Page 1

Technical Manual

™

™

S

M

A

R

S

M

A

R

T

T

T

T

R

R

A

A

C

C

Ett

E

h

h

err

e

n

n

ett

e

C

C

arr

a

d

d

Page 2

Page 3

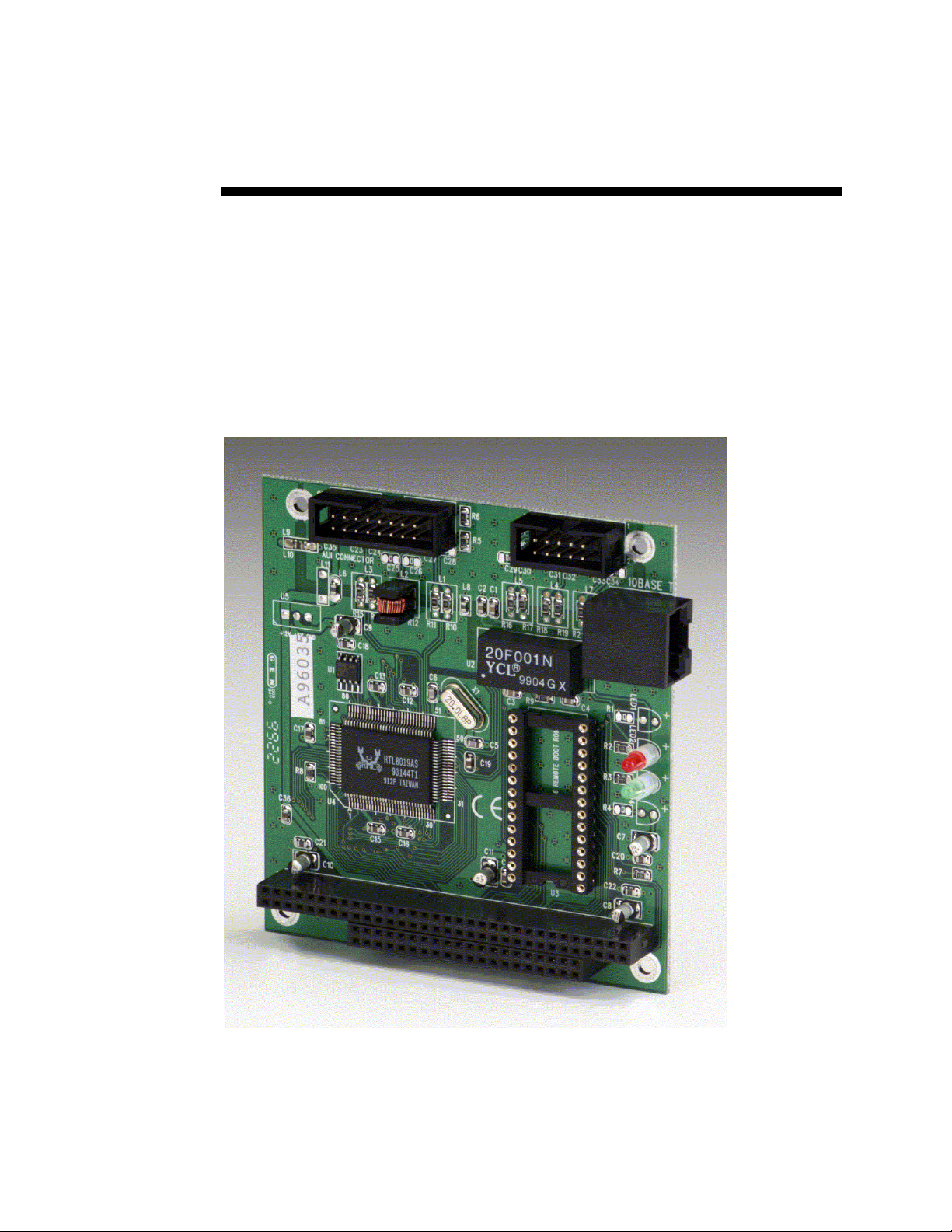

SMART TRAC Ethernet Card

Contents

Safety and Warranty Information 3

Warnings, Cautions and Notes.....................................................................................................................3

General Safety Precautions - Warnings ......................................................................................................4

Important Warranty Information................................................................................................................4

Smart Trac Ethernet Card 5

General Capabilities......................................................................................................................................5

Smart Trac AC1 on an Ethernet Network .................................................................................................5

Specifications .................................................................................................................................................5

System Requirements....................................................................................................................................6

Quick Start.....................................................................................................................................................6

Ethernet Basics 7

Introduction...................................................................................................................................................7

Ethernet and the OSI Model..............................................................................................................8

TCP/IP and the OSI Model ...............................................................................................................8

Ethernet Network Topology.........................................................................................................................8

Bus ....................................................................................................................................................8

Star....................................................................................................................................................9

Cabling and Cable Lengths ........................................................................................................................10

Ethernet Hub or Crossover Cable?............................................................................................................11

Installing the Smart Trac Ethernet Card 13

Unpacking ....................................................................................................................................................13

Electrostatic Discharge (ESD) Procedures......................................................................................13

Unpacking Procedure......................................................................................................................13

Installing the Smart Trac Ethernet Card..................................................................................................14

Connecting the Smart Trac Ethernet Card to an Ethernet Network ....................................................15

Configuring the Smart Trac Ethernet Card 17

The Ethernet Card's Jumperless Settings.................................................................................................17

Interrupt...........................................................................................................................................17

Base I/O Address.............................................................................................................................17

Ethernet Network Configuration...............................................................................................................17

Addresses and subnet mask.............................................................................................................17

Configuration for PC-Based Operation...........................................................................................18

Configuration for an Enterprise-wide LAN ....................................................................................19

Verifying Your TCP/IP Configuration............................................................................................20

Testing Card Installation 23

Technical Manual Smart Trac Ethernet Card Contents •• i

Page 4

SMART TRAC Ethernet Card

Testing the Network....................................................................................................................................23

On-board Indicator Lights .........................................................................................................................23

Troubleshooting Your Smart Trac Ethernet Card 25

Status and Error Messages.........................................................................................................................25

Troubleshooting Ethernet Network Problems..........................................................................................25

Appendix A – Technical Support 29

Technical Support .......................................................................................................................................29

Problem Report ...........................................................................................................................................31

References ....................................................................................................................................................32

Appendix B – Card Layout 33

Smart Trac Ethernet Card Layout............................................................................................................33

Appendix C – Replaceable Parts 37

Replaceable Parts Listing ...........................................................................................................................37

Appendix D – Removing the Smart Trac Card Stack 39

General Procedures.....................................................................................................................................39

Glossary of Terms 43

Index 45

ii •• Contents Technical Manual Smart Trac Ethernet Card

Page 5

SMART TRAC Ethernet Card

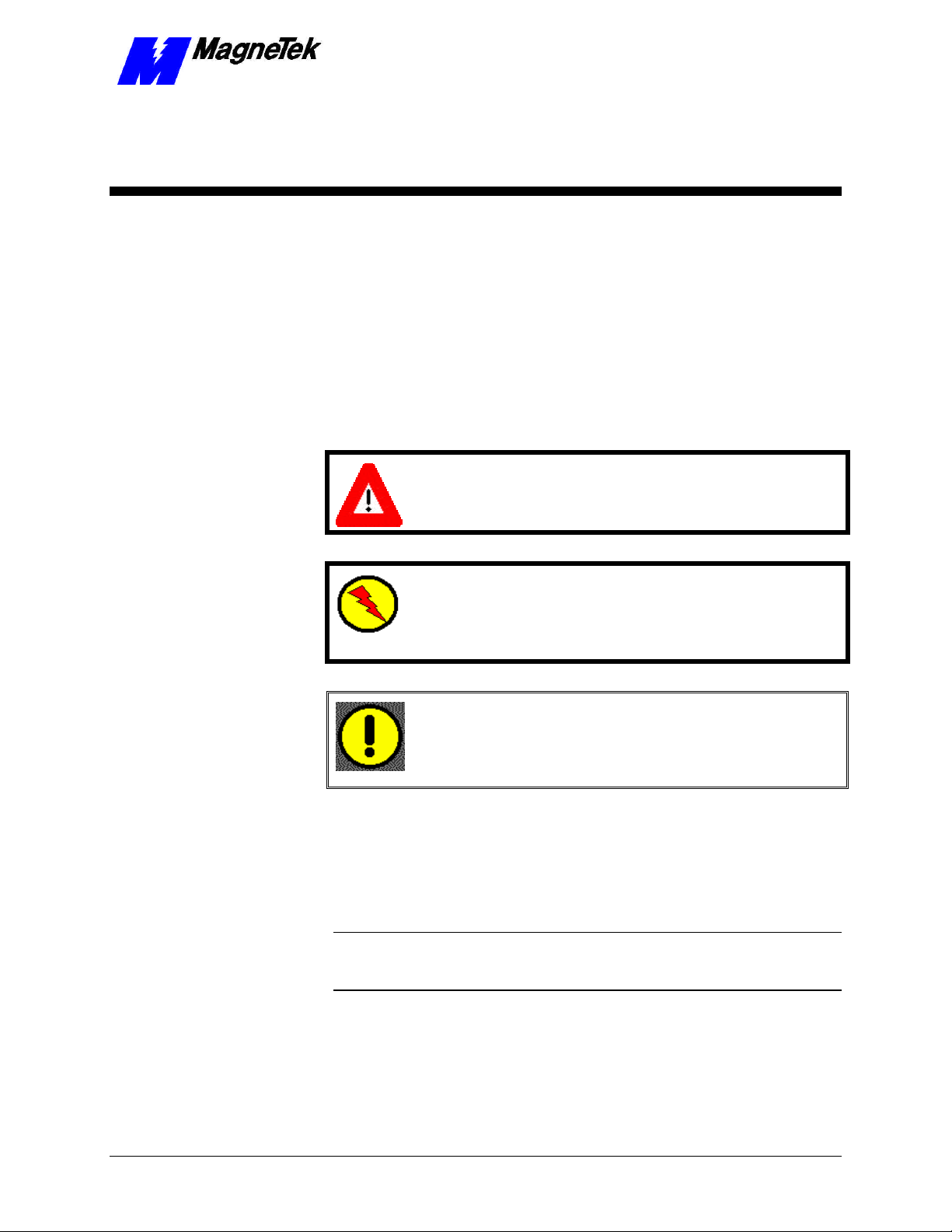

Safety and Warranty Information

Warnings, Cautions and Notes

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or death.

WARNING - ESD

A statement of conditions which must be observed to prevent

damage to components due to ESD (ElectroStatic Discharge) and

to prevent personal injury or death.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults, Smart Trac AC1 system degradation

and damage to equipment.

IMPORTANT

A statement of conditions which should be observed during Smart Trac AC

DeviceNet setup or operation to ensure dependable service.

NOTE: Notes indicate information that is in addition to a discussion of the topic

in adjoining text. Alternatively, it may limit or restrict the paragraph(s) that

follow(s) to specific models or conditions.

TIP - Tips indicate information that should make a procedure easier or more

efficient.

Technical Manual Smart Trac Ethernet Card Safety and Warranty Information •• 3

Page 6

SMART TRAC Ethernet Card

General Safety Precautions Warnings

Important safety information follows. Please read and understand all

precautions listed below before proceeding with the specification, installation,

set-up or operation of your Smart Trac AC1. Failure to follow any of the

following precautions may result in personal injury or death, or damage to the

equipment.

WARNING - ESD

The Control Printed Circuit Board (PCB) employs CMOS

Integrated Circuits that are easily damaged by static electricity.

Use proper ElectroStatic Discharge (ESD) procedures when

handling the Control PCB. See Smart Trac AC1 Technical Manual

for details. Failure to comply may result in damage to equipment

and/or personal injury.

Important Warranty Information.

Do not modify your Smart Trac AC1, its components, or any of the procedures

contained in the technical documentation supplied by MagneTek. Any

modification of this product by the user is not the responsibility of MagneTek

and will void the warranty.

4 •• Contents Technical Manual Smart Trac Ethernet Card

Page 7

SMART TRAC Ethernet Card

Smart Trac Ethernet Card

General Capabilities

With the Smart Trac Ethernet Card in your Smart Trac AC1, your system is

fully compatible with the IEEE 802.3 Ethernet standard, the most widely used

local area network (LAN) standard. The card provides a fast, reliable, PC-based

interface to the Smart Trac AC1. As an alternative to a serial RS-232

connection, a Smart Trac Ethernet card may be used for high speed (10 Mbps)

monitoring, program uploading and downloading, and running diagnostics.

Smart Trac AC1 on an Ethernet

Network

The card also allows quick, easy and inexpensive networking of a Smart Trac

AC1 with PCs, other Smart Trac AC1s, and other industrial devices. Using the

TCP/IP protocol means that your Smart Trac AC1 system may operate as part of

a Local Area Network (LAN) or a Wide Area Network (WAN).

Specifications

• Hardware and software compatible with Novell NE2000 ISA bus

Ethernet adapter and PC/104 standard

• Complies with the 802.3 CSMA/CD Ethernet standard for 10 Mbps

data transfer.

• Built-in 10Base-T transceiver for unsheilded, twisted pair cabling up to

100 meters in length. Optional 10Base2 transceiver module. AUI

connector for external 10Base5 transceiver

• Single +5V power supply at 400 milliamp maximum without external

transceiver).

• Two diagnostic LEDs

• On-board 32K memory provides a high-performance, multi-package

buffer.

• Operating Temperature: 0° C to 70° C

• Operating Humidity: 10% to 90%

Technical Manual Smart Trac Ethernet Card Smart Trac Ethernet Card •• 5

Page 8

SMART TRAC Ethernet Card

System Requirements

• Smart Trac AC1 Drive

• Smart Trac CPU card

• Smart Trac PS card

• Smart Trac Ethernet Network Option Kit

• Microsoft Windows NT 4.0 or newer version

• Smart Trac Workstation Lite™ software

• Ethernet 10Base-T twisted pair crossover cable OR two Ethernet

10Base-T twisted pair straight cables and an Ethernet hub

Quick Start

Your Smart Trac Ethernet card is ready to install. Its base I/O address is set at

0x320 hexadecimal with an IRQ of 5.

1. Power OFF your Smart Trac AC1, lock out and tag "Out of Service."

2. Remove any existing PC/104 option cards from your Smart Trac AC1.

3. Install the Smart Trac Ethernet card on top of the Smart Trac PS Card.

4. Install any Smart Trac cards previously removed.

5. Connect the Ethernet network crossover cable between a PC and your

Smart Trac AC1. Optionally, you may install one Ethernet straight

cable between PC and hub with another straight cable between hub and

Smart Trac AC1.

6. Power up your PC, hub and Smart Trac AC1.

7. Test your card installation.

6 •• Contents Technical Manual Smart Trac Ethernet Card

Page 9

Ethernet Basics

Introduction

Ethernet is a low cost, widely used LAN access method. Originally developed

by Intel, Digital (now Compaq), and Xerox, it is an open network standard

(IEEE 802.3).

SMART TRAC Ethernet Card

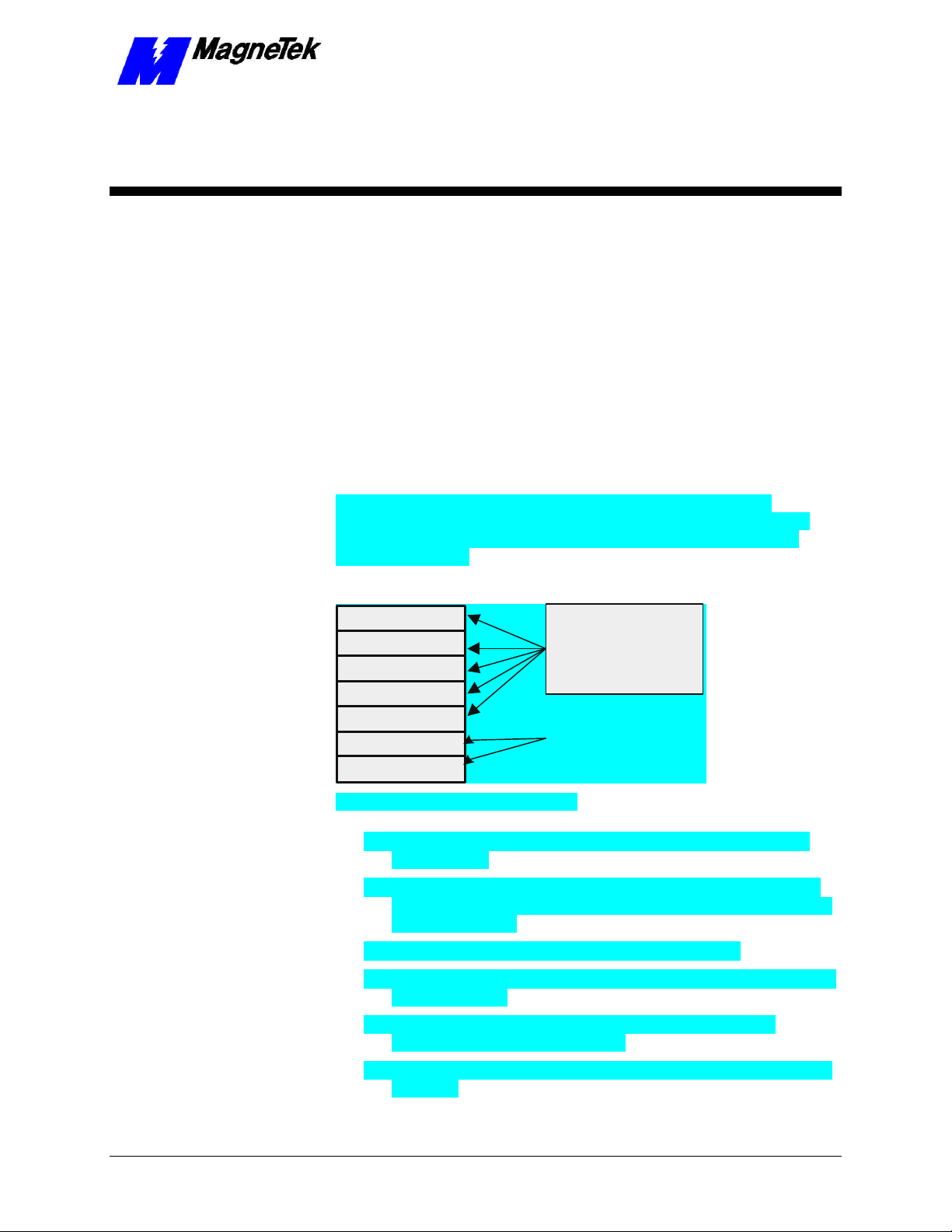

The Open Systems Interconnect (OSI), established in 1984 by the ISO

(International Standards Organization), divides network functions into seven

layers: Physical, Data Link, Network, Transport, Session, Presentation and

Application Protocol.

Application

Presentation

Session

Transport

Network

Data Link

Physical

Figure 1. Ethernet and the OSI Model.

• The Physical Layer transforms data into bits that are sent across the

physical media.

• The Data Link layer determines access to the network media in terms

of frames. Its Media Access Control (MAC) sublayer is responsible for

physical addressing.

• The Network Layer routes data through a large network.

TCP/IP protocol on

Ethernet provides

all seven layers of

the OSI model.

Ethernet provides

these layers of the

OSI (Open Systems

Interconnect) model.

• The Transport Layer provides end-to-end, reliable connections, often in

terms of segments.

• The Session Layer allows users to establish connections using

intelligently chosen names in packets.

• The Presentation Layer negotiates data exchange formats, also in terms

of packets.

Technical Manual Smart Trac Ethernet Card Ethernet Basics •• 7

Page 10

SMART TRAC Ethernet Card

• Finally, the Application Layer provides the interface between the user's

application and the network through messages.

Data is said to move from layer to layer within the seven layers of the OSI

model.

Ethernet and the OSI

Model

TCP/IP and the OSI

Model

Ethernet supports the physical and data link layers. With TCP/IP as its protocol,

it supports all seven layers of the OSI model.

Several types of Ethernet cables support the physical layer. See "Cabling and

Cable Lengths" for details.

Using Carrier Sense Multiple Access/Collision Detection (CSMA/CD), Ethernet

supports the data link layer. CSMA/CD checks the media for other devices

before transmitting, managing data collisions and reducing the number of data

collisions.

Ethernet uses Transmission Control Protocol/Internet Protocol (TCP/IP) to

provide layers of the OSI model. Although developed under an older four-layer

network model developed by the U.S. Department of Defense (DoD), we can

loosely fit the four layers of the DoD model to the seven of the OSI model.

Physical and Data Link layers are supported through the Network Access layer

of the DoD model. TCP/IP can run on many types of network connection,

including ethernet. Ethernet supports both the Physical and Data Link layers of

the OSI model.

The Network layer of the OSI model corresponds with the Internet layer of the

DoD model. Internet Protocol provides this layer, moving data to other devices

on the network.

The Transport layer corresponds to the Host-to-Host layer of the DoD model.

Almost all devices on a TCP/IP network are considered hosts, and this layer

communicates data peer-to-peer (or host-to-host).

Bus

Star

The Session, Presentation and Application layers of the OSI model correspond

to the Process/Application layer of the DoD model, providing network services.

Ethernet Network Topology

Devices on an Ethernet network are arranged in either a bus or star topology.

In a bus topology, all devices on the network connect to one trunk cable. This

makes it easy to install and configure, and inexpensive. Ethernet in a bus

topology requires no special equipment to amplify or regenerate the signal. Any

device wanting to send information must first determine if the bus is being used

by any other device. If no other device is attempting to transmit, the device

sends the data. Bus networks generally require that proper terminations are made

at each end of the trunk. If the trunk cable fails, all devices are affected.

In a star topology, a separate cable connects each device with a central device,

typically a hub. Unlike the bus topology, if a cable fails it affects only the one

device connected to the failed cable. Star networks are easily expanded, easier to

troubleshoot and support many types of cables. To connect more than two

devices together in a star topology requires the use of either a passive or active

hub. Passive hubs do not regenerate the signal. Use of active hubs extends

network length by regenerating the signal and sending it across the network.

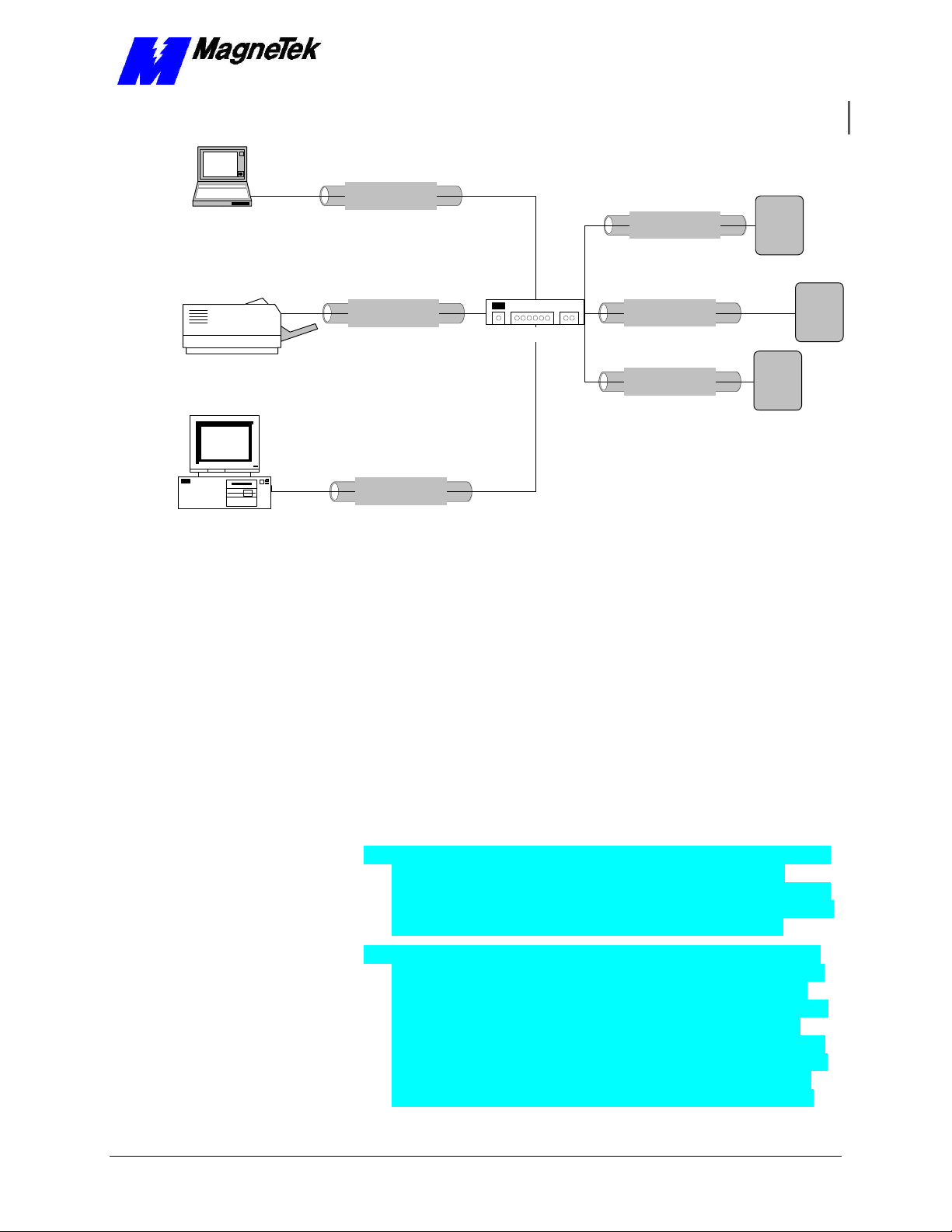

A typical PC-based network for operation of Smart Trac AC1s is depicted in

Figure 2.

8 •• Contents Technical Manual Smart Trac Ethernet Card

Page 11

SMART TRAC Ethernet Card

Cat-5 Twisted Pair

Laptop computer

Ethernet Cable

Cat-5 Twisted Pair

Ethernet Cable

SMART

TRAC

AC 1

Laser printer

IBM Compatible

Cat-5 Twisted Pair

Ethernet Cable

Cat-5 Twisted Pair

Ethernet Cable

Cat-5 Twisted Pair

Ethernet Cable

Hub

Cat-5 Twisted Pair

Ethernet Cable

SMART

TRAC

AC 1

SMART

TRAC

AC 1

Figure 2. A typical local area network used for PC-based operation of Smart

Trac AC1s.

Cabling and Cable Lengths

Ethernet supports several types of cables, each intended for different purposes:

• 10Base-T (Twisted-pair Ethernet) – The most widely used Ethernet

cabling, it supports network speeds of 100Mbps. Uses 22- or 26-AWG

UTP cabling to transmit baseband signals on maximum 100-meter

segments. RJ-45 jacks connect separate cables between device and hub.

Each device must be at least 2 feet apart and no more than 328 feet

from the hub. Bridges or routers may be used to accommodate a larger

network. There is no limit on network length. It permits a maximum of

1,024 segments and 1,024 nodes. See IEEE standard 802.3i.

• 10Base-2 (Thin Ethernet) – Supports network speeds of 10Mbps. Uses

RG-58 coaxial cable to transmit baseband signals on 200-meter

segments. Total network length can be 925 meters. Transceivers reside

on the NIC, simplifying connections. The cable, thinner than 10Base-5,

is more flexible for easier handling. See IEEE standard 802.3a.

• 10Base-5 (Thick Ethernet) – Now rarely used, this cable was popular

for desktop connections until the introduction of 10BaseT. It supports

networks speeds of up to 10Mbps and uses RG-8 or RG-11 coaxial

cable to transmit baseband signals in 500-meter (1,640 feet) segments.

Total network length can be 2,500 meters with up to 300 nodes. It

requires the use of transceivers located at least 8 feet apart and tapped

into the cable. A 15-pin AUI, or DIX (Digital, Intel, Xerox) connector

is used between the network cable and the AUI port on the Ethernet

NIC (Network Interface Card). See IEEE standard 802.3 for details.

Technical Manual Smart Trac Ethernet Card Ethernet Basics •• 9

Page 12

SMART TRAC Ethernet Card

Ethernet Hub or Crossover Cable?

An Ethernet hub is required if connecting more than two devices (more than one

Smart Trac AC1 and one computer). If only connecting a single Smart Trac with

a single computer, you need only a special "crossover" or "uplink" Ethernet

cable.

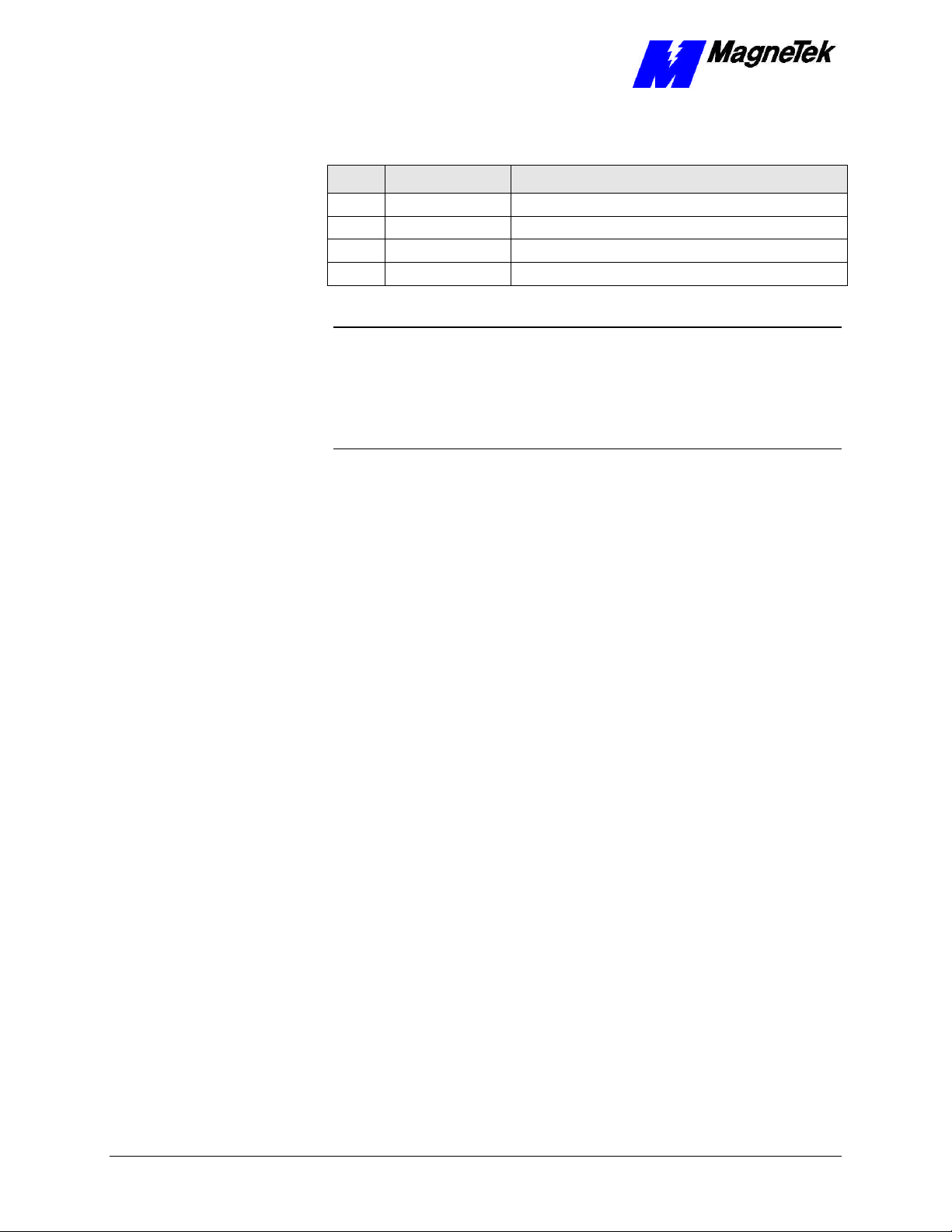

You may construct a crossover cable using UTP Category 5 cable, two twisted

pair connectors (WE8W 8 pin modular) and the pinouts indicated in Figure 3.

The Tx and Rx pairs are swapped (orange and green wires, 1, 2 and 3, 6). You

can locate Pin 1 of a twisted pair connector (WE8W 8-pin modular) by holding

the connector with the keytab down and the contacts up. Looking from the back

of the connector where the wire will be inserted, pin 1 is on the left.

Pin 1 Wht/Org T2

2 Org/Wht R2

3 Wht/Grn T3

4 Blu/Wht R1

5 Wht/Blu T1

6

Grn/Wht R3

7 Wht/Brn T4

8 Brn/Wht R4

Figure 3. Ethernet crossover cable pinout.

Pin 1 Wht/Green T3

2 Grn/Wht R3

3 Wht/Org T2

4 Blu/Wht R1

5 Wht/Blu T1

6 Org/Wht R2

7 Wht/Brn T4

8 Brn/Wht R4

10 •• Contents Technical Manual Smart Trac Ethernet Card

Page 13

SMART TRAC Ethernet Card

Installing the Smart Trac

Ethernet Card

Unpacking

Electrostatic

Discharge (ESD)

Procedures

Unpacking Procedure

WARNING WARNING -- ESD ESD

Keep electronic circuit boards in Electrostatic Discharge (ESD)

protective bags when not being handled. Use proper ESD

procedures (including an ESD wrist strap) when handling circuit

boards. Failure to comply may result in damage to equipment.

When working with an electrostatic discharge (ESD) sensitive device, you

should be grounded at all times. The easiest and most common way to provide

this ground is to use an approved ESD wrist strap. The strap is secured to your

wrist with a wire attached to the strap and clipped or taped to the chassis of the

unit being worked on. Any static is dissipated through the wire to ground,

greatly reducing the possibility of damage to the device.

It is a good idea to touch the chassis with your finger before handling any

electrostatic sensitive device. Any static electricity will be discharged to chassis

ground and will not be transferred to the device.

Always store devices (cards, other electronic components) in ESD protective

bags when not being handled.

Remove the protective shipping and packing material from the card. Ensure

contact wedges and other shipping devices have been removed.

Installing the Smart Trac Ethernet

Card

The Smart Trac Ethernet Card must be positioned above the Smart Trac PS Card

in the Smart Trac card stack.

NOTE: If replacing or adding a Smart Trac Ethernet card to an existing Smart

Trac card stack, see "Appendix D – Removing the Smart Trac Card Stack"

before continuing.

Technical Manual Smart Trac Ethernet Card Installing the Smart Trac Ethernet Card •• 11

Page 14

SMART TRAC Ethernet Card

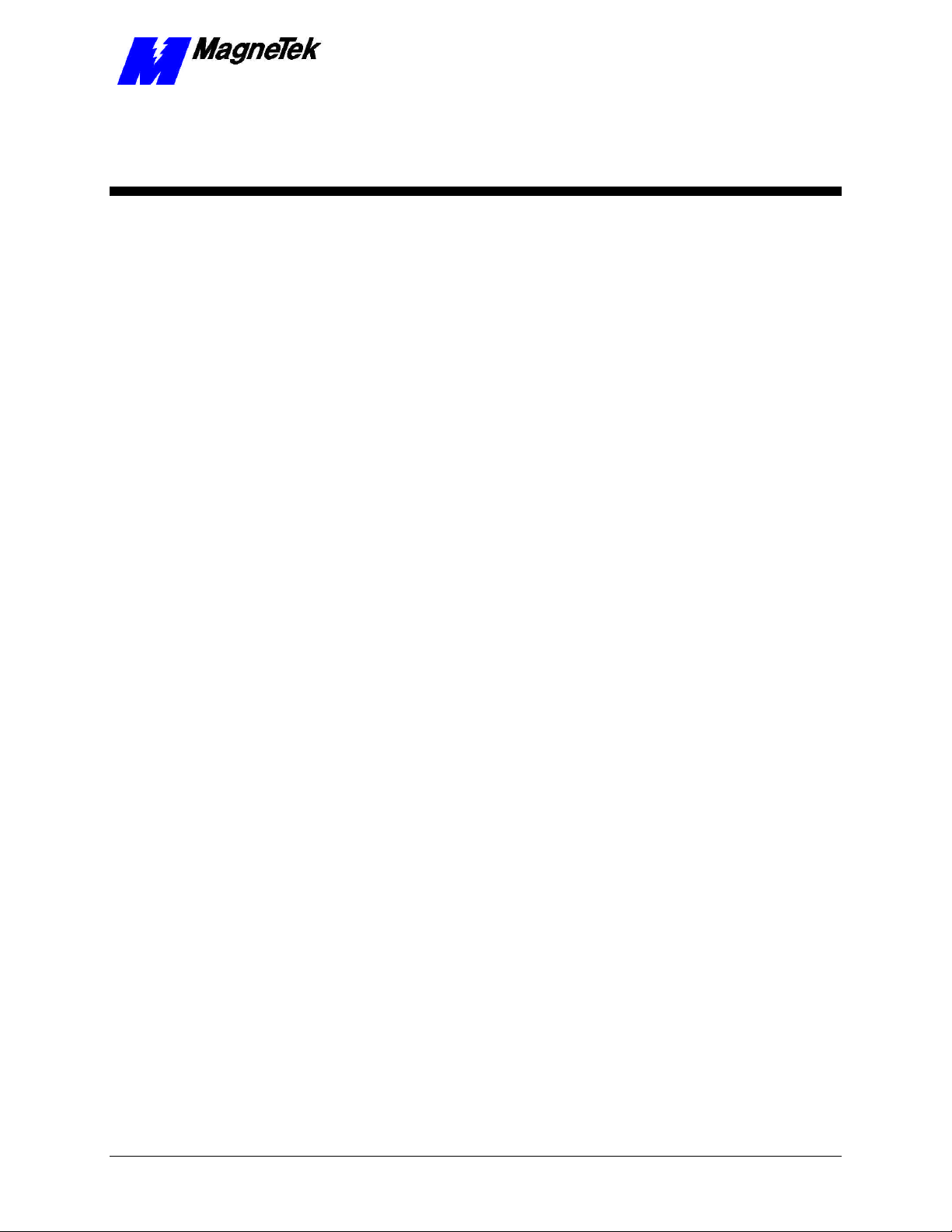

Optional

Standoffs (4

places on top of

each card)

PC/104

Card

Optional

PC/104

Card

Smart Trac

Ethernet

Card

4CN

Smart Trac

PS Card

Connector

Smart Trac

PG Card

2CN

Connector

Smart Trac

CPU Card

Inverter Control

Card

Adapter

Ring

Main Chassis

Figure 4. Smart Trac Ethernet Card Stack Position

1. To install the Ethernet card, orient the pins on the card at ZJ1 and ZJ2

with the female pin connector on the card below it (the PS Card).

Gently but firmly push the Smart Trac Ethernet card onto the card

below it. Make sure connecting pins are in alignment before pushing

the two boards tightly together. Secure the card using four (4) metal

standoffs.

2. Replace all other cards, securing each with four (4) metal standoffs and

the reverse of steps in "Appendix D – Removing the Smart Trac Card

Stack".

12 •• Contents Technical Manual Smart Trac Ethernet Card

Page 15

SMART TRAC Ethernet Card

Connecting the Smart Trac Ethernet

Card to an Ethernet Network

1. Take one of the following three actions:

• Using twisted pair cable for 10Base-T, plug the RJ-45 UTP cable

connector into the receptacle at the RJ-45 connector on the card.

• If using an AUI Ethernet connector for 10Base5, connect the Thick

Ethernet RG-8 or RG-11 cable to the 16-pin AUI connector.

• If using the optional 10Base-2 daughterboard, use either the BNC

connector for a T-connection to 10Base-2 thin cable ethernet or the

16-pin connection to the AUI port.

2. Route cable so that it is not routed along with A/C wires. Ethernet cable

should not be bundled. Before applying power to the system, inspect

the planned cable route to ensure it is not near A/C wires .

Technical Manual Smart Trac Ethernet Card Installing the Smart Trac Ethernet Card •• 13

Page 16

Page 17

SMART TRAC Ethernet Card

Configuring the Smart Trac

Ethernet Card

The Ethernet Card's Jumperless

Settings

Interrupt

Base I/O Address

Addresses and

subnet mask

The Smart Trac Ethernet Card is preconfigured and jumperless.

The interrupt is factory-set to "5."

Using interrupt 5 assures you that there will be no conflicts with other basic

Smart Trac components if all are set according to their default values.

The Base I/O Address is set to 0x320. You must maintain unique addresses and

interrupts for all cards in the Smart Trac card stack.

Ethernet Network Configuration

Depending on whether you are networking for PC-based operation on a small

LAN or an enterprise-wide LAN, you may need the assistance of your LAN

Administrator to specify unique TCP/IP address, a subnet mask, and gateway

addresses.

All Ethernet cards use a unique TCP/IP address. Every device (Smart Trac AC1,

printer, computer, etc) connected to a TCP/IP network requires at least one IP

address, unique within that network. This is true whether the device is part of a

control network or not.

A TCP/IP address (i.e. "207.21.32.12") identifies the unique network ID and

host ID of a computer or host using 32-bit numbers. Each component number of

the TCP/IP address, separated by a decimal point, is referred to as an "octet".

This is because it can be represented by an eight-digit binary number.

For discussion of subnet masks and gateway addresses, see "TCP/IP Subnet

Masks" and "The Gateway Address." However, you may not need to concern

yourself with exactly what they are, viewing them only as values to be entered

during configuration.

For typical applications, you may determine the subnet mask and gateway

address as follows:

Technical Manual Smart Trac Ethernet Card Configuring the Smart Trac Ethernet Card •• 15

Page 18

SMART TRAC Ethernet Card

1. At the PC to which the Smart Trac AC1 is connected, select Start,

Settings, Control Panel. The Control Panel dialog box appears,

displaying the control icons.

2. Click the Network icon. The Network dialog box appears.

3. Click the Protocols tab.

4. In Network Protocols, select TCP/IP Protocol.

5. Click Properties, then read and record the subnet mask and gateway

address of your computer. These same values will be entered into your

Smart Trac AC1s, the desktop PC running Smart Trac Workstation

software and any other devices on your LAN.

NOTE: For most applications, you may set the subnet mask and gateway

address as described. The information in the balance of this chapter supplies

details needed only in unusual situations. Further details are provided in the

Application Notes entitled "TCP/IP and Ethernet Addressing."

Configuration for PCBased Operation

Entering addresses and

subnet mask

You configure each Smart Trac TCP/IP address on your network using the

digital operator. You configure the TCP/IP address, on a PC running Smart Trac

Workstation, in Windows NT.

To enter the TCP/IP address, Subnet Mask, and Gateway Address into the

Digital Operator:

1. Press MENU on the digital operator within 2 seconds of bootup. The

message "TCP/IP Config" screen should appear.

2. Press DATA/ENTER. You are prompted with the message "IP

Address" and below it 0.0.0.0. or another IP address.

3. Press DATA/ENTER. The first digit of the first octet will flash,

indicating it is ready to accept new data. Enter the values of each octet,

in succession, pressing the right arrow key (>RESET) to move one

octet to the right if all three digits of an octet are not required entries.

4. Once all octets are entered, press DATA/ENTER to accept the new IP

Address.

5. Press the UP arrow key to the message "Subnet Mask". Enter it as you

did the IP Address in step 3.

6. In a similar manner, enter the desired Gateway Address and DNS

Server Address, should they be required.

NOTE: For most networks, the default of no gateway address and no DNS

Server address should be accepted.

7. Press MENU when completed.

Configuration for an

Enterprise-wide LAN

16 •• Contents Technical Manual Smart Trac Ethernet Card

Smart Trac AC1s may be connected, in certain situations, to an enterprise-wide

LAN. In such cases, your LAN Administrator will need to be involved to supply

certain required addresses.

While you may be able to determine the TCP/IP address as described in

"Configuration for PC-Based Operation", you may require the more detailed

information below:

Page 19

Obtaining TCP/IP

addresses

SMART TRAC Ethernet Card

The easiest way to obtain a TCP/IP address for your Smart Trac AC1 host or

computer is to request one from your LAN Administrator. This is especially

true if the device will be on a enterprise-wide LAN.

NOTE: If your internal network is to be used on a self-contained network and

not connecting directly to the public internet or a larger enterprise-wide LAN,

you may use any valid TCP/IP address except for certain reserved addresses

(0.0.0.0, 127.0.0.1, 224.0.0.0 and 255.255.255.255). Most industrial devices fall

into this category.

If on a private network (intranet) you may use any valid Class A, B, or C

address, described below. Most other LANs fall into one of these address classes

and are assigned by the corporation's LAN Administrator.

Any device that connects directly to the internet (not through a "proxy" server)

must be assigned a network ID from the Internet Network Information Center

(InterNIC at www.internic.com). Smart Trac AC1s do not fall into this category.

TCP/IP Address

Classes

TCP/IP Subnet Masks

TCP/IP addresses are grouped into five classes, from Class A through Class E.

The first octet of the IP address specifies its classification.

• Class A – First octet is between 1 and 126 (0 is not allowed, 127 is

reserved as "loopback" address). Organizations with a very large

number of hosts (networked devices) require a Class A address.

• Class B – First octet is between 128 and 191. Large organizations with

as many as 65, 534 networked devices (workstations, printers, routers,

etc) require at least a Class B address.

• Class C – First octet is between 192 and 223. A network with less than

255 networked devices may be assigned a Class C address.

• Class D – First octet is between 224 and 239. These addresses are for

multicast groups, such as RealAudio and Microsoft NetShow.

• Class E – First octet is between 240 and 247. These addresses are

reserved for experimental purposes.

A Subnet Mask defines the split between network and host (device) parts of the

TCP/IP address. It identifies the network octets of the IP address with the

number "255" or "252" and the host octets with the number "0". This defines the

maximum number of different devices (hosts) allowed on the network. A subnet

mask of 255.255.255.0, then, identifies the first three octets of the IP address as

network parts and the last as a single host part. The use of "252" provides one or

bits of additional resolution for hosts.

Example: The address 200.20.16.5 with a subnet mask of 255.255.0.0 identifies

a network with (255*255)-2 hosts, or 65,534 hosts (two is subtracted to allow

for reserved numbers) on the network identified as "200.20".

Fortunately, Microsoft's Windows NT assigns a default subnet mask to an IP

address. It can be changed if necessary. The defaults result in the following

maximum number of networks and hosts allowed per TCP/IP address:

• Class A – 126 networks, 16,777,214 hosts (default subnet

mask=255.0.0.0).

• Class B – 16,384 networks, 65,534 hosts (default subnet

mask=255.255.0.0)

Technical Manual Smart Trac Ethernet Card Configuring the Smart Trac Ethernet Card •• 17

Page 20

SMART TRAC Ethernet Card

• Class C – 2,097,152 networks, 254 hosts (default subnet

mask=255.255.255.0)

The Gateway Address

The DNS Server

Address

Verifying Your TCP/IP

Configuration

The Gateway Address provides the IP address to which packets of data should

be sent to route them to their final destination, if on a large enterprise-wide LAN

or the internet. While the Smart Trac AC1 allows you to change the gateway

address to any required, the default of no address will work in nearly all

situations. In enterprise-wide LANs the default may not be acceptable. Contact

your LAN Administrator to determine the proper gateway address.

The DNS Server is unavailable for changes. This accepts the default of no

address. Selecting DNS Server will cause a "Not Available" message to be

displayed on the digital operator.

Refer to your computer's Operating System documentation when installing

TCP/IP services and protocol.

You typically verify your TCP/IP configuration with two simple commands:

IPCONFIG and PING:

1. Click START, PROGRAMS, COMMAND PROMPT. A DOS

window appears with the cursor at the default directory.

Figure 5. The Command Prompt from Windows NT

2. Type IPCONFIG. A listing should appear of the IP Address, subnet

mask, and default gateway for all network adapters to which TCP/IP is

bound on your computer.

Figure 6. IPCONFIG results

18 •• Contents Technical Manual Smart Trac Ethernet Card

Page 21

SMART TRAC Ethernet Card

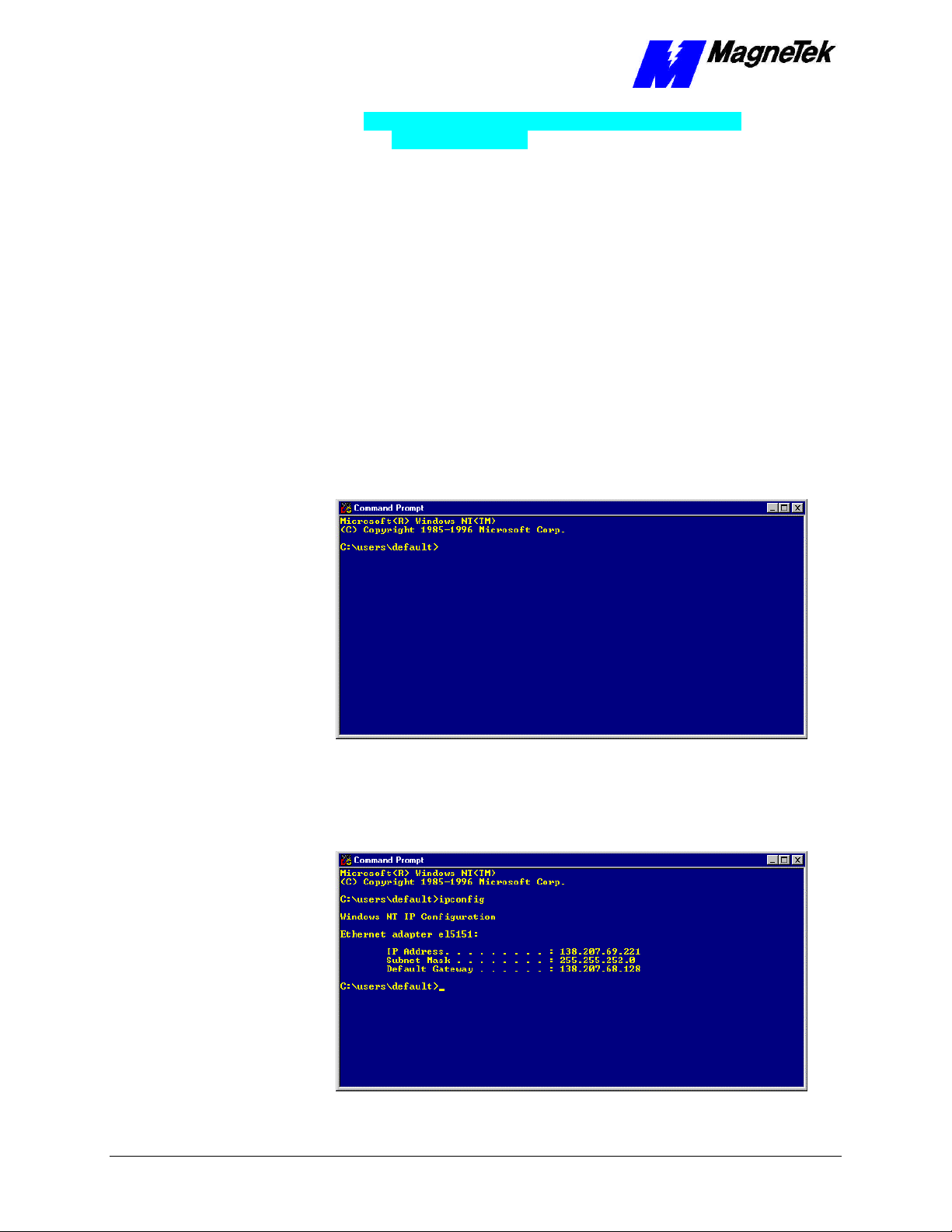

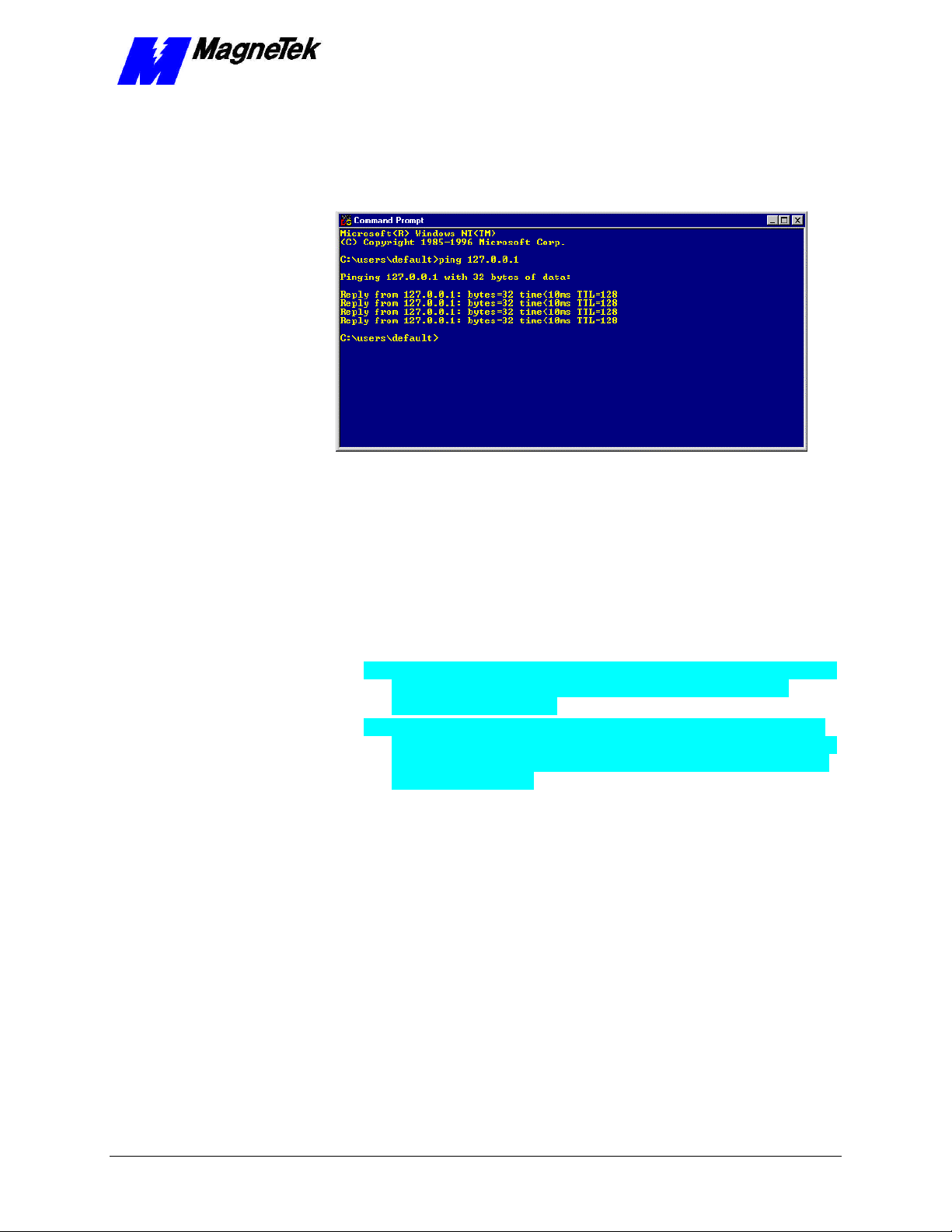

3. Type PING 127.0.0.1. The PING utility, included in Windows NT,

tests for proper TCP/IP configuration on your system with the special

"loopback" address. You should get the results shown in the following

screen. If not, the TCP/IP configuration is not correct and must be fixed

before proceeding.

Figure 7. A successful PING of the computer you are using

4. Type PING [Your IP Address]. For example, type "PING

200.20.16.5" (substitute your computer's IP Address). Results similar to

those in step 2 confirms that the IP address on your computer is

configured correctly. You will also find out if duplicate addresses exist

on your network.

5. Type PING [Address of another networked computer]. You

should get results similar to those in step 2. This confirms the IP

address of the chosen computer. You may test all other networked

computers in the same way.

6. Type PING [Address of the default network gateway]. This step

is necessary only if your system uses a gateway, to confirm your

connection to the gateway.

7. Type PING [Address of computer on other side of gateway].

This step confirms that you can connect to remote computing resources.

Again, it is only needed if your system uses a gateway and you need to

access remote systems.

Technical Manual Smart Trac Ethernet Card Configuring the Smart Trac Ethernet Card •• 19

Page 22

Page 23

SMART TRAC Ethernet Card

Testing Card Installation

Testing the Network

Once installed, check the on-board indicator Light Emitting Diodes (LEDs).

Normally:

• red LED2 should be flashing, indicating network traffic from the card.

• green LED3 should be steady ON, indicating receive activity on the

network and that your Smart Trac AC1 is an active participant in

network activities.

On-board Indicator Lights

Two LEDs on the Smart Trac Ethernet Card indicate network activity and status

information. For location, see "Appendix B – Card Layout."

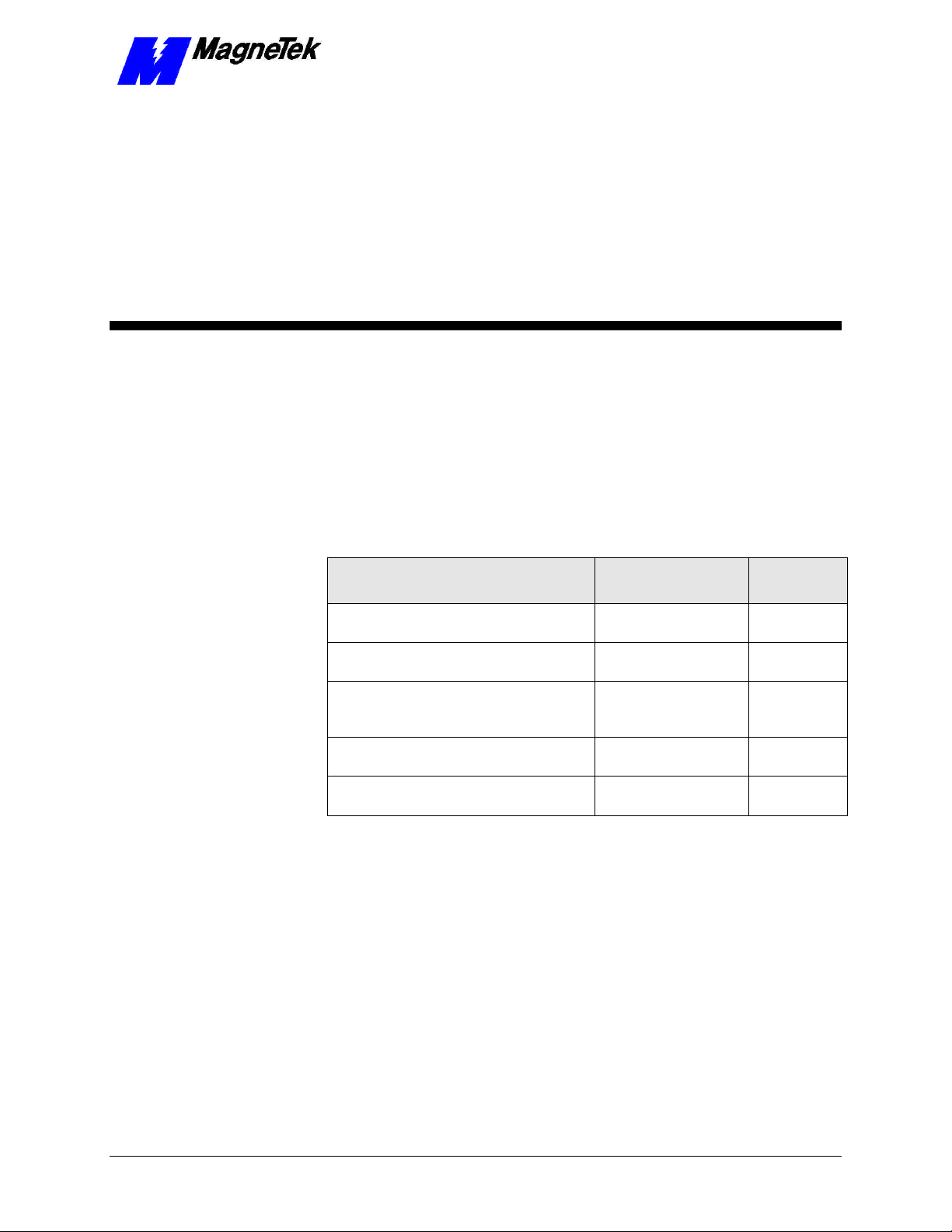

Table 1. Interpretation of the LEDs.

On-board LED Functions

LED Function

LED2 (Red) Network traffic present if flashing

LED3 (Green) Ethernet card status OK if ON, not OK if OFF

Technical Manual Smart Trac Ethernet Card Testing Card Installation •• 21

Page 24

SMART TRAC Ethernet Card

THIS PAGE INTENTIONALLY LEFT BLANK

22 •• Contents Technical Manual Smart Trac Ethernet Card

Page 25

SMART TRAC Ethernet Card

Troubleshooting Your Smart

Trac Ethernet Card

Status and Error Messages

When installed, the Smart Trac Ethernet driver automatically creates a set of

global

These global variables may be assigned symbol names and used in function

blocks, application programs and/or the fault manager. If read by the fault

manager, they may be programmed to annunciate and/or to be displayed on the

Digital Operator as they occur.

Troubleshooting Ethernet Network

Problems

Use the following general guidelines to troubleshoot your Ethernet network:

1. Disconnect parts of the network and watch where the fault goes.

Disconnecting part of the network frequently solves the problem.

2. If the network was previously operating, determine what has changed.

3. Record symptoms in detail. Keep good notes about your network and

its problems to properly define the problem.

• Look for patterns in the symptoms. Do intermittent problems occur

when other un-related equipment is in use?

• Do some nodes communicate correctly? What is the difference

between the functioning nodes and the others?

Technical Manual Smart Trac Ethernet Card Troubleshooting Your Smart Trac Ethernet Card •• 23

Page 26

SMART TRAC Ethernet Card

Table 2. Hardware Configuration Troubleshooting.

Troubleshooting Hardware Configuration

Probable

Symptom

Cause Corrective Action

Devices will

not

communicate

Cable break,

short or

faulty cable

connector

Newly

installed

Ethernet

Card not

configured

properly

Corrupt

Ethernet

card driver

Check cable continuity for break or short.

Inspect connector for damage, broken

pins, or wires that have pulled loose.

Repair or replace as necessary.

Check jumper settings of other cards in

the Smart card stack to eliminate any

conflicting IRQ, I/O Base Address,

modes, etc. Correct as required.

Check LED3 (link activity). It should be

ON, indicating a good connection with

the hub (used if more than two devices

on the network) or other device(s). If not

ON, check for a loose or damaged

connection at hub. Check hub for

damage.

Check LED2 (transmit activity). It should

be ON intermittently, indicating that the

card is transmitting data.

Reinstall driver.

Check configuration of Ethernet card and

driver.

Check IP address, subnet mask, and

default gateway. Make changes as

required.

Improper

network

protocol

If network response slows down, check

for a improper configuration in Windows

NT.

selected

Power loss,

surge or

Install an Uninterruptible Power Supply

(UPS).

large

fluctuations

24 •• Contents Technical Manual Smart Trac Ethernet Card

Page 27

SMART TRAC Ethernet Card

Appendix A – Technical Support

Technical Support

Should you need technical assistance with installation or troubleshooting of your

Smart Trac AC1, you can phone our Help Desk at either (800)-541-0939 or

(262)-782-0200. Alternatively, you may copy the Problem Report form, found

on the next page, and fax it to us at (262)-782-3418.

Technical Manual Smart Trac Ethernet Card Appendix A – Technical Support •• 25

Page 28

SMART TRAC Ethernet Card

Problem Report

Name:

Address:

City: State: Zip

Serial Number: Smart Trac PG Card

Occurrence: Frequently Intermittantly Rarely

Nature of Problem:

Conditions when problem occurs:

26 •• Appendix A – Technical Support Technical Manual Smart Trac Ethernet Card

Page 29

SMART TRAC Ethernet Card

References

Ethernet For a good primer on ethernet, visit Charles

Spurgeon's Ethernet Web Site at:

http://www.ots.utexas.edu:8080/ethernet

IEEE Standards 802.3,

802.3a, 802.3I

MagneTek Drives and

Systems

MagneTek Drives and

Systems Application Note

"TCP/IP and Ethernet

Addressing"

PC/104 Specification,

Version 2.1

Windows NT 4.0 For information about Windows NT 4.0,

Institute of Electrical and Electronics

Engineers. Standards may be downloaded on a

subscription basis from the web site:

http:http://www.standards.ieee.org

For more information about MagneTek drives

and systems, training programs and contacts,

visit:

http://www.magnetekdrives.com

Obtain this Application Note from your

MagneTek representative.

PC/104 Consortium. An overview and the

specification may be obtained at the web site

address:

http://www.controlled.com/pc104/index.html

technical support and troubleshooting your

Ethernet network, contact Microsoft's web site

at:

http://www.microsoft.com

.

Technical Manual Smart Trac Ethernet Card Appendix A – Technical Support •• 27

Page 30

Page 31

LED3 (Link)

10 Base-T

U3

Mounting

(4X)

CN3

CN4

SMART TRAC Ethernet Card

Appendix B – Card Layout

Smart Trac Ethernet Card Layout

LED2 (Traffic)

(RJ45)

Connector

CN1

(16-pin AUI

connector

- not used)

PC/104 Connector

PC/104 Connector

Holes

Technical Manual Smart Trac Ethernet Card Appendix B – Card Layout •• 29

Page 32

SMART TRAC Ethernet Card

Table 3. Pinout of RJ-45 (10Base-T) Connector

Pin Signal Description

1 TD+ Data transmission positive

2 TD- Data transmission negative

3 RD+ Data reception positive

6 RD- Data reception negative

NOTE: To reduce crosstalk noise spikes in the Ethernet cable, it is

recommended that you install a ferrite loop in the cable close to the RJ45

connection.

To further reduce noise in the Ethernet cable, use shielded-twisted pair cable

with shielded connectors.

30 •• Appendix B – Card Layout Technical Manual Smart Trac Ethernet Card

Page 33

SMART TRAC Ethernet Card

Appendix C – Replaceable Parts

Replaceable Parts Listing

Description MagneTek Part

Number

Smart Trac Ethernet Network

Interface Option Kit

Technical Manual TM 73554-0060 –

Smart Trac Ethernet Card

Card Extraction Tool (Parvus Corporation

Standoffs, 4.5mm, Hex, Stl, CL ZINC,

15mm, M/F, M3, M3

Hardware Tools Kit for Smart Trac

AC1

46S03643-0060 1

D-TM3554-0060 1

P/N PRV-0760A-

01)

05P00618-0006 4

TBD Option

Qty

Option

Technical Manual Smart Trac Ethernet Card Appendix C – Replaceable Parts •• 31

Page 34

SMART TRAC Ethernet Card

THIS PAGE INTENTIONALLY LEFT BLANK

32 •• Appendix C – Replaceable Parts Technical Manual Smart Trac Ethernet Card

Page 35

SMART TRAC Ethernet Card

Appendix D – Removing the

Smart Trac Card Stack

General Procedures

1. Power off the Smart Trac AC1. Disconnect it and tag "Out of Service".

2. Do one of the following:

• Open the cover to the Smart Trac AC1 by rotating the spring-

loaded, captive screw counterclockwise. Use a large screwdriver if

necessary to free the slotted screw.

OR

• Loosen the screws holding down the cover.

3. Disconnect the 12-pin wiring harness from connector J4 at the digital

operator.

4. Using the Phillips head screwdriver, remove the ground strap from the

left inside and the ground strap from the top inside of the Smart Trac

AC1 adapter ring.

5. Disconnect the 9-pin RS-232 cable at connector J5 on the Smart Trac

CPU card.

Technical Manual Smart Trac Ethernet Card Appendix D – Removing the Smart Trac Card Stack •• 33

Page 36

chassis

board

SMART TRAC Ethernet Card

12-pin wiring

harness on

Digital Operator

attached to

connector J4 on

Smart Trac

CPU Card

Digital

Operator

9-pin RS-232

cable

attached here

4mm screws

(4 places)

secure ring

to main

Standoffs (4

places)

secure each

board

Smart Trac

Board Stack

PC/104

9-pin RS-232

cable

connector J5

6. Using a 4.5mm hex head driver, remove four standoffs from the

topmost card.

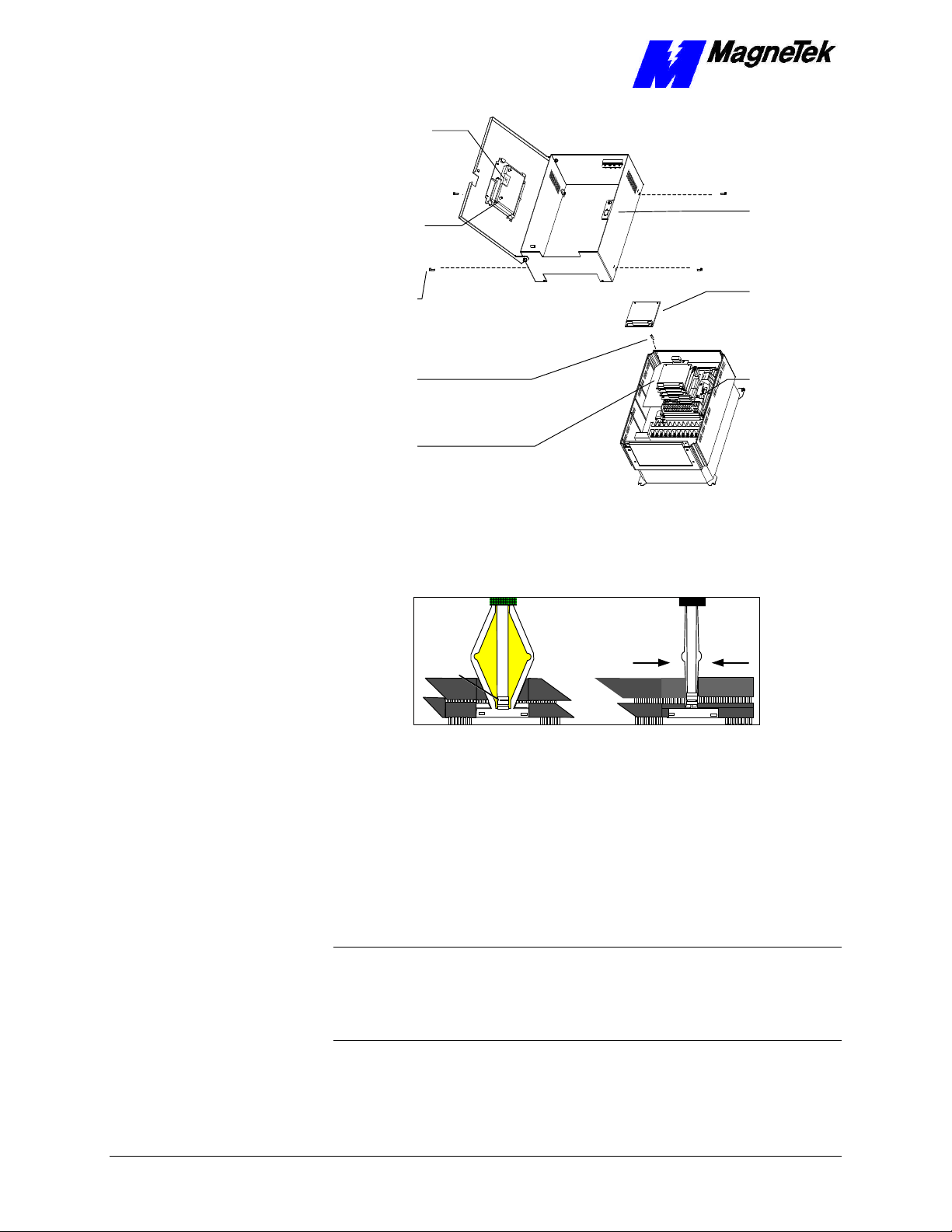

7. Using the PC/104 extraction tool, remove the topmost card from the

stack.

Position

rectangular

"jacks"

around

edges of

PCBs

Squeeze to lift

cards apart

Figure 8. Using the PC/104 Extraction Tool.

8. Repeat step 8 above until all PC/104 cards have been removed.

9. To remove the Smart Trac PG card:

• Disconnect the 4CN connector on the PG card.

• Using a tubular extraction tool or pliers, squeeze the plastic,

spring-loaded retainer built-in to the long plastic standoff located

at the top of the PG card, just above connector J6.

• Using a PC/104 extraction tool, remove the card.

NOTE: The Smart Trac PG card requires unique handling. Wedge the extracting

tool between the PG card and the CPU card. The area between the terminal strip

on the CPU card and the serial numbered edge of the PG card can be lifted first,

then the opposite side (nearest TB1) on the PG card). Alternate sides until the

card is free of the CPU card.

10. To remove the Smart Trac CPU card:

34 •• Appendix D – Removing the Smart Trac Card Stack Technical Manual Smart Trac Ethernet Card

Page 37

SMART TRAC Ethernet Card

• Disconnect the card at the 2CN connector on the CPU card.

• The CPU card is secured with three plastic standoffs with spring-

loaded clips on the end. Squeeze the top of the standoffs (the clips)

with the special cylindrical removal tool, your fingers or needlenosed pliers and lift the CPU card from the Smart Trac Inverter

Control Card.

You have removed the entire card stack. The inverter card, considered part of

the drive, is in clear view.

Technical Manual Smart Trac Ethernet Card Appendix D – Removing the Smart Trac Card Stack •• 35

Page 38

Page 39

Glossary of Terms

SMART TRAC Ethernet Card

Application Layer

AUI

Bridges

CSMA/CD

Data Link layer

enterprise-wide LAN

hub

The seventh layer of the OSI networking model. This layer provides the

translation between an application program (which uses the network to move

data) and the network. When a program makes an API (Application Program

Interface) call, this layer determines the devices it must communicate with,

whether a communications session should be established between devices, and if

packet delivery must be guaranteed.

Acronym for Attachment Unit Interface. An AUI is a 15-pin connector, used to

connect a cable to a network interface card, that allows for the use of a

transceiver and is often used with a coaxial cable.

An intellignet device used to transmit data from one network segment or port to

another, according to a set of rules.

Acronym for Carrier Sense Multiple Access/Collision Detection. It is used to

manage collisions of data packets on the network. When a collision is detected,

it instructs each network card to stop transmitting, wait a random amount of

time, then listen for other data transmissions before proceeding to transmit data

frames.

The second layer of the OSI network model. This layer creates and interprets

frame types, and interprets the information received from the Physical Layer.

A Local Area Network (LAN) that serves more than one purpose, may network

devices physically separated by long distances, and may be connected to the

internet.

A connection device that receives a signal, then transmits it to the connected

devices.

IEEE 802.3

LED

Network Layer

NIC

PC/104 standard

Technical Manual Smart Trac Ethernet Card Glossary of Terms •• 37

The open network Ethernet standard, issued by the Institute of Electrical and

Electronics Engineers. The standard has sections to describe cable types, among

others.

Acronym for Light Emitting Diode.

The thrid layer of the OSI network model. It directs the flow of data from a

source to a destination through addressing and routing. It must do this in spite of

the fact that devices are not always on the same physical wire or segment.

Acornym for Network Interface Card. It is an adapter that transforms data into

signals for transfer across the transmission media to a destination device.

An embedded PC bus standard. The standard defines the mechanical size of a

self-stacking bus. Also an IEEE draft standard, called the P996.1 Standard for

Page 40

SMART TRAC Ethernet Card

Compact Embedded PC Modules, the PC/104 Specification, Version 2.1, July

1994, PC Consortium.

Physical Layer

Presentation Layer

router

Session Layer

topology

Transport Layer

UTP

The first layer of the OSI networking model. This layer provides a physical

connection for transmission of data bits over the network media and between

devices.The layer also maintains data integrity as it moves from source to

destination.

The sixth layer of the OSI network model. This layer translates and converts

data from one format to another as the data moves from one device to another

(i.e. ASCII to EBCDIC).

A device used to regenerate a signal's voltage and retransmit it, allowing longer

network lengths. Unlike bridges, a router does not have the intelligence to

distinguish signals directed to a device on the same segment and instead

retransmits it to all segments on the network. This generates more traffic on the

network than if a bridge were used.

The fifth layer of the OSI networking model. The layer manages connections

between two devices while they are communicating. It has built-in error

correction and recovery. It determines whether all information has been sent or

received between two networked devices.

The manner in which a network is configured, usually one or a combination of

bus, star, ring.

The fourth layer of the OSI networking model. This layer concerns itself with

the delivery of packets transmitted by the Network Layer. This may involve

error control of data to guarantee delivery of the packets.

Acronym for Unshielded Twisted Pair. UTP is a type of cable containing a pair

of wires that are twisted at regular intervals to prevent signal interference with

electrical noise. UTP is commonly used with 10Base-T Ethernet networks.

38 •• Glossary of Terms Technical Manual Smart Trac Ethernet Card

Page 41

Index

1

10Base2 5, 13

10Base5 5, 13

10Base-T 5–6, 9, 13

SMART TRAC Ethernet Card

DeviceNet Network Topology 8

diagnostics 5

digital operator 16, 18

using the 16

Digital Operator 23

DNS Server Error! Not a valid

bookmark in entry on page

16

DoD model 8

downloading 5

E

electrostatic sensitive discharge 11

Electrostatic Sensitive Discharge

11

enterprise-wide LAN 15

ESD 11

ESD 11

ESD Procedures 4, 11

Ethernet 10

extraction tool 34

A

address

gateway 15

loopback 17

TCP/IP 15

Addresses and subnet mask 15

administrator, LAN 15

Application Layer 8

application protocol 7

B

boot 16

bootup 16

bus 5, 8

C

Capabilities, Smart Trac DeviceNet

Card 5

Carrier Sense Multiple

Access/Collision Detection 8

configuration

network 15

TCP/IP 18

Configuring the Smart Trac

DeviceNet Card 15

CPU 33

D

Data Link layer 7–8

default network gateway 19

F

fault manager 23

G

gateway

default network 19

gateway addresses 15

General Capabilities 5

ground 11

H

Help Desk 25

Humidity 5

I

IEEE 802.3 5, 7

indicator lights 21

information, safety 4

Installation

Testing Card 21

Testing the Network 21

Installation, Smart Trac DeviceNet

Card 11

International Standards

Organization 7

Interrupt 15

Inverter 35

IPCONFIG 18

Technical Manual Smart Trac Ethernet Card Index •• 39

Page 42

SMART TRAC Ethernet Card

L

LAN

enterprise-wide network 15

LAN Administrator 15

LEDs 21

On-board Indicator Lights 21

Length

Network 9

loopback 17

M

media, transmission 7

Menu 16

N

names, symbol 23

NE2000 5

network

private 17

Network Configuration 15

Network Layer 7–8

Network Length 9

Networking 15

O

octet 15

ODVA 27

On-board Indicator Lights 21

Open Systems Interconnect 7

Operating Temperature 5

operator, digital 16, 18

Optional Parts 31

OSI model 7–8

OSI Model

application protocol 7

transmission media 7

R

report

problem 25

reset 16

RS-232 5

S

safety information 4

Session Layer 7

Smart Trac AC1

on a DeviceNet Network 5

Smart Trac Workstation 16

static electricity 4, 11

Status and Error Messages 23

strap

wrist 11

symbol names 23

T

TCP/IP 5, 8, 15–18

TCP/IP Address 15

TCP/IP Configuration 18

Technical Manual 4, 11

Testing the Network 21

tool, extraction 34

Topology 8

Bus 5, 8

Transmission Control

Protocol/Internet Protocol 8

transmission media 7

Transport Layer 7–8

Troubleshooting

DeviceNet Network Problems 23

Status and Error Messages 23

Troubleshooting 25

Troubleshooting Your Smart Trac

DeviceNet Card 23

P

parts

optional 31

PC/104 27

Physical Layer 7–8

PING 18

Presentation Layer 7

private network 17

Problem Report 25

protocol 5, 7–8, 16, 24

U

Unpacking 11

uploading 5

Using the Digital Operator 16

W

Warranty 4

Windows NT 16

workstation, Smart Trac 16

wrist strap 11

Q

Quick Start 6

40 •• Index Technical Manual Smart Trac Ethernet Card

Page 43

SMART TRAC Ethernet Card

Data subject to change without notice. Smart Trac is a trademark of MagneTek, Inc. MicroTrac is a registered trademark of MagneTek, Inc. Microsoft, Windows and Windows NT are registered

trademarks of Microsoft Corporation

MagneTek

Drives and Systems

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939, (262) 782-0200, FAX (414) 782-3418

TM 3554-0060 © 1999-2000 MagneTek, Inc. 1/31/2000

Loading...

Loading...