Page 1

Technical Manual

™

™

S

M

A

R

S

M

D

evviicc

D

e

A

R

e

e

T

T

N

N

T

R

T

R

ett

e

A

A

C

C

C

C

arr

a

d

d

Page 2

Page 3

SMART TRAC DeviceNet Card

Contents

Important Safety and Warranty Information 1

Warnings, Cautions and Notes.....................................................................................................................1

General Safety Precautions - Warnings ......................................................................................................2

Important Warranty Information................................................................................................................2

Smart Trac DeviceNet Card 3

General Capabilities......................................................................................................................................3

Smart Trac AC1 on a DeviceNet Network ..................................................................................................3

Specifications .................................................................................................................................................4

Quick Start.....................................................................................................................................................4

DeviceNet Basics 5

Introduction...................................................................................................................................................5

DeviceNet Network Topology..........................................................................................................6

Network Length ................................................................................................................................7

Thick Cable Specifications................................................................................................................8

Thin Cable Specifications .................................................................................................................8

Terminating Resistor Specifications .................................................................................................9

DeviceNet Connector........................................................................................................................9

Installing the Smart Trac DeviceNet Card 11

Unpacking ....................................................................................................................................................11

Electrostatic Sensitive Discharge (ESD) Procedures ......................................................................11

Unpacking Procedure......................................................................................................................11

Installing the Smart Trac DeviceNet Card................................................................................................11

Connecting the Smart Trac DeviceNet Card to a DeviceNet Network...................................................13

Configuring the Smart Trac DeviceNet Card 17

Configuration...............................................................................................................................................17

Default Settings............................................................................................................................................17

Non-Default Settings ...................................................................................................................................17

Interrupt...........................................................................................................................................17

Base I/O Address.............................................................................................................................18

Testing Card Installation 19

Testing the Network....................................................................................................................................19

General Test Parameters..................................................................................................................19

Network Termination & Signal Wires ............................................................................................19

Shield ..............................................................................................................................................19

Grounding .......................................................................................................................................19

Technical Manual 3554-0070 Contents •• i

Page 4

SMART TRAC DeviceNet Card

Network Power - Minimum supply voltage....................................................................................20

Network Power - Common Mode Voltage......................................................................................20

MAC ID/ Baud Rate Settings..........................................................................................................20

On-board Indicator Lights .........................................................................................................................20

Module and Network Status LEDs at Power-Up......................................................................................22

Troubleshooting Your Smart Trac DeviceNet Card 23

Status and Error Messages.........................................................................................................................23

Troubleshooting DeviceNet Network Problems........................................................................................25

Appendix A – Technical Support 27

Technical Support .......................................................................................................................................27

References ....................................................................................................................................................27

Problem Report ...........................................................................................................................................28

Appendix B – Replaceable Parts 29

Replaceable Parts Listing ...........................................................................................................................29

Appendix C – Removing the Smart Trac Card Stack 31

General Procedures.....................................................................................................................................31

Glossary of Terms 35

Index 37

ii •• Contents Technical Manual 3554-0070

Page 5

SMART TRAC DeviceNet Card

Important Safety and Warranty

Information

Warnings, Cautions and Notes

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or death.

WARNING - ESD

A statement of conditions which must be observed to prevent

damage to components due to ESD (ElectroStatic Discharge) and

to prevent personal injury or death.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults, Smart Trac AC1 system degradation

and damage to equipment.

IMPORTANT

A statement of conditions which should be observed during Smart Trac AC

DeviceNet setup or operation to ensure dependable service.

NOTE: Notes indicate information that is in addition to a discussion of the topic

in adjoining text. Alternatively, it may limit or restrict the paragraph(s) that

follow(s) to specific models or conditions.

TIP - Tips indicate information that should make a procedure easier or more

efficient.

Technical Manual 3554-0070 Important Safety and Warranty Information •• 1

Page 6

SMART TRAC DeviceNet Card

General Safety Precautions Warnings

Important safety information follows. Please read and understand all

precautions listed below before proceeding with the specification, installation,

set-up or operation of your Smart Trac AC1. Failure to follow any of the

following precautions may result in personal injury or death, or damage to the

equipment.

WARNING - ESD

The Control Printed Circuit Board (PCB) employs CMOS

Integrated Circuits that are easily damaged by static electricity.

Use proper ElectroStatic Discharge (ESD) procedures when

handling the Control PCB. See Smart Trac AC1 Technical Manual

for details. Failure to comply may result in damage to equipment

and/or personal injury.

Important Warranty Information.

Do not modify your Smart Trac AC1, its components, or any of the procedures

contained in the technical documentation supplied by MagneTek. Any

modification of this product by the user is not the responsibility of MagneTek

and will void the warranty.

2 •• Important Safety and Warranty Information Technical Manual 3554-0070

Page 7

SMART TRAC DeviceNet Card

Smart Trac DeviceNet Card

General Capabilities

Adding the Smart Trac DeviceNet Card to your Smart Trac AC1 makes it fully

compatible with other industrial devices (i.e., drives, limit switches, operator

interfaces, programmable controllers) conforming to the DeviceNet standard. It

also complies with CAN (Controller Area Network) specification 2.0, parts A

and B, Standard Frame Identifiers.

The card also conforms to PC/104 specifications and has its own central

processing unit (CPU). It supports DeviceNet data rates of 125 Kbaud, 250

Kbaud and 500 Kbaud.

While DeviceNet supports up to 64 nodes identified by MAC IDs, the Smart

Trac DeviceNet card uses one MAC ID, leaving 63 other device nodes available

to be addressed.

The Smart Trac DeviceNet driver supports Polled I/O and Bit Strobed I/O

connections as well as explicit messaging. It supports all ODVA (Open

DeviceNet Vendor Association) approved devices.

Smart Trac AC1 on a DeviceNet

Network

With a Smart Trac DeviceNet card and driver installed and connected to a

DeviceNet network, the Smart Trac AC1 communicates in a Master/Slave

relationship (as opposed to peer-to-peer). A Smart Trac AC1 with an installed

Smart Trac DeviceNet card serves as Master of a DeviceNet network. The

Master gathers and distributes I/O data for the process controller. It also gathers

I/O data from Slave devices and distributes the data to Slave devices.

On a DeviceNet Master/Slave network, a Master device "owns" a Slave device.

A Slave device can be "owned" by only one Master. Except for a check for

duplicate MAC IDs, a slave cannot initiate communication transactions unless it

has been told to do so by its Master. The Master (in this case, the Smart Trac

DeviceNet card) scans its Slave devices based on a scan list that it contains. The

Slaves' MAC IDs appear in the Master's scan list of I/O addresses to be scanned

by the card at specified intervals.

Smart Trac systems support single master networks. Only one Smart Trac

DeviceNet Card is allowed per network.

Technical Manual 3554-0070 Smart Trac DeviceNet Card •• 3

Page 8

SMART TRAC DeviceNet Card

Specifications

• 16 MHz V40 microprocessor with 128 Kbytes RAM

• Software configurable interrupts 2, 5 and 7 (7 normally used)

• DeviceNet compatible 5-pin connector

• Network status bicolor indicator

• Operating temperature 32° to 104°F (0° to 40° C)

• Storage temperature -4° F to 140°F (-20° to 60° C)

• Operating Humidity 5% to 90% non-condensing

• Supports standard DeviceNet baud rates of 125, 250 and 500 baud

• UCMM capable and supports Group 1, 2, and 3 dynamic connections.

• Accepts shielded twisted pair cable compatible with target network

Quick Start

1. Check DIP switch settings on the card against the default settings (see

“Default Settings"). You should use default settings except in only

unusual situations. Your Smart Trac Field Engineer can help you if you

need assistance.

2. Power OFF your Smart Trac AC1.

3. Install the card in your Smart Trac AC1 in a PC/104 option card

position (on top of the Smart Trac Ethernet Card or another PC/104

option card).

4. Connect the DeviceNet network cable.

5. If your power supply is not on a common circuit breaker with the Smart

Trac AC1, power up your DeviceNet network.

6. Power up your Smart Trac AC1.

7. Test your card installation.

4 •• Smart Trac DeviceNet Card Technical Manual 3554-0070

Page 9

DeviceNet Basics

Introduction

Originally developed by Bosch for the automotive industry, DeviceNet is a lowcost communications protocol to connect industrial devices (i.e., limit switches,

sensors, bar code readers, variable frequency drives, panel displays and operator

interfaces) to a network. DeviceNet provides an open network standard with

high noise immunity, suitable to industrial environments. The protocol includes

device-level diagnostics. It allows the addition of other devices on a network

without cycling power to the network.

SMART TRAC DeviceNet Card

Configuration Tool

+24 Volt

power supply

Controller

Network

DeviceNet

Other Devices

Motor

Starter

Barcode

Pushbutton

Cluster

Input/Output

Devices

Figure 1. Typical DeviceNet Network configuration

The Open Systems Interconnect (OSI), established in 1984 by the ISO

(International Standards Organization), divides network functions into seven

layers: Physical, Data Link, Network, Transport, Session, Presentation and

Application Protocol. DeviceNet provides the Application Protocol (highest

level 7), Data Link Layer (layer 2), Physical Layer (layer 1) and Transmission

Media (a sublevel of level 1, sometimes referred to as an eighth layer 0).

Smart Trac

AC1

Scanner

DeviceNet incorporates the CAN protocol to provide the Data Link Layer.

Technical Manual 3554-0070 DeviceNet Basics •• 5

Page 10

SMART TRAC DeviceNet Card

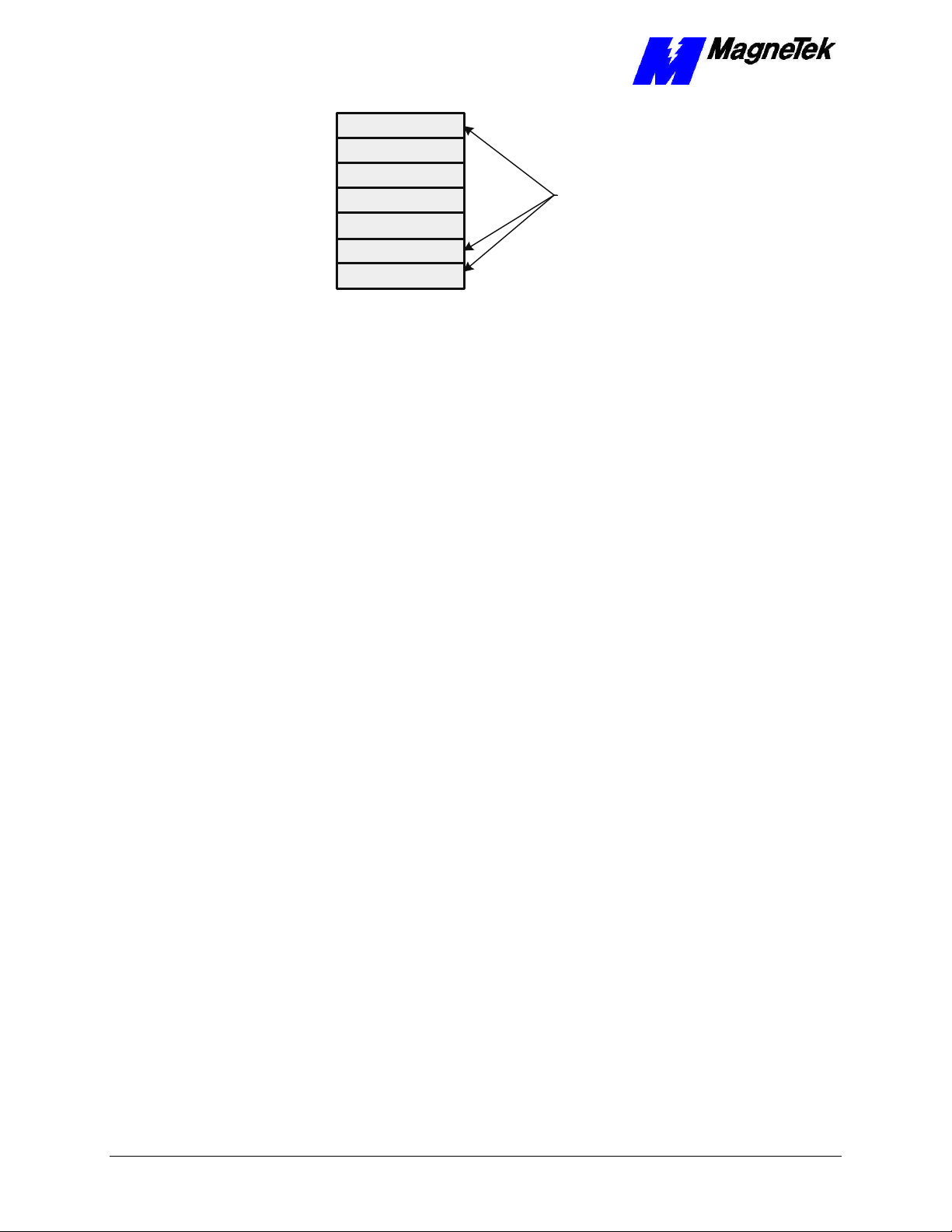

Application

Presentation

Session

Transport

Network

Data Link

Physical

Figure 2. DeviceNet and the OSI Model

• The Physical Layer transforms data into bits that are sent across the

physical media.

• The Data Link layer determines access to the network media in terms

of frames. Its Media Access Control (MAC) sublayer is responsible for

physical addressing.

• The Network Layer routes data through a large network.

• The Transport Layer provides end-to-end, reliable connections, often in

terms of segments.

DeviceNet provides

these layers of the

OSI (Open Systems

Interconnect) model.

DeviceNet Network

Topology

• The Session Layer allows users to establish connections using

intelligently chosen names in packets.

• The Presentation Layer negotiates data exchange formats, also in terms

of packets.

• Finally, the Application Layer provides the interface between the user's

application and the network through messages.

Data is said to move from layer to layer within the seven layers of the OSI

model. CAN (Controller Area Network)-based, DeviceNet permits networking

of up to 64 nodes, called Media Access Control Identifiers, or MAC-IDs. CAN

defines the syntax or form of the data movement. By adhering to the CAN

specification and using CAN Controller chips, DeviceNet completely defines the

Data Link layer of the OSI model.

Devices on DeviceNet networks are physically connected together in a linear

bus topology. All devices on the network are connected to one primary trunk

cable. You must install terminating resistors at the end of the trunk line. You

may install drop lines with lengths of up to 6 meters (20 feet) to attach one or

more nodes. The maximum number of drop lines and their lengths are subject to

maximum drop cable distances (see Table 1). DeviceNet allows for branching

structures only on the drop line. See "Figure 3 " for a typical DeviceNet

topology. In the figure, the thick line represents the trunk line of the network.

Thin lines represent drop lines.

6 •• DeviceNet Basics Technical Manual 3554-0070

Page 11

SMART TRAC DeviceNet Card

Multiple Node

Node

Node

Branching

Drop Line

Multi-Port

Tap

Node

Tap

Tap

Node

Node

Terminating

Resistor

Terminating

Resistor

Node

Zero Length

Drop Line

Network Length

Line Length with Thin

or Thick Cable

Node

Node

Tap

Node

Multi-Port

Tap

Node

Node

Multiple Node

Daisy Chain

Drop Line

Figure 3. Typical DeviceNet Topology.

In a DeviceNet network, end-to-end network (and point-to-point) distance varies

with network transmission speed (baud rate). You may use a combination of

thick and thin cable to construct trunk lines.

For trunk lines constructed of only one type of cable (either thick OR thin), refer

to Table 1. Remember that "network length" includes the combined length of

trunk line cable and drop line cable between the points.

Table 1. DeviceNet Network Length

DeviceNet Network Length

Speed

(Baud

Rate)

125 Kbps 1, 640 ft. (500m) 328 ft (100m)

250 Kbps 820 ft (250 m)

500 Kbps 328 ft. (100m) 328 ft (100m)

Maximum Length Allowed

(Thick Trunk Length)

Maximum Length Allowed

(Thin Trunk Length)

328 ft (100m)

Maximum Drop Length 20 ft (6m) (Drop line length is the longest cable

distance measured from the tap on the trunk line to each of the

transceivers of the nodes on the drop line).

Cumulative Drop Length 512 ft (156 m) at 125 Kpbs; 256 ft (78m) at

250 Kbps; or 128 ft (39m) at 500 Kbps

Data Packets: 0-8 bytes

Bus Topology: Linear (trunkline/dropline) with power and signal on the

same network cable.

Bus Addressing: Peer-to-Peer with Multi-Cast (one-to-many) or Multi-

Master and Master/Slave special case; polled or change-of-state

(exception-based)

Technical Manual 3554-0070 DeviceNet Basics •• 7

Page 12

SMART TRAC DeviceNet Card

System Features: Removal and replacement of devices from the

network under power.

Line Length with both

Thick and Thin Cables

When using a combination of thin and thick cable in a DeviceNet network,

calculate the maximum cable distance according to Figure 4 and the following

formulae:

At 125 Kbps: L

At 250 Kbps: L

At 500 Kbps: L

(L

is length of thick cable and L

thick

+ 5.0 * L

thick

+ 2.5 * L

thick

+ L

thick

= 500

thin

= 250

thin

= 100

thin

is length of thin cable)

thin

100

80

Length of Thin

Cable (meters)

60

40

20

125

500

Kbps

0

Length of Thick Cable (meters)

250

Kbps

200100 300 400 5000

Kbps

Figure 4. Combined Thin and Thick Cable Length Determination

Thick Cable

Specifications

Thin Cable

Specifications

Thick cable consists of two shielded pairs twisted on a common axis with a

drain wire in the center. An overall braid shield covers the shield pairs. Thick

cable is typically used for trunk lines.

The thick cable specified for DeviceNet network connections consists of:

• One (1) twisted signal pair (#18): blue/white

• One (1) twisted power pair (#15): black/red

• Separate aluminized Mylar shields around power pair and signal pair

• Overall foil/braid shield with drain wire (#18): bare

Thinner and more flexible than than Thick Cable, use Thin Cable for drop lines

or for shorter distance trunk lines.

The thin cable specified for DeviceNet network connections consists of:

• One twisted signal pair (#24): blue/white

• One twisted power pair (#22): black/red

• Separate aluminized Mylar shields around power pair and signal pair

• Overall foil/braid shield with drain wire (#22): bare

8 •• DeviceNet Basics Technical Manual 3554-0070

Page 13

Terminating Resistor

Specifications

SMART TRAC DeviceNet Card

You must install a terminating resistor at the farthest ends of a trunk line (and

only two per network). These terminating resistors must be 121 ohm, 1% Metal

Film, 1/4 Watt resistors.

NOTE: DO NOT install terminating resistors at the end of drop lines.

DeviceNet Connector

Your Smart Trac DeviceNet card ships with one female DeviceNet connector. It

mates with a male connector mounted on the card. The pinout of DeviceNet

connectors is described in Table 2.

Technical Manual 3554-0070 DeviceNet Basics •• 9

Page 14

SMART TRAC DeviceNet Card

THIS PAGE INTENTIONALLY LEFT BLANK

10 •• DeviceNet Basics Technical Manual 3554-0070

Page 15

SMART TRAC DeviceNet Card

Installing the Smart Trac

DeviceNet Card

Unpacking

Electrostatic

Sensitive Discharge

(ESD) Procedures

Unpacking Procedure

WARNING WARNING -- ESD ESD

Keep electronic circuit boards in Electrostatic Sensitive Discharge

(ESD) protective bags when not being handled. Use proper ESD

procedures (including an ESD wrist strap) when handling circuit

boards. Failure to comply may result in damage to equipment.

When working with an electrostatic sensitive discharge (ESD) device, you

should be grounded at all times. The easiest and most common way to provide

this ground is to use an approved ESD wrist strap. The strap is secured to your

wrist with a wire attached to the strap and clipped or taped to the chassis of the

unit being worked on. Any static is dissipated through the wire to ground,

greatly reducing the possibility of damage to the device.

It is a good idea to touch the chassis with your finger before handling any

electrostatic sensitive device. Any static electricity will be discharged to chassis

ground and will not be transferred to the device.

Always store devices (cards, other electronic components) in ESD protective

bags when not being handled.

Remove the protective shipping and packing material from the card. Ensure

contact wedges and other shipping devices have been removed.

Installing the Smart Trac DeviceNet

Card

The Smart Trac DeviceNet Card is PC/104 compatible, so it may be positioned

on the very top of the Smart Trac card stack.

NOTE: If replacing or adding a Smart Trac DeviceNet card to an existing Smart

Trac card stack, see "Appendix C – Removing the Smart Trac Card Stack"

before continuing.

Technical Manual 3554-0070 Installing the Smart Trac DeviceNet Card •• 11

Page 16

DeviceNet

SMART TRAC DeviceNet Card

Standoffs (4

places on top of

each card)

4CN

Connector

card in one of

top two stack

positions in

stack

Optional

PC/104

Card

Smart Trac

Ethernet

Card

Smart Trac

PS Card

Smart Trac

PG Card

2CN

Connector

Smart Trac

CPU Card

Inverter Control

Card

Adapter

Ring

Main Chassis

Figure 5. Smart Trac DeviceNet Card Stack Position

1. To install the DeviceNet card, orient the pins on the card with the

female pin connector on the card below it (normally the Ethernet card).

Gently but firmly push the Smart Trac DeviceNet card onto the card

below it. Make sure connecting pins are in alignment before pushing

the two boards tightly together. Secure the card using four (4) metal

standoffs.

2. Replace all other cards, securing each with four (4) metal standoffs and

the reverse of pertinent steps in "Appendix C – Removing the Smart

Trac Card Stack".

12 •• Installing the Smart Trac DeviceNet Card Technical Manual 3554-0070

Page 17

J2

SMART TRAC DeviceNet Card

Connecting the Smart Trac DeviceNet

Card to a DeviceNet Network

1. Connect a DeviceNet cable to the 5-pin connector at J2. The connector

conforms to the standard DeviceNet pinout (see Table 2). A DeviceNet

Master (the Smart Trac AC1) is typically at one end of the trunk line,

installed with a terminating resistor.

NOTE: Typically, a Master DeviceNet unit installed at one end of the trunk line

and NOT on a drop cable.

5

4

3

2

1

Module Status (MS)

Network Status (NS)

SW1

PC/104 Connector

PC/104 Connector

P1/P3

P2/P4

Figure 6. Smart Trac DeviceNet Card layout.

CAUTIONCAUTION

Ensure all strands of wire go into connector. Bent strands may

2. If your Smart Trac AC1 is at the end of DeviceNet network, connect a

120-ohm resistor from pin 2 to pin 4 of the 5-pin connector at J2.

Connector pinouts are described in Table 2.

cause shorts to the adjacent terminal. Failure to comply may

result in damage to the DeviceNet card or Smart Trac

electronics.

Table 2. DeviceNet connector pinout

Smart Trac DeviceNet Card 5-pin Connector

Technical Manual 3554-0070 Installing the Smart Trac DeviceNet Card •• 13

Page 18

SMART TRAC DeviceNet Card

1 2 3 4 5

DeviceNet

Color Code

V+

CANH

SHIELD

CANL

V-

Red

White

Bare

Blue

Black

DeviceNet

Color

Pin

1 Black V- Network negative 24 VDC power supply terminal.

2 Blue CANL A CAN communication bus terminal (one of a pair)

3 Bare Shield Network cable shield terminal. Connect directly to

4 White CANH A CAN communication bus terminal (one of a pair)

5 Red V+ Network positive 24 VDC power supply terminal.

Code Purpose Description

Connect to external 11-25 VDC power supply if

network cable does not have power supply

conductors.

that carries the encoded serial data from one node

to another. The signal pair is based on the

Controller Area Network Specification from Bosch.

Connect shielded twisted pair cable here.

earth ground at only one point in the network, by

the power supply connection.

that carries the encoded serial data from one node

to another. The signal pair is based on the

Controller Area Network Specification from Bosch.

Connect shielded twisted pair cable here.

Connect to external 11-25 VDC power supply if

network cable does not have power supply

conductors.

14 •• Installing the Smart Trac DeviceNet Card Technical Manual 3554-0070

Page 19

SMART TRAC DeviceNet Card

THIS PAGE INTENTIONALLY LEFT BLANK

Technical Manual 3554-0070 Installing the Smart Trac DeviceNet Card •• 15

Page 20

Page 21

SMART TRAC DeviceNet Card

Configuring the Smart Trac

DeviceNet Card

Configuration

You configure the Smart Trac DeviceNet card by either accepting default values

or changing them to suit your unique situation. The values chosen at installation

of the Smart Trac DeviceNet driver must match those set on the card.

Interrupt

Default Settings

The Smart Trac DeviceNet card is shipped from the factory already configured

for the typical installation. The default values are:

• Interrupt: "7" The physical IRQ implements up to 8 logical

interrupts, determined by the application program.

• Base I/O Address (Switch SW1): 0x250 (positions 2 and 4 set to logic

"1", the other positions set to "0." Positions 1-6 of this switch determine

the base I/O address. This default setting causes the card to use the

eight I/O addresses 0x250 through 0x257.

• Memory Address: 0xC8000.

Be sure to set each device's MAC ID correctly to avoid addressing conflicts.

Many simple devices are DIP switch configurable. However, more sophisticated

devices are configured online via the network. Such devices require a DeviceNet

management utility to be properly configured. It is recommended that you use

an ODVA-approved software package to configure your device.

Non-Default Settings

The interrupt may be set to either 5 or 7, with 7 the default and preferred as the

"standard" configuration for Smart Trac components. Using interrupt 7 assures

you that there will be no conflicts with other basic components. Interrupt 5

should be reserved for only unusual situations.

Technical Manual 3554-0070 Configuring the Smart Trac DeviceNet Card •• 17

Page 22

SMART TRAC DeviceNet Card

Base I/O Address

In unusual situations, you may use several other Base I/O Addresses. If an

option must be considered, record the settings of all other cards to be placed in

the Smart Trac card stack. You must maintain unique addresses and interrupts

for all cards in the stack. The recommended optional addresses and

corresponding switch setting (SW1) are listed below:

I/O

Address

0x250 0 1 0 1 0 0 Default

0x258 1 1 0 1 0 0 Recommended as option

0x260 0 0 1 1 0 0 Recommended as option

0x268 1 0 1 1 0 0 Recommended as option

0x650 0 0 1 1 0 1 Recommended as option

0x658 1 0 1 1 0 1 Recommended as option

0x660 0 0 1 1 0 1 Recommended as option

0x668 1 0 1 1 0 1 Recommended as option

1 2 3 4 5 6

SW1 Setting Comment

18 •• Configuring the Smart Trac DeviceNet Card Technical Manual 3554-0070

Page 23

SMART TRAC DeviceNet Card

Testing Card Installation

Testing the Network

Once installed, check the on-board indicator lights. Normally, both LEDs should

be illuminated green and steady (not flashing), indicating the program is loaded

and running, it is an active participant in network activities, and that polled

connections are established with slaves.

General Test

Parameters

Network Termination

& Signal Wires

Shield

• To properly test your DeviceNet network, perform all of the following

steps below in sequence, since some tests require that previous tests

were successful:

NOTE: Do not perform these tests while the system is operating. There must not

be any communications activity.

1. Ensure all devices are installed.

2. Check the resistance from CANH to CANL at each device

• If the value is > 60 ohms there could be a break in one of the signal

wires or missing network terminator(s)

• If the value is < 50 ohms look for; a short between the network

wires, extra terminating resistor(s), faulty node transceiver(s) or

unpowered nodes

3. Power-up all power supplies. Connect a DC ammeter (16 amps max)

from DC common to the shield at the opposite end of the network from

the power supply. There should be no significant current flow. This test

can also be performed at the end of each drop if practical.

• If there is no current, the shield is broken or the network is

improperly grounded

• If the power supply is in the middle of the network, do this test at

each end

Grounding

Technical Manual 3554-0070 Testing Card Installation •• 19

4. Break the shield at a few points in the network and insert a DC

ammeter

• If there is current flow, the shield is connected to DC common or

ground in more than one place (ground loop)

Page 24

SMART TRAC DeviceNet Card

Network Power Minimum supply

voltage

Network Power Common Mode

Voltage

MAC ID/ Baud Rate

Settings

5. Measure the supply voltage at each device. It should be > 11Vdc.

• If not, check for faulty or loose connectors and verify power

system design calculations by measuring current flow in each

section of cable with an ammeter

NOTE: Shield must be continuous and have no current flow in it (tested

previously)

6. Measure and record the voltage between the shield and DC common at

each device. The maximum difference should be < 5V between any two

devices.

7. Check the Network Status LED (see "On-board Indicator Lights." The

LED should be steady green on all devices, or flashing green if polled

connections are not established.

• Solid RED indicates a communication fault (possibly incorrect

baud rate) or a duplicate MAC ID (station address)

8. Use a network configuration tool to perform a "network who" to verify

that all stations are connected and capable of communicating

On-board Indicator Lights

Two LED indicator lights on the Smart Trac DeviceNet card provide systemrelated information:

• Module Status (MS) LED: A two-color LED indicates whether or not

the application program loaded properly. When GREEN, it indicates

that the application program is loaded and running. When RED, it

indicates the application program has not loaded, an error occurred

during the load, or a fatal runtime error occurred.

Table 3. Interpretation of the Module Status Indicator

Module Status (MS) Indicator LED

LED State Device State Description

OFF No power Power is not being supplied to

device.

Flashing GREEN In Standby Needs commissioning due to

missing, incomplete, or

incorrect configuration

parameters.

Solid GREEN Operational Operating in normal condition.

Flashing RED Minor Fault Recoverable fault active.

Solid RED Unrecoverable

Fault

Flash rate for LED is approximately 1 flash per second: ON for

approximately 0.5 second, then OFF for approximately 0.5 second.

Unrecoverable fault active.

20 •• Testing Card Installation Technical Manual 3554-0070

Page 25

SMART TRAC DeviceNet Card

• Network Status (NS) LED: A two-color LED indicates network

communications status. When solid GREEN, it indicates that it is

online and connected to other devices. When flashing GREEN, it

indicates it is online but has not established a network I/O connection.

When solid RED, it indicates that it has not established a network I/O

connection, possibly because a duplicate MAC ID was detected, a busoff conditions exists, or a communications failure. When flashing RED,

the connection has timed out.

Table 4. Interpretation of the Network Status Indicator.

Network Status (NS) Indicator LED

LED State Device State Description

OFF Off-line or not

powered up

Flashing GREEN On-line and NOT

connected

Solid GREEN On-line and

connected

Flashing RED Connection Time-Out One or more of the I/O

Solid RED Critical Link Failure Failed communication device.

Flash rate for LED is approximately 1 flash per second: ON for approximately 0.5

second, then OFF for approximately 0.5 second.

Off-line:

Device has not completed the

duplicated MAC ID (node

address) check.

Device may not be powered.

Check Module Status LED.

On-line, but has no connections

in established state:

Device passed the duplicate

MAC ID (node address) check,

but has no established

connections to other nodes.

On-line and has connections in

established state.

Connections are in the Timedout state. The Smart Trac AC1

has probably stopped polling

slave devices.

An error has been detected that

has rendered the device

incapable of communicating on

the network.

A duplicate MAC ID (node

address) error was detected.

A bus-off condition exists.

Technical Manual 3554-0070 Testing Card Installation •• 21

Page 26

SMART TRAC DeviceNet Card

Module and Network Status LEDs at

Power-Up

At power-up, the LEDs are tested using the following sequence:

1. Module Status LED on GREEN for 0.25 second.

2. Module Status LED on RED for 0.25 second.

3. Module Status LED on GREEN for 0.25 second.

4. Network Status LED on GREEN for 0.25 second.

5. Network Status LED on RED for 0.25 second.

NOTE: The above power-up sequence only occurs if a valid user program is

loaded in the Smart Trac CPU Card.

22 •• Testing Card Installation Technical Manual 3554-0070

Page 27

SMART TRAC DeviceNet Card

Troubleshooting Your Smart

Trac DeviceNet Card

Status and Error Messages

When installed, the Smart Trac DeviceNet driver automatically creates a set of

global variables that provides status and error information on the CAN bus.

Symbolic information is appended to the end of the card name to create each

global variable. Deleting the card name in the dialog disables the creation of

these variables.

These global variables may be assigned symbol names and used in function

blocks, application programs and/or the fault manager. If read by the fault

manager, they may be programmed to annunciate and/or to be displayed on the

Digital Operator as they occur.

Table 5. Status and Error Message Global Variables

Status and Error Message Global Variables

Global Variable (format

is <Card Name>_Variable

<Card Name>_CAN_A

<Card Name>_CAN_ACK

<Card Name>_CAN_BO

Type Source Action

BOOL CAN Bus

Status

Word, Bit

3 (A)

WORD CAN ack

counter

at offset

0034h

BOOL CAN Bus

Status

Word, Bit

2 (BO).

Set when network activity detected

(messages received or transmitted).

Incremented when transmit message

aborted due to lack of

acknowledgment from other stations.

The CAN TX counter is decremented

to compensate for a message not

actually transmitted.

Set when excessive number of

communication errors is detected and

CAN chip automatically goes off-line.

Cleared when CAN interface is reinitialized. BO indicates a serious

communication fault such as incorrect

baud rate or physical layer error

(short, open etc).

Technical Manual 3554-0070 Troubleshooting Your Smart Trac DeviceNet Card •• 23

Page 28

SMART TRAC DeviceNet Card

Status and Error Message Global Variables

Global Variable (format

is <Card Name>_Variable

<Card Name>_CAN_BP

<Card Name>_CAN_BW

<Card Name>_CAN_ER

<Card Name>_CAN_ERROR

<Card Name>_CAN_LOST

<Card Name>_CAN_ML

<Card Name>_CAN_O1

<Card Name>_CAN_O2

<Card Name>_CAN_O5

Type Source Action

BOOL CAN Bus

Status

Word, Bit

9 (BP)

BOOL CAN Bus

Status

Word, Bit

1 (BW

BOOL CAN Bus

Status

Word, Bit

8 (ER).

WORD CAN

error

counter

at offset

0038h

WORD CAN

LOST

counter

at offset

003Ah.

BOOL CAN Bus

Status

Word, Bit

7 (ML)

BOOL CAN Bus

Status

Word, Bit

12 (O1)

BOOL CAN Bus

Status

Word, Bit

13 (O2)

BOOL CAN Bus

Status

Word, Bit

14 (O5).

Indicates presence or absence of

network power. BP bit is clear if the

physical bus interface is not powered.

Set when abnormal number of

communication errors detected and

CAN chip stops transmitting error

frames.

Cleared when error count returns to

normal levels or CAN interface reinitialized.

BW indicates potentially serious

communication fault such as out-oftolerance baud rate or physical layer

error (electrical noise, signal

attenuation, intermittent connections

etc.).

Set each time a CAN communication

error is detected. An excessive

number of errors indicates a faulty

physical media component (cable,

connector etc.) or excessive noise

from external sources (check cable

routing and shield connection).

The CAN communication error counter

is incremented when a CAN frame

error is detected

The CAN lost messages counter is

incremented when a CAN message is

received before the previous message

is placed into the receive queue.

ML is set when a message is received

from the bus while the previous

message is still in the receive buffer.

ML indicates a lower layer application

error (in the kernel interrupt handler).

Report this condition to your

MagneTek Application Engineer.

O1 is set when the scanner is online at

125 Kbaud.

O2 is set when the scanner is online at

250 Kbaud

O5 is set when the scanner is online at

500 Kbaud.

24 •• Troubleshooting Your Smart Trac DeviceNet Card Technical Manual 3554-0070

Page 29

SMART TRAC DeviceNet Card

Status and Error Message Global Variables

Global Variable (format

is <Card Name>_Variable

<Card Name>_CAN_OL

<Card Name>_CAN_OR

<Card Name>_CAN_RO

<Card Name>_CAN_RX

<Card Name>_CAN_SA

<Card Name>_CAN_TA

<Card Name>_CAN_TO

<Card Name>_CAN_TX

Type Source Action

BOOL CAN Bus

Status

Word, Bit

0 (OL)

WORD CAN

overrun

counter

at offset

003Ch

BOOL CAN Bus

Status

Word, Bit

6 (RO).

WORD CAN RX

counter

at offset

0036h

BOOL CAN Bus

Status

Word, Bit

15 (SA)

BOOL CAN Bus

Status

Word, Bit

4 (TA).

BOOL CAN Bus

Status

Word, Bit

5 (TO).

WORD CAN TX

counter

at offset

0032h.

Set when CAN interface initialized and

ready to communicate.

CAN receive queue overrun counter is

incremented when a CAN message is

lost due to a full receive queue.

Set when messages received from

bus faster than application can

process them. RO indicates an upper

layer application error (in the

application module). Report this

condition to your MagneTek

Application Engineer.

CAN receive counter is incremented

when messages are received.

Messages that fail the receive filter still

increment the CAN RX counter.

SA is set when the scanner is active

TA set when a pending transmission is

not acknowledged within 25-50ms. TA

indicates that no other nodes are

present (or on-line) on the network

Set when a pending transmission is

incomplete within 25-50ms. TO

indicates excessive message traffic at

a higher priority than the aborted

message.

The CAN transmit counter is

incremented when messages are

submitted to the CAN controller

Troubleshooting DeviceNet Network

Problems

Use the following general guidelines to troubleshoot your DeviceNet network:

1. Disconnect parts of the network and watch where the fault goes. This

method does not work well for problems such as excessive common

mode voltage, ground loops, electrical interference and signal distortion

because disconnecting part of the network frequently solves the

problem.

2. If the network was previously operating, determine what has changed.

3. Record symptoms in detail. Keep good notes about your network and

its problems to properly define the problem.

Technical Manual 3554-0070 Troubleshooting Your Smart Trac DeviceNet Card •• 25

Page 30

SMART TRAC DeviceNet Card

• Look for patterns in the symptoms. Do intermittent problems occur

when other un-related equipment is in use?

• Do some nodes communicate correctly? What is the difference

between the functioning nodes and the others (proximity to the

power supply, to the terminator, to the scanner)?. Is the device

improperly shielded or tied to ground at each device instead of at

ends?

Table 6. Hardware Configuration Troubleshooting.

Troubleshooting Hardware Configuration

Probable

Symptom

Cause Corrective Action

Devices will

not

communicate

Baud rate

not same for

all devices

MAC IDs not

unique for

each device

on network.

Faulty

devices

Opens or

shorts in the

network

wiring

Incorrect

Baud Rates

on some

devices

Electrical

interference

Signal

distortion &

attenuation

Missing

terminators

Excessive

common

mode

voltage

Check that baud rate is set correctly for

each device on the network.

Check MAC Ids for all devices on the

network.

Check for faulty connectors or cable.

Check that baud rate is set correctly for

each device on the network.

Check for incorrect grounding or broken

shield.

Check for improper termination such as a

failure to adhere to topology guidelines,

or faulty connectors or loose terminal

blocks.

Check for excess current or cable length.

Check for faulty connectors.

Low power

supply

voltage

Check for excess current or cable length

Check for faulty connectors

Check that power supply is correctly

sized for number of devices in network

Excessive

Check for excess cable length.

signal

propagation

delay

26 •• Troubleshooting Your Smart Trac DeviceNet Card Technical Manual 3554-0070

Page 31

SMART TRAC DeviceNet Card

Appendix A – Technical Support

Technical Support

Should you need technical assistance with installation or troubleshooting of your

Smart Trac AC1, you can phone our Help Desk at either (800)-541-0939 or

(414)-782-0200. Alternatively, you may copy the Problem Report form, found

on the next page, and fax it to us at (414)-782-3418.

References

CAN (Controller Area

Network)

DeviceNet Contact the Open DeviceNet Vendor

MagneTek Drives and

Systems

Contact CAN in Automation (CiA), the

international users and manufacturers group, a

non-profit trade association that develops and

supports various CAN-based protocols

including DeviceNet.

http://www.can-cia.de

Association, Inc. at:

http://www.odva.org

For more information about MagneTek drives

and systems, training programs and contacts,

visit:

http://www.magnetekdrives.com

PC/104 Specification,

Version 2.1

Technical Manual 3554-0070 Appendix A – Technical Support •• 27

PC/104 Consortium. An overview and the

specification may be obtained at the web site

address:

http://www.controlled.com/pc104/index.html

Page 32

SMART TRAC DeviceNet Card

Problem Report

Name:

Address:

City: State: Zip

Serial Number: Smart Trac DeviceNet Card

Occurrence: Frequently Intermittantly Rarely

Nature of Problem:

Conditions when problem occurs:

28 •• Appendix A – Technical Support Technical Manual 3554-0070

Page 33

SMART TRAC DeviceNet Card

Appendix B – Replaceable Parts

Replaceable Parts Listing

Description MagneTek Part

Number

Smart Trac DeviceNet Network

Interface option kit

Technical Manual – Smart Trac

DeviceNet Card

Standoff, 4.5mm, Hex, Stl, CL ZINC,

15mm, M/F, M3, M3

Card Extraction Tool (Parvus Corporation

Hardware Tools Kit for Smart Trac

AC1

46S03643-0070 1

TM 3554-0070 1

05P00618-0006 4 each

P/N PRV-0760A-

01)

TBD Option

Qty

DeviceNet

assy

Option

Technical Manual 3554-0070 Appendix B – Replaceable Parts •• 29

Page 34

SMART TRAC DeviceNet Card

THIS PAGE INTENTIONALLY LEFT BLANK

30 •• Appendix B – Replaceable Parts Technical Manual 3554-0070

Page 35

SMART TRAC DeviceNet Card

Appendix C – Removing the

Smart Trac Card Stack

General Procedures

1. Power off the Smart Trac AC1. Disconnect it and tag "Out of Service".

2. Do one of the following:

• Open the cover to the Smart Trac AC1 by rotating the spring-

loaded, captive screw counterclockwise. Use a large screwdriver if

necessary to free the slotted screw.

OR

• Loosen the screws holding down the cover.

3. Disconnect the 12-pin wiring harness from connector J4 at the digital

operator.

4. Using the Phillips head screwdriver, remove the ground strap from the

left inside and the ground strap from the top inside of the Smart Trac

AC1 adapter ring.

5. Disconnect the 9-pin RS-232 cable at connector J5 on the Smart Trac

CPU card.

Technical Manual 3554-0070 Appendix C – Removing the Smart Trac Card Stack •• 31

Page 36

chassis

board

SMART TRAC DeviceNet Card

12-pin wiring

harness on

Digital Operator

attached to

connector J4 on

Smart Trac

CPU Card

Digital

Operator

9-pin RS-232

cable

attached here

4mm screws

(4 places)

secure ring

to main

Standoffs (4

places)

secure each

board

Smart Trac

Board Stack

PC/104

9-pin RS-232

cable

connector J5

6. Using a 4.5mm hex head driver, remove four standoffs from the

topmost card.

7. Using the PC/104 extraction tool, remove the topmost card from the

stack.

Position

rectangular

"jacks"

around

edges of

PCBs

Squeeze to lift

cards apart

Figure 7. Using the PC/104 Extraction Tool.

8. Repeat step 8 above until all PC/104 cards have been removed.

9. To remove the Smart Trac PG card:

• Disconnect the 4CN connector on the PG card.

• Using a tubular extraction tool or pliers, squeeze the plastic,

spring-loaded retainer built-in to the long plastic standoff located

at the top of the PG card, just above connector J6.

• Using a PC/104 extraction tool, remove the card.

NOTE: The Smart Trac PG card requires unique handling. Wedge the extracting

tool between the PG card and the CPU card. The area between the terminal strip

on the CPU card and the serial numbered edge of the PG card can be lifted first,

then the opposite side (nearest TB1) on the PG card). Alternate sides until the

card is free of the CPU card.

10. To remove the Smart Trac CPU card:

32 •• Appendix C – Removing the Smart Trac Card Stack Technical Manual 3554-0070

Page 37

SMART TRAC DeviceNet Card

• Disconnect the card at the 2CN connector on the CPU card.

• The CPU card is secured with three plastic standoffs with spring-

loaded clips on the end. Squeeze the top of the standoffs (the clips)

with the special cylindrical removal tool, your fingers or needlenosed pliers and lift the CPU card from the Smart Trac Inverter

Control Card.

You have removed the entire card stack. The inverter card, considered part of

the drive, is in clear view.

Technical Manual 3554-0070 Appendix C – Removing the Smart Trac Card Stack •• 33

Page 38

Page 39

Glossary of Terms

SMART TRAC DeviceNet Card

Bit Strobed I/O

commissioning

Controller Area

Network

data link layer

explicit messaging

A type of message between Master and Slave devices on a DeviceNet network.

A Bit-Strobe Command message provides 1-bit of data to each Slave. It is sent

by the Master in a specified time interval. A Bit-Strobe Response message

contains the Slave's response to a Bit-Strobe command by providing up to 8 bits

of data back to the Master.

The act of configuring a new DeviceNet network, such as setting baud rate,

MAC ID, and device attributes for all connected nodes on a network.

A type of network (CAN) originally developed for the auto industry. It was later

found useful for many other industrial applications. CAN's communication

protocol is used in DeviceNet because it provides high noise immunity and high

temperature operation. Because it uses a serial bus, it reduces signal wiring

complexity and cost while providing high speed digital control for optimum

performance.

The second lowest layer in the OSI seven-layer model. It splits data into frames

for sending on the physical layer and receives acknowledgement frames. It

performs error checking and re-transmits frames not received correctly. The data

link layer is split into an upper sublayer, Logical Link Control (LLC), and a

lower sublayer, Media Access Control (MAC).

Messages between a Master device and a specific Slave device on a DeviceNet

network. Explicit Request messages, sent by the Master whenever a desired

service is required, may read data from the Slave, write data to the Slave, and/or

reset the Slave. Explicit Response messages are sent by a Slave back to the

Master after receiving an Explicit Request message.

MAC ID

open network

standard

OSI

Technical Manual 3554-0070 Glossary of Terms •• 35

Acronym for Media Access Control Identifier. The identifier or address for the

lower sublayer of the data link layer of the OSI networking model. The MAC is

the interface between a node's Logical Link Control and the network's physical

layer.

An established standard for networking devices that does not require vendors to

purchase hardware, software, or licensing rights to connect devices to a system.

Acronym for Open Systems Interconnect, a model used to describe a network.

The system describes a network in terms of seven layers. Each layer provides a

set of functions to the layer above, and relies on the functions of the layer below.

Each layer communicates with its peer layer on another node by sending

messages back and forth. OSI was developed by the International Standards

Organization (ISO) in 1978. The model was mandated for use by the U.S.

Government until 1995.

Page 40

SMART TRAC DeviceNet Card

physical layer

Polled I/O

protocol

topology

The lowest layer in the OSI seven-layer model. It concerns electrical and

mechanical connections and MAC. It is used by the data link layer. Example

physical layer protocols are CSMA/CD, token ring and bus

Communications messages, 8 bits at a time, used to send commands from

Master to Slave at specified time intervals and provide Slave response to the

Master.

A set of formal rules describing how to transmit data, especially across a

network. At a low level, a protocol defines the electrical and physical standards

to be observed, bit- and byte-ordering and the transmission and error detection

and correction of the bit stream. At higher levels, protocols describe data

formats, including the syntax of messages, handshaking (terminal-to-computer

dialogue), character sets and the sequence of messages, among other related

structures.

The way in which devices on a network are physically connected: star, bus, ring

or mesh. The topology may define transmission media, adapters, and physical

design of the network.

36 •• Glossary of Terms Technical Manual 3554-0070

Page 41

Index

SMART TRAC DeviceNet Card

explicit messaging 3

extraction tool 32

F

fault manager 23

G

General Capabilities 3

global variables 23

ground 11

Grounding 19, 26

H

A

address

memory 17

application protocol 5

B

Baud Rate

and MAC ID settings 20

baud rates 4

Bit Strobed I/O 3

C

Capabilities, Smart Trac DeviceNet

Card 3

Configuring the Smart Trac

DeviceNet Card 17

Connecting to a DeviceNet

Network 12–13

Connector 4, 9, 12–13, 24, 31, 32,

33

Connector, 5-pin 13

Controller Area Network 3, 6, 14,

27

CPU 31

Help Desk 27

I

indicator lights 19–20, 19

information, safety 2

Installation

Termination and Signal Wires 19

Testing Card 19

Testing the Network 19

Installation, Smart Trac DeviceNet

Card 11

Interrupt 17, 24

Inverter 33

L

LEDs 19–20, 19

Module and Network Status at

Power-up 22

On-board Indicator Lights 19–20

Length

Both Thin and Thick Cables 8

Network 7

Line Length with both Thick and

Thin Cables 8

Line Length with Thin or Thick

Cable 7

D

M

data link layer 5–6

Default Settings 4, 17

DeviceNet Network Topology 6

Digital Operator 23

E

electrostatic sensitive discharge 11

ESD 11

ESD Procedures 2, 11

Technical Manual 3554-0070 Index •• 37

MAC ID/ Baud Rate Settings 20

MAC-ID 6

Media Access Control Identifiers 6

media, transmission 5

Memory Address 17

messaging, explicit 3

Module and Network Status LEDs

at Power-Up 22

Module Status 20–22, 20–22

Page 42

SMART TRAC DeviceNet Card

N

names, symbol 23

Network Length 7

Thick or Thin Cables 7

Network Power - Common Mode

Voltage 20

Network Power - Minimum supply

voltage 20

Network Status 4, 20–22,

Network Termination & Signal

Wires 19

O

ODVA 3, 17, 27

On-board Indicator Lights 19–20

Operating temperature 4

Optional Parts 29

OSI Model

application protocol 5

data link layer 5–6

physical layer 5, 23

transmission media 5

P

parts

optional 29

PC/104 27

physical layer 5, 23

Polled I/O 3

Problem Report 27

protocol 5

module 20–22

network 4, 20–22

Status and Error Messages 23

Storage temperature 4

strap

wrist 11

symbol names 23

T

Technical Manual 2, 11

temperature

operating 4

Terminating Resistor

Specifications 9

termperature

storage 4

Testing the Network 19

Thick Cable Specifications 8

Thin Cable Specifications 8

tool, extraction 32

Topology 6–7, 26

transmission media 5

Troubleshooting

DeviceNet Network Problems 25

Status and Error Messages 23

Troubleshooting 27

Troubleshooting Your Smart Trac

DeviceNet Card 23

U

Unpacking 11

Q

Quick Start 4

R

report

problem 27

S

safety information 2

scan list 3

Shield 8, 14, 19, 24, 26

Smart Trac AC1

on a DeviceNet Network 3

Specifications 3–4, 8–9

Terminating Resistor 9

Thick Cable 8

Thin Cable 8

static electricity 2, 11

status

38 •• Index Technical Manual 3554-0070

V

variables, global 23

W

Warranty 2

wrist strap 11

Page 43

SMART TRAC DeviceNet Card

Data subject to change without notice. Smart Trac is a trademark of MagneTek, Inc. MicroTrac is a registered trademark of MagneTek, Inc. Microsoft, Windows and Windows NT are registered

trademarks of Microsoft Corporation

MagneTek

Drives and Systems

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939, (262) 782-0200, FAX (262) 782-3418

TM 3554-0070 © 1999-2000 MagneTek, Inc. 1/31/2000

Loading...

Loading...