Page 1

S

S

M

M

A

A

R

R

T

T

T

T

R

R

A

A

Technical Manual

™

™

C

C

C

C

C

C

P

P

arr

a

U

U

d

d

Page 2

Page 3

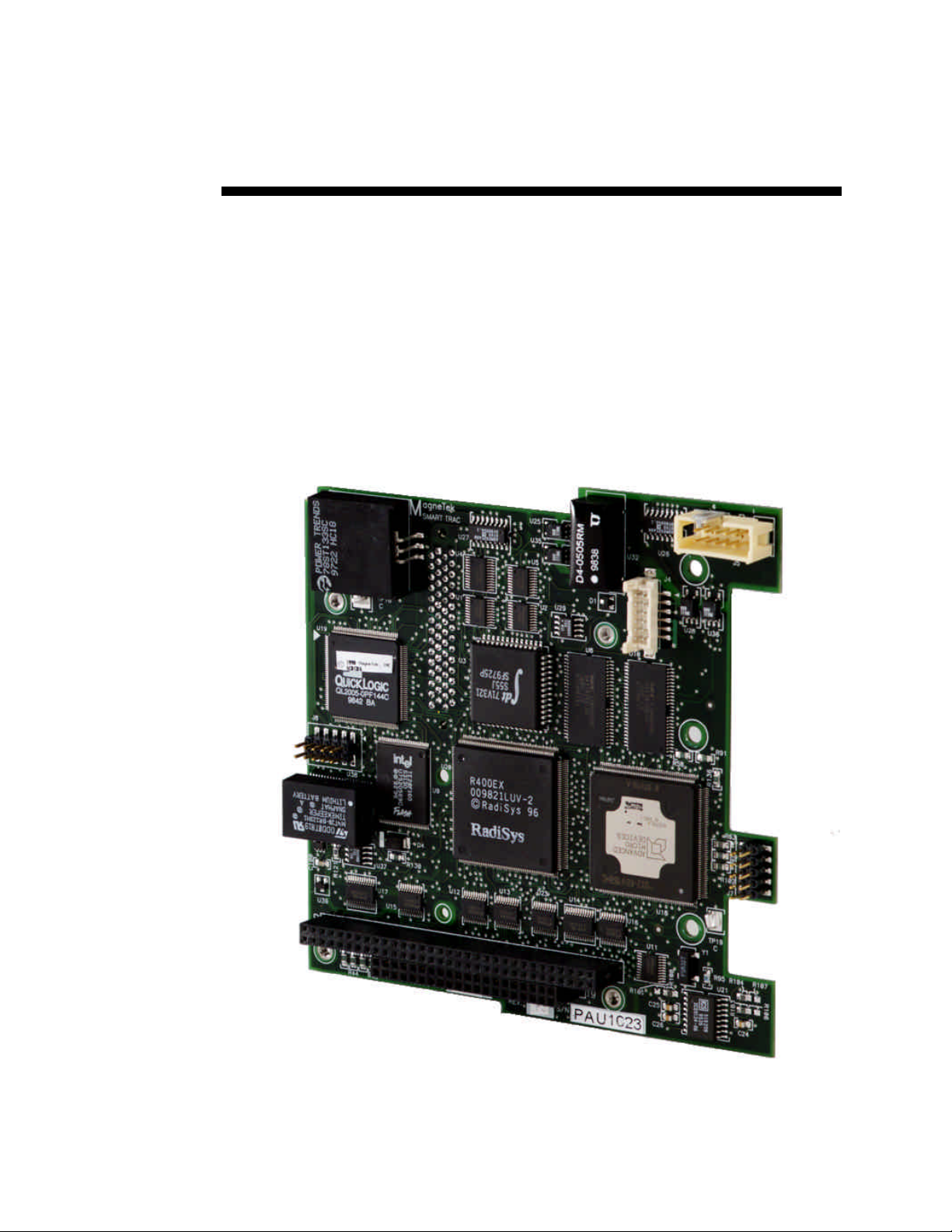

SMART TRAC CPU Card

Contents

Important Safety and Warranty Information 1

Warnings, Cautions and Notes.....................................................................................................................1

General Safety Precautions - Warnings ......................................................................................................2

Important Warranty Information................................................................................................................2

Smart Trac CPU Card 3

General Capabilities......................................................................................................................................3

Specifications .................................................................................................................................................3

Quick Start.....................................................................................................................................................4

Installing the Smart Trac CPU Card 5

Unpacking ......................................................................................................................................................5

Electrostatic Sensitive Discharge (ESD) Procedures ........................................................................5

Unpacking Procedure........................................................................................................................5

Installing the Smart Trac CPU Card...........................................................................................................5

Interrupts and Addresses Used by the Smart Trac CPU Card 9

Configuration.................................................................................................................................................9

Default Interrupts and Base I/O Addresses ................................................................................................9

CPU Card Layout........................................................................................................................................10

Testing Card Installation 13

Booting and Power-Up Self-Test................................................................................................................13

Normal Boot Messages................................................................................................................................13

Troubleshooting Your Smart Trac CPU Card 15

Operating System Status and Error Messages..........................................................................................15

Offset Kernel/Boot Download Errors to 20100 - 20149............................................................................18

Offset I/O Errors from 1 - 59 to 20201 - 20259.........................................................................................19

Offset Trace Errors to 20300 to 20399.......................................................................................................19

Troubleshooting CPU Problems.................................................................................................................19

Battery Low.....................................................................................................................................19

Problems with Other Cards........................................................................................................................20

Corrective Maintenance 21

Replacing the Battery..................................................................................................................................21

Battery Storage............................................................................................................................................22

Proper Battery Disposal..............................................................................................................................22

Technical Manual Contents •• i

Page 4

SMART TRAC CPU Card

Appendix A – Technical Support 23

Getting Help.................................................................................................................................................23

References ....................................................................................................................................................23

Problem Report ...........................................................................................................................................25

Appendix B – Replaceable Parts 27

Replaceable Parts Listing ...........................................................................................................................27

Appendix C – Removing the Smart Trac Card Stack 29

General Procedures.....................................................................................................................................29

Glossary of Terms 33

Index 35

ii •• Contents Technical Manual

Page 5

SMART TRAC CPU Card

Important Safety and Warranty

Information

Warnings, Cautions and Notes

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or death.

WARNING - ESD

A statement of conditions which must be observed to prevent

damage to components due to ESD (ElectroStatic Discharge) and

to prevent personal injury or death.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults, Smart Trac AC1 system degradation

and damage to equipment.

IMPORTANT

A statement of conditions which should be observed during Smart Trac AC

DeviceNet setup or operation to ensure dependable service.

NOTE: Notes indicate information that is in addition to a discussion of the topic

in adjoining text. Alternatively, it may limit or restrict the paragraph(s) that

follow(s) to specific models or conditions.

TIP - Tips indicate information that should make a procedure easier or more

efficient.

Technical Manual Important Safety and Warranty Information •• 1

Page 6

SMART TRAC CPU Card

General Safety Precautions Warnings

Important safety information follows. Please read and understand all

precautions listed below before proceeding with the specification, installation,

set-up or operation of your Smart Trac AC1. Failure to follow any of the

following precautions may result in personal injury or death, or damage to the

equipment.

WARNING - ESD

The Control Printed Circuit Board (PCB) employs CMOS

Integrated Circuits that are easily damaged by static electricity.

Use proper ElectroStatic Discharge (ESD) procedures when

handling the Control PCB. See Smart Trac AC1 Technical Manual

for details. Failure to comply may result in damage to equipment

and/or personal injury.

Important Warranty Information.

Do not modify your Smart Trac AC1, its components, or any of the procedures

contained in the technical documentation supplied by MagneTek. Any

modification of this product by the user is not the responsibility of MagneTek

and will void the warranty.

2 •• Important Safety and Warranty Information Technical Manual

Page 7

Smart Trac CPU Card

General Capabilities

The Smart Trac CPU card permits a Smart Trac AC1 to be quickly programmed

for custom applications using IEC-61131-3 languages. These languages include

Relay Ladder Logic (RLL), Sequential Function Charts (SFC), Function Block

(FB) diagrams, Structured Text (ST), Instruction List (IL) and function blocks

written in the C programming language. It also provides for easily expanded

communications and/or extra Input/Output capabilities.

SMART TRAC CPU Card

The card executes user's programs, provides the interface between the digital

operator and the rest of the Smart Trac AC1, and communicates with other

computers for download, upload and monitoring of programs and data. It

connects to cards conforming to the PC/104 Specification. Several cards,

including option cards, may be added to interact with the Smart Trac CPU card

including: the Smart Trac PG card; Smart Trac Ethernet, Smart Trac LAN,

DeviceNet, Genius PCIM, Modbus, Profi-bus communications cards; and the

Smart Trac Multi-I/O card.

All option cards conform to the PC/104 Specification, Version 2.1. They stack

with the Smart Trac CPU card using its PC/104 expansion bus connector. The

Smart Trac CPU conforms to the PC/104 expansion bus.

Specifications

• Intel 486DX2/66 Mhz processor with 4 Megabytes RAM

• PC/104 expansion bus connector

• Executes programs compliant with IEC-61131-3 languages

• Isolated RS-232 Serial port

• 2 Megabytes programmable flash ROM

• 512 bytes Dual-port RAM

• 32 Kilobytes nonvolatile RAM

• Battery-backed real-time clock

• Chart recording buffer of up to 10 Smart Trac AC1 parameters

• On-board self-test runs at boot-up

Technical Manual Smart Trac CPU Card •• 3

Page 8

SMART TRAC CPU Card

Quick Start

1. Power OFF your Smart Trac AC1.

2. Remove all cards in the Smart Trac card stack except for the Inverter

card (bottom most card of the stack). The Smart Trac CPU card is last

to be removed.

3. Install the replacement Smart Trac CPU Card in your Smart Trac AC1

in the position just above the inverter card.

4. Replace all other cards in their proper position in the card stack.

5. Power up your Smart Trac AC1.

6. Set the Smart Trac system clock and any other boot menu parameters

your application may require.

7. Test your Smart Trac system.

4 •• Smart Trac CPU Card Technical Manual

Page 9

SMART TRAC CPU Card

Installing the Smart Trac CPU

Card

Unpacking

Electrostatic

Sensitive Discharge

(ESD) Procedures

Unpacking Procedure

WARNING WARNING -- ESD ESD

Keep electronic circuit boards in Electrostatic Discharge (ESD)

sensitive protective bags when not being handled. Use proper ESD

procedures (including an ESD wrist strap) when handling circuit

boards. Failure to comply may result in damage to equipment.

When working with an electrostatic discharge (ESD) sensitive device, you

should be grounded at all times. The easiest and most common way to provide

this ground is to use an approved ESD wrist strap. The strap is secured to your

wrist with a wire attached to the strap and clipped or taped to the chassis of the

unit being worked on. Any static is dissipated through the wire to ground,

greatly reducing the possibility of damage to the device.

It is a good idea to touch the chassis with your finger before handling any

electrostatic sensitive device. Any static electricity will be discharged to chassis

ground and will not be transferred to the device.

Always store devices (cards, other electronic components) in ESD protective

bags when not being handled.

Remove the protective shipping and packing material from the card. Ensure

contact wedges and other shipping devices have been removed.

Installing the Smart Trac CPU Card

The Smart Trac CPU Card must be positioned above the Smart Trac Inverter

Control card.

NOTE: If replacing a Smart Trac CPU card to an existing Smart Trac card

stack, see Appendix D – "Removing the Smart Trac Card Stack" before

continuing.

Technical Manual Installing the Smart Trac CPU Card •• 5

Page 10

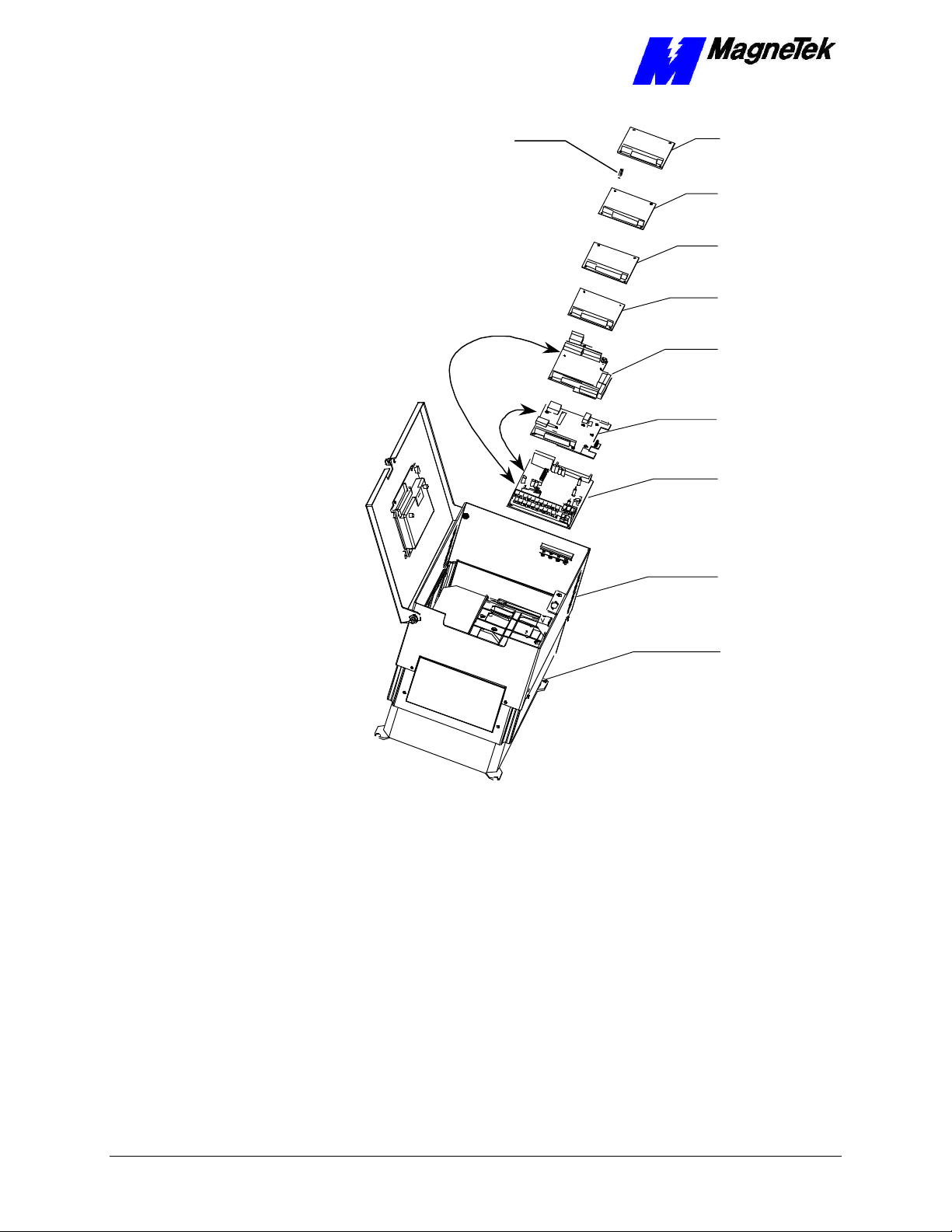

Smart Trac

SMART TRAC CPU Card

Standoffs (4

places on top of

each card)

4CN

Connector

Optional

PC/104

Card

Optional

PC/104

Card

Smart Trac

Ethernet

Card

Smart Trac

PS Card

Smart Trac

PG Card

2CN

Connector

CPU Card

Inverter Control

Card

Adapter

Ring

Main Chassis

Figure 1. Smart Trac CPU Card Stack Position.

1. Install the Smart Trac CPU card. Align the male PC/104 connector pins

on the Smart Trac CPU card with the female PC/104 connector on the

Inverter and the standoff holes with metal standoffs on the Inverter.

When in place, gently but firmly push the Smart Trac CPU card in

place on the Inverter card.

2. Orient the PG card so that the PC/104 connector and the J2 connector

align with the PC/104 connector on the Smart Trac CPU card and the

4CN connector on the Inverter Control board. Be careful to align the

PC/104 connector pins with the receptacle on the Smart Trac CPU card

so the pins don’t bend when the card is pushed into place.

3. Gently but firmly push the Smart Trac PG card onto the Smart Trac

CPU card. Make sure connecting pins are in alignment and J2 mates

with 4CN before pushing the two boards tightly together. Secure the

card using four (4) metal standoffs and one (1) plastic standoff.

6 •• Installing the Smart Trac CPU Card Technical Manual

Page 11

SMART TRAC CPU Card

4. Replace the Smart Trac PG Card and other cards by reversing the

instructions in "Appendix C – Removing the Smart Trac Card Stack".

Technical Manual Installing the Smart Trac CPU Card •• 7

Page 12

Page 13

SMART TRAC CPU Card

Interrupts and Addresses Used

by the Smart Trac CPU Card

Configuration

No configuration switches or jumpers exist on the Smart Trac CPU card. You

simply install the card and connect it as described in "Installing the Smart Trac

CPU Card."

Default Interrupts and Base I/O

Addresses

Interrupt Smart Trac Use Address

IRQ0 System, timer

IRQ1 Systsem, unused

IRQ2 Not available 0x2e0

IRQ3 COM2 Serial Port 0x2f8

IRQ4 COM1 Serial Port - Digital Operator Port 0x3f8

IRQ5 Ethernet card default 0x320

IRQ6 Available for PC/104 option cards

IRQ7 DeviceNet card default 0x250

IRQ8 System, Real-time Clock

IRQ9 ARCNET cascaded IRQ2 default 0x2e0

IRQ10 System, Internal Heartbeat --IRQ11 Smart Trac Genius PCIM default

IRQ12 Available for PC/104 option cards

IRQ13 System, Math coprocessor

IRQ14 Available for PC/104 option cards

IRQ15 Not Available in Smart Trac

Technical Manual Interrupts and Addresses Used by the Smart Trac CPU Card •• 9

Page 14

SMART TRAC CPU Card

Smart Trac CPU Card Layout

J5 Connector

agneTek

M

J4 Connector

Flash ROM

Lithium

Battery

CPU

J7 Connector

(Not Used)

PC/104 Connector

PC/104 Connector

46S03415-

REV. 01 S/N 0000001

Figure 2. Smart Trac CPU Card Layout.

J5 Connector Pinout

The pinout of Smart Trac CPU card connector J5 is shown in the table below.

One end of a ribbon cable plugs into J5 on the CPU card and the other end of the

cable plugs into DB9 connector on the front of the Smart Trac unit. The DB9

Connector, with only 9 pins, has no connection to the J5 pin.

Smart Trac

CPU card

connector

DB9 Pin #

1 1 NC No Connection

2 3 Tx Transmit (from

3 5 Rx Receive (to CPU)

4 7 NC No Connection

5 9 C5ISO Common

6 2 NC No Connection

7 4 CTS Clear to Send (to

8 6 RTS Request to Send

9 8 NC No Connection

- 10 NC No Connection

Smart Trac

Unit

connector J5

Pin #

Signal

Abbreviation

Signal

Description

CPU)

CPU)

(from CPU)

10 •• Interrupts and Addresses Used by the Smart Trac CPU Card Technical Manual

Page 15

Testing Card Installation

Booting and Power-Up Self-Test

Immediately after power-up of the Smart Trac AC1 with the CPU card installed,

the validity of the operating system is checked. The Smart Trac AC1 BIOS

(Basic Input Output System) performs a self-test to determine the integrity of

RAM, flash memory, system timers and interrupts, among other checks. Any

detected faults appear on the Smart Trac AC1 digital operator.

SMART TRAC CPU Card

Next, the system loads any installed drivers. It checks the validity of the user

program before starting its execution.

Once drivers are installed and the user program is validated, the system

performs according to the user program, responding with diagnostics and error

handling as necessary.

NOTE: If communication with the Smart Trac CPU and other cards in the

Smart Trac AC1 are not established within seven (7) seconds of power-up or

after about two (2) seconds without data being transferred, it will shut down.

The LEDs on the digital operator will flash, indicating this lack of

communication.

Normal Boot Messages

When you power-up your Smart Trac AC1, the operating system running within

the CPU displays a series of messages on the Digital Operator.

If MENU key is not pressed at power up, here is what you see:

Technical Manual Testing Card Installation •• 11

Page 16

SMART TRAC CPU Card

MagneTek

Smart Trac

Displayed for 2 seconds

Starting OS

Displayed for 0.25 second

Operating System

Running

For 0.25 second if Digital Operator

Driver installed. Otherwise,

displays continuously.

Press the MENU

Key to begin

Displayed until MENU key

pressed.

Figure 3. Normal Boot Messages.

If you press the Menu key on the Digital Operator within 2 seconds of the start

of the boot process, you will access the Boot Menu, allowing you to configure

various operating parameters. These parameters include TCP/IP Configuration,

Inverter Type, COM1 Configuration, Serial Download from COM1 or Flash

Memory erasure or programming mode, a check of the firmware version, and

Flash ROM access.

NOTE: The second boot message "Starting OS" can be read as an ASCII string,

output from serial port J5.

12 •• Testing Card Installation Technical Manual

Page 17

SMART TRAC CPU Card

Troubleshooting Your Smart

Trac CPU Card

Operating System Status and Error

Messages

Your application program may include programming code to display the

following messages on the Smart Trac AC1 Digital Operator.

These errors are OR'd with 0x80000000 before displaying on the Digital

Operator.

Possible Smart Trac Operating System Status and Error Messages

Hexadecimal

Message

PCODE_SUCCESS 0x00000000

PROG_EXIT 0x00000000

CONTINUE 0x00000001

INVALID_OPCODE 0x00000002 Std. Major Fault -

PSTACK_OVERFLOW 0x00000003 Std. Major Fault -

PSTACK_UNDERFLOW 0x00000004 Std. Major Fault -

PSTACK_CORRUPTED 0x00000005 Std. Major Fault -

BSTACK_UNDERFLOW 0x00000006 Std. Major Fault -

BSTACK_OVERFLOW 0x00000007 Std. Major Fault -

CSTACK_CORRUPTED 0x00000008

OPERAND_UNDERFLOW 0x00000009 Std. Minor Fault -

DIVIDE_BY_ZERO 0x0000000A Std. Minor Fault -

RESULT_UNDERFLOW 0x0000000B Std. Minor Fault -

RESULT_OVERFLOW 0x0000000C Std. Minor Fault -

INVALID_RESULT 0x0000000D Std. Minor Fault -

ADDR_MODE_UNKNOWN 0x0000000E Std. Major Fault -

ADDR_TYPE_MISMATCH 0x0000000F Std. Major Fault -

DATA_TYPE_UNKNOWN 0x00000010 Std. Major Fault -

DATA_TYPE_MISMATCH 0x00000012 Std. Major Fault -

INVALID_DATA_TYPE 0x00000013 Std. Major Fault -

INVALID_ADDRESS 0x00000014 Std. Major Fault -

OPERAND2_INVALID 0x00000015 Std. Major Fault -

OPERAND1_INVALID 0x00000016 Std. Major Fault -

JUMP_OUTOF_BOUNDS 0x00000017 Std. Major Fault -

ADDR_OUTOF_BOUNDS 0x00000018 Std. Major Fault -

UNKNOWN_FLOAT_ERROR 0x00000019 Std. Minor Fault -

FSTACK_OVERFLOW 0x0000001A Std. Minor Fault -

Address

Meaning

Technical Manual Troubleshooting Your Smart Trac CPU Card •• 13

Page 18

SMART TRAC CPU Card

Possible Smart Trac Operating System Status and Error Messages

Hexadecimal

Message

FSTACK_UNDERFLOW 0x0000001B Std. Minor Fault -

INVALID_OPERAND 0x0000001C Std. Major Fault -

NEG_VALUE 0x0000001D Std. Minor Fault -

MALLOC_FAILED 0x0000001E Std. Major Fault -

INVALID_ACTION 0x0000001F Std. Major Fault -

IO_READ_FAILED 0x00000020 Std. Major Fault -

IO_WRITE_FAILED 0x00000021 Std. Major Fault -

CCALL_FAILED 0x00000022 Std. Major Fault -

STRING_OVERRUN 0x00000023 Std. Minor Fault -

NUM_SHIFTBITS_NEG 0x00000024 Std. Minor Fault -

INVALID_COERCION 0x00000025 Std. Major Fault -

INVALID_ADDR_MODE 0x00000026

INVALID_BIT_NUM 0x00000027

INVALID_DATASIZE 0x00000028

BIT_NUM_OUT_OF_RNG 0x00000029

INVALID_C_FUNC_PTR 0x0000002A

INVALID_LOWER_BND 0x0000002B

INVALID_UPPER_BND 0x0000002C

DATE_TIME_INVALID 0x0000002D

MSG_STRLEN_INVALID 0x00004000

USER_TASK_HUNG 0x00007FF8

NO_STARTUP_ROUTINE 0x00007FF9

BREAKPOINT_SET 0x00007FFA

OFFSET_OUT_OF_RNG 0x00007FFB Std. Major Fault -

TASK_OVERRUN 0x00007FFC Std. Major Fault -

TASK_RESTART_FAIL 0x00007FFD Std. Major Fault -

WATCHDOG_TIMEOUT 0x00007FFE Std. Major Fault -

OH_SHTUFF 0x00007FFF Std. Major Fault -

Address Meaning

These following error codes are not OR'ed with 0x80000000.

Hardware Abstraction Layer Error Codes.

Hexadecimal

Message

HAL_SUCCESS 0x0000

HAL_STARTED 0x00020000

HAL_STOPPED 0x00020001

HAL_INVALID_CMD 0x00020002

HAL_NOTASKS 0x00020003

HAL_CREATETASKFAILED 0x00020004

HAL_TOO_MUCHDATA 0x00020005

HAL_NOSTACKMEM 0x00020006

HAL_FORCE_NOTENABLED 0x00020007

HAL_FORCE_ADDRINVALID 0x00020008

HAL_RTLIB_INDEX_ERR 0x00020009 Runtime library index

HAL_INVALID_IOHANDLE 0x00020010 Invalid I/O handle

HAL_CANNOT_SET_FORCED_MEM 0x00020011 Cannot set forced

HAL_IO_LT_BIND_FAILED 0x00020012

HAL_DOWNLOAD_ACTIVE 0x00020013 Download active

HAL_PROG_RUNNING 0x00020014 An application program

HAL_TASK_NOT_FOUND 0x00020015 Cannot find task in ???

HAL_MEM_CORRUPT 0x00020016 Memory corrupt

HAL_NOPROG_LOADED 0x00020017 No program loaded

HAL_START_IO_FAILED 0x00020018 Start of I/O failed

HAL_INVALID_ADDR 0x00020019 Invalid address

HAL_DOWNLOAD_INACTIVE 0x00020020 Download Inactive

Address Meaning

error

memory

is running

14 •• Troubleshooting Your Smart Trac CPU Card Technical Manual

Page 19

SMART TRAC CPU Card

Hardware Abstraction Layer Error Codes.

Hexadecimal

Message

HAL_INVALID_TASKTYPE 0x00020021 Invalid Task Type

HAL_IOINIT_FAILED 0x00020022 I/O Initialization

HAL_TASKINDEX_INVALID 0x00020023 Task index invalid

HAL_ETHERNET_DRV_BAD 0x00020024 Ethernet drive does not

HAL_ETHCFG_OPEN_FAILED 0x00020025 An attempt to open the

HAL_ETHCFG_WRITE_FAILED 0x00020026 An attempt to write the

HAL_NOMEM 0x00020027 No memory found

HAL_THREAD_PRIO_FAILED 0x00020028 Thread priority failed.

HAL_DOWNLOAD_DISABLED 0x00020029 Download of programs

HAL_NODENAME_MISMATCH 0x00020030 The nodename does

HAL_STATIC_STORAGE_OPEN_FAILED 0x00020031

HAL_STATIC_STORAGE_CLEAR_FAILED 0x00020032

HAL_STATIC_STORAGE_WRITE_FAILED 0x00020033

HAL_STATIC_STORAGE_READ_FAILED 0x00020034

HAL_STATIC_STORAGE_CLOSE_FAILED 0x00020035

HAL_STATIC_STORAGE_BAD_FORMAT 0x00020036

HAL_UNABLE_TO_CLEAR_MEM 0x00020037 Not able to clear CPU

HAL_INVALID_SUBCMD 0x00020038 Invalid subcommand.

HAL_BLDNUM_MISMATCH 0x00020039

HAL_STOP_IO_FAILED 0x00020040 An attempt to stop the

HAL_INVALID_NUM_PROGS 0x00020041 The number programs

HAL_DUPLICATE_CONT_TASK 0x00020042

HAL_TOO_MANY_CARDS_PER_TASK 0x00020043 Too many cards per

HAL_STATIC_STORAGE_CHKSUM_INVALID 0x00020044 A checksum test of

HAL_KERNEL_PROGRAM_IN_PROGRESS 0x00020045 A download of the

HAL_INVALID_TASK_PRIORITY 0x00020046

HAL_ADDRESS_OUT_OF_RANGE 0x00020047 A memory or I/O

HAL_KERNEL_DWNLD_ABORTED 0x00020048 A download of the

HAL_NO_RT_EXEC_KEY 0x00020049

HAL_UNABLE_TO_SAVE_RT_EXEC_KEY 0x00020050

HAL_NUM_EXPORT_ENTRIES_MISMATCH 0x00020051

HAL_NUM_IMPORT_ENTRIES_MISMATCH 0x00020052

HAL_DLL_NAME_LENGTH_OVERRUN 0x00020053

HAL_LATEBIND_IO_TOO_FEW_FUNCTIONS 0x00020054

HAL_INVALID_SW_REVISION 0x00020055 Invalid Operating

HAL_INVALID_RT_FUNCTION 0x00020056 A runtime library

HAL_LOAD_LIBRARY_FAILED 0x00020057

Address Meaning

procedure has failed.

pass tests

Ethernet configuration

failed.

Ethernet configuration

failed.

during diagnostics.

and data is disabled.

not match those known

by the Smart Trac

system.

memory.

I/O has failed.

indicated are invalid.

task.

static storage on the

CPU card is invalid.

Kernel is in progress.

address is out of valid

ranges.

kernel has been

aborted.

System Software

Revision

function was attempted

for use but is invalid.

Technical Manual Troubleshooting Your Smart Trac CPU Card •• 15

Page 20

SMART TRAC CPU Card

Hardware Abstraction Layer Error Codes.

Hexadecimal

Message

HAL_DATA_TABLE_PTR_MISMATCH 0x00020058 A pointer within a data

HAL_DATA_TABLE_SIZE_MISMATCH 0x00020059 The sizes of data and

HAL_INVALID_SYNC_TASK 0x00020060

HAL_INVALID_SYNC_CARD 0x00020061

HAL_OPERATION_NOT_SUPPORTED 0x00020062

HAL_NO_ROOM_FOR_SOURCE 0x00020063

HAL_NO_SOURCE_TO_UPLOAD 0x00020064

HAL_UNABLE_TO_SAVE_SOURCE_TO_DISK 0x00020065

HAL_SOURCE_OFFSET_INVALID 0x00020066

HAL_INVALID_TIME_DATE 0x00020067

HAL_NO_ROOM_FOR_DB 0x00020068

HAL_NO_DB_MEMORY 0x00020067

HAL_DB_INVALID_TYPE 0x00020068

HAL_ENGINE_MISMATCH 0x00020069

HAL_SERIAL_CMD_INVALID 0x00020070

HAL_UNABLE_TO_OBTAIN_DATA_MUTEX 0x00020071

HAL_CARD_NOT_FOUND 0x00020072

HAL_ENUM_COMPLETE 0x00020073

HAL_INVALID_DATA_TABLE 0x00020074

HAL_INVALID_SYMTABLE_ADDR 0x00020075

HAL_INVALID_SYMTABLE_SIZE 0x00020076

HAL_ADDRESS_MISMATCH 0x00020077

HAL_IO_PRESCAN_FAILED 0x00020078

Address Meaning

table does not match

any known pointers.

the associated table

are different.

Offset Kernel/Boot Download Errors

to 20100 - 20149

Offset Kernel/Boot Download Errors to 20100 - 20149.

Hexadecimal

Message

HAL_KERNEL_ERR_OFFSET 0x00020100

HAL_NO_KERNEL_DOWNLOAD_IN_PROGR

ESS

HAL_INVALID_KERNEL_CHECKSUM 0x00020101

HAL_INVALID_KERNEL_XFER_TYPE 0x00020102

Address Meaning

0x00020100

Offset I/O Errors from 1 - 59 to 20201

- 20259.

Offset I/O Errors from 1 - 59 to 20201 - 20259

Hexadecimal

Message

HAL_IO_ERR_OFFSET 0x00020200

Address

Meaning

16 •• Troubleshooting Your Smart Trac CPU Card Technical Manual

Page 21

SMART TRAC CPU Card

Offset Trace Errors to 20300 to 20399

Offset Trace Errors to 20300 to 20399

Hexadecimal

Message

HAL_ERR_TRACE_ENABLED. 0x00020300

HAL_ILLEGAL_CONDITION. 0x00020301

HAL_TRACE_PIPE_BROKEN 0x00020302

HAL_TRACE_PIPE_OVERFLOW 0x00020303

HAL_TRACE_PIPE_WRITE_FAILED 0x00020304

HAL_INVALID_TRACE_HANDLE. 0x00020305

HAL_TOO_MANY_TRACE_PARAMS 0x00020306

HAL_TRACE_INVALID_EVENT_INDEX 0x00020307

HAL_TRACE_EVENT_NOT_CONFIGURED 0x00020308

Address Meaning

Troubleshooting CPU Problems

Battery Low

Logic in Non-Volatile RAM (NVRAM) determines battery voltage each 24

hours. If a low voltage condition is detected, a message will appear on the

Digital Operator.

Note: If the voltage is low, it sets a bit register. The bit may be read and

interpreted by an application program, so that when the CPU Card's battery

reaches a low charge state, a message will appear on the Digital Operator.

Problems with Other Cards

Several optional cards may be used with your Smart Trac AC1, all controlled by

the CPU card. To attempt to provide detailed troubleshooting procedures for

each of these in this manual would be impractical.

If you experience problems with network communications or input/output,

isolate the problem to the card level and consult the specific manual that shipped

with the card.

Technical Manual Troubleshooting Your Smart Trac CPU Card •• 17

Page 22

Page 23

Corrective Maintenance

Replacing the Battery

An on-board Lithium battery provides power to NVRAM and maintains the

system time and date. See "Smart Trac CPU Card Layout" for location of the

battery on the CPU Card.

SMART TRAC CPU Card

CAUTIONCAUTION

To avoid draining battery do NOT place SNAPHAT pins in a

conductive foam.

To avoid damaging SNAPHAT sockets do NOT wave solder SOIC.

To replace the battery:

Failure to comply may result in premature battery failure.

1. Power OFF the Smart Trac AC1, lock out and tag "Out of Service."

2. Ensure all parameters held in NVRAM have been recorded. Loss of

battery power or removal of the battery causes NVRAM to lose data

normally retained. These values must be reentered after inserting a new

battery.

3. Remove all cards above the CPU (including PC/104 option cards,

Ethernet card, PS Card, and PG Card) according to "Installing the

Smart Trac CPU Card."

4. Using a chip extractor tool, remove the battery from its socket on the

card.

5. Carefully align pin 1 of the battery (corner of battery with the dot

printed on it) and gently but firmly push into place. A key on the

battery prevents you from installing it with terminals reversed.

6. Replace all cards according card replacement steps in "Installing the

Smart Trac CPU Card."

7. Reenter NVRAM functions (TCP/IP address, Inverter Type, COM1

baud rate, date and time).

Technical Manual Corrective Maintenance •• 19

Page 24

SMART TRAC CPU Card

Battery Storage

Store batteries in a dry place. Storing unpackaged battery cells together could

result in cell shorting and heat build-up.

Proper Battery Disposal

When completely discharged, this type of lithium cell is Non-Hazardous per

USEPA Criteria. Dispose of batteries according to appropriate Local, State and

Federal waste regulations. For unreacted Lithium Metal, see the battery

reference in the Appendix to this manual.

20 •• Corrective Maintenance Technical Manual

Page 25

SMART TRAC CPU Card

Appendix A – Technical Support

Getting Help

Should you need technical assistance with installation or troubleshooting of your

Smart Trac AC1, you can phone our Help Desk at either (800)-541-0939 or

(262)-782-0200. Alternatively, you may copy the Problem Report form, found

on the next page, and fax it to us at (262)-782-3418.

References

MagneTek Drives and

Systems

PC/104 Specification,

Version 2.1

Lithium Batteries Product

Guide

For more information about MagneTek drives

and systems, training programs and contacts,

visit:

http://www.magnetekdrives.com

PC/104 Consortium. An overview and the

specification may be obtained at the web site

address:

http://www.controlled.com/pc104/index.html

For a copy of this publication, contact Rayovac

at 608-275-4735 or visit their web site at:

http://www.rayovac.com

Technical Manual Appendix A – Technical Support •• 21

Page 26

SMART TRAC CPU Card

Problem Report

Name:

Address:

City: State: Zip

Serial Number: Smart Trac CPU Card: 66Mhz 100 Mhz

Occurrence: Frequently Intermittantly Rarely

Nature of Problem:

Conditions when problem occurs:

22 •• Appendix A – Technical Support Technical Manual

Page 27

SMART TRAC CPU Card

Appendix B – Replaceable Parts

Replaceable Parts Listing

Description MagneTek Part

Number

Smart Trac CPU Card option kit 46S03643-0010 1

Standoff, 4.5mm, Hex, Stl, CL ZINC,

15mm, M/F, M3, M3

Standoff, 4.5mm, Hex, Stl, CL ZINC,

14mm, M/F, M3, M3

Battery, Lithium 1

Technical Manual – Smart Trac CPU

Card

Card Extraction Tool (Parvus Corporation

Hardware Tools Kit for Smart Trac

AC1

05P00618-0006 3 each

05P00618-0005 1 each

TM 3415-0010 1

P/N PRV-0760A-01

TBD Option

Qty

CPU assy.

CPU assy.

Technical Manual Appendix B – Replaceable Parts •• 23

Page 28

SMART TRAC CPU Card

THIS PAGE INTENTIONALLY LEFT BLANK

24 •• Appendix B – Replaceable Parts Technical Manual

Page 29

SMART TRAC CPU Card

Appendix C – Removing the

Smart Trac Card Stack

General Procedures

1. Power off the Smart Trac AC1. Disconnect it and tag "Out of Service".

2. Do one of the following:

• Open the cover to the Smart Trac AC1 by rotating the spring-

loaded, captive screw counterclockwise. Use a large screwdriver if

necessary to free the slotted screw.

OR

• Loosen the screws holding down the cover.

3. Disconnect the 12-pin wiring harness from connector J4 at the digital

operator.

4. Using the Phillips head screwdriver, remove the ground strap from the

left inside and the ground strap from the top inside of the Smart Trac

AC1 adapter ring.

5. Disconnect the 9-pin RS-232 cable at connector J5 on the Smart Trac

CPU card.

Technical Manual Appendix C – Removing the Smart Trac Card Stack •• 25

Page 30

chassis

board

SMART TRAC CPU Card

12-pin wiring

harness on

Digital Operator

attached to

connector J4 on

Smart Trac

CPU Card

Digital

Operator

9-pin RS-232

cable

attached here

4mm screws

(4 places)

secure ring

to main

Standoffs (4

places)

secure each

board

Smart Trac

Board Stack

PC/104

9-pin RS-232

cable

connector J5

6. Using a 4.5mm hex head driver, remove four standoffs from the

topmost card.

7. Using the PC/104 extraction tool, remove the topmost card from the

stack.

Position

rectangular

"jacks"

around

edges of

PCBs

Squeeze to lift

cards apart

Figure 4. Using the PC/104 Extraction Tool.

8. Repeat step 8 above until all PC/104 cards have been removed.

9. To remove the Smart Trac PG card:

• Disconnect the 4CN connector on the PG card.

• Using a tubular extraction tool or pliers, squeeze the plastic,

spring-loaded retainer built-in to the long plastic standoff located

at the top of the PG card, just above connector J6.

• Using a PC/104 extraction tool, remove the card.

NOTE: The Smart Trac PG card requires unique handling. Wedge the extracting

tool between the PG card and the CPU card. The area between the terminal strip

on the CPU card and the serial numbered edge of the PG card can be lifted first,

then the opposite side (nearest TB1) on the PG card). Alternate sides until the

card is free of the CPU card.

10. To remove the Smart Trac CPU card:

26 •• Appendix C – Removing the Smart Trac Card Stack Technical Manual

Page 31

SMART TRAC CPU Card

• Disconnect the card at the 2CN connector on the CPU card.

• The CPU card is secured with three plastic standoffs with spring-

loaded clips on the end. Squeeze the top of the standoffs (the clips)

with the special cylindrical removal tool, your fingers or needlenosed pliers and lift the CPU card from the Smart Trac Inverter

Control Card.

You have removed the entire card stack. The inverter card, considered part of

the drive, is in clear view.

Technical Manual Appendix C – Removing the Smart Trac Card Stack •• 27

Page 32

Page 33

Glossary of Terms

SMART TRAC CPU Card

Function Block

IEC-61131-3

languages

Instruction List

PC/104 Specification

Relay Ladder Logic

Sequential Function

Charts

Structured Text

One of three Program Control Unit types. A programming language element,

typically represented by a graphical block, consisting of inputs, outputs, internal

variables, and a set of operations. Function blocks are instantiated and can

contain state information from one invocation of an instantiation to the next.

Part 3 of the international standard on Programmable Controllers, which

specifies Programming Languages, including Relay Ladder Logic (RLL),

Structured Text (ST), Sequential Function Charts (SFC), Function Blocks (FB),

and Instruction Lists (IL).

The IEC 61131-3 Instruction List language for programmable controllers.

Alternatively, a program control unit developed using the Instruction List

language.

An embedded PC bus standard. The standard defines the mechanical size of a

self-stacking bus. Also an IEEE draft standard, called the P996.1 Standard for

Compact Embedded PC Modules, PC/104 Specification, Version 2.1, July 1994,

PC/104 Consortium.

An implementation of the IEC 61131-3 Ladder Diagram language.

The IEC-61131-3 defined Sequential Function Chart language used for

programmable controllers or a program control unit developed using Sequential

Function Chart language.

The Structured Text language specified by IEC 61131-3 used in programmable

controllers. It provides a structured programming environment similar to that in

the computer programming language PASCAL.

Technical Manual Glossary of Terms •• 29

Page 34

SMART TRAC CPU Card

THIS PAGE INTENTIONALLY LEFT BLANK

30 •• Glossary of Terms Technical Manual

Page 35

SMART TRAC CPU Card

I

information, safety 2

Installation 5, 9, 19

Inverter 4–6, 4–5, 12, 19, 27

Index

B

Battery 19

BIOS 11

Booting 11

C

Configuration 9, 12, 15

CPU 25

CPU Card Layout 10, 19

D

Default Interrupts and Base I/O

Addresses 9

L

Layout, CPU Card 10, 19

M

MENU key 11–12

Messages, Normal Boot 11

Messages, Status and Error 13

N

Normal Boot Messages 11

O

Offset I/O Errors 16

Offset Kernel/Boot Download

Errors 16

Offset Trace Errors 17

Optional Parts 23

P

parts

optional 23

PC/104 21

E

Electrostatic Sensitive Discharge 5

Error Codes

Hardware Abstraction Layer 14

Errors

Offset I/O 16

Offset Kernel/Boot Download 16

Offset Trace 17

ESD 5

ESD Procedures 2, 5

extraction tool 26

G

Getting Help 21

ground 5

R

reference 20

Removing 5, 7, 25

Replacing the Battery 19

S

safety 1–2

safety information 2

Self-Test 3, 11

static electricity 2, 5

Status and Error Messages 13

strap

wrist 5

T

H

Hardware Abstraction Layer 14

Help 21

Help Desk 21

Technical Manual Index •• 31

Technical Manual 2

tool, extraction 26

troubleshooting

Help Desk 21

Page 36

SMART TRAC CPU Card

Troubleshooting Your Smart Trac

CPU Card 13

W

warranty 1–2

Warranty 2

wrist strap 5

32 •• Index Technical Manual

Page 37

SMART TRAC CPU Card

Data subject to change without notice. Smart Trac is a trademark of MagneTek, Inc. MicroTrac is a registered trademark of MagneTek, Inc. Microsoft, Windows and Windows NT are registered

trademarks of Microsoft Corporation

MagneTek

Drives and Systems

16555 West Ryerson Road

New Berlin, WI 53151

(800) 541-0939, (262) 782-0200, FAX (262) 782-3418

TM 3415-0010 © 1999-2000 MagneTek, Inc. 1/31/2000

Loading...

Loading...