Page 1

Over 100 years cumulative experience

24 hour rush turnaround / technical support service

Established in 1993

The leading independent repairer of servo motors and drives in North America.

Visit us on the web:

www.servo-repair.com

www.servorepair.ca

www.ferrocontrol.com

www.sandvikrepair.com

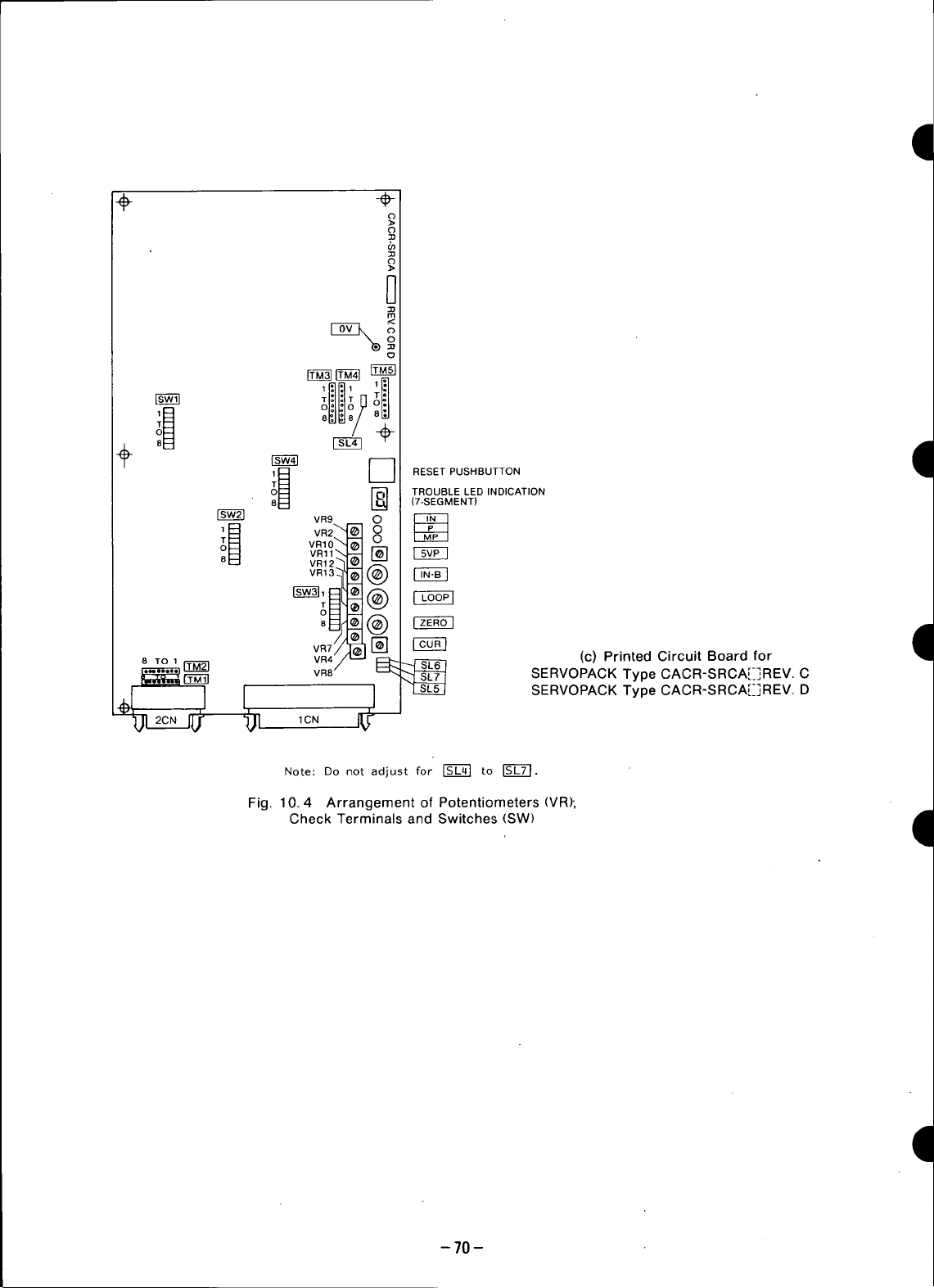

www.accuelectric.com

Scroll down to view your document!

For 24/7 repair services :

USA: 1 (888) 932 - 9183

Canada: 1 (905) 829 -2505

Emergency After hours: 1 (416) 624 0386

Servicing USA and Canada

Page 2

AC SERVO DRIVE M.F-S,D SERIES

I1 BULLETIN

WITH INCREMENTAL ENCODER, FOR SPEED CONTROL

SERVOMOTOR TYPES USAME-_D, USAFED, USASEM, USADED

SERVOPACK TYPES CACR-SRE-_BB1 ,r-__

YASKAWA TSE-S800-2.1J

Page 3

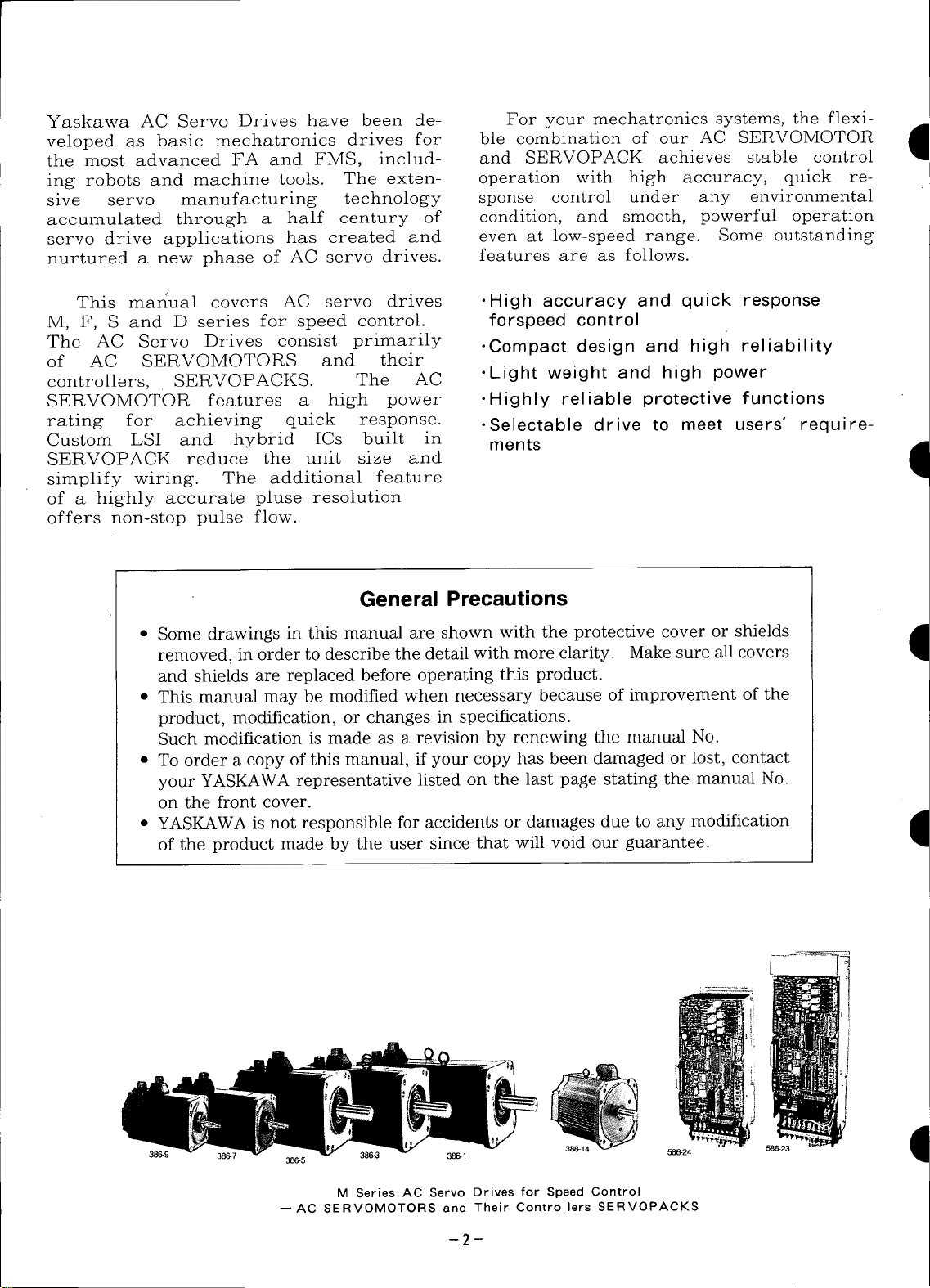

Yaskawa AC Servo Drives have been de- For your mechatronics systems, the flexi-

veloped as basic mechatronics drives for ble combination of our AC SERVOMOTOR i

the most advanced FA and FMS, includ- and SERVOPACK achieves stable control

inK robots and machine tools. The exten- operation with high accuracy, quick re-

sive servo manufacturing technology sponse control under any environmental

accumulated through a half century of condition, and smooth, powerful operation

servo drive applications has created and even at low-speed range. Some outstanding

nurtured a new phase of AC servo drives, features are as follows.

This man_ual covers AC servo drives "High accuracy and quick response

M, F, S and D series for speed control, forspeed control

The AC Servo Drives consist primarily -Compact design and high reliability

of AC SERVOMOTORS and their

controllers, SERVOPACKS. The AC "Light weight and high power

SERVOMOTOR features a high power -Highly reliable protective functions

rating for achieving quick response. -Selectable drive to meet users" require-

Custom LSI and hybrid ICs builtin ments

SERVOPACK reduce the unit size and

simplify wiring. The additional feature

of a highly accurate pluse resolution

offers non-stop pulse flow.

I

q

General Precautions

• Some drawings in this manual are shown with the protective cover or shields

removed, in order to describe the detail with more clarity. Make sure all covers

and shields are replaced before operating this product.

• This manual may be modified when necessary because of improvement of the

product, modification, or changes in specifications.

Such modification is made as a revision by renewing the manual No.

• To order a copy of this manual, if your copy has been damaged or lost, contact

your YASKAWA representative listed on the last page stating the manual No.

on the front cover.

• YASKAWA is not responsible for accidents or damages due to any modification

of the product made by the user since that will void our guarantee.

I

386-9 386-5 386-1 388-14 586-24 1

--AC SERVOMOTORS and Their Controllers SERVOPACKS

M Series AC Servo Drives for Speed Control

--2--

Page 4

D NOTES FOR SAFE OPERATION

Read this manual thoroughly before installation, operation, main-

tenance or inspection of the AC Servo Drives. In this manual, the

NOTES FOR SAFE OPERATION are classified as "WARNING" or

"CAUTION".

,,WARNING

Indicates a potentially hazardous situation which, if not avoided, could

D result in death or serious personal, injury.

CAUTION 1

Indicates a potentially hazardous situation which, if not avoided, may

D result in minor or moderate personal injury and/or damage to the

equipment.

In some instances, items described in /k CAUTION may also result

in a serious accident. In either case, follow these important items.

D

-3-

Page 5

,/K WARNING il

(Wll O)

• Grounding must be in accordance with the national code and consistent with

sound local practices.

Failure to observe this warning may lead to electric shock or fire.

(OPERATION)

• Never touch any rotating motor parts during operation.

Failure to observe this warning may result in personal injury.

(INSPECTION AND MAINTENANCE)

• Be sure to turn OFF power before inspection or maintenance.

Otherwise, electric shock may result.

• Never open the panel cover while power is ON, and never turn ON power when

the panel cover is open.

Otherwise, electric shock may result.

• After turning OFF power, wait at least five minutes before servicing the product.

Otherwise, residual electric charges may result in electric shock.

CAUTION

(RECEIVING)

• Use the specified combination of SERVOMOTOR and SERVOPACK.

Failure to observe this caution may lead to fire or failure.

(INSTALLATION)

• Never use the equipment where it may be exposed to splashes of water,

corrosive or flammable gases, or near flammable materials.

Failure to observe this caution may lead to electric shock or fire.

(WIRING)

• Do not connect three-phase power supply to output terminals (j_) @ and @.

Failure to observe this caution may lead to personal injury or fire.

• Securely tighten screws on the power supply and motor output terminals.

Failure to observe this caution can result in a fire.

-4-

Page 6

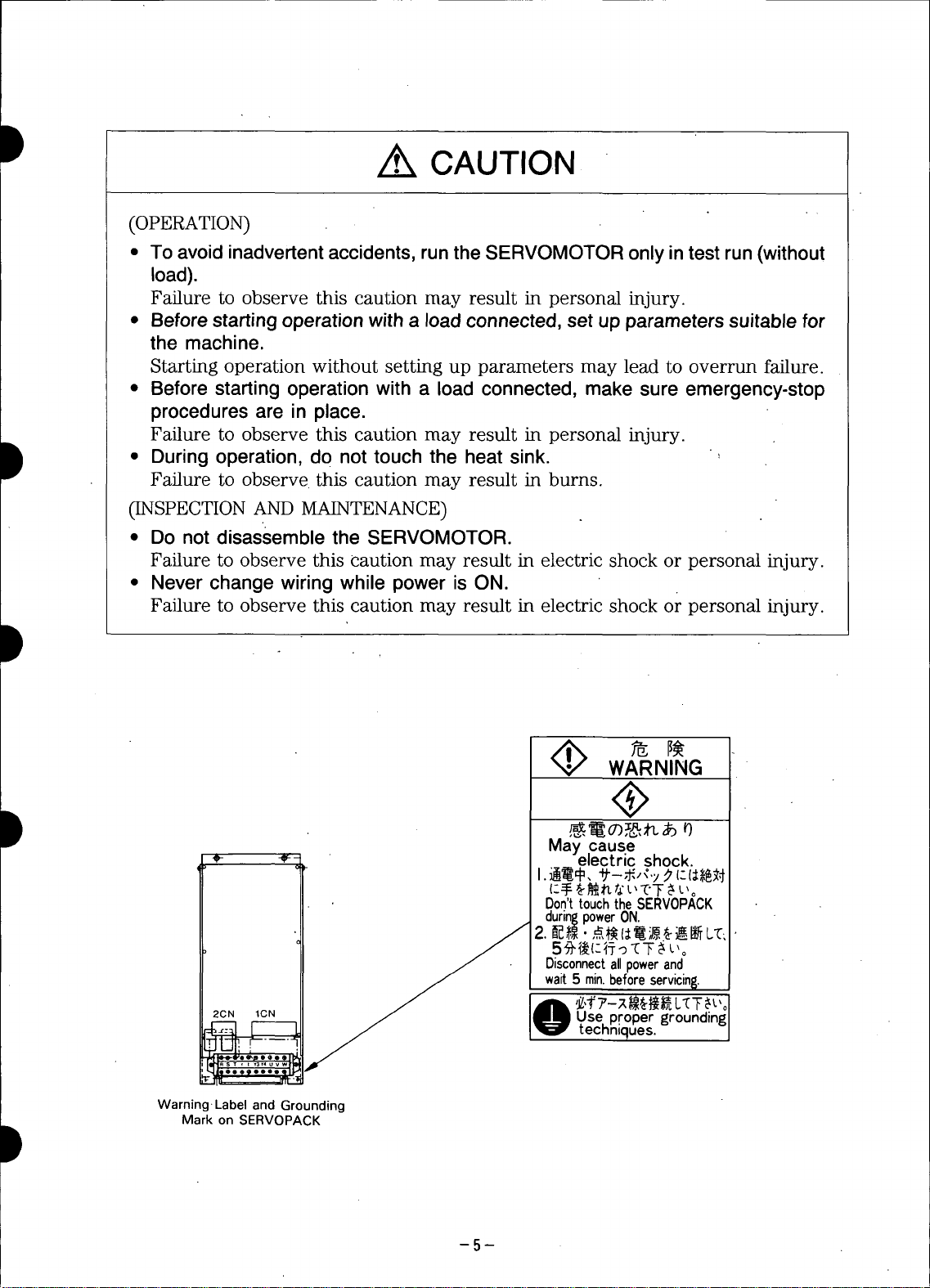

I) CAUTION

(OPERATION)

• To avoid inadvertent accidents, run the SERVOMOTOR only in test run (without

load).

Failure to observe this caution may result in personal injury.

• Before starting operation with a load connected, set up parameters suitable for

the machine.

Starting operation without setting up parameters may lead to overrun failure.

• Before starting operation with a load connected, make sure emergency-stop

procedures are in place.

Failure to observe this caution may result in personal injury.

D • During operation, do not touch the heat sink. ,

Failure to observe• this caution may result in burns.

(INSPECTION AND MAINTENANCE)

• Do not disassemble the SERVOMOTOR.

Failure to observe this caution may result in electric shock or personal injury.

• Never change wiring while power is ON.

Failure to observe this caution may result in electric shock or personal injury.

D

May cause

Don't touchthe SERV0PACK

during power ON.

_ 2._,_. ,_(_,_L'C,

WARNING

electric shock.

D

Disconnect all power and

wait 5 mJn.before serv_in_.

2CN _CN Usepropergrounding

__. -- _1 techniques.

Warning. Label and Grounding

Mark on SERVOPACK

-5-

Page 7

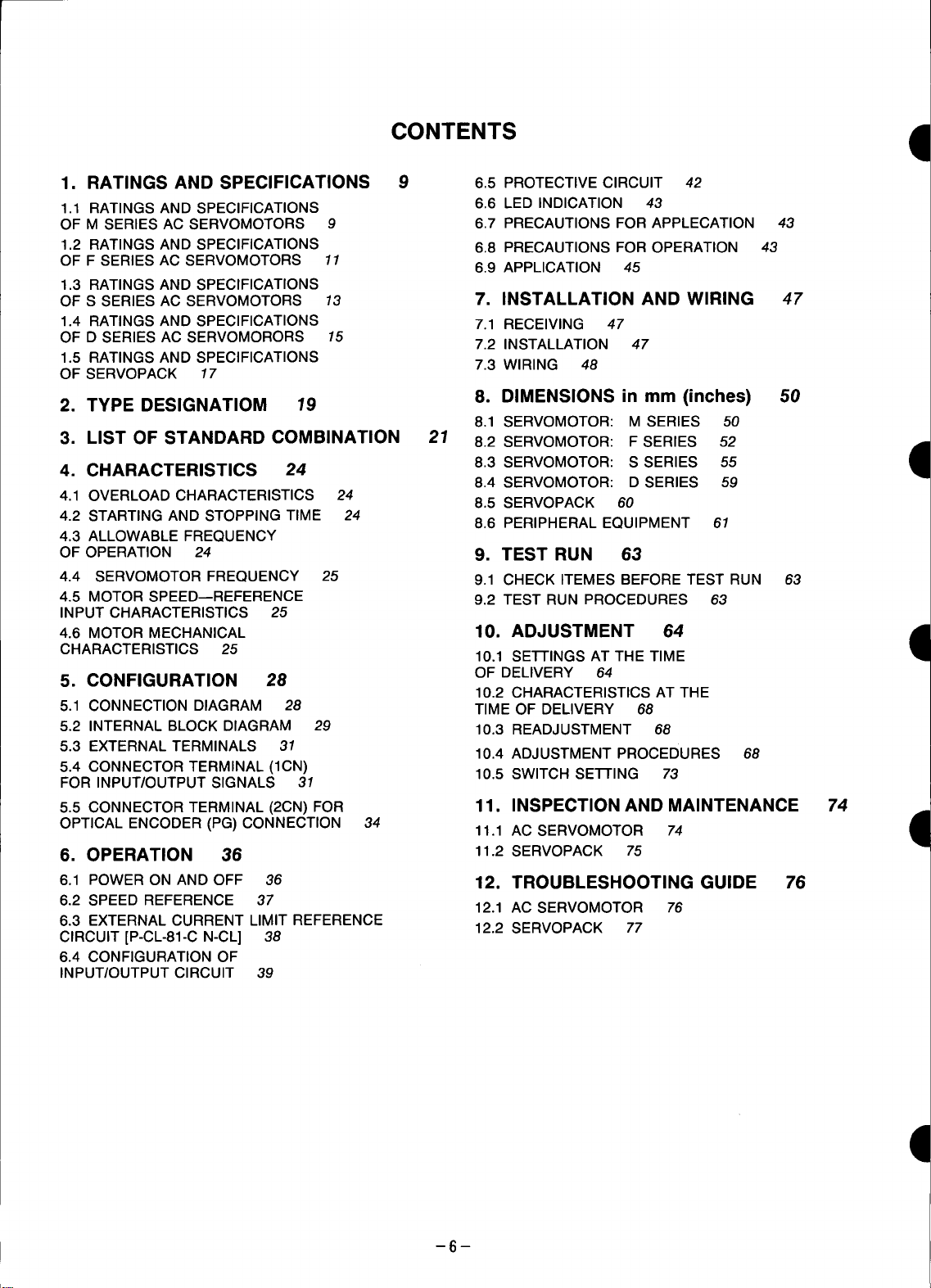

CONTENTS t

1. RATINGS AND SPECIFICATIONS 9 6.5 PROTECTIVECIRCUIT 42

1.1 RATINGS AND SPECIFICATIONS 6.6 LED INDICATION 43

OF M SERIES AC SERVOMOTORS 9 6.7 PRECAUTIONS FOR APPLECATION 43

1.2 RATINGS AND SPECIFICATIONS 6.8 PRECAUTIONS FOR OPERATION 43

OF F SERIES AC SERVOMOTORS 11

1.3 RATINGS AND SPECIFICATIONS

OF S SERIES AC SERVOMOTORS 13 7. INSTALLATION AND WIRING 47

1.4 RATINGS AND SPECIFICATIONS 7.1 RECEIVING 47

OF D SERIES AC SERVOMORORS 15

1.5 RATINGS AND SPECIFICATIONS 7.3 WIRING 48

OF SERVOPACK 17

6.9 APPLICATION 45

7.2 INSTALLATION 47

2, TYPE DESIGNATIOM 19 8. DIMENSIONS in mm (inches) 50

8.1 SERVOMOTOR: M SERIES 50

3. LIST OF STANDARD COMBINATION 21 8.2 SERVOMOTOR:F SERIES 52

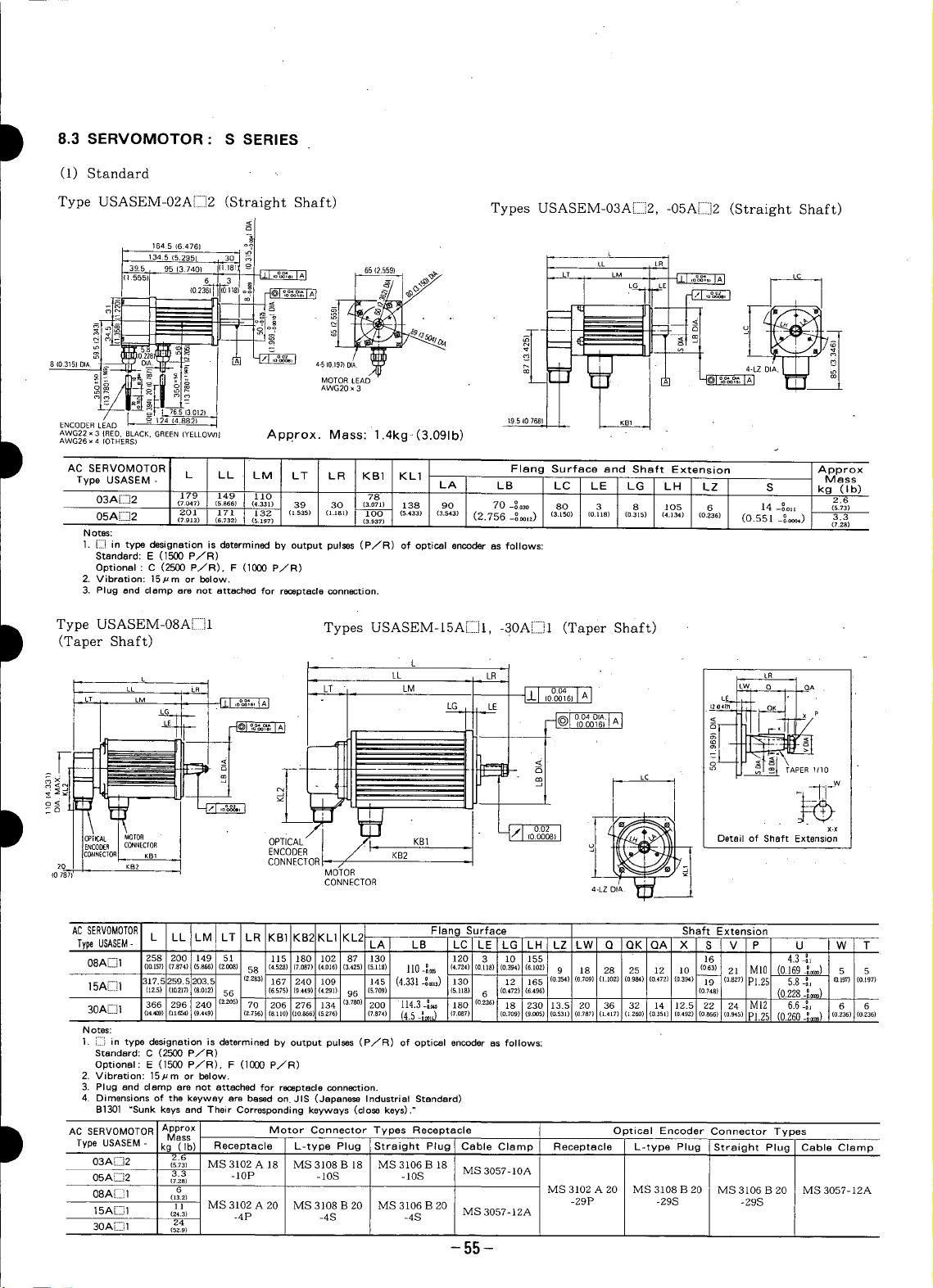

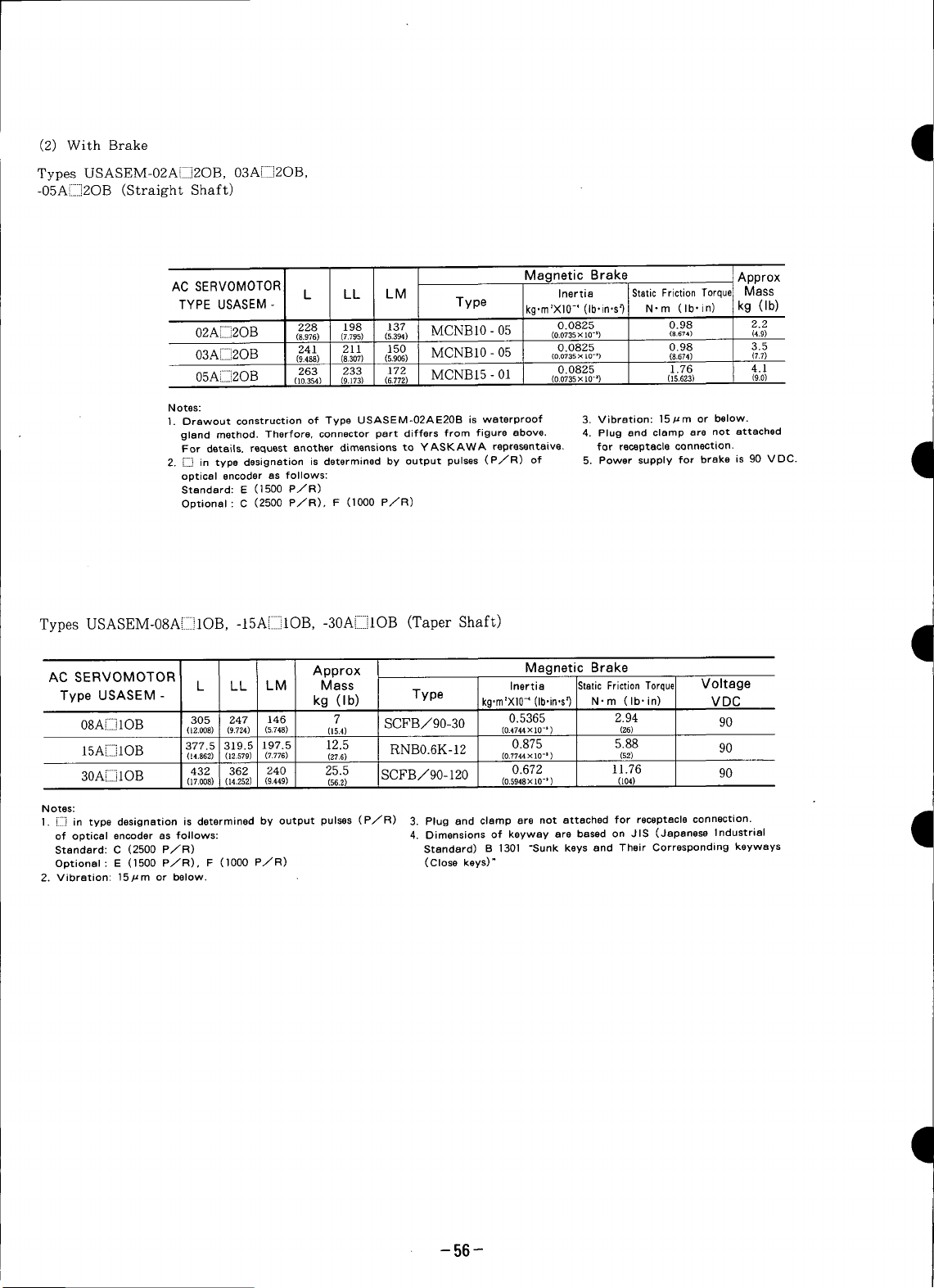

4. CHARACTERISTICS 24 8.3 SERVOMOTOR: S SERIES 55 I

4.1 OVERLOAD CHARACTERISTICS 24

4.2 STARTING AND STOPPING TIME 24

4.3 ALLOWABLE FREQUENCY

OF OPERATION 24 9. TEST RUN 63

4.4 SERVOMOTOR FREQUENCY 25 9.1 CHECK ITEMES BEFORE TEST RUN 63

4.5 MOTOR SPEED--REFERENCE 9.2 TEST RUN PROCEDURES 63

INPUT CHARACTERISTICS 25

4.6 MOTOR MECHANICAL 10. ADJUSTMENT 64 dB

CHARACTERISTICS 25 10.1 SEI-IINGS AT THE TIME

5. CONFIGURATION 28 OFDELIVERY 64

5.1 CONNECTION DIAGRAM 28 TIME OF DELIVERY 68

5.2 INTERNAL BLOCK DIAGRAM 29 10.3 READJUSTMENT 68

5.3 EXTERNAL TERMINALS 31

5.4 CONNECTOR TERMINAL (1CN) 10.5 SWITCH SEI-rlNG 73

FOR INPUT/OUTPUT SIGNALS 31

5.5 CONNECTOR TERMINAL (2CN) FOR 11. INSPECTION AND MAINTENANCE 74 .._

OPTICAL ENCODER (PG) CONNECTION 34 11.1 AC SERVOMOTOR 74

8.4 SERVOMOTOR: D SERIES 59

8.5 SERVOPACK 60

8.6 PERIPHERAL EQUIPMENT 61

10.2 CHARACTERISTICS AT THE

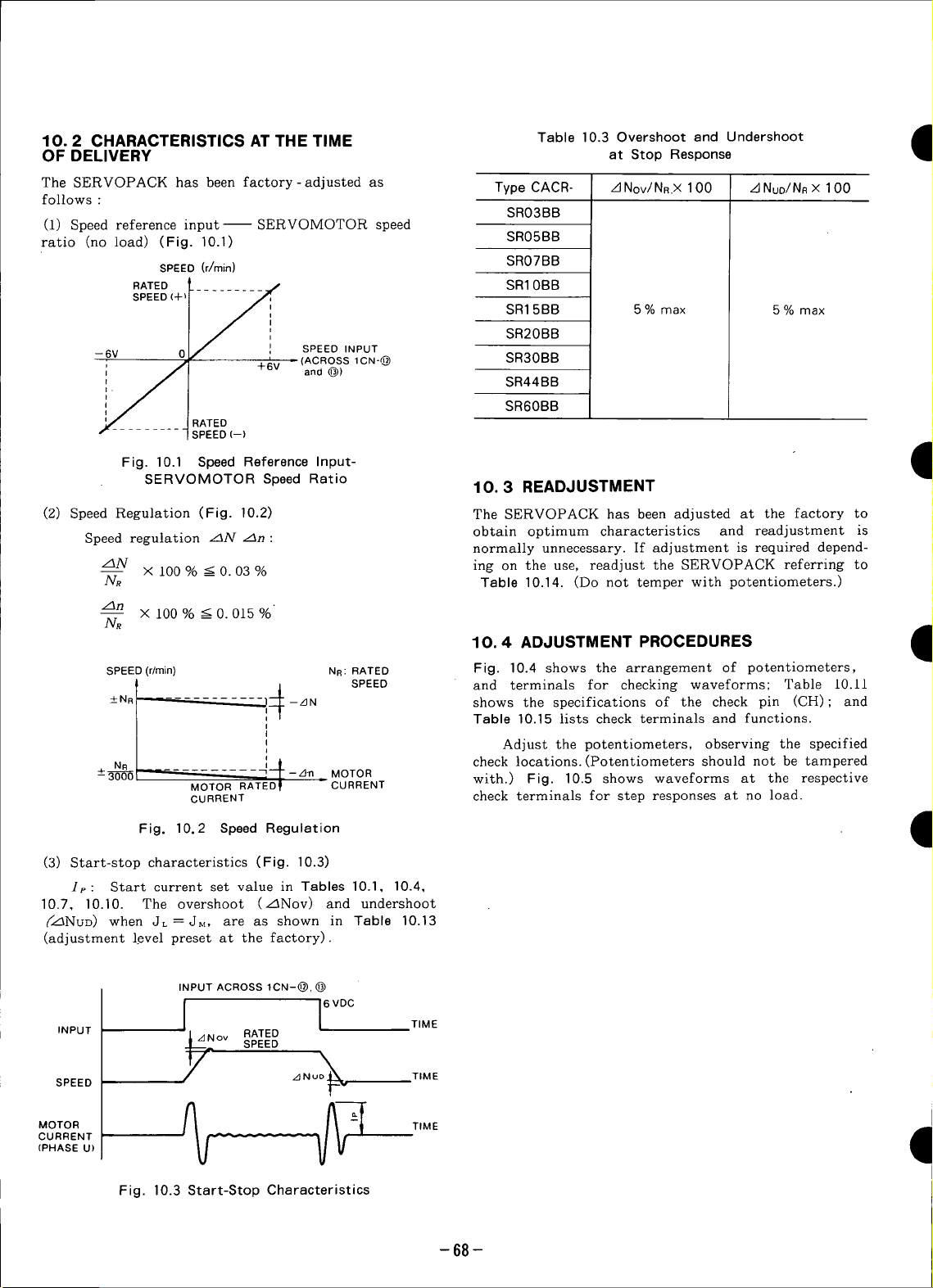

10.4 ADJUSTMENT PROCEDURES 68

JB

I

/

I

6. OPERATION 36 11.2 SERVOPACK 75

6.1 POWER ON AND OFF 36 12. TROUBLESHOOTING GUIDE 76

6.2 SPEED REFERENCE 37 12.1 AC SERVOMOTOR 76

6.3 EXTERNAL CURRENT LIMIT REFERENCE

CIRCUIT [P-CL-81-C N-CL] 38

6.4 CONFIGURATION OF

INPUT/OUTPUT CIRCUIT 39

12.2 SERVOPACK 77

Page 8

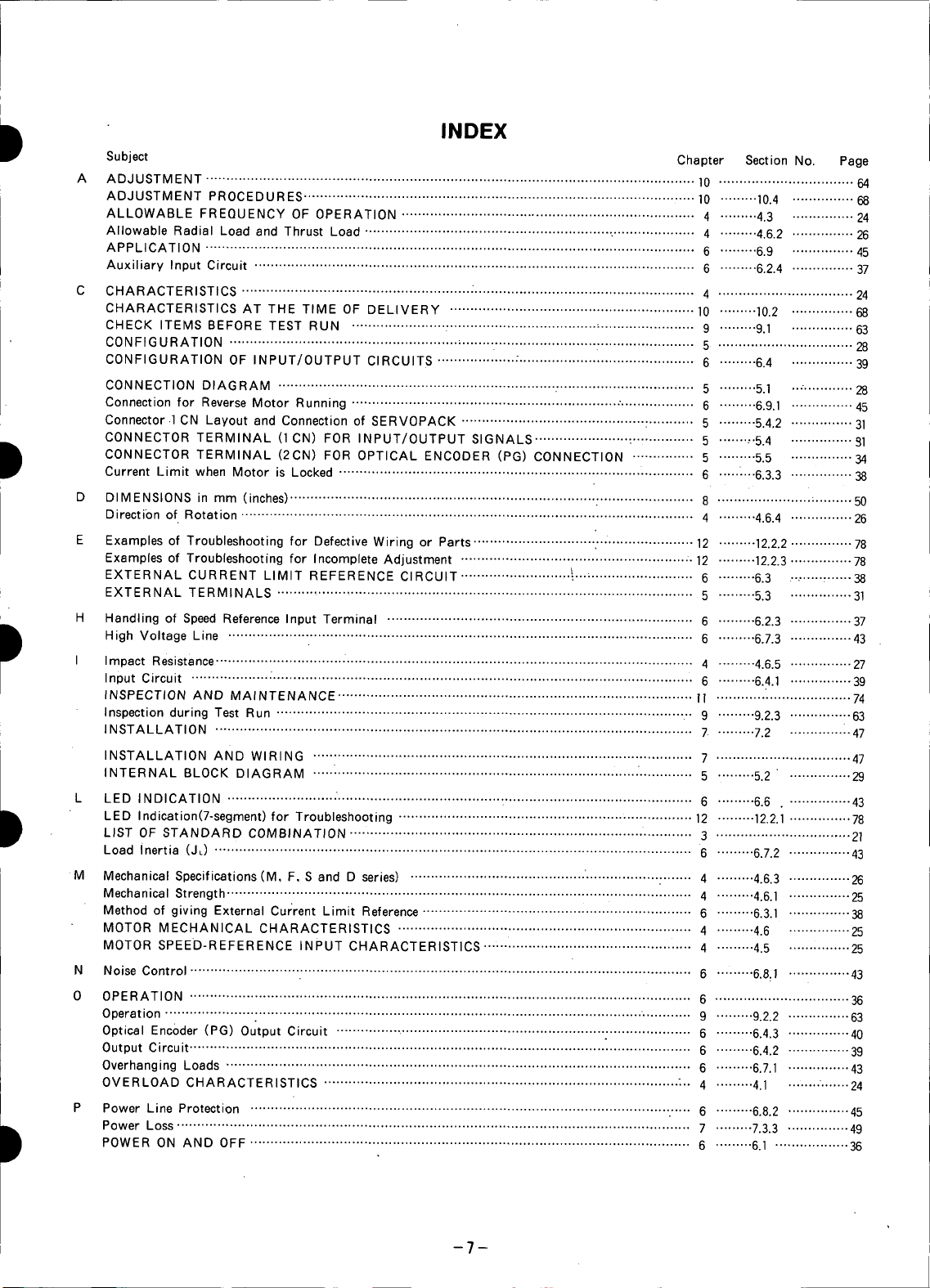

D INDEX

Subject Chapter Section No. Page

A ADJUSTMENT ........................................................................................................................ ]0 ................................. 64

ADJUSTMENT PROCEDURES ................................................................................................ ]0 ......... ]0.4 ............... 68

ALLOWABLE FREQUENCY OF OPERATION ........................................................................ 4 ......... 4.3 ............... 24

Allowable Radial Load and Thrust Load ............................................................ .,.................... 4 ......... 4,6.2 ............... 26

APPLICATION ........................................................................................................................ 6 ......... 6.9 ............... 45

Auxiliary Input Circuit ............................................................................................................ 6 ......... 6.2.4 ............... 37

C CHARACTERISTICS ........................................................ :...................................................... 4 ................................. 24

CHARACTERISTICS AT THE TIME OF DELIVERY ............................................................ 10 ......... ]0.2 ............... 68

CHECK ITEMS BEFORE TEST RUN .................................................................................... 9 ......... 9,] ............... 63

CONFIGURATION .................................................................................................................. 5 ................................. 28

CONFIGURATION OF INPUT/OUTPUT CIRCUITS ................... :........................................... 6 ......... 6.4 ............... 39

CONNECTION DIAGRAM ...................................................................................................... 5 ......... 5.] ": ............ 28

Connection for Reverse Motor Running ................................................................. :.................. 6 ......... 6.9,1 ............... 45

Connector ]CN Layout and Connection of SERVOPACK ......................................................... 5 ......... 5.4.2 ............... 31

CONNECTOR TERMINAL (1CN) FOR INPUT/OUTPUT SIGNALS ....................... :............... 5 ......... 5.4 ............... S]

D CONNECTOR TERMINAL (2CN) FOR OPTICAL ENCODER (PG) CONNECTION ............... 5 ......... 5.5 ............... 34

D NSTALLATION AND WIRING ................................................................................ ............. 7 ................................. 47

Current Limit when Motor is Locked 6 ..... _"'6.3.3 ............... 38

D DIMENSIONS in mm (inches) ........................................................................... :....................... 8 ................................. 50

Direction of Rotation ............................................................................................................... 4 ......... 4.6.4 ............... 26

E Examples of Troubleshooting for Defective Wiring or Parts ]2 ......... 12.2.2 ............... 78

Examples of Troubleshooting for Incomplete Adjustment ....................................................... .-]2 ......... 12.2.3 ............... 78

EXTERNAL CURRENT LIMIT REFERENCE CIRCUIT ........................... _...; ......................... 6 ......... 6.3 ..,...... _...... 38

EXTERNAL TERMINALS ...................................................................................................... 5 ......... 5.3 ............... 3]

H Handling of Speed Reference Input Terminal ........................................................................... 6 ......... 6.2.3 ............... 37

High Voltage Line .................................................................................................................. 6 ......... 6.7.3 ............... 43

Impact Resistance ............................... •..................................................................................... 4 ......... 4.6.5 ............... 27

Input Circuit ................... :....................................................................................................... 6 ......... 6.4.] ............... 39

INSPECTION AND MAINTENANCE ....................................................................................... 11 ................................. 74

Inspection during Test Run ...................................................................................................... 9 ......... 9.2.3 ............... 63

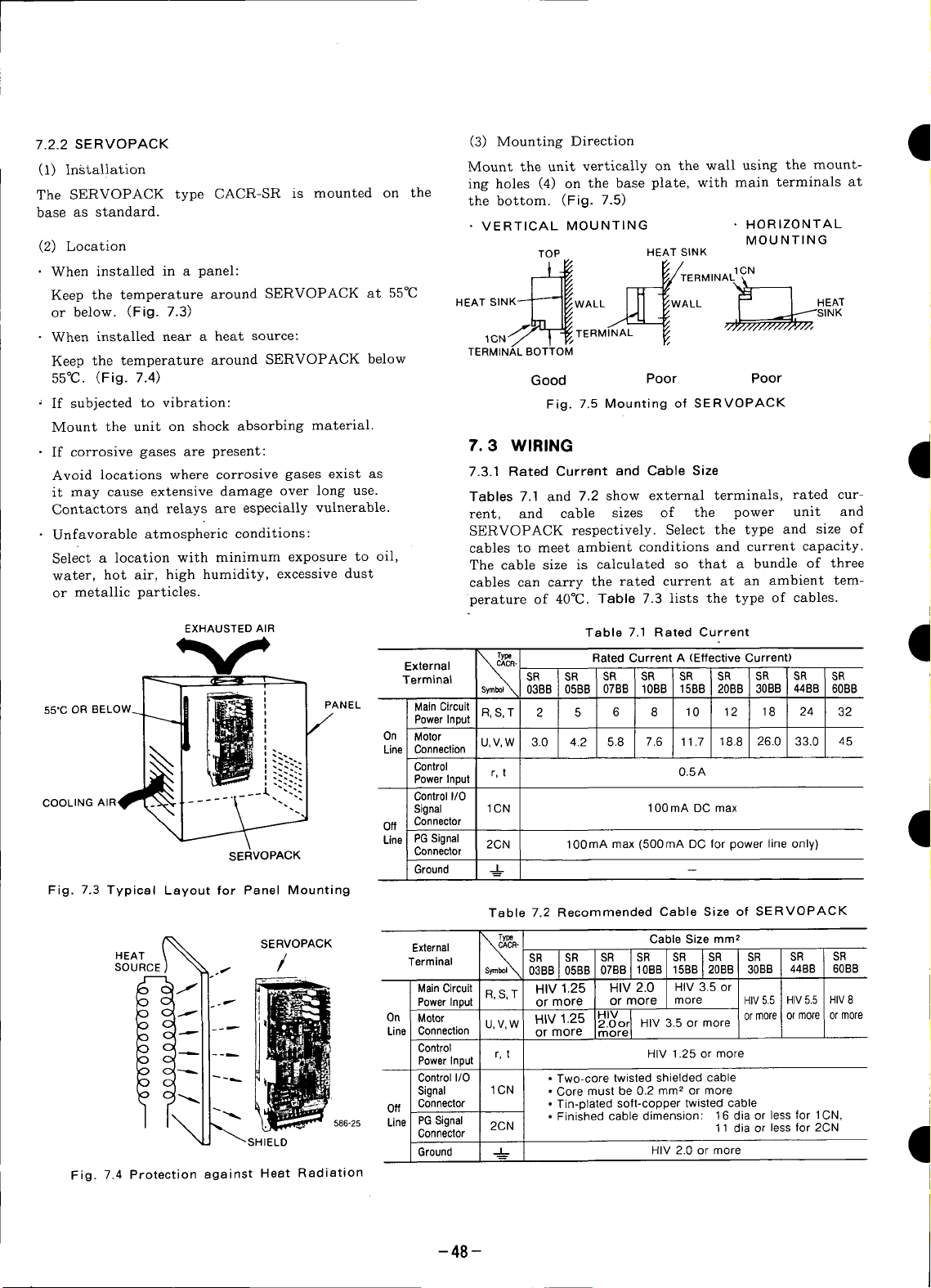

NSTALLATION ..................................................................................................................... 7 -........ 7.2 ............... 47

NTERNAL BLOCK DIAGRAM 5 ......... 5.2 •.............. 29

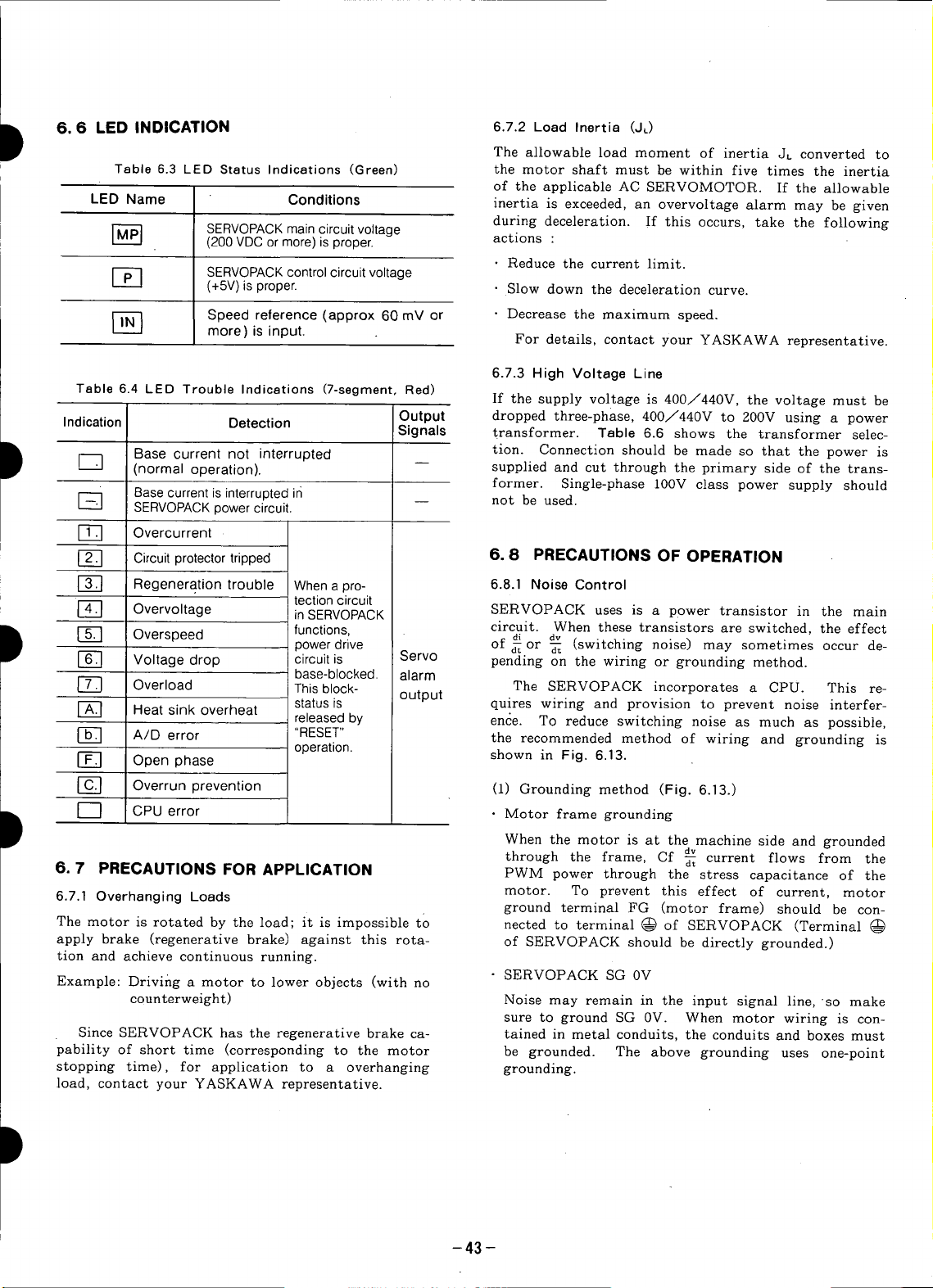

L LED INDICATION 6 ......... 6.6 ,. .............. 43

LED Indication(7-segment) for Troubleshooting ........................................................................ 12 ......... 12,2.1 ............... 78

LIST OF STANDARD COMBINATION .................................................................................... 3 ................................. 21

Load inertia (JL) ..................................................................................................................... 6 ......... 6.7.2 ............... 43

M Mechanical Specifications (M, F, S and D series) ........................................... '.......................... 4 ......... 4.6.3 ............... 26

Mechanical Strength .......................................................................................................... ]....... 4 ......... 4.6.1 ............... 25

Method of giving External Current Limit Reference .................................................................. 6 ......... 6.3.1 ............... 38

MOTOR MECHANICAL CHARACTERISTICS ........................................................................ 4 ......... 4.6 ............... 25

MOTOR SPEED-REFERENCE INPUT CHARACTERISTICS ................................................... 4 ......... 4.5 ............... 25

N Noise Control ........................................................................................................................... 6 ......... 6.8.] ............... 43

O OPERATION ........................................................................................................................... 6 ................................. 38

Operation ..................................................................................................................... ............ 9 ......... 9.2.2 ............... 63

Optical Enc()der (PG) Output Circuit ........................................................................................ 6 ......... 6.4.3 ............... 40

Output Circuit ...................................................................................................... _ .................... 6 ......... 6.4.2 ............... 39

Overhanging Loads .................................................................................................................. 6 ......... 6.7.1 ............... 43

OVERLOAD CHARACTERISTICS ....................................................................................... :" 4 ......... 4.1 ........ ....... 24

P Power Line Protection ............................................................................................................ 6 ......... 6.8.2 ............... 45

D Power Loss .............................................................................................................................. 7 ......... 7.3.3 ............... 49

POWER ON AND OFF ............................................................................................................ 6 ......... 6.1 .................. 36

-7-

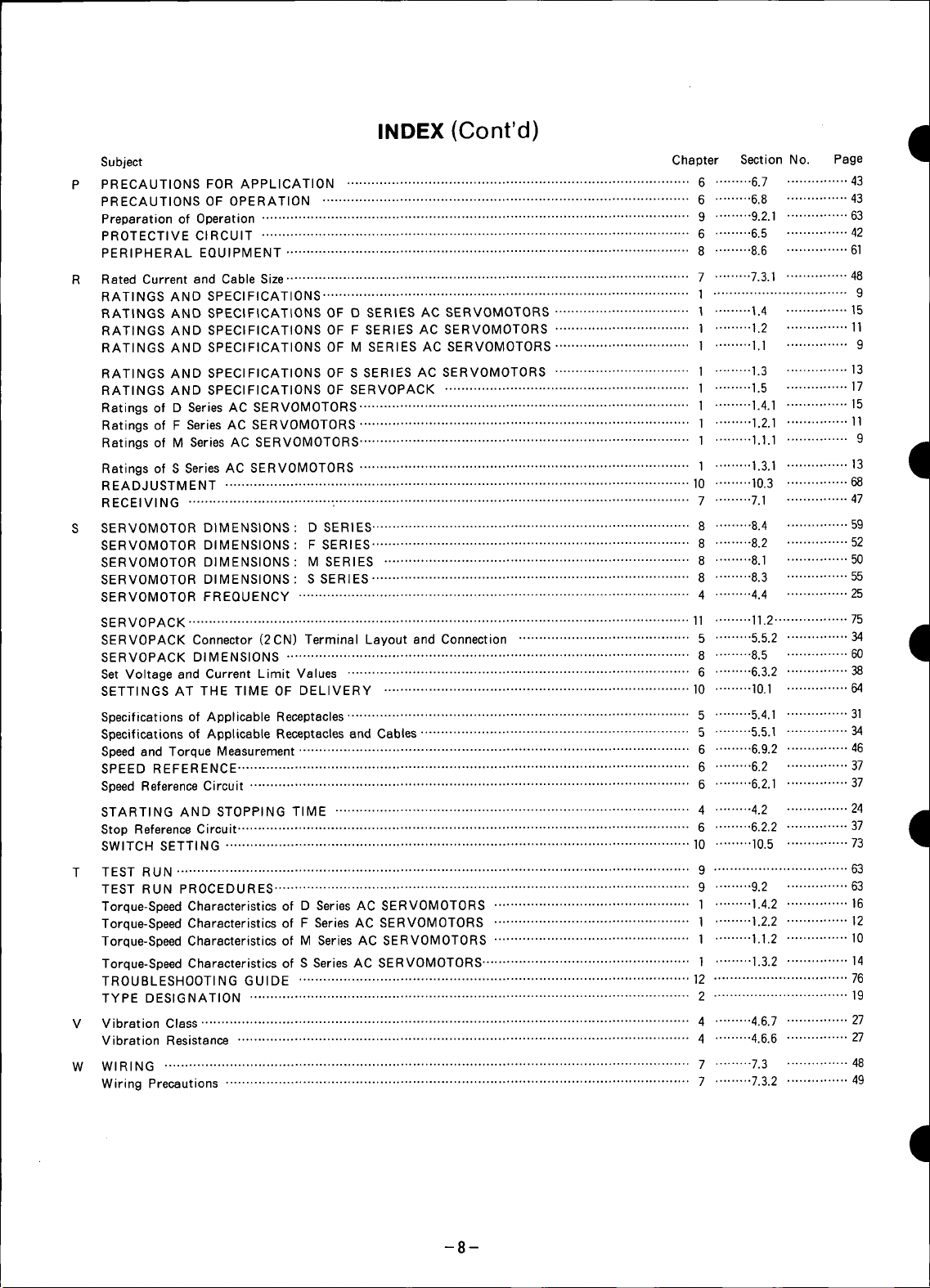

Page 9

Subject Chapter SectionNo. Page

P PRECAUTIONS FOR APPLICATION .................................................................................... 6 ......... 6.7 ............... 43

PRECAUTIONS OF OPERATION .......................................................................................... 6 ......... 6.8 ............... 43

Preparation of Operation ......................................................................................................... 9 ......... 9.2.] ............... 63

PROTECTIVE CIRCUIT ......................................................................................................... 6 ......... 6,5 ............... 42

PERIPHERAL EQUIPMENT ................................................................................................... 8 ......... 8.6 ............... 61

R Rated Current and Cable Size ................................................................................................... 7 ......... 7.3.] ............... 48

RATINGS AND SPECIFICATIONS .......................................................................................... ] ................................. 9

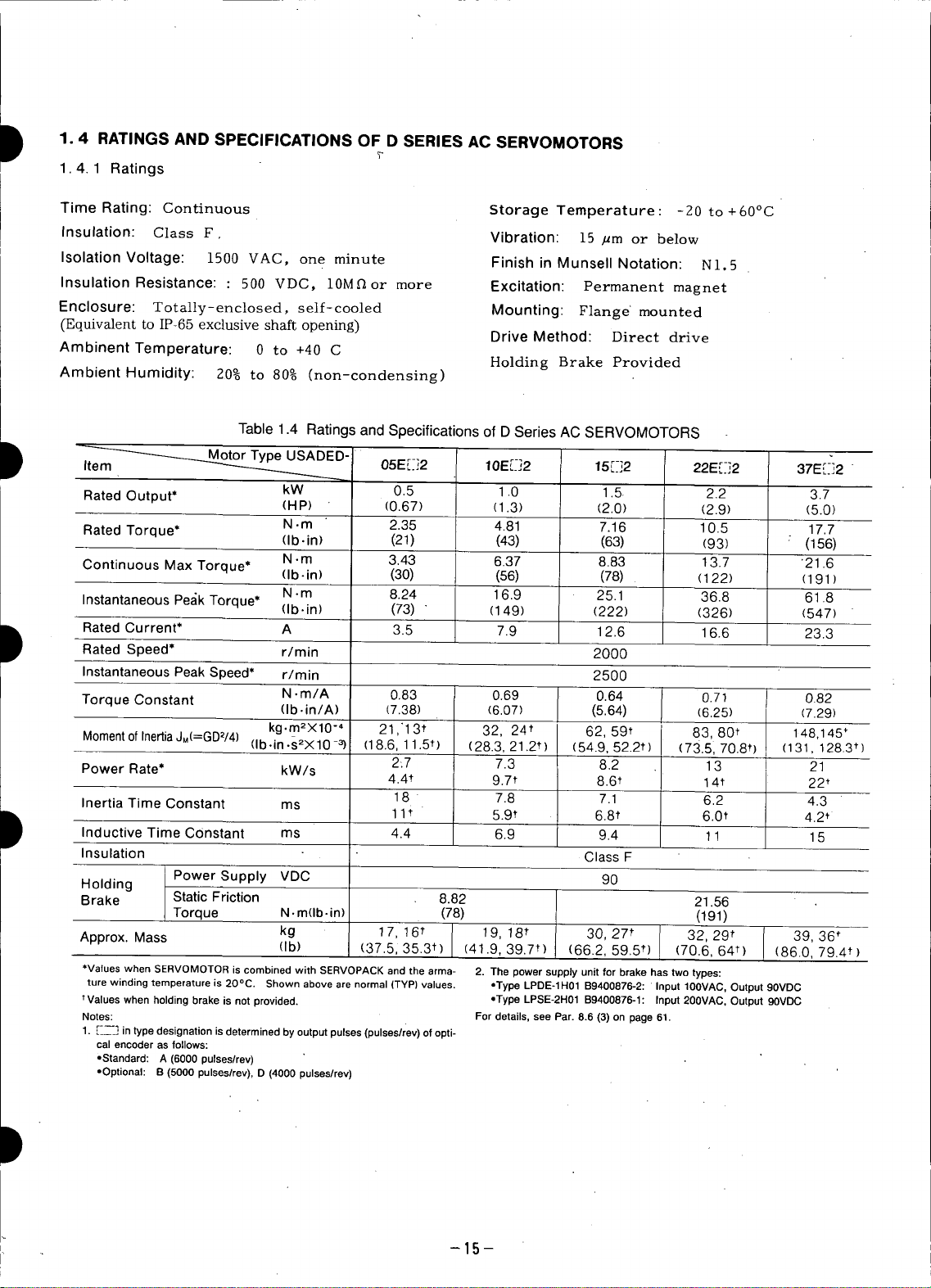

RATINGS AND SPECIFICATIONS OF D SERIES AC SERVOMOTORS ................................. 1 ......... 1.4 ............... _5

RATINGS AND SPECIFICATIONS OF F SERIES AC SERVOMOTORS ................................. 1 ......... 1.2 ............... 11

RATINGS AND SPECIFICATIONS OF M SERIES AC SERVOMOTORS ................................. I ......... ].] ............... 9

RATINGS AND SPECIFICATIONS OF S SERIES AC SERVOMOTORS ................................. ] ......... 1.3 ............... 13

RATINGS AND SPECIFICATIONS OF SERVOPACK ............................................................ I ......... 1.5 ............... 17

Ratings of D Series AC SERVOMOTORS ................................................................................. ] ......... ].4.1 ............... 15

Ratings of F Series AC SERVOMOTORS ................................................................................. I ......... 1.2.1 ............... ]]

Ratings of M Series AC SERVOMOTORS ................................................................................. I ......... 1.1.1 ............... 9

Ratings of S Series AC SERVOMOTORS ................................................................................. I ......... 1.3.1 ............... ]3

READJUSTMENT .................................................................................................................. 10 ......... 10.3 ............... 68

RECEIVING ................................... " ....................................................................................... 7 ......... 7.] ............... 47

S SERVOMOTOR DIMENSIONS: D SERIES .............................................................................. 8 ......... 8.4 ............... 59

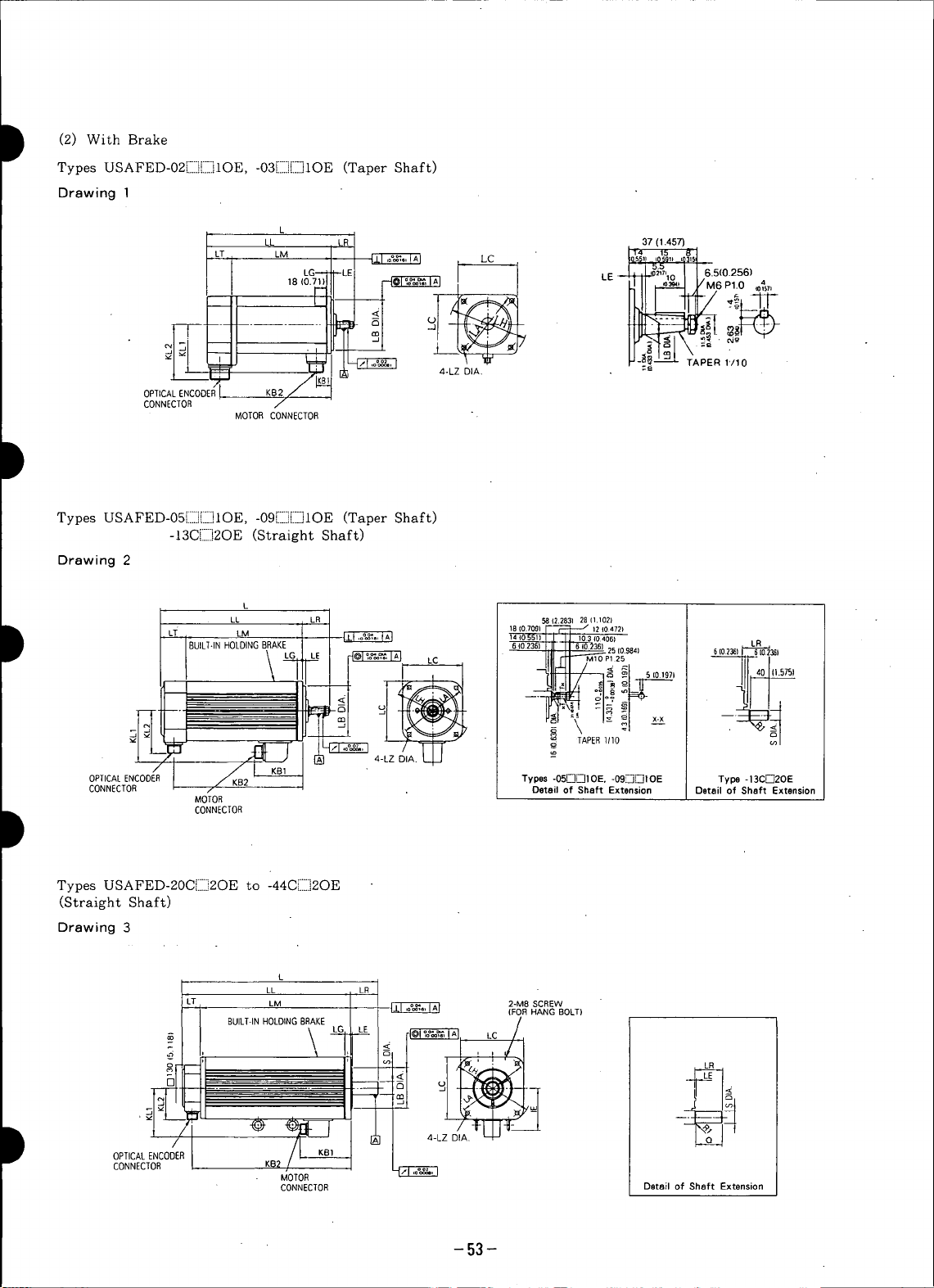

SERVOMOTOR DIMENSIONS: F SERIES .............................................................................. 8 ......... 8.2 ............... 52

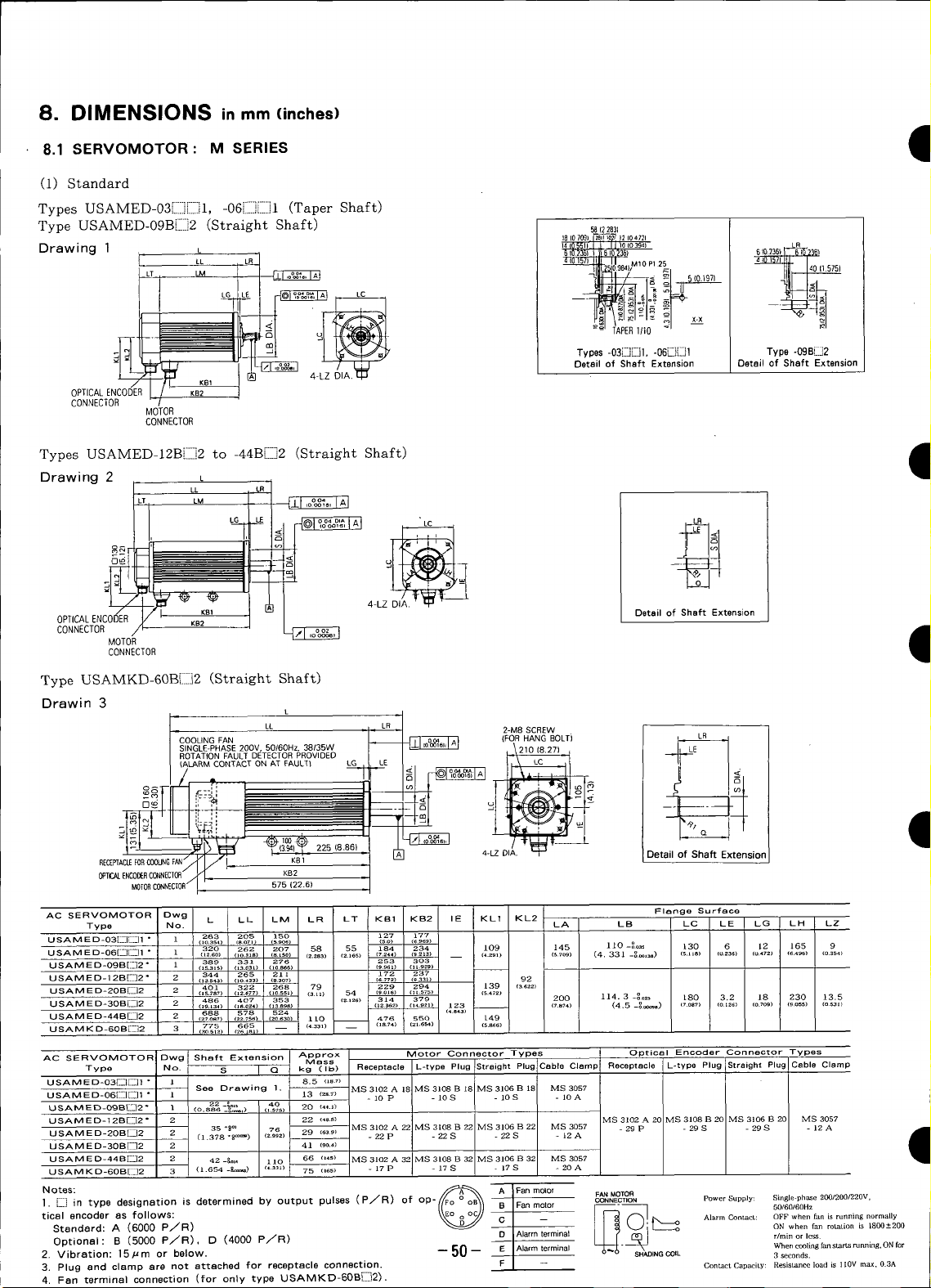

SERVOMOTOR DIMENSIONS: M SERIES ........................................................................... 8 ......... 8.1 ............... 50

SERVOMOTOR DIMENSIONS: S SERIES .............................................................................. 8 ......... 8.3 ............... 55

SERVOMOTOR FREQUENCY ................................................................................................ 4 ......... 4.4 ............... 25

SERVOPACK ........................................................................................................................... 1] ......... 11.2.................. 75

SERVOPACK Connector (2CN) Terminal Layout and Connection .......................................... 5 ......... 5.5.2 ............... 34

SERVOPACK DIMENSIONS ................................................................................................... 8 ......... 8.5 ............... 60

Set Voltage and Current Limit Values .................................................................................... 6 ......... 6.3.2 ............... 38

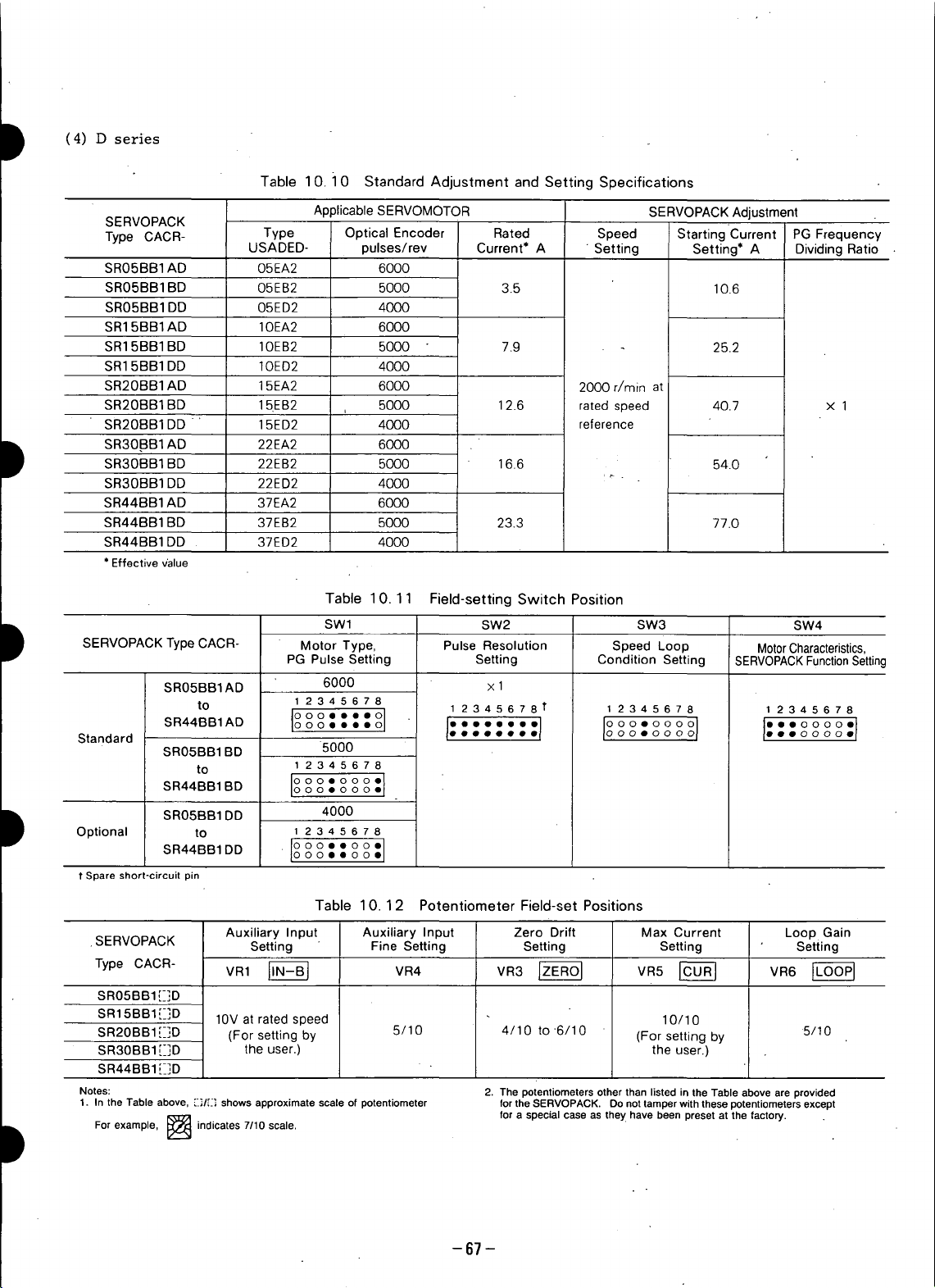

SETTINGS AT THE TIME OF DELIVERY ........................................................................... ]0 ......... ]0.1 ............... 64

Specifications of Applicable Receptacles .................................................................................... 5 ......... 5.4.1 ............... 31

Specifications of Applicable Receptacles and Cables .................................................................. 5 ......... 5.5.1 ............... 34

Speed and Torque Measurement ................................................................................................ 6 ......... 6.9.2 ............... 46

SPEED REFERENCE ............................................................................................................... 6 ......... 6.2 ............... 37

Speed Reference Circuit ............................................................................................................ 6 ......... 6.2.1 ............... 37

STARTING AND STOPPING TIME ....................................................................................... 4 ......... 4.2 ............... 24

Stop Reference Circuit ............................................................................................................... 6 ......... 6.2.2 ............... 37

SWITCH SETTI NG .................................................................................................................. 10 ......... 10.5 ............... 73

T TEST RUN .............................................................................................................................. 9 ................................. 63

TEST RUN PROCEDURES ...................................................................................................... 9 ......... 9.2 ............... 63

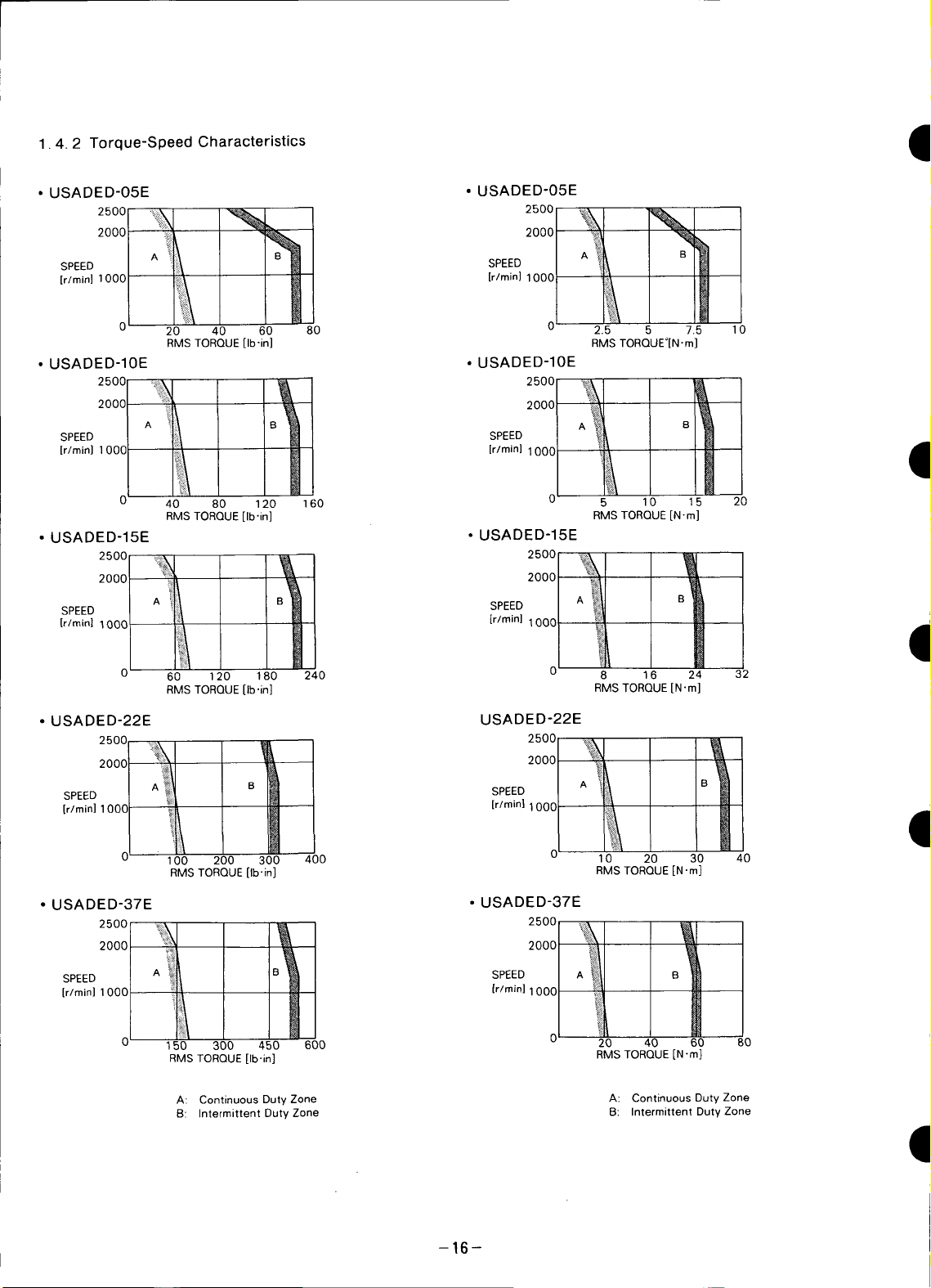

Torque-Speed Characteristics of D Series AC SERVOMOTORS ................................................ ] ......... ].4.2 ............... 16

Torque-Speed Characteristics of F Series AC SERVOMOTORS ................................................ ] ......... ].2.2 ............... ]2

Torque-Speed Characteristics of M Series AC SERVOMOTORS ................................................ ] ......... 1.1.2 ............... ]0

Torque-Speed Characteristics of S Series AC SERVOMOTORS ................................................... 1 ......... ].3.2 ............... ]4

TROUBLESHOOTING GUIDE ................................................................................................ ]2 ................................. 76

TYPE DESIGNATION ............................................................................................................ 2 ................................. ]9

V Vibration Class ........................................................................................................................ 4 ......... 4.6.7 ............... 27

Vibration Resistance ............................................................................................................... 4 ......... 4.6.6 ............... 27

W WIRING ................................................................................................................................. 7 ......... 7.3 ............... 48

Wiring Precautions .................................................................................................................. 7 ......... 7.3.2 ............... 49

INDEX (Cont'd) e

II

Page 10

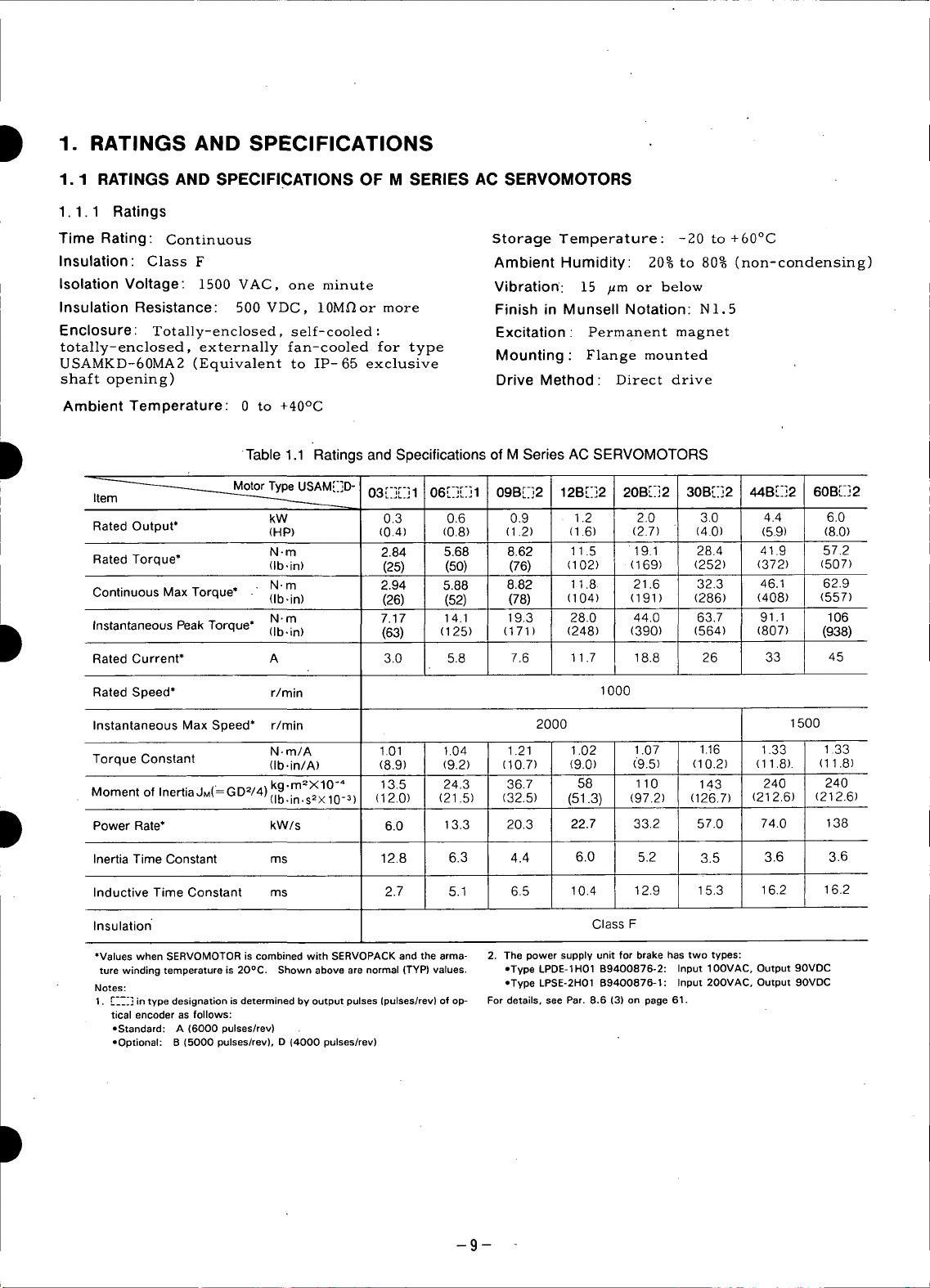

D 1. RATINGS AND SPECIFICATIONS

1.1 RATINGS AND SPECIFICATIONS OF M SERIES AC SERVOMOTORS

1.1.1 Ratings

Time Rating: Continuous Storage Temperature: -20 to +60°C

Insulation: Class F Ambient Humidity: 20%to 80% (non-condensing)

Isolation Voltage: 1500 VAC, one minute Vibration: 15 ILm or below

Insulation Resistance: 500 VDC, 10M_or more Finish in Munsell Notation: N].5

Enclosure: Totally-enclosed, self-cooled : Excitation : Permanent magnet

totally-enclosed, externally fan-cooled for type Mounting" Flange mounted

USAMKD-60MA2 (Equivalent to IP-65 exclusive

shaft opening) Drive Method: Direct drive

Ambient Temperature: 0 to +40°C

Table 1.1 Ratings and Specifications of M Series AC SERVOMOTORS

D

_A ;-I - 03 1 '06 44B[]2

Ite _ -

Rated Output* (HP) (0.4) I (0.8) (1.2) (1.6) (2.7) ' (4.0) (8.0)

Rated Torque* (Ib,in) (25) I (50) (76) (102) (169) (252) (372) (507)

Continuous Max Torque* (Ib,in) (26) I (52) (78) (104) (191) (286) (408) I (557)

kW 0.3 L 0.6 0.9 1.2 2.0 3.0 4.._) 6.0

N-m 2.84 I 5.68 8.62 11.5 19.1 28.4 41.9 57.2

, N-m 2.94 I 5.88 8.82 11.8 21.6 32.3 46.1 I 62.9

N.m 7.17 14.1 19.3 28.0 44.0 63.7 91.1 [ 106

M,.,D ;-_r-;...... r-_r_l...... 09Br-]2 12B[-]2 20B[-]2 30B[]]2 60B[_-]2

D Instantaneous Peak Torque* (Ib,in) (63) (125) (171) (248) (390) (564) (807) (938)

D Power Rate* kW/s 6.0 13.3 20.3 22.7 33.2 57.0 74.0 138

Rated Current* A 3.0 I. 5.8 7.6 11.7 18.8 26 33 45

Rated Speed* r/rain 1000

Instantaneous Max Speed* r/rain 2000 1500

Torque Constant (Ib.in/A) (8.9) (9.2) (10.7) (9.0) (9.5) (10.2) (11.8). (11.8)

Moment of Inertia JM('----GD2/4) kg'm2XlO'" 13.5 24.3 36.7 58 110 143 240 240

Inertia Time Constant ms 12.8 6.3 4.4 6.0 5.2 3.5 3.6 3.6

Inductive Time Constant ms 2.7 5.1 6.5 10.4 12.9 15.3 16.2 16.2

Insulation ClassF

*Values when SERVOMOTOR is combined with SERVOPACK and the arma- 2, The power supply unit for brake has two types:

ture winding temperature is 20°C. Shown above are normal (TYP) values. ,Type LPDE-1H01 B9400876-2: Input IOOVAC, Output 90VDC

Notes: ,,Type LPSE-2H01 B9400876-1: Input 20OVAC, Output 9OVDC

1. [---] in type designation is determined by output pulses (pulses/rev) of op- For details, see Par. 8.6 (3) on page 61.

tical encoder as follows:

oStandard: A (6000 pulses/rev)

oOptional: B (5000 pulses/rev), D (4000 pulses/rev)

N.m/A 1.01 1.04 1.21 1.02 1.07 1.16 1.33 1.33

(Ib.in.s2× 10-3 ) (12.0) (21.5) (32.5) (51.3) (97.2) (126.7) (212,6) (212.6)

-9-

Page 11

1.1.2 Torque-Speed Characteristics g

• TYPE USAMED-03[_-] • TYPE USAMED-20B

,,,ll

E2000 - +.... "_2°°°i ,+ ....... _ ---:_2 '=_ T: -+---,

E '-_'! ' _.isoo _ISOO _ isoo ,

;500 _ 8 "'

"E20001 _,_ _,_ 2 20001 ,, +._,

,ooo__ _ti __1ooo _ / Ai_ LI '_ _,

0 2 4 6 I; 20 40 60 0 10 20 30 40 0 100 200 300 400

RMS TORQUE (N-m) RMS TORQUE (Ib.in) RMS TORQUE (N.m) RMS TORQUE (Ib.in)

• TYPE USAMED-06_] • TYPE USAMED-30B

2ooo_ _2oooI............. 12ooo..................,,-._. _2ooo

++oo+,++,+oop ++oo++

+00_ 2+, 210, +oo_l

1101 +°OOOlBI1 ++,ooo[A!I +++°°°I

0 3 6 9 12 _ 2's8_7_;_0'_5 0 20 ;0 60 0 200 _00 600

RMS TORQUE (N-m) RMS TORQUE (Ib.in) RMS TORQUE (N.m) RMS TORQUE (Ib.in) /

• TYPEUSAMED-09B • TYPEUSAMED-44B

" • _ _-+,....... _1_ooI ,_, -..,._._

4

- __o°°r_---_ __°°°I __ooo_

_1800 r _ _ + 1500F ",_ _l _ 15001 ,++.#_ _ _ 1500_

,9, m,ooo ,,11oooi-"\'_'_ _,1ooo

• [] i I I] + + I++l:11

0 4 8 12 16 0 50 100 150 0 20 40 60 80 0 200 400 600 8001000

RMS TORQUE (N +m) RMS TORQUE (Ib.in) RMS TORQUE (N .m) RMS TORQUE (Ib.in) 4

• TYPEUSAMED-12B • TYPEUSAMKD-60B

2800_ _2000_ _2000r _ ._2°°°I

._2ooo _ _,+oo

_1500F "_+" _ _ 1500r \:5_ _"'_ ....

_1000 _1000 + 1000P ":"/'_% _1000

° t:',x,+,H° i \+ l ,A,.,I,B_

0 10 20 50 100 150 200 250 0 2_5 80 75 100 0 200 400 600 8001000

RMS TORQUE (N.m) RMS TORQUE (Ib-in) RMS TORQUE (N.m) RMS TORQUE (Ib-in)

28001 2_°°/ t _2_°°/

CO A ' ;

A: CONTINUOUS DUTY ZONE

B: INTERMITTENT DUTY ZONE

POWER SUPPLY: 200V i

i

I

-10-

Page 12

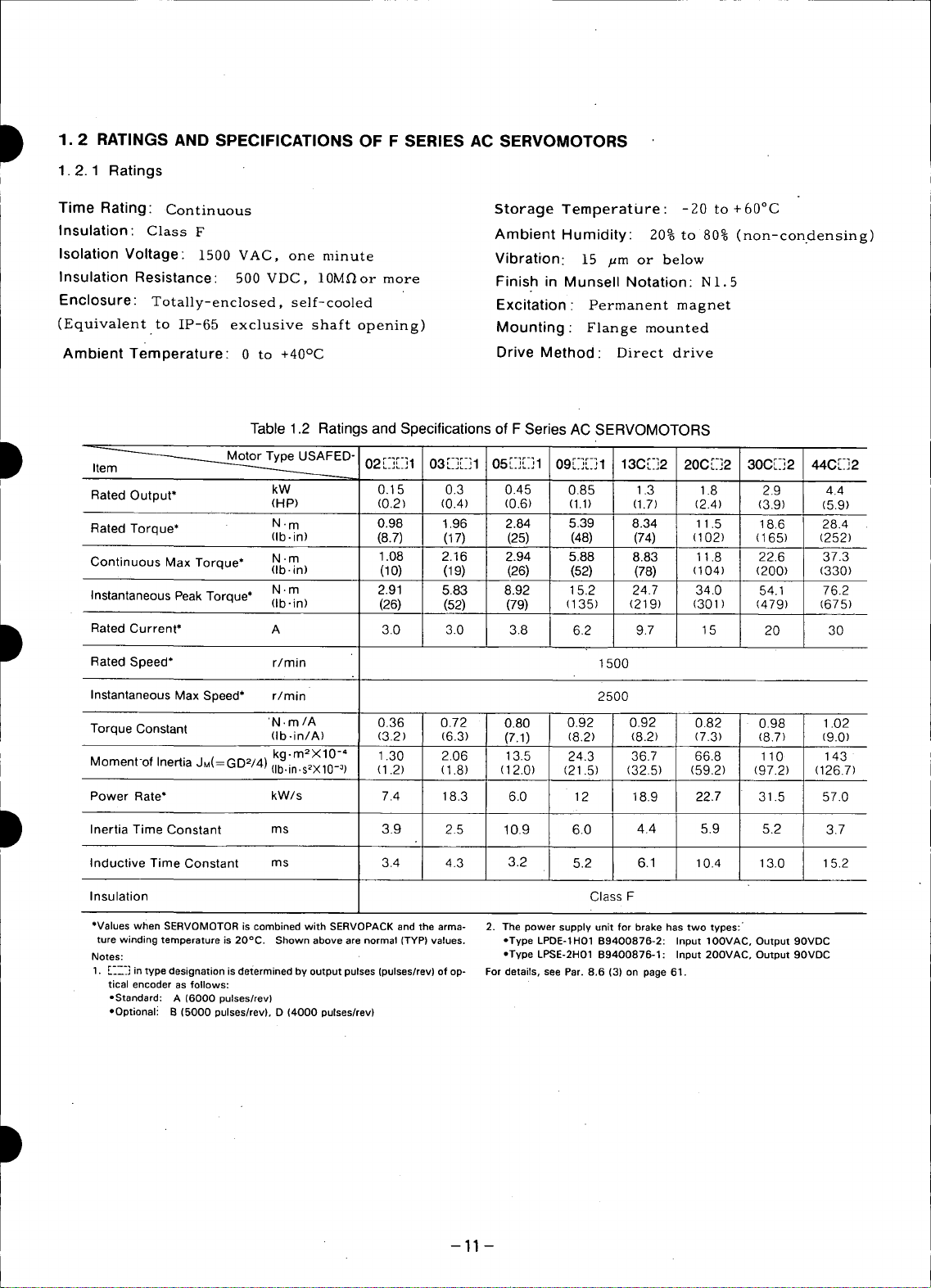

D 1.2 RATINGS AND SPECIFICATIONS OF F SERIES AC SERVOMOTORS

1.2.1 Ratings

Time Rating: Continuous Storage Temperature : -20 to + 60°C

Insulation: Class F Ambient Humidity: 20% to 80% (non-con.densing)

Isolation Voltage: 1500 VAC, one minute Vibration: 15 ,_m or be]ow

Insulation Resistance: 500 VDC, 10M_or more Finish in Munsell Notation: NI.5

Enclosure: Totally-enclosed, self-cooled Excitation : Permanent magnet

(Equivalent to IP-65 exclusive shaft opening) Mounting: Flange mounted

Ambient Temperature: 0 to +40°C Drive Method: Direct drive

Table 1.2 Ratings and Specifications of F Series AC SERVOMOTORS

D _ D" r-_r-il r-lr-i r-lr-_ 09_-'_"1 130_-2

02 ...... I 03 ...... 1 r _r-_ r-i

05 ...... 1 20C [.-]2 30C[-]2 _44C[]2

kW 0.1 5 I 0.3 0.45 0.85 1.3 1.8 2.9 I 4.4

Rated Output* (HP) (0.2) I (0.4) (0.6) (1.1) (1.7) (2.4) (3.9) I (5.9)

Rated Torque* N-m 0.98 I 1.96 2.84 ' 5.39 8.34 11.5 18.6 t 28.4

Continuous Max Torque* N .m 1.08 I 2.16 2.94 5.88 8.83 11.8 22.6 [ 37.3

Instantaneous Peak Torque* N. m 2.91 I 5.83 8.92 15.2 24.7 34.0 h4 1 I 76.2

(Ib.in) (8.7) I (17) (25) : (48) (74) (102) (165) I (252)

(Ib.in) (10) I (19) (26) (52) (78) (104) (200) I (330)

(Ib-in) (26) I (52) (79) (135) (21 9) (301) (47_) I (675)

I

i

i

D Rated Current* A 3.0 I 3.0 3.8 6.2 9.7 15 20 I 30

Rated Speed* r/min 1500

Instantaneous Max Speed* r/rain 2500

Torque Constant 'N. m/A 0.36 0.72 0.80 0.92 0.92 0.82 0.98 1.02

(Ib.in/A) (3.2) (6.3) (7.1) (8.2) (8.2) (7.3) (8.7) (9.0)

kg-m2X10 -" 1.30 2.06 13.5 24.3 36.7 66.8 110 143

Moment-of Inertia JM(= GD2/4) (ib.in.s2X10_3) (1.2) (1.8) (12.0) (21.5) (32.5) (59.2) (97.2) (126.7)

Power Rate* kW/s 7.4 18.3 6.0 12 18.9 22.7 31.5 57.0

4.4

5.9

D Inertia Time Constant ms 3.9 2.5 10.9 6.0 5.2 3.7

Inductive Time Constant ms 3.4 4.3 3.2 5.2 6.1 10.4 13.0 15.2

Insulation ClassF

*Valueswhen SERVOMOTORis combinedwith SERVOPACKandthe arma- 2. The power supply unit for brake hastwo types:

ture windingtemperatureis 20°C. Shown abovearenormal(TYP)values, oType LPDE-1H01B9400876-2: Input IOOVAC,Output 90VDC

Notes: *TypeLPSE-2H01B9400876-1: Input2OOVAC,Output90VDC

1, [-__-_]in type designationis determinedby output pulses(pulses/rev)of op- For details, seePar.8.6 (3) on page61.

tical encoder as follows:

-Standard: A (6000 pulses/rev)

oOptionali B (5000 pulses/rev),D (4000 pulses/rev)

--11 --

Page 13

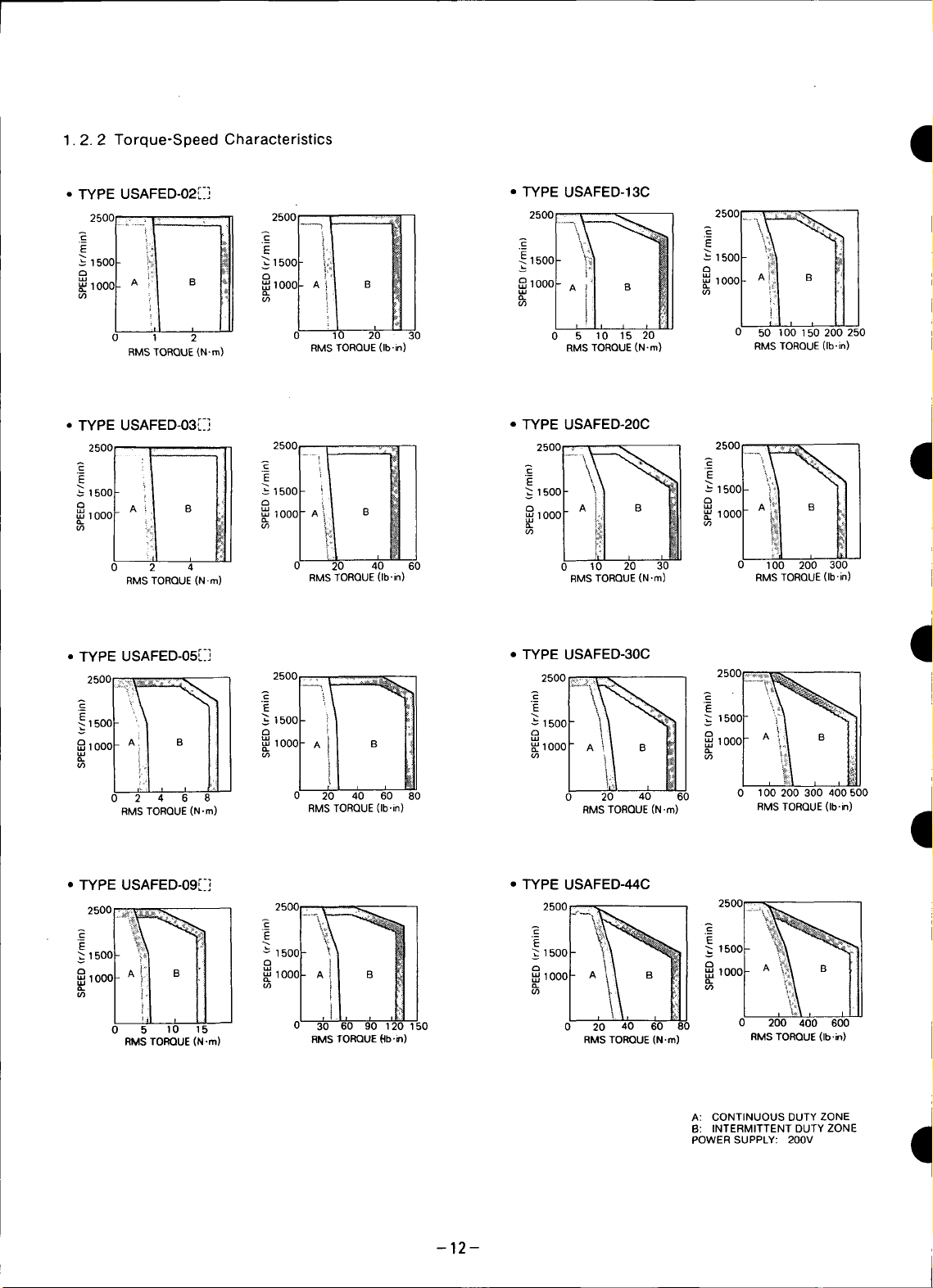

1.2.2 Torque-Speed Characteristics I

• TYPEUSAFED-02[_] • TYPEUSAFED-13C

25oo_ ...... _ _, -_

(_)1000_ __)1ooo_ _/!l MI" /)1_,II1

0 ,--2 0 10 20 30 0 _ ;0 _5_0 0 5010b1_0200250

RMS TORQUE{N,m) RMS TORQUE (Ib-in) RMS TORQUE(N.m} RMS TORQUE(Ibgn)

• TYPEUSAFED-03[_] • TYPEUSAFED-20C

1500 "_ 1500 _1500 " _ 1500l \_% I t

,all

,,a, rA!)t B _t _ O [A \\ _1 8 A! ;_

_iooo _ _,_l _/" _ 'Ill

2500..... I'l 2500, ........ 25°°I,_--_\ I 2500....,.

!i t000 A i "u_' 1000_ l'ill B_l _ 10001- _1 B _!1 /

,iil _!t • _, o, /_!1

0 2 4 20 40 60 0 ,0 20 30 0 100 200 300

RMS TORQUE(N.m) RMS TORQUE(Ib-in) RMS TORQUE(N.m) RMS TORQUE(Ib'in)

dl

• TYPE USAFED-05[:] • TYPE USAFED-30C

E1500 _1500 i ,500

,oooLAi _ 8,ooor__:,I_ II

° il fl

0 2 4 6 8 0 20 40 60 80 0 20 40 60 0 100 200 300 400 500

RMS TORQUE(N.m) RMS TORQUE(Ib.in) RMSTORQUE (N .m) RMS TORQUE(Ib-in)

I

• TYPEUSAFED-09r_] • TYPEUSAFED-44C

1500 "_ 1500

,ooog,l:IB I:I 100o

if) _i"

""'" l'iC""°°°[!i

2500_ _ J 2500 "........... ,- _':_ _11...... i2500-'"_i_ I 2500 __...... ,1.o Ooi.l,i ,,

0 5 10 15 0 30' 60 90 120 150 0 20 40 60 80 0 200 400 600

RMS TORQUE(N-m) RMS TORQUE(-Ib.rl) RMS TORQUE (N.m) RMSTORQUE(Ib.in)

-12-

A: CONTINUOUS DUTY ZONE

B: INTERMITTENT DUTY ZONE

POWER SUPPLY: 200V

Page 14

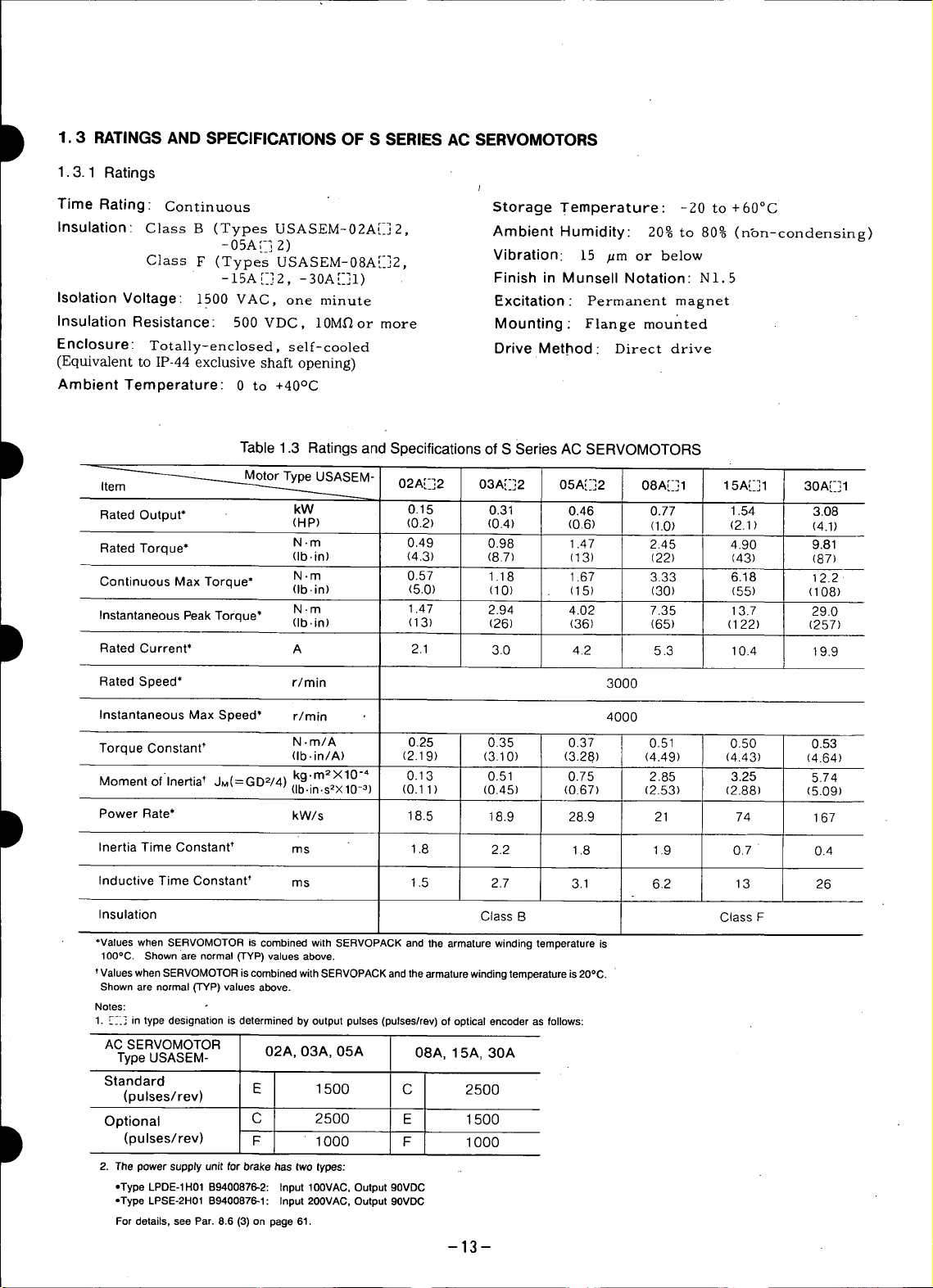

1.3 RATINGS AND SPECIFICATIONS OF S SERIES AC SERVOMOTORS

1.3.1 Ratings

Time Rating Continuous Storage Temperature: -20 to +60°C

Insulation" Class B (Types USASEM-02A[-] 2, Ambient Humidity: 20% to 80% (nt)n-condensing)

- 05A!_] 2)

Class F (Types USASEM-08A[-]2, Vibration. 15 /_m or below

-15At-12, -30A[-]1) Finish in Munsell Notation: NI.5

Isolation Voltage" 1500 VAC, one minute Excitation: Permanent magnet

Insulation Resistance: 500 VDC, 10Mf_or more Mounting" Flange mounted

Enclosure: Totally-enclosed, self-cooled Drive Method Direct drive

(Equivalent to IP-44 exclusive shaft opening)

Ambient Temperature" 0 to +40°C

D Table 1.3 Ratings and Specifications of S Series AC SERVOMOTORS

_EM 02A[-_]2 03A[-]2 05A[_]2 08A[-]1 15A[-]1 30A[[]1

Rated Output* kW 0.15 0.31 0.46 0.77 1.54 3.08

Rated Torque* N. m 0.49 0.98 1.47 2.45 4.90 9.81

Continuous Max Torque* N.m 0.57 I .I 8 1.67 3.33 6.18 12.2

(HP) (0.2) (0.4) (0.8) (1.0) (2.1) (4.1)

(lb. in) (4.3) (8.7) (13) (22) (43) (87)

(lb.in) (5.0) (I 0) (15) (30) (55) (108)

N.m 1.47 2.94 4.02 7.35 13.7 29.0

Instantaneous Peak Torque" (Ib.in) (13) (26) (36) (65) (122) (257)

/

D Rated Current* A 2.1 3.0 4.2 5.3 10.4 19.9

Rated Speed* r/min 3000

Instantaneous Max Speed* r/min 4000

Torque Constant* N. m/A 0.25 0.35 0.37 0.51 0.50 0.53

(Ib-in/A) (2.19) (3.10) (3.28) (4.49) (4.43) (4.64)

" kg.m2X10 "4 0.13 0.51 0.75 2.85 3.25 5.74

Moment of Inertia t JM(=GD2/4) (ib.in.s2×10_3) (0.11 ) (0.45) (0.67) (2.53) (2.88) (5.09)

D Power Rate* kW/s 18.5 18.9 28.9 21 74 167

Inertia Time Constant t ms 1.8 2.2 1.8 1.9 0.7 " 0.4

InductiveTime Constant_ ms 1.5 2.7 3.1 6.2 13 26

Insulation ClassB ClassF

*values whenSERVOMOTORis combinedwith SERVOPACKand the armaturewinding temperatureis

100°C. Shownare normal(TYP)valuesabove.

tValueswhenSERVOMOTORiscombinedwith SERVOPACKandthearmaturewindingtemperatureis 20°C.

Shownare normal(TYP)valuesabove.

Notes:

1. [_-] in type designationis determinedby outputpulses (pulses/rev)ofoptical encoderas follows:

AC SERVOMOTOR

Type USASEM- 02A, 03A, 05A 08A, 1 5A, 30A

Standard

(pulses/rev) E 1 500 C 2500

Optional C 2500 E 1500

D (pulses/rev) F 1000 F 1000

2. The powersupptyunitfor brakehas twotypes:

=TypeLPDE-1H01B9400876-2: Input 100VAC,Output90VDC

*TypeLPSE-2H01B9400876-1: Input200VAC,Output90VDC

Fordetails,seePar.8.6(3) onpage61.

--13--

Page 15

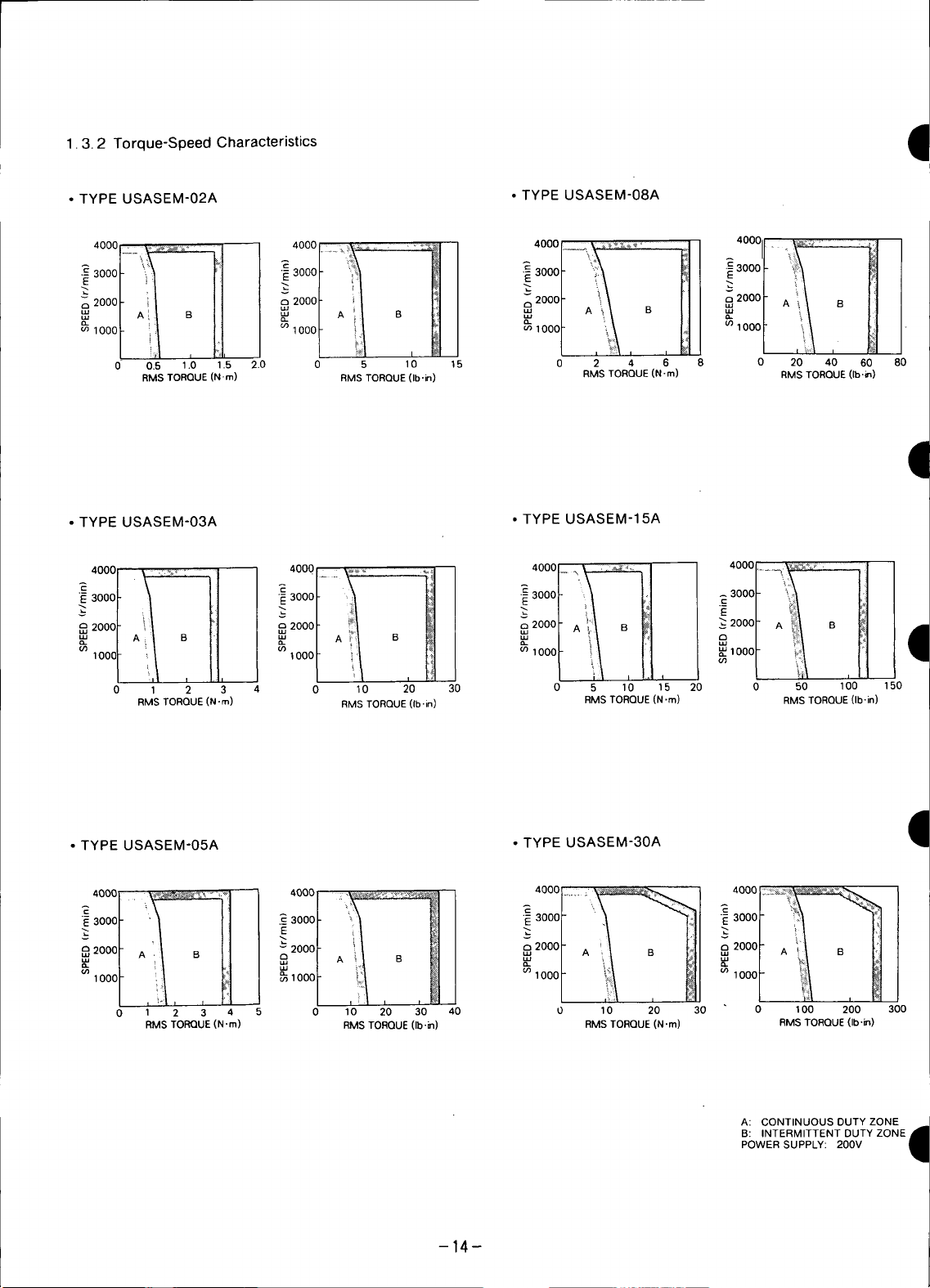

1.3.2 Torque-Speed Characteristics I

• TYPE USASEM-02A •TYPE USASEM-08A

,ooo.....,....... _'°°°t__ ,ooo_ ,oooai._,_....._t

&2ooo__ t_ , _2ooo__ _ H i=°°°r,_\ _ III _:=°°°r*ik _JJi

"_ '°°°Ii/ H

0 0.5 1.0 1.5 2.0 0 5 10 15 0 2 4 6 8 0 20 40 60 80

RMS TORQUE(N-m) RMS TORQUE (Ib.in) RMS TORQUE(N-m) RMS TORQUE (Ib.in)

• TYPEUSASEM-03A ,TYPE USASEM-15A

:_°°°r,/ Li / _°°°r:t _ I _oool-_ L,J _3°°°F'_i_ [:i]

,14i,l°W , ,

0 1 2 3 4 0 10 20 30 0 5 10 15 20 0 50 100 150

RMS TORQUE(N.m) RMS TORQUE(Ib.in) RMS TORQUE (N.m) RMS TORQUE(Ib-in)

•TYPEUSASEM°05A • TYPEUSASEM-30A

t/, []/ •"_ _" 3000I ""/ _!] "_"2000_ A i/ B I!]

(/_1000 _) 1000 i_ (,O1000 (,_ i:_

. ,_.I,, _ . /:I , ,_I, . _,;i_I, M, L _:.:_,iI, _Ii

0 1 2 3 4 5 0 10 20 30 40 0 10 20 30 0 100 200 300

RMS TORQUE(N.m) RMS TORQUE(Ib-in) RMSTORQUE(N.m) RMS TORQUE(Ib.m)

/ ,oooI i:/-,II ,ooo ,ooo, _',_ , ,i, , , / ;,/ , I,t

2oooF ',I _1 I _2000rA _,/ B l;Ii 8

A: CONTINUOUS DUTY ZONE

B: INTERMITTENT DUTY ZONE,_

POWER SUPPLY: 200V

q

-14-

Page 16

1.4 RATINGS AND SPECIFICATIONS OF D SERIES AC SERVOMOTORS

1.4.1 Ratings

Time Rating: Continuous Storage Temperature : -20 to + 60°C

Insulation: Class F. Vibration: 15 /_m or below

Isolation Voltage: 1500 VAC, one minute Finish in MunsellNotation: N1.5

Insulation Resistance: : 500 VDC, 10Mflor more Excitation: Permanent magnet

Enclosure: Totally-enclosed, self-cooled Mounting: Flange' mounted

(Equivalent to IP-65 exclusive shaft opening) Drive Method: Direct drive

Ambinent Temperature: 0 to +40 C

Ambient Humidity: 20% to 80% (non-condensing)

Table 1.4 Ratings and Specifications of D Series AC SERVOMOTORS

Y

Holding Brake Provided

I Motor Type USADED-I

i Rated Current* A 3.5 7.9 12.6 16.6 23.3

D Inductive Time Constant ms 6.9 9.4 11 15

Item -- 05E_-,:2 10E[_-]2 15r-]2 22Er-]2 37E[-_2

kW 0.5 1.0 1.5 2.2 3.7

Rated Output* (HP) (0.67) (1.3) (2.0) (2.9) (5.0)

RatedTorque* N.m 2.35 4.81 7.16 10.5 17.7

Continuous Max Torque* (Ib-in) (30) (56) (78) (122) (191 )

Instantaneous Pe_ikTorque* (Ib.in) (73) " (149) (222) (326) (547)

Rated Speed* r/min 2000

Instantaneous Peak Speed* r/min 2500 :

Torque Constant N .m/A 0.83 0.69 0.64 0.71 0.82

M°ment °f Inertia JM(=GD_/4) (Ib.in.s2X10 -3) (18.6, 11.5t) (28.3, 21.2,) (54.9, 52.2t) (73.51 70.8t) (131, 128.3 t)

Power Rate* kW/s

Inertia Time Constant ms 11_ 5.9t 6.8, 6.0* 4.2_

Insulation ClassF

Holding

Brake Static Friction 8.82 21.56

PowerSupply VDC 90

Torque N. m(Ib-in) (78) (191)

(Ib.in) (21) (43) (63) (93) :(156)

N. m 3.43 6.37 8.83 13.7 '21.6

N. m 8.24 16.9 25.1 36.8 61.8

(lb. in/A) (7.38) (6.07) (5.64) (6.25) (7.29)

kg.m2X10 "" 21,'13, 32, 24t 62, 59t 83, 80t 148,145'

2-.7 7.3 8.2 13 21

4.4t 9.7* 8.6t 14t 22t

18" 7.8 7.1 6.2 4.3

4.4

Approx. Mass (Ib) (37.5, 35.3t) (41.9, 39.7t1 (66.2, 59.5*) (70.6, 64*) (86.0, 79.4t)

*ValueswhenSERVOMOTORiscombinedwithSERVOPACKandthearma- 2. Thepowersupplyunitforbrakehastwotypes:

turewindingtemperatureis20°C. Shownabovearenormal(TYPIvalues, oTypeLPDE-1H01B9400876-2:Input100VAC,Output90VDC

tValueswhenholdingbrakeis notprovided. ,,TypeLPSE-2H01B9400876-1:Input200VAC,Output90VDC

Notes: Fordetails,seePar.8.6(3)onpage61.

1.['__--.]intypedesignationisdeterminedbyoutputpulses(pulsesliev)ofopti-

cal encoder as follows:

-Standard:A (6000pulses/rev)

,Optional: B(5000pulseslrev),O(4000pulses/rev)

kg 17, 16' l 19,18' 30,27' 32,29' [ 39,36'

--15--

Page 17

1.4.2 Torque-Speed Characteristics

• USADED-05E • USADED-05E

2000 : _ 2000

SPEED SPEED I!

oo. oo

[r/mini

1000 [r/min} 1000 1

0 20 40 60 80 2.5 5 7.5 10

RMSTORQUE[Ib-in] RMSTORQUE°[N"m]

• USADED-10E • USADED-10E

2500:_ _ 2500_%1 & I

SPEED ii SPEED

[r/mini 1000 [r/mini 1000 I

0' 40 80 120 160 0 5 10 15 20

RMS TORQUE [Ib'in] RMS TORQUE IN'm]

• USADED-15E • USADED-15E

2500_i_

25°°1A'_ BY_ 2000_il

SPEED i_ii SPEED

[r/minl 1000 ' [r/rain] 1000 _]

20oo _'1 _ A B i

0 60 120 180 240 0 8 36 24 32

RMSTORQUE[Ib'in] RMSTORQUE[N'm]

• USADED-22E USADED-22E

2500 :_, _ 2500 _

I

2ooc 2000 I

SPEED _ [r/mini 1000

[r/mini 100C

100 200 300 400 10 20 30 40

RMSTORQUE[Ib'in] RMSTORQUE[N"m]

• USADED-37E • USADED-37E

2500_ _ 2500_:,_

2000 '_!i_ 2000

SPEED A B SPEED A B

,r,m, ,,000 'r''o' 000

0 150 300 450 600 20 40 60 80

RMSTORQUE[Ib'in] RMSTORQUE[N-m]

A: Continuous Duty Zone A: Continuous Duty Zone

B: Intermittent Duty Zone B: Intermittent Duty Zone

B SPEED A _i,_ B i

I

-16-

I

Page 18

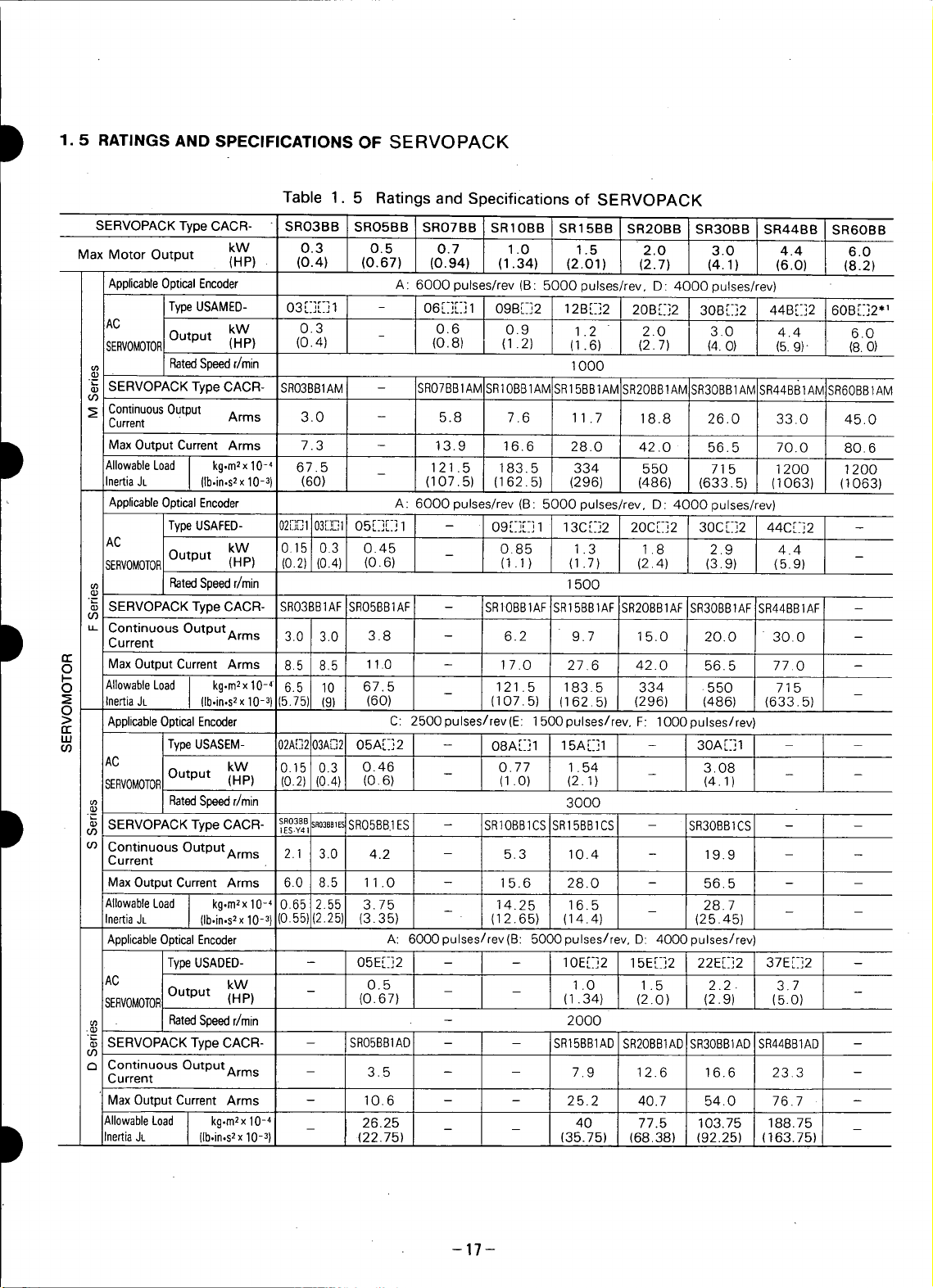

D 1.5 RATINGS AND SPECIFICATIONS OF SERVOPACK

Table 1. 5 Ratings and Specifications of SERVOPACK

SERVOPACKTypeCACR- SRO3BB SRO5BB SRO7BB SRIOBB SR15BB SR2OBB SR3OBB SR44BB SR6OB8

Max Motor Output kW 0.3 0.5 0.7 1.0 1.5 2.0 3.0 4.4 6.0

ApplicableOpticalEncoder A: 6000 pulses/rev (B: 5000 pulses/rev, D: 4000 pulses/rev)

Type USAMED- rqrq

AC

SERVOMOTOFOutput kW 0.3 0.6 0.9 1.2 2.0 3.0 4.4 6.0

_, RatedSpeedr/rain 1000

_ SERVOPACK Type CACR- SRO3B81AM - SRO7BB1AM SRIOBB1AM SR15BB1AM SR20B81AM SR3OBB1AM SR44BB1AM SR60B81AM

03

Continuous Output

Current " Arms 3.0 - 5.8 7.6 11.7 18.8 26.0 33.0 45.0

(HP) (0.4) (0.67) (0.94) (1.34) (2.01) (2.7) (4.1) (6.0) (8.2)

03 ...... 1 - 06[_][-]1 09B[_-]2 12B[-]2 20B[-]2 30B[.-]2 44B[_-]2 60B[_]2"

(HP) (0.4) (0.8) (1.2) (1.6) (2.7) (4.O) (5.9)- (8.O)

D Max Output Current Arms 7.3 - 13.9 16.6 28.0 42.0 56.5 70.0 80.6

D u_ Continuous OutpUtArms

AllowableLoad kg.m2x10-4 67.5 _ 121.5 183.5 334 550 715 1200 1200

InertiaJL (Ib.in.s2x10-3) (60) (107.5) (162.5) (296) (486) (633.5) (1063) (1063)

ApplicableOptical Encoder A: 6000 pulses/rev (B: 5000 pulses/rev, D 4000 pulses/rev)

Type USAFED- 32[][-,"103[]L_1 t-;r-;

AC

SERVOMOTOROutput kW 10.15 0.3 0.45 _ 0.85 1.3 1.8 2.9 4.4

RatedSpeedr/rain 1500

SERVOPACKType CACR- SRO3BB1AFSRO5BB1AF - SRIOBBIAF 'SR158BlAF SR2OgB1AFSR3OBB1AFSR44BBlAF -

O0

- [

Current 3.0 3.0 3.8 - 6.2 9.7 15.0 20.0 " 30.0 -

_) Max Output Current Arms 8.5 8.5 11.0 - 17.0 27.6 42.0 56.5 77.0 -

_) AllowableLoad kg'rn2x10-4 6.5 10 67.5 121.5 183.5 334 -550 715

InertiaJL (Ib,in,s2xlO-3) (5.75) (9) (60) (107.5) (162.5) (296) (486) (633.5) -

ApplicableOpticalEncoder C: 2500pulses/rev(E: 1500pulses/rev, F: lO00pulses/rev)

LU

AC

SERVOMOTOROutput kW 0.15 0.3 0.46 _ 0.77 1.54 _ 3.08 _ _

_, RatedSpeedr/rain 3000

SERVOPACKTypeCACR- sR°38BsRo38B1E.'SRO5BB1ES- SRIOBB1CS SR15BB1CS - SR3OSB1CS - -

-

u) Continuous OutputArms 2.1 3.0 4.2 - 5.3 10.4 - 19.9 - -

Current

MaxOutputCurrent Arms 6.0 8.5 11.0 - 15.6 28.0 - 56.5 - -

AllowableLoad kg,m2xlO-4 0.65 2.55 3.75 14.25 16.5 28.7

InertiaJL (Ib,in,s2xlO-3) 0.55)(2.25) (3.35) (12.65) (14.4) (25.45)

ApplicableOpticalEncoder A: 6000 pulses/rev(B: 5000 pulses/rev, D: 4000 pulses/rev)

AC Output kW _ O.5 _ _ 1.0 1.5 2.2 • 3.7 _

SERVOMOTOR (HP) (0.67) (1.34) (2.0) (2.9) (5.0)

._ RatedSpeedr/min - 2000

$ SERVOPACK Type CACR- - SRO5BB1AO - - SR15BB1AD SR2OBB1ADSR3OSB1ADSR44BB1AD -

(./3

E3 Continuous OutputArms

Current - 3.5 - - 7.9 12.6 16.6 23.3 -

MaxOutputCurrent Arms - 10. 6 - - 25.2 40.7 54.0 76.7 -

TypeUSASEM- 02A[3203A[-J2 05A[-]2 - 08AE]I 15A[_]1 - 30A[r]l - -

Type USADED- - 05E[_]2 - - 10E[-]2 15E[_-]2 22E[.-]2 37E[-]2 -

(HP) (0.2)(0.4) (0.6) (1.1) (1.7) (2.4) (3.9) (5.9) -

(HP) (0.2)(0.4) (0.6) (1.0) (2.1) (4.1)

i ES.Y4i

05 ...... 1 - 09 E][_-] 1 13C [-]2 20C[-]2 30C it]2 44C [_-]2 -

Inertia& (Ib.in.s2x 10-3) (22.75) (35.75) (68.38) (92.25) (163.75)

AllowableLoad kg'm2x10-4 _ 26.25 _ _ 40 77.5 103.75 188.75 _

-17-

Page 19

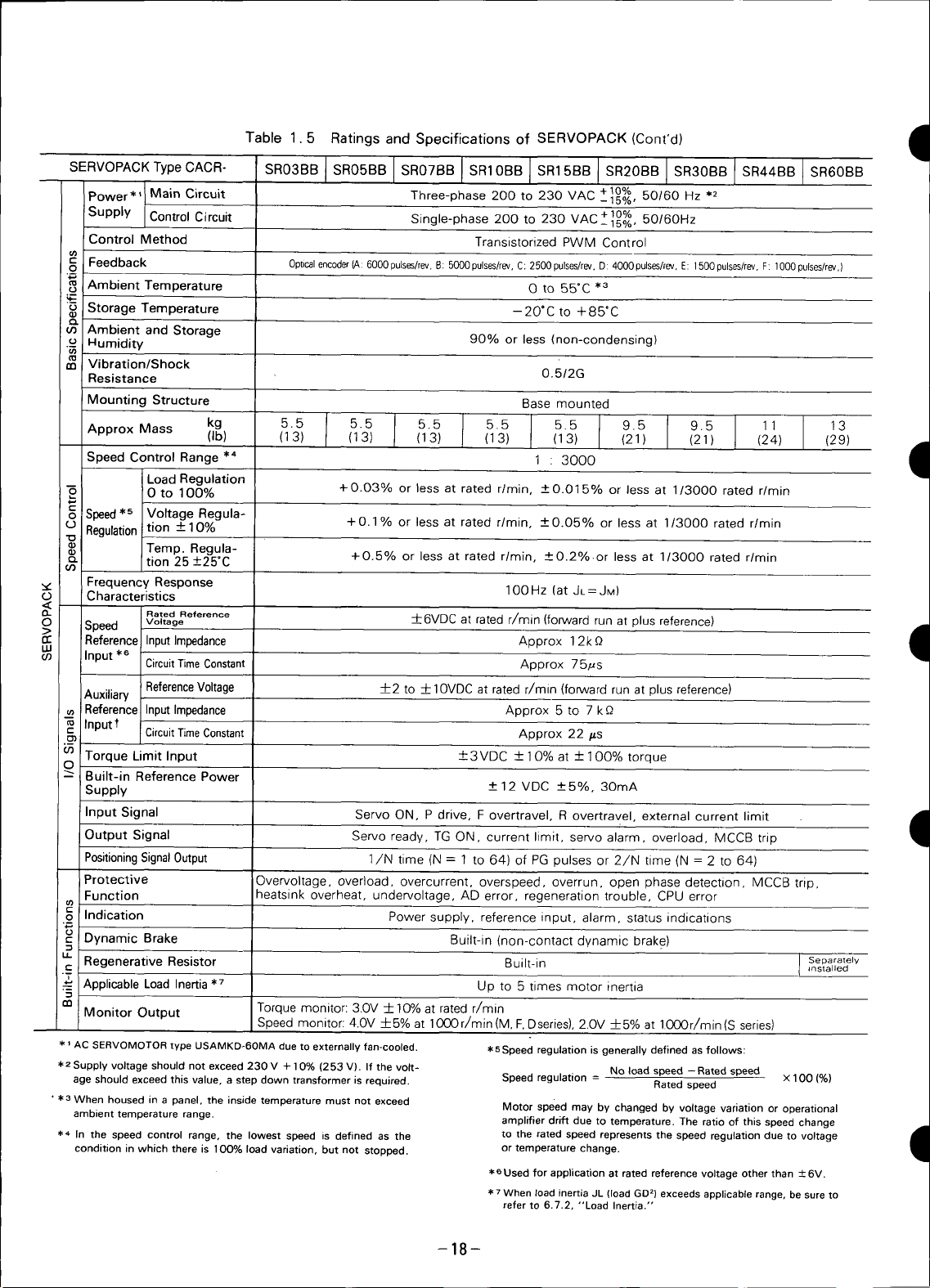

Table 1.5 Ratings and Specifications of SERVOPACK (Cont'd) am

,qu

,do

SERVOPACK Type CACR- SR03BB ] SR05BB I SR07BB _ SR15BB I SR20BB 6_ SR60BB

Power*_ I Main Circuit Three-phase 200 to 230 VAC _ 15%,

Supply Control Circuit Single-phase 200 to 230 _/^r+10% 50/60Hz

Control Method Transistorized PWM Control

Feedback Optical enc0der (A: 6000 pulses/ ev, B 5000puses/rev, C: 2500pulses/rev. D: 4000pulses/rev, E: 1500pulses/rev, F: 1000 pulses/rev,)

Ambient Temperature O to $5°C .3

_ Storage Temperature -20°C to +85°C

u_ Ambient and Storage

o I-lumidity 90% or less (non-condensing)

Resistance 0.5/2G

a_ Vibration/Shock

Mounting Structure Basemounted

Approx Mass kg 5.5 I 5.5 5.5 5.5 I 5.5 9.5 9.5 11 13

Speed Control Range .4 1 ' 3000 I

Load Regulation

Oto 100% +0.03% or less at rated r/rain, -+O.015% or less at 1/3000 rated r/rain

Speed*e Voltage Regula-

-o Regulation tion ---10% +O.1% or less at rated r/rain, -+0.05% or less at 1/3000 rated r/rain

'_ tion25+25°C

u_

Frequency Response

Charactenst_cs

£1 Rated Reference +6VDC at rated r/rain (forward run at plus reference)

Speed Voltage -- •

O ReferenceInputImpedance Approx 12k Q

co Input _,e CircuitTimeConstant Approx 75#s

Temp. Regula-

(Ib) (13) I (13) (13) (13) i _,o_ (21) (21) (24) (29) .din

+0.5% or less at rated r/min, +0.2%or less at 1/3000 rated r/min

1O0Hz(atJL=JM)

+10% 50/ Hz*2

v_ _ 15%,

1

Auxiliary ReferenceVoltage 4-2 to _-----F10VDCat rated r/rain (forward run at plus reference)

ReferenceInputImpedance Approx 5 to 7 kP,

Inputt

.__ CircuitTimeConstant Approx 22 #s

cn Torque Limit Input +3VDC + 10% at --4-100% torque

O

"" Built-in Reference Power

Supply -+ 12 VDC -+5%, 3OmA

Input Signal Servo ON, P drive, F overtravel, R overtravel, external current limit •

Output Signal Servo ready, TG ON, current limit, servo alarm, overload, MCCB trip

PositioningSignalOutput 1/N time (N = 1 to 64) of PG pulses or 2/N time (N = 2 to 64)

Protective Overvoltage, overload, overcurrent, overspeed, overrun, open phase detection, MCCB trip,

Function heatsink overheat, undervoltage, AD error, regeneration trouble, CPU error

o Indication Power supply, reference input, alarm, status indications

Dynamic Brake Built-in (non-contact dynamic brake)

_"_"Regenerative Resistor Built-in I _nstalledSeparately

"_ Applicable Load Inertia .7 Up to 5 times motor inertia

05

Monitor Output Torque monitor: 30V ___10%at rated r/min

_'_ AC SERVOMOTOR type USAMKD-6OMA due to externally fan-cooled. _'eSpeed regulation is generally defined as follows:

2Supply voltage should not exceed 230 V + 10% (253 V). If the volt- No load speed --Rated speed

age should exceed this value, a step down transformer is required. Speed regulation = Rated speed X 100 (%)

• _,3 When housed in a panel, the inside temperature must not exceed Motor speed may by changed by voltage variation or operational

ambient temperature range, amplifier drift due to temperature. The ratio of this speed change

,I,4 In the speed control range, the lowest speed is defined as the to the rated speed represents the speed regulation due to voltage

condition in which there is 1OO% load variation, but not stopped, or temperature change.

Speed monitor: 4.0V 4-5% at 1000r/min(M, F,Dsenes), 2.0V 4-5% at 1000r/min(S series)

e Used for application at rated reference voltage other than ± 6V.

• TWhen load inertia JL (load GD 2) exceeds applicable range, be sure to

refer to 6.7.2, "Load Inertia."

1

I

-18-

Page 20

DESIGNATION

USAFED- 05DA 1

T "- '---T ADDITtON SPECIFICATION

J (Sseries 03 to 30, M series44)

, DRIVE END SPECIFICATION

" • Blank: Standard

Type • S: WithShaftSeal

Externally • T: With Keyway& ShaftSeal"

Type

ORDER

M Series F Series S Series D Series

02 - 0.15kW (0.2HP) 0.15kW (0.2HP) -

03 0.3kW (0.4HP) 0.3kW (0.4HP) 0.31kW (0.4HP)

05 .- 0.45kW (0.6HP) 0.46kW (0.6HP) 0.5kW (0.7HP)

06 0.6kW (0.8H P) - - -

08 ,- - 0.77kW (1.1HP) -

09 0.9kW (1.2HP) 0.85kW(1.2HP) - -

10 - - - 1.0kW(1.3HP)

12 1.2kW (1.6HP) - - -

13 - 1.3kW (1.7H P) - -

15 - - 1.54kW (2.0HP) 1.5kW (2.0HP)

20 2.0kW(2.7HP) 1,8kW(2.4HP) - -

22 - - - 2.2kW(2.9HP)

30 3.0kW (4.0HP) 2.9kW (3.9HP) 3.08kW (4.0HP)' -

37 - - - 3.7kW(5.0HP)

44 4.4kW(5.9HP) 4.4kW (5.9HP) - -

60 6.0kW(8.0HP) - - -

M Series F Series S Series D Series

02 - 0.15kW (0.2HP) 0.15kW (0.2HP)

03 0.3kW (0.4H P) 0.3kW (0.4H P) 0.31kW (0.4H P)

05 - 0.45kW (0.6HP) 0.46kW (0.6HP) 0.5kW (0.7HP)

07 0,6kW(0.8.HP) - - -

10 0.9kW (1.2HP) 0.85kW (1.2HP) 0.77kW (1.1HP) -

15 1.2kW (1.6HP) 1.3kW (1.7HP) 1.54kW (2.0HP) 1.0kW (1.3HP)

20 2.0kW (2.7HP) 1,8kW (2.4HP) - 1.5kW (2.0HP)

30 3.0kW (4.0HP) 2.9kW(3.9H.P) 3.08kW (4.0HP) 2.2kW (2.griP)

44 4.4kW (5.9HP) 4.4kW (5.9HP) - 3.7kW (5.0HP)

• SHAFTTYPE

• Blank: Standard

• B: With Brake

• E: With Brake

(F series 02 to 44, M series 03 to 30, D series)

• O: Standard (With Brake)

• K: With Keyway

• 1: Taper

• 2: Straight

DETECTOR (Table 2.3)

. Table 2.1

Motor Output

Table 2.2

Motor Output

-19-

Page 21

•SERVOPACK Table2.3 •

EncoderResolution(P/R) Series Type

CACR - SRO5BC1 AF USAMEO-03CA_06CA

,din

'qB

SERVOPACKSERIES -44BA

CONTROLTYPE USAFSD-02DA

SR:Speed 6000 -09DA

MOTOROUTPUT -13CA

(Table2.2) to

APPLICATION -44CA

B: M,F,SSeries USADSD-05EA

DESIGN REVISION _ - 37EA

ORDER USAMED-03CB

INPUTFORM -06CB

1:200V,Analog to

DETECTOR _ -44BB

(Table2.4) USAFED-02DB

APPLICABLEMOTOR 5000 to

SERIES F -13CB

• M: M Series

•F: FSeries to

•S: SSeries -440B

•D: DSeries USADED-05EB

___J to

to

__ ...... M -09BA

4000 to

2500 to

1500 S to

i000 to

F

D to

M -09BB

- 09DB

D to

USAMED - 03CD

M -09BD

USAFED - 02DD

F - 13CD

D to

USADED - 05ED

USASEM - 02AC

USASEM - 02AE

USASEM - 02AF

- 06CD

-37EB

to

- 44BD

- 09DD

to

- 44CD

- 37ED

- 30AC

- 30AE

- 30AF

1

I

Table 2.4

Models pulses/rev pulses/rev

M Series A 6000 B 5000 D 4000

F Series A 6000 B 5000 D 4000 - _1_

S Series

D Series A 6000 B 5000 D 4000

Standard Optional Remarks

E 1500 C 2500 F 1000 02A, 03A, 05A

C 2500 E 1500 F 1000 08A, 15A, 30A

g

-20-

Page 22

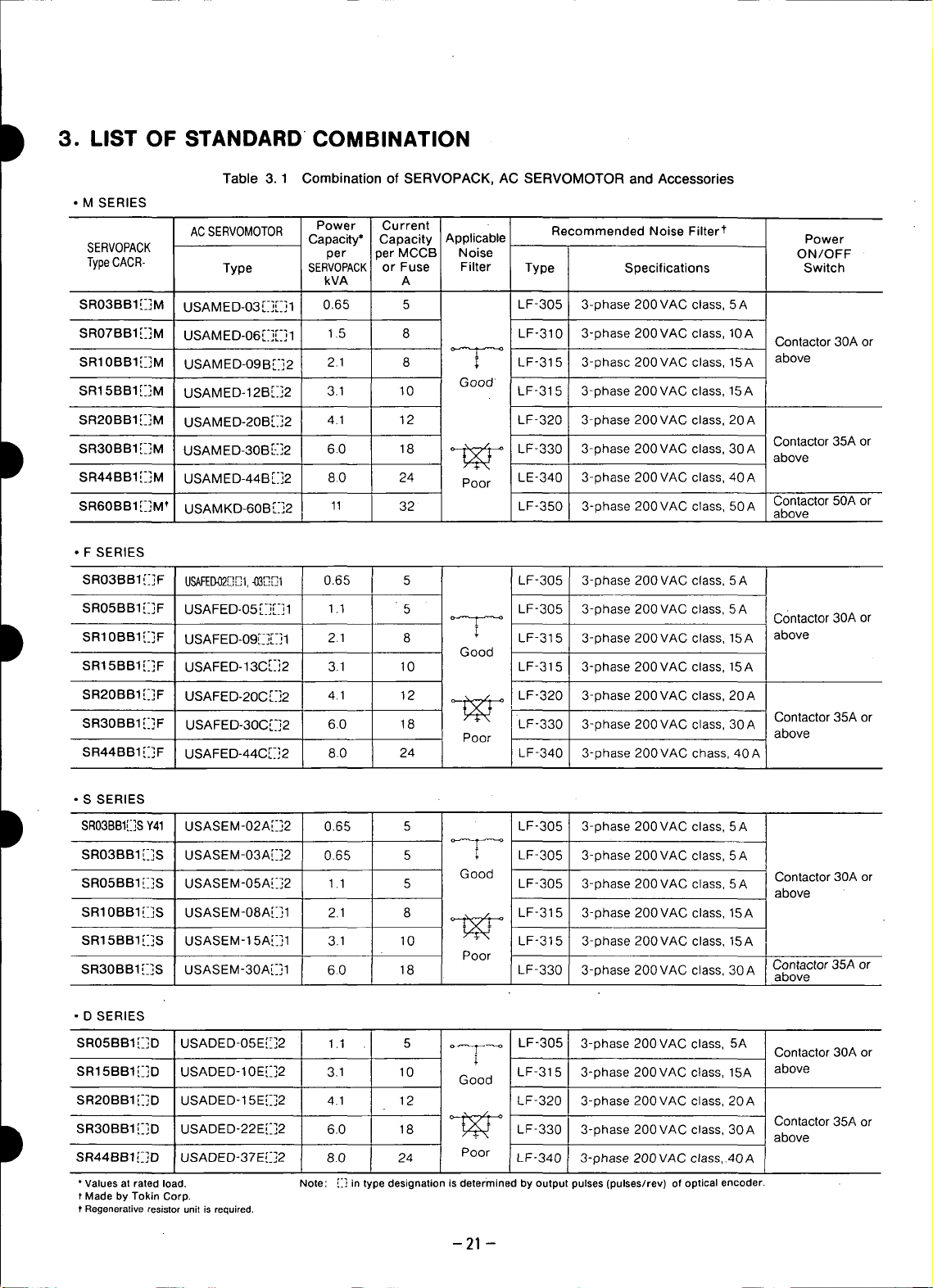

3. LIST OF STANDARD COMBINATION

Table 3.1 Combination of SERVOPACK, AC SERVOMOTOR and Accessories

• M SERIES

ACSERVOMOTOR Power Current Recommended Noise Filter1

SERVOPACK per )er MCCB Noise ON/OFF

TypeCACR- Type SERVOPACKor Fuse Filter Type Specifications Switch

SRO3BBI[_]M USAMED_O3r-]r-]I 0.65 5 LF-305 3-phase 200VAC class, 5A

SR07BB1E[IM USAMED-O6r-]r-]I 1.5 8 LF-310 3-phase 200VAC class, 10A

SR10BBIE]M USAMED-O9Br[]2 2.1 8 :_ LF-315 3-phasc 200VAC class, 15A above

SR15BB1[-_]M USAMED-12Br-]2 3.1 10 LF-315 3-phase 200VAC class, 15A

SR2OBB1 [-]M USAMED-2OBr-]2 4.1 12 LF-320 3-phase 200 VAC class, 20 A

D SR3OBBIE]M USAMED-3OBr--]2 6.0 18 _ LF-330 3-phase 200VAC class, 30A above

D SRIOBBI[-]F USAFED.O9r-]r-]I 2.1 8 _ LF-315 3-phase 200VAC class, 15A above

SR44BB1[-_3M USAMED-44Br[]2 8.0 24 Poor LE-340 3-phase 200VAC class, 40A

SR6OBBI[-]M _ USAMKD_6OBr-]2 11 32 LF-350 3-phase 200VAC class, 50A Contactor 50A or

• F SERIES

SRO3BB1 {-IF USAFED4)2[][]I,-03,[_%.',1 0.65 5 LF-305 3-phase 200 VAC class, 5A

SR05BB1E]F USAFED-O5r.-F]I 1.1 5 LF-305 3-phase 200VAC class, 5A

SR15BBl[_]F USAFED-13cr[]2 3.1 10 LF-315 3-phase 200VAC class, 15A

SR20BBI[[]F USAFED-2OCr_]2 4.1 12 _ LF-320 3-phase 200 VAC class, 20 A

SR3OBB1 [[IF USAFED-3OC.r-]2 6.0 18 tt/_ LF-330 3-phase 200 VAC class, 30 A Contactor 35A or

SR44BBf[[]F USAFED-44C[-]2 8.0 24 LF-340 3-phase 200VAC chass, 40A

- above

Capacity* Capacity Applicable Power

kVA A

Good

Good

Poor above

Contactor 30A or

Contactor 35A or

Contactor30Aor

• S SERIES

D SR03BBI[_]SY41 USASEM-02A['_]2 0.65 5 LF-305 3-phase 200VAC class, 5A

D SR3OBB1 [-]D USADED-22E[[]2 6.0 18 LF-330 3-phase 200 VAC class, 30 A above

SR03BB1 i-iS USASEM-03A[_]2 0.65 5 _; LF-305 3-phase 200 VAC class, 5 A

SRO5BBI[._]S USASEM-O5A[[]2 1.1 5 LF-305 3-phase 200VAC class, 5A

SR10BBI[-]S USASEM-O8AE]I 2.1 8 _ LF-315 3-phase 200VAC class, 15A

SR15BB1[._]S USASEM-15A[[]1 3.1 10 LF-315 3-phase 200VAC class, 15A

SR30BBI[_]S USASEM-30A[-]I I 6.0 18 LF-330 3-phase 200VAC class, 30A Contactor35Aaboveor

• D SERIES

SR05BBI[[]D USADED-O5E[[]2 1.1 5 i LF-305 3-phase 200VAC class, 5A

SR15BB1[_]D USADED-10E[-_]2 3.1 10 Good LF-315 3-phase 200VAC class, 15A above

SR2OBBI[[]D USADED-15E[-]2 4.1 12 LF-320 3-phase 200VAC class, 20A

SR44BBl[-]D USADED-37E,[_]2 8.0 24 Poor I LF-340 3-phase 200VAC class,.40A I

* Values at rated load. Note: [[] in type designation is determined by output pulses (pulses/rev) of optical encoder.

t Made by Tokin Corp.

t Regenerative resistor unit is required,

Good Contactor30Aor

Poor

-21 -

above

Contactor30Aor

Contactor35Aor

Page 23

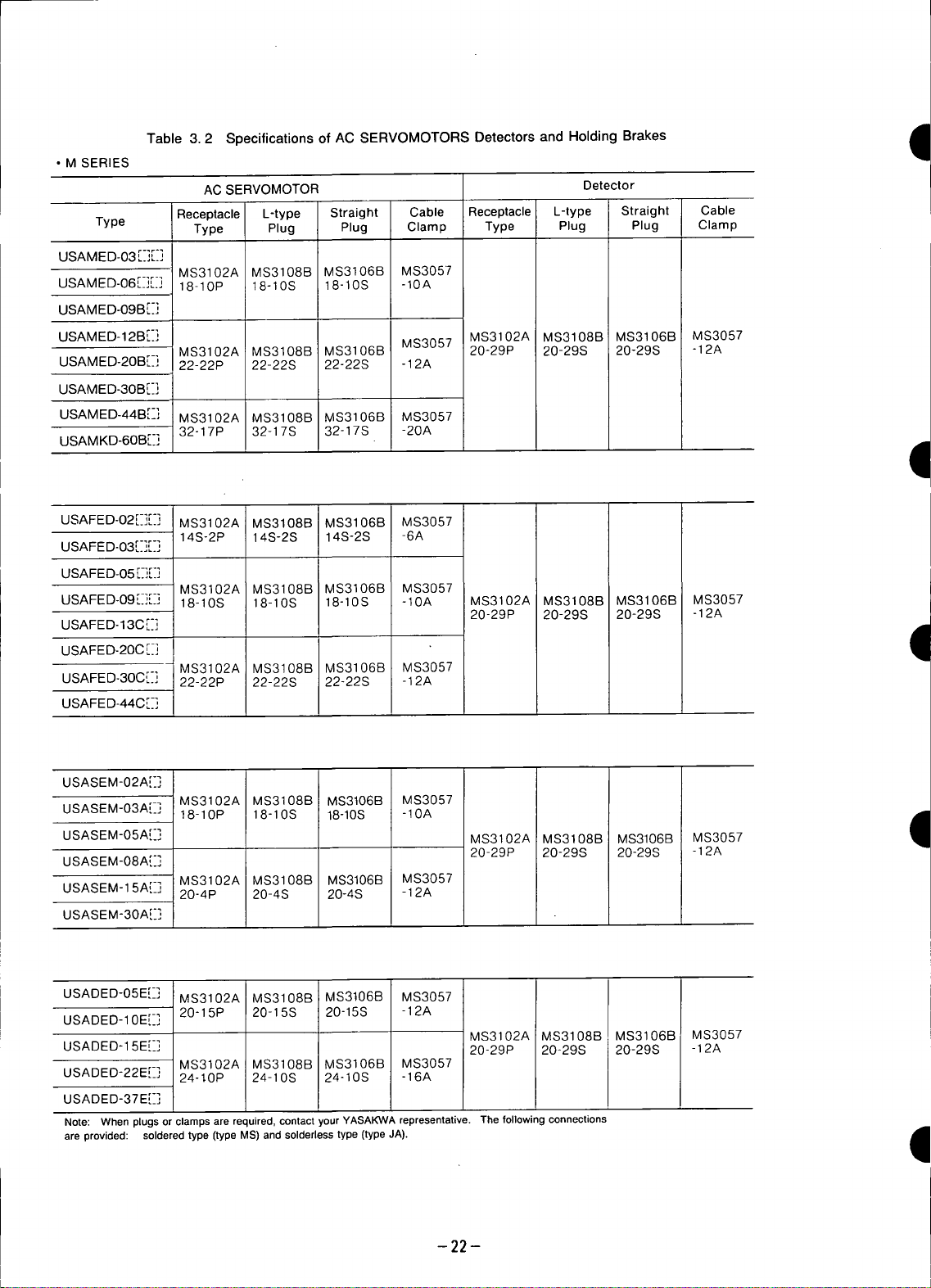

Table 3.2 Specifications of AC SERVOMOTORS Detectors and Holding Brakes I

• M SERIES

ACSERVOMOTOR Detector

Receptacle L-type Straight Cable Receptacle L-type Straight Cable

Type Type Plug Plug Clamp Type Plug Plug Clamp

USAMED-03 [:]E:]

MS3102A MS3108B MS3106B MS3057

USAM ED-06 [_-][_] 18-10P 18-10S 18-10S -10A

USAMED-O9B[-]

'qE

USAMED-12B[-] MS3057 MS3102A MS3108B MS3106B MS3057

USAMED2OBr-] 22-22P 22-22S 22-22S -12A

USAMED-3OB[[]

USAMED-44B[-] MS3102A MS3108B MS3106B MS3057

USAMKD-6OB[-] 32-17P 32-17S 32-17S -20A .,_

USAFED-02[-][.-] MS3102A MS3108B MS3106B MS3057

USAFED-03[-][-]

USAFED-05 [-][[]

USAFED-09[-][:] 18-10S 18-10S 18-10S -10A MS3102A MS3108B MS3106B MS3057

USAFED-13C[.-] 20-29P 20-29S 20-29S -12A

USAFED-20C[:]

USAFE D-30C[:] 22-22P 22-22S 22-22S -12A

USAFED-44C[-]

USASEM-02A[[]

USASEM-O3A[-]t8-10P 18-10S 18-10S -10A

USASEM-05A[-] MS3102A MS3108B MS3106B MS3057

USASEM-08A[-] 20-29P 20-29S 20-29S -12A

USASEM-15A[-] 20-4P 20-4S 20-4S -12A

USASEM-30A[-]

MS3102A MS3108B MS3106B 20-29P 20-29S 20-29S -12A

14S-2P 14S-2S 14S-2S -6A

MS3102A MS3108B MS3106B MS3057

MS3102A MS3108B MS3106B MS3057

MS3102A MS3108B MS3106B MS3057

MS3102A MS3108B MS3106B MS3057

II

I

USADED-05E[-] MS3102A MS3108B MS3106B MS3057

USADED-10E[-] 20-15P 20-15S 20-15S -12A

MS3102A MS3108B MS3106B MS3057

USADED-15E[_] 20-29P 20-29S 20-29S -12A

MS3102A MS3108B MS3106B MS3057

USADED-22EE] 24-t0P 24-10S 24-10S -16A

USADED-37E[-_]

Note: When plugs or clampsare required,contact /our YASA_A representative. Thefollowing connections

are provided: solderedtype (typeMS)and solderlesstype(type JA). ,_

-22-

11

Page 24

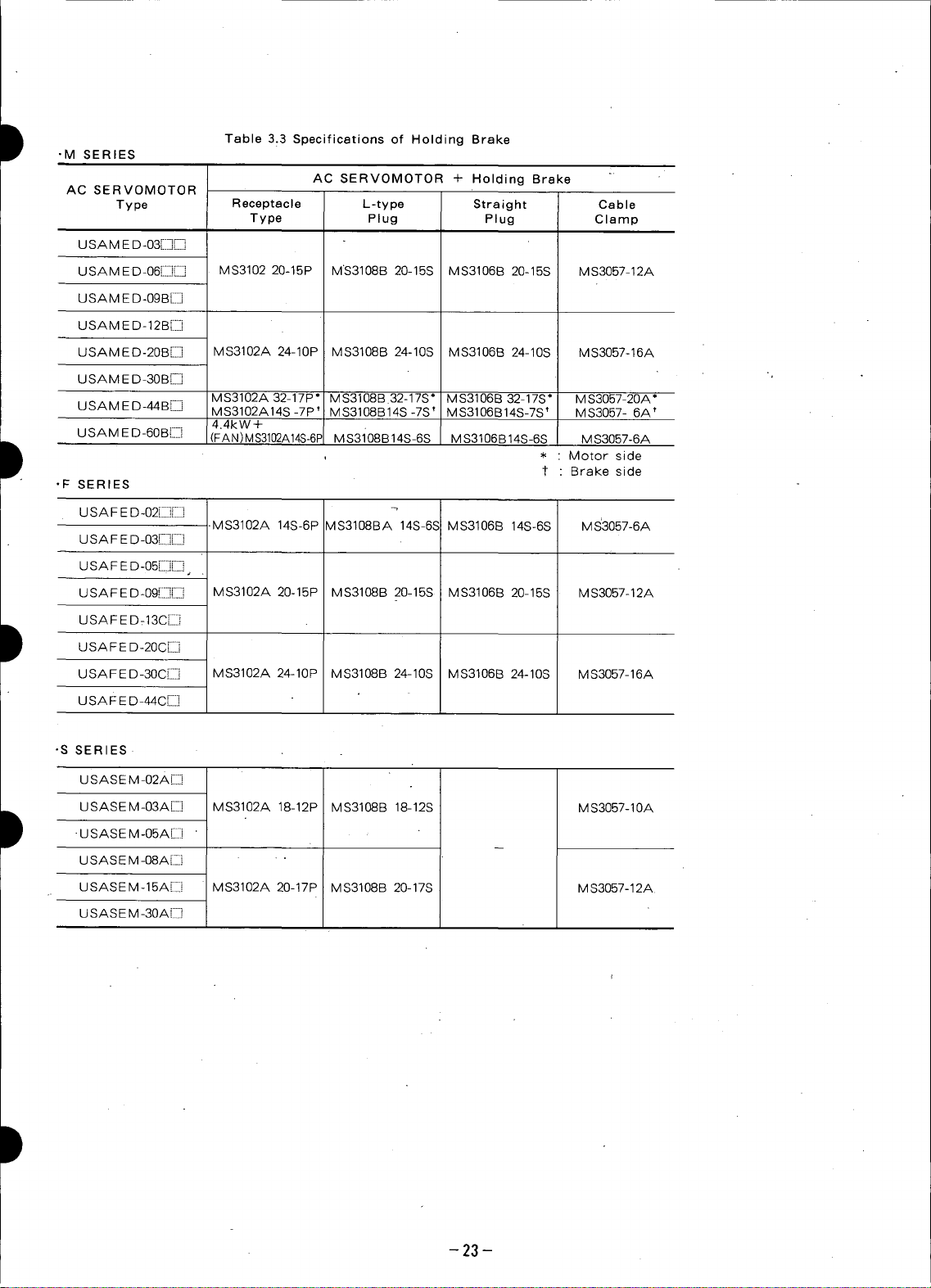

I Table 3.3 Specifications of Holding Brake

•M SERIES

AC SERVOMOTOR

Type Receptacle L-type Straight Cable

U S A M E D-03[]I]]

USAMED-06[][] MS3102 20-15P MS3108B 20-15S MS3106B 20-15S MS3057-12A

U S A M E D-09 B [iii:i:]

USAM E D-12B[]

USAMED-20B[[] MS3102A 24-10P MS3108B 24-10S MS3106B 24-10S MS3057-16A

U SA M ED-30 B{_-.]

USAMED-44B[] MS3102A14S-7P * MS3108B14S-7S t MS3106B14S-7S t MS3057- 6A t

USAM E D-60Bi[] (FAN) MS3102A14S-6F MS3i08B14S-6S M $3106B14S-6S M $3057-6A

-F SERIES

Type Plug Plug Clamp

MS3102A 32-17P ° MS3108B.32-17S* MS3106B 32-17S* MS3057-20A*

4.4kW+

AC SERVOMOTOR + Holding Brake : '

¢ Brake side

* Motorside

USAFED-02[iiq

U SA F E D-03L..JL....i .

U S A F E D-05[][[], .'

USAFED-09iiFI MS3102A 20-15P MS3108B 2045S MS3106B 20-15S MS3057-12A

USA F E D :13C[]

I USA FE D-20C[[i

USAFED-30C[] MS3102A 24-10P MS3108B 24-10S MS3106B 24-10S MS3057-16A

USA F E D-44C[]

• S SERIES=

U S A S E M -02A Eli

USASEM-03A[::] MS3102A 18-12P MS3108B 18-12S MS3057-10A

I -U SAS EM-05A[[] '

U SAS EM -08A[::] " •

USASEM-15A[:::::i MS3102A 20-17P MS3108B 20-17S MS3057-12A

U SAS E M -30A[:::::]

-MS3102A 14S-6P VlS3108BA 14S-6S MS3106B 14S-6S MS'3057-6A

-23-

Page 25

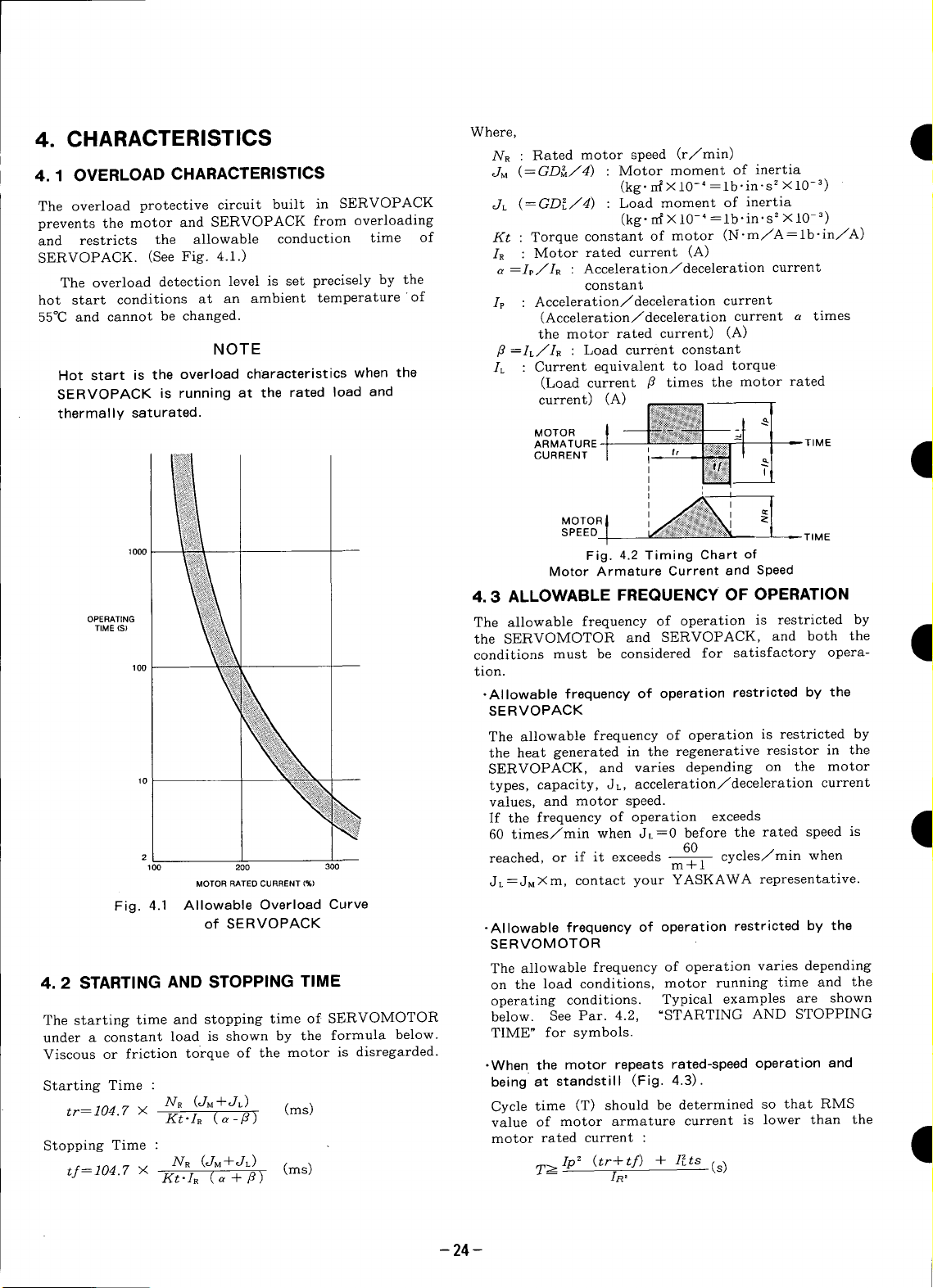

4. CHARACTERISTICS Where, •

NR : Rated motor speed (r/rain)

4.1 OVERLOAD CHARACTERISTICS JM (=GD_/4) : Motor moment of inertia

The overload protective circuit built in SERVOPACK JL (=GD[/4) : Load moment of inertia

prevents the motor and SERVOPACK from overloading (kg" n{ × 10- 4 = lb-in" s 2 x 10- 3)

and restricts the allowable conduction time of Kt : Torque constant of motor (N'm/A=lb'in/A)

SERVOPACK. (See Fig. 4.1.) IR : Motor rated current (A)

The overload detection level is set precisely by the constant

hot start conditions at an ambient temperature of Is : Acceleration/deceleration current

55°C and cannot be changed. (Acceleration/deceleration current a times

NOTE fl =IL/IR : Load current constant

Hot start is the overload characteristics when the IL : Current equivalent to load torque

SERVOPACK is running at the rated load and current) (A)

thermal ly saturated. I_%_,,:_1 l

a =I_/IR : Acceleration/deceleration current

the motor rated current) (A)

(Load current fl times the motor rated

MOTOR _NN N_:

ARMATURE t' I f _TIME

CURRENT I _ - [_| _,

(kg.rr_X10-' =lb'in's 2 ×10 -3)

, I_ T_

1

MOTOR_

SPEED ] = TIME

1000 Fig. 4.2Timing Chart of

Motor Armature Current and Speed

' I

4. 3 ALLOWABLE FREQUENCY OF OPERATION

OPERATING The allowable frequency of operation is restricted by

TIME (S) I

100 tion.

k .Allowable frequency of operation restricted by the

,0 __ values,types'capacity, JL, acceleration/decelerationcurrentandmotor speed.

2100 200 300 m

MOTOR RATED CURRENT (%) JL = JM X m, contact your YASKAWA representative.

Fig. 4.1 Allowable Overload Curve

of SERVOPACK -Allowable frequency of operation restricted by the

4. 2 STARTING AND STOPPING TIME on the load conditions, motor running time and the

The starting time and stopping time of SERVOMOTOR below. See Par. 4.2, "STARTING AND STOPPING

under a constant load is shown by the formula below. TIME" for symbols.

Viscous or friction torque of the motor is disregarded.

Starting Time : being at standstill (Fig. 4.3).

tr=104.7 × NR (JM+JL) (ms) Cycle time (T) should be determined so that RMS

Stopping

Time

tf=104.7 X Kt.I_ (a+fl) In'

Kt'IR (a-fl) value of motor armature current is lower than the

NR (JM+JL) (ms) T_Ip_ (tr+t/) + I[ts (s)

_ 60 times/min when JL=0 before the rated speed is

the SERVOMOTOR and SERVOPACK, and both the

conditions must be considered for satisfactory opera-

SERVOPACK

The allowable frequency of operation is restricted by

the heat generated in the regenerative resistor in the

SERVOPACK, and varies depending on the motor

If the frequency of operation exceeds t_

reached, or if it exceeds -- cycles/rain when

SERVOMOTOR

The allowable frequency of operation varies depending

operating conditions. Typical examples are shown

•When the motor repeats rated-speed operation and

motor rated current : •

6O

II

II

- 24-

Page 26

Where cycle time IT) is determined, values Ip, tr, 4. 4 SERVOMOTOR FREQUENCY

) tf satisfying the formula above, should be specified.

' SERVOMOTOR, motor speed amplitude is restricted by

MOTOR

ARMATURE = T_ME

CURRENT I l ,, I " Itml 1-_I I ; I_!

| _ the maximum armature current controlled by

1

I" ; T I'J_l Trl ] I I_;I The relation between motor speed amplitude IN) and

t_--_ _ _ _ frequency If) is shown by the formula below :

In the serve drive consisting of SERVOPACK and

SERV©PACK.

MOTOR _ _;_'¢;.'_ l I " " "

SPEED I ...._'_'_':_"_ (JM+JL) f

When the motor remains at standstill between cycles _,_ ;!_;_ --t ARMATURE

of acceleration and deceleration without continuous f_ !'_

. j L/

rated speed running (Fig. 4.4).

The timing chart of the motor armature current and N - ._

speed is as shown in Fig. 4.4. The allowable . . /_:_;_ MOTOR

lows:frequencyoperation can as __ . _

n=286"5X NR ('-]M+JL)" X a- _-_ Motor Armature Current end Speed

MOTOR _ -_

ARMATURE

MOTOR TIME to +10V. See Fig.4.8.

SPEED I The forward motor rotation (4-) means counter-

• When the motor accelerates, runs at constant speed,

and decelerates in a continuing cycle without being at

standstill (Fig. 4.5). RATED ADJUSTABLE WITH

I"_' ;_g!}:k ; _ I N = 1.52 X (r/min)

I/;Y(_:_:,::,;:_:,_._'lll I TIME

I

Fig. 4.3 Timing Chart of _ Ip=ala_

Motor Armature Current and Speed

' o

of "n" be calculated fol- _;_< _!_:_y _] _t SPEED

Kt.IR [1 _)21. Fig. 4.6 Timing Chert of

(times/min)

4.5 MOTOR SPEED-REFERENCE INPUT

_;_ _ - _ _ -

I

"_:_ } l I _; TIME Fig. 4.7 shows motor speed and input voltage curve

_!:*:_!iI [ i:_!_ when speed reference input terminals 1CN-@ and @ areCURRENT ( ;_ _ , _:_

I ' I I motor speed can be set to the rating by adjusting]iN-B]

i _:,_:;_1 II I N_: used. With auxiliary input terminals, 1CN-@ andr= _

_ i _ i potentiometer as long as input voltage is within +2V

Fig. 4.4 Timing Chart of clockwise (CCW) rotation-when viewed from the drive

Motor Armature Current and Speed end.

speed is as shown in Fig.4.5. The allowable frequency I

The timing chart of the motor armature current and SPEED (+) / I RATEDSPEED(+) -- -- ,

of operation "n" can be calculated as follows : t

Kt'I, [ 1 [?' ] t I /2/ I I t , ' , , ,. ' ....--6--4 0 2 4 6 -10-8-6-4-21 } 4 6 8 1'0

n=286.5X N. (g_+JL) × [ -- - - J i / INPUT ', /:/ INPUT VOLTAGE(V)

MOTOR I Fig. 4.8

ARMATURE I i J I_!_!! , I_;_I = TIME Fig. 4.7 Speed-Input Voltage

CURRENT - _ a _ Speed-lnput Voltage Characteristics

MOTOR I I

SPEED _ _TIME "

i _l_'_il • _ when Auxiliary Input

I _ _i-,i._l II Characteristics .

II II

I • I

' _ o _ _ Terminals 1CN-@ /

a a VOLTAGE IV) _ /,[

(times/rain) I___ __II ' :

RATED

SPEED (--)

' _-----;_- _ATED SPEED(-)

and(_)are.used.

I 4.6 MOTORMECHANICALCHARACTERISTICS

Fig. 4.5 Timing Chert of

Motor Armature Current and Speed 4.6.1 Mechanical Strength

AC SERVOMOTORS can carry up to 300% of the rated

-" - momentary maximum torque at output shaft:

-25-

Page 27

4.6.2 Allowable Radial Load and Thrust Load 4.6.4 Direction of Rotation •

Table 4.1 shows allowable toads according to AC AC SERVOMOTORS rotate counterclockwise (CCW)

SERVOMOTOR types, when viewed from the drive end when motor and detec-

tor leads are connected as shown below.

Table 4.1 M Series Allowable Radial Load

and Thrust Load

,all

II

Motor Type Allowable Allowable

USAMED- N(Ib) N(Ib)

03[:][:]1 490 (110) 98 (22) t

06 [:][:] 1 490 (110) 98 (22) t

09B[:]2 686 (154) 343 (77)

12BE]2 1470 (330) 490 (110)

20B[;]2 1470 (330) 490 (110)

30B[:]2 1470 (330) 490 (110) Fig. 4.9 AC SERVOMOTOR

44B[_]2 1764 (397) 588 (132)

USAMKD-6OB[:] 2 1764 (397)' 588 (132)

Table 4.2 F Series Allowable Radial Load SERVOMOTORS

Motor Type Allowable Allowable

USAFED- N (Ib) N (Ib)

02[:][:]1 147(33) 49( 11)t

05 [:][_]1 490 (110) 98 (22) t B Phase V

09 [:][:]1 490 (110) 98 (22) t

13C[:]2 686 (154) 343 (77) C Phase W

03,:_],,'_]1 147 (33) 49 ( 11)t @ A Phase U

20CE]2 1470 (331) 490 (110)

30C[:]2 1470 (331) 490 (110) D Frame ground

44cE]2 1470(331) 490 (110)

Table 4.3 S Series Allowable Radial Load (Type USASEM-02A)

Motor Type Allowable Allowable

USASEM- N(Ib) N(Ib)

O2AE]2 78.4 (18) 39.2 (9) Red Phase U

03A[:]2 245 (55) 98 (22) White Phase V

05A[_] 2 245 (55) 98 (22)

08A[:] 1 392 (88) 147 (33)

15AE]I 490 (110) 147 (33)

30A[:]1 686 (154) 196 (44)

Radial Load* Thrust Load

386-5

(i) Connector Specifications for Standard

and Thrust Load (a) Motor receptacle

Radial Load* Thrust Load " M, F Series

• S Series

and Thrust Load

Radial Load* Thrust Load Color of Lead Applicable

Blue Phase W

I

q

Table 4.4 D Series Allowable Radial Load (Types USASEM-03A to 30A)

Motor Type Allowable Allowable

USADED- N(Ib) N (Ib)

O5E[-]2 686 (154) 343 (77) C Phase W

10E[:]2 686 (154) 343 (77)

15EE]2 1176 (265) 490 (110) D Frame ground

22E[:]2 1176 (265) 490 (110)

37E[:]2 1176 (265) 490 (110) (b) Detector receptacle

* Maximum values of the load applying to the shaft extension.

t Do not apply the exceeding load because motor cannot be rotated. _ A Channel A output K Channel U output

4.6.3 Mechanical Specifications

(M, F, S and D Series) C ChannelB output M ChannelV output

Table 4.5 Mechanical Specifications in mm

Flange surface 0.04

perpendicular to shaft _) (0.06) * /-__ G 0V S - __

Flange diameter

concentric to shaft ® 0.04 H +hVDC T -

Shaft run out © 0.02 J Frame ground -- -

Accuracy (T.I.R)t Reference Diagram F Channel _ output R Channel W output

* Accuracy for motor types USADED-15E, -22E, and -37E.

* T.I.R (Total Indicator Reading)

t Accuracy for motor types USAMED-44M[_2 and USAMKD-60M[_-J2.

and Thrust Load _ A PhaseU

Radial Load* Thrust Load B Phase V

B Channel _ output L Channel -U output

D Channel -B output N Channel ? output

E Channel Z output P Channel W output

(0.04) _ i

-26-

I

Page 28

t (2) Connector Specifications for SERVOMOTOR with Arrange the main circuit sequence to stop the

Brake SERVOMOTOR and fan motor when cooling fan alarm

occurs. (Alarm contact is ON at alarm occurrence).

• M, F*, D Series (Brake is provided to all types of D After alarm occurrence, make sure to stop the

series as standard.) SERVOMOTOR and fan motor within five minutes

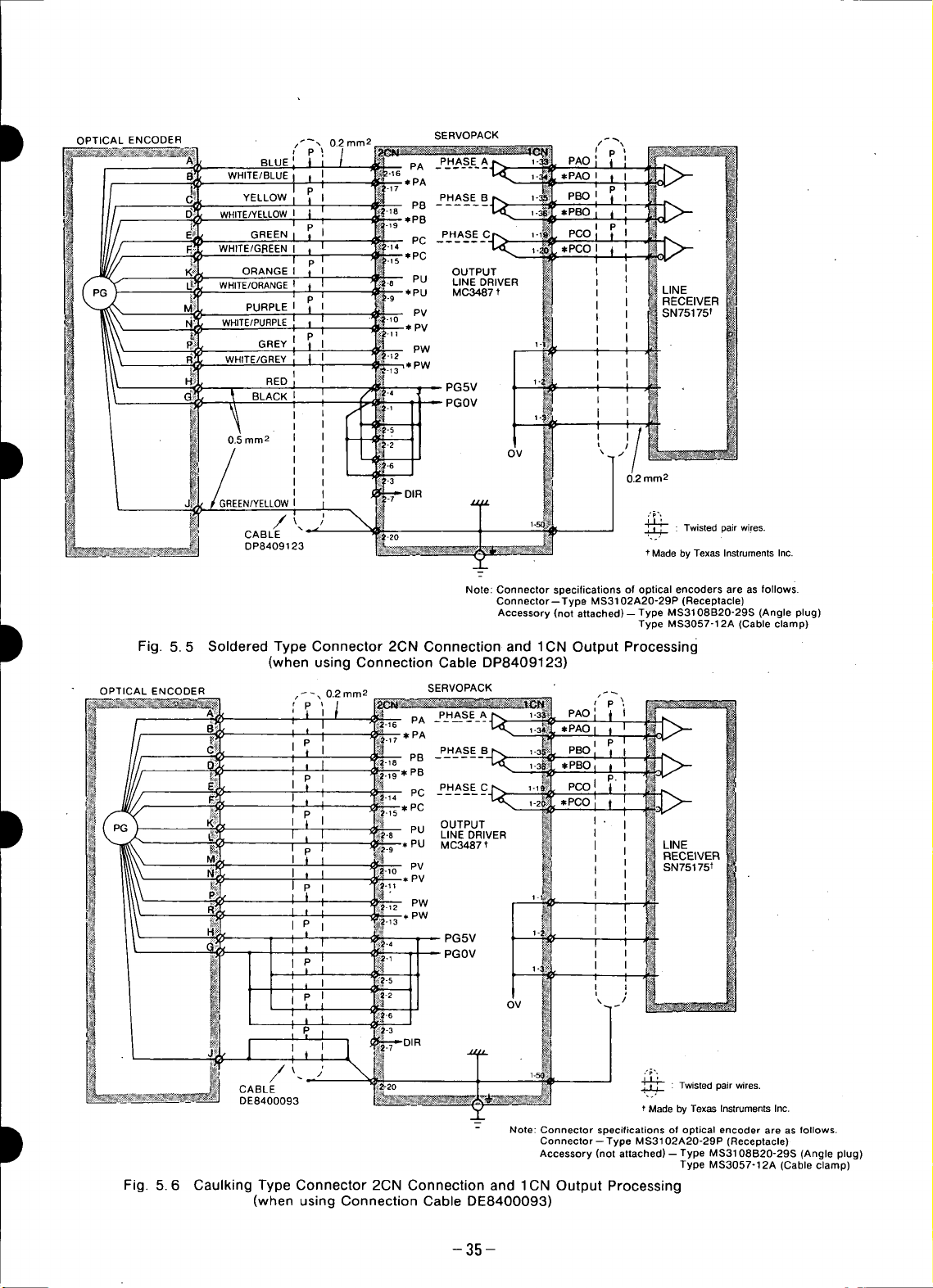

B Phase V F Brake terminal five minutes.

When cooling fan starts running, alarm detection

C Phase W G - signal turns ON for three seconds. Therefore, add a

A Phase U E since SERVOMOTOR self-cooling protection is set to

D FrameGround -- - delay relay to the circuit for this time setting (three

Types without brake of 13 series do not use seconds).

E and F.

4.6.5 Impact Resistance.

*For USAFEM-02 and-03,

seeconnector on the right. When mounted horizontally and exposed to vertical

shock impulses, the motor can" withstand up to two im-

pacts with impact acceleration of 490m/s2(50G) (Fig.

• S Series 4.11).

(USASEM-02A).. NOTE

t A precision detector is mounted on the opposite-

Color of Lead Applicable Color of Lead Applicable drive end of AC SERVOMOTOR. Care should

Red Phase U Black .. be taken to protect the shaft from impacts that

White Phase V Black

Brake could damage the detector.

Blue PhaseW Green Frame Ground IVERTICAL

(USASEM-03A, -05A) (USASEM-08A to -30A) ' --_- IIIIL_=,ZONTAL

t O O Fig. 4.11 Impact ResistanceL I IUJ"V'"

4.6.6 Vibration Resistance

A PhaseU A PhaseU When mounted horizontally, the motor can withstand

B Phase V B Phase V vibration (vertical, lateral, axial) of 24.5m/s 2 (2.5G)

C Phase W - C Phase W (Fig. 4.12).

Brake terminal Brake terminal

E E LAT . L

!

VERTICAL

t F FLameground F Frameground

(3) Fan terminal connector specifications [L_ HORIZONTAL

(Type USAMKD-60BEI]2)

A Fan motor CONNECTION

B Fan motor 4.6.7 Vibration Class

C - Vibration of the motor running at rated speed is 15/_m

D Alarm terminal - or below (Fig. 4.13).

E Alarm terrain,31 POSITION FOR

F -- I IPower Supply: Single-phase 200V,50/60Hz, __

Alarm Contact: OFF when fan is running normally

ON when fan rotation is 1800 +200

r/min or less. Fig. 4.13 Vibration Checking

When cooling fan starts running,

I ONfor 3 seconds.

Contact Capacity: Resistance load is ll0V max, 0.3A 4.6.8 Holding Brake

Fig. 4.10. Fan Terminal Connection Turn ON/OFF according to Par. 6.9.3, "Application

Fig. 4.12 Vibration Resistance

SHADING COIL

CHECKING VIBRATION

of SERVOMOTORS with Holding Magnetic Brake"

since AC SERVOMOTORS with brake is used when the

operation is held.

-27-

Page 29

5.CONFIGURATION 4

5. 1 CONNECTION DIAGRAM

POWER SUPPLY

200 TO 230V +10%

50160 Hz

1MCCB )

-15

Prevent external noise with a noise filter.

f

S NOISE FILTER 1 _ Bold lines indicate power lines

-- _ INDICATION)

_ 1MC: / SERVOPACK

: 1MC| I [CACR-SR J _

(excluding the grounding line). (SERVO TROUBLE

5 Ry _ EXAMPLES OF INDICATION

POWER

POWER ON 5 Ry MAGNETIC CONTACTOR

---.C) I ____-_O O _ 1 Be .... to fit a surge suppressing

OFF --L_ __ _FOR POWER ON/OFF 4

1MC 1SUP i tor and the relay.

1Me a I R "_ U _ ALARM

=_'_1-_- device to both the magnetic contac-

g

,t '_s / TYPE | v_

/ cIRcuIT I _

• : 4

SPEED LEAD LENGTH grounded

REFERENCE 3 METERS OR LESS ,/_.

mPim

P t ( CONNECTING CABLE: ,_

Use relays highly reliable in

contact(YASKAWABestact O TYPEJUSP-RA03

relays or equivalent, or arrange 2 R._.yy .5mA

intwocontactparallelconnec- Y3

tion for low level). 3 Ry 5mA

1 Ry 5mA *RESISTOR UNIT

4 Ry 5_mA

I, Y4

5 Ry

JTERMINALS \7._ _M_besecurely

2Ch I I

(_

1CN Be sure to perform terminal trearment

of shielded cable

i

LEAD LENGTH:

20 METERS OR LESS

YASKAWA DRAWING

No, DP8409123 OR

No, DE8400093

I

+ 24V _ 1V (If connection is wrong, output transistor is damaged). ..,.]

(SUPPLIED BY USER)

Connect the output relay surge absorbing diode with the correct polarity

*Added only for SERVOPACK type CACR-SR60BB

(externally fan-cooled type).

Fig. 5. 1 ExampleofConnectionDiagramofSERVOPACK

witha SERVOMOTORandPeripherals

-28-

(I

Page 30

Page 31

Page 32

D 5. 3 EXTERNAL TERMINALS 5.4 CONNECTOR TERMINAL (1CN) FOR

Table 5.1 shows the specifications of external terminals INPUT/OUTPUT SIGNALS

for SERVOPACK.

5.4.] Specifications of Applicable Receptacles

Table 5.1 External Terminals for SERVOPACK

Table 5.2 Specifications of Applicable Receptacles for

Terminal SERVOPACK Input/Output Signals

Symbol Name Description

(_) ® (!) AC input 50/60 Hz. SERVOPACK Case

Main-circuit Three-phase 200 to 230 VAC,_15 _, Manu- Soldering Caulking

+10o used in Type

Connector Type* Applicable Receptacle

MR-50RMA Honda

facturer Type Type

Motor Connects terminal Q to motor (Right angle Tsushin MR-50F t MRP-

@ O _ connection terminal A, _) to B and _ to C. 50 P) Co., Ltd. 50F01 MR-50Lt

Q O input 50/60Hz MR-50RMA made by Honda Tsushin Co.

Control power Single-phase 200 to 230 VAC +10oz

-15/°, * The connectors for input/output signals usedere type

t Attached to SERVOPACK prior to shipment.

(_ Ground Connects to motor terminal FG.

D Must be securelygrounded.

Regenerative External connection not normally required

(_) (_ resistor except SR60BB.

5.4.2 Connector 1CN Layout and Connection

of SERVOPACK

The terminal layout of the SERVOPACK inputJoutput

signal connectors (1CN) is shown in Table 5.3.

The external connection and external signal processing

D are shown in Fig. 5.4 on page 32.

Table 5.3 Connector tCN Layout of SERVOPACK

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

0 V 0 V 0 V PHA CLT+ CLT- +24V

0 V for PG Output SignaIPGOutput Current Limit Ext Servo Speed Monitor SpeedReference Auxiliary 4- 12V j Frame

Signal 3haspA)t Detection Output Power ON

D 19 20 21 22 23 24 25 26 27 28 29 30 31 32

PCO *PCO PHC TGON TGON P-CON OL N-OT S-RDY S-RDY N-CL SG -12V SG

PG Output IPGoutput TG ON ! P Drive Overload Reverse Servo Ready Reverse Current -- 2 V

Signal(PhaseC) Ip_aseclt Signal Output Input DetectingProhibit

I Signal

IN S-ON TRQ-M VTG-M SG IN-A SG.A IN-B SG.B +12V SG FG

Input Power Torque monitor In)ut Input Output Ground

4- -- -- -- 4-

Signat Input Output Out )ut Out 3ut

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

PAO *PAO PBO *PBO PHB ALM+ ALM- OL P-OT MCCBMCCF P-CL SG -12V SG +12V SG FG

PGOutput PGOutput PGOutpu_Servo Alarm Overload Fwd. MCCB Trip Fwd. Current 12 V 4-12 V Frame

Signal(PhaseA) Signal(Phase B) (PhaseB)t Output Sighal Input Signal Oufput Limit Input Output Output Ground

Signal Detecting Prohibit

tOpen collector

4- -- +

4=

PG Output Signals External Sequence Signals Analog Signals

1: Opencollector

--31 --

Page 33

TORQUEMONITOR TRQ-M

(RATED TORQUE AT 3V)

SPEED MONITOR

4V/1000 r/min (M, F,D SERIES)

2V/1000 r/min (S SERIES)

VTG-M

SERVOPACK t

SPEED REFERENCE INPUT

(RATED SPEED AT ±6V) SG-A

AUX. SPEED REFERENCE IN-B

INPUT SG-B

(RATED SPEED AT ±2 TO _+10V)

CURRENT LIMIT AT REVERSE ._ N-CL _._

RUNNING (- 100%/+ 3.0V # SG-NCL

INPUT)

CURRENT LIMIT AT FORWARD _

RUNNING (+ t 00%/-- 3.OV _._

INPUT) 4 =

SERVO ON AT I

1RyON 21V 1Ry S-ON "=_ =1

PROPORTIONAL -- I

CONTROL 2Ry '.=_ iI = CONTROL

AT 2Ry ON _ P-CON ._ / (P DRIVE)

(PI DRIVE ATOFF) "I REVERSE

REVERSE RUNNING N-LS N-OT '._ [ " RUNNING

PROHIBIT AT N-LS OFF _ L_ _ _ .J PROHIBIT

FORWARD RUNNING =_^ ,_ .

PROHIBITAT P-LS OFF P-LS P-OT

3Ry ON AT +24V 3Ry CLT+ IN I _ _ r .... 1

CURRENT f---'-_?.-_ -5 CURRENT LIMIT

• c,,-IP !+

4Ry ON AT 4Ry TGON+ [_ | I

IN-A

P-CL

SG-PCL

SGOV

+ 24VIN 4.8k/1

_--5 .__j

4.8k_ r- - - - 7

APPROX I _ _i FORWARD

s _'"_ LT_ __.J PROHIBIT

|

i

TGON IP IT_-22I ;F- _ TG ON

TGON-- _ _ / OF MAX SPEED,

5Ry OFF AT ALM+ _

DETECTION 0fVl _ _-6 I - i

SERVOALARM I "38 1 I

6RyONAT 6Ry S-RDY+

ALM P . SERVOALARM

'39 I

S-ROY- P _ SERVO READY

•27 I

VR6

rc¢_

SERVO ON

PROPORTIONAL

RUNNING

(AT 1% OR MORE

MCO TR,P I I

8Ry OFF AT OL+ /

OL ALARM _ O"-L

,RyONAT I 'RYMOOR+P ' ' [I

PHASE{ *PAO

PG OUTPUT B * PBO i

LINE DRIVER LTI MC3487¢

PG OUTPUT =

OPEN COLLECTOR

: Twisted pair wires +12V SG -12V I

1"Made by Texas Instruments Inc.

Notes:

1. Each capacity of output circuit is 30VDC, 100mA or less. --"

2. The user must provide the 24V power supply.

MCCB - _L. MCCB

PAO

( PBO _ LINE DRIVER

PCO

C [ *PCO i

PHB • MAX OPERATING

/ VOLTAGE: 30 VDC

PHC

•42 I

• MAX INPUT CURRENT: 40 m_

FG

Fig. 5.4 Input/output Signals and Connector 1CN

-32 -

Ii

Page 34

D Table 5.4 Input Signals of Connector 1 CN

Signal Connector Function Description

Name ] CN No.

SV-ON 1 CN-8 Servo ON , speedreference input (+6V)

Inputting this signal makes the SERVOPACK ready to receive

Base block and dynamic brake are cleard.

P-CON ] CN-24 reference motionless without command input, while the mamc_rcmt _skept

N-OT 1CN-26

P-OT ] CN-41

24V 1CN:7 24V

IN-A 1 CN-12(13) Speed command input At +6.0V, 4- rated speed is obtained.

D At +2.0to +10.0V, 4- rated speed is obtained.

D Name I CN No. Function Description

D •N-CL P-CLused: TurnsON reaches

IN-B ] CN-14(15) Aux. command input For adjustment, potentiometer _ is used.

N-CL 1CN-29(30) Current limit reference +3.0V +10%/100% torque +9 V max.

P-CL ] CN-44(45) Current limit reference

Signal Connector

OL 1CN-40(25) detection Turns OFF when overload is detected. (SeePar. 4.1 "OVERLOAE:

MCB 1CN-43(42) MCCB trip Turns ON when MCCB trips.

ALM lCN-38(39) Servo alarm

TGON lCN-22(23) detection F Series: Approx 25r/min '

CLT ]CN-5(6) detection -N-CLorP-CLnotused: Turns ON When output torque

S-RDY 1CN-28(27) Servo ready Turns ON when main power supply ON, and no servo alarm.

Jr-12 V 1CN-16, 48

0 V 1CN-17,32,49 power supply Used with speed command or current input.

--12V 1CN-31, 46

TRQ-M 1CN-9 Torque monitor (Rated torque at-+3.0V) -+10%, +gVmax, IoadlmAmax

VTG-M 1CN-10 Speed monitor SSeries (-+2.0V/1000r/min) -+5%. Load: lmAmax

PAO 1CN-33

PAO 1CN-34

PBO 1CN-35 Positioning Pulse after frequency division is output line driver (TI MC3487).

,I,PBO 1CN-36 Output 1 To be received by line receiver (TI SN75115).

Proporitonal drive Proportional control command to prevent drifting when the motor is left

energ ized.

Reverse running

prohibit In the case of linear drive, etc connect limit switch signal according