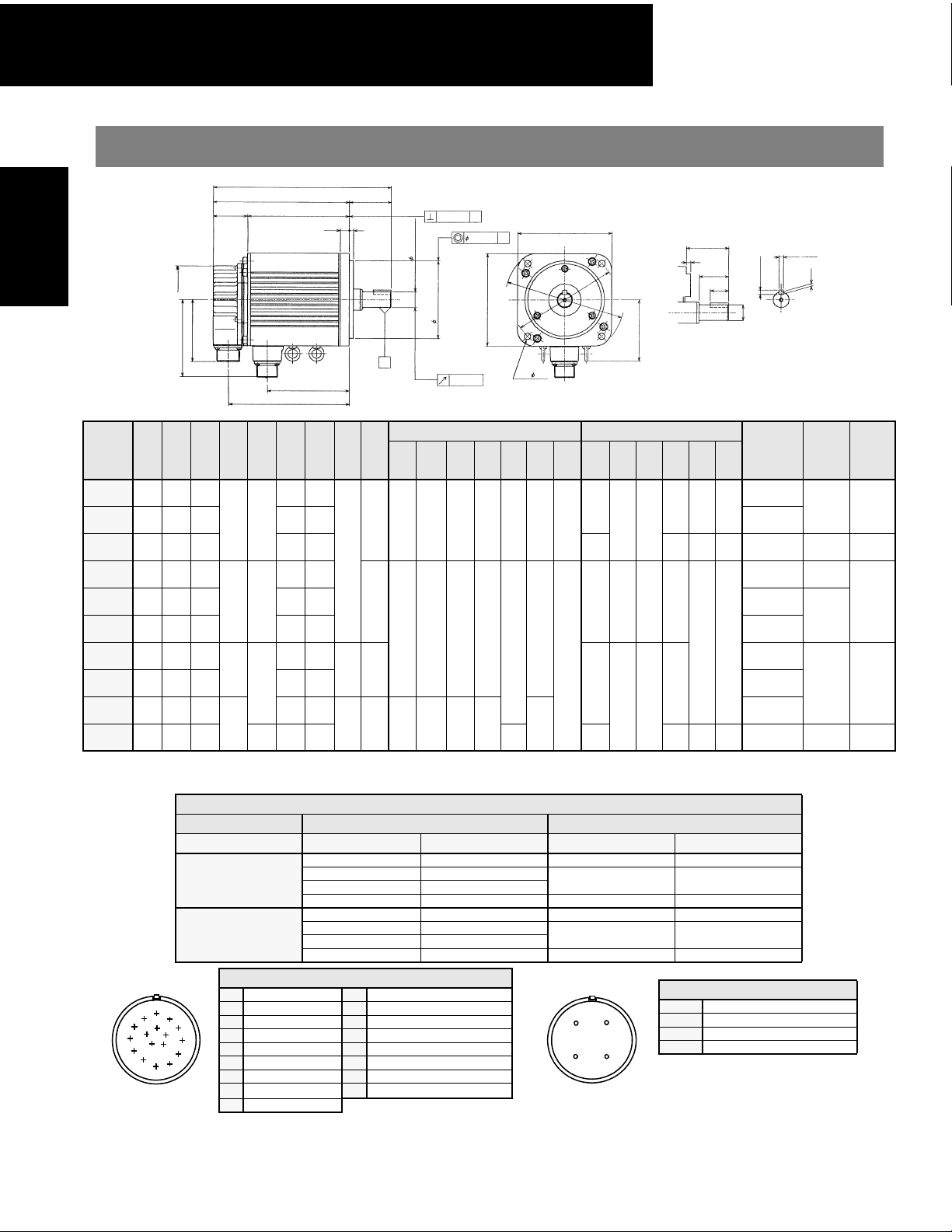

Yaskawa SGMGH Dimensional Sheet

200V Three-phase Sigma II Servo Systems

Dimensions in inches (mm)

(1) 17-Bit Incremental/Absolute Encoder

Servomotors

SGMGH

Typ

e

SGMGH-

05AA61

09AA61

13AA61

20AA61

30AA61

44AA61

55AA61

75AA61

1AAA61

1EAA61

Note: 1. SGMGH-05AA to 44AA do not contain eyebolts.

Encoder Plug

K

MS3102A20-29P

58

L

1.81

(46)

1.85

(47)

1.85

(47)

2.72

(69)

LL

LM

KB1

KB2

2.56

4.61

(65)

(117)

3.46

5.51

(88)

(140)

4.41

6.46

(112)

(164)

3.5

5.71

(89)

(145)

4.53

6.73

(115)

(171)

5.87

8.07

(149)

(205)

6.85

9.41

(174)

(239)

9.76

12.32

(248)

(313)

9.88

12.48

(251)

(317)

13.50

17.13

(343)

(435)

Connector Wiring on the Encoders

+5V

dc

LT

3.94(100)

KL1

3.46 (88)

L LL LM LR LT KB1 KB2 IE KL1

7.72

5.43

3.62

(138)

(92)

6.34

4.53

(161)

7.28

(185)

6.54

(166)

7.56

(192)

8.9

(226)

10.24

(260)

13.15

(334)

13.31

(338)

17.99

(457)

2. Dimensions are the same when using either incremental or absolute encoders (with or without optional shaft seal).

3. Tolerances on the dimensions of flange type LB and of shaft extensions S are based on JIS (Japanese Industrial Standard) B0401 “Limits and Fits for Engineering.”

B

N

P

R

F

G

2.28

(115)

(58)

5.47

(139)

4.69

(119)

5.71

3.11

(145)

(79)

7.05

(179)

8.39

(213)

4.45

(113)

11.3

(287)

11.46

(291)

4.57

(116)

15.28

(388)

Dimension *ΦS **ΦLB

Unit Diameter Tolerance Diameter To l e ra n c e

in

mm

A—K—

B—L—

C Data + M—

C

D Data - N—

D

E

E—P—

F—R—

G0VS Battery - (Note*)

H

J FG (Frame Ground) *Note: Used with an absolute encoder only.

Non-Environmental Mating Connector:

MS3108B20-29S (L Type)

MS3106B20-29S (Straight Type)

L

J

(196)

8.62

(219)

9.57

(243)

9.65

(245)

10.67

(271)

12.01

(305)

14.69

(373)

17.6

(447)

17.87

(454)

22.56

(573)

M

A

S

H

LR

A

LG

LE

A

4.29

5.71

(109)

(145)

—

5.51

(140)

7.87

(200)

4.92

5.91

(125)

(150)

5.59

6.61

(142)

0.7480, 0.8661 +0.0000-0.0005 4.3307 +0.0000 -0.0014

19.000, 22.000 +0.000 -0.013 110.000 +0.000 -0.035

9.25

(168)

(235)

1.3780 +0.0004-0.0000

1.6535 +0.0000 -0.0006

2.1700 +0.0012+0.0004 7.8700 +0.0000 -0.0018

35.000 +0.010 -0.000

42.000 +0.000 -0.016

55.000 +0.030 +0.011 200.000 +0.0000 -0.046

T Battery + (Note*)

0.0016

A

S*

FLA FLB** LC LE LG FLH FLZ FS* Q QK W T U

4.33

(110)

(114.

7.87

(200)

0.0016

LC

LB**

0.0008

Flange Dimensions Shaft End Dimension

5.12

0.24

(6)

0.13

(3.2)

0.16

(4)

0.47

(12)

0.71

(18)

0.79

(20)

(130)

4.5

7.09

(180)

3)

8.66

(220)

Specified Tolerances

L

LZ

4 -

MTG Holes

6.5

(165)

9.06

(230)

10.6

3

(270)

LC

H

0.35

(9)

0.53

(13.5

)

Motor Plug

D

C

LR

0.20

(5)

0.24

(6)

0.39

(10)

0.47

(12)

0.63

(16)

LE

0.20

(5)

0.24

(6)

0.31

(8)

0.39

(10)

Q

QK

0.12

0.14

(3.5)

0.20

0.24

A

L

Φ

IE

0.75

(19)

1.57

0.98

(40)

0.87

(22)

1.38

(35)

1.65

(42)

2.17

(55)

(25)

2.99

2.36

(76)

(60)

4.33

3.54

(110)

(90)

4.5000 +0.0000 -0.0010

114.300 +0.000 -0.025

Connector Wiring on the Motor Side

A

B

AU Phase

B V Phase

C W Phase

D Ground Terminal

(3)

(5)

(6)

W

T

S

Approximate

Mass

(kg)

lb

f

12.1

(5.5)

16.8

(7.6)

21.2

(9.6)

30.9

(14)

39.7

(18)

50.7

(23)

66.1

(30)

88.2

(40)

127

(57.5)

189.6

(86)

U

Allowable

Allowable

Radial

Load

(N)

lb

f

110

(490)22(98)

154

(686)77(343)

265

(1176)

331

(1470)

397

(1764)

1125

(4998)

(2156)

Thrust

Load

(N)

lb

f

110

(490)

132

(588)

485

200V Three-phase Sigma II Servo Systems

(2) 17-Bit Incremental/Absolute Encoder. with Brake

• 0.5 to 4.4kW (0.7 to 5.9hp)

100 (3.94)

KL2

LT

LL

LM

LR

0.0016

LE

LG

S*

A

0.0016

A

LC

LB**

LC

LA

Φ

L

H

LR

LE

Q

QK

W

T

S

U

SGMGH

Servomotors

KL1

KB1

KB2

Type

SGMGH-

05AA6C

09AA6C

13AA6C

20AA6C

30AA6C

44AA6C

L LL LM LR LT KB1 KB2 KL1 KL2

9.21

6.93

(234)

10.1

(257)

11.0

(281)

11.6

(296)

12.6

(322)

14.0

(356)

Note: 1. Dimensions are the same when using either incremental or absolute encoders (with or without optional shaft seal).

5.08

(176)

(129)

7.83

5.98

2

(199)

8.78

6

(223)

8.54

5

(217)

9.57

8

(243)

10.9

2

(277)

2. Tolerances on the dimensions of flange type LB and of shaft extensions S are based on JIS (Japanese Industrial Standard) B0401 “Limits and Fits for Engineering.”

2.28

(152)

(58)

6.93

(176)

6.69

(170)

7.72

3.11

(196)

(79)

9.06

1

(230)

1.85

(47)

2.2

(56)

3.11

(79)

4.06

(103)

3.11

(79)

4.13

(105)

5.47

(139)

6.1

(155)

7.01

(178)

7.95

(202)

7.72

(196)

8.74

(222)

10.0

8

(256)

4.72

(120

5.75

(146

A

ΦLA ΦLB** LC LE LG ΦLH ΦLZ ΦS* Q QK W T U

5.71

(145)

)

3.46

(88)

7.87

(200)

)

0.0008

Flange Dimensions Shaft End Dimension

4.33

5.12

(110)

(130)

4.5

7.09

(114.

(180)

3)

0.24

(6)

0.13

(3.2)

4 -

MTG Holes

0.47

(12)

0.71

(18)

LZ

6.5

(165

9.06

(230

)

)

Specified Tolerances

Dimension *ΦS **ΦLB

Unit Diameter Tolerance Diameter Tolerance

+0.0000-

0.0005

+0.0004-

0.0000

mm

in

0.7480, 0.8661

1.3780

19.000, 22.000 +0.000 -0.013 110.000 +0.000 -0.035

35.000 +0.010 -0.000 114.300 +0.000 -0.025

0.75

(19)

0.35

(9)

0.53

(13.5

1.57

(40)

0.87

(22)

1.38

2.99

(35)

(76)

)

4.3307 +0.0000 -0.0014

4.5000 +0.0000 -0.0010

0.98

(25)

2.36

(60)

0.20

(5)

0.24

(6)

0.39

(10)

0.20

(5)

0.24

(6)

0.31

(8)

0.12

(3)

0.14

(3.5)

0.20

(5)

Approximate

Mass

(kg)

lb

f

16.5

(7.5)

21.2

(9.6)

26.5

(12)

41.9

(19)

51.8

(23.5)

62.8

(28.5)

Allowable

Allowable

Radial

Load

(N)

lb

f

110

(490)22(98)

154

686)77(343)

265

(1176)

331

(1470)

Thrust

Load

(N)

lb

f

110

(490)

Motor Plug

F

A

E

G

D

C

Connector Wiring on the Motor Side

B

A U Phase E Brake Terminal

BV PhaseF Brake Terminal

C W Phase G—

D FG (Frame Ground)

59

Loading...

Loading...