Page 1

S

S

M

M

A

A

R

R

T

T

T

T

R

R

A

A

Technical Manual

™

™

C

C

A

A

C

C

1

1

Page 2

Page 3

SMART TRAC AC1

Table of Contents

List of Figures..................................................................................................................................iv

List of Tables ...................................................................................................................................iv

Warranty............................................................................................................................................v

Limitation of Liability .......................................................................................................................v

Important Safety and Warranty Information 1-1

Warnings, Cautions and Notes.................................................................................................................1-1

General Safety Precautions - Warnings .................................................................................................. 1-2

Important Warranty Information............................................................................................................ 1-2

Smart Trac AC1 2-1

Overview..................................................................................................................................................... 2-1

General Capabilities......................................................................................................................2-1

Specifications................................................................................................................................ 2-2

Assembling a Smart Trac AC1 3-1

The Contents of Your Shipment............................................................................................................... 3-1

Assembly Procedure.................................................................................................................................. 3-1

Option Cards.............................................................................................................................................. 3-5

Smart Trac PG Card...................................................................................................................... 3-6

Smart Trac PS Card....................................................................................................................... 3-6

Smart Trac Ethernet Card.............................................................................................................. 3-6

Optional PC-104 Compliant Cards................................................................................................ 3-6

Smart Trac AC1 Installation 4-1

Installing Your Smart Trac AC1 ............................................................................................................. 4-2

Storage .......................................................................................................................................... 4-2

Unpacking..................................................................................................................................... 4-2

Locating Your Smart Trac AC1.................................................................................................... 4-2

Making Electrical Connections..................................................................................................... 4-4

Smart Trac Grounding................................................................................................................. 4-10

Connecting Auxiliary Input and Output Power Option Devices................................................. 4-12

Connecting the Control Circuit................................................................................................... 4-12

Terminating Shielded Cable........................................................................................................ 4-16

Connecting Optional Cards......................................................................................................... 4-16

Pre-Power Checklist................................................................................................................................ 4-17

Booting and Power-Up Self-Test............................................................................................................ 4-17

The Boot Menu ........................................................................................................................................ 4-17

TCP/IP Address........................................................................................................................... 4-19

Inverter Type............................................................................................................................... 4-19

COM1 Config ............................................................................................................................. 4-19

Serial Download?........................................................................................................................ 4-20

Firmware Version........................................................................................................................ 4-20

Technical Manual TM 3554-000 •• 0-i

Page 4

SMART TRAC AC1

Flash Access................................................................................................................................ 4-20

Start System?............................................................................................................................... 4-20

Setting the System Time ............................................................................................................. 4-20

Connecting the Vector Controlled Motor.............................................................................................. 4-20

Tune Your Smart Trac AC1................................................................................................................... 4-21

Power On and Preliminary Checks ............................................................................................. 4-21

Tachometer and Motor Rotation Check................................................................................................ 4-24

Recording Settings Using the Programming Menu.............................................................................. 4-27

Auto-Tuning Faults and Corrective Actions......................................................................................... 4-29

Networking the Smart Trac AC1 5-1

Types of Networks for Your Smart Trac AC1........................................................................................ 5-1

PC-based Operation ...................................................................................................................... 5-1

Self-Contained, Control Networks................................................................................................ 5-1

Using Ethernet for PC-based Operation........................................................................................ 5-2

Ethernet Network Architecture ............................................................................................................... 5-4

Linear Bus using 10Base-T.......................................................................................................... 5-4

Star network using 10Base-2 or 10Base-T.................................................................................... 5-5

Ethernet Network Configuration............................................................................................................. 5-7

Addresses and subnet mask........................................................................................................... 5-7

Configuration for PC-Based Operation......................................................................................... 5-7

Configuration for an enterprise-wide LAN................................................................................... 5-8

Verifying Your TCP/IP Configuration........................................................................................ 5-10

Troubleshooting Your Smart Trac AC1 6-1

Reporting of Faults and Errors................................................................................................................ 6-1

Fault Histories............................................................................................................................... 6-1

Resetting Faults............................................................................................................................. 6-2

Clearing Faults.............................................................................................................................. 6-2

Troubleshooting Motor Symptoms.......................................................................................................... 6-2

If the drive/motor will not operate ................................................................................................ 6-3

Troubleshooting For Fault Conditions.................................................................................................... 6-3

Smart Trac AC1 Maintenance 7-1

Preventive Maintenance............................................................................................................................ 7-1

Corrective Maintenance............................................................................................................................ 7-3

Replacing Parts.............................................................................................................................. 7-3

Ordering Parts ............................................................................................................................... 7-6

Appendix A – Dimensions 8-1

Smart Trac AC1 Dimensions.................................................................................................................... 8-1

Mounting Hardware and Hole Dimensions............................................................................................. 8-3

Appendix B – Detailed Specifications 8-5

AC1 Specifications..................................................................................................................................... 8-5

Appendix C - Wiring, Grounding and Installation Practices for Noise Immunity 8-9

Wiring, Grounding and Installation Practices........................................................................................ 8-9

Wiring Requirements for Panel Design/Layout:........................................................................... 8-9

Wire separation groups – STANDARD PRACTICE:................................................................. 8-10

Wiring Requirements for Shop Wiring....................................................................................... 8-11

0-ii •• Technical Manual TM 3554-000

Page 5

SMART TRAC AC1

Wiring Requirements and Recommendations for Field Installation: .......................................... 8-12

Appendix D - Application Parameters 8-15

Application Parameter Form ................................................................................................................. 8-15

Appendix E – Installing System Software 8-21

Installing Boot, Monitor or Operating System Software and Recovery from CPU Failure............. 8-21

Kernel Download........................................................................................................................ 8-21

Appendix F – Technical Support 8-25

Getting Help............................................................................................................................................. 8-25

Problem Report ....................................................................................................................................... 8-26

Training.................................................................................................................................................... 8-27

References ................................................................................................................................................ 8-29

Appendix G – Replaceable Parts 8-33

Replaceable Parts Listing ....................................................................................................................... 8-33

Glossary of Terms 8-35

Index 8-39

Technical Manual TM 3554-000 •• 0-iii

Page 6

SMART TRAC AC1

List of Figures

List of Tables

Figure 1. Smart Trac card assembly showing option cards. ............................. 3-6

Figure 2. Grounding of Three Smart Trac AC1s (top) and Grounding of Smart

Trac AC1 with Vector Controlled Motor (VCM) (bottom).................... 4-11

Figure 3. Simplified Customer Connection Diagram ..................................... 4-14

Figure 4. Shielded Termination...................................................................... 4-16

Figure 5. The Smart Trac AC1 Boot Process. ................................................4-19

Figure 6. A typical local area network used for PC-based operation of Smart

Trac AC1s................................................................................................. 5-4

Figure 7. A Linear Bus topology using 10Base-T............................................ 5-5

Figure 8. A Star topolgy using 10Base-T......................................................... 5-6

Figure 9. The Command Prompt from Windows NT..................................... 5-10

Figure 10. IPCONFIG results......................................................................... 5-10

Figure 11. A successful PING of the computer you are using........................ 5-11

Figure 12. Using thePC/104 card extraction tool..............................................7-4

Figure 13. Removing the Smart Trac Card Stack............................................. 7-5

Figure 14. The Kernel Download – Download Operations dialog box. .........8-22

Figure 15. The Kernel Download – Communications Setup dialog box........8-23

Table 1. Smart Trac AC1 Specifications.......................................................... 2-2

Table 2. Terminal screws, connectors and clamping torque by wire size......... 4-5

Table 3. Wire Sizing for Main Circuit, 230 Volt..............................................4-6

Table 4. Wire Sizing for Main Circuit, 460 Volt..............................................4-7

Table 5. Wire Sizing for Main Circuit 600V (575V)........................................ 4-9

Table 6.Terminal Definitions of the Inverter Control Card............................ 4-15

Table 7. Motor Setup Parameters ................................................................... 4-23

Table 8. Troubleshooting Faults....................................................................... 6-3

Table 9. Smart Trac AC1 Replaceable Parts List............................................. 7-7

0-iv •• Technical Manual TM 3554-000

Page 7

SMART TRAC AC1

Warranty

Standard products manufactured by MagneTek are warranted to be free from

defects in workmanship and material for a period of one year from date of

shipment and any products which are defective in workmanship or material will

be repaired or replaced, at MagneTek’s option, at no charge to the Buyer. Final

determination as to whether a product is actually defective rests with MagneTek.

The obligation of MagneTek hereunder shall be limited solely to repair or

replace, at MagneTek’s discretion, products that fall within the foregoing

limitations, and shall be conditioned upon receipt by MagneTek of written

notice of any alleged defects or deficiency promptly after discovery and within

the warranty period, and in the case of components or units purchased by

MagneTek, the obligations of MagneTek shall not exceed the settlement that

MagneTek is able to obtain from the supplier thereof. No products shall be

returned to MagneTek without its prior consent. Products which MagneTek

consents to have returned shall be shipped prepaid f.o.b. MagneTek’s factory.

MagneTek cannot assume responsibility or accept invoices for unauthorized

repairs to its components, even though defective. The life of the products of

MagneTek depends, to a large extent, upon the usage thereof, and MAGNETEK

MAKES NO WARRANTY AS TO FITNESS OF ITS PRODUCTS FOR THE

SPECIFIC APPLICATIONS BY THE BUYER NOR AS TO PERIOD OF

SERVICE UNLESS MAGNETEK SPECIFICALLY AGREES OTHERWISE

IN WRITING AFTER THE PROPOSED USAGE HAS BEEN MADE

KNOWN TO IT.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE AND BUYER HEREBY

WAIVES ANY AND ALL CLAIMS THEREFORE.

Limitation of Liability

IN NO EVENT SHALL MAGNETEK BE LIABLE FOR LOSS OF PROFIT,

INDIRECT, CONSEQUENTIAL, OR INCIDENTAL DAMAGES WHETHER

ARISING OUT OF WARRANTY, BREACH OF CONTRACT OR TORT.

Technical Manual TM 3554-000 •• 0-v

Page 8

SMART TRAC AC1

THIS PAGE LEFT INTENTIONALLY BLANK

0-vi •• Technical Manual TM 3554-000

Page 9

SMART TRAC AC1

Important Safety and Warranty

Information

This Chapter will enable you to:

q Be aware of warnings, cautions and notes as they appear

in the documentation.

q Learn about important warranty information.

Warnings, Cautions and Notes

WARNING

A statement of conditions which MUST BE OBSERVED to

prevent personal injury or death.

WARNING - ESD

A statement of conditions which must be observed to prevent

damage to components due to ESD (ElectroStatic Discharge) and

to prevent personal injury or death.

CAUTION

A statement of conditions which must be observed to prevent

undesired equipment faults, Smart Trac AC1 system degradation

and damage to equipment.

IMPORTANT

A statement of conditions which should be observed during Smart Trac AC

setup or operation to ensure dependable service.

Technical Manual TM 3554-000 Important Safety and Warranty Information •• 1-1

Page 10

SMART TRAC AC1

NOTE: Notes indicate information that is in addition to a discussion of the topic

in adjoining text. Alternatively, it may limit or restrict the paragraph(s) that

follow(s) to specific models or conditions.

TIP - Tips indicate information that should make a procedure easier or more

efficient.

General Safety Precautions Warnings

Important safety information follows. Please read and understand all

precautions listed below before proceeding with the specification, installation,

set-up or operation of your Smart Trac AC1. Failure to follow any of the

following precautions may result in personal injury or death, or damage to the

equipment.

WARNING - ESD

The Control Printed Circuit Board (PCB) employs CMOS

Integrated Circuits that are easily damaged by static electricity.

Use proper ElectroStatic Discharge (ESD) procedures when

handling the Control PCB. See Smart Trac AC1 Technical Manual

for details. Failure to comply may result in damage to equipment

and/or personal injury.

Important Warranty Information.

Do not modify your Smart Trac AC1, its components, or any of the procedures

contained in the technical documentation supplied by MagneTek. Any

modification of this product by the user is not the responsibility of MagneTek

and will void the warranty.

1-2 •• Important Safety and Warranty Information Technical Manual TM 3554-000

Page 11

SMART TRAC AC1

WARNINGWARNING

Verify that the rated voltage of the Smart Trac AC1 matches the

voltage of the incoming power.

Always ground the Smart Trac AC1 using ground terminal G. See the

detailed instructions provided in the Smart Trac Technical Manual.

Wiring must be performed only by qualified personnel.

Do not perform a "HIPOT" or withstand voltage test on any part of

the Smart Trac AC1. The AC1 uses semi-conductors and is vulnerable

to high voltage.

Never connect the main circuit output terminals T1, T2 and T3 to the

AC main circuit power supply.

All parameters have been factory set to values commonly used. Do

not change their settings without good reason.

Failure to comply with this warning may result in damage to the

Smart Trac AC1 and connected equipment along with personal injury

and/or death.

WARNING WARNING -- ESD ESD

The Control Printed Circuit Board (PCB) employs CMOS Integrated

Circuits that are easily damaged by static electricity. Use proper

Electrostatic Discharge (ESD) procedures when handling the Control

PCB. Failure to comply may result in damage to equipment and/or

personal injury.

CAUTIONCAUTION

All parameters have been factory set to values commonly used. Do not

change their settings without a full understanding of their impact on

Smart Trac AC1 and machine operation. Failure to comply may result

in damage to equipment and/or personal injury.

Technical Manual TM 3554-000 Important Safety and Warranty Information •• 1-3

Page 12

SMART TRAC AC1

THIS PAGE INTENTIONALLY LEFT BLANK

1-4 •• Important Safety and Warranty Information Technical Manual TM 3554-000

Page 13

Smart Trac AC1

This Chapter will enable you to:

q Describe the capabilities of the Smart Trac AC1

q Become familiar with the ratings and specifications of the

Smart Trac AC1

SMART TRAC AC1

General Capabilities

Overview

The Smart Trac AC1 is a high performance, programmable AC motor drive that

eliminates the need for an external PLC or PC to control a machine or process.

Utilizing the Windows® environment, Smart Trac Workstation™ software allows

the Smart Trac AC1 to be programmed efficiently and easily. Each Smart Trac

AC1 can be programmed to fulfill a specific function and purpose using any of

the five IEC-61131-3 programming languages. IEC-61131-3 programming

languages include Relay Ladder Logic (RLL), Structured Text (ST), Sequential

Function Charts (SFC), Function Blocks (FB) or Instruction Lists (IL).

Commonly used function blocks may be obtained from MagneTek's Program

Library. Consult your local MagneTek representative for details.

Smart Trac AC1 offers many means of communications with other control

devices using either the built-in RS-232 port or any of the optional add-on

communication cards. A MagneTek ARCNET card may be used to

communicate with MicroTrac® LAN systems, providing backward

compatibility with existing MagneTek systems. In addition, the Smart Trac AC1

system supports off-the-shelf Ethernet, DeviceNet, Profibus, SDS, Interbus-S,

Fiber Optic and local I/O cards conforming to PC/104 specifications for form

and fit.

The Smart Trac AC1 provides a sine-coded and pulse width modulated threephase output with adjustable voltage and frequency. This provides for complete

speed and/or torque control of any conventional squirrel cage induction motor.

Automatic stall prevention and voltage boost prevents nuisance tripping during

load or line side transient conditions. The Smart Trac AC1 will not induce any

voltage line notching distortion back to the utility line and will maintain a

displacement power factor of not less than 0.98 throughout its speed range.

Technical Manual TM 3554-000 Smart Trac AC1 •• 2-1

Page 14

SMART TRAC AC1

Specifications

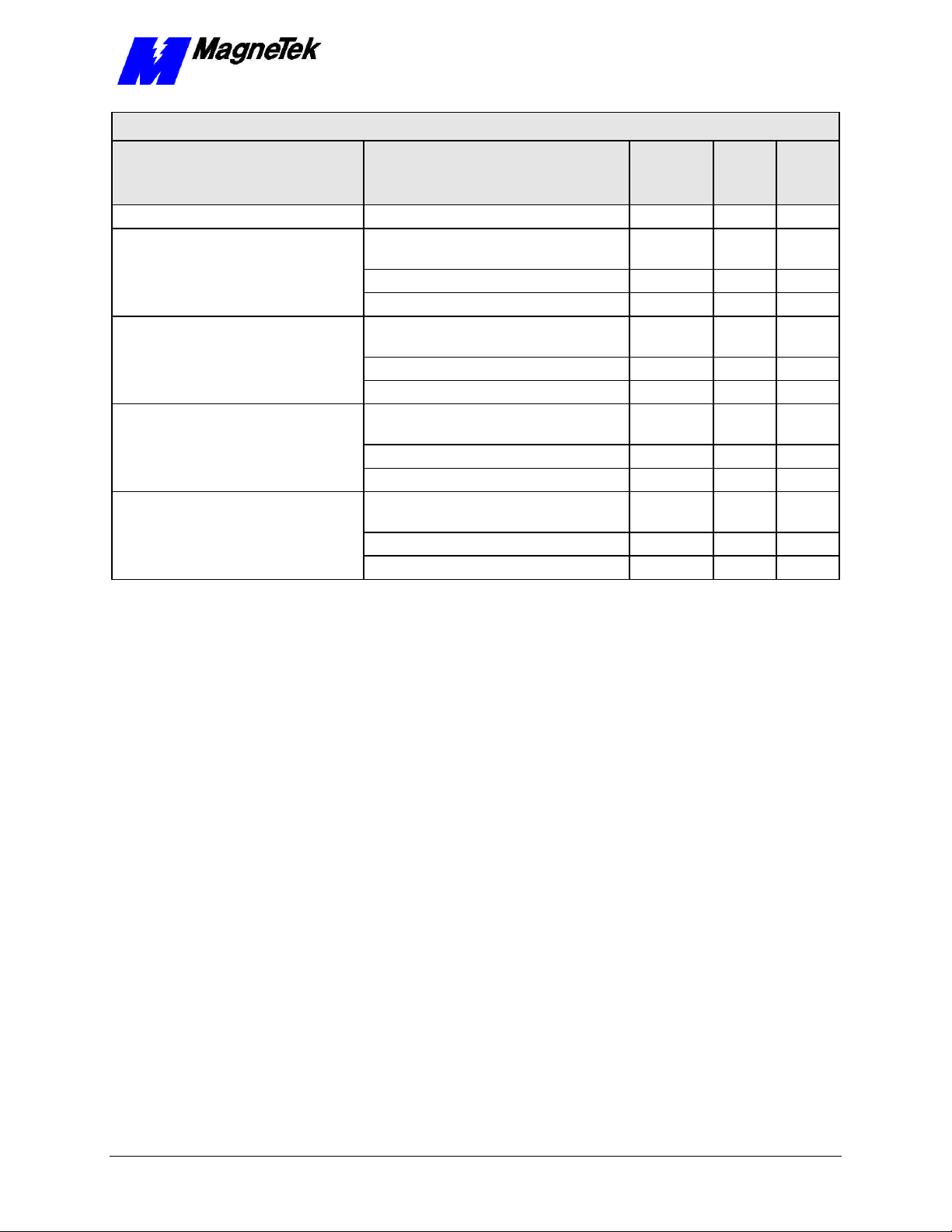

Table 1. Smart Trac AC1 Specifications

Characteristic Specification

Ratings: 0.75 to 100 HP at 230 VAC

1.0 to 1600 HP at 460 VAC

2.0 to 200 HP at 600 VAC

Amperes 3.2 to 1,600 amps, depending on model

Input Power – 208/230V

Class

Output Power-208/230V

Class

Input Power –

380/415/460V Class

Output Power–

380/415/460V Class

Input Power –

575 / 600 V Class

Output Power–

575 / 600 V Class

Overload Capacity 150% for 1 minute

Enclosure Types NEMA 1 Protected Chassis, NEMA 4 , or NEMA 12

Ambient Operating

Temp.

Storage Temperature -20° C to 60° C

Humidity 95% RH non-condensing

Vibration 1G<20Hz, 0.2G 20 to 50 Hz

Location Indoor, protected from corrosive gases and dust

Elevation 3300 ft (1000 M) or less

Voltage: 3 Phase 200/208/220/230 VAC +10%, -15%

Frequency: 50/60 Hz ± 5%

Voltage: 0-230V (proportional to input voltage)

Frequency: 0-400 Hz (V/Hz pattern selectable)

Voltage: 3 Phase 380/400/415/440/460 VAC +10%, -15%

Frequency: 50/60 Hz ± 5%

Voltage: 0-460V (proportional to input voltage)

Frequency: 0-400 Hz (V/Hz pattern selectable)

Voltage: 3 Phase 500/ 575/ 600 VAC ±10%

Frequency: 50/60 Hz ± 5%

Voltage: 0-575V (proportional to input voltage)

Frequency: 0-400 Hz (V/Hz pattern selectable)

0°C to 40° C

2-2 •• Smart Trac AC1 Technical Manual TM 3554-000

Page 15

SMART TRAC AC1

Assembling a Smart Trac AC1

This Chapter will enable you to:

q Understand what is contained within your Smart Trac

AC1

q Learn how to assemble your Smart Trac AC1 from the

components you received.

q Recognize each of the Option cards in your Smart Trac

AC1

The Contents of Your Shipment

Because Smart Trac AC1s are shipped to your specifications, there is wide

variation in the types and numbers of component parts shipped to you. While

some of your components may already be assembled, the assembly procedures

in this chapter assume that you've received the following components :

• Smart Trac AC1 Chassis, Drive and Inverter Card (assembled)

• Cover and Adapter Ring

• Smart Trac CPU Card

• Smart Trac Option Cards (as specified for your configuration)

Assembly Procedure

Use the following procedure for first time installation of your Smart Trac AC1

only!

WARNING WARNING -- ESD ESD

The Smart Trac AC1 electronics are electrostatic sensitive devices.

Follow Electrostatic Discharge (ESD) procedures when handling to

protect components. Failure to follow ESD procedures may result in

damage to the Smart Trac AC1 or its components.

1. Ensure wiring harness at connector 7CN, located at the top of the Smart

Trac Inverter card, is connected to the 7CN connector on the primary

power supply printed circuit board (1PCB). The power supply board is

either a Power PCB (units B034 or less) or a Gate Drive PCB (A064 or

higher number).

Technical Manual TM 3554-000 Assembling a Smart Trac AC1 •• 3-1

Page 16

SMART TRAC AC1

While rotating the Smart Trac CPU card about 45 degrees from its base

should be oriented so the standoff screw hole is on the left and the plate

2. Ensure ground strap E, located at bottom of inverter card, is connected

to the Smart Trac case ground terminal (indicated by the printed ground

symbol .

NOTE: The case ground terminals are the two screw terminals in the lower left

of smaller cases, or placed one on the lower left and one on the lower right sides

of larger cases. You can use either or both terminals to connect ground straps,

depending on the length of the strap or your preference.

3. Connect and tighten all electrical leads to terminal blocks on the Smart

Trac Inverter card to their proper termination, as shown on the specific

connection diagram for your Smart Trac AC1 installation.

4. Remove the Smart Trac CPU card (marked "ST") from its anti-static

bag.

5. Familiarize yourself with the location of the 2CN connector on the

Inverter card. The female half of the black 2CN connector is located on

the Smart Trac Inverter card. The male half is located on the Smart

Trac CPU card.

NOTE: Standoffs used

between the Smart Trac CPU

and Inverter cards are

shorter than other standoffs

6.

position, set the Smart Trac CPU card locking plate into the plastic

locking tab on the Inverter card. Align the holes in the locking plate

with the special, short black plastic standoffs. The metal locking plate

used between all other cards.

is below the plane of the black plastic standoffs. Rotate the card

downward to lock in place.

7. Insert four metal standoffs through four outside holes in the Smart Trac

Inverter card and screw into the four standoffs on the underside of the

card. Tighten standoffs with fingers (torque to about 10 in-lbs).

8. Locate the three plastic standoffs and spring-loaded clips that secure

the Smart Trac CPU card to the Smart Trac Inverter card through holes

in the card.

9. Orient the Smart Trac CPU card with the PC/104 connector at the

bottom. The MagneTek logo, printed on the card, should be at the top.

Slip the Smart Trac CPU card under the wiring harness connector (the

harness is connected to 1CN on the inverter card). Rotate slightly

upward from the left.

10. Align the male and female halves of the 2CN connector and, being

careful not to bend the pins of the 2CN connector, press the Smart Trac

CPU card firmly into place on the Smart Trac Inverter card (1PCB).

You should see and hear the plastic standoffs and spring-loaded clips

snap into place.

NOTE: Depending on the

drive and case size, make

encoder connections before

installing the Smart Trac PG

Card.

11. Install four metal standoffs through four outside holes in the Smart

Trac CPU card and screw into the four standoffs on the underside of

the card. One standoff may be a different color thatn the other three.

This standoff is inserted through the CPU card and into the trhreaded

hole in the metal locking plate. Tighten standoffs with fingers (torque

to about 10 in-lbs).

12. If you purchased the Smart Trac PG card option, install it at as follows.

Otherwise, proceed immediately to step 12.

3-2 •• Assembling a Smart Trac AC1 Technical Manual TM 3554-000

Page 17

SMART TRAC AC1

a. Locate two block pin positions on the female PC/104 connector.

Using a pin or other sharp object, carefully remove two black plugs

from the two blocked pin positions.

b. Orient the Smart Trac PG card so that the PC/104 connector and

the J2 connector (on the solder side of the card) align with the

PC/104 connector on the Smart Trac CPU card and the 4CN

connector on the Inverter Control card. The standoff hole above J6

must slip over the plastic standoff. Be careful to align the PC/104

connector pins with the receptacle on the Smart Trac CPU card so

the pins don't bend when the card is pushed into place.

c. Gently but firmly push the Smart Trac PG card onto the Smart

Trac CPU card. Make sure connecting pins are in alignment and J2

mates with 4CN before pushing the two boards tightly together.

Secure the card using four (4) metal standoffs and one (1) plastic

standoff. Tighten metal standoffs with fingers (torque to about 10

lb-ft).

13. Position the Adapter Ring over the drive chassis, aligning two tabs on

the right side of the ring with slots in the chassis.

14. Secure the Adapter Ring to the chassis using two or four Phillips head

screws, depending on drive case size.

15. Connect the 9-pin RS-232 cable at connector J5 on the Smart Trac CPU

card.

16. If your unit includes a Smart Trac PG card, connect the ground strap

from J11 on the Smart Trac PG card, to the left inside and top inside of

the Adapter Ring.

17. Connect the 12-pin wiring harness from the Digital Operator to

connector J4 on the Smart Trac PS card.

18. Install other option cards per instructions included with each card. See

"Option Cards" below for general information.

19. Close the cover and tighten the screws or single captive screw to secure

the cover.

20. Your Smart Trac AC1 should not be assembled and ready for

connection to a 110V power supply.

Technical Manual TM 3554-000 Assembling a Smart Trac AC1 •• 3-3

Page 18

SMART TRAC AC1

PS Card

Smart Trac

Option Cards

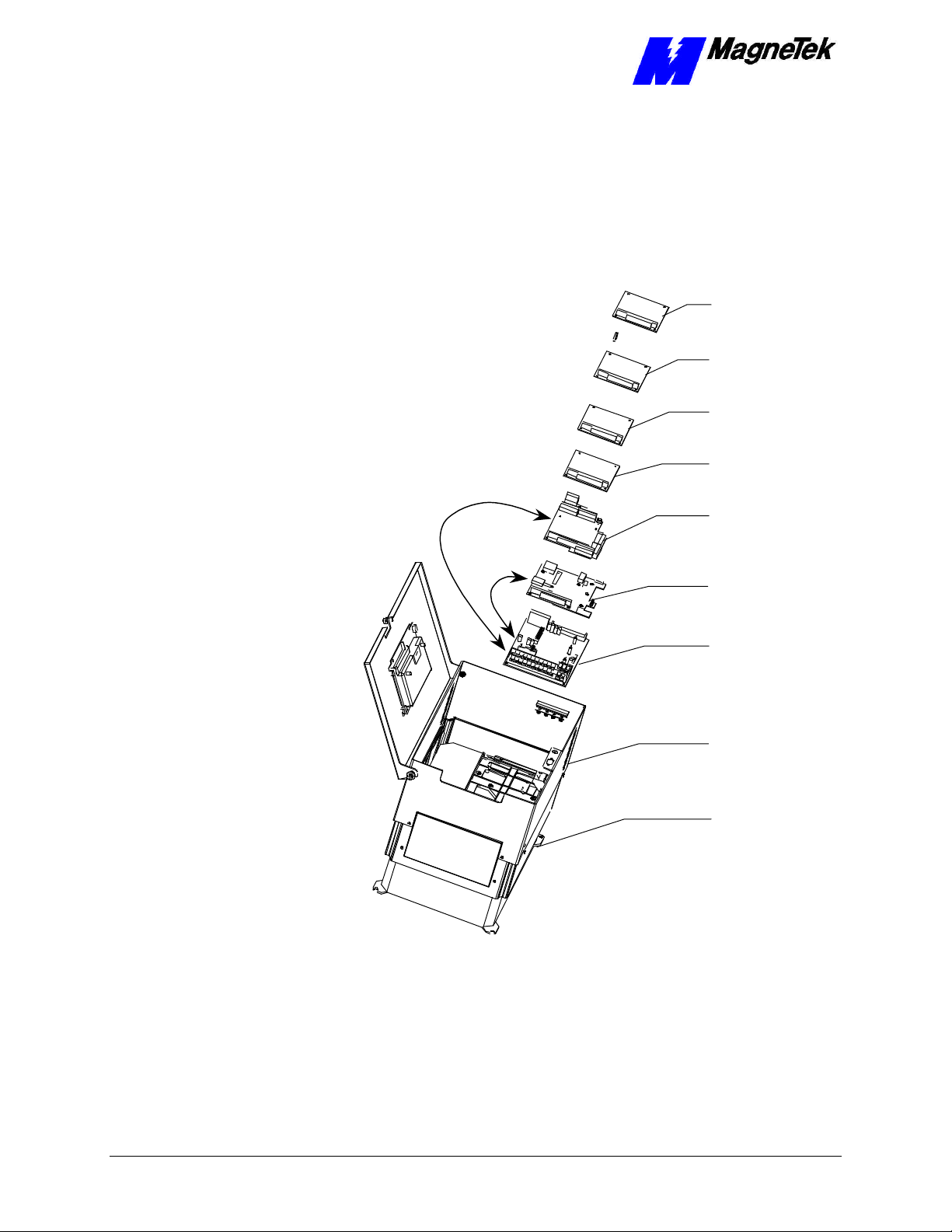

The Smart Trac Inverter Control Card is the first card of the stack. It is the card

on which all others are stacked. The Smart Trac CPU card is mounted on top of

the Smart Trac Inverter and communicates with it via the connector labeled

2CN.

Optional

PC/104

Card

Optional

PC/104

Card

Ethernet

Card

Smart Trac

4CN

Connector

Smart Trac

PG Card

2CN

Connector

Smart Trac

CPU Card

Figure 1. Smart Trac card assembly showing option cards.

Inverter Control

Card

Adapter

Ring

Main Chassis

3-4 •• Assembling a Smart Trac AC1 Technical Manual TM 3554-000

Page 19

SMART TRAC AC1

Smart Trac PG Card

Smart Trac PS Card

Smart Trac Ethernet

Card

Optional PC-104

Compliant Cards

The Smart Trac PG (Pulse Generator) card is installed on top of the Smart Trac

CPU card. It communicates with the Smart Trac Inverter control card via

connector 4CN and the Smart Trac CPU card's PC/104 connector. The Smart

Trac PG card accumulates pulses (A, B and Z) from both master and follower

encoders. It has two analog inputs and can accept two proximity switches. It

includes its own +5V power supply rated at 50 ma. This 50 ma power is

typically ample for applications requiring a load cell.

The Smart Trac PS (Power Supply) card is connected to the Smart Trac PG card

via the PC/104 connector and supplies all the voltages and power to support the

Smart Trac CPU, Smart Trac PG, and all other option cards. If the Smart Trac

PG card is not installed, the Smart Trac PS connects to the Smart Trac CPU.

The Smart Trac Ethernet Card is a PC/104 compliant card included in all Smart

Trac AC1s, providing quick program downloads and uploads and fast, reliable

networking capabilities.

Several additional PC/104 compliant option cards may be stacked on top of the

Smart Trac PG card. Optional cards might include local I/O, ARCNET, Genius,

DeviceNet, Profibus or fiber optic cards for communications and/or additional

system I/O. The Smart Trac ARCNET card allows the Smart Trac AC1 to

communicate with MagneTek Micro Trac drives, making it fully backward

compatible with MagneTek's earlier drive systems. DeviceNet, Profibus and

Fiber Optic cards will support master/slave and peer-to-peer communications.

See the documentation on the individual option cards for further information

Technical Manual TM 3554-000 Assembling a Smart Trac AC1 •• 3-5

Page 20

Page 21

SMART TRAC AC1

Smart Trac AC1 Installation

This Chapter will enable you to:

q Prepare your Smart Trac AC1 for installation

q Determine a physical location for your Smart Trac AC1.

q Make required electrical connections.

q Recommend the proper grounding and shielding for your

Smart Trac AC1.

q Run adequate conduit for the wiring to and from your

Smart Trac AC1.

q Audit your Smart Trac AC1 system using the Pre-power

checklist.

q Become familiar with the Digital Operator

q Start your Smart Trac AC1 for the first time.

q Connect one or more vector-controlled motors.

q Perform an integrated Smart Trac AC1 and motor test.

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-1

Page 22

SMART TRAC AC1

Installing Your Smart Trac AC1

WARNING WARNING -- ESD ESD

Keep electronic circuit boards in Electrostatic Discharge (ESD)

protective bags when not being handled. Use proper ESD

procedures (including an ESD wrist strap) when handling circuit

boards. Failure to comply may result in damage to equipment.

When working with an Electrostatic Discharge (ESD) device, you should be

grounded at all times. The easiest and most common way to provide this ground

is to use an approved ESD wrist strap. The strap is secured to your wrist with a

wire attached to the strap and clipped or taped to the chassis of the unit being

worked on. Any static is dissipated through the wire to ground, greatly reducing

the possibility of damage to the device.

It is a good idea to touch the chassis with your finger before handling any

electrostatic sensitive device. Any static electricity will be discharged to chassis

ground and will not be transferred to the device.

Always store devices (cards, other electronic components) in ESD protective

bags when not being handled.

Storage

Unpacking

Contents Checklist

Locating Your Smart

Trac AC1

If the Smart Trac AC-1 will be stored for a while after receipt, keep the Smart

Trac AC1 in its original packaging material. Store the Smart Trac AC1 in a

controlled environment that meets the following:

q temperature range within –20° C to 60° C

q humidity of less than 95% (no condensation)

Remove the protective shipping and packing material from the equipment.

Ensure contact wedges and other shipping devices have been removed.

You should have received the following with your Smart Trac AC1:

q Smart Trac AC1

q Option card(s) and accessories, if purchased, and option card technical

manuals

q Smart Trac Technical Manual

q Applicable Smart Trac AC-1 Bulletins and Application Notes

To achieve proper performance and normal operating life, your Smart Trac AC1

must be installed in an area where it is protected:

q Excessive heat, direct sunlight, rain or moisture.

q Corrosive gases or liquids.

q Vibration, airborne dust or metallic particles.

4-2 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 23

SMART TRAC AC1

Consider the following when planning the installation and installing your Smart

Trac AC1:

• Always lift your Smart Trac AC1 by its base, never by the front cover.

• Install the Smart Trac AC1 on a flat, non-flammable vertical surface

(wall or panel) using mounting screws specified (See "Smart Trac AC1

Dimensions" for screw specifications).

• Provide a minimum 4.7" (26.1cm) clearance above and below the

Smart Trac AC1. This allows for proper air circulation over the heat

sink fins.

• Provide a minimum 1.2" (3.05cm) clearance on each side of the Smart

Trac AC1.

• Mount your Smart Trac AC1 in a freestanding floor-mount cabinet.

Sufficient clearance must be obtained to permit the door to be opened.

• Add a fan or cooling device as necessary to ensure air entering the

Smart Trac AC1 is below 113° F. (45° C) for protected chassis or

below 104° F. (40° C) for NEMA 1. See "Table 1. Smart Trac AC1

Specifications".

Making Electrical

Connections

Complete wire interconnections per information Table 2 and Table 3, Table 4 or

Table 5 , depending on the voltage of your Smart Trac AC1. Always adhere to

the following:

WARNINGWARNING

Wiring should be performed only by qualified personnel.

Disconnect all power to Smart Trac AC1. Do not remove the front

cover while input power is ON.

Never connect the main circuit output terminals T1, T2 and T3 to

the AC main circuit power supply.

Failure to comply with this warning may result in damage to the

Smart Trac AC1 and connected equipment along with personal

injury and/or death.

• Use 600V vinyl-sheathed wire or equivalent.

• Determine wire size to consider voltage drop of leads.

• Wire size must be suitable for NEC Class I Circuits.

• Use UL approved closed loop connectors or CSA certified ring

connectors sized for the selected wire gauge. Install connectors using

only the connector manufacturer's recommended crimp tool. See Table

2.

• Motor lead length should not exceed 164 feet (50 meters). Motor

wiring should be run in a separate conduit from the power wiring. If

lead length must exceed this distance, reduce the carrier frequency and

consult the motor manufacturer for proper installation procedures.

• Never connect AC main power to drive output terminals T1(U), T2(V),

T3(W).

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-3

Page 24

SMART TRAC AC1

• Never allow wire leads to contact metal surfaces. Short-circuit may

result.

• Never connect power factor correction capacitors or noise filters to

Smart Trac AC1 output.

Table 2. Terminal screws, connectors and clamping torque by wire size

Wire

Size

(AWG)

20 0.50 M3.5 1.25-3.5 7.8 0.9 7.0 0.8

18 0.75 M4 1.25-4 13.0 1.5 10.4 1.2

16 1.25 M4 1.25-4 13.0 1.5 10.4 1.2

14 2

12 3.5

10 5.5

8 8

6 14 M6 14-6 40.9 34.8 4.8 4.1

4 22 M8 22-8 100.0 82.6 11.7 10.7

2 38

1/0 60 M10 60-10 182.6 156.5 21.4 18.4

3/0 80 M10 80-10 182.6 156.5 21.4 18.4

4/0 100

MCM300 150 M12 150-12 313.0 191.3 36.7 23.1

MCM400 200 M12 200-12 313.0 191.3 36.7 23.1

MCM650 325 M12 325-12 313.0 191.3 36.7 23.1

M16 325-16 313.0 191.3 36.7 23.1

Wire

Size

(mm2)

ClosedTerminal

Screw

M4 2-4 13.0 1.5 10.4 1.2

M5 2-5 26.1 20.9 3.1 2.4

M4 3.5-4 13.0 1.5 10.4 1.2

M5 3.5-5 26.1 20.9 3.1 2.4

M4 5.5-4 13.0 1.5 10.4 1.2

M5 5.5-5 26.1 20.9 3.1 2.4

M5 8-5 26.1 20.9 3.1 2.4

M6 8-6 40.9 34.8 4.8 4.1

M8 38-8 100.0 82.6 11.7 10.7

M10 38-10 182.6 156.5 21.4 18.4

M10 100-10 182.6 156.5 21.4 18.4

M12 100-12 313.0 191.3 36.7 23.1

Loop

Connector

Clamping

Torque

Steel,

lb-in

Clamping

Torque

Steel, N-m

Clamping

Torque

Copper,

lb-in

Clamping

Torque

Copper,

lb-in

4-4 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 25

Table 3. Wire Sizing for Main Circuit, 230 Volt

SMART TRAC AC1

Smart Trac AC1 Model No. Terminal Symbol

STAC*A003

STAC*A006

STAC*A011

STAC*A017

STAC*A080

STAC*A130

STAC*A160

STAC*A224

STAC*A300

Wire Sizing for Main Circuit, 230 Volt

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W), GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W), GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W), GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W), GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), ,3, T1(U), T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), ,3, T1(U), T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

Terminal

Screw

Wire

Size

(AWG)

Wire

Size

(mm2)

M4 14-10 2-5.5

M4 14-10 2-5.5

M4 14-10 2-5.5 STAC*A008

M4 12-10 3.5-5.5

M4 12-10 3.5-5.5

M4 10 5.5

M5 8 8 STAC*A025, STAC*A033

M5 10-8 5.5-8

M6 4 22 STAC*A049

M6 8 8

M8 3 30 STAC*A064

M6 8 8

M8 3 30

M8 6 14

M4 20-10 0.5-5.5

M10 4/0 100

M8 4 22

M4 20-10 0.5-5.5

M10 1/0 XP 60 X 2P

M8 4 22

M4 20-10 0.5-5.5

M10 1/0 XP 60 X 2P

M8 3 30

M4 20-10 0.5-5.5

M12 4/0 X 2P 100 X

2P

M8 1 50

M4 20-10 0.5-5.5

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-5

Page 26

SMART TRAC AC1

Table 4. Wire Sizing for Main Circuit, 460 Volt

Smart Trac AC1 Model No. Terminal Symbol

STAC*B001

STAC*B011, STAC*B014

STAC*B041

STAC*B052

STAC*B065

STAC*B080

STAC*B096

STAC*B128

Wire Sizing for Main Circuit, 460 Volt

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W), GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W), GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, 2, 3, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

1(r), 2 200 (s200), 2 400 (s400)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

Terminal

Screw

Wire

Size

(AWG)

Wire

Size

(mm2)

M4 14-10 2-5.5

M4 14-10 2-5.5 STAC*B003, STAC*B004, STAC*B008

M4 12-10 3.5-5.5

M4 12-10 3.5-5.5

M4 8-6 8-14 STAC*B021

M4 8-6 8-14

M5 8-6 8-14 STAC*B027, STAC*B034

M6 8 8

M6 6 14

M8 8 8

M4 20-10 0.5-5.5

M6 4 22

M8 8 8

M4 20-10 0.5-5.5

M8 4 22

M8 8 8

M4 20-10 0.5-5.5

M8 3 30

M8 6 14

M4 20-10 0.5-5.5

M8 1 50

M8 6 14

M4 20-10 0.5-5.5

M10 4/0 100

M8 4 22

M4 20-10 0.5-5.5

M10 1/0 60 x 2P STAC*B165

M8 4 22

4-6 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 27

Wire Sizing for Main Circuit, 460 Volt

SMART TRAC AC1

Wire

Terminal

Smart Trac AC1 Model No. Terminal Symbol

STAC*B224

STAC*B302

STAC*B302

STAC*B450, STAC*B605

1(r), 2 200 (s200), 2 400 (s400)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

1(r), 2 200 (s200), 2 400 (s400)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

1(r), 2 200 (s200), 2 400 (s400)

L1(R), L2(S), L3(T), , 3, T1(U), T2(V),

T3(W)

GND

1(r), 2 200 (s200), 2 400 (s400)

L1(R), L2(S), L3(T), , 1, 3, T1(U), T2(V),

T3(W)

GND

1(r), 2 20 0 (s200), 2 400 (s400)

Screw

M4 20-10 0.5-5.5

M10 1/0 x 2P 60 x 2P

M8 3 30

M4 20-10 0.5-5.5

M10 1/0 x 2P 60 x 2P

M8 3 30

M4 20-10 0.5-5.5

M12 4/0 x 2P 100 x 2P

M8 1 50

M4 20-10 0.5-5.5

M16 MCM65

M8 1/0 60

M4 20-10 0.5-5.5

Size

(AWG)

0 x 2P

Wire

Size

(mm2)

325 x 2P

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-7

Page 28

SMART TRAC AC1

Table 5. Wire Sizing for Main Circuit 600V (575V).

Smart Trac AC1 Model No. Terminal Symbol

STAC*C010

STAC*C027, STAC*C032

STAC*C041

STAC*C052

STAC*C062

STAC*C077

STAC*C099

Wire Sizing for Main Circuit, 600 Volt

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W),

GND

L1(R), L2(S), L3(T), , 1, 2, B1, B2, T1(U),

T2(V), T3(W)

GND

L1(R), L2(S), L3(T), , 1, B1, B2, T1(U),

T2(V), T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

Terminal

Screw

M4

Wire

Size

(AWG)

14-10 2-5.5 STAC*C003, STAC*C004

Wire

Size

(mm2)

12-10 3.5-5.5

M4

14-10 2-5.5 STAC*C006

12-10 3.5-5.5

M4 12-10 3.5-5.5

M4

10 5.5 STAC*C012

12-10 3.5-5.5

M5 STAC*C017

10-6 5.5-14

M6

M5 8-6 8-14 STAC*C022

M6 10-6 5.5-14

M6 8-6 8-14

Ä

10-6 5.5-14

M4 14-10 2-5.5

M8 6-1/0 14-50

* 8-2 8-30

M4 14-10 2-5.5

M8 4-1/0 22-50

* 8-2 8-30

M4 14-10 2-5.5

M8 3-1/0 30-50

* 8-2 8-30

M4 14-10 2-5.5

M8 2-1/0 30-50

* 6-2 22-30

M4 14-10 2-5.5

M8 2/0-1/0 50-60

4-8 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 29

Wire Sizing for Main Circuit, 600 Volt

SMART TRAC AC1

Wire

Terminal

Smart Trac AC1 Model No. Terminal Symbol

STAC*C130

STAC*C172

STAC*C200

* Indicates terminal uses a pressure lug.

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2(s)

L1(R), L2(S), L3(T), , 1, T1(U), T2(V),

T3(W)

GND

1(r), 2 (s)

Screw

* 4-2 22-30

M4 14-10 2-5.5

M10 3/0=300 80-150

* 4-2/0 22-60

M4 14-10 2-5.5

M12 300-400 150-200

* 4-2/0 22-60

M4 14-10 2-5.5

M12 350-400 180-200

* 3-2/0 30-60

M4 14-10 2-5.5

Size

(AWG)

Wire

Size

(mm2)

Smart Trac

Grounding

Your Smart Trac AC1 must be solidly grounded using main circuit ground

terminal GND. Refer to the latest edition of the National Electrical Code (NEC),

Article 250, Grounding, for proper grounding methods, especially ground rod

requirements. Select lead size suitable for size of terminal screw. Make the

length as short as possible.

Never ground the Smart Trac AC1 with the same common as welding machines,

motors, or other large-current electrical equipment. Where several Smart Trac

AC1s are used, ground each directly or daisy chain each to the machine ground

bar or ground rod. Refer to Figure 2. Do not form a loop with the ground

leads.

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-9

Page 30

SMART TRAC AC1

Star

washer

between

cabinet

and bus

wire

Electrical

Cabinet

Copper

Bus

Electrical

Cabinet

Copper

Bus

GROUND

NOT

ACCEPTABLE

ACCEPTABLE

GROUND

NOT

ACCEPTABLE

POLE

Electrical

Cabinet

GROUND

POLES

NOT

ACCEPTABLE

ACCEPTABLE

Figure 2. Grounding of Three Smart Trac AC1s (top) and Grounding of Smart

Trac AC1 with Vector Controlled Motor (VCM) (bottom)

POLE

Connecting Auxiliary

Input and Output

Power Option

Devices

Connecting the

Control Circuit

Proper wiring practices and relative locations within the electrical path, from

line to load, are shown in ." Your application may use some or all of the devices

shown. Disregard items depicted which do not match those in your Smart Trac

AC1 configuration.

WARNINGWARNING

Disconnect all power to Smart Trac AC1. Do not remove the front

cover while input power is ON. Failure to comply may result in

personal injury or death.

Mount all power option devices as close to the Smart Trac AC1 as possible.

Keep electrical connections as short as possible. For Models with base

designations of STAC-A003 through STAC-A064, STACWA003 through

STACWA064, STAC-B001 through STAC-B034, and STACWB001 through

STACWB034, an input or DC reactor should be used.

Basic control circuit (signal) terminations on the Smart Trac AC1 are shown in

the "Simplified Customer Connection Diagram."The use of these terminals,

however, is dependent on the needs of the the application program. Terminal

numbers and their function are listed in the table "Terminal Definitions of the

Inverter Control Card."

4-10 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 31

93

OPTIONAL

SMART TRAC

PC104 Card

(ARCNET,

PCIM,

DeviceNet, etc.)

OPTIONAL

SMART TRAC

ETHERNET

CARD

SMART TRAC AC1

OHM

TERM.

230 VAC

Such as

ARCNET

LAN

33

-15 VDC

Analog Input 1

Fan req'd ST*A080 and

above, ST*B041 and above

Input 1

Input 2

PC104 BUS

Differential

Analog Inputs

A10+

A10-

600MV Input Range

AI1+

AI1AI0+

AI0-

10V Input Range

AI1+

AI1-

COM

COM

+10VDC

-10VDC

Shield, 6 pt.

SMART TRAC

POWER

SUPPLY

Load Cell Power

OPTIONAL

SMART TRAC

PG CARD

SMART TRAC

CPU CARD

INVERTER

CONTROL

CARD

L

N

G

30 Encoder I/O Points

110-115 VAC

or 220 VAC

ENCODER

22

23

Analog Input 2

Analog Input

Open-collector Output

25

Open-collector Output

26

Common, Terms. 25 &

27

26

MOTOR

Inverter

Control

Board

Leads connect to motor

from terminal strip on

drive power supply

Input 3

Input 4

Common for

Terms. 1-8

Input 7

Input 6

Input 5

Input 8

7

8

Figure 3. Simplified Customer Connection Diagram

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-11

Page 32

SMART TRAC AC1

Multifunction Analog Output 2, 0 to +11

POWER CONNECTIONS

1-phase power 90-264 V, to Smart

V to +10V (20K ohms), -10 V to

Analog Input 2, 4-20mA (250

Fault Contact-OPEN, capacity:

Multifunction Analog Output

max), Low=True (ON) when connected to terminal

Terminal Definitions of

the Inverter Control

Card

Term No. Function Term No. Function

1* Multifunction Logic Input 1 23

2* Multifunction Logic Input 2 25

3* Multifunction Logic Input 3 26 Open-collector Output

4* Multifunction Logic Input 4 27 Multifunction Open Collector Common

5* Multifunction Logic Input 5 33

6* Multifunction Logic Input 6

7* Multifunction Logic Input 7 L

8* Multifunction Logic Input 8 N

Multifunction contact output

(N.O.) One of 18 functions

available by setting of

parameter H2-01. Contact

capacity: 250 VAC at 1A or

less; or 30 VDC at 1A or less

9, 10

COM, sequence control input

11

common for terminals 1-6, 0 V L2 3-phase power 230 V/460 V

12 Shield sheath of signal leads L3 3-phase power 230 V/460 V

Typically Speed Reference, but

is multifunction analog input: 0

+10V (20K ohms), Can be

changed to manual by setting

of parameter H3-01.

13

14

ohms) T2 Motor

15 +15 VDC T3 Motor

16 Analog Input 1 B1 Dynamic Braking (option)

Multifunction Analog Input

Common, 0 V for terminals 13

17

thru 16, and 33 B2 Dynamic Braking (option)

Fault Contact-OPEN, capacity:

250 VAC at 1A or less or 30

VDC at 1A or less

18

250 VAC at 1A; or less or 30

19

VDC at 1A or less +2 DC Reactor (option)

Fault Contact-OPEN, capacity:

250 VAC at 1A; or less or 30

20

VDC at 1A or less

Mutlifunction Analog Output 1,

21

0 to +11 V; 2mA maximum

Common for terminals 21 and

22

23, 0 to +11V; 2mA max.

9-pin D

connector Isolated RS-232

* NOTE: Terminals 1-8 source +24 VDC (8MA

11

V; 2mA maximum

Open-collector Output: +48 V, 50 mA

maximum

-15 VDC Control power supply for

frequency settins: 20 mA max

Trac PS

1-phase power 90-264 V, to Smart

Trac PS

L1 3-phase power 230 V/460 V

T1 Motor

+1 DC Reactor (option)

Table 6.Terminal Definitions of the Inverter Control Card

Connections

Lead Length:

Wire Sizes:

4-12 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Make connections according to the "Simplified Customer Connection Diagram"

with the following notes:

Do not exceed 164 feet (50 meters).

Consider voltage drop when determining size. Consult "Table 3. Wire Sizing for

Main Circuit, 230 Volt" on page 6, "Table 4. Wire Sizing for Main Circuit, 460

Volt" on page 7, "Table 5. Wire Sizing for Main Circuit 600V (575V)." on page

9.

Page 33

SMART TRAC AC1

NOTE: Signal and Control Leads require twisted-pair shielded wire (20-16

AWG [0.5 – 1.25mm2]). Shield sheath terminal 12 requires twisted shielded

or twisted-pair shielded wire (20-14 AWG [0.5 – 2.0mm2]).

Signal Leads:

Control Leads:

Power Leads:

Terminating Shielded

Cable

• Multifunction Logic Inputs to Terminals 1 thru 8 and 11.

• Multifunction Analog Inputs to Terminals 12 thru 17, 33.

• Multifunction Analog Outputs to Terminals 21 thru 23.

• Multifunction Open-collector Outputs to Terminals 25 thru 27.

• Multifunction Contacts to Terminals 9 and 10.

• Fault Contacts to Terminals 18, 19 and 20.

• Single Phase Power 90-264 V to Terminals L and N.

• Three Phase Power 230V/460V to Terminals L1, L2 and L3.

• Motor (Output) to Terminals T1, T2 and T3.

Terminate woven metallic shielded cables at only one end, typically at the

power supply end, as shown "Figure 4. Shielded Termination" on page 16.

When using foil type shields, terminate the drain wire in a similar manner.

Connecting Optional

Cards

Figure 4. Shielded Termination

The Optional Smart Trac PG (Pulse Generator) card, Arcnet card and other

cards are described in separate, specific manuals. See the specific manual for

appropriate connection information.

Pre-Power Checklist

q Verify wires are properly connected and no erroneous grounds exist.

q Ensure all debris is removed from the Smart Trac enclosure and there are no

loose wire clippings.

q Verify cooling fans are free of debris and rotate freely.

q Verify all electrical and mechanical connections for the Smart Trac AC1 are

present and tighten, as necessary

q Verify and test source power is correct for the drive installed.

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-13

Page 34

SMART TRAC AC1

Booting and Power-Up Self-Test

Immediately after power-up of the Smart Trac AC1, the validity of the operating

system is checked. The Smart Trac AC1 BIOS (Basic Input Output System)

performs a self-test to determine the integrity of RAM, flash memory, system

timers and interrupts, among other checks. Any detected faults appear on the

Smart Trac AC1 digital operator.

Next, the system loads any installed drivers. It checks the validity of the user

program before starting its execution.

Once drivers are installed and the user program is validated, the system

performs according to the user program, responding with diagnostics and error

handling as necessary.

NOTE: If communication with the Smart Trac processor and its card stack is

not established within 7 seconds of power up or within 2 seconds of no data

transfers, it will shut down. The LEDs on the digital operator will flash,

indicating this lack of communications.

The Boot Menu

CAUTIONCAUTION

Do not change the Boot Menu without understanding the

implications of your actions or unless instructed to do so by a

MagneTek engineer. The menu does not typically require any

Several functions are available by pressing the MENU key within the first 2

seconds of the boot. Figure 5. The Smart Trac AC1 Boot Process." shows the

boot menu and the functions available.

You may scroll through the menu selections using the Up and Down arrow keys

on the Digital Operator. Pressing ENTER while at any one of the menu

selections causes the submenu to display. Some submenus contain entries you

may scroll through using the Up and Down arrow keys. You may change values

of these entries using procedures for those submenus.

To return to the previous menu level, press ESC.

To stop the boot menu from displaying and resume starting the Operating

System, press ESC until a first level menu appears. Scroll using the up and down

arrow keys until the message appears "Start System?". Press ENTER and the

Operating System should resume loading.

changes. Items which may be changed are: setting the system clock;

TCP/IP address; or checking the firmware version. Failure to comply

may result in damage to your Smart Trac AC1 or other equipment.

NOTE: The message "Starting OS" can be used as output at the J5 (serial)

connector if desired. The message is sent after the initial 2 second timeout as

indicated in the "Smart Trac AC1 Boot Process" flow chart.

4-14 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 35

SMART TRAC AC1

MagneTek

Smart Trac

MENU

TCP/IP Config

Inverter Type

COM1 Config

Serial Download?

If 2 sec

timeout

occurs

ENTER

ENTER

ENTER

ENTER

Starting OS

IP Address

Subnet Mask

Gateway Address

DNS Server Addr

2ms Torq Update

5ms Torq Update

Baud Rate

Load from COM1..

Erase FLASH...

Program FLASH...

TCP/IP Address

Inverter Type

COM1 Config

Firmware Version

Flash Access

Start System?

ENTER

ENTER

ENTER

Operating System

Monitor

Boot Code

Erase this?

User Program

Starting OS

Figure 5. The Smart Trac AC1 Boot Process.

Refer to "Addresses and subnet mask" for information on setting the TCP/IP

address through the Boot Menu.

This function changes the Torque Update parameter from 2 milliseconds to 5

milliseconds. Do not change this function without the approval of an application

engineer.

Using this function enables you to change the baud rate of the RS-232

communications port located on display panel. Normally, this port is only used

to download operating system, monitor and boot programs. It should not

normally be changed.

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-15

Page 36

SMART TRAC AC1

Serial Download?

This function allows loading data through the RS-232 port, erasing flash ROM,

or programming Flash ROM. Do not enter this function without the direction or

approval of an application engineer.

Firmware Version

Flash Access

Start System?

Setting the System

Time

Use this function to check the Operating System, Monitor and Boot Code

program versions stored in your Smart Trac AC1.

This function allows erasing of a user program. Do not enter this function

without the direction or approval of an application engineer.

You must always exit the boot menu through this function. Pressing ENTER

starts the operating system for your Smart Trac AC1.

All events occurring in your Smart Trac AC1 are time-stamped with the system

date and time.

To set the system clock:

1. Load Smart Trac Workstation.

2. Right click a node.

3. Click the Set Date/Time selection. The Set Date/Time dialog box

appears indicating the system date and time.

4. Enter a new date in the format DD/MM/YY and time in the format

hh:mm:ss AM/PM. The dialog box indicates the new date and time.

5. Click OK to continue.

Connecting the Vector Controlled

Motor

For best control of

torque or speed

linearity and response

For control in speed

mode or use with

standard motor voltage

ratings

Most MagneTek Vector Controlled Motors (VCMs) may be configured for

either 380V/460V or 190V/230V operation. VMB motors may be configured for

190V or 230V, 380V or 460V. VMC motors may be configure for 230V or

460V. Your application will determine which configuration to use:

To control torque or speed when 150% peak torque is required at a base speed of

90-100%, with 100% torque at 0 RPM, use a low voltage winding – 190V or

380 V motor tap selection mon VMB motor.

Use a high voltage winding, 230V or 460V, when:

• replacing an existing 460V/230V NEMA design B motor with encoder

feedback.

• for speed control when torque limit adjustment is required.

• in high starting torque situations.

Tune Your Smart Trac AC1

Your Smart Trac AC1 does not typically require tuning. Tuning of your Smart

Trac AC1 should be done either by a qualified MagneTek Field Service

Engineer or according to recommended procedures.

4-16 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 37

SMART TRAC AC1

Power On and

Preliminary Checks

1. Verify that the tachometer and motor are rotating properly before

proceeding. Refer to the table "Flux Vector Control Tachometer and

Motor Rotation Check."

2. Make sure that the motor is disconnected from the load. To assure

safety, disconnect the coupling or belt which connects the motor with

the machine so that motor opertion is isolated before testing operations

begin.

3. Power down the Smart Trac AC1. Do not proceed until the CHARGE

light goes OFF.

4. Remove the Digital Operator from the Display Panel and carefully

disconnect the ribbon cable or wiring harness (attached to the Digital

Operator) from its normal location at connector J4 on the CPU card.

5. Disconnect power leads to the Smart Trac CPU at locations L and N.

6. Connect the Digital Operator to connector 1CN on the Smart Trac

Inverter control card PCB.

WARNINGWARNING

Make sure the motor is disconnected from the load before proceeding.

Failure to comply may result in personal injury or death.

7. Power up the Smart Trac AC1.

WARNINGWARNING

Any motor connected to the Smart Trac AC1 will move when autotuning is executed. Take proper precautions. Failure to comply may

result in personal injury or death.

CAUTIONCAUTION

Motor should be disconnected from its load before executing the autotuning routine. Failure to comply may result in damage to the Smart

Trac AC1 and/or other equipment.

NOTE: If the motor cannot be disconnected from the load, or if Auto-Tuning

fails, motor parameters should be entered manually.

8. Enter the motor nameplate values needed to perform Auto-Tuning.

9. Press , then three (3) times. The Smart Trac Main Menu Auto-Tuning will appear.

** Main Menu **

Auto-Tuning

10. Press twice. The message "Rated Voltage" appears.

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-17

Page 38

SMART TRAC AC1

Rated Voltage

400.0 VAC

11. Set the correct Nameplate voltage of the motor, using the and

keys to scroll and the key to move one decimal point to

the right.

Rated Voltage

460.0 VAC

12. Press to store the value in memory. The message "Entry

Accepted" will appear briefly, followed by a return to the previous

"Rated Voltage" message.

Entry Accepted

Rated Voltage

400.0 VAC

13. Enter the current and the rest of the parameters following a similar

procedure to that of the motor nameplate voltage.

14. When all of the parameters are entered, execute Auto-Tuning:

15. Press the . The message "Tuning Ready?" will appear.

Tuning Ready?

Press RUN key

16. Press . The drive will first output current to the motor, then run

the motor at a high speed. During tuning, the following message will

appear.

Tune proceeding

XX Hz X.XX A

• If no problems are encountered., the following message will

appear:

Tune Successful

• If a problem occurs during Auto-Tuning execution, the "Tune

Aborted" message appears with a reason listed. See "Auto-Tuning

Faults and Corrective Actions".

Tune Aborted

"Reason"

17. If successful, record the settings for parameters E2-01 to E2-09. You

use the Programming Menu (see "Checking Motor Parameters").

18. Remove power from the Smart Trac AC1. Wait until the CHARGE

light goes out.

4-18 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 39

SMART TRAC AC1

19. Disconnect the ribbon cable or wiring harness attached to the Digital

Operator from connector PCB 1CN.

20. Connect the Digital Operator to its normal location on connector J4 on

the Smart Trac CPU card.

21. Power up the drive.

22. Load parameters as follows:

Table 7. Motor Setup Parameters

Numeric

Para-

meter Description

Parameter

Number

Displayed

Description

E2-01 Motor rated current 48 RATED MOTOR

AMPS

E2-02 Motor rated slip 47 MOTOR RATED

SLIP

E2-03 Motor no-load current 49 MTR NO LOAD

AMPS

E2-04 Number of motor poles 50 MOTOR POLES

E2-05 Motor line-to-line

51 MTR TERM RES.

resistance

E2-06 Motor leakage inductance 52 MTR LEAKAGE

IND.

E2-07 Motor iron core saturation

53 MTR SAT COEF 1

coefficient 1

E2-08 Motor iron core saturation

54 MTR SAT COEF 2

coefficient 2

E2-09 Motor mechanical loss 55 MTR MECH LOSS

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-19

Page 40

SMART TRAC AC1

Advanced Level

Description Key Sequence

Apply input power to the

drive.

Set the control method of

the drive to Flux Vector

(A1-02 to 3) or to other

control method.

Tachometer and Motor Rotation

Check

Flux Vector Control Tachometer and Motor Rotation Check

Digital Operator

Press , then

Press , then twice

Press ,

Display

** Main Menu **

Initialize

Control Method

Open Loop Vector

A1-02= 3

Flux Vector

Set parameter access

level to Advanced. This

allows all parameters to

be viewed and modified.

then set drive to Flux Vector using:

Write values to memory by pressing

Press , then

Press , then

Press ,

then set drive to Advanced using:

Write value to memory by pressing:

Entry Accepted

briefly, then

Control Method

Flux-Vector

** Main Menu **

Initialize

Access Level

Quick Start

A1-01= 4

** Main Menu **

Initialize

Set PG Pulses/Rev to the

correct value. (NOTE:

For a MagneTek vector

motor, the correct value is

Press , then twice.

** Main Menu **

Programming

1024.)

4-20 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 41

Flux Vector Control Tachometer and Motor Rotation Check

U1-05=- 1.47 Hz

Description Key Sequence

Press , then 4 times

Press 3 times

Set the correct PPR, using:

Write value to memory by pressing:

SMART TRAC AC1

Digital Operator

Display

Group F

Options

PG Pulses/Rev

01024

** Main Menu **

Initialize

Entry Accepted

briefly, then

PG Pulses/Rev

F1-01= 1024

Display motor speed

Rotate the motor shaft

counter-clockwise by

hand (as viewed from the

load end of the motor).

As the shaft is turned

counter-clockwise, a low

positive speed should be

indicated

As the shaft is turned

clockwise, a low negative

speed should be

indicated.

If the speed doesn't

change when the motor

shaft is rotated, check

encoder wiring and

connections. The pulses

from the encoder can also

be checked.

If the polarity is wrong,

switch channels on the

input to the PG card.

Press , then , then

Press , then 4 times

Function U1

Monitor

Motor Speed

U1-05= 0.00 Hz

Motor Speed

U1-05- 2.38 Hz

Motor Speed

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-21

Page 42

SMART TRAC AC1

Description Key Sequence

Check the motor rotation

using the JOG function.

NOTE: The frequency

reference fro this

operation comes from

D1-09 and is factory set

to 6 Hz.

If either or both of the SEQ and REF lights are ON,

The motor should ramp

up to speed, and rotation

should be counterclockwise if the FWD

light is ON. Rotation

should be clockwise if the

REV light is ON. If the

motor does not accelerate

smoothly or oscillates,

reverse any two motor

leads, then repeat the

motor rotation check.

Run the Auto-Tuning

routine:

Flux Vector Control Tachometer and Motor Rotation Check

Digital Operator

Press , then

press

WARNING WARNING The next key-press will

cause the motor to move: take appropriate precautions.

RUN light will

Press and hold

Release

WARNING WARNING

The motor will move when auto-tuning is executed! Take

proper precautions!

illuminate

Display

Frequency Ref

U1-01=0.00 Hz

Frequency Ref

U1-01- 6.00 Hz

CAUTIONCAUTION

The motor should be disconnected from the load before

executing auto-tuning.

NOTE: If the motor

cannot be disconnected

from the load, or if AutoTuning fails, motor

parameters should be

entered manually. (See

manual procedures in this

chapter).

Go to step 8 of the AutoTuning procedure

(above).

4-22 •• Smart Trac AC1 Installation Technical Manual TM 3554-000

Page 43

Recording Settings Using the

Motor Rated FLA

Motor Rated FLA

Programming Menu

Recording Settings Using the Programming Menu

Description Key Sequence

Get to ** Main Menu **

Programming

Enter the motor rated full

load amps (E2-01). This

value can be obtained

from the motor nameplate

(motor full load amps).

Set Full Load Amps (FLA) using:

Press , then twice

Press , then 3 times

Press twice

Write value to memory by pressing

SMART TRAC AC1

Digital Operator

Display

** Main Menu **

Initialize

Group E

Motor

001.00 A

Motor Rated FLA

001.20 A

Entry Accepted

Enter the motor rated slip

(E2-02). This value can

be calculated using the

following formula:

E2-02=

((Ns-Nr)/Ns)*60*.7

Nr=nameplate rated

speed

Ns=synchronous speed

Ns=fR *120 / # of motor

poles

Press , then

Set motor rated slip using:

briefly, then

E2-01= 1.20 A

Motor Rated Slip

02.90 Hz

Motor Rated Slip

1.08 Hz

Technical Manual TM 3554-000 Smart Trac AC1 Installation •• 4-23

Page 44

SMART TRAC AC1

Motor Rated Slip

No-Load Current

Number of Poles

Number of Poles

Description Key Sequence