CONTENTS

GENERAL

PERIODIC INSPECTIONS

ADJUSTMENTS

ENGINE

CARBURETION

INFORMATION

OVERHAUL

AND

CHASSIS

ELECTRICAL

APPENDICES

CHAPTER

1.

GENERAL INFORMATION

MACHINE

Frame serial

Engine

(

SPECIAL

For

For

For

For

Additional

IDENTIFICATION

number

serial

TOOLS

tune-up

engine

chassis

electrical

number

........................................................

.........................................................

service

service

components

tools

and

..............................................

..................................................

.................................................

.....................•..............................

...................................................

.............................................

supplies

..........................................

1-1

1-1

1-1

1-2

1-2

1-2

1-3

1-4

1-4

GENERAL

INFORMATION

MACHINE

Frame serial

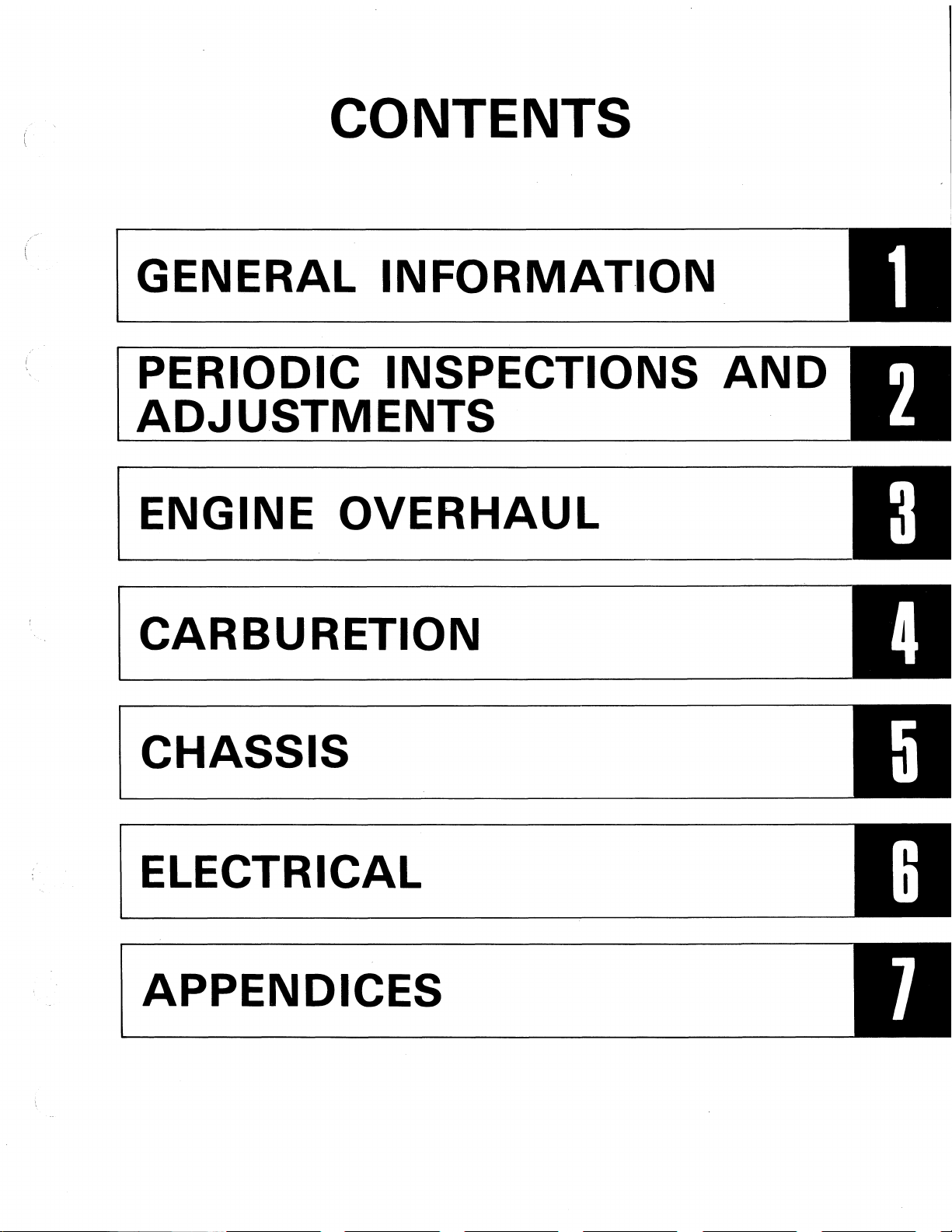

The frame serial number is stamped into the

right-sde

1. Frame serial number

NOTE:

The first three digits

model identification; the remaining digits are

the unit production number.

IDENTIFICATION

number

of

the steering head pipe.

______________________

of

these numbers are

__

for

Engine serial

The engine serial number is stamped into the

elevated part

engine.

number

of

the right rear section

of

the

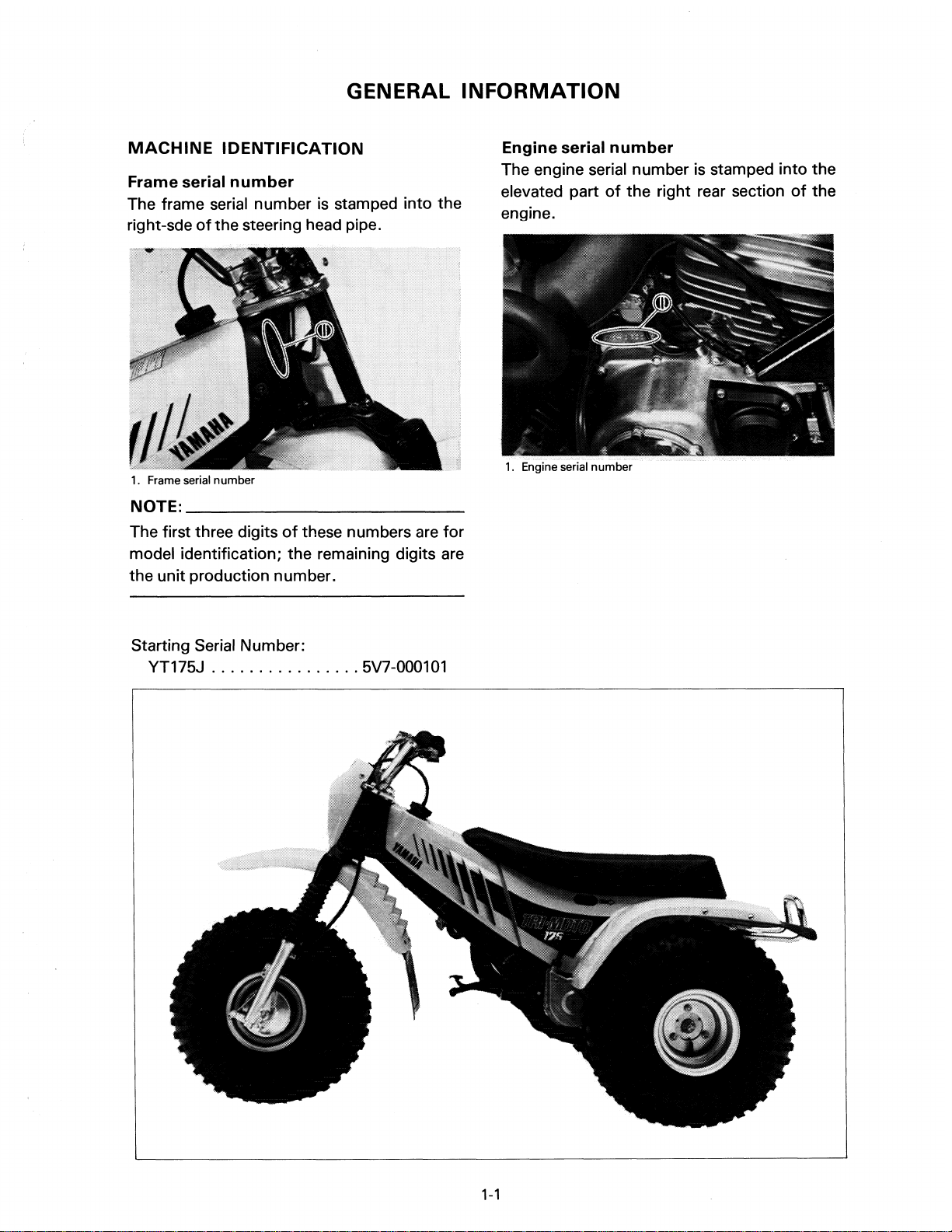

Starting Serial Number:

YT175J

................

5V7-000101

1-1

SPECIAL TOOLS

The proper special tools

complete and accurate

assembly. Using the correct special tool will

help prevent damage caused by the

improper tools or improvised techniques.

Fortune-up

1.

Timing light

2.

Tachometer

For

engine

1.

Dial gauge

service

are

necessary

tune-up

use

for

and

of

PIN 90890-03002-00

Tools

timing.

1,

2,

and 3

4.

Crankcase separation tool

are

PIN 90890-01135-00

use

to

set the ignition

2.

Dial gauge stand

PIN 90890-01256-00

This tool is use

as

remove the crankshaft from either case.

5.

Crank installer

to

split the crankcase

pot

PIN 90890-01275-00

6.

Crank installer bolt

PIN 90890-01275-00

as

well

3.

Dial gauge needle

PIN 90890-03099-00

1-2

7. Spacer

PIN

90890-01288-00

8. Crank installer bolt adapter

PIN

90890-01278-00

10.

Flywheel holding tool

PIN

90890-01235-00

Use

this tool

to

hold the flywheel magneto

while removing or tightening the flywheel

magneto securing nut.

For

chassis

1.

Steering

PIN

service

nut

wrench

90890-01051-00

Tools

5,

crankshaft.

9.

Flywheel puller

PIN

This tool

magneto.

6,

7, and 8 are

90890-01189-00

is

use

to

remove the flywheel

use

to

install the

Use

this wrench

to

put the proper tension on

the steering head bearing.

2. Front-fork-cylinder holder

PIN

90890-01300-00

to

This tool is used

loosen and tighten the

front fork cylinder holding bolt.

1-3

For

electrical

The

use

of

these tools

Chapter

6.

1 . Pocket tester

PIN

90890-03104-00

2. Electro tester

PIN

90890-03021-00

components

are

described in

Additional

1.

Thickness gauge set

tool

and

supplies

2. Torque wrench

3.

Tire pressure gauge

4. Fluid mesuring cup

5.

Micrometer

6. Slide caliper

7. Cylinder gauge

8. Magnetic stand

9.

Grease gun

10.

Yamalube 4-cycle oil

11.

Yamalube 2-cycle oil

12. Yamabond

#4

13. Yamaha chain and cable lube or SAE

10W30

14. Medium

motor

weight

oil

wheel bearing grease

15. Locktit stud N'bearing mount (Red)

1-4

CHAPTER

2.

PERIODIC INSPECTIONS

INTRODUCTION

MAINTENANCE

ENGINE

................................................................

Spark

Fuel

Over

Idle

Throttle

Throttle

Autolube

Minimum

Air

Engine

Checking

Transmission

Checking

plug

line

............................................................

flow

chamber

speed

cable

lever

pump

pump

bleeding

oil

....................................

the

ignition

AND

.........................................................

INTERVALS

..........................................................

...................................................

..........................................................

........................................................

........................................................

cable

stroke

.........................................................

water

oil

release

.....................................................

timing

CHART

adjustment

check

valve

..............................................

......................................

......................................

and

adjustment

.......................................

............................

ADJUSTMENTS

'.'

.....................

2-1

2-1

2-3

2-3

2-3

2-3

2-3

2-3

2-4

2-4

2-4

2-5

2-6

2-6

2-6

2-7

CHASSIS

ELECTRICAL

...............................................................

Air

cleaner

Front

Rear

brake

brake

Brake

Drive

Drive

Drive

Steering

Wheel

Fuel

Tires

Cable

Brake

Headlight

Headlight

adjustment

chain

chain

chain

bearings

cock

..............................................................

inspection

and

..........................................................

shoe

inspection

pad

inspection

....................................................

tension

tension

cleaning

head

..........................................................

change

...........................................................

bulb

beam

check

adjustment

and

adjustment

.....................................................

and

lubrication

pedals/front

replacement

adjustment

...........................................

.............................................

............................................

........................................

lubrication

............................................

..........................................

..........................................

...................................

......................................

and

rear

brake

levers

.....................

2-8

2-8

2-8

2-8

2-9

2-11

2-11

2-11

2-11

2-12

2-13

2-13

2-14

2-14

2-15

2-15

2-15

PERIODIC INSPECTIONS

INTRODUCTION

AND

ADJUSTMENTS

This chapter includes

all

information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced.

This information applies to vehicles already

in

service and to

new

vehicles that are being

prepared for sale. All service technicians should be familiar with this entire chapter.

MAINTENANCE

The following charts should be considered strictly

tion intervals. You must take into consideration

a variety

quirements.

all

of

individual uses. This time schedule should be altered

For

parts must be lubricated much more frequently that shown on the chart to avoid damage

INTERVALS CHARTS

example, if the machine

as

a guide

~hat

weather, terrain, geographical location, and

is

continually operated

to

general maintenance and lubrica-

to

match individual owner's re-

in

an

area

of

high humidity, then

caused by water to metal parts.

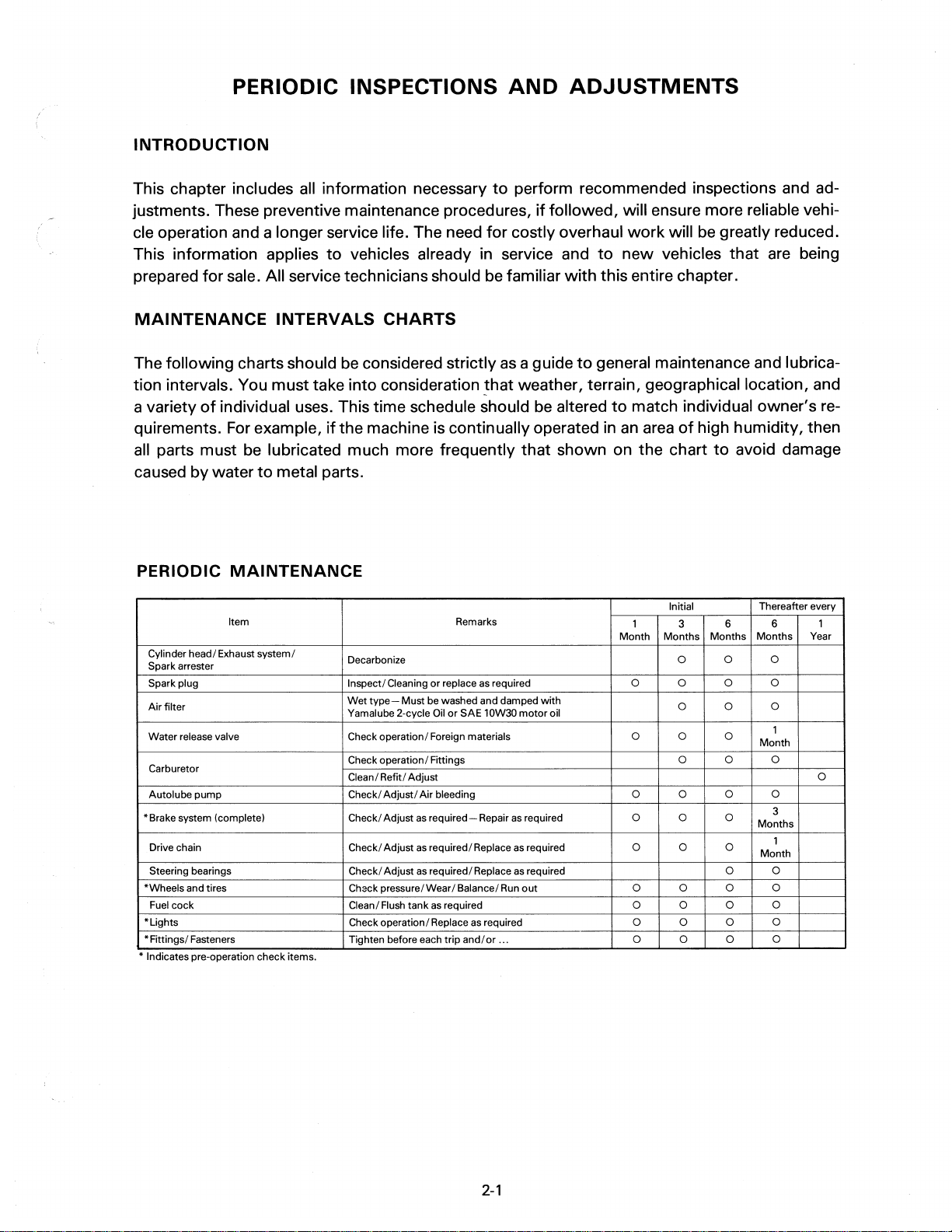

PERIODIC

Cylinder head/ Exhaust

Spark arrester

Spark plug Inspect/ Cleaning

Air

filter

Water

release valve Check operation/ Foreign materials

Carburetor

Autolube

'Brake

system (complete)

Drive chain Check/ Adjust

Steering bearings

'Wheels

Fuel cock

"Lights

'Fittings/

• Indicates pre-operation check Items.

MAINTENANCE

Item Remarks

system/

pump

and tires Chack pressure/Wear/ Balance/

Fasteners Tighten before each

Decarbonize

or

replace

Wet

type-

Yamalube 2-cycle

Check operation/ Fittings

Clean/ Refit/ Adjust

Check/

Check/ Adjust

Check/ Adjust

Clean/ Flush tank

Check operation/Replace

Must be washed and damped

Oil

or

Adjust/

Air

bleeding 0 0 0

as

required-Repair

as

required/ Replace

as

required/ Replace

as

required 0 0

trip

as

SAE 10W30

as

required 0 0 0

and/or

Initial

1

Month

required 0 0 0

with

motor

oil

as

required

as

required 0 0 0

as

required

Run

out

... 0 0 0

3 6

Months

Months

0 0 0

0 0

0

0

0 0 0

0

0

0 0 0

Thereafter every

Months Year

0

Month

0

Months

Month

0 0

0 0

6

0

0

0

0

0

0

1

1

0

3

1

2-1

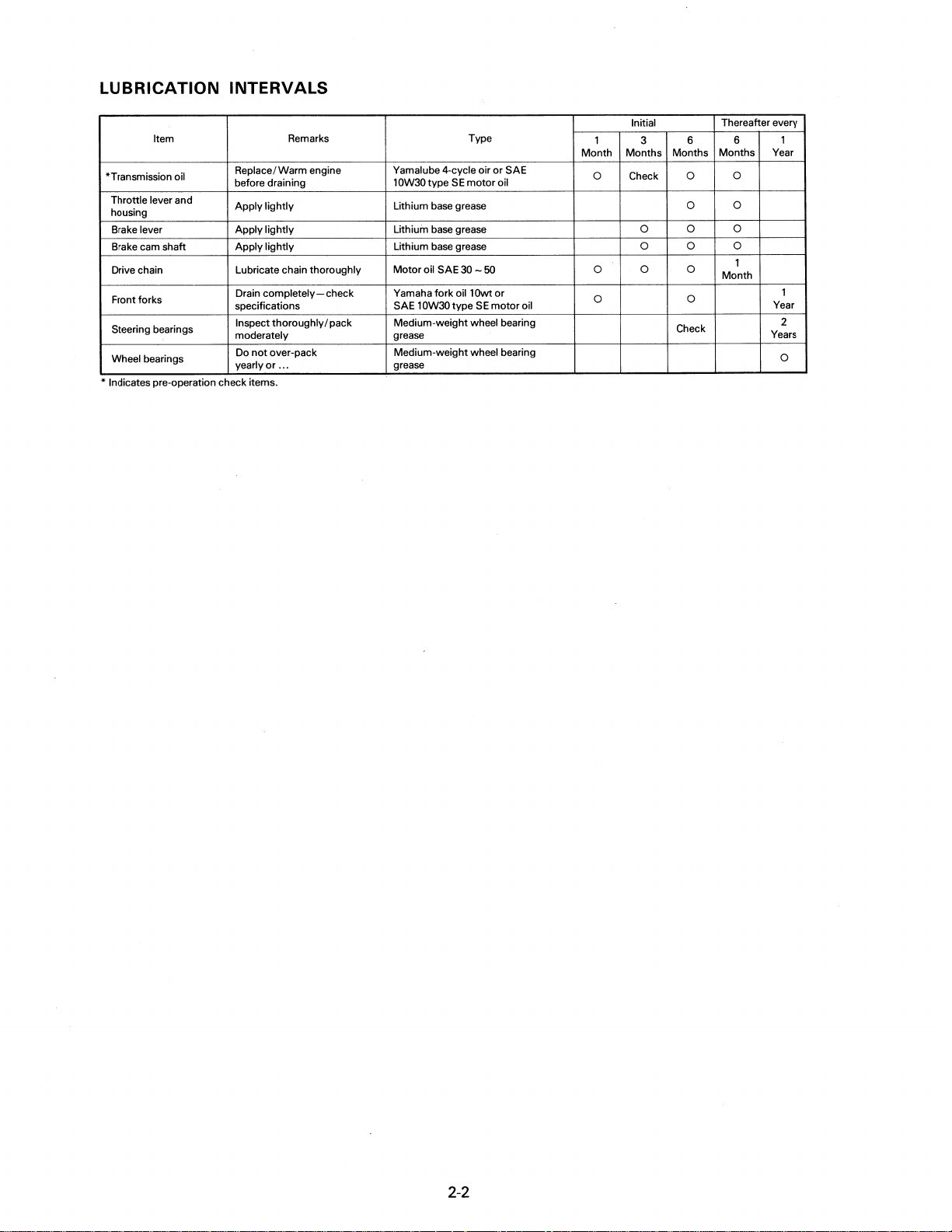

LUBRICATION INTERVALS

Item Remarks Type

"Transmission oil

Throttle lever and

housing

Brake lever

Brake cam shaft

Drive chain Lubricate chain thoroughly

Front forks

Steering bearings

Wheel bearings

" Indicates pre-operation check Items.

Replace/Warm engine Yamalube 4-cycle oir

before draining

Apply lightly

Apply

lightly

Apply

lightly

Drain

completely-check

specifications SAE 10W30 type

Inspect

thoroughly/pack

moderately grease

Do

not

over-pack Medium-weight wheel bearing

yearly

or

...

Initial Thereafter every

1

Month

Months

or

OW30

type

1

Lithium base grease

Lithium base grease

Lithium base grease 0

Motor

Yamaha

Medium-weight wheel bearing

grease

SE

oil SAE 30 - 50 0 0 0

fork

oil10wt

motor

SE

SAE

oil

or

motor

oil

0 Check

0 0

3 6

Months

0

Check

Months

0

0

0 0

0

Month

6 1

Year

0

0

0

1

Year

Years

1

2

0

2-2

ENGINE

Spark

plug

1.

Check electrode condition and wear, insulator color, and electrode gap.

2.

Clean the spark plug

if

cleaner

to

adjust the plug gap

necessary.

with

spark plug

Use

a wire gauge

to

the specifica-

tion.

3.

If

the electrode becomes

too

worn

replace the spark plug.

4. When installing the plug, always clean

the gasket surface, wipe

off

any grime

that might be rresent on the surface

the spark plug, and torque the spark

plug properly.

of

Air screw (Turns out): 1 and

2.

Start the engine and let

3.

Throttle stop screw

Turn throttle stop screw in or

achieve smooth engine operation at

specified idle speed.

±

50

,

Idling speed: 1,600

NOTE:

______________________

r/min

The pilot air and throttle stop screws

separate adjustments

justed at the same time

but

they must be ad-

to

achieve optimum

operating condition at engine idle speeds.

1/4

it

warm up.

out

to

__

are

Standard spark plug: NGK

BP7ES

Spark plug gap:

0.031

0.7 - 0.8 mm (0.028 -

in)

Spark plug tightening torque:

20Nm(2.0m·kg,14.5ft·lb)

Fuel

line

Check the fuel hoses and vacuum lines for

if

cracks or damage; replace

Over

flow

chamber

If gasoline begin

to

show

loosen the three screws from over

necessary.

up in the pipe

II

A"

flow

chamber and completely drain gasoline from

the pipe

II

A"

and chamber.

2.

Pilot air screw

nut

(at

,

1.

Throttle stop screw

Throttle

cable

Loosen cable adjuster lock

buretor) and turn cable adjuster until

specified free play is obtained. Retighten lock

nut.

Free

play: 1

-1.5

mm

(0.04 - 0.06 in)

top

of

car-

Idle

speed

1.

Turn the pilot air screw until

it

seats, then back

out

This adjustment can be made

engine stopped.

it

to

specification.

lightly

with

2-3

1.

Adjuster

2.

Lock

nut

Throttle

Loosen the lock

lever

nut

and turn the adjuster until there is the specified free play at throttle

lever.

1.

Adjuster

2.

Lock nut

Throttle lever play:

3

-5

mm

(0.12

-0.2

in)

Autolube

pump

cable

adjustment

Before adjusting the pump cable, adjust the

throttle cable free play.

1.

Adjust the throttle cable free play

of

1 -

1.5 mm (0.04 - 0.06 in) at the cable ad-

juster on the carburetor.

2. Close the throttle lever completely, then

check

plunger pin is aligned

the Autolube pump pulley.

to

see

that

the Autolube pump

with

the mark on

3.

If

the mark and pin are

not

in alignment,

loosen the cable length adjuster lock nut

on

top

of

crankcase cover and adjust

cable length until alignment is achieved.

4. Tighten adjuster lock nut.

1.

Cable

adjuster

Minimum

pump

justment

1.

While running the engine idle, observe

the pump adjust plate carefully, and

stop the engine the moment

just plate moves

2. Measure the gap

gauge between the raised boss on

pump adjust pulley and the adjust plate.

2. Lock nut

stroke

out

to

with

check

that

the limit.

the thickness

and

the ad-

ad-

the

Match mark: 0

1.

Oil

pump

2.

Pump cable

3. Adjust pulley

4.

Match mark

5.

Guide pin

1.

Adjust plate 2. Adjust pulley

3. Repeat steps

times. When the gap measured is the

largest,

be

2-4

a.

the

pump stroke is considered

at a minimum.

3.

Thickness gauge

and b. above a

few

to

NOTE:

When inserting the thickness gauge between

the adjusting plate and the adjusting pulley,

be

is

the thickness gauge into the gap.

______________________

careful so

not

Minimum pump stroke:

0.20 - 0.25

4. If clearance

adjust plate lock

plate.

5.

Remove or add an adjust shim

quired.

that

moved.

either the plate or the pulley

In

other words, do

mm

(0.008 - 0.010 in)

is

not

correct, remove the

nut

__

not

force

and the adjust

as

re-

1.

Remove the pump cover and remove

the bleed screw.

1.

Bleed screw

2. Keep the oil running

disappear~

NOTE:

________________________

out

until air bubbles

_

1.

Adjust shim

NOTE:

Thicken shims increase pump stroke and output,

output.

Air

The Autolube Pump and delivery lines must

be

________________________

thinner shims decrease pump stroke and

bleeding

bled on the following occasions:

• Whenever the Autolube tank has run

dry.

of

• Whenever any portion

system

• If the machine lies on its side after falling

over.

is

disconnected.

the Autolube

_

Check the bleed screw gasket, and

ed, replace

3.

When air bubbles are expelled completely, tighten the bleed screw and install

the

4.

Start the engine, pull the pump wire

the

maximum.

NOTE:

It is difficult

with

ly

therefore the pump stroke should

maximum.

with a new

pump

way

cover.

out

one.

to

set the pump stroke

________________________

to

bleed the distributor complete-

the

pump stroke at a minimum, and

if

damag-

be

set

to

to

all

a

_

a

5. Keep the engine running at about 2,000

r/min

distributor and delivery pipe can

pletely bled.

2-5

for

two

minutes or so, and both

be

com-

Engine

1.

oil

Place the machine on a level place and

start the engine.

Engine oil:

Yamalube 2-cycle oil or

Air-cooled 2-stroke engine oil

Oil

tank capacity:

1.3 L

(1.1

Imp

qt,

1.4 US qt)

Checking

Before starting

valve

the

water

off,

be

is

closed. Before cleaning the air

cleaner element, check

the element case.

release

sure

if

valve

to

check that the

there is impurities in

1.

Oil

tank filler cap

NOTE:

______________________

Install the oil tank filler cap and push

into the filler.

PUSH PUSH

2. Oil warning indicator light

is

When the engine oil level

proper:

The oil warning light keeps going on

about

temperatures) -

15

seconds

40

seconds (under

(under

temperatures) after the engine has

started, and then goes

When the engine oil level

off.

is

low:

The light keeps going on after the

engine has started.

If

the light bulb is burnt out:

The light will

not

come on after the

engine has started.

it

__

fully

high

low

Transmission

oil

Recommended oil:

Yamalube 4-cycle oil or

SAE 10W30

1.

Filler cap

SE

Transmission oil capacity:

Periodic oil change: 0.7 - 0.8 L

(0.6 - 0.7 Imp qt, 0.7 - 0.8 US qt)

Total: 0.8

-0.9

(0.7 - 0.81mp qt, 0.8

Transmission drain plug torque:

20

Nm (2.0 m

2-6

·kg,

motor

2. Drain plug

L

14.5ft

oil

-1.0

·Ib)

US qt)

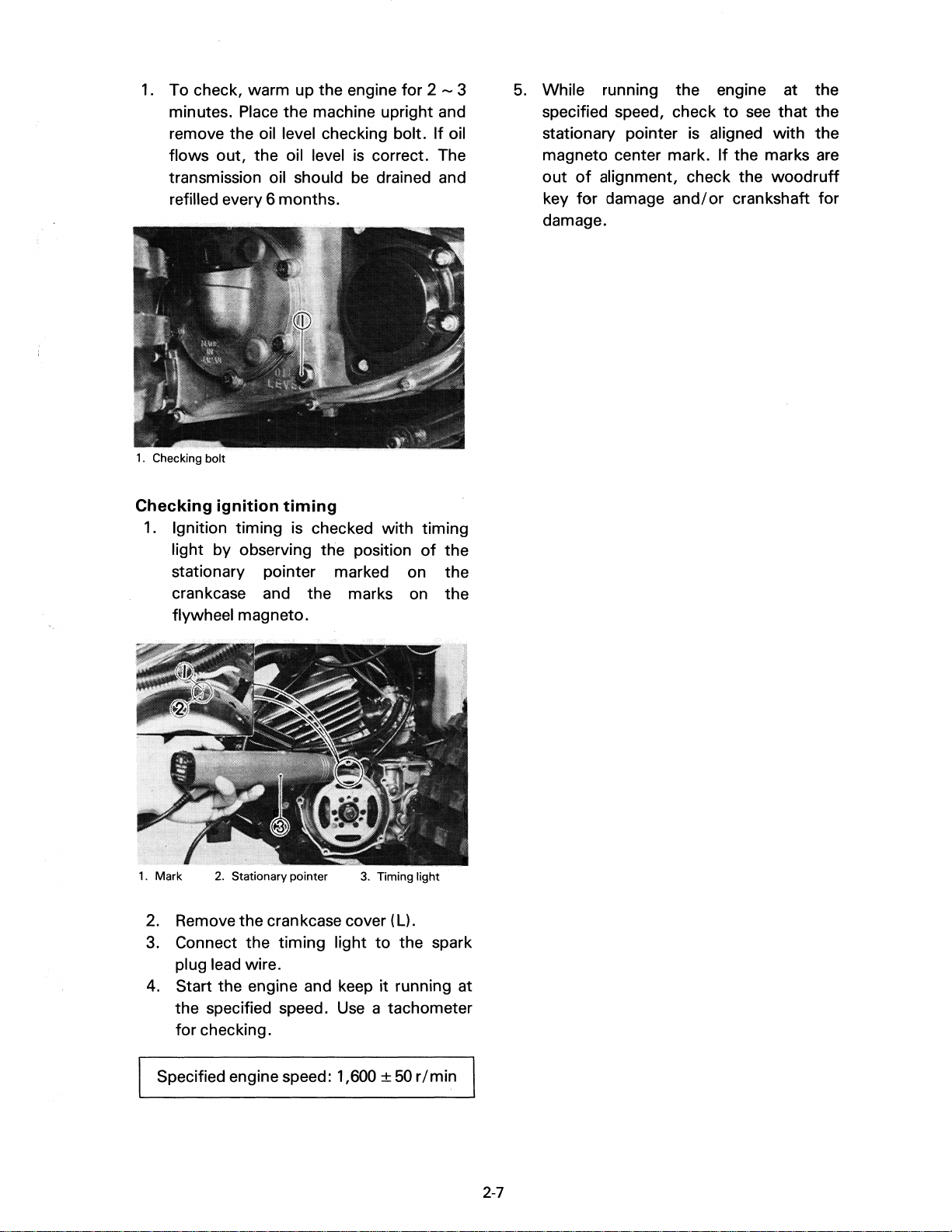

1.

To check, warm up the engine for 2 - 3

minutes. Place the machine upright and

remove the oil level checking bolt.

flows out, the oil level

transmission oil should

is

correct. The

be

drained and

refilled every 6 months.

1.

Checking bolt

If

oil

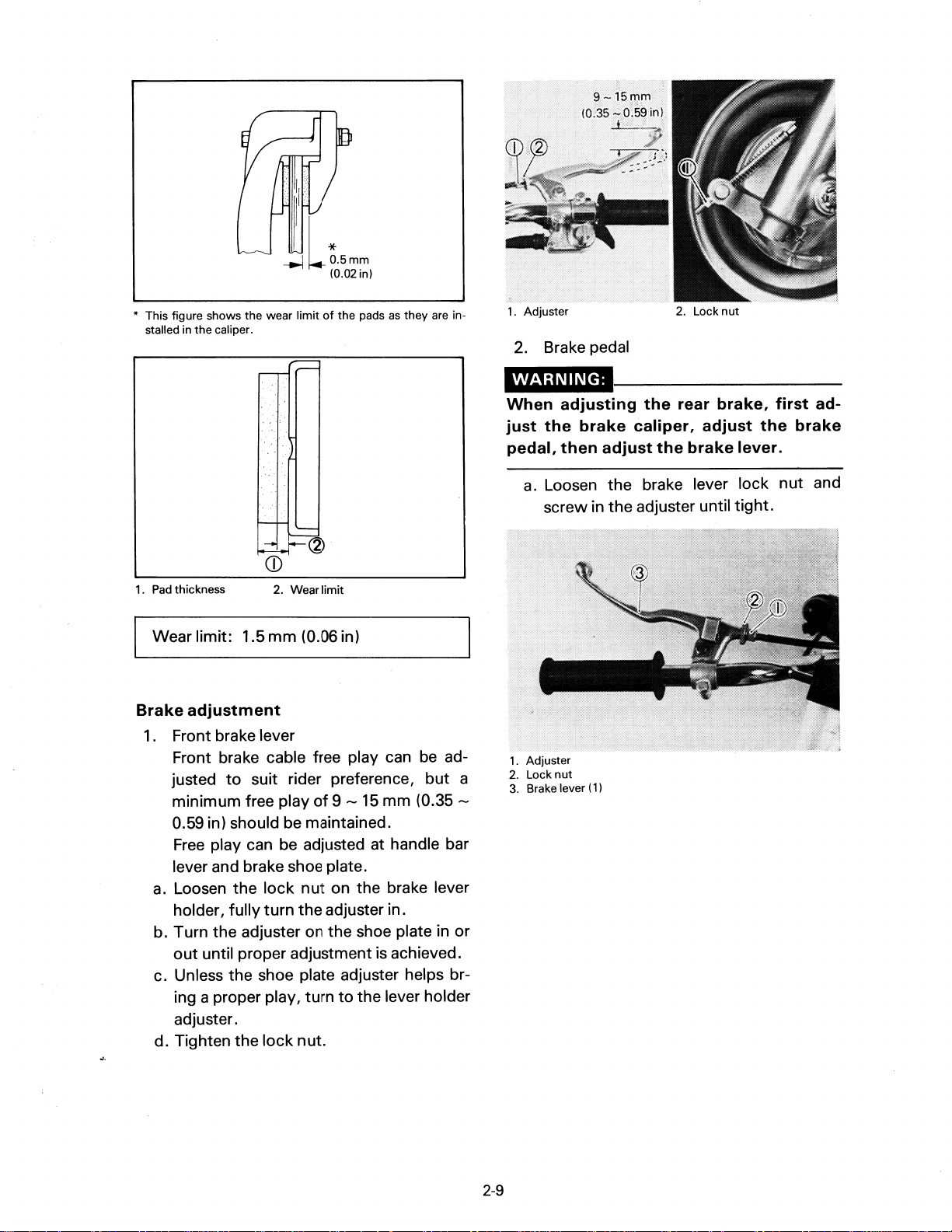

5.

While running the engine at the

specified speed, check

to

see

stationary pointer is aligned with

magneto center mark.

out

of

alignment, check the

key

for

damage

and/or

If

the marks

woodruff

crankshaft for

damage.

that

the

the

are

Checking ignition

1.

Ignition timing is checked with timing

timing

light by observing the position

stationary pointer marked on the

crankcase and the marks on the

flywheel magneto.

1.

Mark 2. Stationary pointer

2.

Remove the crankcase cover (Ll.

3.

Connect the timing light

3.

Timing light

to

plug lead wire.

4. Start the engine and keep

the specified speed.

for

checking.

it

Use

a tachometer

of

the

the spark

running at

Specified engine speed: 1,600

±

50

r / min

2-7

CHASSIS

Air

cleaner

1.

Remove the air cleaner case cap and ele-

ment assembly.

2. Wash

the

thoroughly,

3. Squeeze excess solvent

element

in

solvent.

gently,

out

and dry.

4. Pour

10W

CI

small quantity

30)

onto cleaner element and

of

motor oil (SAE

thoroughly into the porous foam

material. Element must

not

but

dripping.

be

damp with oil

of

element

but

work

cleaner

This

causing

damage.

the

buretor

element

will

allow

rapid

Additionally,

cleaner

jetting

performance

engine

removed.

unfiltered

wear

and

element

with

and

with

air

to

possible

operation

will

affect

subsequent

possible

the

air

enter,

engine

without

car-

poor

engine

overheating.

Front

brake

shoe

inspection

To check, examine the wear indicator position while depressing the brake pedal. If the

indicator reaches

to

the wear limit line,

replace the shoes.

5.

Re-install the element assembly and

case cover.

NOTE:

Each

performed, check the air inlet

case

joint rubber

fittings

thoroughly

______________________

time cleaner element maintenance is

to

of

obstructions. Check the air cleaner

to

the carburetor and manifold

for

an

air-tight seal. Tighten all fittings

to

avoid the possibility

filtered air entering the engine.

__

the cleaner

of

un-

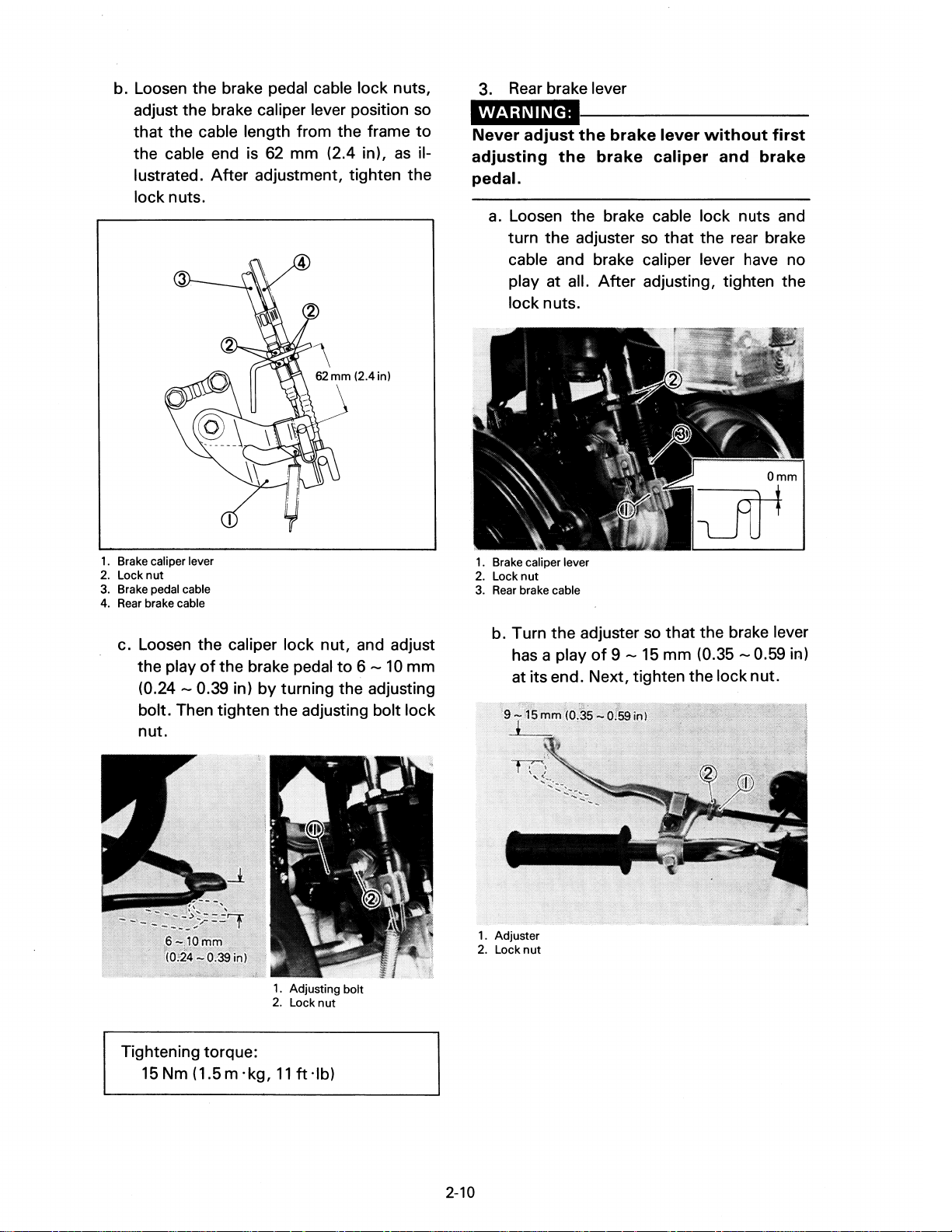

Rear

Check

brake

to

see

pad

inspection

that

the brake operates correctIy. Remove the disc cover, check the brake

pads

for

damage and wear.

If

the thickness is

less than the specified value, replace the pad

as

a set.

2-8

::

I

/1

~L~5mm

* This figure shows the wear limit

stalled in the caliper.

1.

Pad

thickness

Wear limit: 1.5

Brake

adjustment

1.

Front brake lever

Front brake cable free play can

justed

to

minimum free play

2. Wear limit

mm

suit rider preference,

(0.02 in)

of

the pads

(0.06 in)

of

9

-15

as

they

mm

be

(0.35-

0.59 in) should be maintained.

Free

play can be adjusted at handle bar

lever and brake shoe plate.

a.

Loosen the lock

nut

on the brake lever

holder, fully turn the adjuster in.

b. Turn the adjuster on the shoe plate in or

out

until proper adjustment is achieved.

c. Unless the shoe plate adjuster helps br-

ing a proper play, turn

to

the lever holder

adjuster.

d. Tighten the lock nut.

are

but

in-

ad-

a

2.

Lock

1.

Adjuster

2.

Brake pedal

nut

WARNING:

When

just

pedal,

1.

2.

3.

adjusting

the

brake

then

a.

Loosen the brake lever lock nut and

screw in

Adjuster

Lock

nut

Brakelever(l)

the

rear

caliper,

adjust

the

the

brake

adjuster until tight.

brake,

adjust

lever.

first

the

ad-

brake

2-9

b. Loosen the brake pedal cable lock nuts,

adjust the brake caliper lever position so

that the cable length from the frame

the cable end is

lustrated.

After

62

mm (2.4 in),

as

adjustment, tighten the

lock nuts.

1.

Brake caliper lever

2.

Locknut

3.

Brake pedal cable

4.

Rear

brake cable

to

il-

3.

Rear

brake lever

WARNING:

Never

adjusting

adjust

the

the

brake

brake

lever

caliper

without

and

pedal.

a.

Loosen the brake cable lock nuts and

that

turn the adjuster so

the rear brake

cable and brake caliper lever have no

play at all.

After

adjusting, tighten the

lock nuts.

~

1.

Brake caliper lever

2.

Lock nut

3.

Rear

brake cable

first

brake

Omm

c. Loosen the caliper lock nut, and adjust

of

the play

the brake pedal

(0.24 - 0.39 in)

by

turning the adjusting

to

6 -

10

mm

bolt. Then tighten the adjusting bolt lock

nut.

1.

Adjusting bolt

2.

Lock nut

Tightening torque:

15

Nm (1.5 m

'kg,

11

ft

'Ib)

b. Turn the adjuster so

of

has a play

9 -

15

that

the brake lever

mm

(0.35 - 0.59 in)

at its end. Next, tighten the lock nut.

1.

Adjuster

2.

Locknut

2-10

Drive

chain

Inspect the drive chain with both tires

touching the ground. Check the tension at

the position shown in the illustration. The

normal vertical deflection is approximately 5

-

10

mm

ceeds

sion.

5-10mm

(0.2 - 0.4 in)

1.

Inspection

tension

(0.2 - 0.4 in).

10

mm

(0.4 in), adjust the chain ten-

window

check

If

the deflection ex-

3. Tighten

Tightening torque:

46 Nm (4.6 m ·kg,

Drive

This machine has a drive chain

rubber O-rings between the chain plates.

Steam cleaning, high-pressure washes, and

certain solvent can damage these O-rings.

Use

Wipe

SAE

lubricants on the drive chain. They may con-

tain solvents

chain

only kerosene

it

30 -50

the

rear wheel hub bolts.

33

ft-lb)

cleaning

dry, and thoroughly lubricate

motor

that

and

lubrication

with

to

clean the drive chain.

oil. Do

could damage the O-rings.

not

use any other

small

it

with

Drive

chain

1.

Loosen the rear wheel hub bolts.

2. Next, adjust chain play

by turning the chain puller adjuster.

tension

adjustment

to

specification

O-RING

D

Steering

The steering assembly should be checked

periodically

1.

2.

head

adjustment

for

looseness.

Raise

the

front

end

of

the machine so

that

there is no weight on the

wheel.

Grasp

the

bottom

rock the

forward, checking for looseness in the

steering assembly bearings.

fork

of

the forks and gently

assembly backward and

front

1.

Adjuster

2-11

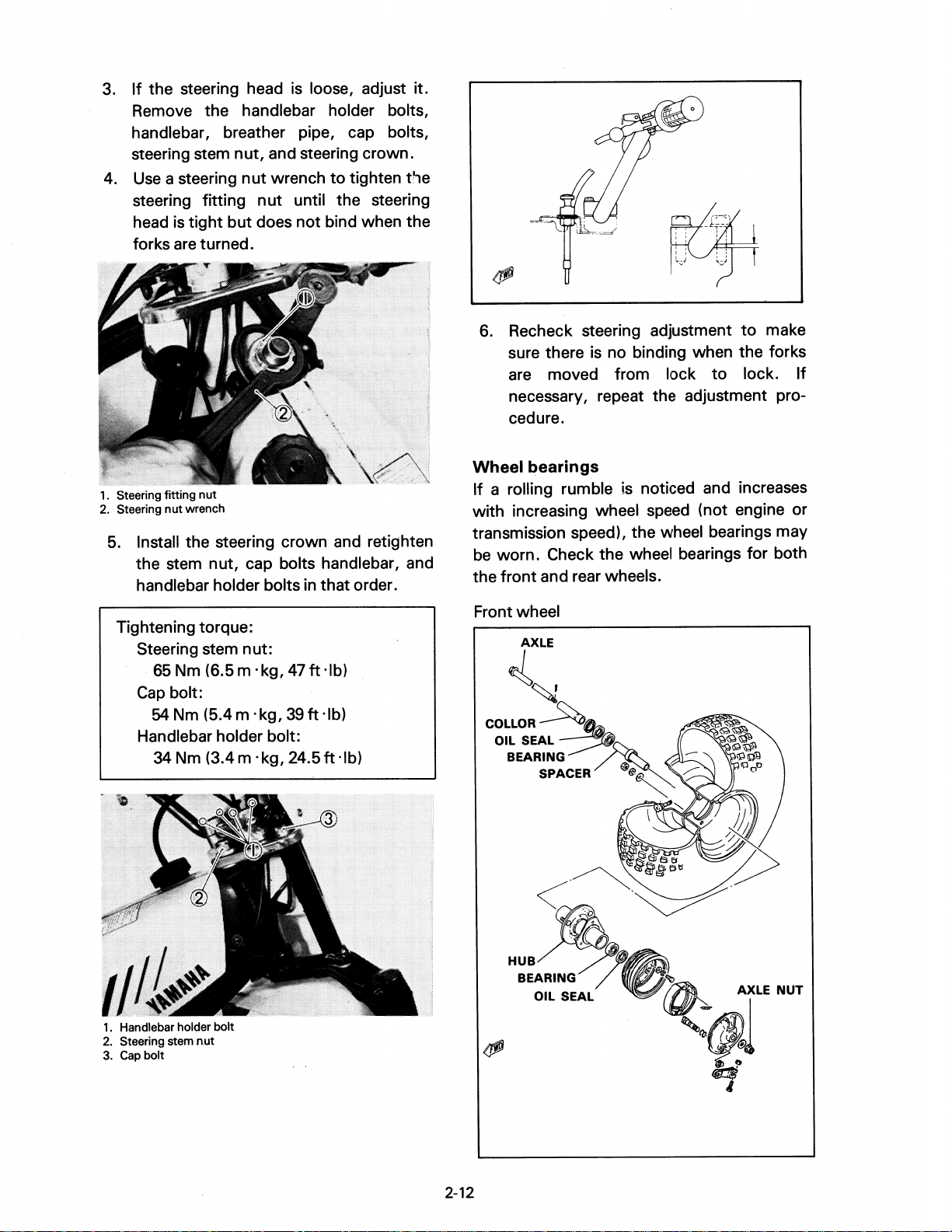

3.

If

the steering head is loose, adjust

Remove the handlebar holder bolts

handlebar, breather pipe, cap bolts,

steering stem nut, and steering crown.

Use

4.

a steering

steering fitting

head

is

forks

are

tight

nut

wrench

nut

to

tighten

until the steering

but does not bind when the

turned.

it.

t'1e

,

6.

Recheck steering adjustment

to

make

sure there is no binding when the forks

are moved from lock

to

lock.

If

necessary, repeat the adjustment procedure.

1.

Steering fitting nut

2.

Steering

5.

nut

wrench

Install the steering crown and retighten

the stem nut, cap bolts handlebar, and

handlebar holder bolts

in

that order.

Tightening torque:

Steering stem nut:

65

Nm (6.5 m . kg,

Cap

bolt:

54

Nm (5.4

m'

kg,

47

39

ft-lb)

ft

'Ib)

Handlebar holder bolt:

34 Nm (3.4

m'

kg, 24.5

ft

'Ib)

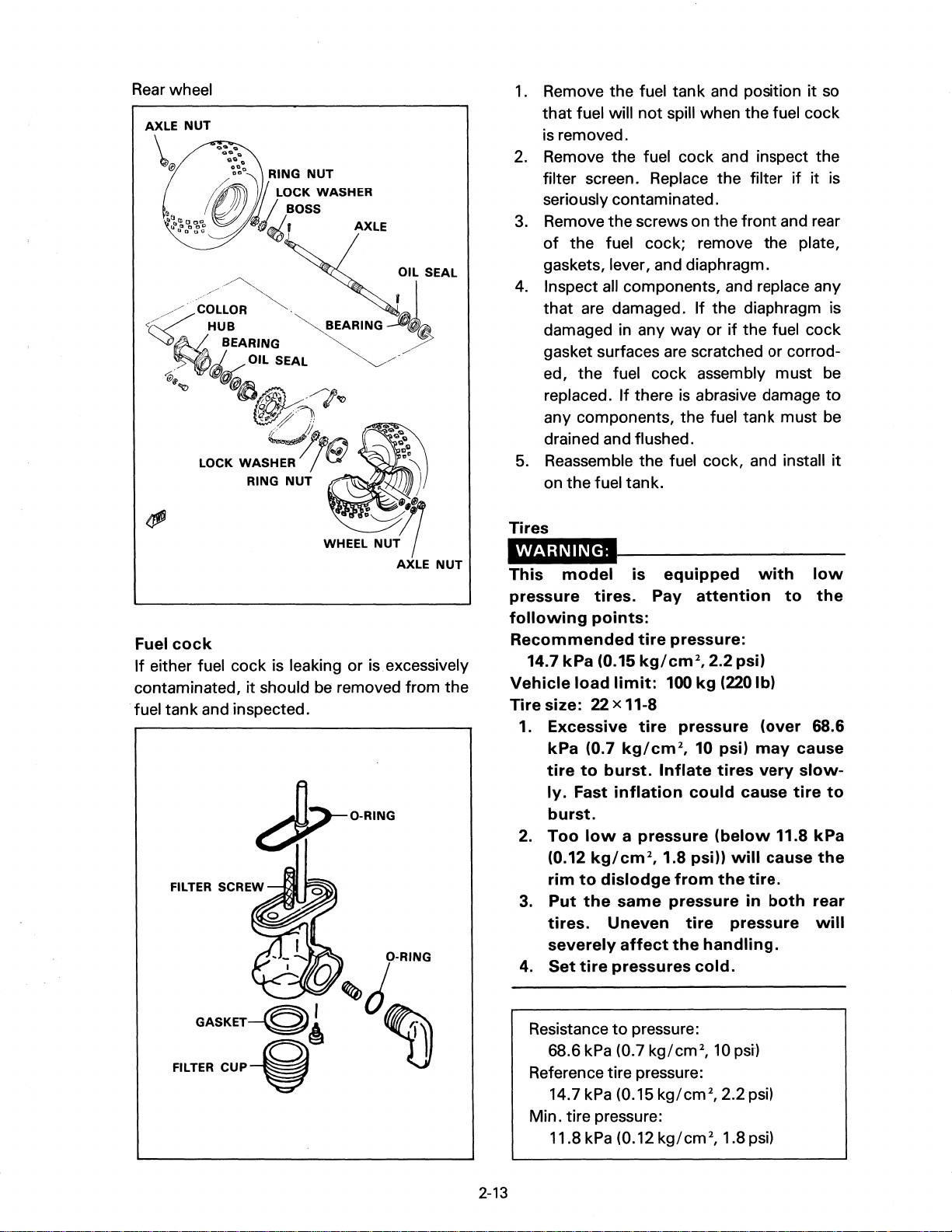

Wheel

bearings

If a rolling rumble is noticed and increases

with increasing wheel speed (not engine or

transmission speed), the wheel bearings may

be worn. Check the wheel bearings for both

front

the

and rear wheels.

Front wheel

AXLE

.{~

COLLORA~

OILSEAL~

BEARING

SPACER /

~

@~~

\ .

c:;

.

~

/

1.

Handlebar holder bolt

2.

Steering stem

3.

Cap

bolt

nut

2-12

BEARING

OIL SEAL

~

..

I

AXLE

NUT

Rear

wheel

AXLE

NUT

......

\

@

t.

•

aj.,:,g'g

......

.....

":,':,0

RING NUT

@)/

":.~~:ASHER

~4.,

/~~~.

<;:::/

~N.

HUB

BEARING /

.-;.~f(t:+'~

@"

~@l

•

.,.,

~~Pl

LOCK WASHER

RING

~EARING

OIL SEAL .

~

'/"'lotrJ

P-

"')

,,,.~

..

~

7~

NUT

AXLE

OIL SEAL

~,I

~~

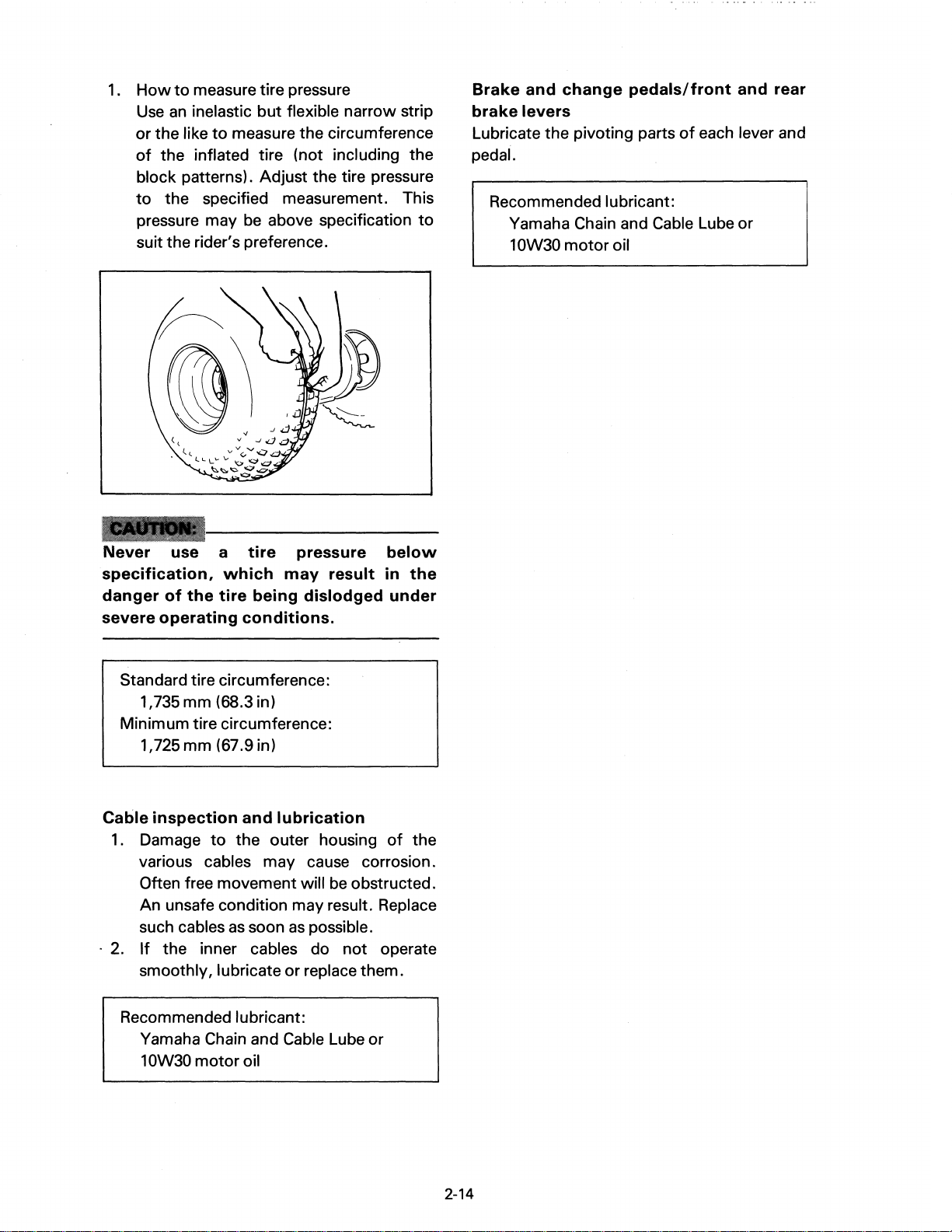

1.

Remove the fuel tank and position

that

fuel will

is removed.

2.

Remove the fuel cock and inspect the

filter screen. Replace the filter

seriously contaminated .

3.

Remove the screws on the

of

the fuel cock; remove the plate,

gaskets, lever, and diaphragm.

4.

Inspect all components, and replace any

that

are damaged.

damaged in any

gasket surfaces

ed, the fuel cock assembly must be

replaced.

any components, the fuel tank must be

drained and flushed.

5.

Reassemble the fuel cock, and install

on the fuel tank.

Tires

If

there

not

spill when the fuel cock

front

If

the diaphragm is

way

or

if

the fuel cock

are

scratched or corrod-

is

abrasive damage

it

so

if

it

is

and rear

to

it

Fuel

cock

If

either fuel cock is leaking or

contaminated,

fuel tank and inspected.

it

should be removed from the

dr~RING

- - _ O-RING

,

v..",J

is.

excessively

This

pressure

following

Recommended

Vehicle

Tire

model

tires.

points:

14.7

kPa

(0.15

load

limit:

size: 22 x 11-8

1. Excessive

kPa

(0.7

tire

to

burst.

ly.

Fast

inflation

burst.

2.

Too

Iowa

(0.12

kg/cm2,

rim

to

dislodge

3.

Put

the

tires.

severely

4.

Set

Uneven

tire

pressures

is

equipped

Pay

tire

kg/cm2,

100

tire

kg/cm2,

Inflate

pressure

1.8 psi))

same

affect

pressure

attention

pressure:

2.2 psi)

kg

(220 Ib)

pressure

10 psi)

tires

could

(below

will

from

the

tire

pressure

the

handling.

cold.

with

(over

may

very

cause

11.8

cause

tire.

in

both

low

to

68.6

cause

slow-

tire

rear

the

to

kPa

the

will

GASKET-g~

FILTER

CUP~

~

U

2-13

Resistance

68.6 kPa (0.7 kg/cm2,

Reference tire pressure:

14.7 kPa (0.15 kg/cm2, 2.2 psi)

Min. tire pressure:

11.8 kPa (0.12 kg/cm2, 1.8 psi)

to

pressure:

10

psr)

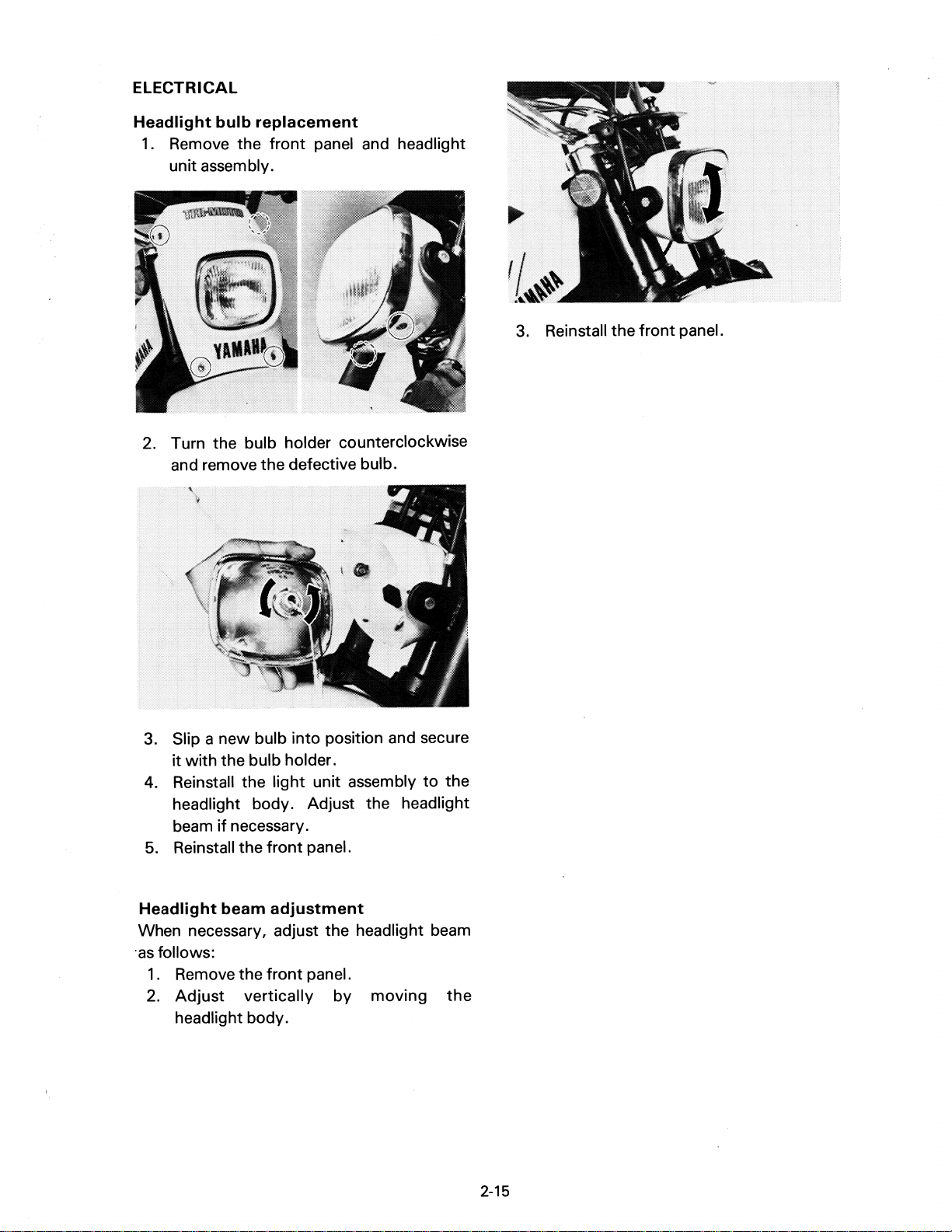

1.

How

to

measure tire pressure

Use

an

inelastic but flexible narrow strip

or

the like

of

the inflated tire (not including the

to

measure the circumference

block patterns). Adjust the tire pressure

to

the specified measurement. This

pressure may

be

above specification

suit the rider's preference.

to

Brake

brake

and

levers

change

pedals/front

Lubricate the pivoting parts

pedal.

Recommended lubricant:

Yamaha Chain and Cable Lube or

10W30

motor

oil

and

of

each lever and

rear

Never

specification,

danger

severe

use a

which

of

the

tire

operating

tire

pressure

may

being

dislodged

conditions.

result

Standard tire circumference:

1,735mm (68.3 in)

Minimum tire circumference:

1,725mm (67.9 in)

Cable

1.

Damage

inspection

to

and

lubrication

the outer housing

various cables may cause corrosion.

Often free movement will

be

An unsafe condition may result. Replace

such cables

. 2.

If

the inner cables do

smoothly, lubricate

as

soon

as

possible .

not

or

replace them.

below

in

the

under

of

the

obstructed.

operate

Recommended lubricant:

Yamaha Chain and Cable Lube or

10W30 motor oil

2-14

ELECTRICAL

Headlight

1.

bulb

Remove the

replacement

front

panel and headlight

unit assembly.

2. Turn the bulb holder counterclockwise

and remove the defective bulb.

3. Reinstall the

front

panel.

new

bulb

into

3. Slip a

it

with

the bulb holder.

4. Reinstall the light unit assembly

position and secure

to

the

headlight body. Adjust the headlight

beam

if

necessary.

5.

Reinstall the

Headlight

beam

front

panel.

adjustment

When necessary, adjust the headlight beam

'asfollows:

1.

Remove the

2.

Adjust

front

vertically

panel.

by

moving

the

headlight body.

2-15

CHAPTER

3.

ENGINE OVERHAUL

ENGINE

Preparation

Exhaust

Wiring

Carburetor

Flywheel

Change

Drive

Removal

ENGINE

Reed

Cylinder

Piston

Cran kcase

Clutch

Change

Drive

Cran kcase

Transmission

Crankshaft

REMOVAL

............................................................

and

magneto

pedal

chain

............................................................

DiSASSEMBLy

valve

head

pin

assembly

shaft

sprocket

......................................................

for

removal

cables

..........................................................

.......................................................

.........................................................

assembly

and

and

piston

cover.

..........................................................

..........................................................

rig

and

assembly

.......................................................

and

...............................................

....................................................

...................................................

..................................................

.................................................

cylinder

.................................................

ht

primary

shifter

............................................

................................................

drive

gear

...............................................

..............................................

..................................

3-1

3-1

3-1

3-1

3-2

3-2

3-3

3-3

3-3

3-3

3-3

3-3

3-4

3-4

3-4

3-6

3-6

3-6

3-6

3-7

INSPECTION

Cylinder

Cylinder

j)iston

Piston

Piston

Autolube

Starter

Clutch

Primary

Change

Transmission

Crankshaft

Bearings

Crankcase

pin

..............................................................

rings

AND

head

............................................................

pump

............................................................

............................................................

drive

shaft

and

REPAIR

.......................................................

and

bearing

.........................................................

......................................................

.......................................................

and

change

.......................................................

.........................................................

oil

seals

.........................................................

..•............................................

................................................

levers

................................................

.......................................

3-7

3-7

3-7

3-8

3-8

3-9

3-9

3-10

3-11

3-14

3-14

3-14

3-15

3-15

3-15

ENGINE ASSEMBLING

Important

Crankshaft

Transmission

Crankcase

Change

Primary

Crankcase

Piston

Cylinder

Cylinder

Reed

information

installation

and

shifter

.........................................................

shaft

assembly

drive

gear

cover

.........................................................

...........................................................

head

valve.

(right)

......................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AND

and

ADJUSTMENT

...............................................

..............................................

installation

..............................................

clutch

assembly

..............................................

............................

...................................

... : ........ ' ....................

~

..

, .

..

.. . ..

3-16

3-16

3-16

3-17

3-19

3-19

3-19

3-19

3-19

3-20

3-20

3-20

MOUNTING

.............................................................

3-21

ENGINE OVERHAUL

ENGINE

Preparation

1.

REMOVAL

for

removal

Always clean engine before removal.

not begin

available. As parts

them and place them

work

until

all

proper tools are

are

removed, clean

in

trays in order

disassem bly.

2. Start the engine and warm it for a

minutes. Turn

oil. Before beginning

off

and drain transmission

of

the servicing,

fully cool the engine down.

Exhaust

1.

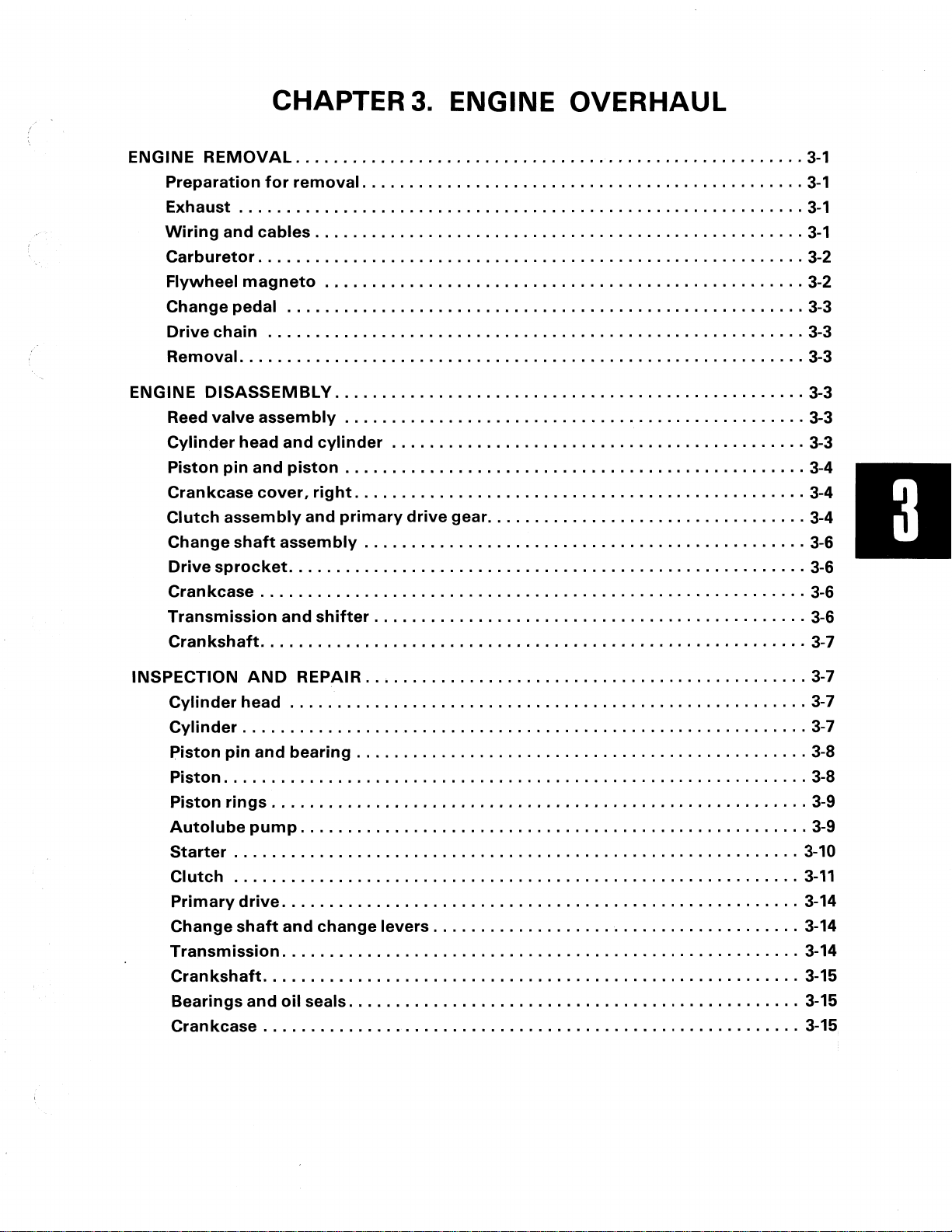

Remove the seat and rear fender.

2. Remove the side cover assembly.

Do

of

few

Wiring

1.

and

cables

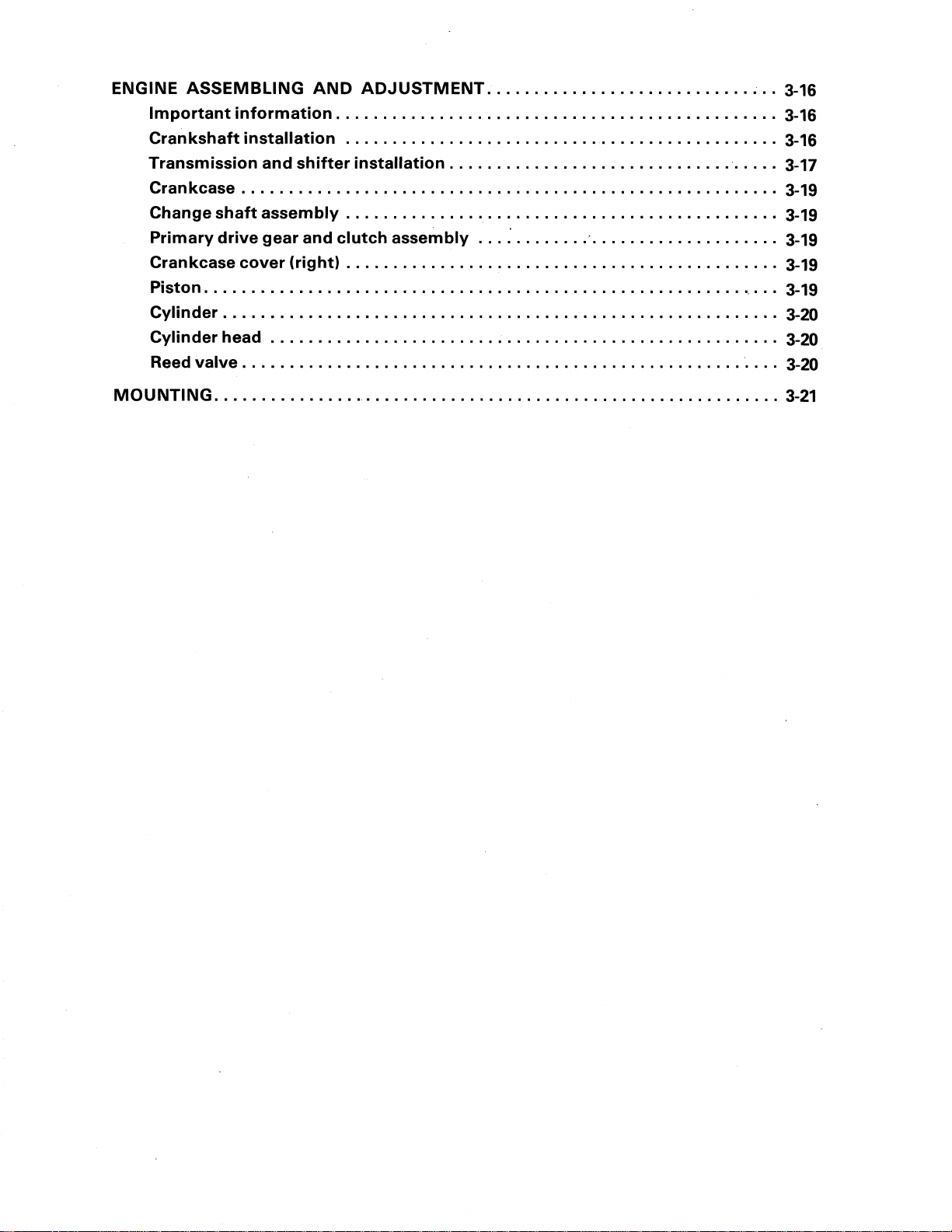

Remove the

spark

cover, pump cable and oil pipe.

plug cap, oil pump

3. Remove exhaust pipe assembly.

1. Clip

NOTE:

Do

the oil pump, or oil will

tank. It is advisable

______

not

leave the oil pipe disconnected from

~----------------

flow

out

to

plug the open pipe end

of

the oil

with a proper size screw.

2. Remove the rear brake wire and spring

from rear brake pedal.

3-1

3.

Remove the air bleed pipes from

crankcase.

4. Remove the starter wire, air vent pipes,

overflow pipe, pulser pipe, and fuel pipe

from carburetor.

5.

Disconnect the magneto lead wire.

Carburetor

1.

Loosen clamps on each end

of

the car-

buretor.

2.

Remove the carburetor.

3.

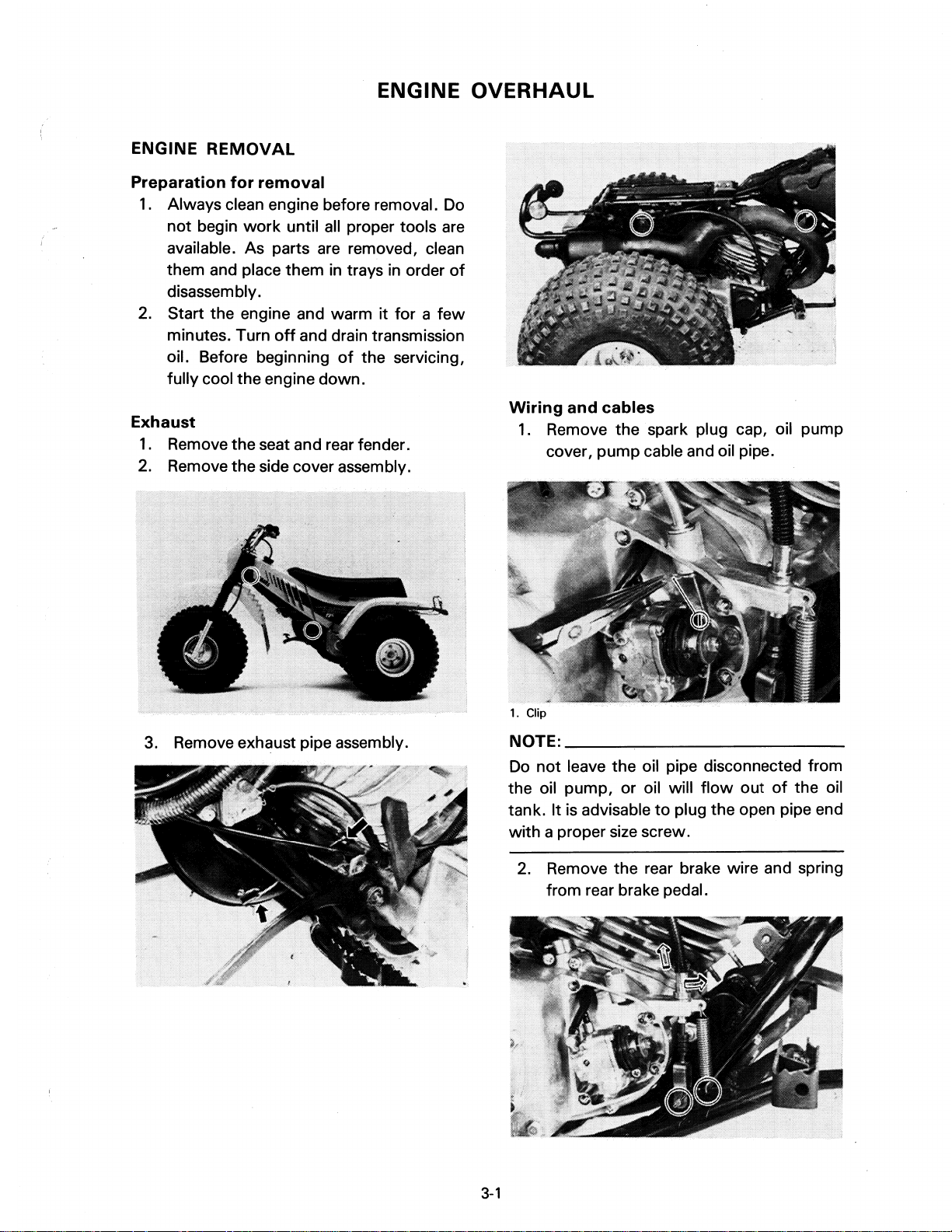

Remove the flywheel securing nut. (use

Flywheel holding tool)

1.

Flywheel holding tool

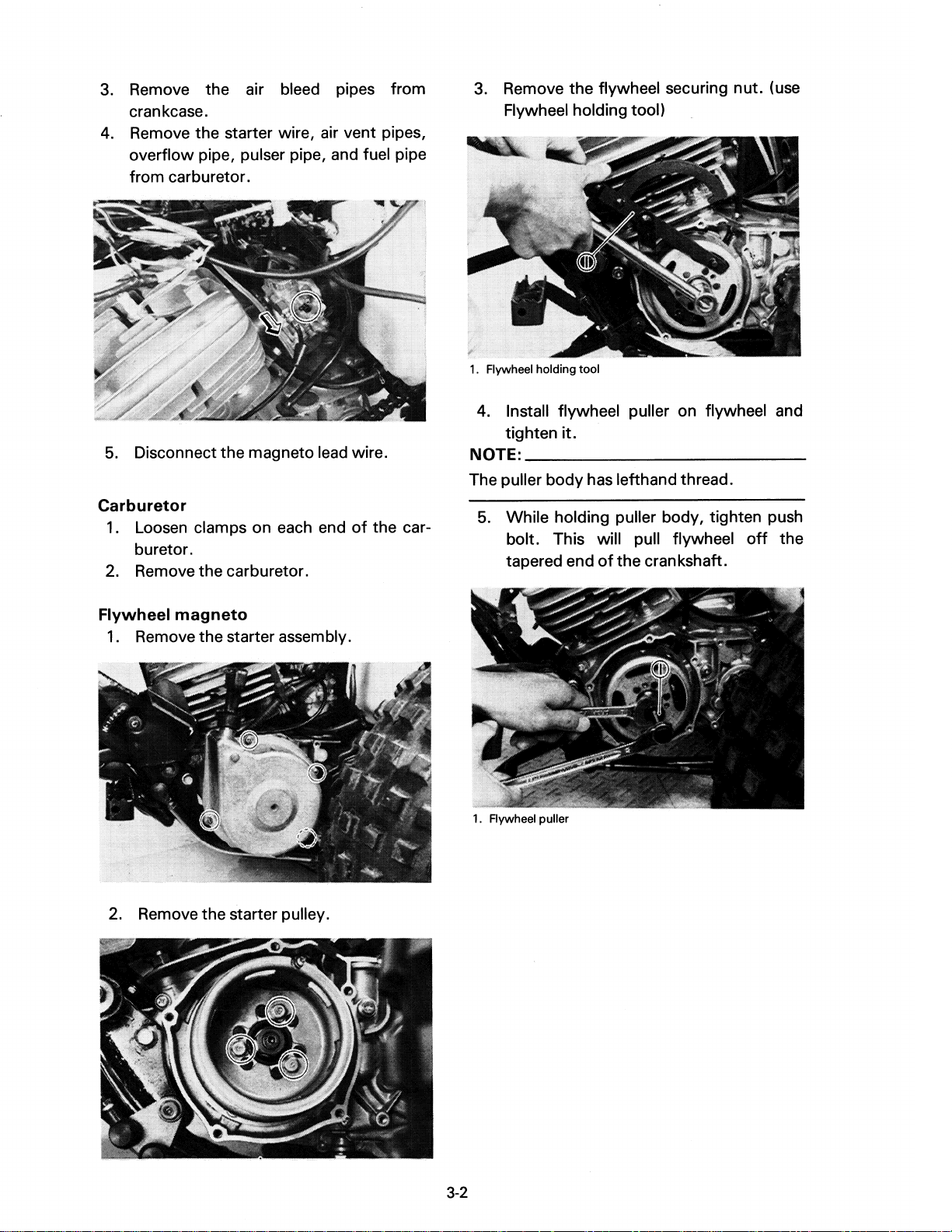

4. Install flywheel puller on flywheel and

tighten

NOTE:

it.

___________

_

The puller body has lefthand thread.

5.

While holding puller body, tighten push

bolt. This will pull flywheel

of

tapered end

the crankshaft.

off

the

Flywheel

1.

magneto

Remove the starter assembly.

2. Remove the starter pulley.

1.

Aywheel puller

3-2

CHARGING COIL

LIGHTING COIL

FLYWHEEL

MAGNETO

Change

1.

Drive

1.

pedal

Remove the change pedal.

chain

Loosen the drive sprocket lock nut, and

remove the drive chain.

Removal

1.

Remove the engine mounting bolts and

remove engine from right side

of

frame.

ENGINE

Reed

1.

DISASSEMBLY

valve

assembly

Remove reed valve assembly holding

bolts (4), carburetor joint and reed valve

assembly.

Cylinder

1.

head

and

cylinder

Remove the cylinder head holding nuts,

cylinder head and head gasket.

3-3

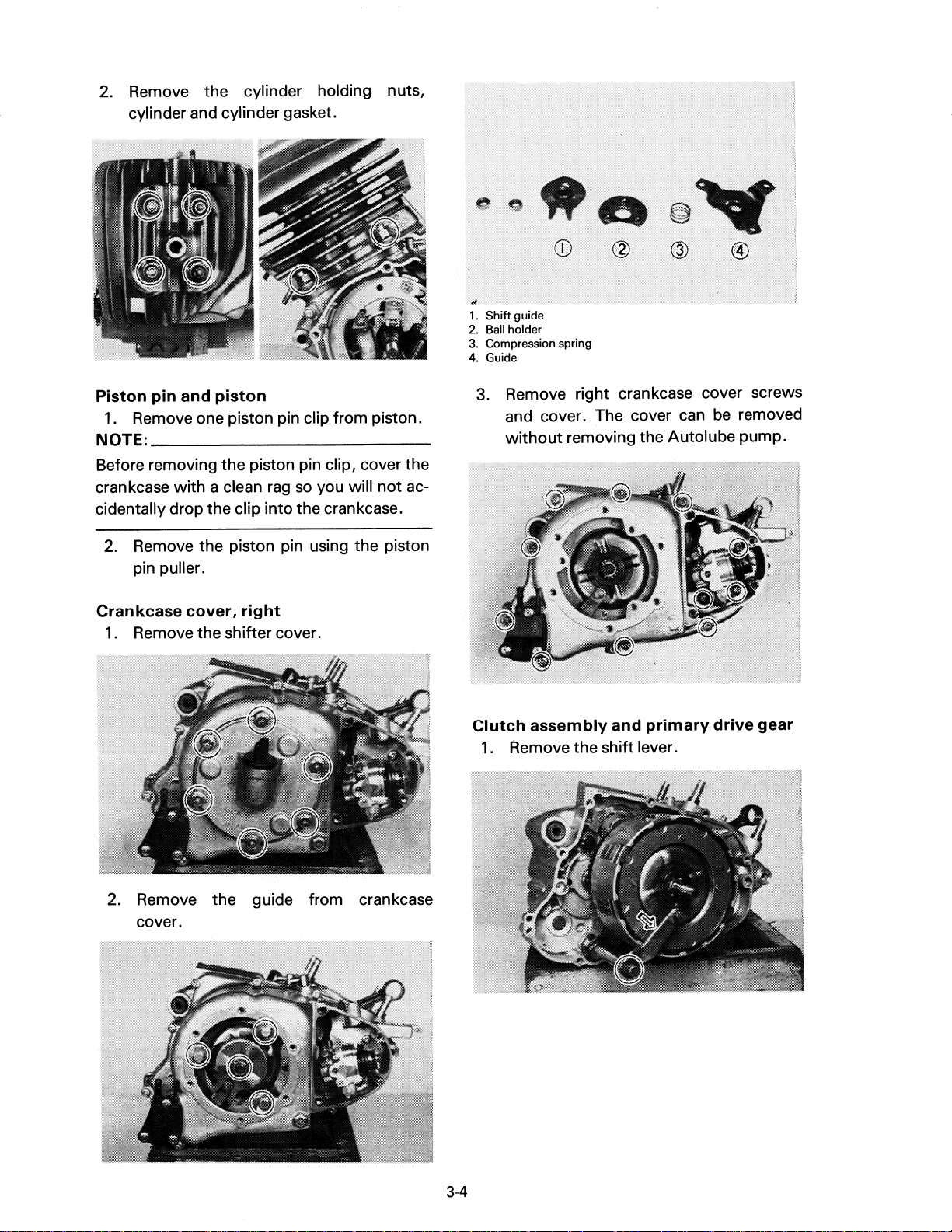

2. Remove the cylinder holding nuts,

cylinder and cylinder gasket.

Piston

1.

NOTE:

pin

and

piston

Remove one piston pin clip from piston.

___________

_

Before removing the piston pin clip, cover the

crankcase with a clean

rag

so

you will

not

ac-

cidentally drop the clip into the crankcase.

1.

Shift guide

2.

Ball

holder

3.

Compression spring

4.

Guide

3.

Remove right crankcase cover screws

and cover. The cover can be removed

without

removing the Autolube pump.

2.

Remove the piston pin using the piston

pin puller.

Crankcase

1.

Remove the shifter cover.

cover,

right

2. Remove the guide from crankcase

cover.

Clutch

1.

assembly

Remove the shift lever.

and

primary

drive

gear

3-4

2. Remove the circlip and pressure plate.

3. Remove the primary drive gear.

rolled-up rag between the tooth

Feed

of

primary drive gear and primary driven

to

gear

lock them and loosen the

primary drive gear lock nut.

a

the

4. Using the Flywheel holding tool, remove

the

nut

and washer. Remove the clutch

boss and driven gear (clutch housing).

1.

Flywheel holding tool

PRESSURE PLATE 2

PRESSURE PLATE 3

3-5

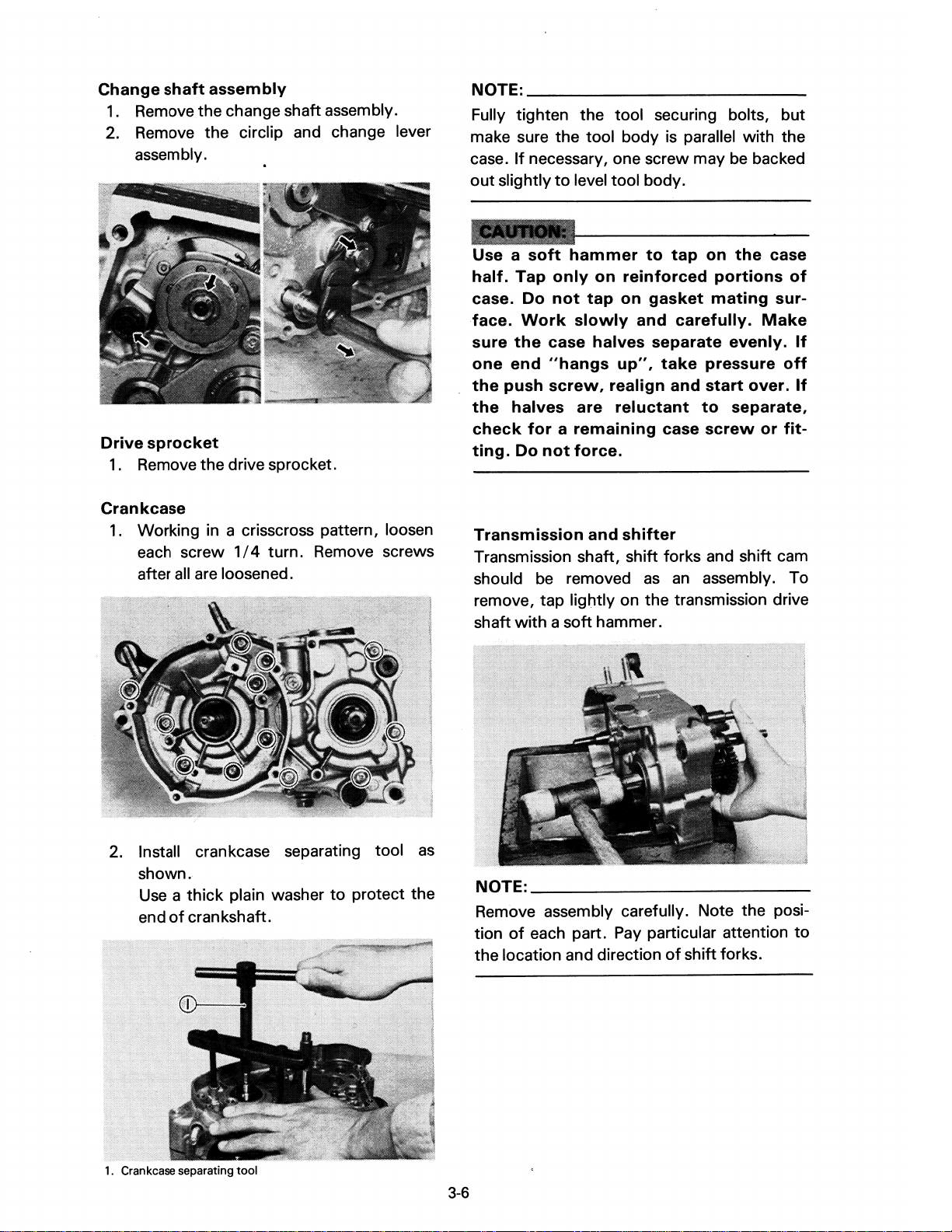

Change

1.

shaft

assembly

Remove the change shaft assembly.

2. Remove the circlip and change lever

assembly.

NOTE:

______________________

__

Fully tighten the tool securing bolts, but

is

make sure the tool body

If

case.

out

necessary, one screw may be backed

slightly

to

level tool body.

parallel with the

Drive

sprocket

1.

Remove the drive sprocket.

Crankcase

1.

Working in a crisscross pattern, loosen

each screw

all

after

1/4

turn. Remove screws

are loosened.

Use a soft

half.

Tap

case.

face.

sure

one

the

the

Do

Work

the

end

push

halves

check

ting.

Do

Transmission

hammer

only

on

reinforced

not

tap

on

slowly

case

"hangs

screw,

are

and

halves

up",

realign

reluctant

for a remaining

not

force.

and

shifter

to

tap

gasket

carefully.

separate

take

and

to

case

on

the

portions

mating

Make

evenly.

pressure

start

over.

separate,

screw

or

case

of

sur-

off

fit-

Transmission shaft, shift forks and shift cam

should be removed

as

an

assembly. To

remove, tap lightly on the transmission drive

shaft

with a soft

hammer.

If

If

2. Install crankcase separating tool

shown.

Use a thick

end

of

1.

Crankcase separating

plain washer

crankshaft.

tool

to

protect the

as

NOTE:

____________

Remove assembly carefully. Note the posi-

of

tion

the location and direction

3-6

each part. Pay particular attention

of

shift forks.

_

to

Loading...

Loading...