YST-SW320

SUBWOOFER SYSTEM

YST-SW320

SERVICE MANUAL

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA

Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry,

and more specifically YAMAHA Products, are already known and

understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety

IMPORTANT: The presentation or sale of this manual to any individual

The data provided is believed to be accurate and applicable to the unit(s)

indicated on the cover. The research, engineering, and service departments

of YAMAHA are continually striving to improve YAMAHA products.

Modifications are, therefore, inevitable and specifications are subject to

change without notice or obligation to retrofit. Should any discrepancy

appear to exist, please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components.

IMPORTANT: Turn the unit OFF during disassembly and part

procedures when servicing this product may result in

personal injury, destruction of expensive components,

and failure of the product to perform as specified. For

these reasons, we advise all YAMAHA product owners

that any service required should be performed by an

authorized YAMAHA Retailer or the appointed service

representative.

or firm does not constitute authorization, certification

or recognition of any applicable technical

capabilities, or establish a principle-agent relationship

of any form.

Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss

in the unit (heavy gauge black wires connect to this

buss).

replacement. Recheck all work before you apply power

to the unit.

100720

■ CONTENTS

TO SERVICE PERSONNEL . . . . . . . . . . . . . . . . . . . .1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

REAR PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

DISASSEMBLY PROCEDURES . . . . . . . . . . . . . . .3–4

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–6

PRINTED CIRCUIT BOARD . . . . . . . . . . . . . . . . . 7–12

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . .13

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . 14

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15–22

YST-SW320

YST-SW320

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked Z

and must be replaced with parts having specifications equal

to those originally installed.

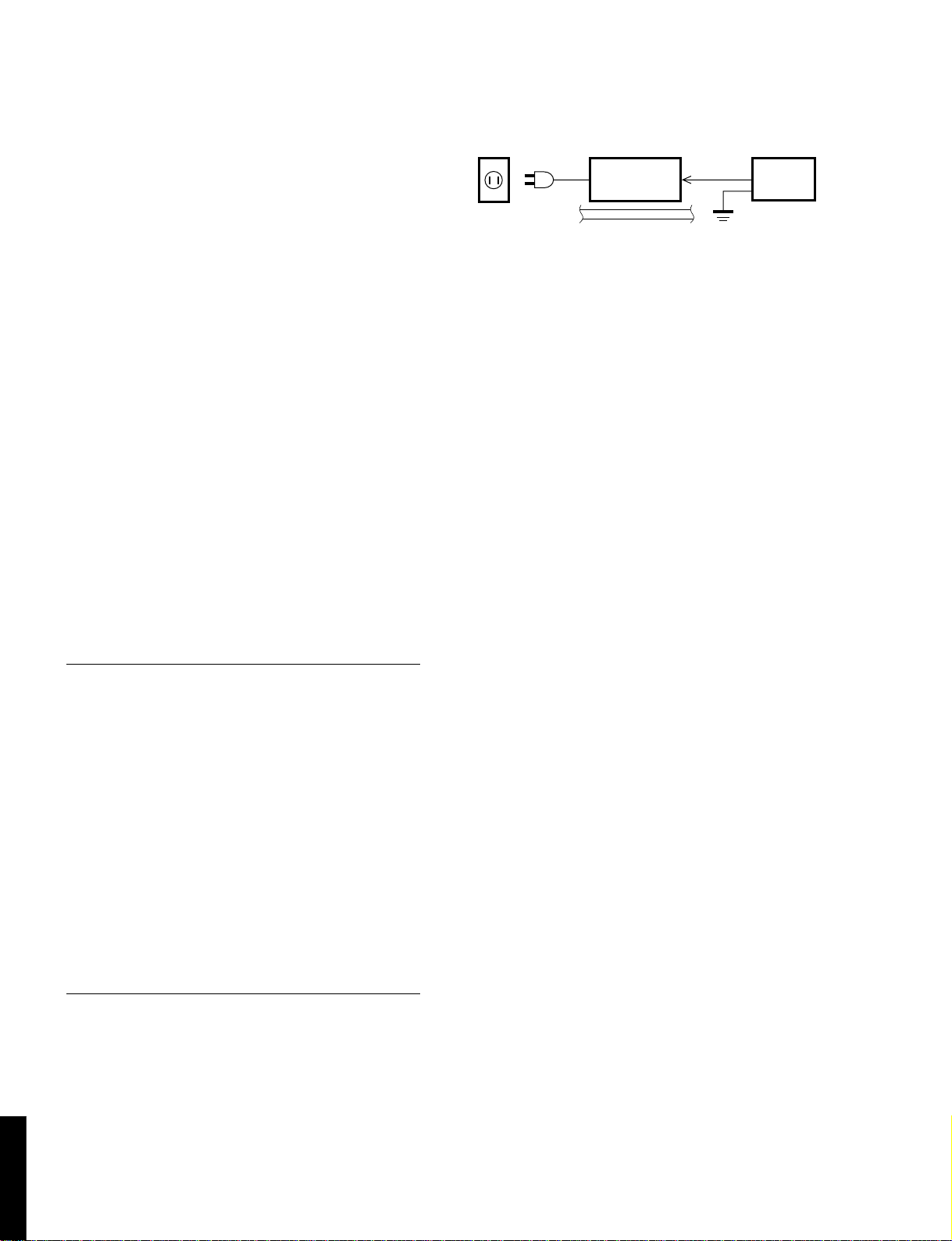

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

WALL

OUTLET

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both

polarities.

EQUIPMENT

UNDER TEST

INSULATING

TABLE

AC LEAKAGE

TESTER OR

EQUIVALENT

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR

ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes

or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

■ SPECIFICATIONS

Type . . . . . . . . . Advanced Yamaha Active Servo Technology

Driver . . . . . . . . . . . 25 cm (9-13/16") cone woofer (JA25600)

Magnetically shielded type

Amplifier Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250W/5Ω

Frequency Response . . . . . . . 20 Hz to 160 Hz (-24 dB/oct.)

Power Supply

U, C models . . . . . . . . . . . . . . . . . . . . . . . . .AC120V, 60 Hz

A model . . . . . . . . . . . . . . . . . . . . . . . . . . . .AC240V, 50 Hz

B, G models . . . . . . . . . . . . . . . . . . . . . . . . .AC230V, 50 Hz

R, T models . . . . . . . . . . . . AC110/120/220/240V, 50/60 Hz

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60W

Dimensions (W x H x D) . . . . . . . . . . . . 340 x 432 x 370 mm

(13-3/8" x 17" x 14-9/16")

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 kg (37 lbs. 7 oz)

Finish

All model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Black color

R, T, G models . . . . . . . . . . . . . . . . . . . . . . . . Cherry color

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . Nonskid pad x 4

* Specifications subject to change without notice.

U . . . . . . . . . . USA model

C . . . . . .Canadian model

A . . . . . Australian model

B . . . . . . . . British model

G . . . . . European model

R . . . . . . . General model

T . . . . . . . . . China model

1

YST-SW320

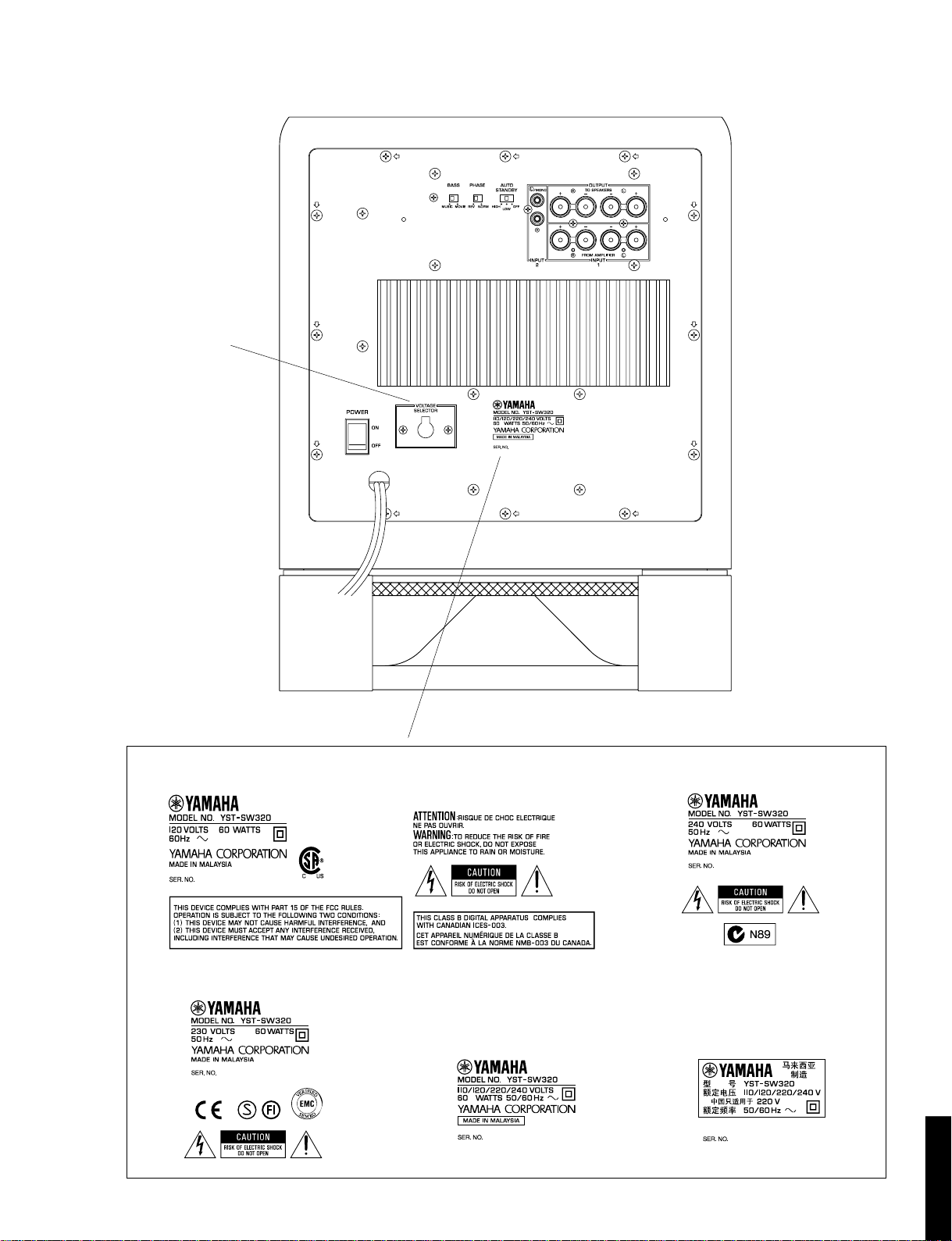

■ REAR PANEL

R, T models only

YST-SW320

▼ U, C models ▼ A model

▼ B, G models

▼ R model ▼ T model

YST-SW320

2

YST-SW320

■ DISASSEMBLY PROCEDURES

(Remove parts in the order as numbered.)

1. Removal of Front Panel Ass'y

Remove 4 screws ( q ) and then remove the Front

Panel Ass'y in Fig. 1.

* Use an Allen wrench (3mm) to unscrew the Front

Panel Ass'y.

Front Panel Ass'y

q

q

Main (5) P.C.B.

Fig. 1

3. Removal of Rear Panel Ass'y

Remove 12 screws ( r ) in Fig. 3.

* Arrow marks ( ) are printed to identify the screws to be

removed.

Rear Panel Ass'y

r

r

r

r

Fig. 3

2. Removal of Loud Speaker

a. Remove 8 screws ( w ) and then remove the Base

Ass'y in Fig. 2.

b. Remove 4 screws ( e ) and then remove the Loud

Speaker in Fig. 2.

w

w

w

e

Loud Speaker

w

Base Ass'y

e

* When assembling the Rear Panel, check to ensure that

the gasket is not damaged so as to prevent air leakage

from occurring.

● Installation of emblem

1. Put the emblem into the cabinet at the specified position.

2. Place a piece of cloth/wood on top of the emblem.

3. Using a mallet, hammer the emblem in place through

the cloth/wood.

* Use special care not to cause damage to the emblem or

cabinet while hammering the emblem.

3

YST-SW320

Fig. 2

● Installation of power switch

Rapid cures bond (such as 5 minute epoxy) is required to fix the power switch.

As shown in Fig. A, apply r apid cures bond (such as 5 minute epo xy) to the pow er s witch (the area which

contacts the rear panel), insert it in the rear panel and make sure it is fixed.

(Inserting the power switch in the rear panel only would not be sufficient for its secure installation.)

●

Precaution for installation of power cord

After connecting the power cord, be sure to apply the rapid cures bond (such as 5 minute epo xy) to the

cord stopper as shown in Fig. A,

YST-SW320

Bond application diagram (Fig. A)

Apply rapid cures bond

Apply rapid cures bond

Glue List

Place Name

Cord stopper

Power switch 5 minute epoxy or Diabond 1620B

5 minute epoxy or

2051(Revertex Finewaters SDN.BHD.) or

VYLOK 917DH (National Starch &

Chemical (M) SDM.BHD.)

● Dimensions

340 (13-3/8")

(5/16")

340 (13-3/8")

432 (17")

8

370 (14-9/16")

340 (13-3/8")

22

(7/8")

YST-SW320

Units : mm (inch)

4

YST-SW320

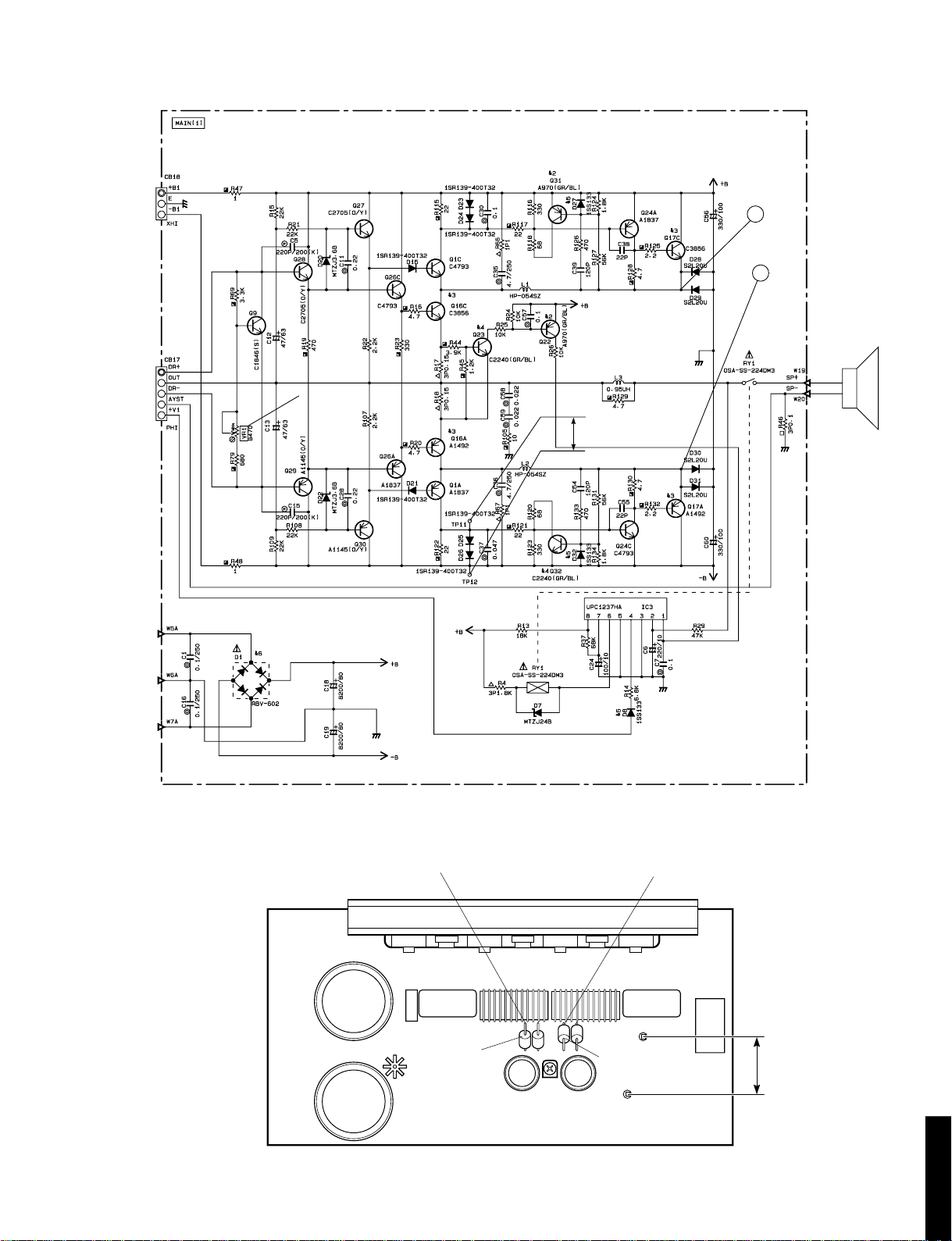

■ ADJUSTMENTS

●

Confirmation of Power Amp operation

For the power amplifier which has been repaired, it

is absolutely necessary to confirm that a correct

waveform is obtained at points indicated by A and B

in the schematic diagram according to the following

procedure.

Devices required

Signal generator

8Ω or 6Ω load resistor

Oscilloscope (dual trace type)

Connection

1) Connect the output signal from the signal generator

to the input terminal of YST-SW320.

2) Disconnect the connector terminal connected to the

speaker unit and reconnect it to the load resistor.

3) Connect the HOT side of the oscilloscope CH1 probe

to the point A or B indicated in the figure and the

GND side to the GND of the main unit.

4) Connect the oscilloscope CH2 input to the red side

of the connector cable, which is connected with the

load resistor.

At this time, the GND terminal of CH2 must be left

unconnected.

Setting

1) Set the signal generator to the sine wave, 100Hz and

minimum output level settings.

2) Set the volume of YST-SW320 to the minimum

position.

3) Turn on the power to YST-SW320.

4) Adjust the output level of the signal generator and the

volume of YST-SW320 so that the output level

observed at oscilloscope CH2 is 28Vp-p.

● Idling Adjustment

To stabilize operation of the amplifier, turn ON the

power with no input signal and wait for 1 or 2 minutes

in non loaded condition before the adjustment.

Adjust VR1 so that the voltage between terminals

TP11 and TP12 is DC 50mV to 250mV.

● Confirmation of AUTO STANDBY

Measuring Condition

R60 = 1MΩ

➔1MΩ//10kΩ

F = 100Hz

Input Level = 4mV

Load = Open

Rating

After 2 to 8 sec.

STANDBY

(LED become red)

Don't STANDBY

Remarks

VOLUME: MAX

HIGH CUT: MAX

AUTO STANDBY: LOW

VOLUME: MAX

HIGH CUT: MAX

AUTO STANDBY: HIGH

Waveform observation

With the settings made as described above, observe

the waveform obtained at CH1 for judgment.

0V

5

YST-SW320

Normal Normal

Point A (Cathode of D29)

V : 20V/div H : 2 msec/div

DC range 1 : 1 probe

Abnormal

+B or GND level

Becomes constant

Point B (Anode of D30)

V : 20V/div H : 2 msec/div

DC range 1 : 1 probe

0V

Abnormal

-B or GND level

Becomes constant

● Schematic Diagram

YST-SW320

A

B

IDLING CURRENT ADJ.

RE

WH

DC 50mV to 250mV

● Test Points

Point A

D29

Main (1) P.C.B

VR1

D30

Point B

TP11 (+)

TP12 (-)

DC 50mV to 250mV

YST-SW320

6