Yamato Scientific DKN302, DKN402, DKN602, DKN612, DKN812 Brochure

...

Forced Convection Oven

Programmable Forced Air Convection Ovens

DKN302/402/602/612/812/912

Operating

temp. range

Room temp.

o

C~210/250/260oC

+10

Temp. distribution

accuracy

±2.5°C

(at 210°C)

Internal

capcaity

27L

DKN302

90L

DKN402

150L

DKN602/612

90L

DKN402

535L

DKN912

Standard "Best Seller" ovens - Fully programmable

Standard forced air convection ovens are programmable

and come with extended functions and safety features.

Operation and functions

DKN302/402/602/612 come with observation windows

Programmable PID controller for easy program settings 30-step,

3-pattern program controller with repeat functions

Fixed setting, programmed, Quick Auto stop, Auto stop, and Auto

start operating modes with easy control capabilities

Over-heating prevention, Key lock function and calibration off-set

are possible with auxiliary functions

Safety features

Self diagnosis functions (Temperature sensor abnormal, Heater

disconnection, SSR-short) Automatic overheating prevention,

Electric leakage breaker with over current protection, Key lock

function

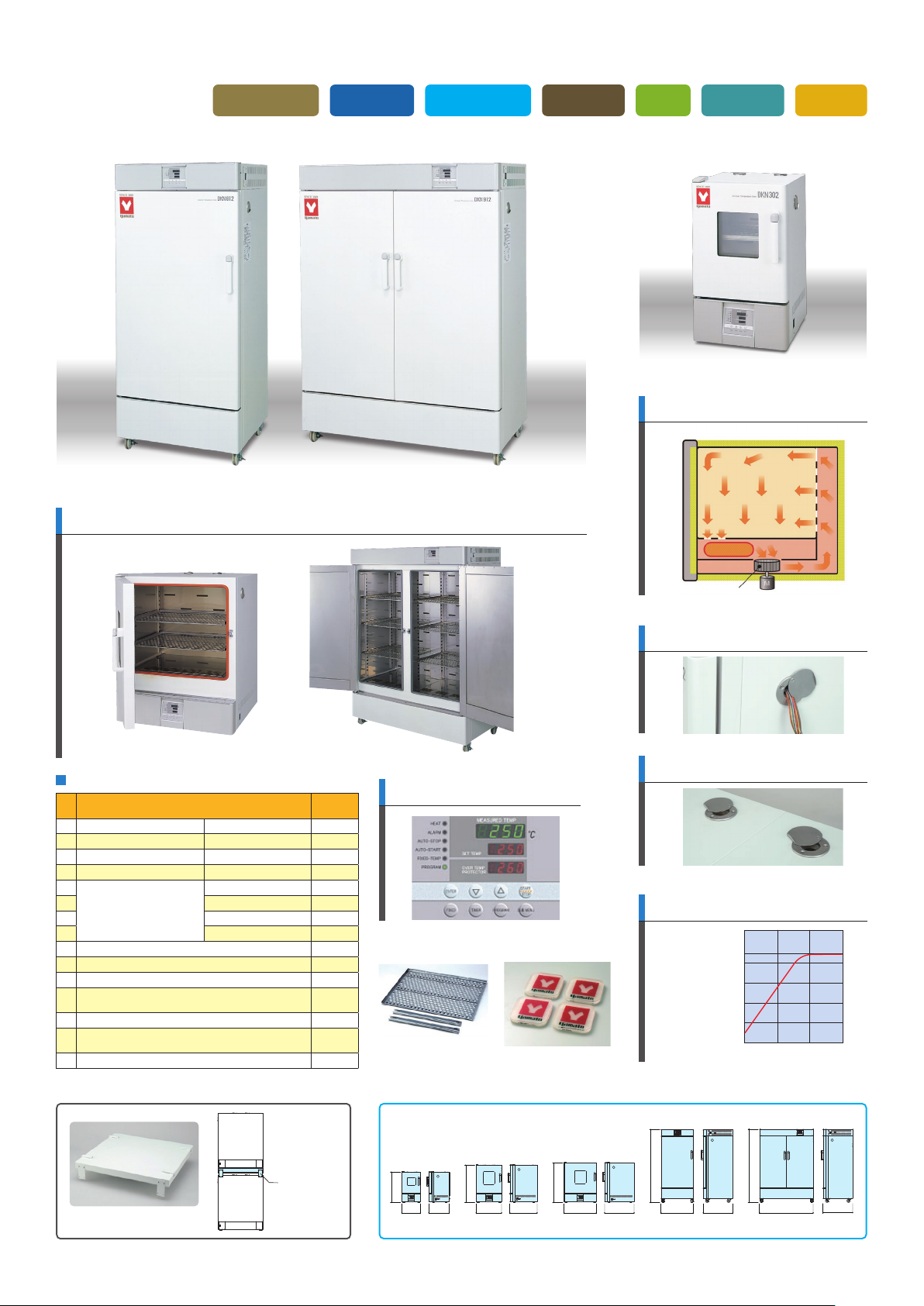

Specifications

Product code 212870 212871 212872 212873 212874 212875

Model DKN302 DKN402 DKN602 DKN612 DKN812 DKN912

Circulation method Forced air circulation

Operating temp. range RT+10°C to 260°C RT+10°C to 250°C

Temp. adjustment accuracy

Temp. distribution accuracy

Max. temp. reaching time*

Interior/Exterior material Stainless steel / Cold rolled steel plate with melamine resin baking finish

Heat insulating material Glass wool

Heater

Fan Type / Fan motor Scirocco fan / Condenser type motor 1pc. 1pc. 2pcs.

Cable hole 30mm I.D. (on the right side) 1pc.

Exhaust port 30mm I.D.×2 (on top) 30mm I.D.×2 (the back)

Observation window

Temp. controller PID control by microprocessor

Temp. setting method Digital setting by UP / DOWN key

Temp. display

Timer 1 min. to 99 hrs. 59 min. and 100 hrs. to 999 Hrs. 50 min. with timer wait function

Operation function Fixed temperature operation, Program operation, Auto start, Quick auto-stop, Auto-stop

Program mode Program operation : 30 steps (30 steps×1 pattern, 15 steps×2 pattern, 10 steps×3 pattern) Repeat function

Additional functions Calibration off-set function, Key lock, Uninterruptible power for memory

Heater circuit control SSR control

Sensor K-thermocouple (for temp. adjustment, indivisual overheating prevention)

Safety device

Internal dimensions (W×D×H)

External dimensions

Internal capacity 27L 90L 150L 300L 535L

Shelf plate with standard load

Shelf rest step number/Shelf

rest pitch

Power source 50/60Hz 115V8A / 220V4A 115V11A / 220V6A 115V13A 220V7A 220V12A 220V15A

Weight Approx. 35kg Approx. 50KG Approx. 65kg Approx. 110kg Approx. 190kg

Shelf plate Stainless steel, 1pc on the bottom screwed (DKN912C, 2 pcs)

Shelf plate / bracket 2 pcs. / 4 pcs. 4 pcs. / 8 pcs. 8 pcs. / 16 pcs.

The length of the power cord is about 2 meters outside the unit

1

Conditions : Temperature and humidity 23°C±5°C, 65%RH±20% (no load). Power supply voltage at 100V AC (200V).

*

*1±1°C (at 210°C) JTM K05

*1±2.5°C (at 210°C) JTM K05

1

Approx. 90 min. Approx. 120 min. Approx. 60 min.

Stainless pipe heater

0.8kW 1.2kW 1.34kW 1.2kW×2 1.5kW×2

180×180mm

Chemical strengthening glass×3

Measurement temp. : Digital display by green LED

Setting temp. : Digital display by red LED

Self diagnosis functions (Temp. sensor abnormal, Heater disconnection, SSR- short, Automatic overheating prevention),

Key lock function, Overheat protector, Electric leakage breaker with over current protection

300×300×300mm 450×450×450mm 600×500×500mm

*1(W×D×H)

410×451×670mm 560×601×820mm 710×651×870mm

Approx. 15kg/piece

6 steps / 30mm 11 steps / 30mm 13 steps / 30mm 29 steps / 30mm

250×280mm Chemical strengthening glass×3 None

L

90

DKN402+Stand (option)

*

L

150

DKN602+Stand (option)

RT +10°C to 210°C

600×500×1000mm

710×651×1608mm

2

Do not include protrusions

1070×500×1000

1180×651×1616

29 steps×2 / 30mm

Yamato Scientific Co.,Ltd. www.yamato-scientific.com

DKN302/402/602/612/812/912

2003

Chamber

Door

Heater

Circulation fan

870

710

1608

710

1616

1180651

651

820

560

670

410 601451 651

Interior

1180 651651710651710601560410 451

870

1608

1616

200

100

210

0 906030

Temperature(℃)

Time(min)

300

DKN812

Forced convection

circulation

L

Auto overheat

prevention

L

535

DKN912

Self-diagnosisoverheat protector Key lock

Method

[Side view]

Power outage

compensation

Overcurrent

ELB

L

27

DKN302

DKN612

Optional Items

No. Product name

Stand ON30 for DKN302 211180

①

Stand ON61 for DKN402/602/612 211856

②

Stacking support OD40 for DKN402 212822

③

Stacking support OD60 for DKN602/612 212823

④

⑤

⑥

Shelf

(with support 2 pcs)

⑦

⑧

*Cable port 25mm dia 281121

⑨

*Cable port 50mm dia 281122

⑩

*Temperature output terminal (4-20 mA) 281123

⑪

*

External alarm terminal/ time-up output terminal

⑫

(to choose either)

*External communication function (RS485) 281125

⑬

*External communication adapter

⑭

(changeable to RS232C)

Seismic mat for DKN302/402/602/612 296902

⑮

* Please specify when ordering main unit.

for DKN302 212068

for DKN402 212246

for D

KN602/612/812

for DKN912 212490

Product

code

212266

281124

281126

DKN912

Control Panel

⑤⑥⑥

Stainless punching

metal shelf

(with bracket 2pcs)

Cable Port (Standard)

Exhaust port (Standard)

DKN302/402/602/611

Temp. Rising Curve

DKN812

DKN912

⑬

Seismic mat

③④

Stacking support

[Back view]

Stacking

support

(OD40/60)

Dimensions (Unit:mm)

DKN302 DKN402 DKN812DKN602/612

DKN302/402/602/612/812/912

DKN912

www.yamato-scientific.comYamato Scientific Co.,Ltd.

2003

Loading...

Loading...