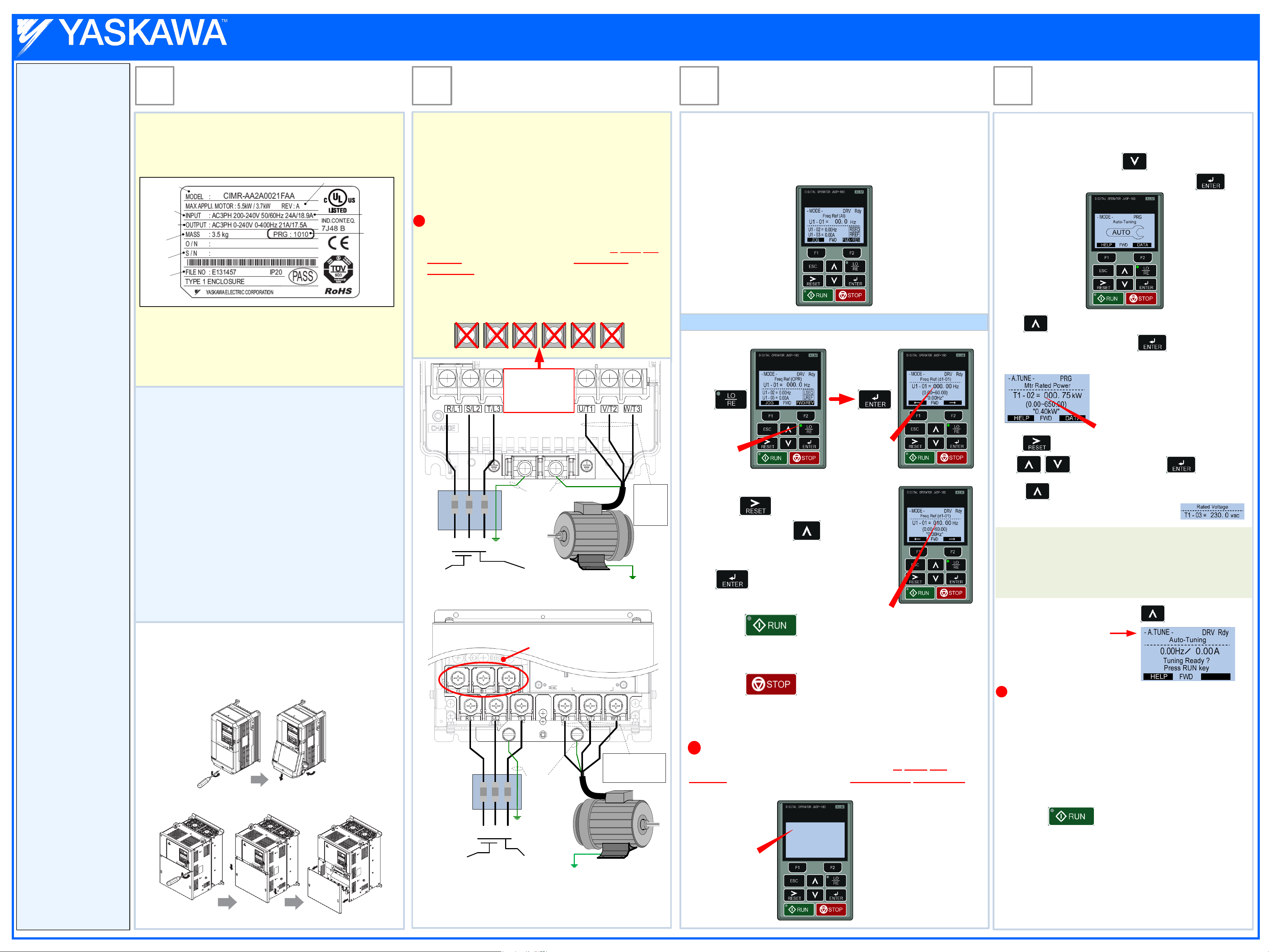

Step

1

Step

2

Step

3

Step

4

The following

procedure is a

supplement to

other

documentation

supplied with this

equipment and will

guide the user in

properly wiring the

A1000 and motor.

It will also show

the user how to

configure the

A1000 in open

loop vector mode

for a general

purpose

application.

Danger: Improper

wiring can and

will cause bodily

harm as well as

damage to the

equipment.

When installing the

system, be sure to

follow good wiring

practices and all

applicable codes.

Ensure that the

mounting of

components is

secure and that

the environment,

such as extreme

dampness, poor

ventilation, etc. will

not cause system

degradation.

Please read this

cheat sheet and

other

documentation

provided with the

A1000 thoroughly

before attempting

any installation.

Motor Rotation Test

In this step the motor is checked for proper direction and operation.

This test is to be performed solely from the digital operator. Apply

power to the A1000 after all the electrical connections have been

made and protective covers have been re-attached. At this point,

DO NOT RUN THE MOTOR, the Digital Operator should display as

shown in Fig. 3.

Fig. 3

Digital Operator

Use precaution, and

refer to Fig.1 or 2, swap

any two of the three

output leads to the motor

(U/T1, V/T2 and W/T3).

After the wiring change,

repeat Step 3 and

recheck motor direction.

After the power has been turned OFF, wait at least five

minutes until the charge indicator extinguishes completely

before touching any wiring, circuit boards or components.

DANGER

If motor rotation is not correct, then either reverse “Phase

Order” using parameter b1-14 or power down the drive, wait

five minutes and swap 2 motor leads.

!

Next, press to move the cursor one

position to the right and to increase the

frequency reference (d1-01) to 10.00 Hz.

Press to save frequency reference.

Next, press on the Digital Operator. The motor

should now be operating at low speed running in the correct

forward (clockwise) direction.

Next, press on the Digital Operator.

Digital Operator

turned off.

First Digit

Flashing

Press

Green LED

turns on.

10.00 Hz

In this step the A1000 is setup for use with the motor. Make sure

all protective covers have been re-attached then apply power to

the A1000. DO NOT RUN THE MOTOR.

From the main reference press once until the Digital

Operator shows the Auto-Tuning menu then press

Press once until the Digital Operator shows parameter

T1-02 Mtr Rated Power then press

Digit Flashing

Press to select the digit you would like to change and

use to adjust value and press to save.

Enter Motor Power in kW (Kilowatt)

Motor HP to kW = HP x 0.746

Example: 10HP = 10 x 0.746 = 7.46 kW

T1-04 Rated Voltage (e.g. 230 V, 460 V)

T1-04 Rated current (e.g. 11.0 A, 22.0 A)

T1-05 Rated Frequency (e.g. 60.0 Hz)

T1-06 Number of Poles (e.g. 4 Poles)

For standard AC motors

use the default setting for

motor base frequency

(60Hz), motor poles (4) and

motor rated speed.

T1-07 Rated Speed (e.g. 1750 rpm)

Press to select the next parameter and follow the same

procedure described above to adjust its value.

Warning! Sudden movement hazard. The A1000 and

motor may start unexpectedly during Auto-Tuning.

Warning! Electric Shock Hazard. High voltage will be

supplied to the motor when stationary Auto-Tuning is

performed. Do not touch the motor during auto-tuning.

Notice: Auto-Tuning will not function properly when a

brake is engaged on the load. Ensure the motor shaft

can freely rotate. Never perform an Auto-Tune with

motor connected to a load.

!

After setting parameter T1-07 press to select the

Auto-Tuning start command.

Next, press on the Digital Operator. The A1000

will now start the Auto-tuning procedure.

The display will show message ―Tune Successful‖ when the

Auto-Tuning procedure has been successfully completed.

Please reference the A1000 User Manual or repeat the

procedure again if the display shows an error message.

WARNING DO NOT CONNECT ANY OF THE

FOLLOWING TERMINALS TO EARTH GROUND

B1 B2

-

+1 +2 +3

NOT USED

Fig.1 & 2 below show the electrical connections for the

input power and motor terminals for various A1000 models.

Select the proper diagram for the model you are installing

(see Step 1). WITH POWER OFF make the appropriate

connections.

Make sure to follow good wiring practices and all

applicable codes. Ensure that the equipment is

grounded properly as shown in fig. 1

DANGER; LETHAL VOLTAGES ARE PRESENT- Before

applying power to the A1000, ensure that the terminal

cover is fastened and all wiring connections are secure.

After the power has been turned OFF, wait at least five

minutes until the charge indicator extinguishes

completely before touching any wiring, circuit boards or

components.

!

Make sure the A1000 has been properly sized for single phase input

power. For best performance, the drive input supply voltage must be at

least equal to or greater than the motor rated voltage.

3Ø Induction

motor

Connect

frame to

ground

Input

Protection

(Fuse or Circuit

Breaker)

To change direction of motor

rotation swap any two of the

three motor leads

(See Step 2)

Fig. 2 Input Power and Output Motor Electrical Connections for

Models: 2_0110 & Larger and 4_0058 & Larger

(R/L1) (S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Connect to

chassis

ground

Use L1, L2, L3 for

3Ø Input Power

L1

L2

L3

Use L1, L2 for

1Ø Input Power

*

BUS TERMINALS:

DO NOT CONNECT TO GROUND

Use L1, L2, L3 for

3Ø Input Power

To change

direction of

motor rotation

swap any two

of the three

motor leads

(See Step 2)

Fig. 1 Input Power and Output Motor Electrical Connections for

Models: 2_0004 - 2_0056, 4_0002 - 4_0044 and 5_0003 - 50011

Use L1, L2 for

1Ø Input Power

3Ø Induction

motor

Connect

frame to

ground

Input

Protection

(Fuse or Circuit

Breaker)

L1

L2

L3

(R/L1)

(S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Connect to

chassis ground

*

DC Bus terminals

location varies by

model.

*

To make sure you received the correct model, it is

essential to verify the A1000 nameplate with your order

and make sure the A1000 has the correct rating so it can

be used with your motor. Please check the nameplate

information as shown in the example below.

· Check that the available power will meet the input

power requirements.

· Ensure that the output power from the A1000 is

compatible with the motor requirements.

Mounting the A1000

· In the case of systems with more than one A1000, follow

the above procedure for each A1000 and motor.

The mounting of the A1000 is extremely important regarding

environment and accessibility. Depending on your system,

there are various models available and the mounting

dimensions (footprint) may be different. Because the

mounting procedure is fairly extensive, it is beyond the scope

of this document; the user is referred to the A1000 User

Manual (Document No. SIEP C710606 21A) received with

the A1000, Section 2.2 Mechanical Installation. Match the

model that you received and follow the procedure described

in the manual to ensure a safe and functional installation. In

cases where the system has more than one A1000, refer to

the proper clearances required for adequate ventilation.

Please pay particular attention to:

· The clearances to be maintained around the enclosure

for adequate ventilation.

· The environmental specifications such as avoiding

excessive dampness, extreme temperatures, chemical

exposure, corrosive areas, etc. to avoid damage to the

equipment and to maintain safety.

Removing and Attaching the Terminal Cover

Improper removal of the A1000 terminal cover as well as

front cover can cause extensive damage to the A1000. To

avoid damage to these items, please pay particular attention

to the A1000 User Manual, Document No. SIEP C710606

21A, Section 3.5, Removing and Attaching the Terminal

Cover.

Open Chassis

NEMA 1

Drive Model

Number

Input Power

Rating

Output

Power

Rating

Serial

Number

UL File

Number

Drive Spec Number

Weight

Software

Version

Normal /

Heavy Duty

Amps

A1000 Model

Identification and Mounting

A1000 Cheat Sheet (Open Loop Vector)

Connect Motor and

Line Power

(Motor uncoupled from Load)

Check Motor Direction

Page 1 of 2

Rotational Auto-tuning

(De-couple Motor from Load)

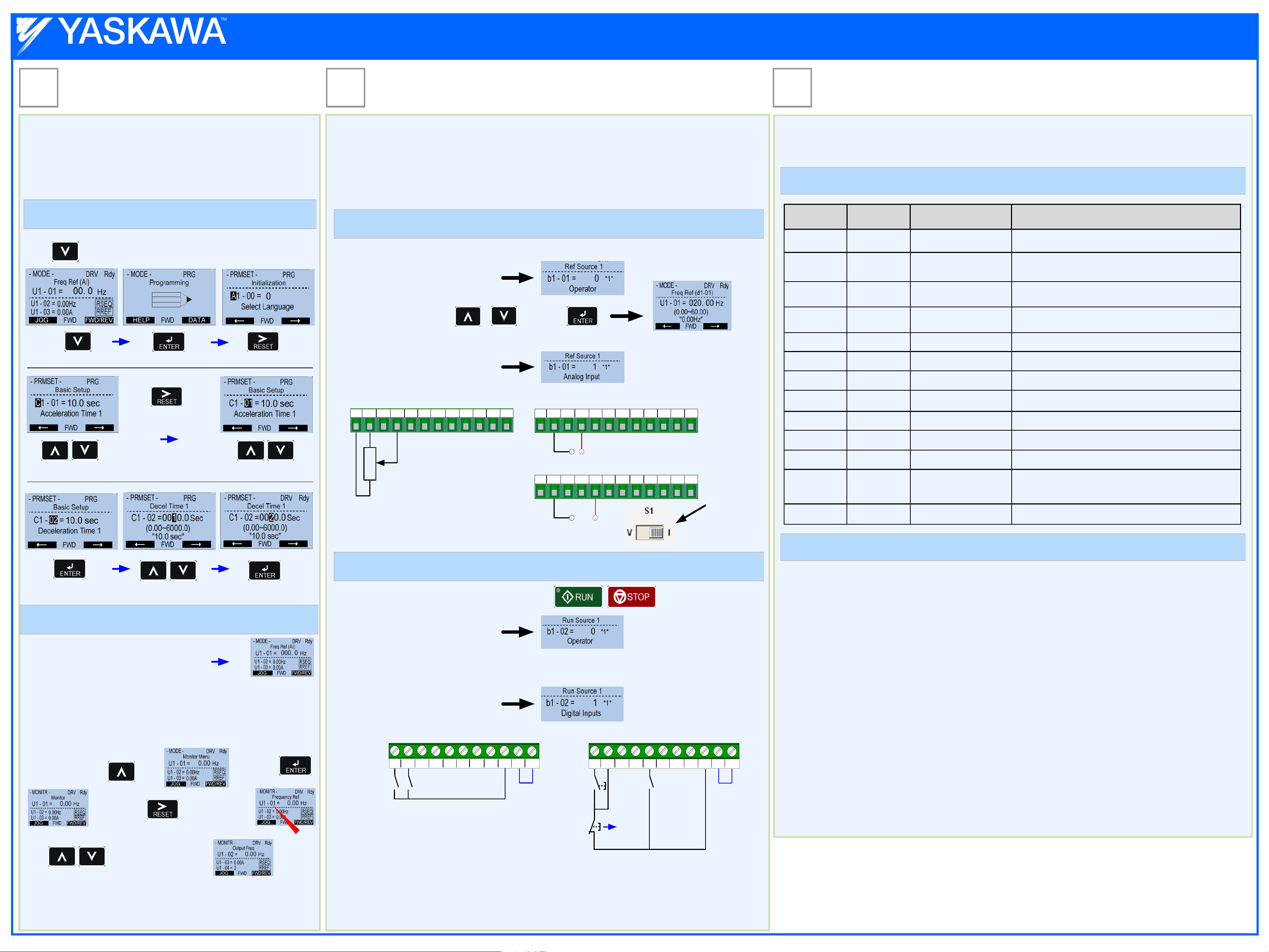

Step

5

Step

6

The following table lists the general purpose application parameters as well as frequently asked questions.

This section may require you to change one or more A1000 parameters. Please refer to Step 5 for a

detailed explanation on how to change parameters.

FREQUENTLY ASKED QUESTIONS

GENERAL PURPOSE APPLICATION PARAMETERS

Question: How do I reset the drive back to factory default settings?

Answer: Go to parameter A1-03 and set value 2220 for 2 wire control or 3330 for 3 wire control

(Please refer to Step 6 for wiring diagram)

Question: How do I adjust the time it takes the motor to speed up or slow down?

Answer: Adjust the acceleration time parameter C1-01 and deceleration time C1-02.

Question: How do I prevent my drive from tripping on an OV fault (overvoltage) while my motor is ramping down?

Answer: Increase deceleration time parameter C1-02.

Question: How do I prevent my drive from tripping on an OL1 fault (overload) while my motor is ramping down?

Answer: Verify motor rated current parameter E2-01 and motor overload parameter settings

L1-01 Motor overload selection, L1-02 Motor overload protection time.

Question: I want to run my motor above the nominal motor speed?

Answer: Increase the value of parameter E1-04 Maximum Frequency

Warning! Verify that the motor and system allow for this.

Yaskawa America, Inc.

2121 Norman Drive South

Waukegan, IL 60085

(800) YASKAWA (927-5292) Fax (847) 887-7310

DrivesHelpDesk@yaskawa.com www.yaskawa.com

Document Number: TM.A1000.01 1/4/2011 © Yaskawa America, Inc.

Step

7

This step shows how to access and modify a A1000 parameter as

well as how to monitor A1000 signals such as output frequency

and motor current.

Make sure all protective covers have been re-attached and power

is turned on. DO NOT RUN THE MOTOR.

Press two times until the digital operator shows the parameter menu.

Select Digit

Access Parameter Menu and Change Parameter Value

Monitor Motor Frequency and Motor Current

To monitor output frequency and motor current or other signals

individually, press once, the press

. Next press to select monitor

Use to select monitor signal.

Please refer to the A1000 User Manual, (Document No.

SIEP C710606 21A) on how to access other drive monitors.

U1-02 Output Frequency

2X

2X

Inc./Dec. Selection Inc./Dec. SelectionGo to Next Digit

Switch to Edit Mode Save New ValueModify Value

A1000 Digital Operator power-up state

Output Frequency and Motor Current can be monitored

simultaneously.

Digits

Flashing

This step shows how to setup the sequence and reference method of the A1000. The sequence

method determines how the A1000 drive receives its start and stop command and the reference

method determines how the speed of the motor is controlled. Make sure all protective covers have

been re-attached and power is turned on. DO NOT RUN THE MOTOR.

This section may require you to change one or more A1000 parameters. Please refer to Step 5

for a detailed explanation on how to change parameters.

SELECT START / STOP CONTROL METHOD

1. Start / Stop Control from Digital Operator

Go to parameter b1-02, set value to

b1-02

2. Start / Stop Control from external terminals (switch or relay contact)

Go to parameter b1-02, set value to

( Factory Default)

NOTE: It is beyond the scope of this document to program the A1000 drive for network communication control.

Please refer to the refer to the A1000 User Manual, (Document No. SIEP C710606 21A) for this selection.

SELECT SPEED METHOD

b1-01

(Factory Default)

1. Adjust motor speed / frequency from the Digital Operator

Go to parameter b1-01, set value to

2. Adjust motor speed / frequency from external terminals (0 - 10V / 4 - 20mA Signal)

Go to parameter b1-01, set value to

(Factory Default)

+

Located inside

the drive on the

terminal board

To adjust frequency use / and press .

V+ AC

V-

A1

A2 A3 FM AM AC

MP

Potentiometer

2K Ohm

User Terminals

RP

AC

V+ AC

V-

A1

A2 A3 FM AM AC

MP

User Terminals

RP

AC

0 ~ 10Vdc

+

V+ AC

V-

A1

A2 A3 FM AM AC

MP

RP

AC

4 ~ 20mA

Note: 2nd row of terminal board is shown here.

S3 S5 S6 S7 S8 SN SC SPS2 S4S1

Wiring Diagram: 2-Wire Control

Forward

Reverse

Wiring Diagram: 3-Wire Control

Use for momentary contacts

Use for maintained contacts

User Terminals User Terminals

(Set Parameter A1-03 to 3330)

Note: 3rd row of terminal board is shown here.

Link

S3 S5 S6 S7 S8 SN SC SPS2 S4S1

Start

Switch

Reverse

Stop

Switch

Normally

Open

Normally

Closed

Link

A1000 Cheat Sheet (Open Loop Vector)

Changing Parameters and

Selecting Start/Stop and Speed Method

Monitoring the A1000

Parameter

Default Value

Quick Start Parameters

Description

Page 2 of 2

Comments

b1-01

b1-02

b1-03

b1-04

C1-01

C1-02

C6-01

d1-01

d2-01

d2-02

1

1

1 Stop Method Selection

0 Reverse Operation

10.0 sec. Acceleration Time The time it takes to ramp up from 0 to maximum motor speed.

10.0 sec. Deceleration Time The time it takes to ramp down from maximum motor speed to 0.

0 Heavy / Normal Duty

0.00 Hz Frequency Reference Frequency setting when speed is set from the keypad.

100.0 % Frequency Upper Limit Maximum motor speed allowed (e.g. 100 % = Max rpm)

0.0 % Frequency Lower Limit Minimum motor speed allowed (e.g. 100 % = Max rpm)

Reference Source

Speed Control Method

Run Source /

Start/Stop Control Method

0 = Digital Operator (Adjust Motor Speed from keypad)

1 = Terminals (Speed Pot. / 0 – 10V / 4—20mA)

0 = Digital Operator (Start/Stop motor from keypad)

1 = Terminals (Start/Stop using external contact / switch)

0 = Ramp to stop (Motor ramps down at stop command)

1 = Coast to stop (Motor freewheels at stop command)

0 = Allow motor to run in reverse direction

1 = Reverse direction prohibited

0 = Heavy Duty (Use for conveyor, mixer, applications)

1 = Normal Duty (Use for fan and pump applications)

E2-01

L1-01

L1-02

* Motor Rated Current Motor nameplate current

0 = Disabled

1 Motor Overload Selection

1.0 min Motor Overload Time Sets the motor thermal overload protection time.

1 = Standard Fan Cooled Motor

2 = Standard Blower Cooled Motor

3 = Vector Duty Motor

Step

1

To make sure you received the correct model, it is

essential to verify the A1000 nameplate with your order

and make sure the A1000 has the correct rating so it can

be used with your motor. Please check the nameplate

information as shown in the example below.

· Check that the available power will meet the input

power requirements.

· Ensure that the output power from the A1000 is

compatible with the motor requirements.

Mounting the A1000

· In the case of systems with more than one A1000, follow

the above procedure for each A1000 and motor.

The mounting of the A1000 is extremely important regarding

environment and accessibility. Depending on your system,

there are various models available and the mounting

dimensions (footprint) may be different. Because the

mounting procedure is fairly extensive, it is beyond the scope

of this document; the user is referred to the A1000 User

Manual (Document No. SIEP C710606 21A) received with

the A1000, Section 2.2 Mechanical Installation. Match the

model that you received and follow the procedure described

in the manual to ensure a safe and functional installation. In

cases where the system has more than one A1000, refer to

the proper clearances required for adequate ventilation.

Please pay particular attention to:

· The clearances to be maintained around the enclosure

for adequate ventilation.

· The environmental specifications such as avoiding

excessive dampness, extreme temperatures, chemical

exposure, corrosive areas, etc. to avoid damage to the

equipment and to maintain safety.

Removing and Attaching the Terminal Cover

Improper removal of the A1000 terminal cover as well as

front cover can cause extensive damage to the A1000. To

avoid damage to these items, please pay particular attention

to the A1000 User Manual, Document No. SIEP C710606

21A, Section 3.5, Removing and Attaching the Terminal

Cover.

Open Chassis

NEMA 1

Drive Model

Number

Input Power

Rating

Output

Power

Rating

Serial

Number

UL File

Number

Drive Spec Number

Weight

Software

Version

Normal /

Heavy Duty

Amps

Step

2

Step

3

The following

procedure is a

supplement to

other

documentation

supplied with this

equipment and will

guide the user in

properly wiring the

A1000, motor and

encoder. It will also

show the user how

to configure the

A1000 in closed

loop mode

operation using a

PG-X3 card for a

dedicated

applications.

Danger: Improper

wiring can and

will cause bodily

harm as well as

damage to the

equipment.

When installing the

system, be sure to

follow good wiring

practices and all

applicable codes.

Ensure that the

mounting of

components is

secure and that

the environment,

such as extreme

dampness, poor

ventilation, etc. will

not cause system

degradation.

Please read this

cheat sheet and

other

documentation

provided with the

A1000 thoroughly

before attempting

any installation.

In this step the PG-X3 encoder feedback card is installed. WITH POWER OFF install the PG-X3 card as shown below. Make sure

to follow good wiring practices and all applicable codes. Ensure that the feedback card is grounded properly as shown in

fig. 3 item H.

This option card can be inserted into either the CN5-B or CN5-C connectors located on the drive’s control board. If only one option

card is connected to the drive, use the CN5-C connector. If two option cards are connected, use both CN5-B and CN5-C.

See the A1000 User Manual, Document No. SIEP C710606 21A, Section 3.5, for directions on removing the front cover.

Insert the PG-X3 card (connector CN5) into the matching CN5 connector on the A1000 control card. Next use the screws to fasten

the card into place. Connect one of the ground lead lines to the ground terminal with one of the screws. Two separate ground lead

lines have been included with the option card. Use the longer one when the option card is plugged into connector CN5-C on the

A1000 control card side and use the shorter one if the PG-X3 card is plugged into connector CN5-B.

PG-X3 Option Card

Option Card Installation

B+ Z+ Z- SD FEA- B-A+

PG-X3 Terminals

a+ a- b- z+IG SGIP

b+

z+

TB1

TB2

PG

Single Channel Feedback (A Only)

Set F1-37 = 0 (default)

+

-

Encoder

Signals

B+ Z+ Z- SD FEA- B-A+

PG-X3 Terminals

a+ a- b- z+IG SGIP

b+

z+

TB1

TB2

Quadrature / Dual Channel Feedback (A & B)

Set F1-37 = 1

+

-

Encoder

Power

Encoder Signals

PG

Encoder Connection

Select Encoder Power Supply

(IP + IG TB2) with Jumper CN3.

Encoder Power Supply

(Max. 200mA)

Default

Connect Encoder (PG) signals to TB1 terminals of the PG-X3 card as shown below.

Connect power supply from the PG-X3 card (TB1 – Terminals IP and IG) to the Encoder (PG).

IMPORTANT: Verify Encoder

Power Supply Rating

Encoder

Power

PG-X3 Encoder Wiring

!

A single channel encoder can only be used in V/f + PG control mode (A1-02 = 1). It is required

to use a quadrature encoder in Flux Vector control mode (A1-02 = 3).

– Connector CN5-C

– Connector CN5-B

– Connector CN5-A

– Drive grounding terminal (FE)

– Insert connector CN5 here

– Option card

– Mounting screw

– Lead line Ground

– Use wire cutters to create an opening for cable lines

– Front cover

– Digital Operator

– Terminal cover

A

B

C

D

E

F

G

H

I

J

K

L

– Terminal block TB1

– Ground terminal (installation hole)

– Jumper for PG power supply voltage (CN3)

– Terminal block TB2

– Model number

– Installation hole

– Connector (CN5)

A

B

C

D

E

F

G

Fig. 3

Ground Lead

Suitable only for

V/f with Feedback.

(Required for FLUX Vector Operation)

Suitable for V/f or Flux Vector with Feedback.

WARNING DO NOT CONNECT ANY OF THE

FOLLOWING TERMINALS TO EARTH GROUND

B1 B2

-

+1 +2 +3

NOT USED

Fig.1 & 2 below show the electrical connections for the

input power and motor terminals for various A1000 models.

Select the proper diagram for the model you are installing

(see Step 1). WITH POWER OFF make the appropriate

connections.

Make sure to follow good wiring practices and all

applicable codes. Ensure that the equipment is

grounded properly as shown in fig. 1

DANGER; LETHAL VOLTAGES ARE PRESENT- Before

applying power to the A1000, ensure that the terminal

cover is fastened and all wiring connections are secure.

After the power has been turned OFF, wait at least five

minutes until the charge indicator extinguishes

completely before touching any wiring, circuit boards or

components.

!

Make sure the A1000 has been properly sized for single phase input

power. For best performance, the drive input supply voltage must be at

least equal to or greater than the motor rated voltage.

3Ø Induction

motor

Connect

frame to

ground

Input

Protection

(Fuse or Circuit

Breaker)

To change direction of motor

rotation swap any two of the

three motor leads

(See Step 2)

Fig. 2 Input Power and Output Motor Electrical Connections for

Models: 2_0110 & Larger and 4_0058 & Larger

(R/L1) (S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Connect to

chassis

ground

Use L1, L2, L3 for

3Ø Input Power

L1

L2

L3

Use L1, L2 for

1Ø Input Power

*

BUS TERMINALS:

DO NOT CONNECT TO GROUND

Use L1, L2, L3 for

3Ø Input Power

To change

direction of

motor rotation

swap any two

of the three

motor leads

(See Step 2)

Fig. 1 Input Power and Output Motor Electrical Connections for

Models: 2_0004 - 2_0056, 4_0002 - 4_0044 and 5_0003 - 50011

Use L1, L2 for

1Ø Input Power

3Ø Induction

motor

Connect

frame to

ground

Input

Protection

(Fuse or Circuit

Breaker)

L1

L2

L3

(R/L1)

(S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Connect to

chassis ground

*

DC Bus terminals

location varies by

model.

*

A1000 Cheat Sheet (Closed Loop Operation)

A1000 Model

Identification and Mounting

Page 1 of 3

Connect Motor and

Install PG-X3 Feedback Card and wire encoder feedback

Line Power

Step

4

In this step the A1000 is setup for use with the motor in closed loop operation. Make sure the following has been done:

· Encoder (PG) connected correctly to the PG-X3 Card

· All protective covers have been re-attached

· Ensure the motor can spin freely and any connected mechanical brake is released

· Connected machinery should be allowed to rotate the motor

IMPORTANT:

To achieve optimal drive performance use rotational Auto-Tuning with the load decoupled from the motor. If motor and load can not be decoupled,

reduce the motor load so that it is no greater than 30% of the rated load. Performing rotational Auto-Tuning with a higher load can result in incorrect

motor parameters and may cause irregular motor rotation.

Next apply power to the A1000. DO NOT RUN THE MOTOR.

From the main reference press once until the Digital Operator

shows the Auto-Tuning menu then press .

Press once until the Digital Operator shows parameter

T1-02 Mtr Rated Power then press

Digit Flashing

Press to select the digit you would like to change and

use to adjust value and press to save.

Enter Motor Power in kW (Kilowatt)

Motor HP to kW = HP x 0.746

Example: 10HP = 10 x 0.746 = 7.46 kW

T1-03 Rated Voltage (e.g. 230 V, 460 V)

T1-04 Rated current (e.g. 11.0 A, 22.0 A)

T1-05 Rated Frequency (e.g. 60.0 Hz)

T1-06 Number of Poles (e.g. 4 Poles)

For standard AC motors

use the default setting for

motor base frequency

(60Hz), motor poles (4) and

motor rated speed.

T1-07 Rated Speed (e.g. 1750 rpm)

Press to select the next parameter and follow the same

procedure described above to adjust its value.

Warning! Sudden movement hazard. The A1000 and

motor may start unexpectedly during Auto-Tuning.

Warning! Electric Shock Hazard. High voltage will be

supplied to the motor when stationary Auto-Tuning is

performed. Do not touch the motor during auto-tuning.

Notice: Auto-Tuning will not function properly when a

brake is engaged on the load. Ensure the motor shaft

can freely rotate. Never perform an Auto-Tune with

motor connected to a load.

!

After setting parameter T1-08 press to select the

Auto-Tuning start command.

Next, press on the Digital Operator. The A1000

will now start the Auto-tuning procedure.

The display will show message “Tune Successful” when the

Auto-Tuning procedure has been successfully completed.

Please refer to the A1000 User Manual or repeat the

procedure again if the display shows an error message.

Select Closed Loop Control Method

A1-02

Select Closed Loop Control Method

Go to parameter A1-02,

Select V/f with PG Method

or Closed Loop Vector

Control Method

To adjust control method use / and press .

V/f with PG

Control method suitable for

applications that require accurate

motor speed regulation (0.02%) but do

not require a high speed response.

Closed Loop Vector

Control method suitable for applications

that medium to high speed control

accuracy, high torque response and full

torque at 0 speed.

(Recommended)

Auto-tuning Procedure

T1-08 Encoder / PG Number of Pulses per Rev. (e.g. 1024)

Continue

Start here

!

Encoder Direction

Check the motor speed monitor U1-05 while turning the motor manually in forward direction (CW). If the sign displayed

is negative, power down the drive, wait at least five minutes until the charge indicator extinguishes completely

then swap encoder wires A+ with A- on the PG-X3 card. Next power-up the drive and repeat this test. Or reverse the

encoder direction with parameter F1-05. For encoders with only A & B outputs, exchange A & B.

Step

5

Step

6

Motor Rotation Test

In this step the motor is checked for proper direction and operation.

This test is to be performed solely from the digital operator. Apply

power to the A1000 after all the electrical connections have been

made and protective covers have been re-attached. At this point,

DO NOT RUN THE MOTOR, the Digital Operator should display as

shown in Fig. 3.

Fig. 3

Digital Operator

Use precaution, and

refer to Fig.1 or 2, swap

any two of the three

output leads to the motor

(U/T1, V/T2 and W/T3).

After the wiring change,

repeat Step 3 and

recheck motor direction.

After the power has been turned OFF, wait at least five

minutes until the charge indicator extinguishes completely

before touching any wiring, circuit boards or components.

DANGER

If motor rotation is not correct, then either reverse “Phase

Order” using parameter b1-14 or power down the drive, wait

five minutes and swap 2 motor leads.

!

Next, press to move the cursor one

position to the right and to increase the

frequency reference (d1-01) to 10.00 Hz.

Press to save frequency reference.

Next, press on the Digital Operator. The motor

should now be operating at low speed running in the correct

forward (clockwise) direction.

Next, press on the Digital Operator.

Digital Operator

turned off.

First Digit

Flashing

Press

Green LED

turns on.

10.00 Hz

This step shows how to access and modify a A1000 parameter as

well as how to monitor A1000 signals such as output frequency

and motor current.

Make sure all protective covers have been re-attached and power

is turned on. DO NOT RUN THE MOTOR.

Press two times until the digital operator shows the parameter menu.

Select Digit

Access Parameter Menu and Change Parameter Value

Monitor Motor Frequency and Motor Current

To monitor output frequency and motor current or other signals

individually, press once, the press

. Next press to select monitor

Use to select monitor signal.

Please refer to the A1000 User Manual, (Document No.

SIEP C710606 21A) on how to access other drive monitors.

U1-02 Output Frequency

2X

2X

Inc./Dec. Selection Inc./Dec. SelectionGo to Next Digit

Switch to Edit Mode Save New ValueModify Value

A1000 Digital Operator power-up state

Output Frequency and Motor Current can be monitored

simultaneously.

Digits

Flashing

A1000 Cheat Sheet (Closed Loop Operation)

Check Motor Rotation in Open Loop

(Motor uncoupled from Load)

Changing Parameters and

Monitoring the A1000

Page 2 of 3

Rotational Auto-Tuning Closed Loop

(De-couple Motor from Load)

Step

8

Step

7

The following tables show how to fine tune motor operation for V/f with PG and Closed Loop Vector Operation.

Please refer to the A1000 User Manual (Document No. SIEP C710606 21A) for additional information.

Yaskawa America, Inc.

2121 Norman Drive South

Waukegan, IL 60085

(800) YASKAWA (927-5292) Fax (847) 887-7310

DrivesHelpDesk@yaskawa.com www.yaskawa.com

Document Number: TM.A1000.02 1/4/2011 © Yaskawa America, Inc.

This step shows how to setup the run and reference source of the A1000. The run source determines

how the A1000 drive receives its start and stop command and the reference source determines how

the speed of the motor is controlled. Make sure all protective covers have been re-attached and power

is turned on. DO NOT RUN THE MOTOR.

This section may require you to change one or more A1000 parameters. Please refer to Step 5

for a detailed explanation on how to change parameters.

SELECT RUN SOURCE

1. Start / Stop Control from Digital Operator

Go to parameter b1-02, set value to

b1-02

2. Start / Stop Control from external terminals (switch or relay contact)

Go to parameter b1-02, set value to

( Factory Default)

NOTE: It is beyond the scope of this document to program the A1000 drive for network communication control.

Please refer to the refer to the A1000 User Manual, (Document No. SIEP C710606 21A) for this selection.

SELECT REFERENCE SOURCE

b1-01

(Factory Default)

1. Adjust motor speed / frequency from the Digital Operator

Go to parameter b1-01, set value to

2. Adjust motor speed / frequency from external terminals (0 - 10V / 4 - 20mA Signal)

Go to parameter b1-01, set value to

(Factory Default)

+

Located inside

the drive on the

terminal board

To adjust frequency use / and press .

V+ AC

V-

A1

A2 A3 FM AM AC

MP

Potentiometer

2K Ohm

User Terminals

RP

AC

V+ AC

V-

A1

A2 A3 FM AM AC

MP

User Terminals

RP

AC

0 ~ 10Vdc

+

V+ AC

V-

A1

A2 A3 FM AM AC

MP

RP

AC

4 ~ 20mA

Note: 2nd row of terminal board is shown here.

Wiring Diagram: 2-Wire Control

S3 S5 S6 S7 S8 SN SC SPS2 S4S1

Wiring Diagram: 3-Wire Control

Start

Switch

Reverse

Stop

Switch

Normally

Open

Normally

Closed

Use for momentary contacts

Use for maintained contacts

User Terminals

(Set Parameter A1-03 to 3330)

Note: 3rd row of terminal board is shown here.

S3 S5 S6 S7 S8 SN SC SPS2 S4S1

Forward

Reverse

User Terminals

Link

Link

A1000 Cheat Sheet (Closed Loop Operation)

Selecting Start/Stop and Speed Reference Sources

V/f Control with encoder feedback (A1-02 = 1)

Problem

· Motor is hunting and oscillation at speeds between 10 and 40Hz.

· Motor noise

· Motor hunting and oscillation at speed up to

40Hz

n1-02 Hunting Prevention Gain

C6-02 Carrier Frequency Selection

Parameter

Page 3 of 3

Motor Performance Fine Tuning

· If insufficient motor torque relative to the size of the load causes

hunting reduce the setting.

· When motor hunting and oscillation occur with a light load increase

setting.

· Lower this setting if hunting occurs when using a motor with a

relatively low inductance such as a high-frequency motor or a motor

with a larger frame size.

· If the motor noise is too loud increase the carrier frequency.

· When motor hunting and oscillation occur at speeds up to 40 Hz

lower the carrier frequency.

· The default setting for the carrier frequency depends on the drive

capacity (o2-04) and the Duty Selection (C6-01).

Action

Default

1.00 0.10 to 2.00

1 (2 kHz) 1 to max. setting

Suggested Setting

· Poor torque or speed response

· Motor hunting and oscillation

· Poor motor torque at speeds below 10 Hz

· Motor hunting and oscillation

· Poor motor torque at low speeds

· Motor instability at motor start

· Poor speed precision

C4-02 Torque Compensation Primary Delay Time

C4-01 Torque Compensation Gain

E1-08 Mid Output Voltage A

E1-10 Minimum Output Voltage

C5-01 ASR Proportional Gain 1 <3>

C5-02 ASR Integral Time 1 <4>

Closed Loop Vector Control (A1-02 = 3)

Problem

C5-01 ASR Proportional Gain 1 <4>

· Poor torque or speed response

· Motor hunting and oscillation

C5-03 ASR Proportional Gain 1 <4>

C5-02 ASR Integral Time 1 <4>

C5-04 ASR Integral Time 2 <4>

Parameter

· If motor torque and speed response are too slow, decrease the

setting.

· If motor hunting and oscillation occur, increase the setting.

· If motor torque is insufficient at speeds below 10 Hz, increase the

setting.

· if motor hunting and oscillation with a relatively light load, decrease

the setting.

· If motor torque is insufficient at speeds below 10 Hz, increase the

setting.

· If motor instability occurs at motor start, decrease the setting.

Note: The recommended setting value shown is for 200 V class drives.

Multiply value x 2 for 400V class drives and x 2.875 for 575V class

drives.

Adjust the ASR proportional gain 1 (C5-01) and the ASR integral

time 1 (C5-02).

Action

· If motor torque and speed response are too slow, gradually increase the ASR gain setting by 5.

· If motor hunting and oscillation occur, decrease the setting.

· Parameter C5-03 needs to be adjusted only if C5-07 > 0.

· Perform ASR Auto-Tuning if possible

· If motor torque and speed response are too slow, decrease the

setting.

· If motor hunting and oscillation occur, increase the setting.

· Parameter C5-04 needs to be adjusted only if C5-07 > 0.

200 ms <1>

1.00 0.50 to 1.50

E1-08: 15.0 V <2>

E1-10: 9.0 V <2>

C5-01: 0.20

C5-02: 0.200

Default

20.00 10.00 to 50.00

0.500 s 0.300 to 1.000 s

100 to 1000 ms

Default setting ±5 V

Prop. gain = 0.10 to 1.00

Int. time = 0.100 to 2.000

Suggested Setting

· Trouble maintaining the ASR proportional gain

or the integral time at the low or high end of

the speed range

· Motor hunting and oscillation

· Motor noise

· Motor hunting and oscillation occurs at speeds

below 3 Hz

· Overshoot or undershoot when the speed

changes with high inertia load

<1> Default setting value is dependent on parameter A1-02, Control Method Selection, and o2-04, Drive Model Selection.

<2> Default settings change when the Control Method is changed (A1-02) or a different V/f pattern is selected using parameter E1-03.

<3> ASR in V/f Control with PG only controls the output frequency, and therefore does not allow for high gain settings like in Close Loop Vector control.

<4> Refer to C5: Automatic Speed Regulator (ASR) in the A1000 User Manual (Document No. SIEP C710606 21A) for details on Automatic Speed Regulator (ASR).

C5-07 ASR Gain Switching Frequency <4>

C5-06 ASR Primary Delay Time Constant <4>

C6-02 Carrier Frequency Selection

Use S-Curve: C2-01, C2-02, C2-03, C2-04 0 1

Have the drive switch between two different ASR proportional gain and

integral time settings based on the output frequency.

· If motor torque and speed response are too slow, gradually

decrease the setting by 0.01.

· If the load is less rigid and subject to oscillation, increase this

setting.

· If there is too much motor noise, the carrier frequency is too low.

· If motor hunting and oscillation occur at low speeds, reduce the

carrier frequency.

Note: The default setting for the carrier frequency depends on the drive

capacity (o2-04) and Drive Duty Selection (C6-01).

0.0 Hz 0.0 to max. freq. output

0.004 s 0.004 to 0.020s

1 2KHz to max. setting

Loading...

Loading...