Page 1

YASKAWA AC Drive - A1000

Spindle Orientation

Custom Software Supplement

Software Number: VSA91009

Drive Models: 200 V Class, CIMR-AU2A0004□A□-063 to CIMR-AU2A0415□A□-063

400 V Class, CIMR-AU4A0002□A□-063 to CIMR-AU4A0250□A□-063

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

□

MANUAL NO. TM.A1000SW.063

Page 2

2 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 SPINDLE ORIENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Refer to the A1000 Technical Manual for content not described in this document.

Copyright © 2011 YASKAWA AMERICA, INC.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is subject to

change without notice. Every precaution has been taken in the preparation of this manual. Yaskawa assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information

contained in this publication.

YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 3

Page 4

This Page Intentionally Blank

4 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 5

1 Preface and Safety

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems and equipment. The selection

and application of Yaskawa products remain the responsibility of the equipment manufacturer or end user. Yaskawa

accepts no responsibility for the way its products are incorporated into the final system design. Under no circumstances

should any Yaskawa product be incorporated into any product or design as the exclusive or sole safety control. Without

exception, all controls should be designed to detect faults dynamically and fail safely under all circumstances. All systems

or equipment designed to incorporate a product manufactured by Yaskawa must be supplied to the end user with

appropriate warnings and instructions as to the safe use and operation of that part. Any warnings provided by Yaskawa

must be promptly provided to the end user. Yaskawa offers an express warranty only as to the quality of its products in

conforming to standards and specifications published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR

IMPLIED, IS OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses, or claims

arising from misapplication of its products.

Applicable Documentation

The following manuals are available for the A1000 Drive:

Custom Software Supplement

Yaskawa AC Drive - Spindle Orientation A1000 Custom Software Supplement

SUPPLEMENT

Manual No: TM.A1000SW.063

Read this manual first. This supplement is an addendum to the A1000 Quick Start Guide and Technical Manual. It lists the effects of this custom software on

the parameters in the drive and function descriptions in the manual.

To obtain the supplement access this site: U.S: http://www.yaskawa.com

Yaskawa Drive

Yaskawa AC Drive A1000 Quick Start Guide

Yaskawa AC Drive A1000 Technical Manual

To obtain instruction manuals for Yaskawa products access these sites:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

Other areas: contact a Yaskawa representative.

For questions, contact the local Yaskawa sales office or the nearest Yaskawa representative.

Supplemental Safety Information

Read and understand this manual and the A1000 Quick Start Guide before installing, operating, or servicing this option

unit. Install the drive according to the A1000 Quick Start Guide and local codes. Observe all cautions and warnings in this

document and the standard drive technical manuals.

Refer to the A1000 Quick Start Guide and Technical Manual for safety information and to install and start-up the drive.

This document is a supplement to the standard drive technical manual. It describes the effects on the drive parameters and

functions with the software installed.

• Custom software is provided to add functionality to a standard drive to enhance or enable use in a specific application.

• The software is loaded to the flash ROM area of the control board, and replaces the standard drive software.

Obtaining Support

When seeking support for a drive with custom software, it is imperative to provide the unique part number shown on the

drive nameplate. The software is flashed to the control board memory and the operation of parameters, functions, and

monitors are different than the standard drive software, as described herein.

Refer to Yaskawa office locations listed on the back cover of this manual.

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 5

Page 6

2 Spindle Orientation

Motor

Encoder

Machine

Motor

Configuration2:IndirectDrivewith

OrientationEncoder

Configuration1:DirectDrive

PG-X3

PG-X3

PG-X3

Orientated

MachinePart

Orientation

Encoder

Orientated

MachinePart

Drivetrain

(GearRatio)

CN5-B

CN5-C

CN5-C

Motor

Encoder

ChA/B/Z

ChA/B/Z

ChA/B

Machine

Motor

Motor

Encoder

Machine

Motor

Configuration3:IndirectDrivewith

ProximitySensor

PG-X3

Proximity

Sensor

Orientated

MachinePart

Drivetrain

(GearRatio)

CN5-C

ChZ

ChA/B

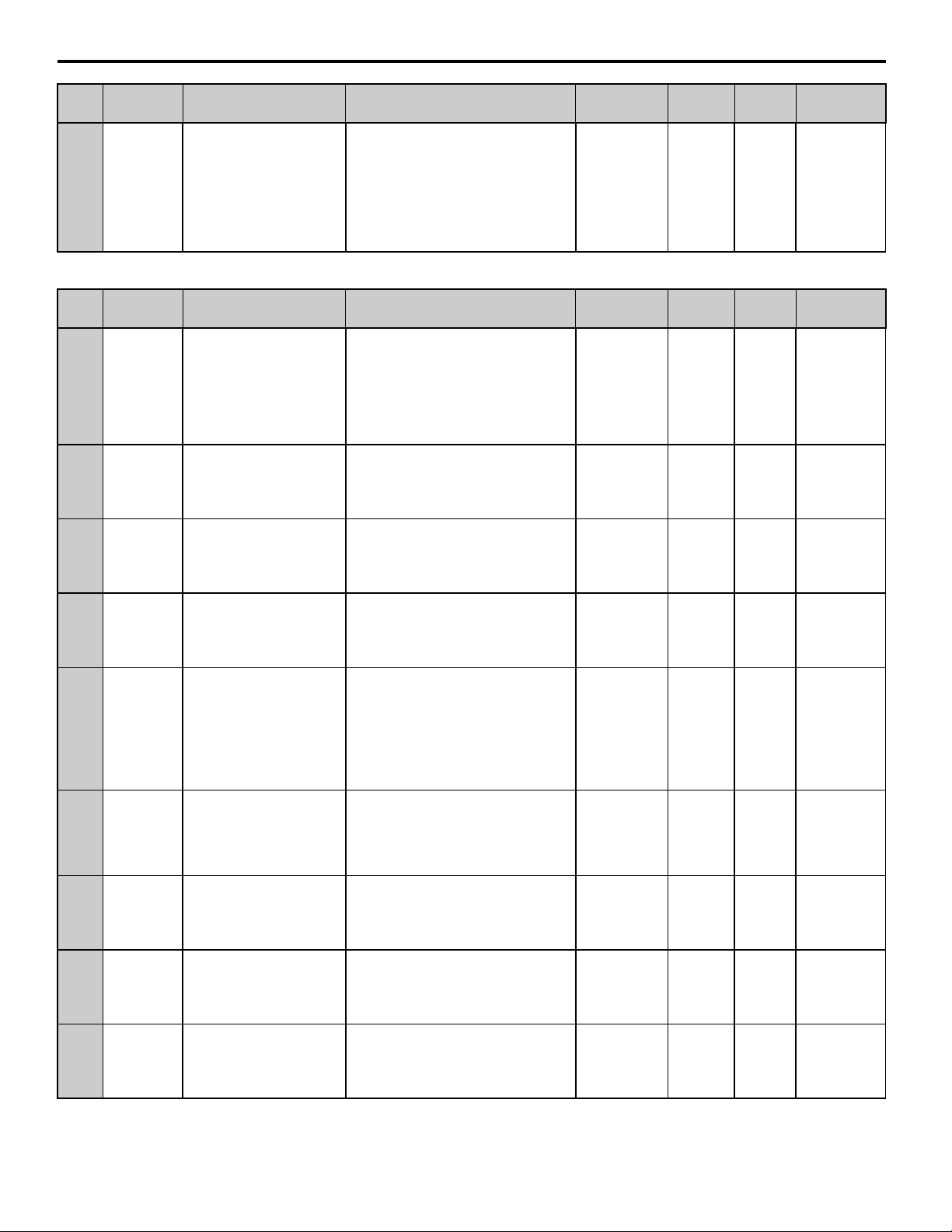

2 Spindle Orientation

Overview

The target applications for this function are on equipment that must stop in specific positions including tool changing for

machine tool spindles and die changing for punch/stamping presses. This software also provides for high frequency

operation with automatic switchover to closed-loop operation at low speed.

Applicable Models

This Spindle Orient software is available for the drive models listed in Tab le 1.

Table 1 Applicable Models

Voltage Class Model Software Version

200 V CIMR-AU2A0004A-063 to CIMR-AU2A0415A-063

400 V CIMR-AU4A0002A-063 to CIMR-AU4A0250A-063

Basic Concepts and Principles

This orientation software allows an A1000 drive to repeatedly stop a machine at a certain point in its rotational cycle. This

is accomplished by means of an orientation encoder directly coupled to the machine part to be positioned. A simple

example is to think of the hands on a clock. If the orientation encoder is mounted to the motor shaft, this software can stop

the motor so that the spindle stops at the 3 o'clock position every time. Application configurations are outlined in

Figure 1. For configurations other than those outlined, contact Yaskawa Application Engineering before applying this

software.

Figure 1

VSA910090

Figure 1 Spindle Orientation Hardware Configurations

6YASKAWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 7

2 Spindle Orientation

Direct Drive

In the first configuration, the drive motor directly drives the machine part being oriented (positioned). When using this

method, the motor encoder is used for both closed loop vector motor control and for orientation. This encoder must have

a C or Z channel which provides a “marker” or “index” pulse with every rotation. If the encoder does not have a C/Z

channel, an external marker pulse can be implemented as outlined in Encoder (PG) Option Card Configuration and

Wiring on page 29. Additionally, a PG-X3 or PG-B3 encoder (PG) feedback option card is required to connect the

encoder to the drive.

Indirect Drive with Orientation Encoder

When the motor and the machine part to be oriented (positioned) are connected through a drive train with a constant ratio,

two encoders are required. The first encoder is mounted on the driven motor, and the second, an orientation encoder, is

mounted on the machine part to be oriented. The orientation encoder must have a C or Z channel which provides a

“marker” or “index” pulse with every rotation. If the encoder does not have a C/Z channel, an external marker pulse can

be implemented as outlined in Encoder (PG) Option Card Configuration and Wiring on page 29. The motor encoder

does not need to have a C/Z channel. Two encoder (PG) feedback option cards are required for this setup.

Indirect Drive with Proximity Sensor

When the motor and the spindle are connected through a drive train and the spindle does not have its own encoder, a

proximity sensor may be used. The proximity sensor is connected as an external marker pulse; therefore this

configuration requires only one PG-X3 encoder (PG) feedback option card. In this configuration, the gear ratio of the

drive train must be expressed as the number of revolutions of the motor per revolution of the spindle.

Online Control Mode Switch Function

This software can switch between Closed Loop Vector Control and V/f Control during run. The 1000 Hz software is

limited to V/f control mode above 400 Hz, it is possible to change tools without stopping the machine if the inverter

switches to Closed Loop Vector Control for Position Control at Low-Speed. At Low-Speed the inverter can be set to

operate in Closed Loop Vector Control and automatically switch to V/f Control when the output is above the frequency

which is set.

Changes from the Standard Product

• Second PG Channel Parameters F1-30 through F1-37 are always visible whether or not digital selection H1-0 =16

(Motor 2 Select) is programmed.

• Only two Control Modes can be set in A1-02 and E3-01, 0:V/f and 3:Closed-Loop Vector.

• Only two Auto-Tuning Mode Selections are available, 0:Rotational Auto-Tuning and 2:Stationary Auto-Tuning for

Line-to-Line Resistance.

Deleted Functions

Certain functions in the standard software of A1000 are deleted in this Orientation software. Deleted functions are listed

in Tab le 2 .

Table 2 Deleted Functions

Speed Search (all methods) KEB Function Fault Restart

High Slip Braking (HSB) Overexcitation Braking Field Weakening Function

Energy Savings Droop Control Field Forcing Function

Frequency Reference Lower Limit Feed Forward Control DC Injection Braking Current Setting in V/f

Torque Detection Stall Prevention Selection during Acceleration Stall Prevention Selection during Run

Function Name

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 7

Page 8

2 Spindle Orientation

±±±<±±<

&/930

2/930

$2/930

&/9

2/9

9)Z3*

9I

1 1RW9LHZDEOH

< 9LHZDEOH$YDLODEOH

±

1RW$YDLODEOH

&RQWURO0HWKRG$FFHVV/HYHO'HFRGLQJ

Limitations

• The multi-function digital input function Motor 2 Select (H1- = 16) and Encoder Option Card Setting F1-30 have

restrictions when used in Closed Loop Vector control mode with an additional orientation encoder. Refer to Tab le 1 5 on

page 16 and Tab le 1 7 on page 31.

• Applications using Configuration 2 and Motor 1/Motor 2 switchover must use a motor encoder and an orientation

encoder of the same PPR.

• DriveWorks EZ functionality is not fully supported when using this software. If DriveWorks EZ support is required,

please contact Yaskawa Application Engineering.

• PG Encoder PPR parameters F1-01 and F1-31 are limited to PPR of 8 to 16384 PPR

(32 to 65536 counts per revolution).

• Orient functionality is disabled when the run command comes from the Local Operator (b1-02 = 0).

• Since all forms of speed search are disabled, the stopping method Coast to Stop (b1-03 = 1) causes inconsistent

operation of the spindle orient routine if an orient digital input is closed while the drive is coasting. This may include

but is not limited to overvoltage trips and faster than expected deceleration.

• Disabling reverse operation by setting Reverse Operation Selection parameter b1-04=1 prohibits the orient function

from maintaining position.

• Frequency Upper Limit parameter d2-01 prevents the spindle orient function from operating if the frequency limit is set

at or below the P1-02 Creep Speed.

• Orient digital inputs are disabled when Forward or Reverse Jog commands (H1-0 = 12 or 13) are active.

• Orient digital inputs are disabled when Control Mode Switchover Prevention digital input H1-0 = 50 is closed while

the drive is not running.

Related Parameters and Functions

The legend below is used in this section to indicate which parameters are available in which control modes.

The parameter tables in this section are used to set up the drive for operation with the software.

Note: Chinese language support is added to certain parameters and functions. Refer to References on page 31 for the parameters and

functions with Chinese language support.

Table 3 Modified Parameters

MEMOBUS/

No.

F1-01 0380h

F1-30 03AAh

Modbus

Address

Digital Operator Display

PG 1 Pulses Per Revolution

PG1 Pulses/Rev

PG Option Card Port for Motor 2

Selection

Mtr2 PG Port Sel

Name

Description Range

Sets the number of encoder pulses per revolution

for the encoder on channel 1.

Specifies the drive port for the PG option card used

for Motor 2.

0: CN5-C

1: CN5-B

Note: This parameter is available without a digital

input H1-0 programmed to 16h (Motor 2 Select).

Default

Value

8 to 16384 PPR 1024 PPR No – – – Y– – N

0 to 1 0 No – – – Y– – N

Change

During

Run

Control Method/

Access Level

8 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 9

2 Spindle Orientation

MEMOBUS/

No.

F1-31 03B0h

F1-32 03B1h

F1-35 03BEh

F1-36 03B5h

L3-04 0492h

S1-01 680h

S1-03 682h

S2-01 691h

Modbus

Address

Digital Operator Display

PG 2 Pulses Per Revolution

PG2 Pulses/Rev

PG2 Rotation Selection

PG2 Rotation Sel

PG2 Division Rate for Pulse

Monitor

PG2 Output Ratio

PG Option Card Disconnect

Detection 2

PGCardDisconDet1

Stall Prevention Selection during

Deceleration

StallP Decel Sel

On-Delay Compensation Selection

OnDelay Comp Sel

Extended Current Sampling Mode

Extend I Sample

Control Mode Switchover

Frequency

HF SwOver Freq

Name

Description Range

Sets the number of encoder pulses per revolution

for the encoder on channel 2.

Note: This parameter is available without a digital

input H1-0 programmed to 16h

(Motor 2 Select).

Determines the direction indicated by the pulses

from the PG feedback encoder for motor 2.

0: Pulse A Leads

1: Pulse B Leads

This parameter is available without a digital input

H1-0 programmed to 16h (Motor 2 Select).

Sets the ratio between the pulse input and the pulse

output of a PG option card.

This parameter is available without a digital input

H1-0 programmed to 16h (Motor 2 Select).

Sets whether the drive detects a fault when a

PG-X3 card is disconnected.

0: Disabled

1: Enabled

This parameter is available without a digital

input H1-0x programmed to 16h

(Motor 2 Select).

Determines how Stall Prevention works during

Run.

The parameter default is changed to 0: Disabled.

0: Disabled

1: General Purpose

2: Intelligent

3: Stall Prevention w/Braking Resistor

4: Overexcitation Deceleration

5: Overexcitation Deceleration 2

Note: Enabling stall prevention extends the decel

time. Other modes such as Intelligent may cause

unintended operation during orient, including

oscillation and inability to maintain position.

Parameter S1-01 is used to enable and disable On

Delay Compensation.

0: Disabled

1: Enabled

Normally there is no need to change S1-03 from its

default setting. If there is a problem with output

voltage weakening when attempting to compensate

for output current distortion as the motor reaches

1000 Hz while decoupled from the load during a

test run, then try setting S1-03 = 1.

0: Disabled

1: Enabled

Sets the frequency of switching from Closed Loop

Vector Control to V/f Control.

This function is disabled when 0 or 400 Hz is set,

the inverter runs as V/f Control when 0 is set and

Closed Loop Vector Control when 400 Hz is set.

However, OPE21 occurs when the relations among

Control Mode Switch Frequency (S2-01) and PG

Pulse per Revolution (F1-01) and Numbers of

Motor Poles (E2-04) are set higher than the

permissible input frequency of PG option.

Default

Value

8 to

16384 PPR

0 to 1 0 No – – – Y– – N

1 to 132 1 No – – – Y– – N

0 to 1 1 No – – – Y– – N

0 to 5 0 No – – – Y– – Y

0 to 1 1 No – – – Y– – Y

0 to 1 1 No – – – Y– – Y

0 to 400 Hz 400 No – – – Y– – N

1024 PPR No – – – Y– – N

Change

During

Run

Control Method/

Access Level

S2-02 692h

Control Mode Switchover

Bandwidth

HF CtrlMode SwBW

Sets the hysteresis width of Control Mode Switch.

Increase if shock occurs during Control Mode

switching.

2 to 100 Hz 20 No – – – Y– – N

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 9

Page 10

2 Spindle Orientation

MEMOBUS/

No.

S2-05 695h

S2-06 696h

S2-07 697h

S2-08 698h

S2-11 699h

Modbus

Address

Digital Operator Display

High Frequency Slip

Compensation Gain

HF SlipComp Gain

High Frequency Slip

Compensation Primary Delay Time

HF SlipComp Time

High Frequency Slip

Compensation Limit

HF SlipComp Lim

High Frequency Slip

Compensation Selection During

Regeneration

HF SlipCompRegen

Motor 2 Control Mode Switchover

Frequency

HF SwOver Freq 2

Name

Description Range

Sets the gain for the Motor Slip Compensation at

Hi-Speed Function. Although this parameter rarely

needs to be changed, adjustments might be needed

under the following circumstances:

If the motor at constant speed is slower than the

frequency reference, increase S2-05.

If the motor at constant speed is faster than the

frequency reference, decrease S2-05.

Sets the filter on the output side of the Slip

Compensation at Hi-Speed Function. Although this

parameter rarely needs to be changed, adjustments

might be needed under the following

circumstances:

-Decrease the setting when the slip compensation

response is too slow.

-Increase this setting when speed is unstable.

Sets the upper limit for the Slip Compensation at

Hi-Speed Function as a percentage of the motor

rated slip (E2-02).

When Slip Compensation during Regeneration at

Hi-Speed is activated and a regenerative load is

applied, it might be necessary to use a dynamic

braking option (braking resistor, braking resistor

unit, or braking unit).

0: Disabled

1: Enabled (6 Hz and Above)

2: Enabled

(Compensation provided wherever possible)

Sets the frequency of switching from Closed Loop

Vector Control to V/f Control for Motor 2

This function is disabled when 0 or 400Hz is set,

the inverter runs as V/f Control when 0 is set, and

Closed Loop Vector Control when 400Hz is set.

However, OPE21 occurs when the relations among

Control Mode Switch Frequency (S2-11) and PG

Pulse per Revolution (F1-31) and Numbers of

Motor Poles (E4-04) are set higher than the

permissible input frequency of PG option.

Default

Value

0.0 to 2.5 0.0 Yes – – – Y– – N

0 to 10000 ms 2000 Yes – – – Y– – N

0 to 250% 200 No – – – Y– – N

0 to 2 0 No – – – Y– – N

0 to 400 Hz 400 No – – – Y– – N

Change

During

Run

Control Method/

Access Level

S2-12 69Ah

S2-15 69Dh

S2-16 69Eh

S2-17 69Fh

Motor 2 Control Mode Switchover

Bandwidth

HF CtrlModeSwBW2

Motor 2 High Frequency Slip

Compensation Gain

HF SlipCompGain2

Motor 2 High Frequency Slip

Compensation Primary Delay Time

HF SlipCompTime2

Motor 2 High Frequency Slip

Compensation Limit

HF SlipComp Lim2

Sets the hysteresis width of Control Mode Switch

for Motor 2.

Increase if shock occurs during Control Mode

switching.

Sets the gain for the Motor Slip Compensation at

Hi-Speed Function for Motor 2. Although this

parameter rarely needs to be changed, adjustments

might be needed under the following

circumstances:

-If the motor at constant speed is slower than the

frequency reference, increase S2-15.

-If the motor at constant speed is faster than the

frequency reference, decrease S2-15.

Sets the filter on the output side of the Slip

Compensation at Hi-Speed Function for Motor 2.

Although this parameter rarely needs to be

changed, adjustments might be needed under the

following circumstances:

-Decrease the setting when the slip compensation

response is too slow.

-Increase this setting when speed is unstable.

Sets the upper limit for the Slip Compensation at

Hi-Speed Function for Motor 2 as a percentage of

the motor rated slip (E4-02).

2 to 100 Hz 20 No – – – Y– – N

0.0 to 2.5 0.0 Yes – – – Y– – N

0 to 10000 ms 2000 Yes – – – Y– – N

0 to 250% 200 No – – – Y– – N

10 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 11

2 Spindle Orientation

MEMOBUS/

No.

S2-18 6A0h

No.

P1-01 0600h

P1-02 0601h

P1-03 0602h

Modbus

Address

MEMOBUS/

Modbus

Address

Digital Operator Display

Motor 2 High Frequency Slip

Compensation During

Regeneration Selection

HF SlipCompRgn 2

Digital Operator Display

Orient Speed

Orient Speed

Creep Speed

Creep Speed

Creep Distance

Creep Distance

Name

Name

Description Range

When Slip Compensation during Regeneration at

Hi-Speed is activated and a regenerative load is

applied, it might be necessary to use a dynamic

braking option (braking resistor, braking resistor

unit, or braking unit).

0: Disabled

1: Enabled (6 Hz and Above)

2: Enabled

(Compensation provided wherever possible)

Table 4 Additional Parameters

Description Range

This parameter sets the frequency at which the

drive switches to the Orient Deceleration Time

(P1-12) and Orient ASR settings (P2-10 and P2-

11) when these parameters are enabled.

Note: P1-01 must be set such that it is not greater

than the control modes switchover frequency:

((S2-01 – S2-02) > P1-01). P1-01 must also be set

lower than the Maximum Output Frequency E1-04.

This parameter sets the speed at which the drive

locates the marker pulse. This is also the speed at

which s-curves are disabled.

This parameter sets the number of quadrature

encoder counts around the orientation position

where the frequency reference is allowed to drop

below the P1-02 Creep Speed. Within the Creep

Distance, the drive accel/decel times are set to 0.

Default

Value

0 to 2 0 No – – – Y– – N

Default

Value

0.00 to 200.00 Hz 20.00 No – – – Y– – N

0.10 to 10.00 Hz 2.00 No – – – Y– – N

0 to 2000 Cnts 200 No – – – Y– – N

Change

During

Run

Change

During

Run

Control Method/

Access Level

Control Method/

Access Level

P1-04 0603h

P1-05 0604h

P1-06 0605h

P1-07 0606h

P1-08 0607h

P1-09 0608h

Approach Speed

Approach Speed

Orientation Complete Detection Set

Window

ORT Set Window

Orientation Complete Detection

Reset Window

ORT Rst Window

Orientation Set Time

ORT Set Time

Positioning Proportional Gain

Pos P Gain

Orientation Compensation Distance

Orient Comp Dist

This parameter sets the minimum speed that the

drive operates at until it reaches the P1-05 ORT Set

Window.

This parameter sets the initial window around the

orientation position that activates the Orient

Complete digital output. The Orient Complete

digital output (H2- = 40) closes when the

encoder quadrature count is within the P1-05

window of the orientation offset and after the P1-07

delay time has expired.

Note: Counts = Encoder PPR x 4.

This parameterr sets, in quadrature encoder counts,

the window around the orient position that keeps the

Orient Complete digital output (H2- = 40)

closed.

Note: Counts = Encoder PPR x 4.

This parameter sets the delay time from when the

P1-05 Orient Set window is satisfied and the

Orientation Complete digital output (H2- = 40)

closes.

This parameter sets the proportional gain used for

the position controller.

This parameter sets the minimum orientation

distance between the orientation encoder marker

pulse at or below P1-02 and the desired orientation

offset. This distance is expressed as a percentage of

the active encoder PPR (e.g. F1-01 x P1-09).

0.00 to 1.00 Hz 0.10 No – – – Y– – N

0 to 100 Cnts 25 No – – – Y– – N

0 to 100 Cnts 0 No – – – Y– – N

0 to 1000 ms 10 No – – – Y– – N

0.10 to 20.00 1.00 No – – – Y– – N

0 to 100% 50% No – – – Y– – N

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 11

Page 12

2 Spindle Orientation

MEMOBUS/

No.

P1-10 0609h

P1-11 061Eh

P1-12 061Fh

P1-13 0620h

P1-14 0621h

Modbus

Address

Digital Operator Display

Orientation Encoder Card Selection

ORT Enc Select

Orientation Deceleration Selection

ORT Dec Sel

Orientation Deceleration Time

ORT Dec Time

Spindle Proximity Sensor

Orientation Enable

Prox Sens Enable

Proximity Sensor Pulse Width

Prox Pulse Width

Name

Description Range

This parameter selects which PG option card is used

for orientation.

0: CN5-C

1: CN5-B

Note: When using only one PG option card, P1-10

must be set to 0.

This parameter selects whether the drive’s C1-0

Deceleration Time is overridden by the P1-12

Orientation Deceleration Time once the drive

reaches the P1-01 Orient Speed.

0: Disabled

1: Enabled

The Orientation Deceleration Time parameter sets

the time to decelerate from the maximum output

frequency (E1-04) to 0 Hz. Refer to Area A:

Deceleration on page 19

This parameter selects whether or not the drive is

configured with a proximity sensor as described in

Configuration 3. Setting parameter P1-13 = 1 causes

the drive to recognize the values set in proximity

sensor parameters P1-14 and P1-15.

0: Disabled

1: Enabled

This parameter defines the pulse width of the

proximity sensor at the P1-02 Creep Speed,

measured in elapsed encoder counts.

Default

Value

0 to 1 0 No – – – Y– – N

0 to 1 0 No – – – Y– – N

0.00 to 600.00 sec 10.00 Yes – – – Y– – N

0 to 1 0 No – – – Y– – N

0 to 60000 Cnts 0 No – – – Y– – N

Change

During

Run

Control Method/

Access Level

P1-15 0622h

P2-01 060Ah

P2-02 060Bh

P2-03 060Ch

P2-04 060Dh

P2-05 060Eh

Proximity Sensor Pulse State

Prox Pulse State

Marker Offset Selection

MarkerOffset Sel

Marker Offset 1

Marker Offset 1

Marker Offset 2

Marker Offset 2

Marker Offset 3

Marker Offset 3

Marker Offset 4

Marker Offset 4

This parameter defines whether or not the proximity

sensor is a Normally Open (rising edge) or

Normally Closed (falling edge).

0: Normally Open

1: Normally Closed

This parameter determines how the orientation

position offset from the marker pulse is determined.

0: Digital Input

1: Sequential

2: Memobus COM

Refer to Orient Position Offset Selection on

page 25.

This parameter, along with parameters P2-03, P204, and P2-05, sets the orientation (or stopped)

position of the machine. P2-01 governs when P2-02

is active. Refer to Orient Position Offset Selection

on page 25.

Note: Counts = Encoder PPR x 4.

This parameter is used in conjunction with

parameters P2-02, P2-04, and P2-05 to determine

the orientation position offset from the marker

pulse. Refer to Orient Position Offset Selection on

page 25.

Note: Counts = Encoder PPR x 4.

This parameter is used in conjunction with

parameters P2-02, P2-03, and P2-05 to determine

the orientation position offset from the marker

pulse. Refer to Orient Position Offset Selection on

page 25.

Note: Counts = Encoder PPR x 4.

This parameter is used in conjunction with

parameters P2-02, P2-03, and P2-04 to determine

the orientation position offset from the marker

pulse. Refer to Orient Position Offset Selection on

page 25.

Note: Counts = Encoder PPR x 4.

0 to 1 0 No – – – Y– – N

0 to 2 0 No – – – Y– – N

0 to 65535 Cnts 0 No – – – Y– – N

0 to 65535 Cnts 0 No – – – Y– – N

0 to 65535 Cnts 0 No – – – Y– – N

0 to 65535 Cnts 0 No – – – Y– – N

12 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 13

2 Spindle Orientation

MEMOBUS/

No.

P2-06 060Fh

P2-07 0610h

P2-08 0611h

P2-09 0612h

P2-10 0613h

P2-11 0623h

P2-12 0624h

P2-13 0625h

Modbus

Address

Digital Operator Display

Motor Gear Ratio 1

Motor Ratio 1

Motor Gear Ratio 2

Motor Ratio 2

Motor Gear Ratio 3

Motor Ratio 3

Orientation ASR Enable

ORT ASR Enable

ASR P Gain 3

ASR P Gain 3

ASR I Time 3

ASR I Time 3

ASR P Gain 4

ASR P Gain 4

ASR I Time 4

ASR I Time 4

Name

Description Range

This parameter sets gear ratio 1 between the driven

motor shaft and the spindle when the drive is set for

an indirect drive configuration. A setting of 2.0000

means that there are two motor shaft revolutions for

every revolution of the spindle. Refer to

Configuration 2: Indirect Drive with Orientation

Encoder on page 23.

This parameter sets gear ratio 2 between the driven

motor shaft and the spindle.

This parameter sets gear ratio 3 between the driven

motor shaft and the spindle.

This parameter enables the ASR Proportional Gain

override used during orientation.

0: Disabled

1: Enabled

This parameter sets the ASR Proportional Gain used

for orientation and becomes active whenever an

Orient Digital Input (H1-0 = 80 ~ 82) is present.

This parameter overrides C5-01 and C5-03 when

P2-09 = 1. The active proportional gain

(C5-01 or C5-03) is ramped to the P2-10 value

using the P2-11 time setting.

This parameter sets the ASR Integral Time used for

orientation and becomes active whenever an Orient

Digital Input (H1-0 = 80 ~ 82) is present.

This parameter automatically overrides C5-02 and

C5-04.

This parameter sets the ASR Proportional Gain used

for orientation and becomes active whenever the

Orientation Compete Digital Output (H2-0 = 40)

is active. This parameter overrides C5-01, C5-03,

and P2-10 ASR gain settings when P2-09 = 1. The

active P2-10 proportional gain is ramped to the P212 value using the P2-13 time setting.

This parameter sets the ASR Integral Time used for

orientation and becomes active whenever the

Orientation Compete Digital Output (H2-0 = 40)

is active. This parameter automatically overrides

C5-02, C5-04, and P2-11.

Default

Value

0.0400 to 2.5000 1.0000 No – – – Y– – N

0.0400 to 2.5000 1.0000 No – – – Y– – N

0.0400 to 2.5000 1.0000 No – – – Y– – N

0 to 1 0 No – – – Y– – N

0.00 to 300.00 20.00 Yes – – – Y– – N

0.000 to

10.000 sec

0.00 to 300.00 20.00 Yes – – – Y– – N

0.000 to

10.000 sec

0.500 Yes – – – Y– – N

0.500 Yes – – – Y– – N

Change

During

Run

Control Method/

Access Level

Table 5 Modified Group Text

Function Group

S

Function Group Name

Digital Operator Display

High Frequency

High Frequency

Table 6 Additional Group Text

Function Group

P

Function Group Name

Digital Operator Display

Spindle Orient Group

Spindle Orient

Table 7 Modified Function Text

Function No.

S1

S2

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 13

Function Name

Digital Operator Display

High Frequency Control

HighFreq Control

Control Mode Switchover

Ctrl Mode Switch

Page 14

2 Spindle Orientation

Function No.

P1

P2

Monitor No.

U7

MEMOBUS/

Monitor No.

U7-02 0661h

Modbus

Address

Digital Operator Display

Distance From Marker

Dist From Marker

Monitor Name

Table 8 Additional Function Text

Function Name

Digital Operator Display

Orient Settings

Orient Settings

Offset and Gear Ratio

Offset & Gear

Table 9 Monitor Function Text

Monitor Name

Digital Operator Display

Spindle Orient Group

Spindle Orient

Table 10 Monitors

Description

Displays the current number of orientation encoder counts the

machine is past the marker pulse. The display range is 0 - 65535

counts and is limited by the PPR setting in parameters F1-01 and

F1-31.

Note: Counts = Encoder PPR x 4.

Analog output

scaling

Full scale: 65535

Counts

Unit

Cnts – – – Y– – Y

Control Method/

Access Level

U7-03 0662h

U7-04 0663h

U7-05 0664h

U7-06 0665h

Address Description

0012h

Distance From Offset

Dist From Offset

Commanded Offset

Commanded Offset

Sequence Step

Sequence Step

Serial Offset

Serial Offset

Orientation Offset

When P2-01 = 2, this Memobus register defines the orientation offset from the marker pulse. The setting range is 0 - 65535. The data is

not saved upon power loss. Register 0012h does not require the use of an Enter or Accept command.

The written data is immediately active.

Displays the number of orientation encoder counts the machine is

away from the active orientation position offset. The display

range is 0 - 65535 counts.

Displays the active value of the orientation offset from the

marker pulse. See parameter P2-01 Orient Position Offset

Selection on page 25. The display range is 0 - 65535 counts.

Note: Counts = Encoder PPR x 4.

Displays the active orientation offset parameter. See parameter

P2-01 and Orient Position Offset Selection on page 25 for more

information.

The display range is 0 - 4.

0: P2-02

1: P2-03

2: P2-04

3: P2-05

4: Memobus

This monitor reflects the data in Memobus register 0012h. Refer

to Orient Position Offset Selection on page 25. The display

range is 0 - 65535 counts.

Table 11 MEMOBUS/Modbus Registers

Full scale: 65535

Counts

No Signal Output

Available

No Signal Output

Available

No Signal Output

Available

Cnts – – – Y– – Y

Cnts – – – Y– – Y

- – – – Y– – Y

Cnts – – – Y– – Y

Table 12 Multi-Function Input Settings (H1-)

Setting Description

Mode Sw Disable

50

80

81

Closed: All frequencies are V/f control. When open, the control mode switches from Closed Loop Vector control to V/f control according to the

Control Mode Switchover Frequency S2-01. This multi-function input is only accepted while the inverter is stopped. The status of this multifunction input is dismissed during run.

Orient CMD

Closed: Causes the drive to orient the motor to the current orientation position offset from the marker pulse. The motor orients in the direction of the

run command. Refer to Function Description on page 17.

Orient CMD FWD

Closed: Causes the drive to run in the forward direction and orient the motor to the current orientation position offset from the marker pulse. Refer to

Function Description on page 17.

14 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Control Method/

Access Level

– – – Y– – N

– – – Y– – N

– – – Y– – N

Page 15

2 Spindle Orientation

Setting Description

82

83

84

85

86

87

Orient CMD REV

Closed: Causes the drive to run in the reverse direction and orient the motor to the current orientation position offset from the marker pulse. Refer to

Function Description on page 17.

Sequential Reset

Closed: Sets the active orientation offset parameter to P2-02 (sequence 0). This function is only active if P2-01 = 1.

Offset Sel 1

Orientation Position Offset Selection 1. See Section Refer to Orient Position Offset Selection on page 25 and parameters P2-02, P2-03, P2-04 and

P2-05.

Offset Sel 2

Orientation Position Offset Selection 2. Refer to Orient Position Offset Selection on page 25 and parameters P2-02, P2-03, P2-04 and P2-05.

Gear Ratio Sel 1

Motor Gear Ratio Selection 1. Refer to Configuration 2: Indirect Drive with Orientation Encoder on page 23 and parameters P2-06, P2-07, and

P2-08.

Gear Ratio Sel 2

Motor Gear Ratio Selection 2. Refer to Configuration 2: Indirect Drive with Orientation Encoder on page 23 and parameters P2-06, P2-07, and

P2-08.

Table 13 Multi-Function Output Settings (H2-)

Setting Description

40

41

Orient Complete

Closed: The machine is within the orient position window established by P1-05 and the P1-07 ORT Set Time has expired. Once this condition is

met, the output remains closed as long as the machine is within the P1-06 window.

Home Position

Closed: The active orientation position offset is P2-02 (sequence 0). This output is only active when P2-01 = 1 (Sequential Marker Offset

Selection).

Troubleshooting

Table 14 Faults

Fault Indication

Digital Operator Display

<Memobus>

Marker Pulse Detection

Error

CDEV

Marker Det Error

<3Ch>

The drive monitors the number of A and B channel

encoder pulses between each marker pulse

(Z or C channel). There should be F1-01

(Encoder PPR) A and B channel pulses between

each marker pulse. If the pulse count exceeds F1-01

x 8, the drive displays a CDEV fault and coasts to a

stop.

Note: If Orientation encoder parameter P1-10 = 1,

parameter F1-31 sets Encoder PPR. If an Indirect

Drive configuration is used, Orientation encoder

PPR is multiplied by the active gear ratio.

Description Cause Countermeasures

This fault is displayed when the motor has gone two

rotations without receiving a marker pulse from the

motor encoder (Z or C channel).

This could be caused by disconnected or

malfunctioning hardware, or inappropriate

parameter settings.

This fault is only triggered while an orient digital

input is activated and the frequency reference is less

than the P1-01 Orient Speed.

Control Method/

Access Level

– – – Y– – N

– – – Y– – N

– – – Y– – N

– – – Y– – N

– – – Y– – N

– – – Y– – N

Control Method/

Access Level

– – – Y– – N

– – – Y– – N

- Remove all run commands from the drive. Check

the wiring of the encoder, especially the Z pulse.

- Check for noise on the encoder feedback signals.

- Check the F1-01/F1-31 parameter setting matches

the encoder being used.

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 15

Page 16

2 Spindle Orientation

Alarm Indication

Digital Operator Display

<Memobus>

This Operator Programming Error occurs when

spindle orient parameters are set in a way that may

cause unintended operation.

This error covers the following parameter settings:

Orient Parameter Selection

Error

OPE12

Orient Param Err

<0Ch>

1. The CN5-B encoder is set as both the position

and motor encoder.

2. The Orient Speed parameter P1-01 is set too

close to Control Mode Switch Frequency S2-01

(S2-11 if Motor 2 is programmed).

3. Reverse Operation (b1-04) is disabled for orient

applications.

4. Minimum Frequency (E1-09) is set too high.

5. Orient Encoder set for CN5-B but the PG option

card is missing.

Table 15 Errors

Description Cause Countermeasures

1. Remove CN5-B Encoder Conflict. Refer to

References on page 31.

1. The drive is in Closed Loop Vector Control Mode

(A1-02 = 3), digital input H1-0 = 16h is

programmed, Motor 2 Option Card Port Selection

Parameter F1-30 = 1 (CN5-B), and Orientation

Encoder Channel Selection Parameter P1-10 = 1

(CN5-B).

2. P1-01 + S2-02 is greater than S2-01.

(Or P1-01 + S2-12 is greater than S2-1

1 if Motor 2 is selected.)

3. Parameter b1-04 = 1 and digital input H1-0 =

80/81/82h.

4. Parameter E1-09 is greater than the P1-02 Creep

Speed while the drive is configured for orient.

5. Orientation Encoder Card Selection Parameter

P1-10 = 1 (CN5-B) and a PG-X3 or PG-B3 option

card is not installed in CN5-B while digital input

H1-0 = 80/81/82h .

a. Program the drive for V/f Control Mode

(A1-02 = 0).

b. De-program the digital input H1-0 = 16h.

c. Change Motor 2 Option Card Port Selection

Parameter F1-30 = 0 (CN5-C).

d. Change Orientation Encoder Channel

Selection Parameter P1-10= 0 (CN5-C).

2. Set P1-01 to at least S2-02 Hz less than S2-01, or

set S2-01 = 0Hz.

3. Enable reverse operation (b1-04 = 0) or

de-program orient digital inputs H1-0 = 80/81/

82h.

4. Set E1-09 less than the P1-02 value or deprogram orient digital inputs H1-0 = 80/81/82h.

5. Power down the drive and install a PG-X3 or

PG-B3 option card into CN5-B, change the

orientation encoder to be CN5-C (P1-10 = 0), or

change digital input H1-0 != 80/81/82h.

Alarm Indication

Digital Operator Display

<Memobus>

Control Mode Switchover

Frequency Error

OPE21

Switch Freq Err

<0Ch>

Table 16 Modified Errors

Description Cause Countermeasures

The permissible hardware frequency limit of PG

option card is exceeded.

The S2-01 Control Mode Switchover frequency is

too high for the encoder with PPR set in parameter

F1-01 (F1-31 for encoders hooked up to option

cards in port CN5-B).

Set the value of Control Mode Switchover

Frequency S2-01 within the conditions below:

PG-B3: F1-01 × S2-01 x 2/E2-04 > 50 kHz

PG-X3: F1-01 × S2-01 x 2/E2-04 >300 kHz

16 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 17

2 Spindle Orientation

MachineSpeed

(Hz)

RunCommand

DecelTime

(C1-0X)

OrientSpeed

(P1-01)

CreepSpeed

(P1-02)

ORTDecTime

(P1-12)

FrequencyReference

(determinedbyb1-01)

OrientDigitalInput

(H1-0X=80/81/82h)

AccelTime

(C1-0X)

ControlModeSwitchover

Frequency(S2-01)

ControlModeSwitchover

Bandwidth(S2-02)

OrientComplete

(H2-0X=40h)

Frequency[(S2-01)‒ (S2-02)]

mustbegreaterthanP1-01or

OPE12errorwilloccur.

Function Description

The spindle orientation function begins when one of the orient digital inputs (80h, 81h, or 82h) outlined in Tabl e 12 is

closed. These orient digital inputs can be broken into two modes: Orient from Run, and Orient from Stop. These two

modes are discussed later in this section.

Orient only occurs when the drive is in Closed Loop Vector (CLV) control mode. This can be achieved by setting the P102 Creep Speed below the window established by the S2-01 Control Mode Switchover Frequency and the S2-02 Control

mode Switchover Bandwidth. Figure 2 shows how the drive returns to Closed Loop Vector operation once an orient is

commanded.

Figure 2

Figure 2 Orient Operation with High Frequency Switchover

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 17

Page 18

2 Spindle Orientation

DriveSFS

FWD

80/81/82hOrient

Command

80/81/82hOrient

Command

OrientFWD

OrientREV

80hOrient

CMD

81hOrient

CMDFWD

82hOrient

CMDREV

FWDRun

REVRun

OrientREV

OrientFWD

OrientFWD

OrientREV

DriveSFS

REV

DriveSFS

Zero

FWDorREV

FWDorREV

FWDorREV

FWDorREV

OrientDirection:OrientFromRun

RunDirection

(RunCommand+

FrequencyReference)

OrientDirectionOrientCommand

DriveSoftstarter

Polarity/Speed

(U1-02)

Orient from Run

An Orient from Run is initiated by closing one of the orient digital inputs (80h, 81h, or 82h) while the drive is running.

These digital inputs command the drive to orient the spindle to the requested offset. In an orient from run, the drive soft

starter status is used to determine the orient direction. If the soft starter output is zero (the drive is holding position), the

orient direction is determined by the commanded run direction when an 80h Orient CMD is given, and by the orient

digital inputs themselves when an 81h Orient FWD or 82h Orient REV is commanded. The run direction logic is outlined

in Figure 3.

Figure 3

Both the run command and an orient digital input must be present for the drive to regulate and hold the desired position.

Figure 3 Orient Direction Determination

The 80h Orient Command digital input is special such that if the run command is removed during orientation, the drive

stops according to the b1-03 Stopping Method and orientation is not completed. Note, however, that the 81h Orient

Command Forward and 82h Orient Command Reverse digital inputs provide their own run command to the drive, so

removing the run command to the drive does not cancel the orient when using these orient digital inputs.

If the run command is present during orientation and all orientation digital inputs (80h, 81h, and 82h) are removed, the

drive resumes normal operation at the current speed reference.

When multiple orient digital inputs are issued simultaneously, the function of the subsequent orient digital inputs are

ignored. The orient command is cleared once all orientation digital inputs are opened.

Figure 4 covers the Orient from Run deceleration profile after an orient digital input is activated. The figure is broken up

into three areas. Area A includes deceleration to the P1-02 Creep Speed. Area B represents locating the marker.

Area C represents the final approach of the spindle once it has reached the desired offset. Each area is described in more

detail in the following sections.

18 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 19

Figure 4

OrientDigitalInput

(H1-0X=80/81/82h)

MachineSpeed

(Hz)

ZMarkerPulse

A/BPulseCount

(Equivalentto

ShaftAngle)

FrequencyReference

(determinedbyb1-01)

OrientSpeed

(P1-01)

DecelTime

(C1-0X)

CreepSpeed

(P1-02)

ORTDecTime

(P1-12)

2 Spindle Orientation

Position-Error×P1-08Gain

BasedSpeed

ApproachSpeed

(P1-04)

OrientCompDist

(P1-09)

CreepDistance

(P1-03)

ORTSetWindow

(P1-05)

Rotationdueto

ExternalInfluence

ORTRstWindow

(P1-06)

OrientComplete

(H2-0X=40h)

ORTSetTime(P1-07)

Figure 4 Orientation Deceleration Profile from Run

Area A: Deceleration

The drive decelerates using the C1-0 deceleration time until it reaches the Orient Speed defined in parameter P1-01.

At the P1-01 Orient Speed, the software checks the status of Orientation Deceleration Selection parameter P1-11 and

Orientation Deceleration Time parameter P1-12 to determine the deceleration time used at frequencies below P1-01.

If parameter P1-11 is enabled, deceleration time switches from C1-0 to P1-12 as shown in Figure 4 above. The drive

ramps its current ASR P Gain to ASR P Gain 3 (P2-10) if Orientation ASR Enable parameter P2-09 is enabled.

Area B: Marker Location

The P1-02 Creep Speed is the speed that the drive will cruise at while determining the location of the marker pulse on the

C/Z channel of the orientation encoder. The purpose of the Creep Speed is to provide a steady speed for reading the

marker pulse which gives consistent and repeatable marker pulse location. Once the marker pulse has been found, the

drive will disable s-curves and calculate the position error. The position error is calculated to be the distance between the

current spindle orientation and the selected P2-02/03/04/05 marker offset. If the position error is less than the number of

counts specified in Orientation Compensation Distance P1-09, the drive will add an additional rotation to allow the drive

to come to a controlled stop once the drive enters position error-based control.

Area C: Position Error-Based Control

The drive enters position error-based control once the calculated position error is less than the P1-03 Creep Distance.

Within the Creep Distance, the frequency reference is calculated using the product of the position error (in encoder

counts) and the Positioning Proportional Gain as determined by Positioning Proportional Gain parameter P1-08.

The frequency reference is upper limited to the P1-02 Creep Speed and lower limited to the P1-04 Approach Speed.

The purpose of the Approach Speed is to decrease the time it takes to complete an orient by ignoring low frequency

references until the drive reaches the P1-05 Orientation Complete Detection Set Window. If the P1-04 is programmed to

be greater than the P1-02, the drive runs at the P1-04 speed while within the creep distance. Within the creep distance, the

drive acceleration and deceleration times are also set to zero. This allows the drive to respond appropriately to the

position error without being influenced by the C1-0 accel/decel times.

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 19

Page 20

2 Spindle Orientation

Once the position is maintained within the Complete Detection Set window P1-05 for the length of time defined by the

ORT Set Time P1-07, the H2-0 digital output programmed to Orient Complete (40h) is set and Zero Servo control is

enabled. With Zero Servo control enabled, any remaining position error is resolved by the Zero Servo algorithm.

Also, if Orientation ASR Enable parameter P2-09 is enabled, the P2-10 ASR Gain setting is ramped to the P2-12

(ASR P Gain 4) setting over the time specified by parameter P2-13 (ASR I Time 4).

Zero Servo Gain parameter b9-01 controls the responsiveness of the drive when external loads are applied. If an external

influence forces the position of the spindle outside of the P1-06 Orientation Detection Complete Reset Window, the

Orient Complete digital output is reset but the drive remains in Zero Servo Control. A detailed description of Orientation

Complete Detection Set and Reset windows can be found in Orientation Set/Reset Window on page 28.

Note: The position control algorithm requires control of the drive at frequencies well below 1 Hz. Therefore, drive parameters b1-05

and E1-09 should remain programmed to their default values.

Orient from Run: Frequency Reference below P1-02

If the drive is running at a frequency reference below P1-02 and an orient digital input is closed, the drive accelerates

towards the P1-02 Creep Speed using the drive Acceleration Time C1-0 until it finds the marker pulse. The drive ramps

its current ASR P Gain to ASR P Gain 3 (P2-10) if Orientation ASR Enable parameter P2-09 is enabled. Once the marker

pulse is found, s-curves are disabled and the position-error is calculated in the same fashion as the Orient from Run

example discussed in the above section.

Note: If the drive has an active run command and a frequency reference of 0 Hz, the drive accelerates in the commanded run direction

when an 80h Orient CMD is given. If an 81h Orient CMD FWD or 82h Orient CMD REV is given, the drive ignores the

Figure 5

commanded run direction.

OrientDigitalInput

(H1-0X=80/81/82h)

MachineSpeed

(Hz)

ZMarkerPulse

A/BPulseCount

(Equivalentto

ShaftAngle)

OrientComplete

(H2-0X=40h)

OrientSpeed

(P1-01)

FrequencyReference

(determinedbyb1-01)

AccelTime

(C1-0X)

ORTSetTime(P1-07)

CreepSpeed

(P1-02)

Position-Error×P1-08Gain

BasedSpeed

ApproachSpeed

(P1-04)

OrientCompDist

(P1-09)

CreepDistance

(P1-03)

ORTSetWindow

(P1-05)

Rotationdueto

ExternalInfluence

ORTRstWindow

(P1-06)

Figure 5 Orientation Profile from Below P1-02

Orient from Stop

An orient from stop is performed when the spindle is at rest, no RUN command is present, and one of the 81h Orient

CMD FWD or 82h Orient CMD REV digital inputs is closed. Separate run commands are not required to perform an

orient from stop, as the 81h and 82h digital inputs provide their own run command to the drive.

20 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 21

2 Spindle Orientation

ORTSetTime(P1-07)

OrientComplete

A/BPulseCount

(Equivalentto

ShaftAngle)

ZMarkerPulse

MachineSpeed

(Hz)

OrientCMDFWD

AccelTime

(C1-0X)

CreepSpeed

(P1-02)

ORTSetWindow

(P1-05)

(H1-0X=81h)

(H2-0X=40h)

CreepDistance

(P1-03)

ApproachSpeed

(P1-04)

PositionError

HighP1-08Gain

OrientationProfile

Position-Error×

P1-08Gain

BasedSpeed

An Orient from Stop can also be performed when the 80h Orient Command is applied while the drive is at rest and the

drive is then issued a run command.

Area A: Acceleration

If the spindle is stopped at a position outside of the Orient Complete Detection Set Window and the Orient CMD FWD

(81h) is issued, the drive begins to run in the forward direction and accelerate to a speed determined by the product of the

real-time position error and the Positioning Proportional Gain P1-08. This speed is limited to a maximum of the P1-02

Creep Speed as demonstrated in Area A of Figure 6. If the spindle is to be oriented in the reverse direction, orient digital

input 82h (Orient CMD REV) should be used.

If the spindle position is within the Orient Complete Detection Set Window, the drive orients as described in Orientation

Set/Reset Window on page 28.

Area B: Deceleration and Control

Area B shows how the position regulator determines the frequency reference during orient. The Positioning Proportional

Gain parameter P1-08 adjusts the responsiveness of the position regulator. Unlike an Orient from run, the drive does not

look for the marker pulse when performing an Orient from Stop because the marker position has already been determined

(except during a power-up condition as described in Orient from Stop - Find Marker on page 22).

Note: Increasing Positioning Proportional Gain parameter P1-08 decreases the orient time when an orient from stop is performed (as

represented by the dashed line machine speed curve as represented in Figure 6 ). Increasing this gain may also cause overshoot, if

this happens, decrease P1-08 until the overshoot disappears. Raising the P1-02 Creep Speed decreases the orient time of an orient

Figure 6

from stop.

Note: If an 81h Orient CMD FWD or 82h Orient CMD REV digital input is removed and reapplied while the Orient Complete output

Figure 6 Orient Profile from Stop

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 21

Page 22

2 Spindle Orientation

ORTSetTime(P1-07)OrientComplete

A/BPulseCount

(Equivalentto

ShaftAngle)

ZMarkerPulse

MachineSpeed

(Hz)

OrientCMDFWD

AccelTime

(C1-0X)

OrientSpeed

(P1-01)

CreepSpeed

(P1-02)

Rotationdueto

ExternalInfluence

ORTSetWindow

(P1-05)

ORTRstWindow

(P1-06)

(H1-0X=81h)

(H2-0X=40h)

OrientCompDist

(P1-09)

CreepDistance

(P1-03)

ApproachSpeed

(P1-04)

Position-Error×

P1-08Gain

BasedSpeed

0

HighP1-08Gain

OrientationProfile

(40h) is active (the spindle remains within the P1-06 window) and the spindle is being commanded to its current offset, the drive

immediately proceeds into final positioning regardless of the error direction.

Orient from Stop - Find Marker

When the drive is first powered up, the location of the marker pulse is not known. If the drive is commanded to perform

an Orient from Stop immediately after power up, the drive will first look for the marker as shown in Area A of Figure 7.

Once the marker pulse is found, operation is identical to the Orient from Run example discussed in Orient from Run on

page 18.

Figure 7

Figure 7 Orient from Stop Including Marker Pulse at P1-02

22 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 23

Application Configurations

Motor

Encoder

Machine

Motor

Configuration 2: Indirect Drive with

Orientation Encoder

Configuration 1: Direct Drive

PG-X3

PG-X3

PG-X3

Orientated

Machine Part

Orientation

Encoder

Orientated

Machine Part

Drivetrain

(Gear Ratio)

CN5-B

CN5-C

CN5-C

Motor

Encoder

Ch A/B/Z

Ch A/B/Z

Ch A/B

Machine

Motor

Motor

Encoder

Machine

Motor

Configuration 3: Indirect Drive with

Proximity Sensor

PG-X3

Proximity

Sensor

Orientated

Machine Part

Drivetrain

(Gear Ratio)

CN5-C

Ch Z

Ch A/B

Typical applications are as follows:

Figure 8

2 Spindle Orientation

Configuration 1: Direct Drive

This is a direct drive system where the encoder, motor and spindle shafts are directly coupled. This system can use the

motor's encoder for orientation and closed loop vector control (A1-02 = 3) of the motor to provide the best performance.

The orientation encoder must have a marker pulse (referred to as the Z or C pulse).

Configuration 2: Indirect Drive with Orientation Encoder

This is an indirect drive system where the motor and the spindle shaft are connected through a drive train. The orientation

encoder is coupled to the spindle shaft which is used for spindle positioning, while the motor encoder is used for closed

loop vector control.

Both encoders must have quadrature feedback (A and B channels with compliments). The orientation encoder must also

have a marker pulse (referred to as the Z or C pulse).

Note: If the Orient encoder phasing is incorrect (A and B phases are swapped), the drive fails to orient. The symptom of incorrect

orientation encoder phasing would be a drive that ramps down to the P1-02 creep speed but does not orient. If the orientation

encoder is CN5-B, then changing PG 2 Rotation Selection Parameter F1-32 or swapping A/B encoder wires on the CN5-B option

card should resolve the issue.

In this configuration, the gear ratio of the drive train must be expressed as an exact number of motor revolutions per

revolution of the spindle. By default, the software is programmed with a gear ratio of 1.0000. If the motor and the

proximity sensor are connected by a gear train, their ratio can be expressed within the range of 0.0400 to 2.5000. A ratio

of 2.0000 means that there are two motor shaft revolutions for every revolution of the spindle (and every proximity sensor

pulse). This gear ratio may be changed by modifying parameters P2-06, P2-07, and P2-08, and then selecting the gear

ratio using Gear Ratio Select digital inputs 86h and 87h. If neither of the digital inputs 86h or 87h is programmed, P2-06

is the active gear ratio.

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 23

Figure 8 Application Configurations for Applicable Control Methods

Page 24

2 Spindle Orientation

A

Channel

B

Channel

Z

Channel

Typical

Encoder

P1-13 = 0

+V

0V

+V

0V

+V

0V

PNP N.C.

Prox

P1-16 = 1

PNP N.O.

Prox

P1-16 = 0

Proximity

Sensor

P1-13 = 1

Presence

of Object

Yes

No

+V

0V

+V

0V

PNP N.O.

Proximity Sensor

Rising Edge

Rising Edge

Forward Rotation

Multi-Function Digital Input (H1-) Selection

87: Motor Ratio Selection 2 86: Motor Ratio Selection 1

Effective Parameter

Open Open P2-06: Motor Gear Ratio 1

Open Closed P2-07: Motor Gear Ratio 2

Closed Open P2-08: Motor Gear Ratio 3

Closed Closed P2-06: Motor Gear Ratio 1

To prevent unintended operation, the motor ratio that is selected when an orient digital input is applied latches until the

orient digital input is removed. If the state of the digital inputs 86h and 87h change during orientation, the new motor ratio

is effective after all orient digital inputs are removed.

Note: This software does not fully support multiple motor selection using the multi-function digital input function Motor 2 Select (H1-

= 16). However, the software can be utilized for winding change applications by setting PG Option Card Port for Motor 2

Selection parameter F1-30 = 0 and Orientation Encoder Card Selection parameter P1-10 = 0. When using two PG-X3 cards, it is

possible to run 2 different motors, provided that they share the same orientation encoder (the orientation encoder is always

defined by P1-10 regardless of Motor 1/2 selection).

Configuration 3: Indirect Drive with Proximity Sensor

When the motor and the spindle are connected through a drive train and the spindle does not have its own encoder, a

proximity sensor may be used. The proximity sensor configuration is enabled by setting Proximity Sensor Enable

parameter P1-13 = 1. The proximity sensor is connected as an external marker pulse as described in Encoder (PG) Option

Card Configuration and Wiring on page 29. Parameter P1-15 (Proximity Sensor Pulse State) allows for configuration of

both normally open and normally closed external marker pulses.

In this configuration (P1-13 = 1), the gear ratio of the drive train must be expressed as an exact number of motor

revolutions per revolution of the spindle. This gear ratio may be changed by modifying parameters P2-06, P2-07, and P208, and then selecting the gear ratio using Gear Ratio Select digital inputs 86h and 87h as discussed in Configuration 2:

Indirect Drive with Orientation Encoder on page 23.

Proximity sensors measure the presence or absence of a target, and therefore the pulse width is often much larger than an

encoder Z channel, as indicated in Figure 9. Since the PG-X3 option card interprets the marker pulse as the rising edge of

the signal on the Z channel, the width of the marker pulse has a significant effect on the positioning accuracy in

applications which require orientation from forward and reverse operation.

Figure 9

24 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Figure 9 Comparison of Encoder and Proximity Sensor Marker Pulses

Page 25

2 Spindle Orientation

Proximity Sensor Pulse Width parameter P1-14 applies an offset to the proximity sensor pulse when the spindle is

commanded to orient in the reverse direction. With parameter P1-14 set to 0 counts and a Marker Offset P2-02 = 0, the

proximity sensor orients to opposite sides of the target when orienting from the forward and reverse directions. When P114 is set to the width of the target in encoder counts, the pulse width is applied in a way such that the spindle always

orients to the side of the target which provides a rising edge when the spindle is turned in the forward direction.

Proximity sensor pulse width can be measured in counts by slowly turning the spindle and observing the elapsed counts

on the U7-02 (Distance from Marker) monitor between the rising and falling edges of the sensor over the target. Some

proximity sensors have an LED indicator to indicate the presence or absence of a target. If this is not present; the output of

the proximity sensor can be viewed on an oscilloscope or measured using a multimeter. On applications requiring higher

precision of orientation, the elapsed counts can be measured by simultaneously monitoring the A/B/Z channels of the

encoder and proximity sensor and observing the elapsed counts during the period in which the marker pulse is sensed.

Orient Position Offset Selection

By default, the software is programmed with an offset of 0 counts from the marker pulse. This means that the spindle

aligns itself to the marker pulse every time an orient is commanded. The drive may be oriented to another position by

setting Marker Offset Selection parameter P2-01 to one of three selections outlined below.

The desired offsets must be programmed into marker offset parameters P2-02 through P2-05 or set using the Memobus

register 0012h. Offsets which are specified as greater than one revolution are normalized to the encoder PPR x 4. If the

offset values are not known, they can be found by rotating the spindle by hand. To find an offset value after powering up

the drive, rotate the motor shaft until the orientation encoder axis turns for 1 rotation (360 deg), or until the drive

recognizes the marker pulse. The drive indicates that the marker pulse is found once monitors U7-02 (Distance from

Marker) and U7-03 (Distance from Offset) stop flashing “Looking for C/Z”. Rotate the machine to the desired position by

hand or by the using the run inputs. Read the marker offset value of U7-02 and enter the value in one of the parameters

P2-02 through P2-05 or the Memobus register.

P2-01 = 0, Digital Input Selection

This method uses the Offset Selection digital inputs 84h and 85h to determine the orient offset based on parameters

P2-02, P2-03, P2-04, and P2-05. When no digital input is programmed or selected, P2-02 is used as the offset.

Multi-Function Digital Input (H1-) Selection

85: Offset Selection 2 84: Offset Selection 1

Open Open P2-02: Marker Offset 1 0

Open Closed P2-03: Marker Offset 2 1

Closed Open P2-04: Marker Offset 3 2

Closed Closed P2-05: Marker Offset 4 3

Note: Offset Selection digital inputs 84h and 85h are only effective while Marker Offset Selection parameter P2-01 = 0.

P2-01 = 1, Sequential Selection

Effective Parameter

U7-05

Seq Step

This method rotates through the offset values specified in parameters P2-02, P2-03, P2-04, and P2-05 each time an orient

is commanded. If the drive power is reset, the offset is re-initialized to P2-02.

Figure 10 demonstrates operation of the sequential offset mode and the Home Position digital output 41h. The Home

Position digital output is functional only when parameter P2-01 is programmed to sequential selection. When the drive

powers up and the first orient digital input is closed, the drive sets the 41h Home Position digital output and orient to the

P2-02 offset. When the orient digital input is removed, the Home Position digital output is opened. The drive orients to

the P2-03, P2-04 and P2-05 offsets when subsequent orient are commanded. When the orient digital input is removed

after the P2-05 offset, the offset returns to P2-02.

When an orient digital input is activated, the drive chooses the orient offset position. This position remains in effect until

all orient digital inputs are removed. If the state of the orient position offset digital inputs changes during orientation, the

selection is not active until the orient digital inputs are removed. One additional digital input is available only during

sequential selection:

YAS KA WA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement 25

Page 26

2 Spindle Orientation

OrientCMDFWD

(H1-0X=81h)

DistanceFrom

Marker

(U7-02)

P2-02

P2-03

P2-04

P2-05

P2-02

P2-03

P2-04

HomePosition

(H2-0X=41h)

SequentialStep

Offset

P2-03

P2-04

P2-05

P2-02

P2-03

P2-04

P2-05

P2-02

Starting

Offset

• Sequential Reset (83h)

When closed, this parameter sets the active orientation offset to the value specified in Marker Offset 1 parameter P2-02.

Figure 10

Figure 10 Operation of Sequential Orientation Feature

P2-01 = 2, Memobus COM Selection

This method uses the network communication offset (Memobus Register 0012h) as the offset from the marker pulse.

When this setting is selected, parameters P2-02, P2-03, P2-04, and P2-05 are ignored. If the drive power is cycled, this

register is reset to 0 counts.

An orient offset written to this register is displayed in monitor U7-06. If a write is performed to the Memobus register

while an orient digital input is active, the value (and the U7-06 monitor) is not effective until the Orient Digital Input

(80h, 81h, or 82h) is released.

Drive Monitors

This software has five monitors to aid in the setup and operation of the spindle orient system.

U7-02: Distance From Marker

This monitor displays the number of counts the orientation encoder is past the marker pulse (relative to the direction of

travel). The monitor counts from 0 up to the number of (F1-01 x 4) encoder counts if CN5-C is the orientation encoder

card, or the number of (F1-31 x 4) encoder counts if the orientation encoder card is CN5-B. Offsets which are specified as

greater than one revolution are normalized to the encoder PPR.

When power to the drive is reset, this monitor is reset to 0. Since the orientation of the spindle is unknown while the drive

is without power, upon power up the monitor alternates “Dist from Marker” / “Looking for C/Z” until the drive finds the

first marker pulse. Once the marker pulse is found, the monitor resets to 0 once again, and the “Looking for C/Z” message

clears.

When the drive exceeds the S2-01 Control Mode Switch Frequency (S2-11 if Motor 2 is selected), the encoder PPR may

exceed the input frequency limit of the PG-X3/PG-B3 Encoder (PG) Feedback Card. Therefore, this monitor ceases to

update when the frequency reference is above S2-01. The monitor alternates the text “Dist from Marker” / “PG Freq

Limit” until the drive frequency is less than S2-01 and the marker pulse is located.

U7-03: Distance from Offset

This monitor displays the number of counts the orientation encoder is past the current offset (relative to forward rotation).

The current offset value is latched at the rising edge of an orient digital input (as displayed in monitor U7-04). The

monitor counts from 0 up to the number of (F1-01 x 4) encoder counts if CN5-C is the orientation encoder card, or the

number of (F1-31 x 4) encoder counts if the orientation encoder card is CN5-B. Offsets which are specified as greater

than one revolution are normalized to the encoder PPR.

26 YASK AWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

Page 27

2 Spindle Orientation

When power to the drive is reset, this monitor is reset to 0. Since the orientation of the spindle is unknown while the drive

is without power, upon power up the monitor alternates “Dist from Offset” / “Looking for C/Z” until the drive finds the

first marker pulse. Once the marker pulse is found, the monitor is reset to 0 once again, and the “Looking for C/Z”

message clears.

When the drive exceeds the S2-01 Control Mode Switch Frequency (S2-11 if Motor 2 is selected), the encoder PPR may

exceed the input frequency limit of the PG-X3/PG-B3 Encoder (PG) Feedback Card. Therefore, this monitor ceases to

update when the frequency reference is above S2-01. The monitor alternates the text “Dist from Offset” / “PG Freq Limit”

until the drive frequency is less than S2-01 and the marker pulse is located.

U7-04: Commanded Offset

This monitor displays the current marker offset position. Each time an orient is commanded, this monitor is updated with

the value of the current marker offset.

If Marker Offset Selection parameter P2-01=0, the drive is in Digital Input Select mode, and monitor U7-04 is updated

with the offset count corresponding to the current state of the digital input(s) at the time when a valid orient digital input

is activated. Refer to Orient Position Offset Selection on page 25 for the digital input states.

If Marker Offset Selection parameter P2-01=1, the drive is in Sequential Select mode, and the monitor displays the next

orient offset.

If Marker Offset Selection parameter P2-01=2, the drive is in Memobus Communication Selection mode, and the monitor

displays the count value currently in Memobus register 0012h.

U7-05: Sequence Step

This monitor displays the range 0 to 4 which corresponds to the parameters P2-02, P2-03, P2-04, and P2-05 and the

Memobus register 0012h. The value corresponds to the offset to which the drive orients when the orient digital input is

activated.

If Marker Offset Selection parameter P2-01=0, the drive is in digital input Select mode, and monitor U7-05 is updated

with the value corresponding to the current state of the digital input(s) at the time when a valid orient digital input is

activated. Orient Position Offset Selection on page 25 for the digital input states.

If Marker Offset Selection parameter P2-01=1, the drive is in Sequential Select mode, and the monitor displays the next

orient offset. This value is reset every time an orient digital input is activated.

If Marker Offset Selection parameter P2-01=2, the drive is in Memobus Communication Selection mode, and the monitor