Page 1

SMC–4000 Installation Guide

SMC–4000 Installation Guide

Upon receipt of the product and prior to initia l operation, read these

instructions thoroughly and retain for future reference.

Page 2

SMC–4000 Installation Guide

Page 3

SMC–4000 Installation Guide

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of industrial

applications. The selection and application of YASKAWA products remain the responsibili ty

of the equipment designer or end user. YASKAWA accepts no responsibility for the way its

products may be incorporated into the final system design.

Under no circumstances should any YASKAWA product be incorporated into any product or

design as the exclusive or sole safety control. Without exception, all controls should be

designed to detect faults dynamically under all circumstances. All products designed to

incorporate a component part manufactured by YASKAW A must be suppli ed to the end user

with appropriate warnings and instructions as to that part’s safe use and operation. Any

warnings provided by Yaskawa must be promptly provided to the end user.

YASKAWA offers an express warranty only as to the quality of its products in conforming to

standards and specifications published in YASKAWA’S manual. NO OTHER WARRANTY,

EXPRESS OR IMPLIED, IS OFFERED. YASKAWA assumes no liability for any personal

injury, prop erty damage, losses or claims arising from misapplication of its products.

Page 4

SMC–4000 Installation Guide

Page 5

SMC–4000 Installation Guide

Introduction

The SMC–4000 is a multi-axis Ethernet motion controller

designed for use with Yaskawa’s SIGMA series and

LEGEND Digital Torque Amplifier.

It provides a structured text programming environment

and the ability to perform many modes of motion

including camming, gearing, and contouring. High

speed product registration is also available as a standard

feature.

Additionally, the Ethernet function allows multiple

devices to communicate with the controller using a

TELNET or MODBUS protocol.

1

Page 6

SMC–4000 Installation Guide

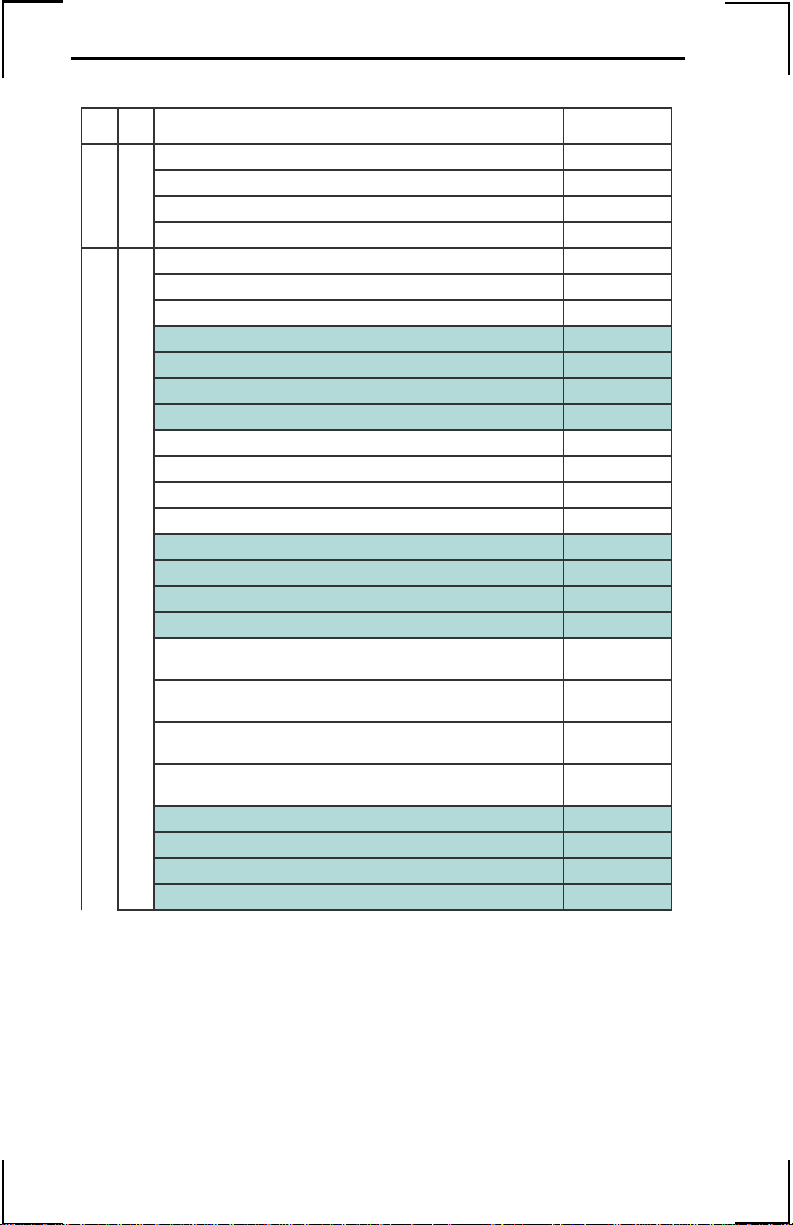

Part Numbers

Description Part Number

a) Two axis motion controller SMC4020

Two axis motion controller w/ absolute encoder option SMC4020W

Four axis motion controller SMC4040

Controller

Four axis motion controller w/ absolute encoder option SMC4040W

b) Pigtail (5 feet) SMCCBL005

Pigtail (10 feet) SMCCBL010

Pigtail (15 feet) SMCCBL015

Prewired for SGD, SGDA, or SGDG (2 feet) SMCCBL102

Prewired for SGD, SGDA, or SGDG (5 feet) SMCCBL105

Prewired for SGD, SGDA, or SGDG (10 feet) SMCCBL110

Prewired for SGD, SGDA, or SGDG (15 feet) SMCCBL115

Prewired for SGDB or SGDH (2 feet) SMCCBL202

Prewired for SGDB or SGDH (5 feet) SMCCBL205

Prewired for SGDB or SGDH (10 feet) SMCCBL210

Prewired for SGDB or SGDH (15 feet) SMCCBL215

Prewired for SGDB or SGDH (2 feet) Includes Alarm & Reset SMCCBLH02

Prewired for SGDB or SGDH (5 feet) Includes Alarm & Reset SMCCBLH05

Prewired for SGDB or SGDH (10 feet) Includes Alarm & Reset SMCCBLH10

Prewired for SGDB or SGDH (15 feet) Includes Alarm & Reset SMCCBLH15

Encoder Cables

Prewired for SGD, SGDA, or SGDG (2 feet) with additional

pigtail

Prewired for SGD, SGDA, or SGDG (5 feet) with additional

pigtail

Prewired for SGD, SGDA, or SGDG (10 feet) with additional

pigtail

Prewired for SGD, SGDA, or SGDG (15 feet) with additional

pigtail

Prewired for SGDB or SGDH (2 feet) with additional pigtail SMCCBLB02

Prewired for SGDB or SGDH (5 feet) with additional pigtail SMCCBLB05

Prewired for SGDB or SGDH (10 feet) with additional pigtail SMCCBLB10

Prewired for SGDB or SGDH (15 feet) with additional pigtail SMCCBLB15

SMCCBLA02

SMCCBLA05

SMCCBLA10

SMCCBLA15

2

Page 7

SMC–4000 Installation Guide

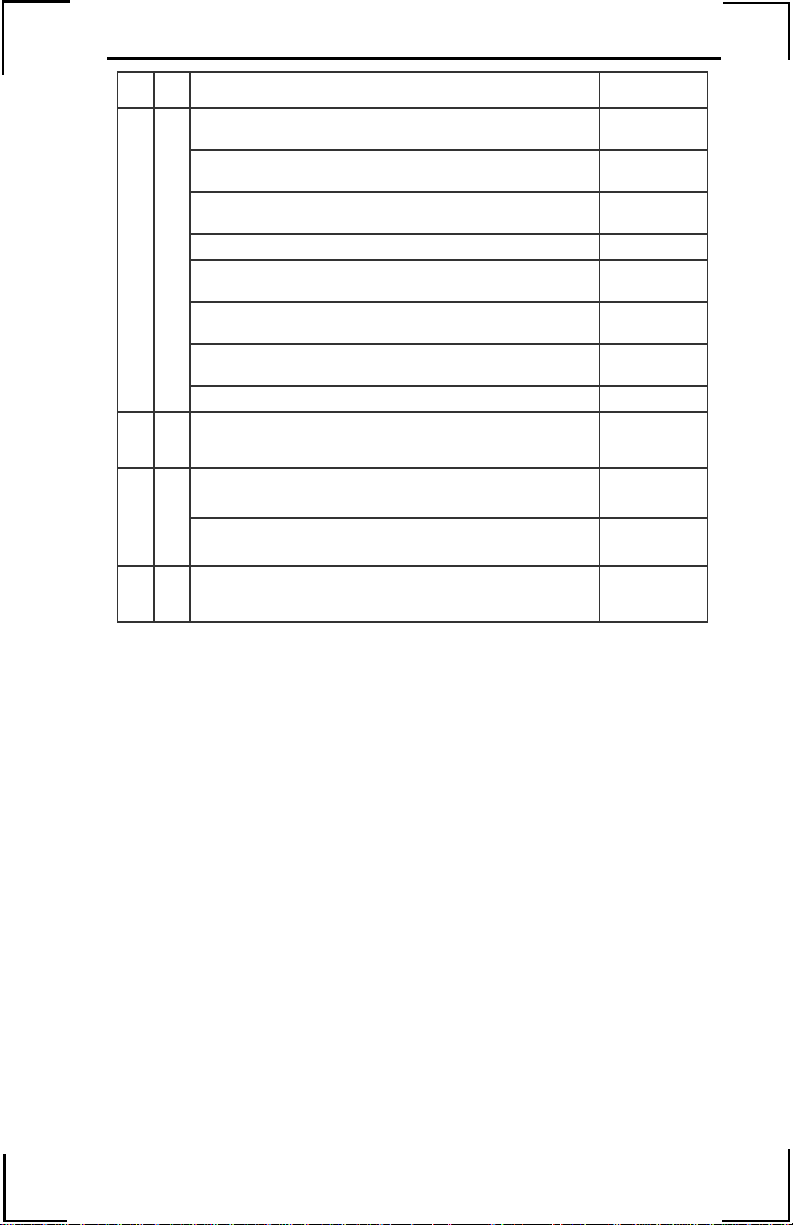

Description Part Number

c) 1.0m pigtail cable JZSP-CKIO1-

2.0m pigtail cable JZSP-CKIO1-

3.0m pigtail cable JZSP-CKIO1-

1.0m cable with OMRON terminal block JUSP TA50P

I/O

0.5m 50 pin I/O cable to DSUB JZSP-CKIOD-

1.0m 50 pin I/O cable to DSUB JZSP-CKIOD-

2.0m 50 pin I/O cable to DSUB JZSP-CKIOD-

CN5 Connector Kit (same as SGDH 1CN kit) JZSP-CKI9

d) 2.0m CN6 serial port cable (included with YTerm software) SMCCBL7

Serial

e) YTerm Integrated Development Environment SMCGUI1

1(A)

2(A)

3(A)

D50

01

02

SMCComm serial & ethernet driver for application development

for all SMC products

Software

f) Replacement power supply connector UFS-0118

SMCOCX1

Other

3

Page 8

SMC–4000 Installation Guide

Start-up

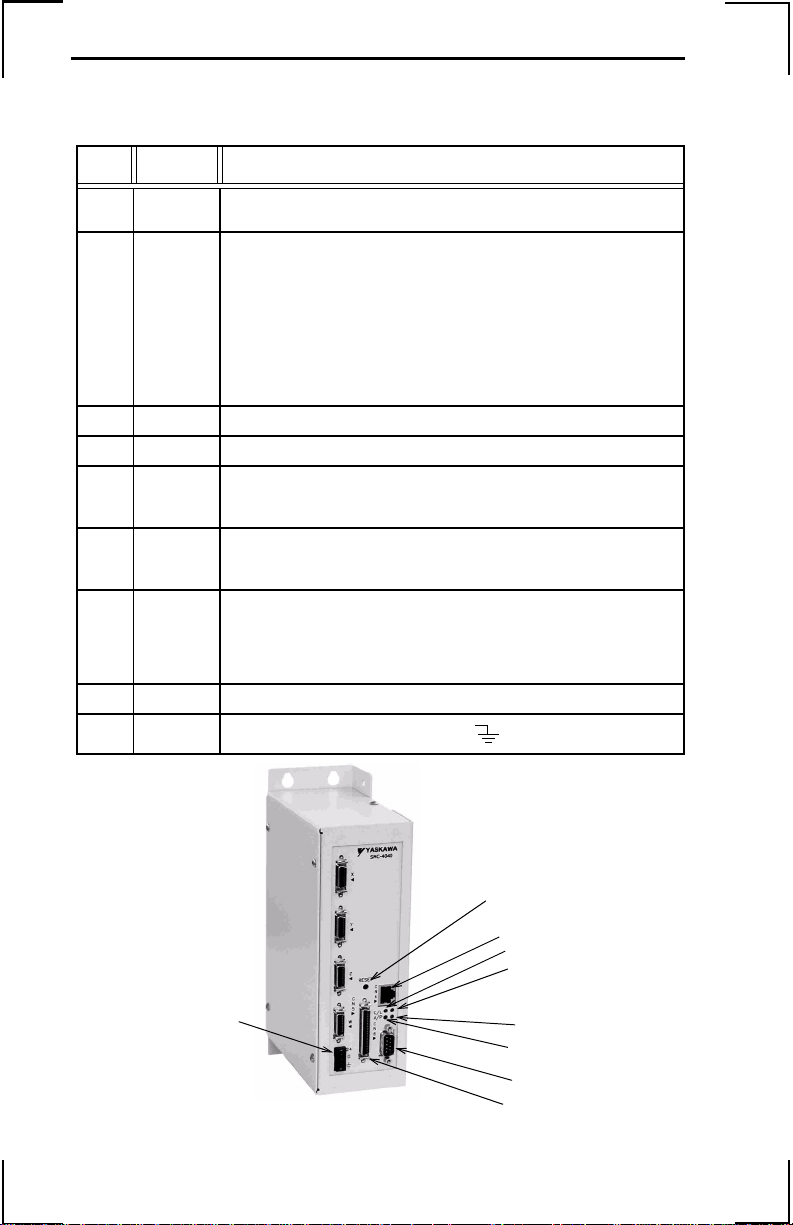

Front Panel Descriptio

No. Name Description

(1) Power

ON

(2) Alarm/

Error

(3) CN6 9 pin male D-Sub serial port connector

(4) CN5 3M 50 pin high density I/O connector

(5) RST Reset button. Causes the controller to reboot, and load the application

(6) Ethernet

status

(7) Ethernet

status

(8) CN4 10 BaseT Ethernet RJ45 Connector

(9)

A green LED that indicates power is being applied to the SMC–4000.

A red LED that will flash ON at power up and stay lit for ap proximately 2

seconds. After power up, the LED will illuminate for the following

reasons:

• An axis has a position error greater than the error limit. The error

limit is set by using the ER command.

• The reset input on the controller is held low or is being affected by

noise.

• There is a failure in the controller and the processor is resetting

itself.

• There is a failure in the output IC which drives the error signal.

program and parameters from flash. If the pro gram contains an #A UTO

label, it will automatically execute.

A green LED that is lit when there is an Ethernet connection to the

controller. This LED indicates physical connection, not active

communication.

The yellow LED indicates traffic across the Ethernet connection. This

LED will show both transmit and receive activity across the connection.

If there is no Ethernet connection or IP address assigned, the LED will

flash at regular intervals to show that the BOOTP packets are being

broadcast.

Power Connector (+24VDC, 0VDC, FG

(5)

(8)

(7)

(6)

(9)

(1)

(2)

(3)

(4)

4

Page 9

SMC–4000 Installation Guide

Axis Connector (20–pin)

SMC Axis Connector SGDH CN1

PIN SIGNAL Reference Pin

1 PA input 33

2 /PA input 34

3 PB input 35

4 /PB input 36

5 PC input 19

6 /PC input 20

7 Motor Command output 9

8 +5 / +12 / -12 Common output 10

9 +5 / +12 / -12 Common output 2

10 +5 / +12 / -12 Common output 6

11 Amplifier Enable output 40

12 Step output 11

13 Sen/Dir output 4

14 +5 / +12 / -12 Common output 1

15 Alarm + input 31

16 Reset output 44

17 ALM - input 32

18 n/c

19 +24 VDC output 47

20 n/c

5

Page 10

SMC–4000 Installation Guide

I/O Connections (50-pin CN5)

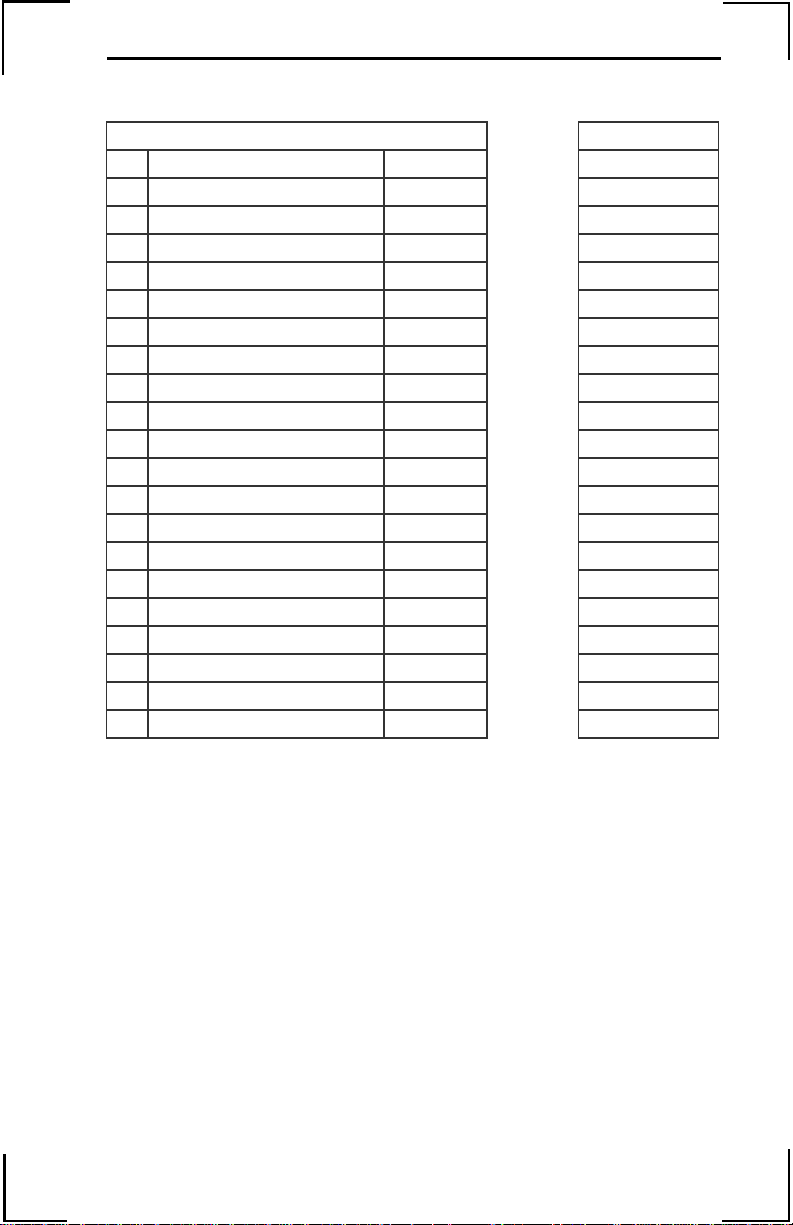

SMC Output Connector CN5 SMC Output Connector CN5

PIN

(Numerical Order)

1 Home W Abort 33

2 Home Z E-Stop1 39

3 Home Y E-Stop2 40

4 Home X Forward Limit W 27

5 Input 1 Forward Limit X 30

6 Input 4 Forward Limit Y 29

7 Input 7 Forward Limit Z 28

8 Output 3 Home W 1

9 Output 5 Home X 4

10 Output 8 Home Y 3

11 X Aux Encoder A+ Home Z 2

12 X Aux Encoder B- Input 1 5

13 Y Aux Encoder B+ Input 2 18

14 Reverse Limit W Input 3 31

15 Reverse Limit Z Input 4 6

16 Reverse Limit Y Input 5 19

17 Reverse Limit X Input 6 32

18 Input 2 Input 7 7

19 Input 5 Input 8 20

20 Input 8 Output 1 34

21 Output 2 Output 2 21

22 Output 7 Output 3 8

23 X Aux Encoder A- Output 4 35

24 Y Aux Encoder A+ Output 5 9

25 Y Aux Encoder B- Output 6 36

26 Reset Output 7 22

27 Forward Limit W Output 8 10

28 Forward Limit Z Reset 26

29 Forward Limit Y Reverse Limit W 14

30 Forward Limit X Reverse Limit X 17

31 Input 3 Reverse Limit Y 16

32 Input 6 Reverse Limit Z 15

33 Abort Spare 1 49

34 Output 1 Spare 2 50

35 Output 4 W Aux Encoder A- 46

36 Output 6 W Aux Encoder A+ 45

37 X Aux Encoder B+ W Aux Encoder B- 48

38 Y Aux Encoder A- W Aux Encoder B+ 47

39 E-Stop1 X Aux Encoder A- 23

6

SIGNAL

SIGNAL

(Alphabetical Order)

PIN

Page 11

SMC–4000 Installation Guide

SMC Output Connector CN5 SMC Output Connector CN5

PIN

(Numerical Order)

40 E-Stop2 X Aux Encoder A+ 11

41 Z Aux Encoder A+ X Aux Encoder B- 12

42 Z Aux Encoder A- X Aux Encoder B+ 37

43 Z Aux Encoder B+ Y Aux Encoder A- 38

44 Z Aux Encoder B- Y Aux Encoder A+ 24

45 W Aux Encoder A+ Y Aux Encoder B- 25

46 W Aux Encoder A- Y Aux Encoder B+ 13

47 W Aux Encoder B+ Z Aux Encoder A- 42

48 W Aux Encoder B- Z Aux Encoder A+ 41

49 Spare 1 Z Aux Encoder B- 44

50 Spare 2 Z Aux Encoder B+ 43

SIGNAL

SIGNAL

(Alphabetical Order)

PIN

7

Page 12

SMC–4000 Installation Guide

P

P

P

Cable Shielding, Segregation and Noise Immunity

Proper

Shields tied

back at device

ROPER

Shield connected ac ross

terminal block.

a)

SMC 3010

Connector

Case

Terminal Block

Connector Case

b)

Improper

Connector

a)

Connector Case

ROPER

Shield tied back a t

terminal block.

Case

WRONG

Shield grounded at

more than one point.

Terminal Block

Terminal Block

Terminal Block

Shields tied

back at device

ROPER

Shields of field

cables grounded at

one point

Shields tied

back at device

Shields tied

back at device

b)

WRONG

Shields of field

cables ungrounded

8

Page 13

SMC–4000 Installation Guide

Digital I/O

Digital Input

Item Specifications

Number of Input Points 8

Input Format Sinking

Isolation Optical

Voltage 24VDC ± 20%

Current Rating (ON) 5.3mA to activate

Input Impedance 2.2kΩ

Operation Voltage Logic 0 <5V

Logic 1 >15V

OFF Current 0.9mA or less

Response Time

(Hardware)

Latch response time Less than 25µsec

Minimum latch width 9µsec

NOTE: Inputs float high unless the input is held low.

OFF to ON: <0.5ms

ON to OFF: <1.5ms

Internal Circuitry

SMC–4000 CN5 Connector

24VDC

2.2K

5

18

31

6

19

32

7

20

Digital Input 1/Latch X

Digital Input 2/Latch Y

Digital Input 3/Latch Z

Digital Input 4/Latch W

Digital Input 5

Digital Input 6

Digital Input 7

Digital Input 8

9

Page 14

SMC–4000 Installation Guide

Digital Output

Item Specifications

Number of Output Points 8

Output Format Sinking

Output Classification Transistor Output

Isolation Optical

Load Voltage 24VDC ± 20%

Load Current 200mA/Output (600mA if activated individually)

Response Time OFF to ON <0.25ms

ON to OFF <0.5ms

External Common Power 24VDC ± 20% 15mA

Common User Fuse Rating 800mA per bank of four

Individual User Fuse Rating 200mA recommended

NOTE: The ULN 2803 output chip is capable of 600mA at a single output,

or 800mA for the eight outputs simultaneously.

Internal Circuitry

SMC–4000 CN5 Connector

Field Wiring

PS2504–4

0VDC from power input

10

10k

ULN2803

4.7k

34

Digital Output 1

Digital Output 2

21

Digital Output 3

8

Digital Output 4

35

Digital Output 5

9

Digital Output 6

36

Digital Output 7

22

10

Digital Output 8

L

L

L

L

L

L

L

L

Fuse

Page 15

SMC–4000 Installation Guide

Emergency Stop Chain

Internal Circuitry

VCC

SMC–4000 CN5 Connector

Field Wiring

-EROUT

39

40

2N7002

1k

E STOP1

E STOP2

The SMC–4000 closes the relay contact under normal operating

conditions. The relay is controlled by the same circuit as the error

LED. The relay will be open if the error LED is ON.

Ratings:

1.0A @ 24VDC

0.5A @ 125VDC

Maximum switching power: 62.5VA, 30W

11

Page 16

SMC–4000 Installation Guide

Serial Communication

Item Specifications

Baud Rate 9600 or 19200 settable by jumper JP2, default is 19200

Data Bits 8

Parity None

Stop Bits 1

Internal Circuitry

C1+

.1 UF

C1C2+

.1 UF

C2T1IN

T2IN

A1OUT

A2OUT

MAX232A

T1OUT

T2OUT

A1IN

A2IN

V+

V-

U7

SMC–4000

VCC

.1 UF

.1 UF

Serial Port 6CN

1

6

8

2

3

7

4

9

5

CTS Output

CTS Output

CTS Output

Transmit Input

Receive Input

RTS Input

RTS Input

N/C

Signal Ground

NOTE: Hardware handshaking must be used with the SMC–4000. If it

is impossible to implement hardware handshaking, use a jumper

between pins 1 and 4 in the connector.

NOTE: Do not connect pin 5 to a 24V ground. This would defeat the

opto isolation.

12

Page 17

SMC–4000 Installation Guide

External Encoder Specifications

Item Specifications

Number of External

One per Main Axis

Encoders

Input Format Quadrature or

Pulse and Direction

Maximum Frequency 12 MHz

Current Draw 940 µAmp

Internal Circuitry

3486

3486

4.7k

4.7k

6.8k

2.4k

SMC–4000

VCC

6.8k

2.4k

X axis internal encoder shown

See 5CN connector for other axis pin connections.

5CN Connector

Field Wiring

11

23

37

12

A+ phase

A- phase

B+ phase

B- phase

Shield

Frame Ground

External Encoder

+5V or +12V

Standard voltage levels are TTL (0V to 5V), however, voltage levels

up to 12V are acceptable. If using differential 12V signals, no

modification is required. Single ended 12V signals require a bias

voltage applied to the complimentary input, i.e.; use two 10k resistors,

one connected to +12V and the other connected to the encoder signal

ground to hold the /A phase and /B phase at 6VDC. Do not use a

24VDC encoder.

13

Page 18

SMC–4000 Installation Guide

Dedicated Inputs

Item Specifications

Number of Input Points Forward limit, Reverse limit, Home for all axes; and

Abort, Reset

Input Format Sinking

Isolation Optical

Voltage 24 VDC ± 20%

Current Rating (ON) 5.3 mA to activate

Input Impedance 2.2k Ω

Operation Voltage Logic 0 <5V

Logic 1 >15V

OFF Current 0.9 mA or less

Limit Switch Response

Time

Internal Circuitry

X axis dedicated inputs shown. Other axes are the

same.

OFF to ON: <0.5 ms

ON to OFF: <1.5 ms

SMC–4000

+24 VDC

2.2k

CN5 Connector

Field Wiring

Forward Limit Switch

30

Reverse Limit Switch

17

4

33

26

External Input Signal

Home Input

Abort Input

Reset Input

0VDC

14

Page 19

SMC–4000 Installation Guide

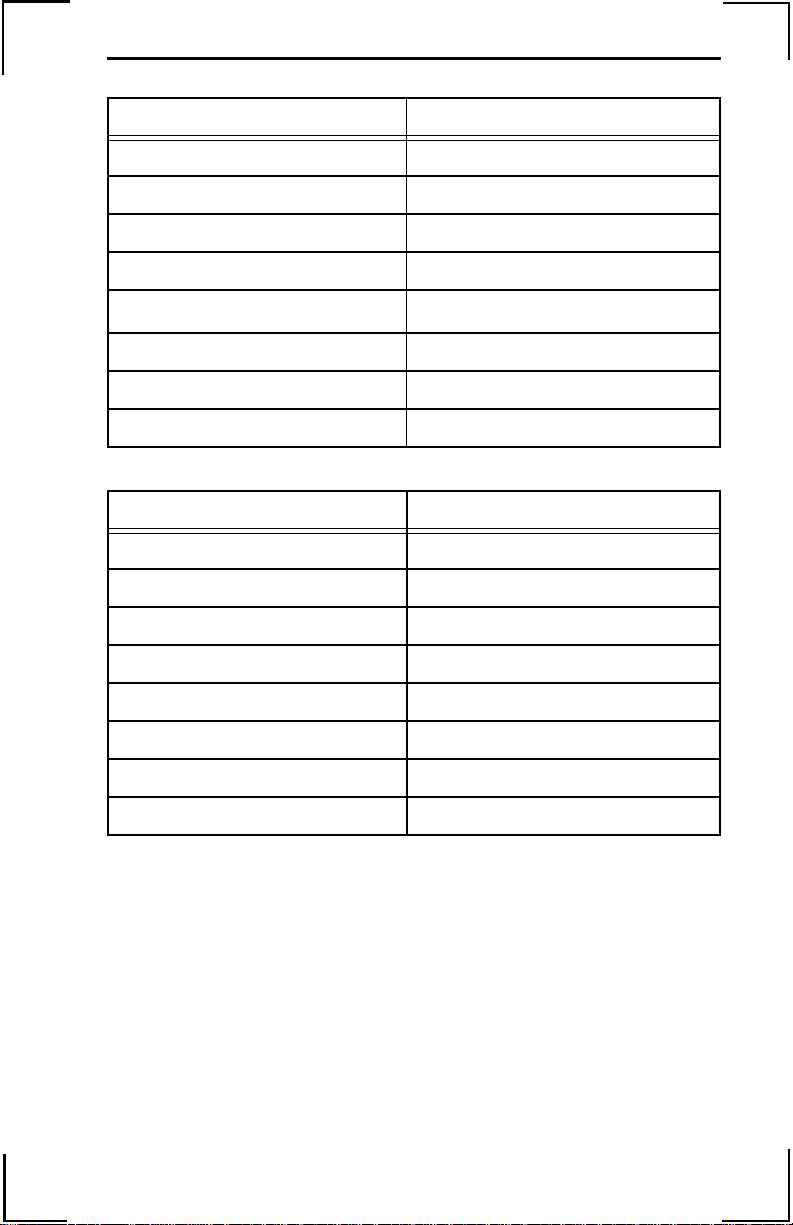

Physical Specifications

Description Specifications

Depth 5 inches

Width 2.6 inches

Height 9.1 inches

Weight 3.52lbs (1.6kg)

Vibration

Ambient Temperature 0 ~ 70° C (32 ~ 158° F)

Humidity Less than 95%

Noise IEC Level 3

9.8 msec

2

(1.0g)

Hardware Specifications

Description Specifications

CPU 25MHz Motorola

Servo Update 1000µs default, 250µs minimum

Digital Inputs (8), +24VDC

Dedicated Inputs (2) +24VDC +3 per axis @24VDC

Digital Outputs (8), +24VDC

Serial port (1) 9600 or 19200 baud

Ethernet (1) 10-base-T

Power Input 24 VDC – 600mA

15

Page 20

SMC–4000 Installation Guide

Dimensional Drawings

16

Page 21

SMC–4000 Installation Guide

I/O Cable with Terminal Block JUSP-TA50P

CN5

Length of cable supplied: 19.69 (500)

50-pin connector plug

MR-50RMD2

50-pin terminal block

M3.5 screws

+10%

-0%

1

2

9.74 (247.5)

49

50

Connector Terminal Block Converter Unit

JUSP-TA50P* (cable included)

Mounting Hole Diagram

10.01 (254.2)

0.14 (3.5)0.14 (3.5)

0.61 (15.5)

0.27 (7.0)

* Terminal specifications: see I/O Connections (50-pin CN5), page 6.

10.28 (261.2)

0.27 (7.0)

1.16

1.77 (45)

(29.5)

1.77 (45)

17

Page 22

SMC–4000 Installation Guide

NOTES

18

Page 23

SMC–4000 Installation Guide

Page 24

SMC–4000 Installation Guide

YASKAWA ELECTRIC AMERICA, INC.

Chicago-Corporate Headquarters 2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (847) 887-7000 Fax: (847) 887-7310 Internet: http://www.yaskawa.com

MOTOMAN INC.

805 Liberty Lane, West Carrollton, OH 45449, U.S.A.

Phone: (937) 847-6200 Fax: (937) 847-6277 Internet: http://www.motoman.com

YASKAWA ELECT R IC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-0022, Japan

Phone: 81-3-5402-4511 Fax: 81-3-5402-4580 Internet: http://www.yaskawa.co.jp

YASKAWA ELETRICO DO BRASIL COMERCIO LTDA.

Avenida Fagundes Filho, 620 Bairro Saude Sao Paolo-SP, Brasil CEP: 04304-000

Phone: 55-11-5071-2552 Fax: 55-11-5581-8795 Internet: http://www.yaskawa.com.br

YASKAWA ELECT R IC EU ROPE GmbH

Am Kronberger Hang 2, 65824 Schwalbach, Germany

Phone: 49-6196-569-300 Fax: 49-6196-888-301 Internet: http://www.yaskawa.de

MOTOMAN ROBOTICS AB

Box 504 S38525, Torsas, Sweden

Phone: 46-486-48800 Fax: 46-486-41410

MOTOMAN ROBOTEC GmbH

Kammerfeldstrabe 1, 85391 Allershausen, Germany

Phone: 49-8166-900 Fax: 49-8166-9039

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods Cumbernauld, G68 9LF, Scotland, United Kingdom

Phone: 44-12-3673-5000 Fax: 44-12-3645-8182

YASKAWA ELECTRIC KOREA CORPORATION

Paik Nam Bldg. 901 188-3, 1-Ga Euljiro, Joong-Gu, Seoul, Korea

Phone: 82-2-776-7844 Fax: 82-2-753-2639

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

Head Office: 151 Lorong Chuan, #04-01, New Tech Park Singapore 556741, SINGAPORE

Phone: 65-282-3003 Fax: 65-289-3003

TAIPEI OFFICE (AND YATEC ENGINEERING CORPORATION)

10F 146 Sung Chiang Road, Taipei, Taiwan

Phone: 886-2-2563-0010 Fax: 886-2-2567-4677

YASKAWA JASON (HK) COMPANY LIMITED

Rm. 2909-10, Hong Kong Plaza, 186-191 Connaught Road West, Hong Kong

Phone: 852-2803-2385 Fax: 852-2547-5773

BEIJING OFFICE

Room No. 301 Office Building of Beijing International Club,

21 Jianguomanwai Avenue, Beijing 100020, China

Phone: 86-10-6532-1850 Fax: 86-10-6532-1851

SHANGHAI OFFICE

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6553-6600 Fax: 86-21-6531-4242

SHANGHAI YASKAWA-TONJI M & E CO., LTD.

27 Hui He Road Shanghai 200437 China

Phone: 86-21-6533-2828 Fax: 86-21-6553-6677

BEIJING YASKAWA BEIKE AUTOMATION ENGINEERING CO., LTD.

30 Xue Yuan Road, Haidian, Beijing 100083 China

Phone: 86-10-6232-9943 Fax: 86-10-6234-5002

SHOUGANG MOTOMAN ROBOT CO., LTD.

7, Yongchang-North Street, Beijing Economic & Technological Development Area,

Beijing 100076 China

Phone: 86-10-6788-0551 Fax: 86-10-6788-2878

YEA, TAICHUNG OFFICE IN TAIWAN

B1, 6F, No. 51, Section 2, Kung-Yi Road, Taichung City, Taiwan, R.O.C.Phone: 886-4-2320-2227 Fax: 886-4-23202239

Phone: 55-11-5071-2552 Fax: 55-11-5581-8795 Internet: http://www.yaskawa.com.br

Yaskawa Electric America, Inc., January 2004 YEA–TOA–SMC–4.3 Printed in U.S.A.

Loading...

Loading...