Page 1

制動ユニット CDBR-

制動抵抗器ユニット LKEB-

制動ユニット,制動抵抗器ユニット

安川インバータオプション

取扱説明書

BRAKING UNIT CDBRBRAKING RESISTOR UNIT LKEB-

Braking unit,

Braking resistor unit

YASKAWA AC Drive Option

Installation Manual

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

MANUAL NO. TOBP C720600 00F

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

3

PREFACE

Braking resistor unit and braking unit are used to con-sume regenerative

energy from motor in the braking resistor unit at deceleration and to

improve the transis-tor inverter braking ability.

Before using the braking resistor unit and braking unit, a thorough understanding of this manual is recom-mended. This instruction manual will be

of great help for daily maintenance, inspection and troubleshoot-ing.

Inverters to which the braking resistor unit and braking unit can be connected are of the following series:

• YASKAWA AC Drive 1000 Series

• Varispeed Series

Wiring sequence should shut of f power to the drive when a braking

resistor Overload Relay Trip Contact (Thermal Protector Contact)

output is triggered.

NOTENOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

4

General Precautions

S Some drawings in this manual are shown with the protective cover or shields

removed, in order to describe with more clarity. Make sure all covers and

shields are replaced before operating this product.

S Since the drawings in this manual are represented examples, some are subject

to differ from delivered products.

S This manual may be modified when necessary because of improvement of the

product, modification or changes in specifications. Such modifications are

denoted by a revised manual No.

S To order a copy of this manual, if your copy has been damaged or lost, contact

your YASKAWA representative.

S YASKAWA is not responsible for any modification of the productmadebythe

user since that will void your guarantee.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

5

NOTES FOR SAFE OPERATION

Read this instruction manual thoroughly before installation, operation,

maintenance or inspection of the braking un it and the braking resistor unit. I n this

manual, NOTES FOR SAFE OPERATION are classified as “WARNING” or

“CAUTION.”

Indicates a potentially hazardo u s situation which, if not avoided, could result in

death or serious injury to personnel.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury to personnel and damage to equipment.

It may also be used to alert against unsafe practices.

Even items described in CAUTION may result in a vital accident in some situations. In either case, follow the se important notes.

: These are steps to be taken to insure proper operation.

WARNING

CAUTION

CAUTION

NOTENOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 6

7

WIRING

(Ref. page)

• Only commence wiring after verifying that the power supply is turned OFF.

Failure to observe this warning can result in an electrical shock

or a fire.

27

• High voltage exists at all terminals of braking unit and

braking resistor unit.

Failure to observe this warning can r esult in an elec trical shock.

27

• Wiring should be performed only by qualified personnel.

Failure to observe this warning can result in an electrical shock

or a fire.

27

• Wiring sequence should shut off power to the drive when

a braking resistor Overload Relay Trip Contact (Thermal

Protector Contact) output is triggered.

Failure to observe this warning can result in a fire.

27

• When wiring the emergency stop circuit, check the wiring

thoroughly before operation.

Failure to observe this warning can result in personal injury.

27

• Make sure to ground the ground terminal.

(Ground resistance

200V class: 100Ω. or less, 400V class: 10Ω. or less)

Failure to observe this warning can r esult in an elec trical shock.

27

• Short Circuit Current Rating (SCCR)

Install adequate branch short circuit protection according to applicable

codes. Failure to comply could result in damage to the drive. The device is

suitable for circuits capable of delivering 31,000 RMS symmet-rical

Amperes, 240 Vac maximum (200V Class), 480 V ac maximum (400V Class)

and 575Vac (600V Class) or the SCCR rating of the drive it is connected to,

which ever is greater.

WARNING

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 7

8

CAUTION

(Ref. page)

S Verify that the rated voltage of the braking unit and the braking

resistor unit coincides with the AC power supply voltage.

Failure to observe this caution can result in personal injury or a fire.

27

S Do not perform a withstand voltage test of the braking unit and

braking resistor unit.

It may cause semi−conductor elements to be damaged.

27

S Connect braking resistors, braking resistor units, and braking

units as shown in the I/O wiring examples. Use properly rated

wire in accordance with table 2 on page 31.

Otherwise, a fire can occur.

27

S Tighten terminal screws to the specified tightening torque.

Failure to observe this caution can result in a fire.

27

S Be sure to connect braking resistors or braking resistor units

to the braking units.

If neither braking resistor nor braking resistor unit is connected to a

braking unit, the fault contact may instantaneously turn ON when

the power is turned ON, resulting in malfunction of the inverter.

27

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 8

9

OPERATION

WARNING

(Ref. page)

S Only turn ON the input power supply after replacing the front

cover. Do not remove the cover while current is flowing.

Failure to observe this warning can result in an electrical shock.

41

CAUTION

(Ref. page)

S Never touch the heatsink or discharging resistor since the

temperature is very high.

Failure to observe this caution can result in harmful burns to the

body.

41

S Do not check signals during operation.

The machine or the inverter may be damaged.

41

S All theconstants of thethebraking unitandthe braking resistor

unit have been preset at the factory. Do not change the

settings unnecessarily.

41

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 10

11

CAUTION

(Ref. page)

S The control PC board employs CMOS ICs. Do not touch the

CMOS elements.

They are easily damaged by static electricity.

46

S Do not connect or disconnect wires orconnectorswhilepower

is applied to the circuit.

Failure to observe this caution can result in personal injury.

46

OTHERS

WARNING

S Never modify the product.

Failure to observe this warning can result in an electrical shock or

personal injury and will invalidate the guarantee.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 11

12

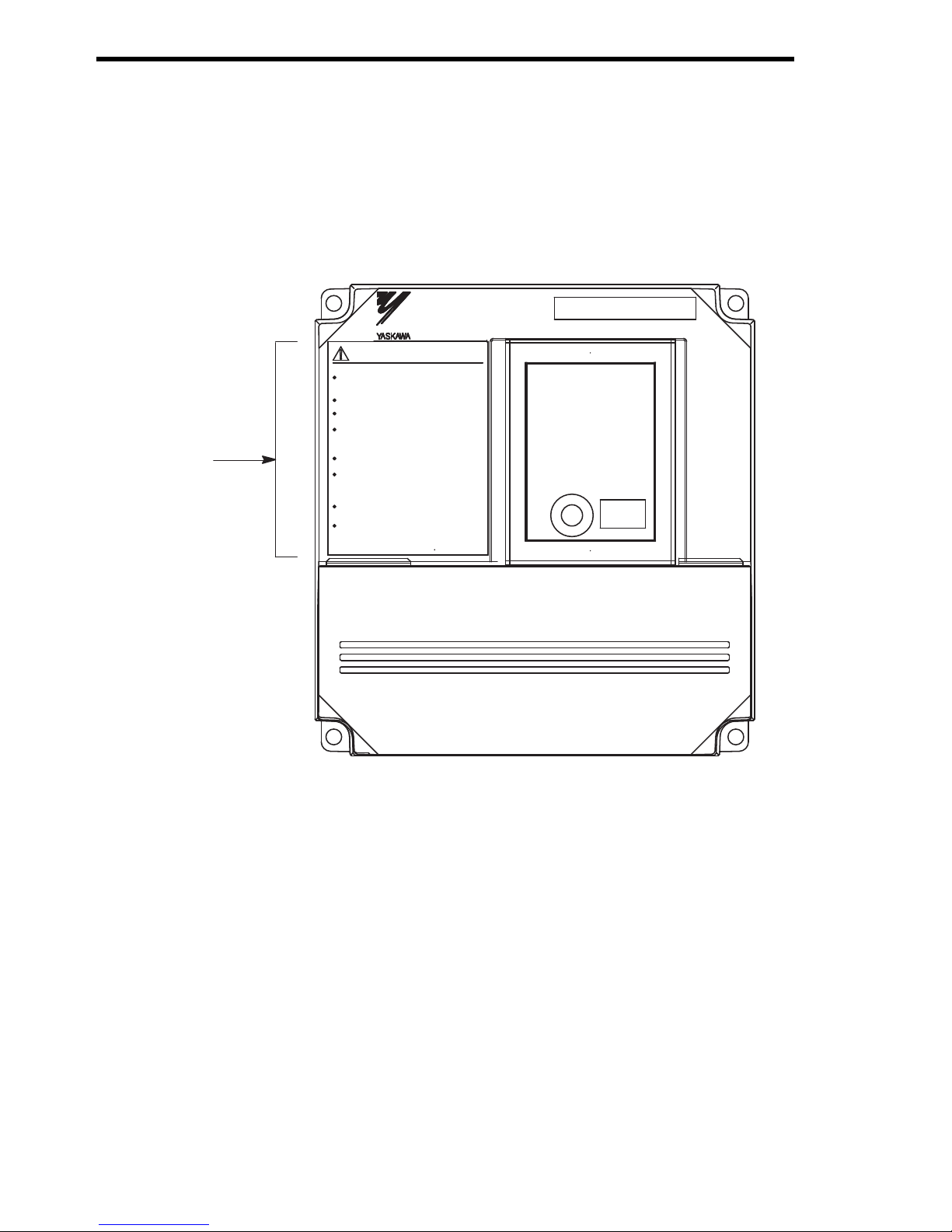

WARNING INDICATION

A warning label is displayed on the front cover of the braking unit, as shown

below. Follow these instructions when handling the braking unit and the braking

resistor unit.

Example of Braking Unit Model CDBR−4045B

Warning

Indication

$4#-+0)70+6

㧹㧻㧰㧱㧸㧦㧯㧰㧮㧾㧙㧠㧜㧠㧡㧮

ޓޓޓޓޓޓ㧠㧜㧜㨂ޓ㧯㧸㧭㧿㧿ޓ㧲㧻㧾ޓ㧠㧡㨗㨃

ߌ߇ޔᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ࠎߢޔ

ޓ

ߘߩᜰ␜

ߦᓥߞߡߊߛߐޕ

ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ㅢ㔚߮㔚Ḯㆤᢿᓟ㧡ಽએౝߪޔ㕙ࠞࡃࠍ㐿ߌ

ޓ

ߥߢ

ߊߛߐޕ

⏕ታߦធࠍⴕߞߡߊߛߐޕ

㧹㨍㨥ޓ㨏㨍㨡㨟㨑ޓ㨕㨚㨖㨡㨞㨥ޓ㨛㨞㨑㨘㨑㨏㨠㨞㨕㨏ޓ㨟㨔㨛㨏㨗㧚

㧼㨘㨑㨍㨟㨑ޓ㨒㨛㨘㨘㨛㨣ޓ㨠㨔㨑ޓ㨕㨚㨟㨠㨞㨡㨏㨠㨕㨛㨚㨟ޓ㨕㨚ޓ㨠㨔㨑

ޓ

㨙㨍㨚㨡㨍㨘ޓ㨎㨑㨒㨛㨞㨑ޓ㨕㨚㨟㨠㨍㨘㨘㨍㨠㨕㨛㨚ޓ㨛㨞ޓ㨛㨜㨑㨞㨍㨠㨕㨛㨚㧚

㧰㨕㨟㨏㨛㨚㨚㨑㨏㨠ޓ㨍㨘㨘ޓ㨜㨛㨣㨑㨞ޓ㨎㨑㨒㨛㨞㨑ޓ㨛㨜㨑㨚㨕㨚㨓

ޓ

㨒㨞㨛㨚㨠ޓ㨏㨛㨢㨑㨞ޓ㨛㨒ޓ㨡㨚㨕㨠㧚

㨃㨍㨕㨠ޓ㧡ޓ㨙㨕㨚㨡㨠㨑㨟ޓ㨡㨚㨠㨕㨘ޓ㧰㧯ޓ㧮㨡㨟ޓ㨏㨍㨜㨍㨏㨕㨠㨛㨞㨟

㨐㨕㨟㨏㨔㨍㨞㨓㨑㧚

㨁㨟㨑ޓ㨜㨞㨛㨜㨑㨞ޓ㨓㨞㨛㨡㨚㨐㨕㨚㨓ޓ㨠㨑㨏㨔㨚㨕㨝㨡㨑㨟㧚

㧺㧼㧶㨀㧠㧞㧡㧜㧞㧙㧝㧙㧜

ෂ㒾ޓ㨃㧭㧾㧺㧵㧺㧳

Ἣἴߩ߅ߘࠇ߇ࠅ߹ߔޕ

േᛶ᛫ེߩࠨࡑ࡞࠻࠶ࡊធὐߢ㔚Ḯࠍ

ޓㆤᢿߔࠆࠪࠤࡦࠬࠍ⚵ࠎߢߊߛߐޕ

㧾㨕㨟㨗ޓ㨛㨒ޓ㨒㨕㨞㨑㧚

㨁㨟㨑ޓ㨟㨑㨝㨡㨑㨚㨏㨑㨞ޓ㨠㨛ޓ㨎㨞㨑㨍㨗ޓ㨜㨛㨣㨑㨞ޓ㨟㨡㨜㨜㨘㨥ޓ㨟㨕㨐㨑

ޓ

㨛㨚ޓ㨛㨢㨑㨞㨘㨛㨍㨐ޓ㨞㨑㨘㨍㨥ޓ㨠㨞㨕㨜ޓ㨏㨛㨚㨠㨍㨏㨠ޓ㨛㨒ޓ

ޓ

㨎㨞㨍㨗㨕㨚㨓ޓ㨞㨑㨟㨕㨟㨠㨛㨞㧚

ㅢ㔚೨ߦᧄࠞࡃࠍߪߕߒߡޔ

ࠦࡀࠢ࠲ߩ⸳ቯࠍ߅ߎߥߞߡߐޕ

㧔ขᛒ⺑ᦠෳᾖߩߎߣޕ㧕

UGVVJGEQPPGEVQTU

DGHQTGVWTPKPIVJG

RQYGTQP

5GG+PUVTWEVKQPU

4GOQXGVJKUEQXGTCPF

.KIJVU

YJGP

DTCMKPI

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 12

13

Warning Indication

ߌ߇ޔᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ࠎߢޔ

ޓ

ߘߩᜰ␜

ߦᓥߞߡߊߛߐޕ

ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ㅢ㔚߮㔚Ḯㆤᢿᓟ㧡ಽએౝߪޔ㕙ࠞࡃࠍ

ޓ

㐿ߌߥߢ

ߊߛߐޕ

⏕ታߦធࠍⴕߞߡߊߛߐޕ

㧹㨍㨥ޓ㨏㨍㨡㨟㨑ޓ㨕㨚㨖㨡㨞㨥ޓ㨛㨞㨑㨘㨑㨏㨠㨞㨕㨏ޓ㨟㨔㨛㨏㨗㧚

㧼㨘㨑㨍㨟㨑ޓ㨒㨛㨘㨘㨛㨣ޓ㨠㨔㨑ޓ㨕㨚㨟㨠㨞㨡㨏㨠㨕㨛㨚㨟ޓ㨕㨚ޓ㨠㨔㨑

ޓ

㨙㨍㨚㨡㨍㨘ޓ㨎㨑㨒㨛㨞㨑ޓ㨕㨚㨟㨠㨍㨘㨘㨍㨠㨕㨛㨚ޓ㨛㨞ޓ㨛㨜㨑㨞㨍㨠㨕㨛㨚㧚

㧰㨕㨟㨏㨛㨚㨚㨑㨏㨠ޓ㨍㨘㨘ޓ㨜㨛㨣㨑㨞ޓ㨎㨑㨒㨛㨞㨑ޓ㨛㨜㨑㨚㨕㨚㨓

ޓ

㨒㨞㨛㨚㨠ޓ㨏㨛㨢㨑㨞ޓ㨛㨒ޓ㨡㨚㨕㨠㧚

㨃㨍㨕㨠ޓ㧡ޓ㨙㨕㨚㨡㨠㨑㨟ޓ㨡㨚㨠㨕㨘ޓ㧰㧯ޓ㧮㨡㨟ޓ㨏㨍㨜㨍㨏㨕㨠㨛㨞㨟

㨐㨕㨟㨏㨔㨍㨞㨓㨑㧚

㨁㨟㨑ޓ㨜㨞㨛㨜㨑㨞ޓ㨓㨞㨛㨡㨚㨐㨕㨚㨓ޓ㨠㨑㨏㨔㨚㨕㨝㨡㨑㨟㧚

㧺㧼㧶㨀㧠㧞㧡㧜㧞㧙㧝㧙㧜

ෂ㒾ޓ㨃㧭㧾㧺㧵㧺㧳

Ἣἴߩ߅ߘࠇ߇ࠅ߹ߔޕ

േᛶ᛫ེߩࠨࡑ࡞࠻࠶ࡊធὐߢ㔚Ḯࠍ

ޓㆤᢿߔࠆࠪࠤࡦࠬࠍ⚵ࠎߢߊߛߐޕ

㧾㨕㨟㨗ޓ㨛㨒ޓ㨒㨕㨞㨑㧚

㨁㨟㨑ޓ㨟㨑㨝㨡㨑㨚㨏㨑㨞ޓ㨠㨛ޓ㨎㨞㨑㨍㨗ޓ㨜㨛㨣㨑㨞ޓ㨟㨡㨜㨜㨘㨥ޓ㨟㨕㨐㨑

ޓ

㨛㨚ޓ㨛㨢㨑㨞㨘㨛㨍㨐ޓ㨞㨑㨘㨍㨥ޓ㨠㨞㨕㨜ޓ㨏㨛㨚㨠㨍㨏㨠ޓ㨛㨒

ޓ

ޓ

㨎㨞㨍㨗㨕㨚㨓ޓ㨞㨑㨟㨕㨟㨠㨛㨞㧚

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 13

14

CONTENTS

NOTES FOR OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

1 RECEIVING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -15

1.1 NAMEPLATE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

2 INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

2.1 LOCATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

2.2 INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

2.3 REPLACEMENT OF CONVENTIONAL BRAKING UNITS

WITH NEW UNITS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

3 WIRING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

3.1 REMOVING AND REPLACING THE COVERS OF

THE BRAKING UNIT (MODELS CDBR-2015B, -2015C,

-2022B, -2022C, -4030B, -4045B) - - - - - - - - - - - - - - - - - - - 27

3.2 SECTION NAMES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

3.3 CIRCUITS AND WIRING SPECIFICATIONS - - - - - - - - - - - 31

3.4 WIRING PRECAUTIONS - - - - - - - - - - - - - - - - - - - - - - - - - 32

3.5 INTERCONNECTION - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

4 OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -41

4.1 ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

4.2 POWER SUPPLY VOLTAGE SELECTION CONNECTOR

SETTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

4.3 MASTER/SLAVE SELECTION CONNECTOR SETTING - - 44

4.4 PARALLEL CONNECTION OF BRAKING UNIT - - - - - - - - - 44

4.5 OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

5 TROUBLESHOOTING - - - - - - - - - - - - - - - - - - - - - - - - - - -46

6 SPECIFICATIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

6.1 BRAKING UNIT AND BRAKING RESISTOR UNIT

APPLICATION LIST - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

6.2 BRAKING UNIT FOR 575V CLASS APPLICATION LIST - - 49

6.3 LIST OF APPLICABLE/NOT APPLICABLE COMBINATIONS

WITH CONVENTIONAL MODELS (VS-616HII/H3,

VS-616GII/G3, VS-676) - - - - - - - - - - - - - - - - - - - - - - - - - - 50

6.4 BRAKING UNIT SPECIFICATIONS - - - - - - - - - - - - - - - - - - 51

6.5 BRAKING RESISTOR UNIT SPECIFICATIONS - - - - - - - - - 52

6.6 MODELS AND CODE NOS. OF BRAKING UNIT AND

BRAKING RESISTOR UNIT - - - - - - - - - - - - - - - - - - - - - - - 53

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 14

1 RECEIVING

15

1 RECEIVING

The braking resistor unit and braking unit have been put through severe tests at

the factory before shipment. After unpacking, however, check and see the following. If any malfunctions are found, contact your YASKAWA representative.

• Their nameplate data meet your requirements.

• They have sustained no damage while in transit.

• Fastening bolts and screws are not loose.

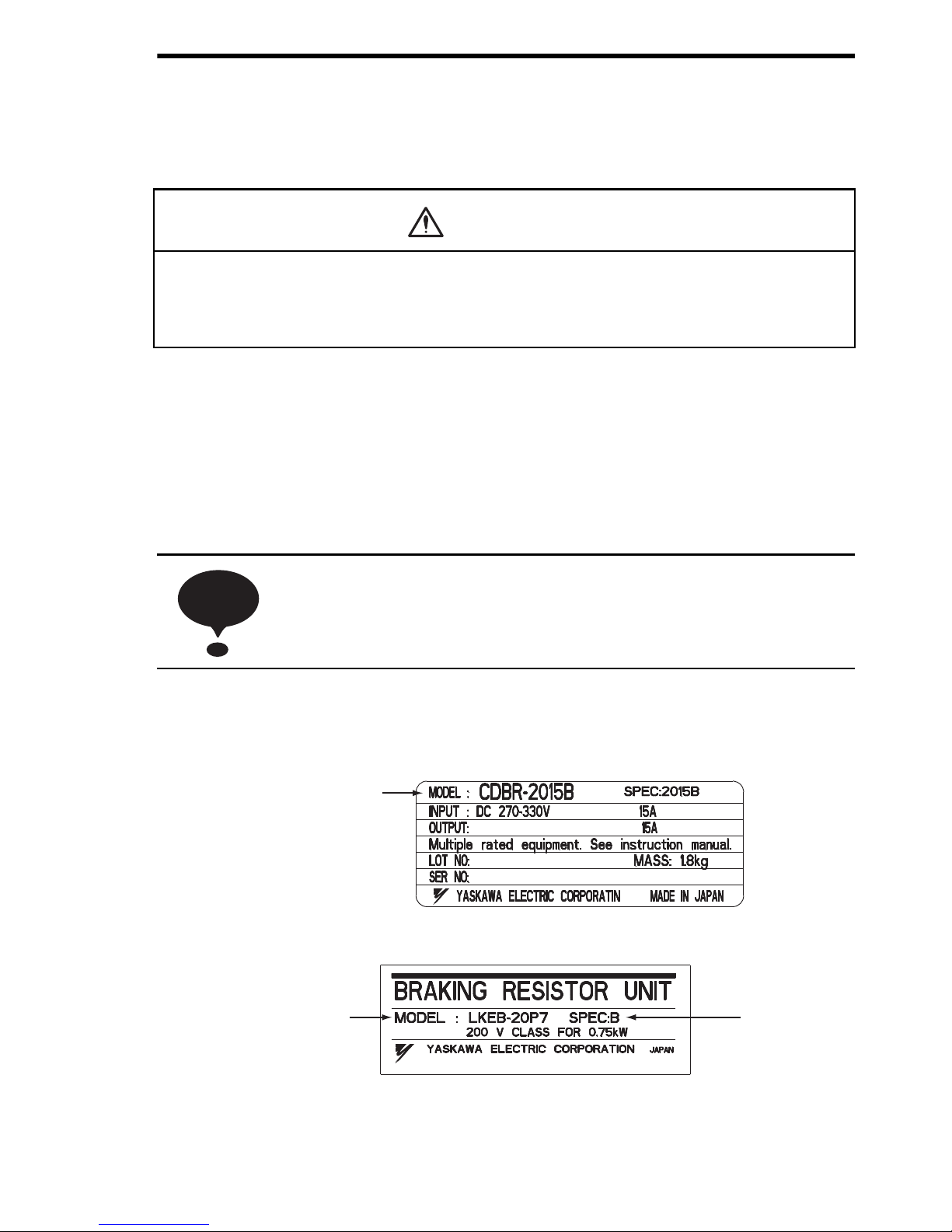

1.1 NAMEPLATE

(1) NAMEPLATE INFORMATION (BRAKING UNIT)

(2) NAMEPLATE INFORMATION (BRAKING RESISTER UNIT)

• Do not install and attempt to use a braking resistor or braking resistor unit If there are any damaged or missing components.

Failure to comply can result in personal injury.

For long term storage, the unit should be kept in a clean area

indoors.

CAUTION

NOTENOTE

Braking Unit

Model Number

Design

Revision

Order

Braking Resistor

Unit Model Number

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 15

16

2 INSTALLATION

2.1 LOCATION

If the units are temporarily stored or machine stops for an extended length of

time, the following precautions should be taken. Store the units at pollution level

2 or less (UL standard) and under the following conditions.

• Free from rainfall and drops of water.

• Clean and dry.

• Free from corrosive gases and liquids.

• Free from dirt and dust.

• Ambient temperature: 14 to 104°F, 10 to 40°C.

• Humidity: 90% RH or less (no condensation)

• Free from vibration.

2.2 INSTALLATION

For full use of the braking resistor unit or braking unit functions, install the units

at pollution level 2 or less (UL standard) and in a location to satisfy the following

conditions:

Figs. 1 to 8 show the external dimensions and the spaces from the periphery.

• Provide the spaces shown in Figs. 1 to 8 between the units and the

periphery.

• Since the braking resistor unit generates heat, provide sufficient

spaces from devices which are weak against heat.

• Install the units at such locations that all requirements described in

Par. 2.1 “LOCATION” are satisfied.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 16

2 INSTALLATION

17

• Install the units in the directions shown in Figs. 1 to 8. There will be

no problem if they are installed vertically.

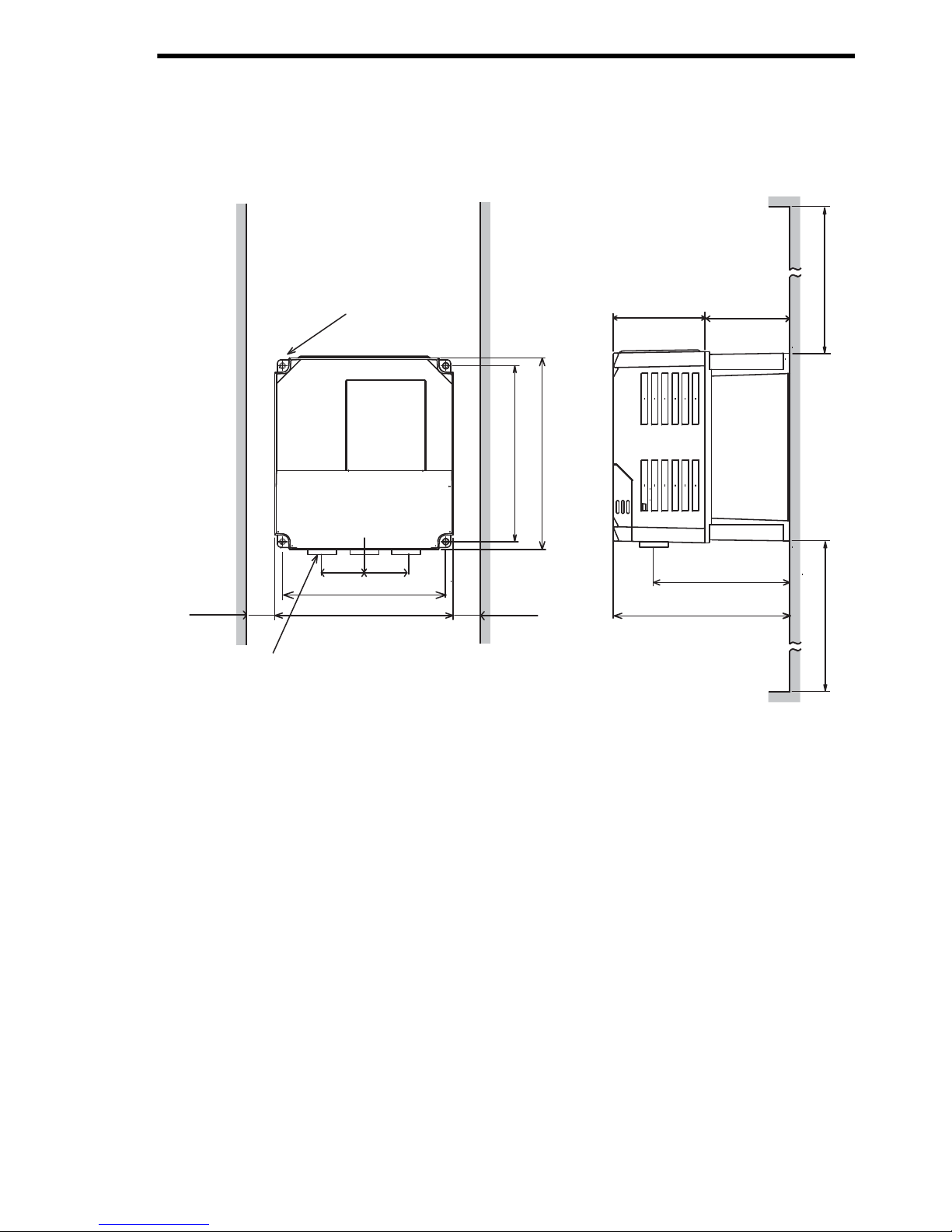

Fig. 1 Braking Unit Dimensions in inches (mm) CDBR-2015B, -2015C,

-2022B,-2022C,-4030B, -4045B

4−M4 MTG HOLE

1.5 (38) 1.5 (38)

1.18 (30)

OR MORE

3−LEAD WIRE OUTLET

[0.87 (20) DIA RUBBER BUSH]

5.04 (128)

5.51 (140)

2.83 (72)

2.73 (66.5)

4.51 (114.5)

5.45 (138.5)

1.18 (30)

OR MORE

5.43 (138)

5.91 (150)

3.94 (100) OR MORE

3.94 (100) OR MORE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 17

18

6.57 (167)

3.94 (100)

OR MORE

5.51 (140)

3.94 (100)

1.97 (50)

1.18 (30)

OR MORE

(58.5)

2.19 (55.5)

11.02 (280)

10.23 (260)

9.25 (235)

0.39 (10)

1.14 (29)

3.94 (100)

MAIN CIRCUIT

TERMINAL M4

3−LEAD WIRE

OUTLET

1.10 (28) DIA

RUBBER BUSH

4−M6

MTG HOLE

2.30

1.18 (30)

OR MORE

3.94 (100)

OR MORE

Fig. 2 Braking Unit Dimensions in inches (mm) CDBR−5037B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 18

2 INSTALLATION

19

Fig. 3 Braking Unit Dimensions in inches (mm) CDBR-2045B

5.51 (140)

(59)

7.09 (180)

4.37 (111)

6.14 (156)

7.87 (200)

3.86 (98)

3.94 (100)

2.95 (75)

12.48 (317)

13.78 (350)

14.57 (370)

1.44 (36.5)

0.47 (12)

5.51 (140)

MAIN CIRCUIT

TERMINAL M5

2−LEAD WIRE OUTLET

1.38 (35) DIA RUBBER

BUSH

4−M6

MTG HOLE

3.94 (100)

OR MORE

WIRE OUTLET 1.10 (28)

DIA RUBBER BUSH

3.94 (100)

OR MORE

2.32

1.97 (50)

1.18 (30)

OR MORE

1.18 (30)

OR MORE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 19

20

MAIN CIRCUIT

TERMINAL M6

2−LEAD WIRE OUTLET

1.38 (35) DIA RUBBER

BUSH

4−M6

MTG HOLE

3.94 (100)

OR MORE

WIRE OUTLET 1.10 (28)

DIA RUBBER BUSH

3.94 (100)

OR MORE

12.48 (317)

13.78 (350)

14.57 (370)

1.44 (36.5)

0.47 (12)

3.94 (100)

2.87 (73)

5.51 (140)

5.51 (140)

(59)

7.09 (180)

2.32

1.97 (50)

1.18 (30)

OR MORE

1.18 (30)

OR MORE

4.37 (111)

6.14 (156)

7.87 (200)

4.09

(104)

Fig. 4 Braking Unit Dimensions in inches (mm) CDBR−2110B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 20

21

MAIN CIRCUIT

TERMINAL M5

4−M6

MTG HOLE

1.44 (36.5)

0.35 (9)

7.09 (180)

12.48 (317)

13.98 (355)

14.57 (370)

5.45 (138.5)

2.95 (75)

8.66 (220)

(68.5)

7.09 (180)

2.70

1.97 (50)

1.18 (30)

OR MORE

1.18 (30)

OR MORE

2−LEAD WIRE OUTLET

1.38 (35) DIA RUBBER

BUSH

WIRE OUTLET 1.10 (28)

DIA RUBBER BUSH

3.94 (100)

OR MORE

4.37 (111)

6.14 (156)

7.87 (200)

3.94 (100)

OR MORE

3.86 (98)

Fig. 5 Braking Unit Dimensions in inches (mm) CDBR−4090B, −5110B

2.INSTALLATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 21

22

MAIN CIRCUIT

TERMINAL M6

4−M6

MTG HOLE

1.44 (36.5)

0.35 (9)

8.27 (210)

12.48 (317)

13.98 (355)

14.57 (370)

2.76 (70)

6.16 (156.5)

8.27 (210)

4.67 (118.5)

1.97 (50)

1.18 (30)

OR MORE

9.84 (250)

1.18 (30)

OR MORE

2−LEAD WIRE OUTLET

1.38 (35) DIA RUBBER

BUSH

WIRE OUTLET 1.10 (28)

DIA RUBBER BUSH

3.94 (100)

OR MORE

4.37 (111)

6.14 (156)

7.87 (200)

3.94 (100)

OR MORE

4.09

(104)

Fig. 6 Braking Unit Dimensions in inches (mm) CDBR−4220B, −5300B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 22

2 INSTALLATION

23

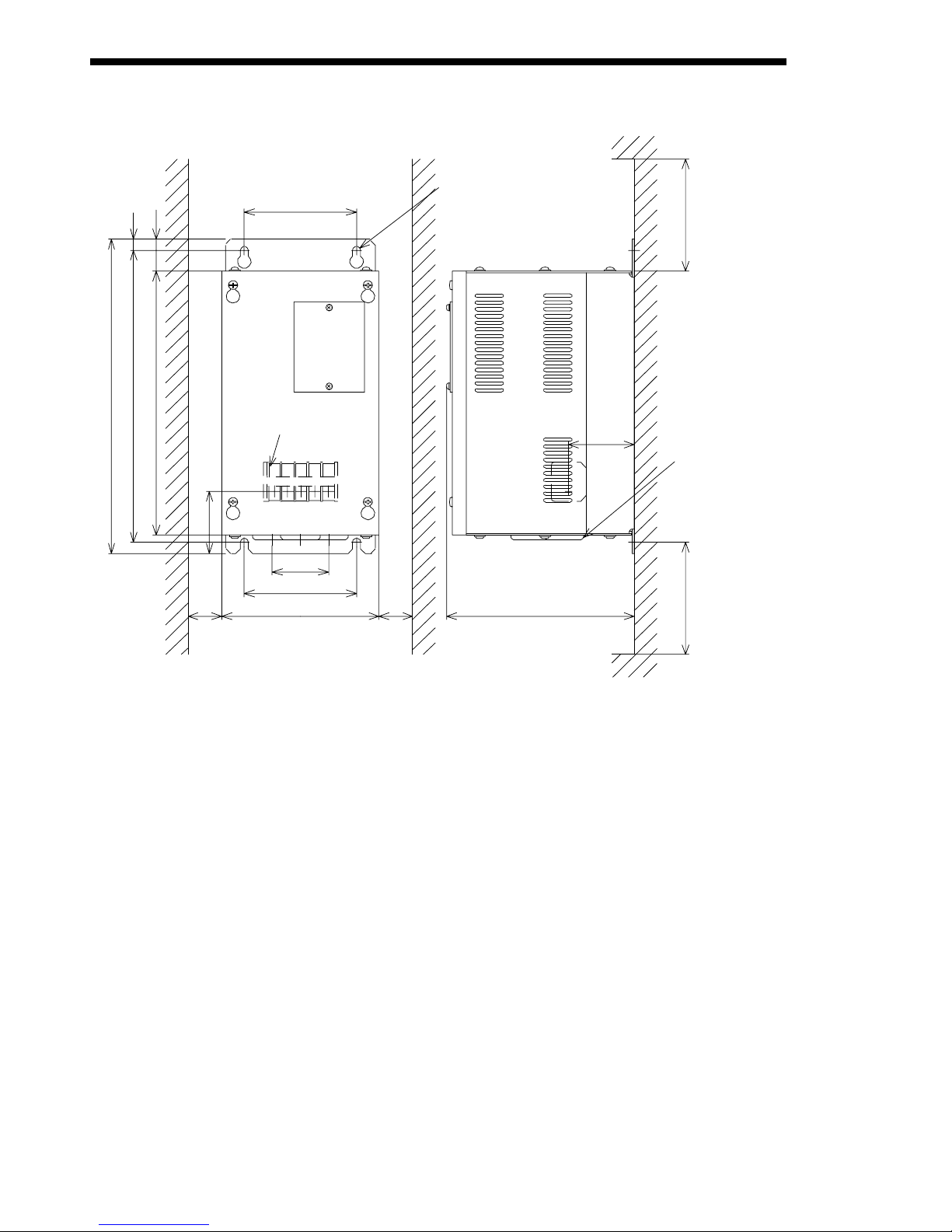

Fig. 7 Braking Resistor Unit Dimensions in inches (mm) [for 0.5 to 10HP (0.4 to

7.5kW)]

a

b

b

Braking Resistor

Unit Model

(LKEB-)

Dimensions in inches (mm)

ABCDE

20P7 4.13 (105) 10.83 (275) 1.97 (50) 10.24 (260) M5

21P5 5.12 (130) 13.78 (350) 2.95 (75) 13.19 (335) M5

22P2 5.12 (130) 13.78 (350) 2.95 (75) 13.19 (335) M5

23P7 5.12 (130) 13.78 (350) 2.95 (75) 13.19 (335) M5

25P5 9.84 (250) 13.78 (350) 7.87 (200) 13.19 (335) M6

27P5 9.84 (250) 13.78 (350) 7.87 (200) 13.19 (335) M6

40P7 4.13 (105) 10.83 (275) 1.97 (50) 10.24 (260) M5

41P5 5.12 (130) 13.78 (350) 2.95 (75) 13.19 (335) M5

42P2 5.12 (130) 13.78 (350) 2.95 (75) 13.19 (335) M5

43P7 5.12 (130) 13.78 (350) 2.95 (75) 13.19 (335) M5

45P5 9.84 (250) 13.78 (350) 7.87 (200) 13.19 (335) M6

47P5 9.84 (250) 13.78 (350) 7.87 (200) 13.19 (335) M6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 23

24

Fig. 8 Braking Resistor Unit Dimensions in inches (mm) [for 15 to 60HP (11 to

45kW)]

Braking Resistor

Unit Model

(LKEB-)

Dimensions in inches (mm)

ABCDE

2011 10.48 (266) 21.38 (543) 9.69 (246) 13.39 (340) M8

2015 14.02 (356) 21.38 (543) 13.23 (336) 13.39 (340) M8

2018 17.56 (446) 21.38 (543) 16.77 (426) 13.39 (340) M8

2022 17.56 (446) 21.38 (543) 16.77 (426) 13.39 (340) M8

4011 13.78 (350) 16.22 (412) 12.99 (330) 12.80 (325) M6

4015 13.78 (350) 16.22 (412) 12.99 (330) 12.80 (325) M6

4018 17.56 (446) 21.38 (543) 16.77 (426) 13.39 (340) M8

4022 17.56 (446) 21.38 (543) 16.77 (426) 13.39 (340) M8

4030 14.02 (356) 37.64 (956) 13.23 (336) 29.13 (740) M8

4037 17.56 (446) 37.64 (956) 16.77 (426) 29.13 (740) M8

4045 17.56 (446) 37.64 (956) 16.77 (426) 29.13 (740) M8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 24

2 INSTALLATION

25

2.3 REPLACEMENT OF CONVENTIONAL BRAKING

UNITS WITH NEW UNITS

T o replace conventional braking units (mod els CDBR-2015, -2022, -4030, -4045)

with new units (CDBR-2015B, -2015C, -2022B, -2022C, -4030B, -4045B), an

exclusive-use attachment is required. Contact your YASKAWA representative.

Fig. 9 Mounting Dimensions of Attachment in inches (mm)

0.39

(10)

0.28(7)

3.94 (100)

11.02 (280)

5.51 (140)

10.24 (260)

ATTACHMENT

5.45 (138.5)

0.39 (10)

0.98

(25)

5.91 (150)

4.13 (105)

4−M6 MTG HOLE

Code No.: DACT32732−AD

3.94 (100)

0.79

(20)

0.28(7)

0.79

(20)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 25

26

The main circuit terminal symbols are dif ferent between conventional models and

new models. Refer to the following table.

Table 1 Main Circuit Terminal Symbols

Conventional Models

Example: CDBR-2015

New Models

Example: CDBR-2015B,

-2015C

N

P

P

0

0

B

0

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 26

3 WIRING

27

3 WIRING

3.1 REMOVING AND REPLACING THE COVERS OF

THE BRAKING UNIT (MODELS CDBR-2015B,

-2015C, -2022B, -2022C,-4030B, -4045B)

(1) Romoving and Replacing the Terminal Cover

For removing, grasp the terminal cover at c on borh sides and then lift in

the direciton of d. For replacing, reverse the method.

(2) Removing and Replacing the lndicating Cover

Remove the terminal cover first. Push down on the lever in the direction of

c and lift the cover in the direction of d. For replacing, reverse the

method.

Terminal

Cover

Indicating Cover

Lever

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 27

28

3.2 SECTION NAMES

Figs. 10, 11 and 12 show appearance and each section name of braking unit and

braking resistor unit respectively.

Thermal overload relay protects th e braking resistor unit for models LKEB-20P7

to -27P5 and -40P7 to -4015. Thermal protector protects the braking resistor unit

for models LKEB-2011 to -2022 and -4018 to -4045.

Fig. 10 Braking Resistor Unit Model CDBR-2015B (Terminal Cover and Indicat-

ing Cover Removed)

Remove the label on the terminal block before using the braking

unit.

/1&'.%&$4$

8%.#55(14M9

$4#-+0)70+6

ߌ߇ޔᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ࠎߢޔߘߩᜰ␜

ޓߦᓥߞߡߊߛߐޕ

ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ㅢ㔚߮㔚Ḯㆤᢿᓟ㧡ಽએౝߪޔ㕙ࠞࡃࠍ㐿ߌߥߢ

ޓߊߛߐޕ

⏕ታߦធࠍⴕߞߡߊߛߐޕ

㧹㨍㨥ޓ㨏㨍㨡㨟㨑ޓ㨕㨚㨖㨡㨞㨥ޓ㨛㨞

㨑㨘㨑㨏㨠㨞㨕㨏ޓ㨟㨔㨛㨏㨗㧚

㧼㨘㨑㨍㨟㨑ޓ㨒㨛㨘㨘㨛㨣ޓ㨠㨔㨑ޓ㨕㨚㨟㨠㨞㨡㨏㨠㨕㨛㨚㨟ޓ㨕㨚ޓ㨠㨔㨑

ޓ㨙㨍㨚㨡㨍㨘ޓ㨎㨑㨒㨛㨞㨑ޓ㨕㨚㨟㨠㨍㨘㨘㨍㨠㨕㨛㨚ޓ㨛㨞ޓ㨛㨜㨑㨞㨍㨠㨕㨛㨚㧚

㧰㨕㨟㨏㨛㨚㨚㨑㨏㨠ޓ㨍㨘㨘ޓ㨜㨛㨣㨑㨞ޓ㨎㨑㨒㨛㨞㨑ޓ㨛㨜㨑㨚㨕㨚㨓

ޓ㨒㨞㨛㨚㨠ޓ㨏㨛㨢㨑㨞ޓ㨛㨒ޓ㨡㨚㨕㨠㧚

㨃㨍㨕㨠ޓ㧡ޓ㨙㨕㨚㨡㨠㨑㨟ޓ㨡㨚㨠㨕㨘ޓ㧰㧯ޓ㧮㨡㨟ޓ㨏㨍㨜㨍㨏㨕㨠㨛㨞㨟

ޓ㨐㨕㨟㨏㨔㨍㨞㨓㨑㧚

㨁㨟㨑ޓ㨜㨞㨛㨜㨑㨞ޓ㨓㨞㨛㨡㨚㨐㨕㨚㨓ޓ㨠㨑㨏㨔㨚㨕㨝㨡㨑㨟㧚

㧺㧼㧶㨀㧠㧞㧡㧜㧞㧙㧝㧙㧜

ෂ㒾ޓ㨃㧭㧾㧺㧵㧺㧳

Ἣἴߩ߅ߘࠇ߇ࠅ߹ߔޕ

േᛶ᛫ེߩࠨࡑ࡞࠻࠶ࡊធὐߢ㔚Ḯࠍ

ޓㆤᢿߔࠆࠪࠤࡦࠬࠍ⚵ࠎߢߊߛߐޕ

㧾㨕㨟㨗ޓ㨛㨒ޓ㨒㨕㨞㨑㧚

㨁㨟㨑ޓ㨟㨑㨝㨡㨑㨚㨏㨑㨞ޓ㨠㨛ޓ㨎㨞㨑㨍㨗ޓ㨜㨛㨣㨑㨞ޓ㨟㨡㨜㨜㨘㨥ޓ㨟㨕㨐㨑

ޓ㨛㨚ޓ㨛㨢㨑㨞㨘㨛㨍㨐ޓ㨞㨑㨘㨍㨥ޓ㨠㨞㨕㨜ޓ㨏㨛㨚㨠㨍㨏㨠ޓ㨛㨒ޓ

ޓ㨎㨞㨍㨗㨕㨚㨓ޓ㨞㨑㨟㨕㨟㨠㨛㨞㧚

/#56'4

5.#8'

㧠㧢㧜㨂

㧠㧜㧜㨂

㧠㧝㧡㨂

㧠㧠㧜㨂

㧟㧤㧜㨂

7UGq%EQRRGTYKTGUQPN[4GHGTVQOCPWCNHQTEQPPGEVKQPU

Charge Indicator

(Charge Lamp)

Master/Slave

Selection Connector

Operation Indicator

(Lights when Discharging.)

Control Circuit

Terminals 1 to 6

Control Circuit Terminals

0 0

Calibration Resistor

(Adjusted Prior to

Shipment)

Power Supply Selection

Connector

NOTENOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 28

3 WIRING

29

Fig. 11 Braking Resistor Unit Model LKEB-20P7 SPEC: B (Front Cover

Removed)

Note: 1. External terminals for SPEC: B models LKEB-

20P7 and 40P7 are located up to 20 mm further

inside the unit when compared to the same models

for SPEC: A.

2. External terminals for SPEC:B models LKEB21P5 to 27P5 and LKEB-41P5 to 47P5 are located

up to 15 mm higher on the unit when compared to

the same models for SPEC: A.

Thermal Overload Relay

(Automatically Reset)

Top Side

Bottom Side

Control Circuit Terminals

B㧘P㧘1㧘2

Lead Wire Outlet

(Rubber Bush)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 29

30

Resistor

Thermal

Overload

Protector

Control Circuit Terminals

B, P, 1, 2

Lead Wire Outlet

(Rubber Bush)

Fig. 12 Braking Resistor Unit Model LKEB−2022 (Front Cover Removed)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 30

3 WIRING

31

3.3 CIRCUITS AND WIRING SPECIFICATIONS

* 1. For wire size of 8-6(8-14), use UL Listed copper wires (rated at 75°C).

* 2. M4 for Models LKEB-20P7 to -27P5 or -40P7 to -4015.

M5 for Models LKEB-2011 to -2022 or -4018 to -4045.

* 3. Models-5037B, -5100B, and -5300B can reach an operating voltage of 1040 VDC.

Please select wire which is suitable for the operating voltage.

Table 2 Circu its and Wiring Specifications

Name Circuit

Termi-

nals

Wire

Size

AWG

(mm

2

)

Wire Type

Terminal

Screw

Max.

Torque

lb.in (N·m)

Braking Unit

(Models CDBR2015B, -2015C

-2022B, -2022C

-4030B, -4045B

-5037B)

Main

0

0

12-10

(3.5-5.5)

600V

(High

Voltage)

*3

vinyl

sheathed

wire or

equivalent

M4 13.3 (1.50)

Con-

trol

1 2 3

4 5 6

18-14

(0.75-2)

Braking Unit

(Model CDBR2045B, -4090B,

-5110B)

Main

0

0

10-8

(5.5-8)

M5 21.7 (2.45)

Con-

trol

1 2 3

4 5 6

18-14

(0.75-2)

M4 15.6 (1.76)

Braking Unit

(Model

CDBR-2110B,

-4220B, -5300B)

Main

0

0

4 (22)

8-6

(8-14)

*1

M6 43.4 (4.90)

Con-

trol

1 2 3

4 5 6

18-14

(0.75-2)

M4 15.6 (1.76)

Braking Resistor

Unit

(Model LKEB-)

Main B P

12-10

(3.5-5.5)

M4

(M5)

*2

15.6 (1.76)

(21.7(2.45))

Con-

trol

1 2

18-14

(0.75-2)

M4 15.6 (1.76)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 31

32

3.4 WIRING PRECAUTIONS

(1) Wiring Leading-in Method

Lead in the wire through the knockout hole on the unit bottom. Since the

knockout hole is provided with a rubber bush, cut the rubber bush central

crosswise with a blade and lead the wire through.

(2) Separation from Signal Lines

Since strong noise component is superimposed on the braking resistor unit

and braking unit wiring, separate the units from signal lines which are weak

against noise.

(3) Wiring Distance

• Wiring distance between the braking resistor unit and braking unit or

braking unit and inverter must be provided as shown in Fig. 13. Make

sure to bundle the wires between the units.

• When connecting two or more braking units in parallel, refer to 4.4,

“Parallel Connection of Braking Unit” for details.

Fig. 13 Wiring Distance

Braking Resistor

Unit

Braking Unit

Inverter

32.8ft

(10 m)

or less

16.4ft

(5 m)

or less

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 32

3 WIRING

33

(4) Grounding Method

• Mount the braking resistor unit on a grounded metallic plate. When it

cannot be mounted on a grounded metallic plate, pull out the lead

wire from the mounting screw section to ground.

• Braking unit grounding terminal must be provided with the ground

resistance of 100Ω or less in 200V class ,or 10Ω or less in 400V class.

• Use the sizes specified in “INTERNAL CONNECTION SPECIFICATIONS” for grounding cables.

3.5 INTERCONNECTION

Figs. 14 to 20 show the interconnecting diagrams of the braking unit or braking

resistor unit and VS-616G5.

Refer to Par. 3.3, “Wiring Precautions” for proper wiring in actual wiring design

and work.

Be sure to connect braking resistors or braking resistor units to the braking units.

Connect only braking resistors or Braking Resistor Units (LKEB-XXXX) to

Braking Units.

1. If using another braking resistor instead of YASKAWA braking

resistor unit, wiring sequence should shut off power to the drive

when a braking resistor Overload Relay Trip Contact (Thermal

Protector Contact) output is triggered.

2. Faulty wiring can result in fire. Make sure the interconnecting

diagrams are followed correctly.

NOTENOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 33

34

1

VS−616G5

R

MC

S

T

THRX

OFF

ON

MC

∗∗

SA

12

MC

TRX

TRX

20 18

2

B1 B2

SA

SA

THRX

U (T1)

V (T2)

W (T3)

IM

12

BP

MC

≈

≈

Motor

Overload Relay Trip Contact

Braking Resistor Unit #

#

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

3−Phase

200 to 230 V

50/60 Hzor380 to 460 V

50/60 Hz

L1 (R)

L2 (S)

L3 (T)

400/200 V

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

DC Reactor

(Option)

Short−circuit

Bar

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

The transformer is not necessary for 200V class.

Where is “E” or “V”.

When installing a DC reactor (option), remove the common bar between 1 and 2 terminals

(provided as standard) and connect a DC reactor with the terminals.

When using the braking resistor unit, set constant L3−04 to “0” (stall prevention selection during

decel is disabled). If it is not changed, the inverter may not stop within set decel time.

MCCB

Fig. 14 For Models CIMR-G5∗20P4 to -G5∗27P5 (200 V Class 0.55 to 7.5 kW),

Models CIMR-G5∗40P4 to -G5∗4015 (400 V Class 0.4 to 15 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 34

3 WIRING

35

U (T1)

V (T2)

W(T3)

MC

S

T

THRX

THRX

OFF

ON

MC

SA

1

2

MC

TRX

TRX

18

20

SA

SA

IM

123

P

0

0

1

2

3

4

VS−616G5

MC

≈

≈

Motor

Braking Resistor Unit

L1 (R)

L2 (S)

L3 (T)

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

MCCB

Overload Relay Trip Contact

DC Reactor

(Option)

Level

Detection

Braking Unit

R

B

3−Phase

200 to 230 V

50/60 Hz

Short−circuit

Bar

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

∗∗

Where is “E” or “V”.

When installing a DC reactor (option), remove the common bar between 1 and 2 terminals

(provided as standard) and connect a DC reactor with the terminals.

When using the braking resistor unit, set constant L3−04 to “0” (stall prevention selection during

decel is disabled). If it is not changed, the inverter may not stop within set decel time.

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

Fig. 15 For Models CIMR-G5∗2011 to -G5∗2015 (200 V Class 11, 15 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 35

36

R

MC

S

T

M

THRX OFF

ON

MC

SA

12

MC

TRX

TRX

20 18

SA

SA

THR

IM

123

P

1

2

34

VS−616G5

B

MC

≈

≈

0

0

Overload Relay Trip Contact

Level

Detection

Braking Unit

Motor

L1 (R)

L2 (S)

L3 (T)

MCCB

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

Braking Resistor

Unit (Option)

Short−circuit Bar

(Provided as

Standard)

Cooling Fan

(

2)

r (

1)

U (T1)

V (T2)

W (T3)

3−Phase

Power Supply

200 to 230 V

50/60 Hz

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

∗∗

Where is “E” or “V”.

When using the braking resistor unit, set constant L3−04 to “0” (stall prevention selection during

decel is disabled). If it is not changed, the inverter may not stop within set decel time.

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

Fig. 16 For Models CIMR-G5∗2018 to -G5∗2022 (200 V Class 18.5, 22 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 36

3 WIRING

37

R

MC

S

T

THRX

OFF

ON

MC

SA

12

MC

TRX

TRX

20 18

SA

SA

THRX

IM

VS−616G5

M

123

P

12

3

4

B

MC

≈

≈

0

0

Overload Relay Trip Contact

Level

Detection

Braking Unit

Braking Resistor

Unit (Option)

Motor

Cooling Fan

L1 (R)

L2 (S)

L3 (T)

Short−circuit Bar

(Provided as

Standard)

(

2

)

r (

1

)

MCCB

3−Phase

Power Supply

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

Voltage

Selection

460/440/415/

400/380V

400/200V

U (T1)

V(T2)

W(T3)

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

∗∗

Where is “E” or “V”.

When using the braking resistor unit, set constant L3−04 to “0” (stall prevention selection during

decel is disabled). If it is not changed, the inverter may not stop within set decel time.

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

Fig. 17 For Models CIMR-G5∗4018 to -G5∗4045 (400 V Class 18.5 to 45 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 37

38

R

MC

S

T

400/200V

M

VS−616G5

3

IM

THRX

OFF

ON

MC

SA

1

2

MC

TRX

TRX

20 18

SA

SA

THRX

MC

P

B

12

3

4

≈

≈

Overload Relay Trip Contact

(Thermal Protector Contact:

230VAC, 1A or less)

Level

Detection

Braking Unit

Braking Resistor

Unit (Option)

Cooling Fan

r (

1

)

Voltage

Selection

Motor

MCCB

Power Supply

380 to 460 V

50/60 Hz

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

400

( 2 400)

Cooling Fin Overheat Contact

(Thermoswitch Contact:

250VAC, 1A or less

30VDC, 1A or less)

U (T1)

V (T2)

W (T3)

L1 (R)

L2 (S)

L3 (T)

0

0

460/440/415/

400/380V

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

∗∗

Where is “E” or “V”.

When using the braking resistor unit, set constant L3−04 to

“0” (stall prevention selection during decel is disabled).

If it is not changed, the inverter may not stop within set decel time.

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

Fig. 18 For Models CIMR-G5∗4055 to -G5∗4160 (400 V Class 55 to 160 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 38

3 WIRING

39

R

MC

S

T

IM

M

3

VS−616G5

THRX

OFF

ON

MC

SA

12

MC

TRX

TRX

18

20

SA

SA

THRX

P

3

4

B

1

2

MC

≈

≈

U (T1)

V(T2)

W(T3)

Overload Relay Trip Contact

(Thermal Protector Contact:

230VAC, 1A or less)

Braking Resistor

Unit (Option)

Motor

Cooling Fin Overheat Contact

(Thermoswitch Contact:

250VAC, 1A or less

30VDC, 1A or less)

Level

Detection

Braking Unit

Cooling Fan

r(

1)

MCCB

L1 (R)

L2 (S)

L3 (T)

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

(

2

)

3−Phase

200 to 230 V

50/60 Hz

0

0

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

∗∗

Where is “E” or “V”.

When using the braking resistor unit, set constant L3−04 to

“0” (stall prevention selection during decel is disabled).

If it is not changed, the inverter may not stop within set decel time.

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

Fig. 19 For Models CIMR-G5∗2030 to -G5∗2075 (200 V Class 30 to 75 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 39

40

R

MC

S

T

400/200V

M

VS−616G5

3

IM

1

THRX

OFF

ON

MC

SA

1

2

MC

TRX

TRX

20

18

SA

SA

THRX

MC

P

34

B

12

≈

≈

U (T1)

V (T2)

W(T3)

Overload Relay Trip Contact

(Thermal Protector Contact:

230VAC, 1A or less)

Braking Resistor

Unit (Option)

Motor

Cooling Fin Overheat Contact

(Thermoswitch Contact:

250VAC, 1A or less

30VDC, 1A or less)

Level

Detection

Braking Unit

Cooling Fan

L1 (R)

L2 (S)

L3 (T)

r(

1)

MCCB

Voltage

Selection

400

( 2 400)

3−Phase

380 to 460 V

50/60 Hz

Overload Relay Trip Contact

of Braking Resistor Unit

Fault

Contact

0

0

460/440/415/

400/380V

Ground (200V Class : 100Ω or less

400V Class : 10Ω or less)

∗∗

Where is “E” or “V”.

When using the braking resistor unit, set constant L3−04 to

“0” (stall prevention selection during decel is disabled).

If it is not changed, the inverter may not stop within set decel time.

Use sequencer to break

power supply side on over-

load relay trip contact of

braking resistor unit.

Failure to observe this can

result in a fire.

Fig. 20 For Models CIMR-G5∗4185 to -G5∗4220 (400 V Class 185 to 220 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 40

41

4. OPERATION

4.1 ADJUSTMENT

The braking resistor unit and braking unit do not have to be adjusted.

Especially, do not readjust the braking unit except in the case described in Par. 4.2,

“Power Supply Voltage Selection Connector Setting.”

4.2 POWER SUPPLY VO LTAGE SELECTION CONNECTOR SETTING

It may be necessary to select power supply voltage selection connector for braking

unit according to main circuit power supply type. Table 3 shows the relationship

between the power supply voltage selection connector and braking start voltage.

The following is the setting prior to shipment:

S 200V class : 220V

S 400V class : 440V

S 575V class : 575V

For removing the terminal cover and the indicating cover, refer to Par. 3.1.

4.OPERATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 41

42

Fig. 21 Braking Unit Power Supply Voltage Selection

(Models CDBR-2015B, -2015C, -2022B, -2022C, -4030B, -4045B,

Terminal Cover and Indicating Cover Removed)

/1&'.%&$4$

8%.#55(14M9

$4#-+0)70+6

ߌ߇ޔᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ࠎߢޔߘߩᜰ␜

ޓߦᓥߞߡߊߛߐޕ

ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ㅢ㔚߮㔚Ḯㆤᢿᓟ㧡ಽએౝߪޔ㕙ࠞࡃࠍ㐿ߌߥߢ

ޓߊߛߐޕ

⏕ታߦធࠍⴕߞߡߊߛߐޕ

㧹㨍㨥ޓ㨏㨍㨡㨟㨑ޓ㨕㨚㨖㨡㨞㨥ޓ㨛㨞

㨑㨘㨑㨏㨠㨞㨕㨏ޓ㨟㨔㨛㨏㨗㧚

㧼㨘㨑㨍㨟㨑ޓ㨒㨛㨘㨘㨛㨣ޓ㨠㨔㨑ޓ㨕㨚㨟㨠㨞㨡㨏㨠㨕㨛㨚㨟ޓ㨕㨚ޓ㨠㨔㨑

ޓ㨙㨍㨚㨡㨍㨘ޓ㨎㨑㨒㨛㨞㨑ޓ㨕㨚㨟㨠㨍㨘㨘㨍㨠㨕㨛㨚ޓ㨛㨞ޓ㨛㨜㨑㨞㨍㨠㨕㨛㨚㧚

㧰㨕㨟㨏㨛㨚㨚㨑㨏㨠ޓ㨍㨘㨘ޓ㨜㨛㨣㨑㨞ޓ㨎㨑㨒㨛㨞㨑ޓ㨛㨜㨑㨚㨕㨚㨓

ޓ㨒㨞㨛㨚㨠ޓ㨏㨛㨢㨑㨞ޓ㨛㨒ޓ㨡㨚㨕㨠㧚

㨃㨍㨕㨠ޓ㧡ޓ㨙㨕㨚㨡㨠㨑㨟ޓ㨡㨚㨠㨕㨘ޓ㧰㧯ޓ㧮㨡㨟ޓ㨏㨍㨜㨍㨏㨕㨠㨛㨞㨟

㨐㨕㨟㨏㨔㨍㨞㨓㨑㧚

㨁㨟㨑ޓ㨜㨞㨛㨜㨑㨞ޓ㨓㨞㨛㨡㨚㨐㨕㨚㨓ޓ㨠㨑㨏㨔㨚㨕㨝㨡㨑㨟㧚

㧺㧼㧶㨀㧠㧞㧡㧜㧞㧙㧝㧙㧜

ෂ㒾ޓ㨃㧭㧾㧺㧵㧺㧳

Ἣἴߩ߅ߘࠇ߇ࠅ߹ߔޕ

േᛶ᛫ེߩࠨࡑ࡞࠻࠶ࡊធὐߢ㔚Ḯࠍ

ޓㆤᢿߔࠆࠪࠤࡦࠬࠍ⚵ࠎߢߊߛߐޕ

㧾㨕㨟㨗ޓ㨛㨒ޓ㨒㨕㨞㨑㧚

㨁㨟㨑ޓ㨟㨑㨝㨡㨑㨚㨏㨑㨞ޓ㨠㨛ޓ㨎㨞㨑㨍㨗ޓ㨜㨛㨣㨑㨞ޓ㨟㨡㨜㨜㨘㨥ޓ㨟㨕㨐㨑

ޓ㨛㨚ޓ㨛㨢㨑㨞㨘㨛㨍㨐ޓ㨞㨑㨘㨍㨥ޓ㨠㨞㨕㨜ޓ㨏㨛㨚㨠㨍㨏㨠ޓ㨛㨒ޓ

ޓ㨎㨞㨍㨗㨕㨚㨓ޓ㨞㨑㨟㨕㨟㨠㨛㨞㧚

7UGq%EQRRGTYKTGUQPN[4GHGTVQOCPWCNHQTEQPPGEVKQPU

200 V

208 V

220 V

230 V

400 V

415 V

440 V

460 V

380 V

200 V class

400 V class

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 42

4 OPERATION

43

Fig. 22 Braking Unit Power Supply Voltage Selection

(Models CDBR-2045B, -2110B, -4090B, -5037B, -5110B, -5300B,

Indicating Cover Removed)

* Allowable voltage fluctuation is ±10%

200 V

208 V

220 V

230 V

400 V

380 V

440 V

415 V

460 V

500 V

575 V

575 V

class

200 V

class

400 V

class

Table 3 Power Supply Voltage Selection Connector and Braking Start Voltage

200 V

Class*

Power

Supply

Voltage

Braking Start

Voltage

(PN Bus-bar

Voltage)

400 V

Class*

Power

Supply

Voltage

Braking St art

Voltage

(PN Bus-bar

Voltage)

575 V

Class*

Power

Supply

Voltage

Braking Start

Voltage

(PN Bus-bar

Voltage)

230 V 380 V (TYP) 460 V 760 V (TYP) 575 V 950 V (TYP)

220 V 365 V (TYP) 440 V 730 V (TYP) – –

208 V 345 V (TYP) 415 V 690 V (TYP) – –

200 V 330 V(TYP) 400 V 660 V (TYP) 500 V 825 V (TYP)

– – 380 V 630 V(TYP) – –

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 43

44

4.3 MASTER/SLAVE SELECTION CONNECTOR

SETTING

Selection Connector Setting MASTER side is selected prior to shipment. Use the

units without changing the setting.

SLAVE side is selected when more than one braking unit is combined to use and

braking start levels must coincide. Refer to Par. 4.4, “Parallel Connection of Braking Unit” for details.

4.4 PARALLEL CONNECTION OF BRAKING UNIT

For using more than one parallel-connected braking unit, connect and select the

connectors as follows. (See Fig. 23.)

• Braking units have a MASTER/SLAVE selection connector. (See

Fig. 10.) Select MASTER side only for braking unit 1 and select

SLAVE side for braking units 2 and 3.

• Properly connect the MASTER output to the SLAVE input. Refer

to Fig. 23 for details.

• Use properly rated wire in accordance with table 2 on page 31.

• Use twisted-pair wires of 1mm or less for connection between 5, 6

and 1, 2 of the braking units.

• Parallel connection of braking unit is possible up to a maximum o f

10 units.

Failure to use the wiring and connectors specified above can damage the braking resistor, braking resistor unit, and the drive itself.

NOTENOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 44

4 OPERATION

45

Fig. 23 Example of Parallel Connection of Three Braking Units

4.5 OPERATION

Check that required deceleration characteristics can be obtained. While the braking unit is operating, BRAKE lamp lights for easy check of operation.

Drive

(Inverter)

Braking Resistor

Overheat Contact

(Thermal Relay Trip Contact)

Braking Resistor

Overheat Contact

(Thermal Relay Trip Contact)

Braking Resistor

Overheat Contact

(Thermal Relay Trip Contact)

Braking

Resistor

Unit

Braking

Resistor

Unit

Braking

Resistor

Unit

Braking Unit 2

+15

5

1

2

6

SLAVE

MASTER

Level Detector

Cooling Fin Overheat Contact

(Thermoswitch Contact)

Master Unit

Cooling Fin Overheat Contact

(Thermoswitch Contact)

Slave Unit 1

Cooling Fin Overheat Contact

(Thermoswitch Contact)

Slave Unit 2

Braking Unit 3

Braking Unit 1

1

34

34 3

5

6

5

6

1

2

4

2

3

1

P

2

B

−

− 0+ 0+

−

+−+−+ 0− 0+ 0 − 0

BPBP

12 1 2

MASTER

SLAVE

MASTER

SLAVE

+

Twisted

pair

cable

Max. 1 m

Twisted

pair

cable

Max. 1 m

High voltage is applied to the braking unit. At normal operation,

do not operate the unit without cover.

NOTENOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 45

46

5 TROUBLESHOOTING

Only authorized personnel should be permitted to perform maintenance and

inspections or replace parts.

No. Fault Status Cause Corrective Action

1

Braking resistor

unit overload relay

(or thermal overload protector) trips

when not decelerating.

• Without braking unit

Inverter built-in main circuit discharging transistor short circuited

Replace the inverter.

• With braking unit

Braking unit main circuit discharging transistor short circuited

Replace the unit.

Improper braking unit power supply

voltage selection connector setting

(Power supply voltage > power supply voltage selection position)

Set it again.

2

Inverter trips at

overvoltage (ov).

Insufficient braking resistor unit

capacity

Examine the braking

conditions again.

Improper wiring Check and repair.

Braking unit fault Replace the unit.

3

Braking resistor

unit overload relay

(or thermal protector) sometimes

trips.

Insufficient braking resistor unit

capacity

Examine the braking

conditions again.

4

Braking unit trips

by heat sink overheat.

Excessive start/stop switching frequency

Examine the operat-

ing conditions again.

Excessive load inertia

Improper combination of braking

unit and braking resistor unit

Reset.

Ambient temperature 104°F (40°C) Reduce it.

Braking unit fault Replace the unit.

5

The fault contact of

a braking unit

instantaneously

turned ON when

the power was

turned ON.

Neither a braking resistor nor a

braking resistor unit is connected to

the braking unit.

Connect a braking

resistor or braking

resistor unit to the

braking unit.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 46

6 SPECIFICATIONS

47

6 SPECIFICATIONS

6.1 BRAKING UNIT AND BRAKING RESISTOR UNIT

APPLICATION LIST

The applicable braking unit and braking resistor unit models differ depending on

the inverter model. Refer to the catalog of the relevant inverter.

Note: The above table lists the applicable braking unit and braking resistor unit models for the 200-V

class inverter model CIMR-G5. For other inverter models, refer to the catalog of the relevant

inverter.

Example: 200-V Class Inverter Model CIMR-G5

Inverter Braking Unit Braking Resistor Unit Approx.

Braking

Torque

(10%ED)

%

Max. Applicable

Motor Capacity

HP(kW)

Model

(CDBR

-)

Unit

Q’ty

Model

(LKEB

-)

Resistor Spec.

(per unit)

Unit

Q’ty

0.5 (0.4) – – 20P7 70W 200Ω 1 220

1 (0.75) – – 20P7 70W 200Ω 1 125

2 (1.5) – – 21P5 260W 100Ω 1 125

3 (2.2) – – 22P2 260W 70Ω 1 120

5 (3.7) – – 23P7 390W 40Ω 1 125

7.5 (5.5) – – 25P5 520W 30Ω 1115

10 (7.5) – – 27P5 780W 20Ω 1 125

15 (11)

2015B,

2015C

1 2011 2400W 13.6Ω 1 125

20 (15)

2015B,

2015C

1 2015 3000W 10Ω 1 125

25 (18.5)

2022B,

2022C

1 2018 4800W 8Ω 1 125

30 (22)

2022B,

2022C

1 2022 4800W 6.8Ω 1 125

40 (30)

2015B,

2015C

2 2015 3000W 10Ω 2 125

50 (37)

2015B,

2015C

2 2015 3000W 10Ω 2 100

60 (45)

2022B,

2022C

2 2022 4800W 6.8Ω 2 120

75 (55)

2022B,

2022C

2 2022 4800W 6.8Ω 2 100

100 (75) 2110B 1 2022 4800W 6.8Ω 3110

120 (90) 2110B 1 2022 4800W 6.8Ω 4 120

150 (110) 2110B 1 2022 4800W 6.8Ω 5 100

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 47

48

Example: 400−V Class Inverter Model CIMR−G5

j

Inverter

Braking Unit Braking Resistor Unit

Approx.

Max Applicable

Motor Capacity

HP(kW)

Model

(CDBR

−j)

Unit

Q’ty

Model

(LKEB

−j)

Resistor Spec.

(per unit)

Unit

Q’ty

Braking

Torque

(10%ED)

%

0.5 (0.4)

− −

40P7

70W 750Ω

1 230

1 (0.75)

− −

40P7

70W 750Ω

1 130

2 (1.5)

− −

41P5

260W 400Ω

1 125

3 (2.2)

− −

42P2

260W 250Ω

1 135

5 (3.7)

− −

43P7

390W 150Ω

1 135

7.5 (5.5)

− −

45P5

520W 100Ω

1 135

10 (7.5)

− −

47P5

780W 75Ω

1 130

15 (11)

− −

4011

1040W 50Ω

1 135

20 (15)

− −

4015

1560W 40Ω

1 125

25 (18.5) 4030B 1 4018

4800W 32Ω

1 125

30 (22) 4030B 1 4022

4800W 27.2Ω

1 125

40 (30) 4030B 1 4030

6000W 20Ω

1 125

50 (37) 4045B 1 4037

9600W 16Ω

1 125

60 (45) 4045B 1 4045

9600W 13.6Ω

1 125

75 (55) 4030B 2 4030

6000W 20Ω

2 135

100 (75) 4045B 2 4045

9600W 13.6Ω

2 145

150 (110) 4030B 3 4030

6000W 20Ω

3 100

200 (160) 4220B 1 4045

9600W 13.6Ω

4 140

300 (220) 4220B 1 4037

9600W 16Ω

5 110

400 (300) 4220B 2 4045

9600W 13.6Ω

6 110

800 (600) 4220B 4 4045

9600W 13.6Ω

12 110

Note:

The abovetable lists the applicable braking unit andbraking resistor unit models for the 400−V class

inverter model CIMR−G5j. For other inverter models, refer to the catalog of the relevant inverter.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 48

6 SPECIFICATIONS

49

6.2 BRAKING UNIT FOR 575V CLASS APPLICA TION

LIST

Example: 575-V Class Inverter Model CIMR-G5

Note: The above table lists the applicable braking unit and braking resistor unit models for the 575-V

class inverter model CIMR-G5. For other inverter models, refer to the catalog of the relevant

inverter.

Inverter Braking Unit Braking Resistor Unit Approx.

Braking

Torque

(10%ED)

%

Max Applicable

Motor Capacity

HP(kW)

Model

(CDBR-)

Unit Q’ty Resistor Spec.

5 (3.7) – – 560W 150Ω 180

7.5 (5.5) – – 560W 150Ω 125

10 (7.5) – – 750W 100Ω 140

15 (11) – – 1100W 75Ω 125

20 (15) – – 1500W 50Ω 140

25 (18.5) – – 2300W 40Ω 140

30 (22) 5037B 1 2800W 38Ω 125

40 (30) 5037B 1 3900W 33Ω 110

50 (37) 5037B 1 4900W 27Ω 110

60 (45) 5037B 2 5900W 22Ω 110

75 (55) 5037B 2 7200W 18Ω 110

100 (75) 5110B 1 9800W 13.6Ω 105

120 (90) 5110B 1 12000W 11Ω 110

150 (110) 5110B 1 15000W 9Ω 110

200 (160) 5300B 1 21000W 6.8Ω 100

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 49

50

6.3 LIST OF APPLICABLE/NOT APPLICABLE COMBINA-

TIONS WITH CONVENTIONAL MODELS (VS−616HII/

H3, VS−616GII/G3, VS−676)

Conventional

Model

Braking

Unit

Braking Re-

sistor Unit

Applicable/

Not Appli-

cable

Remarks

VS−616HII/H3

VS−616GII/G3

VS−676

−

Model

LKEB−20P7

etc.

Applicable

See connection examples of Fig 14.

VS−616HII/H3

VS−616GII/G3

VS−676

Model

CDBR−15H

etc.

Model

LKEB−2015

etc.

Applicable

Use sequencer to break

power supply side on

thermal protector of

the braking resistor

unit side.

VS−616HII/H3

VS−616GII/G3

VS−676

Models

CDBR

−2015,

−2015B etc.

Model

LKEB−4.8K

etc.

Not applicable

No thermal protective

function of braking resistor unit.

VS−616HII/H3

VS−616GII/G3

VS−676

Models

CDBR

−2015,

−2015B etc.

Model

LKEB−2015

etc.

Applicable

See connection examples of Figs. 1 5 to 18.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 50

6 SPECIFICATIONS

51

6.4 BRAKING UNIT SPECIFICATIONS

* Loading time rate can be used below 10% ED (max. 10 sec.)

Braking Unit Model

CDBR-

200V to 300V 380V to 460V 500V to 575V

2015

B,

2015

C

2022

B,

2022

C

2045B2110B4030B4045B4090B4220B5037B5110B5300

B

Applicable Motor Output HP

(kW)

20

(15)

30

(22)

60

(45)

150

(110)

40

(30)

60

(45)

120

(90)

300

(220)

57

(37)

150

(110)

400

(300)

Output

charac-teristics

Max. Discharge

Current(A) (peak

value) *

40 60 100 250 40 60 100 250 40 100 250

Rated Discharge

Current (A)

15 20 30 80 15 18 30 80 15 30 80

Braking Start

Voltage

330/345/365/380V±3V 630/660/690/730/760V ±6V 825V/ 950V ±8V

Max. Hysteresis

Error

Approx. 8V Approx. 16V Approx. 20V

Power

Supply

VDC

243 (1.35

×200×0.9) to

400V peak

460 (1.35×380×0.9) to

800V peak

607 (1.35×500×0.9)

to 1000V

Protective

Functions

Fin Overheat

Thermostat

Power Charge

Indication

Charge lamp stays ON until bus voltage drops below 50V.

Envionmental

Conditions

Location

Indoor (protected from corrosive gases and dust)

Altitude

1000m max.

Ambient

Temperature

+14 to 104°F (-10 to +40°C) (not frozen)

Storage Transportation Temperature

-4 to 140°F (-20 to +60°C)

Humidity

90%RH (non-condensing)

Vibration

1G at 10 to less than 20Hz, up to 0.2G at 20 to 50 Hz

Protective Configuration

Wall-mounted enclosed type

Heat Loss (W)

32 38 31 64 54 59 35 71 22 53 116

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 51

52

6.5 BRAKING RESISTOR UNIT SPECIFICATIONS

Model

(LKEB

-)

Specifications

Allowable

Average

Dissipated

Power

(W)

Allowable

Average

Current

(Effective Value)

(A)

Allowable

Ambient

Temperature

20P7B

200

to

230V

70W 200Ω 30 0.39

+14 to 122°F

(-10 to +50°C)

21P5B 260W 100Ω 60 0.77

22P2B 260W 70Ω 89 1.1

23P7B 390W 40Ω 150 1.9

25P5B 520W 30Ω 220 2.7

27P5B 780W 20Ω 300 3.9

2011 2400W 13.6Ω 440 5.7

2015 3000W 10Ω 600 7.7

2018 4800W 8Ω 740 9.6

2022 4800 W 6.8Ω 880 11.4

40P7B

380

to

460V

70W 750Ω 30 0.20

41P5B 260W 400Ω 60 0.39

42P2B 260W 250Ω 89 0.60

43P7B 390W 150Ω 150 1.0

45P5B 520W 100Ω 220 1.5

47P5B 780W 75Ω 300 2.0

4011B 1040W 50Ω 440 3.0

4015B 1560W 40Ω 600 3.9

4018 4800W 32Ω 740 4.8

4022 4800W 27.2Ω 880 5.7

4030 6000W 20Ω 1200 7.7

4037 9600W 16Ω 1500 9.7

4045 9600W 13.6Ω 1800 11.5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 52

6 SPECIFICATIONS

53

6.6 MODELS AND CODE NOS. OF BRAKING UNIT

AND BRAKING RESISTOR UNIT

(1) Braking Unit

Inverter

Model Code No.

Voltage HP (kW)

200 to

230 V

20 (15)

CDBR-2015B 72600-R2150B

CDBR-2015C 72600-R2150C

30 (22)

CDBR-2022B 72600-R2220B

CDBR-2022C 72600-R2220C

60 (45)

CDBR-2045B 72600-R2450B

150 (110)

CDBR-2110B 72600-R21100B

380 to

460 V

40 (30)

CDBR-4030B 72600-R4300B

60 (45)

CDBR-4045B 72600-R4450B

120 (90)

CDBR-4090B 72600-R4900B

300 (220)

CDBR-4220B 72600-R42200B

500 to

575 V

50 (37)

CDBR-5037B 72600-R5370B

150 (110)

CDBR-5110B 72600-R51100B

400 (300)

CDBR.5300B 72600-R53000B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 53

54

(2) Braking Resistor Unit

Inverter

Resistor Spec.

(per unit)

Model Code No.

Voltage HP(kW)

200 to

230V

1 (0.75) 70W 200Ω

LKEB-20P7 72600-K2P70B

2 (1.5) 260W 100Ω

LKEB-21P5 72600-K2010B

3 (2.2) 260W 70Ω

LKEB-22P2 72600-K2020B

5 (3.7) 390W 40Ω

LKEB-23P7 72600-K2030B

7.5 (5.5) 520W 30Ω

LKEB-25P5 72600-K2050B

10 (7.5) 780W 20Ω

LKEB-27P5 72600-K2070B

15 (11) 2400W 13.6Ω

LKEB-2011 72600-K2110

20 (15) 3000W 10Ω

LKEB-2015 72600-K2150

25 (18.5) 4800W 8Ω

LKEB-2018 72600-K2180

30 (22) 4800W 6.8Ω

LKEB-2022 72600-K2220

380 to

460V

1 (0.75) 70W 750Ω

LKEB-40P7 72600-K4P70B

2 (1.5) 260W 400Ω

LKEB-41P5 72600-K4010B

3 (2.2) 260W 250Ω

LKEB-42P2 72600-K4020B

5 (3.7) 390W 150Ω

LKEB-43P7 72600-K4030B

7.5 (5.5) 520W 100Ω

LKEB-45P5 72600-K4050B

10 (7.5) 780W 75Ω

LKEB-47P5 72600-K4070B

15 (11) 1040W 50Ω

LKEB-4011 72600-K4110B

20 (15) 1560W 40Ω

LKEB-4015 72600-K4150B

25 (18.5) 4800W 32Ω

LKEB-4018 72600-K4180

30 (22) 4800W 27.2Ω

LKEB-4022 72600-K4220

40 (30) 6000W 20Ω

LKEB-4030 72600-K4300

50 (37) 9600W 16Ω

LKEB-4037 72600-K4370

60 (45) 9600W 13.6Ω

LKEB-4045 72600-K4450

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 54

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure

to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2005-2013 YASKAWA ELECTRIC CORPORATION. All rights reserved.

Published in Japan December 2013 05-3

MANUAL NO. TOBP C720600 00F

13-7-11

13

-0

YASKAWA ELECTRIC CORPORATION

Braking unit,

Braking resistor unit

YASKAWA AC Drive Option

Installation Manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...