not accessible during data logging).

Chart

Toggles time resolution to display

Time

more or less of the data acquisition

event, enhancing a user’s ability to

see signicant events (not accessible

during data logging).

Chart

Toggles pressure resolution to t

Pres-

analog pressure data within the

sure

display, enhancing a user’s ability to

see signicant events.

Up/Left Assists in selection of values and

data points depending on the func-

Down/

tion feature involved (not accessible

Right

during data logging).

5

Loading...

Loading...