Page 1

S

S

M

M

A

A

R

R

T

T

P

P

Technical Manual

™

™

T

R

A

T

R

G

G

A

C

C

C

C

arr

a

d

d

Page 2

Page 3

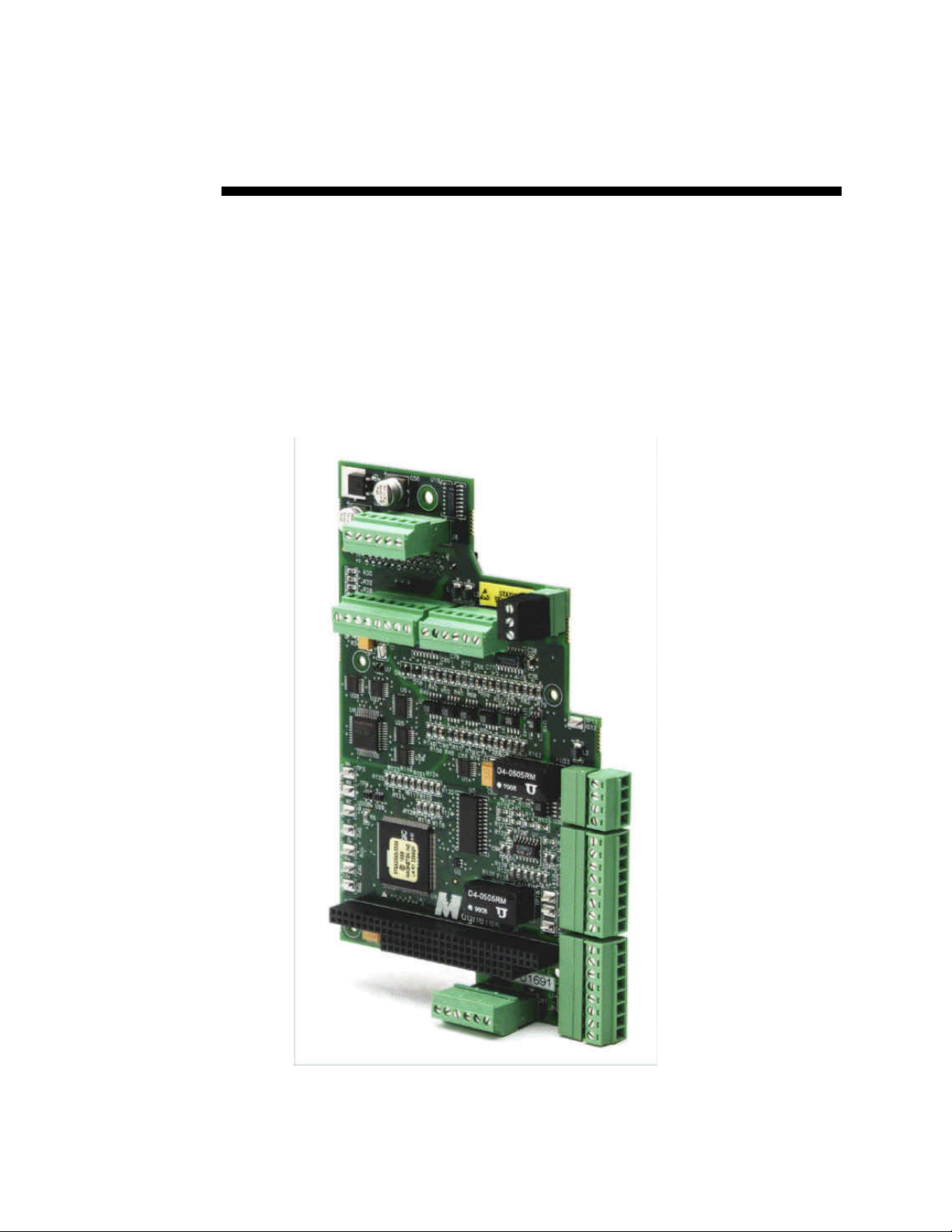

SMART TRAC PG Card

Table of Contents

Important Safety and Warranty Information 1

Warnings, Cautions and Notes.....................................................................................................................1

General Safety Precautions - Warnings ......................................................................................................2

Important Warranty Information................................................................................................................2

Smart Trac PG Card 3

General Capabilities......................................................................................................................................3

Closed-loop Control..........................................................................................................................3

Position Control ................................................................................................................................3

Digital Input......................................................................................................................................3

Analog Input .....................................................................................................................................3

Quick Start.....................................................................................................................................................4

Installing the Smart Trac PG Card 7

Unpacking ......................................................................................................................................................7

ElectroStatic Discharge (ESD) Procedures.......................................................................................7

Unpacking Procedure........................................................................................................................7

Installing the Smart Trac PG Card .............................................................................................................7

Using the Smart Trac PG Card 11

Basic Features..............................................................................................................................................11

Port Address ................................................................................................................................................11

Encoders.......................................................................................................................................................12

Digital Inputs ...............................................................................................................................................12

Analog Inputs...............................................................................................................................................12

Testing Card Installation 15

Test Points....................................................................................................................................................15

Checking Analog Input Signals..................................................................................................................16

Checking the Power Supply........................................................................................................................16

Checking Encoder Pulses............................................................................................................................16

Checking Pulses at Input to Smart Trac PG Card...................................................................................17

Checking Pulses at a MagneTek VCM Motor ..........................................................................................18

Troubleshooting Your Smart Trac PG Card 19

Symptoms and Corrective Action..............................................................................................................19

Appendix A – Specifications 21

Smart Trac PG Card Specifications ..........................................................................................................21

Technical Manual TM 3554-0020 Table of Contents •• i

Page 4

SMART TRAC PG Card

Appendix B - Card Layout 25

Smart Trac PG Card – Component Side...................................................................................................25

Smart Trac PG Card – Solder Side ...........................................................................................................26

Appendix C - Connections 29

Feedback Encoder Input (J3).....................................................................................................................29

Logic Input (J4)...........................................................................................................................................29

Follower Encoder Input (J5) ......................................................................................................................30

Monitor Output (J6)....................................................................................................................................30

Analog Channel 0 (J9).................................................................................................................................30

Analog Channel 1 (J10)...............................................................................................................................31

Shield Termination (J11)............................................................................................................................31

Shield Termination (J12)............................................................................................................................31

Appendix D – Removing the Smart Trac Card Stack 35

General Procedures.....................................................................................................................................35

Appendix E – Technical Support 39

Getting Help.................................................................................................................................................39

References ....................................................................................................................................................39

Problem Report ...........................................................................................................................................40

Appendix F – Replaceable Parts Listing 41

Replaceable Parts Listing ...........................................................................................................................41

Glossary of Terms 43

Index 45

ii •• Table of Contents Technical Manual TM 3554-0020

Page 5

SMART TRAC PG Card

Important Safety and Warranty

Information

Warnings, Cautions and Notes

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or death.

WARNING - ESD

A statement of conditions which must be observed to prevent

damage to components due to ESD (ElectroStatic Discharge) and

to prevent personal injury or death.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults, Smart Trac AC1 system degradation

and damage to equipment.

IMPORTANT

A statement of conditions which should be observed during Smart Trac AC

DeviceNet setup or operation to ensure dependable service.

NOTE: Notes indicate information that is in addition to a discussion of the topic

in adjoining text. Alternatively, it may limit or restrict the paragraph(s) that

follow(s) to specific models or conditions.

Technical Manual TM 3554-0020 Important Safety and Warranty Information •• 1

Page 6

SMART TRAC PG Card

TIP - Tips indicate information that should make a procedure easier or more

efficient.

General Safety Precautions Warnings

Important safety information follows. Please read and understand all

precautions listed below before proceeding with the specification, installation,

set-up or operation of your Smart Trac AC1. Failure to follow any of the

following precautions may result in personal injury or death, or damage to the

equipment.

WARNING - ESD

The Control Printed Circuit Board (PCB) employs CMOS

Integrated Circuits that are easily damaged by static electricity.

Use proper ElectroStatic Discharge (ESD) procedures when

handling the Control PCB. See Smart Trac AC1 Technical Manual

for details. Failure to comply may result in damage to equipment

and/or personal injury.

Important Warranty Information.

Do not modify your Smart Trac AC1, its components, or any of the procedures

contained in the technical documentation supplied by MagneTek. Any

modification of this product by the user is not the responsibility of MagneTek

and will void the warranty.

2 •• Important Safety and Warranty Information Technical Manual TM 3554-0020

Page 7

Smart Trac PG Card

General Capabilities

SMART TRAC PG Card

Closed-loop Control

Position Control

Digital Input

Analog Input

A Smart Trac PG Card added to your Smart Trac AC1 provides closed loop flux

vector control and closed loop speed control. With the card, 5 V to 12 V

differential quadrature signals at a rate of up to 300 KHz with a 540 ohm input

load may be input. Quadrature phasing of encoder inputs is 90 degrees +/- 22

degrees maximum at 300 kHz. Follower applications may use a second encoder

input. A 12 VDC power supply rated at 200 mA supplies power to the encoder.

The Smart Trac PG Card also provides position control. Start and stop signals

control two 32-bit counters that can be used to measure the rotation of either

start or stop signals. The Start and Stop signals can come from one of three

sources: the marker pulse of either encoder; one of the two digital inputs (i.e.,

connected to proximity switches); or software command.

The two 12 VDC input signals can be used as general purpose inputs if not

needed for position control.

Two analog input channels can accommodate either load cells or potentiometers.

The input voltage range for each channel is ± 600 mV or ± 10 Volts, selectable.

The Smart Trac PG Card also supplies:

• an A/D converter with 12 bits of resolution.

• a +5VDC, 50 mA power supply.

• reference voltages of +10VDC and -10VDC, both rated at 10 mA.

Quick Start

1. Remove all Smart Trac cards except the Smart Trac Inverter and CPU

cards per instructions in "Installing the Smart Trac PG Card. "

2. Install the Smart Trac PG card as the second card of the card stack.

3. Make connections to the PG card terminal blocks per information

contained in this manual and your situation.

4. Replace all other cards per the instructions in "Installing the Smart Trac

PG Card."

5. Power up and test functionality of your Smart Trac AC1, including that

of the Smart Trac PG card.

Technical Manual TM 3554-0020 Smart Trac PG Card •• 3

Page 8

SMART TRAC PG Card

THIS PAGE INTENTIONALLY LEFT BLANK

4 •• Smart Trac PG Card Technical Manual TM 3554-0020

Page 9

SMART TRAC PG Card

Installing the Smart Trac PG

Card

Unpacking

ElectroStatic

Discharge (ESD)

Procedures

Unpacking Procedure

WARNING WARNING -- ESD ESD

Keep electronic circuit boards in ElectroStatic Discharge (ESD)

protective bags when not being handled. Use proper ESD

procedures (including an ESD wrist strap) when handling circuit

boards. Failure to comply may result in damage to equipment.

When working with an ElectroStatic Discharge (ESD) sensitive device, you

should be grounded at all times. The easiest and most common way to provide

this ground is to use an approved ESD wrist strap. The strap is secured to your

wrist with a wire attached to the strap and clipped or taped to the chassis of the

unit being worked on. Any static is dissipated through the wire to ground,

greatly reducing the possibility of damage to the device.

It is a good idea to touch the chassis with your finger before handling any

electrostatic device. Any static electricity will be discharged to chassis ground

and will not be transferred to the device.

Always store devices (cards, other electronic components) in ESD protective

bags when not being handled.

Remove the protective shipping and packing material from the card. Ensure

contact wedges and other shipping devices have been removed.

Installing the Smart Trac PG Card

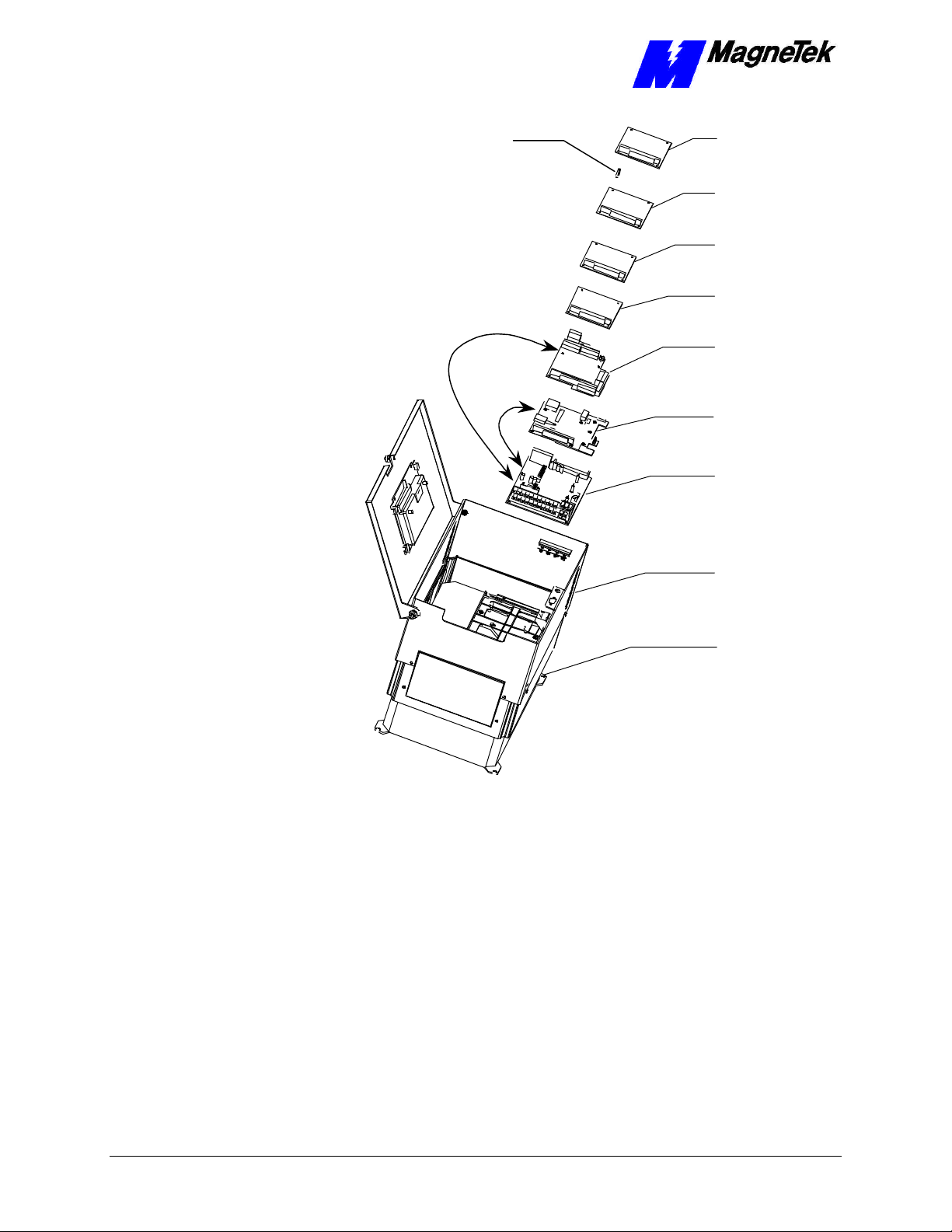

The Smart Trac PG Card must be positioned above the Smart Trac CPU card on

the Smart Trac AC1 card stack.

NOTE: If replacing or adding a Smart Trac PG card to an existing Smart Trac

card stack, see Appendix D – "Removing the Smart Trac Card Stack" before

continuing.

Technical Manual TM 3554-0020 Installing the Smart Trac PG Card •• 5

Page 10

Card

SMART TRAC PG Card

Standoffs (4

places on top of

each card)

4CN

Connector

2CN

Connector

Smart Trac

Genius PCIM

Card

Optional

PC/104

Card

Smart Trac

Ethernet

Smart Trac

PS Card

Smart Trac

PG Card

Smart Trac

CPU Card

Inverter Control

Card

Adapter

Ring

Main Chassis

Figure 1. Smart Trac PG Card Stack Position

1. Power off the Smart Trac AC1. Disconnect it and tag it as "Out of

Service". Perform this and all other steps required to remove all cards

located in a stack position above the PG Card. See "Appendix D –

Removing the Smart Trac Card Stack"

2. To replace the PG card, orient the PG card so that the PC/104

connector and the J2 connector align with the PC/104 connector on the

Smart Trac CPU card and the 4CN connector on the Inverter Control

board. Be careful to align the PC/104 connector pins with the

receptacle on the Smart Trac CPU card so the pins don’t bend when the

card is pushed into place.

3. Gently but firmly push the Smart Trac PG card onto the Smart Trac

CPU card. Make sure connecting pins are in alignment and J2 mates

with 4CN before pushing the two boards tightly together. Secure the

card using four (4) metal standoffs and one (1) plastic standoff.

6 •• Installing the Smart Trac PG Card Technical Manual TM 3554-0020

Page 11

SMART TRAC PG Card

4. Replace the Smart Trac PS or Ethernet card and other cards by

reversing the procedures described in the Appendix "Removal of the

Smart Trac Card Stack."

Technical Manual TM 3554-0020 Installing the Smart Trac PG Card •• 7

Page 12

Page 13

SMART TRAC PG Card

Using the Smart Trac PG Card

Basic Features

The Smart Trac PG card has:

• Two encoder inputs for closed loop flux vector control, closed loop

speed control and position control.

• Digital inputs (if not needed for position control).

• Analog inputs to accommodate load cells or potentiometers.

Port Address

The Smart Trac PG card uses a port address of "1". Hardwired on the card, the

address may be overridden if two Smart Trac PG cards must be used. Contact

MagneTek for details.

Encoders

Connect encoders at Terminal Block J3 (feedback encoder input) or at Terminal

Block J5 (follower encoder input). Only the feedback encoder Terminal Block

J3 provides a 12 volt power supply for the encoder.

Channel 0 - feedback encoder

Use Channel 0 for the encoder of the motor connected to the Smart Trac AC1. It

provides feedback to both the Smart Trac AC1 inverter control card and CPU.

Terminal Block J3 provides these connections for differential A, B and Z inputs

and a 12-volt @200ma power supply. A and B are used for speed and position

control. Z is used for position start and stop only.

Channel 1 - follower encoder

Use Channel 1 for another feedback source. It only provides feedback for the

Smart Trac CPU card. Terminal Block J5 provides connections for differential

A, B and Z inputs.

Digital Inputs

Two +12 Volt digital inputs are located on Terminal Block J4 for proximity

switch inputs (LI0 and LI1). Each of the digital inputs sinks 10mA and may be

used for position start and stop, or as a general purpose input.

Technical Manual TM 3554-0020 Using the Smart Trac PG Card •• 9

Page 14

SMART TRAC PG Card

Analog Inputs

The Smart Trac PG card provides analog input differential pairs of 600mV and

10V at Terminals Blocks J9 (Analog Channel 0) and J10 (Analog Channel 1).

Pins 1-2 of the terminal blocks are inputs for the 600 mV pair. Pins 3-4 of the

terminal blocks are inputs for the 10V pair.

10 •• Using the Smart Trac PG Card Technical Manual TM 3554-0020

Page 15

Testing Card Installation

Test Points

You may test the Smart Trac PG card at eleven test points. The test points and a

description of each follows:

SMART TRAC PG Card

Smart Trac PG Card Test Points

Test Point

Designator Description Purpose

TP1 Analog Common Test analog input signals

TP9 Analog Input 0 Test analog input signals

TP10 Analog Input 1 Test analog input signals

TP2 Digital Common Test encoder test points

TP3 A pulse, encoder channel 0 Test pulse after Smart Trac PG card

TP4 B pulse, encoder channel 0 Test pulse after Smart Trac PG card

TP5 Z pulse, encoder channel 0 Test pulse after Smart Trac PG card

TP6 A pulse, encoder channel 1 Test pulse after Smart Trac PG card

TP7 B pulse, encoder channel 1 Test pulse after Smart Trac PG card

TP8 Z pulse, encoder channel 1 Test pulse after Smart Trac PG card

TP11 +5 V Isolated Common Test pulses at input to Smart Trac PG

TP12 Inverter Digital Common Field Service use only

card

Checking Analog Input Signals

You may check analog inputs using a Digital Voltmeter or Multimeter between

test points TP1 (common) and either TP9 (Analog Input 0) or TP10 (Analog

Input 1). Values should be within a range of –10V to +10V.

Technical Manual TM 3554-0020 Testing Card Installation •• 11

Page 16

SMART TRAC PG Card

Checking the Power Supply

You may check the +5V power supply by connecting a Digital Voltmeter or

Digital Multimeter between J9-6 (5V power supply) and J9-7 (5V power supply

return). It should read between 4.5 and 5.5 volts.

Checking Encoder Pulses

Using an oscilloscope, you can check encoder pulses after they have been

processed by the Smart Trac PG card or at the motor.

Note: Measure all encoder pulses at the input with reference to +5V isolated

common (TP11).

WARNINGWARNING

Take proper precautions when making the following system

checks. Hazardous voltages and amperage are present. The front

door of the Smart Trac AC1 must be open and power applied to

the unit while testing. Electrical shock or damage to the equipment

may result if precautions are not taken while checking encoder

pulses. Failure to comply may result in personal injury or death.

1. Remove power from L1, L2 and L3. Wait for the CHARGE light to go

out.

2. Connect the common of the oscilloscope to TP2 (digital) to check

encoder signals.

NOTE: You may want to remove the adapter ring from the drive for easier

access to test points, especially when testing drives with smaller case sizes (1-4).

3. Connect one channel of the oscilloscope to TP3 if checking channel 0

or TP6 if checking channel 1. If using a two-channel oscilloscope,

connect the second channel to TP4 if checking channel 0 or TP7 if

checking channel 1.

4. Set the oscilloscope for 2V/div, 50ms/div, normal trigger, and rising

edge trigger.

5. Apply power to the Smart Trac AC1, but DO NOT apply a RUN

command.

6. Turn the motor shaft by hand. You should see pulses on both channels

at a +5V level, 50% duty cycle. The pulses should be separated by 90

electrical degrees (half a pulse).

7. If one or both channels do not have the correct pulses present (i.e.

missing pulses, incorrect duty cycle, improper voltage, etc.) check

pulses at input to the Smart Trac PG card (next procedure).

12 •• Testing Card Installation Technical Manual TM 3554-0020

Page 17

SMART TRAC PG Card

Checking Pulses at Input to Smart

Trac PG Card

NOTE: The following procedure describes checking feedback (channel 0)

encoder pulses at terminal J3 and follower (channel 1) encoder pulses at

terminal J5.

1. Remove power from L1, L2 and L3. Wait for the CHARGE light to go

out.

2. Connect the common of the oscilloscope to TP11 (+5 V ISO Common).

NOTE: This procedure requires a two-channel oscilloscope to view the

relationship between A+ and A- at the same time.

3. To check A to /A: Connect one channel of the oscilloscope to J3-1 if

checking channel 0 A pulse or J5-1 if checking channel 1 A pulse.

Connect the second channel to J3-2 (/A pulse) if checking channel 0 or

J5-2 (/A pulse) if checking channel 1.

4. Set the oscilloscope for 5V/div, 50ms/div, normal trigger, and rising

edge trigger.

5. Apply power to the Smart Trac AC1, but DO NOT apply a RUN

command.

6. Turn the motor shaft by hand. You should see pulses on both channels

and 50% duty cycle. The pulses should be separated by 180 electrical

degrees (one the inverse of the other).

7. Disconnect the two oscilloscope channels. Reconnect them to terminals

J3-3 or J5-3 (B pulse) and J3-4 or J5-4 (/B pulse).

8. To check B to /B: Turn the motor shaft by hand. You should see pulses

on both channels and 50% duty cycle. Again, the pulses should be

separated by 180 electrical degrees (one the inverse of the other).

9. To check A to B, Channel 0: Disconnect the two oscilloscope channels.

Reconnect them to terminals J3-1 (Channel 0 A pulse) and J3-3

(channel 0 B pulse) Check the relationship between A and B. They

should be 90 degrees out of phase.

10. To check A to B, Channel 1: Disconnect the two oscilloscope channels.

Reconnect them to terminals J5-1 (Channel 1 A pulse) and J5-3

(channel 1 B pulse) Check the relationship between A and B. They

should be 90 degrees out of phase.

11. If one or both channels do not have the correct pulses present (i.e.

missing pulses, incorrect duty cycle, improper voltage, etc.), check

pulses at the motor (next procedure).

Technical Manual TM 3554-0020 Testing Card Installation •• 13

Page 18

SMART TRAC PG Card

Checking Pulses at a MagneTek VCM

Motor

1. Remove power from L1, L2 and L3. Wait for the CHARGE light to go

out.

2. Take apart the military-style, circular connector at the motor.

3. Connect the common of the oscilloscope to pin F of the circular

connector.

4. Connect one channel of the scope to pin A of the circular connector. If

the oscilloscope is two channel, connect the second channel to pin H.

5. Set the oscilloscope for 5V/div, 50ms/div, normal trigger, and rising

edge trigger.

6. Apply power to the Smart Trac AC1, but DO NOT apply a RUN

command.

7. Turn the motor shaft by hand. You should see pulses on both channels

and 50% duty cycle. The pulses should be separated by 180 electrical

degrees (one the inverse of the other).

If no pulse can be seen on any of the four connector pins (A, B, H or I), check

the power supply between pins D and F. It should be at or near 12 VDC. If not,

check the power supply at the Smart Trac PG card, between J3-7 and J3-8. If the

power supply is not at or near 12VDC, check to make sure J2 is mated with 4CN

on the inverter control board. If it is properly mated, replace the Smart Trac PG

card.

14 •• Testing Card Installation Technical Manual TM 3554-0020

Page 19

SMART TRAC PG Card

Troubleshooting Your Smart

Trac PG Card

Symptoms and Corrective Action

Many problems associated with the functioning of the Smart Trac PG card will

be discovered when troubleshooting the Smart Trac AC1 and its option boards

as an integrated unit. They are listed in the following table along with symptoms

unique to the Smart Trac PG card.

Smart Trac PG Card Symptoms and Corrective Action

Symptoms Probable Cause Corrective Action

Smart Trac PG

Card not

functioning

PG cable wires not installed. Install cable wires.

No encoder pulses

- Smart Trac PG

card installed and

good cable wires

and connections.

Motor does not

rotate

Motor does not

rotate at set speed.

Control method set to Flux

Vector or V/F w/PG but no

PG card installed.

Defective Smart Trac PG

card

Improper connections from

PG

Out of tolerance or no PG

output signal if Flux Vector

or V/F w/PG control

Install Smart Trac PG card.

Check pulses per chapter "Testing

Card Installation." Replace Smart

Trac PG card as required.

Repair or replace connecting

cables.

Replace Smart Trac PG card

PG power supply. Replace power supply.

Technical Manual TM 3554-0020 Troubleshooting Your Smart Trac PG Card •• 15

Page 20

SMART TRAC PG Card

Symptoms Probable Cause Corrective Action

Smart Trac PG Card Symptoms and Corrective Action

Motor hunting

Motor Overload

fault indication

Heatsink Overtemp

fault indication.

Bad or no connections from

inverter control board to PG

card if Flux Vector or V/F

w/PG control.

PG PCB may be faulty.

May be faulty or defective

Smart Trac PG.

Check connections from Inverter

Control board to PG. Repair or

replace, as necessary.

Replace Smart Trac PG card.

Replace Smart Trac PG

16 •• Troubleshooting Your Smart Trac PG Card Technical Manual TM 3554-0020

Page 21

SMART TRAC PG Card

Appendix A – Specifications

Smart Trac PG Card Specifications

Smart Trac PG Card Specifications

Analog Inputs

Digital Inputs

Feedback Encoder

Input

Follower Encoder

Input

Description Two non-isolated differential inputs,

simultaneously sampled

Voltage ± 600 mVDC or ± 10VDC

Input Impedence > 100,000 ohms

Resolution 12 bits

Description Two, opto-isolated

Voltage 12 VDC internal pull-up provided

Sink Current 10 mA

Frequency 10KHz maximum

Pulse Width 0.1 ms minimum

Supply Voltage 12 VDC @ 200mA

Maximum Frequency 300 kHz

Input Differential quadrature, opto-isolated

(A, /A, B, /B)

Optional differential index , opto-

isolated (Z, /Z)

540 ohm input load on each pair

5 to 12 VDC differential input voltage

Quadrature Phasing: 90 degrees +/-

22 degrees max. at 300 KHz.

Maximum Frequency 300 kHz

Technical Manual TM 3554-0020 Appendix A – Specifications •• 17

Page 22

SMART TRAC PG Card

Smart Trac PG Card Specifications

Follower Encoder

Input

Encoder Monitor

Output

Reference Voltage

Outputs

Isolated Power

Supply Output

Input Differential quadrature, opto-isolated

(A,/ A, B, /B)

Optional differential index, opto-

isolated (Z, /Z)

540 ohm input load on each pair

5 to 12 VDC differential input voltage.

Quadrature Phasing: 90 degrees +/-

22 degrees max. at 300 KHz.

Description Quadrature plus index, opto-isolated

(A, /A, B, /B, Z, /Z)

Outputs RS-422 differential

Source Software selectable

+ 10 VDC @ 10mA

- 10 VDC @ 10mA

+ 5 VDC @ 50mA

18 •• Appendix A – Specifications Technical Manual TM 3554-0020

Page 23

SMART TRAC PG Card

Appendix B - Card Layout

Smart Trac PG Card – Component

Side

TP3

TP4

TP5

TP2

TP6

TP7

TP8

Common

J6

J3 J5

A

B

Z

Encoder 0

A

B

Z

Encoder 1

=

Pin 1

J12

J4

J10

PC/104 Receptacle

PC/104 Receptacle

J11

Top (Component) Side

J9

Technical Manual TM 3554-0020 Appendix B - Card Layout •• 19

Page 24

SMART TRAC PG Card

Smart Trac PG Card – Solder Side

J10

Connector

4CN

J4

J9

PC/104 Connector pins

PC/104 Connector pins

(Back Side)

20 •• Appendix B - Card Layout Technical Manual TM 3554-0020

Page 25

SMART TRAC PG Card

Appendix C - Connections

Feedback Encoder Input (J3)

1

2

3

4

5

6

7

8

J3

Encoder 0 A+

Encoder 0 AEncoder 0 B+

Encoder 0 BEncoder 0 Z+

Encoder 0 ZEncoder 12 VDC

Encoder RTN

Logic Input (J4)

1

2

3

4

J4

Logic Input (LI0)

Common for LI0

Logic Input (LI1)

Common for LI1

Follower Encoder Input (J5)

1

2

3

4

5

6

J5

Technical Manual TM 3554-0020 Appendix C - Connections •• 21

Encoder 1 A+

Encoder 1 AEncoder 1 B+

Encoder 1 BEncoder 1 Z+

Encoder 1 Z-

Page 26

SMART TRAC PG Card

Monitor Output (J6)

1

2

3

4

5

6

J6

Monitor A+

Monitor AMonitor B+

Monitor BMonitor Z+

Monitor Z-

Analog Channel 0 (J9)

1

2

3

4

5

6

7

8

J9

Analog Input 1 600 mV +

Analog Input 1 600 mV Analog Input 0 10 V +

Analog Input 0 10 V Analog Common

5 Volt power supply

5 Volt power supply return

Not Used

Analog Channel 1 (J10)

1

2

3

4

5

6

7

8

J10

Analog Input 1 600 mV +

Analog Input 1 600 mV Analog Input 1 10 V +

Analog Input 1 10 V -

Analog Common

+10 Volt Reference

Not Used

-10 Volt Reference

Shield Termination (J11)

1

2

3

4

5

6

Terminating Shield

Terminating Shield

Terminating Shield

Terminating Shield

Terminating Shield

Terminating Shield

J11

22 •• Appendix C - Connections Technical Manual TM 3554-0020

Page 27

SMART TRAC PG Card

Shield Termination (J12)

1

2

3

J12

Terminating Shield

Terminating Shield

Terminating Shield

Technical Manual TM 3554-0020 Appendix C - Connections •• 23

Page 28

SMART TRAC PG Card

THIS PAGE INTENTIONALLY LEFT BLANK

24 •• Appendix C - Connections Technical Manual TM 3554-0020

Page 29

SMART TRAC PG Card

Appendix D – Removing the

Smart Trac Card Stack

General Procedures

1. Power off the Smart Trac AC1. Disconnect it and tag "Out of Service".

2. Do one of the following:

• Open the cover to the Smart Trac AC1 by rotating the spring-

loaded, captive screw counterclockwise. Use a large screwdriver if

necessary to free the slotted screw.

OR

• Loosen the screws holding down the cover.

3. Disconnect the 12-pin wiring harness from connector J4 at the digital

operator.

4. Using the Phillips head screwdriver, remove the ground strap from the

left inside and the ground strap from the top inside of the Smart Trac

AC1 adapter ring.

5. Disconnect the 9-pin RS-232 cable at connector J5 on the Smart Trac

CPU card.

Technical Manual TM 3554-0020 Appendix D – Removing the Smart Trac Card Stack •• 25

Page 30

chassis

board

SMART TRAC PG Card

12-pin wiring

harness on

Digital Operator

attached to

connector J4 on

Smart Trac

CPU Card

Digital

Operator

9-pin RS-232

cable

attached here

4mm screws

(4 places)

secure ring

to main

Standoffs (4

places)

secure each

board

Smart Trac

Board Stack

PC/104

9-pin RS-232

cable

connector J5

6. Using a 4.5mm hex head driver, remove four standoffs from the

topmost card.

7. Using the PC/104 extraction tool, remove the topmost card from the

stack.

Position

rectangular

"jacks"

around

edges of

PCBs

Squeeze to lift

cards apart

Figure 2. Using the PC/104 Extraction Tool.

8. Repeat step 8 above until all PC/104 cards have been removed.

9. To remove the Smart Trac PG card:

• Disconnect the 4CN connector on the PG card.

• Using a tubular extraction tool or pliers, squeeze the plastic,

spring-loaded retainer built-in to the long plastic standoff located

at the top of the PG card, just above connector J6.

• Using a PC/104 extraction tool, remove the card.

NOTE: The Smart Trac PG card requires unique handling. Wedge the extracting

tool between the PG card and the CPU card. The area between the terminal strip

on the CPU card and the serial numbered edge of the PG card can be lifted first,

then the opposite side (nearest TB1) on the PG card). Alternate sides until the

card is free of the CPU card.

10. To remove the Smart Trac CPU card:

26 •• Appendix D – Removing the Smart Trac Card Stack Technical Manual TM 3554-0020

Page 31

SMART TRAC PG Card

• Disconnect the card at the 2CN connector on the CPU card.

• The CPU card is secured with three plastic standoffs with spring-

loaded clips on the end. Squeeze the top of the standoffs (the clips)

with the special cylindrical removal tool, your fingers or needlenosed pliers and lift the CPU card from the Smart Trac Inverter

Control Card.

You have removed the entire card stack. The inverter card, considered part of

the drive, is in clear view.

Technical Manual TM 3554-0020 Appendix D – Removing the Smart Trac Card Stack •• 27

Page 32

Page 33

SMART TRAC PG Card

Appendix E – Technical Support

Getting Help

Should you need technical assistance with installation or troubleshooting of your

Smart Trac AC1, you can phone our Help Desk at either (800)-541-0939 or

(262)-782-0200. Alternatively, you may copy the Problem Report form, found

on the next page, and fax it to us at (262)-782-3418.

References

MagneTek Drives and

Systems

PC/104 Specification,

Version 2.1

For more information about MagneTek drives

and systems, training programs and contacts,

visit:

http://www.magnetekdrives.com

PC/104 Consortium. An overview and the

specification may be obtained at the web site

address:

http://www.controlled.com/pc104/index.html

Technical Manual TM 3554-0020 Appendix E – Technical Support •• 29

Page 34

SMART TRAC PG Card

Problem Report

Name:

Address:

City: State: Zip

Serial Number: Smart Trac PG Card

Occurrence: Frequently Intermittantly Rarely

Nature of Problem:

Conditions when problem occurs:

30 •• Appendix E – Technical Support Technical Manual TM 3554-0020

Page 35

SMART TRAC PG Card

Appendix F – Replaceable Parts

Listing

Replaceable Parts Listing

Description MagneTek Part

Number

Smart Trac PG Card option kit 46S03643-0020 1

Technical Manual – Smart Trac PG

Card

Standoff, 4.5mm, Hex, Stl, CL ZINC,

16mm, M/F, M3, M3

Card Extraction Tool (Parvus Corporation

Hardware Tools Kit for Smart Trac

AC1

TM 3554-0020 1

05P00618-0006 4 each PG

P/N PRV-0760A-

01)

TBD Option

Qty

assy.

1

Technical Manual TM 3554-0020 Appendix F – Replaceable Parts Listing •• 31

Page 36

SMART TRAC PG Card

THIS PAGE INTENTIONALLY LEFT BLANK

32 •• Appendix F – Replaceable Parts Listing Technical Manual TM 3554-0020

Page 37

Glossary of Terms

SMART TRAC PG Card

encoder

Inverter

marker pulse

quadrature

sinks

A device that changes one digital code to another digital code.

Inverter - A device that converts Direct Current (DC) to Alternating Current

(AC).

Sometimes called an "index pulse," a marker pulse is an encoder output that

pulses once each revolution of a rotating device. Position control often employs

marker pulses to home or zero the position.

An encoder output of two channels, one of which is 90 degrees out of phase with

the other. The phase relationship changes depending on the direction of rotation.

Providing a current path to ground.

Technical Manual TM 3554-0020 Glossary of Terms •• 33

Page 38

SMART TRAC PG Card

THIS PAGE INTENTIONALLY LEFT BLANK

34 •• Glossary of Terms Technical Manual TM 3554-0020

Page 39

SMART TRAC PG Card

F

Features, Basic 9

feedback encoder 9, 17, 21

follower encoder 9, 17, 18, 21

Index

A

address,port 9

Analog Input 3, 10, 11

Analog Inputs 9, 10, 11, 17

B

block, terminal 9

C

Checking Analog Input Signals 11

Checking Encoder Pulses 12

Checking Pulses at a MagneTek

VCM Motor 14

Checking Pulses at Input to Smart

Trac PG Card 13

closed loop flux vector control 3, 9

closed loop speed control 3, 9

control

position 3, 9

speed 3, 9

control, closed-loop flux vector 3, 9

CPU 3, 9, 25

D

Digital Input 3

E

Electrostatic Sensitive Discharge 5

encoder

feedback 9, 17, 21

follower 9, 17, 18, 21

Encoder Use 9

ESD 5

ESD Procedures 2, 5

extraction tool 26

G

Getting Help 29

ground 5

H

Help Desk 29

Help, Getting 29

I

information, safety 2

Inputs

Analog 9, 10, 11, 17

Using Digital Inputs 9

Inverter 3, 6, 9, 11, 14, 16, 27

L

Layout, Smart Trac PG Card 19

load cells 3, 9

M

Monitor Output 18, 22

O

Optional Parts 31

oscilloscope 12–14, 12–14, 12–14

Output

Monitor 18, 22

P

parts

optional 31

PC/104 29

port address 9

position control 3, 9

potentiometers 3, 9

power supply 3, 9, 12, 14–15, 14–

15, 14, 18

Problem Report 29–30

proximity switches 3

pulse 3, 11–14, 11–14, 11–13

Pulses

Checking at a MagneTek VCM

Motor 14

Technical Manual TM 3554-0020 Index •• 35

Page 40

SMART TRAC PG Card

Checking at Input to Smart Trac

PG Card 13

Checking Encoder Pulses 12

W

Warranty 2

wrist strap 5

Q

quadrature 3, 17–18, 17

Quick Start 3

R

reference voltages 3

References 29

Report, Problem 29–30

S

safety information 2

Signals

Checking Analog Input Signals

11

Smart Trac PG Card – Component

Side 19

Smart Trac PG Card Specifications

17

Specifications, Smart Trac PG Card

17

static electricity 2, 5

strap

wrist 5

switches

proximity 3

Symptoms and Corrective Action

15

T

Technical Manual 2

terminal block 9

Test Points 11

tool, extraction 26

troubleshooting

Help Desk 29

Troubleshooting

Symptoms and Corrective Action

15

U

Unpacking 5

Using Digital Inputs 9

V

voltage

reference 3

36 •• Index Technical Manual TM 3554-0020

Page 41

SMART TRAC PG Card

Data subject to change without notice. Smart Trac is a trademark of MagneTek, Inc. MicroTrac is a registered trademark of MagneTek, Inc. Microsoft, Windows and Windows NT are registered

trademarks of Microsoft Corporation

MagneTek

Drives and Systems

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939, (262) 782-0200, FAX (262) 782-3418

TM 3554-0020 © 1999-2000 MagneTek, Inc. 1/31/2000

Loading...

Loading...