Page 1

Technical Manual

™

™

S

M

A

R

S

M

A

R

T

T

T

T

F

F

R

R

a

a

A

C

A

C

ulltt

u

T

T

a

a

A

A

bll

b

C

1

C

1

ess

e

Page 2

10/17/00

Smart Trac

Faults.doc

Rev. # 19 Page 1 of 64

New Berlin

Technology Center

Product Development

Design

Document

Title: Fault Declarations

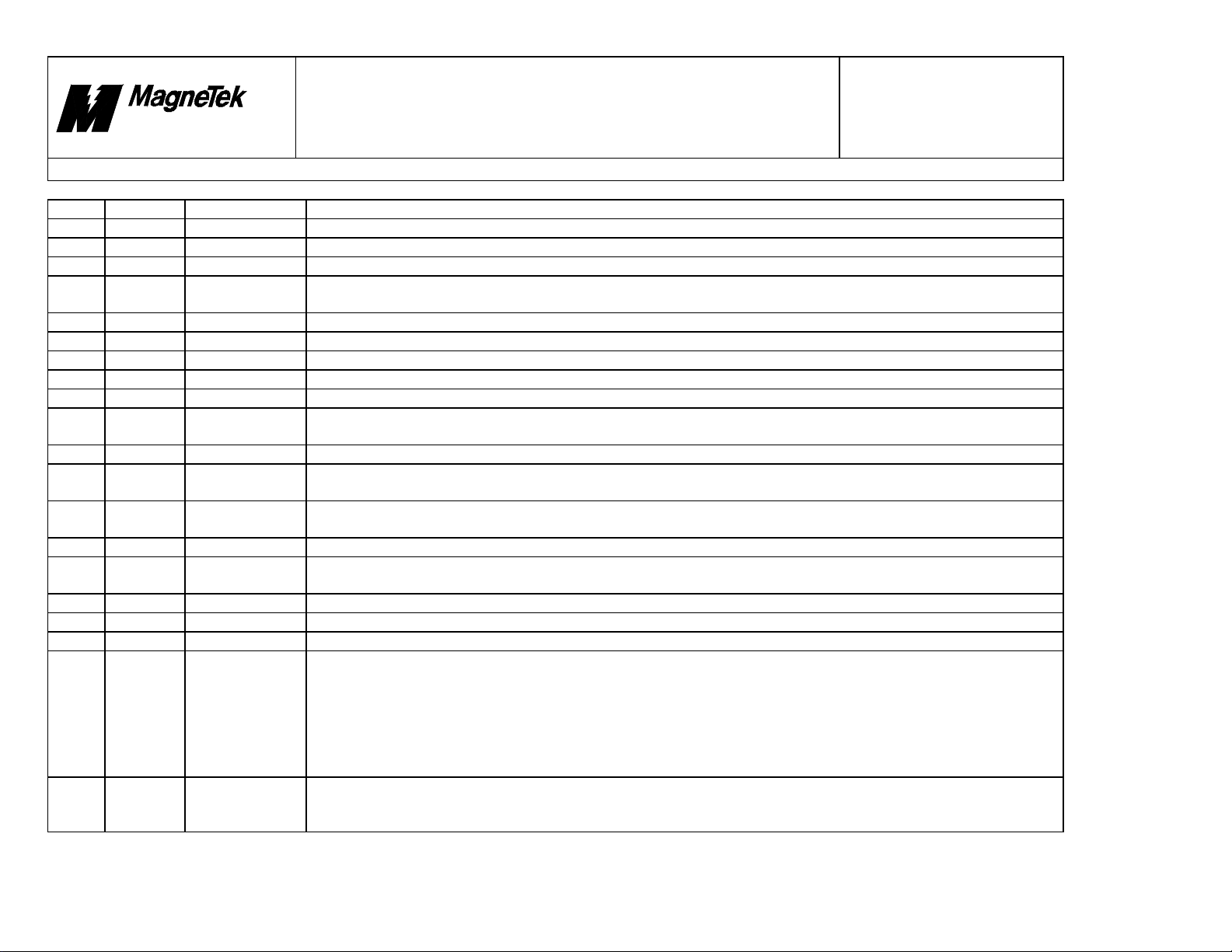

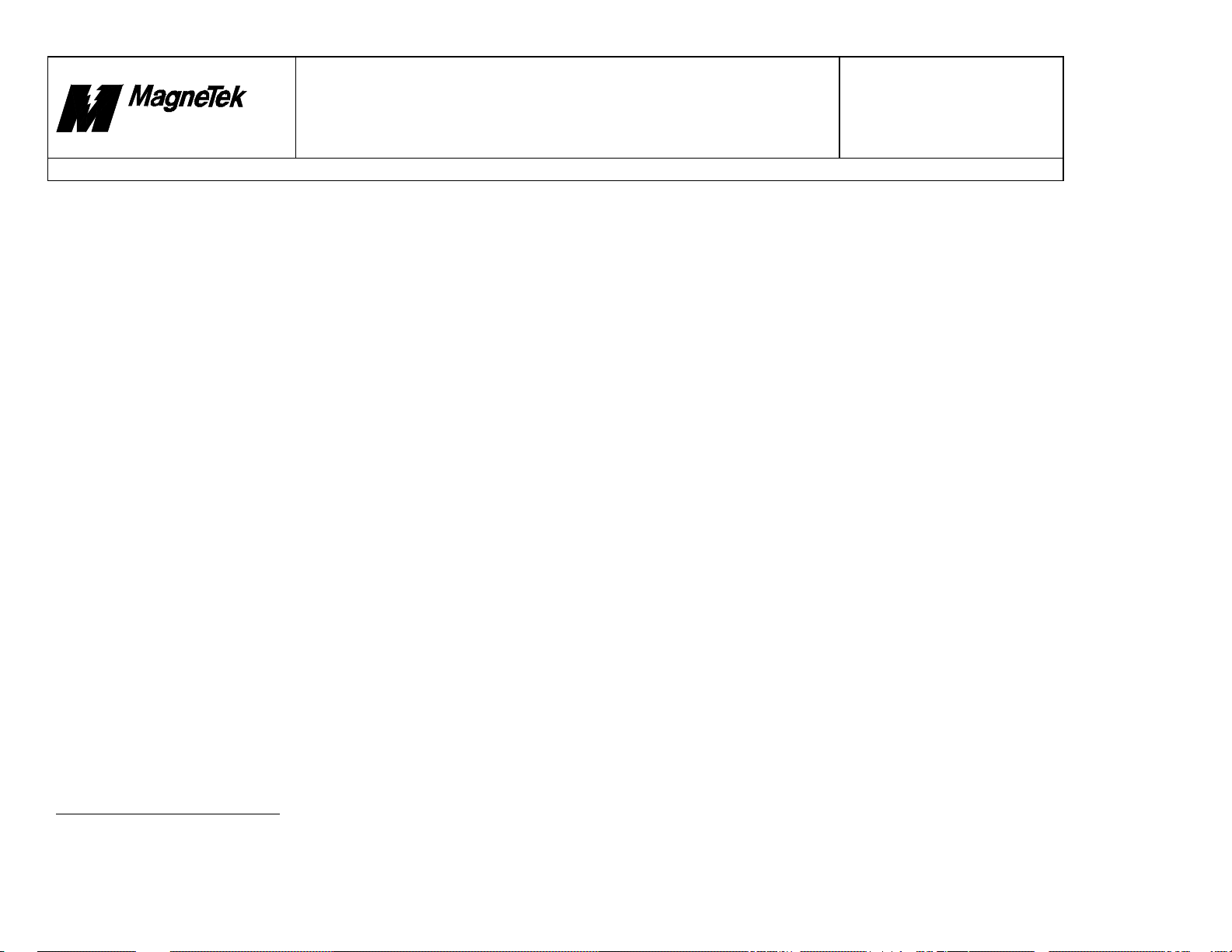

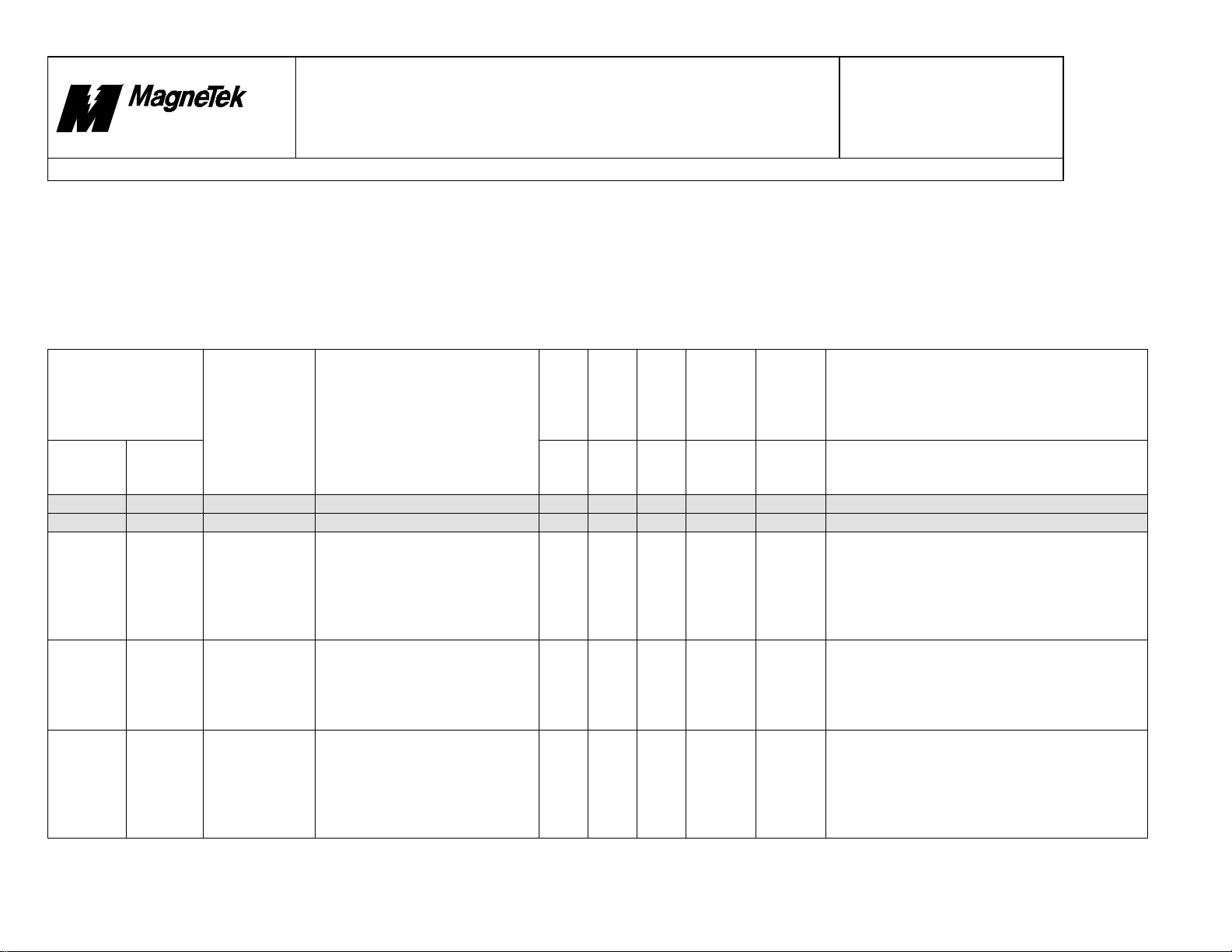

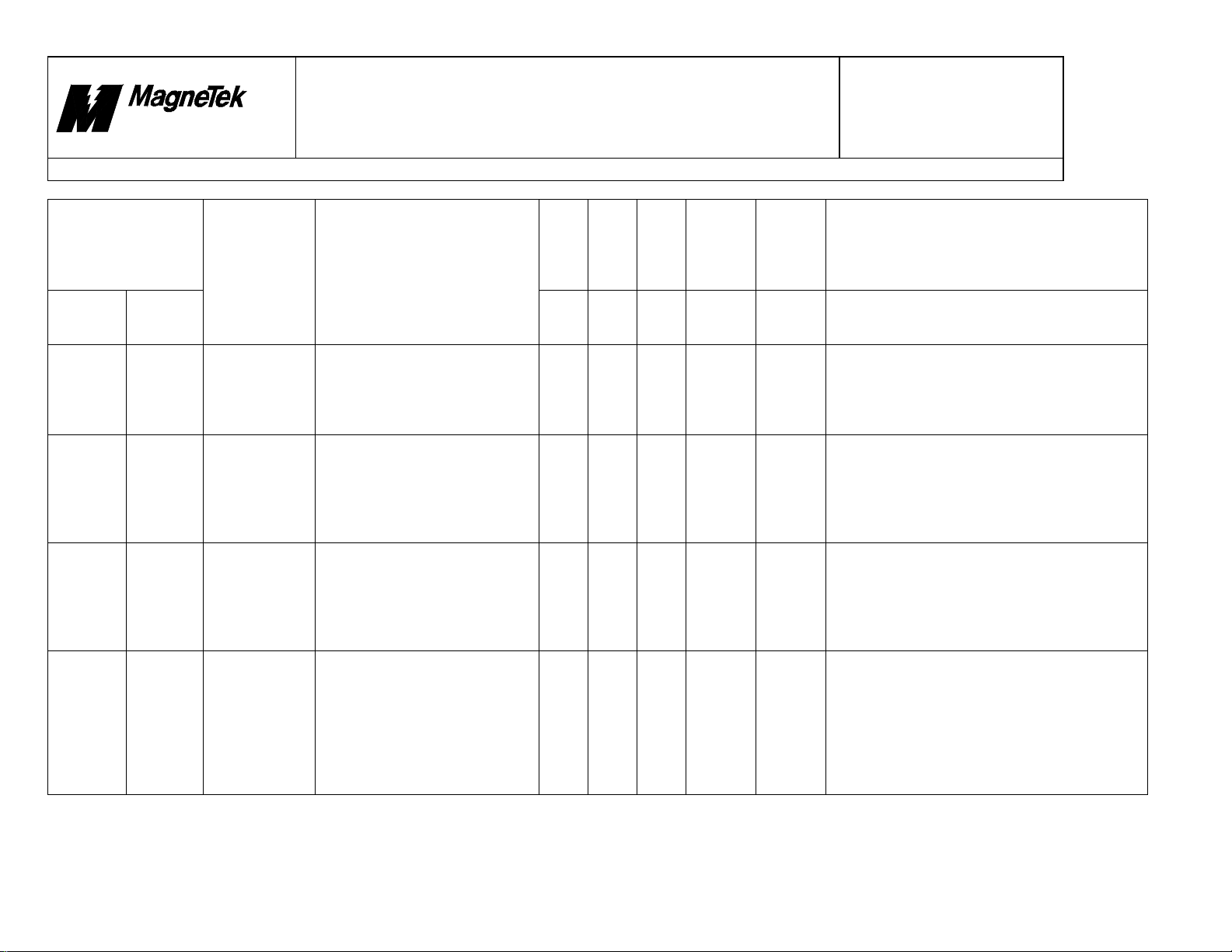

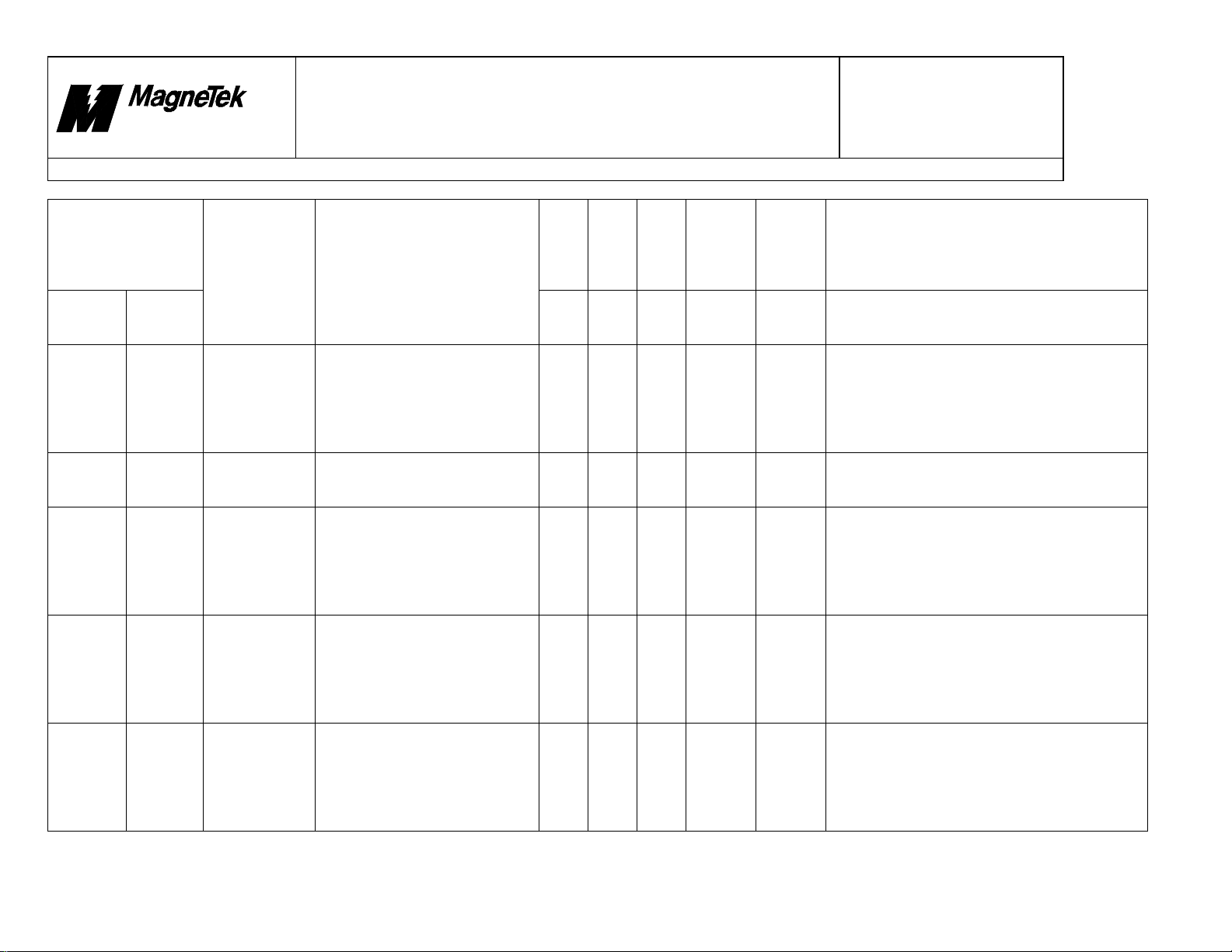

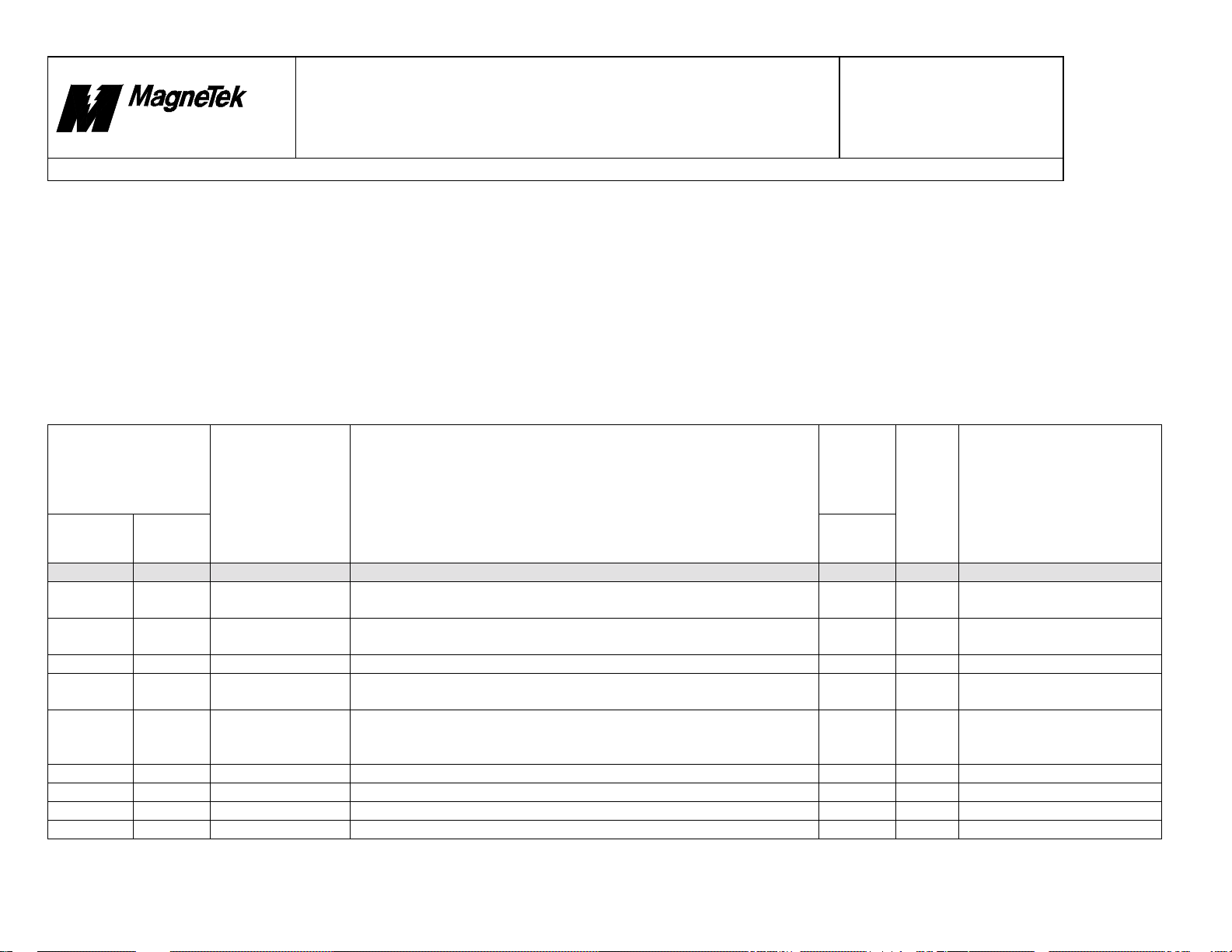

REV DATE NAME DESCRIPTION

0 04/23/98 J. Muszynski Original.

1 08/21/98 D. W. Karraker Split driver fault codes among known I/O drivers. Added sub-heading listing DPRAM faults.

2 12/04/98 D. W. Karraker Updated DPRAM and PCU faults

3 12/04/98 M. DuVal Added faults for PG-SC. Added cross reference column as to the actual error number shown in Smart Trac

Workstation SW

4 01/26/99 J. Cretney Added displayed fault codes to fault # 30016 through 30047

5 02/27/99 M. DuVal Added Smart Trac LAN fault table.

6 03/05/99 J. Cretney Merged C-Function Block Fault descriptions. Added decimal representation of fault codes.

7 03/22/99 M. DuVal Added more Smart Trac LAN fault codes.

8 03/23/99 T. Wiese Change LAN allocation errors from output to I/O

9 08/04/99 M. DuVal Added Operating System faults, Fault Range Map, and Document Revision. Removed unused sections. Reformatted

fault tables. Corrected documentation errors.

10 08/18/99 M. DuVal Include revisions from document design review. Added columns: Corrective Action and Assign Program Inputs.

11 09/10/99 T. Ellis Changed Assign Program Inputs to reflect correct values. Provided information for Corrective Actions. Document

clarification and corrections.

12 12/16/99 S. Mack Added new faults being declared by Function Blocks in MAG_WIND_V1_9 and MAG_STD_V1_9. Added to the

explanations of fault types.

13 12/20/99 D. W. Karraker Added individual CPF and OPE faults under Inverter Faults

14 01/05/00 M . DuVal Renamed references of MAG_CPB_V1_9 to MAG_STD_V1_9. Revised fault definitions in Function Blocks section

specific to MAG_STD_V1_9 library.

15 01/11/00 D. W. Karraker Added revision number for DPRAM driver to section 1.2

16 01/12/00 M. DuVal Minor changes to Function Blocks section.

17 01/31/00 D. W. Karraker Added inverter alarm codes

18 04/03/00 J. Nickel Added 2 fields to each fault code to indicate which list(s) the fault will be placed in by default: OLDEST or NEWEST.

Also added a column to indicate if the fault is considered a PRIORITY fault by default. Changed the description of

fault #77643 (CAVE Input). Changed legends of event codes 95736-95755 to include “Alm:”. Revised many of the

Corrective actions which were labeled ‘Consult Factory’. Added faults 12B08 – 12B0B, & 12B67. These are new

input faults for the DIAM_2, INRT_1, CTCW_0, CTCW_1 and POSR_0 blocks. Corrected some other typos in the

document. Added another Program Input called ‘FB_Setup’ for use to designate improper inputs to various block

inputs.

19 05/09/00 S. Mack DIAM_0 can declare NO_SYSTEM_CLOCK fault. DIAM_2 will declare DIAM_2_INPUT faults if sanity checks are

exceeded for NumberCalculation, RatedLineSpeed, S_RPM_at_M_RPM, MinDiameter, and MaxDiameter. Updated

Fault Document Revisions.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

1

Page 3

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

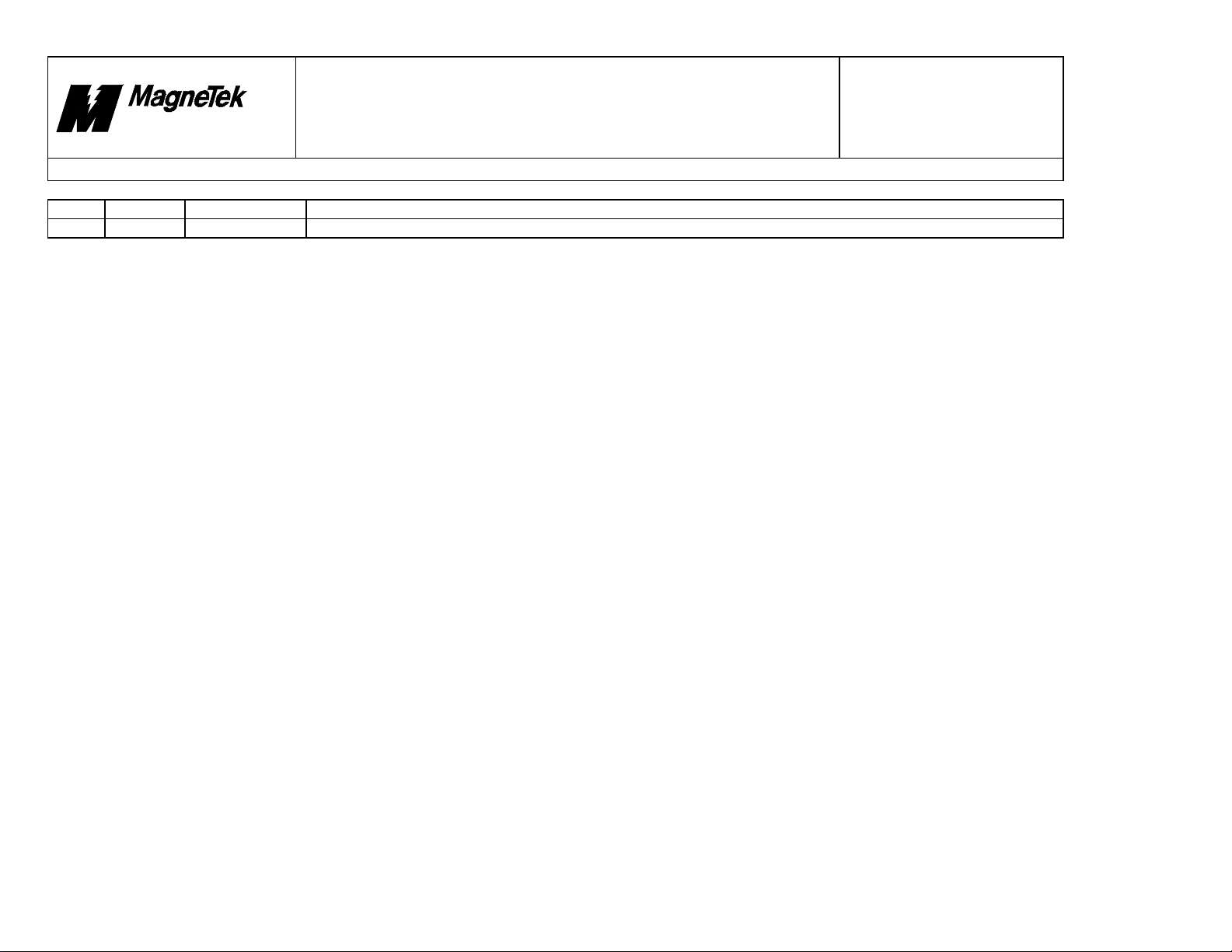

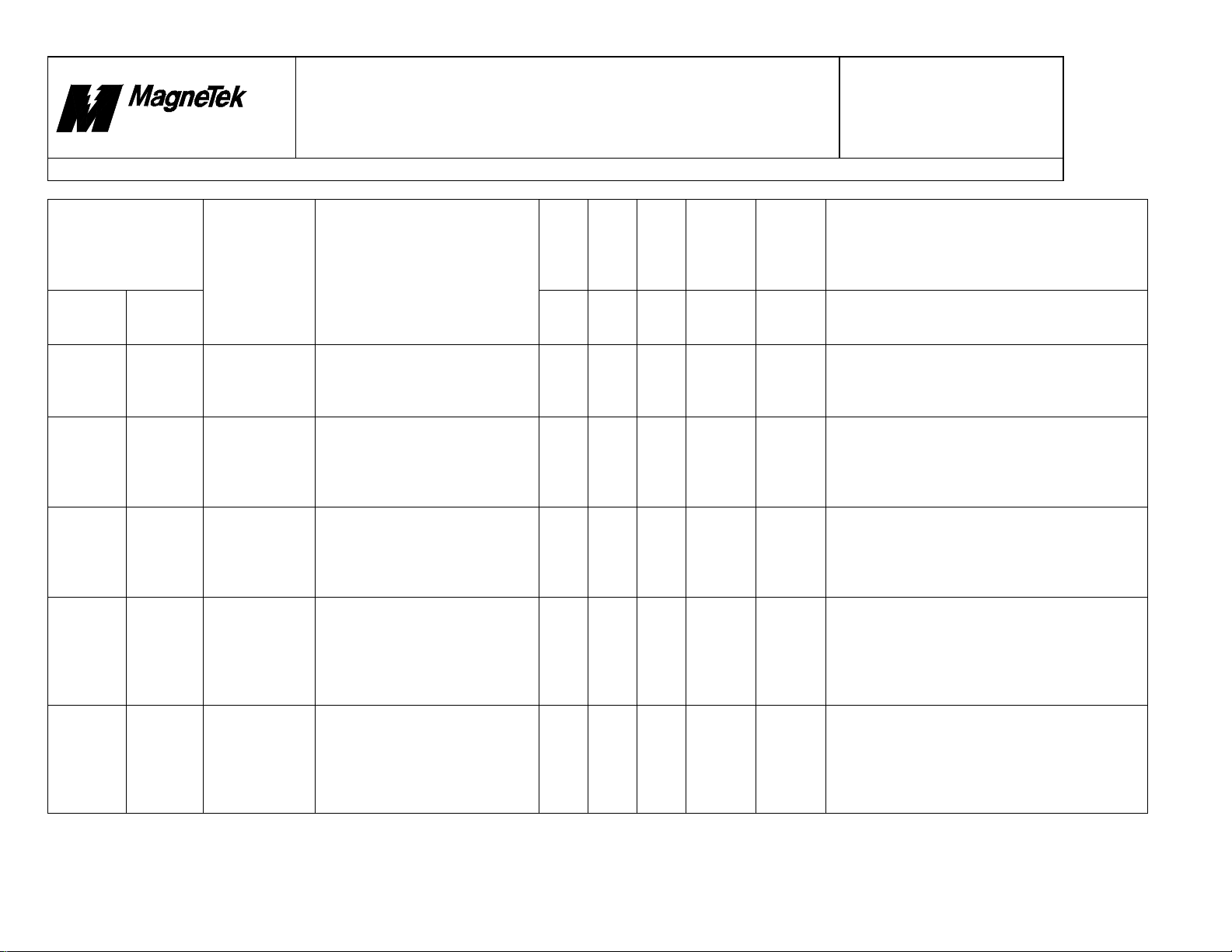

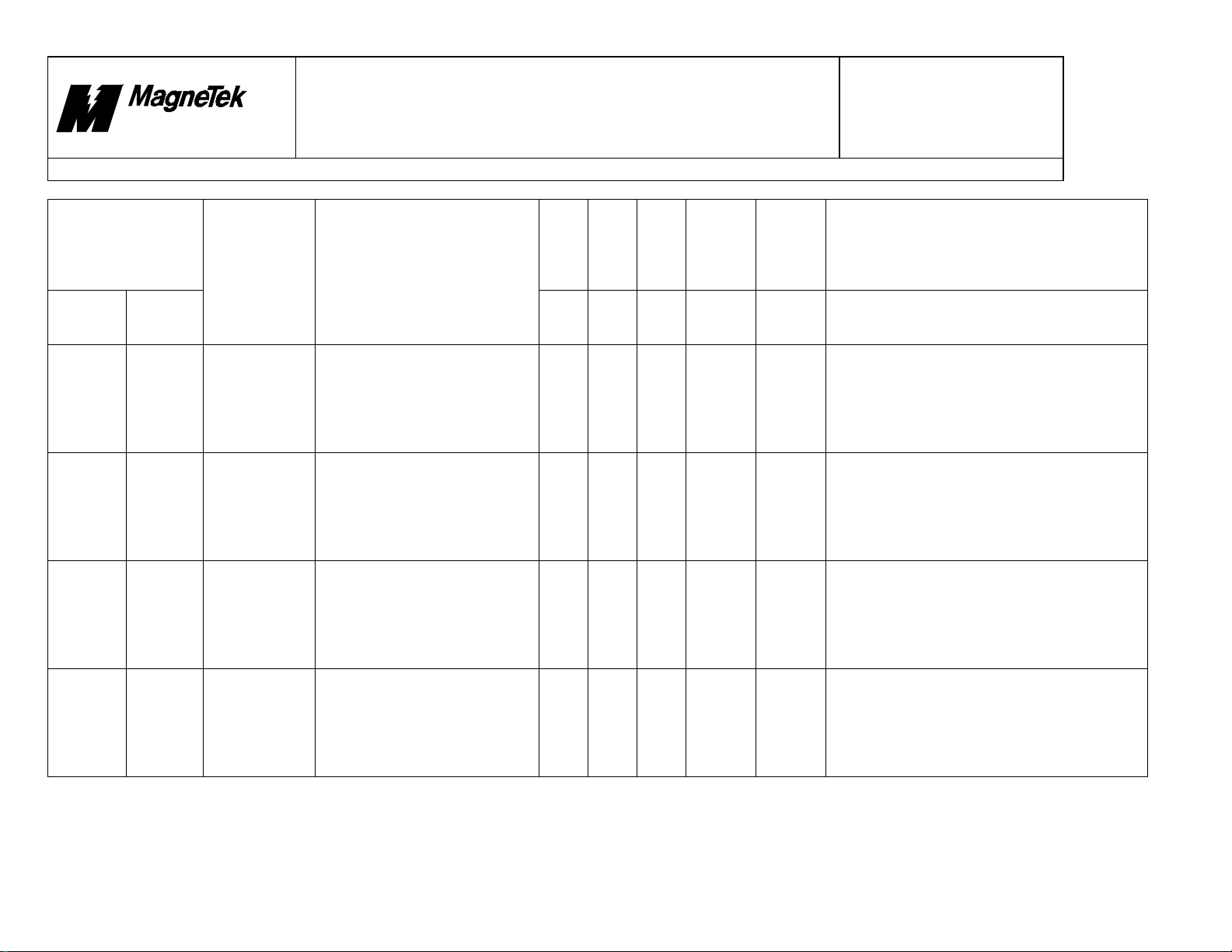

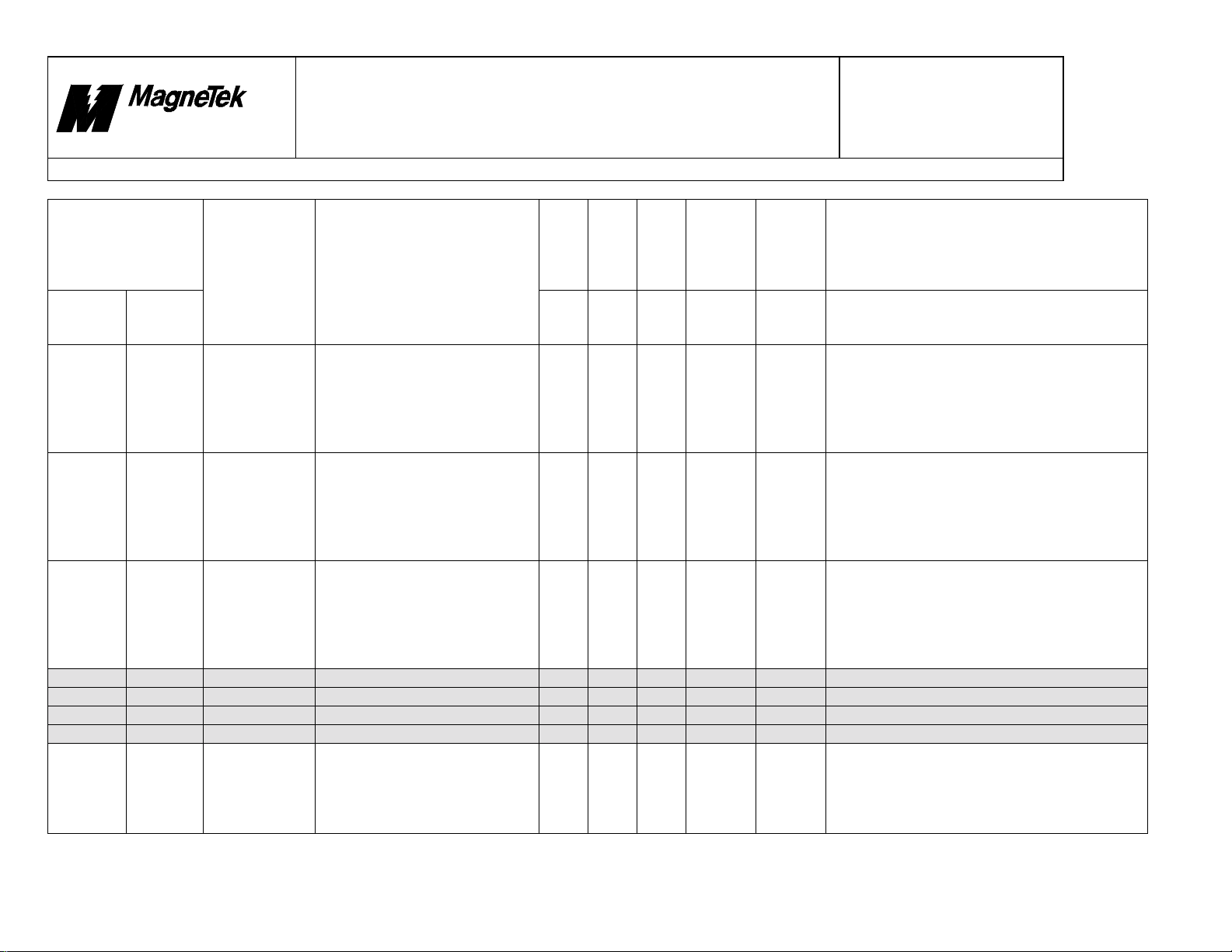

REV DATE NAME DESCRIPTION

20 9/28/00 S. Mack Added PG_TACH Input fault. Fixed fault 11019 from REFQ to CTCW_1 Input fault.

Rev. # 19 Page 2 of 64

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

2

Page 4

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

Table of Contents

1. FAULT NUMBER ASSIGNMENTS 4

1.1 Fault Range Map 6

1.2 Fault Document Revision 7

2. OPERATING SYSTEM 8

3. USER DEFINED FAULTS 20

4. FUNCTION BLOCKS 21

5. DRIVERS 30

Rev. # 19 Page 3 of 64

5.1 DPRAM Driver 30

5.2 STLAN Driver 33

5.3 Operator Driver 37

6. INVERTER 38

7. IO SUBSYSTEM 59

8. BOOT 64

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

3

Page 5

10/17/00

Smart Trac

Faults.doc

Rev. # 19 Page 4 of 64

New Berlin

Technology Center

Product Development

Design

Document

Title: Fault Declarations

1. Fault Number Assignments

Xycom Automation has allowed MagneTek to use any “internal” fault number, in the range of 0 to 65535, to identify declared faults. (Internal faults are elaborated on below.)

This document is meant to assign ranges of numbers to the different aspects of the project, which may need to declare faults. There are a vast number of faults and this should

eliminate need for having duplicate fault numbers.

Faults number ranges will be assigned to the following broad categories:

1. Operating System

2. User Defined Faults

3. Function Bloc ks

4. Communications

5. Drivers

6. Inverter (PCU)

7. Hardware

8. IO Subsystem

9. Boot

10. Future

It shall be the responsibility of software engineers controlling each category to:

1. Further sub-divide the range as they deem appropriate.

2. Keep a common header or include file, under file control, with assigned fault numbers.

3. Keep a Word Document , under file control, defining the fault.

Faults have cl assification levels cal led Severity. Severity is the level at which a fault should be interpreted by the operating system. When a fault condition is detected, the

software that declares the fault also reports its severity. Four types of faults can occur: major faults, minor faults, function block setup faults and critical faults.

Major faults can halt execution of the task or node. Most major faults can be manually cleared and the task and node restarted. Major faults stop execution until they are cleared

by a task’s program or by the operator. If a major fault is encountered, the fault routine is run and the first thing that the fault routine should do is call G_FLT (i.e. Get Fault

function block) to get the current fault code. Depending on the fault code, it should deter mine if the s ystem should be shut down or clear the fault and restart execution. Call

C_FLT to clear the fault. Fault clearing can also be done externally by pressing RESET on the Digital Operator. (Typically, automatic clearing of major faults is not

recommended. Fault clearing should be initiated by the machine operator.) Major faults cleared by the Control Node Monitor will cause execution to begin from the start of the

program. If the Major fault is cleared after executing the fault routine, execution of the function block will restart at the point at which the fault was declared. This very important

to understand. For example in a structured text program, if a fault is declared on a certain line, then it is restarted on the following line.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

4

Page 6

10/17/00

Smart Trac

Faults.doc

Rev. # 19 Page 5 of 64

New Berlin

Technology Center

Product Development

Design

Document

Title: Fault Declarations

Minor faults are logged, but do not halt the system. Minor faults can be cleared. Minor faults do not cause the task’s fault routine to run.

Function block setup faults (FB_SETUP) are those that indicate at least one input of a function block has been supplied with an illegal input.

Critical faults behave similar to major faults in the fact that execution is halted when a critical fault is encountered. The exception is, a critical fault cannot be cleared nor will the

node be allowed to run until node power has been recycled.

The Application Engineer may determine the type of fault (i.e., Major or Minor) only for the User Defined faults. In the other category of faults, the types are predefined and

cannot be changed by the Application Engineer .

1

Faults can be assigned to certain inputs such that the program can react when a fault occurs. These inputs are categorized in this document as Assign Program Input

The Fault Manager I/O Driver has a variable number of logic inputs (BOOLs). Each of these logic inputs will be set true if any of the faults pre-assigned to that logic input is

declared. It will remain true until all faults assigned to that input have been reset. Any number of faults may be assi gned to any of the inputs. The Fault Manager Interface Card is

the mechanism for defining the number of logic inputs, their symbols, and the list of fault codes assigned to that input. The default symbols used in the faults definition document

are “Critical”, “Major”, and “Minor”. These symbol names and the faults assigned to them may be changed by the Application Engineer.

Faults can be displayed in up to three places in a Smart Trac AC1 system: twice in Smart Trac AC1 Workstation and once on the Digital Operator. Specifically, the workstation

shows fault numbers in two places, a) Fault Manager Interface Card, and b) Control Node Monitor. Unfortunately, the same fault has a different number, depending on whether it

is displayed in the Fault Manager or Control Node Monitor. Fault Manager sho ws the fault in decimal while Control Node Monitor shows the number in hexadecimal. This is a

“feature” that was given to us by Xycom Automation. The Digital Operator does not display a fault number rather a Fault Legend. All tables in the ensuing sections have cross

references for each fault.

.

Although fault numbers are displayed in Fault Manager and Control Monitor, a third column has been added to many of the tables in this document: Internal Fault No. An

internal fault number is the number MagneTek development engineers use to identify a fault within a given piece of software and is of no consequence to the Application

Engineer. The displayed fault is equal to the internal fault number + 65,536 (i.e. 10000 HEX). Internal fault numbers are not displayed.

1

Also known as ‘Define Outputs’ tab in Fault Manager Interface Card of Smart Trac AC1 Workstation software.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

5

Page 7

10/17/00

Smart Trac

Faults.doc

Rev. # 19 Page 6 of 64

New Berlin

Technology Center

Product Development

Design

Document

Title: Fault Declarations

There are three columns following the description of each fault. These are labeled Priority Display, Newest List and Oldest List. Faults which are selected to be a Priority

Display will preempt the local operator from whatever it was doing with a display this fault when it happens. Those faults which are selected to be on the Newest List (and/or

Oldest List) will be placed in the ‘newest’ (or ‘oldest’) list maintained by the fault manager. The Newest List can be thought of as a circular buffer that always contains the

newest faults that have been recorded on this drive. Any fault designated as to be placed on the Newest List will cause the oldest entry on this circular buffer to be discarded if

the Newest List already filled to capacity. The Oldest List can best be thought of as a table with 20 slots. Any fault designated to be placed on the Oldest List will remain on

this list until it is cleared via the local operator. If the Oldest List already filled up, and a fault designated to be placed on the Oldest List occurs, it will NOT be placed o n the

Oldest List. This is done to preserve the fault history of the original event that may have caused many subsequent faults to occur.

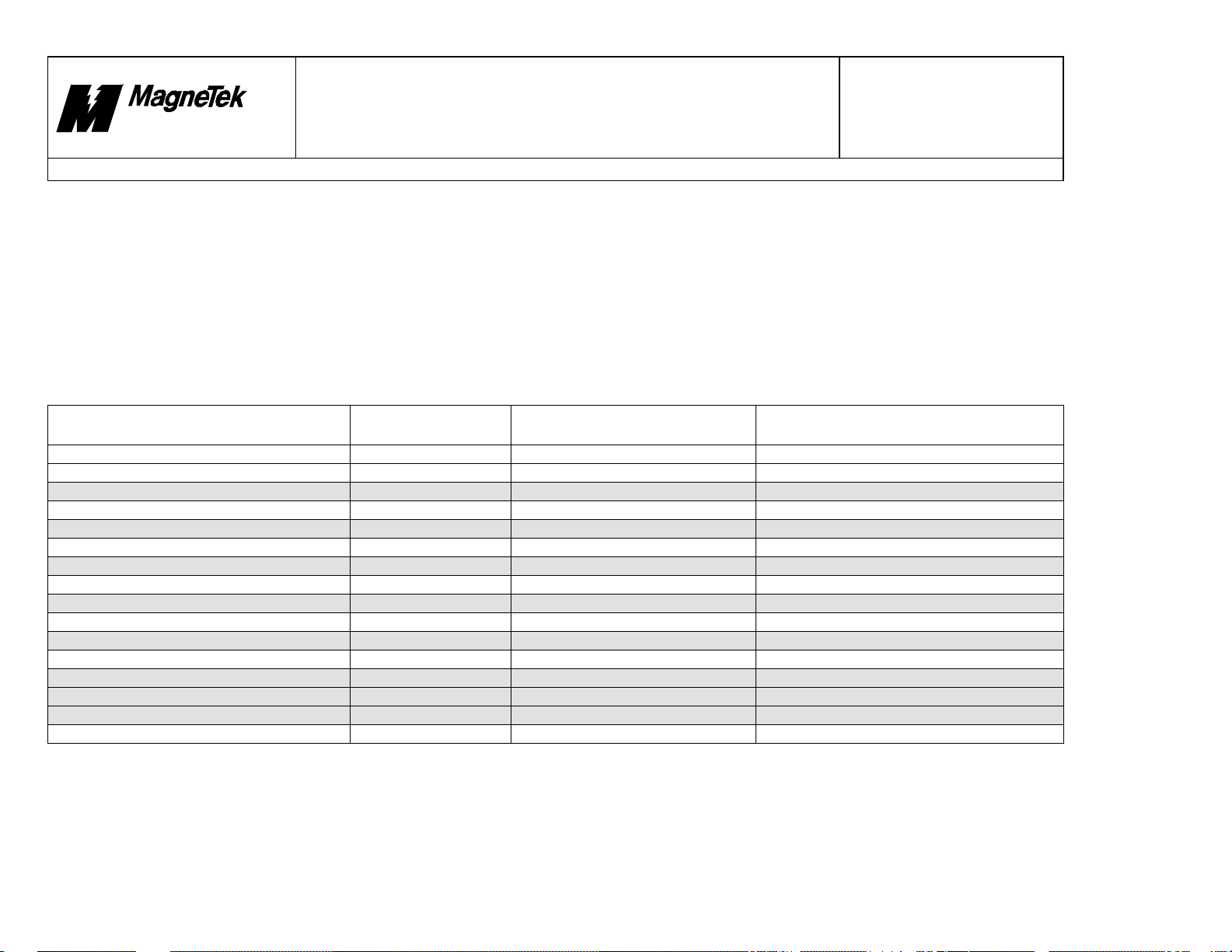

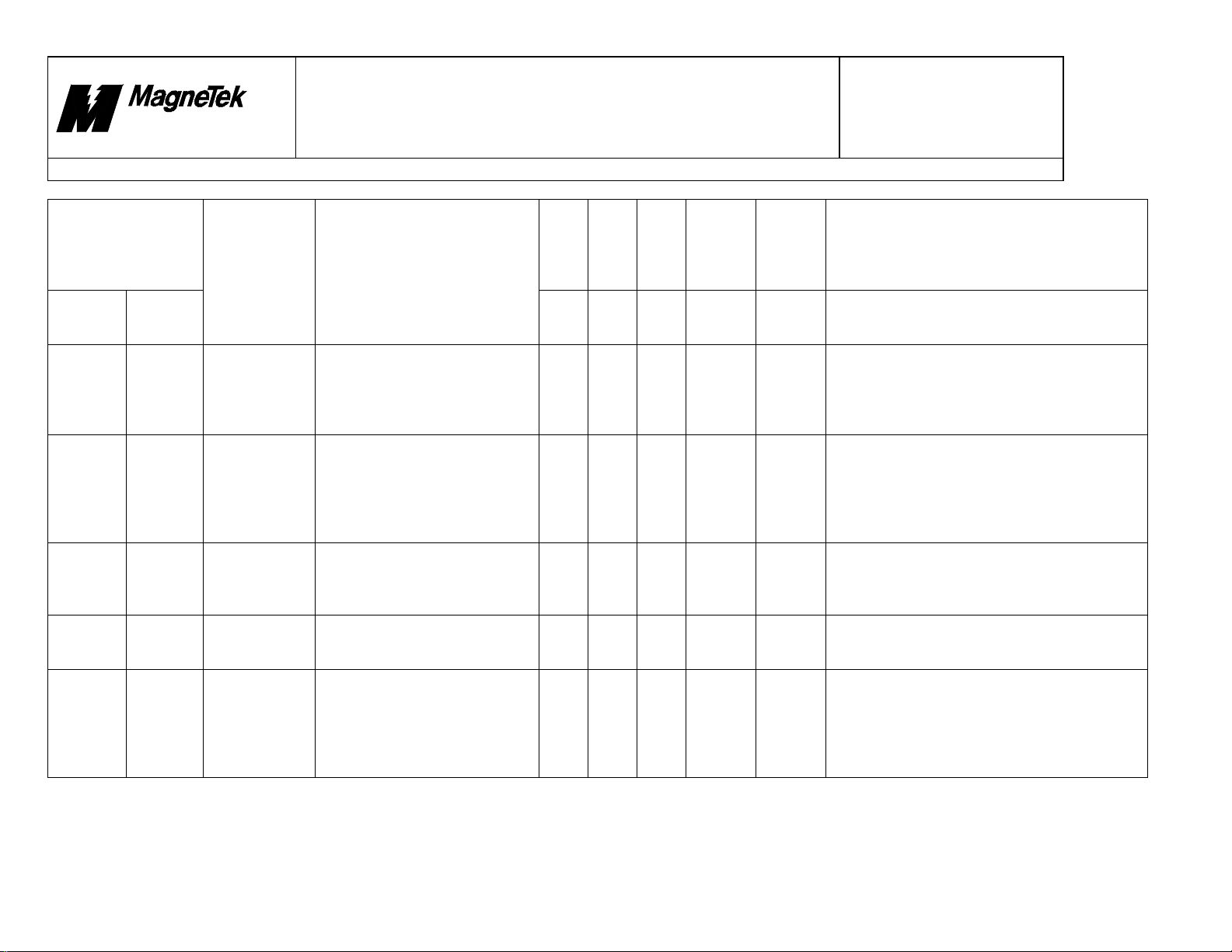

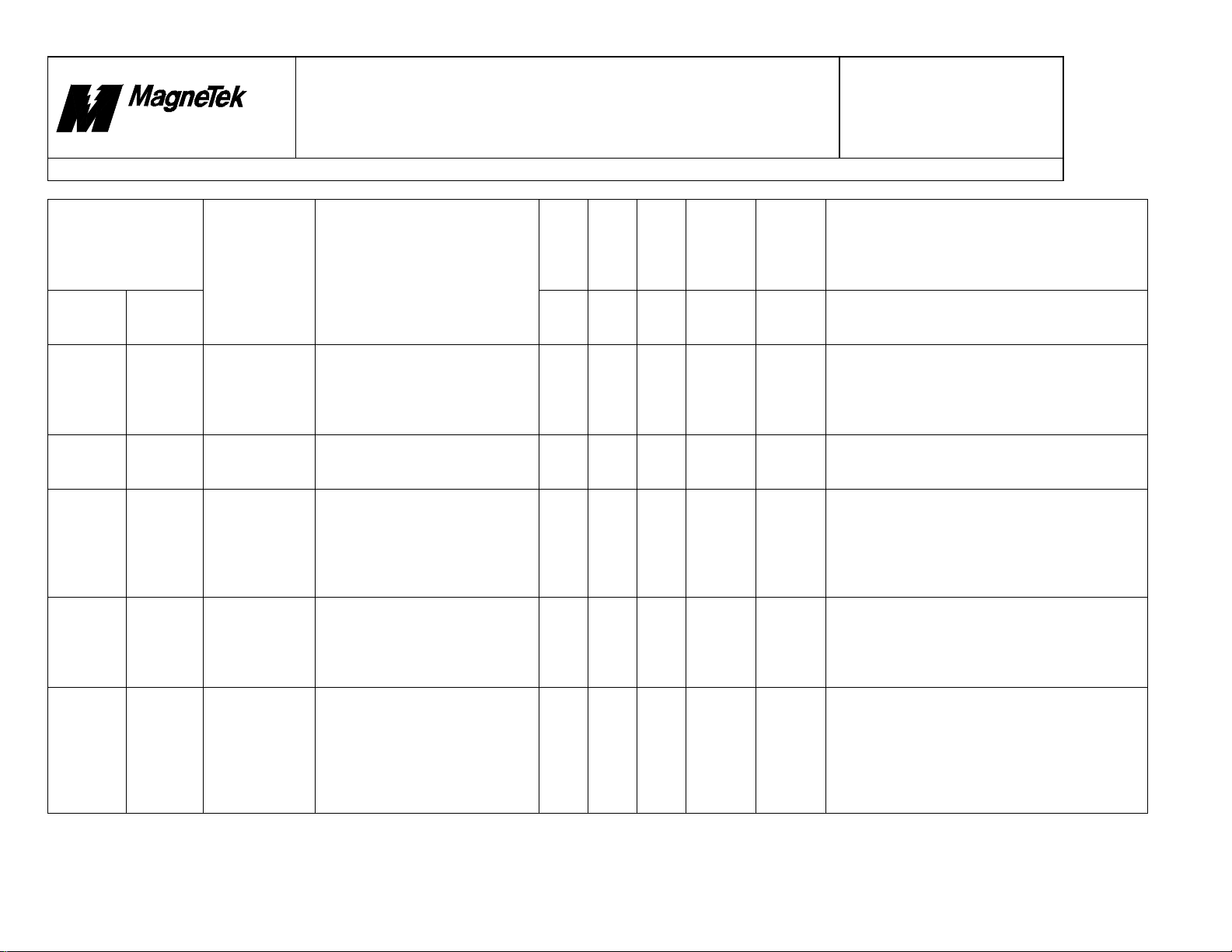

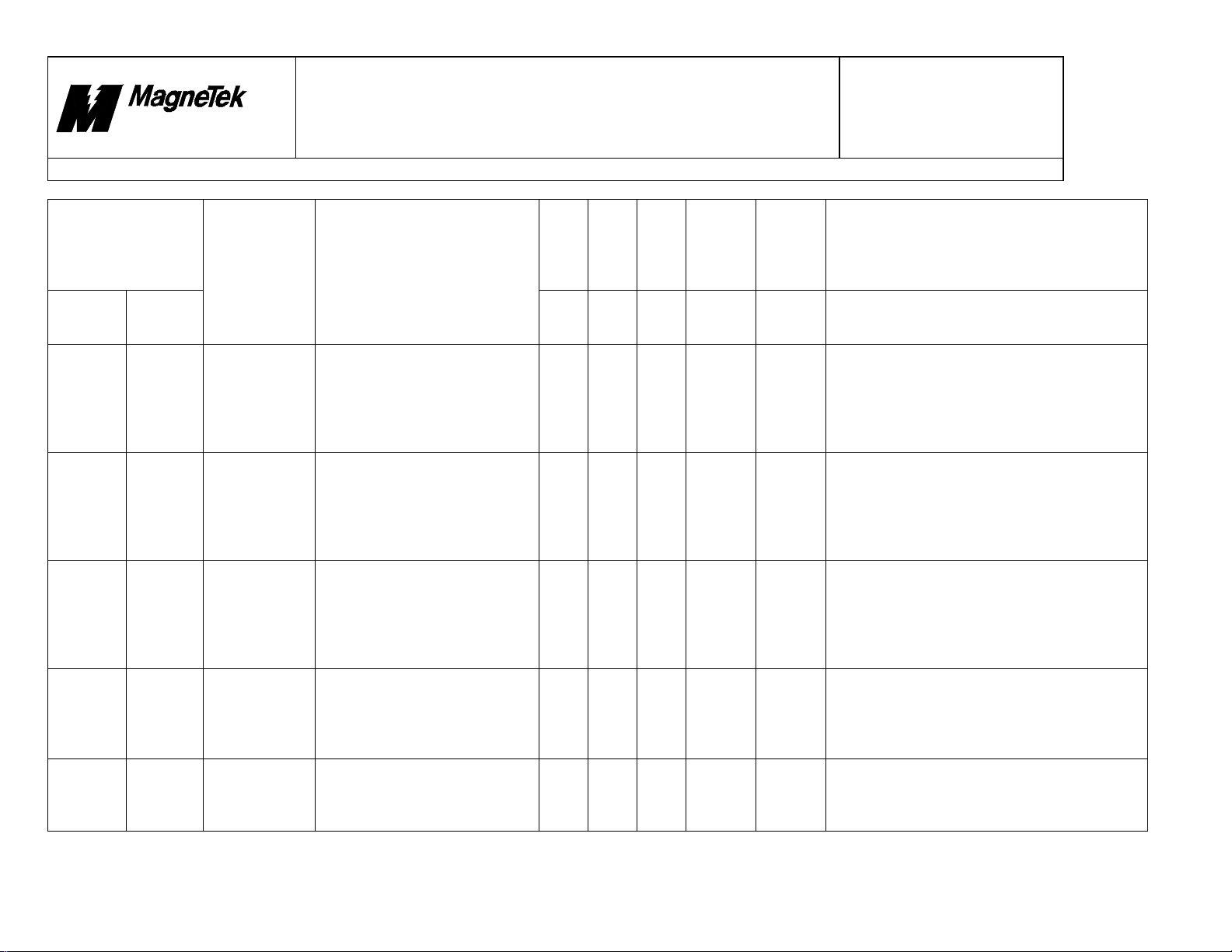

1.1 Fault Range Map

This table summarizes all possible fault value locations.

Fault Type

Operating System N/A 0 to FFFF 0 to 65,535

User Defined Faults 00000 to 09999 10000 to 1270F 65,536 to 75,535

Reserved for future u se #1 10000 to 10999 12710 to 12AF7 75,536 to 76,535

Function Block Faults 11000 to 11999 12AF8 to 12EDF 76,536 to 77,535

Reserved future Communications Protocols 12000 to 19999 12EE0 to 14E1F 77,536 to 85,535

Driver Faults: DPRAM 20000 to 20099 14E20 to 14E83 85,536 to 85,635

Reserved for future d riv e r #1 20100 to 20199 14E84 to 14EE7 85,636 to 85,735

Driver Faults: STLAN 20200 to 20299 14EE8 to 14F4B 85,736 to 85,835

Reserved for future d riv e r #2 20300 to 20399 14F4C to 14FAF 85,836 to 85,935

Driver Faults: OPERATOR 20400 to 20499 14FB0 to 15013 85,936 to 86,035

Reserved for future d riv e r #3 20500 to 29999 15014 to 1752F 86,036 to 95,535

Inverter Faults 30000 to 39999 17530 to 19C3F 95,536 to 105,535

Reserved for future u se #2 40000 to 59999 19C40 to 1EA5F 105,536 to 125,535

Reserved for future hardware platform fau lts 60000 to 65535 1 E A60 to 1FFFF 125,536 to 131,071

Not Used N/A 20000 to 8FFFFFFF 131,072 to 2,415,919,103

IO Subsystem N/A 90000000 to 90000043 N/A

Internal Fault Range

(Decimal)

Displayed in Control Node

Monitor (Hex)

Displayed in Fault Manager Interface Card

(Decimal)

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

6

Page 8

10/17/00

Smart Trac

Faults.doc

Rev. # 19 Page 7 of 64

New Berlin

Technology Center

Product Development

Design

Document

Title: Fault Declarations

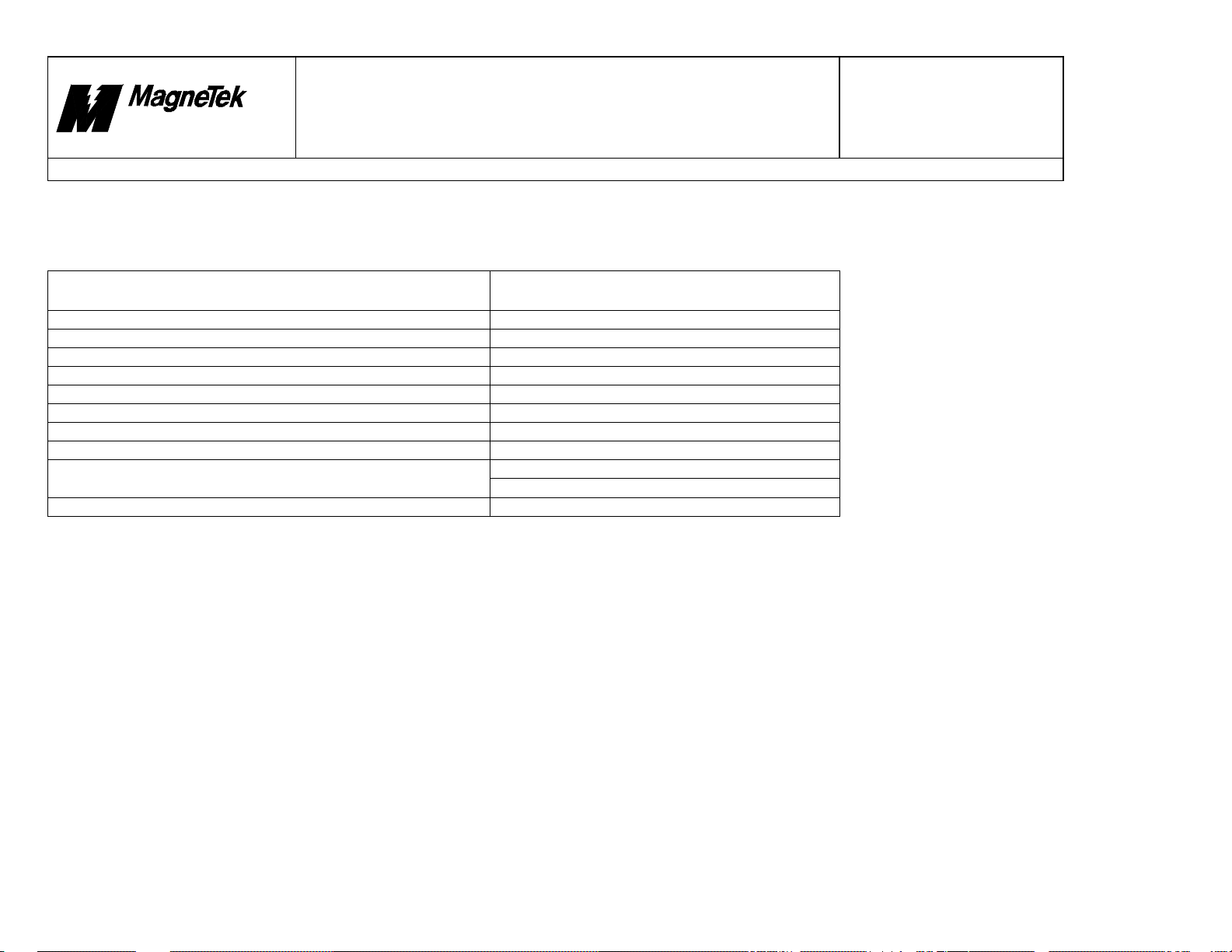

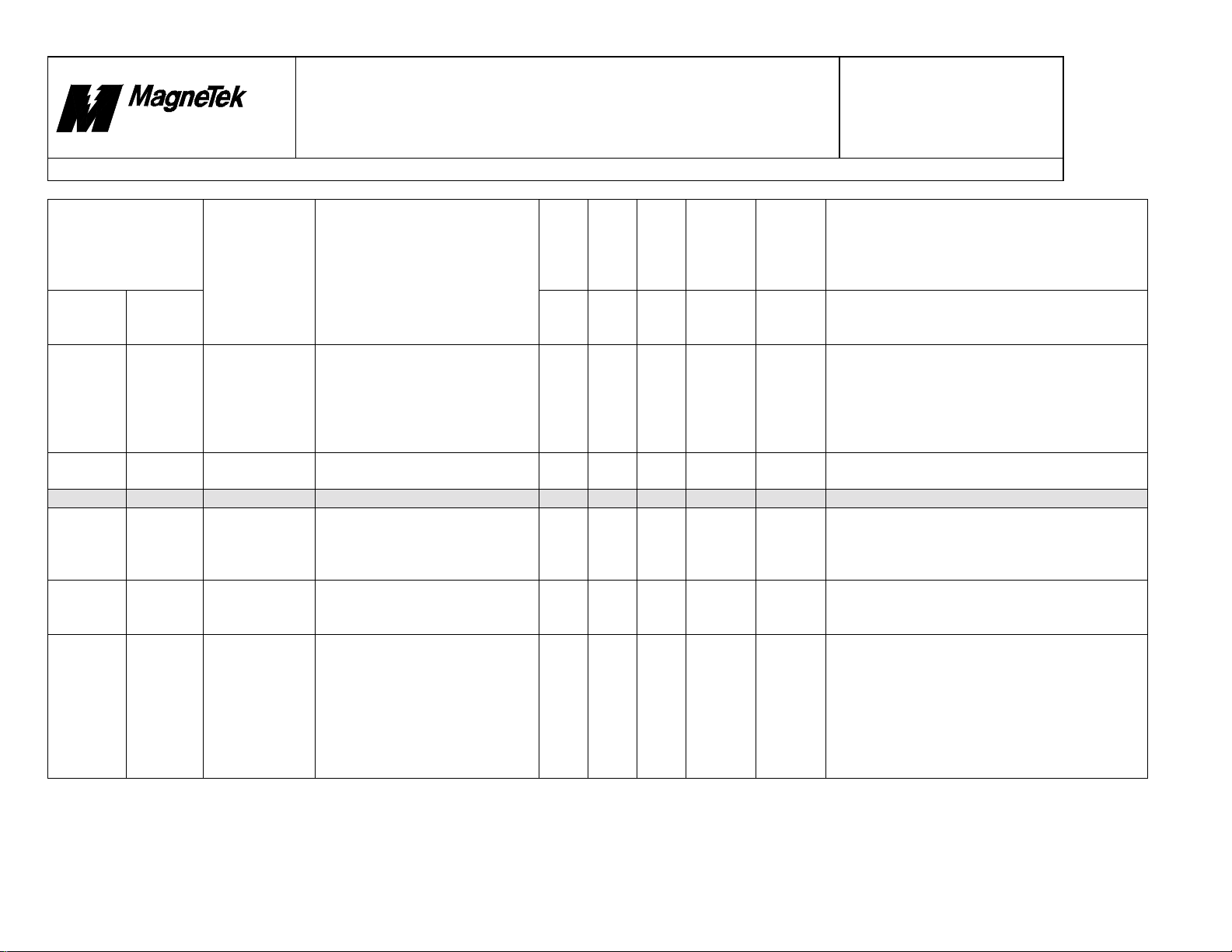

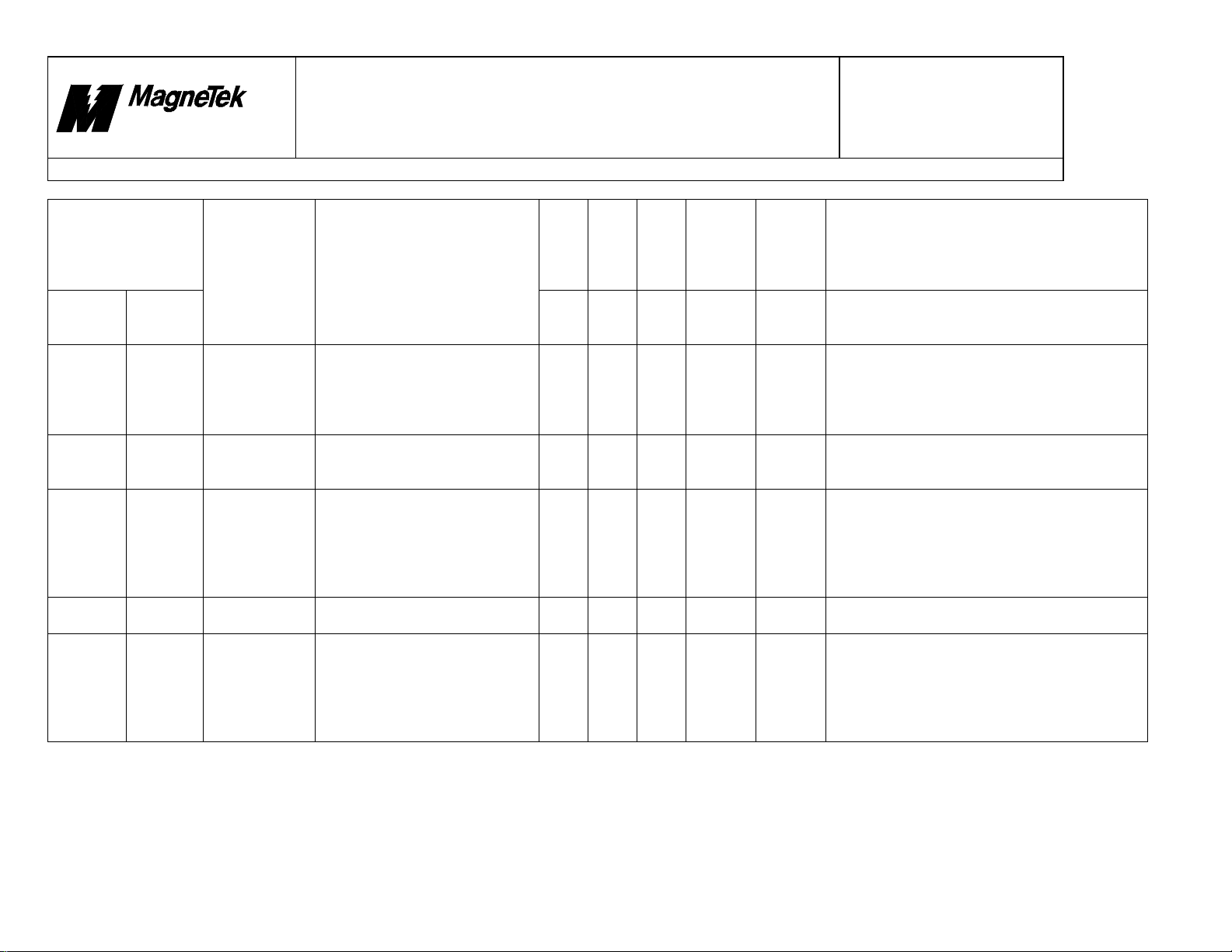

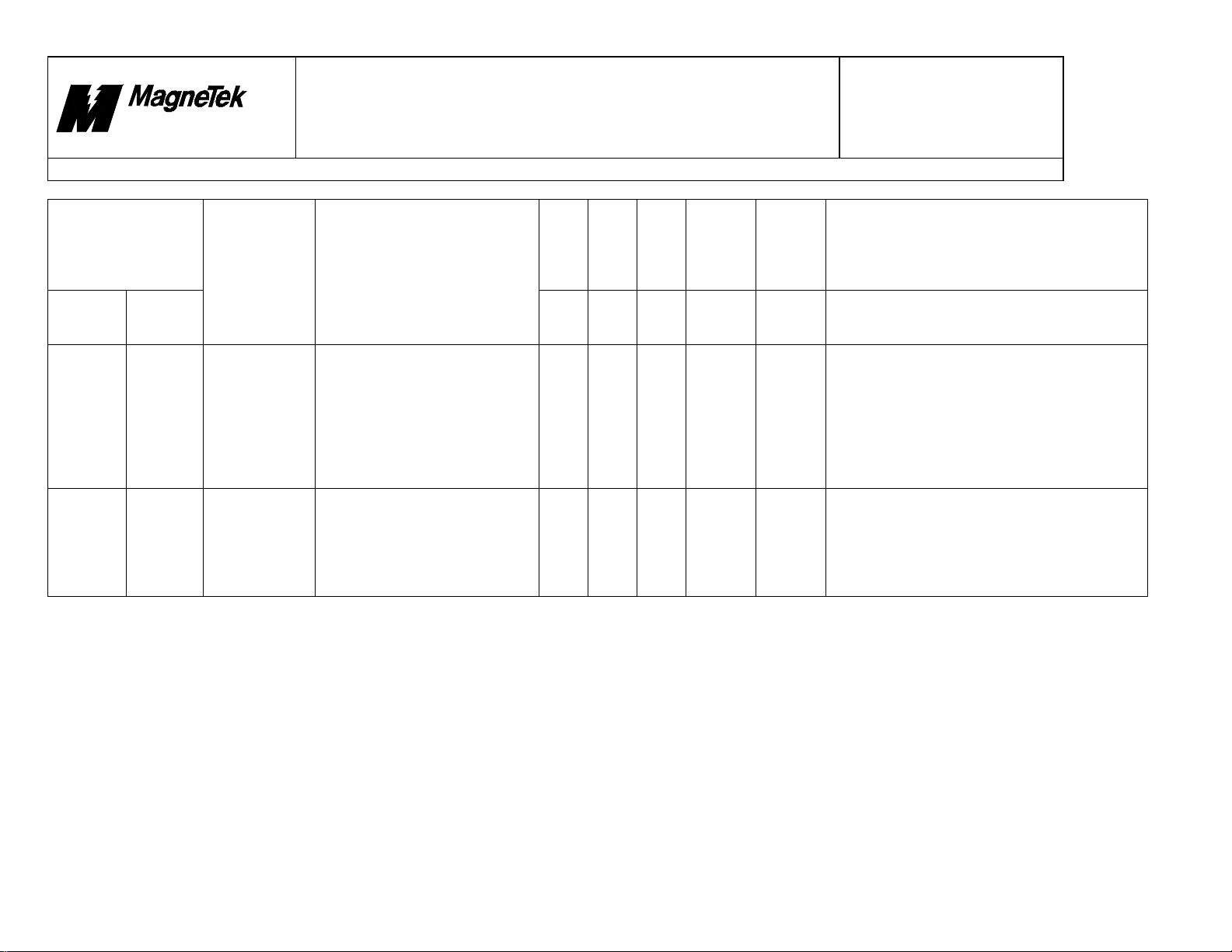

1.2 Fault Document Revision

This table lists the latest version of each fault type. As developers make enhancements that affect faults, they should update the corresponding section and change the

Software/Firmware (SW/FW) Version level accordingly. In this way, we can track whether this document has been properly updated.

SW/FW Type

ASIC-300 Workstation 4.2.4

Operating System and IO Subsystem (i.e., Kernel and Monitor) 4.2.0

Library: MAG_STD_V1_9 1.9

Library: MAG_WIND_V1_10 1.10

Library: MAG_PG_V1_7 1.7

Driver: DPRAM 1.7

Driver: STLAN 2.4

Driver: OPERATOR 1.10

Smart Trac AC1 Inverter

Boot 1.2.0

SW/FW Version

G112131.DAT (R1) for G5+

G110200.DAT (R1) for G5 Parallel HP units

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

7

Page 9

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

2. Operating System

The following section details fault numbers assigned to the Smart Trac AC1 Operating System.

Notes:

• Fault legend cannot be changed in this section.

• Internal fault values do not apply here. Operating System faults are not added with 10000 HEX.

• The Severity for every Operating System fault in this section is fixed in firmware. It cannot be changed

Display?

Priority

Newest

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

0 0 Not a fault

1 1 Not a fault

2 2 Invalid

3 3 Stack

4 4 Stack

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

Fault

Manager

Opcode

Overflow

Underflow

Operand code within program is

unrecognized. Valid Opcodes

are add, subtract, AND, OR, etc.

Program point er has gone past

the end of the program stack.

Stack is checked at the end of

each program scan.

Program pointer has preceded

the beginning of the program

stack. Stack is checked at the

end of each program scan.

8

List?

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Oldest

List?

Severity

Program

Input

Major

Major

Major

Rev. # 19 Page 8 of 64

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Application program may be overburdened –

reduce amount of logic placed in fast Tasks

(15ms or faster) to slow Tasks (30 ms or slower).

This may include reducing number of Program

Units and/or program elements.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Page 10

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

5 5 Stack

66Call

7 7 Call Overflow Cannot process next Opcode

88Task

9 9 Operand

Fault

Manager

Corrupted

Underflow

Corrupted

Undrflow

Location of program stack has

inadvertently changed. Stack is

checked at the end of each

program scan.

Cannot process next Opcode

because a program pointer has

preceded the beginning of the

program stack.

because a program pointer has

gone past the end of the program

stack.

A stack that contains code for

each Task to be run is bad.

A computation is smaller than

the smallest quantity the CPU

can store.

Product Development

Design

Document

Display?

Priority

Newest

List?

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

No Yes Yes Minor

Rev. # 19 Page 9 of 64

Oldest

List?

Severity

Program

Input

Major

Major

Major

Major

Minor

Assign

Corrective Action

The Smart Trac main CPU card may be faulty. If

available, download a small test program to see

if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. Replace the SmartTrac

CPU card.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. Replace the SmartTrac

CPU card.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

9

Page 11

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

A 10 Divide By

B11Result

C12Result

D 13 Invalid Result Fl oating point e rror: Compute d

E 14 Bad Address

Fault

Manager

Zero

Underflow

Overflow

Mode

An attempt was made to use ‘0’

as a divisor during computation.

Floating point error: 1) a

computation is smaller than the

smallest quantity the CPU can

store; 2) An error condition

occurred when an item was

called from an empty stack.

Floating point error: An error

occurred when calculated data

could not fit within the

designated field.

result is incorrect or is not within

bounds.

Operand address mode is not

recognized. Examples of correct

addressing is Direct and Indirect.

Product Development

Design

Document

Display?

Priority

Newest

List?

No Yes Yes Minor Software used to create the application program

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

Yes Yes Yes Major

Rev. # 19 Page 10 of 64

Oldest

List?

Severity

Program

Input

Minor

Minor

Minor

Major

Assign

Corrective Action

may have been old. (Earlier Kernel and library

versions exhibited this problem.) Check the

application program for use of zero during

division.

Check the application program for use of

extremely large and/or small numbers for

computation.

Check the application program for use of

extremely large and/or small numbers for

computation.

Check the application program for use of

extremely large and/or small numbers for

computation.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

10

Page 12

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

F 15 Address

10 16 Data Unknown Operand type does not conform

11 17 Not used

12 18 Data

13 19 Bad Data Type Operand type cannot be used for

14 20 Bad Address An attempt has been made to

Fault

Manager

Mismatch

Mismatch

Address types are not equivalent.

This prohibits a valid

computation or comparison from

taking place.

to any available form.

Operand types are not

equivalent. This prohibits a valid

computation or comparison from

taking place.

this specific computation or

comparison.

access data from an invalid

memory location.

Product Development

Design

Document

Display?

Priority

Newest

List?

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Rev. # 19 Page 11 of 64

Oldest

List?

Severity

Program

Input

Major

Major

Major

Major

Major

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Valid types include byte, unsigned long,

Boolean, float, etc.

Check application program for improper data

type comparisons. Valid types include byte,

unsigned long, Boolean, float, etc.

Check application program for improper

comparisons. Example of this is attempting to

compare a Boolean with a string pointer.

Check memory allocation for this node in Smart

Trac AC1 Workstation software. In Configure

dialog box, make sure the following is true:

Base Address = 0x300000, Base Memory Size =

0x100000, Retentive Address = 0xDC000, and

Retentive Size = 0x3F00. The Smart Trac main

CPU card may be faulty. If available, download

a small test program to see if fault persists

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

11

Page 13

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

15 21 Operand2

16 22 Operand1

17 23 Invalid Jump Calculated offset appears outside

18 24 Invalid

Fault

Manager

Invalid

Invalid

Address

2nd operand code within program

is unrecognized. Valid Opcodes

are add, subtract, AND, OR, etc.

1st operand code within program

is unrecognized. Valid Opcodes

are add, subtract, AND, OR, etc.

the bounds of the program.

Branch cannot be completed.

Address does not appear within

NVRAM, DRAM, nor Task

table.

Product Development

Design

Document

Display?

Priority

Newest

List?

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Rev. # 19 Page 12 of 64

Oldest

List?

Severity

Program

Input

Major

Major

Major

Major

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. Replace the SmartTrac

CPU card.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Check memory allocation for this node in Smart

Trac Workstation software. In Configure dialog

box, make sure the following is true: Base

Address = 0x300000, Base Memory Size =

0x100000, Retentive Address = 0xDC000, and

Retentive Size = 0x3F00. The Smart Trac main

CPU card may be faulty. If available, download

a small test program to see if fault persists

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

12

Page 14

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

19 25 Float Error Floating point error: an unknown

1A 26 Fstack

1B 27 Fstack

1C 28 Bad Operand Based on the operand’s mode,

Fault

Manager

Overflow

Underflow

float error, which is detected

only if all other floating point

errors have not triggered a fault

(underflow, overflow, float

invalid).

Float stack overflow. Float

pointer has gone past the end of

the float stack.

Float stack underflow. Float

pointer has preceded the

beginning of the float stack.

operand address is invalid.

Product Development

Design

Document

Display?

Priority

Newest

List?

No Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Major

Rev. # 19 Page 13 of 64

Oldest

List?

Severity

Program

Input

Minor

Major

Major

Major

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

13

Page 15

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

1D 29 Operand

1E 30 Out of

1F 31 Action Invalid Based on what is encountered in

20 32 I/O Read Fail Could not read input image table

21 33 I/O Write Fail Could not write to output image

Fault

Manager

Negative

Memory

Situation where a value should

not be negati ve. The SQRT,

LOG and LN functions will

declare this fault if their input is

negative.

Attempt to allocate memory for

the program stack and initialize

it to zero has failed.

the program, certain routines or

‘actions’ are processed. If the

requested action does not match

those that are available, this fault

will be realized.

for an associated driver, i.e.,

Interface Card.

table for an associated driver,

i.e., Interface Card.

Product Development

Design

Document

Display?

Priority

Newest

List?

No Yes Yes Minor

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Yes Yes Yes Major

Rev. # 19 Page 14 of 64

Oldest

List?

Severity

Program

Input

Minor

Major

Major

Major

Major

Assign

Corrective Action

Search your application program to ensure that

only positive values can be input to the SQRT,

LOG and/or LN functions.

The Smart Trac main CPU card may be faulty. If

available, download a small test program to see

if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

An Interface Card (driver) may be out of date.

Check for valid installed hardware. For example,

if using the STLAN driver, make sure an

ARCNET card is part of the Smart Trac drive

card stack.

An Interface Card (driver) may be out of date.

Check for valid installed hardware. For example,

if using the STLAN driver, make sure an

ARCNET card is part of the Smart Trac drive

card stack. The Smart Trac main CPU card may

be faulty. If available, download a small test

program to see if fault persists

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

14

Page 16

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

22 34 Bad C Call A functional call within the

23 35 String Overrun Length of text to be displayed

24 36 Negative Shift During conversion of a data type

25 37 Bad Coercion Invalid data type promotion, i.e.,

26 38 Bad Address

Fault

Manager

Mode

program failed. Specifically, the

amount of information being

placed on stack(s) will exceed

limit.

exceeds maximum number of

allowable characters.

(number), the argument used to

specify how many places to shift

was negative .

change a ‘double’ to a ‘byte’.

Problem found when validating

operand types. Incorrect mode

used when processing oper and

and data type.

Product Development

Design

Document

Display?

Priority

Newest

List?

Yes Yes Yes Major

No Yes Yes Minor

No Yes Yes Minor

Yes Yes Yes Major

No Yes Yes Minor

Rev. # 19 Page 15 of 64

Oldest

List?

Severity

Program

Input

Major

Minor

Minor

Major

Minor

Assign

Corrective Action

Application program may be overburdened –

reduce amount of logic placed in fast Tasks

(15ms or faster) to slow Tasks (30 ms or slower).

This may include reducing number of Program

Units and/or program elements.

Avoid use of extremely long text. Function

Block names and symbol names should be kept

to a manageable length (< 64 chars).

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Check application program for data type

mismatches.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

15

Page 17

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

27 39 Bad Bit

28 40 Bad Data Size Mismatch found when

29 41 Bit Out of

2A 42 Bad Function

2B 43 Bad Lower

Fault

Manager

Number

Range

Ptr

Bound

Requested bit number is

unavailable.

performing computation on 2

differing data types.

Logical bit does not fit within

bounds of data type. For

example, an attempted was made

to OR bit 0x0800 with a byte.

Pointer to a Function Block call

is invalid. ‘C’ FB cannot be

processed.

Index into an internal array has

exceeded the lower bounds.

Product Development

Design

Document

Display?

Priority

Newest

List?

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

Rev. # 19 Page 16 of 64

Oldest

List?

Severity

Program

Input

Minor

Minor

Minor

Minor

Minor

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Check application program for data type

mismatches.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

16

Page 18

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

Display?

Priority

Newest

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

2C 44 Bad Upper

2D 45 Invalid

2E 46 Invalid P-code Invalid P-code instruction Yes Yes Yes Critical

2F 47 Not used

… … …

… … …

7FF7 32759 Not used

7FF8 32760 User Task

Fault

Manager

Bound

DateTime

Hung

Index into an internal array has

exceeded the upper bounds.

Invalid date or time has been

specified.

Attempts to terminate a Task, or

remove it completely from the

processing que ue ha ve fa il ed .

List?

No Yes Yes Minor

No Yes Yes Minor

Yes Yes Yes Critical

Oldest

List?

Severity

Program

Input

Minor

Minor

Critical

and

Major

Critical

and

Major

Rev. # 19 Page 17 of 64

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists..

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists..

Application program may be overburdened –

reduce amount of logic placed in fast Tasks

(15ms or faster) to slow Tasks (30 ms or slower).

This may include reducing number of Program

Units and/or program elements.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

17

Page 19

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

7FF9 32761 No Startup FB No startup function block was

7FFA 32762 Breakpoint Set Breakpoint encountered in

7FFB 32763 Bad Offset

7FFC 32764 Task Overrun Task has taken too long to

7FFD 32765 Restart Failed A request to have a Task change

Fault

Manager

Range

configured for a user task.

program. Not really a fault but

used for debug purposes.

Attempt to address data within

memory is out of range.

complete. Applies to Cyclic and

IoSync Tasks only.

from stop to start mode has

failed.

Product Development

Design

Document

Display?

Priority

Newest

List?

Yes Yes Yes Critical

Yes Yes Yes N/A

Yes Yes Yes Critical

Yes Yes Yes Critical

Yes Yes Yes Critical

Rev. # 19 Page 18 of 64

Oldest

List?

Severity

Program

Input

Critical

and

Major

Critical

and

Major

Critical

and

Major

Critical

and

Major

Critical

and

Major

Assign

Corrective Action

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists..

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

Application program may be overburdened –

reduce amount of logic placed in fast Tasks

(15ms or faster) to slow Tasks (30 ms or slower).

This may include reducing number of Program

Units and/or program elements.

Check for valid installed hardware. For example,

if using the STLAN driver, make sure an

ARCNET card is part of the Smart Trac card

stack.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

18

Page 20

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Displayed Fault No.

Fault Legend Description

Control

Node

Monitor

7FFE 32766 Watchdog

7FFF 32767 Fatal Error Unrecoverable fault, usually

Fault

Manager

Timeout

One or more Program Units

associated with a Task have not

been completed within the

‘Watch Dog Timeout’ setting.

occurs during Driver startup.

Product Development

Design

Document

Display?

Priority

Newest

List?

Yes Yes Yes Critical

Yes Yes Yes Critical

Rev. # 19 Page 19 of 64

Oldest

List?

Severity

Program

Input

Critical

and

Major

Critical

and

Major

Assign

Corrective Action

Extend the Watchdog Timeout for the faulted

Task. Generally, do not exceed 3x the cyclic

task’s value nor 300ms for an IoSync Task.

Application program may be overburdened –

reduce amount of logic placed in fast Tasks

(15ms or faster) to slow Tasks (30 ms or slower).

This may include reducing number of Program

Units and/or program elements.

Verify that there are no hardware problems on

the PC used to create the application. Recompile and reload the program and reload it to

the SmartTrac drive. The Smart Trac main CPU

card may be faulty. If available, download a

small test program to see if fault persists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

19

Page 21

10/17/00

Smart Trac

Faults.doc

Rev. # 19 Page 20 of 64

New Berlin

Technology Center

Product Development

Design

Document

Title: Fault Declarations

3. User Defined Faults

These are faults assigned by the Application Engineer using the S_FLT function block.

User defined faults are just that – they’re faults defined by the person who does the Smart Trac AC1 Workstation programming. Faults are defined in the Fault Manager

Interface Card. Fault Legend Text is entered via Fault Editor tab. Fault codes or numbers are automatically assigned for each entry or the Application Engineer can select any

decimal fault code number in the 65,536 to 75,535 range. After text for a user defined fault has been assigned, it needs to be associated with an output. This is done in Define

Outputs tab. Select the desired fault output, or create a new fault output, and then assign any user defined fault to it. It is also in this location where the engineer may choose

“Critical”, “Major”, or “Minor” as the assigned program input. Once a corresponding fault symbol has been added, the Application Engineer is free to use the symbo l in his/her

program. An S_FLT block can be used to annunciate a user defined fault and C_FLT can be used to clear the fault. (It may be desirable to reset the fault via Control Node

Monitor, by setting the Fault Manager’s FaultReset1 symbol, or by pressing RESET on the Digital Operator.) The decimal fault code must be connected to the FCD input (shown

on function block). See S_FLT help in Smart Trac AC1 Workstation software for directions.

Newest List?

Priority

Displayed Fault

Internal Fault #

Display?

No.

Fault Legend Description

Control

Node

Monitor

Fault

Manager

10000 65536 0 User Fault #1 User definition #1 TBD TBD TBD Major or

10001 65537 1 User Fault #2 User definition #2 TBD TBD TBD Major or

… … … … … …

… … … … … …

… … … … … …

… … … … … …

1270F 75535 9999 User Fault

User definition #9999 TBD TBD TBD Major or

#9999

Oldest List?

Severity

Program

Input

Assign

Corrective Action

User corrective action #1.

Minor

Critical, Major,

Minor, or user

defined

User corrective action #2.

Minor

Critical, Major,

Minor, or user

defined

…

…

…

…

User corrective action #9999.

Minor

Critical, Major,

Minor, or user

defined

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

20

Page 22

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

4. Function Blocks

The following section de tails fault numbers assigned to C la nguage function blocks.

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12AF8 76536 11000 No System

12AF9 76537 11001 Web Break The WEBB block has declared a web

12AFA 76538 11002 Ilegal Scan

Fault

Manager

Clock

Time

A ‘C’ language function block

(WEBB or DIAM_0) has made a

system call to get the present time

and the call returned indicating that

the time was not available. This

fault is declared by blocks that need

to know the present relative time to

perform their function.

break.

Either the RAMP, RAMP_1, SCRV

or SPDR_1 block has an illegal scan

time.

Display?

Priority

Newest

List?

No Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 21 of 64

Program

Assign

Input

Corrective Action

Minor

Major

Major

Some incompatibility may be happening

with the version of the operating system

and the downloaded program. The CPU

card may be defective.

Check web material for breakage or look

at logic output for same, and repair if

necessary.

The RAMP and RAMP_1 block cannot

operate with a scan time of less than

0.002 seconds; the SCRV block cannot

operate with a scan time of less than

0.0005 seconds. The SPDR_1 block

must have a scan time > 0.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

21

Page 23

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12AFB 76539 11003 Illegal Input The input to a block has an

12AFC 76540 11004 PG Illegal

12AFD 76541 11005 PG Illegal

Fault

Manager

Port

Chan

inappropriate input. The blocks

declaring this are CAVE, DAVE,

LDelay, NDelay, REFQ, TENR_1,

POSR_1, and POSR_2. These

function blocks expect parameter

inputs within a specified number

range.

( Note: this fault applies to

MAG_CPB libraries V1.8 and

older. )

The port setting to the

PG_ANALOG_IN, PG_DELTA_P,

or PG_TACH block is not one of the

legal values of 0, 1, 2 or 3.

The channel input setting to the

PG_TACH or PG_ANALOG_IN

block is not one of the legal values

of 0 or 1.

Document

Display?

Priority

Newest

List?

Yes Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 22 of 64

Program

Assign

Input

Corrective Action

FB_se

tup

Major

Major

Refer to block description Help in Smart

Trac AC1 Workstation software. Obey

these limits:

Samples for CAVE = 1 to 500;

Samples for DAVE = 1 to 1000;

Delays for LDelay = 1 to 500;

Delays for NDelay = 1 to 500;

REFQ CascadeNumber = 1 to

MaxCascadeNumber;

TENR_1 needs inputs for Webwidth,

WebThickness and TensionZoneLength.

POSR_1 Roll_Diameter > 1;

For POSR_2, all of these must be > 0:

RatedLineSpd, R1_Factor, R2_Factor,

RatedDancerStorage,

S_RPM_At_M_RPM,

POSR_0_ScanTime.

Port number is used to identify the PG

card. Note: older versions of the PG card

had legal values of 0 through 3. Newer

PG cards have only one port setting. Use

PortNumber = 1.

Use only channel 0 or channel 1. All

other values will cause this fault.

Reference drive schematic to set

correctly.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

22

Page 24

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12AFE 76542 11006 PG Card ID

12AFF 76543 11007 PG A/D

12B00 76544 11008 I/O Memory

Fault

Manager

Error

Retries

Alloc

Product Development

Design

Document

The PG card can’t be found. This is

due to the software not seeing the

correct identification code on the PG

card.

The PG_ANALOG_IN function

block senses that the PG card has not

done an analog to digital conversion

in the allotted time after the number

of attempts set by the TriesB4Fault

input to the PG_ANALOG_IN

block.

Dynamic RAM was not available for

use by one or more Function Blocks.

Display?

Priority

Newest

List?

Yes Yes Yes Minor

No Yes Yes Minor

Yes Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 23 of 64

Program

Assign

Input

Corrective Action

Major

Minor

Major

The correct PG card must be installed for

the Smart Trac AC1 function blocks

used.

Try increasing the number of attempts

for conversi on, TriesB4Fault, to a higher

value. Possibility the PG card is

defective.

These Functio n Blocks requi re use of

DRAM: CAVE, LDelay, NDelay, and

REFQ. One of these FBs was unable to

allocate memory to support its function.

Recycle power to Smart Trac AC1. If

problem persists, replace Smart Trac

CPU card.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

23

Page 25

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12B01 76545 11009 TAPER Setup

12B02 76546 11010 PG_DELTA_

12B03 76547 11011 PG_DELTA_

12B04 76548 11012 FGEN5 Input The FGEN5 block declares this fault

12B05 76549 11013 LDel a y Inp u t An LDel a y fu nct io n blo c k has

Fault

Manager

Flt

P ID

P Setup

The TAPER block declares this fault

if input Tension Setpoint < 0, or

input Taper Ratio <=0, or input

Present Diameter <=0, or input Core

Diameter <= 0, or input Full Roll

Diameter <= input Core Diameter, or

input RatioAt20Percent_BU <=0, or

input RatioAt40Percent_BU <=0, or

input RatioAt60Percent_BU <=0, or

input RatioAt80Percent_BU <=0, or

input RatioAt100Percent_BU <= 0.

The PG Delta card can’t be found.

This is due to the software not seeing

the correct identification code on the

PG card which is used for

registration applications.

The PG_DELTA_P function block

declares this fault when the counter

start and stop source inputs are not in

the range from 1 to 4.

if input X_At_X5 is set to a value

less than or equal to input X_At_X0.

detected that its “Delays” input is

outside the valid range of 1 to 500.

Display?

Priority

Newest

List?

No Yes Yes Minor

Yes Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 24 of 64

Program

Assign

Input

Corrective Action

FB_se

tup

Major

Minor

FB_se

tup

FB_se

tup

Change application program to meet the

following:

Tension Setpoint > 0,

Taper Ratio > 0,

Present Diameter > 0,

Core Diameter > 0,

Full Roll Diameter > Core Diam,

RatioAt20Percent_BU > 0,

RatioAt40Percent_BU > 0,

RatioAt60Percent_BU > 0,

RatioAt80Percent_BU > 0,

RatioAt100Percent_BU > 0.

The correct PG card must be installed for

the Smart Trac PG_DELTA_P function

block used.

Change input value(s) to counter start

input and stop source such that they fall

within the range of 1 through 4.

Set inputs such that

X_At_X5 > X_At_X0.

Review the LDelay functio n blo cks to

ensure all “Delays” inputs are within the

range of 1 to 500.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

24

Page 26

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12B06 76550 11014 NDelay Input An NDelay function block has

12B07 76551 11015 REFQ Input A REFQ function block ha s detected

12B08 76552 11016 DIAM_2

12B09 76553 11017 INRT_1 Input An INRT_1 block has detected a

12B0A 76554 11018 CTCW_0

12B0B 76555 11019 CTCW_1

Fault

Manager

Input

Input

Input

detected that its “Delays” input is

outside the valid range of 1 to 500.

a “CascadeNumber” input >

“MaxCascadeNumber” input, or,

“MaxCascadeNumber” input does

not fall within a valid range of 1

through 255.

A DIAM_2 block has detected an out

of range value on one or more of its

inputs labeled RatedLineSpeed,

S_RPM_AT_M_RPM,

MaxDiameter, MinDiameter, or

NumberCalculation.

value of 0 on the RatedHorsepower

input.

A CTCW_0 block has detected a

value of 0 on its Diameter input

A CTCW_1 block has detected a

value of 0 on either the Horsepower

or the S_RPM_AT_M_RPM inputs.

Display?

Priority

Newest

List?

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 25 of 64

Program

Assign

Input

Corrective Action

FB_se

tup

FB_se

tup

FB_se

tup

FB_se

tup

FB_se

tup

FB_se

tup

Review the NDelay function blocks to

ensure all “Delays” inputs are within the

range of 1 to 500.

Ensure the RE FQ function block has a

“CascadeNumber” input less than or

equal to “MaxCascadeNumber” input.

Ensure “MaxCascadeNumber” input

ranges from 1 to 255.

Ensure the DIAM_2 block has the proper

values at its inputs as follows:

RatedLineSpeed > 0,

S_RPM_AT_M_RPM > 0,

MinDiameter > 2 inches, or 5 cm,

MinDiameter <= MaxDiameter <= 99

inches, or 200 cm,

0 <= NumberCalculation <= 255.

Ensure the INRT_1 block has a positive,

non-zero value for its RatedHorsepower

input.

Ensure the CTCW_0 block has a

positive, non-zero value for its Diameter

input.

Ensure that the CTCW_1 block has

positive, non-zero values for both the

Horsepower and S_RPM_AT_M_RPM

inputs.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

25

Page 27

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12B0C 76556 11020 PG_TACH

12B0D

to

12B5B

12B5C 76636 11100 Tach Loss The TMON block has detected a

12B5D 76637 11101 Reverse Tach

12B5E 76638 11102 Fwd

Fault

Manager

76557 to

76635

11021

to

11099

Input

Not Used

Flt

Overspeed

A PG_TACH or PG_TACH2 block

has detected a value of 0 on the

TachCounts or RatedSpeed inputs.

tachometer (encoder) loss.

The TMON block has detected a

reversed tachometer (encoder)

connection.

The TMON block has detected an

overspeed condition in the forward

direction.

Document

Display?

Priority

Newest

List?

No Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 26 of 64

Program

Assign

Input

Corrective Action

FB_se

tup

Major

Major

Major

Ensure the PG_TACH or PG_TACH2

block has non-zero values for the

TachCounts and RatedSpeed inputs.

Check wiring from encoder to PG card.

Tach loss occurs when AuxSpeedSense

> (AuxSenseLevel / 100) and

TachometerInput < (TachSenseLevel /

100).

Change wiring from encoder to PG card.

Declared when AuxSpeedSense >

(AuxSenseLevel / 100) AND

(ReferenceInput > 0 and

TachometerInput < 0) OR

(ReferenceInput < 0 and

TachometerInput > 0).

Motor speed has exceeded the forward

setpoint: TachometerInput >

(FwdOverspeedLimit / 100). Reduce

commanded speed or load if runaway

condition exists.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

26

Page 28

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12B5F 76639 11103 Rev

12B60 76640 11104 TENR Input A TENR function block has detected

12B61 76641 11105 SCRV Input A SCRV function block has detected

12B62 76642 11106 DAVE Input A DAVE function block has detected

Fault

Manager

Overspeed

The TMON block has detected an

overspeed condition in the reverse

direction.

a value of zero for any one of these

inputs: TensionZoneLength,

WebWidth, WebThickness, or

YoungsModulus.

a negative value for one of these

inputs: Accel_Time, Decel_Time,

Accel_Jrk_Percent,

Decel_Jrk_Percent.

an out of range value at its

“NumberOfSamples” input.

Display?

Priority

Newest

List?

Yes Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 27 of 64

Program

Assign

Input

Corrective Action

Major

FB_se

tup

FB_se

tup

FB_se

tup

Motor speed has exceeded the reverse

setpoint: TachometerInput <

(RevOverspeedLimit / 100). Reduce

commanded speed or load if runaway

condition exists.

Ensure that the TENR function block has

non-zero values at TensionZoneLength,

WebWidth, WebThickness or

YoungsModulus inputs. Note that a

function block uses a value of ‘0’ when

an input is left unconnected.

Ensure that the SCRV block has

Accel_Time, Decel_Time,

Accel_Jrk_Percent, and

Decel_Jrk_Percent input values are

greater than or equal to zero.

Ensure that the DAVE function blocks

use values from 1 to 500 at their

“NumberOfSamples” inputs.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

27

Page 29

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12B63 76643 11107 CAVE Input

12B64 76644 11108 POSR_1

12B65 76645 11109 POSR_2

Fault

Manager

Input

Input

Product Development

Design

Document

A CAVE function block has

detected an out of range value at

its "NumberOfSamples" or

"MaxNumberOfSamples" input, or

an infinite or NaN value at its

"InputSignal" in put.

A POSR_1 function block has

detected an out of range value at its

“Roll_Diameter” input or its

RetainMaxValue input is equal to its

RetainMinValue input.

A POSR_2 function block has

detected an out of range value for

one of its inputs labeled

“RatedLineSpd”,

“S_RPM_At_M_RPM”,

“RatedDancerStorage”, “R1_Factor”,

or “R2_Factor”.

Display?

Priority

Newest

List?

No Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 28 of 64

Program

Assign

Input

Corrective Action

FB_se

tup

FB_se

tup

FB_se

tup

Ensure that the CAVE function block

uses a range of 1 to 500 for

“MaxNumberOfSamples” input and

“NumberOfSamples” <

“MaxNumberOfSamples”. Ensure that

the value at "InputSigna l" is not

infinity or NaN (Not A Number).

Infinity can be created by dividing by

zero or taking the logarithm of 0.

NaN values can be created with

equations such as square root of a

negative number or zero divided by

zero.

Ensure that the POSR_1 function block

uses a value for its “Roll_Diameter”

input > 1. Ensure that the Dancer Signal

has been calibrated (i.e. its

RetainMinValue and RetainMaxValue

must both no t equal zero ).

Ensure that the POSR_2 function block

inputs labeled “RatedLineSpd”,

“S_RPM_At_M_RPM”,

“RatedDancerStorage”, “R1_Factor”,

and “R2_Factor” have values > 0.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

28

Page 30

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

12B66 76646 11110 GEAR Input A GEAR function block has detected

12B67 76647 11111 POSR_0

Fault

Manager

Input

a value of ‘0’ for its

“InputGear_Denominator” input.

A POSR_0 function block has

calculated an out of range value for

its “DancerOut” output.

“DancerOut” is the “DancerSignal”

modified by a SPAN and ZERO

adjustments provided by

corresponding the POSR_1 function

block. “DancerOut” is a per-unit

number and this fault is declared if

“DancerOut” calculates as less than

-0.1 or greater than +1.1.

Display?

Priority

Newest

List?

No Yes Yes Minor

No Yes Yes Minor

List?

Severity

Oldest

Rev. # 19 Page 29 of 64

Program

Assign

Input

Corrective Action

FB_se

tup

FB_se

tup

Ensure that the GEAR function block

input(s) “InputGear_Denominator” is not

set to zero.

Ensure that the DancerSignal of the

corresponding POSR_1 function block

has been calibrated. Ensure that the

dancer feedback mechanism has not

moved. The dancer signal in the

corresponding POSR_1 function block

may need recalibration.

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

29

Page 31

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

5. Drivers

5.1 DPRAM Driver

The following section details fault numbers assi gned to Dual Port RAM.

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

14E20 85536 20000 DPRAM HS Resp High Speed response

14E21 85537 20001 DPRAM HS Cmd High Speed co mmand

14E22 85538 20002 DPRAM Response DPRAM response handshake

14E23 85539 20003 DPRAM Co mma nd DPRAM command

Fault

Manager

handshake fault between the

Smart Trac AC1 CPU card

and the inverter control card.

handshake fault between the

Smart Trac AC1 CPU card

and the inverter control card.

fault between the Smart Trac

AC1 CPU card and the

inverter control card.

handshake fault between the

Smart Trac AC1 CPU card

and the inverter control card.

Display?

Priority

Newest

List?

No Yes Yes Minor

Yes Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

Oldest

List?

Severity

Rev. # 19 Page 30 of 64

Program

Assign

Input

Minor

Major

Minor

Minor

High Speed data such as torque reference

and motor speed cannot be obtained from

the inverter card. Recycle drive power. If

problem persists, consult the factory.

High Speed command information such as

Run/Stop cannot be sent to the inverter

card. Drive must be stopped by externallywired E-stop. Recycle drive power. If

problem persists, consult the factory.

Inverter parameters such as ‘Accel Time 1’

cannot be obtained from the inverter card.

Recycle drive power. If problem persists,

consult the factory.

Cannot send parameters values from Smart

Trac drive’s CPU card to inverter card.

Recycle drive power. If problem persists,

consult the factory. Note: there are some

critical parameters that cannot be changed

during Run.

Corrective Action

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

30

Page 32

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

14E24 85540 20004 DPRAM Address DPRAM bad address or

14E25 85541 20005 DPRAM Param

14E26 85542 20006 DPRAM Parm

14E27 85543 20007 DPRAM Chg @

Fault

Manager

Num

Range

Run

register requested fault

between the Smart Trac AC1

CPU card and the inverter

control card.

Bad number of parameters

requested from Dual Port

RAM of the Smart Trac AC1

CPU card (to inverter control

card).

Bad parameter data specified

between the Smart Trac AC1

CPU card and the inverter

control card. Parameter

setting sent to inverter is out

of range for that inverter.

Dual Port RAM non-run

inverter parameter change

requested between the Smart

Trac AC1 CPU card and the

inverter control card while

the inverter is running.

Document

Display?

Priority

Newest

List?

Yes Yes Yes Minor

Yes Yes Yes Minor

No Yes Yes Minor

No Yes Yes Minor

Oldest

List?

Severity

Rev. # 19 Page 31 of 64

Program

Assign

Input

Major

Major

Minor

Minor

Check for correct inverter model number;

don’t forget to initialize the inverter card if

model number was changed. Make sure t he

inverter Control Method is set to ‘Flux

Vector’ (typical).

The Smart Trac main CPU card may be

faulty. If available, download a small test

program to see if fault persists.

Check for correct inverter model number;

don’t forget to initialize the inverter card if

model number was changed. Look for

obvious mistakes in the application

program such as attempting to alter

inverter current settings. Make sure t he

inverter Control Method is set to ‘Flux

Vector’ (typical).

Certain parameters cannot be changed

while the inverter is running a motor.

Application program should be structured

to avoid writes to these parameters during

Run conditions.

Corrective Action

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

31

Page 33

10/17/00

Smart Trac

Faults.doc

New Berlin

Technology Center

Title: Fault Declarations

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

14E28 85544 20008 DPRAM Write@

14E29 85545 20009 DPRAM

14E2A 85546 20010 DPRAM Unknwn

14E2B 85547 20011 DP RAM T ref

Fault

Manager

UV

Write@Calc

Rsp

Hndsk

Product Development

Design

Document

Dual Port RAM write

requested between the Smart

Trac AC1 CPU card and the

inverter control card while

there is an undervoltage fault

Dual Port RAM write

requested between the Smart

Trac AC1 CPU card and the

inverter control card, while a

parameter is being calculated.

Unknown Dual Port RAM

response between the Smart

Trac AC1 CPU card and the

inverter control card.

Dual Port RAM 2ms Torque

Reference handshake fault

between the Smart Trac AC1

CPU card and the inverter

control card.

Display?

Priority

Newest

List?

No Yes Yes Minor

No Yes Yes Minor

Yes Yes Yes Minor

Yes Yes Yes Minor

Oldest

List?

Severity

Rev. # 19 Page 32 of 64

Program

Assign

Input

Minor

Minor

Major

Major

and

Minor

Correct undervoltage issue – check quality

of AC power supply.

The inverter card continually performs

background calculations on internal

parameters. If this fault persists, consult

the factory.

Smart Trac AC1 CPU card received

information from inverter card that is

incorrect. Inverter firmware may be wrong

version or inverter card may be defective.

Check integrity of physical connecti on

between Smart Trac AC1 CPU card and

inverter card. Check Inverter Type in Boot

menu: for most cases, value should be set

for 2 ms Torq Update. Application

program may be overburdened – reduce

amount of logic placed in fast Tasks (15ms

or faster) to slow Tasks (30ms or slo wer).

Corrective Action

The informatio n co ntained in this docum e nt is the CONFIDENTIAL property of MagneTek Inc.

File = N:\PROJECT\515\SmartTrac\DOCS\Faults.DOC Print Date: 10/17/00

32

Page 34

10/17/00

Smart Trac

Faults.doc

Product Development

New Berlin

Technology Center

Design

Document

Title: Fault Declarations

5.2 STLAN Driver

The following section details fault numbers assigned to Smart Trac AC1 Local Area Network (ARCNET).

Internal Fault #

Displayed Fault

No.

Fault Legend Description

Control

Node

Monitor

14EE8 85736 20200 LAN Hardware

14EE9 85737 20201 LAN Max Tx Flt LAN - max number of

14EEA 85738 20202 LAN Illegal Msg LAN - illegal message

14EEB 85739 20203 LAN Missed

14EEC 85740 20204 LAN Missed