Page 1

S

S

M

M

A

A

R

R

T

T

T

T

R

R

A

A

C

C

P

P

™

™

CII

C

Technical Manual

G

e

nii

G

M

M

e

C

C

n

arr

uss

u

a

d

d

Page 2

Page 3

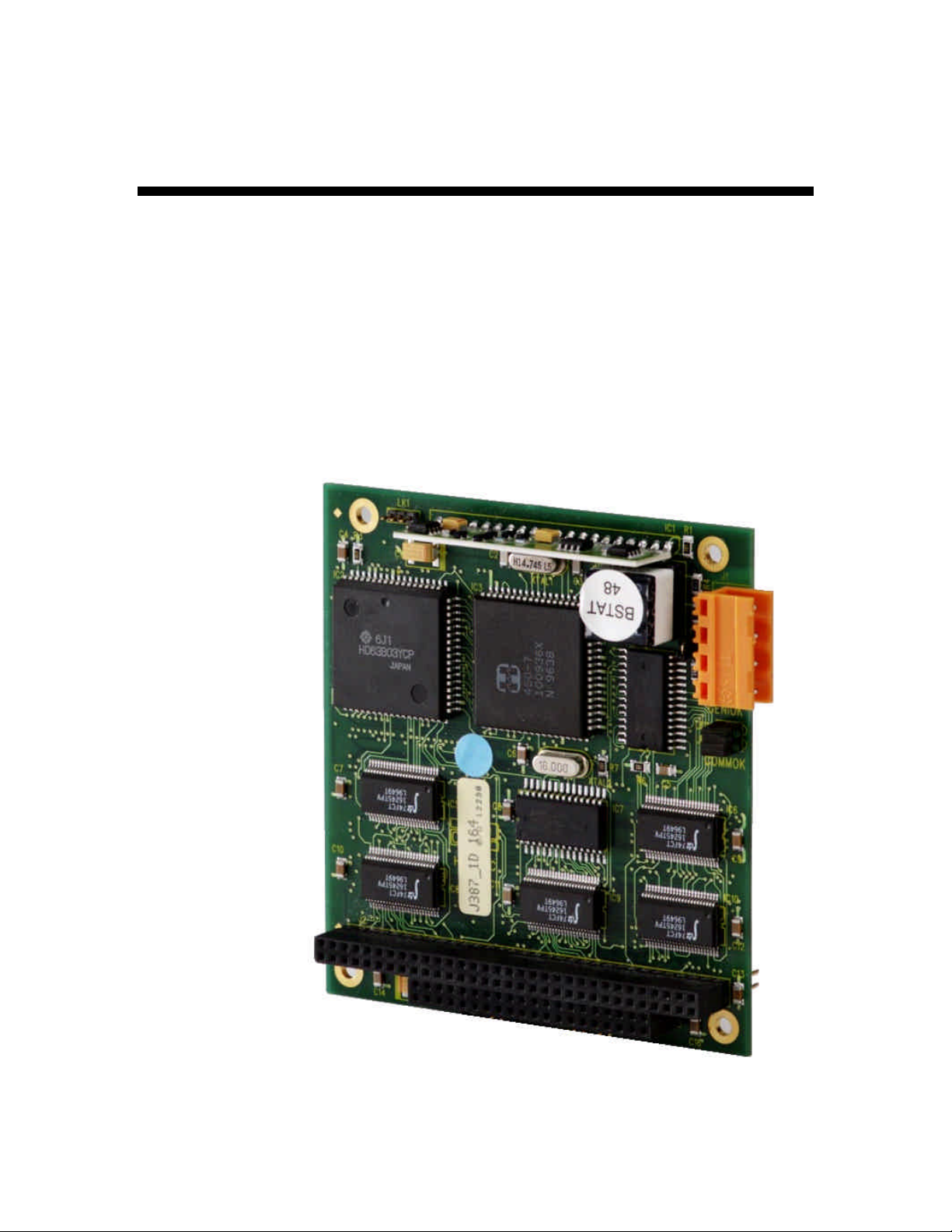

SMART TRAC Genius PCIM Card

Contents

Important Safety and Warranty Information 1

Warnings, Cautions and Notes.....................................................................................................................1

General Safety Precautions - Warnings ......................................................................................................2

Important Warranty Information................................................................................................................2

Smart Trac Genius PCIM Card 3

Capabilities.....................................................................................................................................................3

Specifications .................................................................................................................................................3

Quick Start.....................................................................................................................................................3

Genius Basics 5

Introduction...................................................................................................................................................5

Genius Network Topology ............................................................................................................................6

Cabling ...........................................................................................................................................................6

Network Length and Cabling.......................................................................................................................6

Terminating Resistor Specifications............................................................................................................6

Installing the Smart Trac Genius PCIM Card 7

Unpacking ......................................................................................................................................................7

Electrostatic Discharge (ESD) Procedures........................................................................................7

Unpacking Procedure........................................................................................................................7

Installing the Smart Trac Genius Card.......................................................................................................7

Connecting the Smart Trac Genius Card to a Genius Network..............................................................10

Configuring the Smart Trac Genius Card 11

Configuration...............................................................................................................................................11

Default Settings............................................................................................................................................11

Interrupt...........................................................................................................................................12

Non-Default Settings for Switch SW1........................................................................................................14

Serial Bus Address..........................................................................................................................14

Serial Bus Baud Rate ......................................................................................................................14

Outputs............................................................................................................................................15

Non-Default Settings for Switch SW2........................................................................................................15

Memory Location............................................................................................................................15

I/O Base (Port) Address ..................................................................................................................15

Watchdog Timer..............................................................................................................................16

Testing Card Installation 17

Testing the Network....................................................................................................................................17

On-board Indicator Lights .........................................................................................................................17

Technical Manual 3554-0080 Contents •• i

Page 4

SMART TRAC Genius PCIM Card

Troubleshooting Your Smart Trac Genius PCIM Card 19

General Troubleshooting Procedures........................................................................................................19

Checking Cabling............................................................................................................................19

Fault Isolation .................................................................................................................................19

Troubleshooting Table................................................................................................................................19

Appendix A - Technical Support 21

Getting Help.................................................................................................................................................21

References ....................................................................................................................................................21

Problem Report ...........................................................................................................................................22

Appendix B – Replaceable Parts Listing 23

Replaceable Parts Listing ...........................................................................................................................23

Appendix C – Removing the Smart Trac Card Stack 25

General Procedures.....................................................................................................................................25

Glossary of Terms 29

Index 31

ii •• Contents Technical Manual 3554-0080

Page 5

SMART TRAC Genius PCIM Card

Important Safety and Warranty

Information

Warnings, Cautions and Notes

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or death.

WARNING - ESD

A statement of conditions which must be observed to prevent

damage to components due to ESD (ElectroStatic Discharge) and

to prevent personal injury or death.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults, Smart Trac AC1 system degradation

and damage to equipment.

IMPORTANT

A statement of conditions which should be observed during Smart Trac AC

setup or operation to ensure dependable service.

NOTE: Notes indicate information that is in addition to a discussion of the topic

in adjoining text. Alternatively, it may limit or restrict the paragraph(s) that

follow(s) to specific models or conditions.

TIP - Tips indicate information that should make a procedure easier or more

efficient.

Technical Manual 3554-0080 Important Safety and Warranty Information •• 1

Page 6

SMART TRAC Genius PCIM Card

General Safety Precautions Warnings

Important safety information follows. Please read and understand all

precautions listed below before proceeding with the specification, installation,

set-up or operation of your Smart Trac AC1. Failure to follow any of the

following precautions may result in personal injury or death, or damage to the

equipment.

WARNING - ESD

The Control Printed Circuit Board (PCB) employs CMOS

Integrated Circuits that are easily damaged by static electricity.

Use proper ElectroStatic Discharge (ESD) procedures when

handling the Control PCB. See Smart Trac AC1 Technical Manual

for details. Failure to comply may result in damage to equipment

and/or personal injury.

Important Warranty Information.

Do not modify your Smart Trac AC1, its components, or any of the procedures

contained in the technical documentation supplied by MagneTek. Any

modification of this product by the user is not the responsibility of MagneTek

and will void the warranty.

2 •• Important Safety and Warranty Information Technical Manual 3554-0080

Page 7

SMART TRAC Genius PCIM Card

Smart Trac Genius PCIM Card

Capabilities

The Genius Card Option consists of a Smart Trac Genius PCIM card with

mounting hardware. The card supports Genius network communications using

the GE Fanuc Genius LAN Communications Protocol # 91.

Specifications

• Genius serial bus compatible connector

• Configurable for interrupts 5, 7, 11 and 12

• Supports baud rates of 153.6 Standard, 153.6 Enhanced, 76.8K and

38.4K

• Operating temperature

• Storage temperature

• Humidity 5% to 95% non-condensing

• Status LEDs indicate card health and network activity

Quick Start

1. Check DIP switch settings on the card against the default settings (see

"Default Settings"). You should accept the default settings in all but

unusual situations. Your Smart Trac Field Service Engineer can help

you if you need assistance.

2. Power OFF your Smart Trac AC1 and tag "Out of Service."

3. Install the card in your Smart Trac AC1 in a PC/104 Option card

position (above the Ethernet Card or another PC/104 Option card).

4. Connect the Genius network cable.

5. Test your card installation.

Technical Manual 3554-0080 Smart Trac Genius PCIM Card •• 3

Page 8

SMART TRAC Genius PCIM Card

THIS PAGE INTENTIONALLY LEFT BLANK

4 •• Smart Trac Genius PCIM Card Technical Manual 3554-0080

Page 9

Genius Basics

Introduction

Developed by General Electric, the Genius network provides an industrial

networking scheme with software-configurable fault reporting, input filter time,

overload detection, and I/O mix. Programmable inputs and outputs, part of

Genius I/O Blocks, allow any circuit to be set up for either input or output. This

means that one 8-circuit block is field-configurable to any of 256 distinct

combinations of inputs and outputs.

SMART TRAC Genius PCIM Card

A Genius network passes a token in what are called bus scans. The pass starts at

the controller, which passes the token to the first node. It is next passed on

through consecutively numbered nodes. When it gets the token, a node can send

messages. When done sending, it notifies the network that it is done and passes

the token to the node with the next highest address. Finally, the token is passed

to either node 15 or 31 (the baud rate and cable type determine the maximum

number of nodes). The process repeats.

NOTE: Node 31 is generally reserved for a CPU. Nodes 29 and 30 are generally

reserved for fault tolerant devices.

In each bus scan, inputs are broadcast to all CPUs on the bus. The CPUs send

outputs to specific nodes, as required. Typically, node 31 is the CPU

Information may also be sent using Datagrams. Each datagram includes sourceto-destination routing information. During each bus scan, one datagram may be

automatically sent from one node to another, specific node. It may also be sent

from the PLC or computer to I/O blocks. Each datagram may contain up to 128

bytes of data.

Nodes in a Genius network may automatically broadcast up to 128 bytes of

global data with each bus scan. All CPUs on the bus receive all broadcasts of

global data. The receiving nodes do not acknowledge receipt of global data.

Upon receipt of data, the receiving node performs a cyclic redundancy check

(CRC) to ensure data integrity.

Two or more buses may be used, for example, to split activity to I/O information

on one bus and communications information on another.

Technical Manual 3554-0080 Genius Basics •• 5

Page 10

SMART TRAC Genius PCIM Card

Genius Network Topology

Configured in a bus topology, Genius networks require no special equipment to

amplify or regenerate the signal. Transfer of information occurs across cables

via RS-485 serial modems. You must terminate each end of the bus. A Genius

network will support up to 32 devices at 153.6 Kbaud standard, 153.6 Kbaud

extended, or 76.8 Kbaud and up to 16 devices at 38.4 Kbaud.

You may arrange devices on a Genius network in any physical sequence on the

bus. For efficient communications, however, arrange devices in the same

sequence as their Node (Block) Numbers.

Cabling

Cabling a Genius network consists of single twisted pair shielded cable, daisychained bus cable or fiber optic cable. RS-485 serial modems transmit and

receive data node to node. With simple field wiring to and from a Terminal

Assembly, the cost of wiring and cabling a Genius network is relatively low.

Network Length and Cabling

The maximum bus length depends, in part, on baud rate. The maximums are:

• 7500 feet at 38.4 Kbaud.

• 4500 feet at 76.8 Kbaud.

• 3500 feet at 153.6 Kbaud extended.

• 2000 feet at 153.6 Kbaud, standard.

The maximum length at each baud rate also depends on cable type. See

references in the Appendices for a complete list of cable types, showing

corresponding bus lengths and baud rates.

Greater bus lengths are possible using sections of fiber optics cable with modems.

Terminating Resistor Specifications

You must install 75, 100, 120, or 150 ohm, 1/4 watt resistors at both ends of the

electrical bus cable. Resistors must have a tolerance of -10% to +20%

6 •• Genius Basics Technical Manual 3554-0080

Page 11

SMART TRAC Genius PCIM Card

Installing the Smart Trac Genius

PCIM Card

Unpacking

Electrostatic

Discharge (ESD)

Procedures

Unpacking Procedure

WARNING WARNING -- ESD ESD

Keep electronic circuit boards in Electrostatic Discharge (ESD) protective

bags when not being handled. Use proper ESD procedures (including an

ESD wrist strap) when handling circuit boards. Failure to comply may

result in damage to equipment

When working with an electrostatic discharge (ESD) sensitive device, you

should be grounded at all times. The easiest and most common way to provide

this ground is to use an approved ESD wrist strap. The strap is secured to your

wrist with a wire attached to the strap and clipped or taped to the chassis of the

unit being worked on. Any static is dissipated through the wire to ground,

greatly reducing the possibility of damage to the device.

It is a good idea to touch the chassis with your finger before handling any

electrostatic sensitive device. Any static electricity will be discharged to chassis

ground and will not be transferred to the device.

Always store devices (cards, other electronic components) in ESD protective

bags when not being handled.

Remove the protective shipping and packing material from the card. Ensure

contact wedges and other shipping devices have been removed.

Installing the Smart Trac Genius Card

The Smart Trac Genius Card is PC/104 compatible, so it may be positioned in

one of the PC/104 Option Card positions at the top of the Smart Trac card stack.

NOTE: If replacing or adding a Smart Trac Genius PCIM card to an existing

Smart Trac card stack, see "Appendix C – Removing the Smart Trac Card

Stack" before continuing.

Technical Manual 3554-0080 Installing the Smart Trac Genius PCIM Card •• 7

Page 12

Card

Genius PCIM

Smart Trac

SMART TRAC Genius PCIM Card

Standoffs (4

places on top of

each card)

4CN

Connector

Optional

PC/104

Card

Smart Trac

Ethernet

Card

Smart Trac

PS Card

Smart Trac

PG Card

2CN

Connector

Smart Trac

CPU Card

Inverter Control

Card

Adapter

Ring

Main Chassis

Figure 1. Smart Trac Genius PCIM Card Stack Position

WARNINGWARNING

Turn off and disconnect the main power to the Smart Trac AC1 before

opening the door and removing the PC/104 card from the unit. This avoids

a risk of electric shock. Failure to comply may result in personal injury or

death.

8 •• Installing the Smart Trac Genius PCIM Card Technical Manual 3554-0080

Page 13

SMART TRAC Genius PCIM Card

WARNING WARNING -- ESD ESD

To avoid damage from electrostatic discharge, adhere to the following

precautions when performing this procedure:

• The card is packaged in a static-safe bag which protects the

product during shipping. Before removing the card from this bag,

be prepared to handle it in a static-safe environment.

• Wear a properly functioning antistatic strap and be sure that you

are fully grounded. Never touch the card unless you are wearing

an antistatic strap.

• Any surface upon which you place the unprotected Genius card

should be static-safe, facilitated by antistatic mats, if possible.

• Extra caution should be taken in cold, dry weather, when static

charges can easily build up.

NOTE: It is not necessary to remove any card from the stack to install the Smart

Trac Genius PCIM card. The card can be placed on the very top of the card

stack.

1. Remove the Smart Trac Genius card from its static guard package.

2. Before installing the Smart Trac Genius card, make the proper Jumper

(Link) and Switch settings. A serial bus address of 28 (1Ch) is set as

the default. This can be changed according to your network

requirements.

NOTE: a switch setting of 0 is a logical 1. The Outputs, I/O Port Address, and

Watchdog Timer settings are default and should not be changed.

3. Make sure that a terminating resistor is installed at both ends of the

Genius network.

4. Install the four metal standoffs on the Smart Trac stack.

NOTE: Four metal standoffs are shipped with the Smart Trac Genius card.

These four standoffs are longer than those originally shipped with your Smart

Trac AC1. To provide adequate clearance for components on the Smart Trac

Genius card and those on the card below, use the standoffs provided with the

Smart Trac Genius card to attach the Genius card to the card below it in the card

stack.

5. Orient the Smart Trac Genius card so that the connector pins are

aligned with the PC/104 connector on the board below, and press it

carefully into place until it comes to rest on the four metal standoffs.

6. Secure the Smart Trac Genius card by installing the four 16mm M/F

brass standoffs included in the Smart Trac Genius accessory package

Tighten them down to secure, but DO NOT over tighten.

7. Connect the network cable.

8. Replace the option cards by reversing the above instructions. See

"Smart Trac AC1 Technical Manual" for details.

Technical Manual 3554-0080 Installing the Smart Trac Genius PCIM Card •• 9

Page 14

SMART TRAC Genius PCIM Card

Connecting the Smart Trac Genius

Card to a Genius Network

The Smart Trac Genius card connects to the Genius serial bus via a cable

installed at its 4-terminal connector (see Figure 1). Terminals are labeled Serial

1, Serial 2, Shield In, and Shield Out.

You connect the Serial 1 and Serial 2 terminals of each Smart Trac Genius card

to the corresponding Serial 1 and Serial 2 terminals of the next device.

You connect the Shield In of each block to Shield Out of the preceding device.

You may leave the Shield In of first device and the Shield Out of the last device

disconnected.

When making bus connections, leave no more than two inches of exposed bare

wire. Insultate each drain wire with shrink tube to prevent the Shield In and

Shield Out wires from touching each other.

Installation must conform to Genius I/O product guidelines for the screening of

cables and components for the Genius serial bus. Cable construction must

conform to the pinout below :

Table 1. Pinout for Genius Network Cable.

Pin Connect to: Comments

1 Serial 1 of next block By doing this, each device connects to the

2 Serial 2 of next block By doing this, each device connects to the

3 Shield Out of previous block By doing this, Shield Out of one device

4 Shield In of next block Not required if Smart Trac Genius card is

Shield In of Prev Block Shield Out

Shield Out of Prev Block

X2

X1

Shield In

Serial 2

Serial 1

previous and next devices.

previous and next devices.

connects to Shield In of the next device.

last device on Genius block.

Figure 2. Genius Network Connector.

10 •• Installing the Smart Trac Genius PCIM Card Technical Manual 3554-0080

Page 15

SMART TRAC Genius PCIM Card

Configuring the Smart Trac

Genius Card

Configuration

You configure the Smart Trac Genius card for the Genius serial bus by either

accepting default values or changing them to suit your unique situation. The

values chosen at installation of the Smart Trac Genius card software driver must

match those set on the card.

Bus Termination (LNK1)

Two switches on the Smart Trac Genius card allow user configuration of the

serial bus, memory locations, I/O Base Address, and enabling or disabling of

outputs.

Default Settings

The Smart Trac Genius card is shipped from the factory already configured for

the typical installation. Default Switch settings for SW1 and SW2 are described

below. Generally, you should accept these defaults and ensure the switches are

set correctly before installing your card.

A terminating resistor must be installed across Serial 1 and Serial 2 at both ends

of a Genius serial bus. Depending on the type of cable you use, you will need to

terminate with 75 ohm, 100 ohm, 120 ohm or 150 ohm resistors. When you're

connecting one end of the card to a 150 ohm serial bus, you use the 150 ohm

terminating resistor located onboard the Smart Trac Genius card.

Figure 3. Genius Card Jumpers.

Technical Manual 3554-0080 Configuring the Smart Trac Genius Card •• 11

Page 16

SMART TRAC Genius PCIM Card

Interrupt

Five jumpers on the Smart Trac Genius card, labeled LNK 1 through LNK 5,

determine the interrupt (IRQ) level. Make sure the IRQ of the Genius card does

not conflict with any of the other cards in the Smart Trac card stack.

NOTE: For the Genius card, use of IRQ 11 is highly recommended. IRQ may

be used if IRQ 11 cannot be used. IRQ 5 is the default Ethernet card setting.

IRQ 7 is the default DeviceNet card setting. The card supports IRQ 5, 7, 11 and

12.

To set the IRQ for the Genius card, install a jumper in one of four positions

(LNK2, LNK3, LNK4 or LNK 5).

Table 2. Smart Trac Genius card Jumper Settings.

Jumper Jumper or

IRQ

A LNK 1 Jumper on 150 ohm terminaltion on board.

No jumper Add 120, 100, or 75-ohm termination.

B LNK 2 IRQ 11 Default (Highly recommended)

LNK 3 IRQ 12 Recommended

LNK 4 IRQ 7 (default for Smart Trac DeviceNet card)

Termination Requirements

Switch SW1 (Serial Bus

Address, Baud Rate

and Outputs)

LNK 5 IRQ 5 (default for Smart Trac Ethernet card)

Switch SW1 allows setting the Smart Trac Genius card to match the parameters

of the Genius serial bus. The Standard Serial Bus Baud Rate of 153.6 should be

accepted when connecting the card to a bus on which Phase A devices are used.

0 = OFF 1 = ON

SW1 Default Settings

1 2 3 4 5 6 7 8

Serial Bus Addressing

Address 1 Ch

(Default)

1 1 0 0 0 0 0 0

Serial Bus

Baud Rate

153.6 Standard

(4 bit skip time)

Outputs

Disabled

12 •• Configuring the Smart Trac Genius Card Technical Manual 3554-0080

Page 17

SMART TRAC Genius PCIM Card

Figure 4. Genius Card Switch Locations (back of PCIM Card)

Switch SW2 (Memory

Address, I/O Base

Address, Watchdog

Timer)

Switch SW2 positions 1-4 determine a 16 kilobyte Memory location used by the

Smart Trac Genius card.

Switch SW2 positions 5-7 determine the I/O Base Address for the application

software.

Switch SW2 position 8 determines whether the Watchog Timer is disabled

(default) or enabled.

0 = OFF 1 = ON

SW2 Default Settings

1 2 3 4 5 6 7 8

Serial Bus Addressing

Address CC00h

(Default)

0 1 1 0 0 0 1 1

I/O Port

Address

3E0h

(Default)

Watchdog

Timer

(Disabled)

Technical Manual 3554-0080 Configuring the Smart Trac Genius Card •• 13

Page 18

SMART TRAC Genius PCIM Card

Non-Default Settings for Switch SW1

Your particular situation may demands setting switches to different values than

the defaults.

Serial Bus Address

The Bus Address may be set from 00 to 1F hexadecimal (0 to 31 decimal) using

SW1, Positions 1-5.

Positions 1-5 = Node Address (Position 1 = LSB or 1's digit, Position 5 = MSB

or 16's digit)

0 = Off 1 = On

SW1 Optional Settings – Positions 1-5

Value Position Value Position

1 2 3 4 5 1 2 3 4 5

SBA=0 1 1 1 1 1 SBA=16 1 1 1 1 0

SBA=1 0 1 1 1 1 SBA=17 0 1 1 1 0

SBA=2 1 0 1 1 1 SBA=18 1 0 1 1 0

SBA=3 0 0 1 1 1 SBA=19 0 0 1 1 0

SBA=4 1 1 0 1 1 SBA=20 1 1 0 1 0

SBA=5 0 1 0 1 1 SBA=21 0 1 0 1 0

SBA=6 1 0 0 1 1 SBA=22 1 0 0 1 0

SBA=7 0 0 0 1 1 SBA=23 0 0 0 1 0

SBA=8 1 1 1 0 1 SBA=24 1 1 1 0 0

SBA=9 0 1 1 0 1 SBA=25 0 1 1 0 0

SBA=10 1 0 1 0 1 SBA=26 1 0 1 0 0

SBA=11 0 0 1 0 1 SBA=27 0 0 1 0 0

SBA=12 1 1 0 0 1 SBA=28 1 1 0 0 0

SBA=13 0 1 0 0 1 SBA=29 0 1 0 0 0

SBA=14 1 0 0 0 1 SBA=30 1 0 0 0 0

SBA=15 0 0 0 0 1 SBA=31 0 0 0 0 0

Serial Bus Baud Rate

The Smart Trac Genius card can be set to communicate at four different baud

rates: 153.6 Standard, 153.6K Extended, 38.4K and 76.8K. Use SW1, positions

6 and 7 to set the baud rate.

0 = Off 1 = On\

SW1 Optional Settings – Positions 6-7 (serial bus baud rate)

Baud Rate Position 6 Position 7

153.6K Std (default) 0 0

76.8K 1 0

38.4 0 1

153.6K Extended 1 1

14 •• Configuring the Smart Trac Genius Card Technical Manual 3554-0080

Page 19

SMART TRAC Genius PCIM Card

Outputs

Memory Location

The Smart Trac Genius card may be set to either enable or disable outputs.

SW1 Optional Settings – Position 8 (Outputs)

Outputs Position 8

Outputs Disabled (default) 0

Outputs Enabled 1

Non-Default Settings for Switch SW2

The Smart Trac Genius card uses two consecutive bytes of I/O space and 16

Kbytes of memory in the host system. I/O and memory locations must not

conflict with any other with other memory or device addresses in use. The Smart

Trac Genius card's switch SW2, positions 1-4, determine the starting address for

16 kbytes of memory that is used to store I/O data, for communications buffers,

and other information.

0 = Off 1 = On

SW2 Optional Settings – Positions 1-4 (Memory Location)

16Kb Data

and Comm.

I/O Starting

Address 1 2 3 4

I/O Base (Port)

Address

C800 1 1 1 1

CC00 0 1 0 0

E000 1 0 0 1

E400 0 0 0 1

The I/O registers occupy 2 bytes of space in the host system. The application

software on the host system exchanges data with the Smart Trac Genius card by

reading and writing to the assigned I/O addresses. The host's I/O Base, or

starting, address is set using positions 5, 6 and 7 of SW2.

0 = Off 1 = On

SW2 Non-Default Settings – Positions 5-7 (I/O Base Address)

4-bytes I/O

Memory

Address

360 1 1 1

364 0 1 1

368 1 0 1

36C 0 0 1

3E0 1 1 0

3E4 0 1 0

3E8 1 0 0

3EC 0 0 0

5 6 7

Technical Manual 3554-0080 Configuring the Smart Trac Genius Card •• 15

Page 20

SMART TRAC Genius PCIM Card

Watchdog Timer

The Watchdog Timer monitors the host systemn and resets the Smart Trac

Genius card if the host malfunctions. Unless supported by the host system, it

should remain disabled. When enabled, the Watchdog Timer requires that the

Smart Trac Genius card receive a pulse from the host every 7 milliseconds. If

not, it resets the card.

Outputs Disabled (default) 0

Outputs Enabled 1

SW2 Non-Default Settings – Position 8 (Outputs)

Outputs Position 8

16 •• Configuring the Smart Trac Genius Card Technical Manual 3554-0080

Page 21

SMART TRAC Genius PCIM Card

Testing Card Installation

Testing the Network

Once installed, check the on-board indicator lights. Normally, both LEDs should

be illuminated.

On-board Indicator Lights

Two LED indicator lights on the Smart Trac Genius PCIM card provide systemrelated information:

• GENI 104 Self-test/Health LED: When ON, indicates that power is

available to the card and the card self-test was successful. When OFF,

indicates a card failure, improper address assignment, or that the /RST

input line is low.

• Communications LED: When ON, indicates that power is available to

the card and the controller's communications hardware is functional

and can send data (receives the token) every serial bus scan. When

OFF, indicates that an error has been detected in the communications

hardware or while accessing the Genius serial bus.

LED 1 - GEN 104 OK

LED 2 - Communications

PC/104 Connector

Figure 5. Genius Card Connectors and LEDs

Technical Manual 3554-0080 Testing Card Installation •• 17

Page 22

SMART TRAC Genius PCIM Card

THIS PAGE INTENTIONALLY LEFT BLANK

18 •• Testing Card Installation Technical Manual 3554-0080

Page 23

SMART TRAC Genius PCIM Card

Troubleshooting Your Smart

Trac Genius PCIM Card

General Troubleshooting Procedures

Most problems with installation occur at startup of a new network. Initial checks

include ensuring use of proper cabling and the status of card LEDs. Next,

analyze a problem using the "Troubleshooting Table."

Checking Cabling

Fault Isolation

Check that all cables are connected to the proper terminals and are secure. Make

sure that the proper cable has been chosen and length restrictions are not

exceeded.

Check the condition of the status indicator LEDs (see "On-board Indicator

Lights"). Both LEDs should be ON. If either LED is not ON, check the

troubleshooting table that follows for diagnosis and corrective action.

Troubleshooting Table

The table below describes symptoms, probable causes and correction action for

various problems you may encounter with your Smart Trac PCIM card. For

more general Genius network troubleshooting information, see "References."

Several actions identified in the table require the use of a Handheld Monitor

(HHM). This refers to a type of monitor sold by GE Fanuc. The HHM can force

I/O on and off and perform wiring diagnostics with or without the CPU

connected.

Genius PCIM Card Troubleshooting

Symptom Probable Cause Corrective Action

PCIM card installed, Smart

Trac powered up, both card

LEDs not ON, /RST input

HIGH.

Card not seated properly or

not receiving power.

Ensure card is seated

properly in the correct

position in Smart Trac card

stack.

Ensure power supply to

card is working properly.

Technical Manual 3554-0080 Troubleshooting Your Smart Trac Genius PCIM Card •• 19

Page 24

SMART TRAC Genius PCIM Card

Genius PCIM Card Troubleshooting

Symptom Probable Cause Corrective Action

PCIM card installed, Smart

Trac powered up, GENI104

Self-test/Health LED OFF

and Communications

(COMMS) LED ON.

Hardware failure Replace card.

PCIM card installed, Smart

Trac powered up, GENI 104

Self-test/Health LED ON

and Communications

(COMMS) LED OFF.

Jumper LNK1 not set

Serial bus wiring

High voltage runs interfering

Broken cable. Inspect for broken cable

PCIM card installed, Smart

Trac powered up, both

LEDs flashing together.

Repeated bus errors.

Failure of card. Unplug bus communications

System shuts down with

parity errors

System shuts down with

parity errors and bus errors.

Can't make Genius PCIM

card operable, despite

repeated attempts.

Smart Trac AC1 will not

boot with Genius PCIM card

installed.

DIP switch SW1 or SW2 or

both not set properly.

Improper cable type or

lengths exceeded.

properly.

incomplete.

with operation.

Same serial bus number

(device number) configured

with same address.

Shielding improperly

installed and/or grounded.

Input duplicated on same

bus or overlapping card I/O

references.

Serial 1 and Serial 2

connections crossed.

Short between regulator

U33 on main card and

bottom of option card.

Check switch settings are

correct.

Check cable type and

lengths, replace or

reconfigure as required.

Change to proper LNK1

setting.

Ensure serial bus wiring

completed in a daisy chain

fashion.

Ensure cabling is not near

high voltage runs.

and replace as necessary.

Check device numbers and

change to unique

addresses.

Change to meet proper

shielding and grounding

specifications.

cable from Genius PCIM

card. Use HHM (handheld

monitor) to read

configuration and compare

device numbers and I/O

reference numbers. Ensure

they are as planned.

Replace card as necessary.

Eliminate duplicate input or

overlapping card I/O

references.

Eliminate crossing of Serial

1 and Serial 2.

Bend over the three (3)-pin

regulator U33, so its metal

tab does not contact the

option card.

20 •• Troubleshooting Your Smart Trac Genius PCIM Card Technical Manual 3554-0080

Page 25

SMART TRAC Genius PCIM Card

Appendix A - Technical Support

Getting Help

Should you need technical assistance with installation or troubleshooting of your

Smart Trac AC1, you can phone our Help Desk at either (800)-541-0939 or

(262)-782-0200. Alternatively, you may copy the Problem Report form, found

on the next page, and fax it to us at (262)-782-3418.

References

MagneTek Drives and

Systems

PC/104 Specification,

Version 2.1

Publication GEK-90486-1,

"I/O System and

Communications"

For more information about MagneTek drives

and systems, training programs and contacts,

visit:

http://www.magnetekdrives.com

PC/104 Consortium. An overview and the

specification may be obtained at the web site

address:

http://www.controlled.com/pc104/index.html

GE Fanuc Technical Support. For more

information about Genius networks, design,

architecture and troubleshooting, visit:

http://www.gefanuc.com/infolink/manuals

Technical Manual 3554-0080 Appendix A - Technical Support •• 21

Page 26

SMART TRAC Genius PCIM Card

Problem Report

Name:

Address:

City: State: Zip

Serial Number: Smart Trac PG Card

Occurrence: Frequently Intermittantly Rarely

Nature of Problem:

Conditions when problem occurs:

22 •• Appendix A - Technical Support Technical Manual 3554-0080

Page 27

SMART TRAC Genius PCIM Card

Appendix B – Replaceable Parts

Listing

Replaceable Parts Listing

Description MagneTek Part

Number

Smart Trac PCIM (Genius) Network

Interface option kit

PCB, PCIM, Genius I/O, PC/104 05P00090-0556 1

Standoff, 4.5mm, Hex, Stl, CL

ZINC, 16mm, M/F, M3, M3

DOC, DWG, Assembly, Drive SZ 1-

20, B, PRO/E

Technical Manual – Smart Trac

Genius Card

Hardware Tools Kit for Smart Trac

AC1

Card Extraction Tool (Parvus

46S03643-0080 1

05P00618-0002 4

D-61S03554-0080 1

TM 3554-0080 1

TBD Option

Corporation) P/N

PRV-0760A-01

Qty

Option

Technical Manual 3554-0080 Appendix B – Replaceable Parts Listing •• 23

Page 28

SMART TRAC Genius PCIM Card

THIS PAGE INTENTIONALLY LEFT BLANK

24 •• Appendix B – Replaceable Parts Listing Technical Manual 3554-0080

Page 29

SMART TRAC Genius PCIM Card

Appendix C – Removing the

Smart Trac Card Stack

General Procedures

1. Power off the Smart Trac AC1. Disconnect it and tag "Out of Service".

2. Do one of the following:

• Open the cover to the Smart Trac AC1 by rotating the spring-

loaded, captive screw counterclockwise. Use a large screwdriver if

necessary to free the slotted screw.

OR

• Loosen the screws holding down the cover.

3. Disconnect the 12-pin wiring harness from connector J4 at the digital

operator.

4. Using the Phillips head screwdriver, remove the ground strap from the

left inside and the ground strap from the top inside of the Smart Trac

AC1 adapter ring.

5. Disconnect the 9-pin RS-232 cable at connector J5 on the Smart Trac

CPU card.

Technical Manual 3554-0080 Appendix C – Removing the Smart Trac Card Stack •• 25

Page 30

chassis

board

SMART TRAC Genius PCIM Card

12-pin wiring

harness on

Digital Operator

attached to

connector J4 on

Smart Trac

CPU Card

Digital

Operator

9-pin RS-232

cable

attached here

4mm screws

(4 places)

secure ring

to main

Standoffs (4

places)

secure each

board

Smart Trac

Board Stack

PC/104

9-pin RS-232

cable

connector J5

6. Using a 4.5mm hex head driver, remove four standoffs from the

topmost card.

7. Using the PC/104 extraction tool, remove the topmost card from the

stack.

Position

rectangular

"jacks"

around

edges of

PCBs

Squeeze to lift

cards apart

Figure 6. Using the PC/104 Extraction Tool.

8. Repeat step 8 above until all PC/104 cards have been removed.

9. To remove the Smart Trac PG card:

• Disconnect the 4CN connector on the PG card.

• Using a tubular extraction tool or pliers, squeeze the plastic,

spring-loaded retainer built-in to the long plastic standoff located

at the top of the PG card, just above connector J6.

• Using a PC/104 extraction tool, remove the card.

NOTE: The Smart Trac PG card requires unique handling. Wedge the extracting

tool between the PG card and the CPU card. The area between the terminal strip

on the CPU card and the serial numbered edge of the PG card can be lifted first,

then the opposite side (nearest TB1) on the PG card). Alternate sides until the

card is free of the CPU card.

10. To remove the Smart Trac CPU card:

26 •• Appendix C – Removing the Smart Trac Card Stack Technical Manual 3554-0080

Page 31

SMART TRAC Genius PCIM Card

• Disconnect the card at the 2CN connector on the CPU card.

• The CPU card is secured with three plastic standoffs with spring-

loaded clips on the end. Squeeze the top of the standoffs (the clips)

with the special cylindrical removal tool, your fingers or needlenosed pliers and lift the CPU card from the Smart Trac Inverter

Control Card.

You have removed the entire card stack. The inverter card, considered part of

the drive, is in clear view.

Technical Manual 3554-0080 Appendix C – Removing the Smart Trac Card Stack •• 27

Page 32

Page 33

Glossary of Terms

SMART TRAC Genius PCIM Card

Blocks

Datagram

fault tolerant

Topology

In a Genius networi, blocks are intelligent, self-contained, and configurable I/O

modules. Each block has its own communications capability and

microprocessors, and provides a number of circuits for connecting input and/or

output devices. Analog, discrete, and special-purpose blocks can be used on the

same bus.

A fixed length data packet including information to route it from source to

destination with no reliance on previous transmissions.

Resistant to software errors and hardware problems. A fault tolerant LAN keeps

running in the event of a power failure, a disk crash or other major events.

Redundant backbone cabling provides a degree of fault tolerance, so that if the

cable is cut, the network will continue to run.

The way in which devices on a network are physically connected: star, bus, or

mesh. The topology may define transmission media, adapters, and physical

design of the network.

Technical Manual 3554-0080 Glossary of Terms •• 29

Page 34

Page 35

Index

SMART TRAC Genius PCIM Card

C

cable 3, 5–6, 9, 13, 21–22

Capabilities 3

Configuration 13, 22

CPU 27

E

extraction tool 28

I

Inverter 29

L

LED 19, 21–22

R

registers 17

S

Specifications 3, 6, 22

Switch 3, 9, 13–17, 22

T

tool, extraction 28

troubleshooting 21, 23

Technical Manual 3554-0080 Index •• 31

Page 36

SMART TRAC Genius PCIM Card

Data subject to change without notice. Smart Trac is a trademark of MagneTek, Inc. MicroTrac is a registered trademark of MagneTek, Inc. Microsoft, Windows and Windows NT are registered

trademarks of Microsoft Corporation

MagneTek

Drives and Systems

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939, (262) 782-0200, FAX (262) 782-3418

TM 3554-0080 © 1999-2000 MagneTek, Inc. 01/31/2000

Loading...

Loading...