p

Organic Solvent Recovery Unit

Model

RT200

Instruction Manual

- First Edition -

Thank you for purchasing "Organic Solvent

Recovery Unit, RT200" of Yamato Scientific Co.,

Ltd.

To use this unit properly, read this "Instruction

Manual" thoroughly before using this unit.

Keep this instruction manual around this unit for

referring at anytime.

WARNING!:

Carefully read and thoroughly understand the

ortant warning items described in this

im

Yamato Scientific Co. LTD.

Contents

Cautions in Using with Safety................................................................1

Explanation.................................................................................................................... 1

•

•

Table of Illustrated Symbols .......................................................................................... 2

Fundamental Matters of "WARNING!" and "CAUTION!"............................................... 3

•

Before Using This Unit ...........................................................................4

Requirements for Installation......................................................................................... 4

•

Description and Function of Each Part.................................................5

Main Unit .......................................................................................................................5

•

Installation ...............................................................................................6

Handling Precautions .............................................................................7

Maintenance Method...............................................................................7

Daily Inspection and Maintenance ................................................................................ 7

•

Long storage and disposal.....................................................................8

When not using this unit for long term / When disposing .............................................. 8

•

Trouble Shooting .....................................................................................8

After Service and Warranty ....................................................................9

Specification..........................................................................................10

Piping Diagram......................................................................................10

Replacement Parts Table......................................................................11

Reference...............................................................................................12

List of Dangerous Substances .................................................................................... 12

•

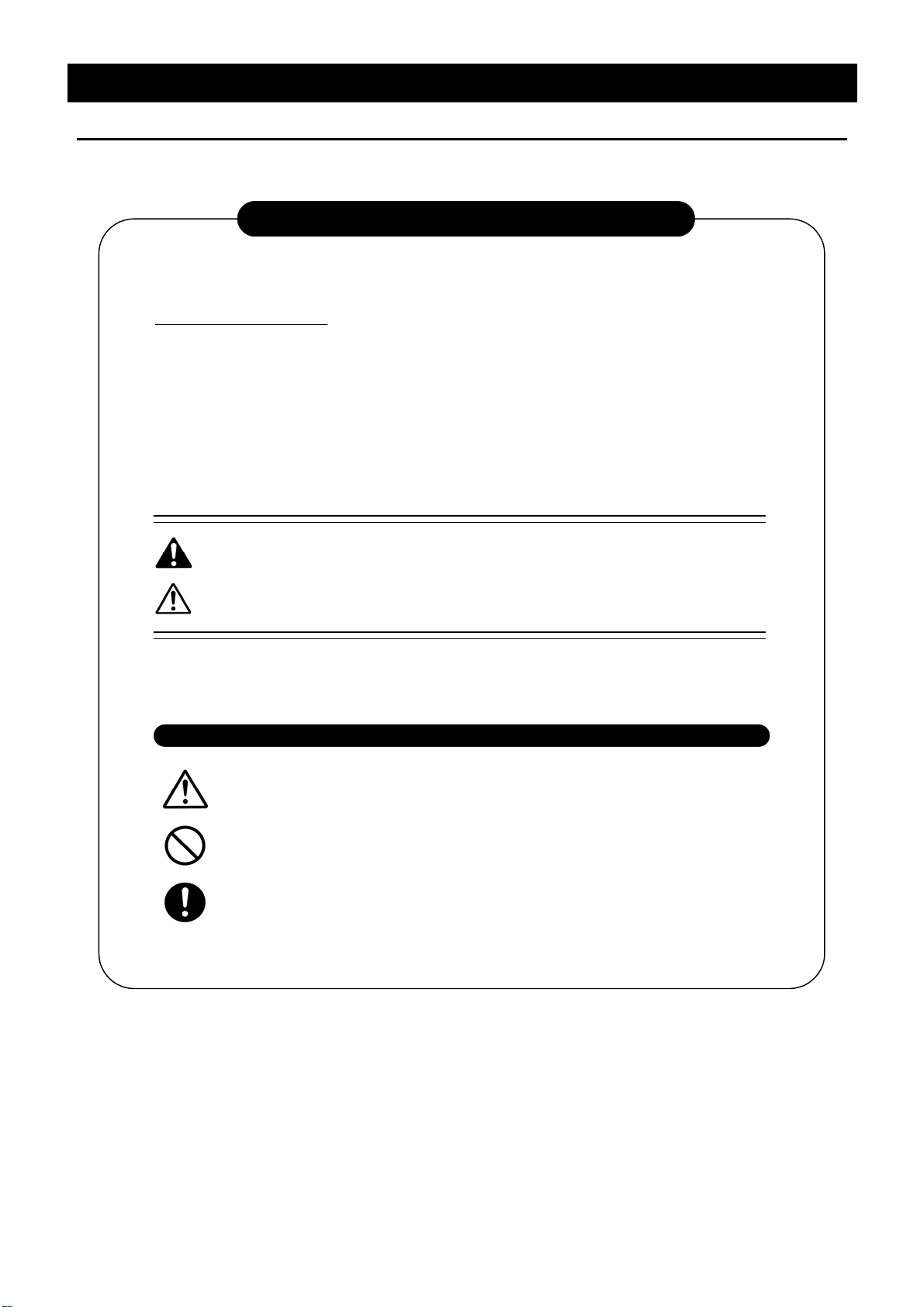

Explanation

Illustrated Symbols

Various symbols are used in this safety manual in order to use the unit without

danger of injury and damage of the unit. A list of problems caused by ignoring

the warnings and improper handling is divided as shown below.Be sure that you

understand the warnings and cautions in this manual before operating the unit.

Cautions in Using with Safety

MEANING OF ILLUSTRATED SYMBOLS

WARNING!

CAUTION!

If the warning is ignored, there is the danger of a problem that

may cause a serious accident or even fatality.

If the caution is ignored, there is the danger of a problem that may

cause injury/damage to property or the unit itself.

Meaning of Symbols

This symbol indicates items that urge the warning (including the caution).

A detailed warning message is shown adjacent to the symbol.

This symbol indicates items that are strictly prohibited.

A detailed message is shown adjacent to the symbol with specific actions not to

perform.

This symbol indicates items that should be always performed.

A detailed message with instructions is shown adjacent to the symbol.

1

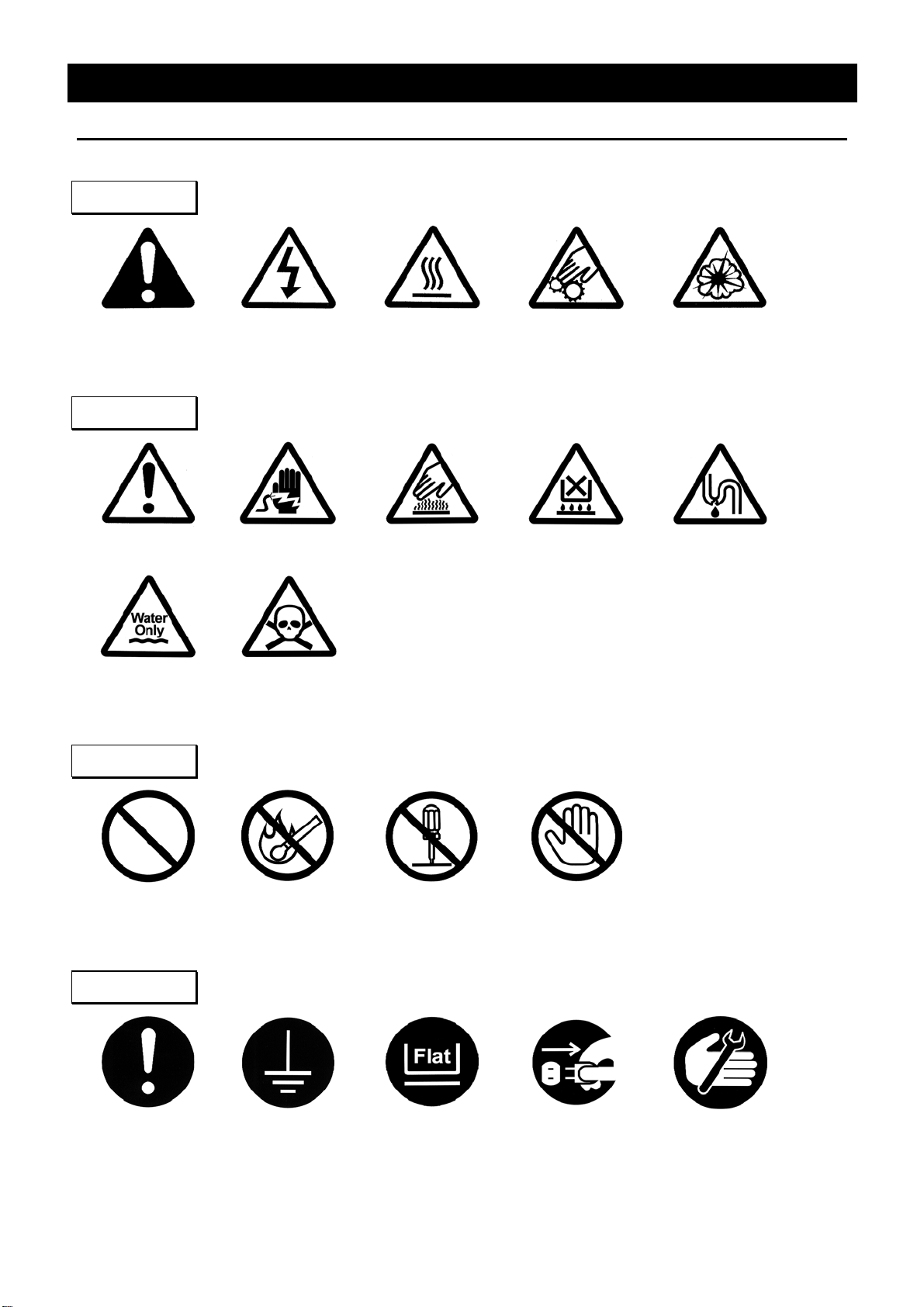

Table of Illustrated Symbols

Warning

Cautions in Using with Safety

Warning,

generally

Caution

Caution,

generally

Caution,

water only

Warning,

high voltage

Caution,

electrical shock

Caution,

deadly poison

Warning,

high temperature

Caution,

Warning,

drive train

Caution,

scald

no road heating

Warning,

explosive

Caution,

not to drench

Prohibit

Prohibit,

generally

Compulsion

Compulsion,

generally

inflammable

Compulsion,

connect to the

Prohibit,

grounding

terminal

to disassemble

Compulsion,

install on a flat

Prohibit,

surface

Prohibit,

to touch

Compulsion,

disconnect the

power plug

Compulsion,

periodical

inspection

2

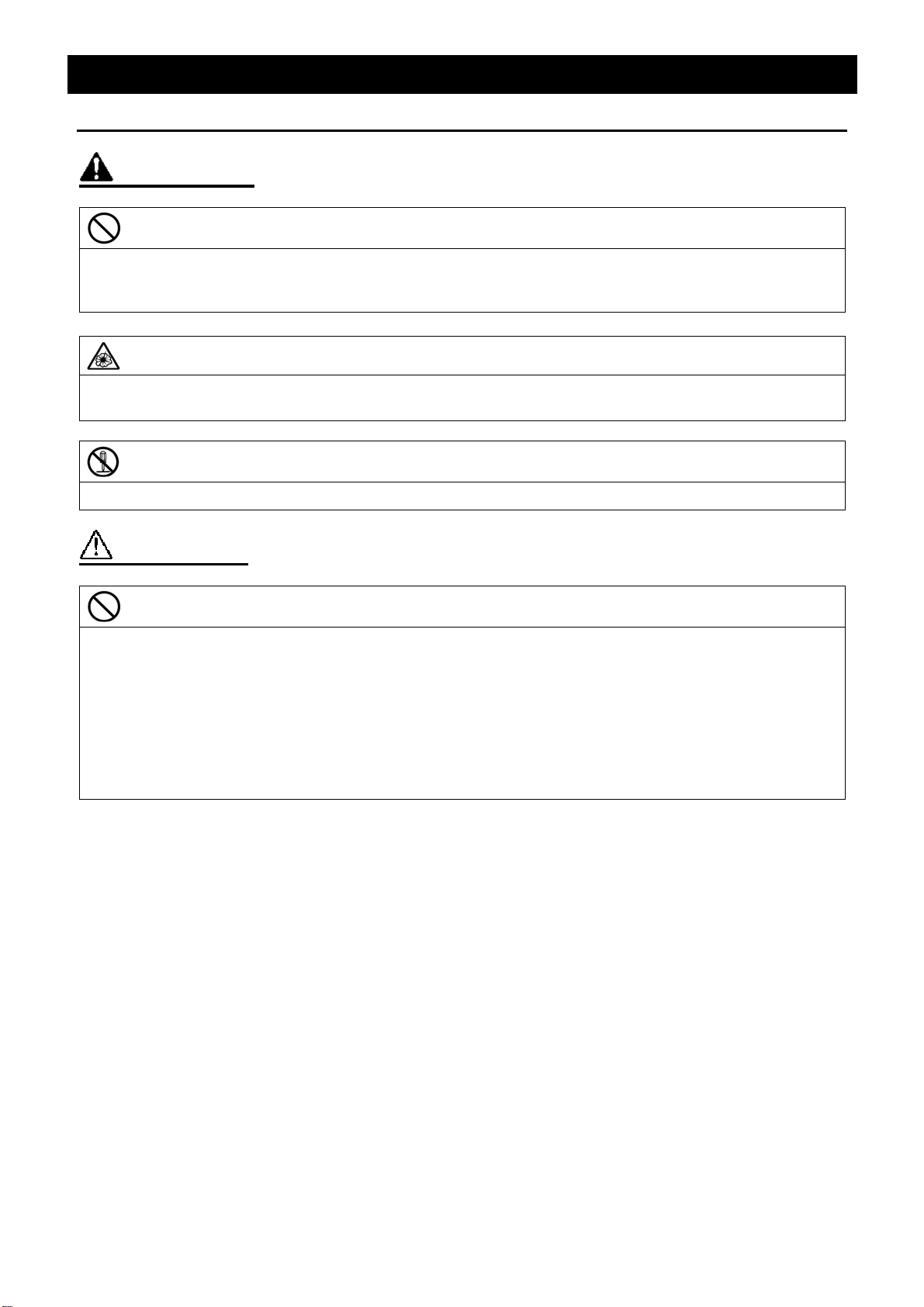

Cautions in Using with Safety

Fundamental Matters of "WARNING!" and "CAUTION!"

WARNING!

Do not use this unit in an area where there is flammable or explosive gas

Never use this unit in an area where there is flammable or explosive gas. This unit is not explosion-proof.

An arc may be generated when the power switch is turned on or off, and fire/explosion may result. (Refer to

page 12 "List of Dangerous Substances".)

Substances that can not be used

Never use explosive substances, flammable substances and substances that include explosive or flammable

ingredients in this unit. Explosion or fire may occur. (Refer to page 12 "List of Dangerous Substances".)

Do not disassemble or modify this unit

Do not disassemble or modify this unit. Fire or electrical shock or failure may be caused.

CAUTION!

Choose a proper place for installation

• Do not install this unit in a place where:

♦ Rough or dirty surface.

♦ Flammable gas or corrosive gas is generated.

♦ Ambient temperature above 35°C.

♦ Ambient temperature fluctuates violently.

♦ There is direct sunlight.

♦ There is excessive humidity and dust.

♦ There is a constant vibration.

♦ Without a ventilation system.

3

Requirements for Installation

Before Using This Unit

WARNING!

1. Do not use this unit in an area where there is flammable or explosive gas

/ Install exhauster and ventilator

• Never use this unit in an area

where there is flammable or

explosive gas.

• Place an exhauster, ventilator and

fire extinguisher near the

equipment because the toxic gas

may generat

Exhauster and ventilator

Extinguisher

2. Do not modify

• Modification of this unit is strictly prohibited.

This could cause a failure.

CAUTION!

3. Installation on horizontal surface

• Place this unit as flat a place as possible. If the

four rubber feet are not in uniform contact with

the floor surface, noise or vibration may result.

Additionally, the unit may cause a problem or

malfunction.

4. Before/after installing

• It may cause injure to a person if this unit falls down or moves by the earthquake and the

impact. etc..To prevent, take measures that the unit cannot fall down, and not install to busy

place.

Modification

4

Acr

Main Unit

Front view

Description and Function of Each Part

mini trap

RT200

Flask clamp

Solvent collecting flask

500mL

yl door

Rear view

Nipple connecting

to a cooling water hose

(inner diameter of hose: 9φ)

Nipple connecting

to a vacuum hose

(inner diameter of hose: 6φ)

5

This equipment is used to collect the solvent in the rotary evaporator.

Specifications for built-in condenser and flask

Condenser: Hard glass, Surface area of condenser

Flask: Hard glass, 500ml round flask

Installation method

The normal installation method is shown below.

A cooling water circulation system and vacuum pump are required in use in addition to the RE main

unit.

Connect the vacuum hose between the exhaust nozzle of vacuum pump and IN nipple on the

RT200, as shown in the figure. The end connection of exhaust piping and cooling water piping on

the RT200 model are placed on the back surface of main unit.

Exhaust IN

Installation

Connected to the nozzle

on the back surface of RT200

Vacuum pump

真空ポンプ

IN

OUT

To ventilation system

(such as a draft chamber)

Exhaust OUT

Cooling IN

Cooling OUT

Cooling water

circulation system

or tap water

IN

OUT

Location of nipple connecting with the hose

Cooling IN

Cooling OUT

6

Vacuum exhaust IN

Vacuum exhaust OUT

WARNING!

Substances that cannot be used

Never use explosive substances, flammable substances and substances that include explosive

or flammable ingredients in this unit. Explosion or fire may occur. (Refer to page 12 "List of

Dangerous Substances".)

If a problem occurs

If an abnormality such as strong odor of the solvent is found, please request a checkout of

equipment from selling office or sales office of Yamato Scientific. Co., Ltd. The fire disaster or

bombing may occur if the abnormality is left. Do not try to repair the equipment by yourselves

for your own safety.

Do not disassemble or modify this unit

Do not disassemble or modify this unit. Fire or electrical shock or failure may be caused.

Handling Precautions

Maintenance Method

Daily Inspection and Maintenance

For the safety use of this unit, please perform the daily inspection and maintenance without fail.

CAUTION!

• Wipe the dirt with soft cloth wrung out with mild detergent. Do not use benzene, thinner or

cleanser, or do not scrub it with a scrubbing brush. Deformation, deterioration or discoloration

may result in.

7

Long storage and disposal

When not using this unit for long term / When disposing

CAUTION!

When not using this unit for long term…

• Turn off the power and disconnect the power cord.

WARNING!

When disposing…

• Keep out of reach of children.

• Remove the residual solvent inside the equipment before disposing it. Consult with the

specialized disposal services when disposing the equipment.

Environmental protection should be considered

We request you to disassemble this unit as possible and recycle the reusable parts considering to the

environmental protection. The feature components of this unit and materials used are listed below.

Component Name Material

Exterior Parts

Outer and inner covering Steel printed coating, ABS resin

Door Acryl resin

Handle Zinc alloy chrome-plating

Main Parts

Condenser, Solvent collecting flask Hard glass

Nipple connecting to a hose Stainless steel and brass

Hose Silicon hose and rubber hose

Heat insulation material Expanded polyethylene, polypropylene and polyurethane

Sticker Resin material

Trouble Shooting

Phenomenon Check point

The equipment fails to collect the solvent.

Solvent odor

In the case if the error other than listed above occurred, turn off the power and disconnect the

power cord immediately. Contact the shop of your purchase or nearest Yamato Scientific Service

Office.

• The cooling water temperature is too high.

• Check if the vacuum pump is actuated.

• Check if the piping is correct.

8

After Service and Warranty

In Case of Request for Repair

If the failure occurs, stop the operation, turn OFF the power switch, and unplug the power plug.

Please contact the sales agency that this unit was purchased, or the Yamato Scientific's sales

office.

< Check following items before contact >

◆ Model Name of Product

◆ Production Number

◆ Purchase Date

◆ About Trouble (in detail as possible)

Minimum Retention Period of Performance Parts for Repair

The minimum retention period of performance parts for repair of this unit is 7 years after

discontinuance of this unit.

The "performance part for repair" is the part that is required to maintain this unit.

See the production plate attached to this unit.

9

Specification

Product name Organic solvent recovery unit

Model RT200

Condenser Hard glass

Solvent collecting flask 500mL hard glass

Outer covering Print coating finish made from cold rolling steel sheet

Door Acryl door

IN/OUT nipple connecting

to a cooling water hose

IN/OUT nipple connecting

to a vacuum water hose

Outer diameter: 9mm

Outer diameter: 6mm

Piping Diagram

Nipples on the back surface

Cooling IN

Cooling OUT

Vacuum exhaust IN

Vacuum exhaust OUT

Condenser

Solvent collecting flask

10

Replacement Parts Table

Part Name Code No. S pecification Manufacturer

Condenser LT00016059 Hard glass Yamato Scientific

Solvent collecting flask LT00016180 Hard glass Yamato Scientific

Flask clamp F0410005 KS35B (black) Yamato Scientific

11

List of Dangerous Substances

Never use explosive substances, flammable substances and substances that include explosive

or flammable ingredients in this unit.

EXPLOSIVE

Ethylene glycol dinitrate (nitro glycol), Glycerin trinitrate (nitroglycerine), Cellulose

nitrate (nitrocellulose), and other explosive nitrate esters

Reference

EXPLOSIVE:

FLAMMABLE

IGNITING:

OXIDIZING:

Trinitrobenzene, Trinitrotoluene, Trinitrophenol (picric acid), and other explosive

nitro compounds

Acetyl hidroperoxide (peracetic acid), Methyl ethyl ketone peroxide, Benzyl

peroxide, and other organic peroxides

Lithium (metal), Potassium (metal), Sodium (metal), Yellow phosphorus,

Phosphorus sulfide, Red phosphorus, Celluloid compounds, Calcium carbide,

Lime phosphate, Magnesium (powder), Aluminum (powder), Powder of metals

other than magnesium and aluminum, Sodium hydrosulfite

Potassium chlorate, Sodium chlorate, Ammonium chlorate, and other chlorate

Potassium perchlorate, Sodium perchlorate, Ammonium perchlorate, and other

perchlorate

Potassium peroxide, Sodium peroxide, Barium peroxide, and other inorganic

peroxide

Potassium nitrate, Sodium nitrate, Ammonium nitrate, and other nitrate

Sodium chlorite and other chlorites

Calcium hypochlorite and other hypochlorites

Ethyl ether, Gasoline, Acetaldehyde, Propylene chloride, Carbon disulfide, and

other flammable substances having a flash point of lower than -30℃

INFLAMMABLE

LIQUID:

FLAMMABLE

GAS:

Normal hexane, ethylene oxide, acetone, benzene, methyl ethyl ketone, and

other flammable substances having a flash point of -30℃ or higher but lower

than 0℃

Methanol, Ethanol, Xylene, Pentyl acetate (amyl acetate), and other flammable

substances having a flash point of 0℃ or higher but lower than 30℃

Kerosene, Light oil (gas oil), Oil of turpentine, Isopentyl alcohol (isoamyl alcohol),

Acetic acid, and other flammable substances having a flash point of 30℃ or

higher but lower than 65℃

Hydrogen, Acetylene, Ethylene, Methane, Propane, Butane, and other flammable

substances which assume a gaseous state at 15℃ and 1 atm

(Source: Appendix Table 1 of Article 6 of the Industrial Safety and Health Order in Japan)

12

Responsibility

Please follow the instructions in this document when using this unit. Yamato Scientific has no

responsibility for the accidents or breakdown of device if it is used with a failure to comply.

Never conduct what this document forbids. Unexpected accidents or breakdown may result in.

Note

◆ The contents of this document may be changed in future without notice.

◆ Any books with missing pages or disorderly binding may be replaced.

Instruction Manual for

Organic Solvent Recovery Unit

Model RT200

First Edition Feb. 09, 2006

13

Yamato Scientific Co., Ltd.

2-1-6 Nihonbashi Honcho, Chuo-ku,

Tokyo, 103-8432, Japan

http://www.yamato-net.co.jp

Loading...

Loading...