Page 1

Heating Block

Type HF100/200

First Edition

Yamato Scientific Co., Ltd.

Page 2

Page 3

Contents

1.Name and Function of Components ..................................................... 1

Main body ........................................................................... 1

Operation panel ...................................................................... 2

Description of characters displayed in the temperature controller ............................ 3

2.Operation Method..................................................................... 4

Preparation .......................................................................... 4

List of operation modes and functions ................................................... 5

Fixed-value operation(continuous operation)mode ...................................... 6

Quick auto-stop operation.............................................................. 8

Auto-stop operation .................................................................. 11

Auto-start operation.................................................................. 15

Other functions...................................................................... 19

3. In Case of Trouble................................................................... 23

Error display ........................................................................ 23

Troubleshooting guide................................................................23

4. Specifications....................................................................... 24

5. Wiring Diagram ..................................................................... 25

Page 4

Page 5

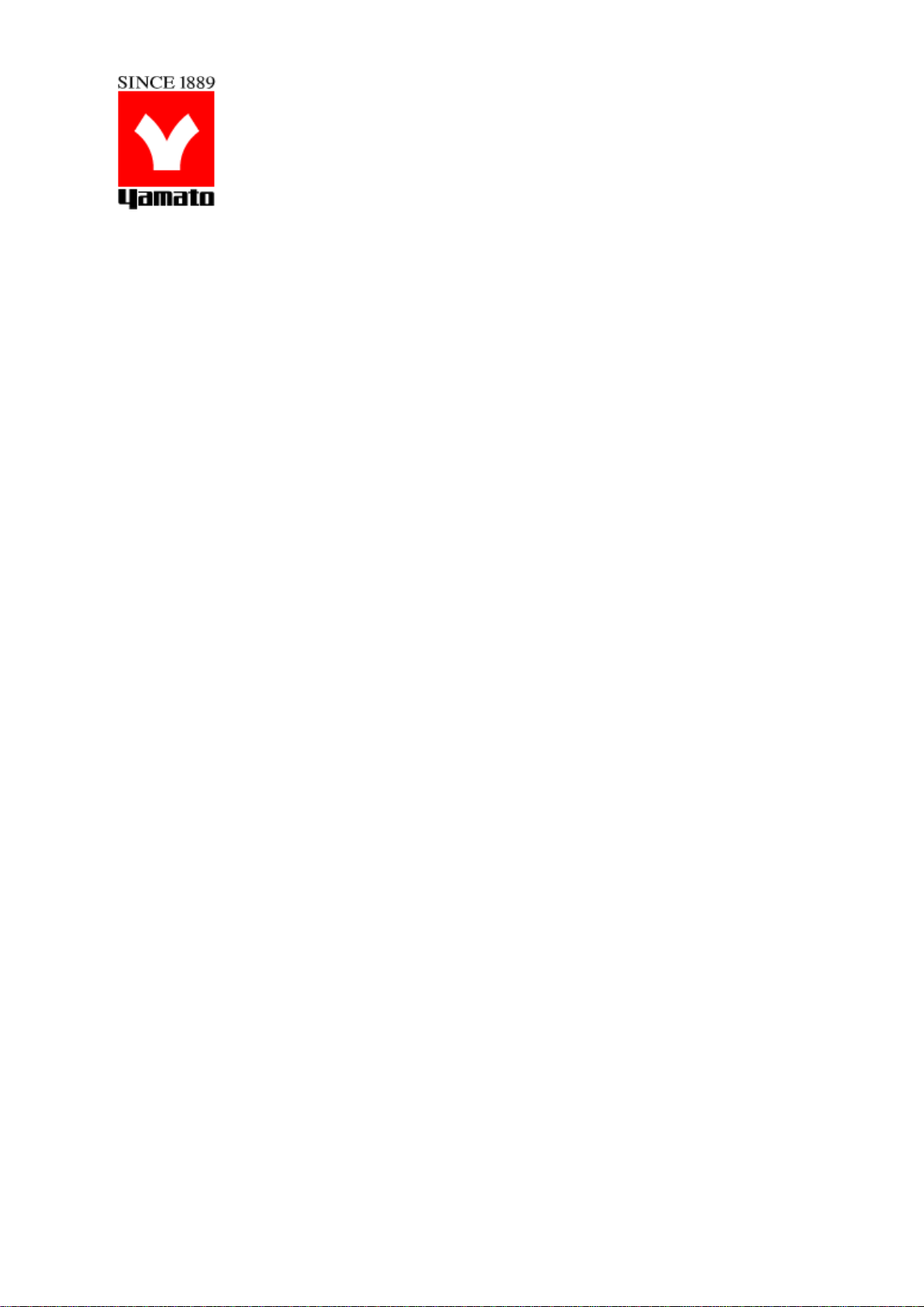

1.Name and Function of Components

Aluminum block mounting portion

(Aluminum block available

separately)

Operation panel

Hand grip for aluminum block

Main body

Power cord

Serial No. plate

Temperature controller

Leg

Power switch

(circuit breaker)

Heating Block

HF100

1

Page 6

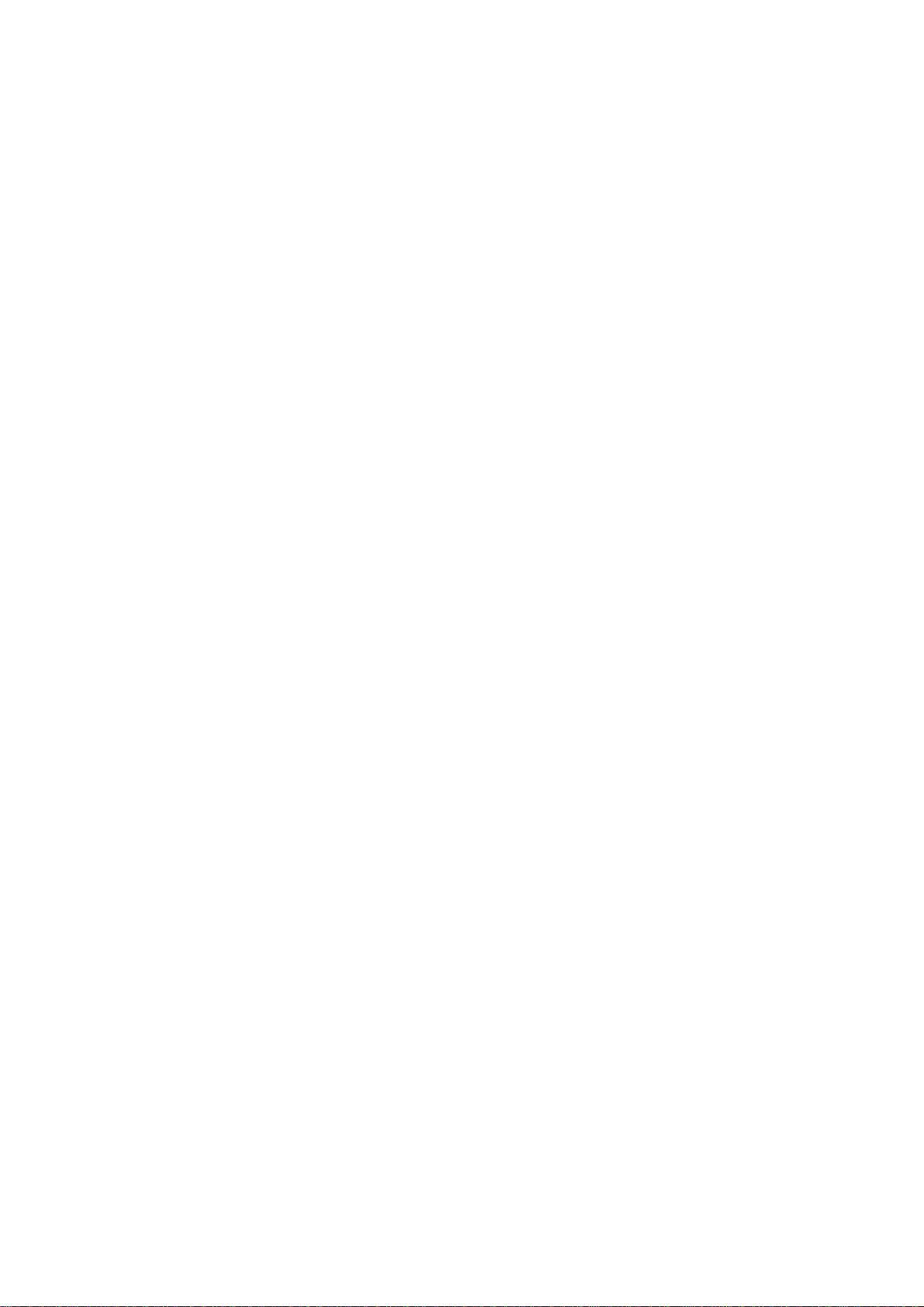

1. Name and Function of Components

Operation panel

⑪

⑩

⑨

⑧

⑦

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

⑥

Measured Temp. POWER

Set Temp.

①

⑫

②

③

No. Name Function

① Measured temperature display Displays the bath measured temperature, set mode

② Set temperature display Displays the set temperature, timer set time, remaining

③ Start/stop key Used to start/stop operation.

④ ▲ key Used to increment the set value.

⑤ ▼ key Used to decrement the set value.

Timer key Used to set the timer and sub-menu. ⑥

Sub-menu selector key Keep pressing the key for four seconds, and such

⑦ Alarm lamp Flashes in case of alarm

⑤

character, alarm temperature.

timer-operation time, character to set the sub-menu.

Keep pressing for one second.

functions as key lock, calibration offset temperature

setting, and power failure compensation selection can be

set.

④

⑧ Heater lamp ON when the heater output is ON

⑨ Fixed-value operation lamp ON during the fixed-value operation

⑩ Auto start operation lamp ON during auto-start operation with the TIMER key

⑪ Auto stop operation lamp ON during auto-stop operation with the TIMER key

⑫ Power switch ON to turn ON system power supply and OFF to turn OFF

system power supply. Circuit breaker to turn OFF power

supply at over-current

2

Page 7

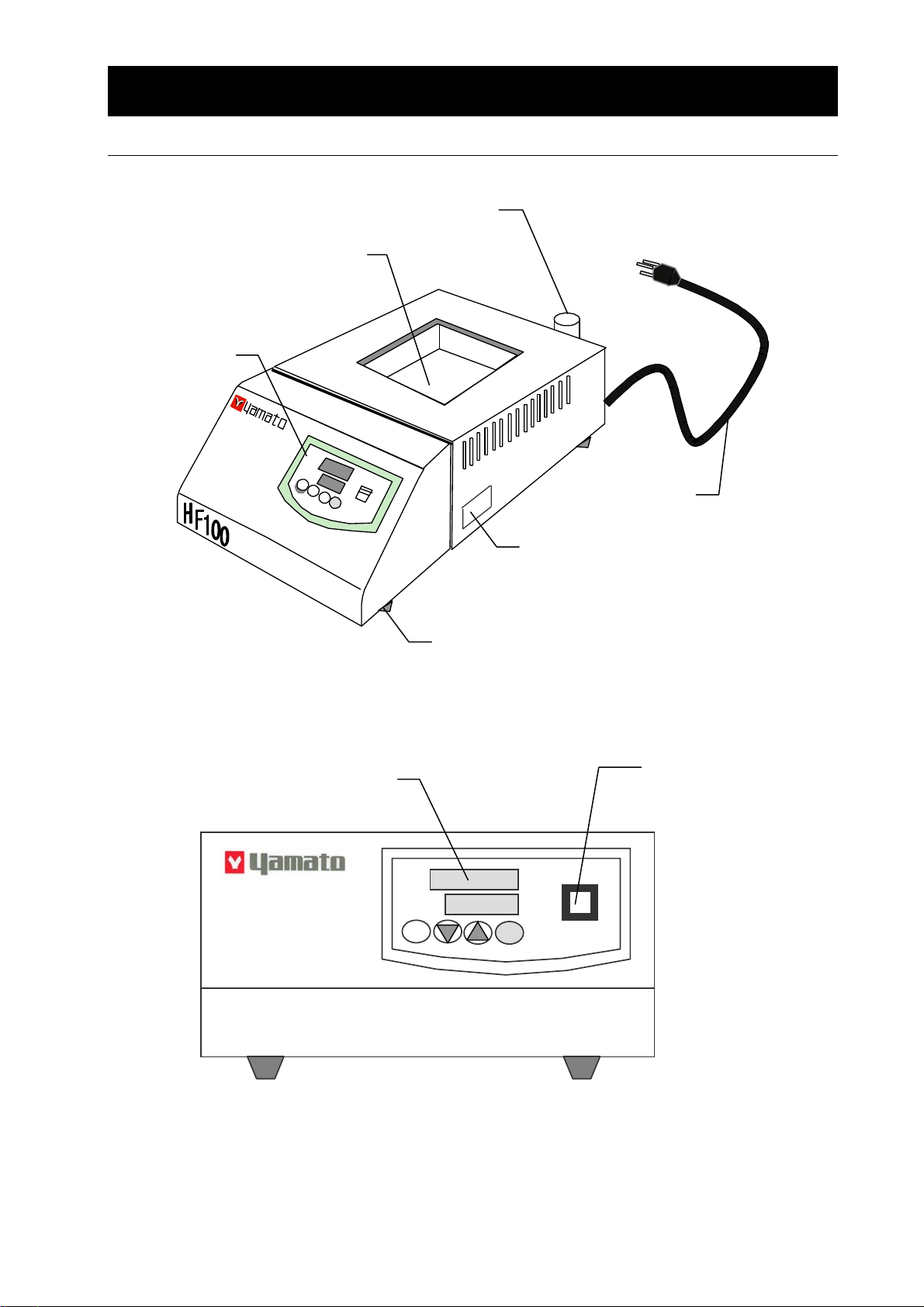

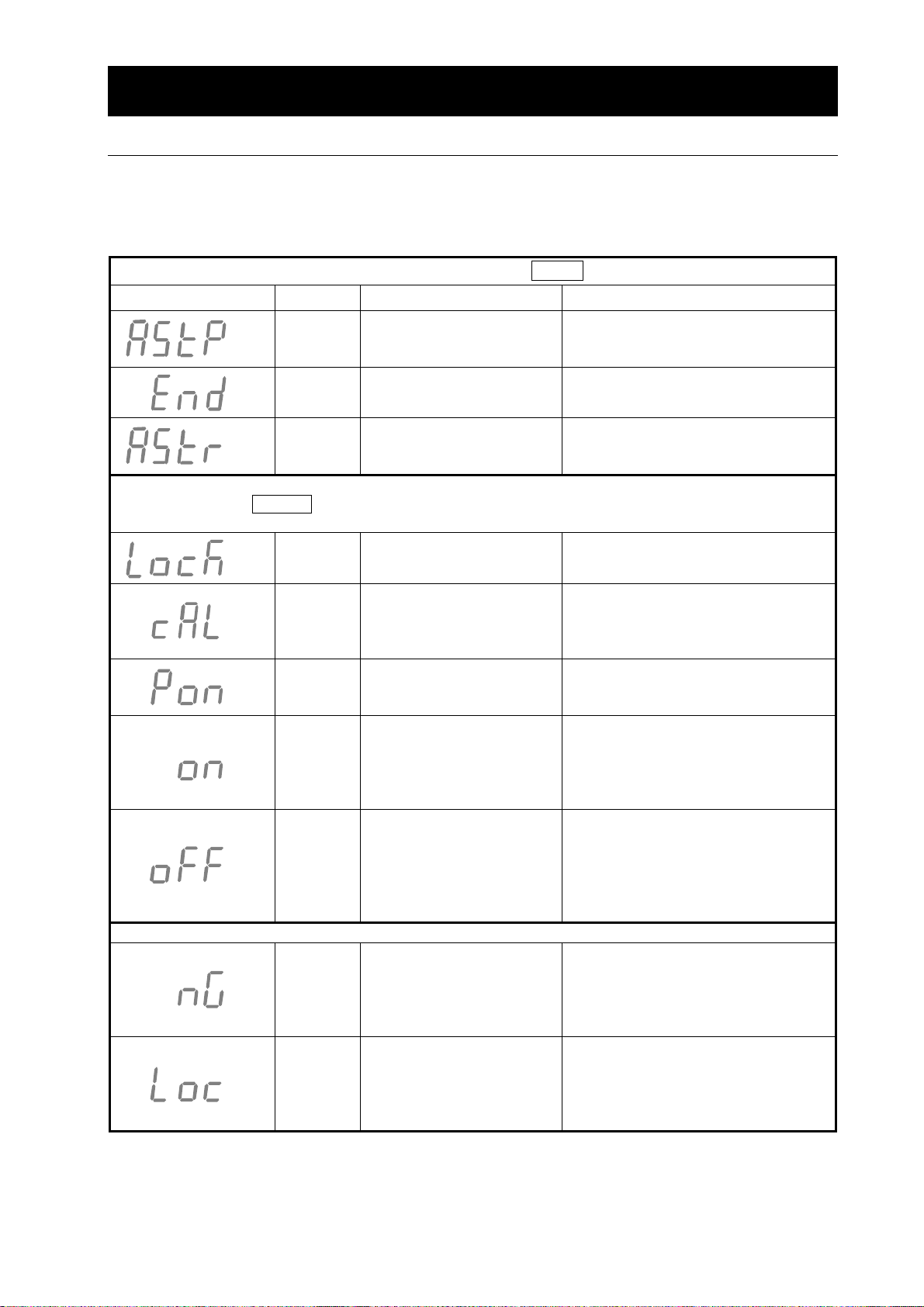

1. Names and functions of parts

Description of characters displayed in the temperature controller

The controller uses a display of 7-segment LED. Characters to display operation functions are

indicated in the “Measured Temp.” screen.

Character displays and corresponding meanings are described below.

Auto-stop or Auto-start operation can be selected with the TIMER key.

Character Identifier Name Meaning

Timer menu mode

AStP

End Time-up

AStr

Function settings as follows can be made from the sub-menu.

Keep pressing the TIMER key for four seconds, and the mode changes to the sub-menu mode.

To return to the original screen, keep pressing the TIMER key.

LocK

cAL

Pon

on

off

Two characters to indicate that operation is not possible

nG Operation impossible

Loc

Timer setting mode

display

Timer menu mode

Timer setting mode

display

Sub-menu mode

Locked at fixed value

Sub-menu mode

Calibration offset

Sub-menu mode

Power failure

compensation selection

Sub-menu mode

Locking the setting

Power failure

compensation selection

auto reset

Sub-menu mode

Canceling locking of the

setting

Power failure

compensation selection

manual reset

Sub-menu mode

Locking the set contents

Means that the auto-stop operation

has been selected.

Means that the auto-stop operation

has ended.

Means that the auto-start operation

has been selected.

Function to lock so as to prevent

changing of the set contents

Temperature compensatio n function

to allow the aluminum block

temperature to agree with the

control temperature (see page 23)

Function to select whether the

recovery from power failure is to be

made automatically or manually.

Select ON with the ▲ key to

activate lock to prevent change of

the setting and when the recovery

from power failure is to be made

automatically.

Select OFF with the ▼ key to

cancel locking to enable free

change of the setting and when the

recovery from power failure is to be

made manually.

Selection of the mode that is

inoperable during operation causes

display of nG in the set temperature

display, rejecting any attempt of

change.

Attempt to change the mode while

the LocK function is ON causes

display of Loc in the set

temperature display, rejecting any

attempt of change.

3

Page 8

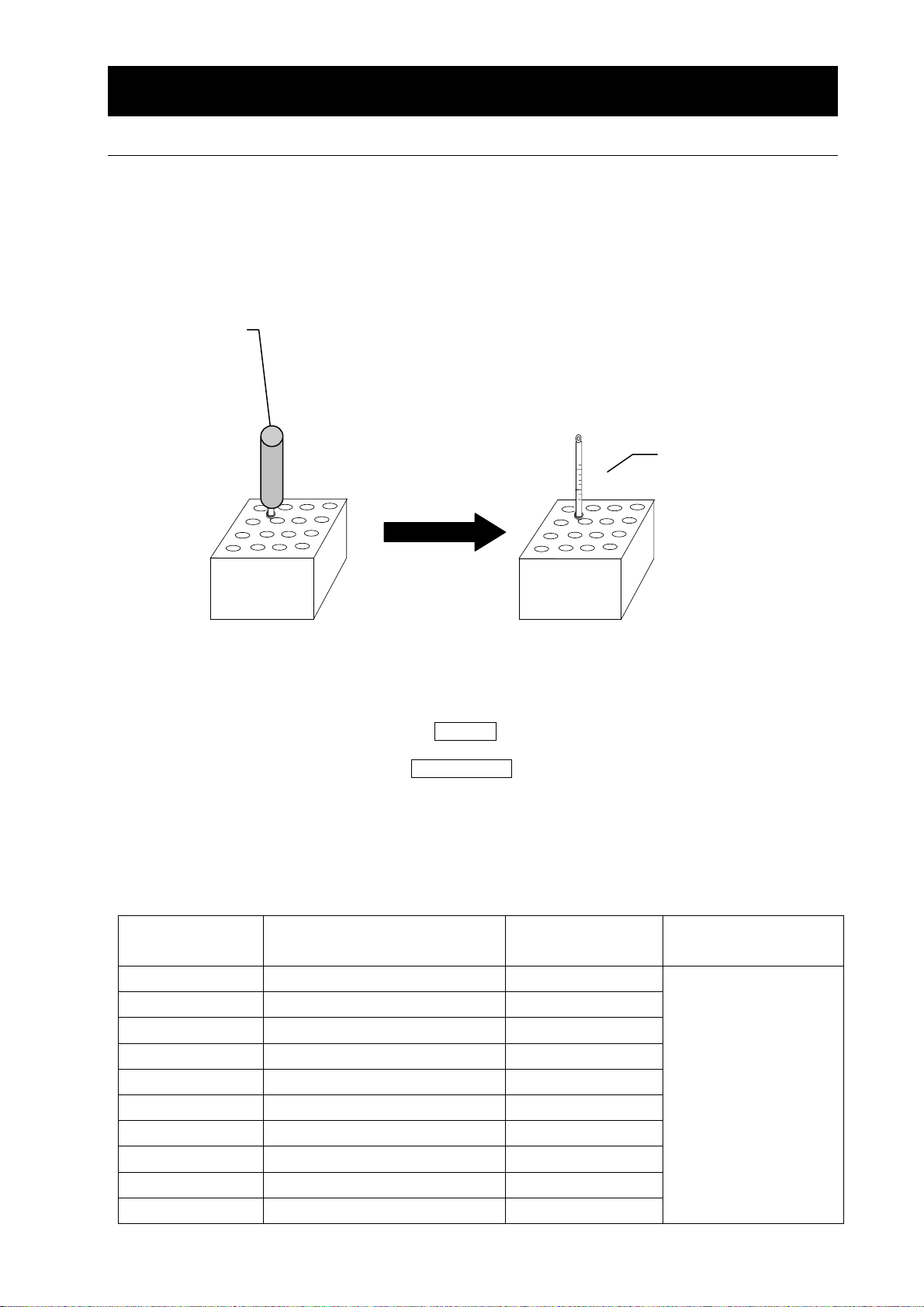

2.Operation Method

From mounting of the aluminum block to operation start

1. Mounting the aluminum

block

Hand grip for

aluminum block

Use the dedicated aluminum block available separately.

The use of an attached dedicated hand grip will prove convenient for

mounting/removal of the aluminum block.

Caution: ・ Possible hazard of burn. Use the hand grip when the

aluminum block is sufficiently cooled.

・ Do not raise the temperature while keeping the hand

grip left attached.

※ If necessary, a bar thermometer may be inserted into a

thermometer hole (used also for attaching the hand grip) of the

aluminum block.

(Use the thermometer of maximum 200℃ or more. Since the bar

thermometer is not attached, obtain it separately.)

Preparation

Bar thermometer

2. Connecting the power

cord

3. Installing the sample To maintain the temperature accuracy, use a sample container

4. Turning ON power

supply

5. Starting operation Press the START/STOP key of the operation panel for one second,

Connect the power cord to an appropriate receptacle firmly.

The receptacle to be connected must be of a 100V 15A type.

appropriate in size to the sample installation hole of the aluminum

block.

Turn ON the POWER switch of the mai n body and set the desired

temperature using▲▼ keys of the operation panel.

and the operation begins.

Aluminum block, which is available separately

The following types of aluminum blocks are available for HF100/HF200. Be sure to use the

aluminum block dedicated to the product concerned.

Specify the product code No. when purchasing.

Product code № Name/size No. of blocks that

can be set

213173 For 0.5m micro tube 48

213174 For 1.5m micro tube 36

213181 For 12 ㎜ test tube 36

213182 For 15 ㎜ test tube 25

213183 For 16.5 ㎜ test tube 25

213184 For 18 ㎜ test tube 20

213175 For 21 ㎜ test tube 12

213176 For 24 ㎜ test tube 12

213185 For 25 ㎜ test tube 12

213177 For 30 ㎜ test tube 8

Can be used

commonly for

HF21/41/61

4

Page 9

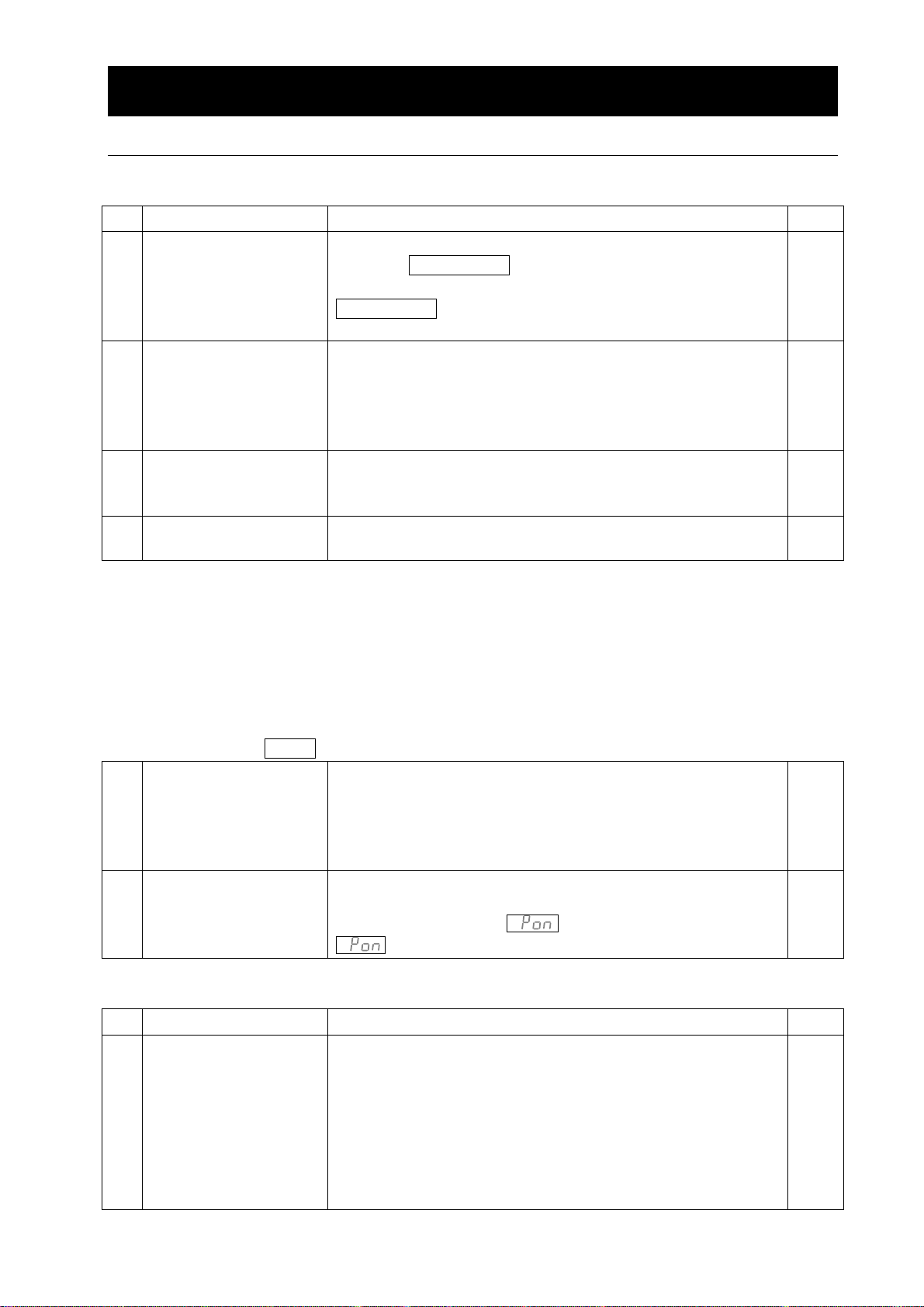

2. How to operate the unit

List of operation modes and functions

The operation functions of the product are as follows.

Nomenclature Description

№

Fixed-value operation Continuous operation mode

1

Press the START/STOP key for one second after temperature

setting, and the continuous operation begins. Pressing the

START/STOP key again for one second causes stop of

operation.

Quick auto-stop

2

operation

Auto-stop operation Used “to set the automatic stop at the specified time” before

3

Auto-start operation Used to start the automatic operation in several hours, that is,

4

※ The temperature and timer’s set time can be changed during operation.

※ Cautions for the auto-stop operation

・ The timer does not start counting till the bath temperature reaches the set level.

・ When the set temperature is below the bath temperature, the timer does not start

counting till the bath temperature drops below the set temperature.

The operation functions of sub-menu of the product are as follows.

Keep pressing the TIMER key for four seconds. The mode changes to the sub-menu mode.

Calibration offset

1

function

Power failure

2

compensation selection

function

The operation function of this device is as follows.

Nomenclature Description

№

Over-temperature

1

preventive function

Causes activation of the timer halfway of fixed-value

operation, then automatic operation stop after the set period.

This function is used “to set the automatic stop after the set

time”, “to set, in the course of operation, the automatic stop in

several hours.”

starting the operation. In the auto-stop mode, the timer starts

counting when the set temperature is reached.

“to set the automatic start at the specified time.”

The calibration offset function is to compensate for any

difference occurring between the target bath temperature and

controller control temperature (sensor temperature).

Compensation can be made either to the positive or negative

side over the entire temperature range of the system.

This is a function to select automatic or manual return to the

operation state after power failure.

Automatic return with

OFF

The automatic over-temperature preventive function is

incorporated.

When the bath temperature rises excessively along with the

set temperature of the device, this is set to activate

automatically at +12℃.

Stop operation when this function is activated. The Alarm

lamp flashes. To cancel, turn ON the power switch newly

again (manual reset).

ON and manual return with

Page

P.6

P.8

P.11

P.15

P.21

Page

P.19

5

Page 10

2 How to operate the unit

Fixed-value operation(continuous operation)mode

For fixed-value operation

In this mode, the operation is started (by pressing the(START/STOP key for one second)and

continued at the set temperature till power supply is turned OFF (by pressing the START/STOP key

for one second).

SV

SV:Temperature set value t:Time

▲

Operation start

1. Turn ON the POWER switch to start power supply.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

t

▲

Power OFF

POWER

The initial screen is shown for four seconds.

OFF

TIMER

SUB MENU 4sec.

START

STOP

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

2.Set the temperature.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

START

STOP

START

STOP

℃

℃

The temperature setting screen appears after the initial

screen has been shown for four seconds.

Shows the current bath temperature.

Shows the current set temperature.

Set the desired temperature with ▼ and ▲ keys.

The set temperature rises with the ▲ key and lowers

with the ▼ key.

Set the temperature over a range from the

room temperature + 5.0℃ up to 200.0℃.

6

Page 11

3. Start operation.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

4. Stop operation.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

2. How to operate the unit

Fixed-value operation(continuous operation)mode

℃

START

STOP

℃

START

STOP

Keep pressing the START/STOP key.

Fixed Temp. and Heater lamps go ON and the operation

begins.

When the bath temperature reaches the set

temperature, the Heater lamp flashes. Now the bath

temperature is under control.

With Fixed and Heater lamps ON, the bath temperature

begins rising and the operation begins.

Keep pressing the START/STOP key.

Fixed Temp. and Heater lamps go OFF and the

operation stops.

Fixed and Heater lamps go OFF and the operation

stops.

The temperature can be set over a range from 0.0℃ to 200.0℃.

Note however that the operating temperature range is from the room temperature + 5.0℃

up to 200.0℃.

With this switch ON, the power is supplied to

Displays of the

operation panel

used for fixed-value

operation

POWER switch

▼ and ▲ keys

Measured Temp. screen

Set Temp. screen

Fixed Temp. lamp

Heater lamp

START/STOP key

:

the system. With the switch OFF, power

supply is turned OFF. This switch is a

circuit breaker.

:

Key to change the set temperature.

:

Shows the current bath temperature.

:

Shows the set temperature.

:

Indicates that the fixed-value operation state

:

is under way.

ON with the heater energized and flashing

:

for the controlled state

Operation start/stop key. Keep pressing for a

certain period.

7

Page 12

2. How to operate the unit

Quick auto-stop operation

For quick auto-stop operation

In this mode, the fixed-value operation being under way is stopped automatically with the timer

setting.

SV

t

Start of fixed-value operation Operation stop (automatic)

SV:Temperature set value t:Time

The quick auto-stop operation is performed in the fixed-value operation mode.

1. Start operation.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

2.Set the desired time.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

STA R T

STOP

Timer setting

▼

Start with timer

℃

℃

Press lightly the TIMER key during fixed-value

operation. The Set Temp. screen changes to display

the time and flashes, with the Auto Stop lamp entering

the flash state.

The time set immediately before the operation is

shown.

Set the desired time with ▼ and ▲ keys.

TIMER

SUB MENU 4sec.

STA R T

STOP

The timer can be set over a range from 0.01(1 minute) to 999.5(999 hours 50 minutes).

The timer indicates the time in minutes from 0.01 to 99.59 and in ten minutes from 100.0

to 999.5.

8

Page 13

3.Start the auto-stop time.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

STA R T

STOP

4. Time-up

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

STA R T

STOP

5. End of the quick auto-stop operation

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Quick auto-stop operation

Press the START/STOP key.

The Auto Stop lamp changes from flashing to the

continuous ON state, and auto-stop operation begins.

The timer starts counting when the bath temperature

reaches the set level.

The display changes from the set time to the remaining

time.

At the set time, the display changes from the remaining

time to the flashing display of End

the end of auto-stop operation.

The display changes to End

.

To cancel the quick auto-stop oper ation, keep pressing

the START/STOP key. The operation ends and the

screen returns to the temperature setting screen.

Indicates the current bath temperature.

Indicates the current set temperature.

. This means

TIMER

SUB MENU 4sec.

STA R T

STOP

Counting of the timer during the quick auto-stop operation

When the temperature set in the quick auto-stop operation is lower than the bath

temperature, the timer does not start counting till the bath temperature reaches the set

level.

9

Page 14

Displays of the

operation panel

used for quick

auto-stop operation

POWER switch

▼ and ▲ keys

Measured Temp. screen

Set Temp. screen

Fixed Temp. lamp

Auto Stop lamp

Heater lamp

START/STOP key

TIMER key

2. How to operate the unit

Quick auto-stop operation

With this switch ON, the power is supplied to

:

the system. With the switch OFF, power

supply is turned OFF. This switch is a circuit

breaker.

:

Key to change the set temperature or the time

of timer

:

Indicates the current bath temperature.

:

Indicates the set temperature. Indicates the

set and remaining times of the timer.

:

Indicates that the operation is in the

:

fixed-value mode.

ON during auto-stop operation and flashing

:

for the time period set with the timer

ON with heater energized and flashing in the

:

controlled state

Operation start/stop key. Keep pressing for a

certain period.

This is also a timer start key for addition of

auto-stop timer operation in the fixed-value

:

operation mode.

Key to set the time during setting of the

auto-stop timer. Press the TIMER key lightly

to show the timer set time.

10

Page 15

2. How to operate the unit

Auto-stop operation

For the auto-stop operation

In this mode, the operation stops automatically according to the setting of the timer.

Timer set

▼

SV

t

SV:Temperature set value t:Time

Quick auto-stop function is to set auto-stop in the course of fixed-value operation. This

section describes the method of operation, in which the auto-stop timer is set at the initial set

time point.

1.Turn ON the POWER switch to start power supply.

Z

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

Timer start

▼

Timer operation start (auto)

Operation stop (auto)

The initial screen is shown for four seconds.

℃

POWER

OFF

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

START

STOP

The temperature setting screen appears after the initial

screen has been shown for four seconds.

Indicates the current bath temperature.

℃

Indicates the current set temperature.

START

STOP

11

Page 16

2.Set the temperature.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

START

STOP

3. Select the auto-stop mode.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Auto-stop operation

Set the desired temperature with ▼ and ▲ keys.

The set temperature rises with the ▲ key and lowers

with the ▼ key.

The temperature can be changed even in the course of

operation.

Press the TIMER key lightly to allow the

AStP indicating the auto-stop operation

mode to appear. The Set Temp. screen shows the time.

Indicates AStP

operation mode.

Indicates the time set immediately before operation.

that means the auto-stop

TIMER

SUB MENU 4sec.

STA R T

STOP

4. Set the time of the timer.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

START

STOP

The timer can set over a range from 0.01(1 minute) to 999.5(999 hours 50 minutes).

The timer indicates the time in minutes from 0.01 to 99.59 and in ten minutes from 100.0

to 999.5.

Set the time with ▼ and ▲ keys.

The time display screen changes to flashing and the

screen changes to the time setting screen.

12

Page 17

5. Start the auto-stop operation.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Auto-stop operation

Keep pressing the START/STOP key.

Auto-stop operation begins.

The timer starts counting when the set temperature is

reached.

TIMER

SUB MENU 4sec.

STA R T

STOP

・Starting counting of the timer in the auto-stop operation mode

When the set temperature is lower than the bath temperature in the auto-stop

operation mode, the timer does not start counting till the bath temperature reaches

the set temperature.

・The set temperature and the time of timer can be changed even during operation.

Change the set temperature directly with ▼ and ▲ keys. The display changes from

the remaining time to the temperature setting screen, enabling temperature change.

The screen changes automatically to the remaining time display. There is not need

to press the START/STOP key after change.

To change the time of timer, press lightly the TIMER key. The set time display

flashes. Change the time to the desired time with ▼ and ▲ keys. The screen

changes automatically to the remaining time display. There is not need to press the

START/STOP key after change.

6. Time-up

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

STA R T

STOP

At the set time, the remaining time display changes to

the flashing display of End

. This means the

end of the auto-stop operation.

Changes over to End

.

13

Page 18

7. End of the auto-stop operation

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Auto-stop operation

To cancel the auto-stop operation, keep pressing the

START/STOP key. The operation ends and the screen

returns to the temperature setting screen.

Indicates the current bath temperature.

Indicates the current set temperature.

TIMER

SUB MENU 4sec.

Displays of the

operation panel

used for auto-stop

operation

POWER switch

▼ and ▲ keys

Measured Temp. screen

Set Temp. screen

Auto Stop lamp

Heater lamp

START/STOP key

TIMER key

STA R T

STOP

With this switch ON, the power is supplied to

:

the system. With the switch OFF, power

supply is turned OFF. This switch is a

circuit breaker.

:

Key to change the set temperature or the

time of timer.

:

Indicates the current bath temperature.

:

Indicates the set temperature. Indicates the

set and remaining times of the timer.

:

ON during auto-stop operation

:

ON with heater energized and flashing in the

controlled state

:

Operation start/stop key. Keep pressing for

a certain period.

:

This is a key to set the time of timer during

setting of the auto-stop timer. Press the

TIMER key lightly during fixed-value

operation to show the timer set time.

14

Page 19

2. How to operate the unit

Auto-start operation

For the auto-start operation

This mode is selected when the operation is to be started automatically in several hours later as

shown below. Since the operation does not stop automatically, it is necessary to stop it manually.

SV

Timer set

t

Timer start Operation start (auto)

Controller start (manual)

SV:Temperature set value t:Time

1.Turn ON the POWER switch to start power supply.

Z

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

POWER

OFF

The initial screen is shown for four seconds.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

START

STOP

The temperature setting screen appears after the initial

screen has been shown for four seconds.

Indicates the current bath temperature.

℃

Indicates the current set temperature.

START

STOP

15

Page 20

2. Set the temperature.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

START

STOP

3. Select the auto-start mode.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Auto-start operation

Set the desired temperature with ▼ and ▲ keys.

The set temperature rises with the ▲ key and lowers

with the ▼ key.

The temperature can be changed even in the course of

operation.

Press the TIMER key lightly to allow AStr

indicating the auto-stop operation mode to appear. The

time is shown in the Set Temp. screen.

Indicates AStr

mode.

Indicates the time set immediately before operation.

meaning the auto-stop operation

TIMER

SUB MENU 4sec.

STA R T

STOP

4. Set the time of timer.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

START

STOP

The timer can set over a range from 0.01(1 minute) to 999.5(999 hours 50 minutes).

The timer indicates the time in minutes from 0.01 to 99.59 and in ten minutes from 100.0

to 999.5.

Set the time with ▼ and ▲ keys.

The time display screen changes to flashing and the

screen changes to the time setting screen.

16

Page 21

5.Start the auto-start operation.

Fixed Temp.

Auto Stop

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Auto-start operation

Keep pressing the START/STOP key.

Auto-start operation begins.

TIMER

SUB MENU 4sec.

START

STOP

6. Time-up

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

STA R T

STOP

7. End of the auto-start operation.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

At the set time, the set temperature is shown in the Set

Temp. screen.

To cancel the auto-start operation, keep pressing the

START/STOP key. The operation ends and the screen

returns to the temperature setting screen.

Indicates the current bath temperature.

Indicates the current set temperature.

TIMER

SUB MENU 4sec.

STA R T

STOP

17

Page 22

Displays of the

operation panel

used for auto-start

operation

POWER switch

▼ and ▲ keys

Measured Temp. screen

Set Temp. screen

Auto Start lamp

Heater lamp

START/STOP key

TIMER key

2. How to operate the unit

Auto-start operation

With this switch ON, the power is supplied to

:

the system. With the switch OFF, power

supply is turned OFF. This switch is a

circuit breaker.

:

Key to change the set temperature or the

time of timer.

:

Indicates the current bath temperature.

:

Indicates the set temperature. Indicates the

set and remaining times of the timer.

:

ON during auto-start operation

:

ON with heater energized and flashing in the

controlled state

:

Operation start/stop key. Keep pressing for

a certain period.

:

This is a key to set the time of timer during

setting of the auto-stop timer. Press the

TIMER key lightly during fixed-value

operation to show the timer set time so as to

show the time set with timer.

18

Page 23

2. How to operate the unit

Other functions

Over-temperature preventive function

This product incorporates two types of over-temperature preventive functions.

1.Automatic over-temperature

preventive device

Before shipment, this device has been set in such a manner that

it interlocks with the set temperature of the device and is

activated automatically at the set temperature + 12℃ in case of

abnormal rising of bath temperature.

When activated, the over-temperature preventive function

causes stop of operation and flashing of the Alarm lamp. To

cancel the function, turn ON the Power switch newly again after

allowing the bath temperature to lower (manual reset).

When the symptom is not improved, the circuitry (temperature

controller, etc.) may be faulty. Contact a shop from which you

have purchased the product, our safes office, or our customer

service center.

2. Independent over-temperature

preventive device

If abnormal overheat continues because of failure of the

automatic over-temperature preventive function, resulting in the

bath temperature rise up to 230 ℃ , the built-in bimetal

over-temperature preventive device is activated, shutting off

power supply to the heater.

Activation of this device may be due to failure of the circuitry

(temperature controller, etc.). Contact a shop from which you

have purchased the product, our safes office, or our customer

service center.

Set value lock function

This function is to lock the set contents to prevent arbitrary change.

1. Select the Lock function from the sub-menu function.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

℃

STA R T

STOP

Keep pressing the TIMER key for four seconds and

select the sub-menu mode. Allow LocK

indicating the set-value lock function to appear. The Set

Temp. screen shows off

been made and on when any setting has been

made.

Shows LocK

indicating the set-value lock mode.

Shows either off

or on .

when no setting has

4 sec.

19

Page 24

2.LocK the set value.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

2. How to operate the unit

Other functions

Select “on” with the ▲ key, and the set value is locked.

Shows on .

TIMER

SUB MENU 4sec.

STA R T

STOP

3. Cancel the LocK function.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

4 sec.

℃

STA R T

STOP

Keep pressing the TIMER key for four seconds to select

the sub-menu mode and to allow LocK

indicating the set-value lock function to appear. The Set

Temp. screen shows off

.

Shows Lock

indicating the set-value lock mode.

Shows off

.

20

Page 25

2. How to operate the unit

Other functions

Calibration offset function

The calibration offset function is to ensure agreement between the bath temperature and set

temperature by compensating the temperature difference, if any, between the bath temperature

actually measured with the reference thermometer or temperatur e recorder and the temperature set

with the controller (as read on the controller).

Enter the plus-side temperature difference to the calibration offset setting when the bath

temperature exceeds the set value and the minus-side temperature difference to the above setting

when the bath temperature is lower than the set level.

1.Measure the bath temperature

Wait till the bath temperature stabilizes, then check the difference between the bath temperature and

the measurement indicator of this device. The bath temperature can be measured corr ectly by using

the calibrated temperature recorder in the small amount of silicone oil filled into the aluminum block.

Temperature after compensation

on the minus side

Current temperature

Temperature after

compensation on the plus

side

Temperature recorder sensor

Small amount (about 2 ml) of silicone oil

(for the aluminum block for 16.5㎜ test tube)

Aluminum block

21

Page 26

2. How to operate the unit

Other functions

2.Select the calibration offset function from the sub-menu function.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

TIMER

SUB MENU 4sec.

Measured Temp.

Set Temp.

4秒

℃

STA R T

STOP

3. Enter the offset temperature.

Enter the temperature difference on the minus side when the bath temperature is lower than the

temperature controller reading value.

Enter the temperature difference on the plus side when the bath temperature is higher than the

temperature controller reading value.

Repeat this step till the bath temperature and the temperature controller reading value agree.

Setting can be completely within a short period by first entering the compensation temperature

lower than the difference of both of them, then by allowing it to approach the target level gradually.

Fixed Temp.

Auto St op

Auto Start

Heater

Alarm

Measured Temp.

Set Temp.

℃

Keep pressing the TIMER key for four seconds to select

the sub-menu mode. First, the set-value lock function is

displayed. Press the TIMER key again, and

cAL

indicating the calibration offset function

appears.

The Set Temp. screen shows the compensation

temperature.

Shows cAL

indicating the calibration offset mode.

Shows the offset temperature set immediately before

operation.

Enter the temperature difference in the Set Temp.

screen.

Upon completion of the setting, keep pressing the

TIMER key. The screen returns to the temperature

setting screen.

Enter the temperature difference.

TIMER

SUB MENU 4sec.

STA R T

STOP

22

Page 27

3. In Case of Trouble

The controller displays the following errors.

In case of error, the heater output stops, the Alarm lamp flashes to notify abnormality.

Record the error code, turn OFF power supply, and carry out the service call.

Error code Details

Temperature input circuit

error

Er01

Er15

Not

displayed

Not

displayed

For details of over-temperature preventive device, refer to P.19.

Alarm lamp

flashing only

-

Temperature sensor error

Error of outside the

measured temperature

display range

Memory error

Over-temperature

prevention error

Over-temperature

prevention error

Broken or disconnected sire of

temperature sensor, error in the

temperature input circuit

Check the sensor and temperature

controller and replace if necessary.

Cancelled by resetting power supply.

Memory set value error in the

temperature controller

Board replacement necessary。

Abnormal temperature rise, resulting in

activation of the auto over-temperature

preventive device

Canceled by resetting power supply.

Abnormal temperature rise, resulting in

activation of the independent

over-temperature preventive device

Carry out the service call.

Error display

T roubleshooting guide

Troubleshooting

Symptom Countermeasure

No startup even with

POWER and START/STOP keys

ON

◆ If neither of above two cases applies, turn OFF the POWER switch immediately.

Disconnect the power plug and contact a shop from which you have purchased the

product, our safes office, or our customer service center.

・Check if the master power supply is ON.

・Check if power failure has occurred.

23

Page 28

4. Specifications

Main body

Type HF100 HF200

No. of installed

aluminum blocks

Operating

temperature range

Temperature control

accuracy

Temperature rise

time

Temperature

controller

Temperature setting

method

Minimum

temperature setting

Temperature setting

method

Heater 370W 600W

Sensor Pt100Ω

Safety devices

Functions

Overall dimensions About 230W×310D×139H About 340W×310D×139H

Internal bath

dimensions

Weight About 5 ㎏ About 6.5 ㎏

About 30 minutes(room temperature at

Automatic over-temperature preventive function (main relay OFF at the set

temperature + 12℃, manual reset)

Independent over-temperature preventive device (manual reset type bimetal,

activated temperature at about 230℃)

Fixed-value operation, quick auto-stop operation, auto-stop operation, auto-start

operation, self-diagnosis function, automatic over-temperature preventive

function, set-value lock function, calibration offset function, power failure

compensation function

(16.5φ block used)

7-segment LED, set temperature, and bath temperature displayed

About 1 12W×112D×70H About 222W×112D×70H

1 piece 2 pieces

Room temperature + 5.0℃~200.0℃

±0.2℃

(16.5φ block used)

About 35 minutes (room

23℃)

PID control with microcomputer

▲ and ▼ keys

0.1℃

Functioning both as POWER switch and circuit breaker

temperature at 23℃)

±0.2℃

Power supply AC100V 3.8A±10% AC100V 6.1A±10%

Accessories Heating block mounting/removal fixture, operation manual, warranty card

※ The temperature control accuracy has been determined according to our testing method.

This is the value measured using an aluminum block for 16.5 mm test tube at the room temperature of

23℃.

Optional accessories

Aluminum block dimensions 110 W×110D×70H(common to all blocks)

№

1 213173 OBH80 For 0.5m micro tube 48

Types of aluminum block

2 213174 OBH82 For 1.5m micro tube 36

3 213181 OBH84 For 12 ㎜ test tube (common to HF21/41/61) 36

4 213182 OBH86 For 15 ㎜ test tube(common to HF21/41/61) 25

5 213183 OBH88 For 16.5 ㎜ test tube(common to HF21/41/61) 25

6 213184 OBH90 For 18 ㎜ test tube(common to HF21/41/61) 20

7 213175 OBH92 For 21 ㎜ test tube 12

8 213176 OBH94 For 24 ㎜ test tube 12

9 213185 OBH96 For 25 ㎜ test tube(common to HF21/41/61) 12

Product

code

Type Aluminum block specification

No. of

racks

10 213177 OBH98 For 30 ㎜ test tube 8

24

Page 29

5. Wiring Diagram

Symbol Name of part Symbol Name of part

H Mica heater X1 Main relay

TIC Control board SSR Non-contact relay

PIO Display board

CP

POWER switch(circuit

breaker)

Pt100Ω

OH

Temperature sensor

Bimetal type

Over-temperature preventive device

25

Loading...

Loading...