Yamaha YW50AT 2001 User Manual [ru]

YW50AP

5PJ-F8197-10LIT-11616-15-39

EB000000

YW50AP

SERVICE MANUAL

©2001 by Yamaha Motor Corporation U.S.A.

First edition, November 2001

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation U.S.A.

is expressly prohibited.

P/N LIT-11616-15-39

EB001000

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in

one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha

vehicles should have a basic understanding of mechanics and the techniques to repair these types

of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to

render the vehicle unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications

and significant changes in specifications or procedures will be forwarded to all authorized Yamaha

deal-ers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

Q

w

cC

NOTE:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

Failure to follow WARNING instructions

to the scooter operator, a bystander or a person checking or repairing the

scooter.

A CAUTION indicates special precautions that must be taken to avoid damage to the scooter.

A NOTE provides key information to make procedures easier or clearer.

could result in severe injury or death

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

1 The manual is divided into chapters. An abbreviation and symbol in the upper right corner of

each page indicate the current chapter. Refer to “SYMBOLS”.

2 Each chapter is divided into sections. The current section title is shown at the top of each

page, except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s) appears.

3 Sub-section titles appear in smaller print than the section title.

4 To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each removal and disassembly section.

5 Numbers are given in the order of the jobs in the exploded diagram. A circled number indi-

cates a disassembly step.

6 Symbols indicate parts to be lubricated or replaced. Refer to “SYMBOLS”.

7 A job instruction chart accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

8 Jobs requiring more information (such as special tools and technical data) are described sequen-

tially.

7

6

5

2

1

4

3

8

12

GEN

SPEC

INFO

34

INSP

ENG

ADJ

56

CARB

78

–+

ELEC

CHAS

TRBL

SHTG

EAS00009

SYMBOLS

The following symbols are not relevant to every vehicle.

Symbols 1 to 8 are designed as thumb tabs

to indicate the chapter’s number and content.

1 General information

2 Specifications

3 Periodic inspection and adjustment

4 Engine

5 Carburetor(s)

6 Chassis

7 Electrical system

8 Troubleshooting

90

qw

er

T

.

R

.

t y

uio

E

pas

G

M

Symbols 9 to y indicate the following.

9 Serviceable with engine mounted

0 Filling fluid

q Lubricant

w Special tool

e Tightening torque

r Wear limit, clearance

t Engine speed

y Electrical data

Symbols u to s in the exploded diagrams in-

dicate the types of lubricants and lubrication

points.

u Engine oil

i Gear oil

o Molybdenum disulfide oil

p Wheel bearing grease

a Lithium soap base grease

s Molybdenum disulfide grease

B

df

LT

LS

M

New

Symbols d to f in the exploded diagrams

indicate the following.

®

d Apply locking agent (LOCTITE

f Replace the part

)

INDEX

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC INSPECTION AND

1

2

ADJUSTMENT

ENGINE OVERHAUL

CARBURETION

CHASSIS

ELECTRICAL

3

4

5

6

– +

TROUBLESHOOTING

7

8

CHAPTER 1.

GENERAL INFORMATION

SCOOTER INDENTIFICATION........................................................................................................... 1-1

VEHICLE IDENTIFICATION NUMBER ........................................................................................... 1-1

MODEL CODE ................................................................................................................................ 1-1

IMPORTANT INFORMATION ............................................................................................................ 1-2

PREPARATION FOR REMOVAL AND DISASSEMBLY ................................................................ 1-2

REPLACEMENT PARTS ................................................................................................................. 1-2

GASKETS, OIL SEALS AND O-RINGS.......................................................................................... 1-2

LOCK WASHERS/PLATES AND COTTER PINS ........................................................................... 1-2

BEARINGS AND OIL SEALS ......................................................................................................... 1-3

CIRCLIPS ........................................................................................................................................ 1-3

CHECKING OF CONNECTIONS ........................................................................................................ 1-4

HOW TO USE THE CONVERSION TABLE ....................................................................................... 1-5

CONVERSION TABLE .................................................................................................................... 1-5

SPECIAL TOOLS ................................................................................................................................ 1-6

CHAPTER 2.

SPECIFICATIONS

GENERAL SPECIFICATION ............................................................................................................... 2-1

MAINTENANCE SPECIFICATION ..................................................................................................... 2-4

ENGINE .......................................................................................................................................... 2-4

TIGHTENING TORQUES ............................................................................................................... 2-6

ENGINE .......................................................................................................................................... 2-6

MAINTENANCE SPECIFICATION ..................................................................................................... 2-7

CHASSIS ........................................................................................................................................ 2-7

TIGHTENING TORQUES ............................................................................................................... 2-8

CHASSIS ........................................................................................................................................ 2-8

MAINTENANCE SPECIFICATION ..................................................................................................... 2-9

ELECTRICAL ................................................................................................................................... 2-9

GENERAL TORQUE SPECIFICATIONS........................................................................................... 2-11

LUBRICATION POINTS AND LUBRICATION TYPE ....................................................................... 2-12

ENGINE ........................................................................................................................................ 2-12

CHASSIS ...................................................................................................................................... 2-13

CABLE ROUTING ............................................................................................................................. 2-14

CHAPTER 3.

PERIODIC INSPECTION AND ADJUSTMENTS

INTRODUCTION ................................................................................................................................ 3-1

PERIODIC MAINTENANCE/LUBRICATION INTERVALS ................................................................ 3-1

COVER AND PANEL .......................................................................................................................... 3-3

SIDECOVER AND SEAT ................................................................................................................ 3-3

LOWER COWLING, UPPER COVER, LEG SHIELD 1, 2 AND FOOTREST BOARD ..................... 3-4

HANDLEBAR COVER(FRONT AND REAR) ................................................................................... 3-5

ENGINE .............................................................................................................................................. 3-6

IDLE SPEED ADJUSTMENT .......................................................................................................... 3-6

THROTTLE CABLE FREE ADJUSTMENT ..................................................................................... 3-7

AUTOLUBE PUMP AIR BLEEDING ............................................................................................... 3-8

SPARK PLUG INSPECTION...........................................................................................................3-9

ENGINE OIL LEVEL INSPECTION ............................................................................................... 3-10

TRANSMISSION OIL REPLACEMENT ........................................................................................ 3-11

AIR FILTER ELEMENT CLEANING .............................................................................................. 3-12

V-BELT INSPECTION ................................................................................................................... 3-14

CHASSIS .......................................................................................................................................... 3-15

FRONT BRAKE LEVER FREE PLAY CHECK ................................................................................ 3-15

REAR BRAKE LEVER FREE PLAY CHECK................................................................................... 3-15

BRAKE PAD INSPECTION ........................................................................................................... 3-15

BRAKE SHOE INSPECTION ........................................................................................................ 3-16

BRAKE FLUID LEVEL INSPECTION ............................................................................................ 3-16

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM) ........................................................................ 3-17

STEERING ADJUSTMENT .......................................................................................................... 3-18

TIRE INSPECTION........................................................................................................................ 3-19

WHEEL INSPECTION ................................................................................................................... 3-22

FRONT FORK INSPECTION......................................................................................................... 3-22

REAR SHOCK ABSORBER INSPECTION.................................................................................... 3-22

SEAT LOCK CABLE ADJUSTMENT ........................................................................................... 3-22

CABLE CHECKING AND LUBRICATING..................................................................................... 3-23

LEVERS LUBRICATING ............................................................................................................... 3-23

CENTERSTAND LUBRICATING .................................................................................................. 3-23

ELECTRICAL ..................................................................................................................................... 3-24

BATTERY INSPECTION ............................................................................................................... 3-24

FUSE INSPECTION ...................................................................................................................... 3-29

HEADLIGHT BEAM ADJUSTMENT ............................................................................................ 3-30

HEADLIGHT BULB REPLACEMENT............................................................................................ 3-30

TURN SIGNAL AND TAILLIGHT BULB REPLACEMENT ........................................................... 3-31

TAILLIGHT BULB REPLACEMENT .............................................................................................. 3-32

LICENSE LIGHT BULB REPLACEMENT...................................................................................... 3-32

CHAPTER 4.

ENGINE

ENGINE OVERHAUL ......................................................................................................................... 4-1

WIREHARNESS AND CABLES ...................................................................................................... 4-1

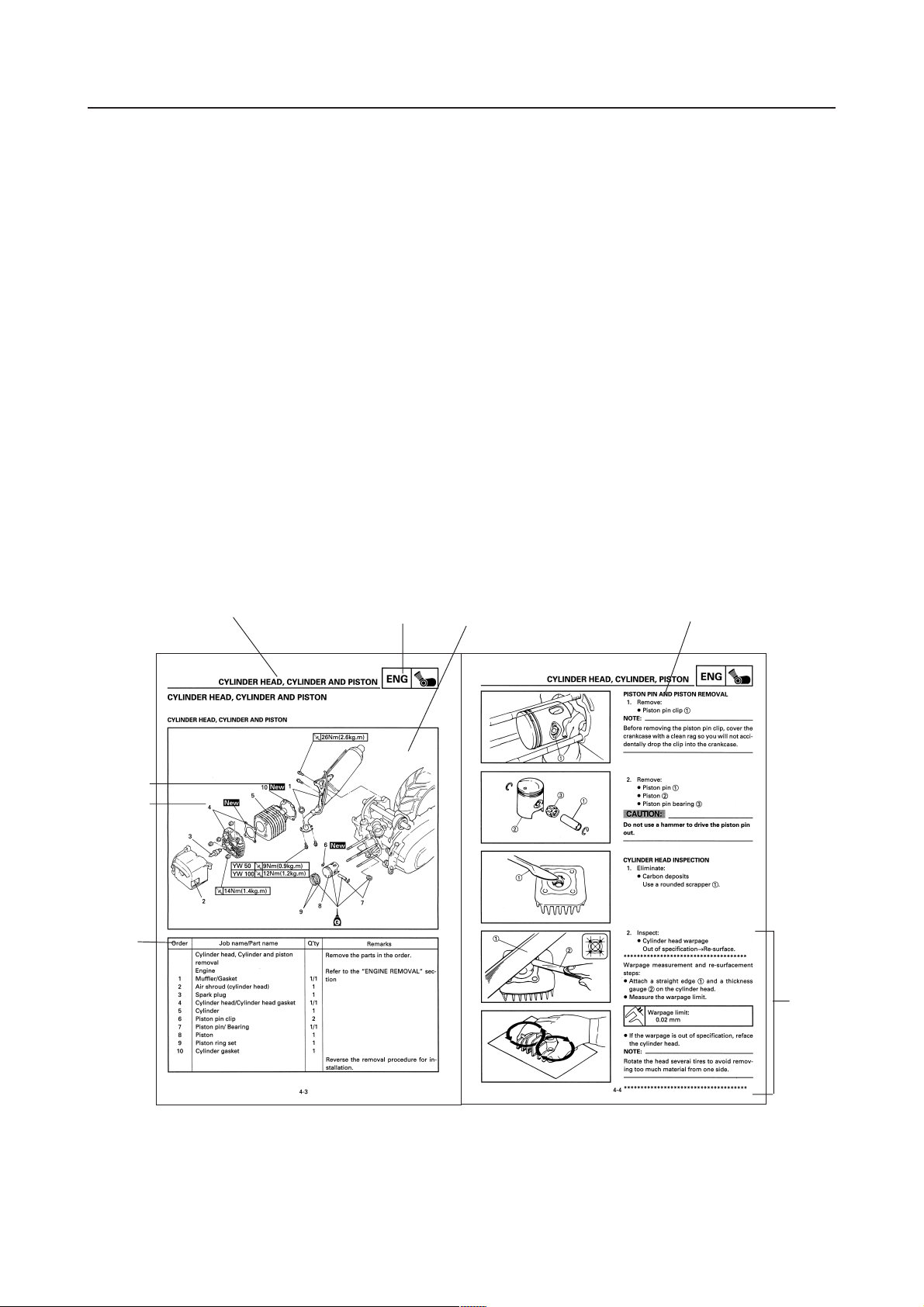

CYLINDER HEAD, CYLINDER AND PISTON .................................................................................... 4-3

CYLINDER HEAD, CYLINDER AND PISTON ................................................................................ 4-3

PISTON PIN AND PISTON REMOVAL .......................................................................................... 4-4

CYLINDER HEAD INSPECTION..................................................................................................... 4-4

CYLINDER AND PISTON INSPECTION ........................................................................................ 4-5

PISTON RINGS INSPECTION........................................................................................................ 4-7

PISTON PIN AND PISTON PIN BEARING .................................................................................... 4-7

PISTON PIN AND PISTON INSTALLATION ................................................................................. 4-8

CYLINDER AND CYLINDER HEAD ................................................................................................ 4-9

V-BELT, CLUTCH AND SECONDARY/PRIMARY SHEAVE ........................................................... 4-11

KICK STARTER AND CRANKCASE COVER(LEFT)..................................................................... 4-11

KICK STARTER............................................................................................................................. 4-12

KICK STARTER INSTALLATION ................................................................................................. 4-13

V-BELT, CLUTCH AND SECONDARY/PRIMARY SHEAVE ........................................................ 4-14

SECONDARY SHEAVE ................................................................................................................ 4-15

PRIMARY SHEAVE REMOVAL.................................................................................................... 4-16

SECONDARY SHEAVE REMOVAL.............................................................................................. 4-16

CLUTCH INSPECTION ................................................................................................................. 4-17

V-BELT INSPECTION ................................................................................................................... 4-18

PRIMARY SHEAVE INSPECTION................................................................................................ 4-19

SECONDARY SHEAVE ................................................................................................................ 4-20

SECONDARY SHEAVE INSTALLATION ..................................................................................... 4-21

PRIMARY SHEAVE ...................................................................................................................... 4-22

STARTER CLUTCH AND STARTER MOTOR ................................................................................. 4-24

STARTER CLUTCH AND STARTER MOTOR.............................................................................. 4-24

STARTER CLUTCH AND GEARS INSPECTION ......................................................................... 4-26

C.D.I. MAGNET ................................................................................................................................ 4-27

C.D.I. MAGNETO ......................................................................................................................... 4-27

C.D.I. MAGNETO REMOVAL....................................................................................................... 4-28

C.D.I. MAGNETO INSTALLATION .............................................................................................. 4-28

AUTOLUBE PUMP ........................................................................................................................... 4-29

AUTOLUBE PUMP ....................................................................................................................... 4-29

AUTOLUBE PUMP INSTALLATION ........................................................................................... 4-30

TRANSMISSION .............................................................................................................................. 4-31

TRANSMISSION .......................................................................................................................... 4-31

CRANKCASE AND REED VALVE.................................................................................................... 4-33

CRANKCASE AND REED VALVE ................................................................................................ 4-33

CRANKCASE(RIGHT) REMOVAL ................................................................................................ 4-35

CHECKING THE CRANKCASE .................................................................................................... 4-35

CHECKING THE BEARINGS AND OIL SEALS ............................................................................ 4-35

REED VALVE INSPECTION ......................................................................................................... 4-36

CRANKCASE (RIGHT) INSTALLATION ...................................................................................... 4-36

CRANKSHAFT .................................................................................................................................. 4-38

CRANKSHAFT .............................................................................................................................. 4-38

CRANKSHAFT REMOVAL ........................................................................................................... 4-39

CRANKSHAFT INSPECTION ....................................................................................................... 4-39

CRANKSHAFT INSTALLATION................................................................................................... 4-40

CHAPTER 5

CARBURETION

CARBURETION .................................................................................................................................. 5-1

CARBURETOR................................................................................................................................ 5-1

CABURETOR DISASSEMBLY ....................................................................................................... 5-2

CABURETOR INSPECTION ........................................................................................................... 5-3

CARBURETOR ASSEMBLY ........................................................................................................... 5-5

FUEL LEVEL ADJUSTMENT ......................................................................................................... 5-6

AUTO CHOKE INSPECTION.......................................................................................................... 5-7

FUEL COCK INSPECTION ............................................................................................................. 5-8

CHAPTER 6

CHASSIS

FRONT WHEEL AND BRAKE DISC ................................................................................................... 6-1

FRONT WHEEL AND BRAKE DISC ............................................................................................... 6-1

FRONT WHEEL DISASSEMBLY .................................................................................................... 6-2

FRONT WHEEL DISASSEMBLY .................................................................................................... 6-3

FRONT WHEEL INSPECTION ........................................................................................................ 6-3

BRAKE DISC INSPECTION ............................................................................................................ 6-4

FRONT WHEEL ASSEMBLY .......................................................................................................... 6-4

FRONT WHEEL INSTALLATION ................................................................................................... 6-5

WHEEL STATIC BALANCE ADJUSTMENT .................................................................................. 6-6

FRONT BRAKE ................................................................................................................................... 6-8

BRAKE PAD .................................................................................................................................... 6-8

BRAKE PAD REPLACEMENT ........................................................................................................ 6-9

MASTER CYLINDER ........................................................................................................................ 6-12

MASTER CYLINDER DISASSEMBLY ............................................................................................. 6-13

MASTER CYLINDER INSPECTION .............................................................................................. 6-14

MASTER CYLINDER ASSEMBLY................................................................................................ 6-14

MASTER CYLINDER INSTALLATION ......................................................................................... 6-15

CALIPER ........................................................................................................................................... 6-17

CALIPER DISASSEMBLY ................................................................................................................. 6-18

BRAKE CALIPER DISASSEMBLY ................................................................................................ 6-19

CALIPER INSPECTION ................................................................................................................. 6-19

BRAKE CALIPER ASSEMBLY ...................................................................................................... 6-20

BRAKE CALIPER INSTALLATION ............................................................................................... 6-20

REAR WHEEL AND REAR BRAKE .................................................................................................. 6-21

REAR WHEEL ............................................................................................................................... 6-21

REAR BRAKE ................................................................................................................................ 6-22

REAR WHEEL INSPECTION ........................................................................................................ 6-23

REAR BRAKE INSPECTION ......................................................................................................... 6-23

REAR BRAKE INSTALLATION .................................................................................................... 6-24

HANDLEBAR .................................................................................................................................... 6-25

HANDLEBAR ................................................................................................................................ 6-25

HANDLEBAR INSTALLATION ..................................................................................................... 6-27

STEERING ........................................................................................................................................ 6-29

STEERING .................................................................................................................................... 6-29

STEERING REMOVAL ................................................................................................................. 6-30

STEERING INSPCTION ................................................................................................................6-31

STEERING INSTALLATION ......................................................................................................... 6-31

FRONT FORK ................................................................................................................................... 6-34

FRONT FORK ............................................................................................................................... 6-34

FRONT FORK DISASSEMBLY ..................................................................................................... 6-35

FRONT FORK REMOVAL ............................................................................................................. 6-36

FRONT FORK DISASSEMBLY ..................................................................................................... 6-36

FRONT FORK INSPECTION ......................................................................................................... 6-37

FRONT FORK ASSEMBLY ...........................................................................................................6-37

FRONT FORK INSTALLATION .................................................................................................... 6-39

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPONENTS ............................................................................................................ 7-1

ELECTRICAL COMPONENTS ........................................................................................................ 7-1

CIRCUIT DIAGRAM........................................................................................................................ 7-2

CHECKING SWITCHES ...................................................................................................................... 7-4

CHECKING STEPS ......................................................................................................................... 7-4

SWITCH CONNECTION AS SHOWN IN THIS MANUAL............................................................. 7-4

SWITCH POSITION AND TERMINAL CONNECTION ...................................................................... 7-5

CHECKING THE BLUBS AND BULB SOCKETS ............................................................................... 7-5

CHECKING THE BULBS AND BULB SOCKETS ........................................................................... 7-6

TYPES OF BULBS .......................................................................................................................... 7-6

CHECKING THE CONDITION OF THE BULBS.............................................................................. 7-7

CHECKING THE CONDITION OF THE BULB SOCKETS .............................................................. 7-8

IGNITION SYSTEM ............................................................................................................................ 7-9

CIRCUIT DIAGRAM........................................................................................................................ 7-9

TROUBLESHOOTING .................................................................................................................. 7-10

CHARGING SYSTEM ....................................................................................................................... 7-14

CIRCUIT DIAGRAM...................................................................................................................... 7-14

TROUBLESHOOTING .................................................................................................................. 7-15

ELECTRIC STARTING SYSTEM ...................................................................................................... 7-18

CIRCUIT DIAGRAM...................................................................................................................... 7-18

TROUBLESHOOTING .................................................................................................................. 7-19

STARTER MOTOR ....................................................................................................................... 7-22

STARTER MOTOR DISASSEMBLY............................................................................................. 7-23

INSPECTION AND REPAIR.......................................................................................................... 7-24

LIGHTING SYSTEM ......................................................................................................................... 7-26

CIRCUIT DIAGRAM...................................................................................................................... 7-26

TROUBLESHOOTING .................................................................................................................. 7-27

LIGHTING SYSTEM CHECK ........................................................................................................ 7-29

SIGNAL SYSTEM............................................................................................................................. 7-33

CIRCUIT DIAGRAM...................................................................................................................... 7-33

TROUBLESHOOTING .................................................................................................................. 7-34

SIGNAL SYSTEM CHECK............................................................................................................ 7-36

AUTO CHOKE SYSTEM .................................................................................................................. 7-42

CIRCUIT DIAGRAM...................................................................................................................... 7-42

TROUBLESHOOTING .................................................................................................................. 7-43

CHAPTER 8

TROUBLESHOOTING

STARTING FAILURE/HARD STARTING........................................................................................... 8-1

FUEL SYSTEM ............................................................................................................................... 8-1

IGNITION SYSTEM ........................................................................................................................ 8-2

COMPRESSION SYSTEM ............................................................................................................. 8-2

POOR IDLE SPEED PERFORMANCE ................................................................................................ 8-3

POOR IDLE SPEED PERFORMANCE ............................................................................................ 8-3

POOR MIDIUM AND HIGH SPEED PERFORMANCE ....................................................................... 8-3

POOR MIDIUM AND HIGH SPEED PERFORMANCE ................................................................... 8-3

FULTY AUTOMATIC(V-BELT TYPE) ................................................................................................. 8-4

SCOOTER DOES NOT MOVE WHILE ENGINE IS OPERATING .................................................. 8-4

CLUTCH OUT FAILURE ................................................................................................................. 8-4

POOR STANDING START(LOW CLIMBING ABILITY) ................................................................. 8-4

POOR ACCELERATION(POOR HIGH SPEED) .............................................................................. 8-4

OVER HEAT........................................................................................................................................ 8-5

OVERHEAT ..................................................................................................................................... 8-5

POOR SPEED ..................................................................................................................................... 8-5

POOR SPEED ................................................................................................................................. 8-5

IMPROPER KICKING .......................................................................................................................... 8-6

SLIPPING ........................................................................................................................................ 8-6

HARD KICKING .............................................................................................................................. 8-6

KICK CRANK NOT RETURNING ................................................................................................... 8-6

FAULTY BRAKE ................................................................................................................................. 8-7

POOR BRAKING EFFECT............................................................................................................... 8-7

MALFUNCTION ............................................................................................................................. 8-7

INSTABLE HANDLING ...................................................................................................................... 8-8

INSTABLE HANDLING .................................................................................................................. 8-8

FAULTY SIGNAL AND LIGHTING SYSTEM .................................................................................... 8-9

HEADLIGHT DARK......................................................................................................................... 8-9

BULB BURNT OUT ........................................................................................................................ 8-9

FLASHER DOES NOT BLINK......................................................................................................... 8-9

FLASHER KEEPS ON ..................................................................................................................... 8-9

FLASHER BLINKS SLOWER........................................................................................................ 8-10

FLASHER BLINKS QUICKER ....................................................................................................... 8-10

HORN DOES NOT SOUND ......................................................................................................... 8-10

SCOOTER INDENTIFICATION

EAS00015

GENERAL INFORMATION

GEN

INFO

1

1

SCOOTER IDENTIFICATION

EAS00017

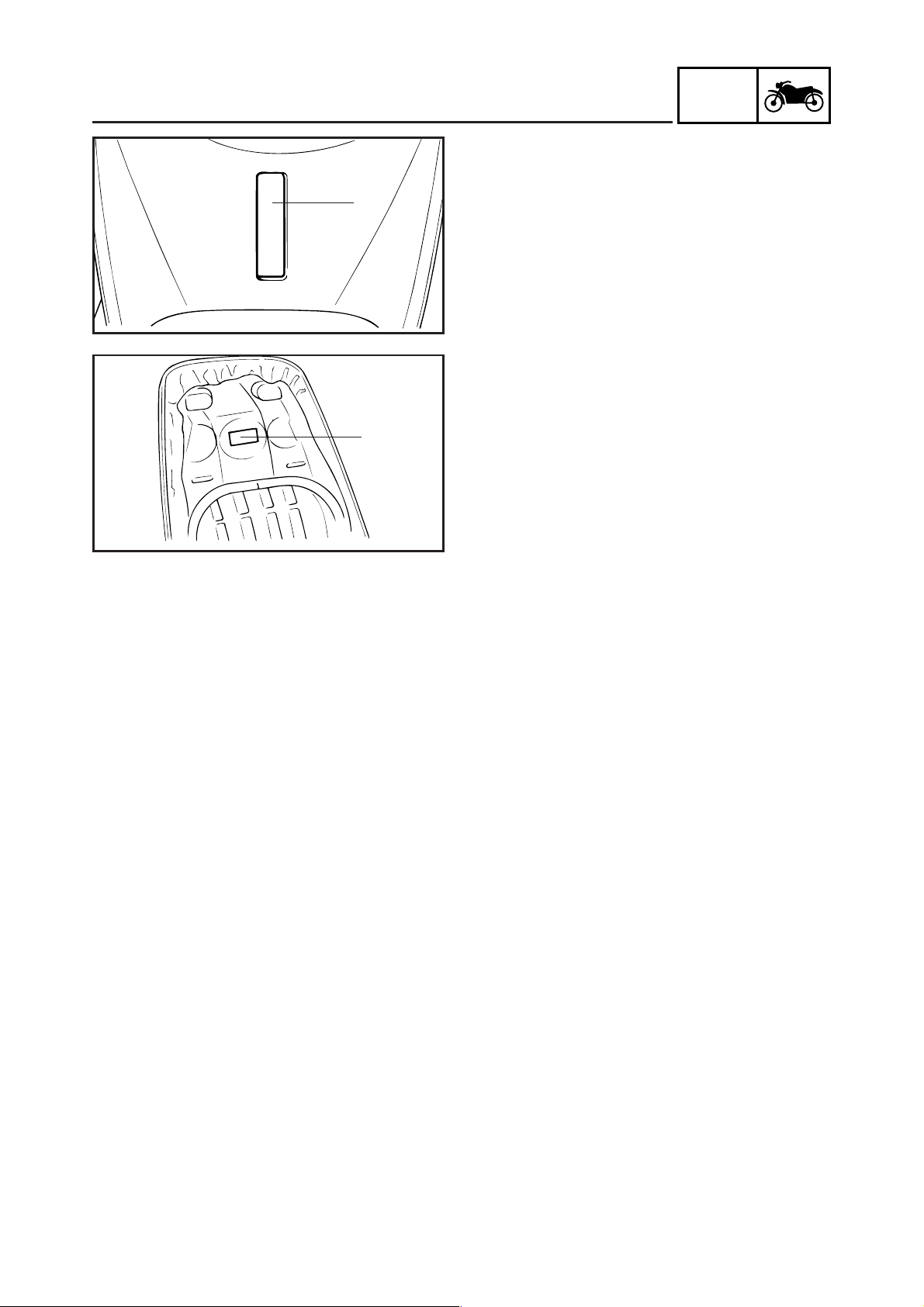

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is stamped

into the frame.

EAS00018

MODEL CODE

The model code label 1 is affixed to the location shown in the figure. Record the information on this label in the space provided. This

information will be needed to order spare parts.

1-1

IMPORTANT INFORMATION

EAS00020

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY

1. Before removal and disassembly, remove

all dirt, mud, dust and foreign material.

2. Use only the proper tools and cleaning

equipment.

Refer to “SPECIAL TOOLS”.

3. When disassembling, always keep mated

parts together. This includes gears, cylinders, pistons and other parts that have

been

“mated” through normal wear. Mated

parts must always be reused or replaced

as an assembly.

4. During disassembly, clean all of the parts

and place them in trays in the order of disassembly. This will speed up assembly

and allow for the correct installation of all

300-008

parts.

5. Keep all parts away from any source of

fire.

GEN

INFO

OR

EAS00021

REPLACEMENT PARTS

Use only genuine Yamaha parts for all replacements. Use oil and grease recom-mended by

Yamaha for all lubrication jobs.

Other brands may be similar in function and

appearance, but inferior in quality.

300-016

EAS00022

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all

gaskets, seals and O-rings. All gasket surfaces, oil seal lips and O-rings must be

cleaned.

2. During reassembly, properly oil all mating parts and bearings and lubricate the

oil seal lips with grease.

EAS00023

LOCK WASHERS/PLATES AND COTTER PINS

After removal, replace all lock washers/plates

1 and cotter pins. After the bolt or nut has been

tightened to specification, bend the lock tabs

along a flat of the bolt or nut.

1-2

IMPORTANT INFORMATION

EAS00024

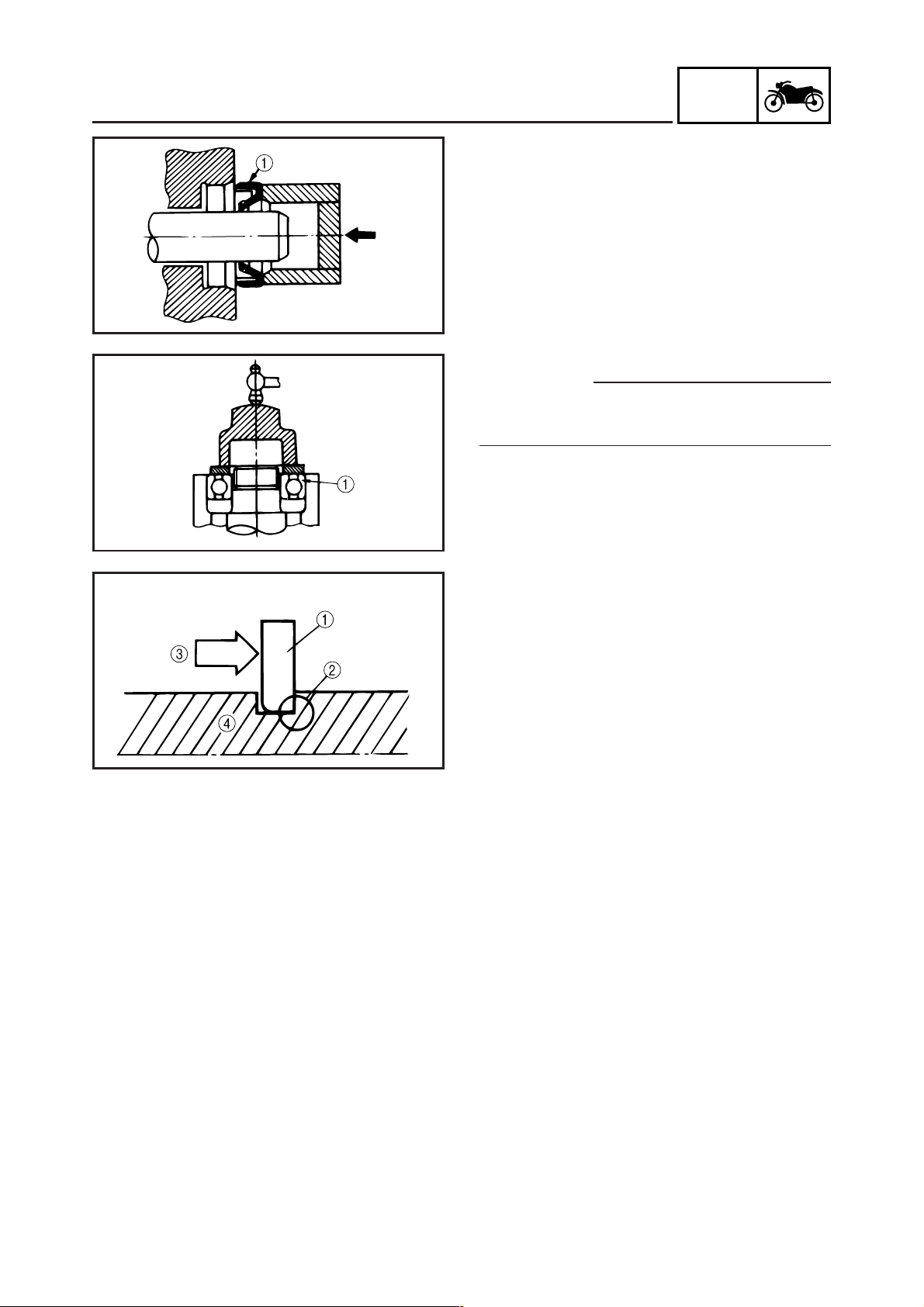

BEARINGS AND OIL SEALS

Install bearings and oil seals so that the manu

facturer’s marks or numbers are visible. When

installing oil seals, lubricate the oil seal lips with

a light coat of lithium soap base grease.

Oil bearings liberally when installing, if appro

priate.

1 Oil seal

cC

Do not spin the bearing with compressed air

because this will damage the bearing surfaces.

1 Bearing

GEN

INFO

EAS00025

CIRCLIPS

Before reassembly, check all circlips carefully

and replace damaged or distorted circlips.

Always replace piston pin clips after one use.

When installing a circlip 1, make sure the

sharp-edged corner 2 is positioned opposite

the thrust 3 that the circlip receives.

4 Shaft

1-3

IMPORTANT INFORMATION

EB801000

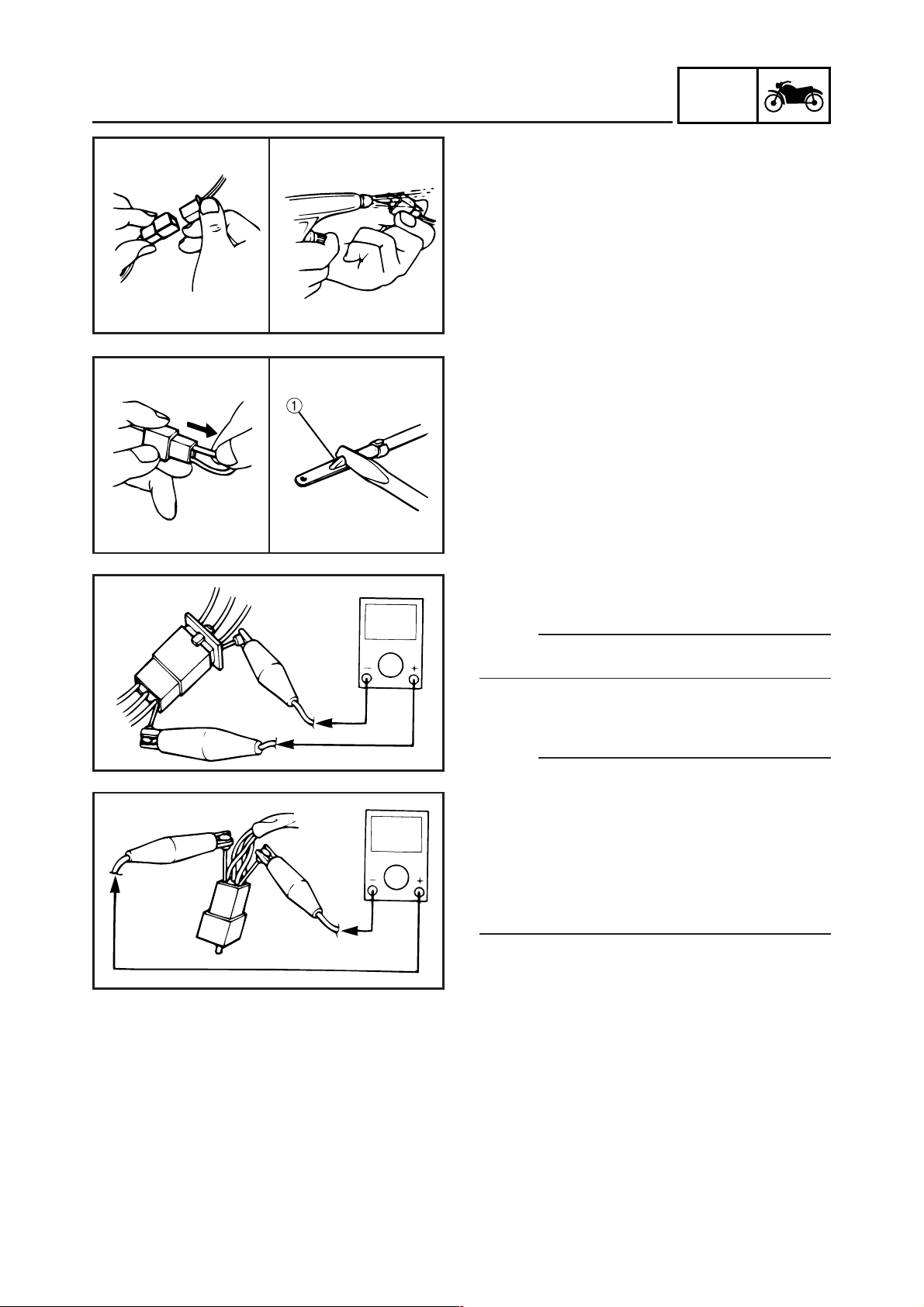

CHECKING OF CONNECTIONS

Dealing with stains, rust, moisture, etc. on the

connector.

1. Disconnect:

8 Connector

2. Dry each terminal with an air blower.

3. Connect and disconnect the connector two

or three.

4. Pull the read to check that it will not come

off.

5. If the terminal comes off, bend up the pin

1 and reinsert the terminal into the connector.

GEN

INFO

6. Connect:

8 Connector

NOTE:

The two connectors “click” together.

7. Check for continuity with a tester.

NOTE:

8 If there is no continuity, clean the termi-

nals.

8 Be sure to perform the steps 1 to 7 listed

above when checking the wireharness.

8 For a field remedy, use a contact revitalizer

available on the market.

8 Use the tester on the connector as shown.

1-4

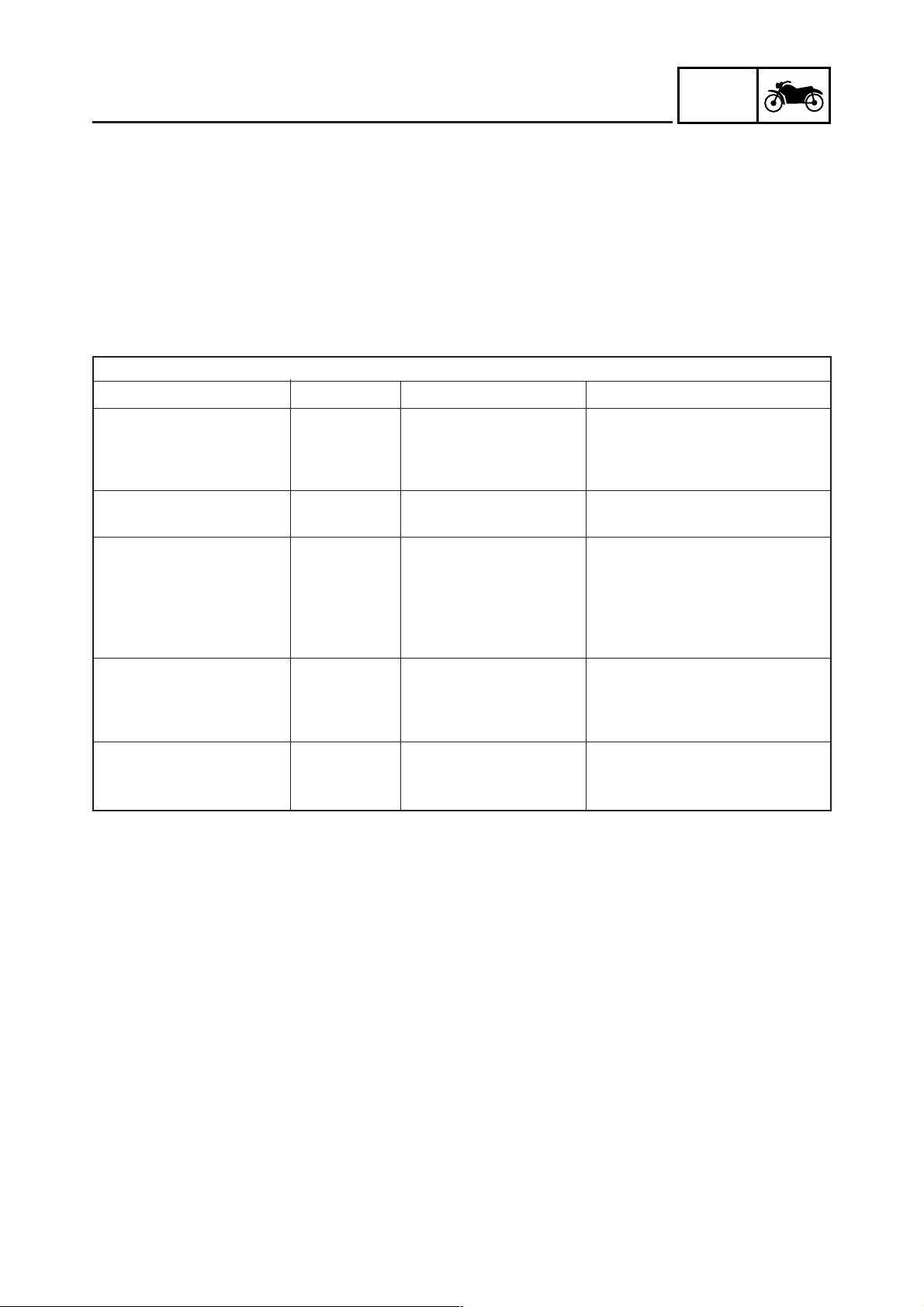

HOW TO USE THE CONVERSION TABLE

EB201000

HOW TO USE THE CONVERSION TABLE

All specification data in this manual are listed in SI and METRIC UNITS.

Use this table to convert METRIC unit data to IMPERIAL unit data.

Ex.

METRIC MULTIPLIER IMP

** mm × 0.03937 = ** in

2 mm × 0.03937 = 0.083 in

CONVERSION TABLE

METRIC TO IMP

Known Multiplier Result

Torque

m.kg

m.kg

cm.kg

cm.kg

7.233

86.794

0.0723

0.8679

ft.lb

in.lb

ft.lb

in.lb

GEN

INFO

Weight

Distance

Volume/

Capacity

Miscellaneous

kg

g

km/h

km

m

m

cm

mm

3

cc(cm

)

3

)

cc(cm

lit(liter)

lit(liter)

kg/mm

2

kg/cm

Centigrade

2.205

0.03527

0.6214

0.6214

3.281

1.094

0.3937

0.03937

0.03527

0.06102

0.8799

0.2199

55.997

14.2234

9/5(°C)+32

lb

oz

mph

mi

ft

yd

in

in

oz (IMP liq.)

cu.in

qt(IMP liq.)

gal(IMP liq.)

lb/in

psi(lb/in

Fahrenheit (°F)

2

)

1-5

GEN

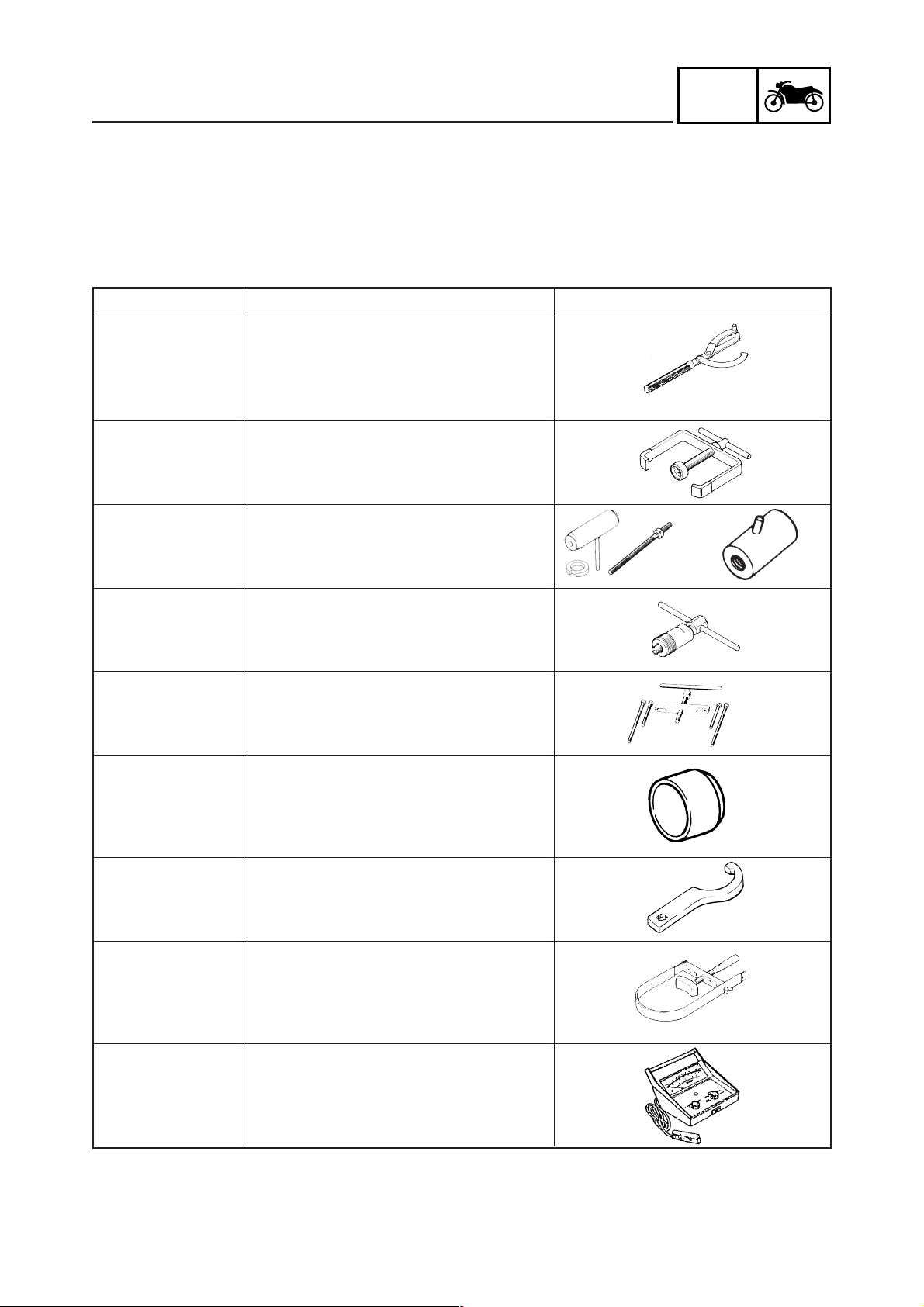

SPECIAL TOOLS

EE102000

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly. Use

only the appropriate special tools; this Will help prevent damage caused by the use of inappropriate tools or improvised techniques.

When placing an order, refer to the list provided below to avoid any mistakes.

INFO

Tool No.

YU-01235

YS-28891

YU -90050

-90062

YU-01189

YU- 01135-A

Tool name / Function

Rotor holding tool

This tool is used to hold the generator rotor when removing or installing the generator rotor bolt.

Clutch spring holder

This tool is used to disassembly and assembly the secondary pulley.

Crankshaft Installation set 1

Adapter 2

These tools are used to install the crankshaft.

Flywheel puller

This tool is used for removing the rotor.

Crankcase Separating tool

This tool is used to remove the crankshaft

or separate the crankcase.

1

Illustration

2

YM-33299

YU-33975

YU-01701

YU-8036-A

Oil seal guide

This tool is used for protecting the oil seal

lip when installing the secondary sliding

sheave.

Steering nut wrench

This tool is used to loosen or tighten the

steering stem ring nut.

Sheave holder

This tool is used to hold the clutch housing when removing or installing the clutch

housing nut.

Inductive tachometer

This tool is used to check engine speed.

1-6

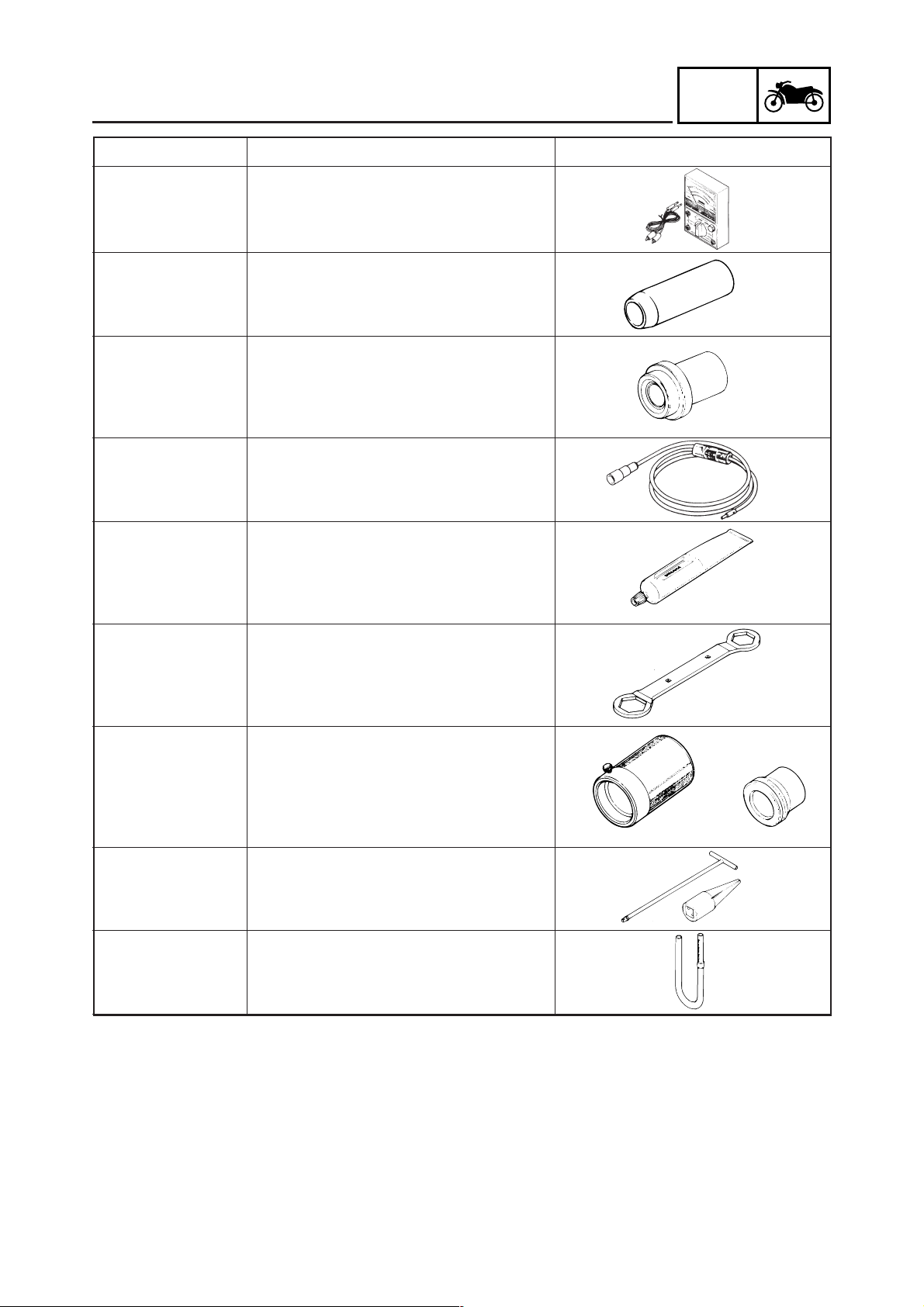

SPECIAL TOOLS

GEN

INFO

Tool No.

YU-03112

YM-1409

YM-1410

YM-34487

ACC-1100-15-01

Tool name / Function

Pocket tester

This tool is used to check the electrical system.

Oil seal guide

This tool is used to install the left side crankcase oil seal.

Oil seal driver

This tool is used to install the left side crankcase oil seal.

Dynamic spark tester

This instrument is necessary for checking

the ignition system components.

Quick Gasket ®

This sealant is used to seal to mating surfaces (e.g., crankcase mating sur-faces).

Illustration

90890-01348

YU-33963 1

-1400 2

T-handle 1

YM-01326

Holder

YM-01300-1 2

YM-01312-A

Locknut wrench

This tool is used to loosen and tighten the

clutch carrier locknut of the secondary

sheave.

Front fork seal driver

Weight 1

Adapter 2

These tools are used when installing the fork

seal.

T-handle 1 / Damper rod holder 2

These tools are needed to loosen and

tighten the damper rod holding bolt.

Fuel level gauge

This gauge is used to measure the fuel level

in the float chamber.

1 2

1 2

1-7

GENERAL SPECIFICATION

GENERAL SPECIFICATION

SPECIFICATION

SPEC

Model

Model code:

Dimensions:

Overall length

Overall width

Overall height

Seat height

Wheelbase

Minimum ground clearance

Minimum turning radius

Basic weight:

With oil and full fuel tank

Engine:

Engine type

Cylinder arrangement

Displacement

Bore × stroke

Compression ratio

Starting system

Lubrication system:

Oil Type or Grade:

Engine Oil

YW50AP

5PJ1

1,890 mm(74.4 in)

705 mm(27.8 in)

1,110 mm(43.7 in)

765 mm(30.1 in)

1,275 mm(50.2 in)

120 mm(4.7 in)

2,000 mm(78.7 in)

94 kg(207 lb)

Air cooled 2 strcke, gasoline torque induction

Forward- inclined single cylinder

3

(2.99 cu.in)

49cm

40.0 × 39.2 mm(1.57 × 1.54 in)

7.2:1

Electric and kick starter

Separate lubrication

For YAMAHA brand:

Yamalube 2 or Air cooled 2-stroke engine oil (ISO

EG-C, EG-D grade)

Transmission Oil

Oil Capacity:

Oil Tank (Engine Oil)

Transmission Oil:

Periodic Oil Change

Total Amount

Air Filter:

Fuel:

Type

Tank Capacity

Carburetor:

Type / Manufacturer

Yamalube 4 SAE 10W/30 SE or GL gear oil

1.4 L (1.23 lmp•qt, 1.48 US qt)

0.11 L(0.096 lmp.qt, 0.12 US qt)

0.13 L(0.11 lmp.qt, 0.13 US qt)

Wet type element

Regular unleaded gasoline

5.7 L (1.25 lmp.gal, 1.5 US gal)

Y14P/1/ TEIKEI

2-1

GENERAL SPECIFICATION

SPEC

Model

Spark Plug:

Type/Manufacturer

Gap

Clutch Type

Transmission:

Primary Reduction System

Primary Reduction Ratio

Secondary Reduction System

Secondary Reduction Ratio

Transmission Type

Operation

Chassis:

Frame type

Caster angle

Trail

Tire:

Type

Size front

rear

Manufacturer front

rear

Type front

rear

YW50A

BPR7HS/NGK

0.6 ~ 0.7 mm(0.02 ~ 0.03 in)

Dry, Centrifugal automatic

Helical gear

4.000

Supur gear

3.666

V-belt

Automatic

Steel tube underbone

26.5˚

93mm(3.7 in)

Tubeless

120/90-10

130/90-10

CHENG SHIN

CHENG SHIN

56J

59J

Maximum load*

Cold tire Pressure:

Up to 90 kg

Front

Rear

90 kgload~Maximum load*

Front

Rear

Brake:

Front brake type

operation

Rear brake type

operation

Suspension:

Front suspension

Rear suspension

Shock absorber:

Front shock absorber

Rear shock absorber

Wheel travel:

Front wheel travel

Rear wheel travel

143 kg(315 lb)

2

200kpa(2.0 kg/cm

200kpa(2.0 kg/cm

200kpa(2.0 kg/cm

200kpa(2.0 kg/cm2, 29 psi)

Single disc brake

Right hand operation

Drum brake

Left hand operation

Telescopic fork

Unit swing

Coil spring/oil damper

Coil spring/oil damper

65 mm(2.56 in)

60 mm(2.36 in)

, 29 psi)

2

, 29 psi)

2

, 29 psi)

Electrical:

Ignition system

Generator system

Battery type

Battery capacity

C.D.I

Flywheel Magneto

YTX5L-BS

12V 4AH

2-2

GENERAL SPECIFICATION

SPEC

Model

Headlight type:

Bulb wattage x quantity:

Headlight

Tail/brake light

Flasher light

Licence plate light

Meter light

High beam indicator light

Oil indicator light

Turn indicator light

YW50A

Bulb

12V 35W/35W×2

12 V 5W/21W×1

10W×4

5W×1

3.4W×1/1.7W×1

1.7W×1

1.7W×1

1.7W×1

2-3

MAINTENANCE SPECIFICATION

MAINTENANCE SPECIFICATION

ENGINE

SPEC

Item

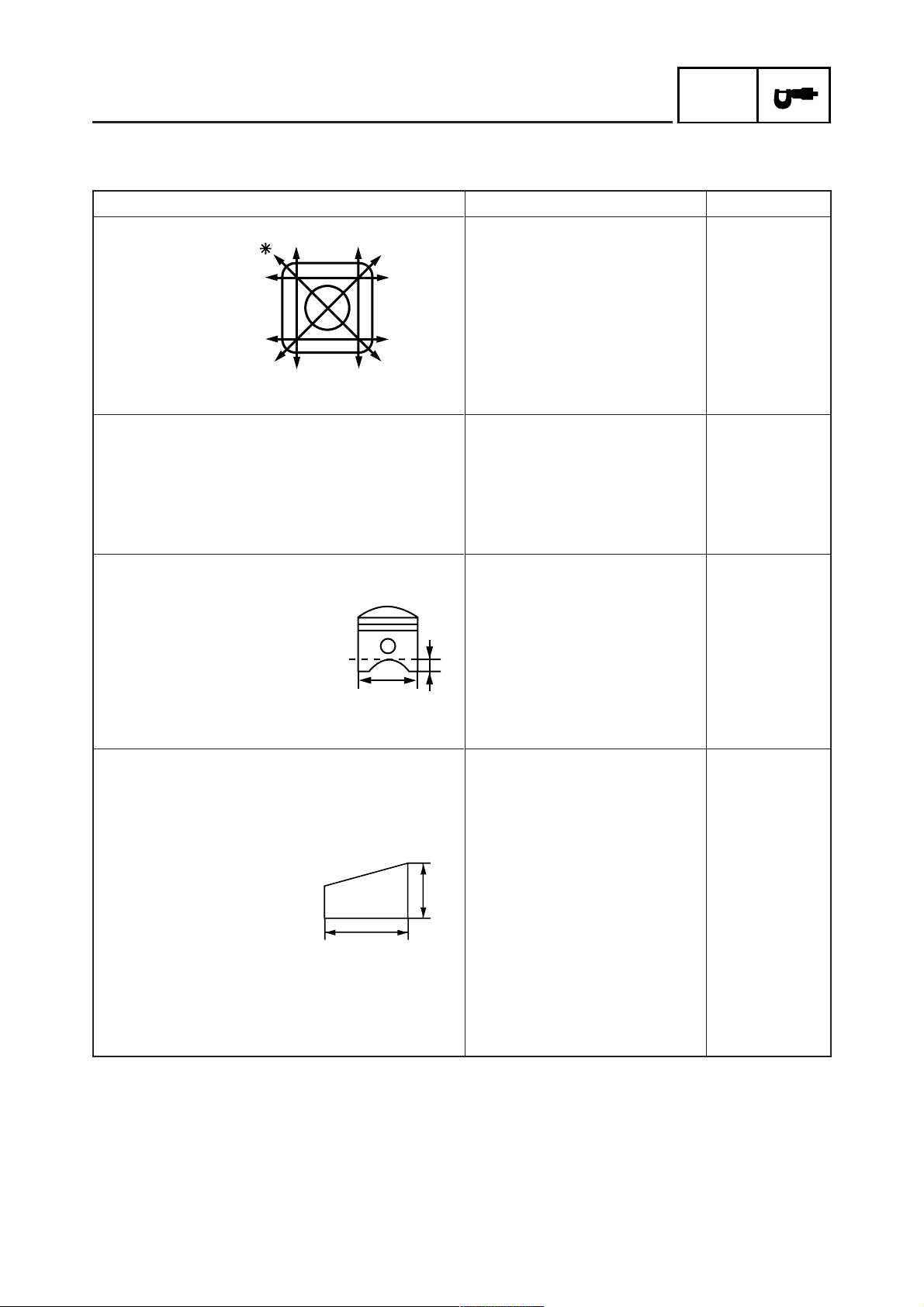

Cylinder head:

Warp limit

*Lines indicate straightedge measurement

Cylinder:

Bore size

Taper limit

Out of round limit

Piston:

Piston to cylinder clearance

Piston size “D”

Measuring point “H”

Piston pin bore inside diameter

Piston pin outside diameter

D

...

40.000~40.014mm

(1.5748~1.5754 in)

...

...

0.035~0.040 mm

(0.0014~0.0016 in)

39.958~39.972 mm

(1.5731~1.5737 in)

5 mm(0.2 in)

H

10.004~10.015 mm

(0.3939~0.3943 in)

9.996~10.000 mm

(0.3935~0.3937 in)

Standard

Limit

0.03 mm

(0.0012 in)

40.10 mm

(1.5787 in)

0.05 mm

(0.0020 in)

0.03 mm

(0.0012 in)

0.10 mm

(0.0039 in)

...

...

10.045 mm

(0.4 in)

9.975 mm

(0.39 in)

Piston Ring:

Sectional Sketch (B × T)/Type

Top Ring

2nd Ring

End Gap (Installed):

Top Ring

2nd Ring

Side Clearance ( Installed):

Top Ring

2nd Ring

1.2 × 1.6 mm/ keystone

(0.05 × 0.06 in)

1.2 × 1.6 mm/ keystone

(0.05 × 0.06 in)

0.15~0.35 mm

(0.005~0.01 in)

0.15~0.35 mm

(0.005~0.01 in)

0.03~0.05 mm

(0.0012~0.0020 in)

0.03~0.05 mm

(0.0012~0.0020 in)

0.6 mm(0.02 in)

0.6 mm(0.02 in)

0.1 mm(0.0039 in)

0.1 mm(0.0039 in)

2-4

MAINTENANCE SPECIFICATION

SPEC

Item

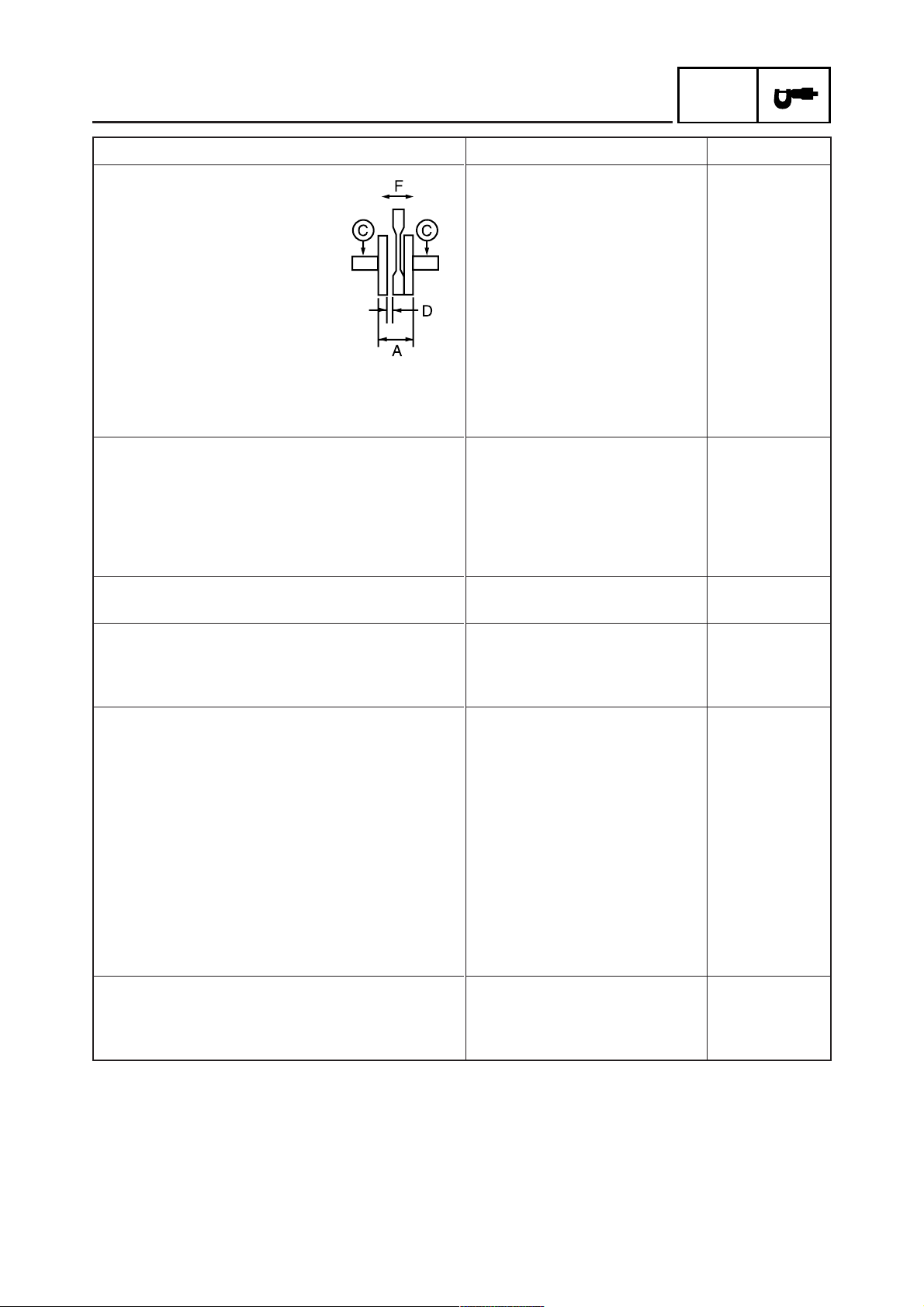

Crankshaft:

Crank Width “A”

Run Out Limit “C”

Connecting Rod Big End Side

Clearance “D”

Small End Free Play “F”

Automatic centrifugal clutch:

Clutch shoe thickness

Clutch housing inside diameter

Clutch shoe spring free length

Clutch - in revolution

Clutch - stall revolution

V-belt:

V-belt width

Standard

37.90~37.95 mm(1.49~1.49 in)

0.03 mm(0.0012 in)

0.2~0.5 mm

(0.0029~0.020 in)

0.4~0.8 mm

(0.016~0.031 in)

4.0 mm(0.16 in)

105 mm

(4.13 in)

94 mm(3.7 in)

3,300~3,700 r/min

5,500~6,500 r/min

16.6 mm(0.65 in)

Limit

...

...

1.0 mm(0.04 in)

...

2.5 mm(0.1 in)

105.5 mm

(4.15 in)

91 mm(3.58 in)

...

...

14.6 mm(0.57 in)

Kick Starter:

Type

Kick Clip Tension

Carburetor:

I.D. Mark

Main Jet (M.J.)

Needle jet (NJ)

Jet Needle-clip Position (J.N.)

Main Air Jet ( M.A.J.)

Cutaway (C.A.)

Pilot Jet (P.J.)

Bypass

Valve Seat Size (V.S.)

Starter Jet (G.S.)

Float Height

Fuel level height

Engine Idling Speed

Reed Valve:

Thickness

Valve Stopper Height

Valve bending limit

Ratchet type

1.5~2.5 N (0.15~0.25 kgf)

(0.34~0.56 lb)

5DA-01

#80

2.085

3N24-3/5

2.0

3.5

#44

0.8

1.8

#48

15 ~17 mm(0.59 ~ 0.67 in)

3.0~4.0 mm(0.12 ~0.16 in)

1,750~1,850 r/min

0.150~0.154 mm(0.059~0.0060 in)

6.0~6.4 mm(0.24~0.25 in)

0.2 mm (0.0078)

2-5

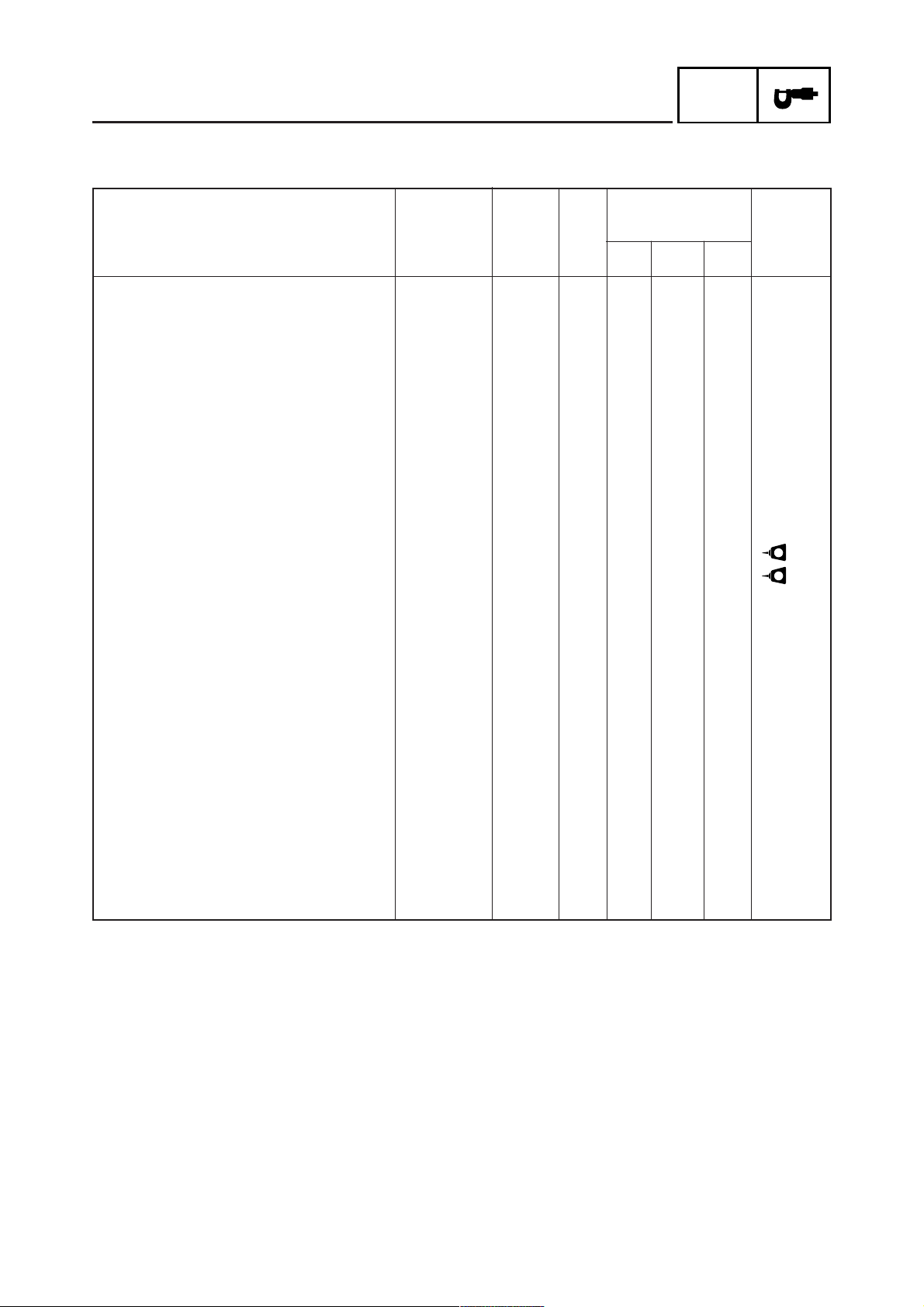

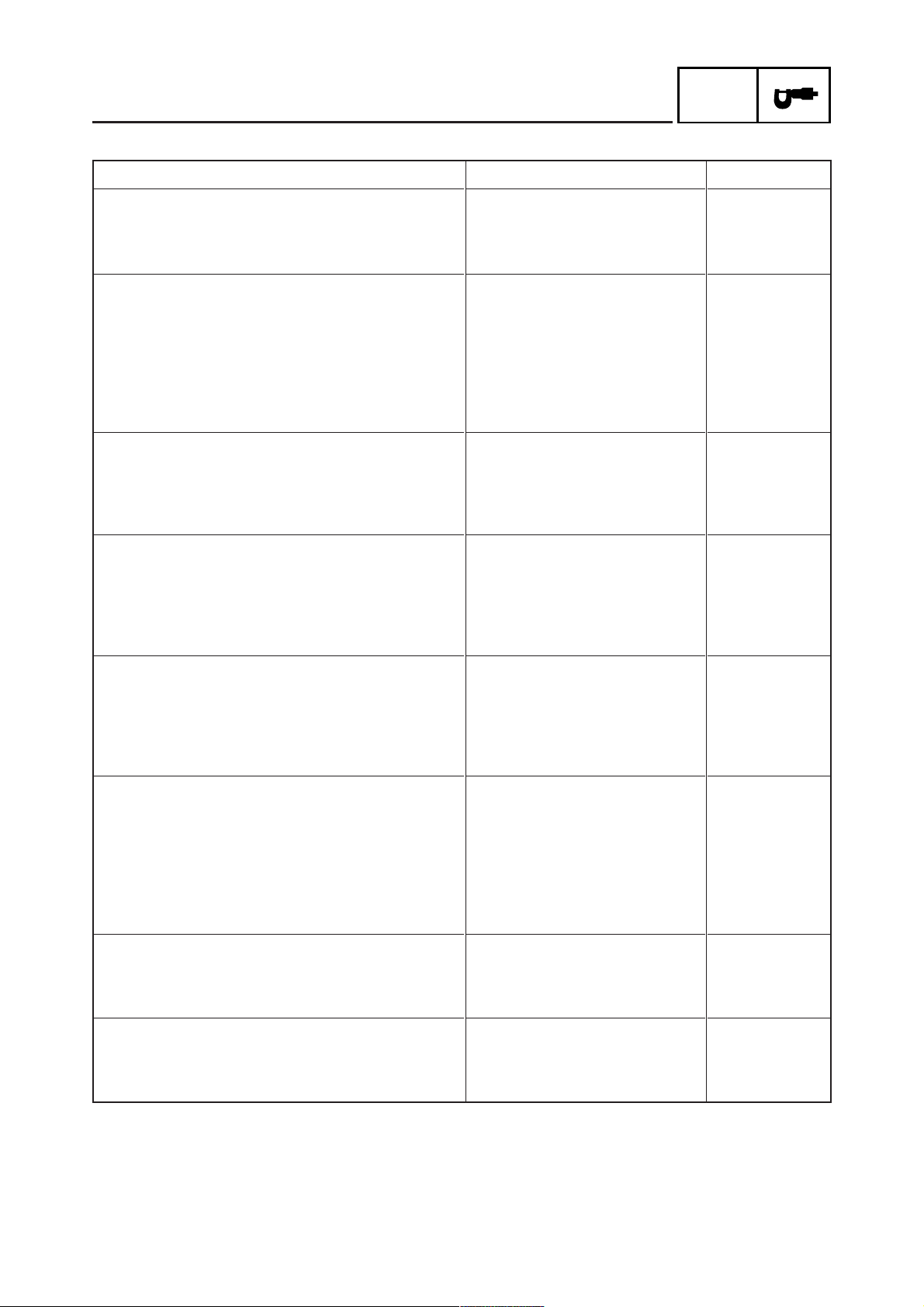

TIGHTENING TORQUES

LT

LT

ENGINE

MAINTENANCE SPECIFICATION

Tightening

Part name

Thread

size

Q’ty RemarksPart to be tightened

Nm m•kg ft•lb

SPEC

torque

Spark plug

Cylinder head and cylinder

Cylinder

Air shroud 1

Air shroud 1×2

Fan

Autolube pump

Reed valve

Air filter

Carburetor cap

Exhaust pipe

Muffler

Exhaust protector

Protector

Crankcase 1×2

Transmission case cover

Crankcase cover 1(left)

Bolt(case2)

Crankcase cover2(left)

Drain bolt

Oil plug

Idle gear plate

Kick crank

Starter motor

Clutch housing

Clutch weight

Magnet base

C.D.I. rotor

—

Nut

Stud bolt

Screw

Screw

Screw

Screw

Bolt

Screw

Screw

Screw

Bolt

Bolt

Screw

Bolt

Bolt

Bolt

Screw

Bolt

Bolt

Plug

Screw

Bolt

Bolt

Nut

Nut

Screw

Nut

M 14

M 7

M 7

M 6

6.0

M 6

M 5

M 6

M 6

M 4

M 6

M 8

M 6

M 6

M 6

M 6

M 6

M 6

M 6

M 8

M 14

M 6

M 6

M 6

M 10

M 10

M 6

M 10

1

4

4

3

1

3

2

4

2

2

2

2

3

1

6

6

12

1

3

1

1

2

1

2

1

1

2

1

20

14

10

7

2

7

4

11

9

2

9

26

11

9

12

12

12

7

7

18

3

8

9

13

40

30

8

38

2.0

1.4

1.0

0.7

0.2

0.7

0.4

1.1

0.9

0.2

0.9

2.6

1.1

0.9

1.2

1.2

1.2

0.7

0.7

1.8

0.3

0.8

0.9

1.3

4.0

3.0

0.8

3.8

14

10

7

5.1

1.4

5.1

2.8

8.0

6.5

1.4

6.5

18.2

8.0

6.5

8.4

8.4

8.4

5.1

5.1

13

22

5.8

6.5

9.4

29

22

5.8

27

2-6

CHASSIS

MAINTENANCE SPECIFICATION

SPEC

Item

Steering system:

Steering bearing type

No /size of steel balls: Upper

Lower

Front suspension:

Front fork travel

Fork spring free length

Fork length (Installed)

Spring rate (K1)

(K2)

Inner tube vend limit

Rear suspension:

Shock absorber stroke

Shock absorber free length (Installed)

Spring free length (Installed)

Spring rate (K1)

Front wheel:

Type

Rim size

Rim material

Rim runout limit radial

lateral

Standard

Ball and race bearing

22 pcs

19 pcs

70 mm(2.8 in)

236.6 mm(9.31 in)

212.1 mm(8.35 in)

15.68 Nm/mm(1.6 kg/mm,90lb/in)

23.5 Nm/mm(2.43 kg/mm,136lb/in)

...

55 mm(2.2 in)

281.8 mm(11.1 in)

159.8 mm(6.29 in)

71.15 N/mm(7.26 kg/mm,407lb/in)

Cast wheel

MT3.50×10

Aluminum

...

...

Limit

...

...

...

...

233.6 mm

...

...

0.2 mm

(0.008 in)

...

...

...

...

...

...

...

...

1 mm(0.04 in)

1 mm(0.04 in)

Rear wheel:

Type

Rim size

Rim material

Rim runout limit radial

lateral

Front disc brake:

Type

Disc outside diameter × thickness

Pad thickness

Master cylinder inside diameter

Caliper cylinder outside diameter

Brake fluid type

Rear drum brake:

Type

Drum inside diameter

Shoe thickness

Brake lever:

Brake lever free play (front at lever side)

Brake lever free play (rear)

Throttle cable free play

Cast wheel

MT3.50×10

Aluminum

...

...

Single

180×4.0mm

(7.1×0.16 in)

6 mm(0.24 in)

11 mm(0.4 in)

34.93 mm(1.38 in)

DOT #4(or DOT #3)

Leading, trailing

130 mm(5.12 in)

4 mm(0.16 in)

2~5 mm(0.08~0.20 in)

10~20 mm(0.39~0.79 in)

3~5 mm(0.12~0.20 in)

...

...

...

1 mm(0.04 in)

1 mm(0.04 in)

...

180×3.5 mm

(7.1×0.14in)

0.8 mm(0.03 in)

...

...

...

...

131 mm(5.16 in)

2 mm(0.08 in)

...

...

...

2-7

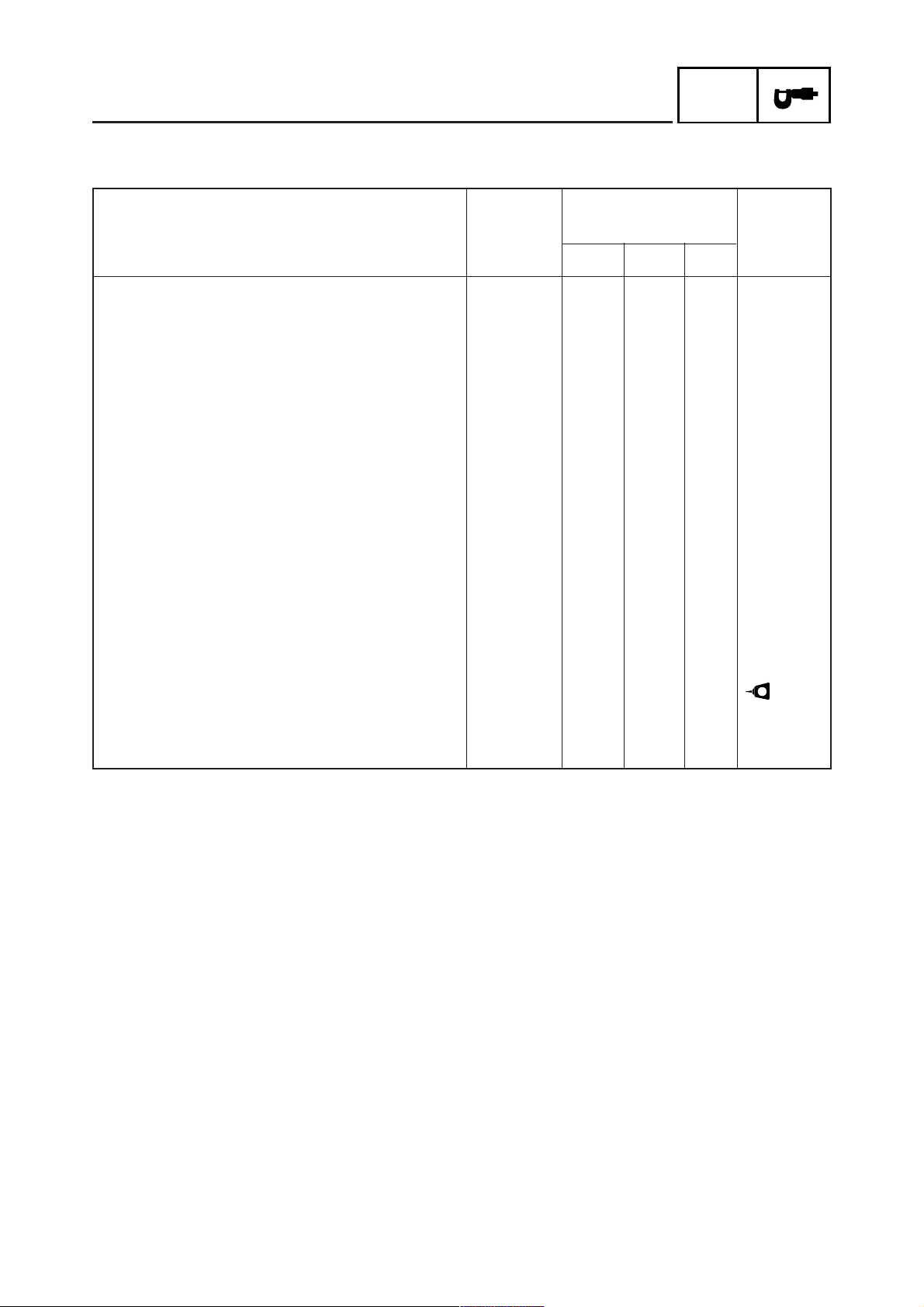

TIGHTENING TORQUES

LT

CHASSIS

MAINTENANCE SPECIFICATION

SPEC

Part to be tightened

Frame and engine bracket

Engine bracket, compression rod and engine

Rear carrier

Rear shock absorber and frame

Rear shock absorber and engine

Steering ring nut

Handle holder and steering shaft

Brake hose and master cylinder

Fuel tank

Fuel cock

Fuel sender

Box

Seat lock assembly

Plastic parts & cover

Footrest board

Front wheel axle and nut

Rear wheel axle and nut

Rear brake cam lever

Front brake caliper and front fork

Brake disc and hub

Brake hose and caliper

Brake caliper and bleed screw

Thread

size

M 12

M 10

M 6

M 10

M 8

M 25

M 10

M 8

M 6

M 6

M 5

M 6

M 6

M 5

M 6

M 10

M 14

M 6

M 8

M10

M 8

M 5

Tightening

torque

Nm m•kg ft•lb

84

45

13

30

16

22

43

20

10

7

4

7

7

2

7

70

120

10

23

20

23

6

8.4

4.5

1.3

3.0

1.6

2.2

4.3

2.0

1.0

0.7

0.4

0.7

0.7

0.2

0.7

7.0

12.0

1.0

2.3

2.0

2.3

0.6

61

31

9.4

22

12

16

37

14

7

5.1

2.9

5.1

5.1

1.4

5.1

51

87

7.2

16.6

14.5

16.6

4.3

Remarks

See

”page3-18”

2-8

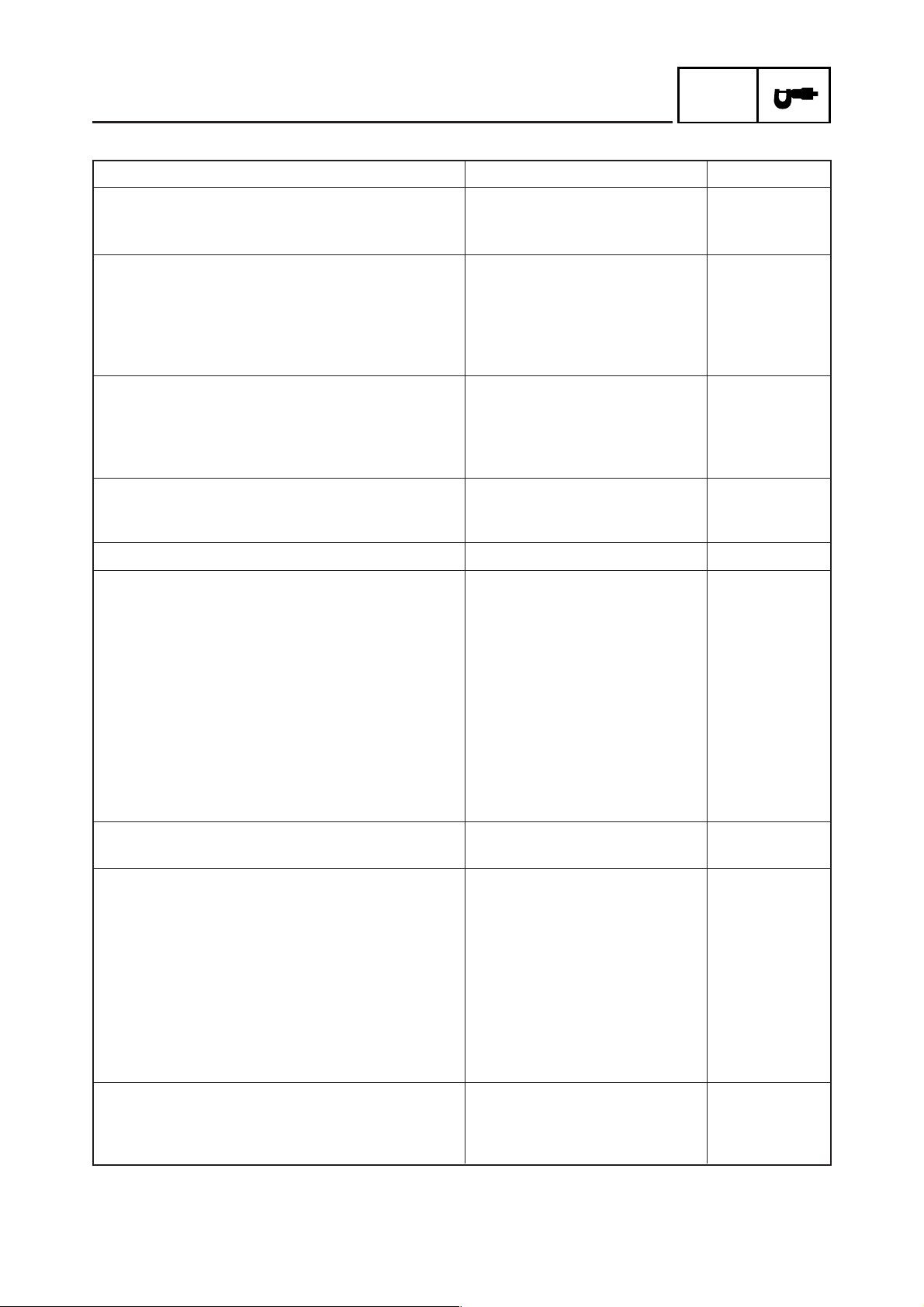

ELECTRICAL

MAINTENANCE SPECIFICATION

SPEC

Item

Ignition timing:

Ignition timing (B.T.D.C.)

Advanced type

C.D.I.:

Pickup coil resistance/color

Source coil resistance/color

C.D.I. unit model/manufacturer

Ignition coil:

Model/manufacturer

Minimum spark gap

Primary winding resistance

Secondary winding resistance

Spark plug cap:

Type

Resistance

Charging System/Type:

C.D.I. Magneto:

Model/Manufacturer

Nominal output

Charging current

Charging voltage

Charging Coil Resistance (Color)

Lighting Coil Resistance (Color)

Lighting Voltage

Rectifier:

Model/Manufacturer

Capacity

Withstand voltage

Standard

14˚ at 5,000 r/min

Fixed

248 ~ 372Ω at 20˚C (68˚F)

(W/R-W/L)

640 ~ 960 Ω at 20˚C (68˚F)

(B/ R-G/W)

5PJ/TIIC

4WX/TIIC

6 mm (0.24 in)

0.32~0.48 Ω at 20˚C (68˚F)

5.68~8.52kΩ at 20˚C (68˚F)

Resin

5 kΩ

Flywheel magneto

5PJ/TIIC

12V 85W/5,000 rpm

0.6A at 3,000r/min

1.2A at 8,000r/min

13~14V at 4,000 rpm

0.48~0.72 Ω (White-Black)

0.4~0.6 Ω (Yellow/Red- Black)

12~15V (3,000~8,000 rpm)

3GF/Taichung

8A

18V

limit

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

Battery:

Specific gravity

Electric starter system:

Type

Starter motor:

Model/manufacturer/ID number

Output

Armature coil resistance

Brush overall length

Spring force

Commutator diameter

Mica undercut (depth)

Starter relay:

Model/manufacturer

Amperage rating

Coil resistance

1.320

Constant mesh type

4WX/shulin

0.14 kw

0.0648 ~ 0.0792 Ω at 20˚C (68˚F)

6.5 mm (0.26 in)

5.49 ~ 8.24 N

(360~540 g) (12.69~19.04 oz)

16.1 mm (0.63 in)

1.05 mm (0.04 in)

4WX/Shulin

20A

54~66 Ω

2-9

...

...

...

...

...

3 mm (0.12 in)

400g

15.1 mm (0.59 in)

...

...

...

...

Loading...

Loading...