Low Temperature Incubator

Model

IJ 100

Instruction Manual

- First Edition -

Thank you for purchasing " Low Temperature

Incubator, IJ100 " of Yamato Scientific Co.,

Ltd.

To use this unit properly, read this "Instruction

Manual" thoroughly before using this unit.

Keep this instruction manual around this unit

for referring at anytime.

WARNING!:

Carefully read and thoroughly understand the

important warning items described in this

manual before using this unit.

Yamato Scientific Co. LTD.

Contents

Cautions in Using with Safety...............................................................1

•

Explanation..................................................................................................................1

•

Table of Illustrated Symbols.........................................................................................2

Fundamental Matters of “WARNING!” and “CAUTION!”...............................................3

•

Before Using this unit............................................................................4

•

Requirements for Installation........................................................................................4

Change the Direction of Opening/Closing Door............................................................7

•

Description and Function of Each Part.................................................8

•

Main Unit......................................................................................................................8

•

Control Panel...............................................................................................................9

Operation Method.................................................................................10

•

Sequence of Operation..............................................................................................10

Independent overheating prevention device...............................................................12

•

Handling Precautions ..........................................................................13

Maintenance Method............................................................................16

•

Daily Inspection and Maintenance .............................................................................16

Setting Air Jacket (Optional accesso ry).............................................17

Long storage and disposal..................................................................18

•

When not using this unit for long term / When disposing............................................18

In the Event of Failure…......................................................................19

•

Safety Device and Error Code....................................................................................19

Trouble Shooting........................................................................................................19

•

After Service and Warranty..................................................................20

Specification.........................................................................................21

Wiring Diagram.....................................................................................22

Replacement Parts Table.....................................................................23

Reference..............................................................................................24

•

List of Dangerous Substances ...................................................................................24

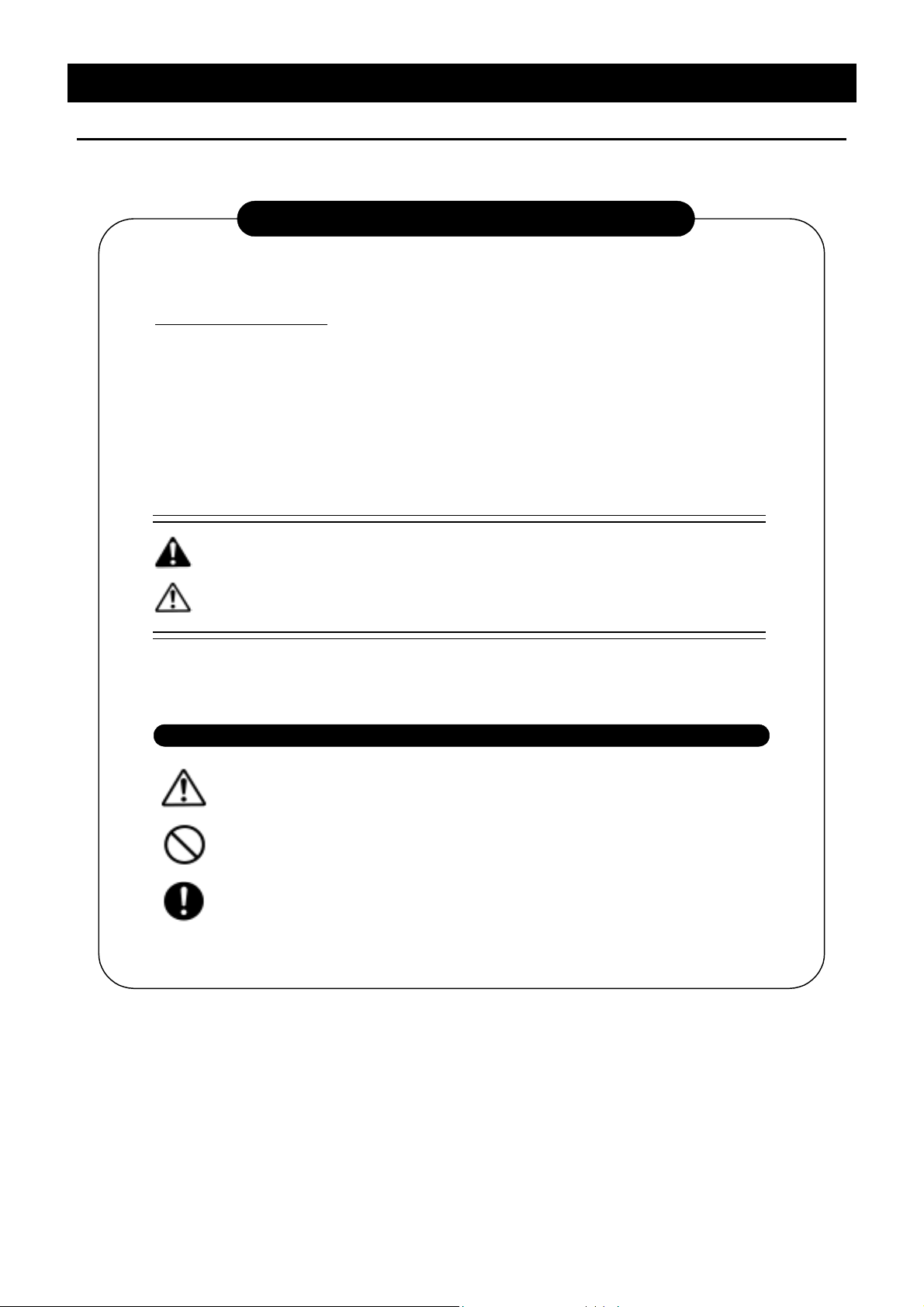

Explanation

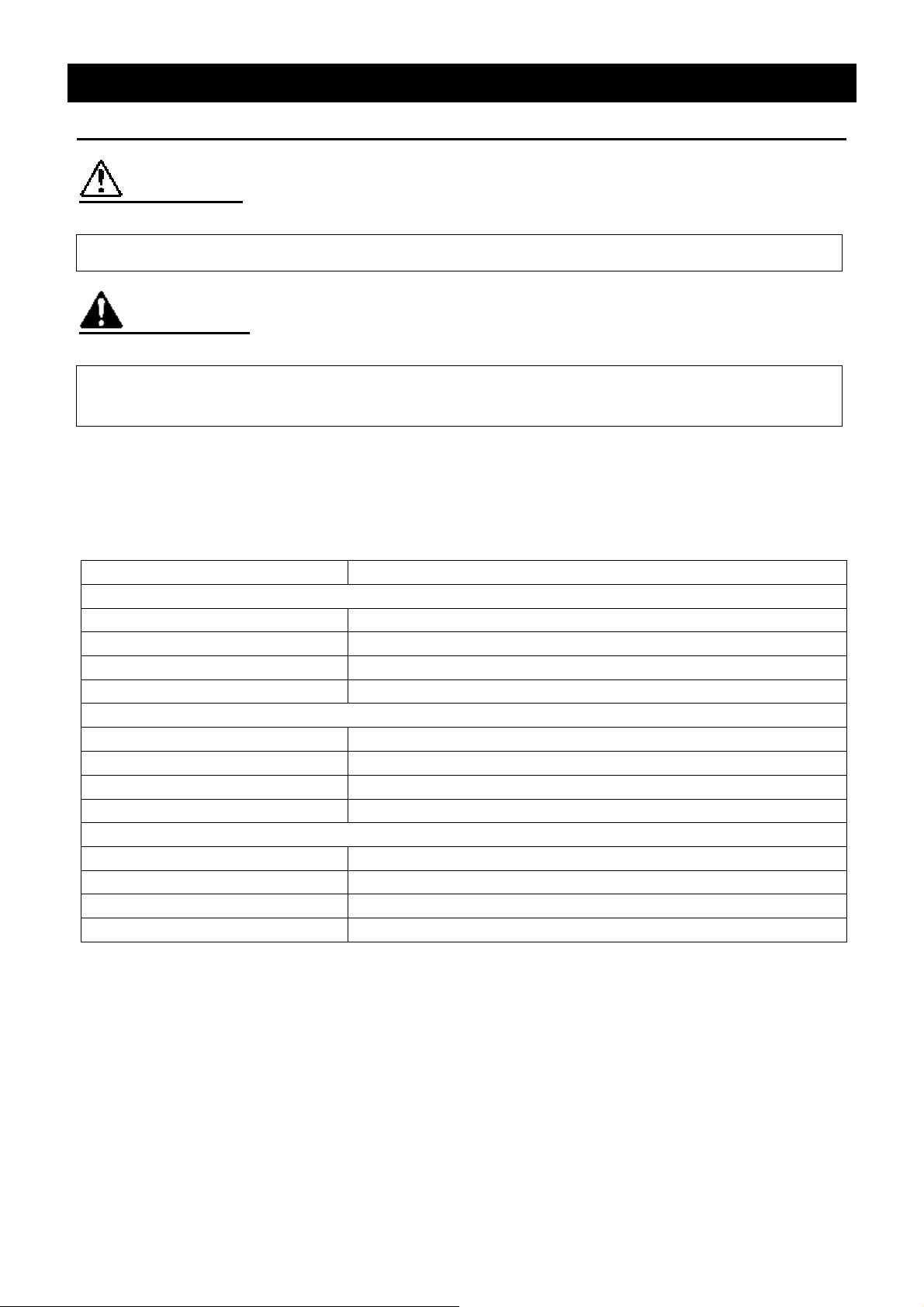

Illustrated Symbols

Various symbols are used in this safety manual in order to use the unit without

danger of injury and damage of the unit. A list of problems caused by ignoring

the warnings and improper handling is divided as shown below.Be sure that you

understand the warnings and cautions in this manual before operating the unit.

Cautions in Using with Safety

MEANING OF ILLUSTRATED SYMBOLS

WARNING!

CAUTION!

If the warning is ignored, there is the danger of a problem that

may cause a serious accident or even fatality.

If the caution is ignored, there is the danger of a problem that may

cause injury/damage to property or the unit itself.

Meaning of Symbols

This symbol indicates items that urge the warning (including the caution).

A detailed warning message is shown adjacent to the symbol.

This symbol indicates items that are strictly prohibited.

A detailed message is shown adjacent to the symbol with specific actions not to

perform.

This symbol indicates items that should be always performed.

A detailed message with instructions is shown adjacent to the symbol.

1

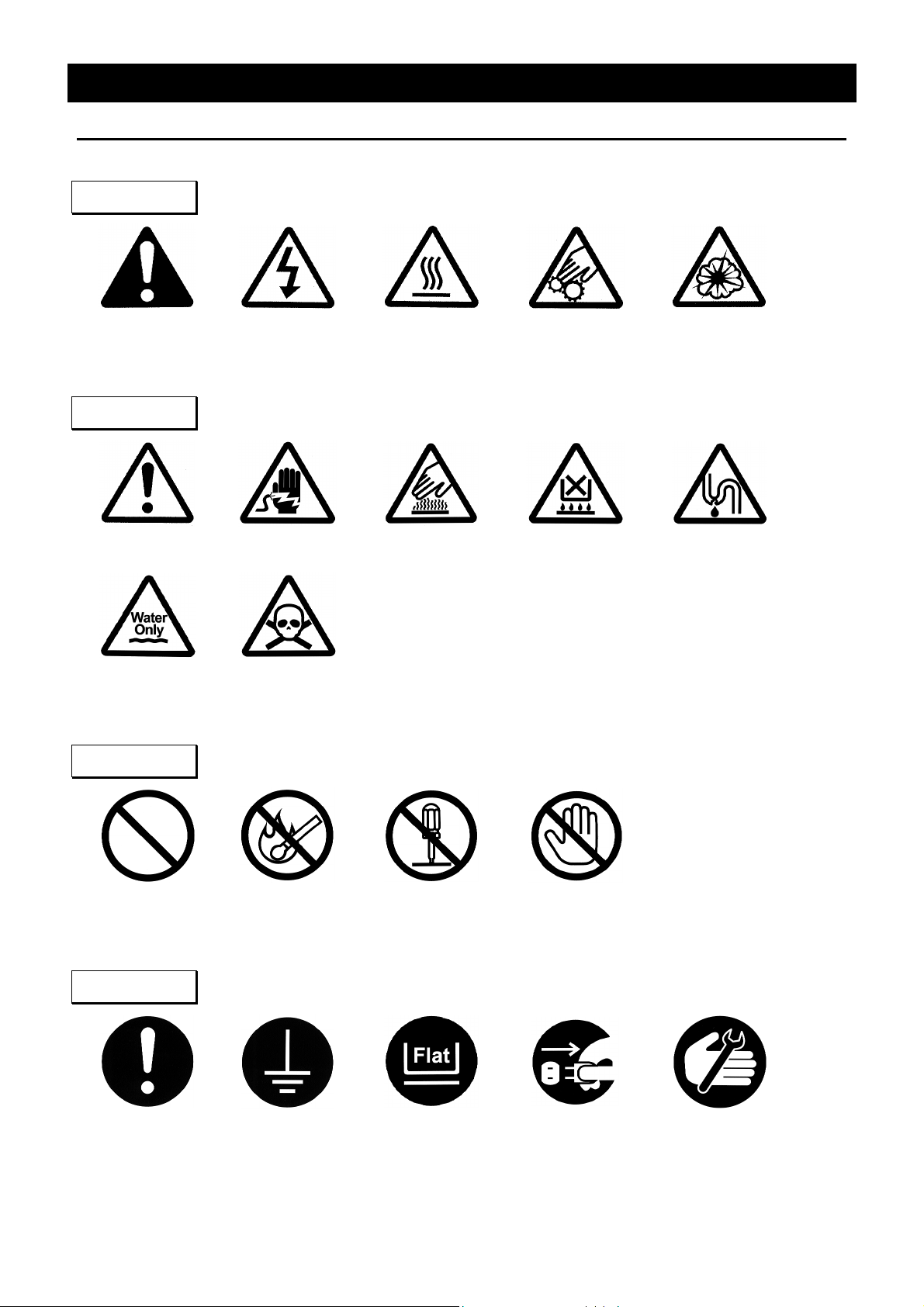

Table of Illustrated Symbols

Warning

Cautions in Using with Safety

Warning,

generally

Caution

Caution,

generally

Caution,

water only

Warning,

high voltage

Caution,

electrical shock

Caution,

deadly poison

Warning,

high temperature

Caution,

scald

Warning,

drive train

Caution,

no road heating

Warning,

explosive

Caution,

not to drench

Prohibit

Prohibit,

generally

Compulsion

Compulsion,

generally

inflammable

Compulsion,

connect to the

Prohibit,

grounding

terminal

to disassemble

Compulsion,

install on a flat

Prohibit,

surface

Prohibit,

to touch

Compulsion,

disconnect the

power plug

Compulsion,

periodical

inspection

2

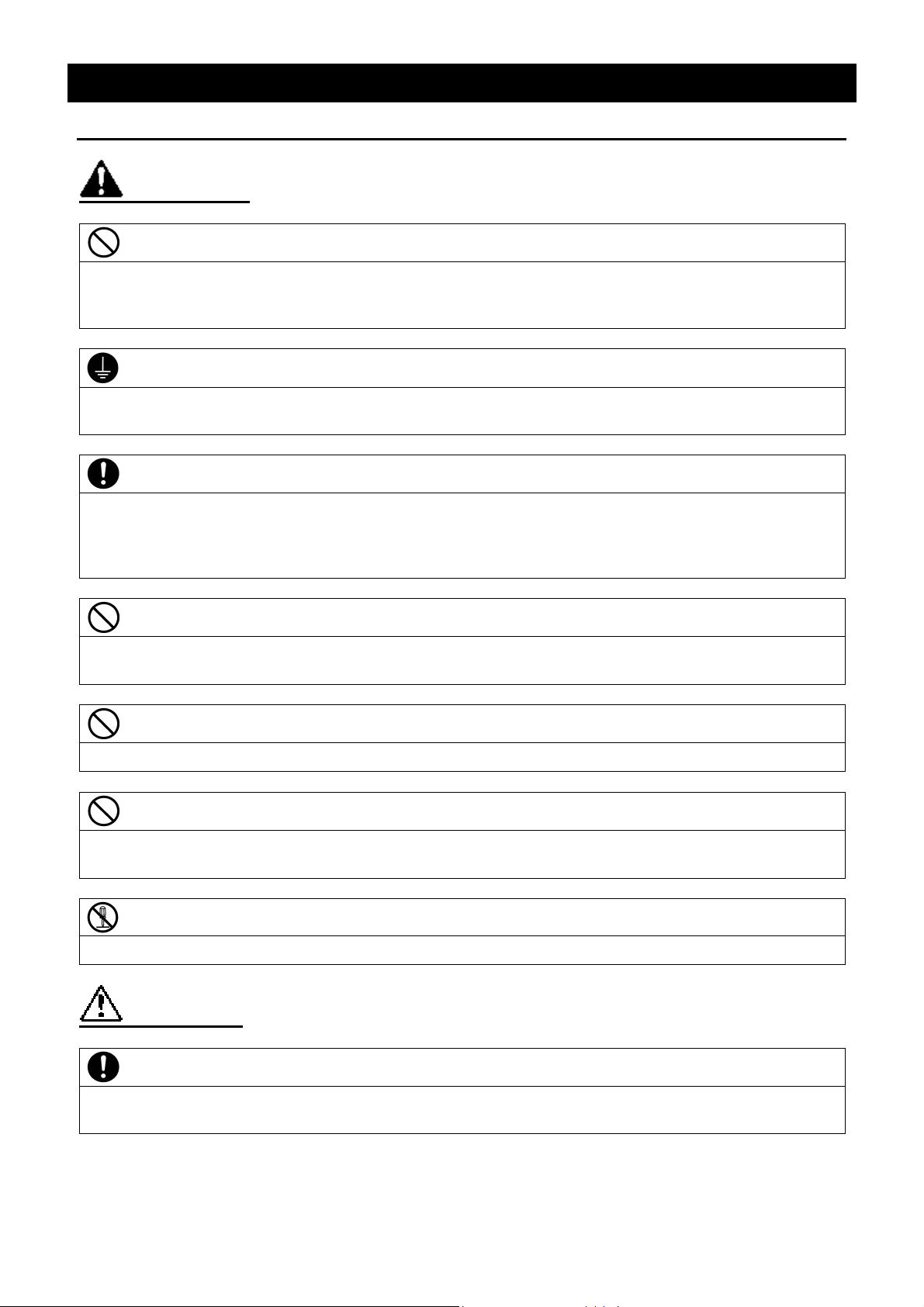

Cautions in Using with Safety

Fundamental Matters of “WARNING!” and “CAUTION!”

WARNING!

Do not use this unit in an area where there is flammable or explosive gas

Never use this unit in an area where there is flammable or explosive gas.

This unit is not explosion-proof. An arc may be generated when the power switch is turned on or off,

and fire/explosion may result. (Refer to page24 “List of Dangerous Substances”.)

Always ground this unit

Always ground this unit on the power equipment side in order to avoid electrical shock due to a power

surge.

If a problem occurs

If smoke or strange odor should come out of this unit for some reason, turn off the power key right

away, and then turn off the circuit breaker and the main power. Immediately contact a service

technician for inspection. If this procedure is not followed, fire or electrical shock may result. Never

perform repair work yourself, since it is dangerous and not recommended.

Do not use the power cord if it is bundled or tangled

Do not use the power cord if it is bundled or tangled. If it is used in this manner, it can overheat and

fire may be caused.

Do not process, bend, wring, or stretch the power cord forcibly

Do not process, bend, wring, or stretch the power cord forcibly. Fire or electrical shock may result.

Substances that can not be used

Never use explosive substances, flammable substances and substances that include explosive or

flammable ingredients in this unit. Explosion or fire may occur.

Do not disassemble or modify this unit

Do not disassemble or modify this unit. Fire or electrical shock or failure may be caused.

CAUTION!

During a thunder storm

During a thunderstorm, turn off the power key immediately, then turn off the circuit breaker and the main

power . If this procedure is not followed, fire or electrical shock may be caused.

3

Requirements for Installation

Before Using this unit

WARNING!

1. Always ground this unit

• Connect the power plug to a receptacle with grounding connectors.

• Do not forget to ground this unit, to protect y ou and t he unit from electrical shock in case of

power surge. Choose a receptacle with grounding connectors as often as possible.

• Do not connect the grounding wire to a gas pipe, or by means of a lightning rod or telephone

line. A fire or electrical shock will occur .

2. Choose a proper place for installation

• Do not install this unit in a place where:

♦ Rough or dirty surface.

♦ Flammable gas or corrosive gas is gene rated.

♦ Ambient temperature exceeds 35°C.

♦ Ambient temperature fluctuates violently.

♦ There is direct sunlight.

♦ There is excessive humidity and dust.

♦ There is a constant vibration.

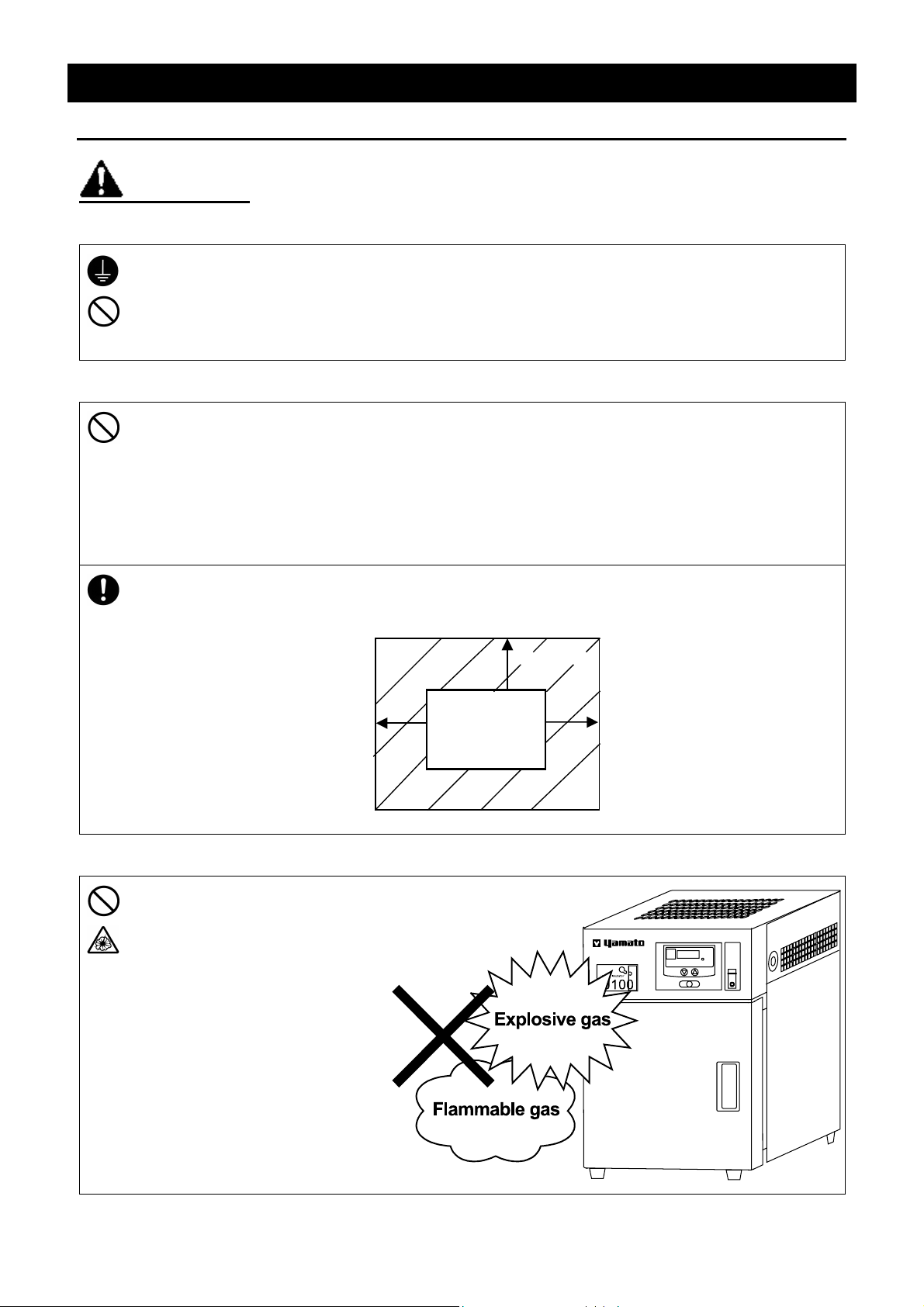

• Install this unit on a stable place with the space as shown below. Furthermore, make a space

30cm or more above this unit.

More than 15cm

More than

15cm

Main Unit

Front side

More than

15cm

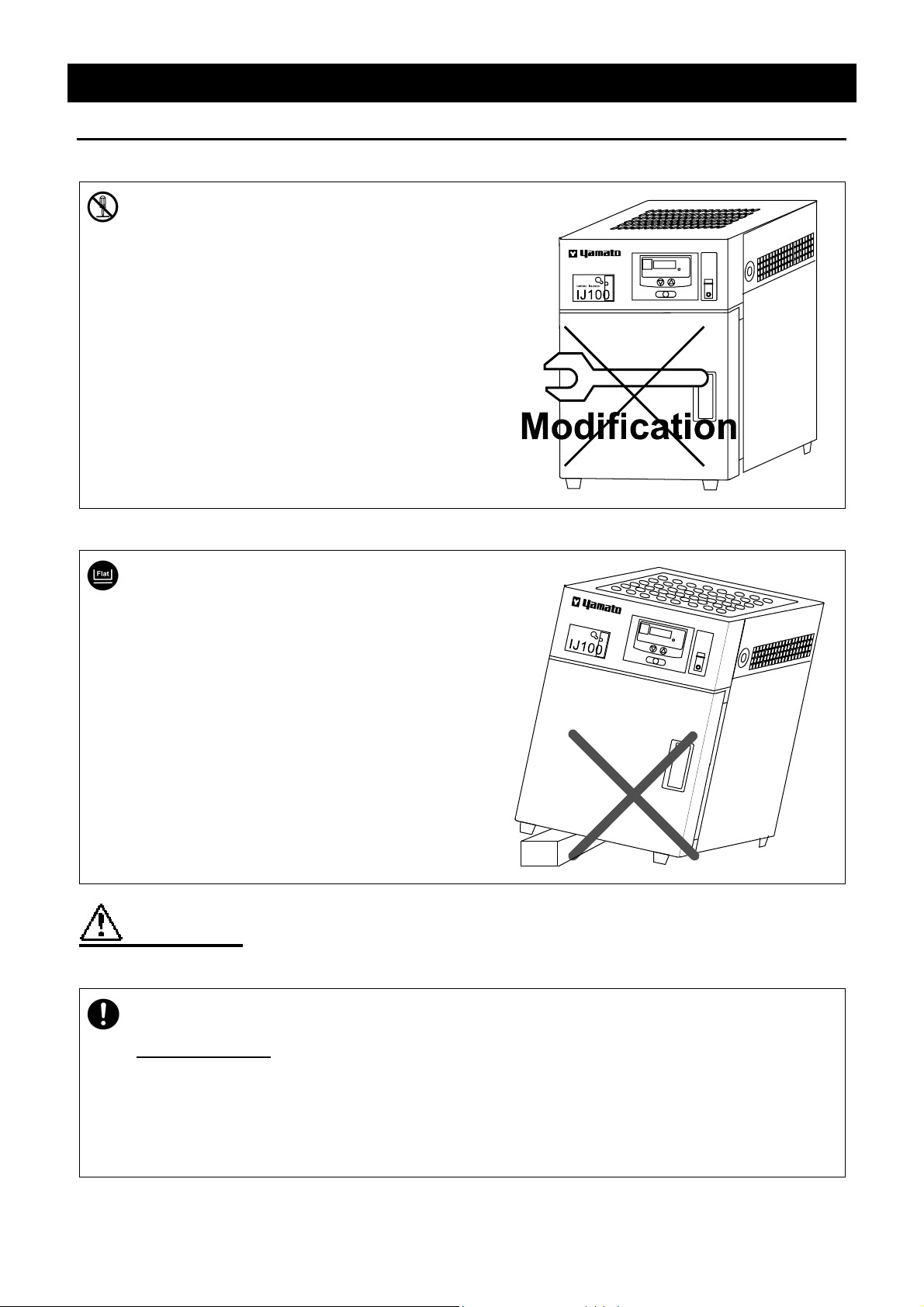

3. Do not use this unit in an area where there is flammable or explosive gas

• Never use this unit in an area

where there is flammable or

explosive gas. This unit is not

explosion-proof. An arc may

be generated when the power

switch is turned ON or OFF,

and fire/explosion may result.

(To know about flammable or

explosive gas, refer to

page24 “List of Dangerous

Substances”.)

4

Requirements for Installation

4. Do not modify

• Modification of this unit is strictly prohibited.

This could cause a failure.

Before Using this unit

5. Installation on horizontal surface

• Set this unit to the flattest place. Setting this

unit on rough or slope place could cause the

vibration or noise, or cause the unexpectible

trouble or malfunction.

CAUTION!

6. Choose a correct power distribution board or receptacle

• Choose a correct power distribution board or receptacle that meets the unit’s rated electric

capacity.

Electric capacity: 100V AC 3.5A

NOTE)

There could be the case that the unit does not run even after turning ON the power. Inspect

whether the voltage of the main power is lowered than the specified value, or whether other

device(s) uses the same power lin e of thi s unit. If the phenomena might be found, change the

power line of this unit to the other power line.

5

Requirements for Installation

Before Using this unit

CAUTION!

7. Before/after installing

• It may cause injure to a person if this unit falls down or moves by the earthquake and the

impact. etc..To prevent, take measures that the unit cannot fall down , and not inst all to busy

place.

8. Handling of power code

• Do not entangle the power cord. This will cause ov er heat ing and possibly a fire.

• Do not bend or twist the power cord, or apply excessiv e tension to it. This may cause a fire

and electrical shock.

• Do not lay the power cord under a desk or chair, and do not allow it to be pinched in order to

prevent it from being damaged and to avoid a fire or electrical shock.

• Keep the power cord away from any heating equipment such as a room heater. The cord's

insulation may melt and cause a fire or electrical shock.

• If the power cord becomes damaged (wiring exposed, breakage, etc.), immediately turn off the

power at the rear of this unit and shut off the main supply power. Then contact y our nearest

dealer for replacement of the power cord. Leaving it may cause a fire or electrical shock.

• Connect the power plug to the outlet which is supplied appropriate pow er and voltage.

9. Draining of condensation

• When the cooling device is operated, condensation may occur on the cooling surface. The

condensation is led out via the drain provided at the bottom on the rear t he unit . Therefore,

be sure to set the attached drain-receiving pan.

10. Setting shelf

• Fix the two shelves (attached accessory) on the appropriat e posit ion.

6

t

Before Using this unit

Change the Direction of Opening/Closi ng Door

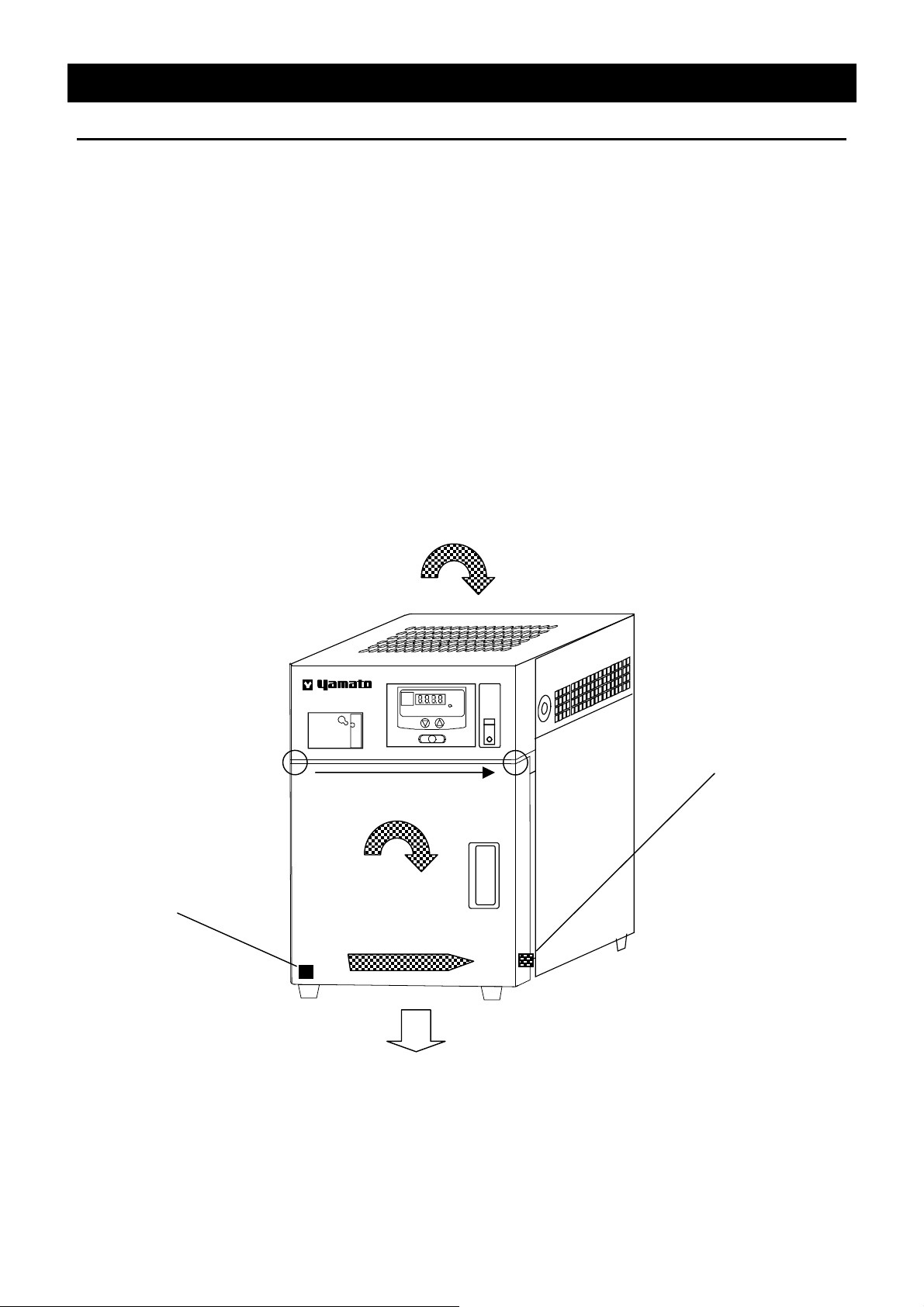

This unit can be changed the direction of opening/closing the door easily.

The door opened/closed to the right or left can be selected according to the place where it is

installed and the convenience of operation.

The direction of opening/closing the door is set to left at the shipping from factory. If the

door should be opened/closed to the right, the direction of opening/closing the door can be

changed by the following procedure:

1. Lay down the main body backward in a way that t he door unit may come abov e.

2. By using phillips screwdriver, remove the hinge mounting screws fixing the door in the lower

part of the main body.

3. Pull off the door downward carefully.

4. Pull off the guide pin fixing the upper part of the door, and insert it into the screw hole on the

opposite side (right side).

5. Turn t he door 180 degrees, and insert it into the upper guide pin.

6. After adjusting the door position, fix the hinge in the lower part of the door.

7. Replace the main body to complete the procedure.

1. Lay down the main body.

4. Remove the guide pin, and

move it to the right side.

2. Remove the lower hinge

and move it to the righ

side.

設定温度

Lowtemp incubator

IJ100

5. Turn around the door

3. Pull out the door.

セット

ヒータ

6. Fix the lower hinge.

7

Main Unit

Description and Function of Each Part

Control panel

Independent overheating

prevention device

Specification plate

(Manufacture number)

Power switch

(Earth leakage breaker)

Front view

Cooling air inhalation

Door handle

Plate for drainage

Exhaust of cooling fan

Cooling air inhalation

Rear view

Power cord

8

②

③

⑤

Control Panel

Description and Function of Each Part

Main Indicator:

①

Heater Lamp:

②

Trouble Indicator:

③

▼▲(Up/Down) Key

④

Enter Key

⑤

Mainly displays measured temperature.

Lights up when electric power is supplied to the heater.

Blank in normal operation. Lights up when the device has a

trouble.

Use these keys when you change the parameters.

Use this key when you decide a modified parameter.

9

Sequence of Operation

Fixed Temperature Operation

Operation Method

1. Turn on t he pow er.

Changing Temperature Setting

1. Press the Enter key.

• The main indicator shows the current internal temperature.

MEASURED TEMP

• Fixed temperature operation is started with the target of the

previously set temperature.

When the power is t urned on, the controller resets a utomatically

to the condition immediately before the previous power-off.

ENTER

• The main indicator blinks the currently set temperature.

MEASURED TEMP

2. Press the ▼ key or ▲

key until the required

value is given in the

blinking number

3. When the temperature

reaches to the required

value, press the Enter

key.

ENTER

• The blinking indicator of the temperature setting is turned on,

and the fixed temperature operation is started toward the

newly set temperature.

10

g

Sequence of Operation

Temperature Preset Function Using Method

• Temperature. Preset is the function to memorize a specified temperature. It is useful to

register any temperature used frequently during operation.

• The preset temperature can be registered any time if the power switch is ON in normal

operation. To register this, follow the procedure shown below.

• Operation continues even when the temperature preset is being registered.

Operation Method

1. Press the Enter key

twice.

• The main indicator shows the temperature registered

currently.

• Then, the dot point to the left of the main indicator blinks and

indicates that the operation is in the preset temperature

registration mode.

Preset Temperature

Re

istration Mode

NOTE) If not registered, the main indicator blinks .

ENTER

MEASURED TEMP

Temperature Setting Method

1. Press the ▼ key or ▲

key until the required

value is given in the

main indicator.

2. When the required value

is given, press the

Enter key.

ENTER

• The previous temperature is deleted.

• Blinking of the previously set temperature is changed to the

display for the current measurement.

11

Operation Method

Independent overheating prevention device

For the safety device to prevent any over-temperature, an independent overheating prevention device

consisted of the circuits and sensors other than those for the controller is provided in addition to the

controller's automatic function (auto reset) to prevent over-temperature, thus configuring a double safety

measure.

Range of Set Temperature & Functions

This unit has two functions for preventing over-temperature; one is in the controller, and set

to automatically operate at the temperature set in the temperature regulator plus 6℃ when

delivered from the factory; the other is the temperature regulating dial provided in the upper

right part of this unit, which is used to set the activating temperature for over-temperature

prevention. Such a temperature setting completes a duplex function to prevent

over-temperature.

The independent overheating prevention device provided in the upper right part of this unit

sets temperatures in the range 0℃-120℃.

If the independent overheating prevention device is activated, the heater circuit is cut off,

and Er03 starts to blink.

If the independent overheating prevention device trips, the status is maintained until the

power is reset, while Er03 is not disabled.

If any wrong value is set for the activating temperature for over-temperature prevention,

units could fail to start, or the independent overheating prevention device could trip even

while the internal temperature is rising, or unexpected accidents including fire could be

occurred.

Using Method

Normally set this to a temperature about 10℃ (about 2 units in dial) higher than the

temperature set for the controller.

F or th e independent overheating prevention device to start at the required temperature, first

establish a stable operation at such a required temperature, and lower gradually the setting

dial of the independent overheating prevention device, and then check if the operation is

maintained with stable at the required temperature. Also set the bath temperature. To a

level higher than the temperature activating the independent overheating prevention device,

and check if the independent overheating prevention device trips at the required

temperature.

Caution

When cleaning the independent overheating prevention device or area around it, any touch

on the over-temperature prevention setting dial could change the set temperature.

Therefore, be sure to check if appropriate value is set for the temperature before starting

operation.

12

Handling Precautions

WARNING!

If a problem occurs

If smoke or strange odor should come out of this unit for some reason, turn off the power key

right away, and then turn off the circuit breaker and the main power. Immediately contact a

service technician for inspection. If this procedure is not followed, fire or electrical shock may

result. Never perform repair work yourself, since it is dangerous and not recommended.

Substances that cannot be used

Never use explosive substances, flammable substances and substances that include explosive

or flammable ingredients in this unit. Explosion or fire may occur. (Refer to page24 “List of

Dangerous Substances”.)

When the setting temperature is 35°C or less

When the setting temperature is 35°C or less, pay attention to dryness of sample. The cooling

device of this unit is operated by peltier ele ment. I t is set to operate when the setting temperature

is 35°C or less. If container for sample is open, sample may dry.

Condensation drainage

The cooling device may have condensation

during operation. It is drained through the port

on the base to the plate. Check the plate

sometime to avoid overflow.

CAUTION!

Do not step on this unit

Do not step on this unit. It w ill c ause injur y if this unit fall down or break.

Do not put anything on this unit

Do not put anything on this unit. I t will cause injury if fall.

During a thunder storm

During a thunderstorm, turn off the power key immediately, then turn off the circuit breaker and

the main power . If this procedure is not followed, fire or electrical shock may be caused.

When you open and close the door

When you open and close the door, be careful not to be hit your hands or face. It may cause

injury.

13

Handling Precautions

CAUTION!

Do not use corrosive sample

Stainless steel SUS304 is used for the main hot-air path. However, it may be corroded by strong

acid etc.. Care must be taken, vinyl chloride rubber may be corroded by some kind of solvent, ex

alkaline, oil, halogen etc.

Setting sample

•••• Do not put sample more than 5kg on the shelf provided. When you use some samples, keep

space between each of them.

• Temperature control may lose accuracy if many samples are set. Set sample making room

more than 30% of the shelf in order to keep accuracy of temperature.

It can be cooled to 0°C(minimum)by the product when the room t emperature is 20°C and there

is no load. The lowest temperature may change by quantity of sample.

Use under proper temperature range

Operational temperature range of this unit is 0 to 60℃. Never set the temperature out of that.

Do not put sample on the internal base

If sample is put directly on the base, device performance will be disturbed. Furthermore, internal

temperature will a bnormally rise and it will cause troub le. Never pu t sample on the b ase. Fix the

shelf on the metal fittings then set sample on it.

14

CAUTION!

Recovery of power failure

When power is supplied after a power failure, the device automatically st arts operation again with

the same state as just before the power failure. It is danger that the device starts unattached

operation after a power failure. We recommend for you to turn off the switch of this unit if a

power failure occurs during operation.

Do not pile up the units

Do not pile up the units like the figure.

This unit is not designed for that using.

Handling Precautions

設定温度

Lowtemp incubator

IJ100

ヒータ

セット

Do not put things on the top.

Don't put things on the top like a figure.

Cooling ability declines, and proper

control can't be done any more.

設定温度

Lowtemp incubator

IJ100

ヒータ

セット

After installing

It may cause injure to a person if this unit falls down or moves by the earthquake and the impact.

etc.. To prevent, take measures that the unit cannot fall down.

15

Daily Inspection and Maintenance

Maintenance Method

WARNING!

• Disconnect the power cable from the power source when doing an inspection or maintenance

unless needed.

• Perform the daily inspection and maintenance after returning the temperature of this unit to the

normal one.

• Do not disassemble this unit.

CAUTION!

Main unit maintenance

• Use a well-drained soft cloth to wipe dirt on this

unit. Do not use benzene, thinner or cleanser for

wiping. Do not scrub this unit. Deformation,

deterioration or color change may result in.

Monthly maintenance

• Check the earth leakage breaker function.

1. Connect the power cord.

2. Turn the breaker on.

3. Push the red test switch by a ballpoint pen etc.

4. If there is no problem, the earth leakage breaker will be turned off.

Cleaning of Heat radiate fin

• Clogging radiate fin causes its performance decreased and also

breakdown.

• Keep periodical cleaning depends on how the operating

environment or time is.

1.Lose 4 of upper shelf board screws and take the shelf off.

2.Take off the fan lead wire and 4 of fan screws.

3.Clean the surface of radi ate f in with vac u um cleaner after take off

the fin.

Fix them as it was following 3 to 1 order.

PRECAUTIONS: Pay attention not to crush the fin during cleaning.

Fin stop screw

Heat radiate fin

For any questions, contact the dealer who you purchased this unit from, or the nearest sales

division in our company.

16

t

Setting Air Jacket (Optional accessory)

1. Set the shelf at the lowest stage in a w ay that the side with margin may come innermost.

Set the shelf on the

lowest stage.

2. Set this on the shelf of the air jacket, and push it in.

3. Pus the air jacket inward until it hits the depth.

Enter this while adjusting i

closely to the edge of the

inner bath.

17

Long storage and disposal

When not using this unit for long term / When disposing

CAUTION!

When not using this unit for long term…

• Turn off the power and disconnect t he pow er cord.

WARNING!

When disposing…

• Keep out of reach of children.

• Treat as large trash.

Environmental protection should be considered

We request you to disassemble this unit as possible and recycle the reusable parts considering to

the environmental protection. The feature components of this unit and materials used are

listed below.

Component Name Material

Main Components of Exterior

Casing Steel plate, melamine resin baking finish

Interior Stainless steel plat e SUS 304

Air jacket (optional accessory) Aluminum, Neoprene rubber packing

Production plates PET resin film

Main Components of Cooling System

Heat absorb fin Aluminum

Heat radiate fin Copper , Lead solder

Heat radiate cover Steel plate, melamine resin baking finish

Parts attaching plate Steel plate, melamine resin baking finish

Main Components of Electric System

Heater Mica heater , Aluminum, Grass coating wire

Fan Aluminum, Copper wire and other composites

Circuit boards Composites of board, condenser, resist or, transformer, etc.

Power cord, Wiring material, etc. Wiring material of synthetic rubber coating and resin coating

18

In the Event of Failure…

Safety Device and Error Code

This unit has an automatic diagnosis function built in the controller and safety devices independent of the

controller . The table below shows the cause and the solution method when the safety device operates.

Error Code:

When an abnormal condition occurs, an error code and the trouble indicator blinks in the

controller, the buzzer sounds simultaneously. Record the error code and turn off the power of

device immediately.

Safety Device Notify Cause/Solution

Sensor trouble detection

Triac short-circuit detect ion

Heater disconnecting detection

(or independent overheating

prevention device is operates)

Main relay trouble detection

Electric circuit trouble detection

Trouble Shooting

Before call us...

“TROUBLE” lamp blinks,

“Er.01” blinks

“TROUBLE” lamp blinks,

“Er.02” blinks

“TROUBLE” lamp blinks,

“Er.03” blinks

“TROUBLE” lamp blinks,

“Er.10” blinks

“TROUBLE” lamp blinks,

“Er.15” blinks

• Temperature sensor is broken or

disconnected.

• Make a call for service.

• Triac is in short-circuit

• Make a call for service.

• Heater is disconnected.

• Independent overheating prevention

device is operates

• Make a call for service.

• Main relay is broken.

• Make a call for service.

• Failure in electric circuit.

• Make a call for service.

Condition Check the following.

The device does not start operation

when turning on the power switch.

Temperature fluctuates during the

operation.

In the case if the error other than listed above occurred, turn off the power switch and primary

power source immediately. Contact the shop of your purchase or nearest Yamato Scientific

Service Office.

• Power plug is not connected to the receptacle correctly.

• Power failure.

• Too much samples.

• The change of ambient temperature is remarkable.

• Samples are too moist.

• The power supply voltage is lower than t he proper value.

19

After Service and Warranty

In Case of Request for Repair

If the failure occurs, stop the operation, turn OFF the power switch, and unplug the power plug.

Please contact the sales agency that this unit was purchased, or the Yamato Scientific's sales

office.

< Check following items before contact >

◆ Model Name of Product

◆ Production Number

◆ Purchase Date

◆ About Trouble (in det ail as possible)

Minimum Retention Period of Performance Parts for Repair

The minimum retention period of performance parts for repair of this unit is 7 years after

discontinuance of this unit.

The "performance part for repair" is the part that is required to maintain this unit.

See the production plate attached to this unit.

20

Model IJ100

Operating temperature range

Temperature adjustment accuracy

Temperature distribution accuracy

Temperature rising time Approx. 40min. (20 to 60°C)

Performance

Temperature falling time Approx. 100min. (20 to 0°C)

Heating device Mica heater 120W

Two peltier cells, forced radiating method:

Cooling device

Configuration

Internal fan Axial fan (DC)

Controller Hitec IV

Temperature control system PID control of heater output by microcomputer

Temperature setting system

Operational mode Fixed temperature operation

Sensor Thermistor

Control Section

Additional function

Self-diagnostic function

Safety

Device

Preservation device

External dimensions

Internal dimensions

Internal capacity 15.6L

Standard

Door

Weight Approx. 20kg

Power supply 100V AC 50/60Hz 3.5A

Accessories

Optional accessories

It works continuous at the setting temperature below 35

(It is turned off at the setting temperature 35

Tem perature preset function (1 f or desired tem perature is able to

set/load)

Sensor error, Heater error, Triac error, Main relay error, Auto

overheating prevention

Earth leakage breaker, Independent overheating prevention

device

Shelf

×2 (Load: 5kg for each), Plate for drainage, Instruction

manual

Extra shelf (with m etal fittings), Air jacket made of aluminum (with

shelf)

The values shown on “Performance” are in power supply 100V AC.

Usable ambient temperature for this unit is 5 to 30℃.

0 to 60

±0.3℃ (the center of inner bath, set temp.:37℃)

±1.0℃ (the center of inner bath, set temp.:37℃)

Digital Setting by

(Air jacket installed: 200

(the direction of opening/closing is changeable)

℃ (room temp: 20℃, no load)*

350(W)

250(W)

Single door with magnet packing

Specification

℃ and over.)

type1

FR

▼▲ (up/down) Keys

×396(D)×535(H) mm

×250(D)×250(H) mm

×200×200 mm)

℃.

21

ELB

AC 100V

Symbol Part name Symbol Part name

ELB Earth leakage breaker F1, F2 Fan

T1, T2 Terminal block H Heater

TR1 Power transformer C1, C2 Peltier cell

X1, X2, X3 Relay PLANAR Control board

SSR SSR PIO Display board

CT1 Current detector TE1 Thermistor sensor

NF1 Noise filter SPS-1 Switching power supply

OH

T1

1.25

1.25

1

1.25

1.25

E

1.25

2

1.25

3

1.25

4

1.25

TR1

X1

J2

PI0

J10

Independent overheating

prevention device

23

1

SSR

4

J6

PLANAR

J8

X2

34 4 5

J7

1

CT1

3

+

NF1

2

SPS-1

4

-

T2

1

X2

2

3

J9

J5

1

2

J4

1

3

J11

4

TE1

+

SPS-2

-

SPS-2 Switching power supply for fan

Wiring Diagram

+

+

-

+

-

C1

+

C2

-

F1

F2

X3

OH

8

7

6

6

X3

X3

4

2

H

X1

22

Replacement Parts Table

Part Name Code No. Specification Manufacturer

Earth leakage breaker 2060000018

Terminal block 2070230001 TS046-1049 4P Yamato Scientific

Relay 2050000013 AJR6010 Matsushita

Relay 2050000040 AP5524K (HL2-HTM-AC100) Matsushita

SSR 2160000026 YLT-SSR-01 Yamato Scientific

Noise filter 2300010009 ZAG2206-11S 6A TDK

Fan 1 (for circulation) 2150000011 109R0812H4021 (DC12V 13W) Sanyo Denki

Fan 2 (for radiation) 2150000012 109R1212H1021 (DC12V 52W) Sanyo Denki

Heater 2260020014 Mica heater 120W Sakaguchi Dennetsu

Switching power supply board 2550000005 DC24V 144W Tenseiramda

Fan power supply board 2550000006 DC12V 15W Tenseiramda

Independent overheating

prevention device

Peltier cell 2600000001 17.5V 40W(950-127-085) Fellow Tech

Power transformer 1013200033 IV FR AC100 Yamato Scientific

PLANAR board 1240000057 IV FR Yamato Scientific

PIO board 1240000030 IV FR Yamato Scientific

1270010010 TO-1124-B Matsushita

FG32R-10-30

mA 10A

Fuji Denki

CPU 1180010011 H8/3256 IJ200 Yamato Scientific

Thermistor 1160050010 Thermistor Yamato Scientific

Current detector 2170010005 CTL-6-S-4-H URD

23

List of Dangerous Substances

Never use explosive substances, flammable substances and substances that include explosive

or flammable ingredients in this unit.

EXPLOSIVE

Ethylene glycol din it r at e (nit ro glycol), Glycerin trinitrat e (nitroglycerine), Cellul ose

nitrate (nitrocellulose), and other explosive nitrat e est ers

Reference

EXPLOSIVE:

FLAMMABLE

IGNITING:

OXIDIZING:

Trinitrobenzene, Trinitrotoluene, Trinitrophenol (picric acid), and other explosive

nitro compounds

Acetyl hidroperoxide (peracetic acid), Methyl ethyl ketone peroxide, Benzyl

peroxide, and other organic peroxides

Lithium (metal), Potassium (metal), Sodium (metal), Yellow phosphorus,

Phosphorus sulfide, Red phosphorus, Celluloid compounds, Calcium carbide,

Lime phosphate, Magnesium (powder), Aluminum (powder), Powder of metals

other than magnesium and aluminum, Sodium hydrosulfite

Potassium chlorate, Sodium chlorate, Ammonium chlorate, and other chlorate

Potassium perchlorate, Sodium perchlorate, Ammonium perchlorate, and other

perchlorate

Potassium peroxide, Sodium peroxide, Barium peroxide, and other inorganic

peroxide

Potassium nitrate, Sodium nitrate, Ammonium nitrate, and other nitrate

Sodium chlorite and other chlorites

Calcium hypochlorite and other hypochlorites

Ethyl ether, Gasoline, Acetaldehyde, Propylene chloride, Carbon disulfide, and

other flammable substances having a flash point of lower than -30℃

INFLAMMABLE

LIQUID:

FLAMMABLE

GAS:

Normal hexane, ethylene oxide, acetone, benzene, methyl ethyl ketone, and

other flammable substances having a flash point of -30℃ or higher but lower

than 0℃

Methanol, Ethanol, Xylene, Pentyl acetate (amyl acetate), and other flammable

substances having a flash point of 0℃ or higher but lower than 30℃

Kerosene, Light oil (gas oil), Oil of turpentine, Isopentyl alcohol (isoamyl alcohol),

Acetic acid, and other flammable substances having a flash point of 30℃ or

higher but lower than 65℃

Hydrogen, Acetylene, Ethylene, Methane, Propane, Butane, and other flammable

substances which assume a gaseous state at 15℃ and 1 atm

(Source: Appendix Table 1 of Article 6 of the Industrial Safety and Health Order in Japan)

24

Responsibility

Please follow the instructions in this document when using this unit. Yamato Scientific has no

responsibility for the accidents or breakdown of device if it is used with a failure to comply.

Never conduct what this document forbids. Unexpected accidents or breakdown may result in.

Note

◆ The contents of this document may be changed in future without notice.

◆ Any books with missing pages or disorderly binding may be replaced.

Instruction Manual for

Low Te mper at ur e I ncubat or

Model IJ 100

First Edition Mar. 19, 2001

Yamato Scientific Co., Ltd.

2-1-6 Nihonnbashi Honcho, Chuo-ku,

Tokyo, 103-8432, Japan

http://www.yamato-net.co.jp

25

Loading...

Loading...