Page 1

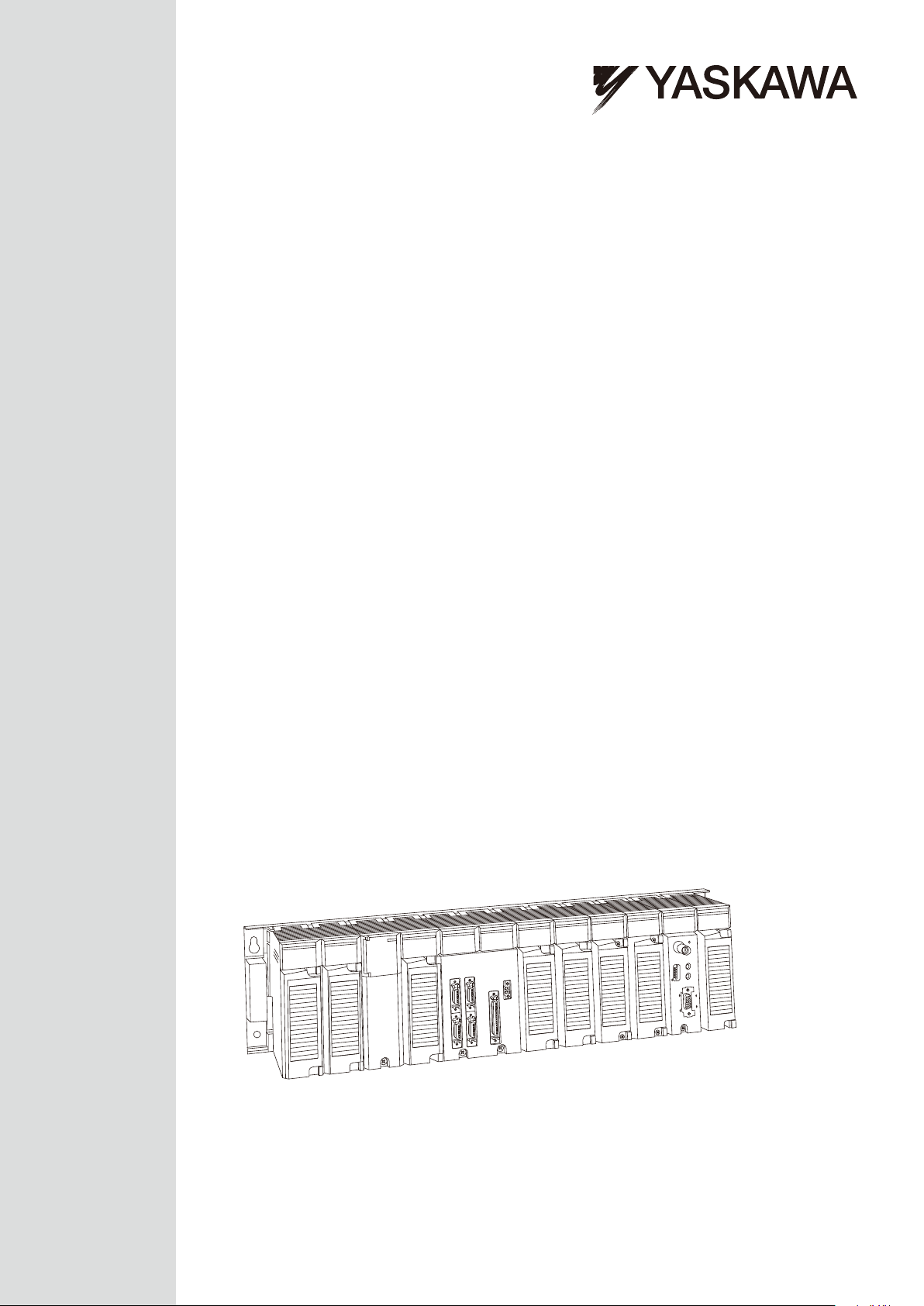

MEMOCON GL120, GL130

120-SERIES I/O MODULES

USER'S MANUAL

MANUAL NO. SIE-C825-20.22C

Page 2

Manual Contents

This manual describes specifications, connections, and precautions for 120-series

I/O Modules. The 120-series I/O Modules are used with the MEMOCON GL120,

GL130 Programmable Controllers (PLCs).

Read this manual carefully and be sure to understand the information provided

before attempting to install or use 120-series I/O Modules.

Also, keep this manual in a safe place so that it can be used whenever necessary.

Visual Aids

The following aids are used to indicate certain types of information for easier refer-

ence.

Indicates references for additional information.

IMPORTANT

EXAMPLE

INFO

SUMMARY

Note

TERMS

Notice

WARNING

Indicates important information that should be memorized.

Indicates application examples.

Indicates supplemental information.

Indicates a summary of the important points of explanations.

Indicates inputs, operations, and other information required for correct operation

but that will not cause damage to the device.

Indicates definitions of terms used in the manual.

The following conventions are used to indicate precautions in this manual. Failure to

heed precautions provided in this manual can result in injury to people or damage to

the products.

Indicates precautions that, if not heeded, could possibly result in loss of life or seri-

ous injury.

CAUTION

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

© Yaskawa, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

iii

Page 3

CONTENTS

Manual Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Visual Aids- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Notice - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

1 Introduction and Precautions

1.1 Overview of Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.2.2 Installation Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.2.3 Removal Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

1.2.4 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-6

1.2.5 Application Precautions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.2.6 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14

1.3 Using This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

2 Models and General Specifications of I/O Modules

2.1 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.2.1 Models of I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

2.2.2 Overview of I/O Module Specifications - - - - - - - - - - - - - - - - - - - - - - -2-5

2.2.3 Using I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-10

3 Digital I/O Specifications

3.1 Digital Input Module specifications - - - - - - - - - - - - - - - - - - 3-2

3.1.1 100-VAC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-2

3.1.2 200-VAC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-6

3.1.3 12/24-VDC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - 3-10

3.1.4 12/24-VDC 32-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.1.5 12/24-VDC 64-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - 3-18

3.2 Digital Output Module Specifications - - - - - - - - - - - - - - - - 3-24

3.2.1 100/200-VAC 8-point Output Module - - - - - - - - - - - - - - - - - - - - - - -3-24

3.2.2 100/200-VAC 16-point Output Module - - - - - - - - - - - - - - - - - - - - - -3-28

3.2.3 12/24-VDC 8-point Output Module - - - - - - - - - - - - - - - - - - - - - - - - -3-32

3.2.4 12/24-VDC 16-point Output Module (Sinking) - - - - - - - - - - - - - - - - - 3-36

3.2.5 12/24-VDC 16-point Output Module (Sourcing) - - - - - - - - - - - - - - - -3-40

3.2.6 12/24-VDC 32-point Output Module - - - - - - - - - - - - - - - - - - - - - - - -3-44

3.2.7 12/24-VDC 64-point Output Module - - - - - - - - - - - - - - - - - - - - - - - -3-49

3.2.8 Relay Contact 16-point Output Module - - - - - - - - - - - - - - - - - - - - - -3-55

3.3 I/O Module Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-60

3.3.1 I/O Module Cable Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-60

3.3.2 W0300 Cables (Model No. JZMSZ-120W0300-) - - - - - - - - - - - -3-62

3.3.3 W0302 Cables (Model No. JZMSZ-120W0302-) - - - - - - - - - - - -3-65

3.3.4 W0301 Cables (Model No. JZMSZ-120W0301-) - - - - - - - - - - - -3-68

3.3.5 32-point I/O Connector Terminal Block - - - - - - - - - - - - - - - - - - - - - -3-71

3.3.6 W5410 Cables (Model No. JEPMC-W5410-) - - - - - - - - - - - - - - - 3-74

v

Page 4

3.4 I/O Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-81

3.4.1 16-point Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-81

3.4.2 32-point Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-84

3.4.3 64-point Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-87

3.4.4 8-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-92

3.4.5 16-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-94

3.4.6 32-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-97

3.4.7 64-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-101

3.5 Operations Using MEMOSOFT - - - - - - - - - - - - - - - - - - - 3-106

3.5.1 MEMOSOFT Versions Supporting 64-point I/O Modules - - - - - - - - 3-106

3.5.2 Digital Input Module I/O Allocation Screen - - - - - - - - - - - - - - - - - - 3-107

3.5.3 Digital Output Module I/O Allocation Screen - - - - - - - - - - - - - - - - - 3-108

3.5.4 I/O Allocations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-109

4 Analog I/O Specifications

4.1 Analog Input Specifications - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.1 Analog Input Modules (±10 V, 4 channels) - - - - - - - - - - - - - - - - - - - - 4-2

4.1.2 Analog Input Modules (0 to 10 V, 4 channels) - - - - - - - - - - - - - - - - - - 4-8

4.1.3 Analog Input Modules (4 to 20-mA, 4 channels) - - - - - - - - - - - - - - - 4-14

4.2 Analog Output Specifications- - - - - - - - - - - - - - - - - - - - - - 4-20

4.2.1 Analog Output Modules (±10 V, 2 channels) - - - - - - - - - - - - - - - - - - 4-20

4.2.2 Analog Output Modules (0 to 10 V, 2 channels) (0 to 5 V, 2 channels)4-25

4.2.3 Analog Output Modules (4 to 20-mA, 2 channels) - - - - - - - - - - - - - - 4-30

4.3 I/O Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-35

4.3.1 Analog Input Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-35

4.3.2 Analog Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-39

4.4 Operations Using MEMOSOFT - - - - - - - - - - - - - - - - - - - - 4-41

4.4.1 Analog Input Module I/O Allocation Screen- - - - - - - - - - - - - - - - - - - 4-41

4.4.2 Analog Output Module I/O Allocation Screen - - - - - - - - - - - - - - - - - 4-42

4.4.3 I/O Allocations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-43

5 Register I/O Specifications

5.1 Register Input Specifications - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 Register Input Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 Register Output Specifications- - - - - - - - - - - - - - - - - - - - - - 5-6

5.2.1 Register Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.3 I/O Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.3.1 Register Input Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.3.2 Register Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.4 Operations Using MEMOSOFT - - - - - - - - - - - - - - - - - - - - 5-17

5.4.1 Register Input Module I/O Allocation Screen- - - - - - - - - - - - - - - - - - 5-17

5.4.2 Register Output Module I/O Allocation Screen - - - - - - - - - - - - - - - - 5-18

5.4.3 I/O Allocations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-20

vi

Page 5

6 Installation and Wiring

6.1 Installing Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Module Installation Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-2

6.1.2 Installing I/O Modules with Terminal Blocks - - - - - - - - - - - - - - - - - - - -6-4

6.1.3 Installing I/O Modules with Connectors - - - - - - - - - - - - - - - - - - - - - -6-10

6.2 Panel Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-13

6.2.1 Separation of Power Supply Systems- - - - - - - - - - - - - - - - - - - - - - -6-13

6.2.2 Wiring AC I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-14

6.2.3 Wiring DC I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-17

6.2.4 Wiring Analog I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-25

6.2.5 Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-28

6.3 External Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-31

6.3.1 External Wiring for Digital I/O Modules - - - - - - - - - - - - - - - - - - - - - -6-31

6.4 Precautions on Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - 6-32

6.4.1 AC Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-32

6.4.2 AC Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-35

6.4.3 DC Input Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-40

6.4.4 DC Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-45

6.4.5 Connections between AC I/O Modules - - - - - - - - - - - - - - - - - - - - -6-49

6.4.6 Connections between DC I/O Modules - - - - - - - - - - - - - - - - - - - - -6-50

6.4.7 Analog Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-50

6.4.8 Analog Output Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-51

6.4.9 External Power Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-52

7 Maintenance

7.1 Built-in Fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.1 I/O Modules with Built-in Fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

7.1.2 Built-in Fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-3

7.1.3 Replacement of Built-in Fuses - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-5

7.2 Hot Swapping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-6

7.2.1 Hot Swapping- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-6

8 EN Standard Low voltage Directive Compliant I/O Modules

8.1 EN Standard Compliant I/O Modules - - - - - - - - - - - - - - - - - 8-2

8.1.1 Low Voltage Directive Compliant I/O Modules - - - - - - - - - - - - - - - - - -8-2

8.1.2 External Appearances- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-3

8.1.3 EN Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-5

8.1.4 Specifications of the I/O Mo

dules - - - - - - - - - - - - - - - - - - - - - - - - - - -8-7

Appendix A External Dimensions

A.1 I/O Module Types- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.2 I/O Modules with Terminal Blocks - - - - - - - - - - - - - - - - - - - A-3

A.3 DC 32-point I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - A-3

A.4 DC 64-point I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - A-4

A.5 Register I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-4

INDEX

vii

Page 6

Introduction and Precautions

This chapter introduces the features of 120-series I/O Modules and pro-

vides precautions for the use of this manual and the product.

Read this chapter before attempting to read the rest of the manual or use

the product.

1.1 Overview of Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.2.1 Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 Installation Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.3 Removal Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.4 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.2.5 Application Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.2.6 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14

1

1

1.3 Using This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

1-1

Page 7

1 Introduction and Precautions

1.1 Overview of Manual

• This manual describes the functional specifications of the 120-series I/O Modules used for the MEMOCON GL120 and GL130 Programmable Controllers.

Read this manual carefully in order to use the 120-series I/O Modules properly.

Also, keep this manual in a safe place so that it can be used whenever necessary.

• Refer to the following manuals for related Peripheral Devices and Modules.

Product Manual Name Manual No. Contents

CPU Module MEMOCON GL120, GL130

Hardware User’s Manual

MEMOCON GL120, GL130

Software User’s Manual Vol. 1

MEMOCON GL120, GL130

Software User’s Manual Vol.2

HumanMachine

Interface

MEMOCON GL120, GL130

MEMOSOFT for P120

Programming Panel

User’s Manual

MEMOCON GL120, GL130

MEMOSOFT

User’s Manual

MEMOCON GL120, GL130

MEMOSOFT for Windows

User’s Manual

SIEZ-C825-20.1 Gives information on the GL120 and GL130 hard-

ware, including explanations on the following items.

1) System configuration

2) System components

3) Function and specifications of system components

4) Installation and wiring

5) Examples of panel-layout and hole dimensions

6) External Dimensions

SIEZ-C825-20.11 Describes the following items for the GL120 and

GL130.

1) Operating principles

2) I/O allocation

3) Overview of instructions

4) Instruction processing times

SIEZ-C825-20.12 Describes the programming instructions used to

create ladder programs for the GL120 and GL130.

The following items are explained in other manuals.

1) Expansion Math instructions

2) Process control instructions

3) Communications instructions

4) Motions control instructions (ladder motion

instructions)

5) Motion language

SIEZ-C825-60.7 Describes the functions, specifications, and opera-

tional methods of the Programming Panel P120 with

built-in MEMOSOFT.

SIEZ-C825-60.10 Describes the functions and operational methods of

MEMOSOFT for DOS.

SIEZ-C825-60.25 Describes the functions and operational methods of

MEMOSOFT for Windows.

• Thoroughly check the specifications and conditions or restrictions of the product

before use.

1-2

Page 8

1.2 Precautions

This section outlines general precautions that apply to using this manual and the

product. Read this section first before reading the remainder of the manual.

1.2.1 Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 Installation Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.3 Removal Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.2.4 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.2.5 Application Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.2.6 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14

1.2.1 Safety Precautions

• The GL120 and GL130 were not designed or manufactured for use in devices or

systems directly related to human life. Users who intend to use the product

described in this manual for special purposes such as devices or systems relating to transportation, medical, space aviation, atomic power control, or underwater use must contact Yaskawa Electric Corporation beforehand.

1.2 Precautions

1

• This product has been manufactured under strict quality control guidelines. However, if this product is to be installed in any location in which a failure of GL120

and GL130 involves a life and death situation or in a facility where failure may

cause a serious accident, safety devices MUST be installed to minimize the likelihood of any accident.

• Any illustrations, photographs, or examples used in this manual are provided as

examples only and may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the manual may be changed without notice to improve the product

and/or the manual. A new version of the manual will be released under a revised

manual number when any changes are made.

• Contact your Yaskawa representative or a Yaskawa office listed on the back of

this manual to order a new manual whenever this manual is damaged or lost.

Please provide the manual number listed on the front cover or this manual when

ordering.

• Contact your Yaskawa representative or a Yaskawa office listed on the back of

this manual to order new nameplates whenever a nameplate becomes worn or

damaged.

• Yaskawa cannot guarantee the quality of any products that have been modified.

Yaskawa assumes no responsibility for any injury or damage caused by a modified product.

1-3

Page 9

1 Introduction and Precautions

1.2.2 Installation Precautions

1.2.2 Installation Precautions

Abide by the following precautions when installing MEMOCON systems.

CAUTION

CAUTION

CAUTION

• The installation environment must meet the environmental conditions given in product catalogs and manuals. Using the GL120 and GL130 in environments subject to

high temperatures, high humidity, excessive dust, corrosive gases, vibration, or

shock can lead to electrical shock, fire, or faulty operation. Do not use the GL120

and GL130 in the following locations.

• Locations subject to direct sunlight or ambient temperatures not between 0 °C

and 60 °C.

• Locations subject to relative humidity in excess of 95%, or condensation

because of rapid changes in humidity.

• Locations subject to corrosive or flammable gas.

• Locations that would subject the GL120 and GL130 to direct vibration or

shock.

• Locations subject to contact with water, oil, chemicals, and so on.

• Install Modules as described in the user’s manuals.

Faulty or inappropriate installation may result in detachment or malfunction.

• Do not remove the connector covers from the Module connectors on the Mounting

Base slots where no Modules are installed.

The presence of any foreign matter in a Module connector may cause the

GL120 and GL130 to malfunction.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

• Make sure that all mounting screws for the Modules are securely tightened.

Loose screws may cause malfunction of the GL120 and GL130.

• Make sure that all mounting screws for the terminal block are securely tightened.

Loose screws may cause a malfunction of the GL120 and GL130.

• When installing the terminal block for the AC I/O Modules, turn OFF the AC power

supply to the I/O Modules for inputting signals and for driving load.

Installing a terminal block with the AC power being supplied to the terminal of

the external power supply for the AC I/O Modules may cause an electric shock if

the power supply terminals are touched.

• When using a single-phase AC power supply (100/200 VAC) for driving loads of the

Relay Contact Output Module, turn OFF the AC power to the Modules for driving

loads before installing the terminal block for the Modules.

Installing a terminal block with the AC power being supplied to the external

power supply terminal of the Relay Contact Output Module may cause an electric shock if the power supply terminals are touched.

• Make sure that all cable connectors for the Module are securely inserted and tightened.

Incorrect connections may cause malfunction of the GL120 or GL130.

1-4

Page 10

1.2.3 Removal Precautions

1.2 Precautions

CAUTION

CAUTION

CAUTION

CAUTION

• Always turn OFF the AC power supply to the AC I/O Modules that are used for

inputting signals and driving loads before removing the terminal block from the AC I/

O Modules.

Removing a terminal block with AC power to the external power supply terminal

of the AC I/O Modules may cause an electric shock at touching the power supply terminals.

1

• When using a single-phase AC power supply (100/200 VAC) for driving loads of the

Relay Contact Output Module, turn OFF the AC power to the Modules for driving

loads before removing the terminal block for the Modules.

Removing a terminal block with the AC power being supplied to the external

power supply terminal of the Relay Contact Output Module may cause an electric shock if the power supply terminals are touched.

• When inserting or removing an AC I/O Module while the AC power supply is turned

ON, install a safety switch for each Module and always turn this safety switch OFF

to turn OFF the AC power supply to the Module.

Inserting or removing an AC I/O Module while AC power is being supplied may

result in an electric shock at touching the power supply terminals.

• When using a single-phase AC power supply (100/200 VAC) for driving the loads of

the Relay Contact Output Module, install a safety switch for each Module. Before

inserting or removing the Relay Contact Output Module, always turn this safety

switch OFF to turn OFF the AC power supply to the Module.

Inserting or removing a Relay Contact Output Module while AC power is being

supplied may result in an electric shock at touching the power supply terminals.

1-5

Page 11

1 Introduction and Precautions

1.2.4 Wiring Precautions

1.2.4 Wiring Precautions

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

• Wiring must be performed by qualified personnel.

Wrong or inappropriate wiring may result in fire, product failure, or electric

shock.

• Connect the correct power supply for the required ratings.

Connecting unsuitable power supplies may result in fires.

• Do not allow foreign matter such as cable chips in the Modules or Mounting Bases.

Foreign matter in the Modules or Mounting Bases may cause fire, failures and/

or malfunctions.

• Connect power supplies of the same phases to the common 1 and common 2 of the

AC I/O Module.

If power supplies of different phases are connected, overheating or fire may

occur.

• If using a single-phase AC power supply (100/200 VAC) for driving the loads of the

Relay Contact Output Module, connect power supplies with the same phases to the

common 1 and common 2 of the Module.

CAUTION

CAUTION

If power supplies of different phases are connected, overheating or fire may

occur.

• If using an Output Module, connect a fuse that complies with the load specifications

in series with the load.

A protective fuse is not built into the following Output Modules. If a fuse is not

connected, a fire or damage to the device or output circuits may occur if the load

is short-circuited or the circuit overloaded.

• 100/200-VAC 8-point Output Module: Model No. JAMSC-120DAO083000

• Relay contact 16-point Output Module: Model No. JAMSC-120DRA84300

• If using an Output Module, connect a fuse that complies with the load specifications

in series with the load.

A protective fuse built into the following Output Modules does not protect the

output element. If a fuse is not connected, a fire or damage to the device or output circuits may occur if the load is short-circuited or the circuit overloaded.

• 100/200-VAC 16-point Output Module: Model No. JAMSC-120DAO84300

• 12/24-VDC 8-point Output Module: Model No. JAMSC-120DDO33000

• 12/24-VDC 16-point Output Module: Model No. JAMSC-120DAO34310

• 12/24-VDC 16-point Output Module: Model No. JAMSC-120DAO34320

• 12/24-VDC 32-point Output Module: Model No. JAMSC-120DAO35410

• 12/24-VDC 64-point Output Module: Model No. JAMSC-120DAO36410

1-6

Page 12

1.2 Precautions

CAUTION

CAUTION

CAUTION

CAUTION

• Connect an AC power supply (100/200 VAC) or a DC power supply (12/24 VDC) to

the Power Supply for driving loads of the Relay Contact Output Module.

Do not connect both an AC power supply and a DC power supply to one Module

at the same time. If unsuitable power supplies are connected, in overheating or

fire may result.

• Although a 0.6-A load can be connected to each output point for the AC 16-point

Output Module, the total load must be 2.4A or less for each common. Keep the

maximum load at 2.4A for each common.

If this limit is exceeded, damage may occur to the output circuit.

• Although a 0.5-A load can be connected to each output point for the DC 16-point

Output Module, the total load must be 1.0 A or less for each of the four output

points. Keep the load distribution within the 1.0 A limit.

If this limit is exceeded, damage may occur to the output circuit.

• Although a 0.3-A load can be connected to each output point of the DC 32-point

Output Module, the total load must be 0.4 A or less for each of the four output

points. Keep the load distribution within the 0.4 A limit.

If this limit is exceeded, damage may occur to the output circuit.

1

CAUTION

CAUTION

• If using an Output Module, connect a fuse that complies with the load specifications

in series with the load.

• 100/200-VAC 8-point Output Module: Model No. JAMSC-120DAO83000

• 100/200-VAC 16-point Output Module: Model No. JAMSC-120DAO84300

• 12/24-VDC 16-point Output Module (sinking output):

Model No. JAMSC-120DDO33000

• 12/24-VDC 16-point Output Module (sourcing output):

Model No. JAMSC-120DAO34320

• 12/24-VDC 32-point Output Module (sinking output):

Model No. JAMSC-120DAO35410

• 12/24 VDC 64-point Output Module (sinking output):

Model No. JAMSC-120DAO36410

• Relay Contact 16-point Output Module: Model No. JAMSC-120DAO84300

If a fuse is not connected, a fire or damage to the device or output circuit may

occur if the load is short-circuited or the circuit overloaded.

• If connecting an inductive load in parallel with AC Input Module, connect the surge

absorber in parallel with the inductive load to prevent surge voltage.

CAUTION

Failure to connect a surge absorber may result in damage to the AC Input Module.

• If connecting an inductive load to the AC Output Module, connect the surge

absorber in parallel with the inductive load to prevent surge voltage.

Failure to connect a surge absorber may result in damage to the AC Output

Module.

1-7

Page 13

1 Introduction and Precautions

1.2.4 Wiring Precautions

CAUTION

CAUTION

CAUTION

CAUTION

• If connecting an inductive load in parallel with DC Input Module, connect the flywheel diode in parallel with the inductive load to prevent surge voltage.

Failure to connect a flywheel diode may result in damage to the DC Input Module.

• If connecting an inductive load to the DC Output Module, connect the flywheel

diode in parallel with the inductive load to prevent surge voltage.

Failure to connect a flywheel diode may result in damage to the DC Output

Module.

• If connecting a contact to an inductive load of the DC Output Module, connect the

flywheel diode in parallel with the inductive load to prevent surge voltage.

Failure to connect a flywheel diode may result in damage to the DC Output

Module.

• Insulation is not provided between the channels of the Analog Input Module.

To insulate all the analog signals connected to the Analog Input Module, use a commercial isolation amplifier for each channel.

Incorrect connections may cause damages and malfunctions of the Analog

Input Modules.

CAUTION

CAUTION

CAUTION

CAUTION

• The maximum allowable load current for Analog Output Modules (±10V, 2 chan-

nels) is ±5 mA (2 kΩ). The load resistance must be 2 kΩ or more.

Incorrect connection may cause the output signal to be overloaded, and result in

damages or malfunction of the Analog Output Module.

• The maximum allowable load current for Analog Output Modules (0 to10V, 2 channels) is 5 mA (2 kΩ). The load resistance must be 2 kΩ or more.

Incorrect connection may cause the output signal to be overloaded, and result in

damages or malfunction of the Analog Output Module.

• The maximum allowable load current for Analog Output Modules (0 to 5V, 2 channels) is 2.5 mA (2 kΩ). The load resistance must be 2 kΩ or more.

Incorrect connection may cause the output signal to be overloaded, and result in

damages or malfunction of the Analog Output Module.

• The maximum allowable load resistance for Analog Output Modules (4 mA to 20

mA, 2 channels) is 550 kΩ). The load resistance must be 550 kΩ or more.

Incorrect connection may cause the output signal to be overloaded, and result in

damages or malfunction of the Analog Output Module.

CAUTION

• If using Low Voltage Directive compliant products, always use round crimp terminals for M3 screws and mount insulation cover at each crimp when connecting

wires to wiring terminals.

If bare wires are used, an electric shock or a short-circuit may result if the wires

become loose.

1-8

Page 14

1.2 Precautions

CAUTION

CAUTION

• Ground the shield of the shielded twisted-pair wire that connects to the Analog I/O

Module to one point (a resistance of 100 Ω max.).

Not grounding the shield of the shielded twisted-pair wire may result in malfunction of the GL120 and GL130.

• Ground the ground terminal of the Analog Input Module to a resistance of 100 Ω

max.

Not grounding the ground terminal may result in malfunction of the GL120 and

GL130.

Power Supply Noise Reduction

• Prevent noise from penetrating into the product by installing an isolation transformer or a noise filter for the external power supply.

Noise from power supply may result in malfunction of the GL120 and GL130.

• Do not install the GL120 and GL130 system components in the same control

panel as high-voltage or high-current circuits.

Here, high-voltage circuits are those with voltages of 600 VAC or 750 VDC

min. and high-current circuits are those with amperages of 800 A min.

1

• When installing the GL120 and GL130 system components in the same control

panel as low-voltage main circuits, separate the low-voltage circuits and related

devices as far as possible from the GL120 and GL130 system components and

wiring.

The recommended separation is 200 mm min. Here. low-voltage main circuits

are those with voltages up to 600 VAC or 750 VDC and amperages of 20 A

min.

• Do not bundle GL120 and GL130 wiring together with wiring for normal control

circuits.

Here, normal control circuits are those with voltages up to 600 VAC or 750

VDC and amperages up to 20 A.

Insert the Interface Cables Properly

• Insert the connectors of the various interface cables that are to be connected to

the GL120 and GL130 into the communication ports and secure them properly.

Improper insertion of interface cables may cause operational errors in the

GL120 and GL130.

1-9

Page 15

1 Introduction and Precautions

1.2.4 Wiring Precautions

Select, Separate, and Lay External Wiring Correctly

• I/O lines connecting external devices to the 120-series I/O Modules must be

selected based on the following considerations: mechanical strength, resistance

to noise, wiring distance, signal voltage, and so on.

• I/O lines must be separated from power lines both inside and outside the control

panel to minimize the affects of noise. Faulty operation may result if I/O lines are

not sufficiently separated from power lines.

Example of external wiring separation

Power lines General control

circuit cables

Steel-plate separator

Digital I/O

signal cables

Analog I/O

signal cables

Pulse input

signal cables

1-10

Page 16

1.2.5 Application Precautions

1.2 Precautions

WARNING

WARNING

WARNING

• Do not touch the Module terminals while the power is ON.

Touching live terminals may cause electric shock.

• Construct an emergency stop circuit and an interlock circuit outside of the GL120

and GL130.

The absence of emergency stop and interlock circuits may result in machine

damage or accidents should the GL120 or GL130 fail.

Install an Emergency Stop Circuit Outside the GL120 and GL130.

An emergency stop circuit for the control system should not be constructed

using the ladder programming in the GL120 and GL130. Always construct the

emergency stop circuit externally using a relay circuit, as shown in the figure

below.

Use an N.C. contact (mechanical contact) in the emergency stop switch. The

main power supply to the servo must be cut off by pressing the switch.

Failure to provide an emergency stop circuit as described above, may result in

failure of the emergency stop when input circuits fail or cables break, and may

cause machine damage or injury.

1

Controlpower

supplyOFF

Emergencystop

ESP-TBOX

Noisefilter

MC1

MC2

ControlpowersupplyON

MC1

ALM

r

SERVOPACK

t

r

s

t

ServoOFF

MC1

Noisefilter

MC1

ServoON

MC2

MEMOCONGL120,GL130

U

V

W

Z

MC2

Z

Surgeabsorber

ControlsignaltoMCModule

Encoder

Servomotor

1-11

Page 17

1 Introduction and Precautions

1.2.5 Application Precautions

External Interlocks for the GL120 and GL130

WARNING

Externally connect an interlock to the GL120 and GL130 if there is any chance

that GL120 and GL130 failure could result in bodily harm or equipment damage.

Always use an external interlock system as shown in the following example

when reciprocal operations (e.g., forward and reverse directions) are being performed with a motor.

An interlock is generally programmed in the GL120 and GL130 ladder program

to ensure that forward and reverse signals are not simultaneously output. An

external interlock circuit must also be provided using the auxiliary contacts of

electromagnetic contactors.

CPU Module

Ladder logic program

Output program with

an interlock which

prohibit simultaneous

forward and reverse

runs

Output Module

R

F

Electric interlock using the auxiliary contacts

of electromagnetic contactors

F

Contact of overcurrent protection

R

device.

OL

CAUTION

CAUTION

F (Forward run)

R (Reverse run)

Induction motor

• When inserting or removing an AC I/O Module while the AC power supply is turned

ON, install a safety switch for each Module and always turn this safety switch OFF

to turn OFF the AC power supply to the Module.

Inserting or removing an AC I/O Module while AC power is being supplied may

result in an electric shock at touching the power supply terminals.

• When using a single-phase AC power supply (100/200 VAC) for driving the loads of

the Relay Contact Output Module, install a safety switch for each Module. Before

inserting or removing the Relay Contact Output Module, always turn this safety

switch OFF to turn OFF the AC power supply to the Module.

Inserting or removing a Relay Contact Output Module while AC power is being

supplied may result in an electric shock at touching the power supply terminals.

1-12

Page 18

1.2 Precautions

CAUTION

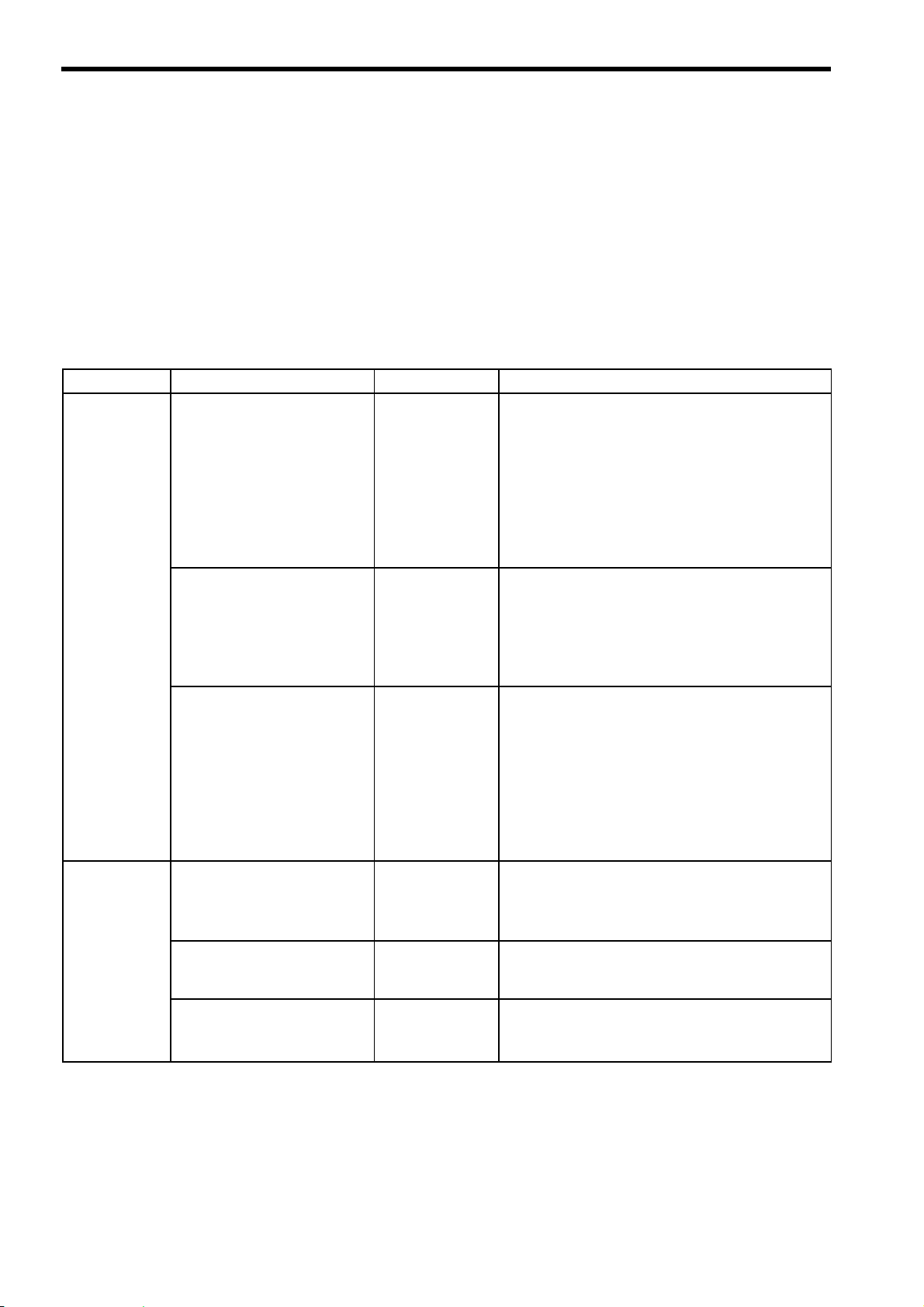

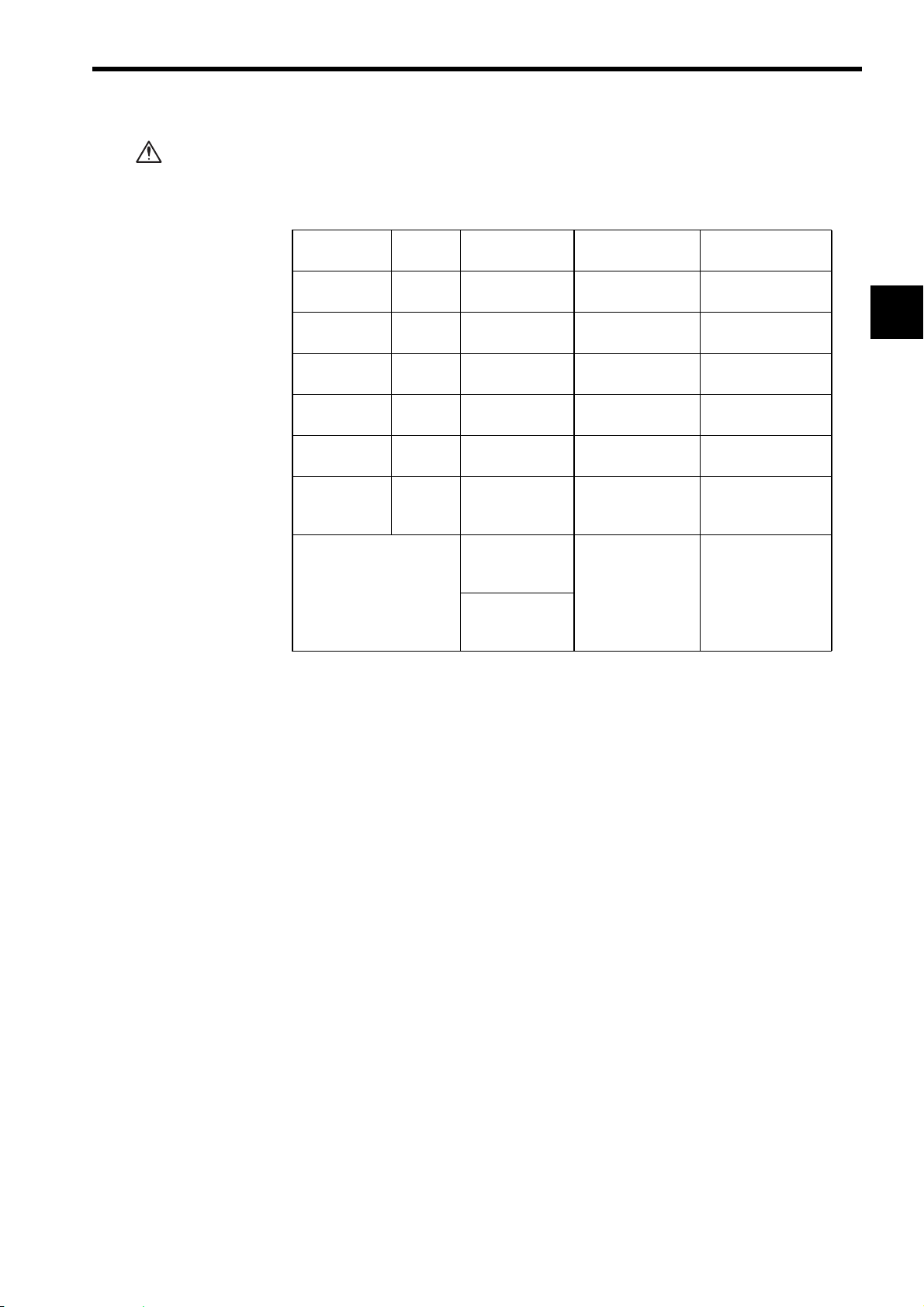

• The following CPU Modules, Remote I/O Receiver Modules, and MEMOSOFT versions are required to use DC 64-point I/O Modules.

Using a version that is not recommended may result in failure or malfunction.

Name Model

Name

CPU Module

(8 kW)

CPU Module

(16 kW)

CPU Module

(16 kW)

CPU Module

(32 kW)

CPU Module

(40 kW)

Remote I/O

Receiver

Module

MEMOSOFT FMSGL-AT3

CPU10 DDSCR-

CPU20 DDSCR-

CPU21 DDSCR-

CPU30 DDSCR-

CPU35 DDSCR-

RIORCOAX

Model No. Version Number Location of

Version Number

A01 and later Module nameplate

120CPU14200

B05 and later Module nameplate

120CPU34100

A01 and later Module nameplate

120CPU34110

B05 and later Module nameplate

120CPU54100

A01 and later Module nameplate

120CPU154110

JAMSC120CRR13100

(for English

DOS)

FMSGL-PP3E

(for P120

English version)

A10 and later Module nameplate

1.21 and later In the middle at the

bottom of the

MEMOSOFT

startup screen.

1

* The nameplate is on the right side of the Module.

1-13

Page 19

1 Introduction and Precautions

1.2.6 Maintenance

1.2.6 Maintenance

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

• Do not disassemble or modify Modules and Mounting Bases.

Failure to observe this caution may result in fire, product failure, or malfunction.

• Do not replace the built-in fuses of the AC 16-point Output Modules.

If the built-in fuses are replaced by anyone other than a Yaskawa-approved

technician, a failure or a malfunction may occur in the AC 16-point Output Modules, and the guarantee is void.

• Do not replace the built-in fuses of the DC 8-point Output Modules.

If the built-in fuses are replaced by anyone other than a Yaskawa-approved

technician, a failure or malfunction may occur in the DC 8-point Output Modules,

and the guarantee is void.

• Do not replace the built-in fuses of the DC 32-point Output Modules.

If the built-in fuses are replaced by anyone other than a Yaskawa-approved

technician, a failure or malfunction may occur in the DC 32-point Output Modules, and the guarantee is void.

• Do not replace the built-in fuses of the DC 64-point Output Modules.

CAUTION

If the built-in fuses are replaced by anyone other than a Yaskawa-approved

technician, a failure or malfunction may occur in the DC 64-point Output Modules, and the guarantee is void.

• Do not replace the built-in fuses of the Register I/O Modules.

If the built-in fuses are replaced by anyone other than a Yaskawa-approved

technician, a failure or malfunction may occur in the Register I/O Modules, and

the guarantee is void.

1-14

Page 20

1.3 Using This Manual

This manual is written for those who already have a basic knowledge of MEMOCON

PLCs. We recommended reading the MEMOCON GL120, GL130 Hardware User’s

Manual (manual No. SIEZ-C825-20.1) before attempting to read this manual.

• Meaning of Basic Terms

1.3 Using This Manual

In this manual, the following terms indicate the meanings as described below,

unless otherwise specified.

Terms Meaning Remarks

PLC Programmable (Logic) Controller Does not mean “personal

computer.”

PP Programming Panel −

GL120, GL130 MEMOCON GL120 and MEMOCON GL130

Programmable Controllers

AC I/O

Module

DC I/O

Module

Analog

I/O

Module

Register I/O Module Register Input Module −

AC input

Module

AC output

Module

DC input

Module

DC output

Module

Analog

input Module

Analog

output Module

100-VAC 16-point Input Module

200-VAC 16-point Input Module

100/200-VAC 8-point Output Module

100/200-VAC 16-point Output Module

Relay Contact 16-point Output Module*

12/24-VDC 16-point Input Module

12/24-VDC 32-point Input Module

12/24-VDC 64-point Input Module

12/24-VDC 8-point Output Module

12/24-VDC 16-point Output Module

12/24-VDC 32-point Output Module

12/24-VDC 64-point Output Module

Relay contact 16-point Output Module*

Analog Input Module (±10V, 4CH)

Analog Input Module (0 to 10V, 4CH)

Analog Input Module (4 to 20mA, 4CH)

Analog Output Module (±10V, 2CH)

Analog Output Module (0 to 10V, 2CH)

Analog Output Module (0 to 5V, 2CH)

Analog Output Module (4 to 20mA, 2CH)

Register Output Module

2

−

−

*1 When the AC load is

applied.

1

−

*2 When the DC load is

applied.

−

−

1

TERMS

• Description of Technical Terms

The bold technical terms in this manual are briefly explained in the Glossary

provided at the bottom of the page. An example is shown below.

Glossary

The following types of terms are described.

• Specific sequence control terms required for explanation of functions.

• Terms that are specific to programmable controllers and electronic devices.

1-15

Page 21

Models and General Specifications of I/O Modules

This chapter describes the models and general specifications of I/O

Modules.

2.1 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.2 I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

2.2.1 Models of I/O Modules - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.2.2 Overview of I/O Module Specifications - - - - - - - - - - - - 2-5

2.2.3 Using I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

2

2

2-1

Page 22

2 Models and General Specifications of I/O Modules

2.1 General Specifications

This section gives the general specifications of I/O Modules.

Item Specification

Environmental

Conditions

Mechanical

Operating

Conditions

Electrical

Operating

Conditions

Installation

Requirements

Ambient Operating Temperature 0 °C to 60 °C

Ambient Storage Temperature -25 C° to 85 °C (excluding battery)

Ambient Operating Humidity 30 % to 95 % RH (with no condensation)

Ambient Storage Humidity 5 % to 95 % RH (with no condensation)

Pollution Level Pollution level 1 (according to JIS B3502)

Corrosive Gas No corrosive gas

Operating Altitude Less than 2,000 m above sea level

Vibration Shock 10 to 57 Hz with half-amplitude of 0.075mm

Shock Resistance

Noise Resistance 1,500 V in either normal or common mode with pulse

Ground Ground to 100 Ω or less

Configuration Building-block, wall-mounted, or DIN track mounted

Cooling Method Natural cooling

Mass See specifications for individual I/O Modules.

External Dimensions See specifications for individual I/O Modules.

Table 2.1 General Specifications

57 to 150 Hz with fixed acceleration of 9.8 m/s

10 sweep times each in X, Y, and Z directions

(sweep time: 1 octave/min) (according to JIS B3502)

Peak acceleration of 147 m/s

and Z directions (according to JIS B3502)

widths of 100 ns and 1 µs and rise time of 1 ns (with

impulse noise simulator) (according to JIS B3502)

2

2

twice for 11 ms in X, Y,

2-2

Page 23

2.2 I/O Modules

2.2 I/O Modules

This section describes various input modules and output modules.

2.2.1 Models of I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

2.2.2 Overview of I/O Module Specifications - - - - - - - - - - - - - - - - - - - - - - -2-5

2.2.3 Using I/O Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-10

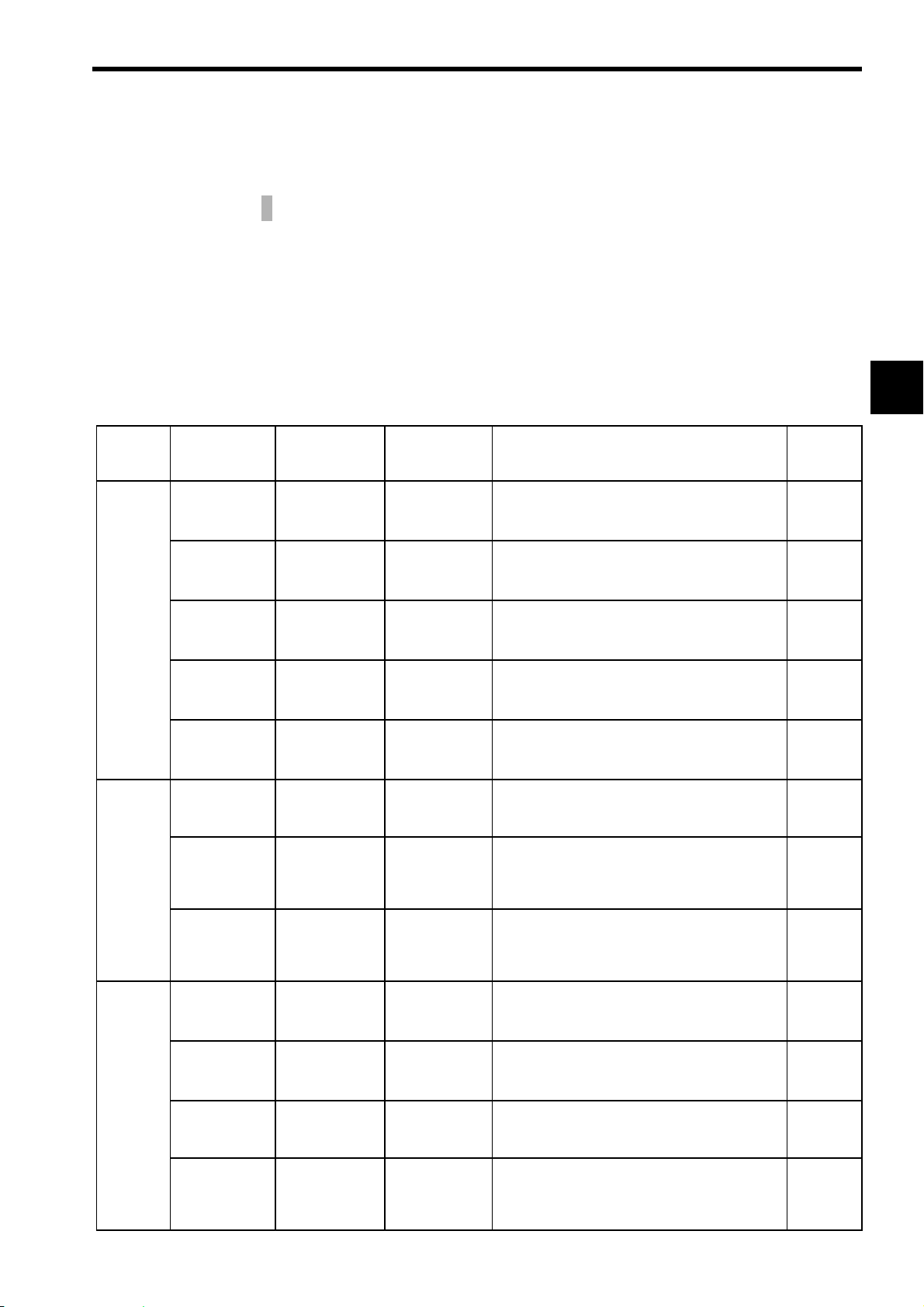

2.2.1 Models of I/O Modules

Twenty models of I/O Modules are available.

Table 2.2 I/O Modules

Product Name Model Name Model No. Features Number

of slots

required

Digital

Input

Modules

Analog

Input

Modules

Digital

Output

Modules

100-VAC

16-point Input

Module

200-VAC

16-point Input

Module

12/24-VDC

16-point Input

Module

12/24-VDC

32-point Input

Module

12/24-VDC

64-point Input

Module

Analog Input

Module (±10V,

4 channels)

Analog Input

Module (0 to

10V, 4 channels)

Analog Input

Module (4 to

20mA, 4 channels)

100/200-VAC

8-point

Output Module

100/200-VAC

16-point

Output Module

12/24-VDC 8point Output

Module

12/24-VDC

16-point Output Module

(sinking)

AC100IN-16P JAMSC-

120DAI54300

AC200IN-16P JAMSC-

120DAI74300

DC24IN-16P JAMSC-

120DDI34300

DC24IN-32P JAMSC-

120DDI35400

DC24IN-64P JAMSC-

120DDI36400

A/D-VOL4CH

A/D 0-10V

4CH

A/D-CUR4CH

ACOUT-8P JAMSC-

ACOUT-16P JAMSC-

DC24OUT-8P JAMSC-

DC24OUT16PSN

JAMSC120AVI02000

JAMSC120AVI02100

JAMSC120ACI02000

120DAO83000

120DAO84300

120DDO33000

JAMSC120DDO34310

1) Used to input digital signals.

2) 100VAC, 16 points, 7mA (50Hz)

1) Used to input digital signals.

2) 200VAC, 16 points, 7mA (50Hz)

1) Used to input digital signals.

2) 12/24VDC, 16 points, 4mA (12VDC), 8mA

(24VDC)

1) Used to input digital signals.

2) 12/24VDC, 32 points, 2mA (12VDC), 4mA

(24VDC)

1) Used to input digital signals.

2) 12/24VDC, 64 points, 2mA (12VDC), 4mA

(24VDC)

1) Used to input analog signals.

2) -10 to 10V, 4 channels

1) Used to input analog signals.

2) 0 to 10V, 4 channels

1) Used to input analog signals.

2) 4 to 20mA/1 to 5V, 4 channels

1) Used to output digital signals.

2) 100/200VAC, 8 points, 1.0 A/point

1) Used to output digital signals.

2) 100/200VAC, 16 points, 0.3 A/point

1) Used to output digital signals.

2) 12/24VDC, 8 points, sourcing/sinking

outputs, 2.0 A/point

1) Used to output digital signals.

2) 12/24VDC, 16 points, sinking outputs, 0.5

A/point, 1.0 A/4points

1

1

1

1

1

1

1

1

1

1

1

1

2

2-3

Page 24

2 Models and General Specifications of I/O Modules

2.2.1 Models of I/O Modules

Table 2.2 I/O Modules

Product Name Model Name Model No. Features Number

of slots

required

Digital

Output

Modules

12/24-VDC

16-point Output Module

DC24OUT16PSR

JAMSC120DDO34320

1) Used to output digital signals.

2) 12/24VDC, 16 points, sourcing outputs,

0.5 A/point, 1.0 A/4points

1

(sourcing)

12/24-VDC

32-point Output Module

DC24OUT32PSN

JAMSC120DDO35410

1) Used to output digital signals.

2) 12/24VDC, 32 points, sinking outputs, 0.3

A/point, 0.4 A/4points

1

(sinking)

12/24-VDC

64-point Output Module

DC24OUT64PSN

JAMSC120DDO36410

1) Used to output digital signals.

2) 12/24VDC, 64 points, sinking outputs, 0.1

A/point

1

(sinking)

Relay Contact

16-point Out-

RELAY-16P JAMSC-

120DRA84300

1) Used to output digital signals.

2) Relay contacts, 16 points, 1.0 A/point

1

put Module

Analog

Output

Modules

Analog Output Module

(±10V, 2 chan-

D/A-VOL-2CH JAMSC-

120AVO01000

1) Used to output analog signals.

2) -10 to 10V, 2 channels

1

nels)

Analog Output Module

D/A 0-10V 2CH JAMSC-

120AVO01100

1) Used to output analog signals.

2) 0 to 10V, 2 channels

1

(0 to 10V, 2

channels)

Analog Output Module

D/A 0-5V 2CH JAMSC-

120AVO01200

1) Used to output analog signals.

2) 0 to 5V, 2 channels

1

(0 to 5V, 2

channels)

Analog Output Module

D/A-CUR- 2CH JAMSC-

120ACO01000

1) Used to output analog signals.

2) 4 to 20mA, 2 channels

1

(4 to 20mA, 2

channels)

Special

Purpose

Modules

Register Input

Module

REGISTER-IN JAMSC-

120RDI34410

1) Used to input a maximum of 8 sets (8

channel) or 16 sets (16 channel) of 16-bit

or BCD 4-digit values.

1

2) The data input cycle can be selected:

For 8 channels: 10/32/64/192/320 ms

For 16 channels: 20/64/128/384/640 ms

Register Output Module

REGISTEROUT

JAMSC120RDO34410

1) Used to output a maximum of 8 sets (8

channel) or 16 sets (16 channel) of 16-bit

1

or BCD 4-digit values.

2) Select the data output cycle.

For 8-channel: 32/64/192/320 ms

For 16-channel: 64/128/640 ms

Note: The 64-point I/O Modules are limited to versions for the CPU Module, remote I/O

Receiver Module and MEMOSOFT. Refer to 2.2.3 Using I/O Modules for details.

2-4

Page 25

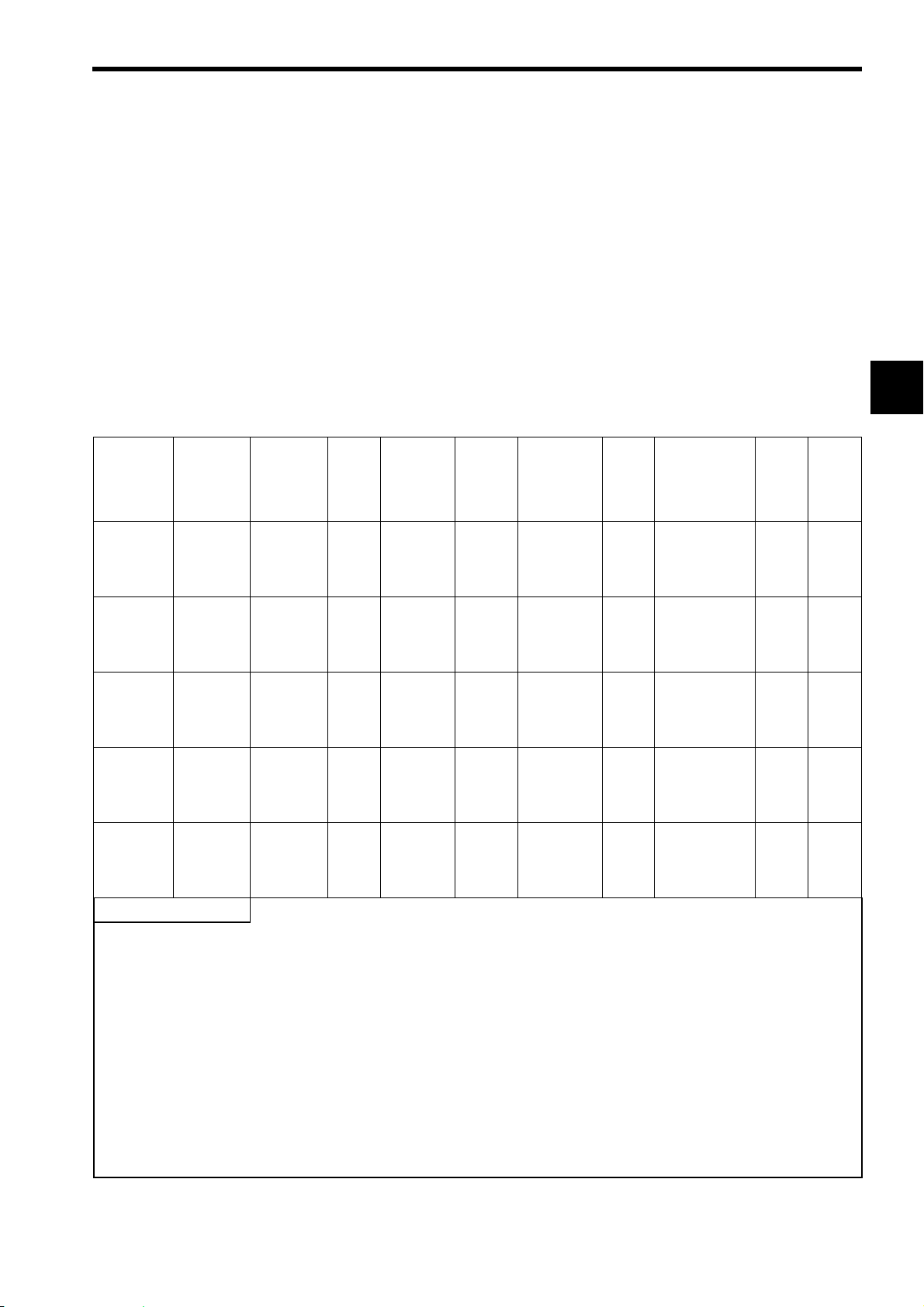

2.2.2 Overview of I/O Module Specifications

1) Digital Input Modules

a) Function

A Digital Input Module converts the digital signals coming from pushbutton switches,

limit switches, and digital switches into signals of appropriate voltage for PLC inter-

nal processing. The converted digital signals are stored by the CPU Module as input

relays and input registers in state memory.

b) Specifications

2.2 I/O Modules

The following table shows the main specifications of Digital Input Modules.

Table 2.3 Main Specifications of Digital Input Modules

Name Model

Name

100-VAC

16-point

Input

Module

200-VAC

16-point

Input

Module

12/24VDC 16point Input

Module

12/24VDC 32point Input

Module

12/24VDC 64point Input

Module

Other Specifications

1) Slots required: 1

2) Width: 40.3 mm Height: 130 mm Depth: 103.9 mm

3) Approx. mass

16-point Input Module: 250 g

32-point Input Module: 250 g

64-point Input Module: 300 g

4) Field connections

16-point Input Module: terminal block

32-point Input Module: connector

64-point Input Module: connector

5) Number of points per common

16-point Input Module: 8 points per common

32-point Input Module: 16 points per common

64-point Input Module: 16 points per common

AC100IN16P

AC200IN16P

DC24IN16P

DC24IN32P

DC24IN64P

Model No. Rated

Vol t-

age

JAMSC120DAI54

300

JAMSC120DAI74

300

JAMSC120DDI34

300

JAMSC120DDI35

400

JAMSC120DDI36

400

100

VAC

200

VAC

12/24

VDC

12/24

VDC

12/24

VDC

Rated

Current

7 mA

(50Hz)

7 mA

(50Hz)

4 mA

(12 VDC)

8 mA

(24 VDC)

2 mA

(12 VDC)

4 mA

(24 VDC)

2 mA

(12 VDC)

4 mA

(24 VDC)

Input

Imped-

ance

14.3 kΩ

(50 Hz)

12.5 kΩ

(60 Hz)

28.6 kΩ

(50 Hz)

23.1 kΩ

(60 Hz)

3.0 kΩ OFF→ON:

5.6 kΩ OFF→ON:

5.6 kΩ OFF→ON:

Input

Delay

Times

OFF→ON:

Max. 20 ms

ON→OFF:

Max. 35 ms

OFF→ON:

Max. 20 ms

ON→OFF:

Max. 35 ms

Max. 5 ms

ON→OFF:

Max. 5 ms

Max. 5 ms

ON→OFF:

Max. 5 ms

Max. 5 ms

ON→OFF:

Max. 5 ms

Num-

ber of

inputs

16 With all points

16 With all points

16 With all points

32 With all points

64 With all points

Internal

Current Con-

sumption

ON: 90 mA

ON: 90 mA

ON: 100 mA

ON: 80 mA

ON: 100 mA

Maxi-

mum

Heat-

ing

Value

2.0 W Per-

3.5 W Per-

3.7 W Per-

3.6 W Per-

7.0 W Per-

Hot

Swap-

ping

mitted

mitted

mitted

mitted

mitted

2

2-5

Page 26

2 Models and General Specifications of I/O Modules

2.2.2 Overview of I/O Module Specifications

2) Analog Input Modules

a) Function

An Analog Input Module converts the analog signals coming from weight sensors,

temperature sensors, etc., into numeric data appropriate for PLC internal process-

ing. The converted numeric data is stored by the CPU Module as the input registers

in state memory.

b) Specifications

The following table shows the main specifications of the Analog Input Modules.

Table 2.4 Main Specifications of Analog Input Modules

Name Model

Name

Analog

Input

Module

A/DVOL-

4CH

(±10 V, 4

channels)

Analog

Input

Module

A/D

0-10V

4CH

(0 to

10 V,

4 channels)

Analog

Input

Module (4

A/D-

CUR-

4CH

to 20 mA,

4 channels)

Other Specifications

1) Slots required: 1

2) Approx. mass: 300 g

3) Width: 40.3 mm Height: 130 mm Depth: 103.9 mm

4) Field connections: Terminal block

Model

No.

JAMSC120AVI

02000

JAMSC120AVI

02100

JAMSC120ACI

02000

Input

Signal

Range

-10 to

+10 V

0 to

+10 V

Current

input:

4 to 20

mA

Voltage

input:

1 to 5 V

Overall

Accuracy

±0.5% F.S.

(25°C)

±1.0% F.S.

(0 to 60°C)

±0.5% F.S.

(25°C)

±1.0% F.S.

(0 to 60°C)

±0.5% F.S.

(25 °C)

±1.0% F.S.

(0 to 60°C)

Resolution

0 to 4000

mode: 12 bits,

binary between

0 and 4000

± 2000 mode:

12 bits, 2’s

complement

between -2000

and +2000

12 bits, binary

between 0 and

4000

12 bits, binary

between 0 and

4000

and Data

Typ es

Num-

nels

Internal

Current

Con-

sump-

tion

Input

Impedance

ber of

Chan-

1 MΩ min. 4 450

mA

1 MΩ min. 4 450

mA

Current

input: 250 Ω

4 450

mA

voltage

input: 1 MΩ

min.

Maxi-

mum

Heat-

Hot

Swap-

ping

ing

Value

2.3 W Permitted

2.3 W Permitted

2.3 W Permitted

2-6

Page 27

3) Digital Output Modules

a) Function

A Digital Output Module converts the numeric data stored in output registers or the

ON/OFF state of the output coil in the state memory of the CPU Module into digital

signals for control of indicators, electromagnetic switches, relays, solenoid valves,

numeric indicators, etc.

b) Specifications

The following table shows the main specifications of Digital Output Modules.

2.2 I/O Modules

Name Model

100/200VAC

8-point

Output

Module

100/200VAC

16-point

Output

Module

12/24-VDC

8-point

Output

Module

12/24-VDC

16-point

Output

Module

(sinking)

12/24-VDC

16-point

Output

Module

(sourcing)

12/24-VDC

32-point

Output

Module

(sinking)

12/24-VDC

64-point

Output

Module

(sinking)

Relay contact

16-point

Output

Module

ACOUT

-8P

ACOUT

-16P

DC24O

UT-8P

DC24O

UT16PSN

DC24O

UT16PSR

DC24O

UT32PSN

DC24O

UT64PSN

RELAY16P

Name

Table 2.5 Main Specifications of Digital Output Modules

Model No. Rated

Vol t-

age

JAMSC120DAO83

000

JAMSC120DAO84

300

JAMSC120DDO33

000

JAMSC120DDO34

310

JAMSC120DDO34

320

JAMSC120DDO35

410

JAMSC120DDO36

410

JAMSC120DRA84

300

100/

200

VAC

100/

200

VAC

12/24

VDC

12/24

VDC

12/24

VDC

12/24

VDC

12/24

VDC

Relay

contact

Load

Current

1.0 A/

point

0.6 A/

point

2.0 A/

point

0.5 A/

point,

1.0 A/

4 points

0.5 A/

point,

1.0 A/

4 points

0.3 A/

point,

0.4 A/

4 points

0.1 A/

point

1.0 A/

point

Remarks Output

Delay

Times

Unprotected

outputs

Unprotected

outputs

Short-circuit protection

Sourcing/

sinking

outputs

Unprotected

outputs

Sinking

outputs

Unprotected

outputs

Sourcing

outputs

Unprotected

outputs

Sinking

outputs

Unprotected

output

Sinking

outputs

Unprotected

outputs

OFF→ON:

Max. 5 ms

ON→OFF:

1/2 cycle +

5 ms max.

OFF→ON:

Max. 5 ms

ON→OFF:

1/2 cycle +

5 ms max.

OFF→ON:

Max. 3 ms

ON→OFF:

Max. 5 ms

OFF→ON:

Max. 1 ms

ON→OFF:

Max. 1 ms

OFF→ON:

Max. 1 ms

ON→OFF:

Max. 1 ms

OFF→ON:

Max. 1 ms

ON→OFF:

Max. 1 ms

OFF→ON:

Max. 1 ms

ON→OFF:

Max. 1 ms

OFF→ON:

Max. 10 ms

ON→OFF:

Max. 15 ms

Num

ber

of

Outputs

8 With all

16 With all

8 With all

16 With all

16 With all

32 With all

64 With all

16 With all

Internal

Current Con-

sumption

points ON:

150 mA

points ON:

300 mA

points ON:

220 mA

points ON:

220 mA

points ON:

300 mA

points ON:

330 mA

points ON:

650 mA

points ON:

610 mA

Maximum

Heat-

ing

Val ue

9.0 W Per-

5.5 W Per-

1.6 W Per-

7.1 W Per-

7.5 W Per-

6.5 W Per-

13.0 W Per-

3.1 W Per-

Hot

Swap

ping

mitted

mitted

mitted

mitted

mitted

mitted

mitted

mitted

2

2-7

Page 28

2 Models and General Specifications of I/O Modules

2.2.2 Overview of I/O Module Specifications

Table 2.5 Main Specifications of Digital Output Modules

Name Model

Name

Model No. Rated

Vol t-

Load

Current

Remarks Output

age

Other Specifications

1) Slots required: 1

2) Width: 40.3 mm Height: 130 mm Depth: 103.9 mm

3) Approx. mass

AC Output Module: 300 g

DC Output Module (8-point, 16-point, 32-point): 250 g

DC Output Module (64-point): 300 g

Relay Contact Output Module: 300 g

4) Field connections

8-point Output Module: terminal block

16-point Output Module: terminal block

32-point Output Module: connector

64-point Output Module: connector

Relay Contact Output Module: terminal block

5) Number of points per common

8-point Output Module: Independent outputs

16-point Output Module: 8 points per common

32-point Output Module: 16 points per common

64-point Output Module: 16 points per common

Relay Contact Output Module: 8 points per common

Delay

Times

Num

ber

of

Outputs

Internal

Current Con-

sumption

Maxi-

mum

Heat-

ing

Value

Hot

Swap

ping

2-8

Page 29

4) Analog Output Module

a) Function

An Analog Output Module converts the numeric data stored in output registers in the

state memory of the CPU Module into analog signals for control of heaters, pumps,

PID adjusters, inverters, etc.

b) Specifications

The following table shows the main specifications of the Analog Output Modules.

Table 2.6 Main Specifications of Analog Output Modules

2.2 I/O Modules

Name Model

Name

Analog

Output

Module

(±10 V, 2

channels)

Analog

Output

Module (0

to 10 V, 2

channels)

Analog

Output

Module (0

to 5 V, 2

channels)

Analog

Output

Module (4

to 20 mA,

2 channels)

Other Specifications

1) Slots required: 1

2) Approx. mass : 350 g

3) Width: 40.3 mm Height: 130 mm Depth: 103.9 mm

4) Field connection: Terminal block

D/AVOL2CH

D/A

0-10V

2CH

D/A

0-5V

2CH

D/ACUR2CH

Model

No.

JAMSC120AVO

01000

JAMSC120AVO

01100

JAMSC120AVO

01200

JAMSC120AC

O01000

Output

Signal

Range

-10 to

+10 V

0 to +10 V±0.2% F.S.

0 to +5 V±0.2% F.S.

4 to 20 mA±0.2% F.S.

Overall

Accuracy

±0.2% F.S.

(25 °C)

±0.5% F.S.

(0 to

60 °C)

(25 °C)

±0.5% F.S.

(0 to 60 °C)

(25 °C)

±0.5% F.S.

(0 to 60 °C)

(25 °C)

±0.5% F.S.

(0 to 60 °C)

Resolution and

Data Types

0 to 4000 mode:

12 bits, binary

between 0 and

4000

±2000 mode: 12

bits, 2’s complements between

-2000 and

+2000

12 bits, binary

between 0 and

4000

12 bits, binary

between 0 and

4000

12 bits, binary

between 0 and

4000

Maxi-

mum

Permis-

sible

Load

Current

±5 mA,

2 kΩ

min.

5 mA,

2 kΩ

min.

2.5 mA,

2 kΩ

min.

550 Ω

max.

Number of

Chan-

nels

2 400

2 400

2 400

2 500

Inter-

nal Cur-

rent

Con-

sump-

tion

mA

mA

mA

mA

Maximum

Heat-

ing

Val ue

2.0 W Permit-

2.0 W Permit-

2.0 W Permit-

2.5 W Permit-

Hot

Swap-

ping

ted

ted

ted

ted

2

2-9

Page 30

2 Models and General Specifications of I/O Modules

2.2.3 Using I/O Modules

2.2.3 Using I/O Modules

1) Installation Location of I/O Modules

(1) I/O Modules can be mounted to any slot of the Mounting Base of any Rack.

Each I/O Module occupies one slot.

(2) The following diagram shows an example on where to mount I/O Modules.

EXAMPLE

1234 5 7

PS10 DODI

1 2 3 4 5 7 10 11 12

05

PS10: Power Supply Module (7 A)

PS05: Power Supply Module (3 A)

CPU30: CPU Module (32 kW)

DI: 12/24-VDC 16-point Input Module

DO: 12/24-VDC 16-point Output Module

CPU30

MP

DI DI DI DI DI DO DO DO DO

6

DI

689

89

MC20

10

MC20

MC20: 4-axis Motion Module

EXP: Expander Module

MB12: 12 slot Mounting Base

W0100-02: Rack-to-rack I/O Cable (0.2 m)

Fig. 2.1 Example of Mounting I/O Modules

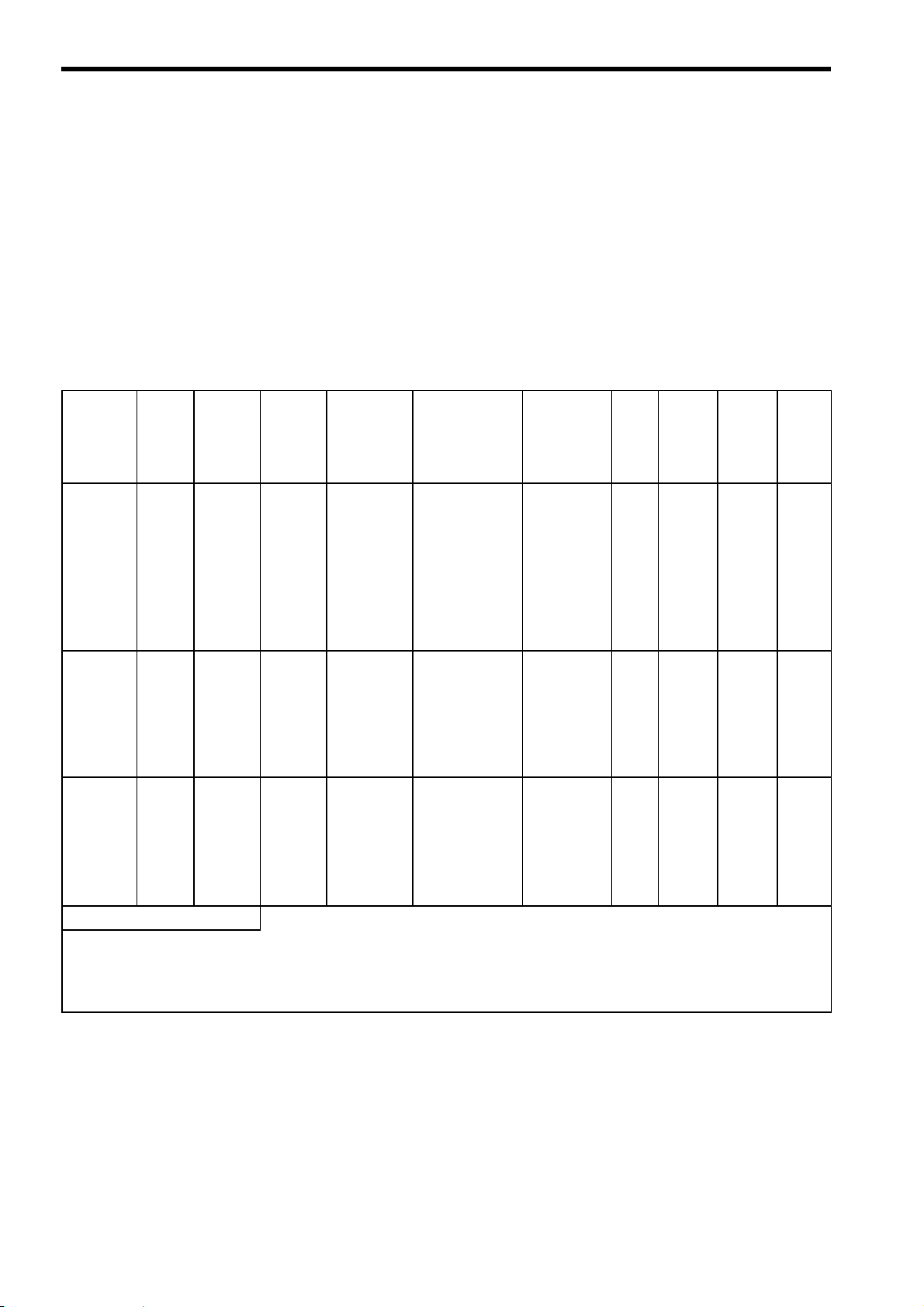

2) Versions Supporting 64-point I/O Modules

11 12

EXP

EXPDIPS

Slot No.

Rack 1 (CPU Rack)

MB12

W0100-02

Rack 2

MB12

The following CPU Modules, Remote I/O Receiver Modules, and MEMOSOFT ver-

sions are required to user 64-point I/O Modules.

Table 2.7 Versions Supporting 64-point I/O Modules

Name Model

Name

CPU Module

CPU10 DDSCR-120CPU14200 A01 and later Module nameplate

(8 kw)

CPU Module

CPU20 DDSCR-120CPU34100 B05 and later Module nameplate

(16 kw)

CPU Module

CPU21 DDSCR-120CPU34110 A01 and later Module nameplate

(16 kw)

CPU Module

CPU30 DDSCR-120CPU54100 B05 and later Module nameplate

(32 kw)

CPU Module

CPU35 DDSCR-120CPU54110 A01 and later Module nameplate

(40 kw)

Remote I/O

Receiver

RIORCOAX

Module

MEMOSOFT FMSGL-AT3

Model No. Version Number Location of Ver-

sion Number

DDSCR-120CRR13100 A10 and later Module nameplate

1.21 and later In the middle at the

(for English DOS)

FMSGL-PP3E

(for P120 English version)

bottom of the

MEMOSOFT

startup screen

Note: The nameplate is on the right side of the Module.

2-10

Page 31

Digital I/O Specifications

This chapter describes the specifications of Digital I/O Modules.

3

3.1 Digital Input Module specifications - - - - - - - - - - - - - - - - - - - 3-2

3.1.1 100-VAC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 200-VAC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.1.3 12/24-VDC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - 3-10

3.1.4 12/24-VDC 32-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.1.5 12/24-VDC 64-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - 3-18

3.2 Digital Output Module Specifications - - - - - - - - - - - - - - - - 3-24

3.2.1 100/200-VAC 8-point Output Module - - - - - - - - - - - - - - - - - - - - - - 3-24

3.2.2 100/200-VAC 16-point Output Module - - - - - - - - - - - - - - - - - - - - - - 3-28

3.2.3 12/24-VDC 8-point Output Module - - - - - - - - - - - - - - - - - - - - - - - - 3-32

3.2.4 12/24-VDC 16-point Output Module (Sinking) - - - - - - - - - - - - - - - - 3-36

3.2.5 12/24-VDC 16-point Output Module (Sourcing) - - - - - - - - - - - - - - - 3-40

3.2.6 12/24-VDC 32-point Output Module - - - - - - - - - - - - - - - - - - - - - - - 3-44

3.2.7 12/24-VDC 64-point Output Module - - - - - - - - - - - - - - - - - - - - - - - 3-49

3.2.8 Relay Contact 16-point Output Module - - - - - - - - - - - - - - - - - - - - - 3-55

3.3 I/O Module Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-60

3.3.1 I/O Module Cable Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-60

3.3.2 W0300 Cables (Model No. JZMSZ-120W0300-) - - - - - - - - - - - 3-62

3.3.3 W0302 Cables (Model No. JZMSZ-120W0302-) - - - - - - - - - - - 3-65

3.3.4 W0301 Cables (Model No. JZMSZ-120W0301-) - - - - - - - - - - - 3-68

3.3.5 32-point I/O Connector Terminal Block - - - - - - - - - - - - - - - - - - - - - 3-71

3.3.6 W5410 Cables (Model No. JEPMC-W5410-) - - - - - - - - - - - - - - 3-74

3

3.4 I/O Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-81

3.4.1 16-point Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-81

3.4.2 32-point Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-84

3.4.3 64-point Input Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-87

3.4.4 8-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-92

3.4.5 16-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-94

3.4.6 32-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-97

3.4.7 64-point Output Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-101

3.5 Operations Using MEMOSOFT - - - - - - - - - - - - - - - - - - - 3-106

3.5.1 MEMOSOFT Versions Supporting 64-point I/O Modules - - - - - - - - 3-106

3.5.2 Digital Input Module I/O Allocation Screen - - - - - - - - - - - - - - - - - - 3-107

3.5.3 Digital Output Module I/O Allocation Screen - - - - - - - - - - - - - - - - 3-108

3.5.4 I/O Allocations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-109

3-1

Page 32

3 Digital I/O Specifications

3.1.1 100-VAC 16-point Input Module

3.1 Digital Input Module specifications

This section describes the performance specifications, circuit configuration, external

connections, and the external appearance of the 120-series Digital Input Modules.

3.1.1 100-VAC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 200-VAC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.1.3 12/24-VDC 16-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - 3-10

3.1.4 12/24-VDC 32-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.1.5 12/24-VDC 64-point Input Module - - - - - - - - - - - - - - - - - - - - - - - - - 3-18

3.1.1 100-VAC 16-point Input Module

1) Performance Specifications

Item Specifications

Name 100-VAC 16-point Input Module

Model Name AC100IN-16P

Model No. JAMSC-120DAI54300

Rated Voltage 100 VAC

Maximum Allowable Voltage 132 VAC

Rated Frequency 50/60 Hz

Allowable Frequency Range 47 to 63 Hz

Inrush Current 160 mA

Rated Current 7 mA (at 100 VAC, 50 Hz)

Input Impedance 14.3 kΩ (at 100 VAC, 50 Hz)

12.5 kΩ (at 100 VAC, 50 Hz)

Standard Operating Ranges ON voltage range: 74 to 132 VAC

OFF voltage range: 30 VAC max.

Input Type AC type2 (according to JIS B3502)

Input Delay Times OFF to ON: 20 ms max.

ON to OFF: 35 ms max.

Number of common 2

Number of Inputs per Common 8 points/common

Input Power Supply per Common Connect power supplies of the same phase to the Common 1 and

Common 2.

External Connections Removable terminal block with M3 screw terminals

Number of Inputs 16

Input Signal Indication Indicator for each point; lit when the input is ON.

Status saved in internal logic.

Status Indication ACTIVE: Lights during input processing

Insulation Method Photocoupler

Dielectric Strength 1,500 VAC for 1 min or 1,800 VAC for 1 s between input terminals and

internal circuits and between all input commons.

Insulation Resistance 100 MΩ min. at room temperature and humidity between input termi-

nals and ground

(measured with a 500-VDC test voltage megohmmeter).

External Power Supply 100 VAC supplied to signals

Derating Conditions None

Internal Current Consumption 90 mA max. at 5 VDC (with all points ON)

3-2

Page 33

Item Specifications

Maximum Heating Value 2.0 W

Hot Swapping

(Removal/insertion under power)

Approx. Mass 250 g

External Dimensions 40.3×130×103.9 mm (W×H×D)

Permitted

2) The following diagram shows the circuit configuration.

Input 1

3.1 Digital Input Module specifications

Input signal

indicator

CAUTION

Input 8

Common 1

100 VAC

Input 9

Input 16

Common 2

100 VAC

Photocoupler

To CPU

Internal circuits

Connect power supplies of the same phase to the Common 1 and Common 2.

If power supplies of different phases are connected, overheating or fire may

occur.

3

3-3

Page 34

3 Digital I/O Specifications

3.1.1 100-VAC 16-point Input Module

3) The following diagram shows an example of terminal connections.

EXAMPLE

Terminals

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Input 7

Input 8

Common 1

Not connected.

Input 9

Input 10

Input 11

Input 12

CAUTION

Connect power supplies of the same phase to the Common 1 and Common 2.

Note: (1) Crimp Terminals

Use M3 terminal for crimping to the terminal block.

(2) Recommended Wires

Use wires of 1.3 mm

block.

(3) Terminal 10 and terminal 20 are not connected.

Input 13

Input 14

Input 15

Input 16

Common 2

100 VAC

Not connected.

If power supplies of different phases are connected, overheating or fire may

occur.

2

(AWG16) to 0.5mm2 (AWG20) to connect to the terminal

3-4

Page 35

Color code (pink)

3.1 Digital Input Module specifications

4) External Appearance

Module description (120DAI54300)

LED area

Module mounting screw

(Use a M4 Phillips screwdriver.)

Field wiring terminal

(Use a M3 Phillips screwdriver.)

Removable terminal block

for field connections

Terminal block mounting screw

(Use a M3 Phillips screwdriver.)

Hinged terminal

cover

Signal label insert

3

LED Area

120 DIA 543 00

ACTIVE

1

2

3

4

5

6

7

8

F

9

10

11

12

13

14

15

16

LED Color Indication when ON

ACTIVE Green Processing I/O.

F Red Always not lit.

1 to 16 Green The corresponding LED is lit when

the input signal is ON.

3-5

Page 36

3 Digital I/O Specifications

3.1.2 200-VAC 16-point Input Module

3.1.2 200-VAC 16-point Input Module

1) Performance Specifications

Item Specifications

Name 200-VAC 16-point Input Module

Model Name AC200IN-16P

Model No. JAMSC-120DAI74300

Rated Voltage 200 VAC

Maximum Allowable Voltage 264 VAC

Rated Frequency 50/60 Hz

Allowable Frequency Range 47 to 63 Hz

Inrush Current 320 mA

Rated Current 7 mA (at 200 VAC, 50 Hz)

Input Impedance 28.6 kΩ (at 200 VAC, 50 Hz)

Standard Operating Ranges ON voltage range: 159 to 264 VAC