Page 1

INSTRUCTION MANUAL

FOR

Vacuum Controller

The 2nd Edition

The 2nd Edition

The 2nd EditionThe 2nd Edition

VR100

Yamato Scientific

Yamato Scientific Co

Yamato Scientific Yamato Scientific

2-1-6,

2-1-6, Nihonbashi Honcho, Chuo-

2-1-6, 2-1-6,

Congratulations on your selection of Yamato Scie ntific’s VR100!

Please read these operating instructions, user notes and the warranty card thoroughly before the

initial operatio n of your VR100. This will ensure proper operati ng procedures and extended life for the

unit. Please keep the operating instructions together with the warranty card for easy access

whenever you need them.

Nihonbashi Honcho, Chuo-ku

Nihonbashi Honcho, Chuo-Nihonbashi Honcho, ChuoTokyo 103-8432 JAPAN

Tokyo 103-8432 JAPAN

Tokyo 103-8432 JAPANTokyo 103-8432 JAPAN

Co...., Ltd.

, Ltd.

CoCo

, Ltd., Ltd.

ku

kuku

Page 2

TABLE OF CONTENTS

Explanation of Picture Display......................................................................................1

Cautions in Using with Safety.......................................................................................2

Notes to Users................................................................................................................3

Description and Function of Each Part.....................................................................................3

Requiremen ts for Installa tion....................................................................................................5

Handling Precautions ....................................................................................................9

Corrosive Resistance.............................................................................................................11

Operation ......................................................................................................................12

The Fixed Value Control.........................................................................................................13

Changing the Set point While the Fixed Value Control Operates............................................14

The Ramp Control..................................................................................................................15

The Free Mode ......................................................................................................................16

Shutdown...............................................................................................................................17

Restart...................................................................................................................................17

Shifting to Oth er Operation .....................................................................................................18

Using the Function Menu.............................................................................................19

Calibrating Measurements.....................................................................................................20

Editing the Set point of the Ramp control...............................................................................21

Error ..............................................................................................................................24

Maintenance..................................................................................................................25

Daily Inspection and Maintenance..........................................................................................25

Replacing Fuse......................................................................................................................26

After Service and Warranty..........................................................................................27

If a Service Call is required:...................................................................................................27

Troubleshooting .....................................................................................................................27

Specifications...............................................................................................................28

Wiring Diagram.............................................................................................................29

Replacement Parts Table.............................................................................................30

Reference......................................................................................................................31

Dangerous Substances..........................................................................................................31

Pressure Conversion..............................................................................................................32

Explanation of Character on the display.................................................................................32

Page 3

Explanation of Picture Display

MEANING OF ILLUSTRATED SYMBOLS

Illustrated Symbols

Various symbols are used in this safety manual in order to use the unit without

danger of injury and damage of the unit. A list of problems caused by ignoring the

warnings and improper handling is divided as shown below.Be sure that you

understand the warnings and cautions in this manual before operating the unit.

Warning

Caution

If the warning is ignored, there is the danger of a problem that may

cause a serious accident or even fatality.

If the caution is ignored, there is the danger of a problem that may

cause injury/damage to property or the unit itself.

Meaning of Symbols

This symbol indicates items that urge the warning (including the caution).

A detailed warning message is shown adjacent to the symbol.

This symbol indicates items that are strictly prohibited.

A detailed message is shown adjacent to the symbol with specific actions not to

perform.

This symbol indicates items that should be always performed.

A detailed message with instructions is shown adjacent to the symbol.

1

Page 4

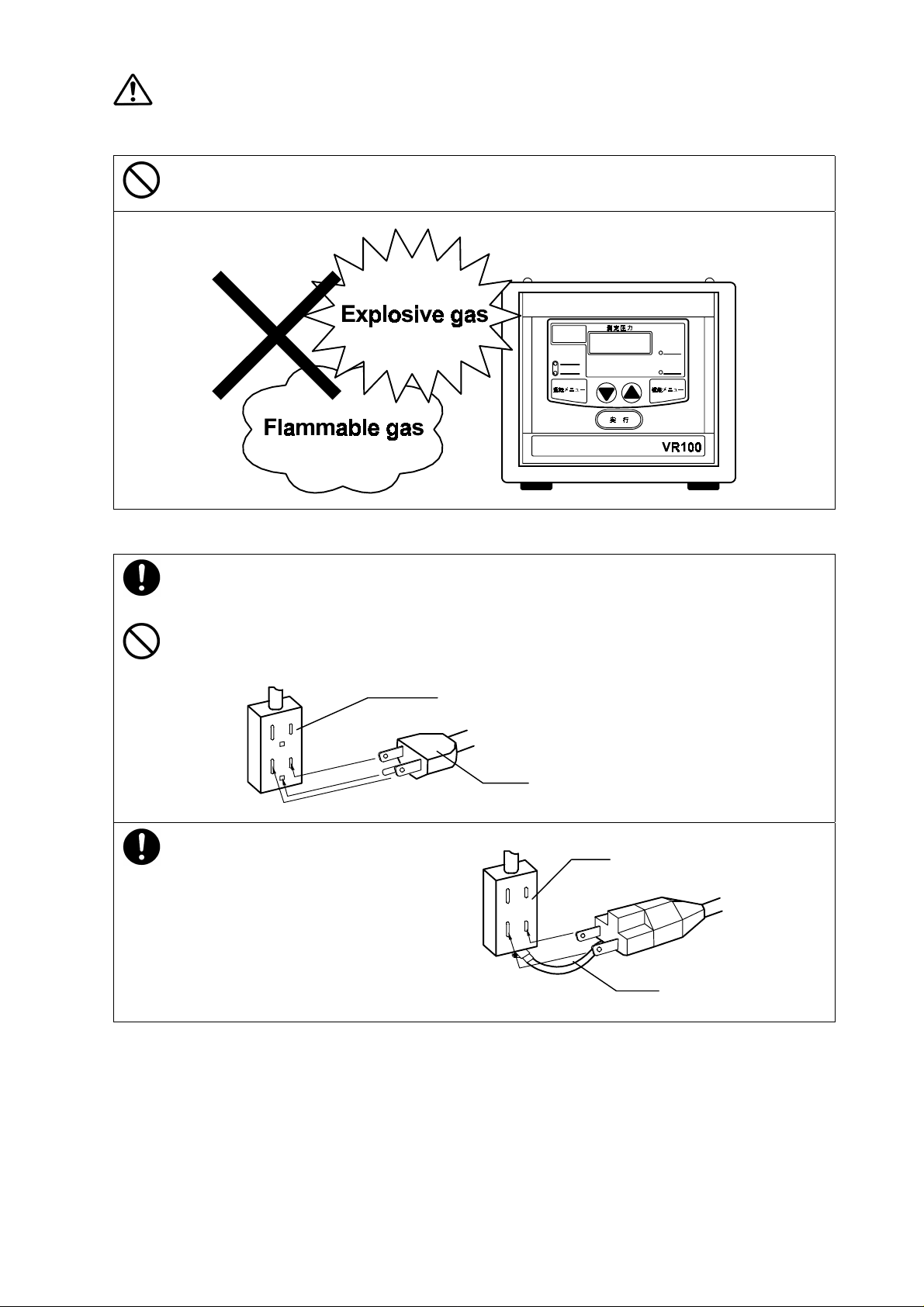

Cautions in Using with Safety

WARNING

Do not use the unit in an area where there is flammable or explosive gas.

••••

Never use the unit in an area where there is flammable or explosive gas.

The unit is not explosion-proof. An arc may be generated when the power switch is turned on or off, and

fire/explosion may result.

Always ground the unit.

••••

Always ground the unit on the power equipment side in order to avoid electrical shock due to a power surge.

If a problem occurs, you should:

••••

If smoke or strange odor should come out of the unit for some reason,

off

the circuit breaker and the main power. Immediately contact a service technician for inspection. If this

procedure is not followed, fire or electrical shock may resul t.

Never perform repair work yourself, since it is dangerous and not recommended.

Do not use the power cord if it is bundled or tangled.

••••

Do not use the power cord if it is bundled or tangled. If it is used in this manner, it can overheat and fire may be

caused.

turn off

the power key right away, then

turn

Do not process, bend, wring, or stretch the power cord forcibly.

••••

Do not process, bend, wring, or stretch the power cord forcibly. Fire or electrical shock may result.

Substances that can not be used.

••••

Never use explosive substances, flammable substances and substances that include explosive or flammable

ingredients in the unit. Explosion or fire may occur.

Do not disassemble or modify the unit.

••••

Do not reconfigure the unit. Fire or electrical shock may be caused.

CAUTION

During a thunder storm

••••

During a thunder storm,

If this procedure is not followed, fire or electrical shock may be caused.

turn off

the power key immediately, then

turn off

the circuit breaker and the main power.

2

Page 5

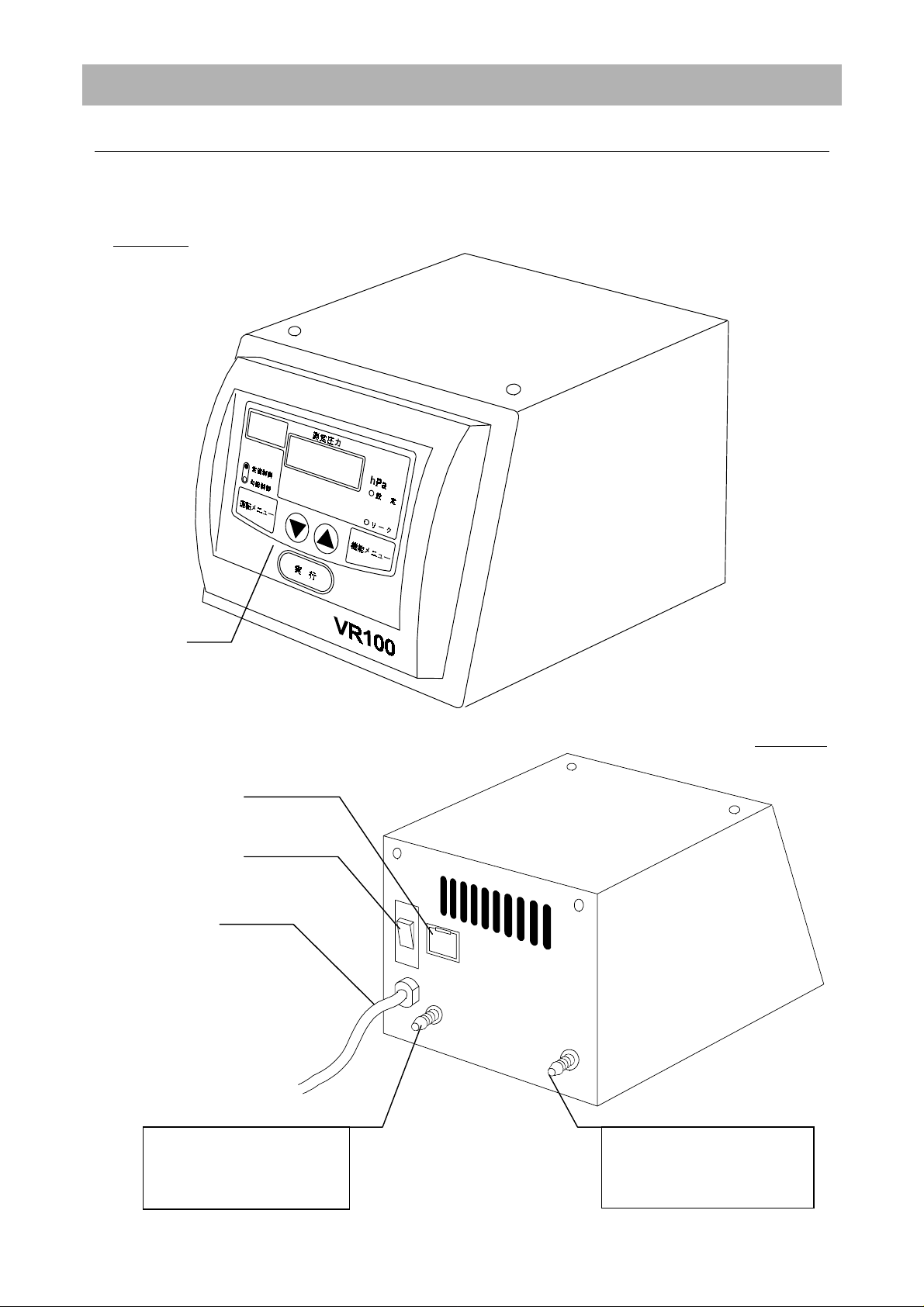

Main unit

Front view

Notes to Users

Description and Function of Each Part

Control panel

Power Switch

Power Cord

Rear view

Fuse Box

Connection for Evaporator

Port for Hose:

Outside Diameter 10mm,

Nominal Size 1/8 x 5/16

Connection for Aspirator

Port for Hose

Outside Diameter 10mm,

Nominal Size 1/8 x 5/16

3

Page 6

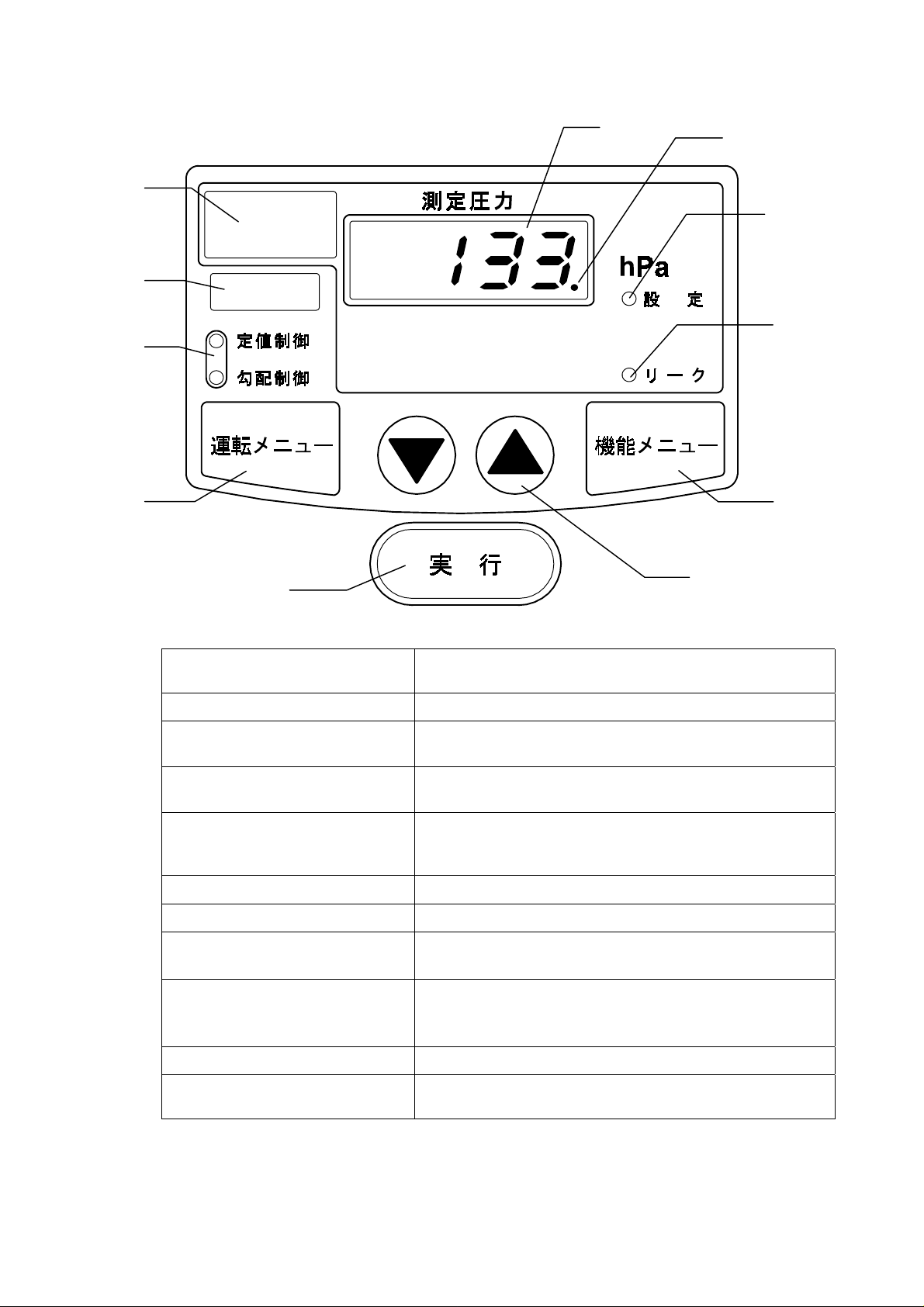

Control Panel

①

⑩

Main Display:

①

Solenoid Valve Lamp (LED):

②

Blind Window:

③

Edit Mode Display Lamp

④

(LED)

Operation Mode Display

⑤

Lamp

Set Mode Display Lamp

⑥

Leak Lamp

⑦

Operation Menu Key

⑧

Function Menu Key

⑨

Up/Down Key

⑩

Enter Key

⑪

Displays measureme nts, set points ( indicated as ~h Pa),

literal informations in the ramp control editing, etc.

Lit while the solenoid valve for control opens.

Indicates a blinking

abnormality occurred.

Lights up

selected.

indicates a selected operation mode. It is lit while

operation, and blinked in the set mode and the edit

mode. Nothing is indicated in the free mode.

lit when settings and edits are done.

lit while the leak valve opens.

used to select one of the following operations.「the fixed

value control」,「the ramp control」,「the free mode

used to select the function;「the measurement

calibrating mode」in the fixed value control and 「the

edit mode」 in the ramp control.

used to change the set point.

used to decide or input set points and modes, such as

operation, calibration, edit.

「編集」

「異常」

(Means

(Means

EDIT

TROUBLE

) when the edit mode is

) when an

」

4

Page 7

Requirements for Installation

Installation to Rotary Evaporator RE400/500/440/540

1. 2.

Unscrew the

screw which fix

the rubber-leg of

the body.

Rubber leg Metal Fixture

3. 4.

Fix the metal

fixture to the

rear of the

control unit with

four screws.

Control Unit of

RE400/500

Fix the metal

fixture

provided as

standard

accessories

with flat-head

screws.

Put the

power plug of

the vacuum

regulator in

the outlet at

the rear of

the control

unit.

5.

Finished View

Power Cord Plug

VR100

RE400/500/440/540

Being the auto lift style, the body-outlook of

RE440/540 is not the same as the drawing on the

left.

5

Page 8

Warn ing

Warning

WarningWarning

Do not use the unit in an area where there is flammable or explosive gas.

•

Never use the unit in an area where there is flammable or explosive gas. The unit is not explosion-

proof. An arc may be generated when the power switch is turned ON or OFF, and fire/explosion may

result.

Always ground the unit.

•

Connect VR100’s power plug to a receptacle with grounding connectors.

•

Do not forget to ground VR100, to protect you and the uni t from electr ical sho ck in cas e of pow er surge.

Choose a receptacle with grounding connectors as often as possible.

•

Do not connect the grounding wire to a gas pipe, or by means of a light ni ng ro d or t ele pho ne line. A fire

or electrical shock will occur.

•

If only bipolar receptacles are available for

VR100, connect an optional grounding

adapter to VR100’s power plug. Check

the polarity of the receptacle before

connecting the adapter to the receptacle.

Connect the adapter’s grounding wire

(green) to a grounding terminal to the

power supply. Contact our sales

representative in your vicinity or our service

center for additional information or

assistance.

100V receptacle with grounding terminals

Power plug

100V bipolar receptacle

Grounding wire

6

Page 9

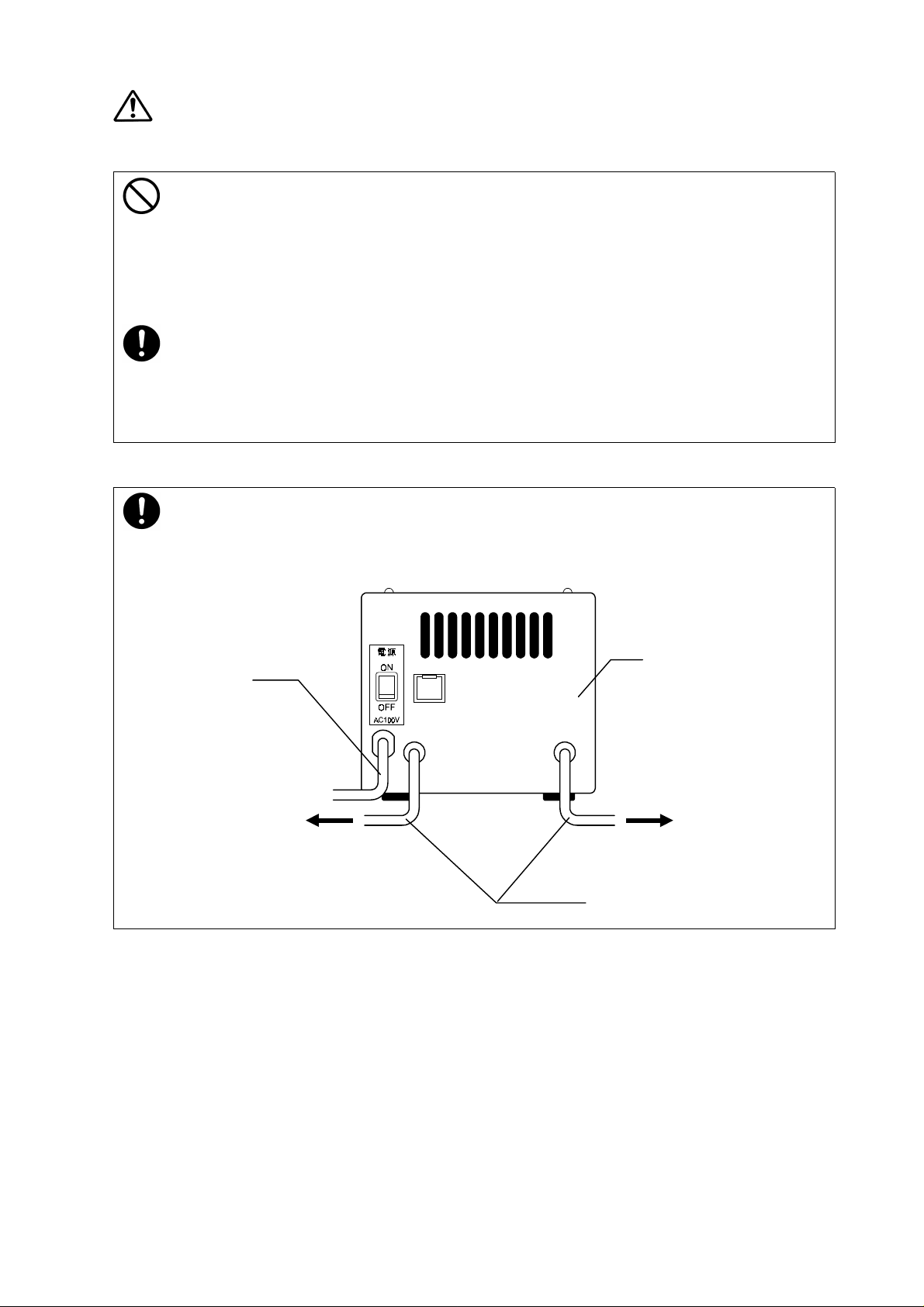

Choose a correct power distribution board or receptacle.

•

Choose a correct power distribution board or receptacle that meets VR100’s rated electric capacity.

Electric capacity : AC100 V, 1A

•

Do not connect VR100 to an outlet that differs from the above spe cif ic ations because a fire or electrical

shock will occur.

Install on a level area.

•

Do not installation VR100

on a non level surface.

This will cause hazards to

the operator and create

problems during actual

operation.

Choose a proper place for installation.

•

Do not install VR100 in a place where:

Flammable gas or corrosive gas is generated.

♦

Ambient temperature exceeds 35°C, also bellow 5°C.

♦

Ambient temperature fluctuates violently.

♦

There is direct sunlight.

♦

There is excessive humidity and dust.

♦

There is constant vibrations.

♦

•

Keep the clearance over 15cm around VR100.

7

Page 10

Caution

Caution

CautionCaution

Handling of power code.

•

Do not entangle the power cord. This will cause overheating and possibly a fire.

•

Do not bend or twist the power cord, or apply excessive tension to it. This may cause a fire and

electrical shock.

•

Do not lay the power cord under a desk or chair, and do not allow it to be pinched in order to prevent it

from being damaged and to avoid a fire or electrical shock.

•

Keep the power cord away from any heating equipment such as a room heater. The cord's insulation

may melt and cause a fire or electrical shock.

•

If the power cord becomes damaged (wiring exposed, breakage, etc.), immediately turn off the power

at the rear of the product and shut off the main supply power. Then contact your nearest dealer for

replacement of the power cord. Leaving it may cause a fire or electrical shock.

•

Connect the power plug to the outlet which is suppl ied appr opriate pow er and voltage . If the p ow er cord

is connected the supply which is also connected to a aspirator or a vacuum pomp etc., with no

sufficient power and voltage, the product may not operate properly because the power would fall.

Piping

•

Vacuum hoses (outside diameter 12 x inside diameter 6mm) are required. These are not included in

accessories.

•

Refer to figure below in order to pipe. Stickers that indicate where to connect are attached at the rear.

Connect the pipes correctly in accordance with each indication of them.

Power code

to condenser's

decompression

port of ROTARY

EVAPORATOR

The rear of the body

to suction port of

ASPIRATOR

Vacuum Hose

8

Page 11

Warn ing

Warning

WarningWarning

Approaching Thunderstorm

•

If a thunderstorm approaches in the distance, immediately turn off the power at the rear panel and shut

off the supply power. Leaving the power turned on may cause a fire or electrical shock.

During Power Failure

•

In case of power failure, the leak valve opens, the atmosphere in the system of the rotary evaporator is

released, and the solenoid valve for control is shut. It prevents spout of organic solvent in distillation,

and back-flow of water from the aspirator.

•

After power failure was repaired, the set mode is automatically switched to the fixed value control. The

indicator displays the set pressure blinking. The leak valve opens and the solenoid valve for control

shuts.

•

The product is not interlocked with neither the rotary evaporator nor bath. Care should be taken that

each movement of them is not the same after the power failure. If power failes wh ile the evaporator is

revolving, it starts revolving after power failure was repaired.

•

Make sure that the aspirator and the cold circulating device etc. is working properly when you start

the vacuum control again.

Handling Precautions

Aspirator Shutdown

•

The device must be stoppe d be fore y o u st op the aspirator. If not,ba ck- f low ,from the aspirator's bath to

the pressure senser,may occur.In case of back-flow, the indicator may not display accurate values,or

the sensor may be damaged.

Using the Product

•

The product is not a pressure measurement apparatus. Do not use it for calibration.

•

There are not functions for vacuum and pressure raising in the product itself. The product is used to

control the pressure in the system. The operation runs in order to reach to the pressure which is set

depending on the rise of pressure, by connecting to a decompression device of aspirator etc. The rise

of pressure (depending on the steam pressure of sample) is that occurs when the rotary evaporator

operates distillations.

Corrosive Samples

•

The product's connections to gas are made of materials given in Table 1. Especially metal piping parts

and gas-joint for pressure sensor are corroded by strong acids and strong alkalines. Do not use the

product for distillation of strong acids and strong alkalines.

•

As the product's gas-joints are exposed to low-concentrated steam that can not be trapped by the

condenser (cooler),the joints are not corroded soon. However a sort of rubber might swell depending

on the kind of solvent or frequency of use. If pressure in the system is not held,or,an abnormality is

shown the indicator ,please contact us.

•

Make sure that vacuum hoses are connected correctly ,to 「pressure」 and to「load」.

9

Page 12

Caution

Caution

CautionCaution

Do not lay down the product.

•

Do not lay down the product. It may cause troubles.

Do not put anything on the product.

•

Do not put anything on the product. It may fall and cause an injury.

10

Page 13

Corrosive Resistance

TABLE:

Corrosive resistance of the parts connected to gas

Methyl alcohol

Ethyl alcohol

Isopropanol

Methyl chloride

Chloroform

Aceton

Methyl ethyl ketone

Benzene

Toluene

FPM: Fluoro Rubber, PTFE: Teflon

Part

Pressure

sensor

Silicon

ceramic

nickel

Solenoid valve Solenoid valve armature

Material

Brass

(body)

FPM

(O-Ring)

FPM

(sheet)

SUS

(body)

Piping

tube

PTFE Brass

Joint

○○××○○○

○○○○○○○

○○○○○○○

×○○○○○○

×○○○○○○

△○××○○○

△○××○○○

×○○○○○○

×○○○○○○

Ethyl acetate

Hydrochloric acid

(20℃ under5%)

Hydrochloric acid

(20℃ over5%)

Sulphuric acid

(20℃ under5%)

Sulphuric acid

(20℃ over5%)

Sodium hydroxide

(20℃ under10%)

△○××○○○

××○○△○×

××○○×○×

××○○△○×

××○○×○×

××○○○○×

○

:suitable for use, △ :not recommended, × :unsuited

NOTE 1

The corrosion resistance above shows the case when samples are immersed in solvent or the

like. Since the product's gas-joints are exposed to low-concentrated steam that can not be

trapped by the condenser(cooler), the joints are not corroded soon. However some sort of

rubber might swell depending on the kind of solvent, or, frequency of use. If pressure in the

system is not held or an abnormality is shown, please contact us.

NOTE 2

Since the pressure detection circuit which is constructed in the pressure sensor is exposed,

care should be taken to see that no liquid touch it. If the aspirator is shutdown without

leaking the vacuum, it may cause a back-flow and sensor parts may be damaged by water

from the aspirator's bath.

11

Page 14

Operation

There are three modes, the fixed value control, the ramp control, free mode (controlfree), as a series in the operation menu.

In the fixed value control mode, step-control runs, aiming at the pressure set point which is

selected freely .

In the ramp control mode, the ramp control runs, aiming at the preset ramp level in the fixed

ramp time.

I n the free mode, the pressure control is cancelled and the solenoid valve is kept opening.

In any control mode, the operation stops after pressing ENTER again. In this case, the

solenoid valve for control is closed and the leak valve is opened.

Shifting to other control mode during operation is accepted in four cases;「the fixed value

control

the free mode」. To shift the mode, press OPERATION MENU. The selecting mode

→

appears on the indicator, showing a feasible control(depending on what operation is

running). Pressing OPERATION MENU makes control modes scroll. Select the control mode

you desired and press ENTER. The present operation continues unless ENTER, which is

used to decide the control mode, is pressed.

the free mode」 「the ramp control→ the fixed value control」 「the ramp control

←→

After turning the power on, the fixed control mode is automatically selected. Everytime

OPERATION MENU is pressed, the modes, the ramp control m ode, t he free mode, the fixed

value control mode, shift and scroll in order.

The operation menu is accepted either before or during operation. If the control menu key

was pressed during operation, the control mode which is placed next to the present mode is

selected. Press ENTER, which is used to decide the control mode, and the operation is shift.

It is possible to stop shifting the operation mode, if it is done on the verge of p ressing ENTER.

Press OPERATUON MENU and select the present operation mode again, or leave it. All

function selecting and set point editing, which have been done during selecting the operation

mode in the function menu,are cancelled.

If there is no key operation for ten seconds after pressing OPERATI ON MENU, the display

returns to the original state.

12

Page 15

1

2

The Fixed Value Control

Display After Operation Key Explanation

•

Turn the power on.

•

After turning the power on, the fixed

value control set mode is

automatically selected. The previous

pressure set point appears blinking

on the indicator.

•

Set at 133hPa in the exam ple on the

left.

•

The fixed value control lamp appears

blinking.

•

The set lamp is on, indicating that the

set mode is ready for operation.

•

The leak lamp is on since the leak

valve opens.

•

The solenoid valve for control closes.

3

4

▼▲

▼▲

▼▲▼▲

ENTER

•

Press

•

Press ENTER and the pressure set

•

The set mode ends so that the set

「▲」or「▼」

pressure set point you desired.

Changed to 60hPa in the example.

point is decided then the fixed value

control starts. The present pressure

measurement is displayed, then the

fixed value control lamp is on but stop

blinking.

lamp turns off. The solenoid valve for

control lamp is on. After the pressure

was reached to the aimed set point,

the solenoid valve opens or close

according to the fluctuations of the

pressure, the fixed value control

continues.

and change to the

13

Page 16

1

Changing the Set point While the Fixed Value Control Operates

Display After Operation Key Explanation

•

The fixed value control is running.

2

3

4

▼▲

▼▲

▼▲▼▲

▼▲

▼▲

▼▲▼▲

ENTER

•

Press

•

The fixed value control lamp is on.

•

The set mode lamp is on, indicating

•

Press

•

Changed to 60hPa in the example.

•

At this stage, the present control is

•

Press ENTER and the fixed value

•

The present pressure measurement

•

The set mode ends so that the set

•

In the example, the solenoid valve

•

After the pressure was reached to the

「▲」or「▼」

pressure values appears blinking on

the indicator. Changed to 200hPa in

the example on the left.

that the set mode is ready for

operation.

「▲」or「▼」

pressure value you desired .

still running.

control (step-control)starts,aiming at

the new-set point you have set.

appears on the indicator. The fixed

value control lamp is on, but stop

blinking.

lamp is off.

lamp is on, since the pressure set

point was lowered and the solenoid

valve for control opened.

aimed set point, the solenoid valve

for control opens or closes according

to the fluctuations of the pressure.

The fixed value control continues.

. The previous set

and change to the

14

Page 17

1

2

3

The Ramp Control

Display After Operation Key Explanation

•

Turn the power on.

•

After turning the power on, the fixed

value control set mode is

automatically selected. The previous

pressure set point appears blinking

on the indicator.

•

Set at 133hPa in the exam ple on the

left.

•

The fixed value control lamp appears

blinking on the indicator.

•

The set mode lamp is on, indicating

that the set mode is ready for

operation.

•

OPERATION

MENU

Press OPERATION MENU to select

the ramp control mode. Then the

previous 「Ramp Level」 and 「Ramp

Time」 appears alternately blinking

on the indicator.

•

The ramp control lamp blinks on the

operation mode indicator.

•

The set mode lamp is on, indicating

that the set mode is ready for

operation.

•

Refer to 「Editing the Set point of the

Ramp Control」 (p.20),when you

change 「Ramp Level」 and 「Ramp

Time」.

4

ENTER

15

•

Press ENTER and 「Ramp Level

and 「Ramp Time」 are decided.

Then the ramp control starts. The

present pressure measurement

appears on the indicator.

•

The ramp control lamp is on, but stop

blinking.

•

The set mode ends and the set lamp

is off, The solenoid valve opens and

the solenoid valve lamp is on.

•

Until the pressure is reached to the

aimed set point, the solenoid valve

for control opens or closes according

to the ramp time. The ramp control

continues.

」

Page 18

1

2

3

The Free Mode

Display After Operation Key Explanation

•

Turn the power on.

•

After turning the power on, the fixed

value control set mode is

automatically selected. The previous

pressure set point appears blinking

on the indicator.

•

Set at 133hPa in the exam ple on the

left.

•

The fixed value control lamp appears

blinking.

•

The set mode lamp is on, indicating

that the set mode is ready for

operation.

•

OPERATION

MENU

Press OPERATION MENU twice to

select the free mode.「FrEE」appears

blinking on the indicator.

•

All operation mode lamp is off,

indicating that the control is

cancelled.

•

The set mode lamp is also off.

4

ENTER

•

Press ENTER and the present

pressure measurement appears.

•

The solenoid valve for control opens

so that the solenoid valve lamp is on.

•

The solenoid valve for control is kept

opening unless ENTER is pressed

again or the power is turned off.

16

Page 19

1

2

Display After Operation Key Explanation

•

The fixed value control is running.

•

ENTER

Press ENTER while operation runs,

and an operation stops at that point.

•

Present pressre measurement and

「

StoP」appear alternately blinking

on the indicator.

•

All operation mode lamp is off and the

leak lamp is on, indicating that it is

opening.

•

The solenoid valve for control closes

and the leak valve opens.

Shutdown

1

2

Display After Operation Key Explanation

•

Stop

•

ENTER

When operation stopped, press

ENTER again. Returned to the

previous mode, which was set just

before shutdown, the operation

restarts in order to achieve the

previous set point. The present

pressure measurement appears. The

operation mode lamp is on, indicating

that the operation which was stoppe d

is now running as before.

•

The leak valve closes and the

solenoid valve for control opens at

this stage.

Restart

17

Page 20

1

2

Shifting to Other Operation

Display After Operation Key Explanation

•

The ramp control is running.

•

OPERATION

MENU

Press OPERATION MENU while the

operation runs, and the selecting

mode appears on the indicator,

showing a feasible controls

(depending on what operation is

running). The control modes are

scrolled by OPERATION MENU.

•

The ramp control is shifted to the

fixed value control or the free mode. It

is shifted to the fixed value control

mode in the example on the left.

Select the control mode you desired

and press ENTER to shift. The

present operations continues unless

ENTER, which is used to decide the

control mode,is pressed. Thus, the

lamp of the present operation mode

is on,at the same time,the next-mode

lamp blinks at this stage.

3

ENTER

•

Select the control mode you desired

and press ENTER. Then the control

is shifted.

•

The lamp of the mode which was

selected newly turned on, and the

privious-mode lamp is off.

18

Page 21

Using the Function Menu

T h e function menu is accepted either before or during operations.

The measurement calibrating system is programmed in the function menues of the fixed

value control mode and of the free mode. The calibration mode is accepted before a control

starts,or,while a control operates.

There are 「Ramp time edi t」and 「Pressure ramp lev el ed it」system in the ramp control as

a series.

When FUNCTION MENU is pressed again, just before ENTER is pressed to decide values;

Function selectings and set point editings, which has been done in the function menu,are

☆

stopped.

Operat ions, which has been running untill FUNCTION MENU was pressed, are returned.

☆

The set point which was decided during editing is restored.

If there is no key operations for ten seconds after FUNCTION MENU was pressed, the

indication is returned to the original state.

19

Page 22

Calibrating Measurements

This function is used to calibrate the deviation which is occurred between the displayed-

measurement of the product and the reading of calibrated vacuum gage you have(e.g.

manometer).The calibrated informations relate to the ramp control mode.

It is programmed in the function menu of the fixed value control mode and of the free mode.

The calibration mode is accepted either before or during operations.

The following shows the proce d ure for calibrating while the fixed value control o per ates.

Display After Operation Key Explanation

•

1

2

FUNCTION

MENU

The fixed value control is running.

•

The present pressure measurement

appears on the indicator. The fixed

value control lamp is on.

•

Press 「FUNCTION MENU」and

「

cAL」appears blinking on the

indicator,showing that the pressure

measurement calibration mode was

shifted.

•

The operation continues and the

operation lamp is still on.

3

4

5

ENTER

▼▲

▼▲

▼▲▼▲

ENTER

•

Press ENTER and the present

pressure measurement appears

blinking on the indicator.

•

The operation is still running.

•

Change to the calibration value you

desired by pressing

Changed to 60hPa in the example.

•

The operation is still running.

•

Press ENTER and the calibration

value is decided. The pressure

measurement appears on the

indicator again.

•

At this stage, the suitable operation is

continued by the controller. Because

deviations occur between the

pressure set point and the pressure

measurement during calibrations.

「▲」or「▼」

.

20

Page 23

Editing the Set point of the Ramp control

The set point of the ramp control can be edited either before operations (the power is

on) or during operations.

Editing the Set point Before Operation

Display After Operation Key Explanation

•

1

OPERATION

MENU

Press OPERATION MENU and

select the ramp control.

•

The ramp control was selected, the

previous 「Ramp Level」 and 「Ramp

Time」 alternately appear blinking on

the indicator.

•

The ramp control lamp is turned on.

•

The set point lamp is turned on,

indicating that the setting mode is

ready for operation.

2

3

4

FUNCTION

MENU

▼▲

▼▲

▼▲▼▲

•

The 「Ramp Time」-edit mode starts

by pressing FUNCTION before or

during the operation. 「rt.」 appears

blinking on the indicator.

•

「Edit」 LED turns on, indicat ing that

the edit mode starts.

•

Three seconds later, the previous

ramp time appears blinking on the

indicator, showing that you can

change values. The ramp time is set

at 20min. in the example.

•

Press

the ramp time you desired. To

increase values, keep on pressing

「▲」

(the maximum:99hours 59 minutes),it

returns to 「00.00」 and starts

increasing again. To decrease

values, keep on pressing

values reached 「00.00」, it returns to

the maximum point and starts

decreasing again.

•

The ramp time is set at 10min.in the

example.

「▲」

. Once values reached 「99.59

or

「▼」

and change to

「▼」

. Once

」

21

Page 24

5

6

Display After Operation Key Explanation

•

ENTER

Press the Enter and the 「Ramp

Level」-edit mode starts. 「rL

appears blinking on the indicator.

•

Three seconds later, the previous

ramp level appears blinking on the

indicator, showing that you can

change values. The ramp level is set

at 500hPa in the example.

」

7

8

▼▲

▼▲

▼▲▼▲

ENTER

•

Press

the ramp level you desired. To

increase values, keep on pressing

「▲」

「

increasing. To decrease values, keep

on pressing

reached 「66hPa」, the minimum, it

stops decreasing.

•

The ramp level is set at 200hPa using

「▼」

•

Press ENTER and the changed set

point is restored. The edit mode

ends.

•

These new level and time alternately

appear blinking on the indicator.

•

「EDIT」 LED is off.

「▲」

. Once values reached

660hPa」 ,the maximum, it stops

in the example.

「▼」

or

「▼」

. Once values

and change to

22

Page 25

Editing the Setting Point During the Ramp Control

Display After Operation Key Explanation

1

2

FUNCTION

MENU

3

•

The ramp control is running.

•

Press FUNCTION MENU while the

ramp control is running, and the

RAMP TIME edit mode starts.「rt.

appears blinking on the indicator.

•

「EDIT」LED is on, indicating that the

edit mode starts.

•

Three seconds later, The previous

ramp time appears blinking,

indicating that you can change

values.

」

4

5

6

7

8

▼▲

▼▲

▼▲▼▲

ENTER

▼▲

▼▲

▼▲▼▲

ENTER

•

Press

•

Press ENTER, and the 「Ramp

•

Three seconds later, the previous

•

Press

•

Press ENTER, and the changed set

•

「EDIT」LED is off.

「▲」or「▼」

ramp time you desired. Refer to the

previous chapter 「EDITING THE

SET POINT BEFORE OPERATION

in order to input the time.

Level」 edit mode starts. 「rL.

appears blinking on the indicator.

ramp level appears blinking,

indicating that you can change the

values.

「▲」or「▼」

ramp level you desired. Refer to the

previous chapter in order to input

ramp level.

point is restored. The ramp control

continues, aiming at the pressure and

the time you have set.

, and change the

」

, and change the

」

23

Page 26

Error

The product features the detection function for breakages of the pressure sensor.

Er01」 appears blinking on the indicator(and two japanese

「

letters appear on the blind window) when breakages of the

pressure sensor occurred. The solenoid valve for control

shuts, the leak valve opens.

During Power Failure

In case of power failure, the leak valve opens, the atmosphere in the system of the rotary

evaporator is released, and the solenoid valve for control is shut. It prevents spout of organic

solvent in distillation, and back-flow of water from the aspirator.

After Power Failure

After power failure was repaired, the set mode is automatically switched to the fixed value

control. The indicator displays the set pressure blinking. The leak valve opens and the leak

lamp is on. The solenoid valve for control shuts. The fixed value control lamp blinks and the

set lamp is on.

•

Make sure that the cooling circulating dev ice or others are worki ng proper ly w hen the vacuum c ontrol i s

started again.

Caution

Caution

CautionCaution

The product is not interlocked with neither the rotary evaporator nor bath. Care should be

taken that each movement of them are not the same after the power failure. If power fa ils

while the evaporator is revolving, it starts to revolve after power failure was repaired.

24

Page 27

Daily Inspection and Maintenance

Warn ing

Warning

WarningWarning

Do not make modifications to this product.

•

Disassembly of the product is strictly prohibited. This may cause an electrical shock since there are

high-voltage circuits inside the product. Inspection, maintenance, or repair of the internal circuits and

mechanism should be inquired of the dealer or your nearest sales representative office.

•

Modification is strictly prohibited. This may cause a fire or electrical shock.

Maintenance

Caution

Caution

CautionCaution

Maintenance

•

Make sure that you turn off the power at the rear and shut off the supply power, before maintenance.

•

Use a soft, dump cloth to wipe off dirt from the resin moldings and operation panel. Do not clean the

product with volatile solvent such as thinner or benzen or cleanser, and do not rub it with a pot cleaner

or brush. This may cause a deformity, alteration, or discoloration.

Warn ing

Warning

WarningWarning

Long Storage and Disposal

Not Using For a Long Period

•

If you will not use the product for a long period, turn off the power switch and shut off the power supply

surely for safety.

Disposing

•

When you dispose the product, do not put the product where children are around.

For any q uestions, contact the dealer who you purchased the product from, or the nearest

sales division in our company.

25

Page 28

Replacing Fuse

1. Put an appropriate tool(e.g. a flathead screw driver) into a hole at the top of the fuse box on

the rear. Hold a lever inside with the tool and pull it.

Fuse Box

2. The fuse is removed with a fuse holder. Pull out the disconnected fuse from the fuse holder

and replace to new one.

3. Insert the fuse holder and push it lightly and the lever is locked.

Fuse Holder

Fuse Pipe

26

Page 29

After Service and Warranty

If a Service Call is Required:

If a Service Call is required Warranty Card (attached to your VR100)

lf a problem occurs with VR100, record the

error code on the display and stop the

operation immediately, turn off the power

switch, and disconnect the power plug from

the receptacle. Contact our sales or service

representative.

Check the warranty card or the name plate

of your VR100 and give us the information

below.

■

Name of the product;

■

Serial product number of the product;

■

Date of purchase;

■

Problem with the product

(as detailed as possible).

Please fill out completely and return the

bottom portion of the warranty card when the

unit is received. The completed top portion is

your Registration Card that should be

retained for your records.

Warranty period is one (1) year after the date

of your purchase. During this warranty

period, we will offer free repair service on the

basis of the conditions provided on the

warranty card.

If you need repair service after expiration of

the warranty period, contact our sales or

service representative in your vicinity or

service office for advice.

Minimum Inventory Period of Repair Parts

Repair parts will be available for at least 7

years after termination of our production of

VR100. Repair parts mean the parts that are

necessary to maintain the performance of

VR100.

Problem Confirm if…

The power turning on, the indicator of the

operation panel is not lit.

The pressure does not fall.

The pressure does not rise.

The decompression speed is slow.

The decompression starts after turning the

power on.

Troubleshooting

•

The power cord is surely connected to an outlet. (If a

rotary evaporator RE400/500/440/540 is installed,

check its power as well.)

•

The fuse is not disconnected.

•

There is not a power failure.

•

The decompression device is working.

•

The atmosphere is n ot e sc apin g fro m th e c ond ens er of

the rotary evaporator(for load).

•

The vacuum hose is surely conn ect ed.

•

Condensation and vaporizati on in th e condenser of the

rotary evaporator have not ended.

•

The hose for vacuum is connected.(The hose is not

crushed.)

•

Cooling operation is done in the conden ser of rot ary

evaporator

•

The vacuum hose is properly connected to the

evaporator, or,to the aspirator.

27

Page 30

Specifications

Model

Pressure Control Range(hPa):

Pressure Measurement/Display

Range(hPa):

Pressure Setting Range(hPa)

Grading Pressure

Setting Range(hPa):

Grading Time Setting Range

Measurement Calibration

Setting Range(hPa):

Pressure Control Method:

Pressure Setting Method:

Pressure (etc.) Indication

Method:

Setting/Displayed Pressu r e

Resolving Power (hPa):

Functions For Operation:

VR100

Reached pressure in the vacuum system ~ 800±5% Full scale

1~1013±5% Full scale

1~1013

66~600

1~99hrs.59min.

Measurement±5% Full scale

Feedback ON/OFF Control by Semiconductor Pressure Sensor

and Control Valve

Digital Setting by

(up/down) Key

▲▼

Measured Pressure, Set point (pressure, ramp time) are digitally

displayed on the indicator

1

Fixed Control Operation(Step-Control ranged1~800hPa), Ramp

Control Operation (ramp control ranged66~600hPa), Free Mode

Operation ( cancels operations. Depends on reached pressure

in the vacuum system)

Control Mode:

Auxiliary Functions:

Controller:

Pressure Sensor:

Solenoid Valve for Control:

Leak Valve:

Safety System:

Dimensions (WxDxH mm):

Power Supply:

Weight:

Accessories:

Optional Accessories:

Fixed Value Control, Ramp Control

Measured Pressure Calibrating Function(fixed value

control; accepted before or during the free mode), Ramp Control

Set point Edit Function

IV LE type Controller +PIO 4 I ndicator

Measurement Range;0~1030 hPa ±5% Full scale

AC100V normally clos e

AC100V normally open

Fuse (rating;AC250V 2A), Leak Function, Self-Diagnostics

Sensor (for disconnectioned sens or)

155x190x145(approximately)

AC100V 1A

3.5kg (approximately)

Metal Fixture, Screws, Fuse(1), Guarantee, Instruction Manual

None

28

Page 31

Wiring Diagram

29

Symbol Part Name

C Condenser

FFuse

S Power switch

P T e rminal table

MV1 Solenoid valve for control

(normally close)

MV2 solenoid valve for leak

(normally open)

Tr Power transformer

X Relay

PLANAR Control circuit board

PIO Displa y circ uit board

SE Pressure sensor board

SSR Solid-state relay

Page 32

Replacement Parts Table

Part Name Code No. Specifications manufacturer

Control Circuit Board IV LE Yamato Scientific

Display Circuit Board IV FR Yamato Scientific

Transformer 1-01-320-0005 IV FR AC100V Yam ato Scientific

TRIAC 1 Board 2-16-000-0010 YLT-SSR-01 Yam a t o Scientif ic

Sensor Placing Board Yam ato Scientific

Relay 2-05-000-0013 JR1aF-TM-DC6V Matsushita

Power Switch DS-850S-F-00 Miyama

Solenoid Valve

for Control

Leak Valve

Fuse

VX2122V-01-1G

NO type(SMC)

VX2122V-01-1G

NO type(SMC)

6.2x30 AC250V 2A Nagasawa

φ

SMC

SMC

30

Page 33

EXPLOSIVE

EXPLOSIVE:

FLAMMABLE

IGNITING:

Reference

Dangerous Substances

•

Ethylene glicol dinitrate (nitroglycol), glycerine trinitrate (nitroglycerine), cellulose

nitrarte (nitrocellulose), and other explosive nitrate esters

•

Trinitrobenzene, trintrotoluene, trinitrophenol (picric acid), and other explosive nitro

compounds

•

Acetyl hidroperoxide (peracetic acid), methyl ethyl ketone peroxide, benzoyl

peroxide, and other organic peroxides

•

Lithium (matal), potassium (metal), sodium (metal), yellow phosphorus, phosphorus

sulfide, red phosphorus, celluloid compounds, calcium carbide, lime phosphide,

magnesium(powder), aluminum(powder), powser of metals other than magnesium

and aluminum, sodium hydrosulfite

•

Potassium chlorate sodium chlorate, ammonium chlorate, and other chlorate

•

Potassium perchlorate, sodium perchlorate ammonium perchlorate, and other

perchlorate

OXIDIZING:

INFLAMMABLE

LIQUID:

FLAMMABLE

GAS:

(Source: Appendix Table 1 of Article 6 of the Industrial Safety and Health Order in Japan)

•

Potassium peroxide, sodium peroxide, barium peroxide, and other inorganic

peroxide

•

Potassium nitrate, sodium nitrate, ammonium nitrate, and other nitrate

•

Sodium chlorite and other chlorites

•

Calcium hypochlorite and other hypochlorites

•

Ethyl ether, gasoline, acetaldehyde, propylene chloride, carbon disulfide, and other

flammable substances having a flash point of -30℃ or higher but lower than 0

•

Normal hexane, ethylene oxide, acetone, benzenz, methyl ethyl ketone, and other

flammable substances having a flash point of -30℃ or higher but lower than 65

•

Methanol, ethanol, xylene, pentyl acetate(amyl acetate),and other flammable

substances having a flash point of 0℃ or higher but lower than 30

•

Kerosene, light oil(gas oil), oil of turpentine, isopentyl alcohol (isoamyl alcohol),

acetic acid, and other flammable substances having a flash point of 30℃ or higher

but lower than 65

•

Hydrogen, acetylene, ethylene, methane, propane, butane, and other flammable

substances which assume a gaseous state at 15℃ and 1 atm

℃

℃

℃

℃

31

Page 34

Refer to the Pressure Conversion Table below.

hPa Torr

1013 760

800 600

600 450

400 300

200 150

60 45

11

Explanation of Character on the Display

Pressure Conversion

(1Torr=1.33hPa)

7 segment LED is applied in the indicator of the product. The meanings of displays

are shown below.

Display Displayed Word Meanings

calibration Calibration mode of measurement

error ## Error No. (in the case of a abnormality)

free Free mode

ramp level Ramp level in ramp control

ramp time Ramp time in ramp control

stop Shutdown

32

Loading...

Loading...