Page 1

THK VLA Indexer

Page 2

Page 3

Table of Contents

Introduction ................................................................1

Opening Screen ..........................................................2

To create a new project ..........................................3

To open an existing project .....................................3

THK Wizard .................................................................4

Main Screen ..............................................................11

Modules .....................................................................11

Sequences ................................................................13

Sequence Events ......................................................14

Start By Events: Expression, Input, and Variable .14

Change Events: Accel and Speed ........................14

Loop Events: Expression and Fixed Number ........14

Move Events: Start and End .................................15

Set Events: Output and Variable ...........................15

Wait For Events: Absolute Position, Distance, Input,

Time, and Variable ................................................16

Skip Event .............................................................16

Sequence Rules ........................................................16

Variables ...................................................................17

Menu Items ...............................................................17

Program Flow ...........................................................17

Sequence Terms .......................................................20

Hardware ...................................................................21

Start-up .................................................................21

Mounting Orientation .............................................21

Power/Connections Wiring - Single Phase ...........23

Power/Connections Wiring - Three Phase ............24

I/O Connections (50-pin CN5) ...............................25

Digital I/O ..............................................................26

Serial Communication ...........................................29

i

Page 4

ii

Page 5

THK VLA Indexer

Introduction

The THK VLA Indexer allows a user to “program” motion on a

VLA slide without ever learning or knowing a programming

language.

The user simply answers a series of questions about the slide

being used, the load connected to it, and what will cause it to

energize and home. Then the user creates one or more sequences

that the slide is required to perform using pre-defined events like

“Move Start”. Once all of the parameters are entered into the

events chosen by the user, a program can be generated and sent to

the controller by compiling and downloading.

The program created and downloaded will begin running

immediately. It will set all necessary parameters, wait for the

condition chosen to energize the servomotor, and then enter

either the manual or automatic mode. The manual or automatic

mode is dictated by the state of input 8. If input 8 is high or off

the program enters Manual mode, if it is low or on, Auto mode is

run; but only after the servo is enabled the first time.

Manual mode allows the user to enable and disable the servo (if

the choice to energize the servo was by input or variable), and

once the servo is enabled, to jog forward or reverse.

Auto mode will home the servo once after a po wer-up when the

condition to home is true, and then run sequences when their

individual start conditions are true. If there is more than one

sequence defined and the condition to start each sequence is true,

then the sequences will be run in order one after the other, and

will continue to run until the start condition is false. Remember,

in order to enter the Auto mode, the servo must be energized.

1

Page 6

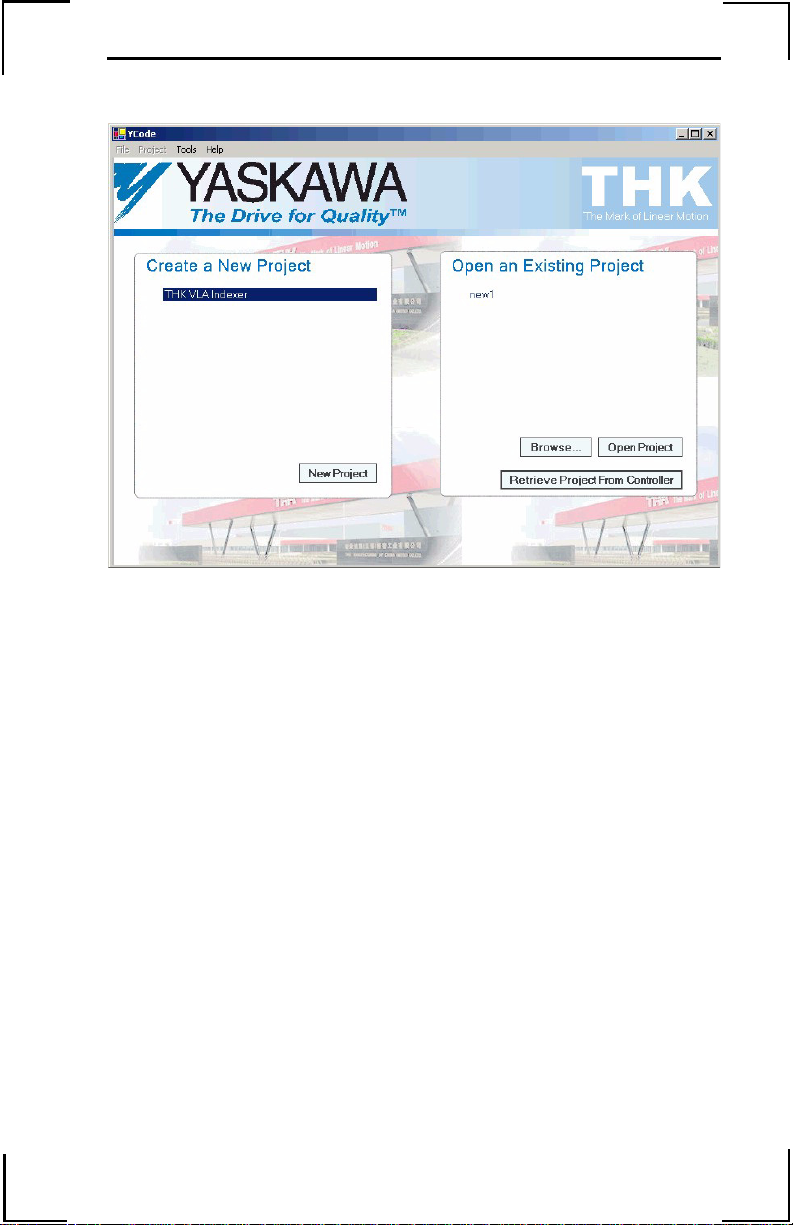

Opening Screen

When the application is started, the user is presented with the

opening screen, which allows the user to create a new project or

open an existing project.

2

Page 7

To create a new project

Select the template name “THK VLA Indexer” and click on the

New Project button.

Enter a project name, select “OK”, and the THK Wizard will

appear.

To open an existing project

An existing project can be opened by selecting it from the list and

clicking on “Open Project”, or by clicking on “Browse…” to

locate the ***.yap file. A project can also be opened from the

controller (if it was previously saved using the save project to

controller option) by selecting “Retrieve Project From

Controller” while connected online.

3

Page 8

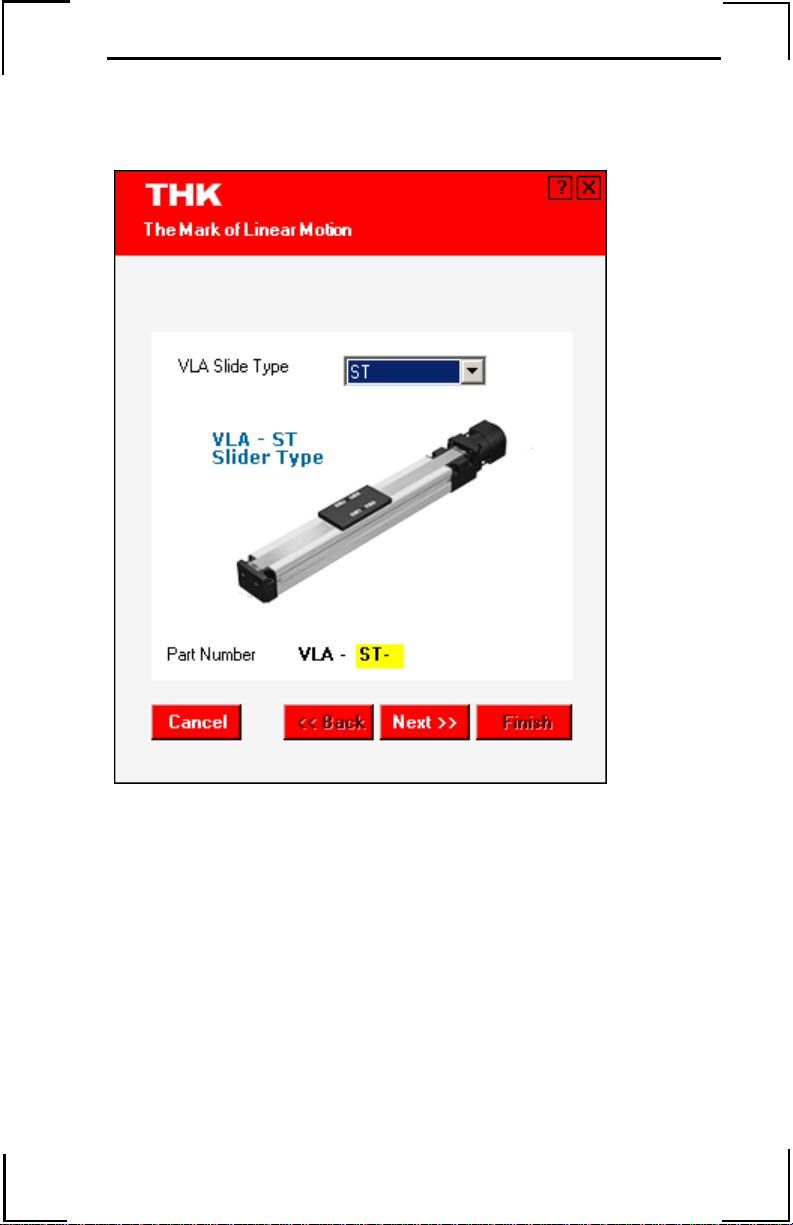

THK Wizard

The THK Wizard will guide the user through entering the THK

part number of the VLA slide and selecting the load connected.

Locate the part number of the VLA slide. The part number is

located on the left side of the actuator if the motor is positioned

on the left.

Select the type of VLA slide by choosing either ST or CT. The

picture changes as the selection is changed. Navigate through the

screens using the Next button to advance.

4

Page 9

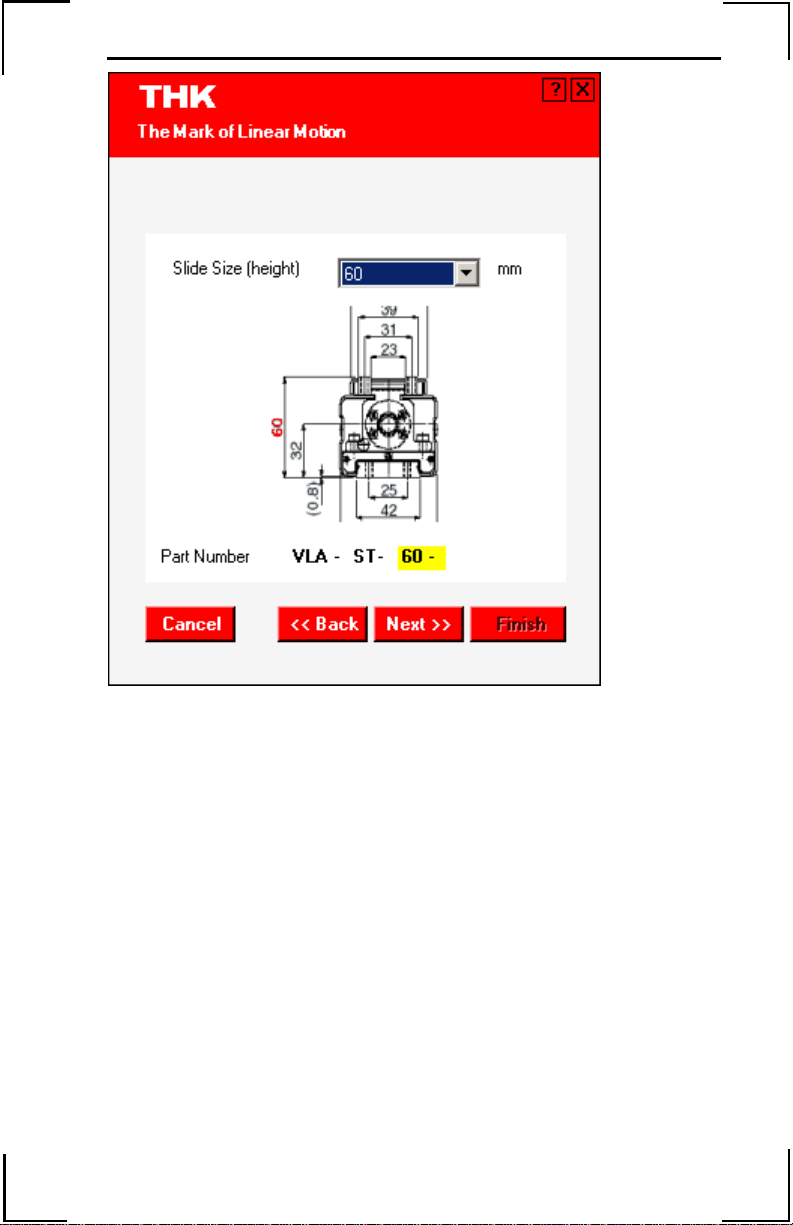

Next enter the Slide Height.

5

Page 10

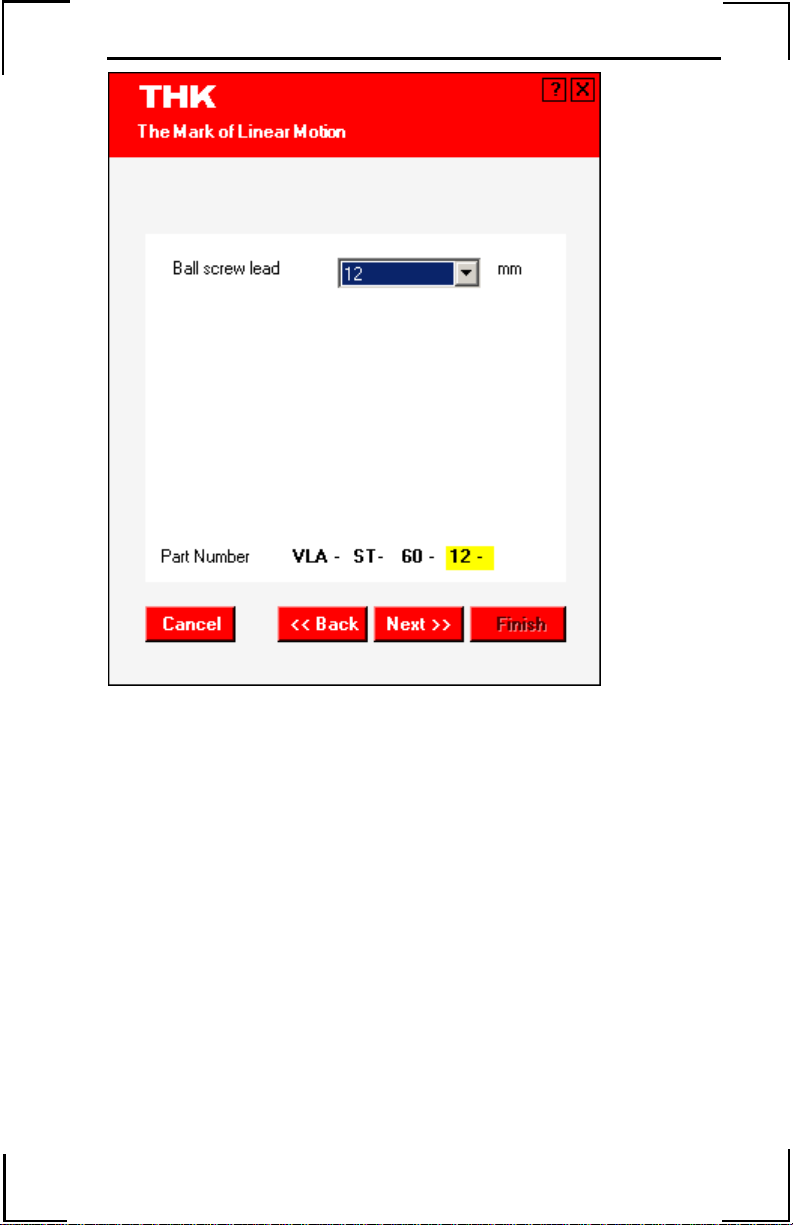

A ball screw lead must be selected if using an ST type slide. For

the CT type, accept the 12mm default.

6

Page 11

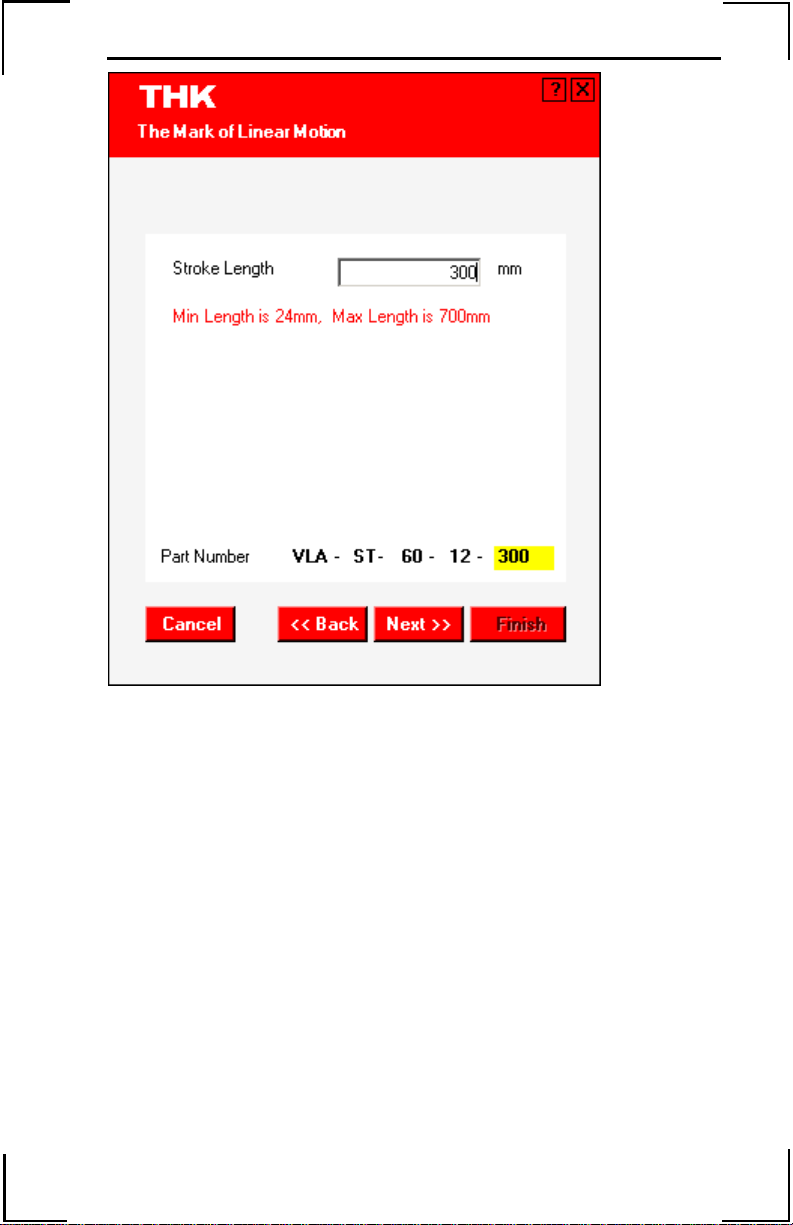

Enter the Stroke Length.

7

Page 12

Specify the Load Direction and Weight.

8

Page 13

Select the Units.

9

Page 14

Select the side on which the actuator will home and click on

“Finish”.

10

Page 15

Main Screen

Project Tree

Main Window

Progress

Window

The main screen features a Project Tree that is used to display

items in the main window and a Progress Window that highlights

the step currently being performed. Clicking on Project Tree will

access the main folders that make up the program (modules,

sequences, and variables).

Modules

Clicking on “Modules” will display the setup questions for the

application. There are two ways to view the questions, one at a

time (Wizard View), or all at once (Table View). Wizard View

displays questions one at a time with question specific help at the

bottom of the main window. This allows the user to navigate back

and forth using the Previous and Next buttons. Wizard View is

the default view and is shown in the main window above.

11

Page 16

Table View displays all of the questions at once, with all but the

last unanswered question grayed out. This focuses the user’s

attention on the last unanswered question while allowing viewing

of the entire set of questions that have been answered.

Clicking on the name of an individual module will filter the

questions in Table View, displaying only the questions in that

module.

12

Page 17

Sequences

To create a sequence, right-click the word “Sequence” in the

Project Tree and select “Add Sequence”.

Sequence view with no

sequences defined

Sequences are given meaning by adding events. To add an event,

select one from the drop down list at the top of the screen and

click the Add Event (+) button.

Delete Event

Move Event, Up

or Down

List of Events

Add Event

All sequences must begin with a Start By event (Input,

Expression, or Variable) and there must be only one Start By

event so place one of these events in the first position of the

sequence window.

13

Page 18

Sequence Events

Start By Events: Expression, Input, and Variable

• Start by Expression must be valid comparison expressions in

the form of x=2, y>7, or similar items that evaluate to Boolean

true or false. This is an advanced event allowing anything to be

specified, and is NOT checked for errors. If unsure, avoid using

this event.

• Start by Input asks the user to specify an input number and

state or transition of the input. Valid input numbers are from

1~7 (and 2000~2255 if using Ethernet I/O). Specifying a state

will cause the sequence to run when the input is On or Off,

while specifying a transition will wait until the edge or change

of the input occurs.

• Start by Variable requires the user to enter a variable name

and value. Valid variable names are 1 to 8 characters in length,

case sensitive, and accept alphanumeric characters and the

underscore. The value entered is the value that will cause the

sequence to run.

The user adds the remaining events as needed to form the custom

sequence required for the application.

Change Events: Accel and Speed

These events are useful for changing values while moving.

• Change Accel allows the user to specify a new acceleration.

• Change Speed allows the user to specify a new speed.

Loop Events: Expression and Fixed Number

A Loop event will cause the program to loop back to a previous

labeled event.

An event is labeled by entering a name for the event in the

response column on the row of the event name. The Loop event

will only allow program flow to return upwards. Program flow

cannot be returned to the start event, or within a Move Start,

Move End pair.

14

Page 19

• Loop Expression will continue to loop while the expression is

true. Expressions are valid comparisons in the form of x=2,

y>7, or similar items that evaluate to Boolean true or false. This

is an advanced event allowing anything to be specified, and is

NOT checked for errors. If unsure, avoid using this event.

• Loop Fixed Number will loop for the number of times

specified.

Move Events: Start and End

• Move Start has the user specify all of the move parameters.

! Acceleration is entered in user units.

! Deceleration is entered in user units.

! S-Curve is the amount of motion smoothing applied to the

move. A value of 1 indicates no S-Curve and .004

indicates the maximum S-Curve. Applying S-Curve

smooths the acceleration and lengthens the move time.

! Speed is entered in user units.

! Move Type can either be absolute or incremental.

Absolute moves go to that absolute position (based on

where the home position is), while incremental moves

advance a certain distance from where they are currently.

! Position is entered in user units.

• Move End requires selection of either profiler or encoder.

! Profiler will wait until the controller finishes calculating

the move and sends the commands to the motor.

! Encoder will wait for the actual position of the motor to

reach the calculated position.

Set Events: Output and Variable

• Set Output specifies an output number and a state (either on or

off).

• Set Variable specifies a variable name and value.

15

Page 20

Wait For Events: Absolute Position, Distance, Input, T ime, and Variable

• Wait for Absolute Position waits for the encoder to reach the

position specified.

• Wait for Distance waits for the encoder to see a movement of

the distance specified from the start of the move.

• Wait for Input waits for the input to be at the state specified,

or for the transition to occur.

• Wait for Time waits for an amount of time specified in

milliseconds (where 1000 = 1 second)

• Wait for Variable waits for the variable specified to be set to

that value.

Skip Event

Allows the program to conditionally skip one or more events.

Sequence Rules

1. All sequences must begin with a Start By event, and there must be only one Start By event. So place one of these events in the first position of the Sequence window.

2. The program cannot loop back to a Start By event.

3. Every Move Start event must have one and only one Move End event.

4. Moves cannot be nested. If a Move Start event is placed in a sequence, then a Move End event must be placed in that sequence before another Move Start event.

5. The events Wait for Absolute Position and Wait for Distance must be placed within a Move Start, Move End pair.

6. If a Loop event is used, there must be a previous event with a label to loop back to.

7. If a Skip event is used, there must be a later event with a label to skip to.

16

Page 21

Variables

When variables are entered into the program, they automatically

appear in the variable table. Variables in the program must be

initialized. Specify a value for all variables used in the program

or the compiler will prompt for values.

Menu Items

The File menu contains the standard items that allow the user to

create a new project (New), open an existing project (Open), save

the current project (Save), and create a copy of the current project

with a new name (Save As).

The Project menu allows the user to create a downloadable

program file (Compile), to download the executable program to

the controller (Send to Controller/Download), and to save the

current project (Send Project File to Controller) on the controller.

All of the questions in the modules must be answered and at least

one move sequence with a minimum of one event existing before

the user is allowed to compile.

The Tools menu allows the user to rerun the VLA slide selection

Wizard if the user needs to change the model number.

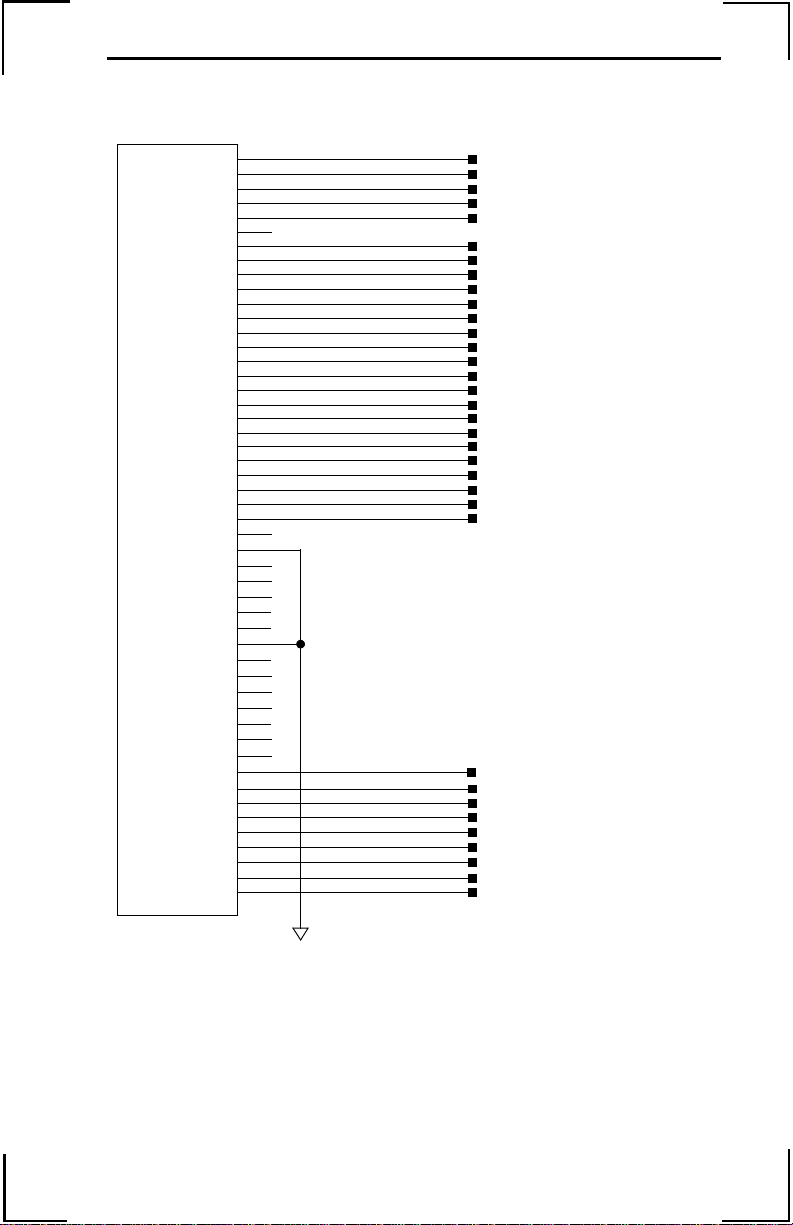

Program Flow

The program will begin running immediately after it is

downloaded or whenever the power is cycled. It will set all

necessary parameters, wait for the condition chosen to energize

the servomotor, and then enter either the manual or automatic

mode. If input 8 is High/Off, the program enters Manual mode. I f

it is Low/On, Auto mode is engaged; but only after the servo is

enabled the first time.

Manual mode allows the user to enable and disable the servo (if

the choice to energize the servo was by input or variable), and

once the servo is enabled, to jog forward or reverse. Jogging

forward or reverse is achieved by pressing the reverse or forward

limit switch respectively. Jogging will continue for as long as the

switch is held on.

17

Page 22

Auto mode requires that the servo be homed once after a powerup. If the servo has not been homed, no sequences will run. When

the condition to home is true, the servo will find the home

position and then run sequences when their individual start

conditions are true. If there is more than one sequence defined

and the condition to start each sequence is true, then the

sequences will be run in order one after the other, and will

continue to run until the start condition is false. Remember, if

Input 8 is High/Off, the program enters the Manual mode. If it is

Low/On, the Auto mode is engaged, but only after the servo is

enabled the first time.

18

Page 23

Auto Mode

Run Sequence 1

Run Sequence n

Yes

Yes

Power On

Set servo gains

Set parameters

Set internal

variables

Is servo on

condition true

Yes

Turn Servo On

Is Manual input

on

No

Home condition

= True & NOT

HOMED

No

Sequence 1

start = True &

HOMED

No

Sequence n

start = True &

HOMED

No

No

Manual Mode

Yes

Is Servo-On

condition True

Start Home

Yes

Yes

Home Complete

No

Home timeout

No

Yes

Set Error

End

Yes

Turn Servo On

Is Jog + input

on

No

Is Jog - input

on

No

Turn Servo Off

No

Jog forward at +

Yes

Jog speed

Jog reverse at -

Yes

Jog speed

Program Flow

19

Page 24

Sequence Terms

• Encoder: The physical device used to track position mounted

on the motor.

• Expression: Must be valid comparison expressions in the form

of x=2, y>7, or similar items that evaluate to Boolean true or

false. This field is NOT checked for errors. If unsure, avoid

using events with this parameter.

• Input: Valid input numbers are from1~7 (and 20 00~2255 if

using Ethernet I/O). Specifying a state will cause the event to

run when the input is on or off while specifying a transition will

wait until the edge or change of the input occurs (i.e. the input

must go from 1 to 0 or from 0 to 1 before the event will run).

• Label: Labels are applied to events by entering characters in the

response column next to the event name.

• Output: Valid output numbers are from1~4 (and 2000~2255 if

using Ethernet I/O).

• Variable: Valid variable names are 1 to 8 characters in length,

case sensitive, and accept alphanumeric characters and the

underscore. Variable values are in the range –

2147483648.9999 ~ 2147483647.9999 and have a fractional

resolution of 1/65536.

20

Page 25

Hardware

Start-up

Mounting the LEGEND-MC to the LEGEND Amplifier

1. Insert the lower two mounting notches of the LEGEND-MC

into the mounting holes at the bottom of the right side of the

LEGEND.

2. Push the LEGEND-MC in the direction indicated by the

arrow in the figure below, and insert the upper mounting

notches of the LEGEND-MC into the upper mounting holes

on the right side of the LEGEND.

Mounting Orientation

Mount the LEGEND-MC and LEGEND vertically for proper

cooling, as shown below. Allow a minimum spacing of 10mm

around the left and right sides and 30mm around the top and bottom

of the LEGEND-MC/LEGEND unit.

21

Page 26

Front Panel Description

No. Name Description

(1) Power

ON

(2) Alarm/

Error

(3) CN6 9 pin male D-Sub serial port connector

(4) CN5 3M 50 pin high density I/O connector

(5) RST Reset switch. Causes the controller to

(6) Ethernet

status

(7) Ethernet

status

(8) CN4 10 BaseT Ethernet RJ485 Connector

(9) FG Frame ground spade terminal.

A lit green LED indicates that the

+5 VDC power supplied to the

LEGEND-MC controller from the

LEGEND amplifier is working.

A red LED that will flash on initially at

power-up and stay lit for approximately

1-8 seconds. After power-up, the LED

will illuminate for the following

reasons:

Position error occurs when the

measured value is greater than the

position error limit setpoint. Manual

reset of the controller, noise and/or a

failure in the processor can also

trigger this alarm for a short time. If

the error does not clear, please

contact your local Yaskawa

representative for assistance.

reboot, and load the application

program and parameters from flash.

A green LED that is lit when there i s an

Ethernet connection to the controller.

This LED tests only for the physical

connection, not for an active or

enabled link.

The yellow LED indicates traffic across

the Ethernet connection. This LED will

show both transmit and receive activity

across the connection. If there is no

Ethernet connection or IP address

assigned, the LED will flash at regular

intervals to show that the BOOTP

packets are being broadcast.

Connect to ground terminal on

LEGEND Amplifier

(2)

(3)

(4)

(8)

(5)

(7)

(9)

(1)

(6)

22

Page 27

Power/Connections Wiring - Single Phase

R

Noise Filter

T

Control

Power

ON

1MC

Servo ON

Control

Power

OFF

Servo

Power

OFF

Emergency

Stop

1MC

1MCCB

1MC

SUP

2MC

2MC

SUP

YASKAWA

C

N

6

LEGEND01

2MC

1MC

Note: The LEGEND-MC receives its power from the LEGEND amplifier through the side

interface connector, however, the digita l I/O receives its power from pins 46, 47,

48, and 49 on the I/O connector.

For maximum noise immunity, connect the FG to a ground terminal on the sub

panel or to the ground terminal on the LEGEND.

CHARGE POWER

L1

L2

L3

1

2

L1C

L2C

B1

B2

B3

U

V

W

C

N

5

C

N

1

C

N

2

R

S

T

C

N

4

F

G

23

Page 28

Power/Connections Wiring - Three Phase

R

T

S

1MCCB

Noise Filter

Control

Power

ON

1MC

Servo ON

Control

Power

OFF

Servo

Power

OFF

Emergency

Stop

1MC

1MC

SUP

2MC

2MC

1MC

2MC

YASKAWA

LEGEND01

CHARGE POWER

L1

L2

L3

1

2

L1C

L2C

B1

B2

B3

U

V

W

SUP

C

N

6

C

N

5

C

N

1

C

N

2

R

S

T

C

N

4

F

G

Note: The LEGEND-MC receives its power from the LEGEND amplifier through the side

interface connector, however, the digita l I/O receives its power from pins 46, 47,

48, and 49 on the I/O connector.

For maximum noise immunity, connect the FG to a ground terminal on the sub

panel or to the ground terminal on the LEGEND.

24

Page 29

I/O Connections (50-pin CN5)

CN5

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Analog 1

Analog 2

+5 Filtered Output power (60 mA available)

-12 Filtered Output power (10 mA available)

+12 Filtered Output power (10 mA available)

Output compare (requires internal jumper)

External encoder AExternal encoder A+

External encoder BExternal encoder B+

Abort Input

Reverse limit switch

Home Input

Forward limit swi tc h

Reset Input

Digital Input 2

Digital Input 1

Digital Input 7

Digital Input 8

Digital Output 4

Digital Output 3

Digital Output 2

Digital Output 1

E STOP2

Analog Output

Digital Input 6

Digital Input 5

Digital Input 4

Digital Input 3

24V GND Input

24V Power Input

24V GND Input

24V Power Input

E STOP1

LEGEND-MC Signal Ground

25

Page 30

Digital I/O

Digital Input

Item Specifications

Number of Input Points 8

Input Format Sinking

Isolation Optical

Voltage 24 VDC ± 20%

Current Rating (ON) 5.3 mA to activate

Input Impedance 2.2k Ω

Operation Voltage Logic 0 <5V

OFF Current 0.9 mA or less

Response Time OFF to ON: <0.5 ms

Latch Response Time Less than 25 µsec

Minimum Latch Width 9 µsec

Note: Inputs float high unless the input is held low.

Internal Circuitry

Logic 1 >15V

ON to OFF: <1.5 ms

2.2k

LEGEND-MC I/O

Legend-MC I/O

Connector CN5

47

49

18

17

45

44

43

42

19

20

Field Wiring

Digital Input 1

(Main Latch)

Digital Input 2

(External Latch)

Digital Input 3

Digital Input 4

Digital Input 5

Digital Input 6

Digital Input 7

Digital Input 8

24VDC

26

Page 31

Digital Output

Item Specifications

Number of Output Points 4

Output Format Sinking

Output Classification Transistor Output

Isolation Optical

Load Voltage 24 VDC ± 20%

Load Current 200 mA/Output (600 mA if activated individually)

Response Time OFF to ON <0.25 ms

External Common Power 24 VDC ± 20% 15 mA

Common User Fuse Rating 1A

Individual User Fuse Rating 200 mA recommended

Note: The ULN 2803 output chip is capable of 600mA at a single output, or 800mA for

the four outputs simultaneously.

Internal Circuitry

PS2505-4

10k

ON to OFF <0.5 ms

ULN2803

LEGEND-MC I/O

Legend-MC I/O

Connector CN5

47

49

4.7k

24

23

22

21

Field Wiring

Digital Output 1

Digital Output 2

Digital Output 3

Digital Output 4

L

L

L

L

Fuse

24VDC

46

48

27

Page 32

Emergency Stop Chain

Internal Circuitry

VCC

U17

LEGEND-MC I/O

Legend-MC I/O

Connector CN5

Field Wiring

50

25

Q1

-EROUT

1k

Note: Note: The LEGEND-MC closes the relay contact under normal operating

conditions.

Ratings: 1.0A @ 24 VDC

0.5A @ 125 VAC

Maximum switching power: 62.5VA, 30W

2N7002

E STOP1

E STOP2

28

Page 33

Serial Communication

-

Item Specifications

Baud Rate 9600 or 19200 set by jumper JP1, default is 19200

Data Bits 8

Parity None

Stop Bits 1

Internal Circuitry

C1+

.1 UF

C1C2+

.1 UF

C2T1IN

T2IN

A1OUT

A2OUT

MAX232A

T1OUT

T2OUT

A1IN

A2IN

U7

V+

V-

LEGEND-MC Serial

Legend-MC Serial

Port Connector CN6

VCC

.1 UF

.1 UF

1

6

8

2

3

7

4

9

5

Field Wiring

CTS Output

CTS Output

CTS Output

Transmit Output

Receive Input

RTS Input

RTS Input

N/C

Signal Ground

Note: NOTE: Hardware handshaking must be used with the LEGEND-MC. If it is impos

sible to implement hardware handshaking, use a jumper between pins 1 and 4 in

the connector.

Note: NOTE: Do not connect pin 5 to a 24V ground.

29

Page 34

30

Page 35

Page 36

YASKAWA ELECTRIC AMERICA, INC.

Chicago-Corporate Headquarters 2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (847) 887-7000 Fax: (847) 887-7310 Internet: http://www.yaskawa.com

MOTOMAN INC.

805 Liberty Lane, West Carrollton, OH 45449, U.S.A.

Phone: (937) 847-6200 Fax: (937) 847-6277 Internet: http://www.motoman.com

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-0022, Japan

Phone: 81-3-5402-4511 Fax: 81-3-5402-4580 Internet: http://www.yaskawa.co.jp

YASKAWA ELETRICO DO BRASIL COMERCIO LTDA.

Avenida Fagundes Filho, 620 Bairro Saude Sao Paolo-SP, Brasil CEP: 04304-000

Phone: 55-11-5071-2552 Fax: 55-11-5581-879 5 Internet: http://www.yaskawa.com.br

YASKAWA ELECTRIC EUROPE GmbH

Am Kronberger Hang 2, 65824 Schwalbach, Germany

Phone: 49-6196-569-300 Fax: 49-6196-888-301 Internet: http://www.yaskawa.de

MOTOMAN ROBOTICS AB

Box 504 S38525, Torsas, Sweden

Phone: 46-486-48800 Fax: 46-486-41410

MOTOMAN ROBOTEC GmbH

Kammerfeldstrabe 1, 85391 Allershausen, Germany

Phone: 49-8166-900 Fax: 49-8166-9039

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods Cumbernauld, G68 9LF, Scotland, United Kingdom

Phone: 44-12-3673-5000 Fax: 44-12-3645-8182

YASKAWA ELECTRIC KOREA CORPORATION

Paik Nam Bldg. 901 188-3, 1-Ga Euljiro, Joong-Gu, Seoul, Korea

Phone: 82-2-776-7844 Fax: 82-2-753-2639

YASKAWA ELECTRIC (SINGAPORE) PT E. LTD.

Head Office: 151 Lorong Chuan, #04-01, New Tech Park Singapore 556741, SINGAPORE

Phone: 65-282-3003 Fax: 65-289-3003

TAIPEI OFFICE (AND YATEC ENGINEERING CORPORATION)

10F 146 Sung Chiang Road, Taipei, Taiwan

Phone: 886-2-2563-0010 Fax: 886-2-2567-4677

YASKAWA JASON (HK) COMPANY LIMITED

Rm. 2909-10, Hong Kong Plaza, 186-191 Connaught Road West, Hong Kong

Phone: 852-2803-2385 Fax: 852-2547-5773

BEIJING OFFICE

Room No. 301 Office Building of Beijing International Club,

21 Jianguomanwai Avenue, Beijing 100020, China

Phone: 86-10-6532-1850 Fax: 86-10-6532-1851

SHANGHAI OFFICE

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6553-6600 Fax: 86-21-6531-4242

SHANGHAI YASKAWA-TONJI M & E CO., LTD.

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6533-2828 Fax: 86-21-6553-6677

BEIJING YASKAWA BEIKE AUTOMATION ENGINEERING CO., LTD.

30 Xue Yuan Road, Haidian, Beijing 100083 China

Phone: 86-10-6232-9943 Fax: 86-10-6234-5002

SHOUGANG MOTOMAN ROBOT CO., LTD.

7, Yongchang-North Street, Beijing Economic & Technological Development Area,

Beijing 100076 China

Phone: 86-10-6788-0551 Fax: 86-10-6788-2878

YEA, TAICHUNG OFFICE IN TAIWAN

B1, 6F, No. 51, Section 2, Kung-Y i Road, Taichung City, T aiwan, R.O.C.Phone: 886-4-2320-2227 Fax: 886-4-2320-2239

Phone: 55-11-5071-2552 Fax: 55-11-5581-879 5 Internet: http://www.yaskawa.com.br

Yaskawa Electric America, Inc., March 2006 YEA–TOA–SMC–1.4 Printed in U.S.A.

Loading...

Loading...