Ratings and Specifications

Time Rating: Continuous

Vibration Class: V15

Insulation Resistance: 500 VDC, 10 M

Ambient Temperature: 0 to 40˚C

Excitation: Permanent magnet

Mounting: Flange-mounted

Thermal Class: B

Ω min.

Withstand Voltage: 1500 VAC for one minute

Enclosure: Totally enclosed, self-cooled, IP65

(except for shaft opening)

Ambient Humidity: 20% to 80% (no condensation)

Drive Method: Direct drive

Rotation Direction: Counterclockwise (CCW) with forward run

reference when viewed from the load side

Voltage 200 V

Servomotor Model: SGMJV-¡¡¡ A5A 01A 02A 04A 08A

Rated Output

Rated Torque

*1

*1, *2

Instantaneous Peak Torque

Rated Current

*1

Instantaneous Max. Current

Rated Speed

Max. Speed

*1

*1

Torque Constant N•m/A

Rotor Moment of Inertia

Rated Power Rate

*1

Rated Angular Acceleration

Applicable SERVOPACK

*1

: These items and torque-motor speed characteristics quoted in combination with an SGDV SERVOPACK are at an armature winding temperature of 100˚C. Other

values quoted are at 20˚C.

*2

: Rated torques are continuous allowable torque values at 40˚C with an aluminum heat sink of the following dimensions attached.

SGMJV-A5A, -01A: 200 mm

SGMJV-02A, -04A, -08A: 250 mm

Note: The values in parentheses are for servomotors with holding brakes.

W 50 100 200 400 750

N•m 0.159 0.318 0.637 1.27 2.39

*1

N•m 0.557 1.11 2.23 4.46 8.36

A

*1

rms

A

rms

-1

min

-1

min

rms

×10-4 kg•m

2

0.61 0.84 1.6 2.7 4.7

2.1 2.9 5.8 9.3 16.9

3000

6000

0.285 0.413 0.435 0.512 0.544

0.0414

(0.0561)0.0561))

0.0665

(0.0812)0.0812))

0.259

(0.323)0.323))

kW/s 6.11 15.2 15.7 36.5 36.3

*1

2

rad/s

SGDV-¡¡¡¡

38400 47800 24600 28800 15200

R70¡ R90¡

1R6A,2R1F

×200 mm×6 mm

×250 mm×6 mm

0.442

(0.506)0.506))

1.57

(1.74)1.74))

2R8¡ 5R5A

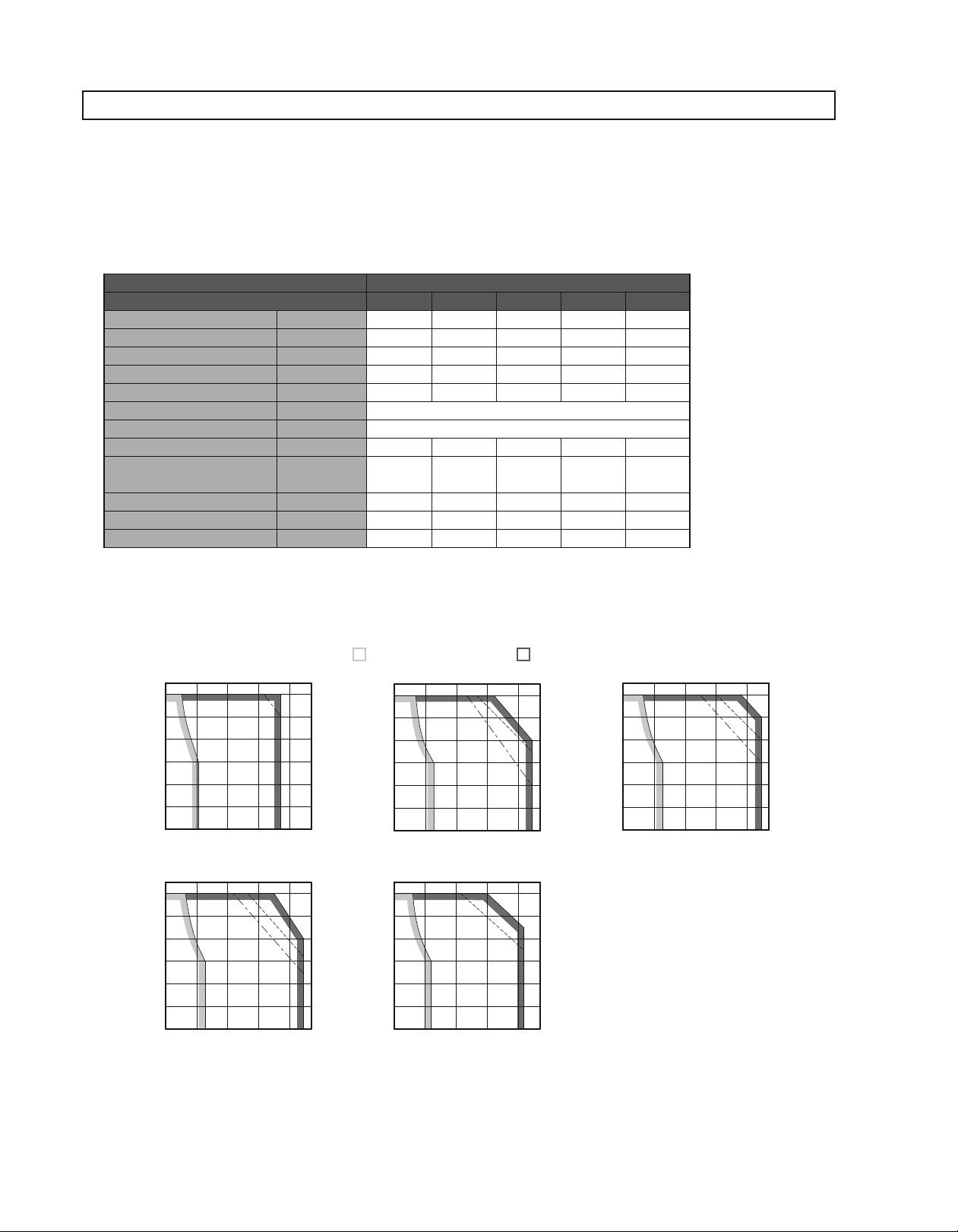

1Torque-Motor Speed Characteristics

A

: Continuous Duty Zone B: Intermittent Duty Zone

(Note3)

SGMJV-A5A SGMJV-01A SGMJV-02A

6000

)

-1

5000

min

(

4000

3000

AB AB

2000

Motor Speed

1000

0

0

0

15 0.30.45 0.6

.

Torque (Nûm

)

SGMJV-04A

6000

)

-1

5000

min

(

4000

3000

AB

2000

Motor Speed

1000

0

01 2 3 4

Torque (N

Notes: 1 The solid, dotted, and dashed-dotted lines of the intermittent duty zone indicate the characteristics when a servomotor runs with the following combinations:

• The solid line: With a three-phase 200 V or a single-phase 230 V SERVOPACK

• The dotted line: With a single-phase 200 V SERVOPACK

• The dashed-dotted line: With a single-phase 100 V SERVOPACK

An SGMJV-A5A servomotor has the same characteristics in combination with three-phase 200 V and single-phase 200 V SERVOPACKs.

2 The characteristics of the intermittent duty zone differ depending on the supply voltages.

3 When the effective torque during intermittent duty is within the rated torque, the servomotor can be used within the intermittent duty zone.

4 When the main circuit cable length exceeds 20 m, note that the intermittent duty zone of the Torque-Motor Speed Characteristics will shrink as the line-to-line

voltage drops.

)

û

m

6000

)

-1

5000

min

(

4000

3000

2000

Motor Speed

1000

0

00

25 0.50.75 1

.

Torque (N

SGMJV-08A

6000

)

-1

5000

min

(

4000

3000

AB

2000

Motor Speed

1000

0

02 468

Torque (Nûm

)

û

m

)

6000

)

-1

5000

min

(

4000

3000

2000

Motor Speed

1000

0

00

AB

51 1.52

.

Torque (N

)

û

m

3

Servomotors

SGMJV

Ratings and Specifications

1Derating Rate for Servomotor Fitted with an Oil Seal

When a motor is fitted with an oil seal, use the following derating rate because of the higher friction torque.

Rotary Motors

Servomotor Model

SGMJV-

Derating Rate % 80 90 95

A5A 01A 02A 04A 08A

1Holding Brake Electrical Specifications

Holding Brake

Rated Voltage

+

10%

24 VDC

0

Notes: 1 The holding brake is only used to hold the load and cannot be used to stop the servomotor.

2 The holding brake open time and holding brake operation time vary depending on which discharge circuit is used. Make sure holding brake open time and holding brake

operation time are correct for your servomotor.

3 A 24-VDC power supply is provided by customers.

Servomotor

Model

SGMJV-A5A 50 5.5 0.159 103 0.23 60 100

SGMJV-01A 100 5.5 0.318 103 0.23 60 100

SGMJV-02A 200 6 0.637 97.4 0.25 60 100

SGMJV-04A 400 6 1.27 97.4 0.25 60 100

SGMJV-08A 750 6.5 2.39 87.7 0.27 80 100

Servomotor

Rated Output

W

CapacityWHolding

Torque N·m

Holding Brake Specifications

Coil Resistance

Rated Current

Ω(at 20˚C)

A(at 20˚C)

Brake Release

Time ms

Brake Operation

Time ms

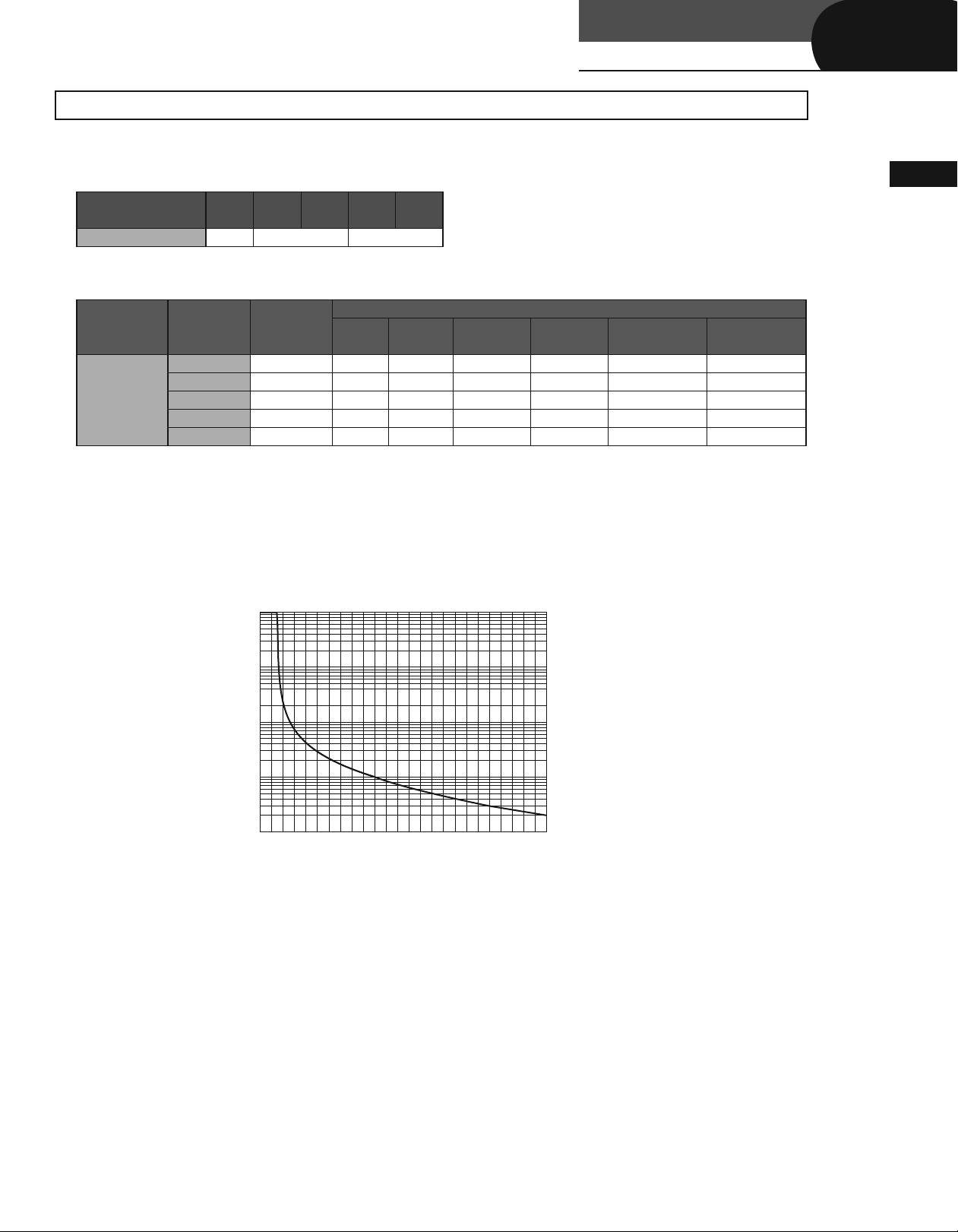

1Overload Characteristics

The overload detection level is set under hot start conditions at a servomotor ambient temperature of 40˚C.

10000

Rotary Servomotors

1000

Detecting time (s

Note: Overload characteristics shown above do not guarantee continuous duty of 100%

or more output. Use a servomotor with effective torque within the continuous duty

zone of Torque-Motor Speed Characteristics.

)

100

10

1

100 150 250200 300 350

Torque reference (percent of rated torque

(%)

)

4

Ratings and Specifications

Ratings and Specifications

1Allowable Load Moment of Inertia at the Motor Shaft

The rotor moment of inertia ratio is the value for a servomotor without a gear and a holding brake.

Servomotor Model

SGMJV-

Servomotor Rated

Output

A5A, 01A 50 ,100 W 20 times

02A 200 W 15 times

04A, 08A 400 to 750 W 10 times

Allowable Load Moment of Inertia

(Rotor Moment of Inertia Ratio)

1Load Moment of Inertia

The larger the load moment of inertia, the worse the movement response.

•

The allowable load moment of inertia (

•

each servomotor (

Use the AC servo drive capacity selection program SigmaJunmaSize+ to check the operation conditions. The program can be

•

JM). This value is provided strictly as a guideline and results may vary depending on servomotor drive conditions.

downloaded for free from our web site (http://www.e-mechatronics.com/).

An overvoltage alarm (A.400) is likely to occur during deceleration if the load moment of inertia exceeds the allowable load moment of

•

inertia. SERVOPACKs with a built-in regenerative resistor may generate a regenerative overload alarm (A.320). Take one of the following

steps if this occurs.

• Reduce the torque limit.

• Reduce the deceleration rate.

• Reduce the maximum speed.

• Install an external regenerative resistor if the alarm cannot be cleared using the steps above. Refer to Regenerative Resistors on

page 293.

Regenerative resistors are not built into SERVOPACKs for 400 W motors or less.

•

External regenerative resistors are required when this condition is exceeded or if the allowable loss capacity (W) of the built-in

•

regenerative resistor is exceeded due to regenerative drive conditions when a regenerative resistor is already built in.

JL) depends on motor capacity and is limited to within 5 to 30 times the rotor moment of inertia of

1Allowable Radial and Thrust Loads

Design the mechanical system so thrust and radial loads applied to the servomotor shaft end during operation fall within the

ranges shown in the table.

Servomotor Model

SGMJV-

Allowable Radial

Load (Fr) N

A5A

78 54 20

01A

02A

245 74 25

04A

08A 392 147 35

Allowable Thrust

Load (Fs) N

LR

mm

Reference Diagram

LR

Fr

Fs

5

Loading...

Loading...