Page 1

Page 2

Copyright © 2011 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of Y askawa. No p atent liab ility is assumed with respect to the use of the

information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality

products, the information contained in th is manual is subject to chan ge without not ice. Every precau tion has

been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

2 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 3

Table of Contents

1 Preface and Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 Option Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6 Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7 Network Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8 Drive Configuration Properties. . . . . . . . . . . . . . . . . . . . . .33

9 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

10 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 3

Page 4

1 Preface and Safety

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems

and equipment. The selection and application of Yaskawa products remain the responsibility

of the equipment manufacturer or end user. Yaskawa accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety

control. Without exception, all controls should be designed to detect faults dynamically and

fail safely under all circumstances. All systems or equipment designed to incorporate a

product manufactured by Yaskawa must be supplied to the end user with appropriate

warnings and instructions as to the safe use and operation of that part. Any warnings

provided by Yaskawa must be promptly provided to the end user. Yaskawa offers an express

warranty only as to the quality of its products in conforming to standards and specifications

published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, I S

OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses,

or claims arising from misapplication of its products.

◆ Applicable Documentation

The following manuals are available for the option:

LONWORKS SI-W3 Option

Yaskawa AC Drive

1000-Series Option

LONWORKS

Installation Manual

Manual No:

TOBP C730600 56

(This book)

Yaskawa AC Drive

1000-Series Option

LONWORKS

Installation ManualManual

No: SIEP C730600 56

Read this manual first.

The installation manual is packaged with

the option and contains information

required to install the option and set up

related drive parameters.

The technical manual contains detailed

information about the option. Access the

following sites to obtain the technical

manual:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

For questions, contact your local

Yaskawa sales office or the nearest

Yaskawa representative.

4 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 5

1 Preface and Safety

Yaskawa Drive

The drive manuals cover basic

installation, wiring, operation procedures,

Yaskawa AC Drive

1000-Series

Quick Start Guide

Yaskawa AC Drive

1000-Series

Technical Manual

functions, troubleshooting, and

maintenance information.

The manuals also include important

information about parameter settings and

drive tuning.

Access these sites to obtain Yaskawa

instruction manuals:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

For questions, contact your local

Yaskawa sales office or the nearest

Yaskawa representative.

◆ Terms and Abbreviations

Note: Indicates supplemental information that is not related to safety messages.

Drive: Yaskawa AC Drive 1000-Series

Option: Yaskawa AC Drive 1000-Series Option LONWORKS SI-W3

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 5

Page 6

1 Preface and Safety

DANGER

W ARNING

CAUTION

NOTICE

◆ Registered Trademarks

• LONWORKS is a trademark of ECHELON USA.

• Trademarks are the property of their respective owners.

◆ Supplemental Safety Information

Read and understand this manual before installing, operating, or servicing this option. Install

the option according to this manual and local codes.

The following conventions indicate safety messages in this manual. Failure to heed these

messages could cause fatal injury or damage products and related equipment and systems.

Indicates a hazardous situation, which, if not avoided, will result in death or serious

injury.

Indicates a hazardous situation, which, if not avoided, could r esult in death or

serious injury.

Indicates a hazardous situation, which, if not avoided, could r esult in minor or

moderate injury.

Indicates an equipment damage message.

6 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 7

1 Preface and Safety

DANGER

NOTICE

■ General Safety

General Precautions

• The diagrams in this book may include options and drives without covers or safety shields to

illustrate details. Be sure to reinstall covers or shields before operating any devices. Use the option

according to the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and

may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering new copies of the manual, contact a Yaskawa representative or the nearest Yaskawa

sales office and provide the manual number shown on the front cover.

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting

from failure to heed the warnings in this manual.

Do not modify the drive or option circuitry.

Failure to comply could result in damage to the drive or option and will void warranty.

Yaskawa is not responsible for any modification of the product made by the user. This

product must not be modified.

Do not expose the drive or option to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the drive or option.

Do not pack the drive in wooden materials that have been fumigated or sterilized.

Do not sterilize the entire package after the product is packed.

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 7

Page 8

2 Product Overview

2 Product Overview

◆ About This Product

The LONWORKS Communication Option Card (Model SI-W3) is based on LonT alk. It acts

as an interface for connecting an AC drive to a LONWORKS network using the LonTalk

protocol.

With the option card insta lled to the drive, the following operations are possible with devices

using the LonTalk protocol.

• operate the drive

• monitor the operation status of the drive

• change parameter settings.

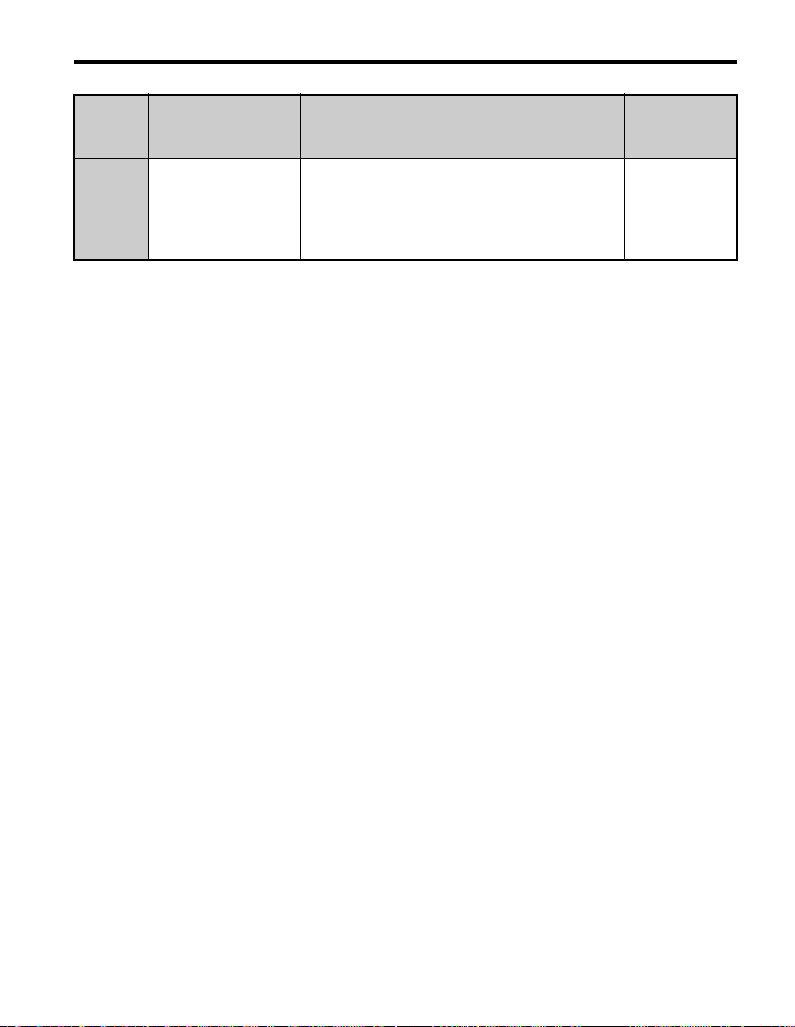

◆ Applicable Models

The option can be used with the models in Table 1.

Table 1 Applicable Models

Drive Series

A1000 ≥ PRG 1017

<1> See “PRG” on the drive nameplate for the software version number.

Software Version <1>

8 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 9

3 Receiving

ERR RUN

RX TX

*123456789ABC*

*123456789ABC*

*123456789ABC*

MANUAL

3 Receiving

Please perform the following tasks upon receiving the option:

• Inspect the option for damage. Contact the shipper immediately if the option appears

damaged upon receipt.

• Verify receipt of the correct model by checking the model number printed on the option

nameplate

(Refer to Figure 1 on page 10 for more information).

• Contact your supplier if you have received the wrong model or the option does not

function properly.

◆ Option Package Contents

Descri

ption:

Quant

ity:

◆ Tools Required for Installation

• A Phillips screwdriver (M3 metric / #1, #2 U.S. standard size) is required to install the

• A straight-edge screwdriver (blade depth: 0.4 mm, width: 2.5 mm) is required to wire the

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 9

Option

_

1131 11

Ground

Wire

Screws

(M3)

LED Label Bar Code

option.

option terminal block.

Note: Tools required to prepare option cables for wiring are not listed in this manual.

Installation

Manual

Page 10

4 Option Components

4 Option Components

◆ LONWORKS Option

Figure 1

M

A

B

C

D

E

F

L K J I H G

A – Connector (CN5) H – LED (SERVICE)

B – Installation hole I – Service Switch

C–LED (ERR)

D – LED (RUN)

E–LED (TX)

F–LED (RX)<1> M – Terminal block CN1

G – Neuron ID

<1> Refer to Option LED Display on page 12 for details on the LEDs.

<2> The ground wire provided in the option shipping package must be connected during installation .

<1> J – Digital operator connector (CN3)

<1> K – Model number

<1> L – Gr ound terminal and installation hole <2>

Figure 1 LONWORKS Option Components

Underside

10 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 11

4 Option Components

◆ Terminal Block CN1

The communication terminal is a pluggable terminal block that serves as the connection

point of the LONWORKS network communication cable to the option.

Table 2 Terminal Descriptions

Terminal Terminal No. Name Description

1

2

3

1 A Signal Line A

2SLDShield

3 B Signal Line B

◆ Connector CN3 for Digital Operator

DANGER! Electric Shock Hazard. Do not touch drive main terminals and control terminals. Failure to

comply will result in death or serious injury.

Connecting the CN3 and the digital operator (model: JVOP-182) lets the user set the DDC

function parameters.

◆ Service Switch

This is a neuron ID output switch. Pressing this switch outputs the neuron ID to the netwo rk.

■ Initializing Bind Data

Cycling power to the drive while holding down the service switch will clear the bind data,

and reset the configuration properties back to the factory sett ings.

Note: Do not turn off the power to the drive while initializing the bind data. The RUN, RX, TX, and

ERR LEDs are lit (ON) during initialization of the bind data.

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 11

Page 12

4 Option Components

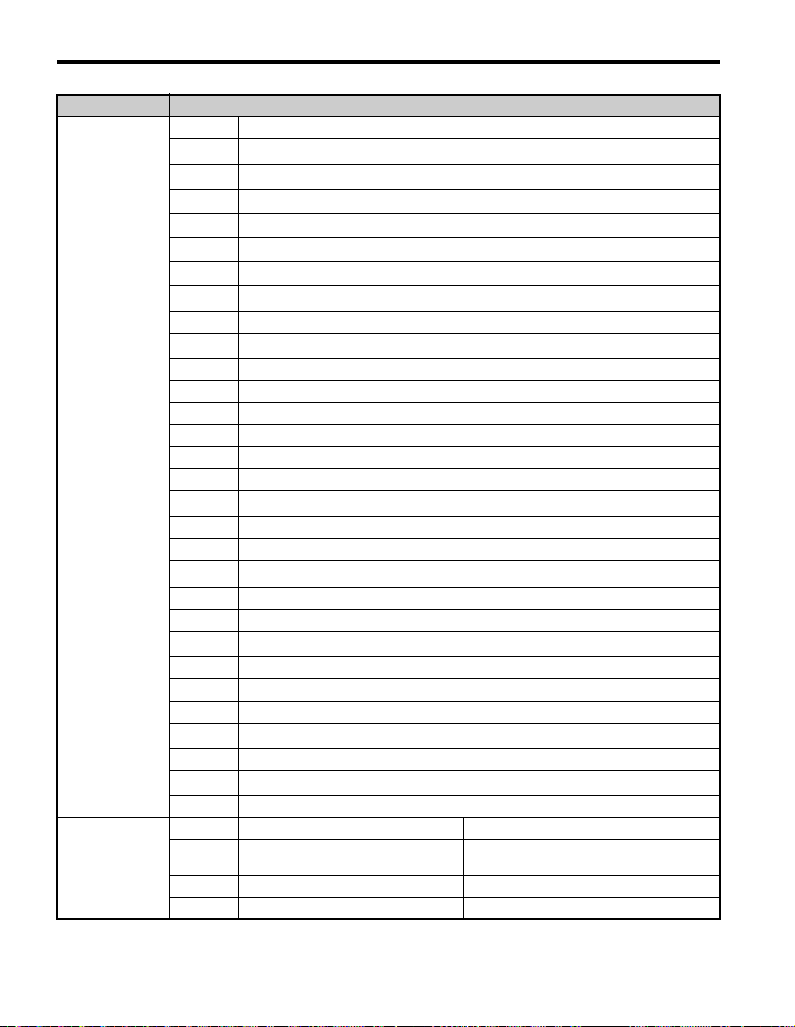

◆ Option LED Display

The option has five LED s .

The operational states of the LEDs are described in Table 3.

Table 3 Option LED States

LED

Name

RUN Green

RX Green

TX Green

ERR Red

SERVICE Green

Display

Color Status

Flashing Network not configured LONWORKS network has not been configured.

OFF

ON/

Flashing

OFF

ON/

Flashing

OFF Not sending data No data is being send

Flashing Comm error CALL or BUSS error has occurred

OFF Normal operation Device is operating normally.

Flashing Network not configured LONWORKS network has not been configured

OFF Normal operation Device is operating normally.

Operating Status Explanation (major faults)

ON Normal operation Device is operating normally.

Power OFF No power is being supplied to the drive.

Hardware fault

Receiving Receiving node data

Node data not yet

received

Sending Sending data

ON Hardware fault

Service switch active Service switch is being held down

ON

Hardware fault

An unrecoverable fault has occurred.

If the unit does not recover after cycling power, then

the option card may need to be replaced.

No input signal

An unrecoverable fault has occurred.

If the unit does not recover after cycling power, then

the option card may need to be replaced.

An unrecoverable fault has occurred.

If the unit does not recover after cycling power, then

the option card may need to be replaced.

Note: The RUN, RX, TX, and ERR LEDs are lit (ON) during initialization of the bind data.

◆ Neuron ID

The neuron ID is written on the side of the service switch. Refer to Figure 1 on page 10 for

details.

The bar code for the neuron ID is included on the device and the packaging.

12 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 13

5 Installation Procedure

DANGER

W ARNING

5 Installation Procedure

◆ Section Safety

Electrical Shock Hazard

Do not connect or disconnect wiring while the power is on.

Failure to comply will result in death or serious injury.

Disconnect all power to the drive and wait at least the amount of time specified on the

drive front cover safety label. After all indicators are off, measure the DC bus voltage to

confirm safe level, and check for unsafe voltages before servicing. The internal capacitor

remains charged after the power supply is turned off.

Electrical Shock Hazard

Do not remove the front covers of the drive while the power is on.

Failure to comply could result in death or serious injury.

The diagrams in this section may include options and drives without covers or safety

shields to show details. Be sure to reinstal l covers or shields before operating any devices.

Use the option according to the instructions described in this manual.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized

personnel familiar with installation, adjustment, and maintenance of this product.

Do not touch the option card while the power to the drive is on.

Do not touch the drive’s main terminals and control circuit terminals when using the

service switch and digital operator connector on the option unit. Failure to comply could

result in death or serious injury.

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 13

Page 14

5 Installation Procedure

NOTICE

W ARNING

Do not use damaged wires, stress the wiring, or damage the wire insulation.

Failure to comply could result in death or serious injury.

Fire Hazard

Tighten all terminal screws to the specified tightening torque.

Loose electrical connections could result in death or serious injury by fire due to

overheating of electrical connections.

Damage to Equipment

Observe proper electrostatic discharge (ESD) procedures when handling the option,

drive, and circuit boards.

Failure to comply may result in ESD damage to circuitry.

Never shut the power off while the drive is running or outputting voltage.

Failure to comply may cause the application to operate incorrectly or damage the drive.

Do not operate damaged equipment.

Failure to comply may cause further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing parts.

Do not use unshielded cable for control wiring.

Failure to comply may cause electrical interference resulting in poor system performance.

Use shielded twisted-pair wires and ground the shield to the ground terminal of the drive.

Properly connect all pins and connectors.

Failure to comply may prevent proper operation and possibly damage equipment.

Check wiring to ensure that all connections are correct after installing the option

and connecting any other devices.

Failure to comply may result in damage to the option.

14 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 15

5 Installation Procedure

◆ Prior to Installing the Option

Prior to installing the option, wire the drive, make the necessary connections to the drive

terminals, and verify that the drive functions normally. Refer to the Quick Start Guide

packaged with the drive for information on wiring and connecting the drive.

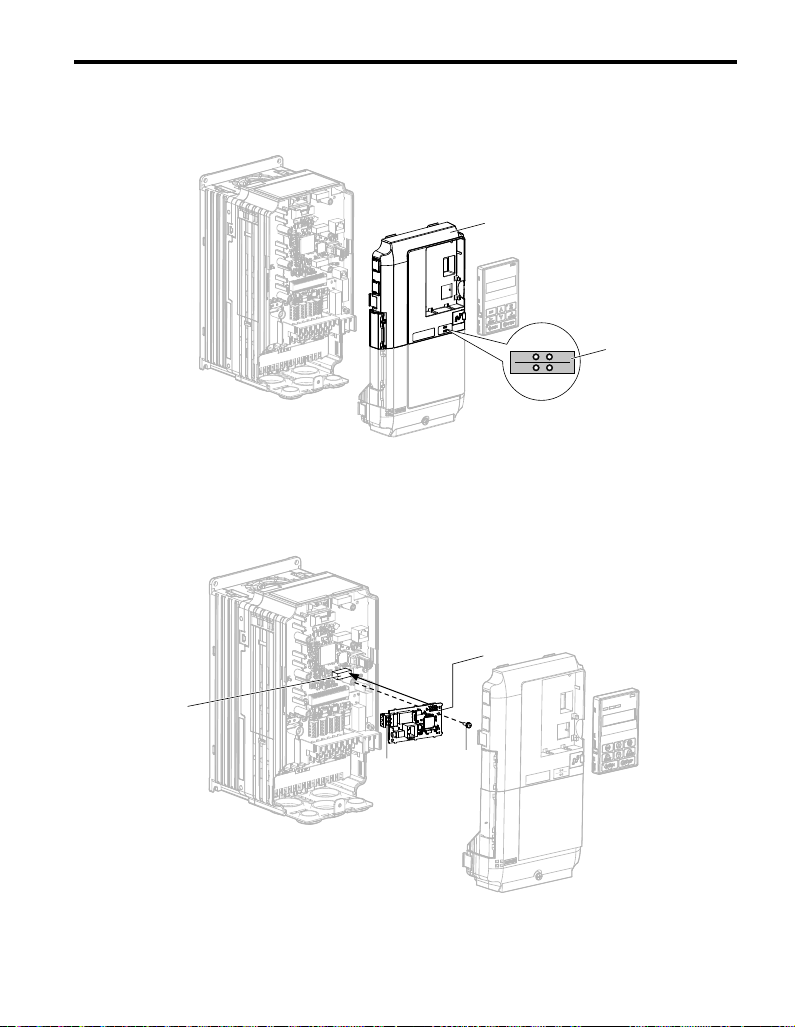

Figure 2 shows an exploded view of the drive with the option and related components for

reference.

Figure 2

N

M

L

K

J

I

H

G

A – Insertion point for CN5 H – Included screws

B – Option card I – Ground wire

C – Front cover J – Option terminal block

D – Digital operator K – Drive grounding terminal (FE)

E – LED label L – Connector CN5-A

F – Terminal cover M – Connector CN5-B

G – Removable tabs for wire routing N – Connector CN5-C

Figure 2 Drive Components with Option

A

B

C

F

D

E

ERR RUN

RX TX

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 15

Page 16

5 Installation Procedure

C

D

F

◆ Installing the Option

Refer to the instructions below to install the option.

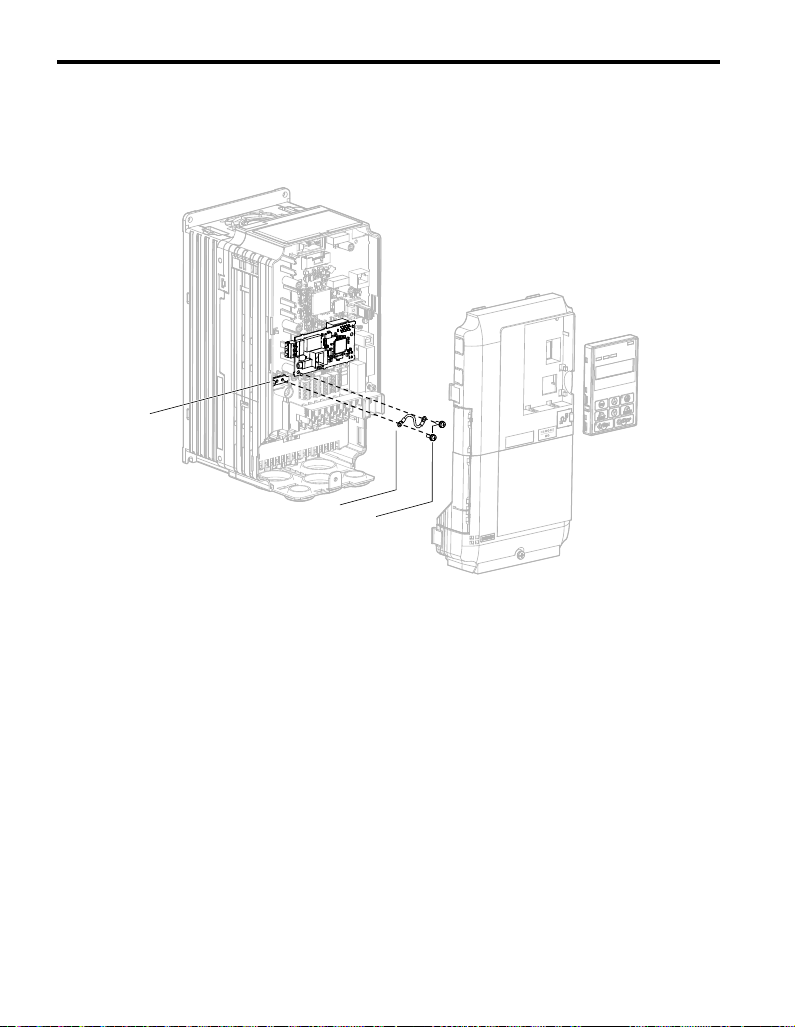

1. Shut off power to the drive, wait the appropriate amount of time for voltage to

dissipate, then remove the digital operator (D) and front covers (C, F). Refer to the

Quick Start Guide packaged with the drive for directions on removing the front

covers. Cover removal varies depending on drive size.

DANGER! Electrical Shock Hazard. Disconnect all power to the drive and wait at least the amount of time

specified on the drive front cover safety label. After all indicators are off , measure the DC bus voltage to

confirm safe level, and check for unsafe voltages before servicing to prevent electric shock. The internal

capacitor remains charged even after the power supply is turned off.

NOTICE: Damage to Equipment. Observe proper electrostatic discharge procedures (ESD) when handling

the option, drive, and circuit boards. Failure to comply may result in ESD damage to circuitry.

Figure 3

Figure 3 Remove the Front Covers and Digital Operator

16 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 17

5 Installation Procedure

2. With the front covers and digital operator removed, apply the LED label (E) in the

Figure 4

appropriate position on the drive top front cover (C).

C

ERR RUN

RX TX

E

Figure 4 Apply the LED Label

3. Make sure the screws on the left and right sides of the option terminal block (J) are

xm) or 4.4 to 5.43 (inch-lbs), then

B

H

NS MS

Figure 5

tightened with a tightening torque of 0.5 to 0.6 (N

insert the option card (B) into the CN5-A connector (L) located on the drive and

fasten it using one of the included screws (H).

L

J

Figure 5 Insert the Option Card

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 17

Page 18

5 Installation Procedure

H

I

K

4. Connect the ground wire (I) to the ground terminal (K) using one of the remaining

provided screws (H). Connect the other end of the ground wire (I) to the remaining

ground terminal and installation hole on the option using the last remaining provided

Figure 6

screw (H).

Figure 6 Connect the Ground Wire

Note: There are two screw holes on the drive for use as ground terminals. When connecting more than

two options, two ground wires will need to share the same drive ground terminal.

5. Select the proper type and length of communication cables.

Refer to Wiring Specifications on page 22 for details on selecting cables.

18 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 19

5 Installation Procedure

A SLD B

Preparing wire ends:

Screwdriver blade size

about 5.5 mm (7/32”)

When not using

crimped insulated

sleeves

Pull back the shielding and lightly

twist the end with fingers, keeping

the ends from fraying.

LONWORKS drop line

(do not solder ends)

Blade depth of

0.4 mm or less

Blade width of

2.5 mm or less

Tightening torque:

0.22 to 0.25 N m

or 4.4 to 5.3 in-lbs

Terminal block CN1

Loosen the screws and

insert the wire into the

opening on the terminal block.

6. Prepare and connect the communication cables to the terminal block as shown in

Figure 7 and Figure 8. Take particular precaution to ensure that each wire is

properly connected and wire insulation is not accidentally pinched into electrical

terminals.

WARNING! Fire Hazard. Tighten all terminal screws according to the specified tightening torque. Loose

electrical connections could result in death or serious injury by fire du e to overheating e lectrical connections.

Tightening screws beyond the specified tightening torque may result in erroneo us opera tion, d amage to the

terminal block, or cause a fire.

NOTICE: Heat shrink tubing or electrical tape may be required to ensure that cable shielding does not come

into contact with other wiring. Insufficient insulation may cause a sh ort circuit that can damage the opt ion or

the drive.

Figure 7

Insulation

Shield

Shield

Figure 7 Preparing Ends of Shielded Cable

Note: Separate communication cables from main circuit wiring and other electrical lines.

Figure 8

Shield sheath

(Insulate with electrical tape

or shrink tubing)

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 19

Figure 8 Preparing and Connecting Communication Cable Wiring

Page 20

5 Installation Procedure

<1>

CN5-A

SI-W3

FE

M

U

V

W

R

S

T

A

B

SLD

Drive

Zero phase

reactor

LONWORKS

Network

E

MCCB

Noise filter

Connection Diagram

Figure 9

Figure 9 Option Connection Diagram

<1> Make sure the lead installed to the FE terminal on the option card is connected to the ground terminal on the drive.

20 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 21

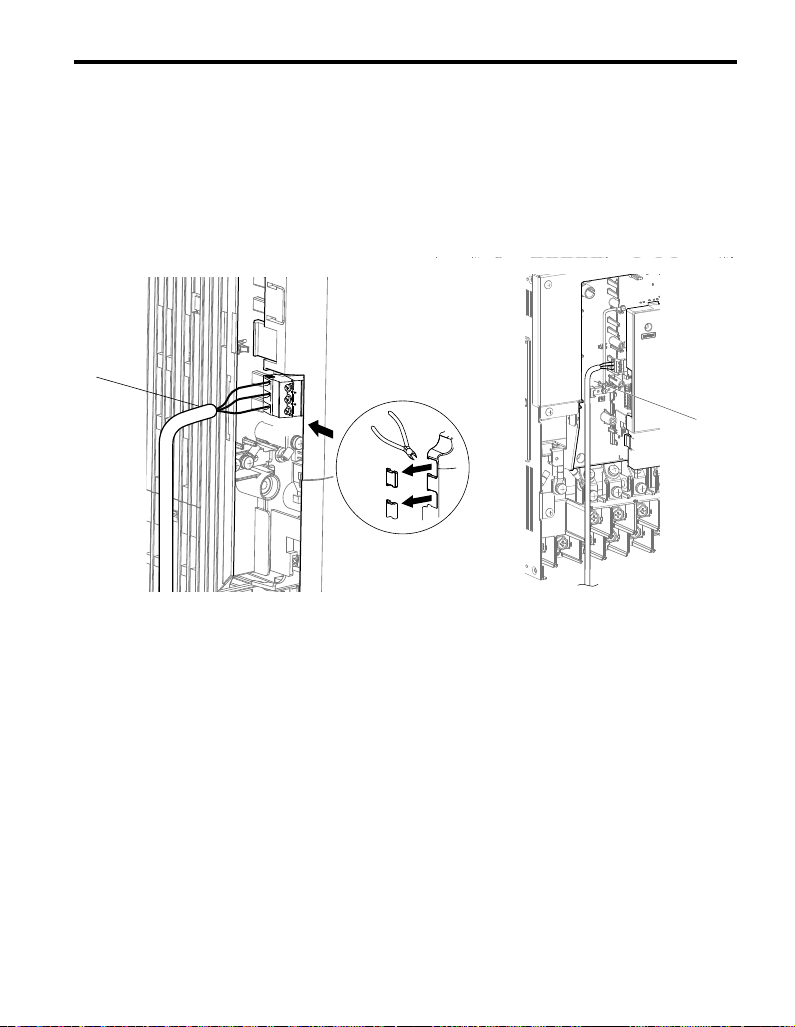

7. Route the option wiring.

B

A

Depending on the drive model, some drives may require routing wire through the

side of the front cover to the outside. In these cases, cut out the perforated openings

in the left side of the drive front cover as shown in Figure 10-A, and leave no sharp

edges to damage wiring.

Route the wiring inside the enclosure as show in Figure 10-B for drives that do not

require routing through the front cover. Refer to the Peripheral Devices & Options

Figure 10

section of the drive Technical Manual for more information.

5 Installation Procedure

A – Route wires through the openings

provided on the left side of the

front cover.

<1> The drive will not meet NEMA Type 1 requirements if wiring is exposed outside the enclosure.

<1>

Figure 10 Wire Routing Examples

B – Use the open space provided

inside the drive to route option

wiring.

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 21

Page 22

5 Installation Procedure

8. After wiring the terminal block, recheck the option wire routing performed in step 7.

9. Replace and secure the front covers of the drive (C, F) and replace the digital

Figure11

operator (D).

C

D

F

Figure 11 Replace the Front Covers and Digital Operator

Note: Take proper precautions when wiring the option so that the front covers will easily fit back onto

the drive. Make sure no cables are pinched between the front covers and the drive when

replacing the covers.

10. Set drive parameters in Table 4 for proper option performance.

◆ Wiring Specifications

Use only the LONWORKS network cables.

Refer to the Echelon web site for more information on network cabling (www.echelon.com).

The performance cannot be guaranteed when using the cables other than LONWORKS

network cables.

Separate the LONWORKS cables from the wiring to the main circuit and other lines.

22 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 23

5 Installation Procedure

◆ Termination

A free topology segment must be terminated. The segment can be terminated anywhere.

Figure 12

Twisted pair terminator

Ra

Ca

100 µF

50 V (min)

Figure 12 RC Network (Ra = 52.3 Ω ±1%, 1/8 W)

Cb

100 µF

50 V (min)

Shielded twisted pair

◆ XIF Files, Resource Files

XIF files and the resource files for this option card are not included. For more information,

either contact Yaskawa's sales department directly or your nearest Yask awa repre se ntative.

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 23

Page 24

6 Related Parameters

6 Related Parameters

The following parameters are used to set up the drive for operation with the option.

Confirm proper setting of the parameters in Table 4 before starting network

communications.

Table 4 Related Parameters

No.

(Addr.

Hex)

b1-01

(180)

b1-02

(181)

F6-01

(3A2)

F6-02

(3A3)

F6-03

(3A4)

F6-06

(3A7)

<2>

F6-07

(3A8)

Name Description Values

Selects the frequency reference input source

Frequency Reference

Selection 1

Run Command

Selection 1

Communications Error

Operation Selection

External Fault from

Comm. Option

Detection Selection

External Fault from

Comm. Option

Operation Selection

Torque Reference/

Torque Limit Selection

from Comm. Option

Multi-Step Speed

Enable/Disable

Selection when

NefRef/ComRef is

Selected

0: Digital Operator - Digital preset speed d1-01 to d1-17

1: Terminals - Analog input terminal A1 or A2

2: MEMOBUS/Modbus communications

3: Option

4: Pulse Input (Terminal RP)

Selects the run command input source

0: Digital Operator - RUN and STOP keys

1: Digital input terminals S

2: MEMOBUS/Modbus communications

3: Option

Determines drive response after a bUS error during

communications with the option

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

Sets the condition for external fault detection (EF0)

0: Always detected

1: Detected only during operation

Determines drive response for external fault input (EF0)

detection during LONWORKS communication

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

0: Torque reference / torque limit via network

communications are disabled.

1: Torque reference / torque limit via network

communications are enabled.

0: Multi-step speed reference disabled (F7 functionality)

1: Multi-step speed reference allowed (V7 functionality)

<1>

<1>

<3>

Default: 1

Range: 0 to 4

(Set to 3 for

LONWORKS

only)

Default: 1

Range: 0 to 3

(Set to 3 for

LONWORKS

only)

Default: 1

Range: 0 to 3

Default: 0

Range: 0, 1

Default: 1

Range: 0 to 3

Default: 0

Range: 0, 1

Default: 0

Range: 0, 1

24 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 25

6 Related Parameters

No.

(Addr.

Hex)

F6-08

(36A)

<1> Setting F6-01 or F6-03 to 3 will allow the drive to continue to operate after detecting a fault. When allowing the

drive to continue operation after fault detection, be sure to take proper safety measures such as installing an

emergency stop switch.

<2> Enabled in CLV, AOLV/PM, and CLV/PM control modes (A1-02 = 3, 6, or 7). When enabled, d5-01 determines

whether the value is read as the torque limit value (d5-01 = 0) or read as the torque reference value (d5-01 = 1).

This value is read as the torque limit in CLV/PM.

<3> Setting specifies that the torque reference or the torque limit is to be provided with Torque Reference/Torque

Limit Selection from Comm. Option (F6-06 = 1). The motor might not rotate if a torque reference or a torque limit

is not received from the network.

Name Description Values

Reset Communication

Parameters

Determines which F6- and F7- parameters are reset to

default values when initializing the drive using A1-03.

0: Do not reset parameters

1: Reset parameters

Default: 0

Range: 0, 1

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 25

Page 26

7 Network Variables

Drive

nviRequest

nvoStatus

NODE object: 0

Node

Networks Variable

VSD

Networks Variable

VSD object: 6010

Config_Property

nvoDrvSpeed

nvoRunStatus

nvoInvOutFreq

nvoDrvCurrent

nvoInvAlarm

nvoReadParamVal

nvoParamErr

nvoSpdStptFb

nvoSpdCmd

nvoDrvStatus

nvoFltstatus1

nvoFltstatus2

nvoFltstatus3

nvoEmergStatus

nvoDrvVolt

nvoDCBUS

nvoDrvPwr

nvoDrvEnergy

nvoDrvRunHours

nvoInvFault

Logic object:20000

analog object:20001

Select object:20002

Compere object:20003

Stepout object:20004

Dlytimer object:20005

Deviation object:20006

PID object:20007

Constout object:20008

Convtype object:20009

Savedata object:20010

nviDrvSpeedStpt

nviDrvSpeedRef

nviInvSetFreq

nviRunCommand

nviOpCommands

nviDrvSpeedScale

nviEmergOverride

nviDrvEnergyClr

nviFltRstCommand

nviReadParamNum

nviWriteParamNum

nviWriteParamVal

nciMaxSpeed nciRcvHrtBt nciInvSetFreq

nciMinSpeed nciMinOutTm nciDrvSpeedRef

nciSndHrtBt nciLocation nciDrvEngylimit

nciNmlSpeed nciPwupOutTm nciEngyMinDelta

nciNmlFreq nciFreqMinDelta1 nciOpMode

nciRampUpTm nciFreqMinDelta2 nciDrvRunMode

nciRampDownTm nciDrvSpeedScale

7 Network Variables

◆ Drive and Network Variables

Figure 13 outlines the relationship between drive and network variables.

Figure 13

26 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Figure 13 Drive and Network Variables

Page 27

◆ Node Objects

■ Object Requests

Iput: FSNVT_obj_request nviRequest

Requests the status for each object in a node.

Member Name Description

Object ID number

0 Entire node

1VSD

2 logic [0]

3 logic [1]

4 logic [2]

5 logic [3]

6 logic [4]

7 logic [5]

8 logic [6]

9 logic [7]

10 Analog [0]

object_id

11 Analog [1]

12 Analog [2]

13 Analog [3]

14 Analog [4]

15 Analog [5]

16 Analog [6]

17 Analog [7]

18 Analog [8]

19 Analog [9]

20 Select [0]

21 Select [1]

22 Select [2]

23 Select [3]

7 Network Variables

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 27

Page 28

7 Network Variables

Member Name Description

24 Select [4]

25 Select [5]

26 Select [6]

27 Select [7]

28 Compare [0]

29 Compare [1]

30 Compare [2]

31 Compare [3]

32 Compare [4]

33 Compare [5]

34 Compare [6]

35 Compare [7]

36 Stepout [0]

37 Dlytimer [0]

38 Dlytimer [1]

object_id

39 Deviation [0]

40 Pidmodule [0]

41 Pidmodule [1]

42 Pidmodule [2]

43 Pidmodule [3]

44 Constout [0]

45 Constout [1]

46 Constout [2]

47 Constout [3]

48 Constout [4]

49 Constout [5]

50 Convtype [0]

51 Convtype [1]

52 Convtype [2]

53 Convtype [3]

54 Savedata [0]

55 Savedata [1]

56 Savedata [2]

28 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 29

Member Name Description

object_id

object_request

57 Savedata [3]

Other invalid_id

0 RQ_NORMAL Enables the object.

1 RQ_DISABLED Disable the object

2 RQ_UPDATE_STATUS Not supported. (Normal response)

3 RQ_SELF_TEST Not supported. (Normal response)

4 RQ_UPDATE_ALARM Not supported. (Normal response)

5 RQ_REPORT_MASK

6 RQ_OVERRIDE

7 RQ_ENABLE Enables the object.

8 RQ_RMV_OVERRIDE

9 RQ_CLEAR_STATUS

10 RQ_CLEAR_ALARM

11 RQ_ALARM_NOTIFY_ENABLED

12 RQ_ALARM_NOTIFY_DISABLED

13 RQ_MANUAL_CTRL

14 RQ_REMOTE_CTRL

15 RQ_PROGRAM

0xff RQ_NUL

7 Network Variables

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

Not supported. (Returns message:

invalid_request.)

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 29

Page 30

7 Network Variables

■ Object Status

Output: FSNVT_obj_status nvoStatus

Displays the status of objects in a node.

Member Name Description

object_id Object ID (refer to the object request)

bit 31 invalid_id Turns ON if the object_id specified by nviRequest is invalid.

bit 30 invalid_request Turns ON if the object_request specified by nviRequest is invalid.

bit 29 disabled

bit 28 out_of_limits Not supported. (Always 0.)

bit 27 open_circuit Not supported. (Always 0.)

bit 26 out_of_service Not supported. (Always 0.)

bit 25 mechanical_fault Not supported. (Always 0.)

bit 24 feedback_failure Not supported. (Always 0.)

bit 23 over_range Not supported. (Always 0.)

bit 22 under_range Not supported. (Always 0.)

bit 21 electrical_fault Not supported. (Always 0.)

bit 20 unable_to_measure Not supported. (Always 0.)

bit 19 comm_failure Not supported. (Always 0.)

bit 18 fail_self_test Not supported. (Always 0.)

bit 17 self_test_in_progress Not supported. (Always 0.)

bit 16 locked_out Not supported. (Always 0.)

bit 15 manual_control Not supported. (Always 0.)

bit 14 in_alarm Not supported. (Always 0.)

bit 13 in_override Not supported. (Always 0.)

bit 12 report_mask Not supported. (Always 0.)

bit 11 programming_mode Not supported. (Always 0.)

bit 10 programming_fail Not supported. (Always 0.)

bit 9 alarm_notify_disabled Not supported. (Always 0.)

bit 8 to 0 reserved Always 0.

Indicates whether or not a given object is enabled for operation.

Turns ON when an object is disabled.

30 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 31

◆ VSD Network Variables

■ VSD Network Input Variables

Name Variable Type Description

nviDrvSpeedStpt SNVT_switch Drive Speed Setpoint

nviInvSetFreq SNVT_freq_hz Drive Frequency Reference (Hz)

nviDrvSpeedRef SNVT_lev_percent Drive Speed SetFreq (%)

nviRunCommand SNVT_switch Drive Run Reference

nviOpCommands SNVT_state Drive Operation Commands

nviDrvSpeedScale SNVT_lev_percent Drive Speed Setpoint Scaling

nviEmergOverride SNVT_hvac_emerg Drive Emergency

nviFltRstCommand SNVT_switch Drive Speed Setpoint Scaling

nviDrvEnergyClr SNVT_switch Drive Speed Setpoint Scaling

nviReadParamNum SNVT_count Drive Parameter Read

nviWriteParamNum SNVT_count Drive Parameter Write

nviWriteParamVal SNVT_count_inc Drive Parameter Write Data

■ VSD Network Output Variables

Name Variable Type Description

nvoDrvSpeed SNVT_lev_percent Drive Speed Feedback (%)

nvoRunStatus SNVT_switch Drive Run Status

nvoInvOutFreq SNVT_freq_hz Drive Output Frequency

nvoDrvCurrent SNVT_amp Drive Output Current

nvoDrvVolt SNVT_volt Drive Output Voltage

nvoDCBUS SNVT_volt Drive DC Voltage

nvoDrvPwr SNVT_power_kilo Drive Output Power

nvoDrvEnergy SNVT_elec_kwh_l Cumulative Drive Energy

nvoDrvRunHours SNVT_time_hour Drive Total Running Hours

nvoInvFault SNVT_switch Drive Fault Status

nvoInvAlarm SNVT_switch Drive Alarm Status

nvoReadParamVal SNVT_count_inc Drive Parameter Read Data

nvoParamErr SNVT_count Drive Parameter Error

nvoSpdStptFb SNVT_lev_percent Drive Speed Setpoint Feedback1

nvoSpdCmd SNVT_lev_percent Drive Speed Setpoint Feedback2

nvoDrvStatus SNVT_state Drive Status

nvoFltstatus1 SNVT_state Drive Fault Status1

7 Network Variables

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 31

Page 32

7 Network Variables

Name Variable Type Description

nvoFltstatus2 SNVT_state Drive Fault Status2

nvoFltstatus3 SNVT_state Drive Fault Status3

nvoEmergStatus SNVT_hvac_emerg Drive Emerg Status

32 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 33

8 Drive Configuration Properties

8 Drive Configuration Properties

◆ Drive Related Network Configuration Properties

Table 5 Drive Configuration Properties

Name Variable Type Description

nciMaxSpeed SNVT_lev_percent Maximum Motor Speed

nciMinSpeed SNVT_lev_percent Minimum Motor Speed

nciSndHrtBt SNVT_time_sec Send Heartbeat Time

nciNmlSpeed SNVT_rpm

nciNmlFreq SNVT_freq_hz Nominal Motor Frequency (Motor Rated Frequency)

nciRampUpTm SNVT_time_sec Drive Ramp Up Time (Drive Acceleration Time)

nciRampDownTm SNVT_time_sec

nciRcvHrtBt SNVT_time_sec Receive Heartbeat Time

nciMinOutTm SNVT_time_sec Minimum Send Time

nciLocation SNVT_str_asc Location Label

nciPwupOutTm SNVT_time_sec P ower delay Timer

nciFreqMinDelta1 SNVT_lev_percent

nciFreqMinDelta2 SNVT_ freq_hz

nciDrvSpeedScale SNVT_lev_percent nviDrvSpeedScale Default

nciInvSetFreq SNVT_ freq_hz nviInvSetFreq Default

nciDrvSpeedRef SNVT_lev_percent nviDrvSpeedRef Default

nciDrvEngylimit SNVT_elec_kwh_l

nciEngyMinDelta SNVT_elec_kwh_l

nciOpMode SNVT_count Reference Selection Mode

nciDrvRunMode SNVT_switch Run Command Status Mode

Nominal Motor Speed in RPM

(Motor Rated Rotation Frequency)

Minimum Ramp Down Time

(Minimum Deceleration Time)

Output Frequency Monitor Minimum Change Range

Setting 1 (nciFreqMinDelta1)

Output Frequency Monitor Minimum Change Range

Setting 2 (nciFreqMinDelta2)

Cumulative Power Monitor Upper Limit:

nciDrvEngylimit

Cumulative Power Monitor Minimum Change Range

Setting

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 33

Page 34

9 Troubleshooting

9 Troubleshooting

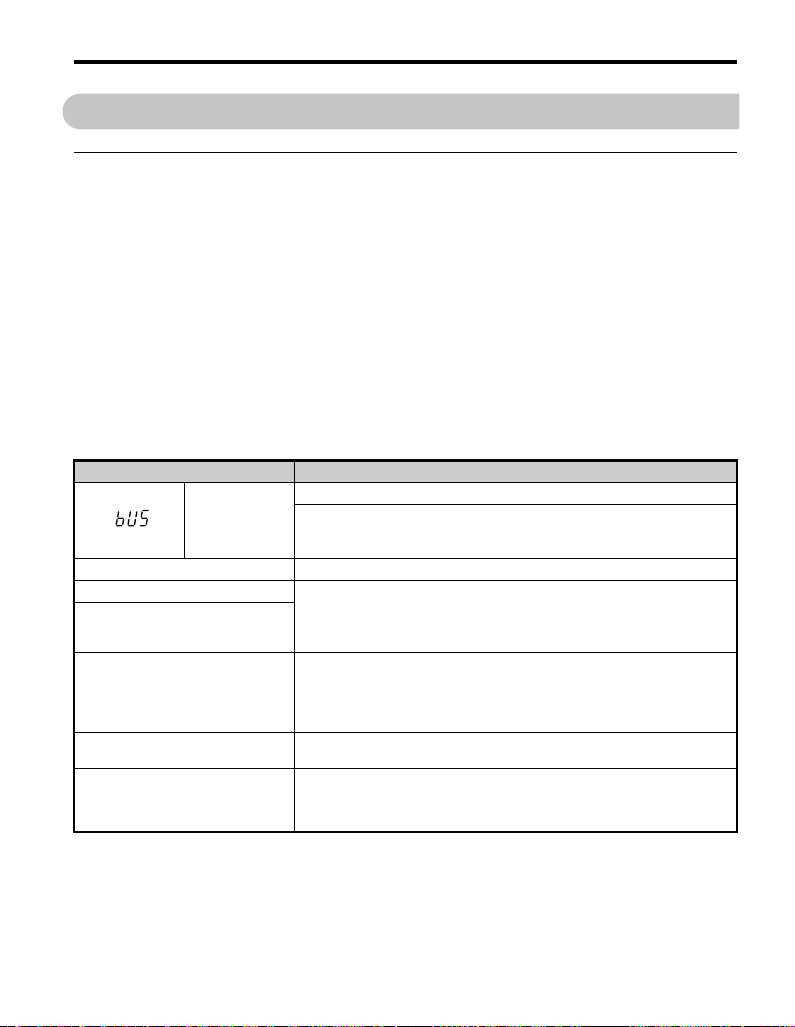

◆ Drive-Side Error Codes

Table 6 lists the various option-related fault codes. Refer to the drive Technical Manual for

further information about fault codes.

■ Faults

Both bUS (Option Communication Error) and EF0 (External Fault Input from the option)

can appear as either an alarm or as a fault. When a fault occurs, the digital operator ALM

LED remains lit. When an alarm occurs, the digital operator ALM LED flashes.

Check the following items first when an error code occurs on the drive:

• Communication cable connections

• Make sure the option is properly installed to the drive

• Did a momentary power loss interrupt communications?

Table 6 Fault Displays, Causes, and Possible Solutions

Digital Operator Display Fault Name

Option Communication Error

bUS

Cause Possible Solution

Network has stopped communicating

Communication cable is not connected

properly

A data error occurred due to noise

Option is damaged

Connection timeout

The connection was lost after establishing initial communication.

Only detected when the run command frequency reference is assigned to

the option

(bl-01 = 3 or bl-02 = 3).

Check for faulty wiring.

Correct any wiring problems.

• Counteract noise in the control circuit wiring, main circuit lines, and

ground wiring.

• If a magnetic contactor is the noise source, install a surge absorber to the

contactor coil.

• Use only the LONWORKS network cables.

Ground the shield on the controller side and on the option side.

If there are no wiring problems and the fault continues to occur, replace

the option.

The option Receive Heart Beat timer timed out.

Make sure that Receive Heart Beat time is set properly.

Check the option connection and communication signal.

34 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 35

9 Troubleshooting

Digital Operator Display Fault Name

EF0

Cause Possible Solution

An external fault is being sent from the

network

Problem with the network program

Digital Operator Display Fault Name

oFA00

Cause Possible Solution

Non-compatible option connected to

drive port CN5-A

Digital Operator Display Fault Name

oFA01

Cause Possible Solution

Problem with the connector between the

drive and option

Digital Operator Display Fault Name

to

oFA30 to oFA43

Cause Possible Solution

Option hardware fault Replace the option. Contact Yaskawa for assistance.

Digital Operator Display Fault Name

oFb00

Cause Possible Solution

Non-compatible option connected to

drive port CN5-B

External Fault Input from the option

The alarm function for an external device has been triggered.

• Remove the cause of the external fault

• Reset the external fault input from the network

Check the program used by the network and make the appropriate

corrections.

Non-Compatible Option connected to drive port CN5-A

Option is not properly connected.

Use only compatible options. Connect the SI-W3 to CN5-A. For other

option connections refer to the Installation Manual for those options.

Option Fault (CN5-A)

Option is not properly connected.

Turn the power off and check the connectors between the drive and option.

Option Fault (CN5-A)

Communication ID error.

Non-Compatible Option connected to drive port CN5-B

Non-compatible option is connected.

Use only compatible options. Connect the SI-W3 to CN5-A. For other

option connections refer to the Installation Manual for those options.

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 35

Page 36

9 Troubleshooting

Digital Operator Display Fault Name

oFb02

Cause Possible Solution

Options AI-A3 or D1-A3 connected to

the CN5-B port while an option was

connected to CN5-A

Digital Operator Display Fault Name

oFc00

Cause Possible Solution

Non-compatible option connected to

port CN5-C

Digital Operator Display Fault Name

oFc02

Cause Possible Solution

Options AI-A3 or D1-A3 connected to

the CN5-C port while an option was

connected to CN5-A

■ Minor Faults and Alarms

Digital Operator Display Minor Fault Name

CALL

Cause Possible Solution

Communication wiring or terminal

resistor connection is faulty. There is a

short circuit, or an option component is

not connected properly

Network programming error

Damaged communication circuitry

Option Fault (CN5-B)

Two of the same option are connected simultaneously.

Only one of these options, AI-A3, DI-A3 or SI- option can be

connected to the drive at the same time. The SI-W3 must be connected to

CN5-A.

Non-Compatible Option connected to drive port CN5-C

Non-compatible option is connected.

Use only compatible options. Connect the SI-W3 to CN5-A. For other

option connections refer to the Installation Manual for those options.

Option Fault (CN5-C)

Two of the same options are connected simultaneously.

Only one of these options, AI-A3, DI-A3 or SI- option can be

connected to the drive at the same time. The SI-W3 must be connected to

CN5-A.

Serial Communication Transmission Error

Communication has not yet been established.

Check for wiring errors and correct the wiring.

Remove any ground shorts and reconnect loose wires.

Check communications at start-up and correct

programming errors.

Cycle power to the drive and replace the drive if the fault

continues to occur.

Minor Fault

(H2- = 10)

Yes

36 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 37

10 Specifications

10 Specifications

Table 7 Option Specifications

Items Specifications

Model SI-W3

Note Type Host Application Node

Communication Speed 78 kbps

Communication IC Neuron chip FT3120

Communication Driver FT-X1 (free topology)

Protocol LonTalk protocol node

Network Variables

Network Variable Alias Maximum: 50

Maximum Number of

Connections

Total Wiring Length Max 500 m

Ambient Temperature -10°C to +50°C (14°F to 122°F)

Humidity 95% RH or lower with no condensation

Storage Temperature -20°C to +60°C (-4°F to 140°F) allowed for short-term transport of the product

Area of Use Indoor (free of corrosive gas, airborne particles, etc.)

Altitude 1000 m (3280 ft.) or lower

Total: 236

Standard Network Variable Types (SNVT): Variable Speed Motor Drive function profile

Ver1.1

64 (in one segment)

YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide 37

Page 38

10 Specifications

QSG_only

◆ Revision History

Revision dates and manual numbers appear on the bottom of the back cover.

MANUAL NO.ޓTOBP C730600 56A

Published in Japan November 2011 11-11

Date of original publication

Date of publication

Date of

Publication

November 2011 −−First edition

Revision

Number

Section Revised Content

38 YASKAWA ELECTRIC TOBP C730600 56A 1000-Series Option SI-W3 Installation Guide

Page 39

This Page Intentionally Blank

Page 40

YASKAWA AC Drive 1000-Series Option

LONWORKS

Installation Manual

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: 81-930-25-3844 Fax: 81-930-25-4369

http://www.yaskawa.co.jp

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4502 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (927-5292) or 1-847-887-7000 Fax: 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenda Fagundes Filho, 620 Bairro Saude, São Paulo, SP04304-000, Brasil

Phone: 55-11-3585-1100

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstrasse 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000

http://www.yaskawa.co.uk

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Yeoungdungpo-gu, Seoul, 150-877, Korea

Phone: 82-2-784-7844

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No. 18 Xizang Zhong Road, 17F, Harbour Ring Plaza, Shanghai, 200001, China

Phone: 86-21-5385-2200

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, 104, Taiwan

Phone: 886-2-2502-5003

Fax: 55-11-5581-8795

Fax: 44-1236-458182

Fax: 82-2-784-8495

Fax: 65-6289-3003

Fax: 86-21-5385-3299

Fax: 86-10-8518-4082

Fax: 886-2-2505-1280

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure

to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2011 YASKAWA ELECTRIC CORPORATION. All rights reserved.

MANUAL NO. TOBP C730600 56A

Published in Japan November 2011 11-11

10-10-6

Page 41

This Page Intentionally Blank

Page 42

Copyright © 2011 株式会社 安川電機

本書の内容の一部または全部を,当社の文書による許可なしに,転載または複製するこ

とは,固くお断り致します。

2 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 43

目次

1 ご使用になる前に . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 製品の概要 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 製品が届いたら . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 各部の名称 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5 取付けと配線 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6 関連するパラメータ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7 ネットワーク変数 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8 ドライブコンフィグレーションプロパティ. . . . . . . . . . . . . . 32

9 異常診断とその対策. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

10 仕様と保証について. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書 3

Page 44

1 ご使用になる前に

1 ご使用になる前に

◆ 取扱説明書について

本オプションカードに関連する取扱説明書には以下のものがあります。目的に応じてご

利用ください。

オプションカード

安川インバータ

1000 シリーズ オプション

LONWORKS 通信

取扱説明書

資料番号:TOBP C730600 56

(本書)

安川インバータ

1000 シリーズ オプション

LONWORKS 通信

テクニカルマニュアル

資料番号:SIJP C730600 56

インバータ本体

安川インバータ 1000 シリーズ

クイックスタートガイド

安川インバータ 1000 シリーズ

テクニカルマニュアル

最初にお読みください。

本製品をお使いいただくうえで基本とな

る,配線,設定,機能,異常診断について

説明しています。ご購入時,オプション

カードに同梱されています。

本製品についてさらに詳しい使い方が知り

たいときにお読みください。取扱説明書に

は記載されていない詳細な内容を確認でき

ます。製品には同梱されておりませんの

で,当社の製品・技術情報サイト

(http://www.e-mechatronics.com/) からご覧

ください。

本オプションカードを取付けるインバータ

の取扱説明書を参照してください。

本オプションカードをお使いいただくうえ

で基本となる,据え付け,配線,操作手

順,機能,異常診断,保守点検を詳細に説

明しています。

パラメータの基本設定や,調整方法につい

ても説明しています。

クイックスタートガイドは,インバータに

同梱されています。テクニカルマニュアル

は,インバータには同梱されておりません

ので,当社の製品・技術情報サイト

(http://www.e-mechatronics.com/) からご覧

ください。

◆ 本書中の用語・略称について

(注) 守っていただきたい重要な事柄です。また,インバータのアラーム表示が発生するな

ど,装置の損傷には至らないレベルの軽度の注意事項や,補足事項を示します。

オプションカード 安川インバータ 1000 シリーズオプション LONWORKS 通信

◆ 登録商標について

•LONWORKS及び LonTalk は米国 Echelon 社の登録商標です。

• その他,本文中に記載してある会社名,製品名は,各社の商標または登録商標です。

4 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 45

1 ご使用になる前に

危険

警告

注意

重要

◆ 安全に関するシンボルマーク

オプションカードの配線・設定,操作をする前に,本取扱説明書をよくお読みくださ

い。オプションカードは,本取扱説明書の記載内容と現地の規格に従って設置してくだ

さい。

以下のシンボルマークは,本取扱説明書内での安全に関する重要な記載を示すために使

用されます。これらの注意事項をお守りいただけない場合は,死亡または重傷につなが

る可能性や,本製品や関連機器及びシステムの破損につながるおそれがあります。

取扱いを誤った場合に,死亡または重傷につながる危険が生じる可能性があり,その危険

の切迫度が高いことが想定されます。

取扱いを誤った場合に,死亡または重傷につながる危険が生じる可能性があります。

取扱いを誤った場合に,軽傷を受ける危険が生じる可能性があります。

取扱いを誤った場合に,物的損害が発生するおそれがあります。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 5

Page 46

1 ご使用になる前に

危険

■ 安全上のご注意

一般注意事項

• 取扱説明書に掲載している図解は,細部を説明するために,カバーまたは安全のための

遮へい物を取り外した状態で描かれている場合があります。この製品を運転するとき

は,必ず規定どおりのカバーや遮へい物を元通りに戻し,取扱説明書に従って運転して

ください。

• 取扱説明書に掲載している図は,代表事例であり,お届けした製品と異なる場合があり

ます。

• 取扱説明書は,製品の改良や仕様変更,及び取扱説明書自身の使いやすさの向上のため

に適宜変更することがあります。

• 取扱説明書を注文される場合は,当社代理店または取扱説明書の裏表紙に記載している

最寄りの当社営業所に,表紙の資料番号を連絡してください。

本取扱説明書に記載された,安全にかかわるすべての情報にご留

意ください。

警告事項をお守りいただけない場合は,死亡または重傷につながるおそれもありますの

で,ご留意ください。

貴社または貴社の顧客において,本取扱説明書の記載内容を守らないことにより生じた,

傷害や機器の破損に対して,当社はいっさいの責任を負いかねます。

6 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 47

1 ご使用になる前に

重要

インバータやオプションカードの内部の回路を変更しないでくだ

さい。

インバータ,またはオプションカードが破損するおそれがあります。貴社及び貴社顧客に

おいて製品の改造がなされた場合は当社の保証外とさせていただきます。

輸送・設置時の木質梱包財(木枠,合板,パレットなど含む)の

消毒・除虫処理についてのご注意

梱包用木質材料の消毒・除虫が必要な場合は,必ずくん蒸以外の方法を採用してくださ

い。

例:熱処理(材心温度 56°C 以上で 30 分間以上)

くん蒸処理をした木質材料にて電気製品(単体あるいは機械などに搭載したもの)を梱包

した場合,そこから発生するガスや蒸気により電子部品が致命的なダメージを受けること

があります。特にハロゲン系消毒剤(フッ素・塩素・臭素・ヨウ素など)はコンデンサ内

部の腐食の原因となります。

また,梱包後に全体を処理する方法ではなく,梱包前の材料の段階で処理してください。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 7

Page 48

2 製品の概要

2 製品の概要

◆ 本製品について

LONWORKS 通信オプションカード(形式:SI-W3)は,LonTalk に準拠しています。

インバータを LONWORKS ネットワークに接続し,LonTalk プロトコルを用いて,

データ通信を行うためのインタフェースです。

インバータにオプションカードを装着すると,LonTalk プロトコルに準拠したデバイス

から以下の操作ができます。

• インバータの運転/停止

• インバータの運転状況のモニタ

• インバータのパラメータの設定変更/参照

◆ 対応するインバータ

本オプションカードは,以下のインバータに対応しています。

表 1 対応するインバータ

インバータ

A1000

<1> インバータのネームプレートにある PRG 欄に表示されています。

ソフトウェアバージョン <1>

1017 以降

8 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 49

3 製品が届いたら

取扱説明書

3 製品が届いたら

製品がお手元に届きましたら,以下の項目を確認してください。

• オプションカードに傷や汚れが付いていないか,外観を点検してください。

製品搬送時の損傷は当社の保証範囲外とさせていただきます。製品に損傷があった

場合は,直ちに運送業者にご連絡ください。

• ご注文どおりの製品かどうか,基板に印刷している形式「SI-W3」を確認してくださ

い。印刷場所については図 1 を参照してください。

• 製品に不具合がありましたら,直ちにご購入いただいた代理店または当社の営業所

へご連絡ください。

◆ 梱包内容の確認

表 2 梱包内容

梱

包

品

数

量

オプションカード

1131 11

リード線

(接地用)

ねじ (M3) LED ラベル バーコードラベル 取扱説明書

*123456789ABC*

ERR RUN

RX TX

*123456789ABC*

*123456789ABC*

◆ 必要な工具

オプションカードをインバータに取付けるときには,以下の工具 が必要です。

• ドライバ ⊕ (M3)

• ドライバ (M2,先端部厚さ:0.4 mm,先端幅:2.5 mm)

(注) 通信ケーブル側のコネクタをお客様が作成される場合,別途工具が必要になります。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 9

Page 50

4 各部の名称

D

B

C

A

E

F

L K J I H G

M

裏面

4 各部の名称

◆ オプションカード

ê}1

A–インバータ接続用コネクタ (CN5)

B–取付穴 I–サービススイッチ

C – LED (ERR)

D – LED (RUN)

E– LED (TX)

F– LED (RX) <1>

G– ニューロン ID 表示

<1> LED の表示内容については,「LED 表示」(12 ページ)を参照してください。

<2> オプションカード取付時に,必ず同梱のリード線(接地用)を接続してください。

10 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

<1>

<1>

<1>

図 1 オプションカード

H – LED (SERVICE)

J–オペレータ接続用コネクタ (CN3)

K–基板形式

L–接地端子(取付穴)<2>

M–端子台 CN1

Page 51

4 各部の名称

1

2

3

◆ 端子台 CN1

端子台 CN1 を使用して,オプションカードを LONWORKS ネットワークに接続しま

す。端子台は,基板から取り外すことができます。

表 3 端子台の詳細

図 端子番号 名称 詳細

1A

シグナルライン

2SLD

3B

通信シールド

シグナルライン

◆ オペレータ接続用コネクタ CN3

危険 ! インバータの主回路端子,制御回路端子に触れないでください。取扱いを誤った場合は,感電のお

それがあります。

オペレータ接続用コネクタ (CN3) にディジタルオペレータ(形式:JVOP-182)を接続

して,DDC ファンクションパラメータを設定することができます。

◆ サービススイッチ

ニューロン ID 出力スイッチです。サービススイッチを押すとニューロン ID がネット

ワークへ出力されます。

■ バインド情報の初期化

サービススイッチを押しながら,インバータの電源を投入するとバインド情報がクリア

され,コンフィグプロパティの設定が出荷時設定になります。

(注) バインド情報初期化中はインバータの電源を遮断しないでください。バインド情報の

初期化中は RUN,RX,TX,ERR の LED が点灯します。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 11

Page 52

4 各部の名称

◆ LED 表示

オプションカードには 5 種類の LED があります。

表 4 の動作状態で LED が点灯/点滅します。

表 4 LED 表示

LED の名称

RUN

RX

TX

ERR

SERVICE

(注) バインド情報の初期化中は RUN,RX,TX,ERR の LEDが点灯します。

表示

色 状態

点灯 正常 正常に動作している。

点滅

緑

消灯

点灯/点滅 受信中 自局宛データ受信中

緑

緑

赤

緑

消灯

点灯/点滅 送信中 データ送信中

消灯 送信なし データ送信していない。

点灯

点滅 通信異常

消灯 正常 正常に動作している。

点灯

点滅

消灯 正常 正常に動作している。

動作状態 詳細(主な異常)

ネットワーク

未構成状態

電源 OFF

ハードウェア

異常

自局宛データ

受信なし

ハードウェア

異常

サービスス

イッチ押下時

ハードウェア

異常

ネットワーク

未構成状態

LONWORKS ネットワークに構成されていない。

電源が供給されていない。

回復不可能な異常が発生している。

電源遮断し再投入しても回復しない場合,オプ

ションカードの交換が必要となる場合がありま

す。

受信信号なし

回復不可能な異常が発生している。

電源遮断し再投入しても回復しない場合,オプ

ションカードの交換が必要となる場合がありま

す。

CALL 発生中,BUS 発生中

サービススイッチが押されている。

回復不可能な異常が発生している。

電源を再投入しても回復しない場合,オプショ

ンカードの交換が必要となる場合があります。

LONWORKS ネットワークに構成されていない。

◆ ニューロン ID

ニューロン ID は,サービススイッチの側に記載されています。詳細は,図 1 を参照し

てください。

ニューロン ID のバーコードラベルが製品と同梱されています。

12 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 53

5 取付けと配線

危険

警告

5 取付けと配線

◆ 安全上のご注意

感電防止のために

オプションカードを接続するときは,事前にインバータの電源をお切りください。

取扱いを誤った場合は,感電のおそれがあります。

インバータに記載された時間内はフロントカバー,ターミナルカバーを取り外さないでく

ださい。作業前にすべての表示灯が消灯し,主回路直流電圧が安全なレベルになったこと

を確認してください。電源を切っても,インバータの内部コンデンサに電圧が残存してい

ます。

感電防止のために

インバータのフロントカバーを外したまま,運転しないでください。

取扱いを誤った場合は,感電のおそれがあります。

本取扱説明書に掲載している図解は,細部を説明するために,カバーまたは安全のための

遮へい物を取り外した状態で描かれている場合があります。この製品を運転するときは,

必ず規定どおりのカバーや遮へい物を元通りに戻し,取扱説明書に従って運転してくださ

い。

電気工事の専門家以外は,保守・点検・部品交換をしないでください。

感電のおそれがあります。

配線・設定,操作は,オプションカードの設置,調整,修理に詳しい人が行ってくださ

い。

インバータの通電中は,オプションカードに触れないでください。

オプションカードのサービススイッチ,オペレータポートを使用する際は,インバータ主

回路端子,制御回路端子に触れないでください。

取扱いを誤った場合は,感電のおそれがあります。

ケーブルは傷つけたり,無理なストレスをかけたり,重たいものを載せたり,挟み込んだ

りしないでください。

感電のおそれがあります。

火災防止のために

端子ねじは指定された締め付けトルクで締め付けてください。

主回路電線の配線接続部に緩みがあると,電線接続部のオーバーヒートにより火災のおそ

れがあります。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 13

Page 54

5 取付けと配線

重要

機器破損防止のために

オプションカードを扱うときは,静電気 (ESD) 対策の決められた手順に従ってください。

取扱いを誤ると,静電気によって,基板上の回路が破損するおそれがあります。

インバータの電圧出力中は,電源を外さないでください。

取扱いを誤ると,インバータが破損するおそれがあります。

破損した機器を運転しないでください。

さらに機器の破損が進行するおそれがあります。

明らかな破損や紛失した部品がある機器を接続したり,操作しないでください。

端子ねじは指定された締め付けトルクで締め付けてください。

端子台が破損するおそれがあります。

配線時には,指定品でないケーブルを使用しないでください。

動作不良の原因となります。

当社の推奨するケーブルを使用してください。

コネクタはしっかりと挿入してください。

機器の誤動作・破損の原因となります。

インバータとその他の機器の配線が完了したら,すべての配線が正しいかどうか確認して

ください。

配線を誤ると,オプションカードが破損するおそれがあります。

14 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 55

5 取付けと配線

ERR RUN

RX TX

F

H

K

L

M

N

I

B

C

D

E

A

G

J

◆ 取付けの前に

オプションカードを取付ける前に,必ずインバータの端子台の配線を行ってください。

オプションカード接続前にインバータが正常に動作するか確認してください。インバー

タの接続・配線に際しては,インバータの取扱説明書を参照してください。

インバータと各部品の展開図を図 2 に示します。

ê}2

A–接続コネクタ (CN5) を差し込む。 H–ねじ

B–オプションカード I–リード線

C–フロントカバー J–端子台

D–オペレータ K–インバータ側接地端子 (FE)

E–LEDラベル L–接続コネクタ CN5-A

F–ターミナルカバー M–接続コネクタ CN5-B

G–ケーブル配線スペースカバー

(切り取り可能)

図 2 各部の名称

N–接続コネクタ CN5-C

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 15

Page 56

5 取付けと配線

C

D

F

◆ オプションカードの取付け

以下の手順に従ってオプションカードを取付けてください。

1. インバータの主回路電源を遮断後, インバータに記載された時間以上待ってからオ

ペレータ (D),フロントカバー (C),ターミナルカバー (F) を取り外します。フロ

ントカバー,ターミナルカバー,オペレータの取り外し・取付けについては,オ

プションカードを取付けるインバータの取扱説明書を参照してください。

危険 ! 感電防止のために。インバータに記載された時間内はフロントカバー,ターミナルカバーを取り外

さないでください。作業前にすべての表示灯が消灯し,主回路直流電圧が安全なレベルになったこ

とを確認してください。電源を切っても,インバータの内部コンデンサに電圧が残存しています。

重要:機器破損防止のために。オプションカードを扱うときは,静電気 (ESD) 対策の決められた手順に

従ってください。取扱いを誤ると,静電気によって,基板上の回路が破損するおそれがあります。

ê}3

図 3 オペレータ,フロントカバー,ターミナルカバーの取り外し

16 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 57

5 取付けと配線

2. フロントカバー (C) とオペレータを取り外した状態で,LED ラベル (E) をフロント

ê}4

カバー下部の図に示す位置に貼り付けてください。

C

ERR RUN

RX TX

E

図 4 LED ラベルの貼り付け

3. オプションカード (B) をインバータの CN5-Aコネクタ (L) に接続し,同梱のねじ (H)

ê}5

で固定してください。

L

B

H

図 5 オプションカードの取付け

NS MS

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 17

Page 58

5 取付けと配線

H

I

K

4. リード線 (I) を同梱のねじ (H) でオプションカードの接地端子(取付穴)に接続し,

ê}6

もう一方をインバータの接地端子 (K) に接続してください。

図 6 リード線の接続

(注) インバータ側の接地端子には 2 つしかねじ穴がありません。オプションカードを 3 枚

取付ける場合は,リード線の端子を重ねて接続してください。

5. LONWORKS 通信専用ケーブルを選定します。ケーブル長の詳細については,「通

信ケーブルの仕様」(22 ページ)を参照してください。

18 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 59

5 取付けと配線

6. 図 7のとおりに LONWORKS 専用ケーブルを末端処理し,図 8 のとおりにオプショ

ンカードにケーブルを接続します。端子台 CN1 を基板に接続するときは,端子台

CN1 が確実に固定されたことを確認してください。

また,すべてのケーブルが確実に固定され,ケーブルの被覆が端子台の挿入部に

噛み込んでいないことを確認してください。はみ出している心線はすべて切断し

てください。

警告 ! 端子ねじは指定された締め付けトルクで締め付けてください。配線接続部に緩みがあると,電線接

続部のオーバヒートにより火災のおそれがあります。また,指定した以上の締め付けトルクでの締

め付けは,機器の誤作動 • 破損,または火災の原因になります。

重要:シールド線は他の信号線や機器に接触しないように,熱収縮チューブやテープなどで絶縁してくだ

さい。 絶縁を怠ると,回路の短絡によりオプションカードまたはインバータの破損の原因になりま

す。

ê}7

外被

シールド外覆

ê}8

ケーブルの先端処理 ドライバの大きさ

ケーブルの被覆をむいたら心線がば

らばらにならないよう,指で軽く心

線をより直してください。

約5.5 mm

棒端子を

(

使用しないとき

熱収縮チューブやテープなどで

絶縁してください。

図 7 シールド線の端末処理

(

ねじを緩めて,挿入部が開口

したらケーブルを挿入してく

ださい。

LONWORKS 通信ケーブル

(ハンダ処理をしないこと)

シールド外覆

先端部厚さ

0.4 mm以下

2.5 mm以下

(締め付けトルク:

ޓ0.22〜0.25 ( N m))

ASLDB

端子台CN1

図 8 通信ケーブルの配線

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 19

Page 60

5 取付けと配線

<1>

CN5-A

SI-W3

FE

M

U

V

W

R

S

T

A

B

SLD

インバータ

零相

リアクトル

LONWORKS

ネットワークへ

E

MCCB

入力用

ノイズ

フィルタ

配線図

<1> オプションカードの FE 端子は付属のリード線を使用し,必ずインバータの接地端子と接続してくだ

さい。

図 9 オプションカードの接続例

20 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 61

5 取付けと配線

B

A

7. ケーブルを配線します。

配線経路はインバータにより異なります。インバータ内部に十分な配線スペース

がない場合は,インバータのフロントカバー左側のケーブル配線スペースカバー

(G) をニッパなどで切り取り,図 10 (A) のようにケーブルをインバータの外に出

して配線してください。切り口でケーブルが傷つくことがないように切断面を紙

やすりなどで処理してください。

インバータ内部に配線スペースがある場合は,図 10 (B) のようにインバータ内に

ケーブルを配線してください。詳細については,インバータのテクニカルマニュ

アルを参照してください。

(注) 通信ケーブルは,主回路配線や他の動力線,電力線と分離して配線してください。

ê}9

A–フロントカバー左側面のケーブル配線用

スペースから外に出して配線

<1> ケーブルを外に出して配線する場合は,閉鎖壁掛形として使用することはできません。

<1>

図 10 ケーブルの配線方法

B–インバータ内部の配線スペース

を利用して配線

8. ケーブルを接続したら,オプションカードの接続を再確認してください。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 21

Page 62

5 取付けと配線

9. フロントカバー (C),ターミナルカバー (F) 及びオペレータ (D) をインバータに取付

ê}10

けます。

C

D

F

図 11 フロントカバー,ターミナルカバー及びオペレータの取付け

(注) カバーを閉じることで,ケーブルに過大な力がかからないように配慮して配線してく

ださい。また,カバーでケーブルを挟み込まないように注意してください。

10. 表 5 のパラメータを設定します。

◆ 通信ケーブルの仕様

LONWORKS システムでは,LONWORKS専用ケーブルを使用してください。

LONWORKS 専用ケーブル以外では,LONWORKSシステムの性能を保証できません。

ケーブルの仕様,お問い合わせ先については,Echelon社のホームページ

(www.echelon.com)を参照してください。

通信ケーブルは,主回路配線や他の動力線,電力線と分離して配線してください。

22 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 63

5 取付けと配線

Ca

100 µF

50 V (min)

Ra

Cb

100 µF

50 V (min)

ツイストペア

終端回路

シールド付き

ツイストペア

(STP)

◆ 終端処理

フリートポロジーのセグメントでは終端を 1 つ置く必要があります。セグメントの任

意の場所に置くことがききます。

ê}11

図 12 RC ネットワーク(Ra = 52.3 Ω ±1%,1/8 W)

◆ XIF ファイル,リソースファイル

XIF ファイルや本オプションカード専用のリソースファイルは,付属しておりません。

当社代理店または営業担当にお問い合わせください。また,当社の製品・技術情報サイ

ト (http://www.e-mechatronics.com/) からもダウンロードできます。

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 23

Page 64

6 関連するパラメータ

6 関連するパラメータ

オプションカードを使用する際に関連のあるパラメータを以下に示します。通信を開始

する前に,すべてのパラメータの設定が正しいか確認してください。

表 5 関連するパラメータ

No.

(MEMO

BUS

レジスタ)

b1-01

(180H)

b1-02

(181H)

F6-01

(3A2H)

F6-02

(3A3H)

F6-03

(3A4H)

F6-06

(3A7H)

<2>

F6-07

(3A8H)

名称 設定範囲 設定範囲

周波数指令の入力方法を選択します。

0: オペレータ

周波数指令選択 1

運転指令選択 1

bUS(オプション通信

異常)検出時の動作選

択

EF0(通信オプション

カードからの外部異常

入力)の検出条件

EF0(通信オプション

カードからの外部異常

入力)検出時の動作選

択

通信オプションからの

トルク指令/トルクリ

ミット選択

NetRef/ComRef 選択

時の多段速指令有効/

無効切り替え

1: 制御回路端子(アナログ入力)

2: MEMOBUS 通信

3: オプションカード

4: パルス列入力

運転指令の入力方法を選択します。

0: オペレータ

1: 制御回路端子(シーケンス入力)

2: MEMOBUS 通信

3: オプションカード

オプションカード通信エラー (bUS) が検出された

ときの停止方法を選択します。

0: 減速停止(C1-02 の減速時間で減速停止)

1: フリーラン停止

2: 非常停止(C1-09 の非常停止時間で減速停止)

3: 運転継続

通信オプションカードからの外部異常入力 (EF0)

が検出される条件を選択します。

0: 常時検出

1: 運転中検出

通信オプションカードからの外部異常入力 (EF0)

が検出されたときの停止方法を選択します。

0: 減速停止

1: フリーラン停止

2: 非常停止

3: 運転継続

0: 伝送からのトルク指令/トルクリミットは無効

1: 伝送からのトルク指令/トルクリミットは有

効

0: 多段速指令無効(F7 互換モード)

1: 多段速指令有効(V7 互換モード)

<1>

<1>

<3>

出荷時設定:1

範囲:0 〜 4

出荷時設定:1

範囲:0 〜 3

出荷時設定:1

範囲:0 〜 3

出荷時設定:1

範囲:0,1

出荷時設定:1

範囲:0 〜 3

出荷時設定:0

範囲:0,1

出荷時設定:0

範囲:0,1

24 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 65

6 関連するパラメータ

No.

(MEMO

BUS

レジスタ)

F6-08

(36AH)

<1> 3(運転継続)を選択すると,異常発生時にインバータ単体で運転を継続します。このため,安全を

確保する別の手段(非常停止スイッチなど)を準備してください。

<2> A1-02(制御モードの選択)で3:PG 付きベクトル制御,6:PM 用 PG なしアドバンスドベクト

ル制御または7:PM 用 PG 付きベクトル制御選択時有効になります。

この場合,d5-01(トルク制御選択)の設定によりトルク指令/トルクリミットが変わります。

d5-01=0(速度制御モード) :トルクリミット値

d5-01=1(トルク制御モード):トルク指令値

7:PM 用 PG付きベクトル制御の場合は,トルクリミット値となります。

<3> F6-06(通信オプションからのトルク指令/トルクリミット選択) に1:伝送オプションからのトル

ク指令/トルクリミットは有効を選択した場合,ネットワークからのトルク指令/トルクリミット

を設定しないとモータが回らないときがあります。

名称 設定範囲 設定範囲

A1-03(イニシャライズ)を実行したときの,

F6-/F7- の初期化動作の選択をします。

通信パラメータリセッ

ト

0: F6-/F7- は A1-03により初期化されない

1: F6-/F7- は A1-03により初期化される

(注)本パラメータ F6-08 はインバータの初期化

に影響されません。

出荷時設定:0

範囲:0,1

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 25

Page 66

7 ネットワーク変数

nviRequest

nvoStatus

NODE object: 0

Node

Networks Variable

VSD

Networks Variable

VSD object: 6010

Config_Property

nvoDrvSpeed

nvoRunStatus

nvoInvOutFreq

nvoDrvCurrent

nvoDrvVolt

nvoDCBUS

nvoDrvPwr

nvoDrvEnergy

nvoDrvRunHours

nvoInvAlarm

nvoReadParamVal

nvoParamErr

nvoSpdStptFb

nvoSpdCmd

nvoDrvStatus

nvoFltstatus1

nvoFltstatus2

nvoFltstatus3

nvoEmergStatus

nvoInvFault

Logic object:20000

analog object:20001

Select object:20002

Compere object:20003

Stepout object:20004

Dlytimer object:20005

Deviation object:20006

PID object:20007

Constout object:20008

Convtype object:20009

Savedata object:20010

nviDrvSpeedStpt

nviDrvSpeedRef

nviInvSetFreq

nviRunCommand

nviOpCommands

nviDrvSpeedScale

nviEmergOverride

nviDrvEnergyClr

nviFltRstCommand

nviReadParamNum

nviWriteParamNum

nviWriteParamVal

nciMaxSpeed nciRcvHrtBt nciInvSetFreq

nciMinSpeed nciMinOutTm nciDrvSpeedRef

nciSndHrtBt nciLocation nciDrvEngylimit

nciNmlSpeed nciPwupOutTm nciEngyMinDelta

nciNmlFreq nciFreqMinDelta1 nciOpMode

nciRampUpTm nciFreqMinDelta2 nciDrvRunMode

nciRampDownTm nciDrvSpeedScale

LONWORKS 対応インバータ

7 ネットワーク変数

◆ LONWORKS 対応インバータとネットワーク変数

図 13 に LONWORKS に対応するインバータとネットワークの変数の関係図を示しま

す。

ê}12

26 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

図 13 LONWORKS 対応インバータとネットワーク変数

Page 67

◆ ノードオブジェクト

■ オブジェクトリクエスト

入力:SNVT_obj_request nviRequest

ノード内の各オブジェクトの状態を要求します。

メンバ名 内容

対象となるオブジェクトの ID 番号

0

ノード全体

1 VSD

2 logic [0]

3 logic [1]

4 logic [2]

5 logic [3]

6 logic [4]

7 logic [5]

8 logic [6]

9 logic [7]

10 Analog [0]

11 Analog [1]

12 Analog [2]

object_id

13 Analog [3]

14 Analog [4]

15 Analog [5]

16 Analog [6]

17 Analog [7]

18 Analog [8]

19 Analog [9]

20 Select [0]

21 Select [1]

22 Select [2]

23 Select [3]

24 Select [4]

25 Select [5]

26 Select [6]

27 Select [7]

28 Compare [0]

7 ネットワーク変数

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 27

Page 68

7 ネットワーク変数

メンバ名 内容

29 Compare [1]

30 Compare [2]

31 Compare [3]

32 Compare [4]

33 Compare [5]

34 Compare [6]

35 Compare [7]

36 Stepout [0]

37 Dlytimer [0 ]

38 Dlytimer [1 ]

39 Deviation [0]

40 Pidmodule [0]

41 Pidmodule [1]

42 Pidmodule [2]

object_id

object_request

43 Pidmodule [3]

44 Constout [0]

45 Constout [1]

46 Constout [2]

47 Constout [3]

48 Constout [4]

49 Constout [5]

50 Convtype [0]

51 Convtype [1]

52 Convtype [2]

53 Convtype [3]

54 Savedata [0]

55 Savedata [1]

56 Savedata [2]

57 Savedata [3]

上記以外

invalid_id

0 RQ_NORMAL

1 RQ_DISABLED

2 RQ_UPDATE_STATUS

3 RQ_SELF_TEST

オブジェクトをイネーブルにします。

オブジェクトをディスエーブルにしま

す。

未対応(正常応答を返します。)

未対応(正常応答を返します。)

28 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 69

メンバ名 内容

4 RQ_UPDATE_ALARM

5RQ_REPORT_MASK

6 RQ_OVERRIDE

7 RQ_ENABLE

8 RQ_RMV_OVERRIDE

9 RQ_CLEAR_STATUS

object_request

10 RQ_CLEAR_ALARM

11 RQ_ALARM_NOTIFY_ENABLED

12 RQ_ALARM_NOTIFY_DISABLED

13 RQ_MANUAL_CTRL

14 RQ_REMOTE_CTRL

15 RQ_PROGRAM

0xff RQ_NUL

■ オブジェクトステータス

出力:SNVT_obj_status nvoStatus

ノード内の各オブジェクトの状態を示します。

メンバ名 内容

object_id

bit 31 invalid_id

bit 30 invalid_request

bit 29 disabled

bit 28 out_of_limits

bit 27 open_circuit

bit 26 out_of_service

bit 25 mechanical_fault

bit 24 feedback_failure

bit 23 over_range

bit 22 under_range

bit 21 electrical_fault

bit 20 unable_to_measure

bit 19 comm_failure

対象となるオブジェクト ID(オブジェクトリクエスト参照)

nviRequest による object_id の指定が不正な場合に 1 となり

ます。

nviRequest による object_request の指定が不正な場合に 1 と

なります。

各オブジェクトが動作イネーブルか否かを示します。ディス

エーブル状態時 1 となります。

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

7 ネットワーク変数

未対応(正常応答を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

オブジェクトをイネーブルにします。

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

未対応(invalid_request を返します。)

㈱安川電機 TOBP C730600 56A 1000シリーズオプション SI-W3 取扱説明書 29

Page 70

7 ネットワーク変数

メンバ名 内容

bit 18 fail_self_test

bit 17 self_test_in_progress

bit 16 locked_out

bit 15 manual_control

bit 14 in_alarm

bit 13 in_override

bit 12 report_mask

bit 11 programming_mode

bit 10 programming_fail

bit 9 alarm_notify_disabled

bit 8 〜 0

reserved

◆ VSD ネットワーク変数

■ VSD 入力ネットワーク変数

変数名 変数の型 内容

nviDrvSpeedStpt SNVT_switch

nviInvSetFreq SNVT_freq_hz

nviDrvSpeedRef SNVT_lev_percent

nviRunCommand SNVT_switch

nviOpCommands SNVT_state

nviDrvSpeedScale SNVT_lev_percent

nviEmergOverride SNVT_hvac_emerg

nviFltRstCommand SNVT_switch

nviDrvEnergyClr SNVT_switch

nviReadParamNum SNVT_count

nviWriteParamNum SNVT_count

nviWriteParamVal SNVT_count_inc

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

未対応(常に 0 )

常に 0

インバータ速度運転指令 (Drive Speed Setpoint)

インバータ周波数指令

(Drive Frequency Reference(Hz))

インバータ速度指令 (Drive Speed SetFreq (%))

インバータ運転指令 (Drive Run Reference)

インバータ制御指令 (Drive Operation Commands)

インバータ速度比率設定

(Drive Speed Setpoint Scaling)

インバータ非常停止 (Drive Emergency)

インバータ異常リセット

(Drive Speed Setpoint Scaling)

積算電力値クリア (Drive Speed Setpoint Scaling)

インバータパラメータ読み出し要求

(Drive Parameter Read)

インバータパラメータ書き込み要求

(Drive Parameter Write)

インバータパラメータ書込データ

(Drive Parameter Write Data)

30 ㈱安川電機 TOBP C730600 56A 1000 シリーズオプション SI-W3 取扱説明書

Page 71

■ VSD 出力ネットワーク変数

変数名 変数の型 内容

nvoDrvSpeed SNVT_lev_percent

nvoRunStatus SNVT_switch

nvoInvOutFreq SNVT_freq_hz

nvoDrvCurrent SNVT_amp

nvoDrvVolt SNVT_volt

nvoDCBUS SNVT_volt

nvoDrvPwr SNVT_power_kilo

nvoDrvEnergy SNVT_elec_kwh_l

nvoDrvRunHours SNVT_time_hour

nvoInvFault SNVT_switch

nvoInvAlarm SNVT_switch

nvoReadParamVal SNVT_count_inc

nvoParamErr SNVT_count