Page 1

YASKAWA AC Drive-V1000 Option

DI-100 120 Vac Interface

Option

Installation Manual

PCB PN: UTC000400

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

MANUAL NO. TOEP YEAOPT 03

Page 2

This Page Intentionally Blank

Copyright 2009 YASKAWA ELECTRIC AMERICA, INC. All rights reserved.

All rights reserved. No part of this publication may be reproduced, stored in a retri eval system, or transmitted, in any form or by any

means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent liability

is assumed with respect to the use of the information contained herein. Moreove r, because Yaskawa is constantly striving to improve its

high-quality products, the information contained in this manual is subject to cha nge without notice. Every precaution has been taken in the

preparation of this manual. Yaskawa assumes no responsibility for errors or omissio ns. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication

2 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 OPTION COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 12

6 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 OPTION SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . .24

YAS KAWA ELE CTR IC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 3

Page 4

This Page Intentionally Blank

4 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 5

1 Preface and Safety

STOP

(Hz)

(Hz)

(A)

(V)

V1000

ᵄᢙᜰ

ᱜォㅒォㆬᛯ

ജᵄᢙ

ജ㔚ᵹ

ജ㔚

ࡕ࠾࠲

ࡌࡈࠔࠗ

࠶࠻ࠕ࠶ࡊ

ࡄࡔ࠲⸳ቯ

ࠝ࠻࠴ࡘ࠾ࡦࠣ

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ߎߣޕ

ㅢ㔚߅ࠃ߮㔚Ḯㆤᢿᓟ

5

ಽએౝߪࡈࡠࡦ࠻ࠞࡃࠍ

ᄖߐߥߎߣޕ

400V

⚖ࠗࡦࡃ࠲ߩ႐วߪޔ㔚Ḯߩᕈὐ߇ធ

ߐࠇߡࠆߎߣࠍ⏕ߔࠆߎߣޕ㧔ޓޓኻᔕ㧕

ߌ߇㧚ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ෂޓ㒾

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems

and equipment. The selection and application of Yaskawa products remain the responsibility

of the equipment manufacturer or end user. Yaskawa accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety

control. Without exception, all controls should be designed to detect faults dynamically and

fail safely under all circumstances. All systems or equipment designed to incorporate a

product manufactured by Yaskawa must be supplied to the end user with appropriate

warnings and instructions as to the safe use and operation of that part. Any warnings

provided by Yaskawa must be promptly provided to the end user. Yaskawa offers an express

warranty only as to the quality of its products in conforming to standards and specifications

published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESSED OR IMPLIED,

IS OFFERED. Yaskawa assumes no liability for any personal injury, property damage,

losses, or claims arising from misapplication of its products.

◆ Applicable Documentation

The following manuals are available for the option and drive:

Option

Yaskawa AC Drive -V1000 Option DI-100 120 Vac Interface Installation Manual

Manual No: TOEP YEAOPT 03

Read this manual first.

The installation manual is packaged with the DI-100 120 Vac Interface Option and contains

installation procedures and precautions.

Yaskawa Drive

Yaskawa AC Drive-V1000

Quick Start Guide

Manual No: TOEP C710606 14

Yaskawa AC Drive-V1000

Technical Manual

Manual No: SIEP C710606 18

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 5

To obtain instruction manuals for Yaskawa products

access this site:

U.S.: http://www.yaskawa.com

For questions, contact the local Yaskawa sales office or

the nearest Yaskawa representative.

Page 6

1 Preface and Safety

DANGER

W ARNING

CAUTION

NOTICE

◆ Terms

Note: Indicates a supplement or precaution that does not cause drive damage.

Drive: Yaskawa AC Drive-V1000 Series.

Option: Yaskawa AC Drive-V1000 DI-100 120 Vac Interface Option.

◆ Registered Trademarks

• All trademarks are the property of their respective owners.

◆ Supplemental Safety Information

Read and understand this manual before installing, operating, or servicing this option unit.

The option unit must be installed according to this manual and local codes.

The following conventions are used to indicate safety messages in this manual. Failure to

heed these messages could result in serious or possibly even fatal injury or damage to the

products or to related equipment and systems.

Indicates a hazardous situation, which, if not avoided, will result in death or serious

injury.

Indicates a hazardous situation, which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate injury.

Indicates an equipment damage message.

6 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 7

1 Preface and Safety

NOTICE

■ General Safety

General Precautions

• The diagrams in this section may include option units and drives without covers or safety shields to illustrate

details. Be sure to reinstall covers or shields before operating any devices. The option should be used according to

the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and may not apply

to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the manual may be

changed without notice to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representative or the nearest

Yaskawa sales office and provide the manual number shown on the front cover.

DANGER

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting

from failure to heed the warnings in this manual.

Do not expose the drive to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the option unit.

Do not pack the drive in wooden materials that have been fumigated or sterilized.

Do not sterilize the entire package after the product is packed.

Do not modify the drive circuitry.

Failure to comply could result in damage to the drive and will void warranty.

Yaskawa is not responsible for any modification of the product made by the user. This

product must not be modified.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 7

Page 8

2 Product Overview

2 Product Overview

◆ About This Product

The DI-100 option has seven optically isolated input terminals which can be used to connect

external 120 Vac control circuitry to the V1000 drive. The DI-100 Option mounts directly to

the V1000 control board terminals (S1 ~ S7 and SC). This option makes it possible to

control the V1000 digital inputs with 120 Vac.

This manual explains the handling, installation and specifications of this product.

Note: With this option is installed, safety input terminals H1 and HC on the V1000 drive are designed

to the functionality but are not certified to EN61800-5-1, EN954-1/ISO13849 Category 3, IEC/

EN61508 SIL2, Insulation cooridination: Class 1.

◆ Applicable Models

This option can be used with the drive models in Table 1.

Table 1 Applicable Models

Drive Models Model Notes

CIMR-VUBA0001~BA0003

CIMR-VU2A0001~2A0006

CIMR-VUBA0006 thru BA0018

CIMR-VU2A0010 thru 2A0020

CIMR-VU4A0001 thru 4A0011

CIMR-VU2A0030 thru CIMR-VU2A0069

CIMR-VU4A0018 thru CIMR-VU4A0038

<1> Because the bottom cover/conduit bracket is discarded for DI-100 installation, the enclosure rating of these

models becomes IP00 or NEMA Open Type after DI-100 option installation.

1-phase 200 V

and 3-phase 200 V

(small frame)

1- phase 200 V

3-phase 200/400 V

(medium frame)

3-phase 200/400 V

(large frame)

<1>

<1>

8 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 9

3 Receiving

3 Receiving

Please perform the following tasks after receiving the option.

• All equipment is tested against defects at the factory. Immediately report any damages or

shortages evident when the equipment is received to the commercial carrier who

transported the equipment.

• Verify receipt of the correct model by checking the information on the nameplate (see

Figure 1).

• If you have received the wrong model or the option does not function properly, contact

your supplier.

◆ Contents and Packaging

Table 2 Option Package Contents

Description:

_

Quantity: 1 1

DI-100 120 Vac Interface Card

UTC000400

DI-100 Installation Manual

MANUAL

◆ Tool Requirements

A flat blade screwdriver (#1) with a blade thickness of 0.4 mm or less and a blade width of

2.5 mm or less is required to install the option.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 9

Page 10

4 Option Components

4 Option Components

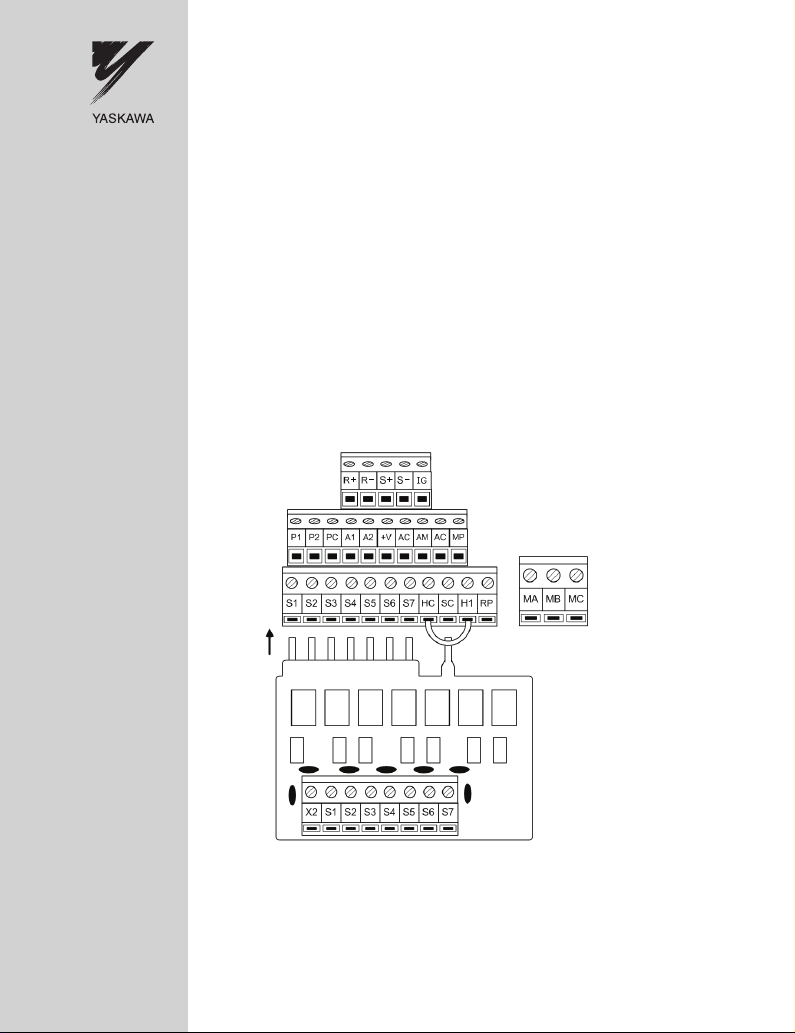

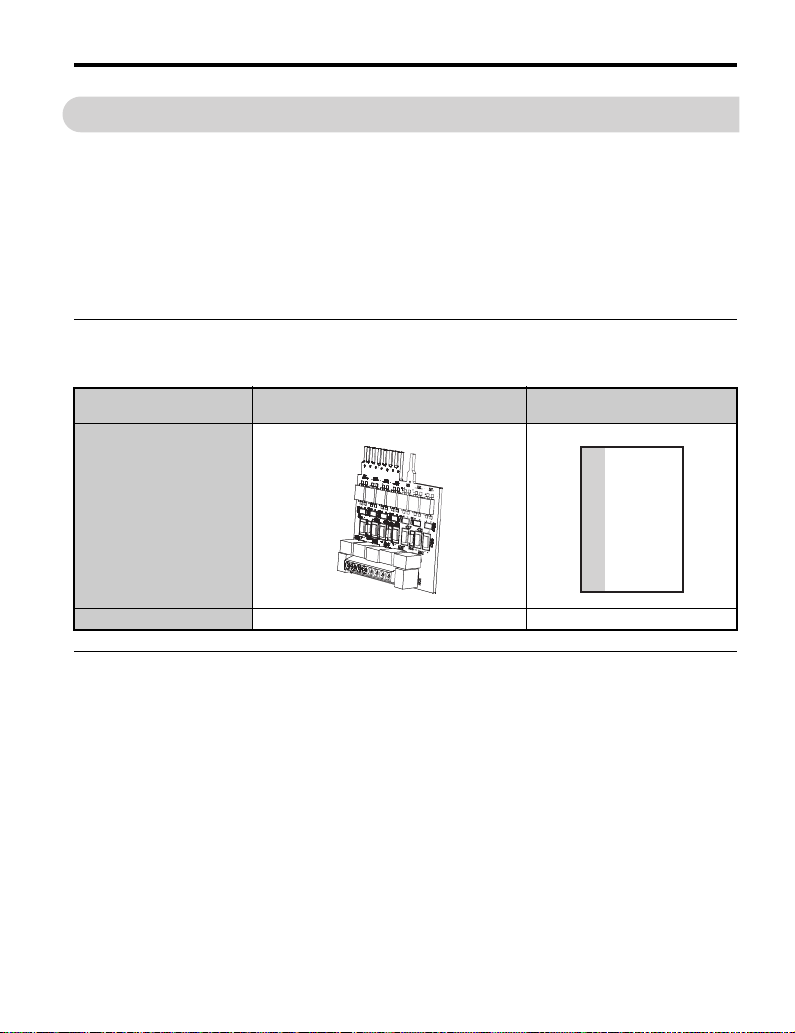

◆ DI-100 Option

Figure 1

B

C

A

A – DI-100 120 V Interface Card

UTC000400

B – Option terminals (to drive)

Figure 1 DI-100 Option

C – Option terminal block

(to control wiring)

◆ Option Terminal Block

An 8-position terminal block is provided for the connection of control wires.

10 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 11

4 Option Components

X2

S1

S2

S3

S4 S5 S6

S7

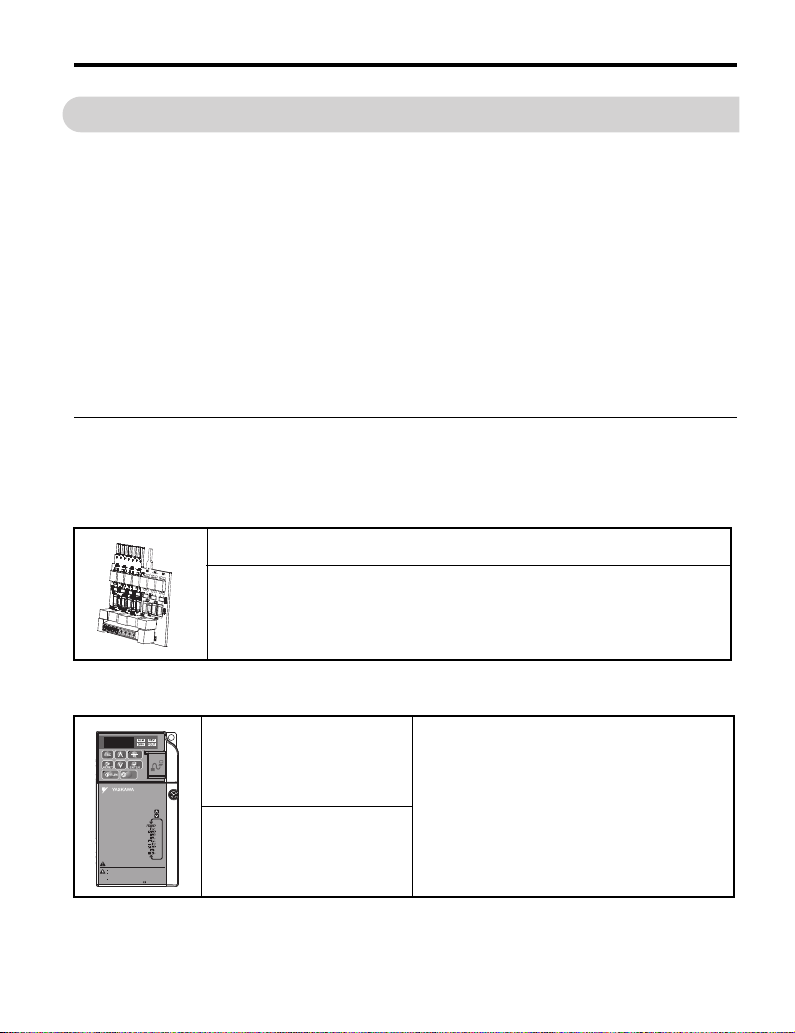

Table 3 Option Terminal Functions

Terminal Functions

D1-100 Option Terminal Block Terminal Sig nal Function Description

Forward Run /

S1

Stop

<1>

Reverse Run /

S2

Stop

<1>

Multi-function

S3

S4

S5

S6

S7

X2 Common

<1> Parameter functions and defaults change based on drive programming.

<1>

Input

Multi-function

<1>

Input

Multi-function

<1>

Input

Multi-function

Input

<1>

Multi-function

<1>

Input

Forward run when

closed, stop when

open.(H1-01)

Reverse run when

closed, stop when open

(H1-02)

Multi-function contact

inputs

(H1-03 to H1-07)

Control Input

Common

Signal

Level

120 Vac

±10 %

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 11

Page 12

5 Installation Procedure

W ARNING

5 Installation Procedure

◆ Section Safety

DANGER

Electrical Shock Hazard

Do not connect or disconnect wiring while the power is on.

Failure to comply will result in death or serious injury.

Disconnect all power to the drive, wait at least five minutes after all indicators are off,

measure the DC bus voltage to confirm safe level, and check for unsafe voltages before

servicing to prevent electric shock. The internal capacitor remains charged even after the

power supply is turned off. The charge indicator LED will extinguish when the DC bus

voltage is below 50 Vdc.

Electrical Shock Hazard

Do not remove option board cover while the power is on.

Failure to comply could result in death or serious injury.

The diagrams in this section may include option units and drives without covers or safety

shields to show details. Be sure to reinstall covers or shields before operating any devices.

The option board should be used according to the instructions described in this manual.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized

personnel familiar with installation, adjustment, and maintenance of this product.

Do not remove option cover while the power to the drive is on.

Failure to comply could result in death or serious injury.

12 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 13

5 Installation Procedure

NOTICE

W ARNING

Do not use damaged wires, place excessive stress on wiring, or damage the wire

insulation.

Failure to comply could result in death or serious injury.

Fire Hazard

Tighten all terminal screws to the specified tightening torque.

Loose electrical connections could result in death or serious injury by fire due to

overheating of electrical connections.

Damage to Equipment

Observe proper electrostatic discharge (ESD) procedures when handling the option

unit, drive, and circuit boards.

Failure to comply may result in ESD damage to circuitry.

Never shut the power off while the drive is outputting voltage.

Failure to comply may cause the application to operate incorrectly or damage the drive.

Do not operate damaged equipment.

Failure to comply may cause further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing parts.

Do not use unshielded cable for control wiring.

Failure to comply may cause electrical interference resulting in poor system performance.

Use shielded twisted-pair wires and ground the shield to the ground terminal of the drive.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 13

Page 14

5 Installation Procedure

NOTICE

Properly connect all pins and connectors.

Failure to comply may prevent proper operation and possibly damage equipment.

Check wiring to ensure that all connections are correct after installing the option

unit and connecting any other devices.

Failure to comply may result in damage to the option unit.

◆ Prior to Installing the Option Unit

Prior to installing the option, wire the drive and make necessary connections to the drive

terminals. Refer to the drive Quick Start Guide for information on wiring and connecting the

drive. First, verify that the drive functions normally without the option installed.

◆ Installing the Option Unit

Remove the front cover of the drive before installing the option. Follow the directions below

for proper installation.

1. Disconnect all electrical power to the drive.

DANGER! Electrical Shock Hazard - Do not connect or disconnect wiring while the power is on. Failure to

comply will result in death or serious injury. Before installing the option, disconnect all power to the drive.

The internal capacitor remains charged even after the power supply is turned off. The charge indicator LED

will extinguish when the DC bus voltage is below 50 Vdc. To prevent electric shock, wait at least five minutes

after all indicators are off and measure the DC bus voltage level to confirm safe level.

Figure 2

Figure 2 Remove Front Cover

2. For certain models remove the bottom cover or conduit brackets and discard. Refer to step

10 on page 20 for which models prohibit cover reinstallation with the DI-100 option.

14 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 15

5 Installation Procedure

Figure 3

Figure 3 Remove Bottom cover

Note: Cover removal steps for larger models of V1000 with a Terminal Cover:

-Single-Phase 200 V Class: CIMR-VUBA0006 to BA0018

-Three-Phase 200 V Class: CIMR-VU2A0008 to 2A0069

-Three-Phase 400 V Class: All models

Note: Remove the terminal cover before removing the bottom cover to install the option. If the drive is

a NEMA Type 1 enclosure, then remove the lower conduit brackets.

Lower conduit bracket removal is not required for these larger models.

-200 V CIMR-VU2A0030F thru CIMR-VU2A0069F

Figure 4

-400 V CIMR-VU4A0018F thru CIMR-VU4A0038F

Figure 4 Models with Terminal Cover

3. Verify that the red color “CHARGE” indicator lamp (LED) inside the drive is off. It may take

as long as 10 min for the charge on the DC bus capacitors to drop to a safe level

4. Use a voltmeter to verify that the voltage at the incoming power terminals (R/L1, S/L2 and

T/L3) is not present and removed by disconnecting means.

5. Loosen terminals S1 ~ S7 and SC on V1000 drive control wiring terminal block TB1-1.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 15

Page 16

5 Installation Procedure

Figure 5

Figure 5 Loosen Drive Control Terminals S1 ~ S7 and SC

6. Remove the 120 Vac Interface Card from the ESD bag.

NOTICE: When handling printed circuit boards (PCB’s) always use electrostatic discharge (ESD) protection.

Keep the boards in the ESD bag as long as you can. Do not lay the board on any surfaces without the ESD

protection. When handling, always hold the board from the edges and do not touch the components. Before

installing this option, a technically qualified individual, familiar with this type of equipment and the hazards

involved, should read this entire installation guide.

Figure 6

Figure 6 Remove DI-100 Option from ESD Bag

16 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 17

5 Installation Procedure

Preparing

wire ends

E

A

B

D

C

X2 S1 S2 S3 S4 S5 S6 S7

7. Prepare external 120 Vac control circuit wires (customer wiring) for terminals S1 ~ S7, X2

on the DI-100 option. Prepare the wire ends using Table 4 and Figure 7 as a guide.

NOTICE: Wires to the option should be stripped according to Figure 7 for maximum system safety. Use of

ferrules on the wire ends are recommended.

Table 4 Terminal and Wire Specifications

Terminal and Wire Specifications

Terminal Symbols Ter min al S c re w

S1 ~ S7, X2 M2 1.9 to 2.2 26 to 16 18 / 16

Figure 7

DI-100 Option

Tightening Torque

(in-lbs)

Control Wiring

(AWG)

Recommended

(AWG)

A – DI-100 terminal block D – Loosen screw to insert wire.

B – Avoid fraying wire strands

C – Single wire or stranded wire

8. Connect the prepared customer wiring to the DI-100 terminal block as shown in Figure 7

and Figure 8. Refer to Table 4 for tightening torque. Figure 9 is an example of a wiring

diagram showing customer interface circuitry.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 17

when stripping insulation from

wire. Strip length 5.08 mm (0.2

in) ±20%

Figure 7 DI-100 Terminal Wiring Guide

E – Blade depth:

0.4 mm (.0157 in) or less

Blade width:

2.5 mm (.089 in) or less

Page 18

5 Installation Procedure

DI-100 Option

120 Vac External

Control Wirin g

Figure 8

Figure 8 120 Vac External Control Wiring (customer wiring) to DI-100 Option

FWD

REV

S3

S4

S5

S6

S7

120 VAC

X2X1

INTERFACE

120 VAC

CARD

X2

S1

S2

S3

S4

S5

S6

S7

Yaskawa V1000

AC Drive

SC C ommon

S1 Forward run/stop

S2 Reverse run/stop

S3 External fault

S4 Fault reset

Multi-step speed 1

S

5

mail/aux switch

S6 Multi-step speed 2

S7 Jog reference

Figure 9 Wiring Diagram Example

18 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 19

5 Installation Procedure

V1000 Drive Terminals

DI-100 Option

120 Vac External

Control Wirin g

Connect the DI-100 to the V1000 drive.

The DI-100 option connects to V1000 drive terminals S1 ~ S7 and SC. External 120 Vac

input devices can then connect to terminals S1 ~ S7 and X2 on the DI-100 option.

Figure 10 shows the control terminal arrangement for the V1000 drive with the DI-100

option.

Figure 9

Figure 10 Terminal Connections

9. Insert the DI-100 Option into the V1000 drive control terminals S1 ~ S7, and SC. Secure

the DI-100 option board by tightening the V1000 terminals. Refer to the V1000 Quick Start

Guide TOEPC71060614, for recommended tightening torque.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 19

Page 20

5 Installation Procedure

REMOVE and

discard this

cover

1

Reinstall

Note 1:

The drive enclosure rating

now becomes IP00/Open Type

with this cover removed.

IP20/Open Type

NEMA Type 1

REMOVE and

discard these

covers

1

Note 1:

The drive enclosure rating

now becomes IP00/Open Type

with this cover removed.

Reinstall

10. Reinstall the front cover(s). NOTE: Cover installation is model dependant.

Use Table 5 and associated figures as a guide to determine which drive models prohibit

bottom cover/conduit bracket reinstallation.

Table 5 Drive Cover Installation

Drive Models See Figure Model Notes

CIMR-VUBA0001~BA0003

CIMR-VU2A0001~2A0006

CIMR-VUBA0006 thru BA0018

CIMR-VU2A0010 thru 2A0020

IP20/Open

IP20/NEMA Type 1

Figure 11

IP20/Open - Figure 12

IP20/NEMA Type 1- Figure 13

CIMR-VU4A0001 thru 4A0011

CIMR-VU2A0030 thru CIMR-VU2A0069

CIMR-VU4A0018 thru CIMR-VU4A0038

<1> Because the bottom cover/conduit bracket is discarded for DI-100 installation, the enclosure rating of these

models becomes IP00 or NEMA Open Type after DI-100 option installation.

NOTICE: Some V1000 models will not allow the bottom conduit covers to be reinstalled. Discard covers

specified in Figures 11 thru 15 after DI-100 installation is complete.

Figure 10

IP20/Open - Figure 14

IP20/NEMA Type 1 - Figure 15

1-phase 200 V

and 3-phase 200 V

(small frame)

1- phase 200 V

3-phase 200/400 V

(medium frame)

3-phase 200/400 V

(large frame)

<1>

<1>

Figure 11 Cover Installation on Models

CIMR-VUBA0001 thru BA0003

CIMR-VU2A0001 thru 2A0006

20 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 21

Figure 11

REMOVE and discard

this cover

Reinstall

Reinstall

Note:

The drive enclosure rating

now becomes IP00/Open Type

with this cover removed.

REMOVE and discard

this cover

Reinstall

Reinstall

Note:

The drive enclosure rating

now becomes IP00/Open Type

with these covers removed.

REMOVE and discard

this cover

Figure 12

5 Installation Procedure

Figure 12 Cover Installation on IP20/Open Type Models

CIMR-VUBA0006 thru BA0018

CIMR-VU2A0010 thru 2A0020

CIMR-VU4A0001 thru 4A0011

Figure 13 Cover Installation on IP20/NEMA Type 1 Models

CIMR-VUBA0006 thru BA0018

CIMR-VU2A0010 thru 2A0020

CIMR-VU4A0001 thru 4A0011

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 21

Page 22

5 Installation Procedure

Reinstall

Reinstall

Reinstall

Reinstall

Figure 13

Figure 14 Cover Installation on IP20/Open Type Models

200 V CIMR-VU2A0030B thru CIMR-VU2A0069B

Figure 14

400 V CIMR-VU4A0018B thru CIMR-VU4A0038B

Figure 15 Cover Installation on IP20/NEMA Type 1 Models

200 V CIMR-VU2A0030F thru CIMR-VU2A0069F

400 V CIMR-VU4A0018F thru CIMR-VU4A0038F

11. This completes the installation procedure.

22 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 23

6 Troubleshooting

6 Troubleshooting

Troubleshooting tips are provided below. Verify these points if the drive is not behaving as

expected after installing the option:

• Verify all wire connections are tight.

• Verify all PCB Fingers are fully inserted into the V1000 drive terminals and the terminals

are fully tightened.

• Verify the signal is present at the option terminal by using a Volt Meter to measure the

input signal with respect to the X2 terminal.

• Verify the input is recognized by the drive by viewing Input Terminal Status monitor

parameter U1-10.

• Verify the drive Multi-Function Digital Input parameters (H1-01 through H1-07) of the

drive are set correctly for the expected S1~S7 input terminal behavior.

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 23

Page 24

7 Option Specifications

7 Option Specifications

Specification Data

Inputs 7 + 1 Neutral

Input Impedance, Nominal 10K ohms

On-State Voltage 93 to 132 Vac (110/120 Vac +10% / -15%)

On-State Current, Nominal 14 mA @ 120 Vac

Off-State Voltage, Maximum 19 Vac

Off-State Leakage Current, Maximum 2.5 mA

Operating Frequency 47 to 63 Hz (50/60 Hz +/15%)

On-State Response Time, Maximum 50 ms

Off-State Response Time, Maximum 50 ms

Terminal Wiring AWG 16 to AWG 26

24 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 25

7 Option Specifications

Published in U.S.A. July 2009 09-07

Date of

publication

Date of original

publication

Minor revision number

1

Major revision letter

MANUAL NO. TOEP YEAOPT 03 A

◆ Revision History

The revision dates and the numbers of the revised manuals appear on the bottom of the back

cover.

Date of

Publication

April 2009 −−First edition

July 2009 <1>

Revision

Number

Section Revised Content

Product

Overview

YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual 25

Added Note concerning terminals H1 and HC to the section; About this

Product.

Page 26

7 Option Specifications

This Page Intentionally Blank

26 YASKAWA ELECTRIC TOEP YEAOPT 03 - V1000 Option DI-100 120 Vac Interface Installation Manual

Page 27

This Page Intentionally Blank

YASKAWA ELECTRIC TOEP YEAOPT 03 V1000 Option DI-100 120 Vac Interface Installation Manual 27

Page 28

YASKAWA AC Drive-V1000 Option

DI-100 120 Vac Interface Option

Installation Manual

YASKAWA ELECTRIC AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: 1-847-887-7000 or (800)YASKAWA (800-927-5292) Fax: 1-847-887-7310

Internet: http://www.yaskawa.com

YASKAWA ELECTRIC AMERICA INC.

YAS K A W A

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be

sure to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2008 YASKAWA ELECTRIC AMERICA INC. All rights reserved.

MANUAL NO. TOEP YEAOPT 03A <1>

Published in U.S.A July 2009

Loading...

Loading...