Page 1

Yaskawa Electric Co.

Motion Control Division

Solution & Support center

Marketing section

Procedure for Replacing ∑I with ∑V

Applicable Model

Motor:∑ ( SGM , SGMP , SGMG )

Servo Amplifier:∑ ( SGDA-S , SGDA-P ,

SGD-N , SGD-H , SGDB-AD )

Table of Contents

1.Notes on application………………………………………..…………………………………………………..2

1-1. Check List at updating……………………………………………………………..…………………….. …4

1-2. Concept of replacement…………………………………………………...……………………………..…6

1-3. Replacement list…………………………………………………………………………………………..…7

2.Motor

2-1. Type comparison table ………………………………………………...………………………..…………11

2-2. Characteristics

(1) Standard product without reduction gears….………..…………………………………….…………. 15

2-3. Installation sizes

(1) Without reduction gearas (standard)…………………….…….………………………………….……17

(2) With general-purpose reduction gears……………………………………….…………………………19

(3) With precise reduction gears……………………………………………………….……………………24

2-4. Notes on machine installation……………………………………………………………………..………….28

3.Servo Amplifier

3-1. Type comparison table………………………………………………………………..……………………29

3-2. Terminal table …………………………………………………………………………...…………….……29

(1) Main circuit terminal…………………………………………………..………………………………..…29

(2) Control circuit terminal……………………………………………………..…………………………..…30

3-3. Installation size …………………………………………………………….…………………………….…35

3-4. Notes on control board installation …………………………………………..……………………………38

4.Cable and peripherals………………………………………………………………………………...………39

5.Parameter converter…………………………………………………………………………..………………43

Revision history……………………………………………………………………………….………….…………44

1/47

Page 2

1.Notes on Application

Check Item

Using SGD/SGDA/SGDB

Type Servo Amplifier

Notes

Usage condition in ∑ Usage of ∑-V

Using S-phase output of absolute

encoder

Using auto tuning function The same auto-tuning function as Σ is

Using speed bias function The speed bias function is not provided

S-phase output is not available in

SGDV. There are no alternatives.

not provided in SGDV. The tuneless

function is the alternative function.

Please use the advanced auto-tuning

function or moment of inertia

identification function of SigmaWin+

when you need to know the moment of

inertia ratio.

in SGDV. The positioning time can be

shortened by using "Positioning setting

(model following control)" of the

advanced auto tuning function.

The main circuit power supply input

terminal and control power supply

input terminal are common in the

SGD/SGDA series

Using SGD(A)-S (speed・torque

control type)

Using SGD(A)-P (position

control type)

The main circuit power supply input

terminal and control power supply input

terminal are separated. Please

confirm the method of power activation.

There is no distinction between the

speed torque control type and

positional control type in SGDV. It is

possible to use either control type.

There is no distinction between the

speed torque control type and

positional control type in SGDV. It is

possible to use either control type.

2/47

Page 3

Using SGD-N or SGDB-AN

Please use MECHATROLINK-II

(MECHATROLINK communication

support type)

Using SGD-H (RS-422

communication support type) or

SGDB-AM (for multi-function

position control)

communication reference servo

amplifier (SGDV-1 type).

SGDV-1 type servo amplifier

corresponds to MECHATROLINK-II

communication (4Mbps).

Changing software of the host controller

may become necessary when using the

SGDV-1 type to replace

SGD-N type, SGDB-AN type,

because the corresponding

MECHATROLINK command is

different.

There is no option module with the

interface that can replace these. Please

consider the replacement with

MECHATROLINK-II communication

reference servo amplifier

(SGDV-1 type).

Using SGDB--P (duct

ventilation type)

The following functions and performances were improved by replacing ∑ with ∑- V.

・Added the small capacity medium inertia series (SGMJV type) to the motor lineup.

・Increased the peak speed of the motor from 4500rpm to 6000 rpm. (SGMJV type and SGMAV type)

・Improved the speed frequency response characteristic for performance.

SGDA / SGDB 250Hz ⇒ SGDV 1.6kHz (Load inertia=Rotor inertia of motor)

・Supports pulse train command input frequency of 4Mpps.

SIGN+PULSE and CW/CCW are 4Mpps. The A/B-phase 2-phase pulse train becomes 4Mpps at 1x2,

2Mpps at 2x2, and 1Mpps at 4x2.

However, it is 200kpps when connecting with open collector output.

・RoHS compliant as standard product.

・Safety standard (Safety Stop-0) embedded in standard products.

Please inquire to the factory. Although

there is a model that corresponds to the

duct ventilation type but the capacity is

limited and the installation size is

different.

・PC connection changed from RS-232C communication to USB.

3/47

Page 4

1-1.Check List when replacing ∑ with ∑-Ⅴ

Category Item Where to check Checked

Motor

Main Body

Voltage <Correspondence of AC100V specification>

<Confirmation of main body installation dimension/position>

・Please confirm installation dimensions of the motor in-use and

machine in-use.

Inside low diameter

Mounting hole pitch

Mounting hole diameter

Axis diameter

Axis shape (straight, key, center tap, and taper)

< Confirmation of special specification >

・Please confirm whether the motor you are using now is a special

type.

Please confirm the specification with the delivery specifications if

you are using a special type.

・Selected the both servo motor and servo amplifier which were for

100V when using the AC100V power supply in ∑-I. However, only

AC200V motor is available in the ∑-V. Select the proper servo

Servo

Amplifier

Hardware

amplifier when using AC100V power supply.

Cable <Confirmation of wiring direction>

・Please confirm how to wire, and also confirm that the machine has no

interference.

< Confirmation of main body mounting position >

・Please confirm the size (W・H・D) and the mounting hole position of

the servo amplifier in-use.

< Confirmation of special specification >

・Please confirm whether the servo amplifier in-use does not have your

own NP, and product shape, and also confirm that any special

processes etc. are not done by referring the delivery specification.

Main

Circuit

< Confirmation of wiring >

・Changed to the connector connection from the terminal block for

models of 1.5kW or less.

The main circuit connector, terminal block position, terminal marking

and order are different between the servo amplifier in-use and the

replacement servo amplifier.

Main Body

Please consider the substitution of extension of wiring when there is

not enough room in wiring.

4/47

Page 5

<Regenerative process>

・Regenerative processing unit (JUSP-RG08/JUSP-RG08C) is used

when regeneration processing is necessary in SGD/SGDA. In the

SGDV, the regeneration processing is possible by connecting the

regenerative resistor between the terminal B1 and B2.

<AC100V specification>

・Corresponds with the voltage specification "F" (Input 100V, Output

200V) servo amplifier. The servo motors are AC200V.

<Single phase AC200V specification>

・Three-phase circuit AC200V is standard in the ∑-V series servo

amplifier.

Change the parameter "Function selection switch B" when using

single-phase power supply. (Pn00B.2=1)

Connect to terminal L1 and L2 when using the single-phase power

supply.

Please note that the torque-speed characteristic is different from the

three-phase circuit power supply specifications.

Also please note that the size of the1.5kW single-phase AC200V

servo amplifier (SGDV-120AA008000) is the same as the 3kW

three-phase AC200V amplifier (SGDV-200AA).

<DC power supply input>

・Change the parameter "Function selection switch 1" when using

Servo

amplifier

software

DC power supply input. (Pn001.2=1)

Note) Connect the main circuit DC power supply only after changing

the parameter.

Control

circuit

Software <Confirmation of special software existence>

Constant <Confirmation of user constant>

Peripherals <Confirmation of the digital operator>

<Confirmation of wiring>

・The control circuit power supply input terminal is separated in the

SGDV type when it is replaced from the SGD type and SGDA type.

・ Confirm whether the software of the servo amplifier in-use is

standard software from the version number. Contact Yaskawa with

the version number if you are not sure the software is standard or

not.

・Confirm the user constant of the servo amplifier in-use.

SigmaWin + has a function to convert from the user constant of ∑

into the parameter of ∑- V.

・The digital operators for ∑ and ∑-V are different. Please purchase a

new digital operator if needed.

5/47

Page 6

<Confirmation of PC connection cable>

・The PC connection cables for ∑ and ∑-V are different.

Please purchase a new cable when using SigmaWin+.

Others In the Σ series, the stopping method is DB stop or free-run stop when

an alarm is detected. On the other hand, factory setting for G2 is 0

speed stop in Σ-V series. It is possible to change to the DB stop or

free-run stop when the parameter Pn00B.1=0 is set to1. The user

constant conversion function of SigmaWin + is not able to convert this.

6/47

Page 7

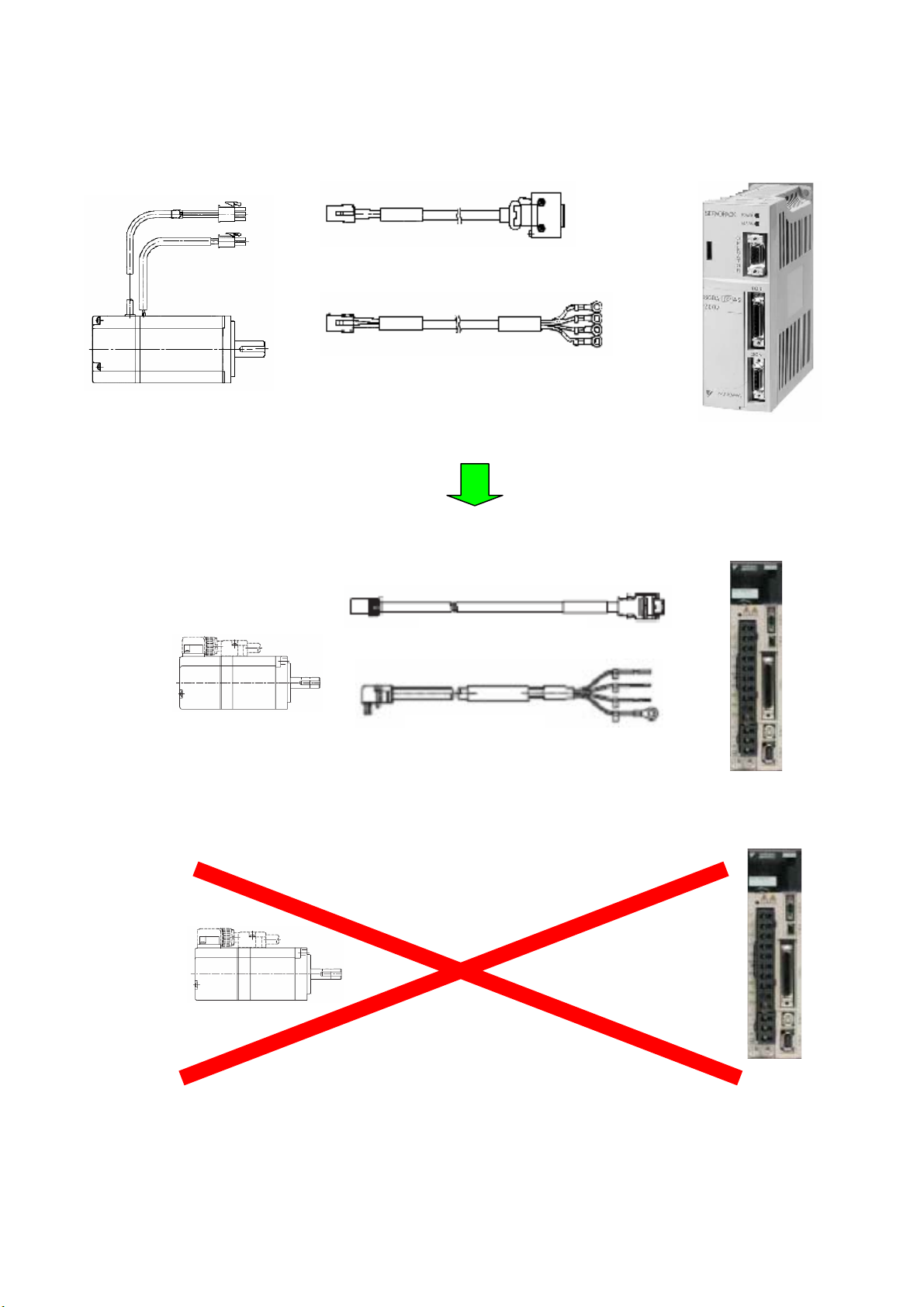

1-2.Concept of Replacement

When replacing ∑ series servo motor/servo amplifier with ∑-V series, the following methods are available.

Encoder Cable

Motor Cable

●Case 1

Replacing all the motors, servo amplifier, and cables with ∑-V series.

●Case 2

Only the motor or amplifier cannot be replaced by itself and the existing cable of ∑ series cannot be used as

is.

Encoder Cable

Motor Cable

7/47

Page 8

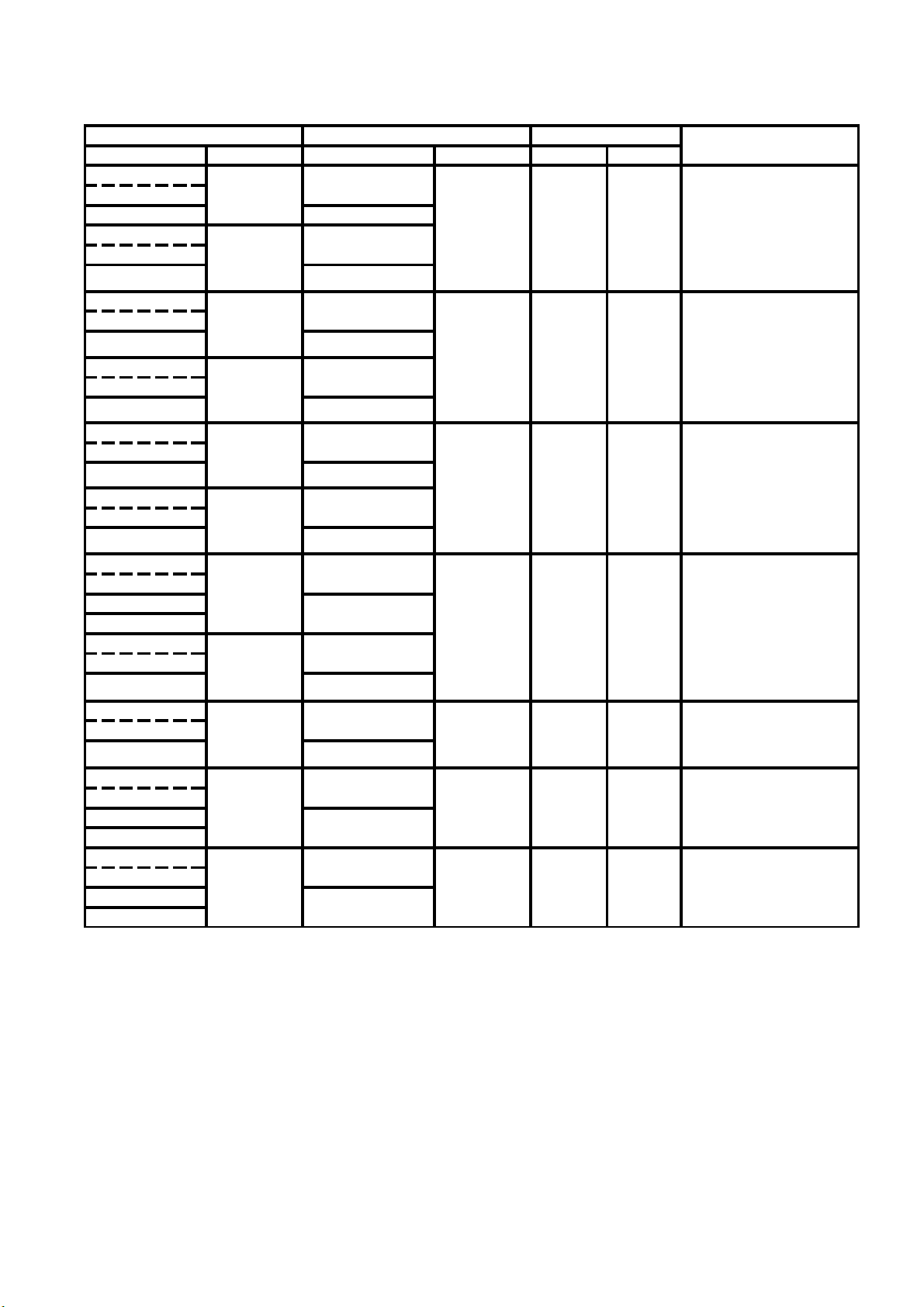

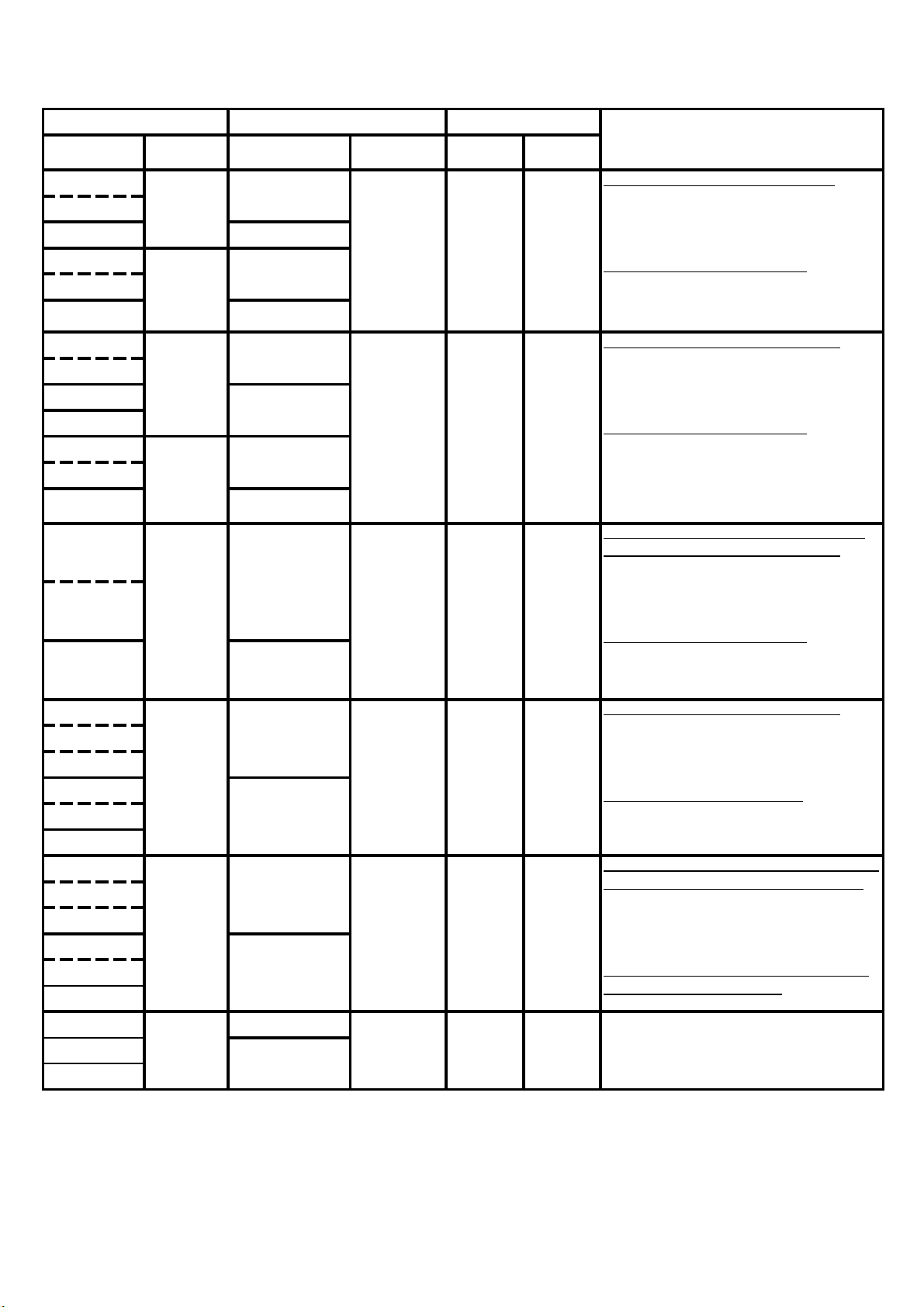

1-3. Replacement List

V

Replacing SGM with SGMJ

Type in-use of ∑ series Replacing type ∑-V series Replacing Method

Servo Amplifier Servo Motor Servo Amplifier Servo Motor Case 1 Case 2

SGDA-A3AS

SGDA-A3AP

SGD-A3AN SGDV-R70A11A

SGDA-A3BS

SGDA-A3BP

SGD-A3BN SGDV- R70F11A

SGDA-A5AS

SGDA-A5AP

SGD-A5AN SGDV-R70A11A

SGDA-A5BS

SGDA-A5BP

SGD-A5BN SGDV- R70F11A

SGDA-01AS

SGDA-01AP

SGD-01AN SGDV-R90A11A

SGDA-01BS

SGDA-01BP

SGD-01BN SGDV- R90F11A

SGDA-02AS

SGDA-02AP

SGD-02AN

SGDB-02AM

SGDA-02BS

SGDA-02BP

SGD-02BN SGDV-2R1F11A

SGDA-03BS

SGDA-03BP

SGD-03BN SGDV-2R8F11A

SGDA-04AS

SGDA-04AP

SGD-04AN

SGDB-05AM

SGDA-08AS

SGDA-08AP

SGD-08AN

SGDB-10AM

SGM-A3A

SGM-A3B

SGM-A5A

SGM-A5B

SGM-01A

SGM-01B

SGM-02A

SGM-02B

SGM-03B

SGM-04A

SGM-08A

SGDV-R70A01A

SGDV-R70F01A

SGDV-R70A01A

SGDV-R70F01A

SGDV-R90A01A

SGDV-R90F01A

SGDV-1R6A01A

SGDV-1R6A11A

SGDV-2R1F01A

SGDV-2R8F01A

SGDV-2R8A01A

SGDV-2R8A11A

SGDV-5R5A01A

SGDV-5R5A11A

SGMJV-A5A Applicable

SGMJV-A5A Applicable

SGMJV-01A Applicable

SGMJV-02A Applicable

SGMJV-04A Applicable

SGMJV-04A Applicable N/A -

SG0MJV-08 Applicable

N/A

N/A

N/A -

N/A

N/A

N/A

Note

30W version is not

available. Use 50W .

Axis diameter changes

to φ8 from φ6

Axis diameter changes

to φ8 from φ6

-

300W version is not

available. Use 400W .

Axis diameter changes

to φ19 from φ16

8/47

Page 9

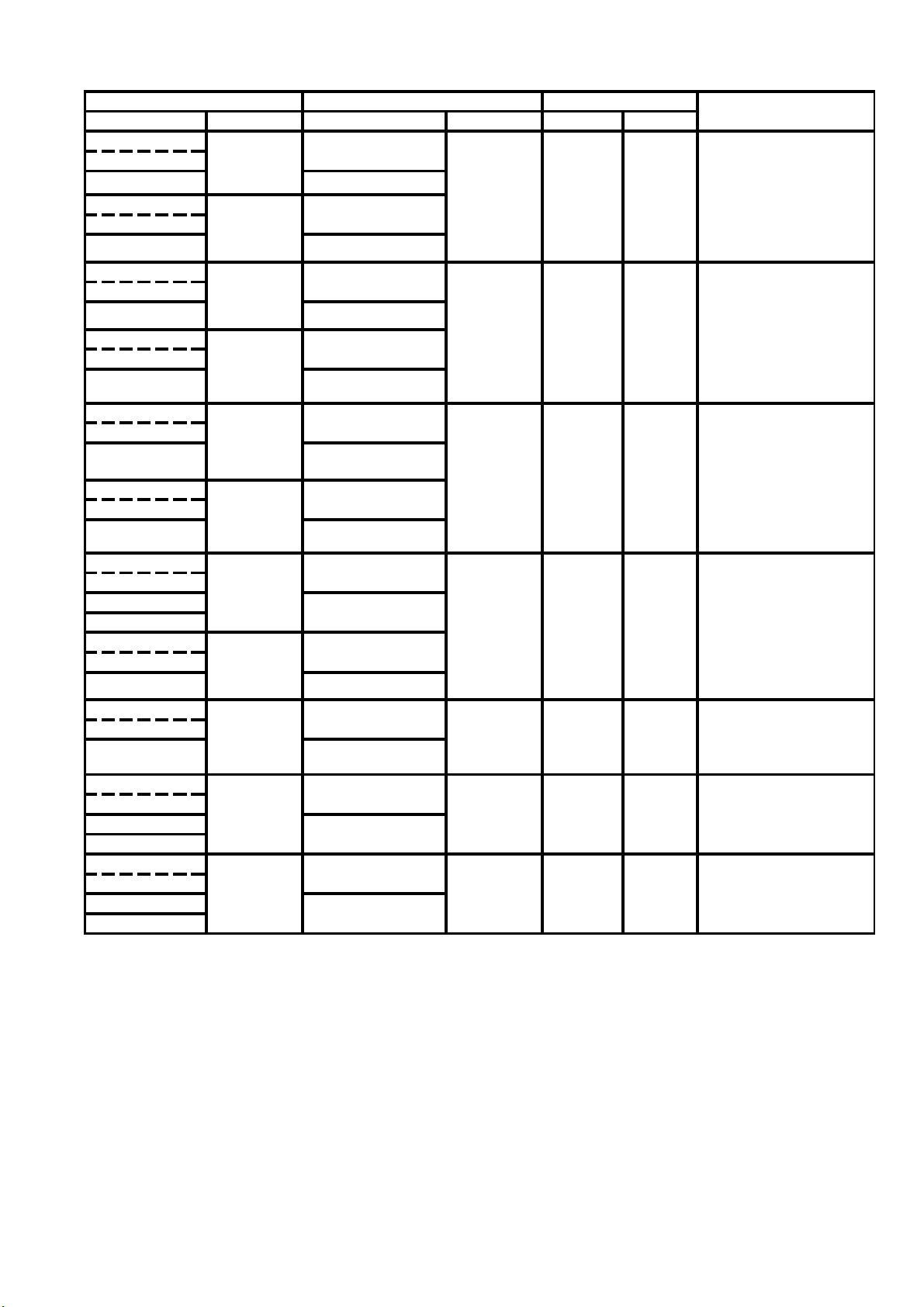

Replacing SGM with SGMAV

Type in-use of ∑ series Replacing type ∑-V series Replacing Method

Servo Amplifier Servo Motor Servo Amplifier Servo Motor Case 1 Case 2

SGDA-A3AS

SGDA-A3AP

SGD-A3AN SGDV-R70A11A

SGDA-A3BS

SGDA-A3BP

SGD-A3BN SGDV- R70F11A

SGDA-A5AS

SGDA-A5AP

SGD-A5AN SGDV-R70A11A

SGDA-A5BS

SGDA-A5BP

SGD-A5BN SGDV- R70F11A

SGM-A3A

SGM-A3B

SGM-A5A

SGM-A5B

SGDV-R70A01A

SGDV-R70F01A

SGDV-R70A01A

SGDV-R70F01A

SGMAV-A5A Applicable

SGMAV-A5A Applicable

N/A

N/A

Note

30W version is not

available. Use 50W .

Axis diameter changes

to φ8 from φ6

Axis diameter changes

to φ8 from φ6

SGDA-01AS

SGDA-01AP

SGD-01AN SGDV-R90A11A

SGDA-01BS

SGDA-01BP

SGD-01BN SGDV- R90F11A

SGDA-02AS

SGDA-02AP

SGD-02AN

SGDB-02AM

SGDA-02BS

SGDA-02BP

SGD-02BN SGDV-2R1F11A

SGDA-03BS

SGDA-03BP

SGD-03BN SGDV-2R8F11A

SGDA-04AS

SGDA-04AP

SGD-04AN

SGDB-05AM

SGDA-08AS

SGDA-08AP

SGD-08AN

SGDB-10AM

SGM-01A

SGM-01B

SGM-02A

SGM-02B

SGM-03B

SGM-04A

SGM-08A

SGDV-R90A01A

SGDV-R90F01A

SGDV-1R6A01A

SGDV-1R6A11A

SGDV-2R1F01A

SGDV-2R8F01A

SGDV-2R8A01A

SGDV-2R8A11A

SGDV-5R5A01A

SGDV-5R5A11A

SGMAV-01A Applicable

SGMAV-02A Applicable

SGMAV-04A Applicable

SGMAV-04A Applicable N/A -

SGMAV-08A Applicable

N/A -

N/A

N/A

N/A

300W version is not

available. Use 400W .

Axis diameter changes

to φ19 from φ16

-

9/47

Page 10

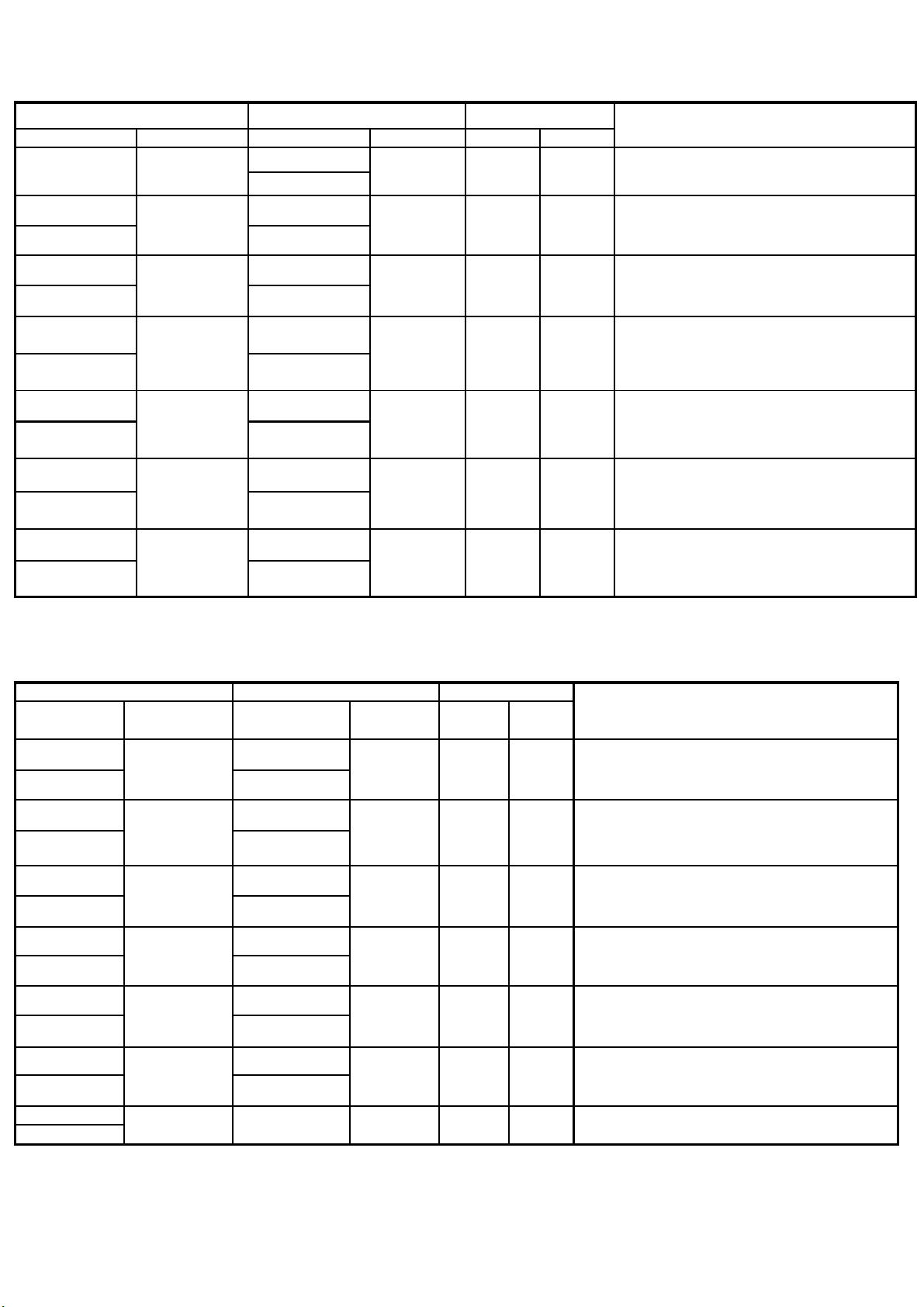

p

Replacing SGMP with SGMJV or SGMPS

Type in-use of ∑ series Replacing type ∑-V series Replacing Method

Servo

lifier

Am

SGDA-01AS

SGDA-01AP

SGD-01AN SGDV-R90A11A

SGDA-01BS

SGDA-01BP

SGD-01BN SGDV- R90F11A

SGDA-02AS

SGDA-02AP

SGD-02AN

SGDB-02AM

SGDA-02BS

SGDA-02BP

SGD-02BN SGDV-2R1F11A

SGDA-03BS

SGDA-03BP

SGD-03BN SGDV-2R8F11A

SGDA-04AS

SGDA-04AP

SGDB-05ADP

SGD-04AN

SGDB-05AN

SGDB-05AM

SGDA-08AS

SGDA-08AP

SGDB10ADP

SGD-08AN

SGDB-10AN

SGDB-10AM

SGDB-15ADP SGDV-120A01A

SGDB-15AN

SGDB-15AM

Servo

Motor

SGMP-01A

SGMP-01B

SGMP-02A

SGMP-02B

SGMP-03B

SGMP-04A

SGMP-08A

SGMP-15A SGMPS-15A Available N/A

Servo Amplifier Servo Motor Case 1 Case 2

SGDV-R90A01A

SGMJV-01A

SGDV-R90F01A

SGDV-1R6A01A

SGDV-1R6A11A

SGDV-2R1F01A

SGDV-2R8F01A

SGDV-2R8A01A

SGDV-2R8A11A

SGDV-5R5A01A

SGDV-5R5A11A

SGDV-120A11A

or

SGMPS-01A

SGMJV-02A

or

SGMPS-02A

SGMJV-04A

or

SGMPS-04A

SGMJV-04A

or

SGMPS-04A

SGMJV-08A

or

SGMPS-08A

Available

Available

Available

Available N/A

Available

N/A

N/A

N/A

N/A

Note

Flange angle changes to 40° from 60

replacing with SGMJV.

SGMJV encoder is either the incremental

encoder 20bit, incremental encoder 13bit or

absolute encoder 20bit.

Flange angle is 60° (no change)

replacing with SGMPS.

SGMPS encoder is either the incremental

encoder 17bit or absolute encoder 17bit.

Flange angle changes to 60° from 80°

replacing with SGMJV.

SGMJV encoder is either the incremental

encoder 20bit, incremental encoder 13bit or

absolute encoder 20bit.

Flange angle is 80° (no change)

replacing with SGMPS.

SGMPS encoder is either the incremental

encoder 17bit or absolute encoder 17bit.

300W version is not available. Use 400W.

Flange angle changes to 60° from 80° when

replacing with SGMJV.

SGMJV encoder is either the incremental

encoder 20bit, incremental encoder 13bit or

absolute encoder 20bit.

Flange angle is 80° (no change)

replacing with SGMPS.

SGMPS encoder is either the incremental

encoder 17bit or absolute encoder 17bit.

Flange angle changes to 60° from 80°

replacing with SGMJV.

SGMJV encoder is either the incremental

encoder 20bit, incremental encoder 13bit or

absolute encoder 20bit.

Flange angle is 80° (no change)

replacing with SGMPS.

SGMPS encoder is either the incremental

encoder 17bit or absolute encoder 17bit.

Flange angle changes to 80° from 120° and

shaft diameter changes to ∅19 from ∅16

when replacing with SGMJV.

SGMJV encoder is either the incremental

encoder 20bit, incremental encoder 13bit or

absolute encoder 20bit.

Flange angle is 80° (no change) and shaft

diameter is ∅16 (no change) when replacing

with SGMPS.

SGMPS encoder is either the incremental

encoder 17bit or absolute encoder 17bit.

° when

when

when

when

when

when

when

10/47

Page 11

Replacing SGMG (1500min-1) with SGMGV

Fl

180⇒130(mm)

p

SGDV

SGDV

SGDV

(

Type in-use of ∑ series Replacing type ∑-V series Replacing Method

Servo Amplifier Servo Motor Servo Amplifier Servo Motor Case 1 Case 2

- - SGMGV-03A N/A N/A

SGDB-05ADG SGDV-3R8A01A

SGMG-05AA

SGDB-05AN SGDV-3R8A11A

SGDB-10ADG SGDV-7R6A01A

SGMG-09AA

SGDB-10AN SGDV-7R6A11A

SGDB-15ADG SGDV-120A01A

SGMG-13AA

SGDB-15AN SGDV-120A11A

SGDB-20ADG SGDV-180A01A

SGMG-20AA

SGDB-20AN SGDV-180A11A

SGDB-30ADG SGDV-330A01A

SGMG-30AA

SGDB-30AN SGDV-330A11A

SGDB-44ADG SGDV-330A01A

SGMG-44AA

SGDB-44AN SGDV-330A11A

SGDV-3R8A01A

SGDV-3R8A11A

SGMGV-05A Available N/A

SGMGV-09A Available N/A

SGMGV-13A Available N/A

SGMGV-20A Available N/A

SGMGV-30A Available N/A -

SGMGV-44A Available N/A

Note

Flange angle: 90mm

Shaft diameter: ∅14mm

Flange angle: 130 ⇒ 90(mm)

Shaft diameter: ∅19⇒ ∅16(mm)

Rotar inertia moment: 7.24⇒ 3.33(x10-

-

Rotar inertia moment: 20.5⇒ 19.9(x10-

4kg・m2)

ange angle:

Shaft diameter: ∅35⇒ ∅24(mm)

Rotar inertia moment: 31.7⇒ 26.0(x10-

・

-

Replacing SGMG (1000min-1) with SGMGV

Capacity of the servo motor SGMGV and servo amplifier go up

Type in-use of ∑ series Replacing type ∑-V series Replacing

Servo

lifier

Am

SGDB-03ADM

SGDB-05AN

SGDB-07ADM

SGDB-10AN

SGDB-10ADM SGDV-120A01A

SGDB-10AN SGDV-120A11A

SGDB-15ADM SGDV-180A01A

SGDB-15AN SGDV-180A11A

SGDB-20ADM SGDV-330A01A

SGDB-20AN SGDV-330A11A

SGDB-30ADM SGDV-330A01A

SGDB-30AN SGDV-330A11A

SGDB-44ADM

SGDB-44AN

Servo Motor

SGMG-03AΒ

SGMG-06AΒ

SGMG-09AΒ

SGMG-12AΒ

SGMG-20AΒ

SGMG-30A

SGMG-44AΒ

Β

Servo

Amplifier

-

-

-

SGDV7R6A11A

---

Servo

Motor

SGMGV-

05A

SGMGV-

09A

SGMGV-

13A

SGMGV-

20A

SGMGV-

30A

SGMGV-

44A

Case 1 Case 2

Available N/A

Available N/A

Available N/A

Available N/A

Available N/A

Available N/A

Note

Flange angle: 130 ⇒ 90(mm)

Shaft diameter: ∅19⇒ ∅16(mm)

Rotar inertia moment: 7.24⇒ 3.33(x10-

Rated torque: 5.68⇒ 5.39(N・m)

Peak torque: 14.1⇒ 13.8(N・m)

Rotar inertial moment: 20.5⇒ 19.9(x10-

4kg・m2)

Rated torque: 8.62⇒ 8.34(N・m)

Flange angle: 180⇒ 130(mm)

Shaft diameter: ∅35⇒ ∅24(mm)

Rotar inertia moment: 31.7⇒ 26.0

Rated torque: 19.1⇒ 18.6(N

-

-

x10-

・m)

11/47

Page 12

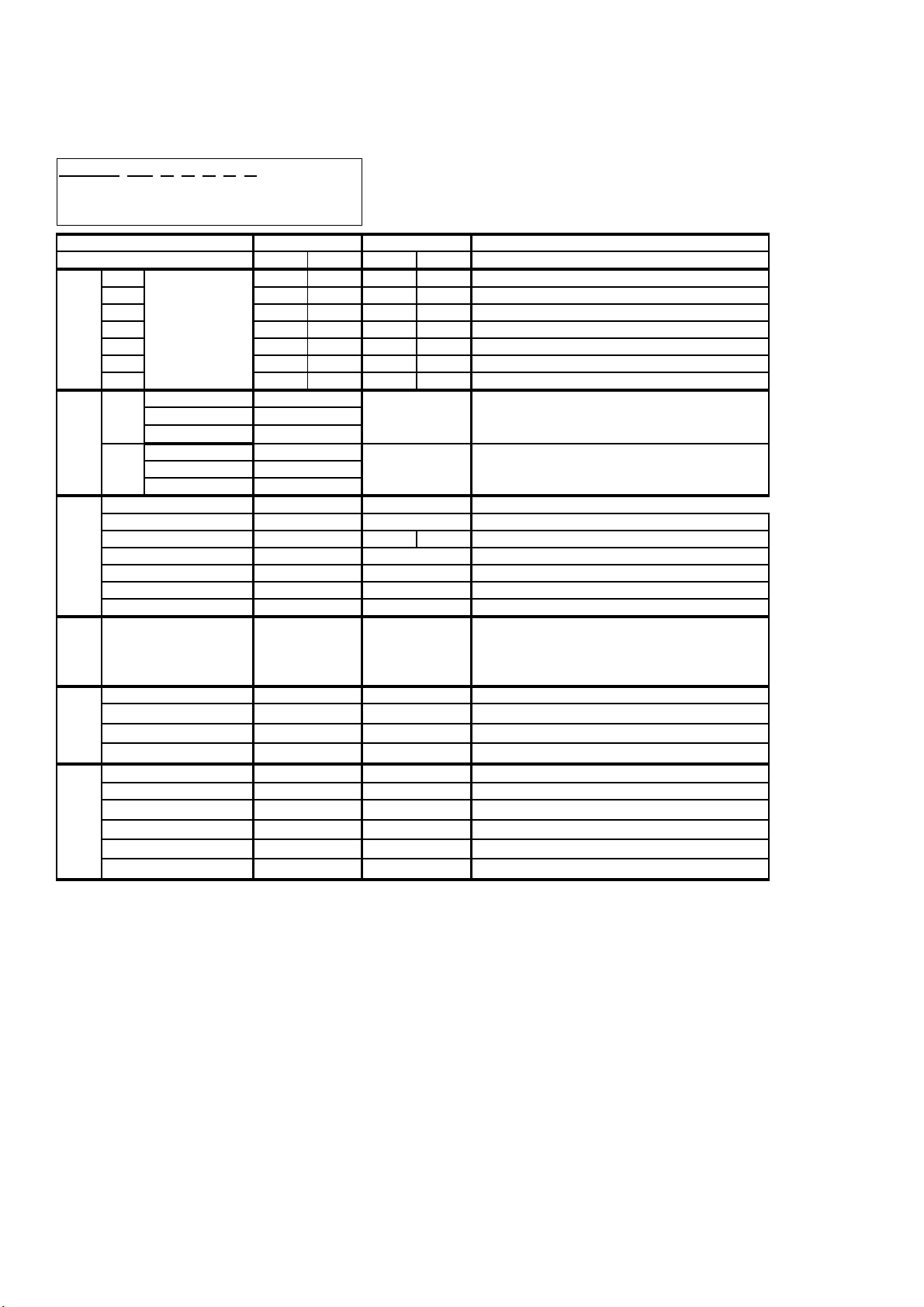

2. Motor

g

p

2-1. Type Comparison Table

・Comparison Table of SGM, SGMP and SGMAV, SGMJV (w/o reduction gears)

SGMJV- □□ □ □ □ □ □

Type Name ① ② ③ ④ ⑤ ⑥

Series Name

Servo Motor Type

30 A3 - - - 50W setting (30W setting is not available)

50 A5 - A5 A5 100 01010101 -

Capacity

①

Voltabe

Spec.

②

Detector

③

Design

Order

④

Shaft-

end

Spec.

⑤

Option

⑥

※ 100V in

W

200 02020202 300 03 03 - - 400W settin

400 04040404 750 08080808 -

Standard

100V

UL certified

CE certified

Standard

200V

UL certified

CE certified

2048p/r incremental encoder

8192p/r incremental encoder

13bit serial incremental encode

20bit serial incremental encode

12bit absolute encoder

15bit absolute encoder

20bit serial absolute encoder

Standard

w/ straight key

w/ straight key tap

w/o straight key w/tap

90V brake 24V brake (90V brake setting is not available)

24V brake Oil seal S

90V brake, Oil seal

24V brake, Oil seal

ut type only for 300W of SGM and SGMP

∑

SGM- SGMP- SGMAV- SGMJV-

B

L

W

A

U

V

3

2

-

W

S

-

1

2w/o straight key

4

6

8

-No option

B

C

D

E

∑-Ⅴ

-

A

-

-

-A D

-

3

A

2

6

8

1

C

S

-

E

Corresponds by combining the Servo amplifier 100V power

supply spec. "F" and motor for 200V

0bit serial incremental encoder (13bit is selectable for SGMJV

20bit serial incremental encoder

SGMJV Standard: Fully-closed, Self-cooling IP65 (excluding

SGMAV Standard: Fully-closed, Self-cooling IP55 (excluding

Set to "1" for no option instead of leaving as a blank

24V brake (90V brake setting is not available)

Supplement

(300W setting is not available)

-

20bit serial absolute encoder

20bit serial absolute encoder

-

shaft penetrated part)

shaft penetrated part)

-

Handle with straight key tap

-

-

-

-

12/47

Page 13

Comparison Table of SGMG and SGMGV

(

)

(

)

g

d

d

・

SGMGV- □□ □ □ □ □ □

Type Name ① ② ③ ④ ⑤ ⑥

w/o reduction gears

Capacity

①

Voltabe

Spec.

②

Detector

③

Design

Order

④

Shaft-

end

Spec.

Option

⑥

Series Name

Servo Motor Type SGMG- SGMGV-

0.3

0.45

0.6

0.85/0.9

1.2

1.3

1.8/2.0

2.9/3.0

4.4

4096p/r incremental encoder 6 8192p/r incremental encoder 2 13bit serial incremental enco

20bit serial incremental enco

12bit absolute encoder W 15bit absolute encoder S 20bit serial absolute encoder - 3

1500min-1 A A

1000min-1 B -

w/o straight key A 2

w/ straight key tap B 6

1/10 taper w/ key C,D -

No option - 1

DC90V brake B B

DC24V brake C C

DC90V brake, Oil seal F D

DC24V brake, Oil seal G E

Oil seal S S

kW

200

V

∑ ∑-Ⅴ

03 03

05 05

06 09

12 13 13

20 20

30 30

44 44

AA

-

-

09

-

D

Supplement

Rating 1000min-1model is not provided in

SGMGV. If you are using SGMG rating

1000min-1 model (SGMG-

the rating 1500min-1 model though the rated torque

and externals are different.

20bit serial incremental encoder

20bit serial incremental encoder

-

20bit serial absolute encoder

20bit serial absolute encoder

Standard: Fully-closed, Self-cooling IP67

excluding shaft penetrated part

Rating 1000min-1model is not provided please

use the ratin

-

No taper is available. Use straight key.

Set to "1" for no option instead of leaving as a

Use 24V Brake version

Use 24V Brake version

-

-

1500min-1 model.

B) please use

13/47

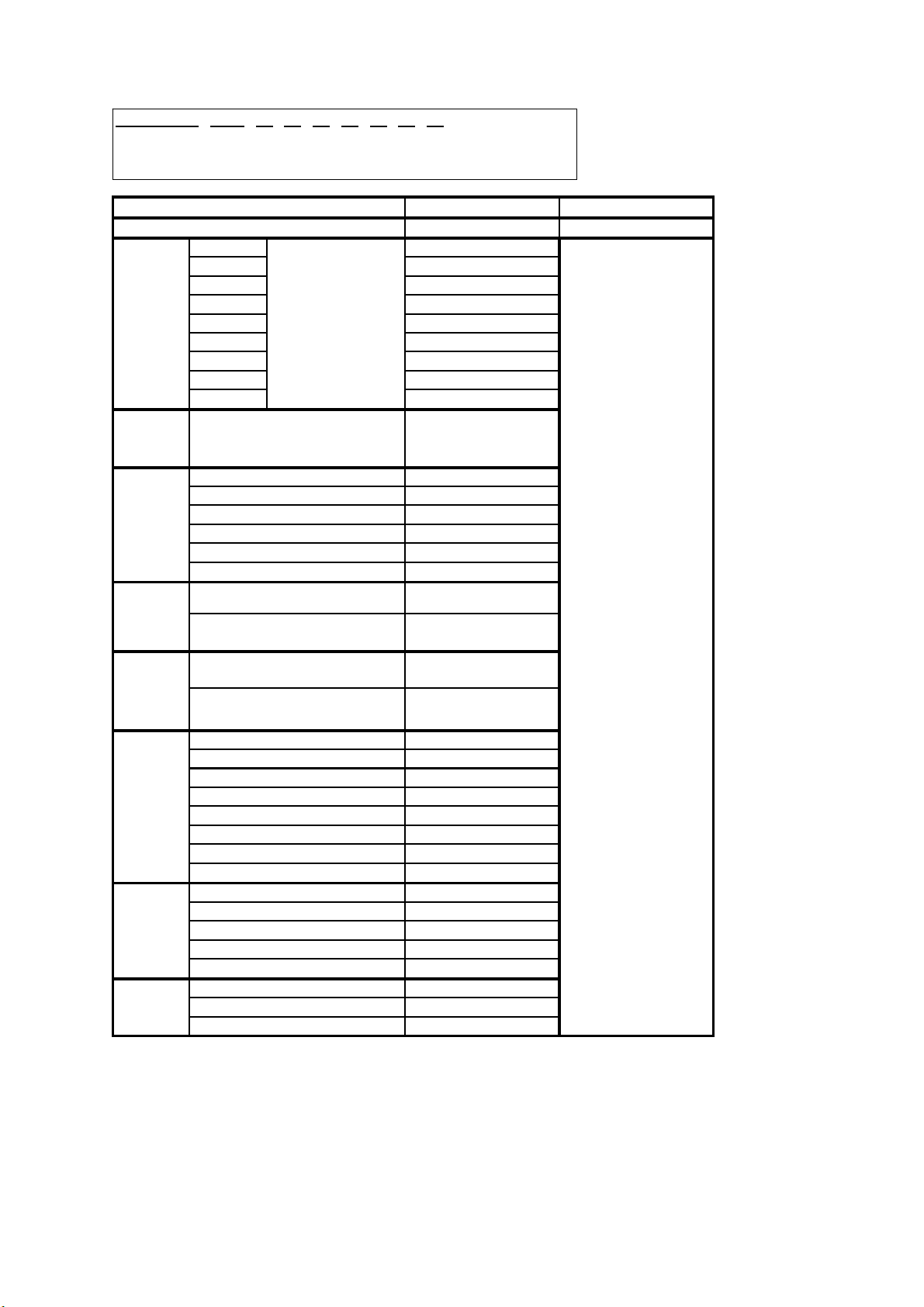

Page 14

・Comparison Table of SGM, SGMP and SGMAV, SGMJV (w/ reduction gears)

0

)

0

0

0

0

)

0

V

p

p

p

g

p

p

0

e

)

868

7

s

e

①④⑦⑧⑥③⑤

②

SGMJV- □□ □ □ □ □ □ □ □

Type Name

Cap ac i ty

①

Vol ta ge

Spec.

②

Det ec tor

③

Design

Or der

④

Ser ies Name ∑

Servo Motor Typ

3

5

10

20

30

40

750 08 08 08 08 -

100V

200V

2048p/r incremental encoder 3

8192p/r incremental encoder 2 13bit serial incremental encoder 20bit serial incremental encoder 12bit absolute encoder W -

20bit serial absolute encoder -

Standar d

W

Standard

UL certi fied

CE certi fi ed

Standard

UL certi fied

CE certi fi ed

SGM- SGMP- SGMAV- SGMJV-

A3 - - - 50W setting (30W setting is not avai lable

A5 - A5 A5 01 01 01 01 02 02 02 02 03 03 - - 400W setting (300W setting is not available

04 04 04 04 -

B

L

W

A

U

V

∑-Ⅴ

-

A

-

-A D

-15bit absolute encoder S

3

A1

Combining the Servo amplifier 100V power supply spec. "F"

0bit serial incremental encoder (13bis is sel ectable for SGMJ

20bit serial incremental encoder

20bit serial absolute encoder

20bit serial absolute encoder

SGMJV Standard: Fully-closed, Self-cooling IP55 (excluding

SGMAV Standard: Fully-closed, Self-cooling IP55 (excluding

Supplement

and motor for 200V

shaft penetrated part)

shaft

enetrated part)

-

-

-

Reduction

Gea r s

Spec.

⑤

Reduction

Rat io

⑥

Shaft-

end Spec.

⑦

Opt i on

⑧

Precision reduction gears

General -purpose reducti on gear

1/5

1/9

3/31

1/11

1/21

1/33

Flange mounting 0

w/o st ra ight key

w/ straight key

w/ straight key tap

w/ straight tap

No Opt ion

V br a k

9

24V brake -

J

1

2 ※

2 ※ 2 ※

3

4

0

2

4

B

C

HH

-

1

2 ※

B ※

C

2

6

1

-

C

●∑ series

SGM :Precision 1/5、1/9(50、100W)、1/11(except 50、100W)、1/21、1/33

General-Purpose 1/5、3/31、1/21、1/33

SGMP:Precision 1/5、1/11、1/21、1/33

General-Purpose 1/5、3/31、1/21、1/33

-

Use the precision reduction gears (general-purpose reduction

gears are not available)

-

onding to 50W

Cor r es

ond by 1/9 (only 50W) or 1/11

Cor res

Not corresponding to 50W

-

-

-

-

Handle with strai

Set to "1" for no o

24V brake (90V brake setting is not available

tion instead of leaving as a blank

ht key ta

-

-

14/47

Page 15

Comparison Table of SGMG and SGMGV

(

)

a

e

①⑥⑤④②⑧⑦

③

・

SGMGV- □□ □ □ □ □ □ □ □

Type Name

w/ reduction gears

Capacity

①

Voltabe

Spec.

②

Detector

③

Design

Order

④

Reduction

Gears

Spec.

⑤

Reduction

Ratio

⑥

Shaft-end

Spec.

⑦

Option

⑧

Series Name

Servo Motor Type SGMG- SGMGV-

0.3

0.45

0.6

0.85/0.9

1.2

1.3

1.8/2.0

2.9/3.0

4.4

4096p/r incremental encoder

8192p/r incremental encoder 2

20bit serial incremental encod

12bit absolute encoder W

15bit absolute encoder

20bit serial absolute encoder -

1500min-1 A

1000min-1 B

Precision reduction gears L

General-purpose reduction ge

Flange mounting (w/o shaft) w/o straight key w/ straight key K

w/ straight key tap

w/ straight tap No option DC90V brake

DC24V brake C

kW

V

200

1/5 1

1/6 A

1/9 2

1/11 B

1/20

1/21 C

1/29 7

1/45 8

∑∑-Ⅴ

03

05

06

09

12

13

20

30

44

A

6

-

S

Quotes in each case

S,T

5

R

B

15/47

Page 16

2-2. Characteristic

(Comparison between SGM, SGMP and SGMJV, SGMAV)

Motor Characteristic

∑ ∑-Ⅴ

Servo Motor Servo Motor

サーボモータ サーボモータ ∑ ∑-Ⅴ ∑ ∑-Ⅴ ∑ ∑-Ⅴ

SGM-A3A SGMJV-A5A 0.021 0.0414 0.095 0.159 0.29 0.557

SGM-A5A SGMJV-A5A 0.026 0.0414 0.159 0.159 0.48 0.557

SGM-01A SGMJV-01A 0.040 0.0665 0.318 0.318 0.96 1.11

SGM-02A SGMJV-02A 0.123 0.259 0.637 0.637 1.91 2.23

SGM-04A SGMJV-04A 0.191 0.442 1.27 1.27 3.82 4.46

SGM-08A SGMJV-08A 0.671 1.57 2.39 2.39 7.1 8.36

SGM-A3A SGMAV-A5A 0.021 0.0242 0.095 0.159 0.29 0.477

SGM-A5A SGMAV-A5A 0.026 0.0242 0.159 0.159 0.48 0.477

SGM-01A SGMAV-01A 0.040 0.038 0.318 0.318 0.96 0.955

SGM-02A SGMAV-02A 0.123 0.116 0.637 0.637 1.91 1.91

SGM-04A SGMAV-04A 0.191 0.19 1.27 1.27 3.82 3.82

SGM-08A SGMAV-08A 0.671 0.769 2.39 2.39 7.1 7.16

SGMP-01A SGMJV-01A 0.065 0.0665 0.318 0.318 0.96 1.11

SGMP-02A SGMJV-02A 0.209 0.259 0.637 0.637 1.91 2.23

SGMP-04A SGMJV-04A 0.347 0.442 1.27 1.27 3.82 4.46

SGMP-08A SGMJV-08A 2.11 1.57 2.39 2.39 7.1 8.36

Rotar Inertia Moment (x10-4kg・m2) Peak Torque (N・m) Rated Torque (N・m)

ロータ慣性 モーメント(x10

-4

kg・m2)

モータ特性

定格トルク(N・m) 瞬時最大トルク(N・m)

100%

80%

60%

40%

20%

Load Ratio of SGM [Rated Ratio]

SGMAV

SGMJV

0%

0 5 10 15 20 25 30

Load Inertia Moment Ratio [SGMAV ratio]

100%

80%

60%

Please refer to the graph on the left

to replace the SGM type with the types

of SGMJV or SGMAV.

Replace with the SGMAV type when

the ratio of load inertia moment and

rotor inertia moment is five times or

less, or the load ratio is 60% or more.

Replace with the SGMJV type as for

the rest of that.

【 Reference 】

The graph on the left shows the load

ratio when replacing the SGM type

which is used by 70% with the types of

40%

SGM-02

Effective Torque [Rated Ratio %]

20%

0%

0倍 5倍 10倍 15倍 20倍 25倍 30倍

Load Inertia Moment [Jm Ratio]

SGMAV-02

SGMJV-02

SGMJV and SGMAV.

The load ratio increases though the

control is steady because the rotor

inertia moment of SGMJV type is large.

16/47

Page 17

(Comparison between SGMG and SGMGV)

∑

(Rating 1500min-1)

(定格1500min-1)

Servo Motor

サーボモータ サーボモータ ∑ ∑-Ⅴ ∑ ∑-Ⅴ ∑ ∑-Ⅴ

SGMG-05A□A SGMGV-05A 7.24 3.33 2.84 2.86 8.92 8.92

SGMG-09A□A SGMGV-09A 13.9 13.9 5.39 5.39 13.8 13.8

SGMG-13A□A SGMGV-13A 20.5 19.9 8.34 8.34 23.3 23.3

SGMG-20A□A SGMGV-20A 31.7 26.0 11.5 11.5 28.7 28.7

SGMG-30A□A SGMGV-30A 46.0 46.0 18.6 18.6 45.1 45.1

SGMG-44A□A SGMGV-44A 67.5 67.5 28.4 28.4 71.1 71.1

The capacity of the servo motor SGMGV and servo amplifier SGDV goes up because of the

SGMG(定格1000min-1)からSGMGVへの置換えでは、定格トルクの違いにより、

rated torque differences when replacing

サーボモータSGMGVとサーボパックSGDVの容量がアップしますのでご注意ください。

∑

(定格1000min-1)

(Rating 1000min-1)

Servo Motor Servo Motor

サーボモータ サーボモータ ∑ ∑-Ⅴ ∑ ∑-Ⅴ ∑ ∑-Ⅴ

SGMG-03A□B

SGMG-06A□B

SGMG-09A□B

SGMG-12A□B

SGMG-20A□B

SGMG-30A□B

SGMG-44A□B SGMGV-44A 89.0 67.5 41.9 28.4 107.0 71.1

∑-Ⅴ

Servo Motor

Rotor Inertia Moment (x10-4kg・m2)

ロータ慣性モーメント(x10

SGMG (Rating 1000min-1) with SGMGV.

∑-Ⅴ

SGMGV-03A 2.48 1.96 5.88

SGMGV-05A 3.33 2.86 8.92

SGMGV-05A 3.33 2.86 8.92

SGMGV-09A 13.9 5.39 13.8

SGMGV-09A 13.9 5.39 13.8

SGMGV-13A 19.9 8.34 23.3

SGMGV-13A 19.9 8.34 23.3

SGMGV-20A 26.0 11.5 28.7

SGMGV-20A 26.0 11.5 28.7

SGMGV-30A 46.0 18.6 45.1

SGMGV-30A 46.0 18.6 45.1

SGMGV-44A 67.5 28.4 71.1

ロータ慣性モーメント(x10

7.24 2.84

13.9

20.5 8.62

31.7 11.5

46.0

67.5 28.4

Motor Characteristic

-4

kg・m2)

Motor Characteristic

-4

kg・m2)

モータ特性

Rated Torque (N・m)

定格トルク(N・m) 瞬時最大トルク(N・m)

モータ特性

定格トルク(N・m) 瞬時最大トルク(N・m)

5.68

19.1

Peak Torque (N・m)

Peak Torque (N・m) Rotor Inertia Moment (x10-4kg・m2) Rated Torque (N・m)

7.17

14.1

19.3

28.0

44.0

63.7

17/47

Page 18

2-3. Mounting Dimensions

L

e

e

e

e

(1) Without Reduction Gears (Standard)

Hatching-displayed the part where size is different between the ∑ motor and ∑-V motor.

LL LC

S

Reductio

n Gears

No

Redution

Gears

Motor

Capacity

Brake

[W] LC LL S LC LL S LC L

N/A 69.5

30

Available 101

N/A 77 70.5 69

50

Available 108.5 115.5 114

100 8

200

400

750 80 16

N/A 94.5 82.5 82.5

Available 135 127.5 127.5

N/A 96.5 80 80

Available 136 120 120

N/A 124.5 98.5 98.5

Available 164 138.5 138.5

N/A 145 115 115

Available 189.5 160 160

∑ series

SGM

40 6

40

6

40

60 14

60 14

∑-Ⅴ series

SGMAV SGMJV

40 8

40 8

60 14

60 14

80 19

S

40 8

40 8

60 14

60 14

80 19

Reduction

Gears

No

Reduction

Gears

Motor

Capacity

[W] LC LL S LC LL S

100 60 8 40 8

200 80 14

400 80 14

Brake

N/A 57 82.5

Availabl

N/A 62 80

Availabl

N/A 82 98.5

Availabl

N/A 81.5 115

Availabl

∑series

SGMP

86 127.5

93.5 120

113.5 138.5

115 160

∑-Ⅴ series

SGMJV

60 14

60 14

80 19750 120 16

18/47

Page 19

Reduction

Gears

No

Reduction

Gears

Motor

Capacity

[kW] LC LL S LC LL S

0.45 130 19

0.85

1.3 130 22

1.8 180 24

2.9 180 35

4.4 180 35 180 35

Brake

N/A 13 8 139

Available 176 172

N/A 16 1 137

Available 199 173

N/A 18 5 153

Available 223 189

N/A 16 6 171

Available 217 207

N/A 19 2 160

Available 243 208

N/A 22 6 184

Available 277 232

130 19

180 35

∑ Series

SGMG(1500r/min)

130 16

130 19

130 22

180 35

Σ-Ⅴ Series

SGMGV

Reduction

Gears

No

Reduction

Gears

Motor

Capacity

[kW] LC LL S LC LL S

0.3 130 19

0.6 130 19 130 16

0.9 130 22 130

1.2 180 35 180 22

2.0 180 35 180

3.0 180 35 180

4.4 180 42 180

Brake

N/A 13 8 126

Available 176 159

N/A 16 1 139

Available 199 172

N/A 18 5 137

Available 223 173

N/A 16 6 153

Available 217 189

N/A 19 2 171

Available 243 207

N/A 22 6 160

Available 277 208

N/A 26 0 184

Available 311 232

∑ Series

SGMG(1000r/min)

130 14

Σ-Ⅴ Series

SGMGV

19

24

35

35

19/47

Page 20

●Shaft Key Size

W

W

e

e

e

e

e

e

e

e

e

e

Shaded area displayed the part where size is different between the ∑ motor and ∑-V motor.

Reduction

Gears

No

Reduction

Gears

QK

U

W

T

Motor

Capacity

Oil Seal

[W]QKUWTQKU

30

50

100

200

N/A

Availabl

N/A

Availabl

N/A

Availabl

N/A 20

Availabl

14 1.2 2 2

14 1.2 2

14 1.8 3 3

14

N/A 20

Availabl

750

N/A 30

Availabl

14

25

∑ Series

SGM

2

35

5

355

355

SGMAV SGMJV

14 1.8 3 3

14 1.8 3 3 14 1.8 3 3

14355

14

355400 14 3 5 5

22 3.5 6 6 622

∑-Ⅴ Series

TQKU

14 1.8 3

14 3 5 5

3.5 6

T

3

Reduction

Gears

No

Reduction

Gears

(2) With General-Purpose Reduction Gears

The customers need to prepare the general-purpose reduction gears by themselves or it might be necessary for

them to consider replacing with a precise decelerator because there is no general-purpose reduction gears in the

in the ∑-V .

Motor

N/A

Availabl

N/A

Availabl

N/A

Availabl

N/A

Availabl

Brake

14 1.8 3 3 14 1.8 3 3

16 3 5

16 3 5

22355

Capacity

[W] QK U W T QK U W T

100

200

400

750

∑ Series

SGMP

5

5

LL LC

14 35

14 3

22 3.5 6

∑-Ⅴ Series

SGMJV

55

5

6

S

20/47

Page 21

L

Reduction

Gears

General-

Purpose

30

50

Reduction

Gear

Brake

Ratio

1/5 60

1/10.3 60 14

1/21 60

1/33 60 14

1/5 60

1/10.3 70 16

1/21 70 16

1/33 70 16

1/5 70 16

1/10.3 70 16

1/21 90 20

1/33 90 20

1/5 90 20

1/10.3 90 20

1/21 105 25

1/33 105 25

1/5 90 20

1/10.3 105 25

1/21 120 32

1/33 120 32

1/5 105 25

1/10.3 120 32

1/21 145

1/33 145 40

N/A 101.5

Available 133.5

N/A 101.5

Available 133.5

N/A 116.5

Available 148.5

N/A 116.5

Available 148.5

N/A 109 110 108.5

Available 141 155 153.5

N/A 114 110 108.5

Available 146 155 153.5

N/A 131 119 117.5

Available 163 164 162.5

N/A 131 134.5 133

Available 163 179.5 178

N/A 131.5 122 122

Available 173 167 167

N/A 131.5 146.5 146.5

Available 173 191.5 191.5

N/A 153 146.5 146.5

Available 194 191.5 191.5

N/A 153 149 149

Available 194 194 194

N/A 138 144 144

Available 178.5 184 184

N/A 138 144 144

Available 178.5 184 184

N/A 165.5 151 151

Available 206 191 191

N/A 165.5 151 151

Available 206 191 191

N/A 166 162.5 162.5

Available 206.5 202.5 202.5

N/A 172.5 169.5 169.5

Available 213 209.5 209.5

N/A 200.5 169.5 169.5

Available 241 209.5 209.5

N/A 200.5 202.5 202.5

Available 241 242.5 242.5

N/A 193 193 193

Available 238.5 238 238

N/A 196 193 193

Available 241.5 238 238

N/A 223 219 219

Available 268.5 264 264

N/A 223 219 219

Available 268.5 264 264

Motor

Capacity

[W]LCL

100

200

400

750

∑ Series

SGM

SLCLLSLCLLS

14

14

14

120 40 120 40

40

120 40 120 40

120 40 120 40

∑-Ⅴ Series (precision reduction gears)

SGMAV SGMJV

40 10 40 10

40 10 40 10

40 10 40 10

60 16 60 16

40 10 40 10

60 16 60 16

60 16 60 16

90 25 90 25

60 16 60 16

60 16 60 16

90 25 90 25

90 25 90 25

60 16 60 16

90

25 90 25

90 25 90 25

90 25 90 25

90 25 90 25

21/47

Page 22

Reduction

Gears

General-

Purpose

Motor

Capacity

[W] LC LL S LC LL S LC LL S

100

200

400

750

Reduction

Gear Ratio

1/5 70 16

1/10.3 70 16

1/21 90 20

1/33 90 20

1/5 90 20

1/10.3 90 20

1/21 105

1/33 105 25

1/5 90 20

1/10.3 105 25

1/21 120 32

1/33 120 32

1/5 105 25

1/10.3 120 32

1/21 145 40

1/33 145 40

Brake

N/A 11 2 122 122

Available 141 167 167

N/A 11 2 146.5 146.5

Available 141 191.5 191.5

N/A 116.5 146.5 146.5

Available 145.5 191.5 191.5

N/A 116.5 149 149

Available 145.5 194 194

N/A 121.5 144 144

Available 153 184 184

N/A 121.5 144 144

Available 153 184 184

N/A 13 2 151 151

Available 163.5 191 191

N/A 13 2 151 151

Available 163.5 191 191

N/A 141.5 162.5 162.5

Available 173 202.5 202.5

N/A 15 2 169.5 169.5

Available 183.5 209.5 209.5

N/A 15 9 169.5 169.5

Available 190.5 209.5 209.5

N/A 15 9 202.5 202.5

Available 190.5 242.5 242.5

N/A 151.5 193 193

Available 188 238 238

N/A 158.5 193 193

Available 195.5 238 238

N/A 169.5 219 219

Available 206 264 264

N/A 169.5 219 219

Available 206 264 264

∑ Series

SGMP

25

∑-Ⅴ Series (precision reduction gears)

SGMAV SGMJV

40 10 40 10

60 16 60 16

60 16 60 16

90 25 90 25

60 16 60 16

60 16 60 16

90 25 90 25

90 25 90 25

60 16 60 16

90 25 90 25

90 25 90 25

120 40 120 40

90 25 90 25

90 25 90 25

120 40 120 40

120 40 120 40

22/47

Page 23

Reduction

Gears

General-

Purpose

Motor

Capacity

[kW] LC LL S LC LL S

0.45

0.85

1.3

1.8

2.9

4.4

Reduction

Gear Ratio

1/6 160

1/11 160 φ28h6

1/21 160

1/29 160 φ38h6

1/6 160

1/11 160 φ28h6

1/21 210 φ38h6

1/29 210 φ38h6

1/6 160 φ28h6

1/11 210 φ38h6

1/21 210 φ38h6

1/29 260 φ58h6

1/6

1/11

1/21

1/29

1/6 210 φ38h6

1/11 210 φ38h6

1/21 260 φ58h6

1/29 340 φ68h6

1/6 260 φ58h6

1/11

1/21 340 φ68h6

1/29 400 φ78h6

Brake

N/A 138

Available 190

N/A 138

Available 190

N/A 138

Available 190

N/A 138

Available 190

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 192

Available 257

N/A 192

Available 257

N/A 192

Available 257

N/A 192

Available 257

N/A 226

Available 291

N/A 226

Available 291

N/A 226

Available 291

N/A 226

Available 291

210 φ38h6

210

260

260 φ58h6

260 φ58h6

∑ Series

SGMG(1500r/min)

φ28h6

φ28h6

φ28h6

φ38h6

φ58h6

∑-Ⅴ Series (precision reduction

gears)

SGMGV

Quotes in Each Case

23/47

Page 24

Reduction

Gears

General-

Purpose

Motor

Capacity

[kW] LC LL S LC LL S

0.3

0.6

0.9

1.2

2.0

3.0

4.4

Reduction

Gear Ratio

1/6 160

1/11 160

1/21 160

1/29 160

1/6

1/11

1/21 210 φ38h6

1/29 210 φ38h6

1/6 160 φ28h6

1/11 160 φ28h6

1/21 210 φ38h6

1/29 210 φ38h6

1/6 210 φ38h6

1/11 210 φ38h6

1/21 260

1/29 260 φ58h6

1/6 210 φ38h6

1/11 210 φ38h6

1/29 340 φ60h6

1/6

1/11

1/21

1/29

1/6 260

1/11 260

1/21 400

Brake

N/A 138

Available 190

N/A 138

Available 190

N/A 138

Available 190

N/A 138

Available 190

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 192

Available 257

N/A 192

Available 257

N/A 192

Available 257

N/A 192

Available 257

N/A 226

Available 291

N/A 226

Available 291

N/A 226

Available 291

N/A 226

Available 291

N/A 260

Available 325

N/A 260

Available 325

N/A 260

Available 325

N/A 260

Available 325

160

160 φ28h6

260 φ58h61/21

260

260

340

400

4001/29

∑ Series

SGMG(1000r/min)

φ28h6

φ28h6

φ28h6

φ28h6

φ28h6

φ58h6

φ50h6

φ50h6

φ60h6

φ70h6

φ50h6

φ50h6

φ70h6

φ70h6

∑-Ⅴ Series (precision reduction

gears)

SGMGV

Quotes in each time

24/47

Page 25

(3)With Precision Reduction Gears

LL LC

S

25/47

Page 26

[

Reduction

Gears

Precision

Reduction

Gears

Motor

Capacity

100

200

400

750

Reduction

Gear Ratio

W] LC LL S LC LL S LC LL S

1/5

1/9

30

1/21

1/33

1/5

1/9

50

1/21

1/33

1/5

1/11

1/21

1/33

1/5

1/11

1/21

1/33

1/5

1/11

1/21

1/33

1/5

1/11

1/21

1/33

Brake

N/A 97.5

Available 129.5

N/A 97.5

Available 129.5

N/A 112.5

Available 144.5

N/A 112.5

Available 144.5

N/A 105 110 108.5

Available 137 155 153.5

N/A 106 110 108.5

Available 138 155 153.5

N/A 123 119 117.5

Available 155 164 162.5

N/A 123 134.5 133

Available 155 179.5 178

N/A 123.5 122 122

Available 164.5 167 167

N/A 140.5 146.5 146.5

Available 181.5 191.5 191.5

N/A 149.5 146.5 146.5

Available 190.5 191.5 191.5

N/A 149.5 149 149

Available 190.5 194 194

N/A 134.5 144 144

Available 175 184 184

N/A 151.5 144 144

Available 192 184 184

N/A 159.5 151 151

Available 200 191 191

N/A 159.5 151 151

Available 200 191 191

N/A 162.5 162.5 162.5

Available 203 202.5 202.5

N/A 187.5 169.5 169.5

Available 228 209.5 209.5

N/A 195.5 169.5 169.5

Available 236 209.5 209.5

N/A 195.5 202.5 202.5

Available 236 242.5 242.5

N/A 187 193 193

Available 232.5 238 238

N/A 216 193 193

Available 261.5 238 238

N/A 223 219 219

Available 268.5 264 264

N/A 223 219 219

Available 268.5 264 264

∑ Series

SGM

60 14

60 14

60

60 14

60

70

70 16

70

90 20

90 20

90 20

105 25 90 25

105 25 90 25

90 20

105 25 90 25

120 32

120 32 120 40

105 25

120 32

145 40

145 40

14

14 40 10

16

16

SGMAV SGMJV

40 10

60 16 16

60 16 60

90 25 90 25

60 16 60 16

60 1690 20

60 16

90 25

90

90 25

120 40

120 40 120

∑-Ⅴ Sereis

40 10

40 1040 10

40 10

60 1660 16

1070 16

25

40 1040

6070 16

60 16

90 25

90 25

60 16

90 25

90 25

120 40

90 25

90

120 40

16

25

40

26/47

Page 27

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

Reduction

Gears

Precision

Reduction

Gears

Motor

Capacity

[W] LC LL S LC LL S LC LL S

100

200

400

750

Reduction

Gear Ratio

1/5 70 16

1/11 70 16

1/21 90 20

1/33 90 20 90 25 90 25

1/5 90 20

1/11 90 20

1/21 105 25

1/33 105 25 90 25 90 25

1/5 90 20 60 16 60 16

1/11 105 25 90 25 90 25

1/21 120 32 90 25 90 25

1/33 120 32 120 40 120 40

1/5 105 25 90 25 90 25

1/11 120 32 90 25 90 25

1/21 145 40 120 40 120 40

1/33 145 40 120 40 120 40

Brake

N/A 104 122 122

Availabl

N/A 104 146.5 146.5

Availabl

N/A 113 146.5 146.5

Availabl

N/A 113 149 149

Availabl

N/A 118 144 144

Availabl

N/A 118 144 144

Availabl

N/A 126 151 151

Availabl

N/A 126 151 151

Availabl

N/A 138 162.5 162.5

Availabl

N/A 146 169.5 169.5

Availabl

N/A 154 169.5 169.5

Availabl

N/A 154 202.5 202.5

Availabl

N/A 145.5 193 193

Availabl

N/A 153.5 193 193

Availabl

N/A 169.5 219 219

Availabl

N/A 169.5 219 219

Availabl

∑ Series

SGMP

133 167 167

133 191.5 191.5

142 191.5 191.5

SGMAV SGMJV

40 10 40 10

60 16 60 16

60 16 60 16

∑-Ⅴ Series

142 194 194

149.5 184 184

149.5 184 184

157.5 191 191

60 16 60 16

60 16 60 16

90 25 90 25

157.5 191 191

169.5 202.5 202.5

177.5 209.5 209.5

185.5 209.5 209.5

185.5 242.5 242.5

182 238 238

187 238 238

203 264 264

203 264 264

27/47

Page 28

Reduction

Gears

Precision

Reduction

Gears

Motor

Capacity

[W] LC LL S LC LL S

0.45

0.85

1.3

1.8

2.9

4.4

Reduction

Gear Ratio

1/5 140

1/9

1/20 245

1/29 245 φ50h6

1/45

1/5 140

1/9

1/20 245 φ50h6

1/29 245 φ50h6

1/45

1/5 245 φ50h6

1/9

1/20 245 φ50h6

1/29

1/45

1/5

1/9

1/20

1/29

1/5 310 φ60h6

1/9 310 φ60h6

1/20

1/5 310

1/9 310 φ60h6

Brake

N/A 138

Available 190

N/A 138

Available 190

140 φ35h6

N/A 138

Available 190

N/A 138

Available 190

N/A 138

Available 190

245 φ50h6

N/A 161

Available 213

N/A 161

Available 213

140 φ35h6

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

310

N/A 185

Available 237

N/A 185

Available 237

245 φ50h6

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

310 φ60h6

310

245 φ50h6

245

310

310

N/A 192

Available 257

N/A 192

Available 257

N/A 192

Available 257

310 φ60h6

N/A 226

Available 291

N/A 226

Available 291

∑ Series

SGMG(1500r/min)

φ35h6

φ50h6

φ35h6

φ60h6

φ60h6

φ50h6

φ60h6

φ60h6

φ60h6

∑-Ⅴ Series

SGMGV

Quotes each time

28/47

Page 29

Reduction

Gears

Precision

Reduction

Gears

Motor

Capacity

[W] LC LL S LC LL S

0.45

1.3

1.8

2.9

4.4

Reduction

Gear Ratio

1/5 140

1/9 140

1/20

1/29 245

1/45

1/5 140 φ35h6

1/9 140 φ35h6

1/20 245 φ50h60.85

1/29 245 φ50h6

1/45 310 φ60h6

1/5 245 φ50h6

1/9 245 φ50h6

1/20 245 φ50h6

1/29 310 φ60h6

1/45 310 φ60h6

1/5 245 φ50h6

1/9 245 φ50h6

1/20 310 φ60h6

1/29 310 φ60h6

1/5 310 φ60h6

1/9 310 φ60h6

1/20 310

1/5 310 φ60h6

1/9 310 φ60h6

Brake

N/A 138

Available 190

N/A 138

Available 190

N/A 138

Available 190

245

N/A 138

Available 190

N/A 138

Available 190

245 φ50h6

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 161

Available 213

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 185

Available 237

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 166

Available 231

N/A 192

Available 257

N/A 192

Available 257

N/A 192

Available 257

N/A 226

Available 291

N/A 226

Available 291

∑ Sereies

SGMG(1000r/min)

φ35h6

φ35h6

φ50h6

φ50h6

φ60h6

∑-Ⅴ Series

SGMGV

Quotes each time

29/47

Page 30

2-4. Notes at Machine Installation

Please cautious about the cable wiring as well as the size of the flange, spigot, and shaft at machine

installation. The pictures shown below are the part of the motor cable wiring of 40 and 60.

40

60

30/47

Page 31

3. Servo Amplifier

3-1. Type Comparison Table

1-3. Please refer to the replacement list

The servo amplifier type has been changed from the capacity value to output current value.

3-2. Terminal Table

(1) Main circuit terminal

Σ

SGDA type SGDB type

Terminal marking Terminal marking Terminal marking Function

RR

TS

T

UU

V

W

Rr

Tt

PP

NN

VV

WW

P,P1,B

∑-Ⅴ

SGDV type

L1

L2

L3

U

L1C

L2C

B1/(+)

B2

B3

(+)1

(+)2

(-)1

(-)2

B1/(+)

(-)

(-)2

・Single-phase power supply AC200V:

Main circuit power supply input terminal

Servomotor connection terminal

Control power supply input terminal (100V/200V type)

External regenerative resistor connection terminal

The connection method is different in Σ-Ⅴ

DC reactor conncetion terminal for power line

harmonics control

Main circuit forward side terminal

Main circuit reverse side terminal

It is possible to change to single phase power supply AC200V by the parameter (Factory setting is “3-phase

power supply”) however, the torque - rotational speed characteristic is different from the three-phase power

supply specification.

31/47

Page 32

(2) Control Circuit Terminal

e

e

(*3)

f

Σ-V Notes

1. Do not use the reserved terminal of "―"

2. Connect the shield line of the cable for I/O with the connector shell. It should be connected with frame

ground (FG) at the servo amplifier side connector.

3. The following input signals can change the parameter allocation

/DEC,P-OT,N-OT,EXT1, EXT2 ,EXT3

4. The signals of /COIN, /V-CMP, /TGON, /S-RDY, /CLT, /VLT, /BK, /WARN, /NEAR are able to allocate to

/SO1, /SO2, /SO3

Please refer to the Σ-V manual for details.

Comparison between SGDA-□□□S type [Analog voltage reference type] (speed & torque control

type) and SGDV type

Terminal No.

SGDA typ

GDV typ

Terminal Marking Function

36pin 50pin

19

35

2,4,6,10 1,2,6,10

54

7-

825

927

11 45

12 46

13 47

14 40

15 41

16 42

17 43

18 44

19 -

20 33

21 34

22 35

23 36

24 19

25 20

26 -

27 -

28 21

29 22

30 37

31 38

32 39

33 -

34 31

35 32

36 Shell

T-REF Torque reference input

V-REF Speed reference input

GND Ground

SEN SEN signal input

/BK+ Brake interlock output (*3)

/V-CMP+(./COIN+)

Speed match detection output (*2)

/TGON+ Rotation detection output (*2)

/P-CL Forward side external torque control input (*2)

/N-CL Reverse side external torque control input (*2)

+24VIN External power supply input

/S-ON Servo ON input (*2)

/P-CON P operation input (*2)

P-OT Forward drive prohibited input (*2)

N-OT Reverse drive prohibited input (*2)

/ALM-RST Alarm reset inupt (*2)

SG-PG Single ground for PG signal output

PAO PG frequence dividing output A-phase

/PAO

PBO PG frequence dividing output B-phase

/PBO

PCO PG frequence dividing output C-phase

/PCO

PSO S-phse signal output

/PSO

BAT(+) Battery(+)

BAT(-) Battery(-)

ALO1 Alarm code output

ALO2

ALO3

SG-AL Signal ground for alarm code output

ALM+ Servo alarm output

ALMFG Frame Ground

(*2): The sequence I/O is factory setting

The allocation change is possible by using the user parameter in ∑-V, but not in ∑ series

:Change the setting of one of three factory setting output signals by user parameter i

needed

32/47

Page 33

The number of CN1 input signal connector pins of ∑ series SGDA type and ∑-V series SGDV type are

different.

The CN2 encoder connector is not compatible.

The CN5 analogue monitor connector is compatible.

33/47

Page 34

Comparison between SGDA-□□□P type [pulse train reference type] (position control type) and

e

SGDV type

SGDA typeGDV typ

36pin 50pin

17

28

311

412

515

614

7-

825

927

10 1,2,6,10

11 45

12 46

13 47

14 40

15 41

16 42

17 43

18 44

19 -

20 33

21 34

22 35

23 36

24 19

25 20

26 -

27 -

28 21

29 22

30 37

31 38

32 39

33 -

34 31

35 32

36 Shell

Terminal Marking Function

PULS Reference pule input

/PULS

SIGN Reference symbol input

/SIGN

CLR Clear input

/CLR

/BK+ Brake interlock output (*3)

/V-CMP+(./COIN+)

/TGON+ Rotation detection output (*2)

GND Ground

/P-CL Forward side external torque control input (*2)

/N-CL Reverse side external control input (*2)

+24VIN External power supply input

/S-ON Servo ON input (*2)

/P-CON P operation input (*2)

P-OT Forward drove prohibited input (*2)

N-OT Reverse drive prohibited input (*2)

/ALM-RST Alarm reset input (*2)

SG-PG Single ground for PG signal output

PAO PG frequency dividing output A-phase

/PAO

PBO PG frequency dividing output B-phase

/PBO

PCO PG frequency dividing output C-phase

/PCO

PSO S-phase signal output

/PSO

BAT(+) Battery(+)

BAT(-) Battery(-)

ALO1 Alarm code output

ALO2

ALO3

SG-AL Signal ground for alarm code output

ALM+ Servo alarm output

ALMFG Frame ground

Speed match detection output (*2)

(*2): The sequence I/O is factory setting

The allocation change is possible by using the user parameter in ∑-V, but not in ∑ series

(*3):Change the setting of one of three factory setting output signals by user parameter

if needed

The number of CN1 input signal connector pins of ∑ series SGDA type and ∑-V series SGDV type are

different.

The CN2 encoder connector is not compatible.

The CN5 analogue monitor connector is compatible.

34/47

Page 35

Comparison between SGDB-□□□D type and SGDV type

e

Terminal No.

SGDB type

50pin 50pin

11

22

33

44

55

66

77

88/PULS

99

10 10

11 11

12 12

13 13

14 14

15 15

16 17 18 18

19 19

20 20

21 21

22 22

23 24 25 25

26 26

27 27

28 28

29 29

30 30

31 31

32 32

33 33

34 34

35 35

36 36

37 37

38 38

39 39

40 40

41 41

42 42

43 43

44 44

45 45

46 46

47 47

48 49 50 -

GDV typ

Terminal Marking Function

SG Signal Ground

SG Signal Ground

PL1 Battery for open collector reference

SEN SEN signal input

V-REF Speed reference input

SG Signal Ground

PULS Reference pulse input

Reference pulse input

T-REF Tordque reference input

SG Signal Ground

SIGN Reference code input

/SIGN Reference code input

PL2 Battery for open collector reference

/CLR Clear input

CLR Clear input

TRQ-M Torque monitor

VTG-M Speed monitor

PL3 Battery for open collector reference

PCO PG frequency dividing output C-phase

/PCO PG frequency dividing output C-phase

BAT /BAT(+) Battery (+)

BAT0 / BAT(-) Battery (-)

+12V Battery for analog refernce

-12V Battery for analog refernce

/V-CMP//COIN Speed match detection output

/V-CMP//COIN Speed match detection output

/TGON+ Rotating detection output

/TGON- Rotating detection output

/S-RDY+ Servo-ready output

/S-RDY- Servo-ready output

ALM+ Servo alarm output

ALM- Servo alarm output

PAO PG frequency dividing output A-phase

/PAO PG frequency dividing output A-phase

PBO PG frequency dividing output B-phase

/PBO PG frequency dividing output B-phase

ALO1 Alarm code output

ALO2 Alarm code output

ALO3 Alarm code output

/S-ON Servo ON inuput (*2)

/P-CON P operation input (*2)

P-OT Forward drive prohibit input (*2)

N-OT Reverse drive prohibit input (*2)

/ALMRST Alarm reset input

/P-CL Forward side external torque limit input

/N-CL Reverse side external torque limit input

+24 VIN External power supply input

PSO S-phase signal output

/PSO S-phase signal output

FG Frame Ground

(*2): The sequence I/O is factory setting

The allocation change is possible by using the user parameter in ∑-V, but not in ∑ series

(*3):Change the setting of one of three factory setting output signals by user parameter if

needed

35/47

Page 36

Comparison between SGDA-□□□N type [MECHATROLINK communication reference type] and

SGDV type

ΣΣ-Ⅴ

SGDA-

Terminal

No.

26pin 26pin

□□□

Terminal

Marking

N

SGDVTerminal

1/BK 1

2BK-SG 2

3ALM 3ALM+ Servo alarm outptu

4 ALM-SG 4 ALM- Servo alarm outptu

5― 5― ― Reserved terminal

6 +24VIN 6 +24VIN External power supply input

7P-OT 7

8N-OT 8

9/DEC 9

10 /EXT 10

―― 11

―― 12

― ― 13 /SI0 General purpose inut

14 BAT(+) 14 BAT(+) Battery(+) When using absolute encoder

15 BAT(-) 15 BAT(-) Battery(-) When using absolute encoder

― ― 16 SG Signal ground

―― 17PAO

― ― 18 /PAO

―― 19PBO

― ― 20 /PBO

―― 21PCO

― ― 22 /PCO

― ― 23 /SO2+ General purpose output

― ― 24 /SO2- General purpose output

― ― 25 /SO3+ General purpose output

― ― 26 /SO3- General purpose output

26FG ――Frame Ground

□□□□1□□

No.

Terminal

Marking

/BK(+)

(/SO1+)

/BK(-)

(/SO1-)

P-OT

(/SI1)

N-OT

(/SI2)

/DEC

(/SI3)

/EXT1

(/SI4)

/EXT2

(/SI5)

/EXT3

(/SI6)

Function

Brake interlock output

Brake interlock output

Forward drive prohibit input

Reverse drive prohibit input

Homing deceleration LS input

External latch signal 1 input

External latch signal 2 input

External latch signal 3 input

PG frequency dividing output A-phase

PG frequency dividing output B-phase

PG frequency dividing output C-phase

Remarks

Function is the same though the

terminal marking is different

Function is the same though the

terminal marking is different

There is just one external latch

signal in Σ

The connector is different though the number of CN1 I/O signal pins of the Σseries and Σ-V series are the same.

36/47

Page 37

Comparison between SGDB-□□□N type [MECHATROLINK communication reference type] and

―

∑

e

SGDV type

ΣΣ-Ⅴ

SGDB-

Terminal

No.

26pin 26pin

□□□

NSGDV-

Terminal

Marking

Terminal

1/BK 1

2 BK-SG 2

3 ALM 3 ALM+ Servo alarm output

4 ALM-SG 4 ALM- Servo alarm output

5― 5―

6 +24VIN 6 +24VIN External power supply output

7P-OT 7

8N-OT 8

9/DEC 9

10 /EXT 10

―― 11

―― 12

― ― 13 /SI0 General input

― ― 14 BAT(+) Battery(+) When using absolute encoder

― ― 15 BAT(-) Battery(-) When using absolute encoder

― ― 16 SG Signal Ground

―― 17PAO

― ― 18 /PAO

―― 19PBO

― ― 20 /PBO

―― 21PCO

― ― 22 /PCO

― ― 23 /SO2+ General purpose output

― ― 24 /SO2- General purpose output

― ― 25 /SO3+ General purpose output

― ― 26 /SO3- General purpose output

26 FG ― ― Frame Ground

□□□□1□□

No.

Terminal

Marking

/BK(+)

(/SO1+)

/BK(-)

(/SO1-)

P-OT

(/SI1)

N-OT

(/SI2)

/DEC

(/SI3)

/EXT1

(/SI4)

/EXT2

(/SI5)

/EXT3

(/SI6)

Function

Remarks

Brake interlock output

Brake interlock output

Funciton is the same though the terminal

marking is different

Funciton is the same though the terminal

marking is different

Reserved terminal

Forward drive prohibit input

Reverse drive prohibit input

Homing deceleration LS input

External latch signal 1 input There is just one external latch signal in

External latch signal 2 input

External latch signal 3 input

PG frequency dividing A-phase

PG frequency dividing B-phase

PG frequency dividing C-phase

The connector is different thought the number of CN1 I/O signal pins of the Σ series and Σ-Ⅴ series are the sam

37/47

Page 38

3-3. Installation Size

Σ-V series servo amplifier is not compatible with Σ series servo amplifier in the dimension and mounting

dimension. The position of the screw for the installation is different.

【AC200V, 200W or less】

2-M4 Tap

【AC100V, 200W or less and AC200V, 400W】

2-M4 Tap

38/47

Page 39

【AC100V, 400W and AC200V, 750W】

S-N4 Tap

【0.5kW~1.5kW】

4-M5 Mounting Hole

Vent

10 or more

Mounting Pitch

4-M4 Screw Hole

External

Mounting Pitch

10 or more

Mounting Pitch

39/47

Page 40

【2.0 kW, 3.0kW】

4-M5 Mounting Hole

Vent

4-M5 Screw Hole

10 or more

External

Mounting Pitch

10 or more

Mounting Pitch

【5.0kW】

4-M5 Screw Hole

External

4-M5 Tap Vent Hole

Mounting Pitch

Mounting Pitch

40/47

Page 41

3-4. Notes when Installing Control Board

Please note the difference of the electrical conduction state of frame ground when producing the

attachment to accommodate the difference of the installation hole size. An alarm may occur and the

machine may operate improperly because the amount of noise changes when the electrical conduction

state changes.

Servo Amplifier

The frame ground of the control

board and servo amplifier

conduct through the installation

screw.

Control Board Side

Attachment

Control Board Side

Conducting Part

Servo Amplifier

When painting and/or surface treatment is

given to the attachment for rust prevention,

electrical conduction between the attachment

and control board may be impossible.

41/47

Page 42

4. Cable and Peripherals

All the cables and peripherals of ∑ series are not compatible with Σ-V series’s so please confirm the

applicable products by referring to the catalog and manual, etc.

Please refer to the following comparison table for the type of the applicable products.

■ Connector for I/O Signal

■入出力信号用コネクタ

Analog・Pulse Train Reference Type

アナログ・パルス列指令形

名称

Name

コネクタ端子台変換ユニット JUSP-TA36P JUSP-TA50P JUSP-TA50PG-E

Connector Terminal Block Conversion Unit

片側ばら出しケーブル DE9404859 DE9406969-1 JZSP-CSI01-1-E

One-sided individual pull out cable

Connector Kit (for CN1)

コネクタキット(CN1用) DP9420007 DE9406970 JZSP-CSI9-1-E

Type

形式

(for SGDA type)

Σ (SGDA形用) Σ (SGDB形用) Σ-Ⅴ (SGDV形用)

(for SGDB type) (for SGDV type)

JUSP-TA50PG-1-E

JUSP-TA50PG-2-E

DE9406969-2 JZSP-CSI01-2-E

DE9406969-3 JZSP-CSI01-3-E

■ MECHATROLINK Communication Reference Type

MECHATROLINK通信指令形

名称 形式

Name

Connector Terminal Block Conversion Unit

コネクタ端子台変換ユニット JUSP-TA26P JUSP-TA26P -

Connector Kit (for CN1)

コネクタキット(CN1用) DE9411354 DE9411354 JZSP-CSI9-2-E

Σ(SGD-□□□N) Σ(SGDB-□□□N) Σ-Ⅴ(SGDV)

Type

■ Analog Monitor

■アナログモニタ

名称 形式

Name

Cable for Analog Monitor

アナログモニタ用ケーブル DE94094559 DE94094559 JZSP-CA01-E

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ(SGDV)

■ PC Connection Cable

■パソコン接続ケーブル

名称 形式

Name

パソコン接続ケーブル DE9405258 DE9405258 JZSP-CVS06-02-E

PC Connection Cable

■ MECHATROLINK Communication Cable

■MECHATROLINK通信ケーブル

名称 形式

Name

両端コネクタ付きケーブル JEPMC-W6002-A5-E

Cable with both-ended Connector

Terminator

ターミネータ - - JEPMC-W6022-E

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ(SGDV)

DE9408564 DE9408564 (USB接続)

DE9408565 DE9408565

(USB connection)

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ(SGDV)

--

JEPMC-W6002-01-E

JEPMC-W6002-**-E

■ Cable for Safety Feature

■セーフティ機能用ケーブル

名称 形式

Name

Cable for Safety Feature

セーフティ機能用ケーブル - - JZSP-CVH03-03-E

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ(SGDV)

42/47

Page 43

■ Digital Operator

■ディジタルオペレータ

名称 形式

Name

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ (SGDV)

ディジタルオペレータ JUSP-OP02A-1 JUSP-OP02A-1 JUSP-OP05A-1-E

Digital Operator

JUSP-OP03A JUSP-OP03A

■ノイズフィルタ

■ Noise Filter

AC100V

名称 サーボ容量/電流表記 形式

Name

ノイズフィルタ 50W/R70 LF205-A FN2070-6/07

Noise

Filter

Servo Capacity

/Current Display

100W/R90 LF-210 FN2070-6/07

200W/1R6 LF-210 FN2070-10/07

Type

Σ(SGDA) Σ-Ⅴ (SGDV)

300W LF-220 -

400W/2R8 - FN2070-16/07

■ AC200V

AC200V

名称 サーボ容量/電流表記 形式

Name

ノイズフィルタ 50W/R70 LF-205A - FN2070-6/07

Noise

Filter

Servo Capacity

/Current Display

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ (SGDV)

100W/R90 LF-205A - FN2070-6/07

200W/1R6 LF-205A - FN2070-6/07

400W/2R8 LF-210 - FN2070-10/07

750W/5R5 LF-220 - FN2070-16/07

1.0kW/7R6 - LF-315 FN258L-16/07

1.5kW/120 - LF-315 HF3020C-UQC

2.0kW/180 - LF-320 HF3020C-UQC

3.0kW/200 - LF-330 HF3030C-UQC

5.0kW/330 - LF-340 HF3050C-UQC

■ Battery

■バッテリ

名称 形式

Name

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ (SGDV)

バッテリ ER6V C3相当品 ER6V C3相当品 JZSP-BA01

Battery

Cable with both-ended connector

両端コネクタ付きケーブル(バッテリユニット付き)

(w/ battery unit)

■ Brake Power Supply

■ブレーキ電源

名称 入力電圧 形式

Name

Input Voltage

Equivalent to

ER6V C3

Equivalent to

ER6V C3

Equivalent to ER6V C3

ER6V C3N相当品

- - JZSP-CSP□□-□□-E

Type

Σ(SGDA) Σ(SGDB) Σ-Ⅴ (SGDV)

Brake Power

ブレーキ電源AC100V LPDE-1H01 LPDE-1H01 LPDE-1H01-E

Supply

Brake Power Supply (for DC24V brake) Customer Provides Customer Provides Customer Provides

ブレーキ電源(DC24Vブレーキ用) お客様準備 お客様準備 お客様準備

AC200V LPSE-2H01 LPSE-2H01 LPSE-2H01-E

43/47

Page 44

■ DC Reactor for Power Line Harmonics Control

■電源高調波抑制用DCリアクトル

AC100V

AC100V

サーボ容量/電流表記

Servo Capacity

/Current Display

Σ(SGDA) Σ-Ⅴ (SGDV)

50W/R70F -

100W/R90F -

200W/2R1F - X5054

400W/2R8F - X5056

AC200V

AC200V

Servo Capacity

サーボ容量/電流表記

/Current Display

Σ(SGDA、SGDB) Σ-Ⅴ (SGDV)

50W/R70A -

100W/R90A -

200W/1R6A -

400W/2R8A -

500W/3R8A -

750W/5R5A -

1.0kW/7R6A -

1.5kW/120A -

2.0kW/180A -

3.0kW/200A - X5059

5.0kW/330A - X5068

Typ e

Typ e

形式

X5053

形式

X5061

X5060

■ Surge Absorber/Serge Protector/Surge Suppressor

■サージアブソーバ/サージプロテクタ/サージサプレッサ

AC100V

AC100V

Surge Absorber/Surge Protector

サージアブソーバ/サージプロテクタ/サージサプレッサ

/Surge Suppressor

Name

Servo Capacity

名称

サーボ容量/電流表記

/Current Display

50W/R70F

100W/R90F

200W/2R1F

400W/2R8F

AC200V

Servo Capacity

Name

Surge Absorber/Surge Protector

/Surge Suppressor

サージアブソーバ/サージプロテクタ/サージサプレッサ

名称

サーボ容量/電流表記

/Current Display

50W/R70A

100W/R90A

200W/1R6A

400W/2R8A

750W/5R5A

1.0kW/7R6A

1.5kW/120A

2.0kW/180A

3.0kW/200A

5.0kW/330A

Typ e

形式

Σ(SGDA) Σ-Ⅴ

LT-C12G801WSCR50500BA

Typ e

形式

Σ(SGDA,SGDB) Σ-Ⅴ

LT-C12G801WSCR50500BA

44/47

Page 45

■ Electromagnetic Contactor

■電磁接触器

AC100V

名称 サーボ容量/電流表記 形式

Name

Servo Capacity

/Current Display

電磁接触器 50W/R70 HI-15E5 SC-03

Electromagnetic Contactor

100W/R90 HI-15E5 SC-03

200W/2R1 HI-15E5 SC-03

400W/2R8 HI-15E5 SC-4-1

Typ e

Σ(SGDA) Σ-Ⅴ

AC200V

名称 サーボ容量/電流表記 形式

Name

電磁接触器 50W/R70 HI-15E5 ― SC-03

Electromagnetic Contactor

Servo Capacity

/Current Display

100W/R90 HI-15E5 ― SC-03

200W/1R6 HI-15E5 ― SC-03

400W/2R8 HI-15E5 ― SC-03

750W/5R5 HI-15E5 ― SC-4-1

1.0kW/7R6 ― HI-15E5 SC-4-1

1.5kW/120 ― HI-15E5 SC-4-1

2.0kW/180 ― HI-18E SC-5-1

3.0kW/200 ― HI-18E SC-5-1

5.0kW/330 ― HI-18E SC-N1

Typ e

Σ(SGDA) Σ(SGDB) Σ-Ⅴ(SGDV)

45/47

Page 46

5.Parameter Converter

The user constant of the ∑ series servo amplifier is able to be converted automatically into the parameter of

the ∑-V servo amplifier by using a parameter converter in the Sigma V engineering tool SigmaWin+

Ver.5.00 or later.

The procedure is shown below.

1. Open the Sigma Component of SigmaWin+ then confirm and save the user constant of the ∑ servo

amplifier.

If a user constant file taken from the servo amplifier is available use that file.

【Example of user constant save screen】 【Example of parameter converter screen】

2. Open Sigma V Component, and start the parameter converter.

3. Specify the user constant file of the ∑ servo amplifier which was saved in step 1 to the former

conversion file name.

4. Specify where to save the converted file.

5. The user constant is converted to the parameter when the conversion button is pushed. The part

where readjustment might be needed is highlighted in yellow.