Page 1

● Thank you for choosing DP Series Vacuum Drying

Ovens by Yamato Scientific Co., Ltd.

● For proper equipment operation, please read this

instruction manual thoroughly before use. Always

keep equipment documentation safe and close at

hand for convenient future reference.

Warning: Read instruction manual warnings and

cautions carefully and completely

before proceeding.

VACUUM DRYING OVENS

Model DP200/300/410/610

Instruction Manual

First Edition

Yamato Scientific Co., Ltd.

Printed on recycled paper

Page 2

TABLE OF CONTENTS

1. SAFETY PRECAUTIONS ........................................................................................................... 1

Explanation of Symbols ......................................................................................................................... 1

Symbol Glossary ................................................................................................................................... 2

Warnings and Cautions ......................................................................................................................... 3

2. PRE-OPERATION PROCEDURES ............................................................................................ 4

Installation Precautions & Procedures .................................................................................................. 4

Vacuum System Information ................................................................................................................. 9

3. COMPONENT NAMES AND FUNCTIONS ............................................................................... 11

Unit Overview 1 ................................................................................................................................... 11

Control Panel ....................................................................................................................................... 13

4. OPERATION PROCEDURE ..................................................................................................... 14

Prior Confirmation ............................................................................................................................... 14

Decompression/Purge Procedure ....................................................................................................... 14

Setting Date & Time ............................................................................................................................ 15

Keypad Tone Function ........................................................................................................................ 16

Mode and Function Flow ..................................................................................................................... 17

Constant Temperature Mode .............................................................................................................. 18

Auto Stop Mode ................................................................................................................................... 20

Auto Start Mode................................................................................................................................... 22

Programmed Operation ....................................................................................................................... 24

Building Programs ............................................................................................................................... 27

Keypad Lock Function ......................................................................................................................... 31

Calibration Offset Function .................................................................................................................. 32

Recovery Modes ................................................................................................................................. 33

CO2 Emissions & Power Consumption Settings ................................................................................ 34

Data Backup & Reset .......................................................................................................................... 35

Data Monitoring ................................................................................................................................... 36

Independent Overheat Prevention Device .......................................................................................... 37

5. HANDLING PRECAUTIONS .................................................................................................... 38

6. MAINTENANCE PROCEDURE ................................................................................................ 43

Inspection and Maintenance ............................................................................................................... 43

7. EXTENDED STORAGE & DISPOSAL ..................................................................................... 44

Extended Storage / Unit Disposal ............................................................................................................. 44

Disposal Considerations...................................................................................................................... 44

8. TROUBLESHOOTING .............................................................................................................. 45

Error Code Guide ................................................................................................................................ 45

Troubleshooting Guide ........................................................................................................................ 46

9. SERVICE & REPAIR ................................................................................................................ 48

10. SPECIFICATIONS .................................................................................................................. 49

11. ACCESSORIES ...................................................................................................................... 51

Optional Accessory Guide ................................................................................................................... 51

12. WIRING DIAGRAM................................................................................................................. 53

13. WEAR ITEMS ......................................................................................................................... 57

14. LIST OF HAZARDOUS SUBSTANCES ................................................................................. 58

15. SETUP CHECKLIST ............................................................................................................... 59

Page 3

A Word Regarding Symbols

Various symbols are provided throughout this text and on equipment to

ensure safe operation. Failure to comprehend the operational hazards and

risks associated with these symbols may lead to adverse results as explained

below. Become thoroughly familiar with all symbols and their meanings by

carefully reading the following text regarding symbols before proceeding.

Warning

Caution

Signifies a situation which may result in minor injury (Note 2)

and/or property damage (Note 3)

(Note 1) Serious injury is defined as bodily wounds, electrocution, bone

breaks/fractures or poisoning, which may cause debilitation requiring

extended hospitalization and/or outpatient treatment.

(Note 2) Minor injury is defined as bodily wounds or electrocution, which will not

require extended hospitalization or outpatient treatment.

(Note 3) Property damage is defined as damage to facilities, equipment, buildings or

other property. ( Note 1 ) Serious injury is defined as bodily wounds,

Symbol Meanings

Signifies warning or caution.

Specific explanation will follow symbol.

Signifies restriction.

Specific restrictions will follow symbol.

Signifies an action or actions which operator must undertake.

Specific instructions will follow symbol.

Signifies a situation which may result in serious

injury or death (Note 1)

1. SAFETY PRECAUTIONS

Explanation of Symbols

1

Page 4

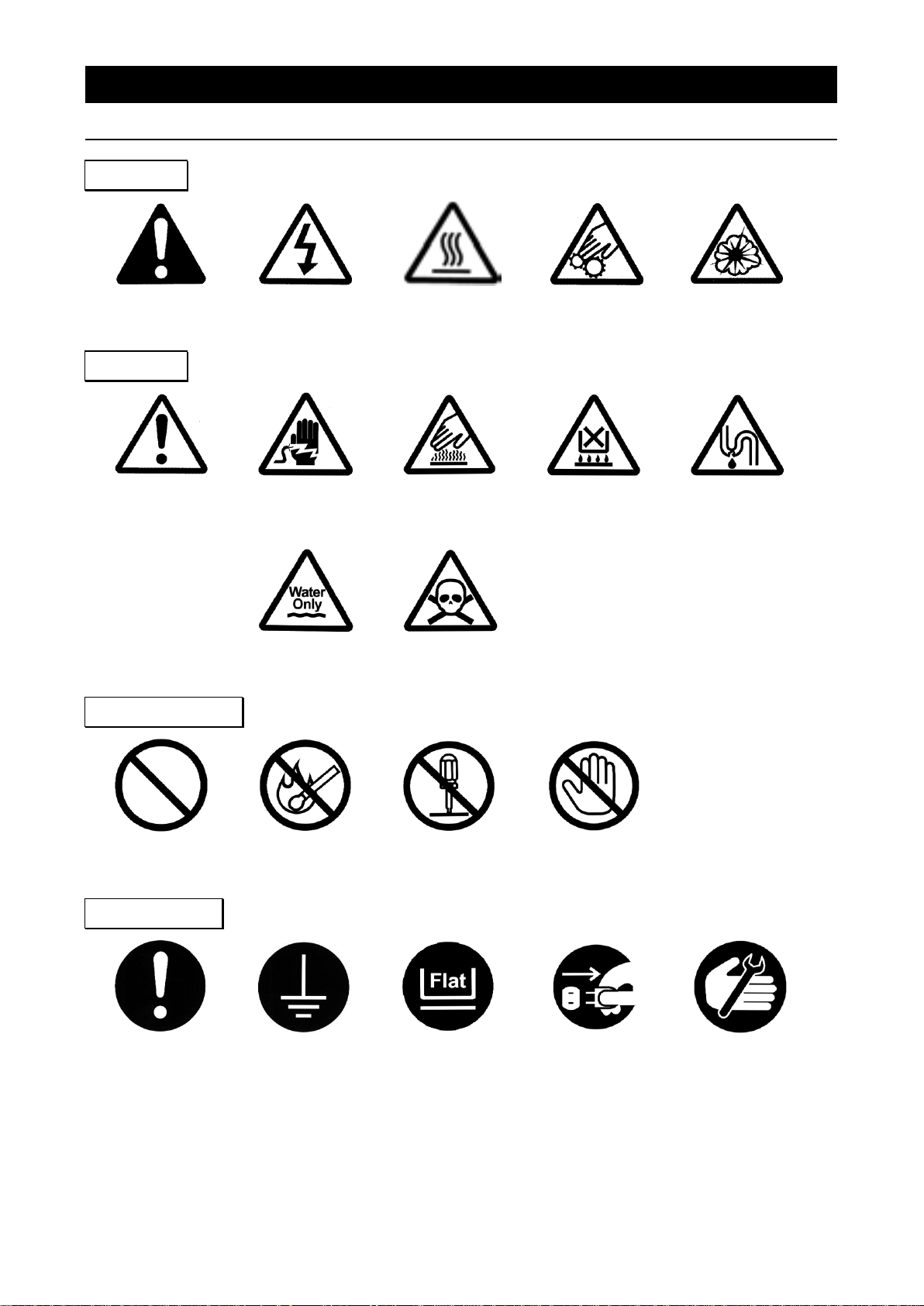

General Warning

Danger!:

High Voltage

Danger!:

Extremely Hot

Danger!:

Moving Parts

Danger!:

Blast Hazard

General Caution

Caution:

Electrical Shock

Hazard!

Caution: Burn

Hazard!

Caution: Do Not

Heat Without

Water!

Caution: May

Leak Water!

Caution: Water

Only

Caution: Toxic

Chemicals

General

Restriction

No Open Flame

Do Not

Disassemble

Do Not Touch

General Action

Required

Connect Ground

Wire

Level Installation

Required

Disconnect Power

Inspect

Regularly

Warning

Caution

1. SAFETY PRECAUTIONS

Symbol Glossary

Restriction

Action

2

Page 5

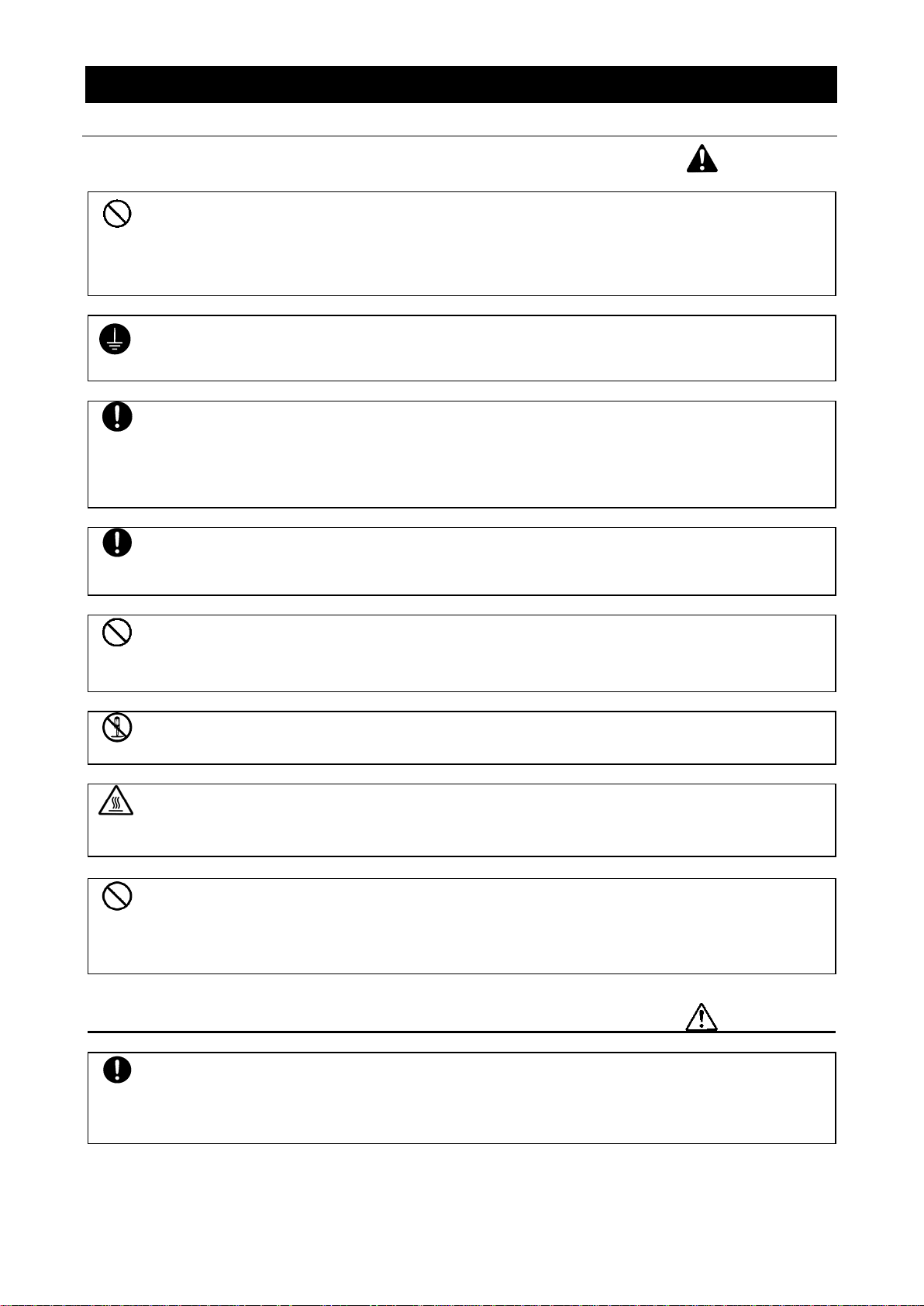

Warning

Never operate equipment near combustible gases/fumes.

Do not install or operate DP series unit near flammable or explosive gases/fumes. Unit is NOT fire

or blast resistant. Negligent use could cause a fire/explosion.

See “List of Hazardous Substances” (P.58).

Always ground equipment.

Always ground this unit properly to avoid electric shock.

DO NOT operate equipment when abnormalities are detected.

If smoke or unusual odors begin emitting from unit, or if any other abnormalities are detected,

terminate operation immediately, turn off main power switch (Earth Leakage Breaker - “ELB”) and

disconnect power cable. Continued operation under such conditions may result in fire or electric

shock.

DO NOT operate with bundled or tangled power cable.

Operating unit with the power cable bundled or otherwise tangled, may cause power cable to

overheat and/or catch fire.

DO NOT damage power cable.

Damaging the power cable by forcibly bending, pulling or twisting may cause fire or electric shock to

the operator.

NEVER disassemble or modify equipment.

Attempting to dismantle or modify unit in any way, may cause malfunction, fire or electric shock.

DO NOT touch hot surfaces.

Some surfaces on this unit become extremely hot during operation. Exercise vigilance in order to

avoid getting burned.

DO NOT insert multiple power cables into a single outlet.

Inserting multiple cords into a single outlet, using branch outlets or extension cords, may cause

power cable to overheat and/or catch fire. Other issues may include a drop in voltage, which may

affect performance, resulting in failure to control or maintain proper temperatures.

Caution

DO NOT operate equipment during thunderstorms.

In the event of a thunderstorm, terminate operation and turn off main power switch (ELB)

immediately. A direct lightning strike may cause damage to equipment, or result in fire or electric

shock.

1. SAFETY PRECAUTIONS

Warnings and Cautions

3

Page 6

Do not install DP series unit:

・where flammable or corrosive gases/fumes will be generated.

・where exterior temperature will exceed 35ºC, will fall below 5ºC or will fluctuate.

・in excessively humid or dusty locations.

・where there is constant vibration.

・where power supply is erratic.

・in direct sunlight or outdoors.

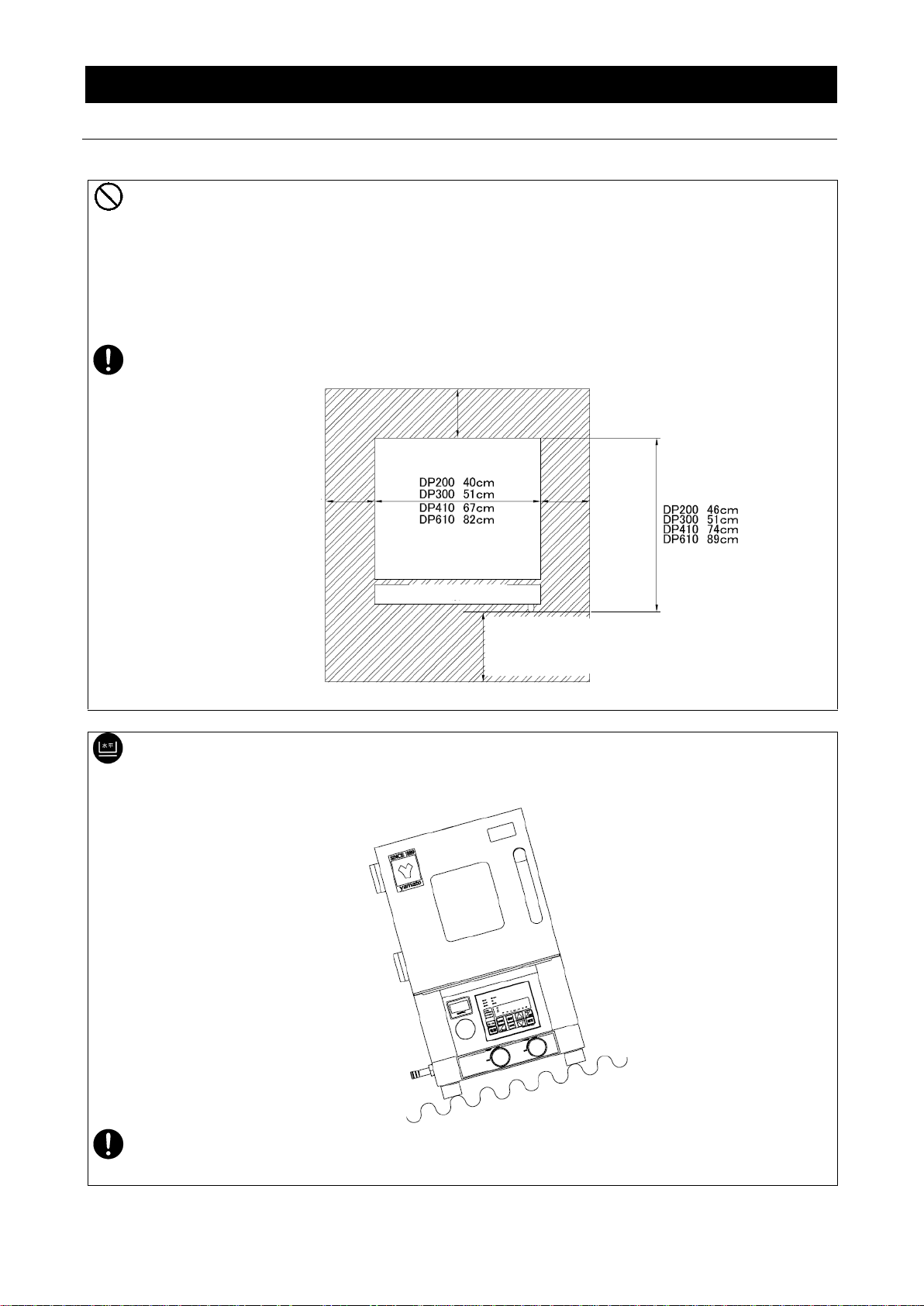

Install DP series oven(s) in a location with sufficient space and ventilation as specified as below.

Install unit on a level and even surface. Failure to do so may result in abnormal vibrations or

noise, possibly causing complications and/or malfunction.

Approximate unit weight:

DP200: approx. 45kg, DP300: approx. 72kg, DP410: approx. 210kg, DP610: approx. 310kg.

Handle with care. Transportation and installation should always be done by two or more people.

Min. 20cm

Min. 20cm

Equipment

Door

DP200: Min. 40cm

DP300: Min. 50cm

DP410: Min. 65cm

DP610: Min. 80cm

Min. 20cm

2. PRE-OPERATION PROCEDURES

1. Choose an appropriate installation site.

Installation Precautions & Procedures

2. Install on a level surface.

4

Page 7

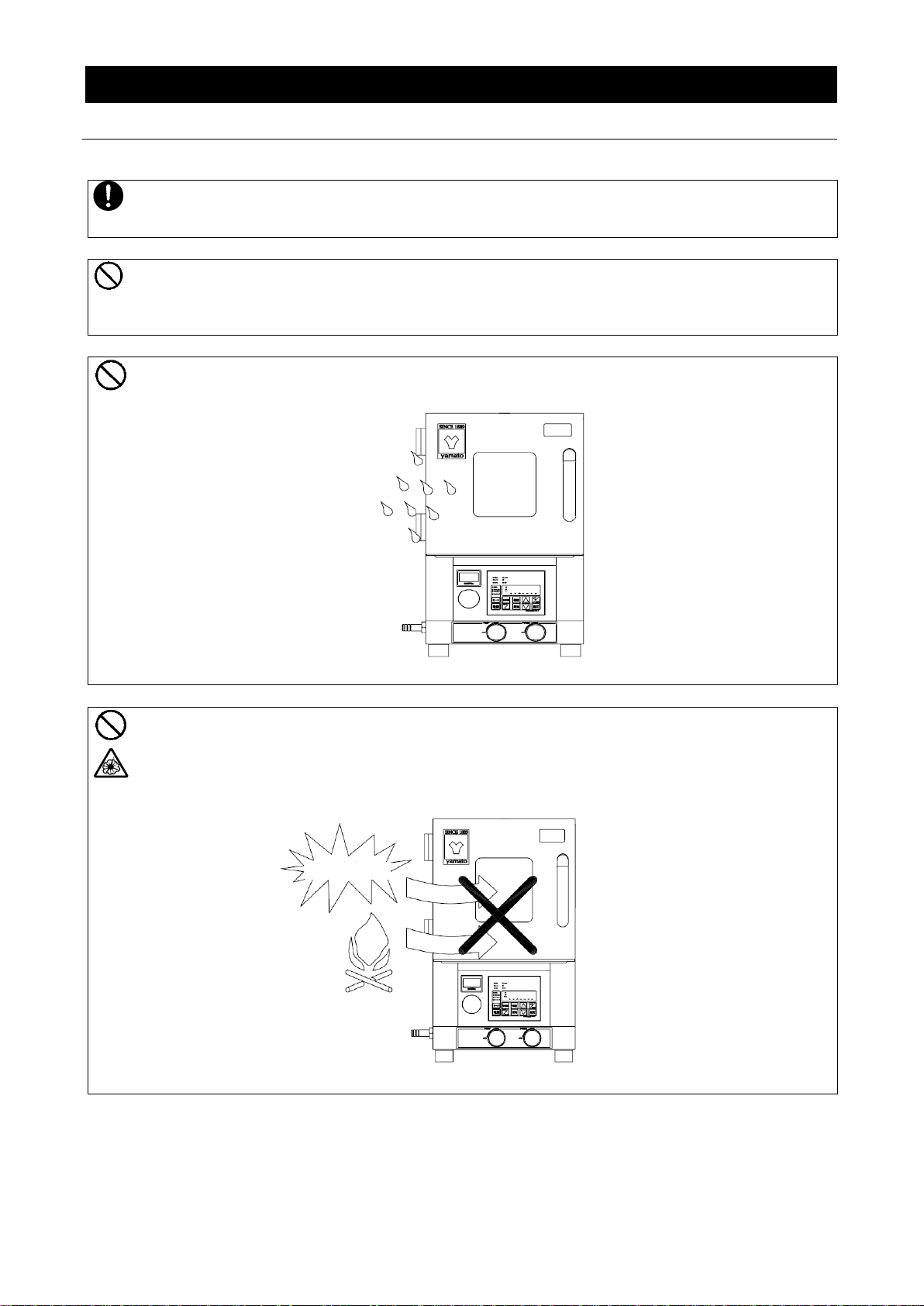

In the event of an earthquake or other unforeseen incident, equipment may unexpectedly shift or

fall, causing injury. Taking preventative steps to install unit in a safe location, away from room

access doors and out of other danger is strongly recommended.

Install unit so that side panel heat vents (see “Unit Overview 1” on P.11 for location) are

unobstructed and allowed to sufficiently diffuse heat. Failure to do so may result in excessive

temperatures inside the unit control panel, causing possible degraded CPU board performance,

malfunction or fire. See installation specifications above.

Install unit where it will be free from liquid spray and other moisture. Failure to do so may result

in control mechanisms becoming wet, causing malfunction, electrical shock and/or fire.

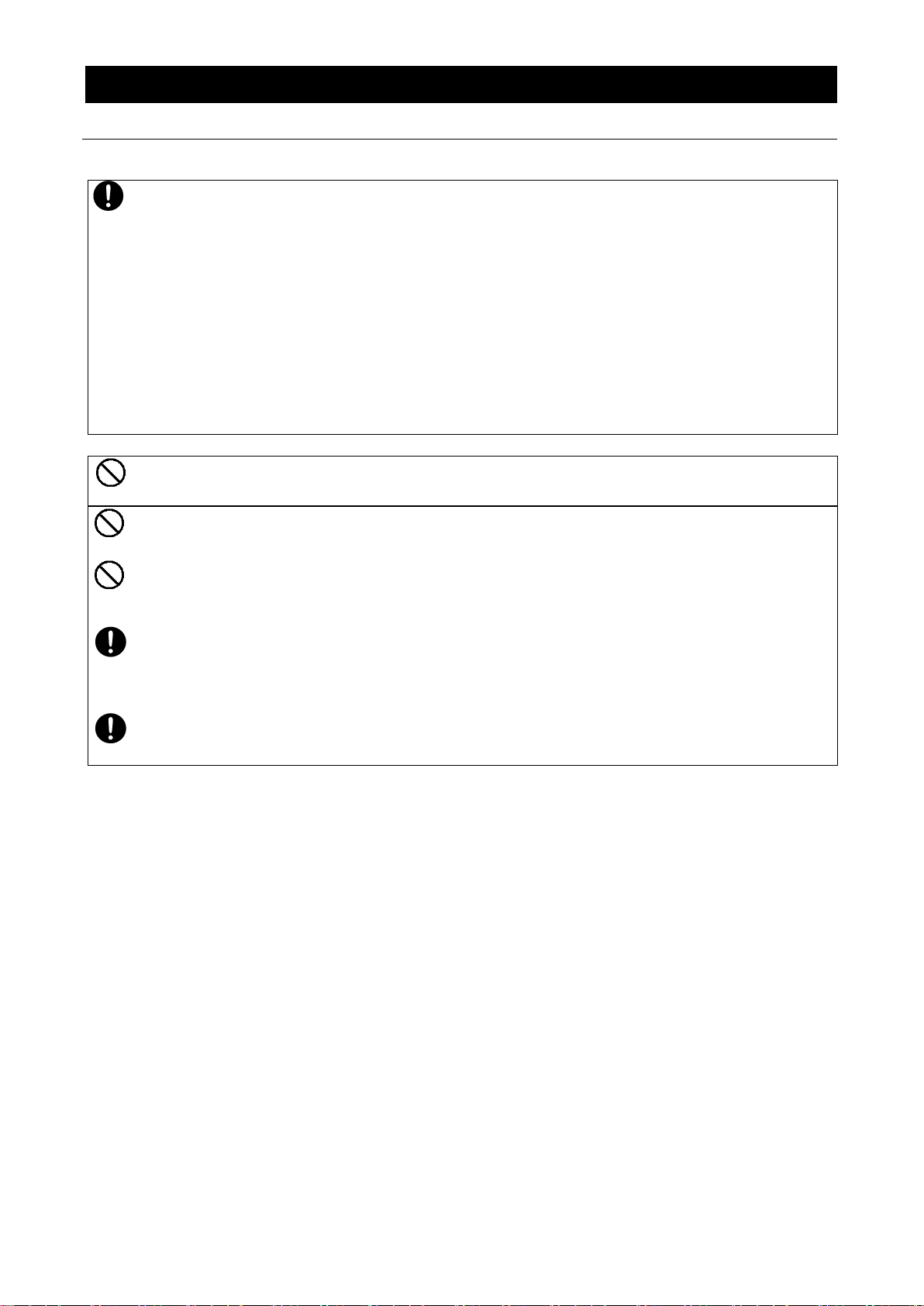

Never install near flammables or explosives. This unit is NOT fire or blast resistant. Simply

switching the main power switch (ELB) “ON” or “OFF” can produce a spark, which could relay

during operation, causing a fire or explosion when near flammable or explosive fluids, chemicals

or gases/fumes. See “List of Hazardous Substances” (P.58).

Explosives

Flammables

2. PRE-OPERATION PROCEDURES

Installation Precautions & Procedures

3. Install in a safe location.

4. Install in a well-ventilated area (DP200/300 only).

5. Install in a dry location.

6. Install in a location free of flammables and explosives.

5

Page 8

Connect power cable to a suitable facility outlet or terminal, according to the following electrical

requirements.

Electrical requirements:

DP200 Single phase 100V AC 50/60Hz 7A

DP300 Single phase 100V AC 50/60Hz 11A

DP410 Single phase 200V AC 50/60Hz 11.5A

DP610 Single phase 200V AC 50/60Hz 16A

※Check the line voltage on outlet or terminal to be used and properly evaluate whether to utilize

a line being shared by other equipment. If the unit is not activated by turning on the main

power switch (ELB), take an appropriate course of action, such as connecting the unit to a

dedicated power source.

※Multiple power cables connected to a single outlet may cause unit input voltage to drop,

resulting in degraded heating and temperature control performance.

Never operate unit with power cable bundled or tangled; and do not modifiy, bend, forcibly twist

or pull on power cable. Doing so may cause fire and/or electrical shock.

Do not risk damage to power cable by positioning it under desks or chairs, or by pinching it

between objects. Doing so may cause fire and/or electrical shock.

Do not place power cable near kerosene/electric heaters or other heat-generating devices.

Doing so may cause power cable insulation to overheat, melt and/or catch fire, which may result

in electric shock.

Turn off main power switch (ELB) immediately and disconnect from facility terminal or outlet, if

power cable becomes partially severed or damaged in any way. Failure to do so may result in

fire or electric shock.

Contact a local dealer or Yamato sales office for information about replacing power cable if it is

damaged.

Always connect power cable to appropriate facility outlet or terminal.

7. Connect to power supply.

8. Handle power cable with care.

2. PRE-OPERATION PROCEDURES

Installation Precautions & Procedures

6

Page 9

・ Ground wire must be connected to a proper grounding line or teminal in order to avoid

electrical shock.

・ Never connect ground wire to gas lines or water pipes.

・ Never connect ground wire to telephone grounding lines or lightening rods. Doing so may

result in fire or electric shock.

・ Never insert multiple plugs into a single outlet. Doing so may result in power cable

overheating, fire or drop in voltage.

Connect to grounded outlet.

Outlet with ground receptacle

When no grounding terminal is found:

●Grounding to Electrical Equipment Technical

Standards, Section 19, class D (Grounding

Resistance Max. 100Ω) is required in Japan.

Contact a local dealer, electrician, or Yamato

Sales office for location-specific electrical

requirements.

Use grounded adapter for ungrounded outlets.

Outlet with no ground receptacle

Ground adapter

●Insert grounded power plug into ground

adapter. Connect grounding wire (green) from

ground adapter to a ground terminal.

・ Grounding to Electrical Equipment Technical Standards, Section 19, class D (Grounding

Resistance Max. 100Ω) is required in Japan where no grounding terminal is provided. Contact a

local dealer, electrician, or Yamato Sales office for location-specific electrical requirements.

・ Connect terminals securely to facility terminal or to an appropriate connector.

Plugs and connectors are not included with

this unit. Ground unit properly to facility

outlet or terminal as required.

Never connect ground wire to gas lines, water pipes, telephone grounding lines or lightening

rods. Doing so may result in fire or electrical shock.

Confim that the facility main breaker is OFF before

connecting the round terminals from the power cable. No

power plugs or connectors of any kind are included with

DP410/610. Where required, purchase an appropriate

plug and properly connect using the round terminals.

Wire color

Terminal

Black

Live side

White

Neutral side

Green

Ground

Ungrounded outlet

100V AC only

Ground adapter

Grounded plug

Grounding wire

with Y-terminal

W

w

G

Grounded plug

3 (three) Round Terminals for M5 screws

Green (to grounding terminal)

Black (to facility terminal)

White (to facility terminal)

Grounding prong

2. PRE-OPERATION PROCEDURES

Installation Precautions & Procedures

9.(1) Ground wire MUST be connected properly (DP200/300 at 100V AC).

9.(2) Ground wire MUST be connected properly (DP410/610 220V AC).

10. Observe wire color designation when connecting to facility terminal (DP410/610

200V AC) See table below.

7

Page 10

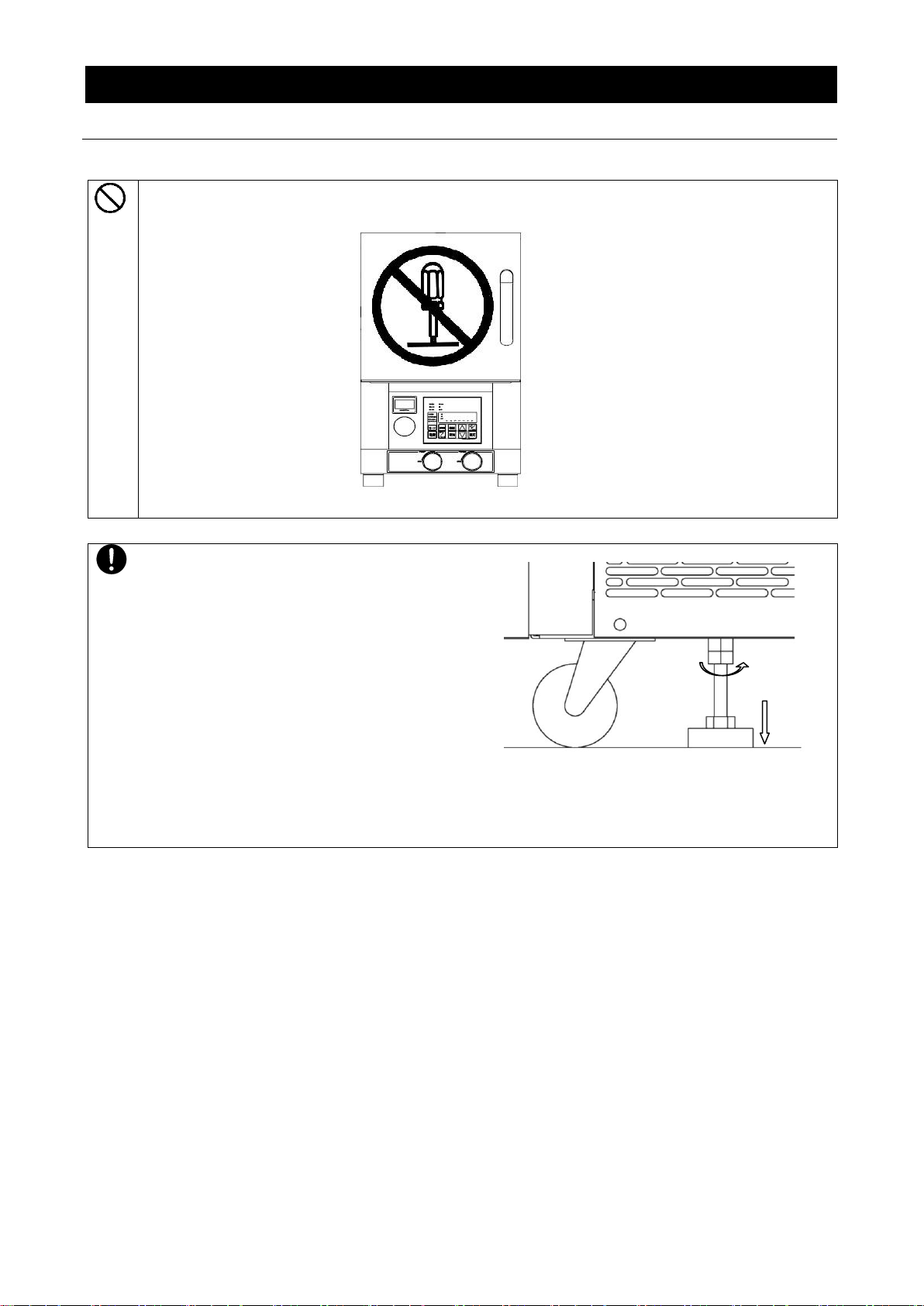

11. DO NOT disassemble or modify.

Attempting to disassemble or modifiy this unit in any way may result in malfunction, fire or

electric shock.

Position the 2 (two) adjustable leveling feet,

located on the undercarriage of DP410/610

units.

After unit is installed, position the adjustable

leveling feet using the following procedure:

① Rotate leveling feet down until unit stands

securely on the floor.

② Check for any gaps between the floor and

4 (four) contact points (e.g. the 2 ‘two’

front leveling feet and the 2 ‘two’ rear

casters).

③ Once unit is secure, tighten both leveling

feet stop nuts firmly against the topmost

nut, to prevent leveling feet from turning

under vibration.

①

③

2. PRE-OPERATION PROCEDURES

Installation Precautions & Procedures

12. Position adjustable leveling feet (DP410/DP610 only).

8

Page 11

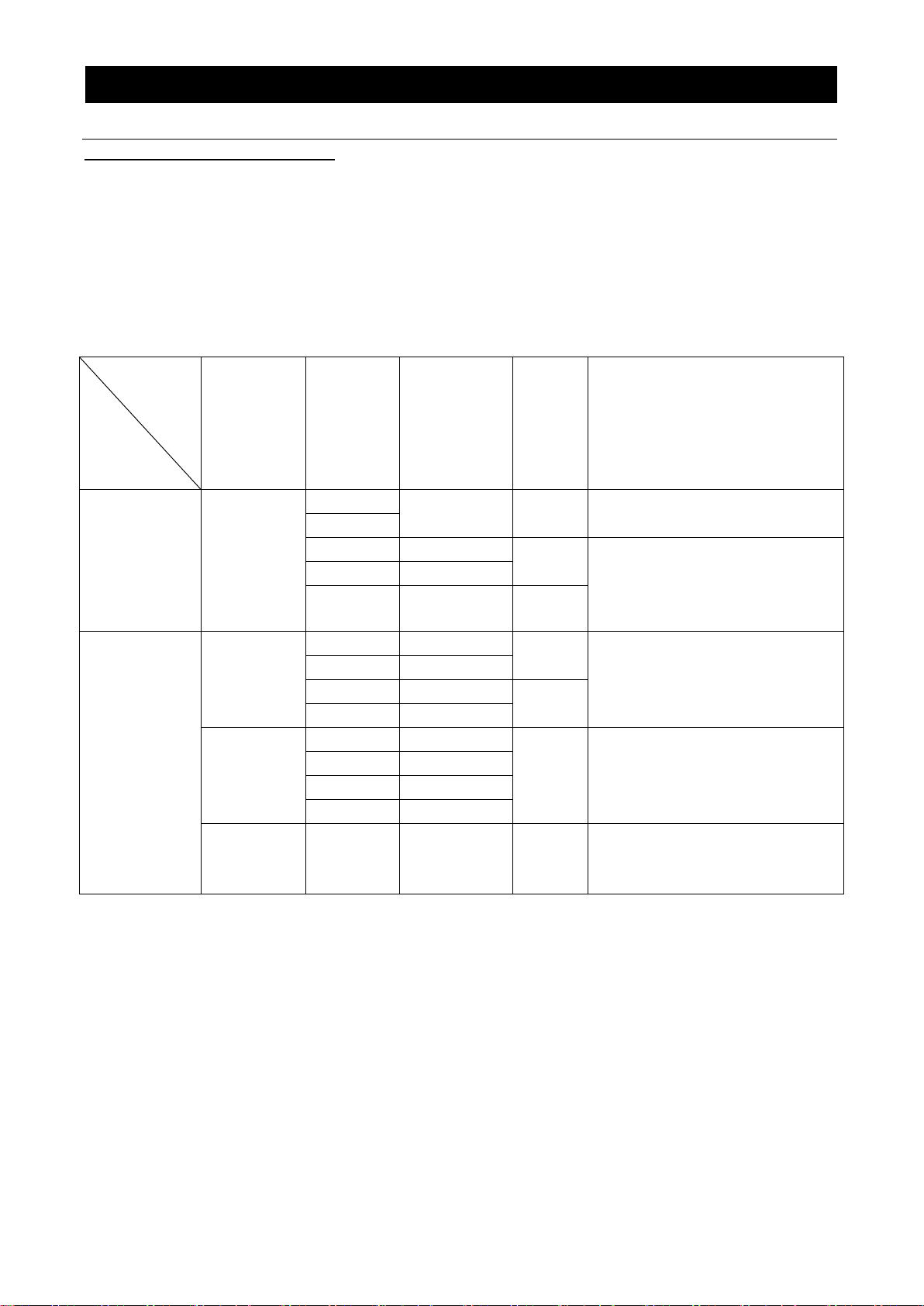

Item

Model

(Pump

Connection

Port Size)

Manufacturer

or Supplier

Vacuum

Pump

Model

(sold

separately)

Effective

Pump

Displacement

(at 50/60Hz)

in litters/min.

Pump

Inlet

Size

Required vacuum line components

DP200/300

(Pump

connection port

:18mm)

Yamato

Science

PD53*1

50/60

18 mm

・15 mm ID vacuum hose

Qty 1

PX52*1

PD103

100/120

27 mm

・15 mm ID vacuum hose

・25 mm ID vacuum hose

・Reducing pipe(18/27)

A(Brass)/C(Stainless St.)

Qty 1

Qty 1

Qty 1

PD138*1

135/162

PX137*1

135/162

30 mm

DP410/610

(Pump

connection

port

:NW25

flange)

Yamato

Science

PD138

*1

135/162

27 mm

・25 mm ID vacuum hose

・Vacuum hose adapter

・Clamp (NE20/25)

・Center ring (NW25)

Qty 1

Qty 1

Qty 1

Qty 1

PD203*1

200/240

PX137

135/162

30 mm

PX202

200/240

Adixen

M(T)2010

142/170

NW25

flange

・Flexible hose

・Clamp (NW20/25)

・Center ring (NW25)

Qty 1

Qty 2

Qty 2

M(T)2015

208/250

M(T)2010C

142/170

M(T)2015C

208/250

Kashiyama

NeoDry15E

250

NW25

flange

・Flexible hose

・Clamp (NW20/25)

・Center ring (NW25)

Qty 1

Qty 2

Qty2

2. PRE-OPERATION PROCEDURES

Vacuum System Information

Vacuum System Information

Vacuum pumps and vacuum line components (sold separately) for DP series ovens

(1) Vacuum pump models and vacuum line components (sold separately), required for DP series

ovens, are shown in Table 2.1. Select an appropriate vacuum pump and vacuum line components

(sold separately) using the table below. Note that an appropriate check valve must also be selected

for vacuum pumps (sold separately). Vacuum line components are also offered as options and

available upon request.

Table 2.1 Vacuum pump models and required line components (sold separately) for DP series ovens

【Note】

・ *1 These pump models can be fitted with components for the KF-style quick-coupling flange, as on

all Adixen pump models.

・ If an existing vacuum pump is to be connected to a new DP series unit, and their inlet sizes do not

match, use an appropriate reducing joint.

(2) Be sure to use the proper vacuum line components between vacuum pump (sold separately) and

DP series unit to prevent any vacuum leaks.

(3) If an existing pump cabinet is to be used for a new vacuum pump (sold separately) installation on

DP models 410/610, be sure to place the vacuum pump (sold separately) inside of the cabinet so

that the oil gauge faces front and can be easily viewed and regularly inspected.

9

Page 12

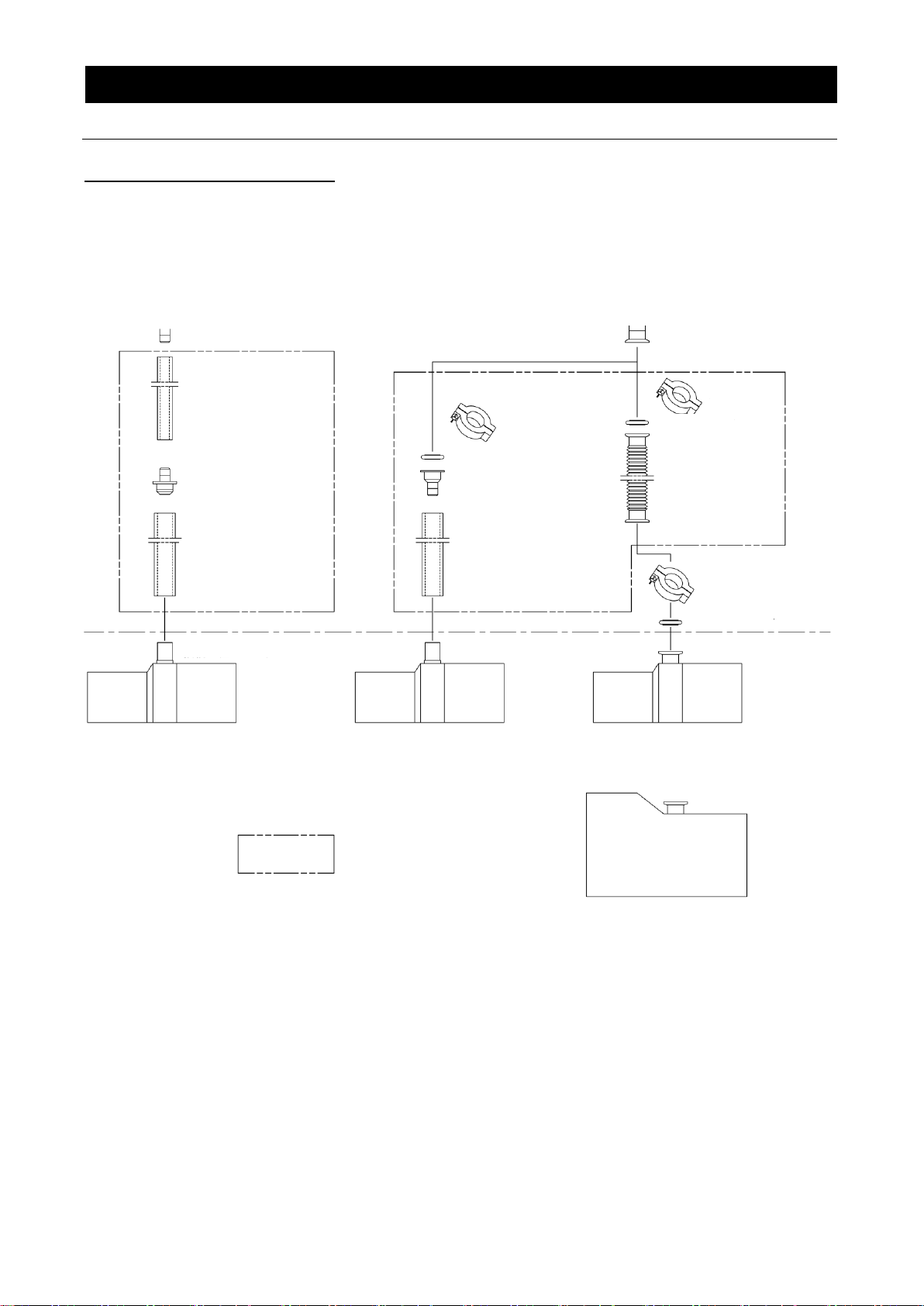

φ18mm OD

DP200/DP300 pump connection port

Reducing joint

A(Brass) or C(Stailess St.)

Vacuum hose(φ15mm ID )

Vacuum hose (φ25mm ID)

DP410/610 pump connection port

NW25 flange

Clamp

Clamp

Center ring

Center ring

Vacuum hose adapter

Flexible hose

Vacuum hose (φ25mm ID)

Connection port sizeφ30mm, φ27mm

Connection port sizeφ30mm, φ27mm

Connection port size NW25 flange

Clamp

Center ring

Rotary Vacuum Pump

PD138/203, PX137/202 etc.

Rotary Vacuum Pump

KF25 quick-coupling specifications for M(T)2010/2015/2021,

PD/PX etc.

(Note)

components inside

broken line are

optional

Air-cooled Dry Vacuum Pump

NeoDry 15E

2. PRE-OPERATION PROCEDURES

Vacuum System Information

Vacuum System Information

Vacumm pump and vacuum line components (sold separately) for DP series ovens

10

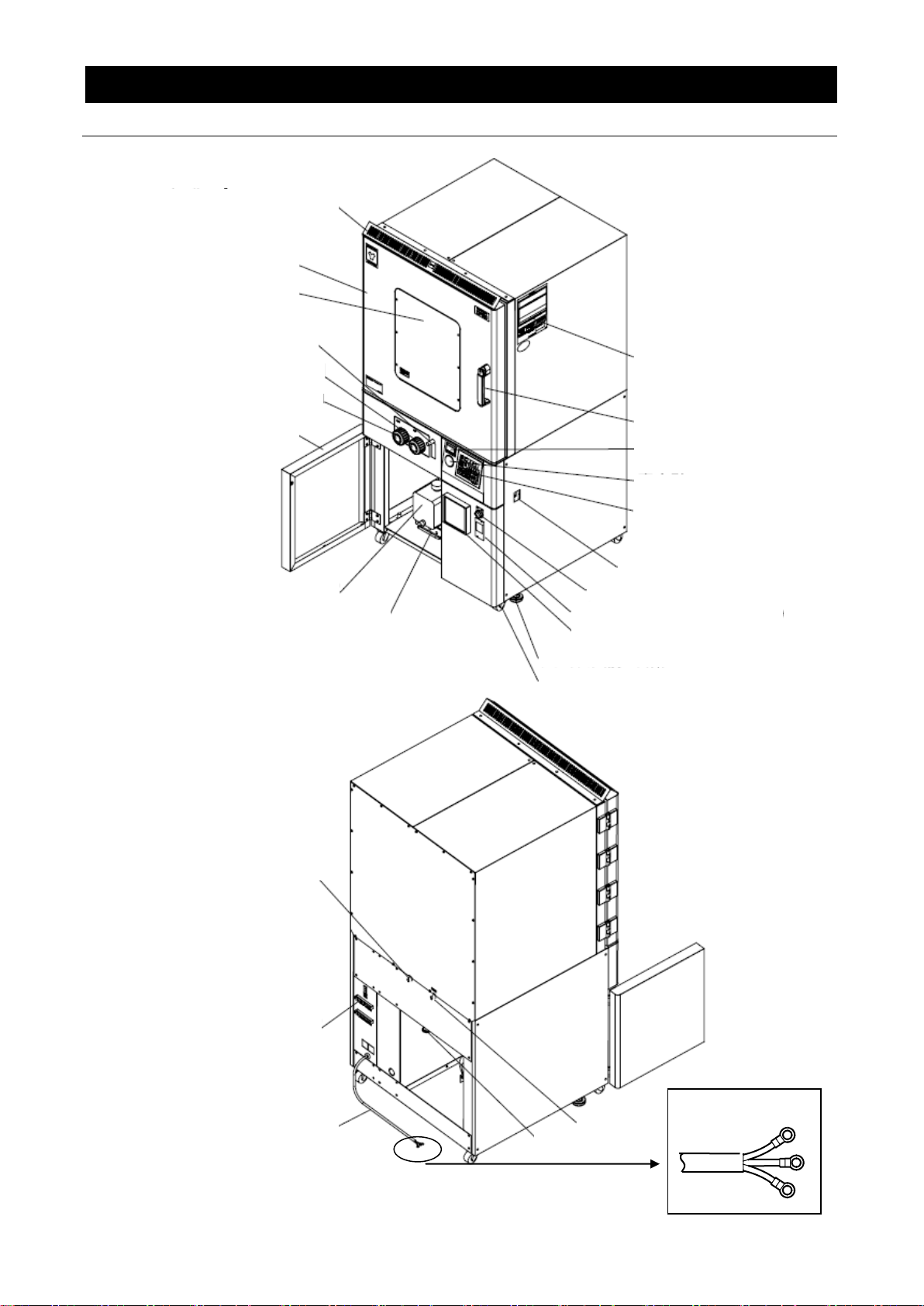

Page 13

Control Panel

Independent

Overheati

Door Handle

Viewing Window

Vacuum Gauge

Pump Valve Knob

(closes with CW rotation)

Purge Valve Knob

(closes with CW rotation)

Caution-Rating

Spec. sticker

Heat Vents

Terminal Block Cover

(Terminal Block: option)

Main Power Switch (ELB)

Legs

Serial No. sticker

Door

Heat Vents

Pump Port

Purge Port

Power Cable w/plug

3. COMPONENT NAMES AND FUNCTIONS

DP200/300 overview

Unit Overview 1

11

Page 14

Round Terminals

Purge Port

Pump Port

N2 Gas Inlet

(optional)

4(four) Casters

Safety Cover (DP610 only)

Door

Viewing Window

Flow Meter

(option)

Pump Valve Knob

(closes with CW rotation)

Purge Valve

(closes with CW rotation)

Vacuum Pump Cabinet Door

Vacuum Pump

(sold separately)

Pump slide tray (optional)

Caution-Rating sticker

Serial No. sticker

Door Handle

Independent

Overheat

Prevention Device

Vacuum Gauge

Control Panel

Main Power Switch

(ELB)

External Vacuum Pump Switch (optional)

Adjustable Leveling Feet (2 ‘two’ on undercarriage)

Digital Pirani Vacuum Gauge (optional)

Memory Recorder (option)

Terminal Block

(optional)

Power Cable

(Round terminals)

DP410/610 overview

3. COMPONENT NAMES AND FUNCTIONS

Unit Overview 2

12

Page 15

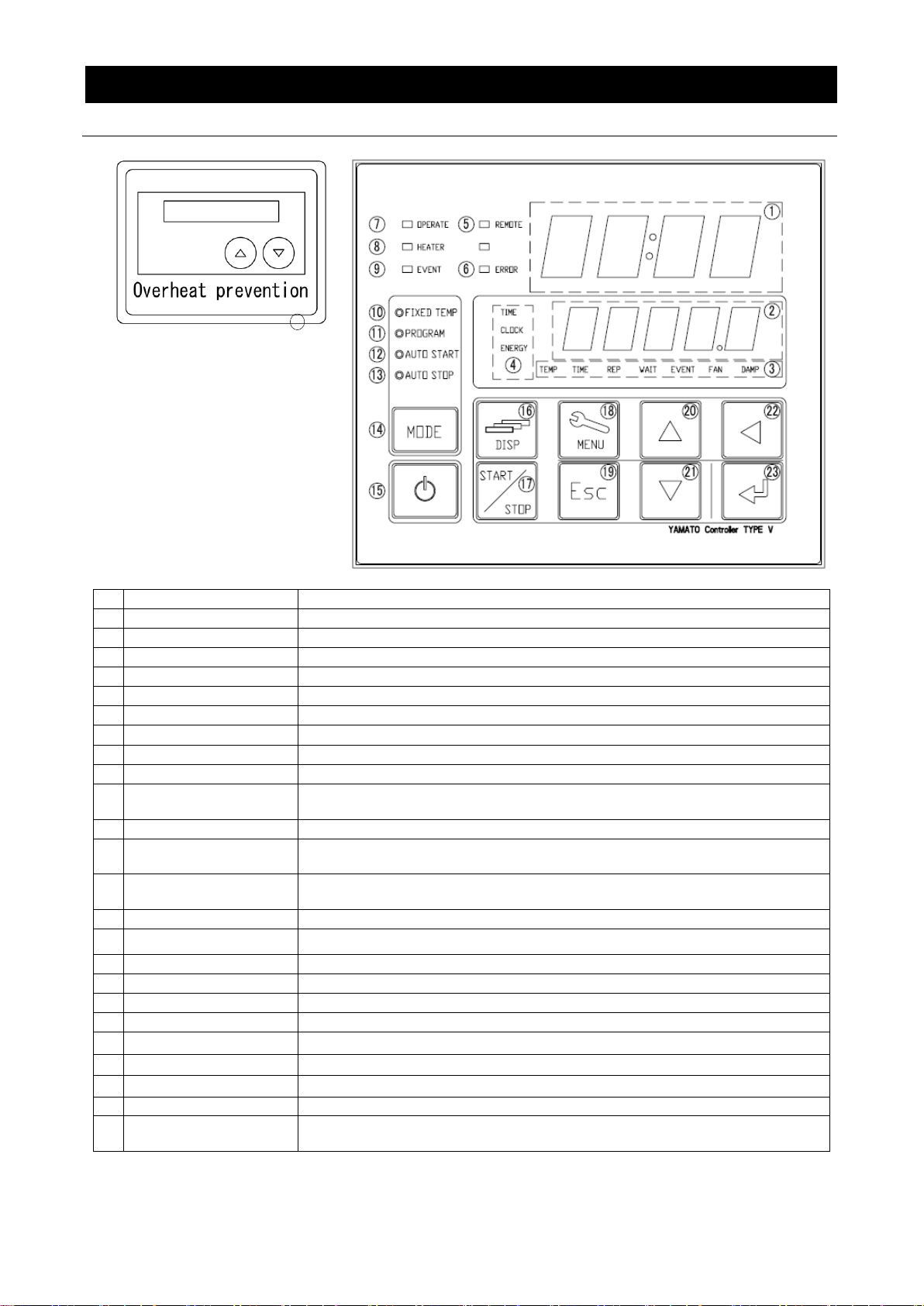

No

Name

Description

1

Upper Display

Readout for temperature reading (current chamber temp), error codes, etc.

2

Lower Display

Readout for temperature setting, clock, timer, etc.

3

Function Indicator Lamps

Illuminates (one or more) to show which function is currently running or active

4

Mode Indicator Lamps

Illuminates (only one) to show which mode is currently running.

5

REMOTE Indicator Lamp

Illuminates while remote comm (optional item) transmission is in progress.

6

ERROR Indicator Lamp

Illuminates when an error occurs.

7

OPERATE Indicator Lamp

Illuminates during operation. Flashes in operation standby mode.

8

HEATER Indicator Lamp

Illuminates when heaters are receiving power.

9

EVENT Indicator Lamp

Illuminates when event output (optional item) is transmitted.

10

FIXED TEMP Indicator

Lamp

Illuminates during constant temperature operation.

11

PROGRAM Indicator Lamp

Illuminates during programmed operation. Flashes while entering program settings.

12

AUTO START Indicator

Lamp

Illuminate during auto start operation.

13

AUTO STOP Indicator

Lamp

Illuminates during auto stop operation.

14

MODE key

Press to switch between operation modes, ⑩~⑬ on control panel.

15

POWER key

Press and hold to switch between unit idle and unit standby.

16

DISP key

Press to switch between monitoring options in lower display.

17

START/STOP key

Press to start or stop an operation.

18

MENU key

Press to switch between setting options.

19

Esc key

Press to return to previous menu without finalizing settings.

20

▲(Up) key

Press to increase setting value.

21

▼(Down) key

Press to decrease setting value.

22

key

Press to move cursor left.

23

ENTER key

Press to finalize setting items.

24

Independent Overheat

Prevention Device

Set device to keep unit from exceeding a certain temperature.

24

3. COMPONENT NAMES AND FUNCTIONS

Control Panel

13

Page 16

4. OPERATION PROCEDURE

Prior Confirmation

(1) Power source and ground wire

Be sure to connect power cable to an appropriate power source and confirm that ground wire is

connected.

(2) Main power switch (ELB)

Turn ELB ON.

Test ELB function once a month or before extended operation. See “Maintenance Procedures”

(P.43) for details.

Check the lower display on the control panel when ELB is turned on and confirm it is showing

current time.

(3) Independent Overheat Prevention Device (IOPD)

Be sure to set IOPD temperature 20ºC over the chamber temperature setting.

Test IOPD function before each instance of extended operation. See “Maintenance Procedures”

(P.43) for details.

(4) Vacuum line connection

Be sure to connect unit securely to vacuum pump (sold separately).

(5) Vacuum pump (sold separately)

Check vacuum pump oil level and be sure it is free of contamination.

Decompression/Purge Procedure

(1) Decompressing unit chamber

1. Close purge valve.

2. Close the pump valve.

3. Turn vacuum pump ON.

4. Open the pump valve.

Note: open pump valve gradually when processing powdery or frothy test samples.

(2) Repressurizing unit chamber

1. Close pump valve.

2. Open purge valve to allow ambient pressure back into chamber.

3. Open Pump Valve.

4. Shut vacuum pump OFF.

Note: open purge valve gradually when processing powdery test samples.

14

Page 17

The backup battery installed in DP series units, is a wear item and has an estimated life of

approximately 5 years. Replacing battery within the 5-year lifespan is recommended.

※ Contact a local dealer or Yamato sales office to request a replacement battery. If unit has

program data in memory, make a data backup file before replacing backup battery. See “Data

Backup” (P.35) in this section for details.

To set the current date & time,after replacing backup battery, follow the steps below.

1

Turn on power.

Turn ON the main power switch (ELB), located on the right

panel of the DP series units.

Lower display on the control panel will show the time.

This indicates that the machine is in “idle”.

Press and hold to display the standby screen.

Upper display shows current temperature in the chamber

while lower display shows current temperature setting.

This indicates that the machine is in “standby”.

2

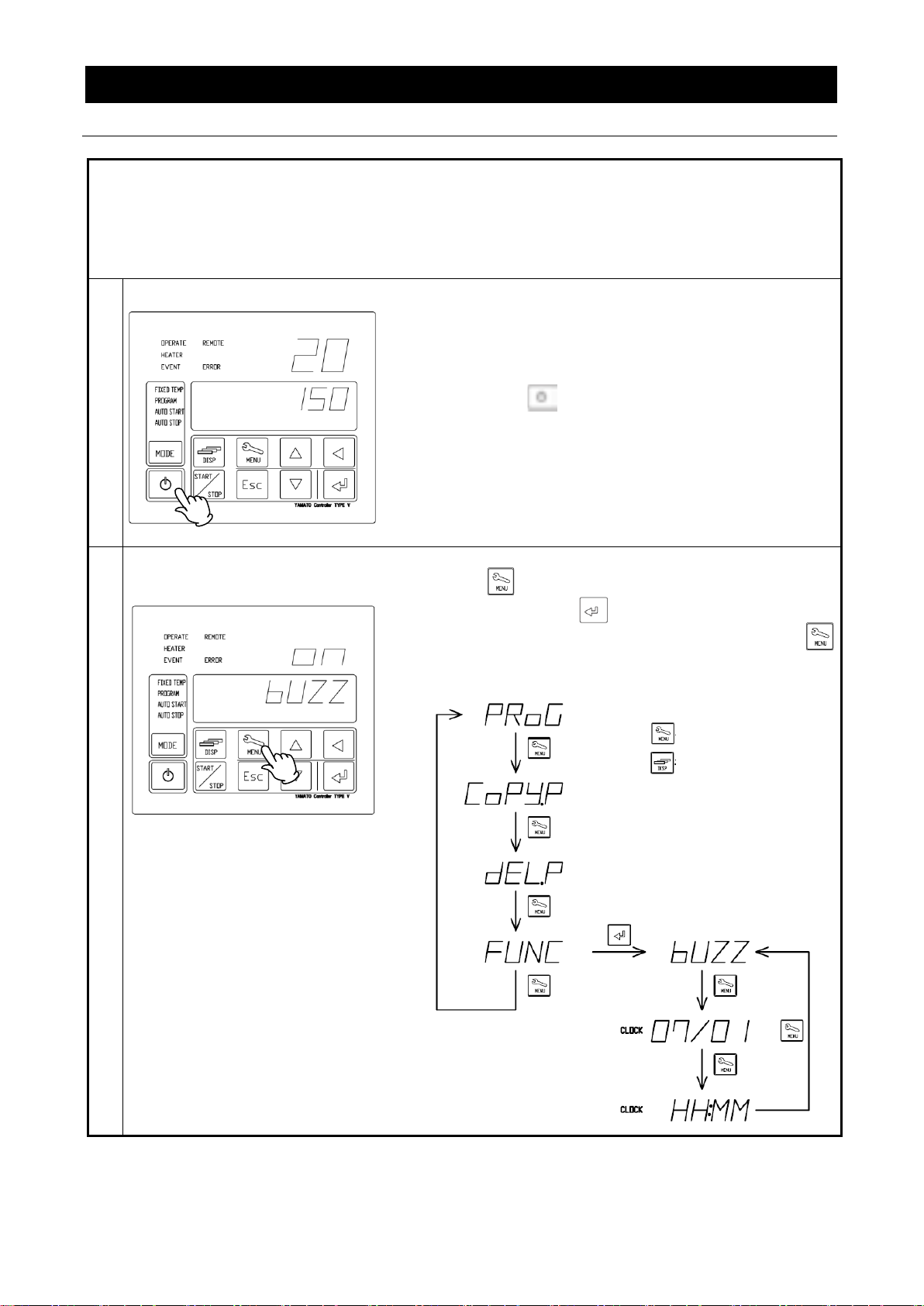

Use the MENU key to view date

and time in displays

①

Press repeatedly until FUNC appears in lower

display, then press .

②

When [bUZZ] is shown in the lower display, press

to view the year in upper display, and month/date in

lower display.

is used to advance to

next item

is used to return to

previous item

4. OPERATION PROCEDURE

Setting Date & Time

15

Page 18

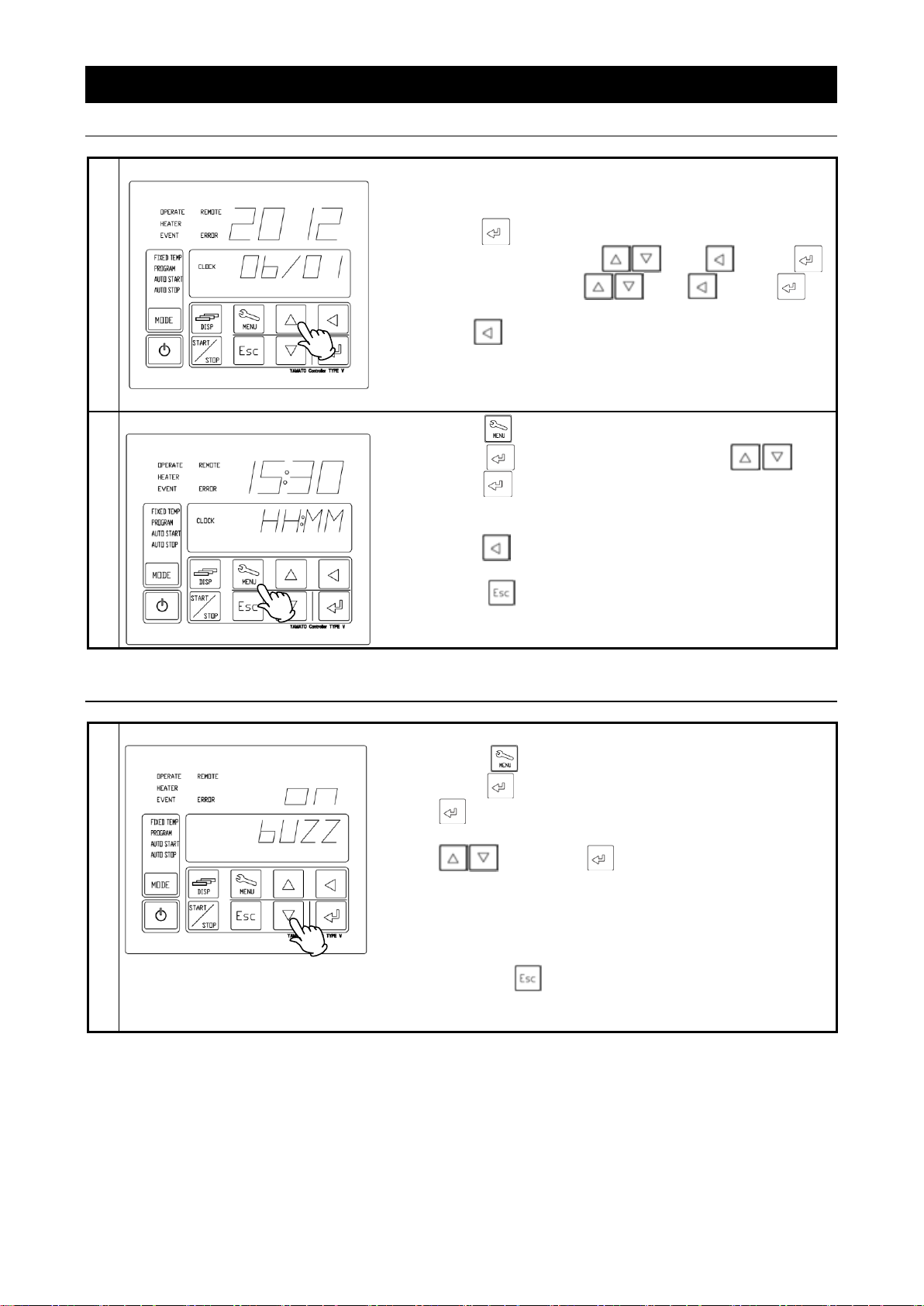

3

Set the date.

Setting the year/month/date and clock.

①

Year and month/date are shown on upper and lower

displays respectively.

②

Press . Settable value begins flashing.

③

Set calendar year with and . Press .

④

Set month/date with and . Press .

※

Press to change digit (flashing) positions.

4

Set the time.

①

Press .

②

Press and set current time with and

press .

Set time in conformance to the 24-hour time system

(e.g. military time, continental time or railway time).

※Press to change digit (flashing) positions.

③

Press twice to return to initial screen when

time/date settings are completed.

1

Set keypad tone.

①

Press repeatedly until FUNC is shown, then

press to bring up bUZZ in lower display. Press

. oFF begins flashing in upper display.

②

Select one of three keypad tone modes using

and press .

on: Activates tone for all keys. (factory default).

CLK: Activates tone for POWER and ENTER keys

only.

oFF: Deactivates tone for all keys.

Press the key twice to go back to initial screen

when keypad tone settings are completed.

4. OPERATION PROCEDURE

Setting Date & Time

Keypad Tone Function

16

Page 19

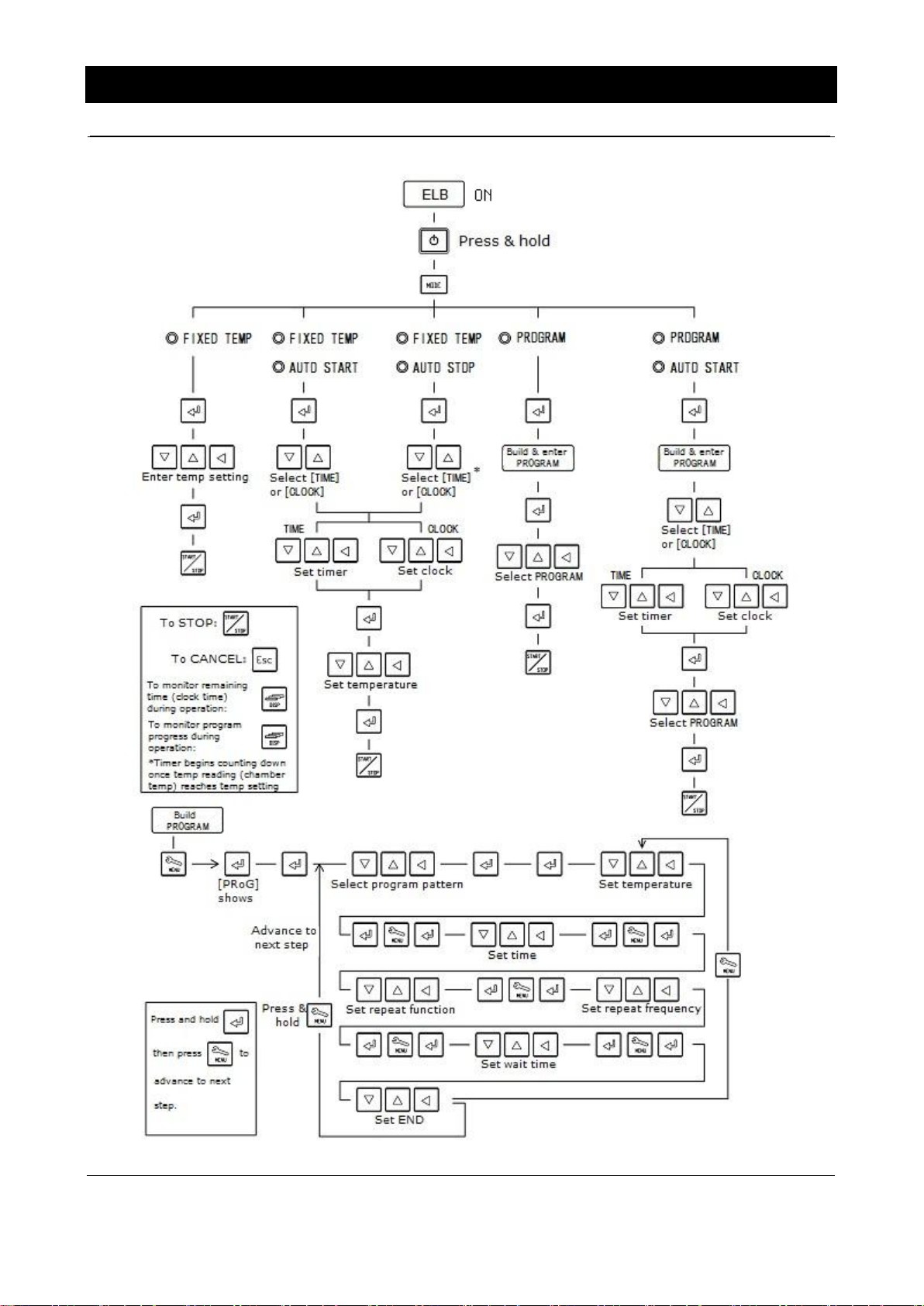

Mode and Function Flow

4. OPERATION PROCEDURE

17

Page 20

FIXED TEMP (constant temperature) mode runs DP series unit at a constant selected

temperature until START/STOP key is pressed, manually terminating operation.

SV: Set Value (temperature setting), t:Time

Setting constant temperature mode.

1

Turn on power.

Turn ON main power switch (ELB), located on right

panel of unit. (idle)

Press and hold to turn on power.

(standby)

Chamber temperature is shown in upper display,

Temperature setting is shown in lower display.

2

Select constant temperature mode.

Press repeatedly until FIXED TEMP indicator

lamp comes on.

※ Factory default temperatures are shown in upper

and lower displays on first-time start-up. All

subsequent start-ups will default to last temperature

values entered.

3

Set objective temperature.

①

Press . Changeable digits flash in lower

display.

②

Toggle between digits using and enter

desired value using .

Operating Temperature Range:

DP200/300:40~240ºC (Setting range: 0~250ºC)

DP410/610: 40~20ºC (Setting range: 0~210ºC)

③

Press once temperature setting has been

entered.

Press once or twice to cancel setting.

SV

t

▲

Set temperature → START

▲

Press POWER key or

Press STOP key to terminate program.

4. OPERATION PROCEDURE

Constant Temperature Mode

18

Page 21

4

Start/stop constant temperature

operation

Press to start or stop (terminate)

constant temperature operation.

5

Set quick auto stop mode

The quick auto stop function is used to

automatically stop constant temperature operation

at a certain time (clock) or after a certain time

(timer) has passed.

(decided during operation)

①

Press while unit is running in constant

temperature mode.

②

QStoP is shown in lower display and the [TIME]

lamp will begin flashing.

③

Select the stop mode (TIME or CLOCK) using

, and press .

④

Set TIME(setting range: 0~99hr:0~59min)or

CLOCK (24-hour time system only) in upper

display and press .

⑤

When timer reaches 0:00 or when clock and the

time setting agree, operation stops and “ENd”

appears in lower display.

⑥

Press to clear “End” from display.

※

Press to monitor temperature and remaining

time during operation, when desired.

Example 1. Quick auto stop mode w/timer:

In the example below, operation stops automatically

in 2 hours and 30 minutes AFTER target

temperature is reached.

Example 2. Quick auto stop mode w/clock:

In the example below, operation is stopped

automatically at 3:00 p.m. REGARDLESS of

when target temperature is reached.

4. OPERATION PROCEDURE

Constant Temperature Mode

19

Page 22

AUTO STOP (Automatic Stop) utilizes timer or clock to automatically stop an operation.

Operation must be started manually. See below.

SV: Set Value (Temperature setting), t:Time

Programming auto stop mode

1

Turn on power

Turn on main power switch (ELB), located on the right

panel of unit. (idle)

Press and hold to turn on power. (standby)

Chamber temperature is shown in upper display.

Temperature setting is shown in lower display.

2

Select auto stop mode

Press repeatedly until both the FIXED TEMP

and AUTO STOP indicator lamps are illuminated.

※

Constant temperature mode is the factory default

setting and will be the mode selected on first-time

startup. On subsequent startups will default to last

mode run.

3

Set temperature and operation time.

①

Press .

Select TIME or CLOCK using , and press

.

②

Set TIME (setting range: 0~99hr:0~59min)or

CLOCK (24-hour time system only) in upper

display and press .

③

Set temperature in lower display and press .

※See explanation

regarding “wait mode”

on page 29.

t

SV

Operation start

(manual)

Operation stop

(automatic)

Timer: Start counting

Timer: Wait

4. OPERATION PROCEDURE

Auto Stop Mode

20

Page 23

4

Start / stop operation

①

Press to start or stop (terminate) operation

at any time.

②

When timer reaches 0:00, or when clock and

slected end-time agree, “ENd” will show in lower

display.

③

Press to clear “ENd” from display.

※

Press to monitor temperature and remaining

time during operation, when desired.

Example 1. Auto stop mode w/timer:

In the example below, operation is stopped

automatically in 2 hours and 30 minutes AFTER

temperature setting of 50ºC is reached.

Example 2. Auto stop mode w/clock:

In the example below, operation will automatically

terminate at 3:00 p.m. REGARDLESS of when target

temperature is reached.

4. OPERATION PROCEDURE

Auto Stop Mode

21

Page 24

AUTO START (Automatic Start) mode utilizes timer or clock to automatically begin an operation.

Operation must be stopped manually.

Start timer counting Start operation (automatically)

Setting Automatic Start Mode

1

Turn on power

Turn on main power switch (ELB), found on the right

panel of unit. (idle)

Press and hold to turn on power.

(standby)

Chamber temperature is shown in upper display.

Temperature setting is shown in lower display.

2

Select auto start mode

Press repeadedly until both FIXED TEMP and

AUTO START lamps illuminate.

※

Constant temperature mode is the factory default

setting and will be the mode selected on first-time

startup. On subsequent startups will default to last mode

run.

3

Set temperature and start time.

①

Press .

Select TIME or CLOCK using , and press

.

②

Set TIME (setting range: 0~99hr:0~59min) or

CLOCK (24-hour time system only) in upper display

and press .

③

Set temperature in lower display and press .

t

4. OPERATION PROCEDURE

Auto Start Mode

22

Page 25

4

Start /stop operation

④

Press to enter standby (wait) mode.

⑤

The OPERATE indicator lamp begins flashing and

start timer or clock shows in the lower display.

※ Chamber temperature is shown in upper display.

Timer or clock is seen in lower display, depending

on which mode is selected for auto start.

⑥

Press to terminate operation at any time.

※

Press to monitor temperature and remaining

time during operation, when desired.

Example 1.

Auto start mode w/timer:

in the example below, operation automatically

begins 2 hours and 30 minutes, after is

pressed.

Example 2.

Auto start mode w/clock:

When is pressed In the example below,

operation begins automatically at 3:00 p.m.

4. OPERATION PROCEDURE

Auto Start Mode

23

Page 26

PROGRAM mode runs a combination of times and temperatures in a series of programmed

steps as one operation. See below.

PV: Process Value (ambient temperature)

Entering Pattern Programs

1

Turn on power

Turn on main power switch (ELB) found on the right

panel of unit. (idle)

Press and hold to turn on power.

(standby)

Chamber temperature is shown in upper display.

Temperature setting is shown in lower display.

*Enter a target program prior to running first cycle.

2

Enter a program.

Program steps entered and program patterns saved

may not exceed 99 in total.

Example:

A total of 11 program patterns can be stored with a

maximum of 9 programmed steps each.

※Note regarding “program repeat function”.

It is not possible to cut into and repeat process

steps, in part (crossing) or in full (reduplication),

from anywhere upstream in the process program,

during operation.

See "Programming Procedure" (P.27) for details on

program entry.

(Temp.)

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step8

Start programmed cycle

End programmed cycle

(Time)

Start PV

Target temp.

4. OPERATION PROCEDURE

Programmed Operation

24

Page 27

3

Select program mode

Press repeatedly until PROGRAM lamp

illuminates.

“PGM:XX” will show in lower display. (Last program entered

or used will always be the one shown in the display on

start-up)

※

Constant temperature mode is the factory default

setting and will be the mode selected on first-time

startup. On subsequent startups will default to last mode

run.

4

Select program pattern number

Press . “01” begins flashing in lower display. Select

the desired program pattern number using and

press .

5

Start program mode

Press to start programmed operation.

※

If the “end” setting is left out on the final step of a

program pattern, the entire program will not run. If newly

entered programs fail to run, confirm that all settings

have been entered correctly.

4. OPERATION PROCEDURE

Programmed Operation

25

Page 28

Example 1: Program pattern #2 has 6 steps and contains a repeat cycle which, repeats steps 4

to 6, five times and ends. (STEP1,2,3→STEP 4, 5 and 6× five times→END)

Program Criteria:

STEP1: Set 100°C, 0 minute, wait ON

STEP2: Set 100°C, 2 hours, wait OFF

STEP3: Set 150°C, 0 minute, wait ON

STEP4: Set 150°C, 2 hours, wait ON

STEP5: Set 200°C, 1 hour, wait OFF

STEP6: Set 200°C, 2 hours, repeat from step #4, repeat 5 times, wait ON, end ON

NO

Display

Entry procedures (for Example1 above)

1-1

Standby screen

1-2

Step1

1-3

Enter 02:01 (Pattern #02, step #01)

1-4

Enter 100 (100°C)

1-5

Enter 00:00 (00 hr 00 min)

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

END

5 回繰返し

Repeat five times

Temperature

Time

Entering a new program.

4. OPERATION PROCEDURE

Building Programs

26

Page 29

1-6

Enter 0 (no repeat)

1-7

Enter 0 (no repeat)

1-8

Select “on” (to activate Wait Function)

(A set countdown time to when temperature reading is within ± 1℃ of

temperature reading)

1-9

Select “oFF” (Select "oFF" to program next step. Select "on" to program

current step as “end step”)

1-10

Programming for Step #1

complete. Now:

Press and hold .

2-1

Enter 02:02 (Pattern #02, step #02)

Step2

Step3

Step4

Step5

Enter the parameters for

steps #2 to #5 in the same

manner as step #1. (repeat

entry procedures 1-3~1-9)

※Press at any time while entering a program to show

[RESt.P] in the lower display and see remaining available steps in

upper display.

~ ~ ~

~

~

4. OPERATION PROCEDURE

Building Programs

27

Page 30

Step6

6-1

Enter 02:06 (Pattern #02, step #06)

6-2

Enter 200 (200°C)

6-3

Enter 02:00 (02 hr 00 min)

6-4

Enter 4 (to repeat step #4 from the beginning)

6-5

Enter 5 (to repeat five times)

6-6

Select “on” (to activate wait function)

(A set countdown time to when temperature reading is within ±1°C of

temperature reading)

6-7

Select “on” (Select "oFF" to advance to the next step. Select "on" to program

as the “end step”)

※Last step in the program MUST include “END setting”.

4. OPERATION PROCEDURE

Building Programs

28

Page 31

【Wait function explained】

If "starting temperature" and "temperature setting" are equal, chamber temperature is

maintained until timer reaches 0 (zero),.

If chamber temperature drops more than 3°C below or goes more than 6°C beyond

temperature setting, however, timer countdown stops and unit enters "wait mode" until

coolant temperature returns to within -3°C or +6°C of temperature setting. Timer then begins

counting down once again, from where it left off, until it reaches 0 (zero) and operation

finishes.

Target Temp.

Starting

Temp.

Temp.

Time

Set time

If timer setting is 0 (zero), temperature in chamber is raised to “temperature setting” on full

power. If "wait" is set to "on" (program mode), “wait mode” will be activated until chamber

temperature is within -3°C or +6°C of temperature setting.

Objective temp.

Start

Temp.

Temp.

Time

Time to objective Temp.

The following flowchart illustrates the repeat function concept.

Note that the first cycle of the repeating section is not counted as a repeating cycle.

Step # 1

No repeat command

Step # 2

No repeat command

Step # 3

No repeat command

Step # 4

Repeat start

Step :2

Times:5

Step # 5

Process repeat section to run five times

No repeat command

Waiting

4. OPERATION PROCEDURE

Wait Function

29

Page 32

Copy/delete program

・Copying a program.

①

Press repeatedly until [CoPY.P] appears in

lower display and press .

②

[SrC] shows in upper display. Use to select

program to copy in lower display and press .

Program is copied.

③

[dESt] appears in upper display. Using ,

select a number which the copied program will be

stored as and press . Program is duplicated with

new designation.

・

Deleting a program.

①

Press repeatedly until [dEL.P] appears in lower

display, then press .

②

[dEL] appears in upper display. Select a program

number to delete using , then press and hold

.

③

[dEL] flashes in upper display as warning that the

program number shown is about to be deleted.

Press again. Program is deleted.

4. OPERATION PROCEDURE

Program Copy & Delete

30

Page 33

1

Turn power OFF

Press and hold to turn power OFF so that current

time is showing in lower display (idle).

2

Enter password

①

Press and hold .

[UPASS] appears in lower display. “00” shows in

upper display with right digit flashing.

②

Use and to enter password “11” in

upper display and press (password is locked

to “11”).

3

Set keypad lock mode

①

[KLoCK] is shown in lower display. Press .

②

Use to select keypad lock mode and

press .

③

Press and hold to return to initial idle screen.

:

All keys enabled. (factory default)

:

All keys disabled except

key

and

START key.

:

key only is disabled.

:

key only is disabled.

4. OPERATION PROCEDURE

Keypad Lock Function

31

Page 34

The calibration offset feature makes it possible to compensate for any difference between the

temperature reading on the control panel and actual chamber temperature (taken manually). This

enables parallel compensation in either direction (+ or -) over the entire temperature setting

range on all DP series units.

Example

Actual chamber temperature is lower than the conrol panel temperature reading by 2°C:

Temperature reading can be calibrated by entering a calibration offset value of -2.0 to

compensate against the actual temperature deficiency of 2°C.

If the initial temperature reading was 200°C, it will read 198°C after offset calibration, and be brought

into agreement with the actual temperature.

※The -2°C calibration in the example above is applied over the entire temperature setting

range (0~250°C for DP200/300, & 0~210°C for DP410/610). Note that offset values may

change slightly depending on test sample arrangement in the chamber and/or

temperature setting.

1

Turn power OFF.

Press and hold to turn power OFF so that

current time shows in lower display (idle).

2

Enter password.

①

Press and hold .

[UPASS] will show in lower display. [00] shows in

upper display.

②

Using and , enter password, “11” in

upper display and press .

3

Set calibration offset value.

①

Press repeatedly until [CAL:oS] can be seen

in lower display and [0.0] in upper display. Press

.

②

Enter offset value using and . Press

.

Example

Temperature reading is 200°C, while actual

temperature (manually taken) is 198°C

⇒

Offset input value: -2

③

Press and hold to return to idle screen.

4. OPERATION PROCEDURE

Calibration Offset Function

32

Page 35

1

Turn power OFF

Press and hold to turn power OFF so the current

time shows in lower display (standby).

2

Enter the password

①

Press and .

[UPASS] will show in lower display and [00] in

upper display.

②

Use and to enter password “11” in

upper display and press .

3

Set recovery option.

①

Press repeatedly until [RECoV] shows in

lower display and press .

②

Use to select recovery mode and press

.

Cnt: Operation will resume where it left off at

power failure. (factory default)

StoP: Operation will teminate and unit will go into

idle when power is restored.

③

Press and hold to return to idle screen.

4. OPERATION PROCEDURE

Recovery Modes

Setting the recovery option in case of a power failure.

33

Page 36

1

Turn power OFF.

Press and hold to turn power OFF so that current

time is showing in lower display (idle).

2

Enter password.

①

Press and hold .

[UPASS] appears in lower display. “00” shows in upper

display with right digit flashing

②

Use and to enter password “11” in

upper display and press (password is locked to

“11”).

3

Set/reset monitored items.

①

Press repeatedly to show [ENERG] in lower

display. Press .

②

Press to select an item in lower display:

“PoW:Rt” (“oFF” in upper display)

:

Press to change “oFF” (constant) to → rUn

(flashing) in lower display.

Press to reset accumulated power

consumption.

Press to return to [PoW:Rt] screen.

KG.K 0555 (denoting 0.555 - factory default value):

Press to make value changeable (flashing).

Use and to change conversion factor

value.

Press , then to return to [KG.K] screen.

“Co2:Rt” (“oFF” in upper display)

:

Press to change “oFF” (constant) to → “rUn”

(flashing) in upper display.

Press to reset accumulated CO2 emissions.

Press to return to [Co2:Rt] screen.

③

Press and hold to return to initial idle screen.

4. OPERATION PROCEDURE

CO2 Emissions & Power Consumption Settings

Setting CO2 conversion factor & resetting total CO2 emissions/power consumption.

34

Page 37

1

Turn power OFF.

Press and hold to turn power OFF so that current

time is showing in lower display (idle).

2

Enter password.

①

Press and hold .

[UPASS] appears in lower display. “00” shows in

upper display with right digit flashing.

②

Use and to enter password “11” in

upper display and press (password is locked to

“11”).

3

Save data/show saved data/reset.

①

Press repeatedly to toggle through the

following items respectively in lower display:

U Bks: Backs up all setting information.

U bKR: Displays back up data.

INI.U: Resets all settings to factory default.

✴

Backup items include programs entered,

temperature offset values and other data, such as

keypad lock modes, calibration offsets, recovery

modes, etc.

②

Select one of the 3 modes desicribed above.

Press . [rUn] will be shown in upper display.

Press .

4. OPERATION PROCEDURE

Back up data, show saved data or reset to factory default settings.

Data Backup & System Reset

35

Page 38

※Current power consumption, accumulated hours of operation, etc. can be viewed by

using the data monitoring feature on this unit.

Setting information shown in upper display cannot be modified.

1

Values appear in upper display

※ Data can be viewed in standby

mode or during operation.

Press and hold the key to view

current power consumption (kW).

Now press the key repeatedly to

scroll through and view the following

items respectively:

↓Accumulated power consumption (tot:MW)

↓Accumulated power consumption (tot;kW)

↓Total CO2 Emission (Co2:t)

↓Total CO2 Emissin (Co2:KG)

↓Heater output (PId:MV)

↓Accumulated hours in power-on (PoW:tM)

(□××××) Shows first digit only(of 5).

↓Accumulated hours in power-on (PoW:tM)

(×□□□□) Shows last four digits only

(of 5).

↓Accumulated operation run hours

(RUN;tM)

(□××××) Shows first digit only(of 5).

↓Accumulated operation run hours

(RUN:tM)

(×□□□□) Shows last four digits only

(of 5).

↓Return to standby or mode screens.

*Current power consumption is power consumed from

moment of activation and calculated in hourly

increments.

Accumulated power consumtion is updated hourly

by using the sum total of current power

consumption.

* CO2 emission (CE) is calculated using

C E=(Conversion Coefficient)x(Power Consumption)

Coefficient value will differ by local power supply

company and must be confirmed and set

accordingly in order to view accurate data.

(Coefficient of -0.555 is set for TEPCO by default)

* Heater operation output is a parameter to control the

output power ratio of heater’s rated capacity in

percentile units. Heater output will be controlled by a

PID operation value between 100 and 0% until

reaching objective temperature.

* Accumulated hours in power-on is the sum total of

hours, aggregated between ELB ON and OFF.

Maximum total for this value is 65,535 hours.

Example

First digit: 2

last four digits: 35

⇒Accumulated hours in power-on: 20035 hours

*Accumulated operation run hours is the sum total of

hours, aggregated between the start and end of

operation runs.

Maximum total for this value is 65,535 hours.

Example

Top digit: 0

Lower four digits: 135

⇒Accumulated operation run hours: 0135 hours

4. OPERATION PROCEDURE

Data Monitoring

36

Page 39

Set temperature on Independent

Overheat Prevention Device

(IOPD)

* Set temperature using the ▼▲ keys on IOPD

panel.

Operation may be terminated by Independent Overheat Prevention Device (IOPD) activation,

when IOPD temperature setting and target temperature are less than 20°C apart.

IOPD temperature must be set at least 20°C higher than target temperature.

Note: main function of IOPD is to keep DS unit from overheating, NOT to protect test samples from

damage. Likewise, it is NOT intended for protection against accident or injury resulting from the

negligent use of explosives and flammables.

IOPD factory settings and temperature setting ranges are shown below by model:

To confirm whether IOPD functions as intended, set chamber temperature to any value within

unit specification range and allow temperature to stabilize. Gradually lower IOPD temperature

setting. If IOPD activates within 10°C of temperature setting, it is functioning normally.

Note: it normally takes 5 (five) seconds for IOPD to activate. Waiting 5 seconds each time

temperature is lowered in the confirmation test above, is therefore recommended. When IOPD

activates, error code Er07 shows in the display and operation will be terminated.

When changing the IOPD temperature setting, it takes a few seconds for the changes to finalize.

For this reason, wait 5 seconds after entering the change before turning the power off.

Model

Factory default

temperature setting

Temperature setting

range

DP200

270°C

0°C~270°C

DP300

270°C

0°C~270°C

DS410

230°C

0°C~230°C

DS610

230°C

0°C~230°C

4. OPERATION PROCEDURE

Independent Overheat Prevention Device

DP series units feature redundant safety devices: 1) The internal automatic overheat prevention

(automatic reset) feature, and 2) the Independent Overheat Prevention Device (IOPD) with

discrete power supply, circuit and sensor; completely independent of the CPU control board.

The IOPD main relay functions to activate and cut power to the heater when chamber temperature

goes too far beyond objective temperature.

These functions are enabled while the main power switch (ELB) is ON.

37

Page 40

Warning

1. DO NOT process hazardous or harmful substances.

Never process explosive or flammable items. Fire or explosion causing serious injury or death

may result. See “List of Hazardous Substances” (P.58) for more information on these items.

2. DO NOT operate equipment when abnormalities are detected.

If unit begins emitting smoke or abnormal odors for reasons unknown, turn off main power

(ELB) immediately, disconnect power cable from power supply, and contact a local dealer or

Yamato sales office for assistance. Continuing to operate without addressing abnormalities

may cause fire or electric shock, resulting in serious injury or death. Never attempt to

disassemble or repair unit. Repairs should be always be performed by a certified technician.

Caution

1. DO NOT climb on top of equipment.

Do not attempt to climb onto unit or substitute it for a proper step ladder. Units are not

designed to support bodily weight and damage may result. In addition, unit may become

unstable and tip over or fall resulting in equipment damage, serious injury or death.

2. DO NOT place items on top of equipment.

Do not place any objects on unit. Doing so may cause unit to become unstable and tip over,

resulting in possible equipment damage, injury or death.

3. DO NOT operate equipment during thunderstorms.

In the event of a thunderstorm, turn off main power switch (ELB), and disconnect power cable

immediately. A direct lightning strike may cause equipment damage, fire or electric shock,

resulting in serious injury or death.

Do not leave DP unit door open (i.e. to cool test samples in the chamber down, etc.) following

an operation run. Heat from chamber may damage and/or deform control panel, causing CPU

board malfunction or failure. Always remove processed test samples and close chamber door.

Do not process items containing corrosive chemicals of any kind. Although chamber interior is

manufactured of 304 stainless steel, damage may still occur from exposure to strong

chemicals. Likewise, vacuum lines contain copper and nylon, which are easily damaged by

corrosive substances. Avoid processing test samples which contain corrosives such as acid

alkaline, heavy metal salts, etc. or solvents such as halogens, aminities, esters, etc.

Operating temperature range is 40°C~240°C for DP200/300 and 40°C ~200°C for DP410/610.

Never attempt to operate unit outside of the above specified temperature range. Doing so may

cause equipment malfunction or damage.

5. HANDLING PRECAUTIONS

4. DO NOT leave chamber door open after operation.

5. DO NOT process corrosive items.

6. ALWAYS run equipment within specified temperature range.

38

Page 41

Caution

Weight capacity for one chamber rack is approximately 15kg. Test sample load total for each

rack should thus not exceed this specification.

Arrange test samples evenly on racks, leaving as much space between them as possible.

Do not place too many test samples on rack at once. Doing so may prevent proper temperature

control in chamber. Test samples should be managed in the following way;

1. Install the supplied chamber racks, 2. Leave as much space between test samples as

possible. 3. As a rule of thumb, leave 30% or more of the total space on each rack unoccupied.

Leave 30% of total rack space open

Operating unit with test samples placed directly on bottom surface of chamber may cause unit

to perform poorly. Likewise, chamber temperature may become excessive, causing malfunction

or damage. Always use the supplied chamber racks, supported on the standard guide rails, to

avoid placing items directly on chamber floor. Further, do not allow test samples to contact

chamber walls.

9. Power outages.

In the event of a power loss during operation, one of the following will occur when power is

restored, depending on what settings have been selected:

● Continued operation: if power recovery settings have been set to continue (factory

default), the START/STOP key can be pressed and operation will pick up where it left off

with the power failure.

● Stop operation: if recovery settings have been set to stop, operation will be terminated

and unit will go into idle when power is restored.

See “Recovery Modes” (P.33) for details.

If unit has not been stabilized, it may tip over or fall, causing injury or death, during an

earthquake or other unforseen incident. Be sure to stabilize unit properly (adjustable leveling

feet securely positioned, etc.) to ensure safe operation.

Chamber rack

Test

samples

15 kg max

7. Arrange test samples appropriately.

5. HANDLING PRECAUTIONS

8. DO NOT place items in bottom of chamber.

10. Confirm equipment stability.

39

Page 42

Caution

Chamber door seals are manufactured of silicon rubber. Benzoic acid, oil, and other

components, used during the silicone rubber manufacturing process, may be emitted during

operation, spoiling incompatible test samples. If test samples, sensitive to silicone rubber

by-products, are to be processed; specially formulated fluoro-rubber seals may be requested as

an option.

Note that acids, alkaline, and halogenated solvents are all corrosive to rubber.

Substance

Classification

Silicon Rubber

Fluoro Rubber

Hydrocarbons

Butane, Isooctane, Benzine,

Toluene, Xylene, Styrene, Diphenyl,

Pinene, Kerosene

Propane

Halogen,

Haloid Hydrocarbon

Methyl Chloride,

Methylene Chloride, Chloroform,

Carbon Tetrachloride,

Trichloroethylene, Phlorobenzene,

Monochloronaphthalene, R-11、

R-12、R-21、R-22、R-113、R-114、

Bromine

R-21、R-22

Ketone, Aldehyde

Methyl Ethyl Ketone,

Diisopropyl Ketone, Diclohexanon,

Acetophenone

Acetone, Methyl Ethyl Ketone,

Methyl Isobutyl Ketone,

Diisopropyl Ketone, Diclohexanon,

Acetophenone

Ester

Methyl Acetate, Ethyl Acetate,

Propyl Acetate, Butyl Acetate,

Amyl Acetate, Methyl Acetoacetate,

Butyl Acrylate, Ethyl Methacrylate

Methyl Acetate, Ethyl Acetate,

Propyl Acetate, Isopropyl Acetate,

Butyl Acetate, Amyl Acetate,

Ethyl Acetoacetate, Ethyl Acrylate,

Butyl Acrylate, Ethyl Methacrylate

Ether

Diethyl Ether, Dibutyl Ether,

Ethylene Oxide, Dioxane,

Epichlorohydrin, Tetrahydrofuran

Diethyl Ether, Isopropyl Ether,

Dibutyl Ether, Dibenzyl Ether,

Ethylene Oxide、Dioxane,

Epichlorohydrin, Furfural,

Tetrahydrofuran

Alcohol

Amyl alcohol

Multiple Alcohol

Derivative

Cellosolve Acetate, Butyl Cellosolve,

Triacetin

Fatty Acid, Phenol

Acetic Anhydride, Oleic Acid,

Phenol Palmitate

Formic Acid、Acetic Anhydride,

Hydroquinone

Substances which are corrosive to the silicon or fluoro rubber used for chamber door seals are

shown in Table 5.1.

Do not process test samples that contain any of the substances shown in this table.

For further assistance, contact a Yamato sales office or dealer..

【Caution】

5. HANDLING PRECAUTIONS

11.Chamber door seal.

Table 5.1 - Substances corrosive to rubber used in chamber door seals

40

Page 43

Caution

Material

Classification

Silicon Rubber

Fluoro-rubber

Nitrogen Chemical

Compounds

Nitromethane, Nitroethane,

Nitropropane

Nitromethane, Nitroethane,

Nitropropane, Ethylenediamine,

Dimethylaniline, Ethanol amine,

Hydrazine, Triethanol Amine,

Dimethyl Formamide, Pyridine,

Piperidine

Sulfur and phosphorus

compounds

Hydrosulfuric

Hydrosulfuric,

Tributyl Phosphate

Other Chemical

Compounds

Nickel Acetate, Lead Acetate,

Zinc Acetate, Tetraethyl Lead,

Vegetable Oil, Silicon Oil

Calcium Acetate, Nickel Acetate,

Lead Acetate, Zinc Acetate

Inorganic Solvent

Hydrochloric Acid, Nitric Acid,

Sulfuric Acid, Hydrobromic Acid,

Phosphoric Acid, Hypochlorous Acid,

Chromic Acid, Perchloric Acid,

Sodium Hydrate

Sodium Hydrate,

Aqueous Ammonia

The temperature sensor for this unit is installed on the inside wall of the chamber and used to

control chamber temperature. The chamber temperature reading, as read by the sensor, may

not always be the same as that of test samples/specimens.

The main power switch (ELB) and Independent Overheat Prevention Device (IOPD) in

particular, are key devices in maintining the safety of DP series units, and must be

inspected/maintained regularly.

See “Inspection & Maintenance” (P.43) for details.

Activation temperature for the Independent Overheat Prevention Device (IOPD) must be set in

order to protect unit from damage, should overheating occur.

Note that temperature on the IOPD should be set 20°C above chamber temperature setting.

See “Independent Overheat Prevention Device” (P.37) for more on setting up this

device and for other warnings.

Remove excess and unneeded moisture and water from test samples (i.e. thoroughly dry test

sample container exterior, etc.) before processing.

A cooling trap, such as model CA301/801 by Yamato Scientific, should be installed between the

chamber and vacuum pump, particularly when processing test samples containing organic

solvents. This device will dispel gases/fumes thrown off by processing caustic test samples,

and prolong the life of vacuum lines, door seals and other system components that are easily

damaged by solvents.

5. HANDLING PRECAUTIONS

Table 5.1 - Substances corrosive to rubber used in chamber door seals (continued)

12. Temperature sensor.

13. Inspect equipment regularly.

14. Independent Overheat Prevention Device activation temperature must be set.

15. Solvents and excess moisture in test samples.

41

Page 44

Caution

Powder may spew suddenly from unit if purge valve or pump valve is opened abruptly with

chamber still decompressed. Open these valves and restore normal pressure gradually when

processing test samples containing powder or micro-particle substances.

When running DP series units at high temperature, exercise extreme caution so that hands and

skin do not contact hot surfaces. Always wear heat-resistant gloves when inserting and

removing test samples/specimens from oven chamber.

Also note that extended high temperature use may cause chamber door seal to become

adhered to window glass, preventing the door from being opened. Avoid more than 72 hours of

continuous operation.

Shut vacuum pump down using following procedure:.

1) Close pump valve.

2) Gradually open purge valve.

3) Confirm that ambient pressure has been restored to chamber.

4) Open pump valve, then shut down vacuum pump.

Warning: oil from the vacuum pump may flow backward into the chamber, if vacuum pump is

shut down with chamber decompressed.

To keep chamber decompressed, leave the vacuum pump running with the pump valve open.

Warning: oil from the vacuum pump my enter the vacuum lines if pump is shut down with valve

closed.

Never attempt to clean DP series units with paint thinner, alcohol or solvents of any kind. Doing

so may cause coating to peel, discoloration, superficial damage and deformity to some

components.

Note: Always turn off main power switch (ELB) prior to cleaning or maintenance.

Always read instruction manual(s) for all equipment, thoroughly, before beginning setup,

installation or operation.

Do not attempt remove polycarbonate covering from outer surface of viewing window. The

viewing window itself can shatter from even the smallest scratch (even those not seen with the

naked eye) or impact. The polycarbonate covering acts as a protective screen in the event of

such incidents.

Covering may cloud over time, depending on operating environment and use. Do not attempt to

replace covering. All such repairs should be done by a certified technician.

5. HANDLING PRECAUTIONS

16. Samples/specimens containing powder.

17. High temperature operation.

18. Shutting vacuum pump down.

19. Maintaining chamber decompression.

20. DO NOT apply paint thinner, alcohol or other solvents to equipment.

21. Read instruction manual before operation.

22. DO NOT remove polycarbonate covering from window.

42

Page 45

Warning

● Be sure that main power switch (ELB) is OFF before daily inspection and maintenance of DP series

units.

● Perform inspections and maintenance when inside of chamber is at room temperature.

● Never attempt to disassemble unit.

Caution

● Clean unit using soft damp cloth.

● Never use benzene, paint thinner, scouring powder, scrubbing brush or other abrasives and

solvents to clean unit. Superficial damage and/or discoloration, as well as deformity to some

components may result.

● Inspect main power switch (ELB) ON and OFF function.

・Prepare unit for inspection by connecting power cable to a facility outlet or terminal.

・Confirm that main switch (ELB) is “OFF” then, turn main switch (ELB) back “ON”.

・With the main switch “ON”, depress the test button on the main switch (ELB) using a ball-point pen

or other fine-tipped object. If main switch (ELB) shuts off, it is functioning normally.

● Test Independent Overheat Prevention Device (IOPD).

・Run unit in constant temperture mode and allow temperature to stabilize.

・Set the activation temperature for the IOPD to approximately 5C below chamber temperature.

・If overheating prevention device is functioning normally, heater will shut off within few seconds and

error code “Er07” will appear in the upper display. An alarm will also sound and ERROR lamp will

illuminate.

*Main power switch (ELB) and overheat prevention device must be inspected, as prescribed above,

prior to every instance of extended or overnight operation.

● Check oil level of vacuum pump (sold separately).

・Check oil level in vacuum pump at least once a month. Add or change oil as required.

・Check pump oil periodically and change ahead of specified life span, if possible. Depending on

operation environment and other factors, oil may degrade quickly and cause poor performance or

damage to pump.

・See vacuum pump instruction manual for additional information on oil changes.

・Having vacuum pump overhauled annually by original manufacturer is recommended for best

performance.

Inspect monthly.

6. MAINTENANCE PROCEDURE

Inspection and Maintenance

◆Contact a local dealer or Yamato sales office for further assistance.

43

Page 46

Warning

Caution

If unit will be out of service for an extended

period, turn off main power switch (ELB) and

disconnect power cable from facility outlet or

terminal.

Unit disposal.

● Remove door handle and hinges to prevent unit

from being locked.

● Do not leave unit unattended, or in a place

where children may have access.

● Dispose of this unit in accordance with local

laws and regulations.

Component

Material

External Structure

Chrome free electro-galvanized carbon steel, sheet coated

w/chemical-proof baked-on finish

Chamber

304 Stainless steel

Heat Insulator

Mineral wool

View Window

Reinforced glass and Polycarbonate resin

Major electrical components

Switches and Relays

Resin composites, copper and other material

Operation Panel

Polycarbonate resin

Printed Circuit Boards

Fiber glass composites and other material

Heater

Mica heater

Power Cable

Composite of synthesized rubber coating, copper, nickel and other

compound material

Wires

Composite of fiber glass, fire-retardant vinyl, copper, nickel and

other material

Stickers

Resin material

Sensor (Pt&K TC Sensor)

304 stainless steel and other material

7. EXTENDED STORAGE & DISPOSAL

Extended Storage / Unit Disposal

Disposal Considerations

Dispose of or recycle this unit in a responsible and environmentally friendly manner.

Yamato Scientific Co., Ltd. strongly recommends disassembling unit, as far as is possible, in order to

separate parts and recycle them in contribution to preserving the global environment.

Major components and materials, comprising DP series units are listed in table 7.1 below:

Table 7.1 Major Components of DP Series Units

44

Page 47

Display code

Description

Possible causes and solutions

Sensor Failure

Failure in temperature input circuit.

Open circuit in temperature sensor line.

Temperature out of specification range.

Contact a local dealer or Yamato sales office.

SSR Short Circuit

Electrical short in SSR circuit.

Failure in current transformer (CT) sensor.

Contact a local dealer or Yamato sales office.

Faulty Heater Line

Heater line faulty or severed.

Failure in current transformer (CT) sensor.

Drop in supply voltage.

Contact a local dealer or Yamato sales office.

Independent

Overheat Prevention

Device (IOPD)

activated

Independent Overheat Prevention Device (IOPD)

activated.

Turn ELB on again and check both chamber temperature and

IOPD temperature setting.

Contact a local dealer or Yamato sales office, if unit does not

activate when ELB is switched back on.

Main relay contact

failure

Turn ELB back on and confirm:

whether contact point on main relay is damaged.

whether current transformer (CT) sensor(s) has failed.

Contact a local dealer or Yamato sales office.

RAM Failure

Turn ELB back on and confirm whether there is a drop in

backup battery capacity or whether backup battery is dead.

Replace backup battery

Contact a local dealer or Yamato sales office, if this error

cannot be reset by turning ELB back on.

EEPROM Failure

Turn ELB back on and confirm whether there is a change in

data code on EEPROM.

Replace backup battery

Contact a local dealer or Yamato sales office, if this error

cannot be reset by turning ELB back on.

8. TROUBLESHOOTING

All possible error codes are shown in Table 8.1 below.

On DP series units, operation stops and a sounding alarm accompanies occurring errors.

Error codes will appear in the upper display of control panel. Confirm code and see associated

details in Table 8.1 below.

Turn off main power switch (ELB) immediately and block access to unit.

Table 8.1 Error Code Table

Error Code Guide

45

Page 48

Symptom

Possible causes

Possible solutions

Unit does not turn

on/nothing is displayed

in control panel displays

when power switch is

turned “ON”.

・ No power

・ ELB failure

・ CPU board failure