Page 1

Operation Manual for

Incubator

IC101

IC101W

Ver. 3

● Thank you very much for purchasing this Yamato

Scientific IC101/IC101W Incubator.

● Please read the “Operating Instructions” and

“Warranty” before operating this unit to assure proper

operation. After reading these documents, be sure to

store them securely together with the “Warranty” at a

handy place for future reference.

Warning: Before operating the unit, be sure to

read carefully and fully understand

important warnings in the operating

instructions.

Yamato Scientific Co., Ltd.

This paper has been printed on recycled paper.

Page 2

Table of contents

1. Safety precautions ............................................................................................... 1

Explanation of pictograms.................................................................................1

List of symbols..................................................................................................2

Warning・Cautions...........................................................................................3

2. Before operating the unit...................................................................................... 4

Precautions on installation................................................................................4

3. Names and functions of each part........................................................................ 8

Main unit ...........................................................................................................8

Operation panel ..............................................................................................10

Heater construction and operation, features, and recovery time.....................11

Description of characters ................................................................................12

4. Operating procedures......................................................................................... 13

List of operation modes and functions ............................................................13

List of operation modes and functions ............................................................14

Operation mode, function setting keys and character codes...........................15

Operating procedures(fixed value operation) .............................................16

Operating procedures(Quick auto stop operation) .....................................17

Operating procedures(quick auto stop operation) ......................................18

Operating procedures(auto stop operation)................................................19

Operating procedures (auto stop operation)..............................................20

Operating procedures(auto start operation) ...............................................21

Operating procedures(auto start operation) ...............................................22

Useful functions(power failure compensation function) ..............................23

Useful functions(calibration offset function)................................................24

Useful functions(setting key lock function) .................................................25

Useful functions (Using the service outlet)......................................................26

5. Handling precautions.......................................................................................... 27

6. Maintenance procedures.................................................................................... 29

Daily inspection/maintenance .........................................................................29

7. When the unit is not to be used for a long time or when disposing .................... 30

When the unit is not to be used for a long time or when disposing.................30

Notes about disposition ...................................................................................30

8. When a trouble occurs ....................................................................................... 31

Safety device and error codes ........................................................................31

If a malfunction is suspected...........................................................................32

9. After sales service and warranty........................................................................ 33

When requesting a repair................................................................................33

10. Specifications..................................................................................................... 34

11. Wiring Diagram .................................................................................................. 35

12. List of replacement parts.................................................................................... 36

13. List of dangerous materials ................................................................................ 37

Page 3

1.Safety precautions

A

y

r

Explanation of pictograms

variety of pictograms are indicated in this operating instruction and on

products for safe operation. Possible results from improper operation

ignoring them are as follows.

Be sure to fully understand the descriptions below before proceeding to the

text.

About pictograms

Warning

Caution

(

Note 1)Serious injury means a wound, an electrical shock, a bo ne fra ctur e or intoxication that ma

leave after effects or require hospitalization or outpatient visits for a long time.

(

Note 2)Minor injury means a wound or an electrical shock th at does not requi re hospitali zation o

outpatient visits for a long time.

(

Note 3)Property damage means damage to facilities, devices and buildings or other properties.

This pictogram indicates a matter that encour ages th e user t o adher e to warning

(“caution” included).

Specific description of warning is indicated near this pictogram.

This pictogram indicates prohibitions

Specific prohibition is indicated near this pictogram.

This pictogram indicates matters that the user must perform

Specific instruction is indicated near this pictogram.

Indicates a situation which may result in death or serious injury (Note 1.)

Indicates a situation which may result in minor injury (Note 2) and

property damages (Note 3.)

Meanings of pictograms

1

Page 4

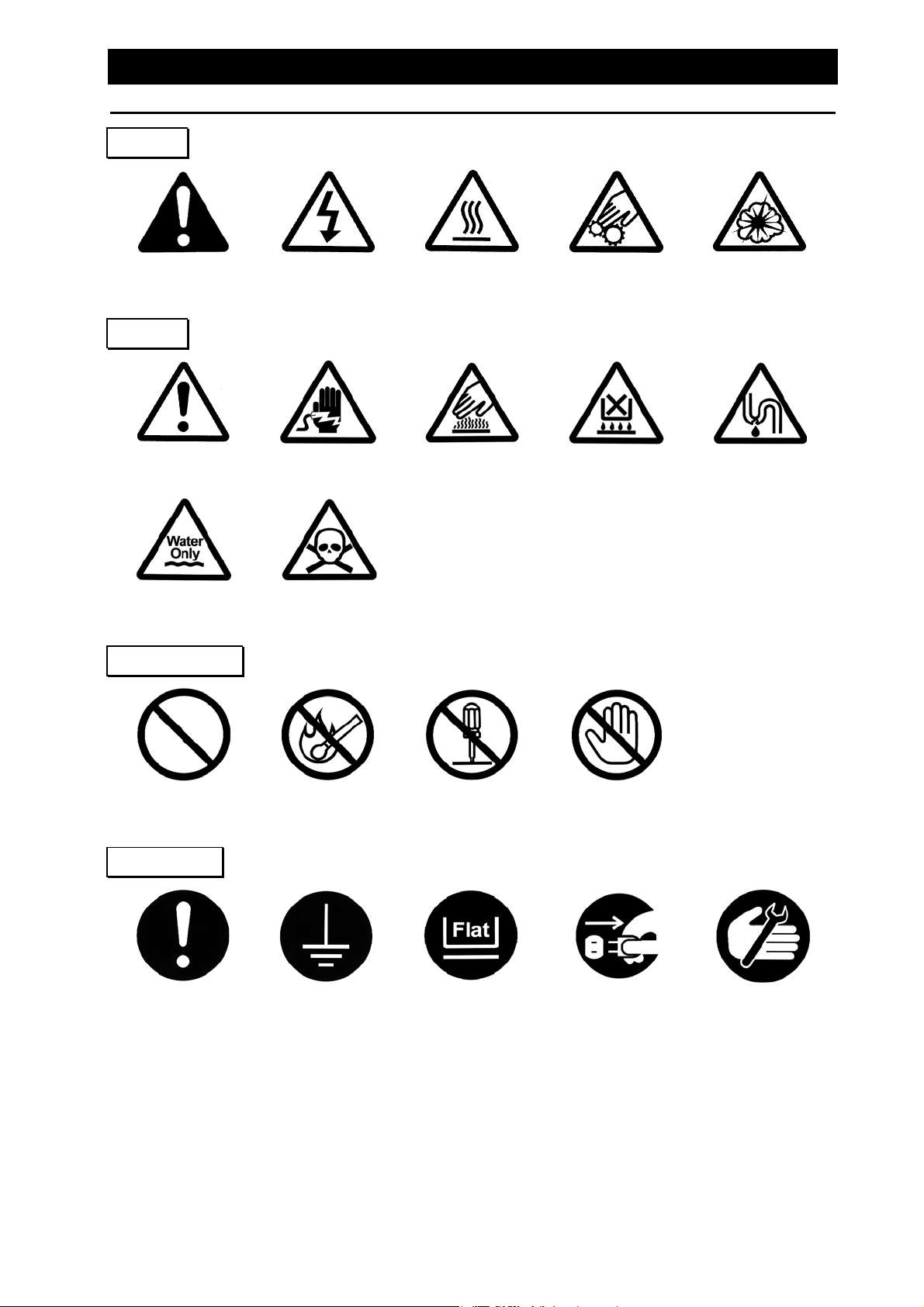

1.Safety precautions

List of symbols

Warning

General warnings

Caution

General cautions Electrical shock! Burning!

For water only

Prohibitions

Danger!: High

voltage

Poisonous

material

Danger!: High

temperature

Danger!: Moving

Caution for no

liquid heating!

part

Danger!: Hazard

of explosion

Caution for water

leak!

General bans Fire ban

Compulsions

General

compulsions

Connect ground

wire

Do not

disassemble

Install levelly

Do not touch

Pull out the power

plug

Regular

inspection

2

Page 5

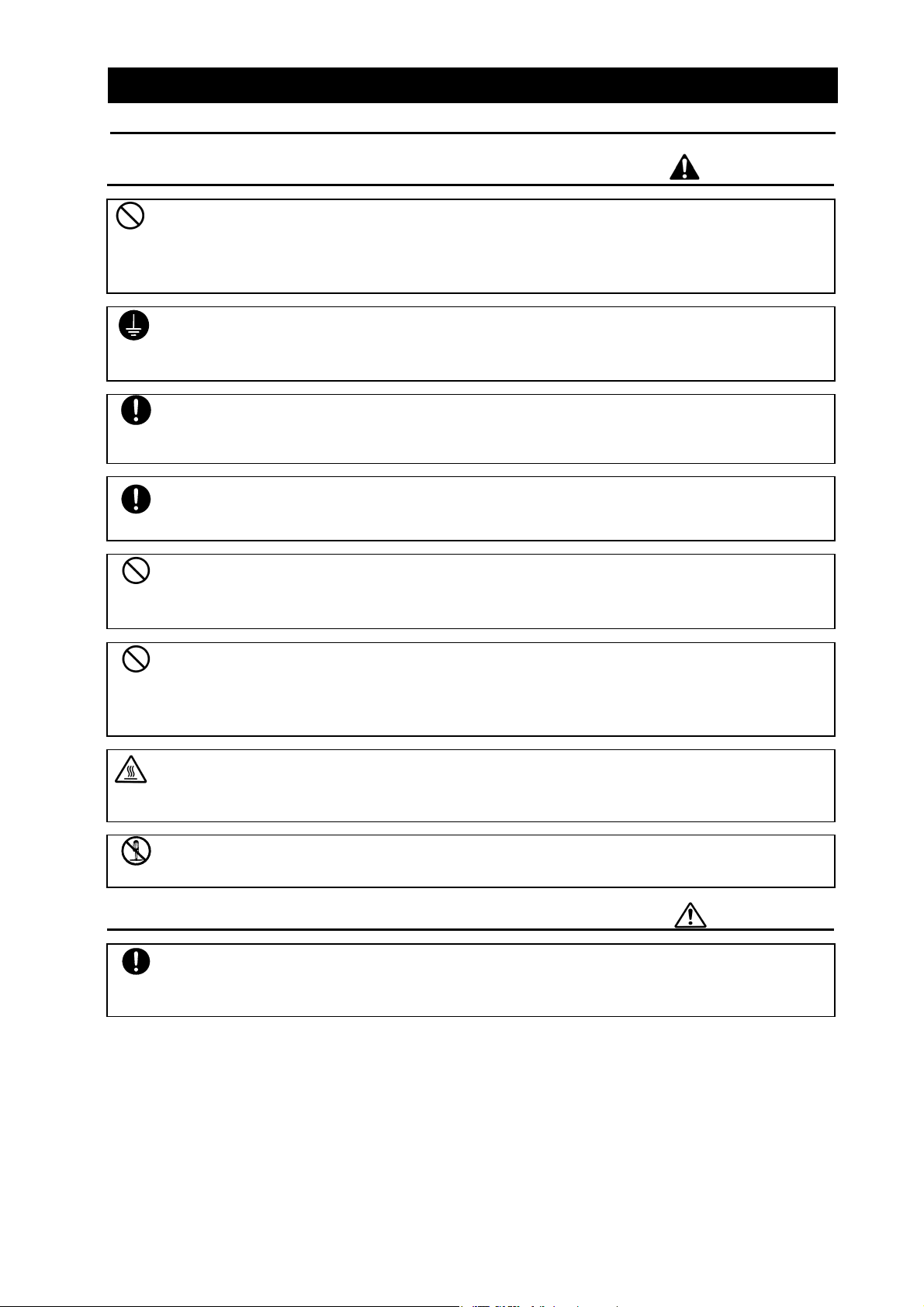

1.Safety precautions

Warning・Cautions

Warning

Never operate the unit in an atmosphere containing flammable or explosive gas.

Otherwise, an explosion or a fire may result since the unit is not explosion-proof.

See page 37.

Be sure to connect the ground wire correctly. Otherwise, electrical leak may result and cause an

electrical shock or a fire.

When a smoke or a unusual odor is seen or sensed, immediately turn the electric leakage

breaker on the main unit off and pull out the power plug. A fire or an electrical shock may result.

When these are used bundled, they might overheat causing a fire.

Avoid tightly bend, pull with a strong force or twist to prevent electrical power cords from

damaging. A fire or an electrical shock may result.

Never use an explosive material, a flammable material or a material containing them.

Otherwise, an explosion or a fire may result.

See page 37.

Some parts of the unit are hot during and immediately after operation. Take special care for

possible burning.

Never try to disassemble or alter the unit. A malfunction, a fire or an electrical shock may result.

When a thunder is heard, turn the main power off immediately . A malfunction, fire or an electrical

shock may result.

Never operate the unit in an atmosphere containing flammable or explosive gas

Be sure to connect the ground wire.

Ban on operation when an abnormality occurs

Never use electrical power cords bundled.

Take care not to damage electrical power cords.

Never use an explosive or a flammable material with this unit.

Never try to touch a hot part.

Never try to disassemble or alter the unit.

When a thunder is heard.

Caution

3

Page 6

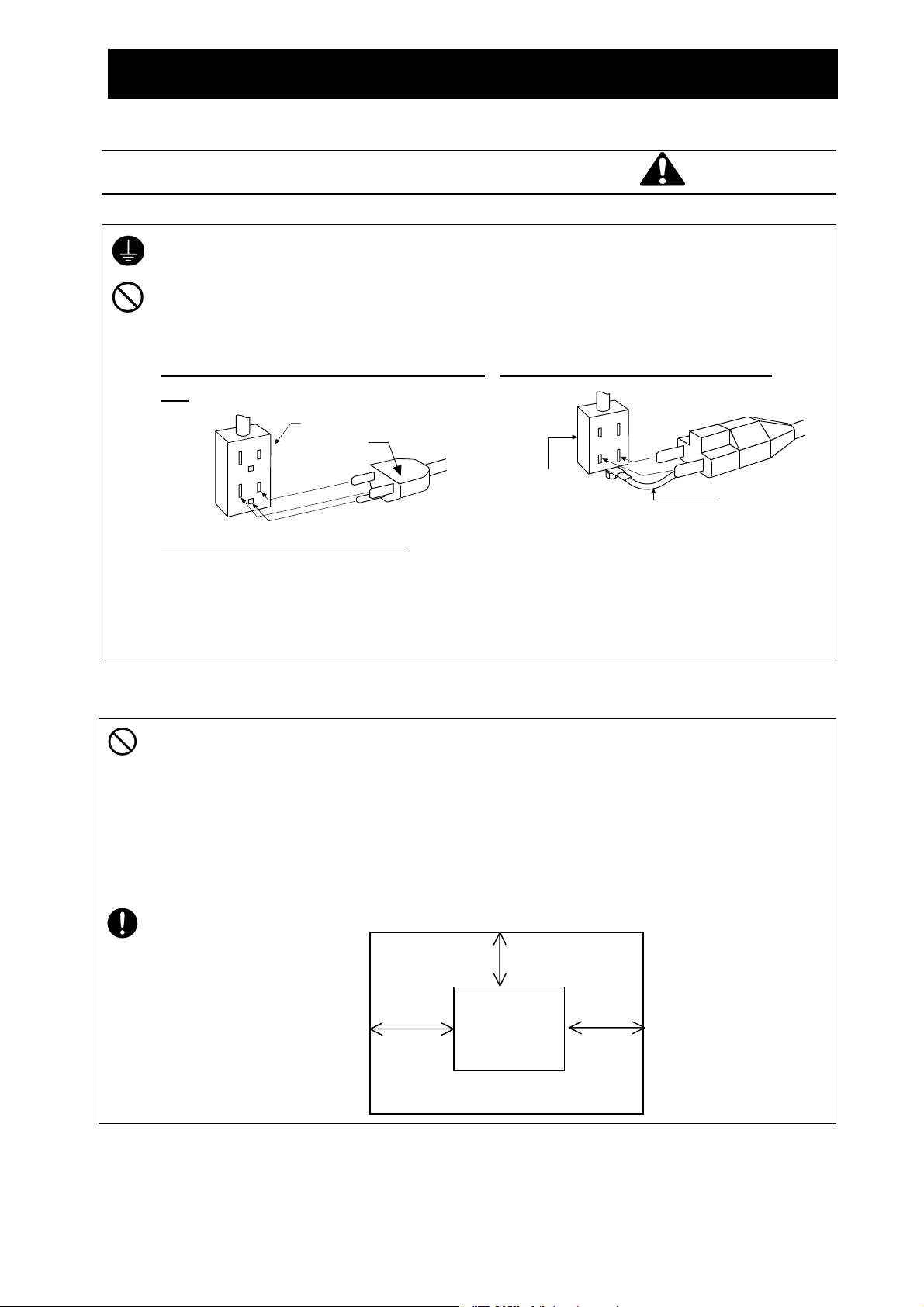

1.Be sure to connect the earth.

Bipol

・ Be sure to connect the earth wire (green core wire of the power cord) to the earth wire or

the earth terminal to avoid an electrical shock due to earth leakage.

・ Never connect the earth wire to a gas pipe or a water pipe. Otherwise, a fire may result.

・ Never connect the earth wire to the earth terminal for a telephone line or to a lightening

conductor. Otherwise, a fire or an electrical shock may result.

・ Never use a branching outlet, which might generate heat and cause a danger.

We recommend use of a ground type outlet

tap.

G

G

When there is no ground terminal.

In this case, class 3 grounding work is

necessary and please consult your dealer or

our nearest sales office.

Grounded receptacle

Power plug

2. Before operating the unit

Precautions on installation

Warning

When a bipolar type outlet tap is used

ar

recep tacle

Insert the ground adaptor included as an option,

into a power plug confirming the polarity of the

outlet. Connect the grounding wire (green) of

the ground adaptor to the ground terminal on

the power supply equipment.

Grounded wire

2. Carefully select an installation site.

Take special care not to install the unit at a place described below:

・Uneven surfaces or dirty surfaces

・Where flammable gas or corrosive gas exists

・ Where the ambient temperature is 35 ℃ or more

・Where temperature changes severely

・Where humidity is high

・Where subject to direct sunlight

・Where vibration is severe

Install this unit at a place with spaces shown below.

15cm or

more

10cm or more

Man body

Front

10cm

or more

4

Page 7

2. Before operating the unit

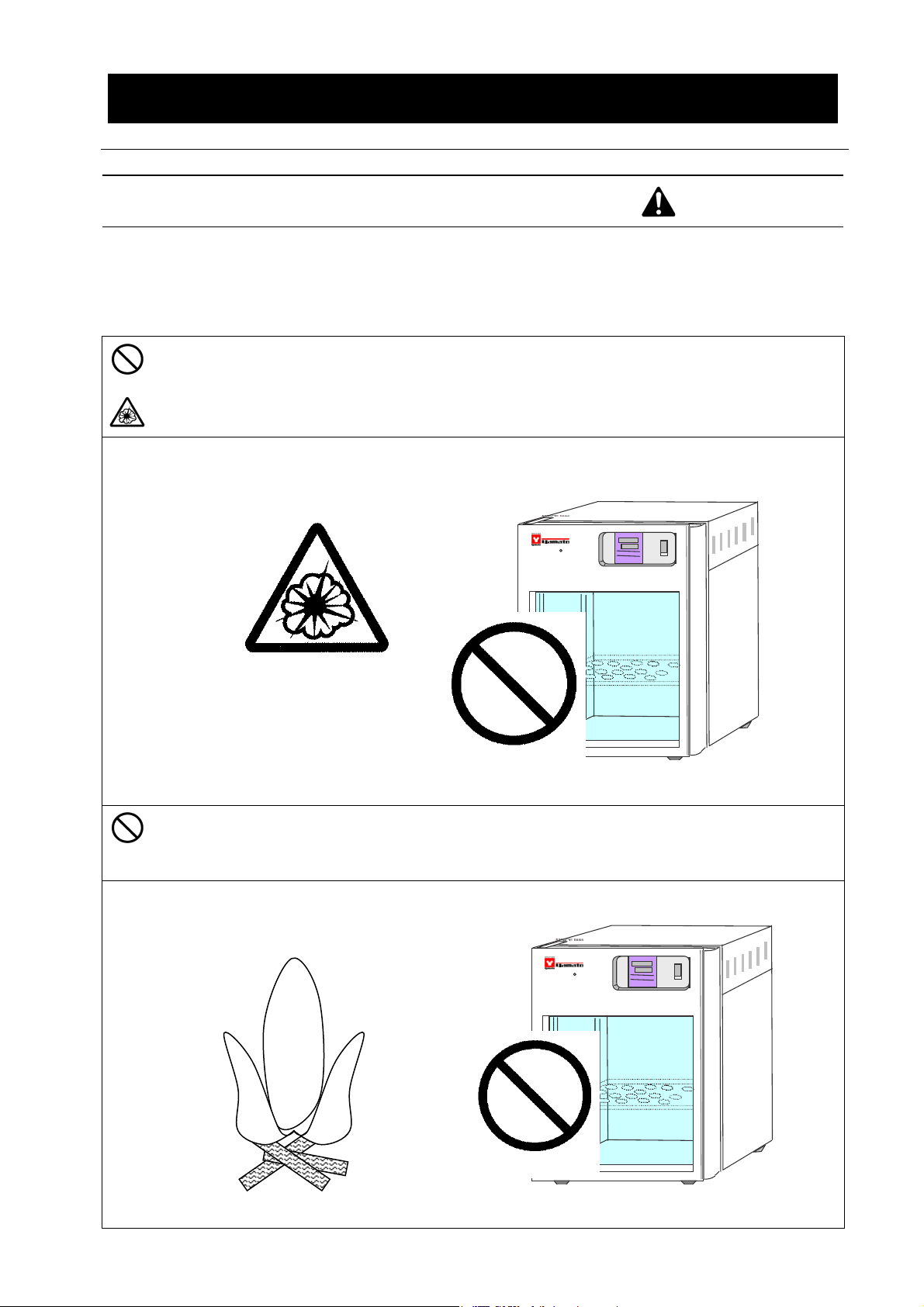

3. Never operate the unit in an atmosphere containing flammable or explosive gas. No

flammable matters

See the section “13. List of dangerous materials” on page 37 for flammable and

explosive gases.

Never operate the unit in an atmosphere containing flammable or explosive gas. Since the unit

is not explosion-proof, an arc is discharged when switching “ON” and “OFF” and during

operation and a fire or an explosion may result.

Precautions on installation

Warning

DO NOT USE

IC101W

Explosive gas

Flammable gas

Do not operate the unit with flammable material inside. Otherwise, a fire may

result.

Do not use

flammable

matters

IC101W

5

Page 8

g

e

2. Before operating the unit

Precautions on installation

Warning

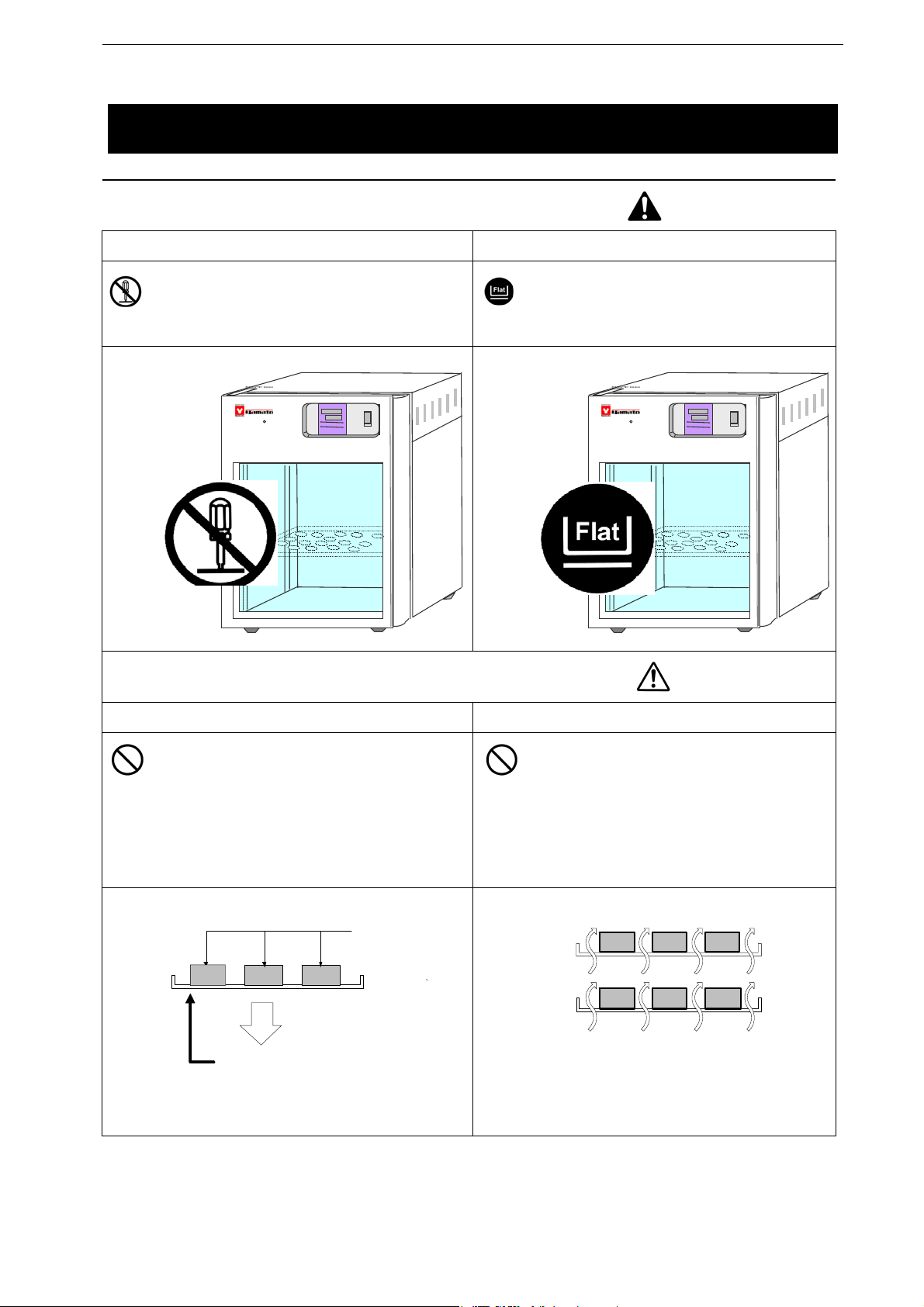

4.Do not attempt to alter the unit 5.Install the unit on a level surface

The customer shall never attempt to alter

the unit. Otherwise a malfunction may

result.

IC101W

Install the unit on a level surface.

Otherwise unexpected troubles or a

malfunction may result.

IC101W

6.Do not put too many specimens.

The withstand load of a shelf board is 10kg

when the load is evenly distributed.

Put specimens dispersed.

7.Do not set too many specimens.

Too many specimens will prevent correct

temperature control. In order to assure

temperature precision, be sure to use

shelf boards and put specimens

dispersed, and secure at least 30% of

space inside the bath.

Specimen

10k

Shelf board

Secure at least 30% of spac

Cautions

6

Page 9

2. Before operating the unit

Precautions on installation

Cautions

8. Connect the power plug to the dedicated outlet

Use an outlet that is suited to the electrical capacity.

When the unit does not start even when power is turned ON, check if main voltage is too low

Electrical capacity

or if the unit is connected to the same power line as other devices. If this is the case, use a

different power line from those for other devices as the power supply.

IC101 AC100V 1.1A

IC101W AC100V 3.1A (While using a service outlet MAX2A)

9. On installation

An earthquake or a shock may cause the unit fall over or move and personal injuries may

result. We recommend exercising safety precautions including selecting an installation place

where less people are passing by.

10. Installation of shelf boards or specimens

The product includes two shelf boards.

One of them is fixed at the lowest stage in the bath. Do not remove this board except when

you install an optional stirrer stand with slide rail.

Set a shelf board at an appropriate position in the bath with included shelf cramps.

The bottom and side surfaces in the bath will become hot. Avoid putting specimens directly

on the bottom surface or allow them to touch with the side surface.

11. Handling of a power cord

Never use electrical power cords bundled. When these are used bundled, they might

overheat causing a fire.

Do not convert, forcibly bend, twist or pull the power cord. Otherwise, a fire or an electrical

shock may result.

Do not place the power cord under a desk or a chair, or sand between objects to avoid it from

being damaged.

Otherwise, a fire or an electrical shock may result.

Do not place the power cord close to a stove or other heat generating device. Sheath of the

cord may burn and result in a fire or an electrical shock.

If the power cord should be damaged (exposure of core wire or disconnection), immediately

turn the ELB off, pull out the power cord (plug) out of the power supply and ask your dealer to

replace the cord. Operating the unit with a damaged power cord may cause a fire or an

electrical shock.

Connect the power cord to an appropriate wall outlet.

7

Page 10

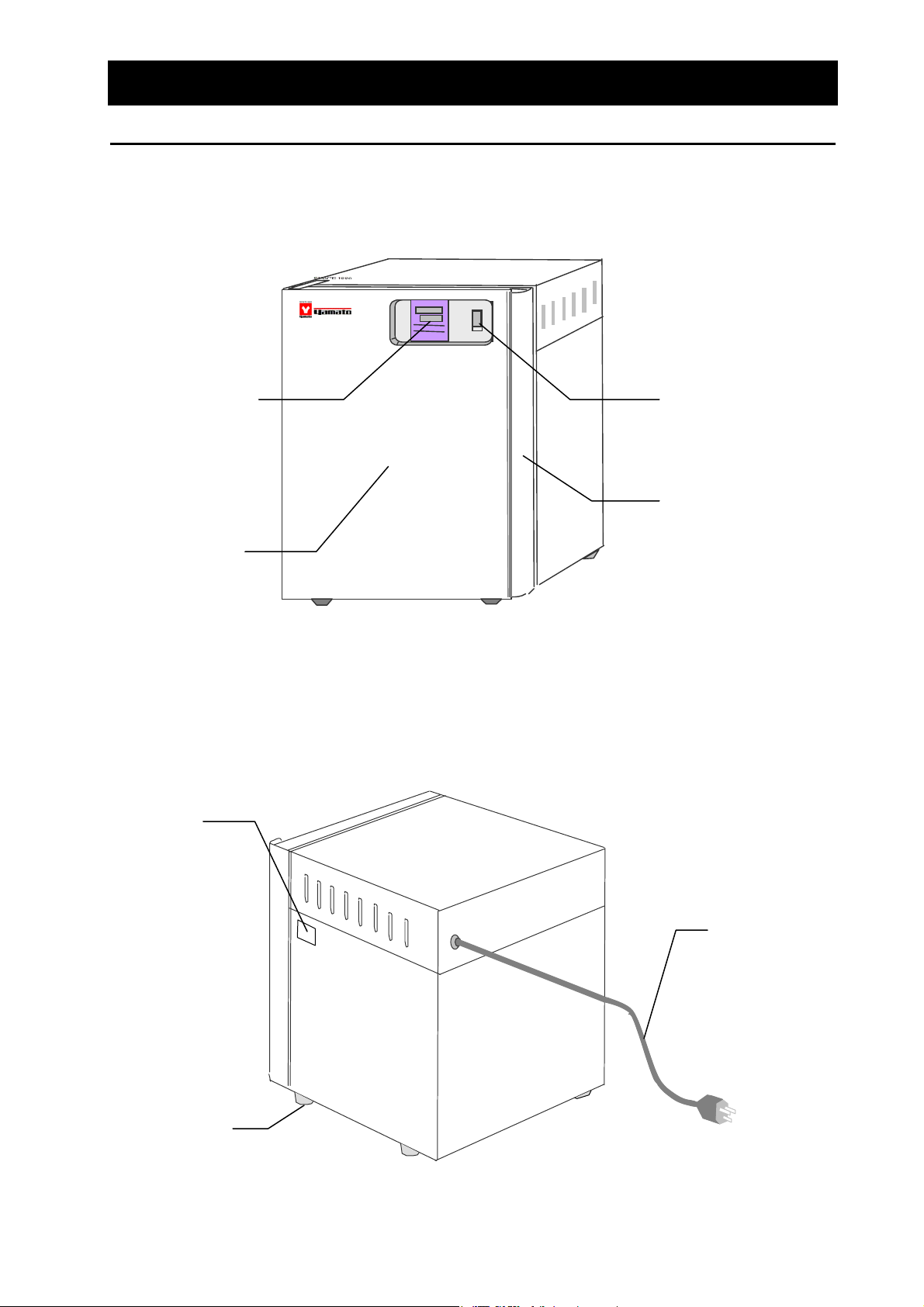

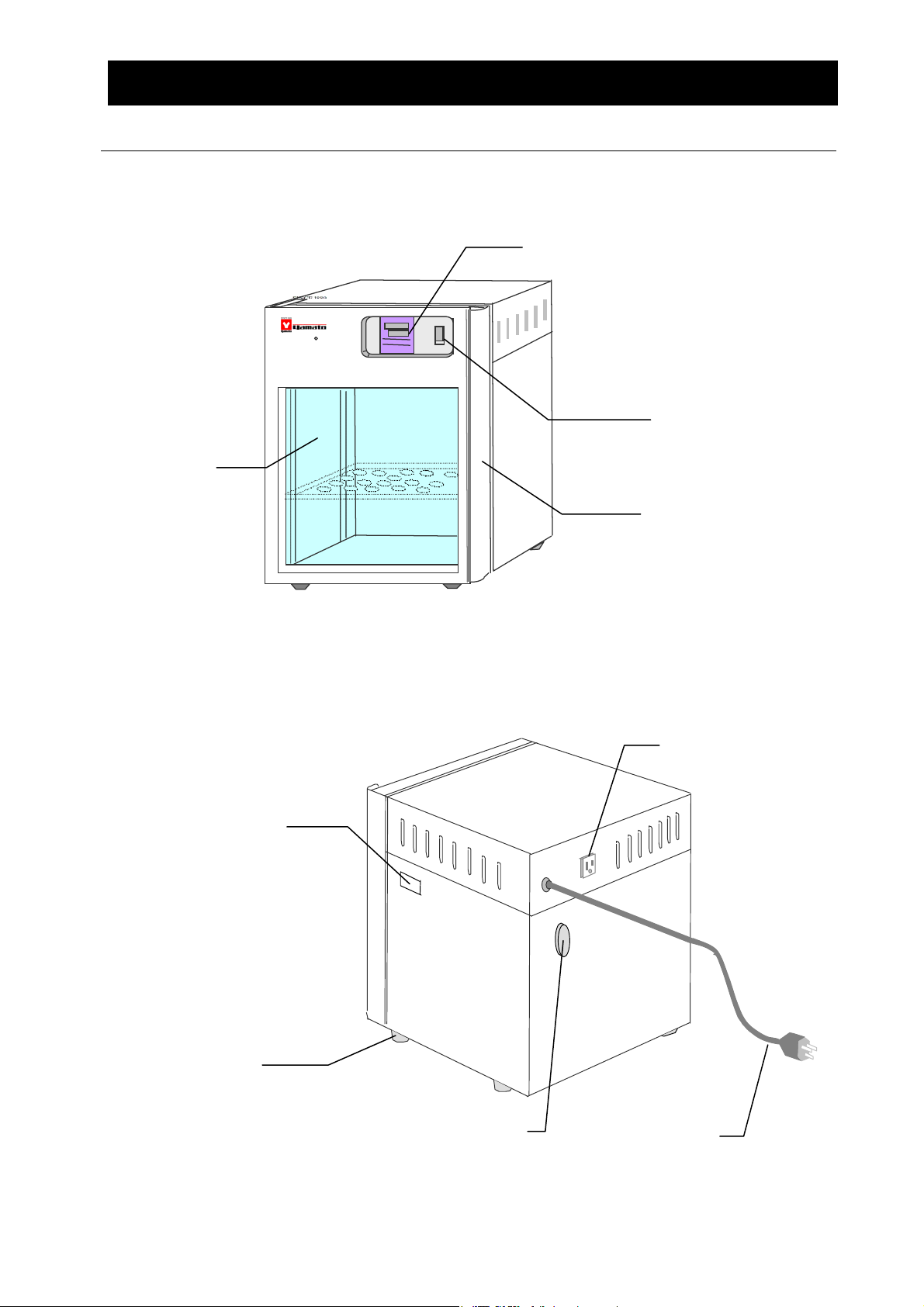

3. Names and functions of each part

Main unit

IC101 Front view

IC101

Temperature

controller

Serial number

nameplate

Main switch

(Circuit breaker)

Handle

Door

IC101 Rear view

Rubber foot

Power cord

8

Page 11

3. Names and functions of each part

do

IC101W Front view

Door with

observation

win

w

Main unit

Temperature controller

IC101W

Main switch

(Circuit breaker)

Handle

Serial number

nameplate

Rubber foot

IC101W Rear view

Cable port

Service outlet

Power cord

9

Page 12

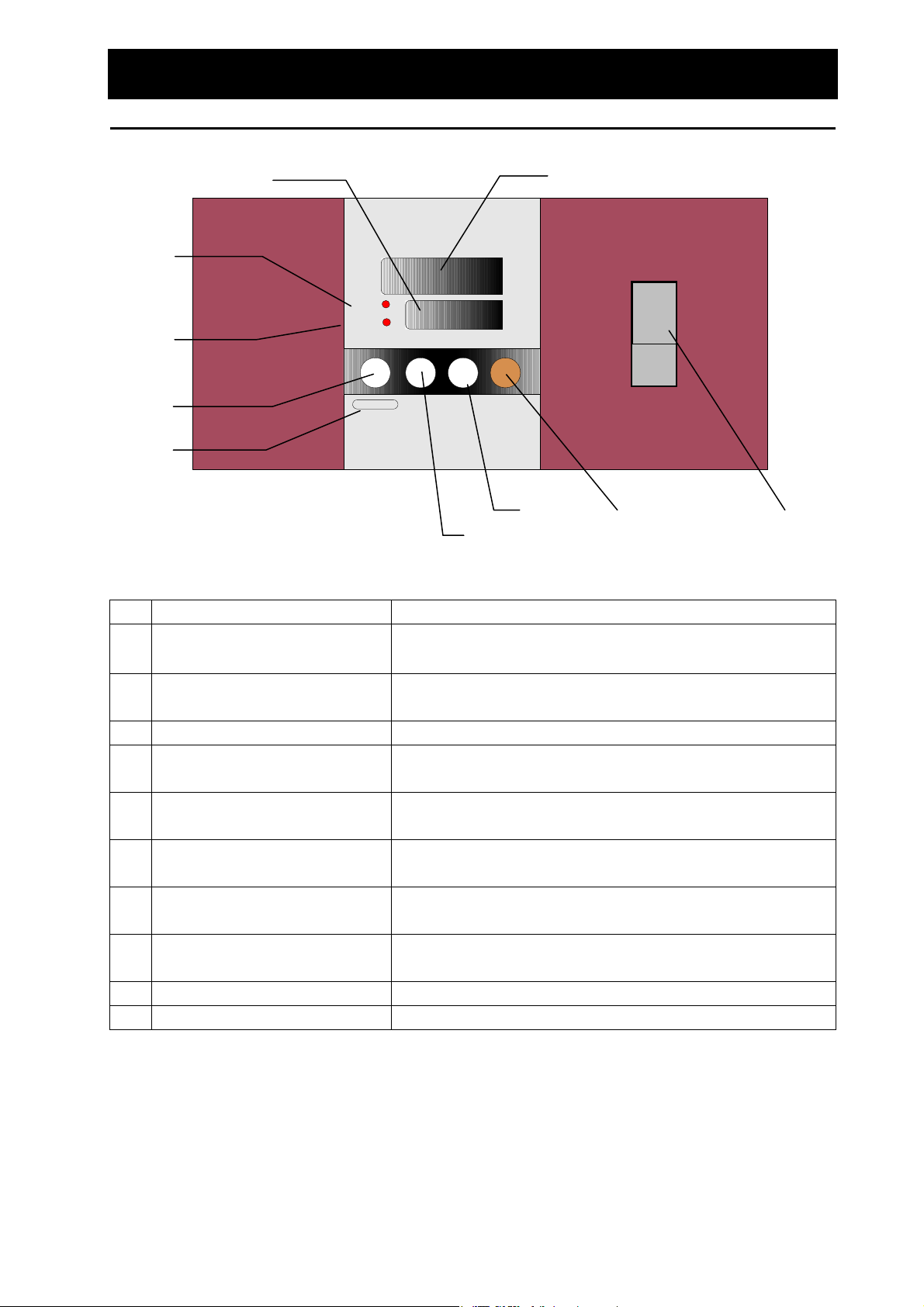

3. Names and functions of each part

Operation panel

MEASURED TEMP.

① ②

③

ON

OFF

④

⑤

⑥

HEATER

OPERATION

Timer

MAINTENANCE

SET TEMP.

▽ △

START

STOP

℃

I

14.6

×

34.0

○

POWER

⑦

⑧ ⑨ ⑩

No Name Operation/action

MEASURED TEMP. indicator

①

Indicates the measured temperature in the bath, set

characters, and error information.

② SET TEMP. indicator Indicates set temp., functional settings, timer settings, and

remaining time of the timer.

③ HEATER lamp Comes on while power is supplied to the heater.

④ OPERATION lamp Stays on during fixed-setting operation; flashes during timer

operation.

⑤ TIMER key Used for timer operation of quick auto stop, auto stop, and auto

start.

⑥

MAINTENANCE key

Pressing the TIMER longer enters the maintenance mode.

This key is used to select and set various sub-functions.

⑦ Down key The key is used to select a setting. Used to increment the

setting.

⑧ Up key The key is used to select a setting. Used to decrement the

setting.

⑨ START/STOP key The key is used to start or stop operation.

⑩ Power switch(Circuit breaker) Used fo r turning power ON or OFF.

10

Page 13

3. Names and functions of each part

r

Heater construction and operation, features, and recovery time

Heater construction and operation

Control

sensor

Heat

insulato

ヒータ

運転ランプ

タイマ

メンテナンス

Temperature

controller

測定温度

℃

設定温度

スタート

ストップ

▽ △

When you turn the main switch on and

Main switch

ON

14.6

×

34.0

OFF

POWER

press the start key of temperature

controller, the cord heater starts heating

to warm air inside the bath.

The temperature in the bath is controlled

Internal bath

with the temperature controller and the

control sensor and becomes stable at the

Cord

heater

set temperature.

Shelf board

Characteristics of the model IC101/IC101W

The internal wall heating system of this product can keep temperature in the bath at a certain level with

higher precision and has advantages such as spe cimens are not likely to dry like the air jacket system

when compared with a system that uses direct air blasting and circulation.

Since models IC101 and IC101W detect internal bath wall temperat ure with the control sensor and

control and display that temperature with the temperature controller, these have a characteristic that

displayed temperature remains relatively stable even when temperature in the internal bath changes

tentatively during temperature rise or from open/close of the door.

Above all, a symptom that the temperature controller does not show any temperat ure changes even

when the temperature inside the bath shall be low im mediately after opening or clo sing of the door i s one

of the characteristics of this internal bath wall heating system.

Temperature recovery time after opening/closing of the door of models IC101 and IC101W

The temperature will recover in about three to four minutes de pending on the env ironmental tempe rature

or amount of specimen.

(Testing condition:Door open time: 30 sec. Environmental temp.: 23℃)

Functions of the model IC101W

You can install a small stirrer or other devices in the bath of the model IC101. Th e power co rd of a small

stirrer can be connected using the cable port and the service outlet (Max. capacity : 2A) on the rear of the

unit.

In this case, care must be taken for possible heating at the small stirrer in the bath. Devices that

generate heat will influence proper temperature control of the incubator and therefore may be

inappropriate for continued operation for a long time.

IC101W

Service outlet (up to 2 A)

Cable port

11

Page 14

3. Names and functions of parts

Description of characters

Character codes used for the controller will be described below.

Character codes Descriptor Name Application

AStP Auto Stop se ttin g

Used for setting quick auto stop or

auto stop operation.

AStr Auto St a r t setting

End Time up

Pon

cAL Calibration offset setting

Lock Key lock of a setting

※For operation modes and function character codes, see P.15 “Operation mode, function setting keys

and character codes”.

Power failure

compensation setting

Used for setting auto start operation.

Displayed when auto stop timer

operation finishes.

See P.17 and 19.

You can select whether operation shall

continue automatically when

recovered from a power failure or

operation shall remain stopped.

See P.23.

Used for inputting a calibration offset

temperature.

See P.24 “Using the calibration offset

function”.

Locks keys to prevent changes of

settings.

See P.25.

12

Page 15

4. Operating procedures

y

List of operation modes and functions

Operation modes of this unit are as follows.

№ Name Description Page

Operates continuously at the set temperature from start to stop

of operation.

1 Fixed value operation

After turning the main switch ON(I), use the

the temperature.

Press the START/STOP key to start operation and press the

START/STOP key again to stop operation.

Used to “stop operation after several hours in the middle of

operation”.

Press the TIMER ke

during fixed value operation and select

▼▲ keys to set

P.16

Quick auto stop

2

operation

Select

Press the START/STOP key to start quick auto stop operation,

the timer starts in the middle of operation to automatically stop

operation after the set time.

Used to “set auto stop before starting operation”.

First set a temperature with the

3 Auto stop operation

Auto start operation

4

※

※You cannot switch the operation mode to 3 auto stop operation nor 4 auto start operation while

the unit is in operation. First stop operation when you want to change the operation mode.

Then press the TIMER key to select

you want with the ▼▲ keys.

Press the START/STOP key to start auto stop operation.

Used to “start auto start automatically after certain hours”.

First set a temperature with the

Then press the TIMER key to select

time you want with the ▼▲ keys.

Press the START/STOP key to start auto start operation.

. You can set a time until operation stops.

and set a time using the ▼▲ keys.

▼▲ keys.

and set a time

▼▲ keys.

and set a

P.17

P.19

P.21

13

Page 16

4. Operating procedures

List of operation modes and functions

Operation functions of the unit are as follows.

№ Name Description Page

:

-

P.23

P.24

P.25

Overheat prevention

1

function

Power failure

2

compensation function

Calibration offset

3

function

4 Setting lock function

Automatic overheat prevention function

The function is set to activate automatically (automatically

return) at a temperature 6

it has risen together with the unit set temperature.

Overheat preventive device

A bimetal overheat preventive device of manual recovery

type is installed.

If the overheat preventive device has activated, the u nit

will stop and will not recover until the recovery button of

the device is pressed.

Call for service when the overheat preventive device is

activated.

When a power failed during operation, operation resumes at

the state immediately before the power failure. (The unit

may remain stopped in the timer operation mode.)

If you want to keep operation stopped when recovering from

a power failure, cancel the power failure compensation

function (OFF).

The calibration offset function is a function that compensates

errors by 1

controlled temperature (indicated temperature) when the

temperature in the bath is controlled to a value different from

the set temperature.

Compensation can be made for plus or minus side.

This function locks the set status currently in operation.

You can set or cancel the function with the SUB MENU key.

℃ between the set temperature and the

℃ above that in t he bath when

:

(Manual recovery)

Service outlet

5

(Model IC101W only)

1. Customer cannot change the setting of the item 1.

2. Functions in the items 2, 3, and 4 can be set using the maintenance function (MAINTENANCE) key.

This is a service outlet useful to use a small stirrer. Run the

power cord through the cable port on the r ear of the main

unit. The maximum capacity is 2 A.

14

P.26

Page 17

4.Operating procedures

A

e

t

Operation mode, function setting keys and character codes

Operation modes and functions require the following key operations and character codes

below for setting.

Main switch

ON

Indication of

initial screen for

4 sec.

Fixed value operation

wait screen

Note:Check set temperature

Maintenance mode

Useful function

Timer

Switch to mainten ance mode by pressing

TIMER key longer.

Fixed value

operation

1sec

Fixed value

operation

Fixed value

operation temp

change

Temp. setting

Fixed value

operation

Start/

Stop

Quick auto stop

operation

Timer

Auto s top

operation

Timer

uto start

operation

Timer

Time setting

Time setting

Start/

1sec

Stop

Timer operation

start

Stop operation

automatically

Start/

1sec

Stop

Returns to the fixed

value operation wait

screen

Time setting

Start/

1sec

Stop

Timer operation

start

Stop operation

automatically

Start/

1sec

Stop

Returns to the fixed

value operation wait

screen

Start/

1sec

Stop

Start fixed valu

operation at se

time

Stop operation

automatically

Start/

1sec

Stop

Returns to the fixed

value operation wait

screen

Operation lock

setting

Set during

operation

Timer

Press TIMER key once

OFF ON

ON to lock keys

OFF to release

Calibration

offset

Set during

operation

Timer

Press TIMER key twice

Temp. UP Temp. DOWN

▽ to increase in-bath

temp

△ to decrease in-bath

temp.

Power failure

compensation

Set before

operation

Timer

Press TIMER key thrice

OFF ON

ON to turn power failure

compensation func ON

OFF to turn power failure

compensation func OFF

15

Page 18

4. Operating procedures

Operating procedures(fixed value operation)

Procedures for fixed value

operation

HEATER

OPERATION

MAINTENANCE

Timer

MEASURED TEMP.

SET TEMP.

▽ △

℃

START

STOP

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

MEASURED TEMP.

HEATER

TIMER

MAINTENANCE

OPERATION

SET TEMP.

ON

14.6

×

34.0

OFF

POWER

℃

℃

START

STOP

1. Turn the main switch on. (Turn the switch to “I”.)

Turning the switch on will display the initial values for

about four seconds, then the screen will change to the

initial setting screen and indicators show the current

in-bath temperature and the last set temperature.

MEASURED TEMP. screen

: Displays the current

temperature in the bath

SET TEMP screen:Displays the last set temperature

2. Setting the temperature

Set the temperature you want using the ▼▲ keys.

MEASURED TEMP.

℃

START

STOP

TIMER

MAINTENANCE

HEATER

OPERATION

SET TEMP.

Changing the temperature

3. Starting operation

Press the START/STOP key longer.

The fixed value operation will start and the operation lamp

and the heater lamp will come on.

4. Stopping operation

Press the START/STOP key longer.

The operation will stop, the operation lamp will go off and

the screen will change to the initial setting screen.

You can change the set temperature by simply pressing the

▼▲ keys.

Pressing the

▼▲ keys during operation immediately b rings

you to the setting mode where you can change the

temperature.

After setting a new temperature, wait a while until the new

temperature will be active and then the screen returns to the

previous one.

16

Page 19

4. Operating procedures

Operating procedures(Quick auto stop operation)

This is used to “stop operation automatically after several hours in the middle of the fixed value

operation”.

The quick auto stop operation allows setting of auto stop timer during operation.

How to start auto stop

operation

MEASURED TEMP.

℃

②

START

STOP

TIMER

MAINTENANCE

HEATER

OPERATION

①

SET TEMP.

1. Setting time before stop during fixed value operation

Confirm that the operation lamp is on, which indicates

①

the unit is in operation.

Press the TIMER key.

The character AstP t hat indicat es the auto stop

operation mode appears in the MEASURED TEMP.

screen and the set time flashes in the SET TEMP

screen.

② Use the ▼▲ keys to set the time you want.

About the timer function

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

TIMER

MAINTENANCE

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

TIMER

MAINTENANCE

℃

START

STOP

1 sec

℃

START

STOP

1 sec

The maximum settable time of the timer is 999 hours 50

minutes.

You can set time in the unit of minutes up to 99 hours 59

minutes.

Time of 100 hours or longer shall be set in the unit of 10

minutes.

You can continuously change the set t ime and find the time

you want quickly by keeping the

adjust the time, press the

▼▲ keys for one digit at a time.

▼▲ ke ys pressed. To fine

2. Starting the timer operation

When you have set the time you want, press the

START/STOP key again while it is flashing.

The operation lamp will flash and timer operation will start.

Note

: Timer counting starts when the temperature in the

bath reaches the set temperature.

When the timer starts counting, the SET TEMP

screen will switch to the remaining time indication.

3. Stopping/finishing the timer operation

When the set time has passed, the timer will stop

automatically but the character End

flashes in the

set temperature indicator to indicate that operation has

finished.

To return to the initial setting screen, press the

START/STOP key longer f or about one second to finish

the timer operation mode.

The screen will return to the initial setting screen.

17

Page 20

4. Operating procedures

Operating procedures(quick auto stop operation)

To change the set

temperature or the set time

Pressing the ▼▲ keys during operation immediately brings

you to the setting mode where you can change the

temperature.

Pressing the TI MER key during operation immediately brings

you to the setting mode where you can change the set time.

In this case, you need to set a time obtained by addin g time

that has already passed to time you want to add.

After you have changed time, press the START/STOP key to

finish.

The remaining time indication

down while its dot is flashing.

When the dot stays on, it indicates the wait status

(temperature is increasing or decreasing to the set

temperature) during which timer count is stopped.

indicates count

18

Page 21

4. Operating procedures

Operating procedures(auto stop operation)

The timer is set from the start of fixed value operation and the operation is automatically stopped when

the set temperature comes.

How to start auto stop

operation

MEASURED TEMP.

℃

②

START

STOP

TIMER

MAINTENANCE

HEATER

OPERATION

①

SET TEMP.

1. Setting the stop time

Confirm that the temperature you wa nt is set and then

①

press the TIMER key.

The character AStP that indicates the auto stop

operation appears in the MEASURED TEMP. and th e

set time flashes in the SET TEMP screen.

② Use the ▼▲ keys to set the time you want.

About the timer function

MEASURED TEMP.

HEATER

OPERATION

TIMER

MAINTENANCE

MEASURED TEMP.

HEATER

OPERATION

TIMER

MAINTENANCE

SET TEMP.

SET TEMP.

The maximum settable time of the timer is 999 hours 50

minutes.

You can set time in the unit of minutes up to 99 hours 59

minutes.

Time of 100 hours or longer shall be set in the unit of 10

minutes.

You can continuously change the set t ime and find the time

you want quickly by keeping the

adjust the time, press the

▼▲ keys for one digit at a time.

▼▲ ke ys pressed. To fine

2. Starting the timer operation

When you have set the time you want, press the

ST AR T/STOP key longer for about one second. Press the

℃

START/STOP key longer for about one second.

The operation lamp flashes and the timer operation starts.

START

STOP

Note:T imer counting starts when the temperature in the bath

reaches the set temperature.

When the timer starts counting, the SET TEMP screen will

switch to the remaining time indication.

3. Stopping/finishing the timer operation

When the set time has passed, the unit will stop operation

automatically.

℃

The character End

fl ashes in the set temperature

indicator to indicate that operation has finished.

START

STOP

Press the START/STOP key longer for about one second

to finish the timer operation mode. The screen will switch

to the initial setting screen.

19

Page 22

4. Operating procedures

Operating procedures (auto stop operation)

To change the set

temperature or the set time

Pressing the ▼▲ keys during operation immediately brings

you to the setting mode where you can change the

temperature.

Pressing the TIMER key during operation immediately brin gs

you to the setting mode where you can change the set time.

In this case, you need to set a time obtained by addin g time

that has already passed to time you want to add.

The remaining time indication

while its dot is flashing.

When the dot stays on, it indicates the wait status

(temperature is increasing or decreasing to the set

temperature) during which timer count is stopped.

indicates count down

20

Page 23

4. Operating procedures

Operating procedures(auto start operation)

The mode starts operation automatically after the time set with the timer has passed.

Note that the operation will not stop automatically but must be stopped manually in this mode.

To start auto start operation

MEASURED TEMP.

℃

②

START

STOP

TIMER

MAINTENANCE

HEATER

OPERATION

①

SET TEMP.

1. Setting the operation start time

Confirm that the temperature you want has been set

①

and press the TIMER key.

The character AStr that indicates the auto start

operation appears in the MEASURED TEMP. screen

and the set temperature flashes in the SET TEMP.

screen.

② Use the ▼▲ keys to set the time you want.

About the timer function

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

TIMER

MAINTENANCE

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

TIMER

MAINTENANCE

℃

START

STOP

℃

START

STOP

The maximum settable time of the timer is 999 hours 50

minutes.

You can set time in the unit of minutes up to 99 hours 59

minutes.

Time of 100 hours or longer shall be set in the unit of 10

minutes.

You can continuously change the set time and find the time

you want quickly by keeping the

▼▲ keys pressed. To fine

adjust the time, press the ▼▲ keys for one digit at a time.

2. Starting the timer operation

When you have set the time you want, press the

START/STOP key long er for about one second while it is

flashing.

Timer counting starts when the START/STOP key is

pressed.

The MEASURED TEMP. screen switches indication from

the set time to the remaining time.

Operation starts automatically when the set time comes

and the operation lamp will come on.

3. Stopping/finishing the timer operation

To stop operation, press the START/STOP key longer for

about one second to finish the timer operat ion mode. The

screen will switch to the initial setting screen.

21

Page 24

4. Operating procedures

Operating procedures(auto start operation)

To change the set

temperature or the set time

If you want to change the set temperature or the set time during

operation, press the TIMER key during operation and set the

temperature or time for auto start operation using the ▼▲ keys.

However, to change the set time, you need to set a time obtained by

adding time that has already passed to time you want to add.

Note

:You cannot change time once the auto start time has passed and

operation has started. Since the operation mode is fixed value, f irst

stop operation using the START/STOP key and make set tings from

the beginning.

22

Page 25

4. Operating procedures

Useful functions(power failure compensation function)

When a power failure occurs in the middle of operation, the unit resumes operation in the state

immediately before the power failure after recovering from the power failure.

(The unit may remain stopped in the case of timer operation.)

If you want to keep the unit stopped when recovering from a power failure, release t he power failure

compensation function (OFF).

MEASURED TEMP.

③

℃

START

STOP

MAINTENANCE

②

TIMER

HEATER

OPERATION

SET TEMP.

① Operate the unit with the initial screen status.

② Press the TIMER key longer to switch to the

MAINTENANCE menu mode. (You are already in the

MAINTENANCE menu mode if LOCK

appears.

)

indication

Press the TIMER key several times to select the

character Pon that indicates the power failure

compensation function.

③ Turn “on” in the MEASURED TEMP. screen to “oFF”

using the

▼ key and you have finished setting.

23

Page 26

4. Operating procedures

p

Useful functions(calibration offset function)

Using the calibration offset

function

The calibration offset function is a function that compensates

differences that may be generated between the temperature

in the bath and the set temperature.

This function can make parallel compensation to the plus or

minus side for the entire temperature range. You can

set/release using the MAINTENANCE key.

The offset is set at “0” at the time of shipping from the factory.

Controlled temp.

after minus

compensation

Current

tem

Controlled temp.

after plus

compensation

erature

① Start operation at the target set temperature, and after

the temperature has become stable, check the

MAINTENANCE

③

MEASURED TEMP.

HEATER

OPERATION

TIMER

SET TEMP.

℃

④

START

STOP

temperature in the bath with a temperature recorder.

② Check difference between the set temperature and the

temperature in the bath.

③ Press the TIMER key longer to switch to the

MAINTENANCE menu mode. (You are already in the

MAINTENANCE menu mode if LOCK

appears.

)

indication

Press the TIMER key several times to select the

character cAL that indicates the calibration

offset function.

④ Enter the difference between the set temperature and

the temperature in the bath using the

▼▲ keys to

complete setting.

※ Offset temperature may be set to either of + or – side.

Setting to the

- side will decrease the displayed

measured temperature by the offset amount while the

temperature in the bath will increase by the same

amount.

Setting to the

+ side will increase the displayed

measured temperature by the offset amount while the

temperature in the bath will decrease by the same

amount.

Note: Temperature in the bath changes tentatively immediately after placing a specimen. Therefore,

wait until the temperature in the bath become stable before checki ng for a temperature

difference.

24

Page 27

4. Operating procedures

Useful functions(setting key lock function)

The function is to lock the settings during operation for safety. You can set or release this function

with the MAINTENANCE

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

TIMER

MAINTENANCE

MEASURED TEMP.

HEATER

OPERATION

SET TEMP.

TIMER

MAINTENANCE

key.

① Press the TIMER key longer to switch to the

MAINTENANCE menu mode.

℃

Press the TIMER key to select the character

Lock that indicates the settings lock.

START

STOP

② "oFF” will appear in the SET TEMP screen. You can

switch this to “on” with the

℃

▲ key to lock the settings.

START

STOP

MEASURED TEMP.

℃

START

STOP

TIMER

MAINTENANCE

HEATER

OPERATION

SET TEMP.

③ If you want to cancel lock, press the TIMER key longer

again and select the character Lock that

indicates the setting lock using the

Selecting “oFF” with the

▼ key releases the lock.

▼▲ keys.

※ While the lock function is “on”, any keys other than

the START/STOP key and TIMER key are locked.

25

Page 28

4.Operating procedures

Useful functions (Using the service outlet)

Using the service outlet(Model IC101W only)

Model IC101W has a useful service outlet to which a device up to 2 amperes can be connected.

This outlet can be used as a power supply for a small stirrer or other device that can be installed

on the IC101W.

Service outlet(Up to 2A)

Power cord of the small stirrer

Small stirrer

Operational precautions

・

・ When a device that generates heat has been installed, proper temperature control may not

・ Install an optional stirrer stand with slide rail if you want to install a small stirrer.

・ The bottom surface and walls in the bath will hot and avoid putting specimen directly on the

When a small stirrer has been installed, operate the unit at 45℃ or lower set temperature to

protect the stirrer.

be possible.

If this occurs, stop using that device.

bottom surface or allow them to touch with the side surface.

Cable port

26

Page 29

5. Handling precautions

1.About materials that cannot be used

Never use an explosive material, a flammable material, or a material that contains such

materials for this unit. They may cause an explosion or a fire. (See P.37 “List of dangerous

materials”.

2.About banning of operation/solutions when an abnormality occurs

When smoke or strange odor is generated from this unit for some reason, immediate turn

power of the unit off, shut the power supply off and ask inspection to your dealer, one of our

sales offices, or the customer center. Leaving the unit as it is may cause a fire or an electrical

shock. The user must not attempt a repair, which may cause a danger.

1. Do not put any object on the unit

Do not put any object on the unit. It might fall off and cause a personal injury.

2. During a thunder storm

When a thunder begins, immediately turn power of the unit off, shut the power supply off.

Leaving the unit as it is might cause a malfunction or a fire from lightening.

)

Warning

Caution

3. When opening or closing the door

When opening or closing the door, do not put your hands or face close to the area (space)

where the door moves.

The door might hit the hand or the face and cause an injury.

4. Banning of use of corrosive materials

Although inside the bath is made of SUS304 stainless steel, it might corrode from a strong

acid. The door packing is made of silicone rubber. Take care it might corrode with acid,

alkaline, oil, or halogen based solvent.

5. Operate the unit at an appropriate temperature

The operational temperature range is +5℃~60℃ room temperature.

Never operate the unit at a temperature out of the operational temperature range.

6. Placement of specimen

The withstand load of a shelf board is 10kg. Do not put a specimen exceeding this limit.

Put two or more specimens dispersed.

Putting too many specimens may cause imperfect transmission of heat to them and prevent

even heating. Make sufficient spaces between specimens.

27

Page 30

5.Handling precautions

7. About recovery from a power failure

When power is recovered after stoppage from power failure during operation, the unit

automatically returns to the state immediately before power failure and resume operation.

Set the power failure compensation function of the sub menu functions OFF if you do not

want to allow the unit to automatically resume operation. See P.23.

8. About stacking in two layers

You can stack the units up to two layers only using the special stacking fittings of optional

accessories.

Never stack the units in three or more layers.

9.After installation

An earthquake or a shock may cause the unit fall over or move and personal injuries may

result. Implement appropriate fall-over preventive measures for safety.

Caution

28

Page 31

6. Maintenance procedures

Daily inspection/maintenance

Warning

● Be sure to pull out the power cord unless necessary before trying to do inspection and maintenance

works.

● Start these works after the device has returned to the normal temperature.

● Never try to disassem ble the unit.

Caution

● Wipe off any dirt with a tightly wrung soft cloth. Never try to clean the unit with benzene, thinn er or

scouring powder, or rub with a scrubbing brush. Deformation, degradation or discoloration may

result.

29

Page 32

7. When the unit is not to be used for a long time

or when disposing

When the unit is not to be used for a long time or when disposing

Caution

When the unit is not going to be used for a long

time

● Turn the power to off and pull out the power

cord.

Warning

When disposing the unit

● Do not leave the unit in the area where children

may have access.

● Be sure to remove handles before disposing

the unit to prevent the doors from locking.

● In general, dispose the unit as a bulky waste.

Notes about disposition

Always pay attention to the preservation of the global environment.

・ We highly recommend taking the unit apart as far as possible for separation or recycling to

contribute to the preservation of the global environment. Major components and materials for the

unit are as follows:

Names of major components Major materials

Major components

Chassis Steel sheet iron, melamine resin baking finish

Interior Stainless steel SUS304

Observation window (only

IC101W)

Insulating material Glass wool

Door packing Silicon rubber

Nameplates Polyethylene (PET) resin film

Major electric parts

Heater

Boards

Power cord & wiring materials,

etc.

Reinforced glass, Silicon rubber

SUS

-Chrome heater

Resin, board, condenser, resistor, transformer, or other

composite parts

Wiring materials with resin cladding

30

Page 33

8. When a trouble occurs

Safety device and error codes

The table below shows the possible causes and solutions for a trouble and a safety device has

activated.

[Error code]

When an operational abnormality or a malfunction occurs, “MALFUNCTION” sign and an error

code will appear on the operation panel. When a malfunction occurs, note the error code and

immediately stop operation.

Safety device Symptom Possible causes and solutions

Wrong temperature

input

Malfunction of

memory

Abnormal measured

temperature

Abnormal measured

temperature

Alarm lamp on

indication

Alarm lamp on

indication

No indication z When the automatic overheat preventive

All function stop z When the independent overheat preventive

z Abnormal temperature input circuit

z Disconnection or malfunction of the

temperature sensor

z The measured temperature is out of the

display range.

Contact the customer service center.

z Abnormal settings in memory

Contact the customer service center.

device activated due to abnormal increase in

temperature in the bath.

Contact the customer service center.

device activated due to abnormal increase in

temperature in the bath.

Contact the customer service center.

About the activation of the circuit breaker(main switch)

The unit is equipped with a circuit breaker with the main switch function.

When excessive current flows through the unit for some reason, the circuit breaker will turn OFF

I to

○) and shut the power off. To recover, first remove the causes and then turn the switch ON

again.

○

I

When the breaker activates, the switch

returns from I to

○.

(from

31

Page 34

8. When a trouble occurs

If a malfunction is suspected

In the following cases

Symptom Possible Causes

The unit will not start

even if power is turned

on.

Temperature changes

during operation.

There is a difference

between the set

temperature and the

temperature in the

bath.

◆When the symptom does not correspond to any of the above, immediately turn the pow er

switch off, pull out the power plug and contact your dealer, one of our sales offices, or our

customer service center.

● Power plug is not connected to the receptacle correctly.

● Power failure.

● Too many specimens are placed.

● Air from an air conditioner is blowing directly against.

● Outside temperature is too low.

● Changes in the environmental temperature are too large.

● Specimen may contain too much water.

● Source voltage may be too low.

● The temperature compensation value of the calibration offset

may be too small or too large. Set the compensation to ±0

once and wait until the temperature in the bath becomes stable (after

about two hours), reenter the correct compensation value.

(See P.24.)

32

Page 35

9. After sales service and warranty

When requesting a repair

When requesting a repair

If any trouble occurs, immediately stop operation, turn the power switch off, pull out the power plug and

contact your dealer, our sales office or our customer service center.

Information necessary for requesting a repair

● Model name of the product

● Serial number

● Date (y/m/d) of purchase

● Description of trouble (as in detail as possible)

Be sure to indicate the warranty card to our service representative.

See the warranty card or the nameplate on the unit.

(See P.8

~P.9).

Warranty card (attached separately)

● Warranty card is given by your dealer or one of our sales offices and please fill in your dealer,

date of purchase and other information and send it to our customer service center by Facsimile

(03-3231-6523). Then, store it securely.

Warranty period is one full year from the date of purchase. Repair service for free is available

●

according to the conditions written on the warranty card.

For repairs after the warranty period consult your dealer, one of our sales offices or our

●

customer service center.

Paid repair service is available on your request when the product’s functionality can be

maintained by repair.

Minimum holding period of repair parts

The minimum holding period of repair parts for this product is seven years after end of production.

Repair parts here refer to parts necessary for maintaining performance of the product.

33

Page 36

10. Specifications

Specification of the main unit

Product name Incubator

Model IC101 w IC101

System

Exterior material

Interior material Stainless steel

Heater Silicon code heater:100W

Cable hole Inner dia. 30φ x 1

Observation window 290W×240H Dual semi-reinforced

Construction

Service outlet An outlet 3P Max 2A

Operation temperature

range

Temperature control

precision

Temperature distribution

precision

Performance

Time to attain the max.

temperature

Temperature controller

Controller PID control, digital setting

Temperature sensor K-thermocouple

Temperature control

system

Temperature setting

system

Control

Timer resolution 1 minute (0 hour 00min―99 hours 59mins)

Temp. controller alarm

function

Overheat prevention unit Manual recovery bimetal (70℃)

Safety

function

Main switch Circuit breaker(locker switch type)

Operation function

External dimension 410 x 380 x 520

Internal dimension 350 x 300 x 360

Capacity 37L

Power supply AC100V 50/60Hz 3.1A

Standard

Power cord 3P cord with plug

Weight Approx.17Kg Approx.16kg

Accessories 2 sets of shelf boards(One is fixed in the bath), operating instruction,

Optional parts

* Performance is measured with the power of AC100V.

* The operation temperature range of the unit is 5℃~35℃. Note that a lower environmental temperature ma y

prolong temperature attainment time or enlarge difference between set temperature and that in the bath. We

recommend using the unit at the environmental temperature of 18℃~30℃.

External dimensions exclude protruding parts.

*

Internal bath wall heating natural convection system

Steel plate, melamine b ake d finishing

glass

Room temperature of +5℃ to 60℃

±0.5℃(at37℃)

±1.5℃(at37℃) ±1.0℃(at37℃)

Approx. 40 minutes

PID control by micro computer

Up/Down key

Setting by 1 minute up to 99 hours 59mins

Setting by 10 minutes from 100 hours

Automatic overheat prevention function:Set temperature +6℃ main

relay shut-off (Auto recovery)

Operation functions: fixed value, quick auto stop, auto stop, auto start

Functions: operation key lock, calibration offset, power failure

compensation

AC100V 50/60Hz 1.1A

Service outlet 2A included

warranty card

Stacking fittings

Set of shelf boards

Stirrer stand with slide rail (IC101 w

only)

34

Page 37

Wiring diagram

(IC101/IC101W)

OH

AC100V

T:Model IC101W only

Model IC101 does not have a service outlet.

MBC

TB

T

H

1

2

3

2

4

SSR

1

Symbol Part name

MCB Main switch

(Circuit breaker)

H Cord heater TH K sensor for control

TB Terminal block OH Overheat preventive bimetal

T Service outlet (IC101w only) SSR Contact less relay

11. Wiring Diagram

9

8

7

6

5

4

-

TH

3

4

3

2

+

1

Symbol

TC Temperature controller

CONT

22

1

Part name

22

1

PIO

35

Page 38

12. List of replacement parts

Replacement parts for IC101/IC101W

Part Name Specification Manufacturer Code No.

Control board for

1

temperature controller

display board for

2

temperature controller

3 K sensor for control

4 SSR TRS5225 Toho Denshi 2160000035

5 Power cord kit

6 Circuit breaker 3130-F110 10A

Overheat preventive

7

device

Cord heater

8

9 Terminal block TBF-250ABC-4P

10 Service outlet

CN40BY-IC

CN40BY-IC

φ0.32 K-thermocouple,

with protective tube

1.25

sq3Pwith plug 2 m

Manual recovery bimetal 70

Silicon cord heater

S-150 125V 15A

100W

℃

Yamato

Scientific

Yamato

Scientific

Yamato

Scientific

Yamato

Scientific

ETA

components

Matsuo

electric

Yamato

Scientific

Sakazume

electric

Sato parts LT00002360

LT00007640

LT00007639

LT00009502

LT00001745

LT00001299

LT00002216

LT00020099

LT00002219

36

Page 39

Explosive

substance

13. List of dangerous materials

Never use an explosive substance a flammable substance or a substance

containing them for this device.

① Nitroglycol, glycerine trinitrate, cellulose nitrate and other explosive nitrate esters

② Trinitrobenzen, trinitrotoluene, picric acid and other explosive nitro compounds

③ Acetyl hydroperoxide, methyl ethyl ketone peroxide, benzoyl peroxide and other

Explosive

substance

organic peroxides

Metal “lithium”, metal “potassium”, metal “natrium”, yellow phosphorus, phosphorus

sulfide, red phosphorus, celluloids, calcium carbide (a.k.a, carbide), lime phosphide,

magnesium powder, aluminum powder, metal powder other than magnesium and

Explosive

aluminum powder, sodium dithionous acid (a.k.a., hydrosulphite)

substances

① Potassium chlorate, sod iu m ch lora te , ammon i um ch lo ra te , a nd o ther ch lo ra te s

② Potassium perchlorate, sodium perchlorate, ammonium perchlorate, and other

perchlorates

③ Potassium peroxide, sodium peroxide, barium peroxide, and other inorganic

peroxides

④Potassium nitrate, sodium nitrate, ammonium nitrate, and other nitrates

⑤ Sodium chlorite and other chlorites

Oxidizing substances

⑥ Calcium hypochlorite and other hypochlorites

① Ethyl ether, gasoline, acetaldehyde, propylene chloride, carbon disulfide, and othe r

substances with ignition poin t a t a de gree 3 0 or more degrees below zero.

② n-hexane, ethylene oxide, acetone, benzene, methyl ethyl ketone and other

Flammable substances

Combustible

(Quoted from the separate table 1 in Article 6, the enforcement order of the Industrial

substances with ignition point between 30 degrees below zero and less than zero.

③ Methanol, ethanol, xylene, pentyl acetate, (a.k.a.amyl acetate) and other

substances with ignition point between zero and less than 30 degrees.

④ Kerosene, light oil, terebinth oil, isopenthyl alcohol(a.k.a. isoamyl alcohol), acetic

acid and other substances with ignition point between 30 degrees and less than 65

Flammable substances

degrees.

Hydrogen, acetylene, ethylene, methane, ethane, propane, butane and other

gas

Substance which is a flammable gas at 15

℃, one air pressure.

Safety and Health Law

37

Page 40

Limited liability

Be sure to use the unit strictly following the handling and operating instructions in this

operating instruction.

Yamato Scientific Co.,Ltd. assumes no responsibility for an accident or a malfunction

caused by use of this product in any way not specified in this operating instruction.

Never attempt to perform matters prohibited in this operation instruction.

Otherwise, an unexpected accident may result.

Notice

● Descriptions in this operating instruction are subject to change without notice.

● We will replace a manual with a missing page or paging disorder.

Operating instruction

Incubator

IC101/IC101W

3rd edition 1 August, 2007

Revised 22 February, 2012

Yamato Scientific Co.,Ltd.

〒103-8432

2-1-6, Nihonbashi, Honcho, Chuo-ku, Tokyo

Customer Service Center

Tool free: 0120-405525

http://www.yamato-net.co.jp

Loading...

Loading...