Page 1

-7-Series AC Servo Drive

Peripheral Device

Selection Manual

Applicable SERVOPACK Model: SGD7S, SGD7W, SGD7C

Applicable Rotary Servomotor Model:

Applicable Direct Drive Servomotor Model: SGM7D, SGM7E, SGM7F, SGMCV, SGMCS

Applicable Linear Servomotor Model: SGLG, SGLF, SGLT

SGM7M, SGM7J, SGM7A, SGM7P, SGM7G, SGMMV

Peripheral Devices

and System Configurations

Cables and User-Assembled Wiring

Materials for SGM7M Rotary Servomotors

Cables and User-Assembled Wiring

Materials for SGM7J Rotary Servomotors

Cables and User-Assembled Wiring

Materials for SGM7A Rotary Servomotors

Cables and User-Assembled Wiring

Materials for SGM7P Rotary Servomotors

Cables and User-Assembled Wiring

Materials for SGM7G Rotary Servomotors

Cables and User-Assembled Wiring

Materials for SGMMV Rotary Servomotors

Cables and User-Assembled Wiring

Materials for Direct Drive Servomotors

Cables and User-Assembled Wiring

Materials for Linear Servomotors

Cables and User-Assembled Wiring

Materials for SERVOPACKs

Option Modules

SERVOPACK

Peripheral Devices

1

2

3

4

5

6

7

8

9

10

11

12

MANUAL NO. SIEP S800001 32K

Software

Other Peripheral

Devices and Options

13

14

Page 2

Copyright © 2014 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission

of Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to

improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

Page 3

About this Manual

This manual provides information required to select cables, peripheral devices, and options for Σ-7-

Series AC Servo Drives. It also describes the wiring materials that you can use to make your own cables.

Read and understand this manual to ensure correct usage of the Σ-7-Series AC Servo Drives.

Keep this manual in a safe place so that it can be referred to whenever necessary.

Outline of Manual

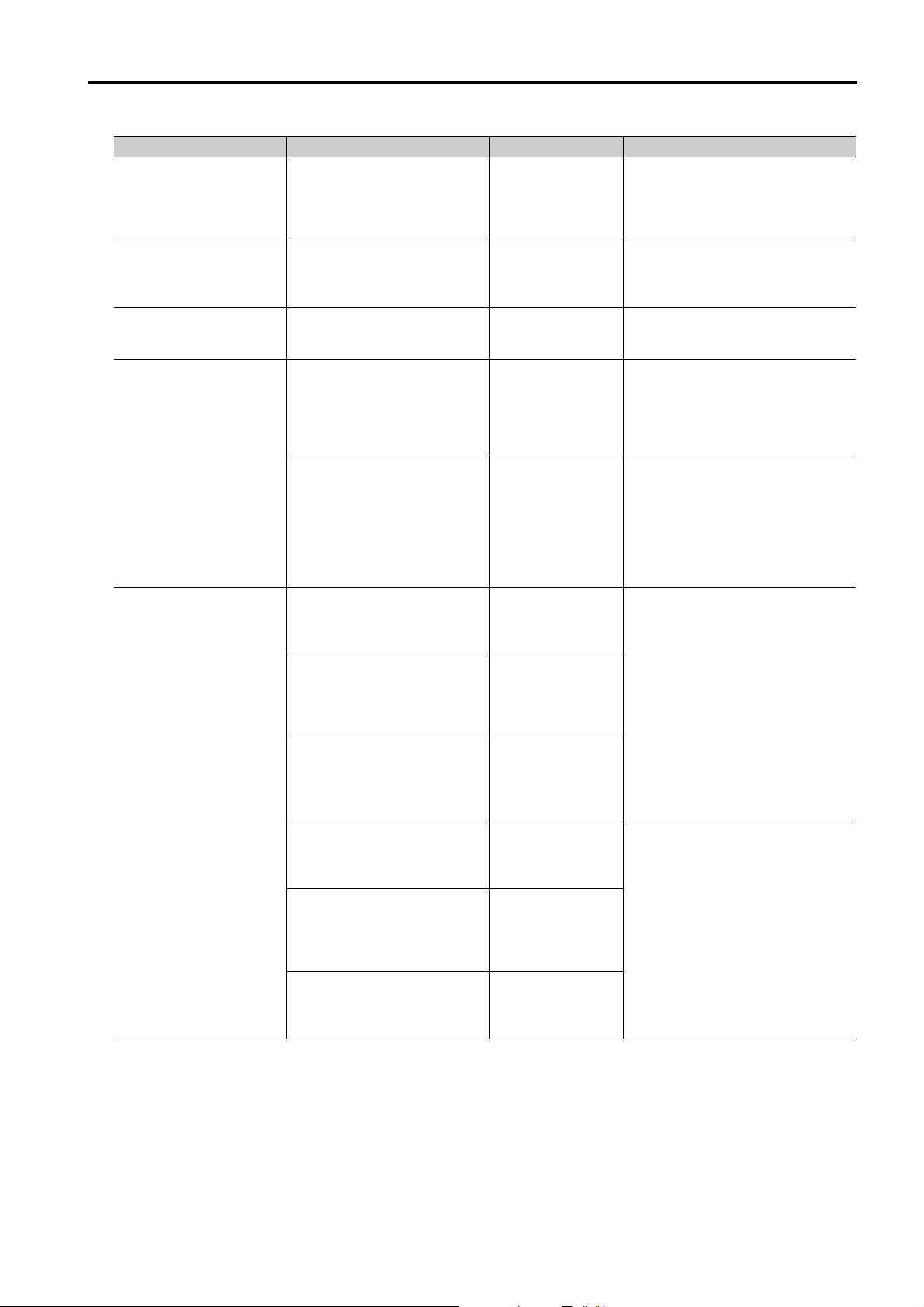

The contents of the chapters of this manual are described in the following table.

Refer to these chapters as required.

Chapter Chapter Title Contents

Peripheral Devices and

1

System Configurations

Cables and User-Assembled

2

Wiring Materials for SGM7M

Rotary Servomotors

Cables and User-Assembled

3

Wiring Materials for SGM7J

Rotary Servomotors

Cables and User-Assembled

4

Wiring Materials for SGM7A

Rotary Servomotors

Cables and User-Assembled

5

Wiring Materials for SGM7P

Rotary Servomotors

Cables and User-Assembled

6

Wiring Materials for SGM7G

Rotary Servomotors

Cables and User-Assembled

7

Wiring Materials for SGMMV

Rotary Servomotors

Cables and User-Assembled

8

Wiring Materials for Direct

Drive Servomotors

Cables and User-Assembled

9

Wiring Materials for Linear

Servomotors

Cables and User-Assembled

10

Wiring Materials for

SERVOPACKs

11 Option Modules

SERVOPACK Peripheral

12

Devices

13 Software

Other Peripheral Devices and

14

Options

This chapter provides system configuration diagrams of Servo Drives and

peripheral devices. References are provided to detailed information.

These chapters provide the following information.

• Selection tables, specifications, and dimensional drawings for Servomotor

Main Circuit Cables, Encoder Cables, and user-assembled wiring materials

Note: References to detailed information are provided in the system configu-

ration diagrams.

This chapter provides the following information.

• Information on recommended Linear Encoders and connected system

configurations

• Selection tables, specifications, and dimensional drawings for Servomotor

Main Circuit Cables, Linear Encoder Cables, Sensor Cables, and userassembled wiring materials

• Selection tables, specifications, and dimensional drawings for Serial Converter Units and Cables

Note: References to detailed information are provided in the system configu-

ration diagrams.

This chapter provides selection tables, specifications, and dimensional

drawings for SERVOPACK cables.

This chapter provides the specifications and dimensional drawings of Option Modules.

This chapter provides selection tables, specifications, and dimensional

drawings for SERVOPACK peripheral devices.

This chapter provides information on the SigmaWin+, Yaskawa’s AC Servo

Drive Engineering Tool, and MPE720, our System Integrated Engineering Tool.

This chapter provides information on surge absorbers and diodes for hold-

ing brake power supplies. It also provides information on the battery

required to use an absolute encoder.

And it provides information on the compatibility of cables for Σ-V-Series Servomotors and information on metal connectors.

iii

Page 4

Related Documents

The relationships between the documents that are related to the Servo Drives are shown in the following figure. The numbers in the figure correspond to the numbers in the table on the following

pages. Refer to these documents as required.

System Components

Machine

Controller

and

Servo Drive

General

Catalog

Machine Controllers

MP3300

Catalog

Machine Controllers

Built-in

Function

Manuals

SERVOPACKs:

Σ-7S and Σ-7W

Enclosed

Documents

Option

Module

User’s

Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

Product

Manuals

Servo Drives

Σ-7-Series

Catalog

SERVOPACKs with Built-in Controllers:

Enclosed

Documents

Σ-7-Series

Σ-7C

SERVOPACK

Product

Manual

Built-in

Function

Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

Hardware Option

Product Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

FT/EX

Product Manuals

Σ-7C

Σ-7-Series

Σ-7C

SERVOPACK

Troubleshooting

Manual

Option

Module

User’s

Manuals

iv

Manuals Catalogs

Servomotors

Enclosed

Documents

Other Documents

Σ-7-Series

Peripheral

Device

Selection Manual

(this manual)

Σ-7-Series

Servomotor

Product

Manuals

Σ-7-Series

MECHATROLINK

Communications

Command

Manuals

Programming

Manuals

Σ-7-Series

Operation

Interface

Operating

Manuals

Distributed

I/O Module

User’s

Manuals

Page 5

Classification Document Name Document No. Description

Machine Controller and

Servo Drive

General Catalog

MP3300 Catalog

Σ-7-Series Catalog

Built-in Function Manuals

Option Module

User’s Manuals

Machine Controller and

AC Servo Drive

Solutions Catalog

Machine Controller

MP3300

AC Servo Drives

Σ-7 Series

Σ-7-Series AC Servo Drive

Σ-7C SERVOPACK

Motion Control

User’s Manual

Machine Controller

MP3000 Series

Communications

User’s Manual

Machine Controller

MP2000 Series

Communication Module

User’s Manual

Machine Controller

MP2000 Series

262IF-01 FL-net

Communication Module

User’s Manual

Machine Controller

MP2000 Series

263IF-01 EtherNet/IP

Communication Module

User’s Manual

Machine Controller

MP2000 Series

I/O Module

User’s Manual

Machine Controller

MP2000 Series

Analog Input/Analog Output

Module AI-01/AO-01

User’s Manual

Machine Controller

MP2000 Series

Counter Module CNTR-01

User’s Manual

KAEP S800001 22

KAEP C880725 03

KAEP S800001 23

SIEP S800002 03

SIEP C880725 12

SIEP C880700 04

SIEP C880700 36

SIEP C880700 39

SIEP C880700 34

SIEP C880700 26

SIEP C880700 27

Describes the features and application examples for combinations of

MP3000-Series Machine Controllers and Σ-7-Series AC Servo

Drives.

Provides detailed information on

MP3300 Machine Controllers,

including features and specifications.

Provides detailed information on

Σ-7-Series AC Servo Drives, including features and specifications.

Provides detailed information on

the specifications, system configuration, and application methods of

the Motion Control Function Modules (SVD, SVC4, and SVR4) for Σ-

7-Series Σ-7C SERVOPACKs.

Provides detailed information on

the specifications, system configuration, and communications connection methods for the Ethernet

communications that are used with

MP3000-Series Machine Controllers and Σ-7-Series Σ-7C SERVOPACKs.

Provide detailed information on the

specifications and communications methods for the Communications Modules that can be mounted

to MP3000-Series Machine Controllers and Σ-7-Series Σ-7C

SERVOPACKs.

Provide detailed information on the

specifications and communications methods for the I/O Modules

that can be mounted to MP3000Series Machine Controllers and

Σ-7-Series Σ-7C SERVOPACKs.

Continued on next page.

v

Page 6

Classification Document Name Document No. Description

Enclosed Documents

Σ-7-Series

Σ-7C SERVOPACK

Product Manual

Σ-7-Series

Σ-7C SERVOPACK

Troubleshooting

Manual

Σ-7-Series AC Servo Drive

Σ-7S, Σ-7W, and Σ-7C SER-

VOPACK

Safety Precautions

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Safety Precautions

Option Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

Command Option Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

Fully-closed Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

Safety Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

INDEXER Module

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

Installation Guide

DeviceNet Module

Σ-7-Series AC Servo Drive

Σ-7C SERVOPACK

Product Manual

Σ-7-Series AC Servo Drive

Σ-7C SERVOPACK

Troubleshooting Manual

TOMP C710828 00

TOBP C720829 00

TOBP C720829 01

TOBP C720829 03

TOBP C720829 06

TOBP C720829 02

TOBP C720829 07

SIEP S800002 04

SIEP S800002 07

Continued from previous page.

Provides detailed information for

the safe usage of Σ-7-Series

SERVOPACKs.

Provides detailed information for

the safe usage of Option Modules.

Provides detailed procedures for

installing the Command Option

Module in a SERVOPACK.

Provides detailed procedures for

installing the Fully-closed Module in

a SERVOPACK.

Provides detailed procedures for

installing the Safety Module in a

SERVOPACK.

Provides detailed procedures for

installing the INDEXER Module in a

SERVOPACK.

Provides detailed procedures for

installing the DeviceNet Module in a

SERVOPACK.

Provides detailed information on

selecting Σ-7-Series Σ-7C SERVOPACKs; installing, connecting, setting, testing in trial operation, and

tuning Servo Drives; writing, monitoring, and maintaining programs;

and other information.

Provides detailed troubleshooting

information for Σ-7-Series Σ-7C

SERVOPACKs.

Continued on next page.

vi

Page 7

Continued from previous page.

Classification Document Name Document No. Description

Σ-7-Series AC Servo Drive

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK

Product Manuals

Σ-7-Series

Σ-7S/Σ-7W

SERVOPACK with

Hardware Option

Specifications

Product Manuals

Σ-7S SERVOPACK with

MECHATROLINK-4

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

MECHATROLINK-III

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

MECHATROLINK-II

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

Analog Voltage/Pulse Train

References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK

Command Option Attachable

Type with INDEXER Module

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK

Command Option Attachable

Type with DeviceNet Module

Product Manual

Σ-7-Series AC Servo Drive

Σ-7W SERVOPACK with

MECHATROLINK-III

Communications References

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S/Σ-7W SERVOPACK with

Hardware Option Specifications

Dynamic Brake

Product Manual

Σ-7-Series AC Servo Drive

Σ-7W/Σ-7C SERVOPACK with

Hardware Option Specifications

HWBB Function

Product Manual

SIEP S800002 31

SIEP S800001 28

SIEP S800001 27

SIEP S800001 26

SIEP S800001 64

SIEP S800001 70

SIEP S800001 29

SIEP S800001 73

SIEP S800001 72

Provide detailed information on

selecting Σ-7-Series Σ-7S and

Σ-7W SERVOPACKs; installing,

connecting, setting, testing in trial

operation, tuning, monitoring, and

maintaining Servo Drives; and other

information.

Provides detailed information on

Hardware Options for Σ-7-Series

SERVOPACKs.

Continued on next page.

vii

Page 8

Classification Document Name Document No. Description

Σ-7-Series

Σ-7S/Σ-7W SERVOPACK

FT/EX

Product Manuals

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification for Indexing Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification for Tracking Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Application with Special

Motor,

SGM7D Motor

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Press and Injection

Molding Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Transfer and Alignment

Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Torque/Force Assistance

for Conveyance Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Cutting Application

Feed Shaft Motor

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Three-Point Latching

for Conveyance Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7S SERVOPACK with

FT/EX Specification

for Semi-/Fully-Closed Loop

Control Online Switching

for Conveyance Application

Product Manual

Σ-7-Series AC Servo Drive

Σ-7W SERVOPACK with

FT/EX Specification

for Gantry Applications

Product Manual

Continued from previous page.

SIEP S800001 84

SIEP S800001 89

SIEP S800001 91

SIEP S800001 94

SIEP S800001 95

Provides detailed information on

the FT/EX Option for Σ-7-Series

SERVOPACKs.

SIEP S800002 09

SIEP S800002 10

SIEP S800002 17

SIEP S800002 27

SIEP S800002 29

Continued on next page.

viii

Page 9

Continued from previous page.

Classification Document Name Document No. Description

AC Servo Drives

Option Module

User’s Manual

Enclosed Documents

Σ-7-Series

Servomotor

Product Manuals

Σ-7-Series

Peripheral Device

Selection Manual

Σ-7-Series

MECHATROLINK

Communications

Command Manuals

Programming

Manuals

Σ-V-Series/Σ-V-Series

for Large-Capacity Models/

Σ-7-Series

User’s Manual

Safety Module

AC Servo Drive

Rotary Servomotor

Safety Precautions

AC Servomotor

Linear Σ Series

Safety Precautions

Σ-7-Series AC Servo Drive

Rotary Servomotor

Product Manual

Σ-7-Series AC Servo Drive

Linear Servomotor

Product Manual

Σ-7-Series AC Servo Drive

Direct Drive Servomotor

Product Manual

Σ-7-Series AC Servo Drive

Peripheral Device

Selection Manual

Σ-7-Series AC Servo Drive

MECHATROLINK-II

Communications

Command Manual

Σ-7-Series AC Servo Drive

MECHATROLINK-III

Communications

Standard Servo Profile

Command Manual

Σ-7-Series AC Servo Drive

MECHATROLINK-4

Communications

Standard Servo Profile

Command Manual

Machine Controller

MP3000 Series

Ladder Programming

Manual

Machine Controller

MP3000 Series

Motion Programming

Manual

SIEP C720829 06

TOBP C230260 00

TOBP C230800 00

SIEP S800001 36

SIEP S800001 37

SIEP S800001 38

This manual

(SIEP S800001 32)

SIEP S800001 30

SIEP S800001 31

SIEP S800002 32

SIEP C880725 13

SIEP C880725 14

Provides detailed information

required for the design and maintenance of a Safety Module.

Provides detailed information for

the safe usage of Rotary Servomotors and Direct Drive Servomotors.

Provides detailed information for

the safe usage of Linear Servomotors.

Provide detailed information on

selecting, installing, and connecting

the Σ-7-Series Servomotors.

Provides the following information

in detail for Σ-7-Series Servo Systems.

• Cables: Models, dimensions, wiring materials, connector models,

and connection specifications

• Peripheral devices: Models,

specifications, diagrams, and

selection (calculation) methods

Provides detailed information on

the MECHATROLINK-II communications commands that are used

for a Σ-7-Series Servo System.

Provides detailed information on

the MECHATROLINK-III communications standard servo profile commands that are used for a Σ

Series S

Provides detailed information on

the MECHATROLINK-4 communications standard servo profile commands that are used for a Σ-7-

Series Servo System.

Provides detailed information on

the ladder programming specifications and instructions for MP3000Series Machine Controllers and

Σ-7-Series Σ-7C SERVOPACKs.

Provides detailed information on

the motion programming and

sequence programming specifications and instructions for MP3000Series Machine Controllers and

Σ-7-Series Σ-7C SERVOPACKs.

ervo System.

-7-

Continued on next page.

ix

Page 10

Classification Document Name Document No. Description

Σ-7-Series

Operation Interface

Operating Manuals

Distributed

I/O Module

User’s Manual

Machine Controller

MP2000/MP3000 Series

Engineering Tool

MPE720 Version 7

User's Manual

Σ-7-Series AC Servo Drive

Digital Operator

Operating Manual

AC Servo Drive

Engineering Tool

SigmaWin+

Operation Manual

MECHATROLINK-III

Compatible I/O Module

User’s Manual

MECHATROLINK-4

Compatible I/O Module

User’s Manual

SIEP C880761 03

SIEP S800001 33

SIET S800001 34

SIEP C880781 04

SIEP C880782 01

Continued from previous page.

Describes in detail how to operate

MPE720 version 7.

Describes the operating procedures for a Digital Operator for a

Σ-7-Series Servo System.

Provides detailed operating procedures for the SigmaWin+ Engineering Tool for a Σ-7-Series Servo

System.

Describes the functions, specifications, operating methods, and

MECHATROLINK-III communications for the Remote I/O Modules

for MP2000/MP3000-Series

Machine Controllers.

Describes the functions, specifications, operating methods, and

MECHATROLINK-4 communications for the Remote I/O Modules

for MP3000-Series Machine Controllers.

x

Page 11

Using This Manual

Important

Term

Example

Information

Technical Terms Used in This Manual

The following terms are used in this manual.

Term Meaning

Servomotor A Σ-7-Series Rotary Servomotor, Direct Drive Servomotor, or Linear Servomotor.

Rotary Servomotor A Rotary Servomotor (SGM7M, SGM7J, SGM7A, SGM7P, SGM7G, or SGMMV).

Direct Drive Servomotor A Direct Drive Servomotor (SGM7D, SGM7E, SGM7F, SGMCV, or SGMCS).

Linear Servomotor A Σ-7-Series Linear Servomotor (SGLG, SGLF, or SGLT).

SERVOPACK A Σ-7-Series amplifier.

Servo Drive The combination of a Servomotor and SERVOPACK.

Servo System

Main Circuit Cable

SigmaWin+

absolute encoder

A servo control system that includes the combination of a Servo Drive with a host controller and peripheral devices.

One of the cables that connect to the main circuit terminals, including the Main Circuit

Power Supply Cable, Control Power Supply Cable, and Servomotor Main Circuit Cable.

The Engineering Tool for setting up and tuning Servo Drives or a computer in which the

Engineering Tool is installed.

The general term used for absolute encoders with batteries and batteryless absolute

encoders.

In cases where the general term causes confusion, the term “batteryless absolute

encoder” may also be used.

Trademarks

• Ethernet is a registered trademark of the Xerox Corporation.

• EtherCAT is a registered trademark of Hans Beckhoff.

• EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vendor Association, Inc.).

• DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association, Inc.).

• MECHATROLINK is a trademark of the MECHATROLINK Members Association.

• Other product names and company names are the trademarks or registered trademarks of the

respective company. “TM” and the

® mark do not appear with product or company names in this

manual.

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

Indicates precautions or restrictions that must be observed.

Also indicates alarm displays and other precautions that will not result in machine damage.

Indicates definitions of difficult terms or terms that have not been previously explained in this manual.

Indicates operating or setting examples.

Indicates supplemental information to deepen understanding or useful information.

xi

Page 12

DANGER

WARNING

CAUTION

NOTICE

Safety Precautions

Safety Information

To prevent personal injury and equipment damage in advance, the following signal words are used

to indicate safety precautions in this document. The signal words are used to classify the hazards

and the degree of damage or injury that may occur if a product is used incorrectly. Information

marked as shown below is important for safety. Always read this information and heed the precautions that are provided.

Indicates precautions that, if not heeded, are likely to result in loss of life, serious injury, or fire.

Indicates precautions that, if not heeded, could result in loss of life, serious injury, or fire.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, or in

fire.

Indicates precautions that, if not heeded, could result in property damage.

xii

Page 13

Safety Precautions That Must Always Be Observed

DANGER

WARNING

CAUTION

NOTICE

General Precautions

Read and understand this manual to ensure the safe usage of the product.

Keep this manual in a safe, convenient place so that it can be referred to whenever necessary.

Make sure that it is delivered to the final user of the product.

Do not remove covers, cables, connectors, or optional devices while power is being supplied to

the SERVOPACK.

There is a risk of electric shock, operational failure of the product, or burning.

Use a power supply with specifications (number of phases, voltage, frequency, and AC/DC

type) that are appropriate for the product.

There is a risk of burning, electric shock, or fire.

Do not attempt to disassemble, repair, or modify the product.

There is a risk of fire or failure.

The warranty is void for the product if you disassemble, repair, or modify it.

The regenerative resistors, External Dynamic Brake Resistors, and other peripheral devices can

be very hot while power is ON or soon after the power is turned OFF. Implement safety measures, such as installing covers, so that hands and parts such as cables do not come into contact with hot components.

There is a risk of burn injury.

For a 24-VDC power supply, use a power supply device with double insulation or reinforced

insulation.

There is a risk of electric shock.

Do not damage, pull on, apply excessive force to, place heavy objects on, or pinch cables.

There is a risk of failure, damage, or electric shock.

Do not use the product in an environment that is subject to water, corrosive gases, or flamma-

ble gases, or near flammable materials.

There is a risk of electric shock or fire.

Do not attempt to use a peripheral device that is damaged or that has missing parts.

Install external emergency stop circuits that shut OFF the power supply and stops operation

immediately when an error occurs.

In locations with poor power supply conditions, install the necessary protective devices (such as

AC reactors) to ensure that the input power is supplied within the specified voltage range.

There is a risk of damage to the SERVOPACK.

Use a Noise Filter to minimize the effects of electromagnetic interference.

Electronic devices used near the SERVOPACK may be affected by electromagnetic interference.

Always use peripheral devices in the specified combinations.

Do not touch peripheral devices with wet hands.

There is a risk of product failure.

xiii

Page 14

CAUTION

NOTICE

CAUTION

NOTICE

Storage Precautions

Do not place an excessive load on the product during storage. (Follow all instructions on the

packages.)

There is a risk of injury or damage.

Do not install or store the product in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that exceed product specifications

• Locations that are subject to relative humidities that exceed product specifications

• Locations that are subject to condensation as the result of extreme changes in temperature

• Locations that are subject to corrosive or flammable gases

• Locations that are near flammable materials

• Locations that are subject to dust, salts, or iron powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock that exceeds product specifications

• Locations that are subject to radiation

If you store or install the product in any of the above locations, the product may fail or be damaged.

Transportation Precautions

Transport the product in a way that is suitable to the mass of the product.

When you handle a peripheral device, be careful of sharp parts, such as the corners.

There is a risk of injury.

Do not place an excessive load on the product during transportation. (Follow all instructions on

the packages.)

There is a risk of injury or damage.

Peripheral devices are precision devices. Do not drop it or subject it to strong shock.

There is a risk of failure or damage.

Do not subject connectors to shock.

There is a risk of faulty connections or damage.

If disinfectants or insecticides must be used to treat packing materials such as wooden frames,

plywood, or pallets, the packing materials must be treated before the product is packaged, and

methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines,

are packed with fumigated wooden materials, the electrical components may be greatly damaged

by the gases or fumes resulting from the fumigation process. In particular, disinfectants containing

halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the

capacitors.

xiv

Page 15

Installation Precautions

CAUTION

NOTICE

DANGER

WARNING

Install a peripheral device in a way that will support the mass given in technical documents.

Install SERVOPACKs, Servomotors, regenerative resistors, and External Dynamic Brake Resis-

tors on nonflammable materials.

Installation directly onto or near flammable materials may result in fire.

Install the SERVOPACK in the specified orientation.

There is a risk of fire or failure.

Do not step on or place a heavy object on the product.

There is a risk of failure, damage, or injury.

Do not allow any foreign matter to enter a peripheral device.

There is a risk of failure or fire.

Do not install or store the product in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that exceed product specifications

• Locations that are subject to relative humidities that exceed product specifications

• Locations that are subject to condensation as the result of extreme changes in temperature

• Locations that are subject to corrosive or flammable gases

• Locations that are near flammable materials

• Locations that are subject to dust, salts, or iron powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock that exceeds product specifications

• Locations that are subject to radiation

If you store or install the product in any of the above locations, the product may fail or be damaged.

Wiring Precautions

Do not change any wiring while power is being supplied.

There is a risk of electric shock or injury.

Wiring and inspections must be performed only by qualified engineers.

There is a risk of electric shock or product failure.

Check all wiring and power supplies carefully.

Incorrect wiring or incorrect voltage application to the output circuits may cause short-circuit failures. If a short-circuit failure occurs as a result of any of these causes, the holding brake will not

work. This could damage the machine or cause an accident that may result in death or injury.

xv

Page 16

CAUTION

NOTICE

Wait for at least six minutes after turning OFF the power supply (with a SERVOPACK for a 100-

VAC input, wait for at least nine minutes) and then make sure that the CHARGE indicator is not

lit before starting wiring or inspection work. Do not touch the power supply terminals while the

CHARGE lamp is lit after turning OFF the power supply because high voltage may still remain in

the SERVOPACK.

There is a risk of electric shock.

Check the wiring to be sure it has been performed correctly.

Always confirm the pin layouts and wiring methods in technical documents for your peripheral

devices before operation.

There is a risk of failure or malfunction.

Connect wires to your peripheral devices securely with the specified methods and tightening

torque.

Insufficient tightening may cause wires and terminal blocks to generate heat due to faulty contact,

possibly resulting in fire.

Use shielded twisted-pair cables or screened unshielded multi-twisted-pair cables for I/O Sig-

nal Cables and Encoder Cables.

The maximum wiring length is 3 m for I/O Signal Cables, and 50 m for Encoder Cables or Servo-

motor Main Circuit Cables.

Observe the following precautions when wiring the SERVOPACK’s main circuit terminals.

• Turn ON the power supply to the SERVOPACK only after all wiring, including the main circuit terminals, has been completed.

• If a connector is used for the main circuit terminals, remove the main circuit connector from the SERVOPACK before you wire it.

• Insert only one wire per insertion hole in the main circuit terminals.

• When you insert a wire, make sure that the conductor wire (e.g., whiskers) does not come into con-

tact with adjacent wires.

Install molded-case circuit breakers and other safety measures to provide protection against

short circuits in external wiring.

There is a risk of fire or failure.

Whenever possible, use the Cables specified by Yaskawa.

If you use any other cables, confirm the rated current and application environment of your model

and use the wiring materials specified by Yaskawa or equivalent materials.

Securely tighten cable connector screws and lock mechanisms.

Insufficient tightening may result in cable connectors falling off during operation.

Do not bundle power lines (e.g., the Main Circuit Cable) and low-current lines (e.g., the I/O Sig-

nal Cables or Encoder Cables) together or run them through the same duct. If you do not place

power lines and low-current lines in separate ducts, separate them by at least 30 cm.

If the cables are too close to each other, malfunctions may occur due to noise affecting the low-current lines.

Install a battery at either the host controller or on the Encoder Cable.

If you install batteries both at the host controller and on the Encoder Cable at the same time, you

will create a loop circuit between the batteries, resulting in a risk of damage or burning.

When connecting a battery, connect the polarity correctly.

There is a risk of battery rupture or encoder failure.

xvi

Page 17

Maintenance and Inspection Precautions

DANGER

WARNING

CAUTION

Do not change any wiring while power is being supplied.

There is a risk of electric shock or injury.

Wiring and inspections must be performed only by qualified engineers.

There is a risk of electric shock or product failure.

Wait for at least six minutes after turning OFF the power supply (with a SERVOPACK for a 100-

VAC input, wait for at least nine minutes) and then make sure that the CHARGE indicator is not

lit before starting wiring or inspection work. Do not touch the power supply terminals while the

CHARGE lamp is lit after turning OFF the power supply because high voltage may still remain in

the SERVOPACK.

There is a risk of electric shock.

Disposal Precautions

Correctly discard the product as stipulated by regional, local, and municipal laws and

regulations. Be sure to include these contents in all labelling and warning notifications

on the final product as necessary.

General Precautions

Figures provided in this document are typical examples or conceptual representations. There

may be differences between them and actual wiring, circuits, and products.

The products shown in illustrations in this document are sometimes shown without covers or

protective guards. Always replace all covers and protective guards before you use the product.

If you need a new copy of this document because it has been lost or damaged, contact your

nearest Yaskawa representative or one of the offices listed on the back of this document.

This document is subject to change without notice for product improvements, specifications

changes, and improvements to the manual itself.

We will update the document number of the document and issue revisions when changes are

made.

Any and all quality guarantees provided by Yaskawa are null and void if the customer modifies

the product in any way. Yaskawa disavows any responsibility for damages or losses that are

caused by modified products.

xvii

Page 18

Warranty

Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called the “delivered product”) is

one year from the time of delivery to the location specified by the customer or 18 months from the

time of shipment from the Yaskawa factory, whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to

Yaskawa occurs during the above warranty period.

This warranty does not cover defects caused by the delivered product reaching the end of its service life and replacement of parts that require replacement or that have a limited service life.

This warranty does not cover failures that result from any of the following causes.

• Improper handling, abuse, or use in unsuitable conditions or in environments not described in

product catalogs or manuals, or in any separately agreed-upon specifications

• Causes not attributable to the delivered product itself

• Modifications or repairs not performed by Yaskawa

• Use of the delivered product in a manner in which it was not originally intended

• Causes that were not foreseeable with the scientific and technological understanding at the time

of shipment from Yaskawa

• Events for which Yaskawa is not responsible, such as natural or human-made disasters

Limitations of Liability

• Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer

that arises due to failure of the delivered product.

• Yaskawa shall not be responsible for any programs (including parameter settings) or the results of

program execution of the programs provided by the user or by a third party for use with programmable Yaskawa products.

• The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not

guarantee that there are no infringements of intellectual property rights or other proprietary rights

of Yaskawa or third parties, nor does it construe a license.

• Yaskawa shall not be responsible for any damage arising from infringements of intellectual property rights or other proprietary rights of third parties as a result of using the information described

in catalogs or manuals.

xviii

Page 19

Suitability for Use

• It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations

that apply if the Yaskawa product is used in combination with any other products.

• The customer must confirm that the Yaskawa product is suitable for the systems, machines, and

equipment used by the customer.

• Consult with Yaskawa to determine whether use in the following applications is acceptable. If use

in the application is acceptable, use the product with extra allowance in ratings and specifications, and provide safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use

in conditions or environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems,

vehicle systems, medical equipment, amusement machines, and installations subject to separate industry or government regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or

electricity, or systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

• Never use the product for an application involving serious risk to life or property without first

ensuring that the system is designed to secure the required level of safety with risk warnings and

redundancy, and that the Yaskawa product is properly rated and installed.

• The circuit examples and other application examples described in product catalogs and manuals

are for reference. Check the functionality and safety of the actual devices and equipment to be

used before using the product.

• Read and understand all use prohibitions and precautions, and operate the Yaskawa product

correctly to prevent accidental harm to third parties.

Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and

manuals may be changed at any time based on improvements and other reasons. The next editions of the revised catalogs or manuals will be published with updated code numbers. Consult

with your Yaskawa representative to confirm the actual specifications before purchasing a product.

xix

Page 20

1

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Outline of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Peripheral Devices and System Configurations

2

1.1

1.2

1.3

Configuration with a Rotary Servomotor. . . . . . . . . . . . . . . . . . . . . .1-2

Configuration with a Direct Drive Servomotor . . . . . . . . . . . . . . . . .1-3

Configuration with a Linear Servomotor . . . . . . . . . . . . . . . . . . . . . .1-4

Cables and User-Assembled Wiring Materials for SGM7M Rotary Servomotors

2.1

2.2

2.3

2.4

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.1 Servomotor Main Circuit Cables for Servomotors without Holding Brakes . .2-3

2.2.2 Servomotor Main Circuit Cables for Servomotors with Holding Brakes . . . .2-4

Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3.1 Encoder Cables for Incremental Encoders . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3.2 Encoder Cables for Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

User-Assembled Wiring Materials for Encoder Cables. . . . . . . . . . .2-7

2.4.1 Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4.2 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

xx

3

2.5

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.5.1 Precautions for Standard Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.5.2 Precautions for Flexible Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Cables and User-Assembled Wiring Materials for SGM7J Rotary Servomotors

3.1

3.2

3.3

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.2.1 Servomotor Main Circuit Cables for Servomotors without Holding Brakes . .3-3

3.2.2 Servomotor Main Circuit Cables for Servomotors with Holding Brakes . . . .3-4

User-Assembled Wiring Materials for Servomotor Main Circuit Cables . . 3-5

3.3.1 Servomotor Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.3.2 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Page 21

4

3.4

3.5

3.6

3.7

Encoder Cables of 20 m or Less . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.4.1 Encoder Cables for Incremental Encoders or Batteryless Absolute

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.4.2 Encoder Cables for Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Relay Encoder Cables of 30 m to 50 m . . . . . . . . . . . . . . . . . . . . . .3-12

3.5.1 Motor-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.5.2 SERVOPACK-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.5.3 Relay Encoder Cables with Battery Cases . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

User-Assembled Wiring Materials for Encoder Cables . . . . . . . . .3-14

3.6.1 Precautions When Using Encoder Cables with a Wiring Length of

30 m to 50 m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.6.2 SERVOPACK Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.6.3 Encoder Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.6.4 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Cables and User-Assembled Wiring Materials for SGM7A Rotary Servomotors

4.1

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.1 SGM7A-A5 to -10 (50 W to 1.0 kW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.2 SGM7A-15 to -70 (1.5 kW to 7.0 kW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2

4.3

4.4

4.5

4.6

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.2.1 Servomotor Main Circuit Cables for Servomotors without

Holding Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.2 Servomotor Main Circuit Cables for Servomotors with Holding Brakes . . . . 4-7

User-Assembled Wiring Materials for Servomotor Main Circuit Cables: SGM7A-A5 to -10 . .4-11

4.3.1 Servomotor Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.3.2 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

User-Assembled Wiring Materials for Servomotor Main Circuit Cables: SGM7A-15 to -70 . .4-15

4.4.1 Connector Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.4.2 Main Power Supply Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.4.3 Holding Brake Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.4.4 Built-in Cooling Fan Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.4.5 Connector External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Encoder Cables of 20 m or Less . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

4.5.1 Encoder Cables for Incremental Encoders or Batteryless Absolute

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.5.2 Encoder Cables for Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Relay Encoder Cable of 30 m to 50 m. . . . . . . . . . . . . . . . . . . . . . .4-27

4.6.1 Motor-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.6.2 SERVOPACK-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.6.3 Relay Encoder Cables with Battery Cases . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

xxi

Page 22

5

4.7

4.8

User-Assembled Wiring Materials for Encoder Cables. . . . . . . . . .4-30

4.7.1 Precautions When Using Encoder Cables with a Wiring Length of

30 m to 50 m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

4.7.2 SERVOPACK Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

4.7.3 Encoder Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.7.4 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

Cables and User-Assembled Wiring Materials for SGM7P Rotary Servomotors

5.1

5.2

5.3

5.4

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.1 Servomotor Main Circuit Cables for Servomotors without Holding Brakes . .5-4

5.2.2 Servomotor Main Circuit Cables for Servomotors with Holding Brakes . . . .5-5

User-Assembled Wiring Materials for Servomotor Main Circuit Cables . . 5-6

5.3.1 Servomotor Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.3.2 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Encoder Cables of 20 m or Less . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.1 Encoder Cables for Incremental Encoders or Batteryless Absolute

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.2 Encoder Cables for Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

6

5.5

5.6

5.7

Relay Encoder Cable of 30 m to 50 m . . . . . . . . . . . . . . . . . . . . . . .5-13

5.5.1 Motor-End Relay Encoder Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.5.2 SERVOPACK-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.5.3 Relay Encoder Cables with Battery Cases . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

User-Assembled Wiring Materials for Encoder Cables. . . . . . . . . .5-15

5.6.1 Precautions When Using Encoder Cables with a Wiring Length of

30 m to 50 m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.6.2 SERVOPACK Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.6.3 Encoder Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.6.4 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Cables and User-Assembled Wiring Materials for SGM7G Rotary Servomotors

6.1

6.2

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.1.1 SGM7G-03 and -05 (300 W and 450 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.1.2 SGM7G-09 to -1E (850 W to 15 kW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.2.1 Servomotor Main Circuit Cables for Servomotors

without Holding Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.2.2 Servomotor Main Circuit Cables for Servomotors with Holding Brakes . . . .6-7

xxii

Page 23

6.3

6.4

6.5

6.6

6.7

User-Assembled Wiring Materials for Servomotor Main Circuit Cables: SGM7G-03, -05

6.3.1 Servomotor Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.3.2 Wiring Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

User-Assembled Wiring Materials for Servomotor Main Circuit Cables: SGM7G-09 to -1E

6.4.1 Connector Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4.2 Main Power Supply Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.4.3 Holding Brake Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4.4 Connector External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

. .6-11

. .6-12

Encoder Cables of 20 m or Less . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

6.5.1 Encoder Cables for Incremental Encoders or Batteryless Absolute

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.5.2 Encoder Cables for Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Relay Encoder Cables of 30 m to 50 m . . . . . . . . . . . . . . . . . . . . . .6-22

6.6.1 Motor-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.6.2 SERVOPACK-End Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.6.3 Relay Encoder Cables with Battery Cases . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

User-Assembled Wiring Materials for Encoder Cables . . . . . . . . .6-24

6.7.1 Precautions When Using Encoder Cables with a Wiring Length of

30 m to 50 m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.7.2 SERVOPACK Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.7.3 Encoder Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.7.4 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

7

6.8

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Cables and User-Assembled Wiring Materials for SGMMV Rotary Servomotors

7.1

7.2

7.3

7.4

7.5

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.2.1 Servomotor Main Circuit Cables for Servomotors

without Holding Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2.2 Servomotor Main Circuit Cables for Servomotors with Holding Brakes . . . . 7-4

Encoder Cables of 20 m or Less . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.3.1 Encoder Cables for Incremental Encoders. . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.3.2 Encoder Cables for Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Relay Encoder Cable of 30 m to 50 m. . . . . . . . . . . . . . . . . . . . . . . .7-7

7.4.1 Relay Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.4.2 Relay Encoder Cables with Battery Cases . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

User-Assembled Wiring Materials for Encoder Cables . . . . . . . . . .7-9

7.5.1 Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.5.2 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.6

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

xxiii

Page 24

Cables and User-Assembled Wiring Materials for Direct Drive Servomotors

8

8.1

8.2

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.1 SGM7D Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.2 SGM7E Motors and SGM7F-A to -D Motors . . . . . . . . . . . . . . . . . .8-4

8.1.3 SGM7F-M and -N Motors and SGMCS Motors . . . . . . . . . . . . . . . .8-5

8.1.4 SGMCV Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.2.1 SGM7D Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.2.2 Main Circuit Cables for SGM7E and SGM7F-A to -D Motors . . . . . .8-8

8.2.3 Main Circuit Cables for SGM7F-M, -N, and SGMCS Motors . . . . . .8-9

8.2.4 SGMCV Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

8.3 User-Assembled Wiring Materials for Servomotor Main Circuit Cables

8.3.1 Servomotor Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.3.2 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-16

8.4

8.5

Encoder Cables of 20 m or Less . . . . . . . . . . . . . . . . . . . . . . . . . . .8-18

8.4.1 SGM7D Encoder Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-18

8.4.2 Encoder Cables for SGM7E and SGM7F Servomotors . . . . . . . . . . . . . . . .8-20

8.4.3 SGMCV Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-24

8.4.4 SGMCS Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Relay Encoder Cable of 30 m to 50 m . . . . . . . . . . . . . . . . . . . . . . .8-29

8.5.1 SGM7D Encoder Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-29

8.5.2 Encoder Cables for SGM7E and SGM7F Servomotors . . . . . . . . . . . . . . . .8-31

8.5.3 SGMCV Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-34

8.5.4 SGMCS Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

. .8-12

9

8.6

8.7

User-Assembled Wiring Materials for Encoder Cables. . . . . . . . . .8-39

8.6.1 SERVOPACK Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-39

8.6.2 Encoder Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

8.6.3 Cables without Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-40

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-41

Cables and User-Assembled Wiring Materials for Linear Servomotors

9.1

9.2

Recommended Linear Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.1.1 Incremental Linear Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.1.2 Absolute Linear Encoders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

9.2.1 Connections to Linear Encoder from

Dr. JOHANNES HEIDENHAIN GmbH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

9.2.2 Connections to Linear Encoder from RSF Elektronik GmbH . . . . . . . . . . . .9-10

9.2.3 Connections to Linear Encoder from Renishaw plc . . . . . . . . . . . . . . . . . .9-11

9.2.4 Connections to Linear Encoder from RLS d.o.o.. . . . . . . . . . . . . . . . . . . . .9-14

9.2.5 Connections to Linear Encoder from Magnescale Co., Ltd. . . . . . . . . . . . .9-15

9.2.6 Connections to Linear Encoders from Mitutoyo Corporation . . . . . . . . . . .9-22

9.2.7 Connections to Linear Encoder from Fagor Automation S. Coop. . . . . . . .9-23

9.2.8 Connections to Linear Encoder from Canon Precision Inc. . . . . . . . . . . . . .9-24

xxiv

Page 25

10

9.3

9.4

Cable Selection Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-25

9.3.1 Servomotor Main Circuit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

9.3.2 Linear Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

9.3.3 Serial Converter Unit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

9.3.4 Sensor Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

9.3.5 Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

9.3.6 Cable Dimensional Drawings and Wiring Specifications . . . . . . . . . . . . . . 9-28

9.3.7 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Serial Converter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-37

9.4.1 Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-37

9.4.2 Characteristics and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

9.4.3 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

9.4.4 Analog Signal Input Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

Cables and User-Assembled Wiring Materials for SERVOPACKs

10.1

10.2

System Configuration Diagrams and Selection Tables . . . . . . . . . 10-3

10.1.1 Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.2 Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Analog Monitor Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-10

10.3

10.4

10.5

10.6

10.7

10.8

Digital Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

10.3.1 Digital Operator for Σ-7-Series SERVOPACKs: JUSP-OP05A-1-E . . . . . . 10-11

10.3.2 Digital Operator Conversion Cable (for Σ-III-Series Digital Operators) . . . 10-12

10.3.3 Digital Operator Conversion Cable with Lock Screws . . . . . . . . . . . . . . . 10-12

10.3.4 Communications Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Computer Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

I/O Signal Cables for SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . .10-15

10.5.1 For Σ-7S Analog Voltage/Pulse Train Reference SERVOPACKs . . . . . . . . 10-15

10.5.2 For Σ-7S MECHATROLINK-II/-III Communications Reference or

Command Option Attachable-Type SERVOPACKs . . . . . . . . . . . . . . . . . 10-18

10.5.3 For Σ-7W SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

10.5.4 For Servo Section of Σ-7C SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.5.5 For Controller Section of Σ-7C SERVOPACKs . . . . . . . . . . . . . . . . . . . . . 10-27

Safety Function Device Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-30

10.6.1 Cables with Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-30

10.6.2 Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-30

MECHATROLINK-II Communications Cable . . . . . . . . . . . . . . . . .10-31

MECHATROLINK-III Communications Cable . . . . . . . . . . . . . . . . 10-32

10.9

10.10

MECHATROLINK-4 Communications Cable . . . . . . . . . . . . . . . . .10-33

Cables to Connect to MP3000/MP2000-Series Machine Controllers

10.10.1 Cables to Connect to SVA-01 Analog Output Motion Modules . . . . . . . . 10-34

. . 10-34

xxv

Page 26

11

10.11

10.12

10.13

I/O Signal Cables for INDEXER Modules . . . . . . . . . . . . . . . . 10-35

10.11.1

10.11.2

10.11.3

Cables with Loose Wires at One End . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-35

Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-36

Cables with Terminal Block on One End . . . . . . . . . . . . . . . . . . . . . . . . . . 10-38

Serial Command Cables (Connector Kit Only) . . . . . . . . . . . . 10-39

DeviceNet Communications Cable . . . . . . . . . . . . . . . . . . . . 10-40

Option Modules

11.1

11.2

11.3

Feedback Option Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

11.1.1 Fully-Closed Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Safety Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-11

11.2.1 Applicable Standards and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

11.2.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

11.2.3 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Option Case Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

12

SERVOPACK Peripheral Devices

12.1

12.2

12.3

12.4

Molded-Case Circuit Breakers and Fuses. . . . . . . . . . . . . . . . . . . .12-3

12.1.1 Using an AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

12.1.2 Using a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Magnetic Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

SERVOPACK Main Circuit Wires . . . . . . . . . . . . . . . . . . . . . . . . . .12-10

12.3.1 Three-Phase, 200-VAC Wires for Σ-7S SERVOPACKs . . . . . . . . . . . . . . .12-10

12.3.2 Single-Phase, 200-VAC Wires for Σ-7S SERVOPACKs . . . . . . . . . . . . . . .12-13

12.3.3 Single-Phase, 100-VAC Wires for Σ-7S SERVOPACKs . . . . . . . . . . . . . . .12-14

12.3.4 DC Power Supply Wires for Σ-7S SERVOPACKs . . . . . . . . . . . . . . . . . . .12-15

12.3.5 Three-Phase, 200-VAC Wires for Σ-7W SERVOPACKs and

Σ-7C SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-18

12.3.6 Single-Phase, 200-VAC Wires for Σ-7W SERVOPACKs and

Σ-7C SERVOPACKs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19

12.3.7 DC Power Supply Wires for Σ-7W SERVOPACKs . . . . . . . . . . . . . . . . . . .12-19

12.3.8 Wire Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-20

Crimp Terminals and Insulating Sleeves . . . . . . . . . . . . . . . . . . . .12-21

12.4.1 Σ-7S SERVOPACKs with Three-Phase, 200-VAC or

DC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21

12.4.2 Σ-7S SERVOPACKs with Single-Phase, 200-VAC . . . . . . . . . . . . . . . . . . . 12-22

12.4.3 Σ-7S SERVOPACKs with Single-Phase, 100-VAC . . . . . . . . . . . . . . . . . . . 12-22

12.4.4 Σ-7W SERVOPACKs with Three-Phase, 200-VAC or DC Power Supplies

and Σ-7C SERVOPACKs with Three-Phase, 200-VAC. . . . . . . . . . . . . . . .12-23

12.4.5 Σ-7W SERVOPACKs and Σ-7C SERVOPACKs with Single-Phase,

200-VAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-23

xxvi

12.5

Noise Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-25

Page 27

13

12.6

12.7

12.8

12.9

AC/DC Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-28

12.6.1 Using a Three-Phase, 200-VAC Power Supply Input . . . . . . . . . . . . . . . . 12-28

12.6.2 Using a Single-Phase, 200-VAC Power Supply Input. . . . . . . . . . . . . . . . 12-29

12.6.3 Using a Single-Phase, 100-VAC Power Supply Input. . . . . . . . . . . . . . . . 12-29

12.6.4 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-30

Surge Absorbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-31

Regenerative Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-32

12.8.1 Regenerative Power and Regenerative Resistance . . . . . . . . . . . . . . . . . 12-32

12.8.2 Types of Regenerative Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-32

12.8.3 Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-33

12.8.4 Specifications of Built-in Regenerative Resistors in SERVOPACKs . . . . . 12-33

12.8.5 Specifications and Dimensions of External Regenerative Resistors . . . . . 12-34

12.8.6 Selecting External Regenerative Resistor . . . . . . . . . . . . . . . . . . . . . . . . 12-37

Inrush Current Suppression Devices. . . . . . . . . . . . . . . . . . . . . . .12-53

Software

13.1

SigmaWin+: AC Servo Drive Engineering Tool . . . . . . . . . . . . . . . .13-2

14

13.2

MPE720: System Integrated Engineering Tool . . . . . . . . . . . . . . . .13-3

Other Peripheral Devices and Options

14.1

14.2

14.3

14.4

Surge Absorbers (Varistors) and Diodes for Holding Brake Power Supplies

Batteries for Servomotors with Absolute Encoders . . . . . . . . . . . .14-4

14.2.1 Using Encoder Cables with Battery Cases . . . . . . . . . . . . . . . . . . . . . . . . 14-4

14.2.2 When Installing a Battery on the Host Controller . . . . . . . . . . . . . . . . . . . . 14-5

Precautions for Connecting a Σ-V-Series Cable to a Σ-7-Series Servomotor

14.3.1 Restrictions in Using Σ-V-Series Cables . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

14.3.2 Precautions When the Encoder Cable Is Installed toward the Load Side . . 14-6

14.3.3 Cables That Connect to Σ-7-Series Servomotors . . . . . . . . . . . . . . . . . . . 14-7

Optional Metal Connectors for Servomotor Main Circuit Cables. .14-8

14.4.1 SGM7J and SGM7A (50 W to 150 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8

14.4.2 SGM7J and SGM7A (200 W to 600 W) . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8

14.4.3 SGM7J and SGM7A (750 W and 1.0 kW) . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

Revision History

. .14-2

. .14-6

xxvii

Page 28

Peripheral Devices and System Configurations

1

1.1

1.2 Configuration with a Direct Drive Servomotor . . 1-3

1.3

Configuration with a Rotary Servomotor . . 1-2

Configuration with a Linear Servomotor . . . 1-4

Page 29

1.1 Configuration with a Rotary Servomotor

R S T

C

N

6

Ground

cable

(Wiring required for a

Servomotor with a Brake)

Encoder Cable

Refer to chapter 2 to 7 depending

on the motor that you are using.

Holding Brake

Power Supply Unit

*3, *4, *5

Brake Relay

*4

External Regenerative

Resistor

Noise Filter

Molded-case

circuit breaker

Magnetic Contactor

I/O Signal Cable

SERVOPACK

*1

Servomotor

Power supply

Three-phase, 200 VAC

*1

Computer

Computer Cable

Control Power

Supply Cable

Digital Operator

(JUSP-OP05A-1-E)

Digital

Operator cable

200 VAC

Host controller

MECHATROLINK Communications Cable

*1

To next

MECHATROLINK-III

station

*2

Analog Monitor Cable

Safety Function Device Cable

Safety function device

SERVOPACK

main circuit wires

Engineering

Tool

Battery Case

(Required when an

absolute encoder is

used.)

When not using a safety function,

leave the Safety Jumper Connector

connected to the SERVOPACK.

External

Regenerative

Resistor

Cable

Servomotor

Main Circuit Cable

Refer to chapter 2 to 7

depending on the motor

that you are using.

(page 12-3)

(page 12-25)

(page 12-6)

Surge Absorbers (page 12-31)

Reactors (page 12-28)

Surge Absorbers (Varistors) and Diodes for Holding Brake Power Supplies

(page 14-2)

(page 12-10)

(pages 10-31 and 10-32)

(page 10-11)

(page 10-14)

(pages 10-15, 10-18 and 10-21)

(page 10-10)

(page 14-4)

(page 10-30)

(page 12-32)

(pages 10-12 and

10-12)

(page 13-2)

1.1

Configuration with a Rotary Servomotor

*1. The peripheral devices are described using a MECHATROLINK-III Communications Reference SERVOPACK for

a three-phase 200-VAC power supply input as an example. The shapes of the connectors and pin layout may

be different for SERVOPACKs with other power supply input specifications and for other interfaces.

Refer to the product manual for your SERVOPACK when using a SERVOPACK other than the above.

*2. The connected devices depend on the interface.

For MECHATROLINK-4 communications references: Other MECHATROLINK-4 stations

For MECHATROLINK-II communications references: Other MECHATROLINK-II stations

For analog voltage/pulse train references: There is no CN6 connector.

*3. A Holding Brake Power Supply Unit is required to use a Servomotor with a Holding Brake. Holding Brake Power

1-2

*4. If you use a Servomotor with a Holding Brake, select a brake relay according to the power supply voltage and

*5. The power supply for the holding brake is not provided by Yaskawa. Select a power supply based on the hold-

Supply Units for 24 VDC are not provided by Yaskawa. Obtain these from other manufacturers.

Never connect Holding Brake Power Supply Units with different output voltages to a SERVOPACK. Overcurrent

may result in burning in the brake.

current of the brake. Yaskawa does not recommend any particular brake relays. Select an appropriate brake

relay using the selection method of the brake relay manufacturer.

ing brake specifications. If you use a 24-V brake, install a separate power supply for the 24-VDC power supply

from other power supplies, such as the one for the I/O signals of the CN1 connector. If the power supply is

shared, the I/O signals may malfunction.

Page 30

1.2 Configuration with a Direct Drive Servomotor

1

Peripheral Devices and System Congurations

External Regenerative

Resistor

Noise Filter

Molded-case

circuit breaker

Magnetic Contactor

I/O Signal Cable

SERVOPACK

*1