Page 1

YASKAWA AC Drive V1000

Compact Vector Control Drive

Quick Start Guide

Type: CIMR-VA , CIMR-VT

Models:

To properly use the product, read this manual thoroughly

and retain for easy reference, inspection, and maintenance.

Ensure the end user receives this manual.

200 V Class, Three-Phase Input: 0.1 to 18.5 kW

200 V Class, Single-Phase Input: 0.1 to 3.7 kW

400 V Class, Three-Phase Input: 0.2 to 18.5 kW

Start-Up Programming

Receiving

Mechanical

Installation

Electrical

Installation

& Operation

1

2

3

4

MANUAL NO. TOEP C710606 12B

Troubleshooting

Specifications

Parameter List

Standards

Compliance

5

6

7

8

Page 2

2 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 3

Table of

Contents

i. PREFACE & GENERAL SAFETY .................................. 7

i.1 Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Applicable Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

i.2 General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supplemental Safety Information . . . . . . . . . . . . . . . . . . . . .9

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Label Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1. RECEIVING ................................................................... 15

1.1 Model Number and Nameplate Check . . . . . . . . . 16

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2. MECHANICAL INSTALLATION ................................... 19

2.1 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . 20

Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Installation Orientation and Spacing . . . . . . . . . . . . . . . . . .21

Exterior and Mounting Dimensions . . . . . . . . . . . . . . . . . . .23

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 3

Page 4

3. ELECTRICAL INSTALLATION..................................... 29

3.1 Standard Connection Diagram . . . . . . . . . . . . . . . 30

3.2 Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . 33

Main Circuit Terminal Functions . . . . . . . . . . . . . . . . . . . . . 33

Wire Gauges and Tightening Torque . . . . . . . . . . . . . . . . . 33

Main Circuit Terminal Power Supply and Motor Wiring . . . 36

Control Circuit Terminal Block Functions . . . . . . . . . . . . . .38

Removable Terminal Block Configuration . . . . . . . . . . . . . 41

Wiring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3 I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sinking/Sourcing Mode Switch . . . . . . . . . . . . . . . . . . . . . .45

3.4 Main Frequency Reference . . . . . . . . . . . . . . . . . . 47

Terminal A2 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.5 Wiring Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4. START-UP PROGRAMMING & OPERATION ............. 51

4.1 Using the Digital LED Operator . . . . . . . . . . . . . . 52

Keys, Displays, and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . 52

LED Screen Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

LO/RE LED and RUN LED Indications . . . . . . . . . . . . . . . . 54

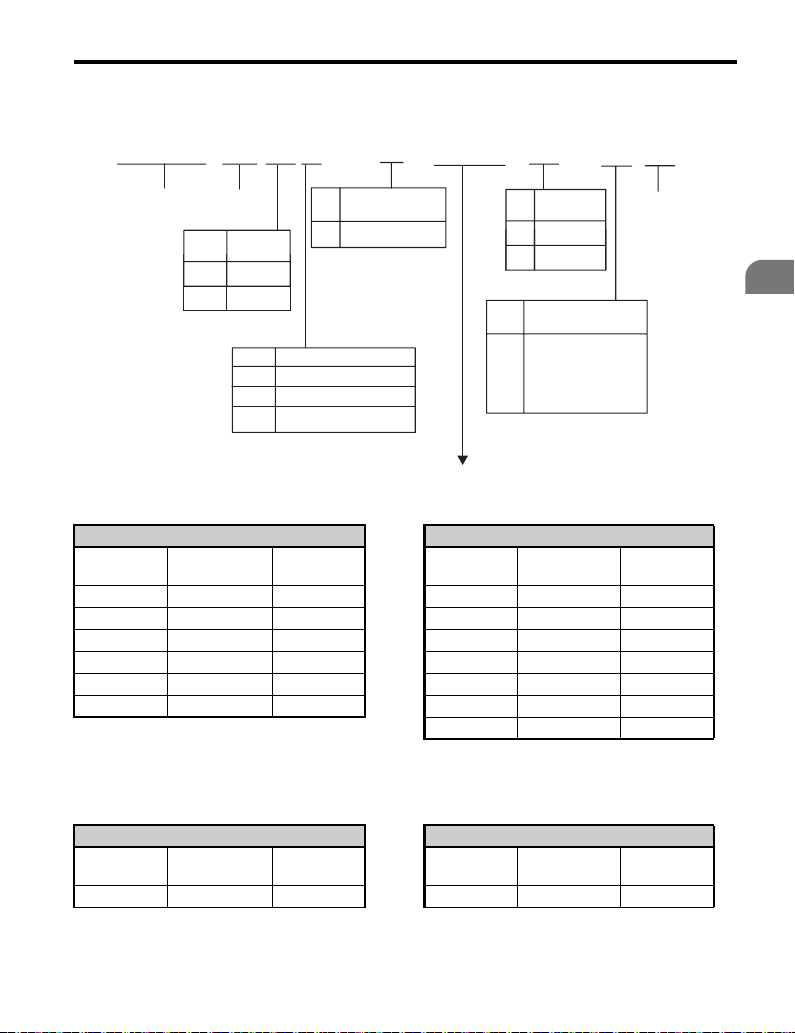

Menu Structure for Digital LED Operator . . . . . . . . . . . . . . 55

4.2 The Drive and Programming Modes . . . . . . . . . . 56

Changing Parameter Settings or Values . . . . . . . . . . . . . .56

Switching Between LOCAL and REMOTE . . . . . . . . . . . . . 57

Parameters Available in the Setup Group . . . . . . . . . . . . . 58

4.3 Start-up Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . 59

Flowchart A: Basic Start-Up and Motor Tuning . . . . . . . . . 59

Subchart A1: Simple Motor Set-Up with Energy Savings

or Speed Search using V/f Mode . . . . . . . . . . . . . . . . . . . . 61

Subchart A2: High Performance Operation Using

Open Loop Vector Motor Control . . . . . . . . . . . . . . . . . . . . 62

4 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 5

Subchart A3: Operation with Permanent Magnet Motors . 63

4.4 Application Presets . . . . . . . . . . . . . . . . . . . . . . . . 64

Application Preset Function (APPL) . . . . . . . . . . . . . . . . . 64

Application Presets: A1-06 . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5 Basic Drive Setup Adjustments. . . . . . . . . . . . . . . 66

Control Mode Selection: A1-02 . . . . . . . . . . . . . . . . . . . . . 66

Initialize Parameter Values: A1-03 . . . . . . . . . . . . . . . . . . 66

Frequency Reference Source: b1-01 . . . . . . . . . . . . . . . . 67

Run Command Input Selection: b1-02 . . . . . . . . . . . . . . . 69

Drive Duty Mode and Carrier Frequency Selection:

C6-01 and C6-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Drive Input Voltage Setting: E1-01 . . . . . . . . . . . . . . . . . . 72

4.6 Test Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Powering Up the Drive and Operation Status Display . . . 73

Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Operating with the Load Connected . . . . . . . . . . . . . . . . . 78

4.7 Test Run Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 79

5. TROUBLESHOOTING .................................................. 81

5.1 Drive Alarms, Faults, and Errors . . . . . . . . . . . . . . 82

Types of Alarms, Faults, and Errors . . . . . . . . . . . . . . . . . 82

5.2 Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fault Displays, Causes, and Possible Solutions . . . . . . . . 83

5.3 Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Alarm Codes, Causes, and Possible Solutions . . . . . . . . . 96

5.4 Operator Programming Errors. . . . . . . . . . . . . . . . 99

oPE Codes, Causes, and Possible Solutions . . . . . . . . . . 99

5.5 Auto-Tuning Fault Detection . . . . . . . . . . . . . . . . 100

Auto-Tuning Codes, Causes, and Possible Solutions . . 100

5.6 Diagnosing and Resetting Faults . . . . . . . . . . . .103

Fault Reset Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 5

Page 6

6. SPECIFICATIONS....................................................... 105

6.1 Heavy Duty and Normal Duty Ratings . . . . . . . . 106

6.2 Single/Three-Phase 200 V Class Drive. . . . . . . . 107

6.3 Three-Phase 400 V Class Drives . . . . . . . . . . . . 110

7. PARAMETER LIST ..................................................... 113

7.1 Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8. STANDARDS COMPLIANCE ..................................... 143

8.1 European Standards . . . . . . . . . . . . . . . . . . . . . . 144

CE Low Voltage Directive Compliance . . . . . . . . . . . . . . . 144

EMC Guidelines Compliance . . . . . . . . . . . . . . . . . . . . . . 146

8.2 UL Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

UL Standards Compliance . . . . . . . . . . . . . . . . . . . . . . . . 151

Drive Motor Overload Protection . . . . . . . . . . . . . . . . . . . 154

8.3 Safe Disable Input Precautions . . . . . . . . . . . . . 156

Safe Disable Function Description . . . . . . . . . . . . . . . . . .156

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

6 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 7

i

Preface &

General Safety

This section provides safety messages pertinent to this product,

that, if not heeded, may result in fatality, personal injury, or

equipment damage. Yaskawa is not responsible for the

consequences of ignoring these instructions.

I.1 PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

I.2 GENERAL SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

7

Page 8

i.1 Preface

i.1 Preface

This manual is designed to ensure correct and suitable application of variable V1000-Series

Inverters. Read this manual before attempting to install, operate, maintain, or inspect an

inverter and keep it in a safe, convenient location for future reference. Understand all

precautions and safety information before attempting application.

◆ Applicable Documentation

The following manuals are available for V1000 series drives:

V1000 Series AC Drive Installation & Start-Up Manual

Read this manual first.

This manual describes installation, wiring, operation procedures, functions,

STOP

V1000

ᵄᢙᜰ

ᱜォㅒォㆬᛯ

ജᵄᢙ

ജ㔚ᵹ

ജ㔚

ࡕ࠾࠲

ࡌࡈࠔࠗ

࠶࠻ࠕ࠶ࡊ

ࡄࡔ࠲⸳ቯ

ࠝ࠻࠴ࡘ࠾ࡦࠣ

ߌ߇㧚ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ෂޓ㒾

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ߎߣޕ

ㅢ㔚߅ࠃ߮㔚Ḯㆤᢿᓟ

ಽએౝߪࡈࡠࡦ࠻ࠞࡃࠍ

5

ᄖߐߥߎߣޕ

⚖ࠗࡦࡃ࠲ߩ႐วߪޔ㔚Ḯߩᕈὐ߇ធ

400V

ߐࠇߡࠆߎߣࠍ⏕ߔࠆߎߣޕ㧔ޓޓኻᔕ㧕

(Hz)

(Hz)

(A)

(V)

troubleshooting, maintenance, and inspections to perform before operation.

V1000 Series AC Drive Technical Manual

Read this manual for detailed information about parameter usage. Contact a

Yaskawa representative to order this manual.

V1000 Series AC Drive Quick Start Guide

This guide is packaged together with the product. It contains basic

information required to install and wire the drive. This guide provides basic

programming and simple set-up and adjustment. Refere to the V1000

Technical Manual for complete descriptions of drive features and functions.

8 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 9

i.2 General Safety

i.2 General Safety

◆ Supplemental Safety Information

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details.

Restore covers or shields before operating the drive and run the drive according to the instructions

described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and

may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa

representative or the nearest Yaskawa sales office and provide the manual number shown on the

front cover.

• If nameplate becomes worn or damaged, order a replacement from your Yaskawa representative or

the nearest Yaskawa sales office.

WARNING

Read and understand this manual before installing, operating or servicing

this drive. The drive must be installed according to this manual and local

codes.

The following conventions are used to indicate safety messages in this

manual. Failure to heed these messages could result in serious or possibly

even fatal injury or damage to the products or to related equipment and

systems.

t\

Preface & General Safety

i

DANGER

Indicates a hazardous situation, which, if not avoided, will result in

death or serious injury.

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 9

Page 10

i.2 General Safety

WARNING

Indicates a hazardous situation, which, if not avoided, could result in

death or serious injury.

WARNING! will also be indicated by a bold key word embedded in the text followed by an italicized safety

message.

CAUTION

Indicates a hazardous situation, which, if not avoided, could result in

minor or moderate injury.

CAUTION! will also be indicated by a bold key word embedded in the text followed by an italicized safety

message.

NOTICE

Indicates a property damage message.

NOTICE: will also be indicated by a bold key word embedded in the text followed by an italicized safety

message.

10 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 11

◆ Safety Messages

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment

damage resulting from failure to heed the warnings in this manual.

Do not connect or disconnect wiring while the power is on.

Failure to comply will result in death or serious injury.

Before servicing, disconnect all power to the equipment. The internal

capacitor remains charged even after the power supply is turned off. The

charge indicator LED will extinguish when the DC bus voltage is below 50

Vdc. To prevent electric shock, wait at least five minutes after all indicators

are OFF and measure the DC bus voltage level to confirm safe level.

DANGER

Electrical Shock Hazard

WARNING

t\

i.2 General Safety

Preface & General Safety

i

Sudden Movement Hazard

System may start unexpectedly upon application of power, resulting in

death or serious injury.

Clear all personnel from the drive, motor and machine area before applying

power. Secure covers, couplings, shaft keys and machine loads before

applying power to the drive.

When using DriveWorksEZ to create custom programming, the drive

I/O terminal functions change from factory settings and the drive will

not perform as outlined in this manual.

Unpredictable equipment operation may result in death or serious injury.

Take special note of custom I/O programming in the drive before

attempting to operate equipment.

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 11

Page 12

i.2 General Safety

Do not attempt to modify or alter the drive in any way not explained in

this manual.

Failure to comply could result in death or serious injury.

Yaskawa is not responsible for any modification of the product made by the

user. This product must not be modified.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only

by authorized personnel familiar with installation, adjustment and

maintenance of AC drives.

Do not remove covers or touch circuit boards while the power is on.

Failure to comply could result in death or serious injury.

Do not use an improper voltage source.

Failure to comply could result in death or serious injury by fire.

Verify that the rated voltage of the drive matches the voltage of the

incoming power supply before applying power.

WARNING

Electrical Shock Hazard

Fire Hazard

CAUTION

Crush Hazard

Do not carry the drive by the front cover.

Failure to comply may result in minor or moderate injury from the main

body of the drive falling.

12 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 13

i.2 General Safety

NOTICE

Observe proper electrostatic discharge procedures (ESD) when

handling the drive and circuit boards.

Failure to comply may result in ESD damage to the drive circuitry.

Never connect or disconnect the motor from the drive while the drive

is outputting voltage.

Improper equipment sequencing could result in damage to the drive.

Do not perform a withstand voltage test on any part of the drive.

Failure to comply could result in damage to the sensitive devices within the

drive.

Do not operate damaged equipment.

Failure to comply could result in further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing

parts.

Install adequate branch circuit short circuit protection per applicable

codes.

Failure to comply could result in damage to the drive.

The drive is suitable for circuits capable of delivering not more than 30,000

RMS symmetrical Amperes, 240 Vac maximum

(200V Class) and 480 Vac maximum (400V Class).

t\

Preface & General Safety

i

Do not expose the drive to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the

drive.

Do not pack the drive in wooden materials that have been fumigated or

sterilized.

Do not sterilize the entire package after the product is packed.

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 13

Page 14

i.2 General Safety

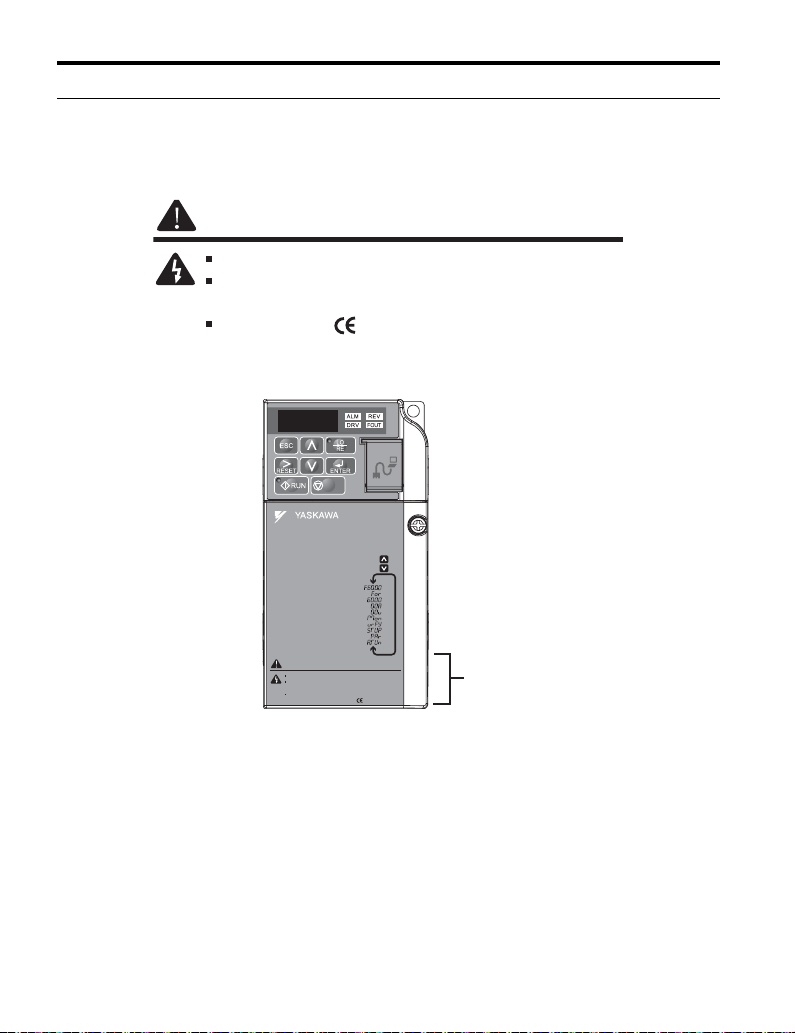

◆ Drive Label Warnings

Always heed the warning information listed in Figure i.1 in the position shown in

Figure i.2.

Figure i.1

Figure i.2

WARNING

Risk of electric shock.

Read manual before installing.

Wait 5 minutes for capacitor discharge after

disconnecting power supply.

To conform to requirements, make sure

to ground the supply neutral for 400V class.

Figure i.1 Warning Information

STOP

V1000

(Hz)

ᵄᢙᜰ

ᱜォㅒォㆬᛯ

(Hz)

ജᵄᢙ

(A)

ജ㔚ᵹ

(V)

ജ㔚

ࡕ࠾࠲

ࡌࡈࠔࠗ

࠶࠻ࠕ࠶ࡊ

ࡄࡔ࠲⸳ቯ

ࠝ࠻࠴ࡘ࠾ࡦࠣ

ߌ߇㧚ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ෂޓ㒾

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ߎߣޕ

ಽએౝߪࡈࡠࡦ࠻ࠞࡃࠍ

ㅢ㔚߅ࠃ߮㔚Ḯㆤᢿᓟ

5

ᄖߐߥߎߣޕ

⚖ࠗࡦࡃ࠲ߩ႐วߪޔ㔚Ḯߩᕈὐ߇ធ

400V

ߐࠇߡࠆߎߣࠍ⏕ߔࠆߎߣޕ㧔ޓޓኻᔕ㧕

Figure i.2 Warning Information Position

Warning

Display

14 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 15

1

Receiving

This chapter describes the proper inspections to perform after

receiving the drive and illustrates the different enclosure types

and components.

1.1 MODEL NUMBER AND NAMEPLATE CHECK. . . . . . . . . 16

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

15

Page 16

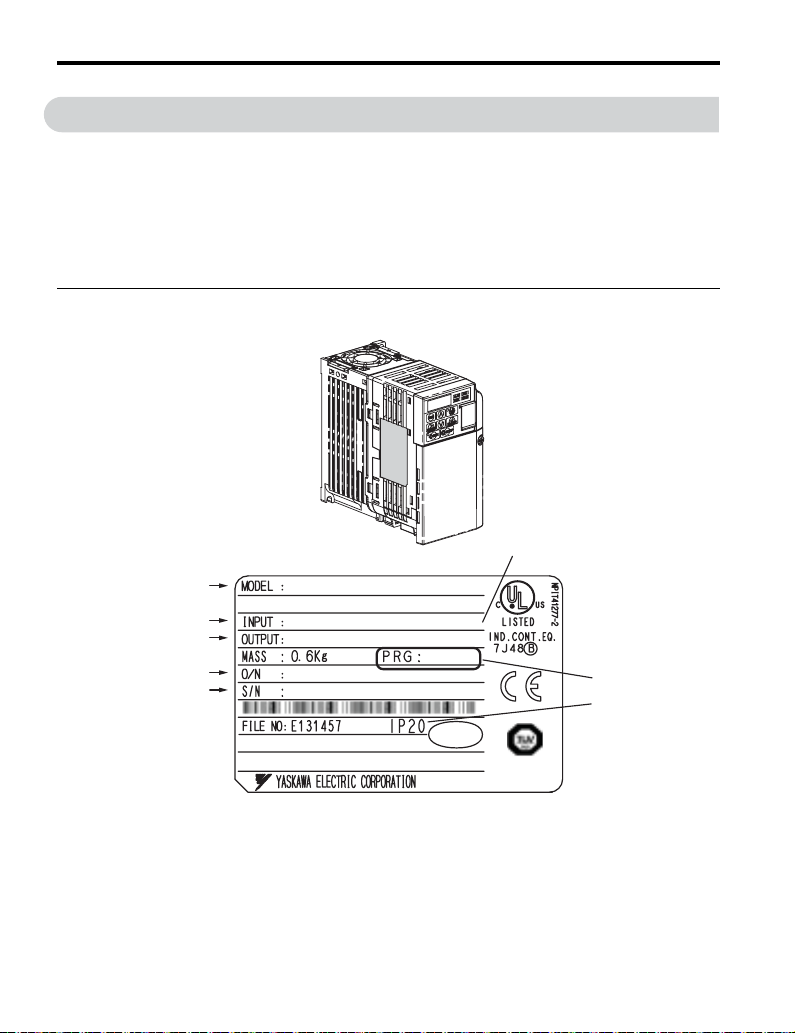

1.1 Model Number and Nameplate Check

++

RoHS

1.1 Model Number and Nameplate Check

Please perform the following tasks after receiving the drive:

• Inspect the drive for damage.

If the drive appears damaged upon receipt, contact the shipper immediately.

• Verify receipt of the correct model by checking the information on the nameplate.

• If you have received the wrong model or the drive does not function properly, contact

your supplier.

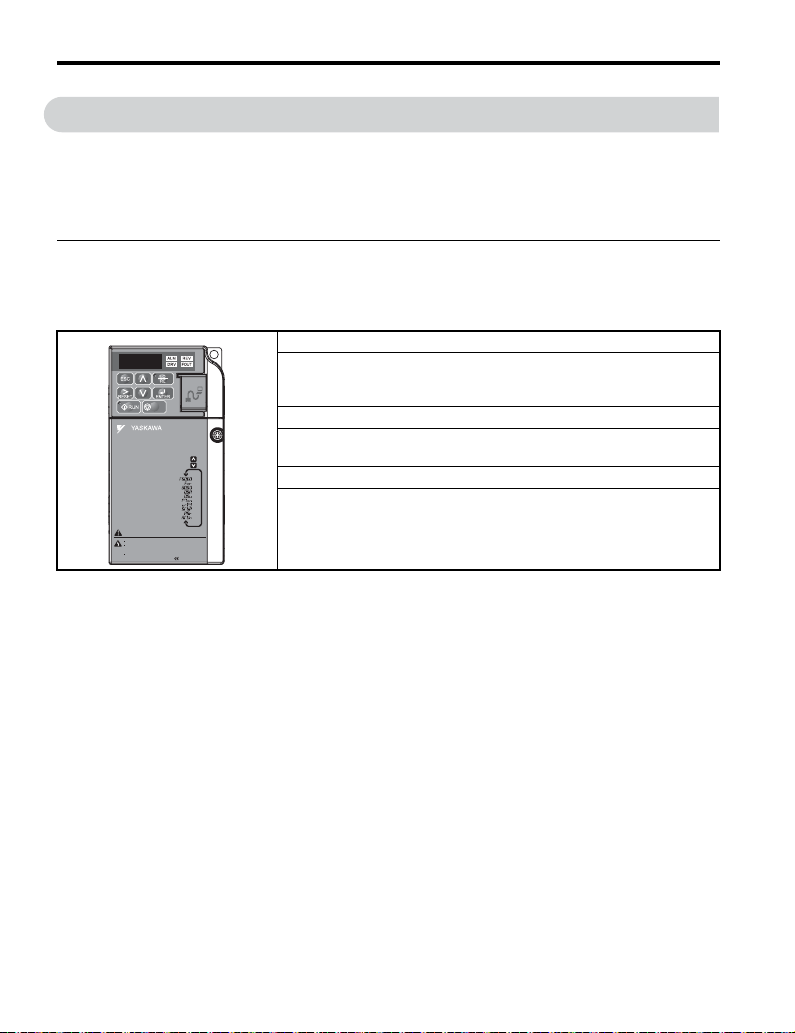

◆ Nameplate

Figure 1.1

Normal Duty Amps/Heavy Duty Amps

AC drive model

Input specifications

Output specifications

Lot number

Serial number

%+/48##$##

/#:#22.+/1614M9M94'8#

#%2*8*\

#

#%2*8*\##

Software version

Enclosure Type

+056#..#6+10%#6')14;

Figure 1.1 Nameplate Information

16 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

PA SS

++

/#&'+0,#2#0

RoHS

Page 17

1.1 Model Number and Nameplate Check

CIMR-

Drive

V

V1000

Series

Region

No.

Code

A Japan

T Asia

2

U

Customized

No.

Specifications

A Standard model

No. Voltage Class

1-phase, 200-240 Vac

B

3-phase, 200-240 Vac

2

3-phase, 380-480 Vac

4

A

0001

B

Enclosure

No.

Type

B IP20

F

NEMA1

Environmental

No.

Specification *

A

Standard

M

Humidity- and

dust-resistant

Oil-resistant

N

Vibration-resistant

S

Single-Phase 200 V

Normal Duty Heavy Duty

No.

0001 0.2 1.2 0001 0.1 0.8

0002 0.4 1.9 0002 0.2 1.6

0003 0.75 3.3 0003 0.4 3

0006 1.1 6 0006 0.75 5

0010 2.2 9.6 0010 1.5 8

0012 3.0 12

Max. Motor

Capacity kW

Rated Output

Current A

No.

0012 2.2 11

0018 3.7 17.5

Max. Motor

Capacity kW

A

Design

Revision

Order

Rated Output

Current A

A

Receiving

1

Note: CIMR-VBA0018 is available with a Heavy Duty rating only.

Three-Phase 200 V

Normal Duty Heavy Duty

No.

0001 0.2 1.2 0001 0.1 0.8

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 17

Max. Motor

Capacity kW

Rated Output

Current A

No.

Max. Motor

Capacity kW

Rated Output

Current A

Page 18

1.1 Model Number and Nameplate Check

Normal Duty Heavy Duty

0002 0.4 1.9 0002 0.2 1.6

0004 0.75 3.5 0004 0.4 3

0006 1.1 6 0006 0.75 5

0008 1.5 8.0 0008 1.1 6.9

0010 2.2 9.6 0010 1.5 8

0012 3.0 12 0012 2.2 11

0018 3.7 17.5 0018 3.0 14.0

0020 5.5 19.6 0020 3.7 17.5

0030 7.5 30 0030 5.5 25

0040 11 40 0040 7.5 33

0056 15 56 0056 11 47

0069 18.5 69 0069 15 60

Three-Phase 400 V

Normal Duty Heavy Duty

No.

0001 0.4 1.2 0001 0.2 1.2

0002 0.75 2.1 0002 0.4 1.8

0003 1.5 4.1 0003 0.75 3.4

0004 2.2 5.4 0004 1.5 4.8

0005 3.0 6.9 0005 2.2 5.5

0007 3.7 8.8 0007 3.0 7.2

0011 5.5 11.1 0011 3.7 9.2

0018 7.5 17.5 0018 5.5 14.8

0023 11 23 0023 7.5 18

0031 15 31 0031 11 24

0038 18.5 38 0038 15 31

Max. Motor

Capacity kW

Rated Output

Current A

No.

Max. Motor

Capacity kW

Rated Output

Current A

* Drives with these specifications do not guarantee complete protection for the specified

environmental condition.

18 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 19

2

Mechanical

Installation

This chapter explains how to properly mount and install the

drive.

2.1 MECHANICAL INSTALLATION. . . . . . . . . . . . . . . . . . . . . 20

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

19

Page 20

2.1 Mechanical Installation

2.1 Mechanical Installation

This section outlines specifications, procedures, and environment for proper mechanical

installation of the drive.

◆ Installation Environment

To help prolong the optimum performance life of the drive, install the drive in the proper

environment. The table below provides description of the appropriate environment for the

drive.

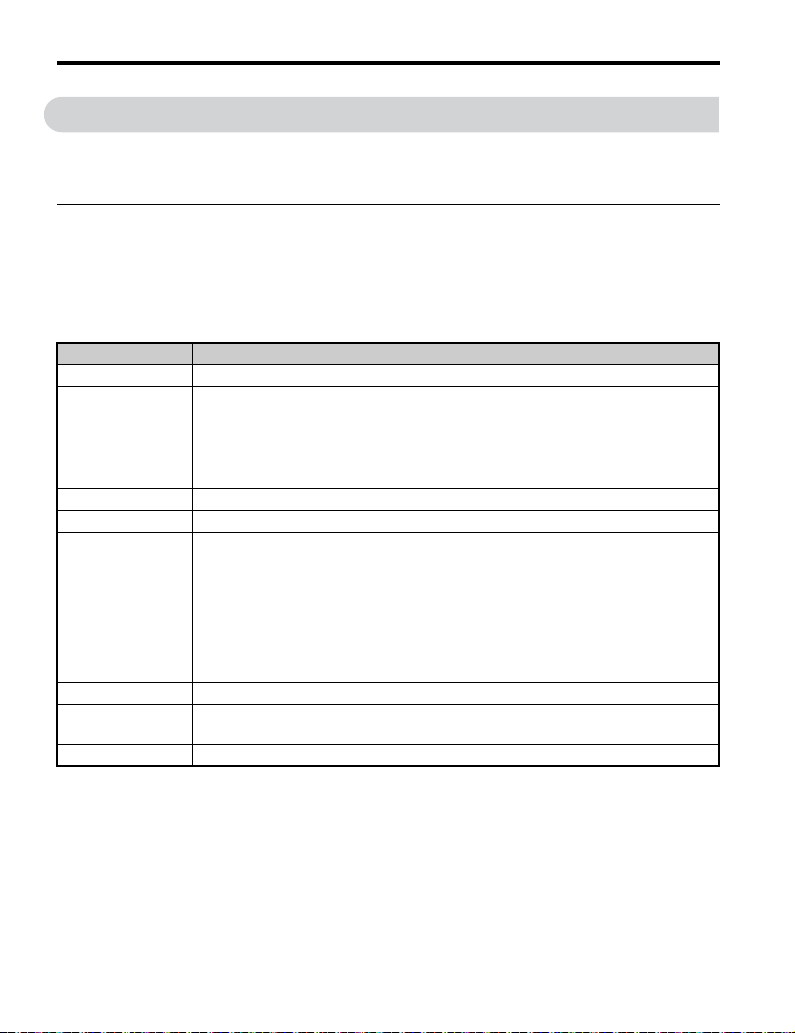

Table 2.1 Installation Environment

Environment Conditions

Installation Area Indoors

-10 °C to +40 °C (IP20/NEMA Type 1)

Ambient

Temperature

Humidity 95% RH or less and free of condensation

Storage Temperature -20 °C to +60 °C

Surrounding Area

Altitude 1000 m or lower

Vibration

Orientation Install the drive vertically to maintain maximum cooling effects.

-10 °C to +50 °C (IP20/Open-Chassis)

Drive reliability improves in enviroments without wide temperature fluctuations.

When using an enclosure panel, install a cooling fan or air conditioner in the area to ensure

that the air temperature inside the enclosure does not exceed the specified levels.

Do not allow ice to develop on the drive.

• Install the drive in an area free from:

• oil mist and dust

• metal shavings, oil, water or other foreign materials

• radioactive materials

• combustible materials (e.g., wood)

• harmful gases and liquids

• excessive vibration

•chlorides

• direct sunlight.

10 to 20 Hz at 9.8 m/s

20 to 55 Hz at 5.9 m/s

2

2

NOTICE: Prevent foreign matter such as metal shavings or wire clippings from falling into the drive during

installation and project construction. Failure to comply could result in damage to the drive. Place a

temporary cover over the top of the drive during installation. Remove the temporary cover before start-up, as

the cover will reduce ventilation and cause the drive to overheat.

20 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 21

2.1 Mechanical Installation

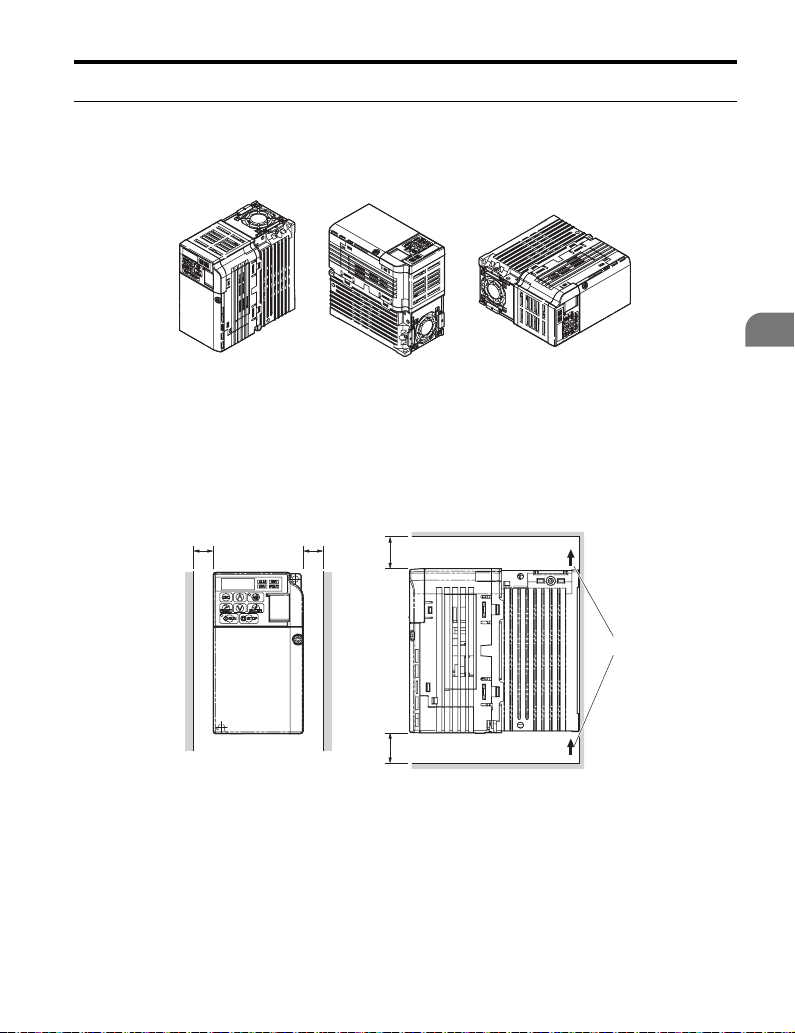

◆ Installation Orientation and Spacing

Install the drive upright as illustrated in Figure 2.1 to maintain proper cooling.

Figure 2.1

■ Single Drive Installation

To maintain sufficient space for airflow and wiring, refer to Figure 2.2. Install the heatsink

against a closed surface to avoid diverting cooling air around the heatsink.

Figure 2.2

ABB

A – Correct B – Incorrect

Figure 2.1 Correct Installation Orientation

Side Clearance

AA

Top/Bottom Clearance

C

Mechanical Installation

2

B

C

A – 30 mm minimum C – 100 mm minimum

B – Airflow direction D –

Figure 2.2 Correct Installation Spacing

Note: IP20/NEMA Type 1 and IP20/Open-Chassis models require the same amount of space above

and below the drive for installation.

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 21

Page 22

2.1 Mechanical Installation

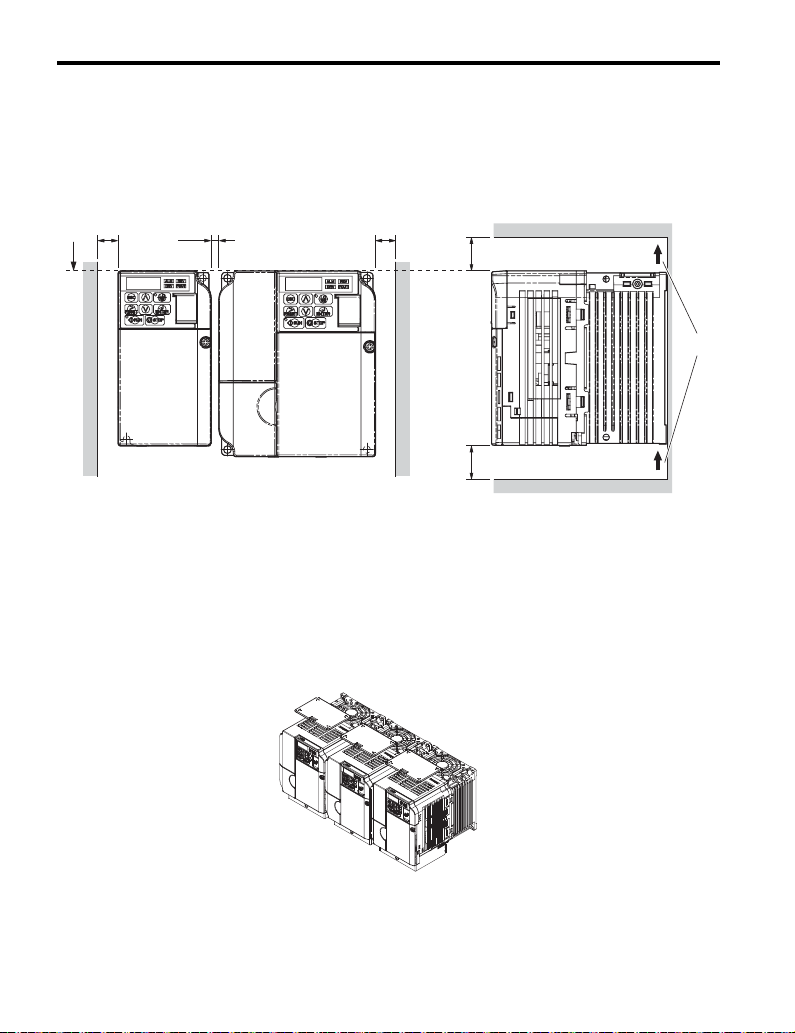

■ Multiple Drive Installation

When installing multiple drives into the same enclosure panel, mount the drives according to

Figure 2.2. When mounting drives with a minimum side-by-side clearance of 2 mm

according to Figure 2.3, derating must be considered and parameter L8-35 must be set.

Refer to Parameter List on page 113.

Figure 2.3

B

A

2 mm

B

C

D

C

A – Line up the tops of the drives. C – 100 mm minimum

B – 30 mm minimum D – Airflow direction

Figure 2.3 Space Between Drives (Side-by-Side Mounting)

Note: When installing drives of different sizes into the same enclosure panel, the tops of the drives

should line up. Leave space between the top and bottom of stacked drives for cooling fan

replacement if required. Using this method, it is possible to replace the cooling fans later.

NOTICE: When drives with IP20/NEMA Type 1 enclosures are mounted side-by-side, the top covers of all

drives must be removed as shown in the figure below.

Figure 2.4

Figure 2.4 IP20/NEMA 1 Side-by-Side Mounting in Enclosure

22 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 23

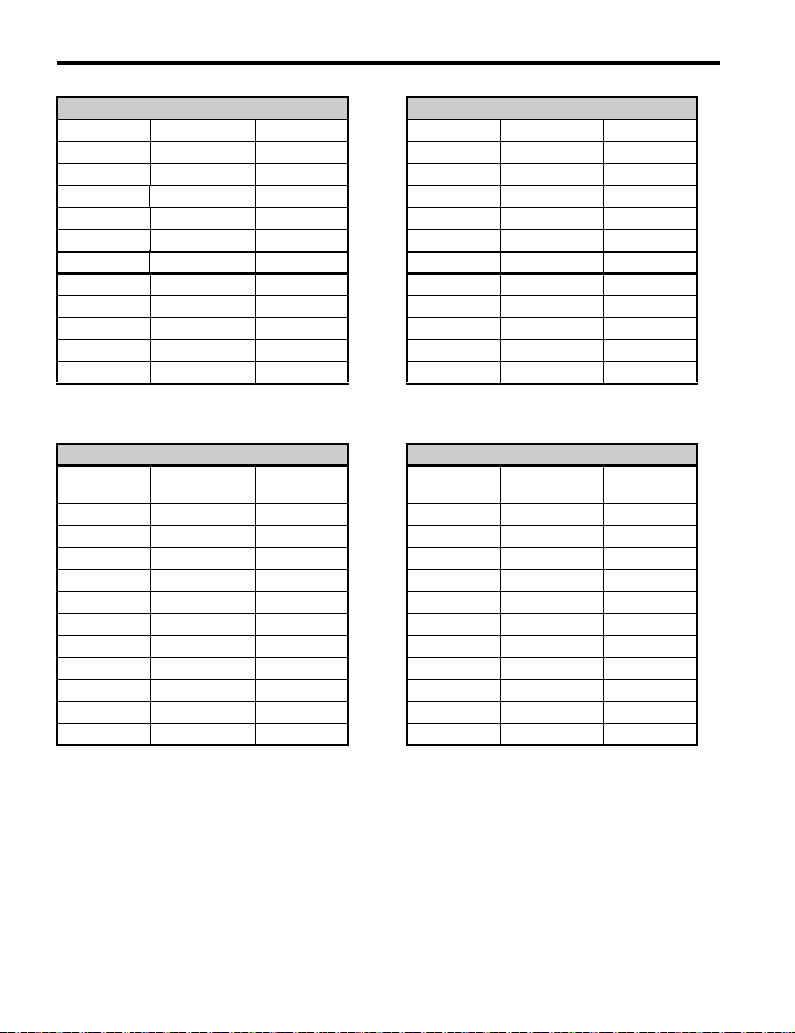

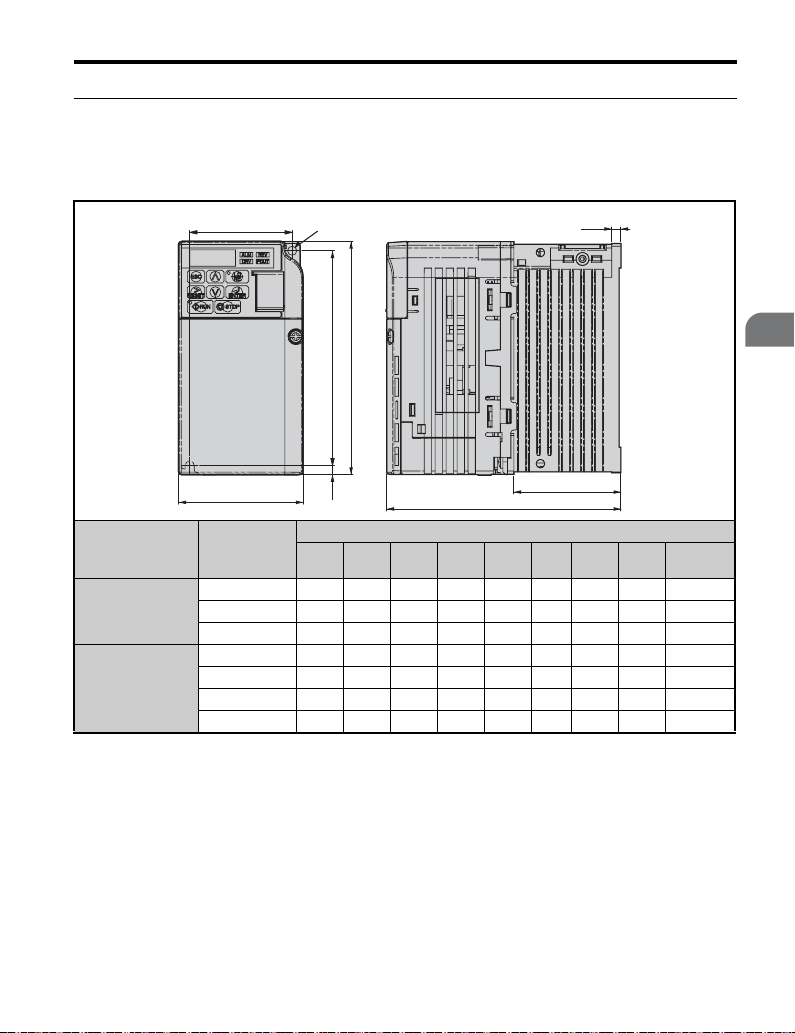

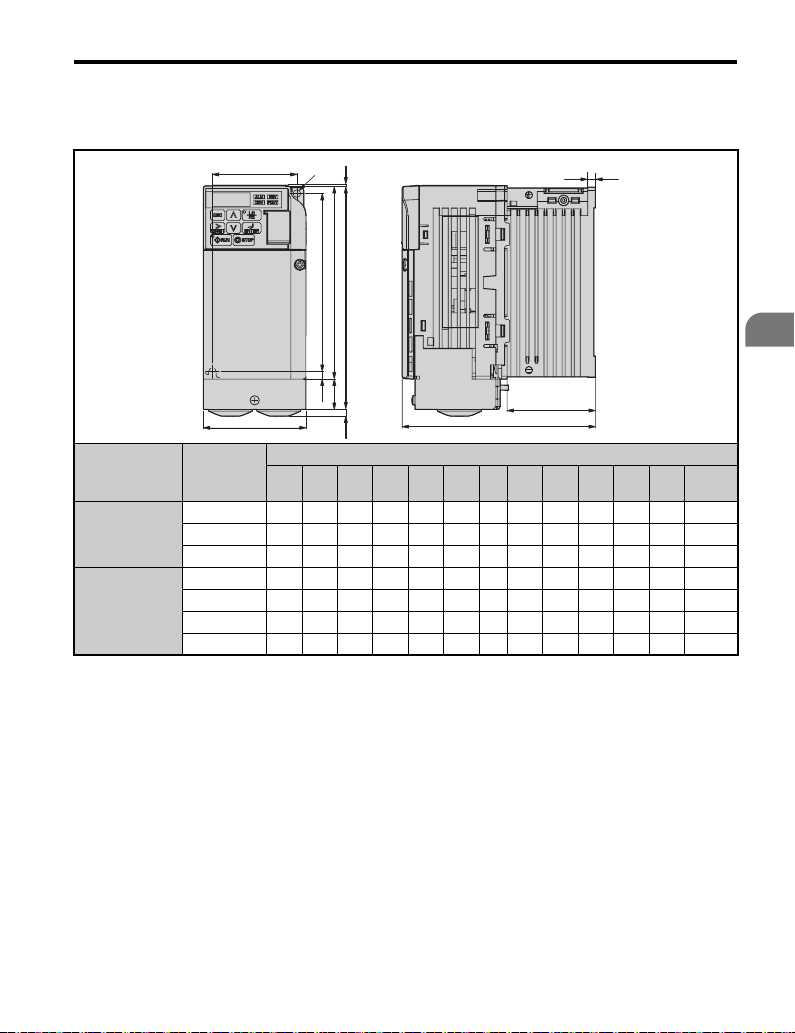

◆ Exterior and Mounting Dimensions

■ IP20/Open-Chassis Drives

Table 2.2 IP20/Open-Chassis (without an EMC filter)

2.1 Mechanical Installation

Voltage Class

Single-Phase

200 V Class

Three-Phase

200 V Class

W1

W

Drive Model

CIMR-V

BA0001B 56 118 68 128 76 3 5 6.5 0.6

BA0002B 56 118 68 128 76 3 5 6.5 0.6

BA0003B 56 118 68 128 118 5 5 38.5 1.0

2A0001B 56 118 68 128 76 3 5 6.5 0.6

2A0002B 56 118 68 128 76 3 5 6.5 0.6

2A0004B 56 118 68 128 108 5 5 38.5 0.9

2A0006B 56 118 68 128 128 5 5 58.5 1.1

2-M4

H

H1H2

D

Dimensions (mm)

W1 H1 W H D t1 H2 D1

t1

D1

Weight

(kg)

Mechanical Installation

2

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 23

Page 24

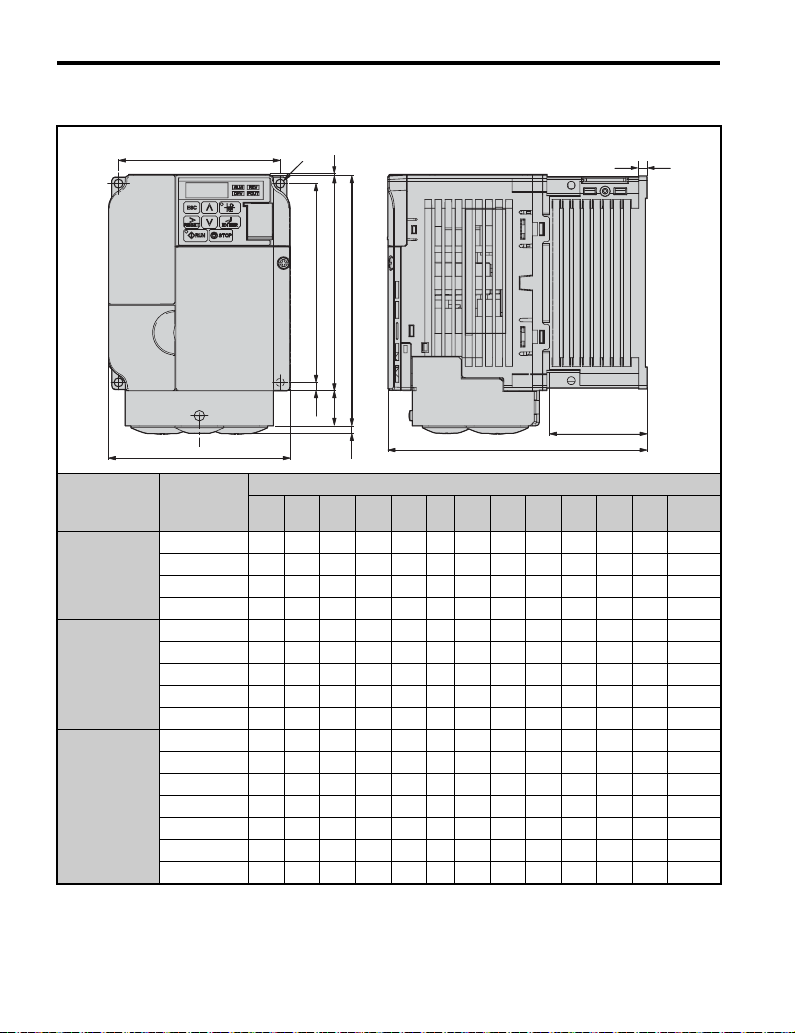

2.1 Mechanical Installation

Table 2.3 IP20/Open-Chassis (without an EMC filter)

Voltage Class

W1

W

Drive Model

CIMR-V

4-M4

H

t1

H2 H1

D

D1

Dimensions (mm)

W1 H1 W H D t1 H2 D1

BA0006B 96 118 108 128 137.5 5 5 58 1.7

Single-Phase

200 V Class

BA0010B 96 118 108 128 154 5 5 58 1.8

BA0012B 128 118 140 128 163 5 5 65 2.4

BA0018B 158 118 170 128 180 5 5 65 3.0

2A0008B 96 118 108 128 129 5 5 58 1.7

Three-Phase 2A0010B 96 118 108 128 129 5 5 58 1.7

200 V Class 2A0012B 96 118 108 128 137.5 5 5 58 1.7

2A0018B 128 118 140 128 143 5 5 65 2.4

2A0020B 128 118 140 128 143 5 5 65 2.4

4A0001B 96 118 108 128 81 5 5 10 1.0

4A0002B 96 118 108 128 99 5 5 28 1.2

Three-Phase

400 V Class

4A0004B 96 118 108 128 137.5 5 5 58 1.7

4A0005B 96 118 108 128 154 5 5 58 1.7

4A0007B 96 118 108 128 154 5 5 58 1.7

4A0009B 96 118 108 128 154 5 5 58 1.7

4A0011B 128 118 140 128 143 5 5 65 2.4

Weight

(kg)

24 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 25

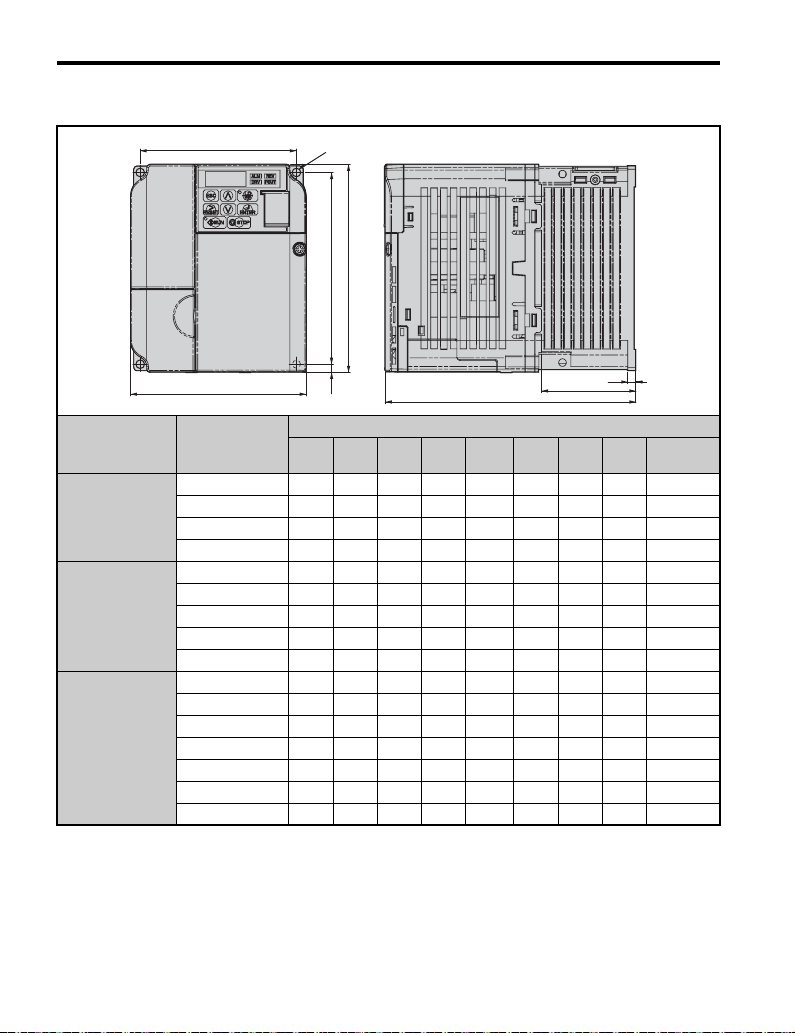

■ IP20/NEMA Type 1 Drives

Table 2.4 IP20/NEMA Type 1 (without an EMC filter)

W1

2-M4

2.1 Mechanical Installation

H6

HH3

H1H4

t1

Mechanical Installation

2

Voltage Class

Single-Phase

200 V Class

H5 H2

W

Drive Model

CIMR-V

W1 H2 W H1 D t1 H5 D1 H H4 H3 H6

Dimensions (mm)

BA0001F 56 118 68 129.5 76 3 5 6.5 149.5 20 4 1.5 0.8

BA0002F 56 118 68 129.5 76 3 5 6.5 149.5 20 4 1.5 0.8

BA0003F 56 118 68 129.5 118 5 5 39 149.5 20 4 1.5 1.2

D1

D

Weight

(kg)

2A0001F 56 118 68 129.5 76 3 5 6.5 149.5 20 4 1.5 0.8

Three-Phase

200 V Class

2A0002F 56 118 68 129.5 76 3 5 6.5 149.5 20 4 1.5 0.8

2A0004F 56 118 68 129.5 108 5 5 39 149.5 20 4 1.5 1.1

2A0006F 56 118 68 129.5 128 5 5 59 149.5 20 4 1.5 1.3

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 25

Page 26

2.1 Mechanical Installation

Table 2.5 IP20/NEMA Type 1 (without an EMC filter)

Voltage Class

W1

W

Drive Model

CIMR-V

4-M4

H6

HH3

H1

H5 H2

H4

D

t1

D1

Dimensions (mm)

W1 H2 W H1 D t1 H5 D1 H H4 H3 H6

Weight

BA0006F 96 118 108 129.5 137.5 5 5 58 149.5 20 4 1.5 1.9

Single-Phase

200 V Class

BA0010F 96 118 108 129.5 154 5 5 58 149.5 20 4 1.5 2.0

BA0012F 128 118 140 133 163 5 5 65 153 20 4.8 5 2.6

BA0018F 158 118 170 133 180 5 5 65 171 38 4.8 5 3.3

2A0008F 96 118 108 129.5 129 5 5 58 149.5 20 4 1.5 1.9

Three-Phase 2A0010F 96 118 108 129.5 129 5 5 58 149.5 20 4 1.5 1.9

200 V Class 2A0012F 96 118 108 129.5 137.5 5 5 58 149.5 20 4 1.5 1.9

2A0018F 128 118 140 133 143 5 5 65 153 20 4.8 5 2.6

2A0020F 128 118 140 133 143 5 5 65 153 20 4.8 5 2.6

4A0001F 96 118 108 129.5 81 5 5 10 149.5 20 4 1.5 1.2

4A0002F 96 118 108 129.5 99 5 5 28 149.5 20 4 1.5 1.4

Three-Phase

400 V Class

4A0004F 96 118 108 129.5 137.5 5 5 58 149.5 20 4 1.5 1.9

4A0005F 96 118 108 129.5 154 5 5 58 149.5 20 4 1.5 1.9

4A0007F 96 118 108 129.5 154 5 5 58 149.5 20 4 1.5 1.9

4A0009F 96 118 108 129.5 154 5 5 58 149.5 20 4 1.5 1.9

4A0011F 128 118 140 133 143 5 5 65 153 20 4.8 5 2.6

(kg)

26 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

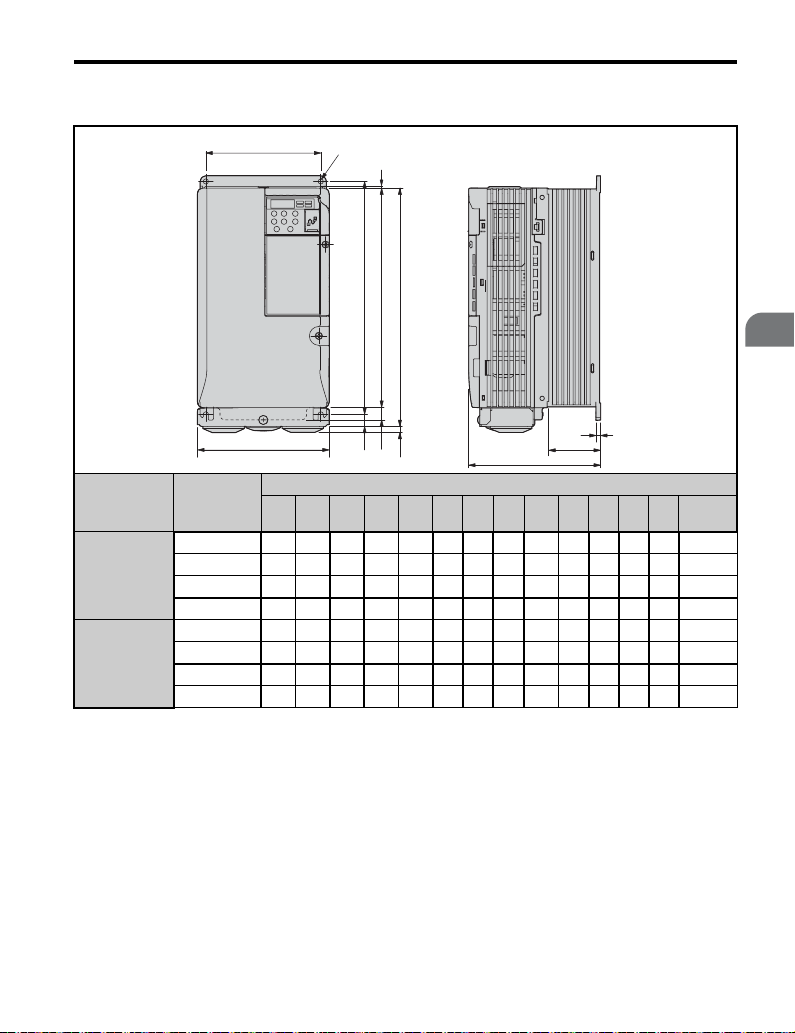

Page 27

2.1 Mechanical Installation

Table 2.6 IP20/NEMA Type 1 (without an EMC filter)

Voltage Class

Three-Phase

200 V Class

Three-Phase

400 V Class

Drive Model

CIMR-V

W1

W

W1 H2 W H1 D t1 H5 D1 H H4 H3 H6 d

4-d

H6

H

H2

H1

t1

H4

H5

H3

D1

D

Dimensions (mm)

2A0030B 122 248 140 234 140 5 13 55 254 13 6 1.5 M5 3.8

2A0040B 122 248 140 234 140 5 13 55 254 13 6 1.5 M5 3.8

2A0056B 160 284 180 270 163 5 13 75 290 15 6 1.5 M5 5.5

2A0069B 192 336 220 320 187 5 22 78 350 15 7 1.5 M6 9.2

4A0018B 122 248 140 234 140 5 13 55 254 13 6 1.5 M5 3.8

4A0023B 122 248 140 234 140 5 13 55 254 13 6 1.5 M5 3.8

4A0031B 160 284 180 270 143 5 13 55 290 15 6 1.5 M5 5.2

4A0038B 160 284 180 270 163 5 13 75 290 13 6 1.5 M5 5.5

Weight

(kg)

Mechanical Installation

2

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 27

Page 28

2.1 Mechanical Installation

28 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 29

3

Electrical

Installation

This chapter explains proper procedures for wiring the control

circuit terminals, motor and power supply.

3.1 STANDARD CONNECTION DIAGRAM. . . . . . . . . . . . . . . 30

3.2 MAIN CIRCUIT WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 I/O CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.4 MAIN FREQUENCY REFERENCE . . . . . . . . . . . . . . . . . .47

3.5 WIRING CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

29

Page 30

3.1 Standard Connection Diagram

3.1 Standard Connection Diagram

Connect the drive and peripheral devices as shown in Figure 3.1. It is possible to run the

drive via the digital operator without connecting digital I/O wiring. This section does not

discuss drive operation; Refer to Start-Up Programming & Operation on page 51 for

instructions on operating the drive.

NOTICE: Inadequate branch short circuit protection could result in damage to the drive. Install adequate

branch circuit short circuit protection per applicable codes. The drive is suitable for circuits capable of

delivering not more than 30,000 RMS symmetrical amperes, 240 Vac maximum (200 V Class) and 480 Vac

maximum (400 V Class).

NOTICE: When the input voltage is 480 V or higher or the wiring distance is greater than 100 meters, pay

special attention to the motor insulation voltage or use an inverter duty motor. Failure to comply could lead

to motor insulation breakdown.

NOTICE: Do not connect the AC control circuit ground to the drive enclosure. Improper drive grounding can

cause the control circuit to malfunction.

NOTICE: The minimum load for the multi-function relay output MA-MB-MC is 10 mA (reference value). If a

circuit requires less than 10 mA, connect it to a photocoupler output (P1, P2, PC). Improper application of

peripheral devices could result in damage to the photocoupler output of the drive.

30 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 31

3.1 Standard Connection Diagram

Figure 3.1

For single phase 200 V

power supply, use

R/L1 and S/L2.

Three phase

power supply

200 to 240 V

THRX

2 MCCB

Thermal relay for

motor cooling fan

Terminals +1, +2, , B1, and B2

are for connecting options.

Never connect power supply

lines to these terminals.

1 MCCB

R/L1

S/L2

T/L3

MC

OFF

ON

SA

MC

THRX

SA

MC MA

Fault relay

Digital inputs

(default setting)

Main speed

frequency

reference.

Multi-function

programmable

Safe Disable

Input

TRX

TRX

SA

MC

_

2 MCCB

MC

Forward run/stop

Reverse run/stop

External fault

Fault reset

Multi-step

speed 1

main/aux switch

Multi-step

speed 2

Jog reference

2 k

Safety switch

Jumper

DC reactor

(option)

*3

r1

s1

t1

R/L1

S/L2

T/L3

4

*

S1

S2

S3

S4

S5

S6

S7

*

DIP

switch S3

SC

Shield ground

terminal

Pulse train input

RP

(max. 32 kHz)

Setting power supply

+V

+10.5 max. 20 mA

A1

0 to +10 V (20 k )

A2

0 to +10 V (20 k )

(0)4 to 20 mA (250 )

AC

HC

8

*

H1

main circuit terminal

Jumper

Main circuit

Control circuit

5

DIP

switch

S2

shielded line

1

*

Thermal relay

(option)

-

B1+1+2 B2

V1000

+

24

V 8 mA

V

24

Sink

Source

V

0

Cable shield ground

twisted-pair shielded line

control terminal

2

*

Braking resistor

(option)

U/T1

V/T2

W/T3

Option card

connector

DIP switch S1

VI

MP

AM

AC

Termination

resistor

120

, 1/2 W

MA

MB

MC

P1

P2

PC

R

R

S

S

IG

Figure 3.1 Drive Standard Connection Diagram

Motor

Cooling fan

FU

r1

FV

s1

FW

t1

U

V

W

Ground

or less (400 V class)

10

100 or less (200 V class)

6

*

Digital output

250 Vac, 10 mA to 1 A

30 Vdc, 10 mA to 1 A

(default setting)

Fault

Digital output

5 ~ 48 Vdc

2 to 50 mA

(default setting)

During Run

(photocoupler 1)

Frequency agree

(photocoupler 2)

Photocoupler

output common

Pulse train output

0 to 32 kHz

Analog monitor

output

+

AM

0 to +10 Vdc

(2 mA)

-

+

-

+

-

Comm.

connector

Monitor

output

MEMOBUS/

Modbus comm.

RS-485/422

M

M

Electrical Installation

3

7

*

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 31

Page 32

3.1 Standard Connection Diagram

* 1. Remove the jumper when installing an optional DC reactor.

* 2. The MC on the input side of the main circuit should open when the thermal relay is triggered.

* 3. Self-cooled motors do not require separate cooling fan motor wiring.

* 4. Connected using sequence input signal (S1 to S7) from NPN transistor; Default: sink mode ( 0 V com)

* 5. Use only a +24 V internal power supply in sinking mode; the source mode requires an external power

supply. Refer to I/O Connections on page 45.

* 6. Minimum load: 5 Vdc, 10 mA (reference value).

* 7. Monitor outputs work with devices such as analog frequency meters, ammeters, voltmeters and

wattmeters; they are intended for use as a feedback-type of signal.

* 8. Disconnect the wire jumper between HC and H1 when utilizing the safety input.

WARNING! Sudden Movement Hazard. Do not close the wiring for the control circuit unless the

multifunction input terminal parameter is properly set (S5 for 3-wire; H1-05 = “0”). Improper sequencing of

run/stop circuitry could result in death or serious injury from moving equipment.

WARNING! Sudden Movement Hazard. Ensure start/stop and safety circuits are wired properly and in the

correct state before energizing the drive. Failure to comply could result in death or serious injury from

moving equipment. When programmed for 3-wire control, a momentary closure on terminal S1 may cause

the drive to start.

WARNING! When 3-Wire sequence is used, set the drive to 3-Wire sequence before wiring the control

terminals and ensure parameter b1-17 is set to 0 (drive does not accept a run command at power up

(default)). If the drive is wired for 3-Wire sequence but set up for 2-Wire sequence (default) and if parameter

b1-17 is set to 1 (drive accepts a Run command at power up), the motor will rotate in reverse direction at

power up of the drive and may cause injury.

WARNING! When the application preset funcion is executed (or A1-06 is set to any value other than 0) the

drive I/O terminal funcitons change. This may cause unexpected operation and potential damage to

equipment or injury.

Figure 3.2 illustrates an example of a 3-wire sequence.

Figure 3.2

Stop relay (N.C.)

Run relay (N.O.)

S1

Run command (run on momentary close)

S2

Stop command (stop on momentary open)

S5

Foward/reverse command

(multi-function input: H1-05 = 0)

SC

Sequence input common

Drive

Figure 3.2 3-Wire Sequence

32 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 33

3.2 Main Circuit Wiring

3.2 Main Circuit Wiring

This section describes the functions, specifications, and procedures required to safely and

properly wire the main circuit of the drive.

NOTICE: Do not solder the ends of wire connections to the drive. Soldered wiring connections can loosen

over time. Improper wiring practices could result in drive malfunction due to loose terminal connections.

◆ Main Circuit Terminal Functions

Table 3.1 Main Circuit Terminal Functions

Ter mi nal Typ e Function Reference

R/L1

S/L2

T/L3

U/T1

W/T3

B1

B2

+1

+2

+1

–

(2 terminals)

Main circuit power

supply input

Drive output Connects to the motor. 37V/T2

Braking resistor

DC reactor

connection

DC power supply

input

Ground

Connects line power to the drive.

Drives with single phase 200 V input power use terminals R/L1

and S/L2 only (T/L3 must not be used).

Available for connecting a braking resistor or the braking resistor

unit option.

These terminals are shorted at shipment. Remove the shorting bar

between +1 and +2 when connecting to this terminal.

For connecting a DC power supply. -

Grounding Terminal

For 200 V class: 100 Ω or less

For 400 V class: 10 Ω or less

37

Electrical Installation

3

◆ Wire Gauges and Tightening Torque

Select the appropriate wires and crimp terminals from Ta bl e 3. 2 through Table 3.5.

Note: 1. Wire gauge recommendations based on drive continuous current ratings using 75°C 600 Vac vinyl-

• Consider the amount of voltage drop when selecting wire gauges.

Increase the wire gauge when the voltage drop is greater than 2% of motor rated voltage.

Ensure the wire gauge is suitable for the terminal block. Use the following formula to

calculate the amount of voltage drop:

• Line drop voltage (V) = 3 x wire resistance (Ω/km) x wire length (m) x current (A) x10

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 33

sheathed wire assuming ambient temperature within 30°C and wiring distance less than 100 m.

2. Terminals +1, +2, –, B1 and B2 are for connecting optional devices such as a DC reactor or braking

resistor. Do not connect other non-specified devices to these terminals.

-3

Page 34

3.2 Main Circuit Wiring

• Refer to instruction manual TOBPC72060000 for braking unit or braking resistor unit

wire gauges.

• Refer to Standards Compliance on page 143 for information on UL compliance.

■ Single-Phase 200 V Class

Table 3.2 Wire Gauge and Torque Specifications

Model

CIMRVBA

0001

0002

0003

0006

0010

0012

0018

■

Three-Phase 200 V Class

Ter min al

R/L1, S/L2, U/T1, V/T2, W/

T3, –, +1, +2, B1, B2,

R/L1, S/L2, U/T1, V/T2, W/

T3, –, +1, +2, B1, B2,

R/L1, S/L2, U/T1, V/T2, W/

T3,

–, +1, +2, B1, B2, M4

R/L1, S/L2, U/T1, V/T2, W/

T3, –, +1, +2, B1, B2,

R/L1, S/L2, U/T1, V/T2, W/

T3, –, +1, +2, B1, B2,

Table 3.3 Wire Gauge and Torque Specifications

Model

CIMRV2A

0001

0002

0004

0006

0010

0012

0020

Ter min al

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2,

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2,

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2,

Screw

Size

M3.5

M4

M4

M4

M5

Screw

Size

M3.5

M4

M4

M4

M4

Tightening

Torque

N•m (lb.in.)

0.8 to 1.0

(7.1 to 8.9)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

2 to 2.5

(17.7 to 22.1)

Tightening

Torque

N•m (lb.in.)

0.8 to 1.0

(7.1 to 8.9)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

Applicable

Gauge

2

(AWG)

mm

0.75 to 2.0

(18 to 14)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

3.5 to 8

(12 to 8)

Applicable

Gauge

2

(AWG)

mm

0.75 to 2.0

(18 to 14)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

Recommended

Gauge

2

(AWG)

mm

2

(14)

2

(14)

3.5

(12)

5.5

(10)

5.5

(10)

8(8) Note: 1.

Recommended

Gauge

2

(AWG)

mm

2

(14)

2

(14)

3.5

(12)

3.5

(12)

5.5

(10)

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Line

Typ e

Line

Typ e

34 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 35

3.2 Main Circuit Wiring

Model

CIMRV2A

0030

0040

0056

0069

Ter min al

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M4

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M4

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M5

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M5

■ Three-Phase 400 V Class

Table 3.4 Wire Gauge and Torque Specifications

Model

CIMRV4A

0001

0002

0004

0005

0007

0009

Ter mi nal

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2,

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2

Screw

Size

M5

M5

M5

M5

M6

M6

M8

M6

Screw

Size

M4

M4

M4

Tightening

Torque

N•m (lb.in.)

2 to 2.5

(17.7 to 22.1)

1.2 to 1.5

(10.6 to 13.3)

2 to 2.5

(17.7 to 22.1)

2 to 2.5

(17.7 to 22.1)

1.2 to 1.5

(10.6 to 13.3)

2 to 2.5

(17.7 to 22.1)

4 to 6

(35.4 to 53.1)

2 to 2.5

(17.7 to 22.1)

4 to 6

(35.4 to 53.1)

9 to 11

(79.7 to 11.0)

2 to 2.5

(17.7 to 22.1)

4 to 6

(35.4 to 53.1)

Tightening

Tor que

N•m (lb.in.)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

Applicable

Gauge

2

(AWG)

mm

5.5 to 14

(10 to 6)

2.0 to 5.5

(14 to 10)

5.5 to 14

(10 to 6)

5.5 to 14

(10 to 6)

2.0 to 5.5

(14 to 10)

5.5 to 14

(10 to 6)

14 to 22

(6 to 4)

5.5 to 8

(10 to 8)

14 to 22

(6 to 4)

8 to 38

(8 to 2)

8 to 14

(8 to 6)

8 to 22

(8 to 4)

Applicable

Gauge

2

(AWG)

mm

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

Recommended

Gauge

2

(AWG)

mm

8

(8)

5.5

(10)

8

(8)

14

(6)

5.5

(10)

8

(8)

22

(4)

8

(8)

22

(4)

38

(2)

14

(6)

22

(4)

Recommended

Gauge

2

(AWG)

mm

2

(14)

2

(14)

3.5

(12)

Line

Typ e

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Line

Typ e

Note: 1.

Note: 1.

Note: 1.

Electrical Installation

3

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 35

Page 36

3.2 Main Circuit Wiring

Model

CIMRV4A

0011

0018

0023

0031

0038

Ter min al

R/L1, S/L2, T/L3, U/T1, V/T2,

W/T3, –, +1, +2, B1, B2

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M4

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M4

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M5

R/L1,S/L2,T/L3,U/T1,V/

T2,W/T3,-,+1,+2

B1,B2 M5

Screw

Size

M4

M4

M4

M5

M5

M5

M5

M6

M5

M6

Tightening

Tor que

N•m (lb.in.)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

1.2 to 1.5

(10.6 to 13.3)

2 to 2.5

(17.7 to 22.1)

2 to 2.5

(17.7 to 22.1)

1.2 to 1.5

(10.6 to 13.3)

2 to 2.5

(17.7 to 22.1)

2 to 2.5

(17.7 to 22.1)

2 to 2.5

(17.7 to 22.1)

4 to 6

(35.4 to 53.1)

2 to 2.5

(17.7 to 22.1)

2 to 2.5

(17.7 to 22.1)

4 to 6

(35.4 to 53.1)

Applicable

Gauge

2

(AWG)

mm

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

2.0 to 5.5

(14 to 10)

5.5 to 14

(10 to 6)

5.5 to 14

(10 to 6)

2.0 to 5.5

(14 to 10)

5.5 to 14

(10 to 6)

5.5 to 14

(10 to 6)

5.5 to 8

(10 to 8)

5.5 to 14

(10 to 6)

5.5 to 14

(10 to 6)

5.5 to 8

(10 to 8)

5.5 to 14

(10 to 6)

Recommended

Gauge

2

(AWG)

mm

2

(14)

3.5

(12)

5.5

(10)

5.5

(10)

5.5

(10)

8

(8)

5.5

(10)

5.5

(10)

8

(8)

8

(8)

8

(8)

14

(6)

8

(8)

8

(8)

Line

Typ e

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

Note: 1.

◆ Main Circuit Terminal Power Supply and Motor Wiring

This section outlines the various steps, precautions, and checkpoints for wiring the main

circuit terminals and motor terminals.

NOTICE: When connecting the motor to the drive output terminals U/T1, V/T2, and W/T3, the phase order

for the drive and motor should match. Failure to comply with proper wiring practices may cause the motor to

run in reverse if the phase order is backward.

NOTICE: Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits. Improper

application of noise filters could result in damage to the drive.

NOTICE: Do not connect the AC power line to the output motor terminals of the drive. Failure to comply

could result in death or serious injury by fire as a result of drive damage from line voltage application to

36 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 37

3.2 Main Circuit Wiring

output terminals.

■ Cable Length Between Drive and Motor

When the cable length between the drive and the motor is too long (especially at low

frequency output), note that the cable voltage drop may cause reduced motor torque. Drive

output current will increase as the leakage current from the cable increases. An increase in

leakage current may trigger an overcurrent situation and weaken the accuracy of the current

detection.

Adjust the drive carrier frequency according to the following table. If the motor wiring

distance exceeds 100 m because of the system configuration, reduce the ground currents.

Refer to Carrier Frequency Selection: C6-02 on page 71.

Refer to Table 3.5 to set the carrier frequency to an appropriate level.

Table 3.5 Cable Length Between Drive and Motor

Cable Length 50 m or less 100 m or less Greater than 100 m

Carrier Frequency 15 kHz or less 5 kHz or less 2 kHz or less

Note: When setting carrier frequency, calculate the cable length as the total distance of wiring to all

connected motors when running multiple motors from a single drive.

■ Ground Wiring

Follow the precautions to wire the ground for one drive or a series of drives.

WARNING! Electrical Shock Hazard. Always use a ground wire that complies with technical standards on

electrical equipment and minimize the length of the ground wire. Improper equipment grounding may cause

dangerous electrical potentials on equipment chassis, which could result in death or serious injury.

WARNING! Electrical Shock Hazard. Be sure to ground the drive ground terminal. (200 V Class: Ground to

100 Ω or less, 400 V Class: Ground to 10 Ω or less). Improper equipment grounding could result in death or

serious injury by contacting ungrounded electrical equipment.

NOTICE: Do not share the ground wire with other devices such as welding machines or large-current

electrical equipment. Improper equipment grounding could result in drive or equipment malfunction due to

electrical interference.

NOTICE: When using more than one drive, ground multiple drives according to instructions. Improper

equipment grounding could result in abnormal operation of drive or equipment.

Refer to Figure 3.3 when using multiple drives. Do not loop the ground wire.

Electrical Installation

3

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 37

Page 38

3.2 Main Circuit Wiring

A

Figure 3.3

A

A – Correct B – Incorrect

Figure 3.3 Multiple Drive Wiring

A

B

■ Wiring the Main Circuit Terminal

WARNING! Electrical Shock Hazard. Shut off the power supply to the drive before wiring the main circuit

terminals. Failure to comply may result in death or serious injury.

Note: 1. A cover placed over the DC Bus and braking circuit terminals prior to shipment helps prevent

miswiring. Cut away covers as needed for terminals with a needle-nose pliers.

A – Protective Cover to Prevent Miswiring

2. The ground terminal screw on IP20/NEMA Type 1 holds the protective cover in place.

◆ Control Circuit Terminal Block Functions

Drive parameters determine which functions apply to the multi-function digital inputs (S1 to

S7), multi-function digital outputs (MA, MB), multi-function pulse inputs and outputs (RP,

MP) and multi-function photocoupler outputs (P1, P2). The default is called out next to each

terminal.

WARNING! Sudden Movement Hazard. Always check the operation and wiring of control circuits after being

wired. Operating a drive with untested control circuits could result in death or serious injury.

WARNING! Confirm the drive I/O signals and external sequence before starting test run. Setting parameter

A1-06 may change the I/O terminal function automatically from the factory setting. Refer to Application

Presets on page 64. Failure to comply may result in death or serious injury.

NOTICE: Do not switch an input contactor more often than once every 30 minutes. Improper equipment

sequencing could shorten useful life of the drive electrolytic capacitors and circuit relays. Normally the drive

I/O should be used to stop and start the motor.

38 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 39

3.2 Main Circuit Wiring

■ Input Terminals

Table 3.6 Control Circuit Input Terminals

Typ e No. Terminal Name (Function) Function (Signal Level) Default Setting

Multi-function input 1 (Closed: Forward

S1

run, Open: Stop)

Multi-function input 2 (Closed: Reverse

S2

run, Open: Stop)

Photocoupler

24 Vdc, 8 mA Note: Drive preset to sinking mode.

When using source mode, set DIP switch S3 to allow

for a 24 Vdc (±10%) external power supply. Refer to

page 45.

Sequence common

Open: Coast to stop safety input

Closed: Normal operation Note: Disconnect wire

jumper between HC and H1 when using safety input.

Response frequency: 0.5 to 32 kHz

(Duty Cycle: 30 to 70%)

(High level voltage: 3.5 to 13.2 Vdc)

(Low level voltage: 0.0 to 0.8 Vdc)

(input impedance: 3 kΩ)

Input voltage 0 to +10 Vdc (20 kΩ) resolution

1/1000

Input voltage or input current (Selected by DIP

switch S1) 0 to +10 Vdc (20 kΩ) resolution: 1/1000

4 to 20 mA (250 Ω) or 0 to 20 mA (250 Ω)

resolution: 1/500

MultiFunction

Digital

Inputs

Safety

Input

Main

Frequency

Reference

Input

Multi-function input 3 (External fault

S3

(N.O.))

S4 Multi-function input 4 (Fault reset)

Multi-function input 5 (Multi-step speed

S5

reference 1)

Multi-function input 6 (Multi-step speed

S6

reference 2)

S7 Multi-function input 7 (Jog reference)

Multi-function input common (Control

SC

common)

HC Power supply for safety input command +24 Vdc (max 10 mA allowed)

H1 Safety input command

Multi-function pulse train input (frequency

RP

reference)

+V Analog input power supply +10.5 Vdc (max allowable current 20 mA)

Multi-function analog input (frequency

A1

reference)

Multi-function analog input (frequency

A2

reference)

AC Frequency reference common 0 Vdc

Electrical Installation

3

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 39

Page 40

3.2 Main Circuit Wiring

■ Output Terminals

Table 3.7 Control Circuit Output Terminals

Typ e No. Terminal Name (Function)

MA N.O. (fault) Digital output

Multi-Function

Digital Output

Multi-Function

Photocoupler

Output

Monitor Output

MB N.C. output (fault)

MC Digital output common

P1 Photocoupler output 1 (during run)

PC Photocoupler output common

MP Pulse train output (input frequency) 32 kHz (max)

AM Analog monitor output 0 to 10 Vdc (2 mA or less) Resolution: 1/1000

AC Monitor common 0 V

Function (Signal Level)

Default Setting

30 Vdc, 10 mA to 1 A; 250 Vac, 10 mA to 1

A.

Minimum Load: 5 Vdc, 10 mA (reference

value)

Photocoupler output 48 Vdc, 2 to 50 mAP2 Photocoupler output 2 (Frequency agree)

Connect a suppression diode as shown in Figure 3.4 when driving a reactive load such as a

relay coil. Ensure the diode rating is greater than the circuit voltage.

40 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 41

3.2 Main Circuit Wiring

A

Figure 3.4

B

C

D

A – External power, 48 V max. C – Coil

B – Suppression diode D – 50 mA or less

Figure 3.4 Connecting a Suppression Diode

■ Serial Communication Terminals

Table 3.8 Control Circuit Terminals: Serial Communications

Typ e No. Signal Name Function (Signal Level)

R+ Communications input (+)

MEMOBUS/

Modbus

Communication

R- Communications input (-)

S+ Communications output (+)

S- Communications output (-)

IG Shield ground 0 V

◆ Removable Terminal Block Configuration

Figure 3.5

R+ R

㧙

S+ S㧙IG

P1 P2 PC A1 A2 +V AC AM AC MP

S1 S2 S3 S4 S5 S6 S7 HC SC H1 RP

MCMBMA

MEMOBUS/Modbus

communication: Use a RS-485

or RS-422 cable to connect the

drive.

㧙

S+ S㧙IG

R+ R

P1 P2 PC A1 A2 +V AC AM AC MP

S1 S2 S3 S4 S5 S6 S7 HC SC H1 RP

RS-485/422 MEMOBUS/

Modbus communication

protocol 115.2 kbps (max.)

MCMBMA

Electrical Installation

3

Figure 3.5 Removable Control Circuit Terminal Block

(CIMR-VA; CIMR-VU)

■ Wire Size and Torque Specifications

Select the appropriate wires and crimp terminals from Ta bl e 3. 3. Crimp a ferrule to signal

wiring to improve wiring simplicity and reliability. Refer to Ferrule Terminal Types and

Sizes on page 42.

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 41

Page 42

3.2 Main Circuit Wiring

Table 3.9 Wire Size and Torque Specifications (Same for All Models)

Tightening

Ter mi nal

Screw

Size

Tor que

Nxm

MA, MB, MC M3 0.5 to 0.6

S1-S7, SC, RP, +V, A1,

A2, AC, HC, H1, P1,

P2, PC, MP, AM, AC,

S+, S-, R+, R-, IG

■

Ferrule-Type Wire Terminations

M2 0.22 to 0.25

Crimp a ferrule to signal wiring to improve wiring simplicity and reliability. Use

CRIMPFOX ZA-3, a crimping tool manufactured by PHOENIX CONTACT.

Figure 3.6

Bare Wire Terminal Ferrule-Type Terminal

Applicable

wire size

2

mm

(AWG)

Stranded wire:

0.25 to 1.5

(24 to 16)

Single wire:

0.25 to 1.5 (24

Recomm.

mm

(AWG)

0.75 (18)

2

Applicable

wire size

2

mm

(AWG)

0.25 to 1.0

(24 to 18)

Recomm.

mm

(AWG)

0.5 (20)

to 16)

Stranded wire:

0.25 to 1.0

(24 to 18)

Single wire:

0.25 to 1.5

0.75 (18)

0.25 to 0.5

(24 to 20)

0.5 (20)

(24 to 16)

φd1

6 mm

L

2

Wire Type

Shielded

line, etc.

φd2

Figure 3.6 Ferrule Dimensions

Table 3.10 Ferrule Terminal Types and Sizes

Size mm2 (AWG) Ty pe L (mm) d1 (mm) d2 (mm) Manufacturer

0.25 (24) AI 0.25-6YE 10.5 0.8 2

0.34 (22) AI 0.34-6TQ 10.5 0.8 2

0.5 (20) AI 0.5-6WH 12 1.1 2.5

0.75 (18) A1 0.75-6GY 12 1.3 2.8

1.0 AI 1-6RD 12 1.5 3.0

42 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

PHOENIX CONTACT

Page 43

3.2 Main Circuit Wiring

◆ Wiring Procedure

This section describes the proper procedures and preparations for wiring the terminal board.

WARNING! Electrical Shock Hazard. Do not remove covers or touch the circuit boards while the power is

on. Failure to comply could result in death or serious injury.

NOTICE: Separate control circuit wiring from main circuit wiring (terminals R/L1, S/L2, T/L3, B1, B2, U/T1,

V/T2, W/T3, -, +1, +2) and other high-power lines. Improper wiring practices could result in drive malfunction

due to electrical interference.

NOTICE: Separate wiring for digital output terminals MA, MB and MC from wiring to other control circuit

lines. Improper wiring practices could result in drive or equipment malfunction or nuisance trips.

NOTICE: Use a class 2 power supply (UL standard) when connecting to the control terminals. Improper

application of peripheral devices could result in drive performance degradation due to improper power

supply.

NOTICE: Insulate shields with tape or shrink tubing to prevent contact with other signal lines and

equipment. Improper wiring practices could result in drive or equipment malfunction due to short circuit.

NOTICE: Connect the shield of shielded cable to the appropriate ground terminal. Improper equipment

grounding could result in drive or equipment malfunction or nuisance trips.

Wire the terminal board using Figure 3.13 as a guide (control circuit terminal block). Be

sure to prepare the ends of the control circuit wiring as shown in Figure 3.14. Refer to Wire

Gauges and Tightening Torque on page 33 for tightening torque specifications.

NOTICE: Do not tighten screws beyond the specified tightening torque. Failure to comply may damage the

terminal block.

NOTICE: Use shielded twisted-pair cables as indicated to prevent operating faults. Improper wiring

practices could result in drive or equipment malfunction due to electrical interference.

Figure 3.7

A

D

Preparing wire

terminal ends

B

E

Electrical Installation

3

C

A – Control terminal block D – Loosen screw to insert wire.

B – Avoid fraying wire strands when

stripping insulation from wire.

Strip length 5.5 mm.

C – Single wire or stranded wire

Figure 3.7 Terminal Board Wiring Guide

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 43

E – Blade depth of 0.4 mm or less

Blade width of 2.5 mm or less

Page 44

3.2 Main Circuit Wiring

A

Figure 3.8

F

B

C

E

A – Drive side D – Control device side

B – Connect shield to ground terminal

of drive.

E – Shield sheath

(Insulate with tape)

C – Insulation F – Shield

Figure 3.8 Preparing the Ends of Shielded Cables

D

44 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 45

3.3 I/O Connections

3.3 I/O Connections

◆ Sinking/Sourcing Mode Switch

Set the DIP switch S3 on the front of the drive to switch the digital input terminal logic

between sinking mode and sourcing mode; the drive is preset to sinking mode.

Table 3.11 Sinking/Sourcing Mode Setting

Set Value Details

SINK Sinking Mode (0 V common): factory setting

SOURCE Sourcing Mode (+24 V common)

Figure 3.9

DIP Switch S3

SINK

SOURCE

Electrical Installation

3

Figure 3.9 DIP Switch S3

■ Transistor Input Signal Using 0 V Common/Sink Mode

When controlling the digital inputs by NPN transistors (0 V common / sinking mode), set

the DIP switch S3 to SINK and use the internal 24 V power supply.

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 45

Page 46

3.3 I/O Connections

Figure 3.10

SINK

SOURCE

Forward run/stop

Reverse run/stop

External fault N.O.

Fault reset

Multi-speed step 1

Multi-function input

Multi-speed step 2

Jog reference

Shielded cable

Drive

S1

S2

S3

S4

S5

S6

S7

SINK

S3

SOURCE

SC

+24V

Figure 3.10 Sinking Mode: Sequence from NPN Transistor (0 V Common)

■ Transistor Input Signal Using +24 V Common/Source Mode

When controlling digital inputs by PNP transistors (+24 V common / sourcing mode), set the

DIP switch S3 to SOURCE and use an external 24 V power supply.

Figure 3.11

SINK

SOURCE

External

power supply

+24 V

Multi-function input

Forward run / stop

Reverse run / stop

External fault N.O.

Fault rest

Multi-step speed 1

Multi-step speed 2

Jog frequency

Shielded cable

Drive

S1

S2

S3

S4

S5

S6

S7

SINK

S3

SC

+24V

SOURCE

Figure 3.11 Source Mode: Sequence from PNP Transistor (+24 V Common)

46 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 47

3.4 Main Frequency Reference

3.4 Main Frequency Reference

◆ Terminal A2 Switch

The main frequency reference can either be a voltage or current signal input. For voltage

signals both analog inputs, A1 and A2, can be used, for current signals A2 must be used.

To use current input at terminal A2, set the DIP switch S1 to "I" (factory setting) and set

parameter H3-09 = “2” or “3” (4-20 mA or 0-20 mA). Set parameter

H3-10 = “0” (frequency reference).

Note: If Terminals A1 and A2 are both set for frequency reference (H3-02 = 0

and H3-10 = 0), the addition of both input values builds the frequency reference.

When using input A2 as voltage input, set the DIP switch S1 to “V” (left position) and

program parameter H3-09 to “0” (0 to 10 Vdc with lower limit) or “1” (0 to +10 Vdc without

lower limit).

Table 3.12 Frequency Reference Configurations

Voltage Input Current Input

Drive

+10.5 V

+V

20 mA current

Main speed

A1

frequency reference

(voltage input)

Main speed

A2

frequency reference

(current input)

AC

Frequency reference

common

2 kΩ

0 to 10 V

Drive

+10.5 V

+V

20 mA current

Main speed

frequency reference

A1

(voltage input)

Main speed

A2

frequency reference

(current input)

AC

Frequency reference

common

4 to 20 mA input

or

0 to 20 mA input

Electrical Installation

3

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 47

Page 48

3.4 Main Frequency Reference

Figure 3.12

DIP Switch S1

VI

Figure 3.12 DIP Switch S1

Table 3.13 DIP Switch S1 Settings

Setting Value Description

V (left position) Voltage input (0 to 10 V)

I (right position) Current input (4 to 20 mA or 0 to 20 mA): factory setting

Table 3.14 Parameter H3-09 Details

No. Parameter Name Description

Selects the signal level for terminal A2.

0: 0 to +10 V, unipolar input (negative frequency

Frequency ref. (current)

H3-09

terminal A2 signal level selection

reference values are zeroed)

1: 0 to +10 V, bipolar input (negative frequency

reference changes the direction)

2: 4 to 20 mA

3: 0 to 20 mA

Setting

Range

0 to 3 2

Default

Setting

48 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 49

3.5 Wiring Checklist

No. Item Page

Drive, peripherals, option cards

1 Check drive model number to ensure receipt of correct model. 16

Check for correct braking resistors, DC reactors, noise filters, and other peripheral

2

devices.

3 Check for correct option card model.

Installation area and physical setup

4 Ensure area surrounding the drive complies with specifications. 20

Power supply voltage, output voltage

The voltage from the power supply should fall within the input voltage specification

5

range of the drive.

6 The voltage rating for the motor should match the drive output specifications.

Main circuit wiring

7 Confirm proper branch circuit protection exists per National and Local codes. 30

8 Properly wire the power supply to drive terminals R/L1, S/L2 and T/L3.

Properly wire the drive and motor together.

The motor lines and drive output terminals R/T1, V/T2 and W/T3 should match in order

9

to produce the desired phase order. If the phase order is incorrect, the drive will rotate in

the opposite direction.

10 Use 600 Vac vinyl-sheathed wire for the power supply and motor lines. 33

Use the correct wire gauges for the main circuit. Refer to Table 3.2, Table 3.3, or

11

Ta bl e 3 . 4.

• When using comparatively long motor cable, calculate the amount of voltage drop.

Motor rated voltage (V) x 0.02 ≥

3 x voltage resistance (Ω/km) x cable length (m) xmotor rated current (A) x10

• If the cable between the drive and motor exceeds 500 m, adjust the carrier frequency

(C6-02) accordingly.

12 Properly ground the drive. Review page 37. 37

Tightly fasten all terminal screws (control circuit terminals, grounding terminals).

13

Refer to Table 3.2, Table 3.3 or Table 3.4.

3.5 Wiring Checklist

72

16

36

33

-3

33

37

71

33

Electrical Installation

3

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide 49

Page 50

3.5 Wiring Checklist

r

No. Item Page

Set up overload protection circuits when running multiple motors from a single drive.

Power supply

14

Note: Close MC1 through MCn before operating the drive.

If using a braking resistor or dynamic braking resistor unit, install a magnetic contactor.

15

Properly install the resistor, and ensure that overload protection shuts off the power

supply.

16 Verify phase advancing capacitors are NOT installed on the output side of the drive.

17 Use twisted-pair cables for all drive control circuit wiring.

18

Ground the shields of shielded wiring to the GND terminal.

If using a 3-wire sequence, properly set parameters for multi-function contact input

19

terminals S1 through S7, and properly wire control circuits.

20 Properly wire any option cards.

Check for any other wiring mistakes.

21

Only use a multimeter to check wiring.

Properly fasten the control circuit terminal screws in the drive.

22

Refer to Table 3.2, Table 3.3 or Table 3.4.

23 Pick up all wire clippings.

Ensure that no frayed wires on the terminal block are touching other terminals or

24

connections.

25 Properly separate control circuit wiring and main circuit wiring.

26 Analog signal line wiring should not exceed 10 m.

27 All other wiring should be less than 50 m.

Drive

MC1 - MCn

OL 1 - OLn

Control circuit wiring

OL1

MC1

OL2

MC2

OLn

MCn

... magnetic contacto

... thermal relay

M1

M2

Mn

46

32

-

33

50 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 51

4

Start-Up Programming

& Operation

This chapter explains the functions of the LED operator and

how to program the drive for initial operation.

4.1 USING THE DIGITAL LED OPERATOR . . . . . . . . . . . . . .52

4.2 THE DRIVE AND PROGRAMMING MODES. . . . . . . . . . . 56

4.3 START-UP FLOWCHARTS . . . . . . . . . . . . . . . . . . . . . . . .56

4.4 APPLICATION PRESETS . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5 BASIC DRIVE SETUP ADJUSTMENTS . . . . . . . . . . . . . . 66

4.6 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.7 TEST RUN CHECKLIST. . . . . . . . . . . . . . . . . . . . . . . . . . . 79

YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

51

Page 52

4.1 Using the Digital LED Operator

4.1 Using the Digital LED Operator

Use the LED operator to enter run and stop commands, display data, edit parameters, as well

as display fault and alarm information.

◆ Keys, Displays, and LEDs

13

1

5

2

12

11

9

3

15

14

STOP

10

STOP

V1000

WARNING

Read manual before installing.

Wait 1 minute for capacitor discharge after

disconnecting power supply.

To conform to requirements, make sure to

ground the supply neutral for 400V class.

46

(Hz)

Fref

:

FWD/REV Sel

:

(Hz)

Fout

:

(A)

lout

:

(V)

Mon1

:

Monitor

:

Verify

:

SetUpGuide

:

Program

:

Auto-Tuning

:

Risk of electric shock.

7

8

52 YASKAWA ELECTRIC TOEP C710606 12B YASKAWA AC Drive V1000 Quick Start Guide

Page 53

4.1 Using the Digital LED Operator

Table 4.1 Keys and Displays on the LED Operator

No. Display Name Function

1 Data Display Area Displays the frequency reference, parameter number, etc.

2 ESC Key Returns to the previous menu.

3RESET Key

4 RUN Key Starts the drive.

5 Up Arrow Key Scrolls up to select parameter numbers, setting values, etc.