Yaskawa SGMSH Operation Diagram

400V Three-phase Sigma II Servo Systems

Selecting Your SGMSH/UH Sigma II Servo System

First, select the Sigma II servomotor suited for your application using SigmaSize: the Yaskawa

servomotor sizing software, available at no charge. (Request SigmaSize software via e-mail, at:

literature@yaskawa.com).

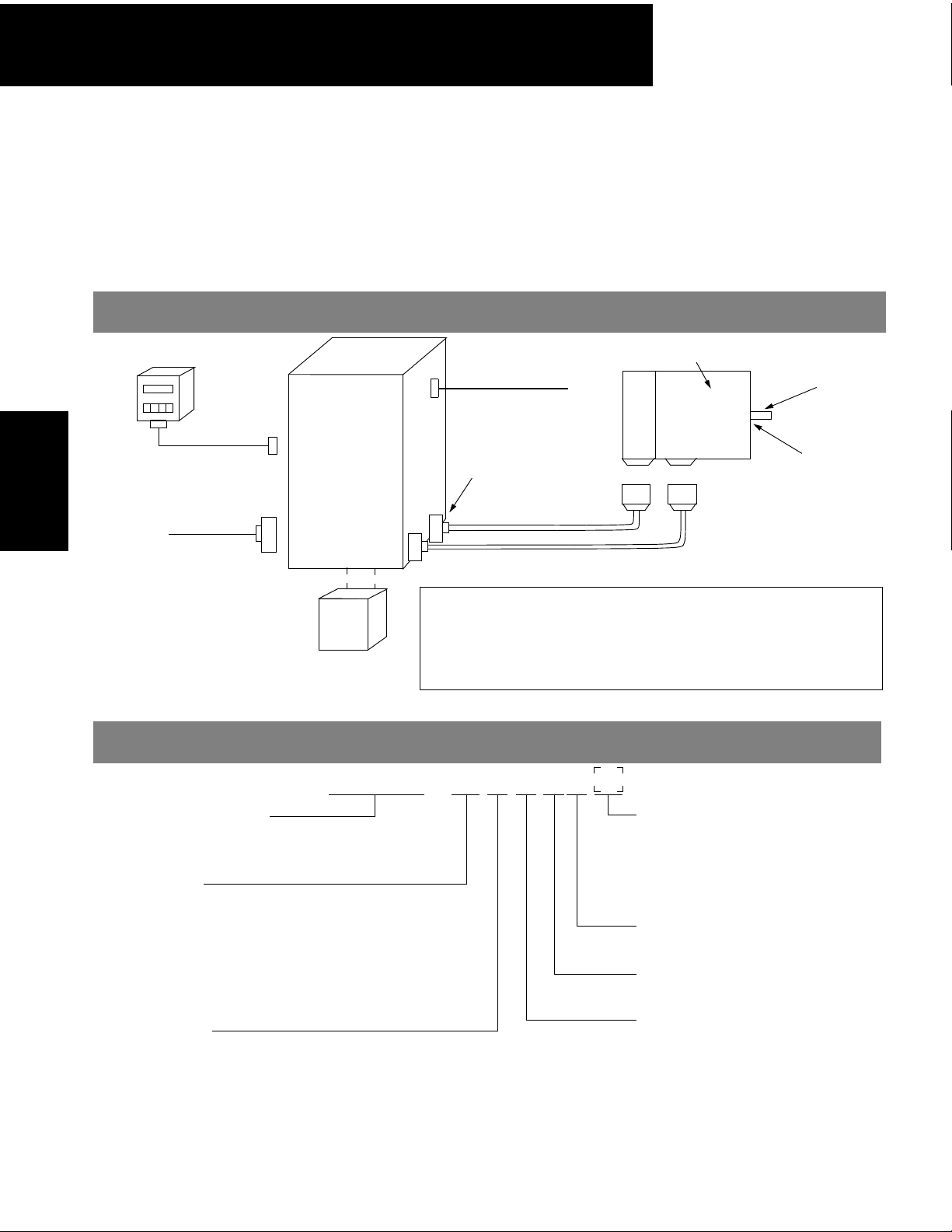

Use the diagram below to locate and identify the components of your system. Each item is lettercoded and cross-referenced in the option tables on the following pages.

System Configuration

Digital Operator (E)

Servomotors

SGMSH/UH

Model Number Designation

3CN

Peripheral

Signal

Connector (D)

1CN

I/O Signal

Connector

(D)

Regenerative Unit (E)

5CN

For Monitor (D)

SGDH

Amplifier

(B)

Connector for

Encoder Signal (D)

Encoder side

2CN

Connector (D)

Encoder Cable (C)

Motor Cable (C)

Specify a technical manual, if it is needed, on your

servo system purchase order:

Sigma II Series Servo System User’s Manual: YEA-SIA-S800-32.2

(Manual is provided at no charge with a purchase order,

but it must be requested).

SGMSH - 10 D C A 6 1

Optional Holding Brake

Shaft Keyway

SGMSH/UH

Servomotor

(A)

Shaft Seal

Motor side

Connector (D)

Sigma Servomotor Type

SGMSH: 5000rpm

SGMUH: 6000rpm

Rated Output

10: 1.0kW (1.3hp)

15: 1.5kW (2.0hp)

20: 2.0kW (2.7hp)

30: 3.0kW (4.0hp)

40: 4.0kW (5.4hp)

50: 5.0kW (6.7hp)

Power Supply

D: 400V

144

Accessories

1: Standard

C: 24V

S: Shaft Seal

E: Shaft Seal and Brake

Shaft Specifications

6: Straight Shaft with Keyway

Rated Speed

A: Revision Level

Encoder Specifications

C: 17-bit Incremental

2: 17-bit Absolute Encoder*

*SGMUH is not available with absolute

encoder

DC

Encoder

Brake

Loading...

Loading...