Page 1

Model High -TechⅣ

Ⅳ

ⅣⅣ

Programmable Controller

Operating Instructions

Version 2

Yamato Scientific Co., Ltd

Page 2

1111. INTRODUCTION

. INTRODUCTION ................................

. INTRODUCTION. INTRODUCTION

Explanation of Character on the display

Explanation o f Character on the d i s play................................

Explanation of Character on the displayExplanation of Character on the display

2.

2. INPUTTING, EDITION AND DELETING PROGRAMS

INPUTTING, EDITION AND DELETING PROGRAMS ......................

2.2.

INPUTTING, EDITION AND DELETING PROGRAMS INPUTTING, EDITION AND DELETING PROGRAMS

2.1 Program Composition

2.1 Program Composition................................

2.1 Program Composition2.1 Program Composition

2.2 Inputting Programs

2.2 Inputting P r ogra ms ................................

2.2 Inputting Programs2.2 Inputting Programs

2.3 Editing Programs

2.3 Editing Pr o gra ms................................

2.3 Editing Programs2.3 Editing Programs

2.4 Deleting Programs

2.4 Deleting Progra ms ................................

2.4 Deleting Programs2.4 Deleting Programs

3. INPUTTNG AND SETTING FUNCTIONS

3. INPUTTNG AND SETTING FUNCTIONS................................

3. INPUTTNG AND SETTING FUNCTIONS3. INPUTTNG AND SETTING FUNCTIONS

3.1 Switching between Time and Period

3.1 Switching between T ime and Period ................................

3.1 Switching between Time and Period3.1 Switching between Time and Period

3.2 Setting and Releasing Panel Key Lock

3.2 Setting and R eleasing Panel Key Lock................................

3.2 Setting and Releasing Panel Key Lock3.2 Setting and Releasing Panel Key Lock

3.3 Turning ON and OFF Buzzer Sound

3.3 Turning ON an d OFF Buzzer Sound ................................

3.3 Turning ON and OFF Buzzer Sound3.3 Turning ON and OFF Buzzer Sound

3.4 Indication of Integrating Operation Time

3.4 Indication of Integrating Operation Time................................

3.4 Indication of Integrating Operation Time3.4 Indication of Integrating Operation Time

3.5 Setting Date and Time

3.5 Setting Date and T i me................................

3.5 Setting Date and Time3.5 Setting Date and Time

3.7 Communication lock out function

3.7 Communication l o ck o u t fu n c ti o n ................................

3.7 Communication lock out function3.7 Communication lock out function

4. SAFETY MEASURES AND PRECAUTIONS

4. SAFETY MEASURES AND PRECAUTIONS ................................

4. SAFETY MEASURES AND PRECAUTIONS4. SAFETY MEASURES AND PRECAUTIONS

4.1 POST Function

4.1 POST Functi on................................

4.1 POST Function4.1 POST Function

4.2 Precautions

4.2 Precaution s................................

4.2 Precautions4.2 Precautions

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

..................................................

................................................................

................................................................

................................................................

.........................................................

................................................................

..........................................................

................................................................

..............................................................

................................................................

............................................................

................................................................

.........................................

................................................................

...............................................................

................................................................

............................................................

................................................................

...............................................................

................................................................

.......................................................

................................................................

......................................................

................................................................

................................................................

................................................................

......................................

................................................................

................................................................

................................................................

........................................

................................................................

..................2222

....................................

....................................3333

................................................................

......................5555

............................................

......................... 5555

..................................................

.......................... 11

....................................................

.............................. 17

............................................................

............................ 19

........................................................

.........21

..................

............................... 21

..............................................................

............................ 23

........................................................

............................... 24

..............................................................

....................... 25

..............................................

...................... 26

............................................

....................................

................................................................

......31

............

..................................

................................................................

........ 31

................

11

1111

17

1717

19

1919

21

2121

21

2121

23

2323

24

2424

25

2525

26

2626

.... 29

29

........

2929

31

3131

.. 31

31

....

3131

31

3131

5. Behavior after Power Restoration

5. Behavior after Power Restoration ................................

5. Behavior after Power Restoration5. Behavior after Power Restoration

.......................................................

................................................................

.......................32

..............................................

32

3232

Page 3

Cautions on the backup battery

Cautions on the backup battery

Cautions on the backup batteryCautions on the backup battery

Charge the backup battery for memorizing program built-in the unit when

you use the unit for the first time., and also do that when you have not used

the unit for 3 weeks and more. To turn off the circuit breaker without

charging may delete the programmed data

Once turned on the circuit breaker, the battery can be charged.

It takes about 48 hours to charge the battery completely when discharged.

1

Page 4

1. INTRODUCTION

Congratulations on your purchase of a Yamato Scientific's product. 'I his document

discusses the operation of Model High-Tech IV Programmable Controller, especially

the inputting and presetting methods of its various functions, whi ch are not described

in the operating instructions of the systems equipped with the programmable

controller. The programmable controller supports the operations and performances of

Yamato Scientific's machinery and equipment, This means that some of the functions

discussed in this document may not work on the system you have purchased. Please

refer to the operating instructions of your system for the operations and performance

which are supported by the programmable controller.

This Operating Instructions 1 is the basic user's guide of Model High-Tech IV

Programmable Controller. Upon your request, Yamato Scientific will furnish you with

Operating Instructions 2, which discusses detailed operating procedures and

programming concepts of the programmable controller

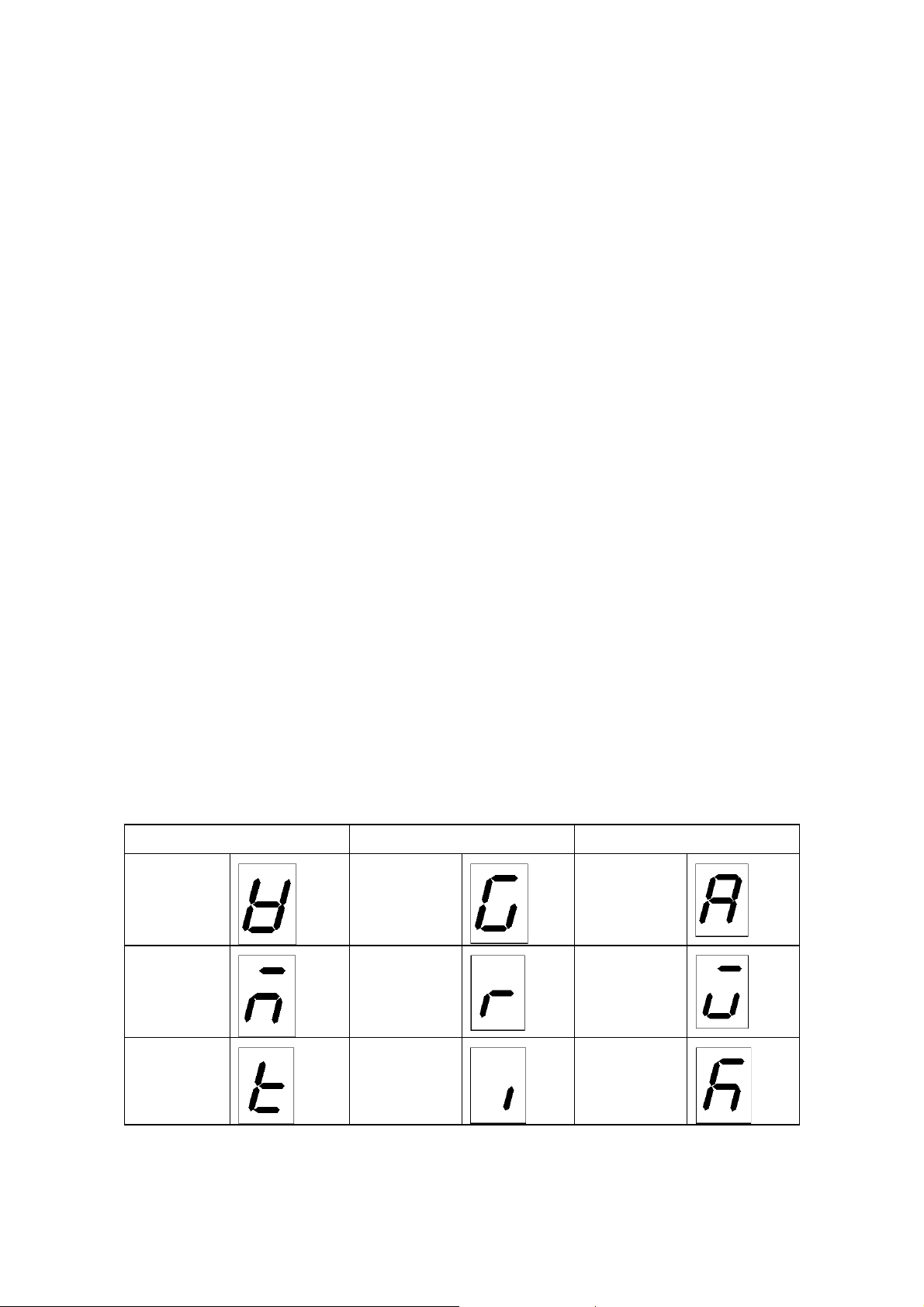

Indication of Characters

The control panel of Model High-Tech TV Programmable Controller uses 7-segment

light emitting diode (LED) to show alphanumeric characters 04 its d splay. This 7segment LED naturally has its limitation in expressing individual characters. Please

take note that the alphabetical characters of 'W." "m," t," "G," "r," "i," "A,"V and k"

are expressed by the substitutes below.

Character Indication Character Indication Character Indication

W G A

m

t i k

r

V

2

Page 5

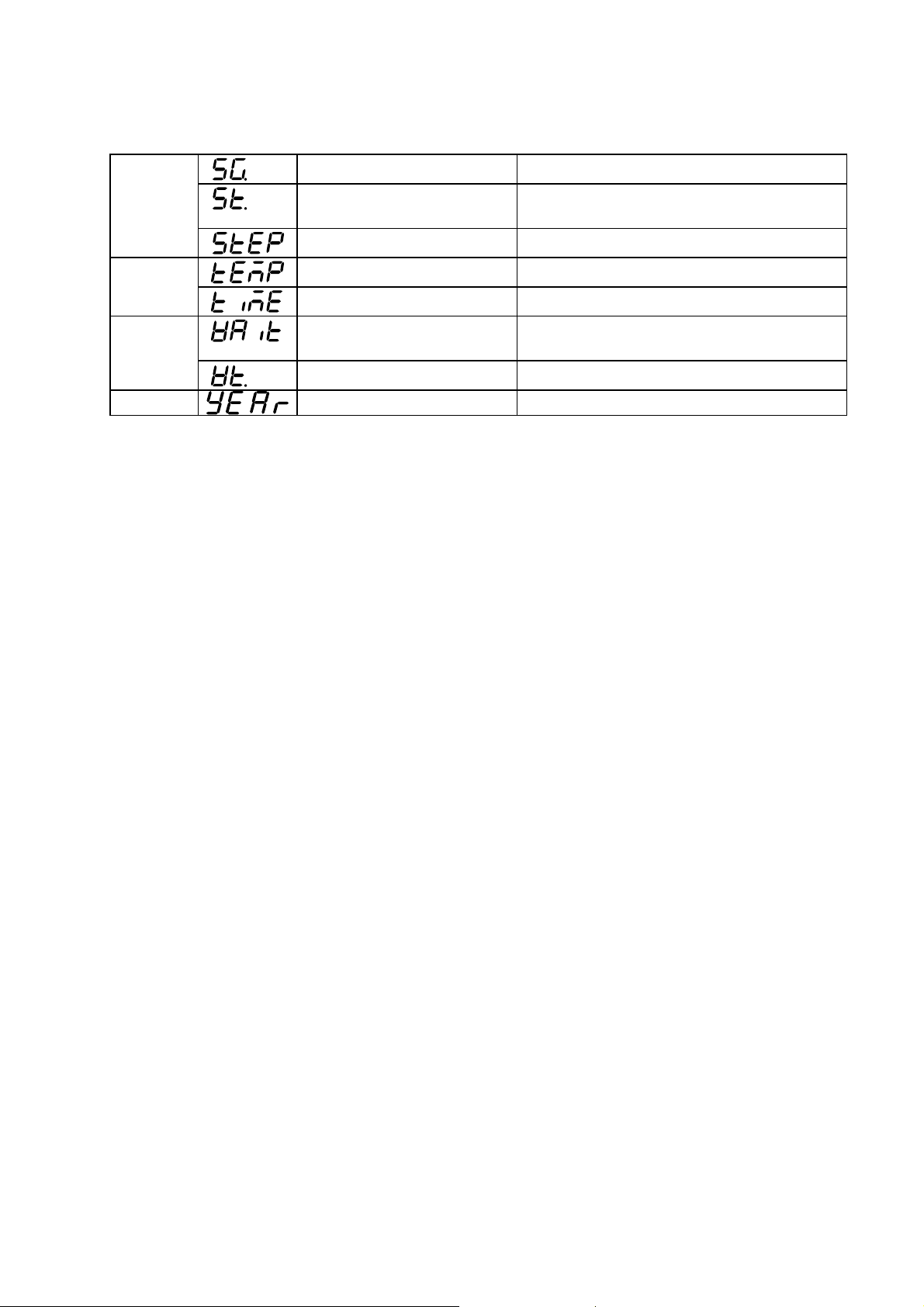

Explanation of Character on the display

The oven has the controller with the 4-digit LED display.

The meaning of Character on the display is as follows:

Capital

Capital Character

CapitalCapital

A accumulation Integrated time

B beep Alarm sound setting mode

Character Meaning of Abbreviation

CharacterCharacter

Meaning of Abbreviation Meaning of Character on the display

Meaning of AbbreviationMeaning of Abbreviation

Meaning of Character on the display

Meaning of Character on the displayMeaning of Character on the display

C

D delete program Deleting a program

E end Setting mode for program end

F

H hold Hold funct ion m ode

L lock Panel locking mode

M

O off Make a function inactive

P program ## Program number

clock Setting of the date and the hour

door The open door

display Sub display switching mode

error ## Error code ##

fan fan

f. wt (Forced wait) Forced wait state after the power

restoration

fn. ## Fan condition of Segment ##

hr. mn (hour. minute) Setting of time (hour, minute)

mn. dy (month. day) Setting of the date (month and day)

on Make a function active

program Program mode

program, segment Ongoing program and ongoing segment

R repeat count Repeat frequency setting mode

repeat Repeat command mode

rest time Rest for remaining time

ramp level Ramp level of Segment ## (Desired set

temperature)

repeat start Repeat start segment setting mode

ramp time Ramp time of Segment ##

(Time required to reach the ramp level)

real (real time) The hour

r. tim (real time) the hour

3

Page 6

S

T temp Temperature mode

W wait Wait function (Keep the operation until

segment Segment number

soak time Soak time of Segment ##

(Holding time of the ramp level)

step Not in Ramp Operation

time Time mode

the desired temperature is achieved)

wait ## Wait function of Segment ##

Y

year the Christian era

4

Page 7

2. INPUTTING, EDITION AND DELETING PROGRAMS

2.1 Program Composition

A program is a combination of segments and repeat commands, in which ramp time,

ramp level, repeat frequency, end segment and other parameters should be preset.

[Segment]

Fig 2.1 shows the concept of a segment. Temperature and time patterns of a segment

are determined by the 3 basic parameters below.

Ramp level : Desired temperature

Ramp time : Time required to achieve the preset ramp level

Soak time : Time to hold the ramp level

Fig. 2.1: Concept of A Segment

In Section (① of Fig. 2.1~ temperature varies at a fixed gradient rate toward the

desired temperature set as the ramp level . After reaching the ramp level , temperature

is kept in Section② of Fig 2.1 for the time preset as the soak time. These sections of

and② compose a segment.

If you want to vary the temperature in Section① on a step (for full-power increase or

decrease), instead of a faced gradient rate, set for the ramp time. Fig. 2.2

shows the pattern of a step variation of the ramp time.

5

①

Page 8

Fig. 2.2: Step Variation of Ramp Time

The soak time is set at zero (0) for a s egment with only gradient-operation, wh ile the

ramp time is set at zero (0) for a segment with only fixed -value operation. Figure 2.3

shows a connected pattern of these 2 segments. In this figure, Section (4) is a segment

only with the soak time set at zero (0).

Fig. 2.3: Connection of Segmen4

Attribute Parameters of Segments

Attribute Parameters of Segments

■■■■

Attribute Parameters of Segments Attribute Parameters of Segments

In addition to the three basic parameters discussed above, you may preset the following

parameters.

6

Page 9

Wait Function ON/OFF: This function temporarily suspends counting time of the

program operation when influence of loads in the chamber or external disturbance such

as door operation has the chamber temperature failed in achieving the preset desired

temperature until the chamber temperature reaches the preset value. You may either

turn ON or OFF the function.

7

Page 10

Fan Revolution

Fan Revolution: You may preset the revolution of the internal agitation fan in the

Fan RevolutionFan Revolution

range from 1 (low speed) to 10 (high speed). See the operating instructions of your

system for the fan revolution (rpm), which varies with systems.

If your system cannot control the fan revolution, the programmable controller

automatically skips this functi on. If your system is equipped with optional automatic

damper controller, you may preset the damper aperture at 5 different levels.

End Segment

End Segment :When you want to complete programming, input "End" in the ramp

End SegmentEnd Segment

time, which creates the end segment. You may preset the fan controller at ON/OFF or

one of its 10 levels as a parameter of the end segment.

Hold

Hold: If you preset

HoldHold

in the soak time ,the program continues the fixed-value

operation thereafter

hours) on the display.

Note

Note: Model High-Tech IV Programmable Controller allows you to compose a program

NoteNote

of maximum 16 segments, which can be divided to make several different programs.

[Repeat Command]

[Repeat Command]

[Repeat Command][Repeat Command]

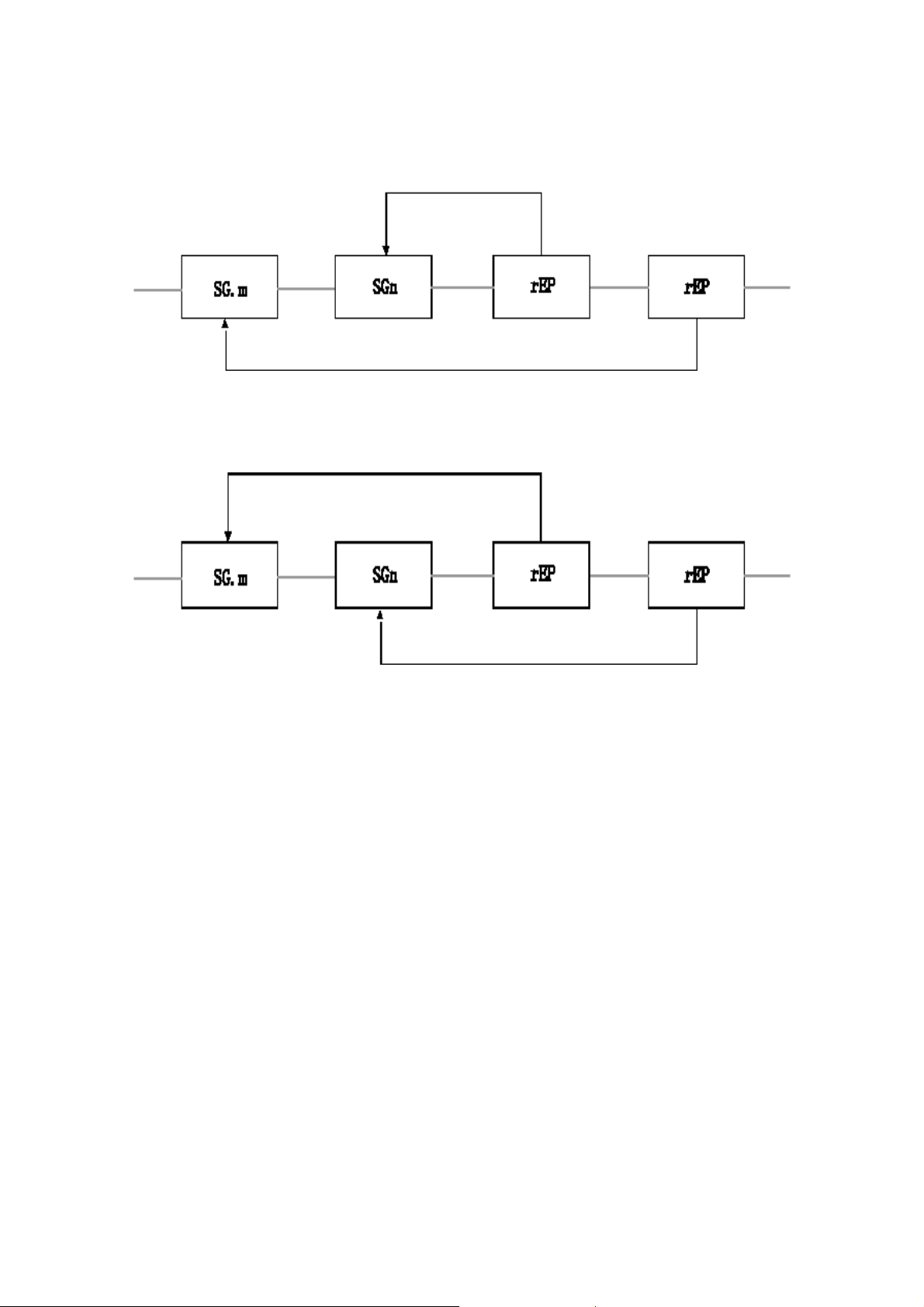

Repeat Command allows you to repeat a series of segments as many time as yon wan t.

This command is composed of 2 parameters; Repeat Start Segment and Repeat

Frequency.

Repeat Start Segment: Program repeats the section between the segment designated

as the repeat start segment and the segment immediately before the repeat start

segment.

Note

Note: (1) Repeat Command works for only the segments that were input and preset

NoteNote

before the command. In other words, you cannot repeat the segmen4 which

you preset after the repeat command.

appears next to a time setting of (999

(2) You cannot preset the nesting of a repeat command, which means to insert a

repeat command into the existing repeat command , as sh own in F ig. 2.4.1. It

is also impossible, as shown in Fig. 2.4.2, to preset a repeat command across

the existing repeat command.

8

Page 11

Fig.2.4.1:Nesting of a Repeat Command

Fig.2.4.2:Cross Setting of Repeat Commands

Repeat frequency

Repeat frequency :You may preset Repeat Frequency in the range from 1 to 9999

Repeat frequencyRepeat frequency

times. If you set the repeat frequenc y at zero(0),wh i ch means endless repetition of th e

segments ,the program continues repeat operation until it is fo rced t o st op.

9

Page 12

Indication of the rest of the repeat count

Indication of the rest of the repeat count

Indication of the rest of the repeat countIndication of the rest of the repeat count

The rest of the repeat frequency including the ongoing segment can be shown on the

sub display by using the DISPLAY key while performing the repeat command of

the program operation.

[Operation Procedure]

[Operation Procedure]

[Operation Procedure][Operation Procedure]

Key Operation Main Display Sub Display Explanation

The repeat operation is on : Ex. While performing the repeat operation the segment 2 to 3 of the

program 2

Push the Display

key several times

Push either ▲ key

or ▼ key

It shows the present

measured

temperature

It shows the present

measured

temperature

(Ex.: Indication of

the execution

segment)

(Ex.: Indication of

the execution

segment)

↑↓

alternately

(Ex.: Indication of

the remaining repeat

frequency)

Shown

Push the display key and

make the sub display shown

the execution segment.

The sub display shows the

ongoing program number at

the left double-digit and the

ongoing segment at the

right double-digit.

When performing this

operation while running the

repeat operation, the dot

point of the LSB (the right

most digit) flashes.

The remaining repeat

frequency can be shown on

the sub display by pushing

the ▲ key or ▼key while the

dot point located at the

corner of the below to the

right of the segment number

is flashing ( during running

the repeat operation.)

The remaining repeat

frequency shown at this

time includes the ongoing

segment.

When you perform the

repeat operation infinitely

(the setting of the repeat

frequency is 0), 0 is shown

on the sub display.

10

Page 13

2.2 Inputting Programs

In this paragraph , you will learn how to input the program shown in Fig.2.5 as an

example into Program No.2.

Fig.2.5:Sample Program

11

Page 14

Note: In the tables below, hollow alphanumeric characters mean that they

Note: In the tables below, hollow alphanumeric characters mean that they

Note: In the tables below, hollow alphanumeric characters mean that theyNote: In the tables below, hollow alphanumeric characters mean that they

are flashing on the corresponding display.

are flashing on the corresponding display.

are flashing on the corresponding display.are flashing on the corresponding display.

[Setting Program Number]

[Setting Program Number]

[Setting Program Number][Setting Program Number]

Key

Operation

MODE key

and then

push either

key or ▼ key

key,

Push ▲ key.

[Setting Segment 1]

[Setting Segment 1]

[Setting Segment 1][Setting Segment 1]

Main

Display

▲

e.g., e.g.,Push ENTER

Sub

Display

e.g.,Push the

Explanation

Left 2 digits: Number of the existing

programs

Right 2 digits Remaining memory size (%)

Activates Program input & Edit mode.

Main: Indicates Program No. 1.

Left 2 digits: Memory size of Program No. 1

Right 2 digits: Remaining memory size

Same as above.

The slob display shows that the memory size

of Program No. 2 is zero (O) or that Program

No. 2 has not been programmed.

Key

Operation

key.

Push ENTER

key.

Main

Display

Approx. 1 second laterPush ENTER

Approx. I second later

e. g

Sub

Display

Explanation

Activates Program input mode for .

Requesting to input Ramp Time 1

of Segment 1. Push ▲ or ▼ key

when you want to switch Prom STEP to real

time. In this example, you are working on a

step operation so that you do not need to

change the indication.

The main display stops flashing and keeps

lighting the indication , notifying that Ramp

Time 1 was set.

Requesting to input the temperature of

Ramp Level 1

12

Page 15

Push

▲

or

▼

Push ▲or ▼ key to show a desired

key and ENTER

key.

Push

key and ENTER

key.

▲

or

▼

↓

(Lighting)

Approx. l second later

e. g.,

(Lighting)

Approx. 1 second later

temperature of 150_C and push ENTER

key to accept it as Ramp Level 1. The

main display changes from flashing to

lighting,

Requesting to input Soak Time 1 of

Segment 1.

Push ▲or▼ s key to show a desired

soak time of 1 hour 20 minutes and

push ENTER key to accept it as Soak

Time 1. The main display changes from

flashing to lighting.

Push ▲or ▼ key to turn on or off Wait

Function 1. In this example, you are

working on a step operation so that you

do not need to change the indication.

Push ENTER

key,

Approx. 1 second later Requesting to input Fan Revolution.

push ENTER

key.

You have finished setting Segment 1.

The main, display changes from

flashing to lighting, notifying that Wit

Function 1 was set.

Push ▲ or ▼ key to set a level of Fan

Revolution in the range from Level 10

(fast) to Level 1 (slow). Default is Level

10. In this example, you accept a fan

revolution of Level 10.

The main display changes from flashing

to lighting, notifying that the fan

revolution of Level 10 was set.

13

Page 16

[SettingSegment2]

[SettingSegment2]

[SettingSegment2][SettingSegment2]

Key Operation Main

Display

Push ENTER

Approx. 1 second later

key,

↓↓

Sub

Display

Explanation

Activates Input mode for Segment 2.

Left 2 digits. Program number you are

working on.

Right 2 digits: Remaining memory size

Requesting to input Ramp Time 2

of Segment 2.

Input and preset the following parameters for this example in the same manner as

Segment 1.

:20 minutes

: 200

℃

: 30 minutes

: ON

: 10

[Setting Segment 3]

Input and preset the following parameters in She same manner as above.

: StEP

: 150

℃

: 0 minute (This is a segment of only the gradient operation.)

: OFF

: 10

You have finished setting Segment 2 and 3.

14

Page 17

[Setting a Repeat Command]

[Setting a Repeat Command]

[Setting a Repeat Command][Setting a Repeat Command]

hey

Operation

Main

Display

Sub Display Explanation

Approx. 1 second later

Push ▲ or

key.

▼

Push

↓

ENTER

key.

↓

The main display shows that the

programmable controller is ready for

inputting Segment 4.

Push▲ or ▼ key to change the controller

to the input mode of Repeat Command. The

main display flashes

(Repeat).

Requesting to input the number of Repeat

Start Segment

Push ▲ or

key and

▼

ENTER

key.

↓

Lighting

Push ▲ or ▼ key to show the desired

repeat start segment number of 2 and push

ENTER key to accept it. The main display

changes from flashing to lighting.

↓↓

input the repeat frequency. Default is set at

1.

Push▲ or

key and

▼

↓

ENTER

key.

You have finished setting Repeat Command..

You have finished setting Repeat Command..

You have finished setting Repeat Command..You have finished setting Repeat Command..

[Setting Segment 4]

[Setting Segment 4]

[Setting Segment 4][Setting Segment 4]

Key

Operation

Push

Lighting

Main

Display

Sub

Display

Approx. 1 second later

Push ▲or ▼ key to show a repeat frequency

of 2 and push ENTER key to accept it. The

main display changes from flashing to

lighting.

Explanation

Activates Input mode for Segment 4 when

.

(Repeat Count): Requesting to

ENTER

key.

↓↓

you accept the repeat command.

Requesting to input Ramp Time 4

of Segment 4.

Input and preset the following parameters in the same manner as previous segments.

: 0 minute (This is a segment of only the fixed value operation )

: 150

℃

: 50 minutes

: ON

: 10

You have finished setting Segment 4.

You have finished setting Segment 4.

You have finished setting Segment 4.You have finished setting Segment 4.

15

Page 18

[Inputting and Setting End Segmen t]

[Inputting and Setting End Segmen t]

[Inputting and Setting End Segmen t][Inp utti n g an d Setti n g E nd Segment]

Key

Operation

Push ENTER

key.

Push ▲or

▼

key

Push ENTER

key

Push ▲or

▼

key.

key.

Main

Display

Sub

Display

↓↓

↓

Approx. 1 second laterPush ENTER

Explanation

Activates Input mode for Segment 5.

Requesting to input Ramp Time5

(

) of Segment 5.

Push ▲ or ▼ key to change to Program

Input mode for End Segm e nt.

Requesting to turn on or off the fan or input

its revolution level.

Push A or t key to change the setting. In

this example, turn off the fan.

Push ENTER key to accept the setting of

the fan, This completes all the setti ngs for

Program No. 2. The displays return to thei r

initial indications of Program Input a Edit

mode.

16

Page 19

2.3 Editing Programs

Model High-Tech IV Programmable Controller supports Edit function of only

Segment parameters; and

・

Repeat parameters

・

or editing programs. Take note that the programmable controller does not support

Delete of repeat command and Insert of new segments or a new repeat command.

In this paragraph, you will edit Segment 3 of Program No. 2

which is composed of the following segments and a repeat command.

Key Operation Main

Display

Push the

MODE key

and then

push either

key or ▼key

Push ENTER

key.

Push▲or▼key

▲

e

.g.,

↓↓

Sub

Display

.g.,

e

.g.,

e

.g.,

e

Explanation

Left 2 digits: Number of the existing

programs

Right 2 digits: Remaining memory size (%)

Activates Program Input & Edit mode.

Push ▲ or ▼ key to show the program

number you want to edit on the main display.

Left 2 digits: Memory size of Program No. 2

Right 2 digits: Remaining memory size

in Fig. 2.6,

Push ENTER

key.

Push

key.

▲

or

▼

The main display Rashes the first segment

number of the program.

Left 2 digits: Program number you are

working on.

Right 2 digits: Remaining memory size (%)

Every time you push A or Y key, the main

display scrolls the segments of the program

in the preset sequence. In this example, you

are going to edit Segment 3

which should be shown on the main display.

17

,

Page 20

Push ENTER

Indicates that the ramp time of Segment S

key.

is set at the step operation. Change it to

the gradient operation with a ramp time

the gradient operation with a ramp time

the gradient operation with a ramp timethe gradient operation with a ramp time

of 45 minutes.

of 45 minutes.

of 45 minutes.of 45 minutes.

Change it to

Change it toChange it to

Input and preset the following parameters in the same manner as discussed in

"inputting Programs."

: 45 minutes

: 150

℃

: o minutes (This is a s egment of only the gradi ent operation.)

: ON

: 10

You have changed the parameters with asterisks. For the other parameters you do not

change, push only ENTER key.

Whenever you have finished editing a

Whenever you have finished editing a

Whenever you have finished editing aWhenever you have finished editing a

parameter, the displays return to s h ow

parameter, the displays return to s h ow

parameter, the displays return to s h owparameter, the displays return to s h ow

the initial indications of Program Edit

the initial indications of Program Edit

the initial indications of Program Editthe initial indications of Program Edit

mode.

mode.

mode.mode.

↓

If you leave them for about 10 seconds,

the programmable controller understands

that you have finished editing the

program and returns to the displays

shown immediately before you pushed

MODE key.

18

Page 21

2.4 Deleting Programs

You can delete the programs not in use any longer from the programmable controller.

Take note that on Program Delete mode, you cannot check the contents of the program

you are going to delete.

In this paragraph, you v ill learn how to delete Program No. 1

Key

Operation

Push the

MODE key

and then

push either

key or

▲

key

Push

ENTER key.

▼

Main

Display

Sub

Display

Explanation

Push MODE key several times to flash

(Delete Program) on the man

display.

Left 2 digits: Number of the existing

programs

Right 2 digits: Remaining memory size (%)

Activates Program Delete mode.

The main display shows the smallest

number of the existing programs.

Every time you push ▲ or ▼ key, the

main display scrolls the program number

in sequence. In this example/ you are going

to delete Program No. 1, so that don't touch

s and t keys.

Push

ENTER key.

(Lighting)

Approx, 1 second later

Pushing ENTER key deletes Program No.

Pushing ENTER key deletes Program No.

Pushing ENTER key deletes Program No.Pushing ENTER key deletes Program No.

1, and the main display returns to the

1, and the main display returns to the

1, and the main display returns to the1, and the main display returns to the

initial indication of Program Delete mode.

initial indication of Program Delete mode.

initial indication of Program Delete mode.initial indication of Program Delete mode.

Deleting Program No. 1 (with a memory

size of 43%) reduces the number of the

existing programs to 1, and the remaining

memory size to 74%.

19

Page 22

Temporary Suspension of Program Operation

Temporary Suspension of Program Operation

Temporary Suspension of Program OperationTemporary Suspension of Program Operation

Temporary suspension of program operation means to stop the program timer and

temporarily keep the programmable controller at the status of ready-for-operation.

During the suspension, the programmable controller shuts off power supply to heaters

and does not regulate chamber temperature.

[Suspending Program Operation Temporarily]

[Suspending Program Operation Temporarily]

[Suspending Program Operation Temporarily][Suspending Program Operation Temporarily]

Key

Operatio

Main

Display

Sub Display Explanation

n

Push

Operatio

If you push Operation Menu key during the

program operations the main display shows

n Menu

key

(Pause) while the sub display

shows the ongoing program number. When

you want to cancel Temporary Suspension of

Program Operation, leave the programmable

controller for 20 seconds or push ESC key.

Push

Suspends program operation temporarily.

Suspends program operation temporarily.

Suspends program operation temporarily.Suspend s p rogram operation temp orarily.

ENTER

key.

(Lighting)

Approx. 1 second later

The main display shows chamber

temperature, while the sub display

alternately shows , and the program number

.,

e.g

↑↓

[Restarting Program Operation]

[Restarting Program Operation]

[Restarting Program Operation][Restarting Program Operation]

Alternate

indicator.

(left 2 digits)

segment number (right 2 digits).

Ready indicator lamp Rashes on the

operation monitor.

and the ongoing

Push Operation Menu key and operation starts again automatically. If chamber

temperature deviated from the preset temperature during the suspension of operation,

the sub display flashes its indication. When chamber temperature reaches the desired

temperature, the operation timer starts again and the sub d isplay shows the correct

temperature.

Important

Important

ImportantImportant

Program input, Edit and Delete modes can be activated only during the program

operation, and they do not work in the fixed-value operation and the automatic

star/stop operation. These modes can work when you have pushed Operation Menu key

at the status of ready-for -operation, including temporary suspension of program

operation. When the programmable controller is on the mode which cannot execute

Program input, Edit and Delete, pushing MODE key skips the indication of these

modes.

20

Page 23

3. INPUTTNG AND SETTING FUNCTIONS

↑

↓

You can add a variety of functions by using MODE key. This section discusses the

inputting and setting functions, which are common to all Yamato Scientific's machinery

and equipment. For setting the functions particular to your system, see the operating

instructions of the system. If your system does not support certain functions, pushing

MODE key simply skips those functions, which are not shown on the displays.

3.1 Switching between Time and Period

Starting time of the automatic state operation and the program operation, and ending

time of automatic stop operation can be designated by either time or period-of

operation, If you set them by time, the sub display shows it at the upper left corner.

In this paragraph, you will learn how to change the setting from time to period of

operation.

[Procedure]

[Procedure]

[Procedure][Procedure]

Key

Operation

Push the

MODE key

and then

push either

key or

▲

key

Push ENTER

key.

Push ▲or

key.

▼

▼

Main

Display

(Lighting)

Approx. l second later

Alternate

indication

Sub

Display

Explanation

Push MODE key several times to

show

display, The sub display shows the present

time.

Activates Time/Period Switching mode.

or XXX hours)

Push ▲ or ▼ key to show

the main display.

(Time) on the main

:Time (XX o'clock XX minutes)

:Interval (E hours XX minutes

on

21

Page 24

Accepts the change of the setting from time

Push

ENTER

key.

Note: Time is default setting. When you are setting the operation parameters, you

cannot switch this setting.

(Lighting)

Approx. 1 second later

The displays return to

their initial indications

shown immediately before

you pushed MODE key.

Accepts the change of the setting from time

Accepts the change of the setting from timeAccepts the change of the setting from time

to period of operation.

to period of operation.

to period of operation.to period of operation.

22

Page 25

3.2 Setting and Releasing Panel Key Lock

Panel Key Lock deactivates the eight keys on the control panel, except for indication

Switching key. With this special function, you can prevent accidental or unauthorized

key operation ashen the programmable controller is in service.

[Setting Panel Key Lock]

[Setting Panel Key Lock]

[Setting Panel Key Lock][Setting Panel Key Lock]

Key

Operation

Push the

MODE key

and then

push either

key or

▲

key

Push

ENTER

key.

Main

Display

▼

(Lighting)

Approx. 1 second later

Sub

Display

Explanation

Push MODE key several times to show

(Lock) on the main display. The

display shows the present setting

Activates Panel Key Lock Set/Release mode.

Activates Panel Key Lock Set/Release mode.

Activates Panel Key Lock Set/Release mode.Activates Panel Key Lock Set/Release mode.

Push ▲ or

key.

▼

↑

↓

Alternate

indication

:Releases Panel Key Lock.

: Sets Panel Key Lock

When you want to lock the panel keys, push

or ▼ key to show

▲

on the

main display

Accept the setting of Panel Key L ock.

Push

Accept the setting of Panel Key L ock.

Accept the setting of Panel Key L ock.Accept the setting of Panel Key L ock.

ENTER

key.

(Lighting)

Approx. 1 second later

The displays return to

The displays return to their initial

indications shown immediately before you

pushed MODE key.

their initial indications

shown immediately

before you pushed MODE

key.

Note: Panel Key Lock ON is default setting When you are setting the operation

parameters, you cannot switch this setting.

[Releasing Panel Key Lock]

[Releasing Panel Key Lock]

[Releasing Panel Key Lock][Releasing Panel Key Lock]

Push MODE key to activate Panel Key Lock Set/Release mode, and switch OFF

(

) the lock

Note. When the panel key lock is turned on, MODE key skips all the modes except for

Panel Key Lock Set/Releasing mode.

23

Page 26

3.3 Turning ON and OFF Buzzer Sound

If something abnormal happens on your system, all the indicator lamps including

alarm indicator lamps start flashing, the main display shows the present chamber

temperature and the sub display shows the error code of the abnormal condition. You

can choose to activate or deactivate buzzer sound when your system is in trouble.

In this paragraph, you will learn how to turn on the buzz er sound.

[Procedure]

[Procedure]

[Procedure][Procedure]

Key

Operation

Push the

MODE key

and then

push either

key or

▲

▼

key

Push

ENTER

key.

Main

Display

(Lighting)

Approx. 1 second later

Sub

Display

.,

e.g

Explanation

Push MODE key several times to show

(Beep) on the main display. The

sub display shows the present setting.

Activates Buzzer Sound ON/OF F mod e

Activates Buzzer Sound ON/OF F mod e

Activates Buzzer Sound ON/OF F mod eActivates Buzzer Sound ON/OF F mod e

Push ▲ or

key.

▼

↑

Alternate

↓

indication

When you want to turn on the buzzer sound,

push ▲or ▼ key to show

the main display

Push

ENTER

key

.

(Lighting)

Approx. 1 second later

Accepts the setting of Buzzer Sound .

Accepts the setting of Buzzer Sound .

Accepts the setting of Buzzer Sound .Accepts the setting of Buzzer Sound .

The displays return to

their initial indications

shown immediately

before you pushed MODE

key.

Note: Buzzer Sound

Note: Buzzer Sound is default setting.

Note: Buzzer Sound Note: Buzzer Sound

is default setting.

is default setting. is default setting.

: Deactivates buzzer Soured

:Activates buzzer sound.

on

24

Page 27

3.4 Indication of Integrating Operation Time

This function accumulates the op eration ti me when P ower key is turn ed on. Maxi mum

accumulation of time is 49,999 hours, which cannot be reset. Accumulated operation

time provides useful information when you determine the timing of maintenance.

In this paragraph, you will learn how to show the accumulat ed operat ion t im e.

[Procedure]

[Procedure]

[Procedure][Procedure]

(1) Push the MODE key and then push either ▲ key or ▼ key

(2) Push the MODE key and then push either ▲key or ▼ key to show

(Accumulation) on the main displ ay. T h e s ub d i s p l ay s h ows th e accu mul a ted

operation time at present (in the unit of hours),

Note: You do not need to push ENTER key, because this function only shows the

accumulated operation time. In this functi on, ENTER key and ▲and ▼ keys do not

work.

(3) When you want to cancel the function, push ESC key or leave the programmable

controller for 20 seconds, The displays return to their indications shown immediately

before you pushed MODE key.

[Expression of Accumulated Operation Time]

[Expression of Accumulated Operation Time]

[Expression of Accumulated Operation Time][Expression of Accumulated Operation Time]

When the accumulated operation time exceeds 9999 hours 59 minutes, the sub display

goes back to 0 (zero) and starts emulating ti me again. Decimal p oint al so moves to the

left by one digit at every operation time of 10,000 hours.

Figure① shows an accumulated operation time of 10,050 hours.

In the same manner, ② means 20,050 hours, ③ 30,050 hours and

40,050 hours

④

①

②

③

④

25

Page 28

3.5 Setting Date and Time

The timer clock built in Model High-Tech IV Programmable Controller has been

calibrated at the standard time in our factory. However, you still need to adjust it

periodically to make sure of its correct time indication in your operating environment.

In this paragraph, you will learn how to calibrate the built- in tim er clock .

Note: The built-in timer clock causes an daily error of 12 seconds at a working

temperature of 25℃.

[Procedure]

[Procedure]

[Procedure][Procedure]

Key

Operation

Push the

MODE key

and then

push either

key or

▲

key

push ENTER

key.

Push ENTER

key.

▼

Main

Display

Sub

Display

.,

e.g

Explanation

Push MODE key several times to

show

display. The sub display show j the

accumulated operation time in the order of

year, date and time at an interval of 2

seconds.

Activates Date & Time Set mode.

The sub display shows

and the main display flashes the present

data.

push ▲ or ▼ key to set the correct year.

In about 1 second, Date Set mode is

activated. The sub display shows

(Clock) on the main

(Year)

(Month and Day) and the main

display flashes the present data. Push ▲or

key to set the correct date.

▼

Push ENTER

key.

Approx.1 second laterPush ENTER

key.

Note:

Note: if you want to cancel the calibration of Date & Time, push ESC key or leave

Note:Note:

the programmable controller for 20 seconds. Date & Time Setting Function works

only when the programmable controller is ready for operation with Operation

Menu selected or after operation.

The displays return to

their initial indications

shown immediately

before you pushed MODE

key.

In about 1 second, Time Set mode is

activated. The sub display shows

(Hours and Minutes) and the

main display flashes the present data,

Push ▲or ▼ key to set the correct time.

Accepts the setting of Date & Time.

26

Page 29

3.6 Hold Function

3.6 Hold Function

3.6 Hold Function3.6 Hold Function

Hold function is the one of functions that the HitecⅣcontroller supports by using the

MODE key.

It can work only if the setting time of the operation start time of the Auto-Start

operation and the Program operation and the operation stop time are not set in

hours but in a period of time.

General Description of the Hold Function

General Description of the Hold Function

General Description of the Hold FunctionGeneral Description of the Hold Function

Once the Hold Function is on, i mmediately the HitecⅣcontroller stops the built-in

timer and keeps the condition. The definite examples are shown below.

1. When the Hold Function activated while the unit is in standby condition of starting

operation, the waiting time to start is extended by a period of time when the Hold

Function was on

2. When the Hold Function activated while performing the fixed gradient rate operation

toward the desired temperature, the controller stops the gradient operation and

changes to the fixed temperature operation to keep the internal target temperature of

the controller at the point of time. ( The internal target temperature is not always same

as the ramp level in the program segment) Once the Hold Function is off, the

controller resumes performing the gradient operation that had been performed just

before the Hold Function was on.

3. When the Hold Function activated while performing the gradient operation with full

power , the controll er changes to the fi xed temperature operat ion to keep the chamb er at

the ramp level in the program segment after reaching the ramp level (the desired

temperature)

4. When the Hold Func tion activated while keepin g the chamber at the ramp lev el, the

setting soak time in the Auto-Stop operation and the Program operation are extended

by a period of time when the Hold Function was on

5. When you change a certain ongoing operation to the other operation by pushing

the MENU key with the Hold Function is on, the Hold Function is automatically

released at the point of time when the operation is changed.

27

Page 30

Operating procedure

Operating procedure

Operating procedureOperating procedure

Key Operation Main Display Sub Display Explanation

Push the MODE

key and then

push either▲key

or ▼ key

Push the ENTER

key

Push either

key or ▼ key

▲

Approx. 1 second later

Blink (Hold) on the main

display.

The sub display shows the present

setting.

Activates Hold Function Setting

Activates Hold Function Setting

Activates Hold Function SettingActivates Hold Function Setting

mode.

mode.

mode.mode.

:Hold function is off (inactive)

:Hold function is on (activate)

The main display blinks the present state

of Hold mode and sub display shows

: Releases Hold state

: Sets Hold state

Choose if you want to bring

the unit to the Hold state.

Push the ENTER

key

Approx. 1 second later

It shows the

present

measured

temperature.

Hold Function was set to when the unit is shipped from the factory.

Accepts the setting of Hold state

Accepts the setting of Hold state

Accepts the setting of Hold stateAccepts the setting of Hold state

The main display shows the present

measured temperature

and the sub display blinks in

the Hold state.

The present set temperature can be

shown on the sub display only for 10

seconds by pushing the DISPLAY key.

28

Page 31

3.7 Communication lock out function

This function makes the communication between the PC and HitecⅣcontroller

enable / disable.

If this function is activated during communicating with a host computer, the

controller closes the communication

Operating Procedure

Operating Procedure

Operating ProcedureOperating Procedure

Key Operation Main Display Sub Display Explanation

Push the MODE

key and then

push either

key or ▼ key

Push the ENTER

key

Push either

key or ▼ key

▲

▲

Approx. 1 second later

Blink (Communication Lockout) on the main display.

The sub display shows the present

setting.

Activates Communication Lock-out

Activates Communication Lock-out

Activates Communication Lock-outActivates Communication Lock-out

Function setting and releasing mode

Function setting and releasing mode

Function setting and releasing modeFunction setting and releasing mode

:Communication with PC is

enable.

: Communication with PC is

disable.

: Releases Communication

Lock-out state

: Sets Communication Lock-

out state

Choose if you want to bring

the unit to the Communication Lock-out

state.

Push the ENTER

key

Approx. 1 second later

Communication Lock-out Function was set to when the unit is shipped

from the factory.

29

Accepts the setting of Communication

Accepts the setting of Communication

Accepts the setting of CommunicationAccepts the setting of Communication

Lock-out.

Lock-out.

Lock-out.Lock-out.

Both displays return to the indicating

state just before you pushed the MODE

key when Communication Lock-out is on.

Page 32

Releasing the Communication Lock-out

Releasing the Communication Lock-out

Releasing the Communication Lock-outReleasing the Communication Lock-out

By pushing the MODE key while the C ommunication Lock-out function is on, Hitec

controller goes to the setting and releasing the Communication Lock-out mode,

Ⅳ

and then you can release the Communication Lock-out condition to choose ‘off’ by

pushing the ▲key or the ▼ key.

Precaution in handling

Precaution in handling

✻✻✻✻

Precaution in handlingPrecaution in handling

※

The remote operation cannot be performed while the Communication

The remote operation cannot be performed while the Communication

The remote operation cannot be performed while the CommunicationThe remote operation cannot be performed while the Communication

Lock-out function is on.

Lock-out function is on.

Lock-out function is on.Lock-out function is on.

※

The unit without the PC communication feature may show the

The unit without the PC communication feature may show the

The unit without the PC communication feature may show theThe unit without the PC communication feature may show the

indication of this function at its di splay by operating the MODE key.

indication of this function at its di splay by operating the MODE key.

indication of this function at its di splay by operating the MODE key.indication of this function at its display by operati ng the MODE key.

Setting does not bring any effective result.

Setting does not bring any effective result.

Setting does not bring any effective result.Setting does not bring any effective result.

✻✻✻✻

30

Page 33

4. SAFETY MEASURES AND PRECAUTIONS

This section discusses the safety measures provided for Model High-Tech IV

Programmable Controller, and the operational precautions of the controller and your

system regulated by the controller. See the operating instructions of your system,

which also describe safety measures and precautions.

4.1 POST Function

POST stands for Power On Self Test, which is a special function to check the

controller's microprocessor, memory, peripheral LSI's and peripheral circuits whenever

you turn on Power key. With this POST function, you can make sure that the controller

is free of serious troubles before starting operation.

If the function defects something abnormal, the sub display shows one of error codes

corresponded to the trouble from among error codes of

.

These error codes mainly indicates a trouble of electronic circuits If this is the case,

turn off the breaker and co ntact th e d eal er of your s ystem, Yama to Sci enti fic C D., L td.

or Yamato Engineering Co., Ltd. in your vicinity.

, and

4.2 Precautions

1) To prevent overheating, Model High-Tech IV Programmable Controller is equipped

with automatic attempering function In ad dition, some of our systems also have their

own attemperators in the circuit separated from the programmable controller.

However, when you are working on exothermic samples or supplying electricity to

samples to generate heat, those temperature regulating systems do not work

effectively.

When temperature goes up abnormally high, shut down power supply or take any other

appropriate measures Yamato Scientific is prep ared to modify your system to manage

such troubles.

2) In case of power failure, the programmable controller of the standard specifications

automatically resets itself and restarts operation when electric power becomes

available again. If you install the optional Restart Selector Function In the controller,

you can select either Automatic Reset or Manual Reset to restart operation after power

failure for a certain period of time.

31

Page 34

5. Behavior after Power Restoration

When having a blackout during operation, the controller resumes the following

operations after the power restoration.

5.1

5.1 When having a blackout during the program operation

When having a blackout during the program operation

5.15.1

When having a blackout during the program operation When having a blackout during the program operation

The controller automatically resume the program operation where it left at the

power shutdown. In case that the temperature inside the chamber is outside the

specified temperature range based on the setpoint temperature, the controller goes

to the FORECED WAIT STATE until the

temperature inside the chamber comes back to the specified temperature range.

When selecting the indication of the remaining time by pushing the Display key in

this condition, the sub display shows

The timer built-in the controller does not count a period of having a blackout as

running time.

5.2

5.2 When having a blackout during the Auto-Stop operation

When having a blackout during the Auto-Stop operation

5.25.2

When having a blackout during the Auto-Stop operation When having a blackout during the Auto-Stop operation

The controller automatically resume the Auto-Stop operation where it left at the

power shutdown. In case that the temperature inside the chamber is outside the

specified temperature range based on the setpoint temperature after the power

restoration, the controller goes to the FORECED WAIT STATE until the

temperature inside the chamber comes back to the specified temperature range.

When selecting the indication of the remaining time by pushing the Display key in

this condition, the sub display shows

In case that the operation stop time is set in a period of time, the timer built in the

controller does not count a period of a blackout as running time. On the contrary,

in case that the operation stop time is set in hours , the timer built in the controller

counts a period of a blackout as running time.

When the operation stop time reaches during a blackout, the controller stops

running just after the power restoration.

5.3

5.3 When having a blackout while the operation is in standby condition

When having a blackout while the operation is in standby condition

5.35.3

When having a blackout while the operation is in standby condition When having a blackout while the operation is in standby condition

In case that the operation start time is set in a period of time, the timer buil t in the

controller does not count a period of a blackout as standby time. On the contrary,

in case that the operation start time is set in hours , the timer built in the controller

counts a period of a blackout as standby time.

When the operation start time reaches during a blackout, the controller starts

running just after the power restoration.

.

.(Forced Wait)

5.4

5.4 When having a blackout during the Fixed temperature operation and a soak

When having a blackout during the Fixed temperature operation and a soak

5.45.4

When having a blackout during the Fixed temperature operation and a soak When having a blackout during the Fixed temperature operation and a soak

period of the Auto-Start operation

period of the Auto-Start operation

period of the Auto-Start operationperiod of the Auto-Start operation

The controller resumes running toward to the preset temperature after the power

restoration.

32

Loading...

Loading...