Page 1

YASKAWA ELECTRIC ENGINEERING

Re-engineered AC SERVOPACK

USER'S MANUAL

CACR-SR□□BF SERVOPACK

YA S K A WA

YASKAWA ELECTRIC ENGINEERING CORPORATION

MANUAL NO. KG22E

Page 2

Copyright © 2004 YASKAWA ELECTRIC ENGINEERING CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa Electric Engineering. No patent

liability is assumed with respect to the use of the information contained herein. Moreover,

because Yaskawa Electric Engineering is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa Electric

Engineering assumes no responsibility for errors or omissions. Neither is any liability assumed

for damages resulting from the use of the information contained in this publication.

Page 3

About this manual

Description of Technical Terms

The terms in this manual are defined as follows:

• Re-engineered AC SERVOPACK:

The SERVOPACKs that have been developed to be used for replacement of the conventional

SERVOPACK models prior to Σ series.

• CACR-SRBF1:

The re-engineered AC SERVOPACK model designation. The code in differs depending on the

SERVOPACK capacity and specifications. Refer to 2.2 SERVOPACK Model Designations.

Quick access to your required information

Read the chapters marked with 9 to get the information required for your purpose.

SERVOPACKs,

Chapter

Chapter 1

Outline

Chapter 2

Specifications and

Dimensional

Drawings

Chapter 3

Wiring

Chapter 4

Settings and Display

Chapter 5

Maintenance,

Inspection, and

Alarm/Warning

Display

Servomotors,

and Peripheral

Devices

9

999

9999

Related Manuals

Refer to the following manuals as required.

Ratings and

Characteristics

Panel

Configuration

and Wiring

Trial Operation

9

Maintenance

and Inspection

9

Manual Name Manual Number Contents

Σ-III Series

SGMS/SGDS

Digital Operator

Operation Manual

Σ-III Series

SGMS/SGDS

User’s Manual

TOBPS80000001

SIEPS80000000

Provides detailed information on the operation of the

JUSP-OP05A Digital Operator.

Describes the following items of Σ-III Series

SERVOPACKs and Servomotors.

• Selection of model and capacity

• Ratings, characteristics, and dimensional drawings

• Cables and peripheral devices

• Panel configuration and wiring

• Trial operation, servo adjustment, and functions

• Inspection, maintenance, and troubleshooting

iii

Page 4

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions pro-

vided in this manual can result in serious or possibly even fatal injury or damage to the products or to related

equipment and systems.

WARNING

CAUTION

PROHIBITED

MANDATORY

Indicates precautions that, if not heeded, could possibly result in loss of life or serious

injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have series consequences if not

heeded.

Indicates prohibited actions that must not be performed. For example, this symbol

would be used to indicate that fire is prohibited as follows: .

Indicates compulsory actions that must be performed. For example, this symbol would

be used as follows to indicate that grounding is compulsory: .

The warning symbols for ISO and JIS standards are different, as shown below.

ISO JIS

The ISO symbol is used in this manual.

Both of these symbols appear on warning labels on Yaskawa Electric Engineering products. Please abide by

these warning labels regardless of which symbol is used.

iv

Page 5

Notes for Safe Operation

Read this manual thoroughly before checking products on delivery, storage and transportation, installation,

wiring, operation and inspection, and disposal of the AC servo drives.

WARNING

• Never touch any rotating motor parts while the motor is running.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make sure that an emergency stop can

be applied at any time.

Failure to observe this warning may result in injury.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

• Do not touch terminals for five minutes after voltage resistance test.

Residual voltage may cause electric shock.

• Follow the procedures and instructions for trial operation precisely as noted in this Manual.

• Follow the procedures and instructions for the trial operation as noted in the applicable man-

ual for that product.

Malfunctions that occur after the servomotor is connected to the equipment not only damage the

equipment, but may also cause an accident resulting in death or injury.

• Do not remove the front cover, cables, connectors, or optional items while the power is ON.

Failure to observe this warning may result in electric shock.

• Installation, disassembly, or repair must be performed only by authorized personnel.

Failure to observe this warning may result in electric shock or injury.

• Do not damage, press, exert excessive force or place heavy objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or

burning.

• Provide an appropriate stopping device on the machine side to ensure safety. A holding

brake for a servomotor with brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting momentary power loss to

avoid an unexpected restart. Take appropriate measures to ensure safety against an unex-

pected restart.

Failure to observe this warning may result in injury.

• Do not modify the product.

Failure to observe this warning may result in injury or damage to the product.

• Connect the ground terminal to electrical codes (ground resistance: 100 Ω or less).

Improper grounding may result in electric shock or fire.

v

Page 6

Checking on Delivery

CAUTION

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution so may result in fire or malfunction.

Storage and Transportation

CAUTION

• Do not store or install the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the storage/installation temperature conditions.

• Locations subject to humidity outside the range specified in the storage/installation humidity conditions.

• Locations subject to condensation as the result of extreme changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Failure to observe this caution may result in fire, electric shock, or damage to the product.

• Do not hold the product by the cables or motor shaft while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

Installation

• Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

Failure to observe this caution may result in electric shock or fire.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

• Do not cover the inlet or outlet ports and prevent any foreign objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and the control panel or with other

devices.

Failure to observe this caution may result in fire or malfunction.

• Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

CAUTION

vi

Page 7

Wiring

CAUTION

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminal screws and motor output terminal screws.

Failure to observe this caution may result in fire.

• Do not bundle or run power and signal lines together in the same duct. Keep power and signal

lines separated by at least 30 cm (11.81 in).

• Use twisted-pair shielded wires or multi-core twisted pair shielded wires for signal and encoder

(PG) feedback lines.

The maximum length is 3 m (118.11 in) for reference input lines and is 20 m (787.40 in) for PG feedback

lines.

• Do not touch the power terminals for 5 minutes after turning power OFF because high voltage may

still remain in the SERVOPACK.

Make sure the charge indicator is out first before starting an inspection.

• Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than once per

minute.

Since the SERVOPACK has a capacitor in the power supply, a high charging current flows for 0.2 seconds

when power is turned ON. Frequently turning power ON and OFF causes main power devices like capacitors

and fuses to deteriorate, resulting in unexpected problems.

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Always use the specified power supply voltage.

An incorrect voltage may result in burning.

• Take appropriate measures to ensure that the input power supply is supplied within the specified

voltage fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the product.

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each when installing systems in the following

locations.

Failure to observe this caution may result in damage to the product.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

• Do not reverse the polarity of the battery when connecting it.

Failure to observe this caution may damage the battery or cause it to explode.

vii

Page 8

Operation

CAUTION

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from machine to

avoid any unexpected accidents.

Failure to observe this caution may result in injury.

• Before starting operation with a machine connected, change the settings to match the parameters

of the machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

• Forward run prohibited (P-OT) and reverse run prohibited (N-OT) signals are not effective during

JOG mode operation using parameter Fn002 and zero point search mode using parameter Fn003.

• When using the servomotor for a vertical axis, install the safety devices to prevent workpieces to

fall off due to occurrence of alarm or overtravel. Set the servomotor so that it will stop in the zero

clamp state at occurrence of overtravel.

Failure to observe this caution may cause workpieces to fall off due to overtravel.

• When not using the normal autotuning, set to the correct moment of inertia ratio.

Setting to an incorrect moment of inertia ratio may cause vibration.

• Do not touch the SERVOPACK heatsinks, regenerative resistor, or servomotor while power is ON

or soon after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury due to unstable operation.

• When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume

operation.

Failure to observe this caution may result in injury.

• Do not use the servo brake of the servomotor for ordinary braking.

Failure to observe this caution may result in malfunction.

viii

Maintenance and Inspection

CAUTION

• When replacing the SERVOPACK, resume operation only after resetting the potentiometers, pins,

and parameters to their original settings.

Failure to observe this caution may result in damage to the product.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

• Do not disassemble the SERVOPACK.

Failure to observe this caution may result in electric shock or injury.

Page 9

Disposal

CAUTION

• When disposing of the products, treat them as ordinary industrial waste.

General Precautions

The following describes general precautions. Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards. Always

replace the cover or protective guard as specified first, and then operate the products in accordance with

the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

• This manual is subject to change due to product improvement, specification modification, and manual

improvement. When this manual is revised, the manual code is updated and the new manual is published

as a next edition. The edition number appears on the front and back covers.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa Electric Engineering

representative or one of the offices listed on the back of this manual.

• Yaskawa Electric Engineering will not take responsibility for the results of unauthorized modifications of

this product. Yaskawa Electric Engineering shall not be liable for any damages or troubles resulting from

unauthorized modification.

ix

Page 10

CONTENTS

About this manual- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

SAFETY INFORMATION- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iv

Notes for Safe Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

1 Outline

1.1 Outline- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2.1 Compatible with SERVOPACK Operating Environments Prior to Σ-Series - - - - - - - - - - - - - - -1-2

1.2.2 Updated with the Latest Technologies- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.2.3 Wide Range of Applicable Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.3 Applicable Servomotors and Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.4 SERVOPACK Part Names- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

2 Specifications and Dimensional Drawings

2.1 Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 SERVOPACK Model Designations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.3 Re-engineered AC SERVOPACK Selection - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.4 Dimensional Drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.4.1 Re-engineered AC SERVOPACKs for CACR-SR02B to SR44B - - - - - - - - - - - - - - - - - - -2-7

2.4.2 Re-engineered AC SERVOPACK Models for CACR-SR60BB, 60BZ, 60BE, and 60BY - - - - - -2-9

3 Wiring

3.1 Wiring for Re-engineered AC SERVOPACKs CACR-SRBF1 - - - - - - - 3-2

3.1.1 Connection Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-2

3.1.2 Names and Description of Main Circuit Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-2

3.1.3 Connector Receptacle Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-3

3.1.4 CN1 I/O Signal Connector Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-3

3.1.5 CN2 Optical Encoder (PG) Connector Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-5

3.2 I/O Signal Connector Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.2.1 Re-engineered SERVOPACKs for CACR-SRBE

(for Multiplexed Incremental Encoder) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-6

3.2.2 Re-engineered SERVOPACKs for CACR-SRBB

(for Conventional Incremental Encoder) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-8

3.2.3 Re-engineered SERVOPACKs for CACR-SRBY (for Absolute Encoder) - - - - - - - - - - - -3-10

3.2.4 Re-engineered SERVOPACKs for CACR-SRBZ (for Absolute Encoder)- - - - - - - - - - - - -3-12

x

Page 11

4 Settings and Display

4.1 Setting Switches- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.1 Setting Fixed Switches (User’s Modification Prohibited) - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.2 Switches To Be Set According to Application - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.3 Potentiometers VR and RH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.4 Alarm Reset Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.1.5 LED Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.1.6 Monitoring Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.1.7 Digital Operator Connector- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.2 Factory Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.2.1 Pin Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.2.2 List of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

5 Maintenance, Inspection and Alarm/Warning Display

5.1 Status Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 Alarm Display Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.3 Warning Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.4 Inspection and Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

5.4.1 Servomotor Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

5.4.2 SERVOPACK Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

5.4.3 SERVOPACK’s Parts Replacement Schedule - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

xi

Page 12

1

Outline

1.1 Outline - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2.1 Compatible with SERVOPACK Operating Environments Prior to Σ-Series - - - - - - - - - - 1-2

1.2.2 Updated with the Latest Technologies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2.3 Wide Range of Applicable Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.3 Applicable Servomotors and Encoders - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.4 SERVOPACK Part Names - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1

1-1

Page 13

1 Outline

1.2.1 Compatible with SERVOPACK Operating Environments Prior to Σ-Series

1.1 Outline

The re-engineered AC SERVOPACK model CACR-SRBF has been developed to be used for replacement of

the conventional SERVOPACK models that had been introduced before Σ-series, using the latest technologies in

its circuit configuration.

The re-engineered AC SERVOPACK supports all the types of encoders for AC servodrives: serial encoders and

encoders older than serial encoders

The re-engineered AC SERVOPACK provides the operating environment of the following conventional

SERVOPACK models.

CACR-SRBA

(Speed control/analog control, incremental encoder applicable, base-mounted type)

CACR-SRBB

(Speed control/analog control, incremental encoder applicable, base-mounted type)

CACR-SRBZ

(Speed control/analog control, absolute encoder applicable, base-mounted type)

CACR-SRBE

(Speed control/digital control, incremental encoder applicable, base-mounted type)

CACR-SRBY

(Speed control/digital control, absolute encoder applicable, base-mounted type)

1.2 Features

1.2.1 Compatible with SERVOPACK Operating Environments Prior to Σ-Series

Operating Environments:

• External dimensions/installation

(Some models require attachments.)

• Main circuit terminals

• Control connector and signal layout

• Recognizes the encoder type prior to Σ series by the switch setting

(An encoder signal converter is built in.)

• Important adjustments such as speed gain adjustment can be made

using the potentiometers VR.

(In the same way as of the conventional models CACR-SRBB and BZ)

1.2.2 Updated with the Latest Technologies

• The basic functions and performance are equivalent to those of Σ-III

series SERVOPACK

• The parameters of Σ-III series SERVOPACK are applied.

(Parameter setting using a digital operator.)

1.2.3 Wide Range of Applicable Servomotors

The re-engineered AC SERVOPACKs can be combined with various models of servomotors by setting the internal parameters: C series, M series, F series, G series, D series, S series, Σ-series, Σ-II series, and Σ-III series Servomotors.

1-2

Page 14

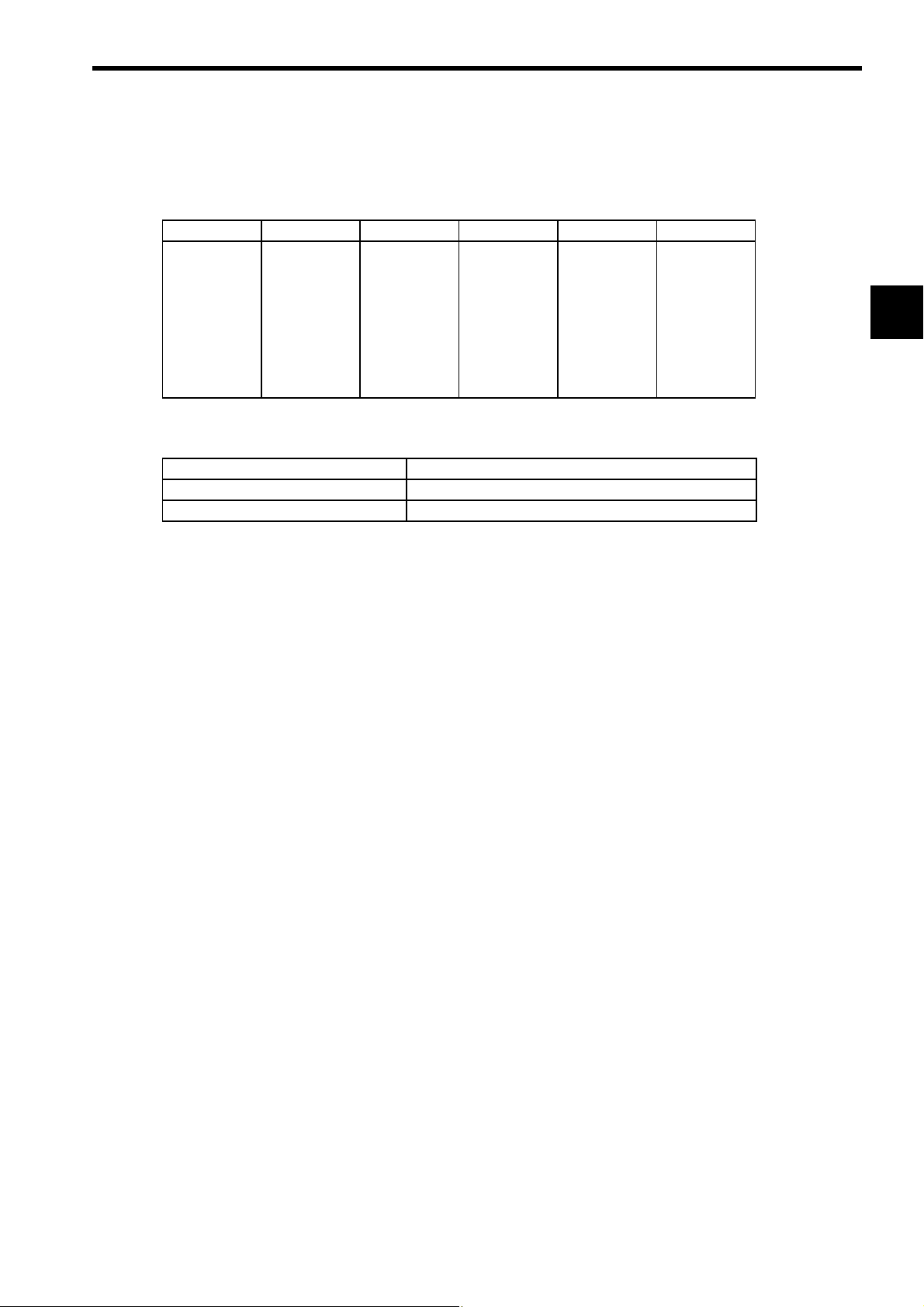

1.3 Applicable Servomotors and Encoders

The following servomotors besides Σ series, Σ-II series, Σ-III series are applicable.

Αpplicable Servomotor Models Prior to Σ Series

C Series M Series F Series G Series D Series S Series

USACED-03A

USACED-05A

USACED-12A

USACED-20A

USACED-30A

USACED-44A

USACED-60A

Applicable Encoders

Conventional Incremental Encoders 1000 p/r, 1500 p/r, 2500 p/r, 4000 p/r, 5000 p/r, 6000 p/r

Multiplexed Incremental Encoders 2048 p/r, 8192 p/r

Absolute Encoders 1024 p/r, 8192 p/r

USAMED-03

USAMED-06

USAMED-09

USAMED-12

USAMED-20

USAMED-30

USAMED-44

USAMED-60

USAFED-02

USAFED-03

USAFED-05

USAFED-09

USAFED-13

USAFED-20

USAFED-30

USAFED-44

USAGED-02A

USAGED-03A

USAGED-05A

USAGED-09A

USAGED-13A

USAGED-20A

USAGED-30A

USAGED-44A

1.3 Applicable Servomotors and Encoders

USADED-05E

USADED-10E

USADED-15E

USADED-22E

USADED-37E

USAGED-44A

USASEM-02A

USASEM-03A

USASEM-05A

USASEM-08A

USASEM-15A

USASEM-30A

1

1-3

Page 15

1 Outline

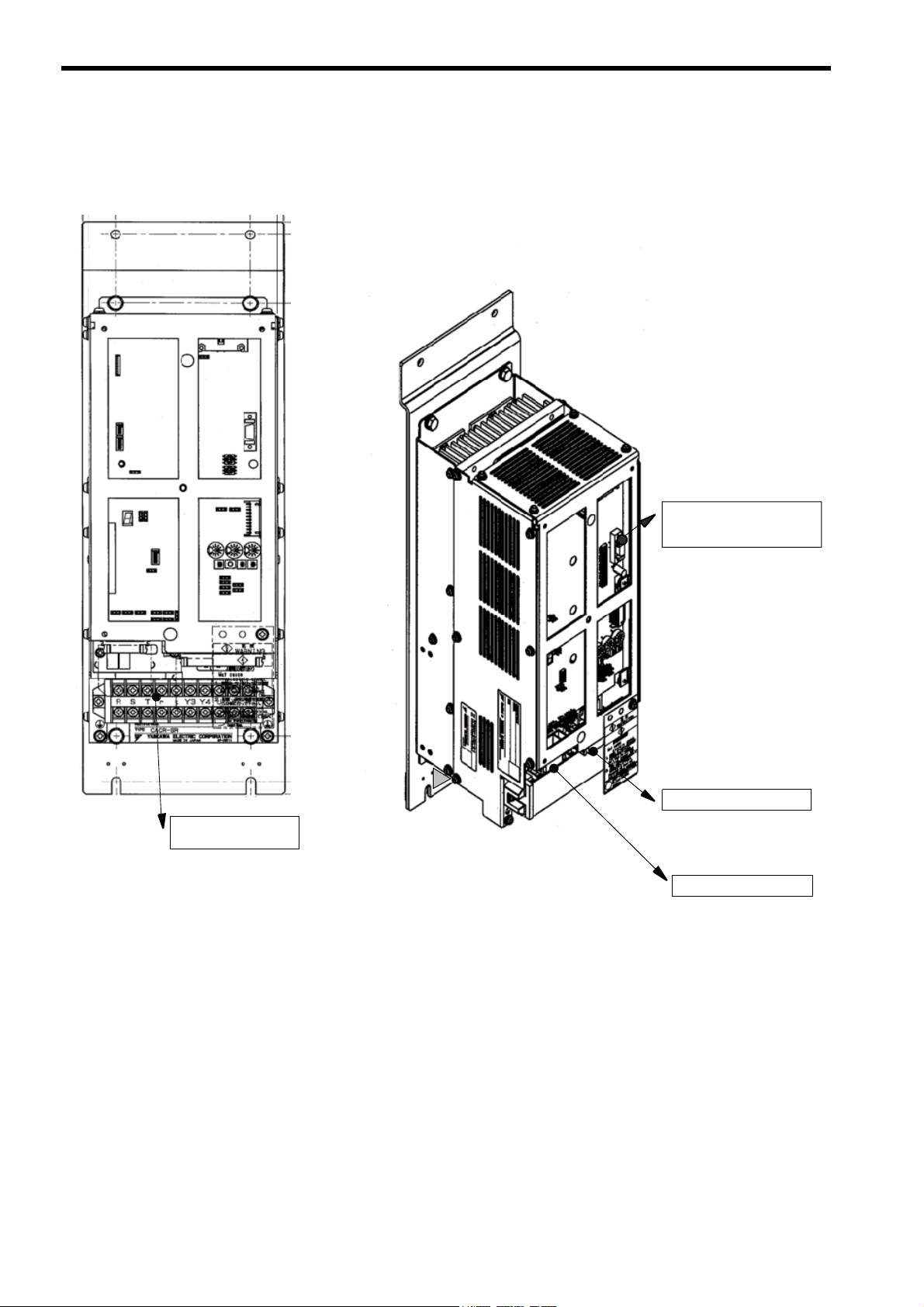

1.4 SERVOPACK Part Names

Control/main circuit

power supply terminal

CN3 Connector for personal

computer monitoring or

digital operator

CN1 I/O signal connector

CN2 Encoder connector

1-4

Page 16

2

Specifications and Dimensional Drawings

2.1 Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.2 SERVOPACK Model Designations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.3 Re-engineered AC SERVOPACK Selection - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.4 Dimensional Drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.4.1 Re-engineered AC SERVOPACKs for CACR-SR02B to SR44B - - - - - - - - - - - - - - 2-7

2.4.2 Re-engineered AC SERVOPACK Models for CACR-SR60BB, 60BZ, 60BE, and 60BY 2-9

2

2-1

Page 17

2 Specifications and Dimensional Drawings

2.1 Ratings and Specifications

Re-engineered SERVOPACK Model

CACR-

Max. Applicable Servomotor Capacity

[kW]

Input

Power

Supply

Continuous Output Current [Arms]

Max. Output Current [Arms]

Control Method Three-phase full-wave rectification IGBT-PWM (sine-wave driven)

Feedback

Operating

Conditions

Configuration Base-mounted

Approx. Mass 10 kg

Basic Specifications

Speed

Control

Torque Control (Repeatability) ±2 %

Acceleration Time Setting 0 to 10 s

Performance

Main Circuit Three-phase 200 to 230 VAC +10 to -15 %, 50/60 Hz

Control Circuit Single-phase 200 to 230 VAC +10 to -15 %, 50/60 Hz

Ambient

Temperature

Storage

Temperature

Ambient/

Storage

Humidity

Vibration/

Shock

Resistance

Speed Control Range 1:3000

Load Regulation 0 to 100 % load: 0.01 % max. (at rated speed)

Speed

Regulation

Frequency

Characteristics

Voltage

Regulation

Temperature

Regulation

SR03BF SR05BF SR07BF SR10BF SR15BF SR20BF SR30BF SR44BF SR60BF

0.3 0.5 0.7 1.0 1.5 2.0 3.0 4.4 6.0

3.0 4.2 5.8 7.6 11.7 19.0 26.0 33.0 45.0

8.5 11.0 13.9 17.0 28.0 42.0 56.6 70.0 80.6

Incremental encoder/Absolute encoder

(8192 p/r, 2048 p/r, 1024 p/r, 6000 p/r, 5000 p/r, 4000 p/r, 2500 p/r, 1500 p/r, 1000 p/r, etc.)

0 to 55 °C

-20 to 85 °C

90 % RH or less (with no condensation)

5 m/s2 / 20 m/s2 (0.5G/2G)

0 %

25±25 °C: 0.1% max. (at rated speed)

100 Hz

2-2

Page 18

2.1 Ratings and Specifications

Speed control

Rated Refer-

Speed/Torque

References

Auxiliary Inputs

Built-in Reference Power Supply ±12 VDC±5 %, ±30 mA

Position Output

(PG pulses)

Sequence Input Servo ON, P control, forward run prohibited, reverse run prohibited, and alarm reset

Sequence Output Servo alarm, servo ready, TG ON, current limit, and alarm code (3-bit output)

External Current Limits

I/O Signals

Dynamic Brake (DB) Operated at main power OFF, servo alarm, servo OFF.

Regenerative Processing Built-in

Allowable Load Moment of Inertia 5 times of rotor moment of inertia

Overtravel Prevention Operated at P-OT and N-OT

Protection

LED Display 7-segment LED (status and alarm display)

Monitor

Built-in Functions

ence Voltage

Input Impedance About 30 kΩ

Circuit Time

Constant

Rated Reference Voltage

Input Impedance About 30 kΩ

Circuit Time

Constant

Form Line-driver or open-collector (phase A, phase B, phase C)

Frequency

Dividing

Ratio

mode

Torque control

mode

About 70 µs

±2 V to ±10 VDC (forward rotation with positive reference) at rated speed.

About 70 µs

Any setting ratio

±0 V to ±9 VDC, forward rotation: -3 VDC/rated current, reverse rotation: 3 VDC/rated

current

Overcurrent, regeneration error, overvoltage, input overvoltage, overspeed, insufficient

voltage, overload, zero-point pulse error, A/D error, overrun detection, open-phase, and

CPU error

Speed monitor 1000 r/min

±6 VDC (forward rotation with positive reference) at rated speed

±3 VDC (forward rotation with positive reference) at rated torque

-1

and torque monitor 3V/rated torque

(cont’d)

2

2-3

Page 19

2 Specifications and Dimensional Drawings

2.2 SERVOPACK Model Designations

This section explains how to check the SERVOPACK model.

CACR-SRBF1-Y

SERVOPACK prior to the Σ series

SERVOPACK for speed control

Capacity.

Base-mounted re-engineered AC SERVOPACK

Input voltage: 200 V

Applicable encoder

Applicable servomotor

Conventional SERVOPACK model

Y-specification code (Customer-specified code)

(1) SERVOPACK Capacity and Applicable Servomotors (*1, *2)

∗1

∗3

∗2

∗4

*1 Capacity code

(2) Encoders (*3)

Type Pulse Code Type Pulse Code Type Pulse Code

1000 F

1440 H 8192 2 8192 S

1500 E 2500 4

Conventional

incremental

2000 K

2500 C

4000 D

5000 B

6000 A

*2 Applicable servomotor code

MFGSDC

02 − 0.15 0.15 0.15 −−

03 0.3 0.3 0.3 0.31 − 0.25

05 − 0.45 0.45 0.46 0.5 0.5

07 0.6 −−−−−

10 0.9 0.85 0.85 0.77 −−

15 1.2 1.3 1.3 1.54 1.0 1.2

20 2.0 1.8 1.8 − 1.5 1.8

30 3.0 2.9 2.9 3.08 2.2 2.9

44 4.4 4.4 4.4 − 3.7 4.4

60 6.0 −−−−6.0

2048 3

Multiplexed

Absolute

incremental

Unit: kW

1024 W

2-4

(3) Conventional SERVOPACKs (*4)

Model Code

CACR-SRBB B

CACR-SRBZ Z

CACR-SRBE E

CACR-SRBY Y

CACR-SRBA A

Page 20

2.3 Re-engineered AC SERVOPACK Selection

2.3 Re-engineered AC SERVOPACK Selection

Conventional SERVOPACK Model SRBB

Applicable

Servomotors

USAMED-03 CACR-SR03BB1MCACR-SR03BF1MB CACR-SR03BZ1M CACR-SR03BF1MZ

USAMED-06 CACR-SR07BB1MCACR-SR07BF1MB CACR-SR07BZ1M CACR-SR07BF1MZ

USAMED-09 CACR-SR10BB1MCACR-SR10BF1MB CACR-SR10BZ1M CACR-SR10BF1MZ

USAMED-12 CACR-SR15BB1MCACR-SR15BF1MB CACR-SR15BZ1M CACR-SR15BF1MZ

M

USAMED-20 CACR-SR20BB1MCACR-SR20BF1MB CACR-SR20BZ1M CACR-SR20BF1MZ

USAMED-30 CACR-SR30BB1MCACR-SR30BF1MB CACR-SR30BZ1M CACR-SR30BF1MZ

USAMED-44 CACR-SR44BB1MCACR-SR44BF1MB CACR-SR44BZ1M CACR-SR44BF1MZ

USAMED-60 CACR-SR60BB1MCACR-SR60BF1MB CACR-SR60BZ1M CACR-SR60BF1MZ

USAFED-02 CACR-SR03BB1F CACR-SR03BF1FB CACR-SR03BZ1F CACR-SR03BF1FZ

USAFED-03 CACR-SR03BB1F CACR-SR03BF1FB CACR-SR03BZ1F CACR-SR03BF1FZ

USAFED-05 CACR-SR05BB1F CACR-SR05BF1FB CACR-SR05BZ1F CACR-SR05BF1FZ

USAFED-09 CACR-SR10BB1F CACR-SR10BF1FB CACR-SR10BZ1F CACR-SR10BF1FZ

F

USAFED-13 CACR-SR15BB1F CACR-SR15BF1FB CACR-SR15BZ1F CACR-SR15BF1FZ

USAFED-20 CACR-SR20BB1F CACR-SR20BF1FB CACR-SR20BZ1F CACR-SR20BF1FZ

USAFED-30 CACR-SR30BB1F CACR-SR30BF1FB CACR-SR30BZ1F CACR-SR30BF1FZ

USAFED-44 CACR-SR44BB1F CACR-SR44BF1FB CACR-SR44BZ1F CACR-SR44BF1FZ

USAGED-02A

USAGED-03A

USAGED-05A

USAGED-09A

G

USAGED-13A

USAGED-20A

USAGED-30A

USAGED-44A

USADED-05E CACR-SR05BB1D CACR-SR05BF1DB CACR-SR05BZ1D CACR-SR05BF1DZ

USADED-10E CACR-SR10BB1D CACR-SR10BF1DB CACR-SR10BZ1D CACR-SR10BF1DZ

D

USADED-15E CACR-SR20BB1D CACR-SR20BF1DB CACR-SR20BZ1D CACR-SR20BF1DZ

USADED-22E CACR-SR30BB1D CACR-SR30BF1DB CACR-SR30BZ1D CACR-SR30BF1DZ

USADED-37E CACR-SR44BB1D CACR-SR44BF1DB CACR-SR44BZ1D CACR-SR44BF1DZ

USASEM-02A CACR-SR02BB1S CACR-SR02BF1SB CACR-SR02BZ1S CACR-SR02BF1SZ

USASEM-03A CACR-SR03BB1S CACR-SR03BF1SB CACR-SR03BZ1S CACR-SR03BF1SZ

USASEM-05A CACR-SR05BB1S CACR-SR05BF1SB CACR-SR05BZ1S CACR-SR05BF1SZ

S

USASEM-08A CACR-SR10BB1S CACR-SR10BF1SB CACR-SR10BZ1S CACR-SR10BF1SZ

USASEM-15A CACR-SR15BB1S CACR-SR15BF1SB CACR-SR15BZ1S CACR-SR15BF1SZ

USASEM-30A CACR-SR30BB1S CACR-SR30BF1SB CACR-SR30BZ1S CACR-SR30BF1SZ

and Re-engineered SERVOPACK Model

Conventional Model

SRBB

Re-engineered Model

SRBF

Conventional SERVOPACK Model SRBZ

and Re-engineered SERVOPACK Model

Conventional Model

SRBZ

Re-engineered Model

SRBF

2

2-5

Page 21

2 Specifications and Dimensional Drawings

Conventional SERVOPACK Model SRBE

Applicable

Servomotors

USAMED-03 CACR-SR03BE1M CACR-SR03BF1ME CACR-SR03BY1M CACR-SR03BF1MY

USAMED-06 CACR-SR07BE1M CACR-SR07BF1ME CACR-SR07BY1M CACR-SR07BF1MY

USAMED-09 CACR-SR10BE1M CACR-SR10BF1ME CACR-SR10BY1M CACR-SR10BF1MY

USAMED-12 CACR-SR15BE1M CACR-SR15BF1ME CACR-SR15BY1M CACR-SR15BF1MY

M

USAMED-20 CACR-SR20BE1M CACR-SR20BF1ME CACR-SR20BY1M CACR-SR20BF1MY

USAMED-30 CACR-SR30BE1M CACR-SR30BF1ME CACR-SR30BY1M CACR-SR30BF1MY

USAMED-44 CACR-SR44BE1M CACR-SR44BF1ME CACR-SR44BY1M CACR-SR44BF1MY

USAMED-60 CACR-SR60BE1M CACR-SR60BF1ME CACR-SR60BY1M CACR-SR60BF1MY

USAFED-02 CACR-SR03BE1F CACR-SR03BF1FE CACR-SR03BY1F CACR-SR03BF1FY

USAFED-03 CACR-SR03BE1F CACR-SR03BF1FE CACR-SR03BY1F CACR-SR03BF1FY

USAFED-05 CACR-SR05BE1F CACR-SR05BF1FE CACR-SR05BY1F CACR-SR05BF1FY

USAFED-09 CACR-SR10BE1F CACR-SR10BF1FE CACR-SR10BY1F CACR-SR10BF1FY

F

USAFED-13 CACR-SR15BE1F CACR-SR15BF1FE CACR-SR15BY1F CACR-SR15BF1FY

USAFED-20 CACR-SR20BE1F CACR-SR20BF1FE CACR-SR20BY1F CACR-SR20BF1FY

USAFED-30 CACR-SR30BE1F CACR-SR30BF1FE CACR-SR30BY1F CACR-SR30BF1FY

USAFED-44 CACR-SR44BE1F CACR-SR44BF1FE CACR-SR44BY1F CACR-SR44BF1FY

USAGED-02A CACR-SR02BE1GCACR-SR02BF1GE CACR-SR02BY1G CACR-SR02BF1GY

USAGED-03A CACR-SR03BE1GCACR-SR03BF1GE CACR-SR03BY1G CACR-SR03BF1GY

USAGED-05A CACR-SR05BE1GCACR-SR05BF1GE CACR-SR05BY1G CACR-SR05BF1GY

USAGED-09A CACR-SR10BE1GCACR-SR10BF1GE CACR-SR10BY1G CACR-SR10BF1GY

G

USAGED-13A CACR-SR15BE1GCACR-SR15BF1GE CACR-SR15BY1G CACR-SR15BF1GY

USAGED-20A CACR-SR20BE1GCACR-SR20BF1GE CACR-SR20BY1G CACR-SR20BF1GY

USAGED-30A CACR-SR30BE1GCACR-SR30BF1GE CACR-SR30BY1G CACR-SR30BF1GY

USAGED-44A CACR-SR44BE1GCACR-SR44BF1GE CACR-SR44BY1G CACR-SR44BF1GY

USADED-05E CACR-SR05BE1DCACR-SR05BF1DE CACR-SR05BY1D CACR-SR05BF1DY

USADED-10E CACR-SR10BE1DCACR-SR10BF1DE CACR-SR10BY1D CACR-SR10BF1DY

D

USADED-15E CACR-SR20BE1DCACR-SR20BF1DE CACR-SR20BY1D CACR-SR20BF1DY

USADED-22E CACR-SR30BE1DCACR-SR30BF1DE CACR-SR30BY1D CACR-SR30BF1DY

USADED-37E CACR-SR44BE1DCACR-SR44BF1DE CACR-SR44BY1D CACR-SR44BF1DY

USASEM-02A CACR-SR02BE1S CACR-SR02BF1SE CACR-SR02BY1S CACR-SR02BF1SY

USASEM-03A CACR-SR03BE1S CACR-SR03BF1SE CACR-SR03BY1S CACR-SR03BF1SY

USASEM-05A CACR-SR05BE1S CACR-SR05BF1SE CACR-SR05BY1S CACR-SR05BF1SY

S

USASEM-08A CACR-SR10BE1S CACR-SR10BF1SE CACR-SR10BY1S CACR-SR10BF1SY

USASEM-15A CACR-SR15BE1S CACR-SR15BF1SE CACR-SR15BY1S CACR-SR15BF1SY

USASEM-30A CACR-SR30BE1S CACR-SR30BF1SE CACR-SR30BY1S CACR-SR30BF1SY

and Re-engineered SERVOPACK Model

Conventional Model

Re-engineered Model

SR

BF

Conventional SERVOPACK Model

SRBYand Re-enginerred SERVOPACK

Model

Conventional Model

Re-engineered Model

SR

BF

2-6

Page 22

2.4 Dimensional Drawings

2.4 Dimensional Drawings

2.4.1 Re-engineered AC SERVOPACKs for CACR-SR02B to SR44B

(1) Re-engineered AC SERVOPACK Models for Conventional Models CACR-SRBB

and -SRBZ

Note: at the end of the model codes of the re-engineered AC SERVOPACK for CACR-SRBB is “B” , and

that for CACR-SRBZ is “Z” .

For Conventional M-series For Conventional F-series For Conventional D-series For Conventional S-series

Models for which no mounting attachment is required

CACR-SR03BF1M CACR-SR03BF1F CACR-SR05BF1D CACR-SR02BF1S

CACR-SR07BF1M CACR-SR05BF1F CACR-SR10BF1D CACR-SR03BF1S

CACR-SR10BF1M CACR-SR10BF1F CACR-SR05BF1S

CACR-SR15BF1M CACR-SR15BF1F CACR-SR10BF1S

CACR-SR15BF1S

CACR-SR30BF1S

Models for which the mounting attachment F352086-A is required

CACR-SR20BF1M CACR-SR20BF1F CACR-SR20BF1D CACR-SR30BF1S

CACR-SR30BF1M CACR-SR30BF1F CACR-SR30BF1D

CACR-SR44BF1M CACR-SR44BF1F CACR-SR44BF1D

2

2-7

Page 23

2 Specifications and Dimensional Drawings

2.4.1 Re-engineered AC SERVOPACKs for CACR-SR02B to SR44B

(2) Re-engineered AC SERVOPACK Models for Conventional Models CACR-SRBE

and -SRBY

Note: at the end of the model codes of the re-engineered AC SERVOPACK for CACR-SRBE is “E” , and

that for CACR-SRBY is “Y” .

For Conventional

M-series

For Conventional

F-series

For Convention

D-series

For Conventional

S-series

For Conventional

G-series

No mounting attachment is required for SERVOPACKs 4.4 kW or less.

CACR-SR03BF1M CACR-SR03BF1F CACR-SR05BF1D CACR-SR02BF1S CACR-SR02BF1G

CACR-SR07BF1M CACR-SR05BF1F CACR-SR10BF1D CACR-SR03BF1S CACR-SR03BF1G

CACR-SR10BF1M CACR-SR10BF1F CACR-SR20BF1D CACR-SR05BF1S CACR-SR05BF1G

CACR-SR15BF1M CACR-SR15BF1F CACR-SR30BF1D CACR-SR10BF1S CACR-SR10BF1G

CACR-SR20BF1M CACR-SR20BF1F CACR-SR44BF1D CACR-SR15BF1S CACR-SR15BF1G

CACR-SR30BF1M CACR-SR30BF1F CACR-SR30BF1S CACR-SR20BF1G

CACR-SR44BF1M CACR-SR44BF1F CACR-SR30BF1G

CACR-SR44BF1M CACR-SR44BF1F CACR-SR44BF1G

Attachment

product code:

F352086-A

2 × 7 dia. holes

Dimensions in mm

F352086-A includes:

y Attachment

y SERVOPACK mounting bolts

Mounting base

(included)

Attachment

product code:

F352086-A

4 × SERVOPACK mounting

screws M6 × 16 (included)

2-8

Page 24

2.4 Dimensional Drawings

2.4.2 Re-engineered AC SERVOPACK Models for CACR-SR60BB, 60BZ, 60BE, and 60BY

(1) Re-engineered AC SERVOPACK Models for CACR-SR60BB, 60BZ, 60BE, and 60BY

CACR-SR60BF1MB

CACR-SR60BF1MZ

CACR-SR60BF1ME

CACR-SR60BF1MY

Attachment

product code:

F352087-A

2

2 × 7 dia. holes

F352087-A includes:

y Attachment

y SERVOPACK mounting bolts

Mounting base (included)

Dimensions in mm

4 × SERVOPACK mounting

screws M6 × 16 (included)

Attachment

product code:

F352087-A

2-9

Page 25

3

Wiring

3.1 Wiring for Re-engineered AC SERVOPACKs CACR-SRBF1 - - - 3-2

3.1.1 Connection Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 Names and Description of Main Circuit Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.3 Connector Receptacle Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.1.4 CN1 I/O Signal Connector Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.1.5 CN2 Optical Encoder (PG) Connector Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - 3-5

3.2 I/O Signal Connector Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.2.1 Re-engineered SERVOPACKs for CACR-SRBE

(for Multiplexed Incremental Encoder) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.2.2 Re-engineered SERVOPACKs for CACR-SRBB

(for Conventional Incremental Encoder) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

3.2.3 Re-engineered SERVOPACKs for CACR-SRBY (for Absolute Encoder) - - - - - - - 3-10

3.2.4 Re-engineered SERVOPACKs for CACR-SRBZ (for Absolute Encoder) - - - - - - - 3-12

3

3-1

Page 26

3 Wiring

3.1.1 Connection Diagram

3.1 Wiring for Re-engineered AC SERVOPACKs

CACR-SRBF1

3.1.1 Connection Diagram

Re-engineered AC SERVOPACK

Regenerative

resistor

Main circuit power supply

Three-phase 200V/220V

50/60 Hz

Control circuit power supply

Single-phase 200V/220V

50/60Hz

Y3 Y4

R

S

T

r

t

Encoder signal

conversion function

built-in

U

V

W

AC Servomotor

A

B

C

M

D

I/O signals

y Speed reference

y PG signal

y Operation signal

Digital operator

JUSP-OP05A

CN1

CN3

CN2

3.1.2 Names and Description of Main Circuit Terminals

Terminal Symbol Name Description

(R) (S) (T)

(U) (V) (W)

(r) (t)

(Y3) (Y4)

Main circuit input

terminals

Servomotor

connection terminals

Control circuit input

terminals

Three-phase 200 to 230 VAC

Connect (U) to the terminal A, (V) to the terminal B, (W) to the terminal C of

Servomotor.

Single-phase 200 to 230 VAC

Ground terminal Connect to the power supply ground terminal and the Servomotor D terminal.

Regenerative resistor

terminals

Regenerative resistor connection terminals (normally not to be connected

externally.)

PG

Encoder

+10 to -15 %, 50/60 Hz

+10 to -15 %, 50/60 Hz

3-2

Page 27

3.1 Wiring for Re-engineered AC SERVOPACKs CACR-SRBF1

3.1.3 Connector Receptacle Specifications

CN1: For I/O signals

Applicable Receptacle Model

Inside

SERVOPACK

MR-50RMA MR-50F MRP-50F01 MR-50L

Soldered Type Caulking Type Case Manufacturer

CN2: For connecting the optical encoder (PG)

Applicable Receptacle Model

Inside

SERVOPACK

MR-20RMA MR-20F MRP-20F01 MR-20L

Soldered Type Caulking Type Case Manufacturer

CN3: For connecting the digital operator

Half-pitch Connector

Plug Shell Manufacturer

10114-3000VE 10314-52A0-008

SUMITOMO 3M

Limited

3.1.4 CN1 I/O Signal Connector Terminal Layout

Re-engineered AC

SERVOPACK

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Model

Model No. ended

with B (Model for

SRBB)

SG SG SG SG

SG SG SG SG

SG SG SG SG

PHA SEN PHA SEN

/V-CMP+ /V-CMP+ /V-CMP+ /V-CMP+

/V-CMP- /V-CMP- /V-CMP- /V-CMP-

+24V-IN +24V-IN +24V-IN +24V-IN

/S-ON /S-ON /S-ON /S-ON

TMON TMON TMON TMON

VTG VTG VTG VTG

SG SG SG SG

IN-A IN-A V-REF V-REF

SG SG SG SG

IN-B IN-B T-REF T-REF

SG SG SG SG

+12V +12V +12V +12V

SG SG SG SG

FG FG FG FG

PCO PCO PCO PCO

/PCO /PCO /PCO /PCO

PHC BAT+ PHC BAT+

/TGON+ /TGON+ /TGON+ /TGON+

/TGON- /TGON- /TGON- /TGON-

CACR-SRBF1

Model No. ended

with Z (Model for

SRBZ)

Model No. ended

with E (Model for

SRBE)

Honda

Communication

Industries Co., Ltd.

Honda

Communication

Industries

Model No. ended

with Y (Model for

Co., Ltd.

SRBY)

3

3-3

Page 28

3 Wiring

3.1.4 CN1 I/O Signal Connector Terminal Layout

Re-engineered AC

SERVOPACK

Model

Pin No.

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Model No. ended

with B (Model for

SRBB)

/P-CON /P-CON /P-CON /P-CON

OL- OL- AL01

N-OT N-OT N-OT N-OT

/S-RDY- /S-RDY- /S-RDY- /S-RDY-

/S-RDY+ /S-RDY+ /S-RDY+ /S-RDY+

N-CL N-CL N-CL N-CL

SG SG SG SG

-12V -12V -12V -12V

SG SG SG SG

PA O PAO PA O PAO

/PAO /PAO /PAO /PAO

PBO PBO PBO PBO

/PBO /PBO /PBO /PBO

PHB BAT- PHB BAT-

ALM+ ALM+ ALM+ ALM+

ALM- ALM- ALM- ALM-

OL+ OL+ AL02

P-OT P-OT P-OT P-OT

empty

empty

P-CL P-CL P-CL P-CL

SG SG SG SG

-12V -12V -12V -12V

SG SG SG SG

+12V +12V +12V +12V

SG SG SG SG

FG FG FG FG

* 1. The MCB trip signal output function is not provided for SRBB and SRBZ.

* 2. The PG signal output phase S is not provided for SRBY.

(cont’d)

CACR-SRBF1

Model No. ended

with Z (Model for

SRBZ)

*1

*1

empty

empty

*1

*1

Model No. ended

with E (Model for

SRBE)

Model No. ended

with Y (Model for

SRBY)

*2

empty

*2

empty

AL03 empty

/ALM-RST /ALM-RST

3-4

Page 29

3.1 Wiring for Re-engineered AC SERVOPACKs CACR-SRBF1

3.1.5 CN2 Optical Encoder (PG) Connector Terminal Layout

For Conventional

Pin No.

1 0 V 0 V 0 V

2 0 V 0 V 0 V

3 0 V 0 V 0 V

4 PG5 V PG5 V PG5 V

5 PG5 V PG5 V PG5 V

6 PG5 V PG5 V PG5 V

7 DIR DIR DIR

8 PU −

9 /PU −

10 PV Absolute RST Absolute RST

11 /PV −−

12 PW BAT BAT

13 / PW B AT 0 B AT 0

14 PC PC PC

15 /PC /PC /PC

16 PA PA PA

17 /PA /PA /PA

18 PB PB PB

19 /PB /PB /PB

20 FG FG FG

Incremental

Encoder

For Multiplexed

Type Incremental

Encoder

For Absolute

Encoder

*

−

*

−

3

* The phase S rotation amount serial data of 12-bit absolute PG is not processed.

3-5

Page 30

3 Wiring

3.2.1 Re-engineered SERVOPACKs for CACR-SRBE (for Multiplexed Incremental Encoder)

3.2 I/O Signal Connector Terminals

3.2.1 Re-engineered SERVOPACKs for CACR-SRBE

(for Multiplexed Incremental Encoder)

Example: CACR-SR20BF12FE that have replaced CACR-SR20BE12F

Torque monitor

F-series: 3.0 V±10 %/100 %

Speed monitor

F-series: 2.0 V±10 %/1000 min

Speed reference input

±6V/rated speed

Auxiliary speed reference input

±2 to ±10 V/rated speed

Reverse rotation current limit

-100 %±10 %/+3.0V input

Forward rotation current limit

+100 %±10 %/-3.0V input

Servo ON

24V

when 1RY is ON

P control when 2Ry is ON

(PI control when 2Ry is OFF)

Reverse run prohibited

when N-LS is open

Forward run prohibited

when P-LS is open

Alarm reset

when 9Ry is ON

3Ry turns ON when

current limit detected

4Ry turns ON when

TG turns ON.

5Ry turns OFF for a

servo alarm

6Ry turns ON when

servo ready

Phase A

Phase B

Phase C

PG signal

open collector output

Alarm code output

24V

0 V

0 V

0 V

1Ry

-1

2Ry

N-LS

P-LS

9Ry

3Ry

4Ry

5Ry

6Ry

PAO

/PAO

PBO

/PBO

PCO

/PCO

PHA

PHB

PHC

ALO1

ALO2

ALO3

+24Vin

S-ON

P-CON

N-OT

P-OT

ALM-RST

CLT+

CLT-

TGON+

TGON-

ALM+

ALM-

S-RDY+

S-RDY-

SERVOPACK

CN1

1-9

1-10

1-12

1-13

1-14

1-15

1-29

1-30

1-44

1-45

1-7

1-8

1-24

1-26

1-41

1-43

1-5

1-6

1-22

1-23

1-38

1-39

1-28

1-27

1-33

P

1-34

1-35

P

1-36

1-19

P

1-20

1-4

1-37

1-21

1-25

1-40

1-42

1-3

1-2

1-1

1-50

1-18

LPF

LPF

LPF

LPF

SG

5 mA

5 mA

5 mA

5 mA

5 mA

SG

CACR-SR20BF12FE

16-bit

D/A

16-bit

D/A

16-bit

D/A

Output

Max. voltage

Max. current

Output line driver

LS75ALS174

+12 V

SG

Output open

collector

LS07

-12 V

CPU

30 VDC

30 mA

1-16

1-48

1-17

1-32

1-47

1-49

1-11

1-31

1-46

3-6

Page 31

3.2 I/O Signal Connector Terminals

Optical encoder

PG

SERVOPACK

CACR-SR20BF12FE

CN2

A

B

C

D

E

F

K

Z

L

/Z

P

P

P

2-16

2-17

2-18

2-19

2-14

2-15

PA

/PA

PB

/PB

PC

/PC

3

H

G

2-4

2-1

2-5

PG5 V

PG0 V

2-2

2-6

2-3

2-7

J

2-20

DIR

1-50

3-7

Page 32

3 Wiring

3.2.2 Re-engineered SERVOPACKs for CACR-SRBB (for Conventional Incremental Encoder)

3.2.2 Re-engineered SERVOPACKs for CACR-SRBB

(for Conventional Incremental Encoder)

Example: CACR-SR20BF1AMB that have replaced CACR-SR20BB1AM

Torque monitor

M-series: 3.0 V±10 %/100 %

Speed monitor

M-series: 4.0 V±10 %/1000 min

Speed reference input

±6 V/rated speed

Auxiliary speed reference input

±2 to ±10 V/rated speed

Reverse rotation current limit

-100 %±10 %/+3.0 V input

Forward rotation current limit

+100 %±10 %/-3.0 V input

Servo ON

when 1Ry is ON

24V

P control when 2Ry is ON

(PI control when 2Ry is OFF)

Reverse run prohibited

when N-LS is open

Forward run prohibited

when P-LS is open

3Ry turns ON when

current limit detected

24V

4Ry turns ON

when TG turns ON

5Ry turns OFF for a

servo alarm

6Ry turns ON when

servo ready

1Ry

2Ry

N-LS

P-LS

3Ry

4Ry

5Ry

6Ry

-1

+24Vin

S-ON

P-CON

N-OT

P-OT

CLT+

CLT-

TGON+

TGON-

ALM+

ALM-

S-RDY+

S-RDY-

SERVOPACK

CN1

1-9

1-10

1-12

1-13

1-14

1-15

1-29

1-30

1-44

1-45

1-7

1-8

1-24

1-26

1-41

1-5

1-6

1-22

1-23

1-38

1-39

1-28

1-27

5 mA

5 mA

5 mA

5 mA

SG

CACR-SR20BF1AMB

limit

Current

Output

Max. voltage: 30 VDC

Max. current: 30 mA

3-8

8Ry

PAO

/PAO

PBO

/PBO

PCO

/PCO

PHA

PHB

PHC

OL

OL-

1-40

1-25

1-33

P

1-34

1-35

P

1-36

1-19

P

1-20

1-4

1-37

1-21

1-3

1-2

1-1

1-50

1-18

8Ry turns OFF for a

OL alarm

Phase A

Phase B

Phase C

PG signal

open collector output

0 V

0 V

0 V

Note: MCB trip (CN1-43 and -42) outputs are not provided.

SG

Output line driver

LS75ALS174

+12 V

SG

Output open

collector

LS07

-12 V

1-16

1-48

1-17

1-32

1-47

1-49

1-11

1-31

1-46

Page 33

3.2 I/O Signal Connector Terminals

PG

SERVOPACKOptical Encoder

A

B

C

D

E

F

K

L

M

N

P

R

H

G

P

P

P

P

P

P

CN2

2-16

2-17

2-18

2-19

2-14

2-15

2-8

2-9

2-10

2-11

2-12

2-13

2-4

2-1

PA

/PA

PB

/PB

PC

/PC

PU

/PU

PV

/PV

PW

/PW

CACR-SR20BF1AMB

3

PG5V

PG0V

2-5

2-2

2-6

2-3

2-7

J

2-20

DIR

1-50

3-9

Page 34

3 Wiring

3.2.3 Re-engineered SERVOPACKs for CACR-SRBY (for Absolute Encoder)

3.2.3 Re-engineered SERVOPACKs for CACR-SRBY (for Absolute Encoder)

Example: CACR-SR20BF1SFY that have replaced CACR-SR20BY1SF

SERVOPACK CACR-SR20BF1SFY

Torque monitor

F-series: 3.0 V±10 %/100 %

Speed monitor

F-series: 2.0 V±10 %/1000 min

Speed reference input

±6 V/rated speed

Auxiliary speed reference input

±2 to ±10 V/rated speed

Reverse rotation current limit

-100 %±10 %/+3.0 V input

Forward rotation current limit

+100 %±10 %/-3.0 V input

Servo ON

24 V

when 1Ry is ON

P control when 2Ry is ON

(PI control when 2Ry is OFF)

Reverse run prohibited

when N-LS is open

Forward run prohibited

when P-LS is open

Alarm reset

when 9Ry is ON

3Ry turns ON when

current limit detected

4Ry turns ON when

TG turns ON

5Ry turns OFF for a

servo alarm

6Ry turns ON when

servo ready

Phase A

Phase B

Phase C

Battery

2.8 to 4.5 V

24 V

SEN

0SEN

0V

0V

-1

+24Vin

1Ry

+

2Ry

N-LS

P-LS

9Ry

3Ry

4Ry

5Ry

6Ry

/PAO

PBO

/PBO

PCO

/PCO

BAT

BAT0

S-ON

P-CON

N-OT

P-OT

ALM-RST

CLT+

CLT-

TGON+

TGON-

ALM+

ALM-

S-RDY+

S-RDY-

PAO

CN1

1-9

1-10

1-12

1-13

1-14

1-15

1-29

1-30

1-44

1-45

1-7

1-8

1-24

1-26

1-41

1-43

1-5

1-6

1-22

1-23

1-38

1-39

1-28

1-27

1-33

P

1-34

1-35

P

1-36

1-19

P

1-20

1-2

LPF

LPF

LPF

LPF

SG

5 mA

5 mA

5 mA

5 mA

5 mA

1-4

1-3

1-1

1-21

1-37

16-bit

D/A

16-bit

D/A

16-bit

D/A

Output

Max. voltage: 30 VDC

Max. current: 30 mA

Output line driver

LS75ALS174

+12 V

SG

-12 V

CPU

1-16

1-48

1-17

1-32

1-47

1-49

1-11

1-31

1-46

3-10

1-50

1-18

FG

Page 35

3.2 I/O Signal Connector Terminals

Optical encoder

15-bit absolute encoder

A

B

C

D

E

F

PG

H

G

R

T

S

J

SERVOPACK CACR-SR20BF1SFY

CN2

PA

P

P

P

P

2-16

2-17

2-18

2-19

2-14

2-15

2-4

2-1

2-5

2-2

2-6

2-3

2-10

2-12

2-13

2-20

/PA

PB

/PB

PC

/PC

PG5 V

PG0 V

1-21

1-37

1-50

3

BAT

BAT0

Optical encoder

12-bit absolute encoder

A

B

C

D

E

F

K

PG

L

H

G

R

T

S

J

PS

/PS

Note

SERVOPACK CACR-SR20BF1WFY

CN2

PA

P

P

P

P

2-16

2-17

2-18

2-19

2-14

2-15

2-4

2-1

2-5

2-2

2-6

2-3

2-10

2-12

2-13

2-20

/PA

PB

/PB

PC

/PC

PG5 V

PG0 V

1-21

1-37

1-50

BAT

BAT0

Note: Cut the rotation amount data signal line on the Servomotor encoder cable side.

3-11

Page 36

3 Wiring

3.2.4 Re-engineered SERVOPACKs for CACR-SRBZ (for Absolute Encoder)

3.2.4 Re-engineered SERVOPACKs for CACR-SRBZ (for Absolute Encoder)

Example: CACR-SR20BF1SMZ that have replaced CACR-SR20BZ1SM

Torque monitor

M-series: 3.0 V±10 %/100 %

Speed monitor

M-series: 4.0 V±10 %/1000 min

-1

SERVOPACK CACR-SR20BF1SMZ

CN1

1-9

1-10

Speed reference input

±6 V/rated speed

Auxiliary speed reference input

±2 to ±10 V/rated speed

Reverse rotation current limit

-100 %±10 %/+3.0 V input

Forward rotation current limit

+100 %±10 %/-3.0 V input

Servo ON

24 V

when 1Ry is ON

P control when 2Ry is ON

(PI control when 2Ry is OFF)

Reverse run prohibited

when N-LS is open

Forward run prohibited

when P-LS is open

3Ry turns ON when

current limit detected

24 V

4Ry turns on when

TG turns ON

5Ry turns OFF for a

servo alarm

6Ry turns ON when

servo ready

1Ry

2Ry

N-LS

P-LS

3Ry

4Ry

5Ry

6Ry

+24Vin

S-ON

P-CON

N-OT

P-OT

CLT+

CLT-

TGON+

TGON-

ALM+

ALM-

S-RDY+

S-RDY-

1-12

1-13

1-14

1-15

1-29

1-30

1-44

1-45

1-7

1-8

1-24

1-26

1-41

1-5

1-6

1-22

1-23

1-38

1-39

1-28

1-27

SG

5 mA

5 mA

5 mA

5mA

limit

Current

Output

Max. voltage: 30 VDC

Max. current: 30 mA

8Ry

PAO

/PAO

PBO

/PBO

PCO

/PCO

BAT

BAT0

OL

OL-

1-40

1-25

1-33

P

1-34

1-35

P

1-36

1-19

P

1-20

1-4

1-3

1-2

1-1

1-21

1-37

1-50

1-18

8Ry turns OFF for a

OL alafm

Battery

2.8 to 4.5 V

Phase A

Phase B

Phase C

SEN

0SEN

0 V

0 V

+

Note: MCB trip (CN1-43 and -42) outputs are not provided.

SG

Output line driver

LS75ALS174

+12 V

SG

-12 V

1-16

1-48

1-17

1-32

1-47

1-49

1-11

1-31

1-46

3-12

Page 37

3.2 I/O Signal Connector Terminals

Optical encoder

15-bit absolute encoder

PG

SERVOPACK

CACR-SR20BF1SMZ

CN2

A

B

C

D

E

F

H

G

P

P

P

2-16

2-17

2-18

2-19

2-14

2-15

2-4

2-1

2-5

2-2

2-6

/PA

PB

/PB

PC

/PC

PA

PG5 V

PG0 V

3

2-3

R

T

S

J

P

2-10

2-12

2-13

2-20

1-21

1-37

1-50

BAT

BAT0

3-13

Page 38

4

Settings and Display

4.1 Setting Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.1 Setting Fixed Switches (User’s Modification Prohibited) - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.2 Switches To Be Set According to Application - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.3 Potentiometers VR and RH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.4 Alarm Reset Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.1.5 LED Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.1.6 Monitoring Pins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.1.7 Digital Operator Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.2 Factory Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-5

4.2.1 Pin Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.2.2 List of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

4

4-1

Page 39

4 Settings and Display

4.1 Setting Switches

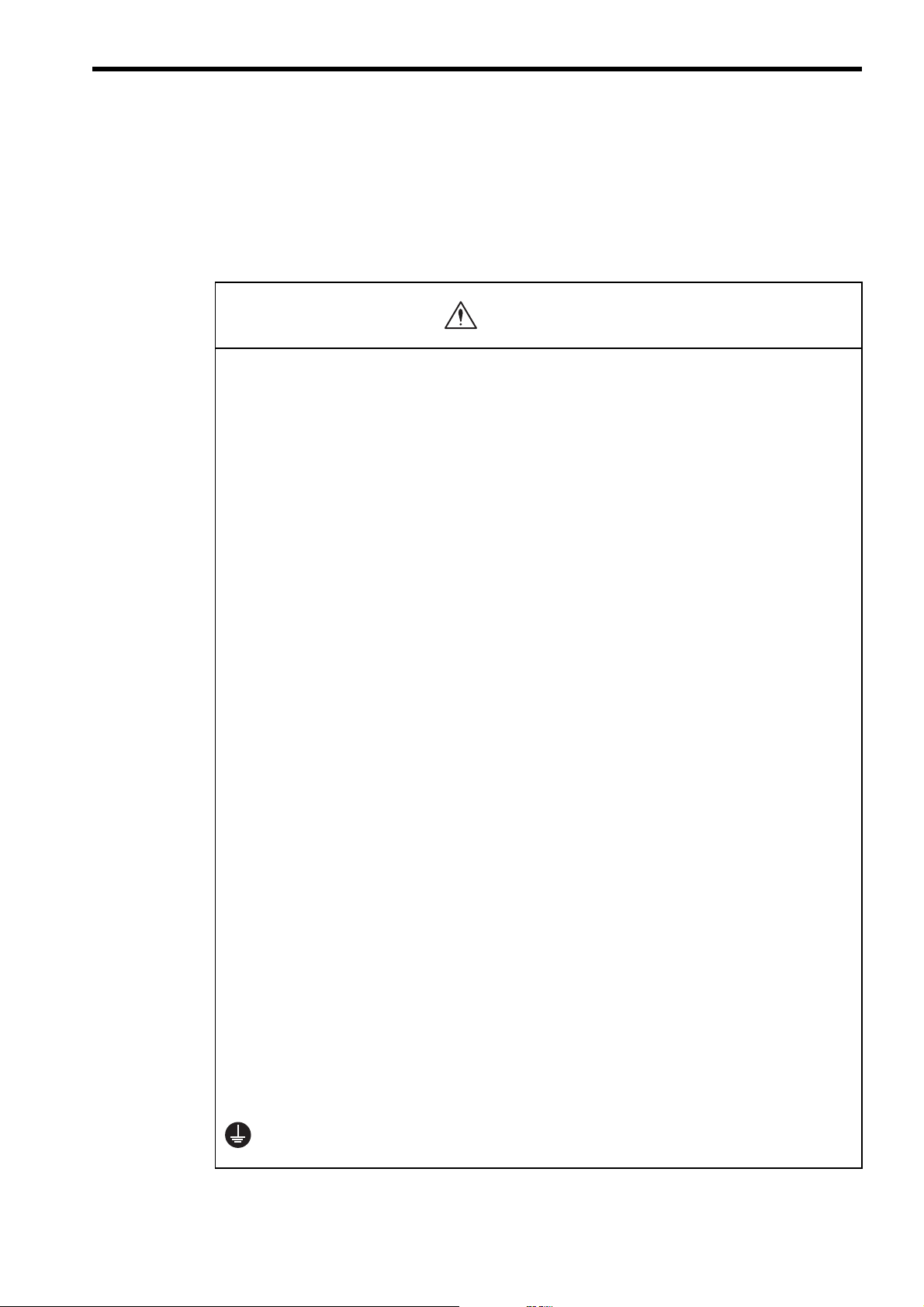

The setting switches are provided on the board inside the re-engineered AC SERVOPACK CACR-SRBF to

ensure the operating environment of the corresponding conventional model.

There are two types of switches: The switches that have been set and fixed according to the corresponding con-

ventional model before shipment, and the switches that need to be set by users according to the application.

CN503

CN17

31

SL5

LED lamp

(1

(CHARGE)

DS1

CN12

CN22 CN23

S2

SW2

CN24

31

3

3

CN13

CN14

1

1

SW3

31

SL7

CN21 CN11 CN10

331131

CN2

3131

3131

CN4 CN16

TMON

VTG

GND

LED lamp (2

RUN ALARM

31

CN20

LED lamp (3

CN15

1

DSW1 DSW5

CN26

331

ZERO LOOP IN-B

PG5V RESET VR5 FINE

CN18

CN7

CN5

31

31

31

31

CUR

CN6

CN1

CN3

CN19

CN8

CN9

4-2

Page 40

4.1.1 Setting Fixed Switches (User’s Modification Prohibited)

The switches listed in the table below have been set to the appropriate values before shipment.

Do not change the settings of these switches. Doing so will cause motor runaway or SERVOPACK failure.

Switch No. Name Remarks

CN4 Model depended function selection switch

CN5 Model depended function selection switch

CN6 Model depended function selection switch

CN7 Model depended function selection switch

CN8 Model depended function selection switch Not mounted

CN9 Model depended function selection switch Not mounted

CN10 Model depended function selection switch

CN11 Model depended function selection switch

CN13 Model depended function selection switch

CN14 Model depended function selection switch

CN15 Model depended function selection switch

CN16 Model depended function selection switch

CN18 Model depended function selection switch

CN20 Model depended function selection switch

CN21 Model depended function selection switch

CN22 Model depended function selection switch

CN23 Model depended function selection switch

CN24 Model depended function selection switch

CN26 Model depended function selection switch

S2 Model depended function selection switch

SL5 Speed feedback gain switching

SW3-7 Speed feedback gain switching

CN503 PC connection connector Connector for personal computer cable

4.1 Setting Switches

4

4.1.2 Switches To Be Set According to Application

The switches listed in the table below need to be set by users according to the application.

Switch No. Name Remarks

SL7 Torque filter switching

SW2 Frequency dividing ratio setting

SW3 Setting for CACR-SRBB/BZ

DSW1 Encoder setting

DSW5 Encoder setting

4.1.3 Potentiometers VR and RH

Set the following potentiometers to the same scale positions as those of your conventional SERVOPACK to

obtain the same performance as before replacement.

VR1 IN-B IN-B input gain

VR6 LOOP Speed loop gain

VR3 ZERO Speed amplifier zero adjustment

VR4 FINE IN-B fine adjustment

VR5 CUR Starting current adjustment

RH2 PG5V PG voltage adjustment

4-3

Page 41

4 Settings and Display

4.1.4 Alarm Reset Button

4.1.4 Alarm Reset Button

When a SERVOPACK alarm occurs, eliminate the cause and then press the RESET Button to reset the servo

alarm.

If the cause has not been eliminated, the alarm will occur again.

RESET Alarm reset button

4.1.5 LED Display

There are four LEDs on the board as follows.

DS1 7-Segment LED SERVOPACK status and alarm display

LED lamp (1) Main circuit CHARGE LED Main circuit with high-voltage

LED lamp (2) Encoder conversion function Lit in yellow during normal operation

LED lamp (3) Encoder conversion alarm Lit in red at alarm occurrence

4.1.6 Monitoring Pins

The monitoring pins listed in the table below are provided for monitor signals.

The levels are the same as the conventional models.

TMON For torque monitor

VTG For speed monitor

GND GND for monitor signal line

4.1.7 Digital Operator Connector

When using the re-engineered SERVOPACK as the replacement of the conventional model CACR-SRBE or

CACR-SRBY, the connector CN3 is used to connect the digital operator JUSP-OP05A.

CN3

Connector for Σ-III series

digital operator

Cable connector

4-4

Page 42

4.2 Factory Settings

4.2.1 Pin Settings

4.2 Factory Settings

Switch

No.

CN4 Short-circuited Pins 1-2 2-3 1-2 open

CN5 Short-circuited Pins 1-2 1-2 2-3 2-3

CN6 Short-circuited Pins 1-2 1-2 2-3 2-3

CN7 Short-circuited Pins 1-2 1-2 2-3 2-3

CN8 Short-circuited Pins

CN9 Short-circuited Pins

CN10 Short-circuited Pins 1-2 2-3 1-2 2-3

CN11 Short-circuited Pins 1-2 2-3 1-2 2-3

CN13 Short-circuited Pins 1-2 1-2 1-2 1-2

CN14 Short-circuited Pins 1-2 1-2 1-2 1-2

CN15 Short-circuited Pins

CN16 Short-circuited Pins 1-2 2-3 1-2 open

CN18 Short-circuited Pins 1-2 1-2 1-2 1-2

CN20 Short-circuited Pins 1-2 2-3 1-2 2-3

CN21 Short-circuited Pins 1-2 1-2 2-3 2-3

CN22 Short-circuited Pins 1-2 1-2 2-3 2-3

CN23 Short-circuited Pins 1-2 1-2 2-3 2-3

CN24 Short-circuited Pins 1-2 2-3 1-2 1-2

CN26 Short-circuited Pins

Setting

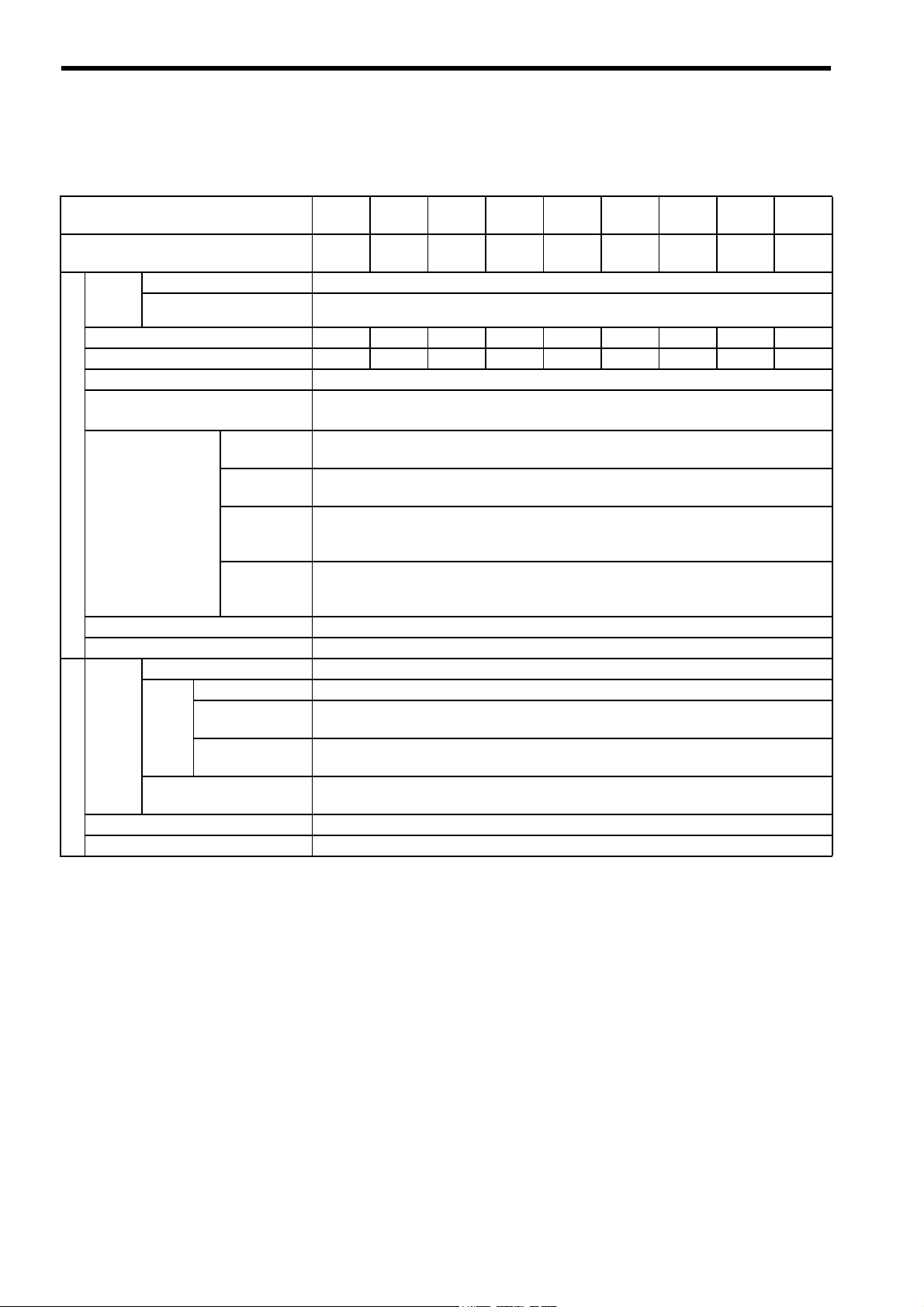

Applicable Conventional SERVOPACK Model

SRBA

SRBB

Set to the defaults at factory depending on re-engineered

Set to the defaults at factory depending on re-engineered

SRBE SRBZ SRBY

Not mounted

AC SERVOPACK model

AC SERVOPACK model

Remarks

See Table 4.1

4

See Table 4.1

S2 6-digit ON/OFF

SL5 Short-circuited Pins

SL7 Short-circuited Pins

SW2 8-digit ON/OFF See Table 4.6

SW3 8-digit ON/OFF See Table 4.4

DSW1 Hexadecimal switching

DSW5 Hexadecimal switching

Model CACR- S2-1 S2-2 S2-3 S2-4 S2-5 S2-6 CN15 CN26

SR03BF

SR05BF

SR07BF to 10BF

SR15BF

SR20BF

SR30BF

SR44BF

SR60BF

OFFONONONONONOPENOPEN

OFFONONONONOFF2-3 2-3

OFF ON ON ON OFF ON 1-2 1-2

OFF ON ON OFF ON ON 1-2 1-2

OFF ON ON OFF OFF OFF 1-2 1-2

OFF ON OFF ON ON OFF 1-2 1-2

OFF ON OFF ON OFF ON 1-2 1-2

OFF ON OFF OFF ON ON 1-2 1-2

Set to the defaults at factory depending on re-engineered

AC SERVOPACK model

Set to the defaults at factory depending on re-engineered

AC SERVOPACK model

These switches are set to the defaults at factory.

Change the setting according to the application.

Set to the defaults at factory depending on encoder type See Table 4.2

Table 4.1

See Table 4.1

See Table 4.3

See Table 4.5

4-5

Page 43

4 Settings and Display

4.2.1 Pin Settings

Table 4.2

Servomotor Encoder Specifications Setting

Encoder Type

Model

Code

No. of

Pulses

DSW1DSW51234567

F 1000 P/R

0 ONONONONOFFOFFOFF

SW2

Status

H 1440 P/R 1 ON ON ON ON OFF ON OFF

E 1500 P/R 2 OFF OFF ON ON OFF OFF OFF

Conventional

incremental

K 2000 P/R 3 OFF ON OFF ON OFF OFF OFF

C 2500 P/R 4 ON ON ON OFF OFF OFF OFF

0

D 4000 P/R 5 ON OFF ON OFF OFF OFF OFF

B 5000 P/R 6 ON ON OFF OFF OFF OFF OFF

A 6000 P/R 7 OFF ON OFF OFF OFF OFF OFF

M 30000 P/R 9 ON ON ON ON ON ON OFF

Multiplexed incremental

Absolute

3 2048 P/R

2 8192 P/R 1 OFF OFF OFF OFF OFF OFF OFF

W 1024 P/R

S 8192 P/R 1 OFF OFF OFF OFF OFF OFF OFF

1

2

Set according to

the number of

encoder pulses.

0 ONOFFOFFONOFFOFFOFF

0 OFF ON ON ON OFF OFF OFF

When the SERVOPACK output dividing

ratio is set to 1/1

Pn212 is enabled when SW2-8 is ON.

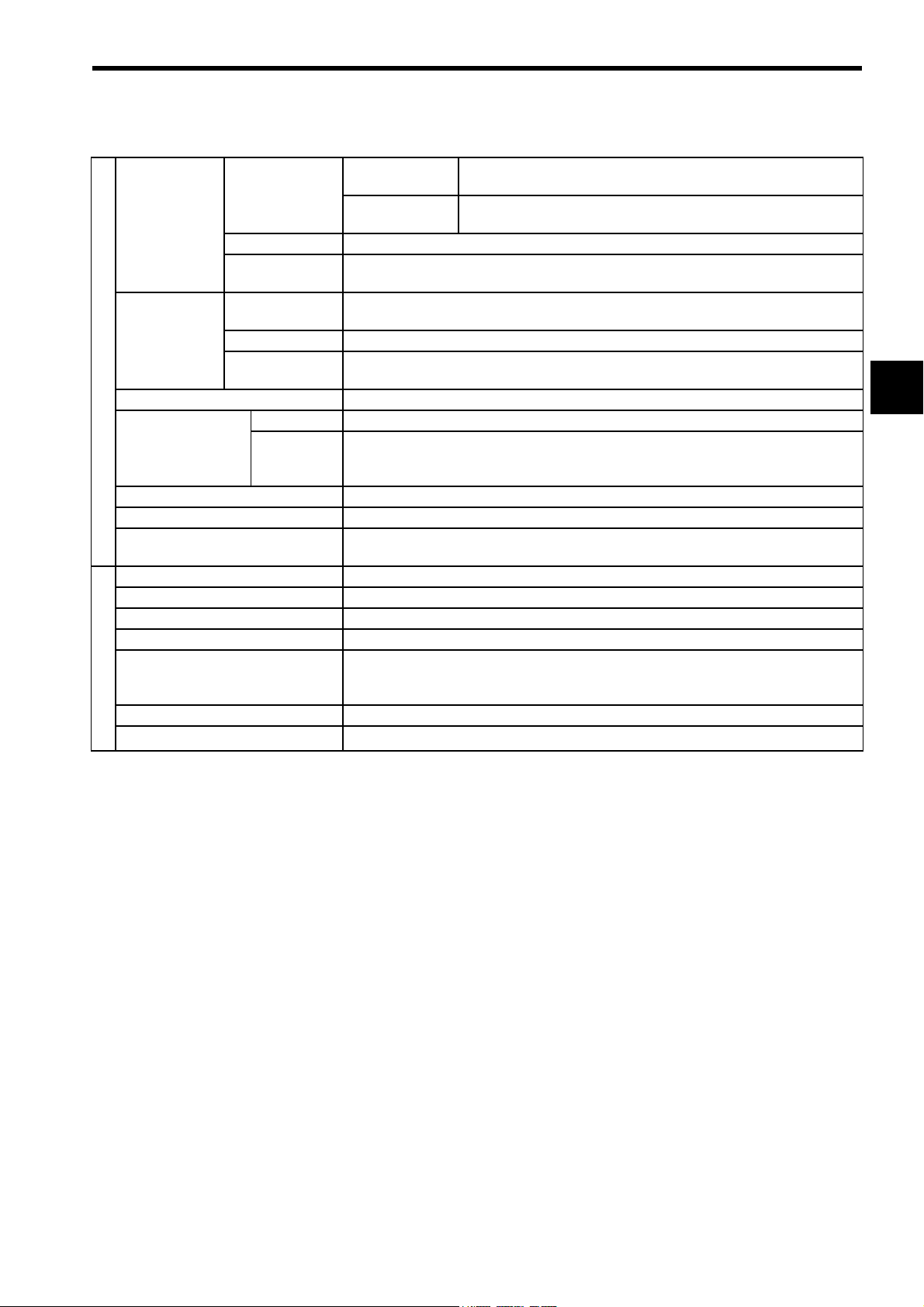

The settings shown in Tables 4.3, 4.4 and 4.5 are valid on the re-engineered AC SERVOPACKs for CACR-

SRBB and -SRBZ, but invalid for the re-engineered AC SERVOPACK for CACR-SRBE and -

SRBY.

Table 4.3 Motor Rated Speed

(Valid for CACR-SRBB and -SRBZ)

Servomotor Rated Speed SL5 SW3-7

1000 r/min

1500 r/min

2000 r/min

3000 r/min

-1

-1

-1

-1

1-2 ON

2-3 ON

2-3 OFF

2-3 ON

Table 4.4 Speed Amplifier Gain (Valid for CACR-SRBB and -SRBZ)

SW3 Specifications Factory Settings

S-series

0.5 kW or

less, and

3.0 kW

Pin No. Functions OFF ON

M-series

F-series

S-series

1 kW and

1.5 kW

1 Proportional gain 100 kΩ Valid Invalid ON OFF OFF OFF

2 Proportional gain 220 kΩ Valid Invalid OFF ON ON OFF

3 Imperfect integration 6.6 MΩ Valid Invalid OFF OFF OFF OFF

4 Integration 0.033 uF Invalid Valid ON OFF ON ON

5 Integration 0.033 uF Invalid Valid OFF OFF OFF OFF

6 Integration 0.22 uF Invalid Valid OFF ON OFF OFF

7 For servomotor rated speed ON ON ON OFF

8 Mode selection switch Valid Invalid OFF OFF OFF OFF

D-series

4-6

Page 44

Table 4.5 Torque Filter Switching

(Valid for CACR-SRBB and -SRBZ)

4.2 Factory Settings

SL7 Specifications

Connection Selected Capacitor

Short-circuited

between 1-2

Short-circuited

between 2-3

Open 1000 pF

3200 pF

2000 pF Factory setting

Factory Setting

The PG pulse outputs from the SERVOPACK can be set using SW2 pins 1 through 8.

Caution: The maximum number of output pulses that can be set is the number of encoder pulses.

Table 4.6 SW2: No. of Dividing Output Pulses

Settings for Re-engineered AC SERVOPACKs CACR-SRBF

12345678

OFF OFF OFF OFF OFF OFF OFF OFF 8192

ON OFF OFF OFF OFF OFF OFF OFF 8000

OFF ON OFF OFF OFF OFF OFF OFF 6000

ON ON OFF OFF OFF OFF OFF OFF 5000

OFF OFF ON OFF OFF OFF OFF OFF 4096

ON OFF ON OFF OFF OFF OFF OFF 4000

OFF ON ON OFF OFF OFF OFF OFF 3000

ON ON ON OFF OFF OFF OFF OFF 2500

OFF OFF OFF ON OFF OFF OFF OFF 2400

ON OFF OFF ON OFF OFF OFF OFF 2048

OFF ON OFF ON OFF OFF OFF OFF 2000

ON ON OFF ON OFF OFF OFF OFF 1600

OFF OFF ON ON OFF OFF OFF OFF 1500

ON OFF ON ON OFF OFF OFF OFF 1250

OFF ON ON ON OFF OFF OFF OFF 1024

ON ON ON ON OFF OFF OFF OFF 1000

OFF OFF OFF OFF ON OFF OFF OFF 800

ON OFF OFF OFF ON OFF OFF OFF 750

OFFONOFFOFFONOFFOFFOFF 625

ON ON OFF OFF ON OFF OFF OFF 600

OFF OFF ON OFF ON OFF OFF OFF 512

ON OFF ON OFF ON OFF OFF OFF 500

OFF ON ON OFF ON OFF OFF OFF 480

ON ON ON OFF ON OFF OFF OFF 400

OFF OFF OFF ON ON OFF OFF OFF 375

ON OFF OFF ON ON OFF OFF OFF 300

OFF ON OFF ON ON OFF OFF OFF 256

ON ON OFF ON ON OFF OFF OFF 250

OFF OFF ON ON ON OFF OFF OFF 240

ON OFF ON ON ON OFF OFF OFF 200

OFFONONONONOFFOFFOFF 160

ON ON ON ON ON OFF OFF OFF 150

OFF OFF OFF OFF OFF ON OFF OFF 128

ON OFF OFF OFF OFF ON OFF OFF 125

OFF ON OFF OFF OFF ON OFF OFF 120

ON ON OFF OFF OFF ON OFF OFF 100

OFF OFF ON OFF OFF ON OFF OFF 80

ON OFF ON OFF OFF ON OFF OFF 64

OFF ON ON OFF OFF ON OFF OFF 60

No. of Dividing

Output Pulses

4

4-7

Page 45

4 Settings and Display

4.2.1 Pin Settings

Settings for Re-engineered AC SERVOPACKs CACR-SRBF (cont’d)

Table 4.6 SW2: No. of Dividing Output Pulses

12345678

ON ON ON OFF OFF ON OFF OFF 50

OFF OFF OFF ON OFF ON OFF OFF 40

ON OFF OFF ON OFF ON OFF OFF 32

OFF ON OFF ON OFF ON OFF OFF 30

ON ON OFF ON OFF ON OFF OFF 25

OFF OFF ON ON OFF ON OFF OFF 20

ON OFF ON ON OFF ON OFF OFF 16

OFFONONONOFFONOFFOFF 1200

ON ON ON ON OFF ON OFF OFF 1440

OFF OFF OFF OFF ON ON OFF OFF 360

ON OFF OFF OFF ON ON OFF OFF 720

OFF ON OFF OFF ON ON OFF OFF 2880

ON ON OFF OFF ON ON OFF OFF 6000

OFF OFF ON OFF ON ON OFF OFF 6000

ON OFF ON OFF ON ON OFF OFF 6000

OFF ON ON OFF ON ON OFF OFF 6000

ON ON ON OFF ON ON OFF OFF 6000

OFFOFFOFFONONONOFFOFF 6000

ON OFF OFF ON ON ON OFF OFF 6000

OFF ON OFF ON ON ON OFF OFF 10000

ON ON OFF ON ON ON OFF OFF 12500

OFF OFF ON ON ON ON OFF OFF 15000

ON OFF ON ON ON ON OFF OFF 20000

OFF ON ON ON ON ON OFF OFF 25000

ON ON ON ON ON ON OFF OFF 30000

−−−−−−−ON Pn212

No. of Dividing

Output Pulses

4-8

Page 46

4.2 Factory Settings

Settings for Conventional SERVOPACK SRBB with Incremental Encoder for Reference

Check the number of dividing output pulses on the SRBB in the following table.

(A)

(B)

(D)

(C)

1234567

{{{{{{{ 1/1 6000 5000 4000 2500 1500 1000

{{{{{{ 1/2 3000 2500 2000 1250 750 500

{ {{{{{ 1/3 2000 −−−500 −

{{{{{ 1/4 1500 1250 1000 625 375 250

{{ {{{{ 1/5 1200 1000 800 500 300 200

{{{{{1/6 1000 −−−250 −

{{{{ 1/8 750 625 500 −−125

{{ {{{ 1/10 600 500 400 250 150 100

{{{{1/12 500 −−−125 −

{{{{1/15 400 −−−100 −

{{{ 1/16 375 − 250 −−−

{{ {{ 1/20 300 250 200 125 75 50

{{{1/24 250 −−−−−

{{{ {{ 1/25 240 200 160 100 60 40

{{{1/30 200 −−−50 -

{{ { 1/40 150 125 100 −−25

{{1/48 125 −−−−−

{{{ { 1/50 120 100 80 50 30 20

{{1/60 100 −−−25 −

{{{{{ 2/2 6000 5000 4000 2500 1500 1000

{{{{{ 2/3 4000 −−−1000 −

{{{{ 2/4 3000 2500 2000 1250 750 500

{{ {{{ 2/5 2400 2000 1600 1000 600 400

{{{{ 2/6 2000 −−−500 −

{{{ 2/8 1500 1250 1000 625 − 250

{{ {{ 2/10 1200 1000 800 500 300 200

{{{ 2/12 1000 −−−250 −

{{{2/15 800 −−−200 −

{{ 2/16 750 − 500 −−125

{{ { 2/20 600 500 400 250 150 100

{{ 2/24 500 −−−125 −

{{{ { 2/25 480 400 320 200 120 80

{{2/30 400 −−−100 −

{{ 2/40 300 250 200 125 75 50

{ 2/48 250 −−−−−

{{{ 2/50 240 200 160 100 60 40

{ 2/60 200 −−−50 −

Note: The pin SW2-8 is reserved. The pins marked with { are short-circuited.

Dividing

Ratio

6000

5000

4000

2500

(E)

1500

(F)

1000

4

4-9

Page 47

4 Settings and Display

4.2.1 Pin Settings

Settings for Conventional SERVOPACK SRBZ with Absolute Encoder for Reference

Check the number of dividing output pulses on the SRBZ in the following table.

123456

(s)

8192

123456

{{{{{{6000 {{{{{ 60

{{{{{5000 {{{{ 50

{ {{{{4000 { {{{ 40

{{{{3000 {{{ 30

{{ {{{2500 {{ {{ 25

{ {{{2400 {{{ 20

{ {{{2000 {{{8192

{{{1600 {{ 4096

{{{ {{1500 {{{ { 2048