Page 1

@YAM

AHA

Service

Page 2

YS R5OT

SERVICE MANUAL

01987 by

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation,

Yamaha Motor Corporation, U.S.A.

1st Edition, March 1987

U.S.A. is expressly prohibited.

Printed in U.S.A.

PINO. LIT-Il616-O6-05

Page 3

NOTICE

This manual was written by the Yamaha Motor Company primarily for use by Yamaha dealers and

It

their qualified mechanics.

it

is assumed that persons using this book to perform maintenance and repairs on Yamaha motor-

so

cycles have a basic understanding of the mechanical concepts and procedures inherent in motorcycle

repair technology. Without such knowledge, attempted repairs or service to this model may render

it

unfit to use andlor unsafe.

Yamaha Motor Company, Ltd. is continually striving to improve all models manufactured by Yamaha.

Modifications and significant changes in specifications or procedures will be forwarded to all Authorized

Yamaha dealers and will, where applicable, appear in future editions of this manual.

is not possible to put an entire mechanic's education into one manual,

HOW TO USE THIS MANUAL

PARTICULARLY IMPORTANT INFORMATION

This material is distinguished by the following notation.

NOTE:

MANUAL FORMAT

A NOTE provides key information to make procedures easier or clearer.

A CAUTION indicates special procedures that must be followed to avoid damage

to the motorcycle.

A WARNING indicates special procedures that must be followed to avoid injury to

a motorcycle operator or person inspecting or repairing the motorcycle.

TECHNICAL

MOTORCYCLE OPERATIONS

YAMAHA MOTOR CO., LTD.

PU

BLlCATlONS

SERVICE DIVISION

All of the procedures in this manual are organized in a sequential, step-by-step format. The information has been compiled to provide the mechanic with an easy to read, handy reference that contains

comprehensive explanations of all disassembly, repair, assembly, and inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the course

of action required will follow the symbol, e.g.,

Bearings

Pitting1 Damage-, Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in identifying cor-

rect disassembly and assembly procedures.

Page 4

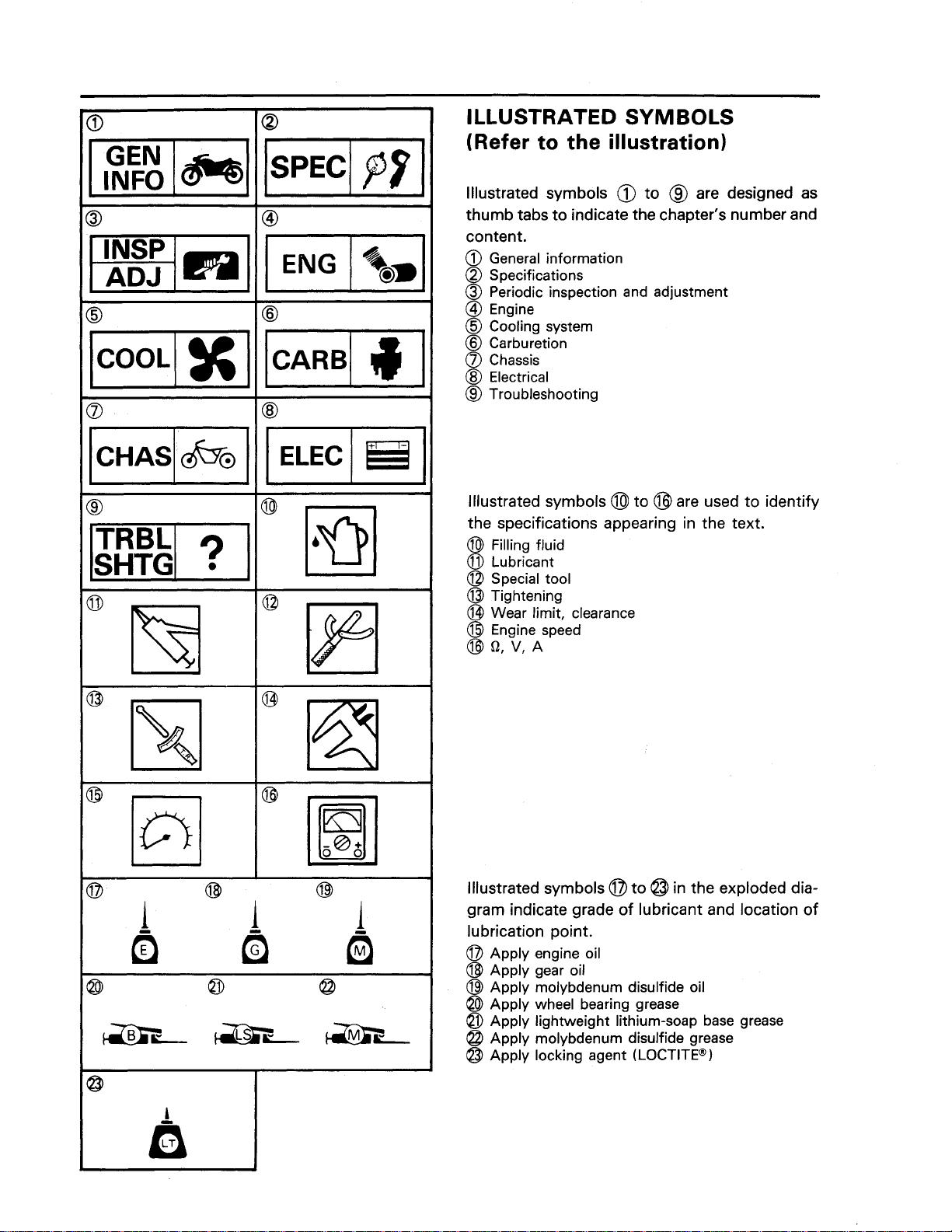

ILLUSTRATED SYMBOLS

(Refer to the illustration)

I

ENG

1

Illustrated symbols

thumb tabs to indicate the chapter's number and

content.

a

General information

@

Specifications

@

Periodic inspection and adjustment

@

Engine

@

Cooling system

@

Carburetion

a

Chassis

@

Electrical

@

Troubleshooting

Illustrated symbols @ to @ are used to identify

the specifications appearing in the text.

@

Filling fluid

Lubricant

@

Special tool

@

Tightening

@

Wear limit, clearance

@

Engine speed

@

9,

v,

A

@

to @ are designed as

Illustrated symbols

gram indicate grade of lubricant and location of

lubrication point.

0

Apply engine oil

@

Apply gear oil

8

Apply molybdenum disulfide oil

@

Apply wheel bearing grease

Apply lightweight lithium-soap base grease

@

Apply molybdenum disulfide grease

@

Apply locking agent (LOCTITE@)

0

to @ in the exploded dia-

Page 5

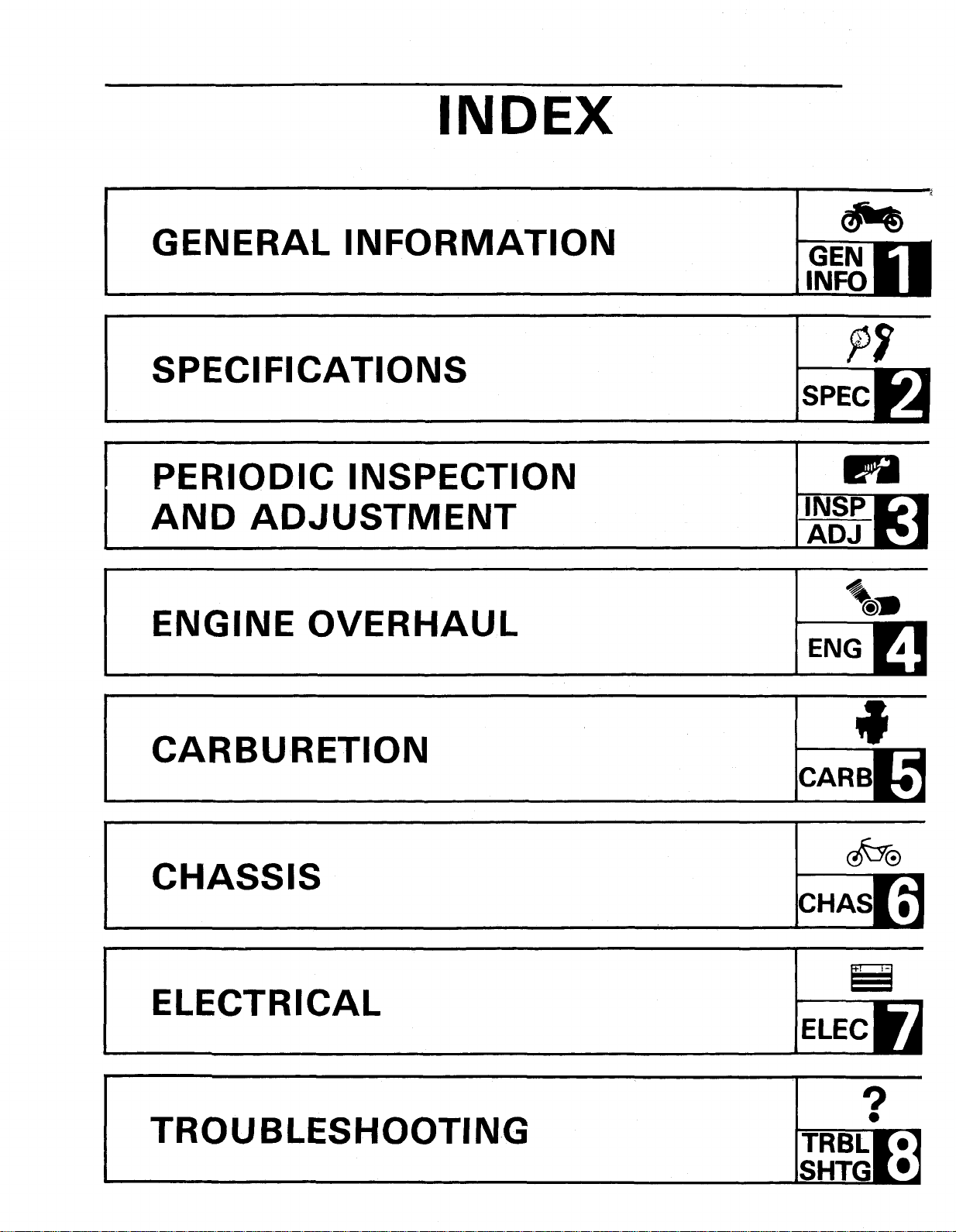

INDEX

GENERAL INFORMATION

SPECIFICATIONS

m

GEN

INFO

P

f

PERIODIC INSPECTION

AND ADJUSTMENT

ENGINE OVERHAUL

CHASSIS

em

INSP

ADJ

@

+o,

&O

ELECTRICAL

TROUBLESHOOTING

El

ELEC

0

Page 6

CONTENTS

CHAPTER

1

.

GENERAL INFORMATION

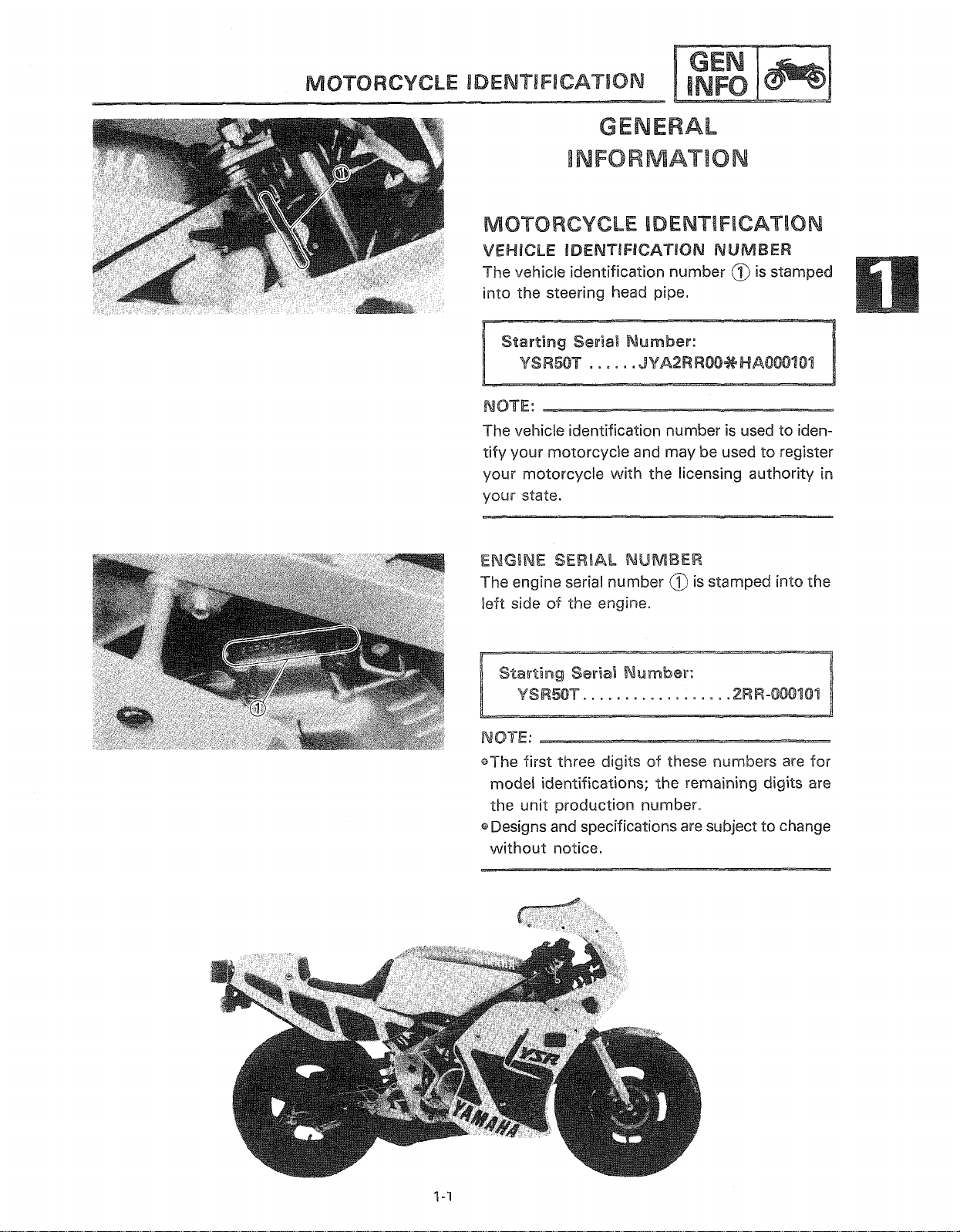

MOTORCYCLE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

ENGINE SERIAL NUMBER

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY

ALL REPLACEMENT PARTS

GASKETS, OIL SEALS. AND O.RINGS

LOCK WASHERSIPLATE AND COTTER PINS

BEARINGS AND OIL SEALS

ClRCLlPS

SPECIAL TOOLS

FOR TUNE

FOR ENGINE SERVICE

FOR CHASSIS SERVICE

FOR ELECTRICAL COMPONENTS

.......................................................

..................................................

UP

..................................................

..........................................

.........................................

...................................

..............................

.......................................

......................................

.....................................

...........................

.....................................

................................

..............

....................

1.1

1.1

1.1

1.2

1.2

1.3

1.3

1.3

1.3

1-4

1-4

1-4

1.5

1.6

1.7

CHAPTER

SPECIFICATIONS

GENERAL SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

CHASSIS

ELECTRICAL

GENERAL TORQUE SPECIFICATIONS

DEFINITION OF UNITS

tNtiINt

CHASSIS

CABLE ROUTING

........................................................

.......................................................

...................................................

.......................................................

......................................................

................................................

.......................................

.................................

...........................................

2 .

2.11

............................

2.14

2.14

2-15

2-15

2.16

2.1

2.4

2-4

2-8

Page 7

--

CHAPTER

3

.

-

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION

PERIODIC MAINTENANCE/LUBRlCATlON INTERVALS

COWLINGS REMOVAL AND INSTALLATION

COWLINGS

SIDE COVER

ENGINE

...........................................................

IDLE SPEED ADJUSTMENT

THROTTLE CABLE FREE PLAY ADJUSTMENT

AUTOLUBE PUMP CABLE ADJUSTMENT

AUTOLUBE PUMP STROKE ADJUSTMENT

AUTOLUBE PUMP AIR BLEEDING

SPARK PLUG INSPECTION

IGNITION TIMING CHECK

ENGINE OIL LEVEL CHECK

TRANSMISSION OIL LEVEL INSPECTION

TRANSMISSION OIL REPLACEMENT

CLUTCH ADJUSTMENT

AIR FILTER CLEANING

CARBURETOR JOINT INSPECTOIN

FUEL LINE INSPECTION

Y.E.I.S. HOSE INSPECTION

EXHAUST SYSTEM INSPECTION

...................................................

......................

.....................................................

...................................................

.....................................

....................

........................

.......................

................................

......................................

......................................

.....................................

........................

............................

........................................

..........................................

..............................

........................................

....................................

...............................

............

3.10

3.10

3.11

3.12

3.13

3.14

3.16

3.17

3.17

3.17

3-1

3.1

3.3

3-3

3.4

3.4

3.4

3.5

3.5

3.6

3.8

3.9

INFO

CHASSIS

FRONT BRAKE ADJUSTMENT

REAR BRAKE ADJUSTMENT

BRAKE FLUID INSPECTION

BRAKE PAD INSPECTION

BRAKE SHOE INSPECTION

BRAKE LIGHT SWITCH ADJUSTMENT

BRAKE HOSE INSPECTION

DRIVE CHAIN SLACK ADJUSTMENT

DRIVE CHAIN LUBRICATION

STEERING HEAD ADJUSTMENT

TIRE INSPECTION

WHEEL INSPECTION

CABLE INSPECTION AND LUBRICATION

LEVER AND PEDAL LUBRICATION

SIDESTAND LUBRICATION

........................................................

..................................

...................................

....................................

......................................

.....................................

.....................................

...................................

.............................................

...........................................

.....................................

..........................

...........................

................................

........................

.............................

3-17

3.17

3.18

3.18

3.19

3.19

3.19

3.19

3.20

3.21

3.21

3.23

3.24

3.24

3.25

3.25

Page 8

ELECTRICAL

BATTERY INSPECTION

FUSE INSPECTION

HEADLIGHT BEAM ADJUSTMENT

HEADLIGHT REPLACEMENT

.....................................................

.........................................

.............................................

3-26

3.26

3.28

..............................

....................................

3.29

3.29

CHAPTER

ENGINE

ENGINE REMOVAL

TRANSMISSION OIL

COWLING AND SIDE COVER

FUEL TANK

MUFFLER

CARBURETOR

AUTOLUBE PUMP CABLE AND HOSE

LEADS

CLUTCH CABLE

DRIVE CHAIN

ENGINE REMOVAL

ENGINE DISASSEMBLY

CYLINDER HEAD. CYLINDER AND PISTON

CLUTCH AND PRIMARY DRIVE GEAR

KICK AXLE

SHIFT SHAFT

CDI MAGNETO

CRANKCASE

TRANSMISSION. SHIFTER AND CRANKSHAFT

......................................................

.........................................................

................................................

............................................

....................................................

..................................................

................................................

..................................................

..............................................

...........................................

.....................................................

..................................................

.................................................

..................................................

OVERHAUL

....................................

4

...........................

...........................

.

......................

..................

4-1

4-1

4-1

4-1

4-2

4-2

4.2

4-3

4.3

4-3

4.4

4.5

4.5

4.6

4-8

4-9

4-9

4-10

4.11

INSPECTION AND REPAIR

CYLINDER HEAD 4-13

CYLINDER AND PISTON 4.13

PISTON RINGS 4-15

PISTON PIN AND BEARING

rl

I

IT~U

...

w. . w..

SHIFT SHAFT

TRANSMISSION AND SHIFTER

CRANKSHAFT

CRANKCASE

AUTOLUBE PUMP

ENGINE ASSEMBLY AND ADJUSTMENT

CRANKSHAFT. SHIFTER AND TRANSMISSION

CRANKCASE

CDI MAGNETO

SHIFT SHAFT

....

..............................................

................................................

L.

...................................................

.................................................

.................................................

..................................................

.............................................

..................................................

................................................

.................................................

.......................................

.......................................

....................................

.................................

........................

..................

4.13

4.16

4-17

"

4-19

4-20

4-21

4-22

4-22

4.24

4.24

4-25

4-30

4-32

Page 9

KICK AXLE

CLUTCH AND PRIMARY DRIVE GEAR

CYLINDER HEAD. CYLINDER AND PISTON

REMOUNTING ENGINE

....................................................

..........................

.........................................

4-32

4.34

..................... 4.37

4.40

CHAPTER

5

.

CARBURETION

CARBURETOR

REMOVAL

DISASSEMBLY

INSPECTION

INSTALLATION

ADJUSTMENT

REED VALVE

REMOVAL

INSPECTION

INSTALLATION

...................................................

......................................................

.................................................

....................................................

..................................................... ASSEMBLY 5-5

.................................................

..................................................

.....................................................

......................................................

....................................................

.................................................

CHAPTER

6

.

CHASSIS

FRONT WHEEL

REMOVAL 6-2

INSPECTION 6-2

INSTALLATION

....................................................

......................................................

....................................................

.................................................

-5-1

5-2

5-2

5.4

5.6

5-7

5-8

5-8

5-8

5.9

6-1

6-4

REAR WHEEL

REMOVAL 6.6

INSPECTION 6.6

INSTALLATION 6.8

FRONT BRAKE

BRAKE PAD REPLACEMENT 6.11

CALIPER DISASSEMBLY 6.13

MASTER CYLINDER DISASSEMBLY 6.14

INSPECTION AND REPAIR 6.15

ASSEMBLY

AIR BLEEDING 6-19

FRONT FORK

REMOVAL 6.21

DISASSEMBLY 6.21

INSPECTION 6.23

ASSEMBLY 6.23

INSTALLATION 6-26

.....................................................

......................................................

....................................................

.................................................

...................................................

...................................

.......................................

............................

......................................

....................................................

................................................

....................................................

.....................................................

................................................

...................................................

....................................................

................................................

6-5

6.10

6-16

6.20

Page 10

STEERING HEAD AND HANDLEBAR

REMOVAL

INSPECTION

l

NSTALLATION

.....................................................

...................................................

................................................

............................. 6.27

6-28

6-29

6.30

REAR SHOCK ABSORBER AND SWINGARM

REMOVAL

DISASSEMBLY

INSPECTION

ASSEMBLY

INSTALLATION

DRIVE CHAIN AND SPROCKETS

REMOVAL

INSPECTION

INSTALLATION

.....................................................

................................................

...................................................

....................................................

...............................................

................................. 6.38

..................................................... 6-38

...................................................

................................................

CHAPTER

7

.

ELECTRICAL

YSR50T CIRCUIT DIAGRAM

COLOR CODE

ELECTRICAL COMPONENTS

IGNITION AND STARTING SYSTEM

IGNITION CONTROL CIRCUIT OPERATION

TROUBLESHOOTING

.................................................. 7-2

.......................................

......................................

...............................

............................................

....................

6.33

6-34

6-35

6-35

6-36

-6-36

6.38

6.39

7-1

7.3

7-4

....................... 7.6

7.7

CHARGING SYSTEM

TROUBLESHOOTING

LIGHTING SYSTEM

TROUBLESHOOTING (1) 7.24

TROUBLESHOOTING (2) 7.27

SIGNAL SYSTEM

TROUBLESHOOTING

DISPLAY SYSTEM

TROUBLESHOOTING

TROUBLESHOOTING (2)

DISPLAY SYSTEM TEST AND CHECK

.............................................

...........................................

...............................................

........................................

........................................

.................................................

........................................... 7.32

................................................

(1

)

........................................ 7.44

........................................

...........................

CHAPTER

8

.

TROUBLESHOOTING

STARTING FAILUREIHARD STARTING

FUEL SYSTEM

ELECTRICAL SYSTEM

COMPRESSION SYSTEM

.................................................

...........................................

........................................

............................

7.16

7.18

7.22

7.30

7.42

7.48

7.50

8.1

8.1

8.2

8.3

Page 11

POOR IDLE SPEED PERFORMANCE

POOR IDLE SPEED PERFORMANCE

...............................

..............................

8.3

8.3

POOR MEDIUM AND HIGH SPEED PERFORMANCE

FUEL SYSTEM

ELECTRICAL SYSTEM

COMPRESSION SYSTEM

FAULTY GEAR SHIFTING

HARD SHIFTING

CHANGE PEDAL DOES NOT MOVE

JUMP-OUT GEAR

CLUTCH SLIPPINGIDRAGGING

CLUTCH SLIPPING

CLUTCH DRAGGING

IMPROPER KICKING

SLIPPING

HARD KICKING

KICK CRANK NOT RETURNING

FAULTY BRAKE

POOR BRAKING EFFECT

.................................................

...........................................

........................................

.........................................

................................................

..............................

...............................................

...................................

..............................................

............................................

..............................................

......................................................

.................................................

.................................

...................................................

........................................

..............

8.4

8.4

8.4

8.5

8.6

8-6

pqm

INFO

8-6

8-6

8.7

8.7

8-7

8-8

8-8

8-8

8.8

8-9

8.9

FRONT FORK OIL LEAKAGE AND FRONT FORK MALFUNCTION

OIL LEAKAGE

MALFUNCTION

INSTABLE HANDLING

INSTABLE HANDLING

FAULTY SIGNAL AND LIGHTING SYSTEM

HEADLIGHT DARK

BULB BURNT OUT

FLASHER DOES NOT LIGHT

FLASHER KEEPS ON

FLASHER WINKS SLOWER

FLASHER WINKS QUICKER

HORN IS INOPERATIVE

OVERHEATING

OVERHEATING

YSR5OT WIRING DIAGRAM

..................................................

.................................................

........................................... 8.10

.........................................

.......................

.............................................

............................................

...................................

.......................................... 8.11

....................................

....................................

........................................

...................................................

................................................

.... 8.9

8-9

8-9

8.10

8.11

8-11

8.11

8.11

8.12

8.12

8.12

8.13

8-13

Page 12

Page 13

your state.

IAL

N

The engine serial num

sf

the

left side

en

::.

cThe first three di ts sf these numbers are for

ns;

%he

model identificat

duction number.

specifications are su

without notice.

remainin

-

Page 14

IMPORTANT INFORMATION

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1.

Remove all dirt, mud, dust, and foreign

material before removing and disassembling.

2.

Use proper tools and cleaning equipment.

Refer to "SPECIAL TOOL."

I

1-1

3.

When disassembling the motorcycle, keep

mated parts together. This includes gears,

cylinders, pistons, and other mated parts that

have been "mated" through normal wear.

Mated parts must be reused as an assembly

or replaced.

4.

During the motorcycle disassembly, clean all

parts and place them in trays in the order of

disassembly. This will speed up assembly time

and help assure that all parts are correctly rein-

stalled.

5.

Keep away from fire.

Page 15

IMPORTANT INFORMATION

ALL REPLACEMENT PARTS

1.

We recommend to use Yamaha genuine parts

for all replacements. Use oil and/or grease

recommended by Yamaha for assembly and

adjustment.

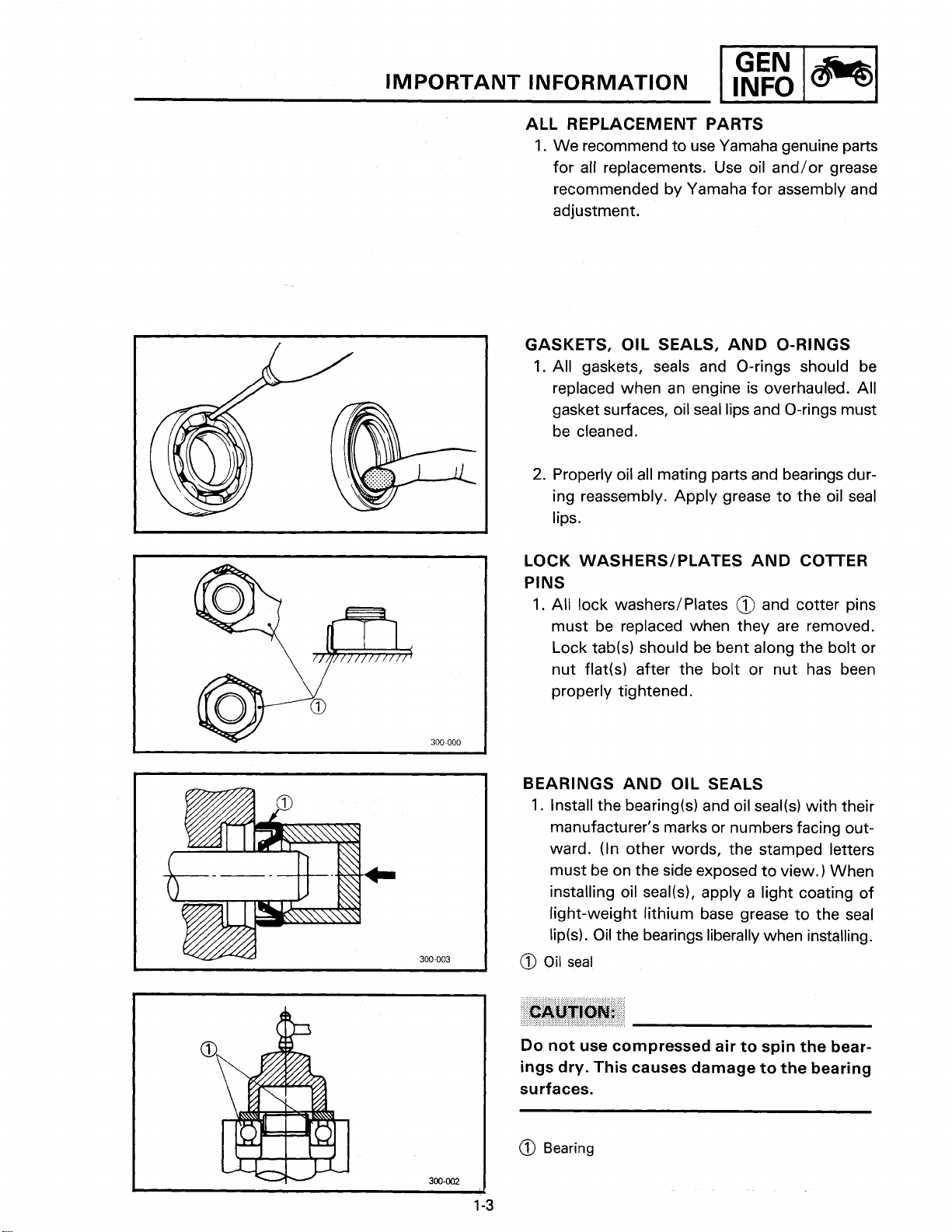

GASKETS, OIL SEALS, AND O-RINGS

1.

All gaskets, seals and O-rings should be

replaced when an engine is overhauled. All

gasket surfaces, oil seal lips and O-rings must

be cleaned.

2.

Properly oil all mating parts and bearings during reassembly. Apply grease to the oil seal

lips.

PI

LOCK WASHERSIPLATES AND COlTER

PINS

1.

All lock washers1Plates @ and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

BEARINGS AND OIL SEALS

1.

Install the bearing(s1 and oil seal(s) with their

manufacturer's marks or numbers facing outward. (In other words, the stamped letters

must be on the side exposed to view. When

installing oil

light-weight lithium base grease to the seal

lip(s). Oil the bearings liberally when installing.

@

Oil

seal

seal(s), apply a light coating of

Do not use compressed air to spin the bearings dry. This causes damage to the bearing

surfaces.

@

Bearing

Page 16

SPEClAL TOOLS

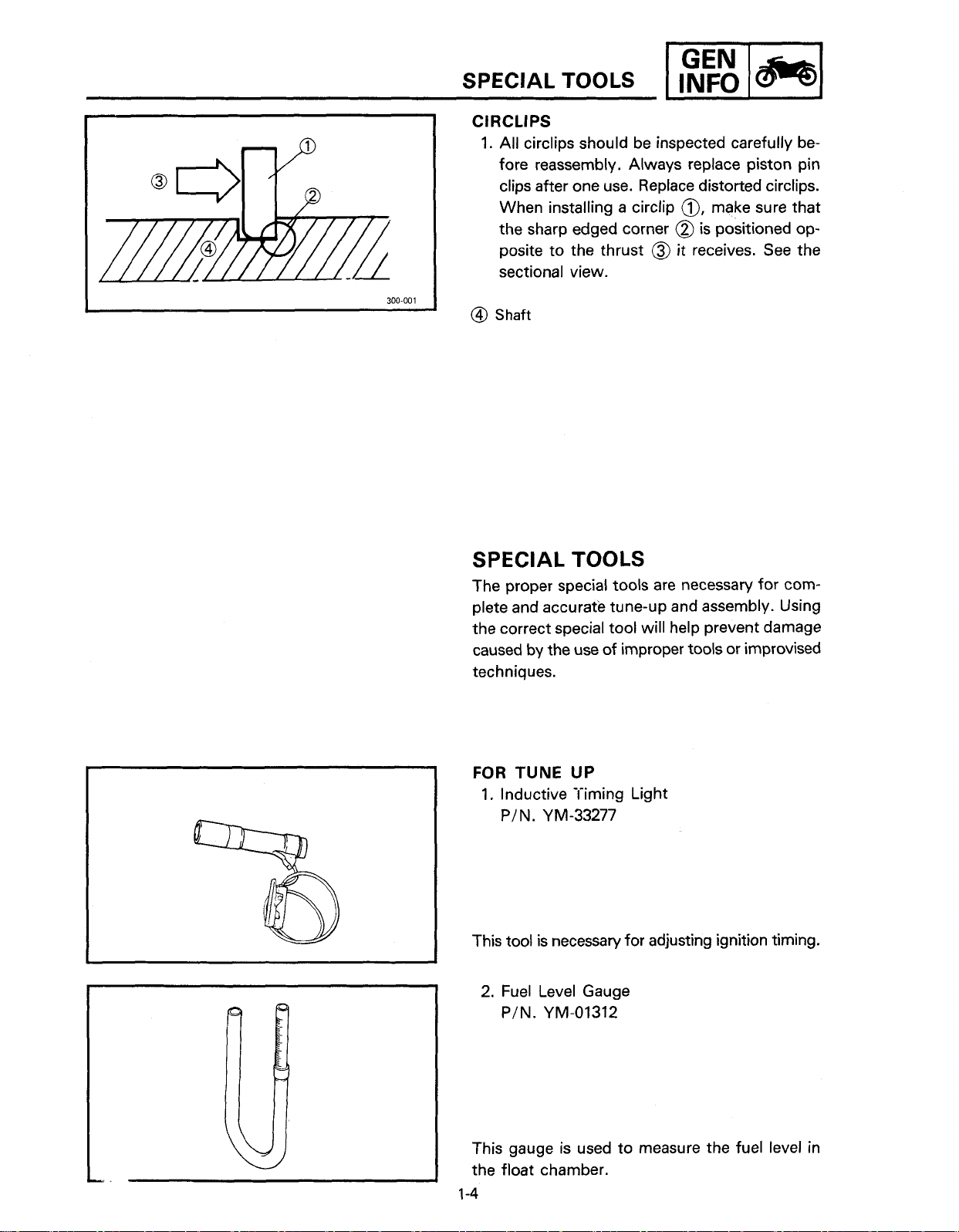

ClRCLlPS

1.

All circlips should be inspected carefully before reassembly. Always replace piston pin

clips after one use. Replace distorted circlips.

When installing a circlip

the sharp edged corner

posite to the thrust

sectional view.

@I

Shaft

-1

@,

make sure that

@

is

positioned op-

@

it receives. See the

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using

the correct special tool will help prevent damage

caused by the use of improper tools or improvised

techniques.

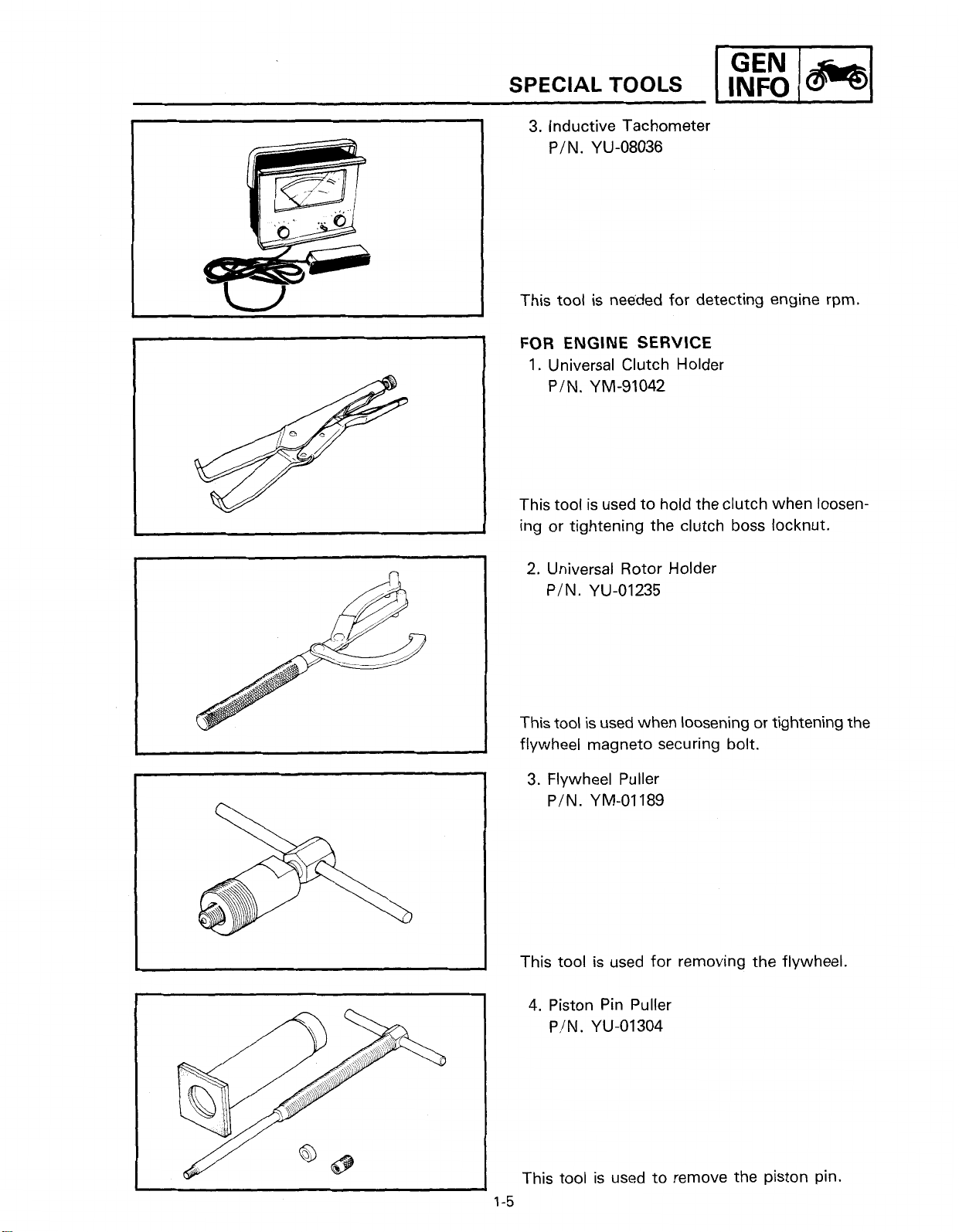

FOR

TUNE

1.

Inductive Timing Light

PIN.

This tool is necessary for adjusting ignition timing.

2.

Fuel Level Gauge

PIN.

UP

YM-33277

YM-01312

This gauge is used to measure the fuel level in

the float chamber.

1-4

Page 17

3.

Inductive Tachometer

YU-08036

PIN.

This tool is needed for detecting engine rpm.

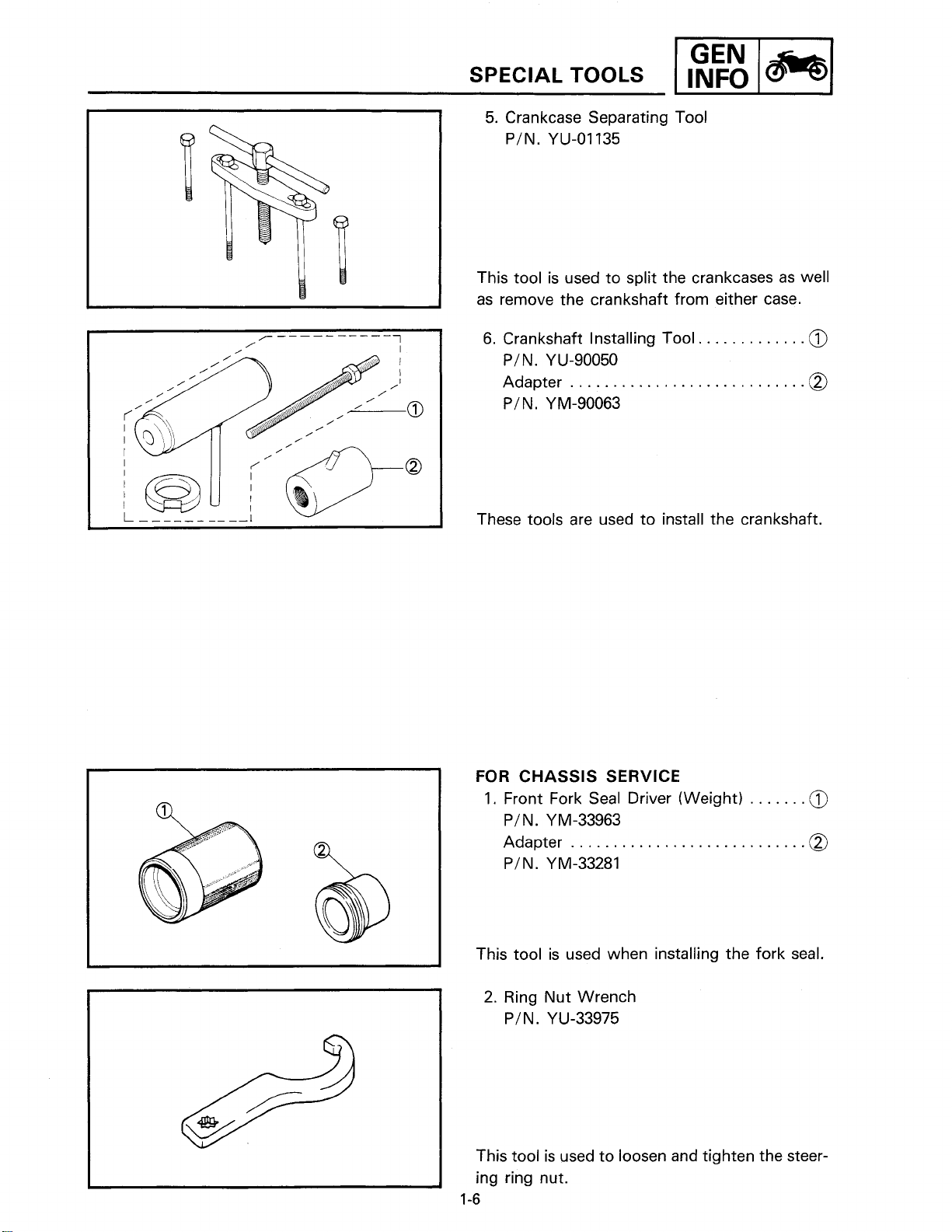

FOR ENGINE SERVICE

1.

Universal Clutch Holder

YM-91042

PIN.

This tool is used to hold the clutch when loosening or tightening the clutch boss locknut.

2.

Universal Rotor Holder

YU-01235

PIN.

This tool is used when loosening or tightening the

flywheel magneto securing bolt.

3.

Flywheel Puller

YM-01189

PIN.

This tool is used for removing the flywheel.

4.

Piston Pin Puller

YU-01304

PIN.

This tool is used to remove the piston pin.

Page 18

SPECIAL

5.

Crankcase Separating Tool

PIN.

This tool is used to split the crankcases as well

as remove the crankshaft from either case.

TOOLS

YU-01135

wl

6.

Crankshaft Installing Tool

PIN.

YU-90050

Adapter

PIN.

These tools are used to install the crankshaft.

FOR

CHASSIS SERVICE

1.

Front Fork Seal Driver (Weight)

PIN.

Adapter

PIN.

............................

YM-90063

YM-33963

..........................

YM-33281

.............

0

0

.....

This tool is used when installing the fork seal.

2.

Ring Nut Wrench

YU-33975

PIN.

This tool is used to loosen and tighten the steering ring nut.

1-6

Page 19

GEN

SPECIAL TOOLS

FOR

ELECTRICAL COMPONENTS

1.

Coil Tester

YU-33261

PIN.

This tester is necessary for checking the ignition

system components.

2.

Pocket Tester

YU-03112

PIN.

This tester is invaluable for checking the electrical system.

wl

Page 20

Page 21

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model

Model Code Number:

Vehicle Identification Number:

Engine Starting Number

Dimensions:

Overall Length

Overall Width

Overall Height

Seat Height

Wheel base

Minimum Ground Clearance

Basic Weight:

With Oil and Full Fuel Tank

1,630 mm (64.2 in)

635 mm (25.0 in)

930 mm (36.6 in)

660 mm (26.0 in)

1,055 mm (41.5 in)

120 mm (4.7 in)

I

SPEC

/

pf

I

Minimum Turning Radius:

Engine:

Engine Type

Induction System

Cylinder Arrangement

Displacement

x

Bore

Compression Ratio

Starting System

Lubrication System:

TY pe

Engine Oil Type

Transmission Oil Type

Oil Capacity:

Engine Oil (Oil Tank)

Transmission Oil:

Stroke

Periodic Oil Change

Total Amount

2,400 mm (94.5 in)

Air cooled 2-stroke

Reed valve

Forward inclined single cylinder

49.3 cm3

x

40.0

7.4

Kick starter

Separate lubrication (Yamaha Autolube)

0.73

0.60 L (0.53 Imp qt, 0.63 US qt)

0.65

39.2 mm (1.57 x 1.54 in)

:

1

Yamalube

"BIA certified for service TC-W"

Yamalube

"GL"

"2

or air cooled 2 stroke engine oil with

"4,

SAE 10W30 type SE motor oil or

gear oil

L

(0.64 Imp qt, 0.77 US qt)

L

(0.57 Imp qt, 0.69 US qt)

Air Filter

Type

Wet type element

Page 22

Model

Fuel:

TY pe

Fuel Tank Capacit

Full Amount

Reserve Amount

Carburetor:

Type/ Quantity

Manufacturer

Spark Plug:

TypeIQuantity

Manufacturer

Plug Gap

Clutch:

Type

Transmission:

TY pe

Primary Reduction System

Primary Reduction Ratio

Secondary Reduction System

Secondary Reduction Ratio

Operation

Gear Ratio

1 st

2nd

3rd

4th

5th

I

GENERAL SPECIFICATIONS

Regular gasoline

8.0 L (1.76 Imp gal, 2.1 1 US gal)

1.5 L (0.33 Imp gal, 0.39 US gal)

VM16SH/1 pc.

MIKUNI

B7HS or B8HS

NGK

-

0.6 mm (0.020 - 0.024 in)

0.5

Wet, multiple disc

Constant mesh 5-speed

Helical gear

68/19 (3.579)

Chain drive

44/12 (3.667)

Left foot operation

I

SPEC

/

pf

I

Chassis:

Frame Type

Caster Angle

Trail

Tire:

TY pe

Size

Front

Rear

Tire Pressure (Cold Tire):

Basic Weight:

With Oil and Full Fuel Tank

Maximum Load*

Cold Tire Pressure:

-

Zero

*

Load is total weight of cargo, rider, and accessories.

Maximum Load*

Double cradle

25.3'

64 mm (2.52 in)

Tubeless

3.50-12 2PR

4.00-12 2PR

FRONT

2-2

Page 23

Model

Brake:

Front Brake Type

Front Brake Operation

Rear Brake Type

Rear Brake Operation

Suspension:

Front Suspension Type

Rear Suspension Type

Shock Absorber:

Front Shock Absorber

Rear Shock Absorber

Wheel Travel:

Front Wheel Travel

Rear Wheel Travel

Electrical:

Ignition System

Generator System

GENERAL SPECIFICATIONS

Single disc brake

Right hand operation

Drum brake

Right foot operation

Telescopic fork

Swingarm (Monocross suspension)

Coil springloil damper

Coil springloil damper

90 mm (3.5 in)

75

mm (3.0 in)

CDI Magneto

Flywheel magneto

-1

Battery:

Type

Capacity

Headlight:

TY pe

Bulb Wattage (Quantity):

Headlight

TailIBrake Light

Flasher Light

Licence Light

Meter Light

"NEUTRAL" lndicator Light

"HIGH BEAM" lndicator Light

"TURN" lndicator Light

"OIL" Warning lndicator Light

(Light Emitting Diode)

Sealed beem

Page 24

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

Model

I

SPEC

1

p9

I

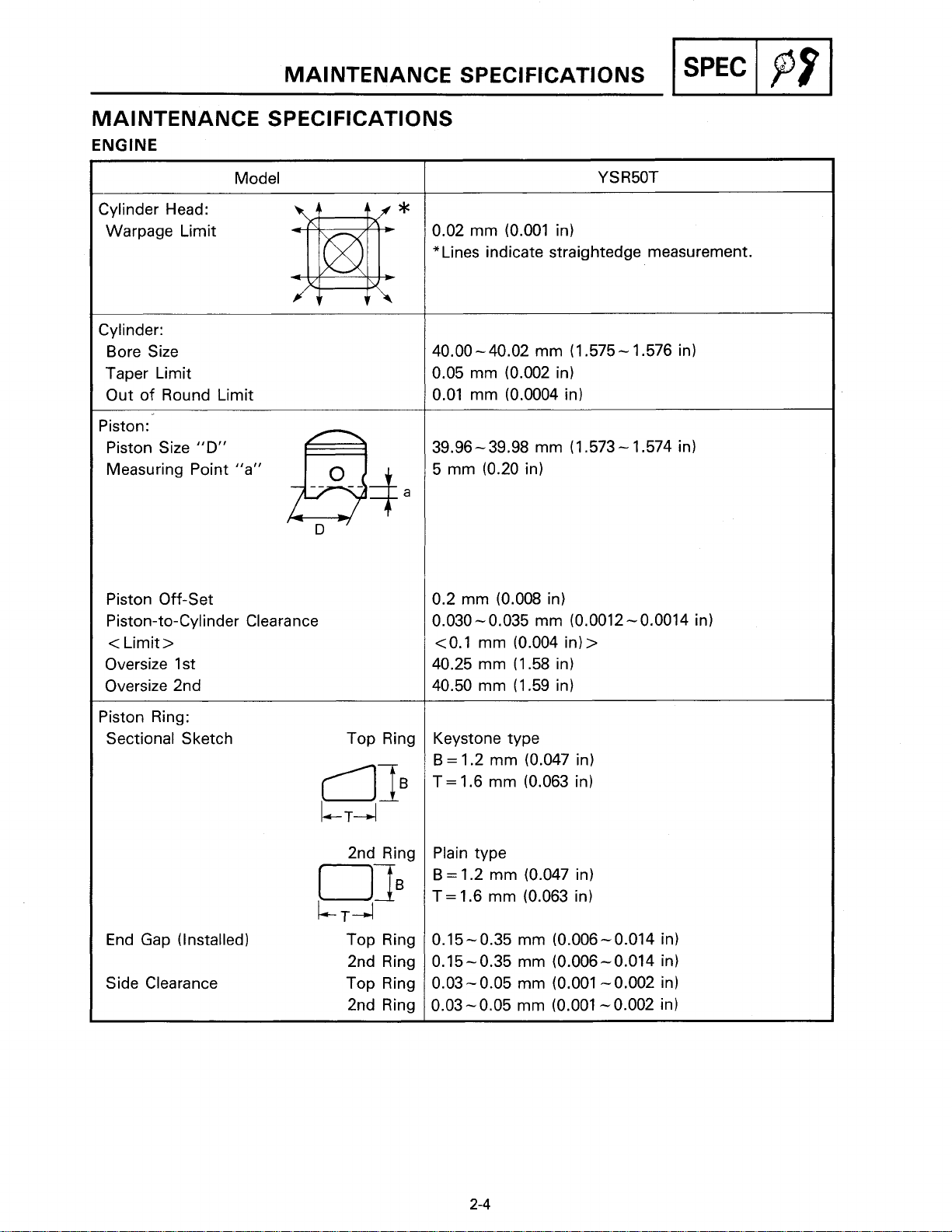

Cylinder Head:

Warpage Limit

Cylinder:

Bore Size

Taper Limit

Out of Round Limit

Piston:

Piston Size

Measuring Point "a"

Piston Off-Set

Piston-to-Cylinder Clearance

<

Limit

Oversize

Oversize

"D"

>

1st

2nd

*

0.02 mm (0.001 in)

"Lines indicate straightedge measurement.

40.00-40.02 mm (1.575- 1.576 in)

0.05 mm (0.002 in)

0.01 mm (0.0004 in)

39.96-39.98 mm (1.573- 1.574 in)

5 mm (0.20 in)

0.2 mm (0.008 in)

-

0.030

<

40.25 mm (1.58 in)

40.50 mm (1.59 in)

0.035 mm (0.0012 - 0.0014 in)

0.1 mm (0.004 in)

>

Piston Ring:

Sectional Sketch Top Ring

OTg

LT~

End Gap (Installed) Top Ring

2nd Ring

Side Clearance Top Ring

2nd Ring

Keystone type

B = 1.2 mm (0.047 in)

=

1.6 mm (0.063 in)

T

Plain type

B

=

1.2 mm (0.047 in)

=

1.6 mm (0.063 in)

T

-

0.15

0.15-0.35 mm (0.006-0.014 in)

0.03-0.05 mm (0.001 -0.002 in)

0.03-0.05 mm (0.001 -0.002 in)

0.35 mm (0.006 - 0.014 in)

Page 25

MAINTENANCE SPECIFICATIONS

Model

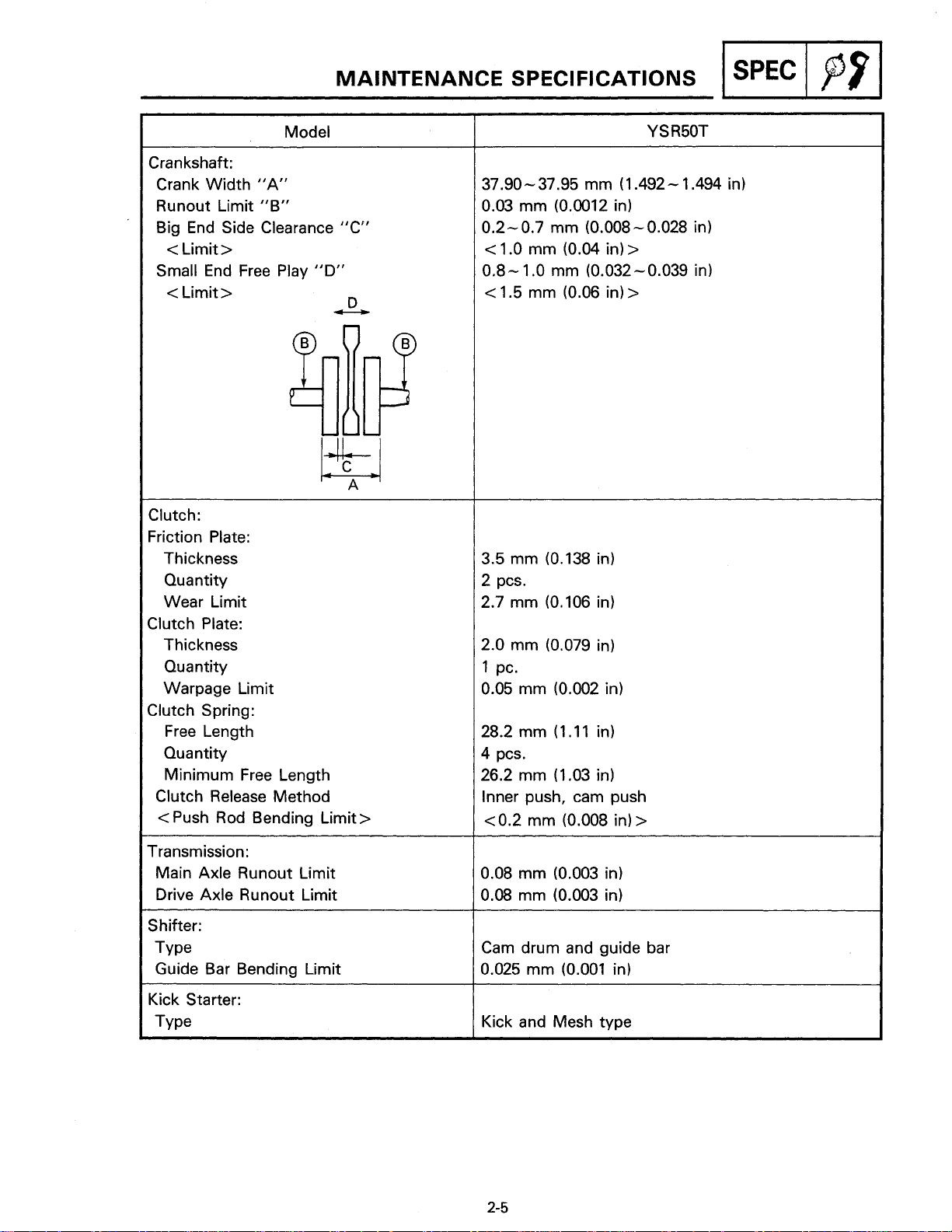

Crankshaft:

Crank Width "A"

Runout Limit "B"

Big End Side Clearance "C"

<

Limit

>

Small End Free Play "D"

<

Limit

>

-

Clutch:

Friction Plate:

Thickness

Quantity

Wear Limit

Clutch Plate:

Thickness

Quantity

Warpage Limit

Clutch Spring:

Free Length

Quantity

Minimum Free Length

Clutch Release Method

<

Push Rod Bending Limit

D

>

I

SPEC

37.90-37.95 mm (1.492- 1.494 in)

0.03 mm (0.0012 in)

-

0.2- 0.7 mm (0.008

<

1.0 mm (0.04 in)

0.8- 1.0 mm (0.032-0.039 in)

<

1.5 mm (0.06 in)

3.5 mm (0.138 in)

2 pcs.

2.7 mm (0.106 in)

2.0 mm (0.079 in)

PC.

1

0.05 mm (0.002 in)

28.2 mm (1.11 in)

4 pcs.

26.2 mm (1.03 in)

Inner push, cam push

~0.2 mm (0.008 in)

0.028 in)

>

>

>

1

pp

I

Transmission:

Main Axle Runout Limit

Drive Axle Runout Limit

Shifter:

TY pe

Guide Bar Bending Limit

Kick Starter:

TY pe

-

0.08 mm (0.003 in)

0.08 mm (0.003 in)

Cam drum and guide bar

0.025 mm (0.001 in)

Kick and Mesh type

Page 26

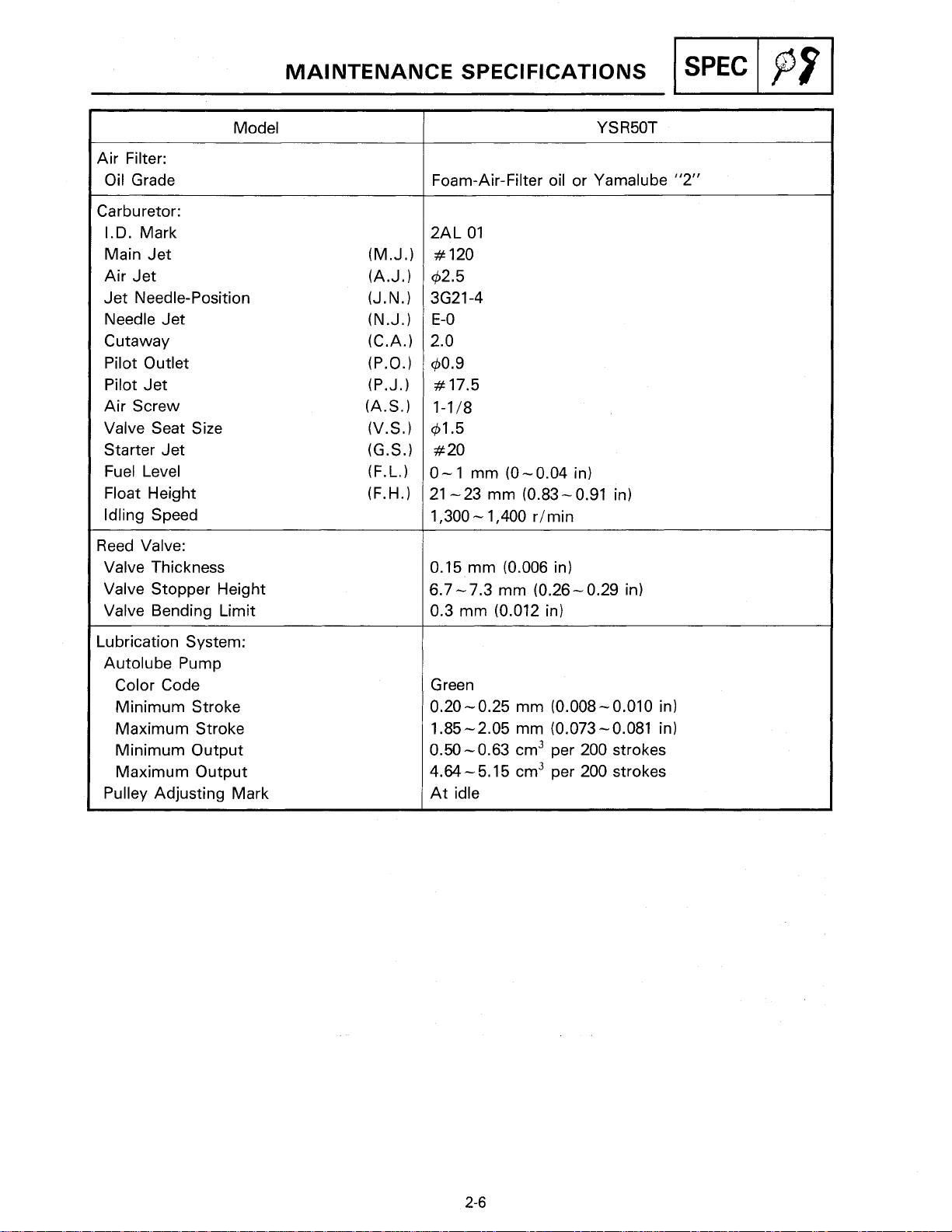

Air Filter:

Oil Grade

Carburetor:

I.D. Mark

Main Jet

Air Jet

Jet Needle-Position

Needle Jet

Cutaway

Pilot Outlet

Pilot Jet

Air Screw

Valve Seat Size

Starter Jet

Fuel Level

Float Height

Idling Speed

Model

MAINTENANCE SPECIFICATIONS

Foam-Air-Filter oil or Yamalube

2AL 01

#

120

42.5

3621 -4

E-0

2.0

40.9

#

17.5

1-118

41.5

#

20

0- 1

mm (0- 0.04 in)

21 -23 mm (0.83 - 0.91 in)

1,300 - 1,400 rlmin

-1

"2"

Reed Valve:

Valve Thickness

Valve Stopper Height

Valve Bending Limit

Lubrication System:

Autolube Pump

Color Code

Minimum Stroke

Maximum Stroke

Minimum Output

Maximum Output

Pulley Adjusting Mark

0.15 mm (0.006 in)

6.7-7.3 mm (0.26- 0.29 in)

0.3 mm (0.012 in)

Green

0.20 - 0.25 mm (0.008 - 0.010 in)

1.85-2.05 mm (0.073-0.081 in)

0.50-0.63 cm3 per 200 strokes

4.64 - 5.15 cm3 per 200 strokes

At idle

Page 27

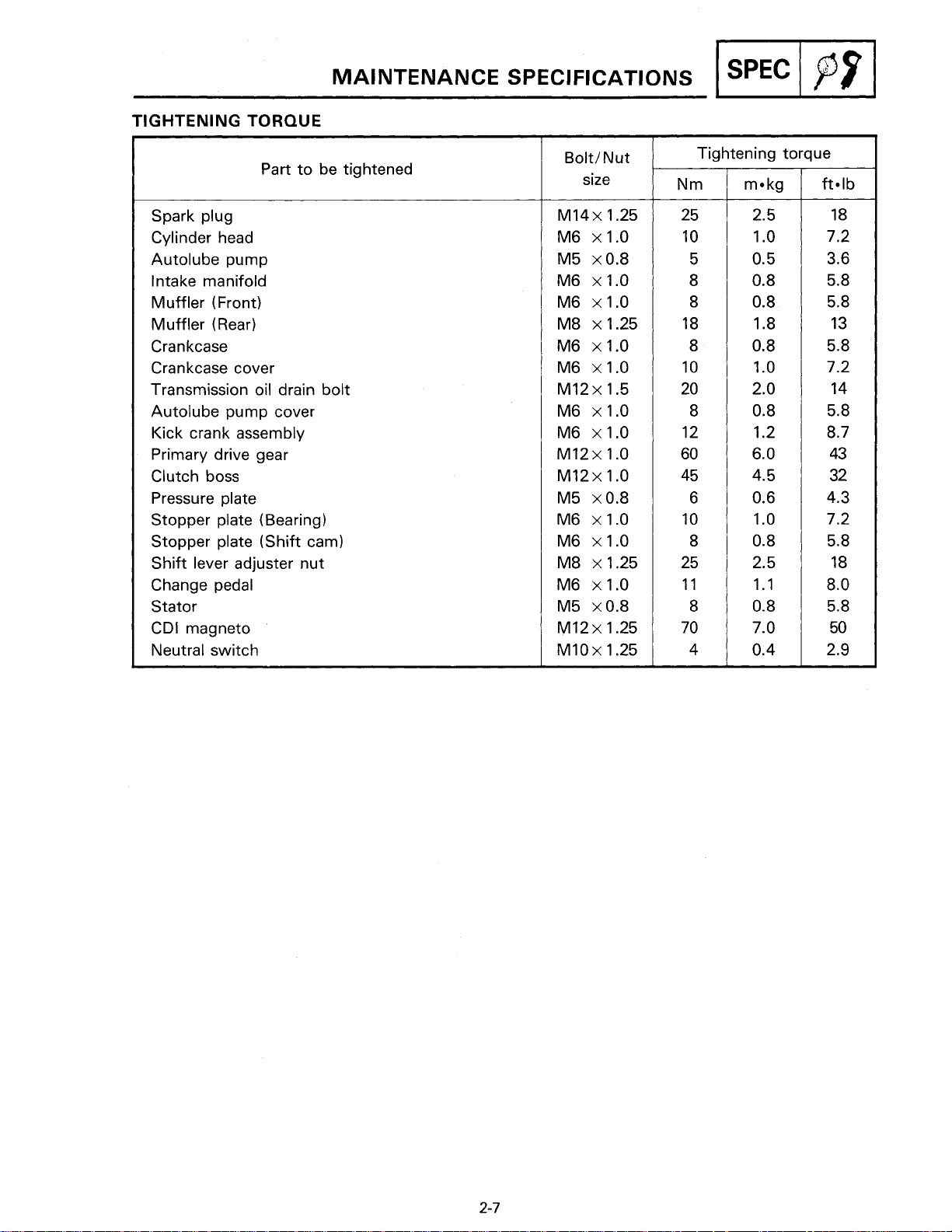

TIGHTENING TORQUE

MAINTENANCE SPECIFICATIONS

I

SPEC

/

p9

I

Part to be tightened

Spark plug

Cylinder head

Autolube pump

Intake manifold

Muffler (Front)

Muffler (Rear)

Crankcase

Crankcase cover

Transmission oil drain bolt

Autolube pump cover

Kick crank assembly

Primary drive gear

Clutch boss

Pressure plate

Stopper plate (Bearing)

Stopper plate (Shift cam)

Shift lever adjuster nut

Change pedal

Stator

CDI magneto

Neutral switch

BoltINut

size

Tightening torque

Page 28

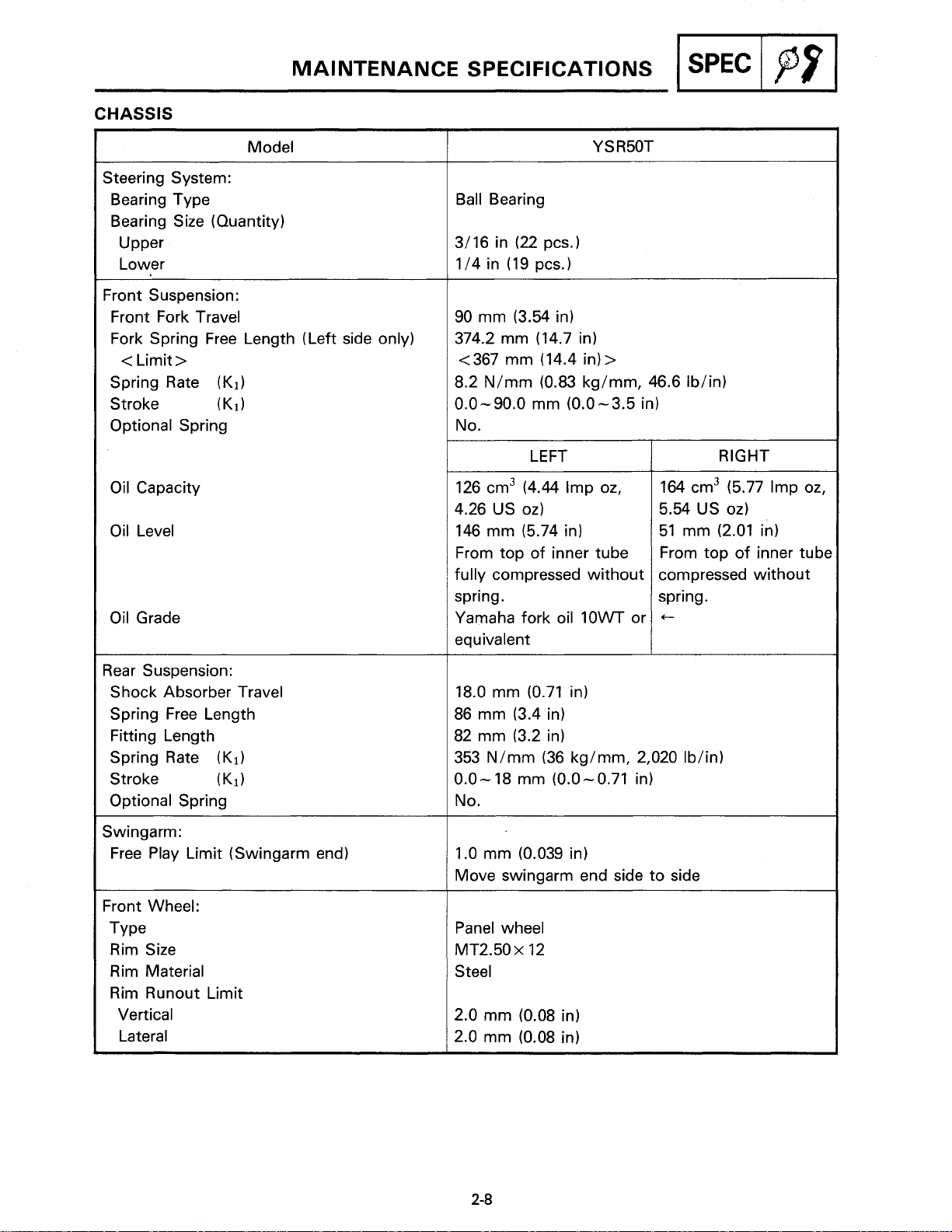

MAINTENANCE SPECIFICATIONS

CHASSIS

Model

Steering System:

Bearing Type

Bearing Size (Quantity)

Upper

Lower

Front Suspension:

Front Fork Travel

Fork Spring Free Length (Left side only)

<

Limit

>

Spring Rate (K1)

Stroke (KI)

Optional Spring

pi+q

Ball Bearing

90 mm (3.54 in)

374.2 mm (14.7 in)

<367 mm (14.4 in)

8.2 Nlmm (0.83 kglmm, 46.6 Iblin)

0.0-90.0 mm (0.0 -3.5 in)

No.

>

Oil Capacity

Oil Level

Oil Grade

3ear Suspension:

Shock Absorber Travel

Spring Free Length

Fitting Length

Spring Rate

Stroke (K1)

Optional Spring

Swingarm:

Free Play Limit (Swingarm end)

Front Wheel:

TY pe

Rim Size

Rim Material

Rim Runout Limit

Vertical

Lateral

(K1)

LEFT

126 cm3 (4.44 Imp oz,

4.26 US oz)

146 mm (5.74 in)

From top of inner tube

fully compressed without

spring.

Yamaha fork oil 10WT or

equivalent

18.0 mm (0.71 in)

86 mm (3.4 in)

82 mm (3.2 in)

353 Nlmm (36 kglmm, 2,020 Iblin)

0.0- 18 mm (0.0-0.71 in)

No.

1.0 mm (0.039 in)

Move

swingarm end side to side

Panel wheel

MT2.50

Steel

2.0 mm (0.08 in)

2.0 mm (0.08 in)

x

12

164 cm3 (5.77 Imp oz,

5.54 US oz)

51 mm (2.01 in)

From top of inner tub(

compressed without

spring.

t

RIGHT

Page 29

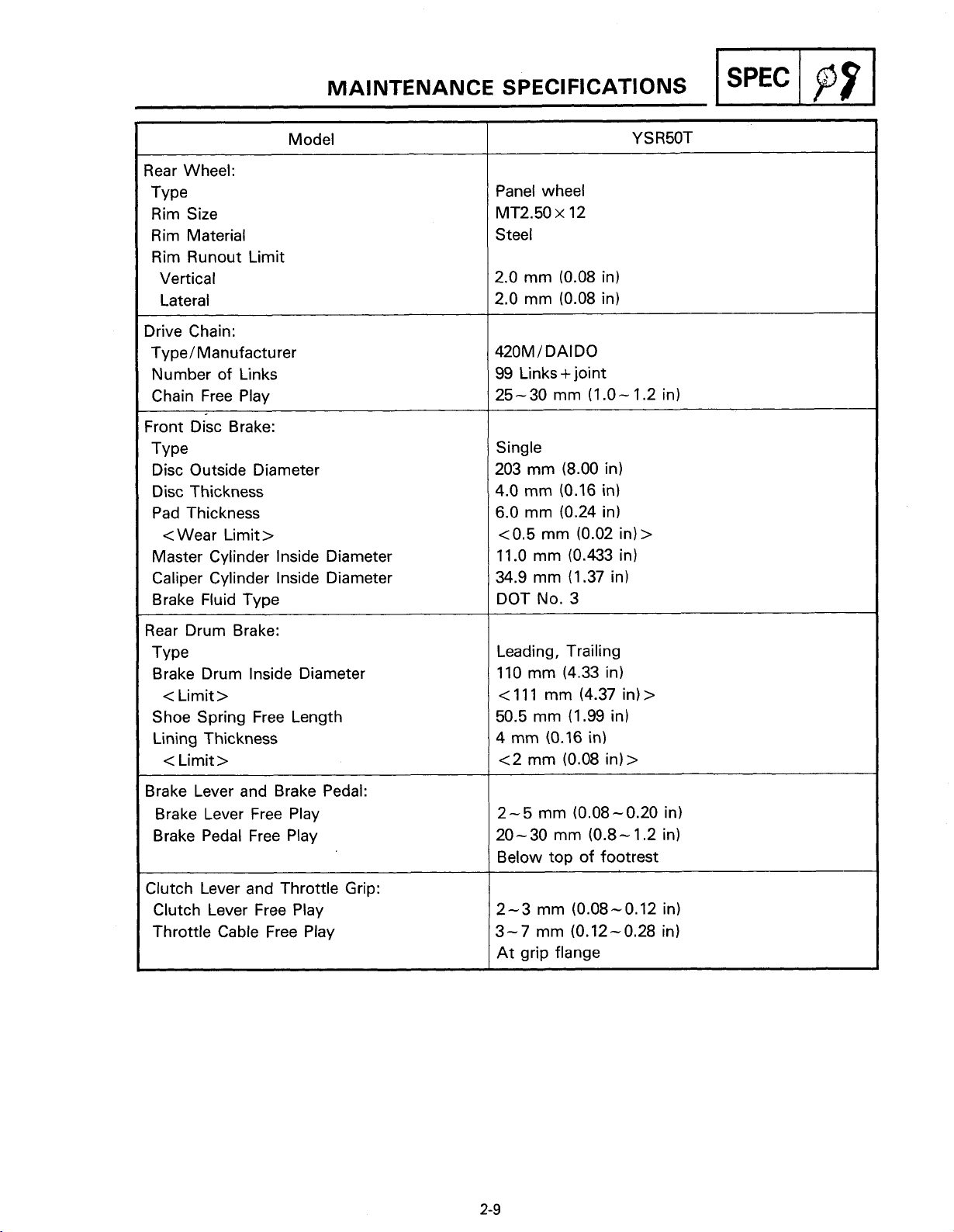

MAINTENANCE SPECIFICATIONS

pqi$q

I

Rear Wheel:

Type

Rim Size

Rim Material

Rim Runout Limit

Vertical

Lateral

Drive Chain:

Type! Manufacturer

Number of Links

Chain Free Play

Front Disc Brake:

TY pe

Disc Outside Diameter

Disc Thickness

Pad Thickness

<Wear Limit

Master Cylinder lnside Diameter

Caliper Cylinder lnside Diameter

Brake Fluid Type

Model

>

Panel wheel

MT2.50

Steel

2.0 mm (0.08 in)

2.0 mm (0.08 in)

420M/ DAIDO

99 Links +joint

25-30 mm (1.0- 1.2 in)

Single

203 mm (8.00 in)

4.0 mm (0.16 in)

6.0 mm (0.24 in)

<

11

34.9 mm (1.37 in)

DOT No.

x

12

0.5 mm (0.02 in)

.O

mm (0.433 in)

3

>

Rear Drum Brake:

TY pe

Brake Drum lnside Diameter

<

Limit

>

Shoe Spring Free Length

Lining Thickness

<

Limit

>

Brake Lever and Brake Pedal:

Brake Lever Free Play

Brake Pedal Free Play

Clutch Lever Free Play

Throttle Cable Free Play

Leading, Trailing

110 mm (4.33 in)

<

11 1 mm (4.37 in)

50.5 mm (1.99 in)

4

mm (0.16 in)

<2 mm (0.08 in)>

2-5 mm (0.08-0.20 in)

20-30 mm (0.8-1.2 in)

Below top of footrest

2-3 mm (0.08-0.12 in)

3-7 mm (0.12-0.28 in)

At grip flange

>

Page 30

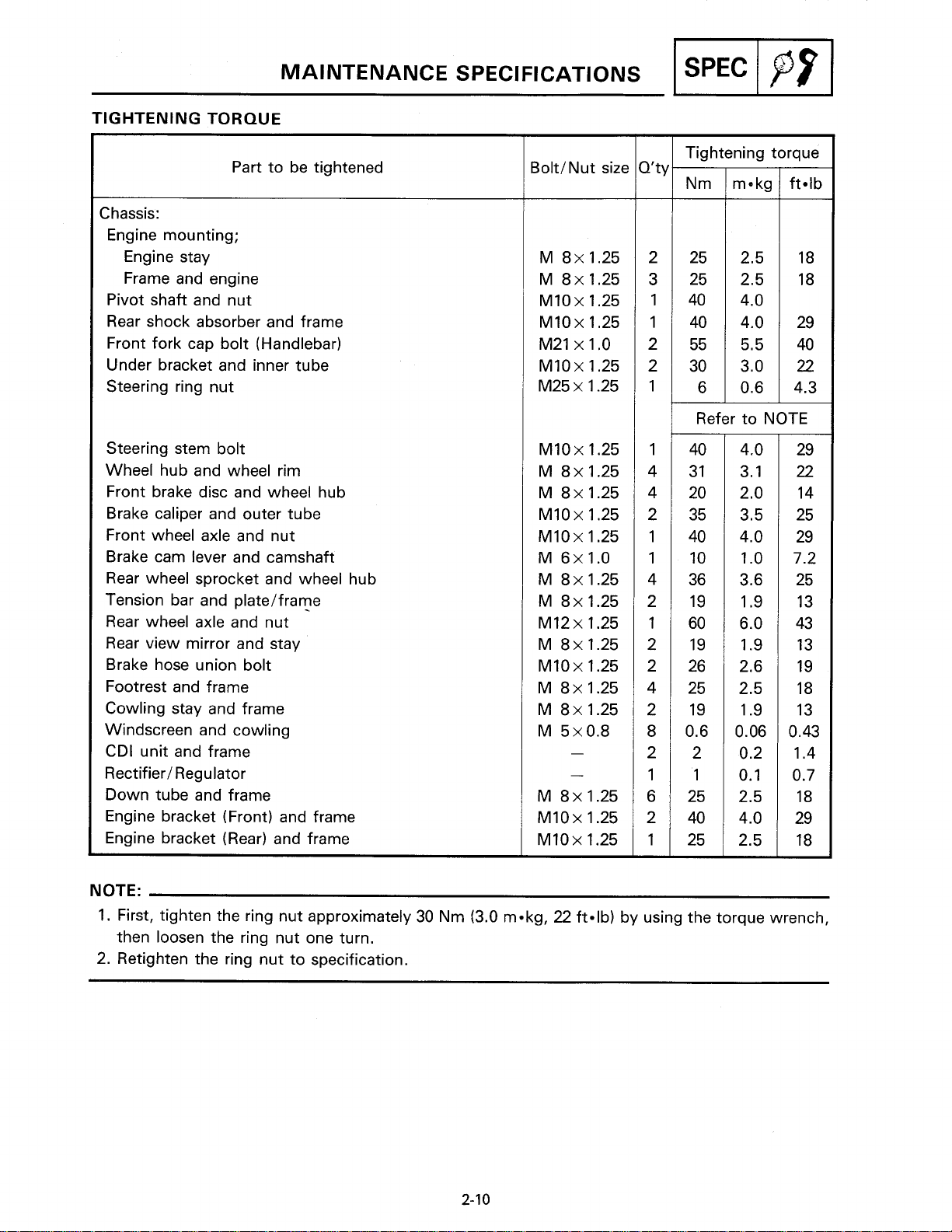

MAINTENANCE SPECIFICATIONS

TIGHTENING

Chassis:

Engine mounting;

Engine stay

Frame and engine

Pivot shaft and nut

Rear shock absorber and frame

Front fork cap bolt (Handlebar)

Under bracket and inner tube

Steering ring nut

Steering stem bolt

Wheel hub and wheel rim

Front brake disc and wheel hub

Brake caliper and outer tube

Front wheel axle and nut

Brake cam lever and camshaft

Rear wheel sprocket and wheel hub

Tension bar and

Rear wheel axle and nut

Rear view mirror and stay

Brake hose union bolt

Footrest and frame

Cowling stay and frame

Windscreen and cowling

CDI unit and frame

Rectifier1 Regulator

Down tube and frame

Engine bracket (Front) and frame

Engine bracket (Rear) and frame

TORQUE

Part to be tightened

platelframe

BoltlNut size

Tightening torque

ft-lb

Refer to NOTE

NOTE:

1.

First, tighten the ring nut approximately 30 Nm (3.0 m-kg,

then loosen the ring nut one turn.

2.

Retighten the ring nut to specification.

22

ft-lb) by using the torque wrench,

Page 31

ELECTRICAL

MAINTENANCE SPECIFICATIONS

-1

--

-

-

Voltage:

Ignition System:

Ignition Timing (B.T. D.C.)

Advancer Type

Model

22O at 5,000 rlmin

Electrical type

01234

C.D.I.:

Magneto ModelIManufacturer

C.

D. I. Unit Model/ Manufacturer

Pickup Coil Resistance (Color)

Source Coil Resistance (Color)

Ignition Coil:

ModelIManufacturer

Minimum Spark Gap

Primary Coil Resistance

Secondary Coil Resistance

Spark Plug Cap:

TY pe

Plug Cap Resistance

Engine

2RRlYAMAHA

2GXlYAMAHA

16-240 at 20°C (68OF)

(WhiteIRed- Black)

264- 396fl at 20°C (68OF)

-

(Black/ Red

2JNlYAMAHA

6 mm (0.24 in)

0.7- 1.1Q at 20°C (68OF)

5.7-8.5kQ at 20°C (68OF)

Resin Type

4-6kQ at 20°C (68OF)

Black)

Page 32

MAINTENANCE SPECIFICATIONS

-1

-

Charging System:

C.D.I. Magneto:

ModelIManufacturer

Charging Coil Resistance (Color)

Standard Output

Model

Y S R50T

I

Flywheel Magneto

2RRlYAMAHA

0.24-0.36Q at 20°C (68OF) (White- Black)

7.4-8.2V at 5,000 rlmin

Lighting Coil Resistance (Color)

Standard Output

Voltage Regulator:

ModelIManufacturer

I

Rectifier:

ModelIManufacturer

Capacity

Withstand Voltage

Battery:

Specific Gravity

Horn:

TY pe

Quantity

Model1 Manufacturer

Maximum Amperage

Engine Speed

(

x

1,000

rlmin)

0.16-0.24Q at 20°C (68OF) (YellowIRed- Black)

6.2-7.2V at 3,000 rlmin or more

Plane Type

1 PC.

GF-12lNIKKO

1.5A

Page 33

Model

Flasher Relay:

Type

ModelIManufacturer

Self Cancelling Device

Flasher Frequency

Wattage

Oil Level Switch:

ModelIManufacturer

Curcuit Breaker:

Type

Curcuit (Fuse):

"MAIN"

MAINTENANCE SPECIFICATIONS

Condenser Type

FZ636SDlNIPPON DENS0

No

-

95

75

17W

Fuse

cycles1 min

x

2

+

3W

(6V)

I

SPEC

I

p?

I

Page 34

GENERAL TORQUE SPECIFICATIONS1

DEFINITION OF UNITS

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for standard fasteners

with standard I.S.O. pitch threads. Torque specifi-

cations for special components or assemblies are

included in the applicable sections of this book.

To avoid

blies in a crisscross fashion, in progressive stages,

until full torque is reached. Unless otherwise

specified, torque specifications call for clean, dry

threads. Components should be at room temperature.

warpage, tighten multi-fastener assem-

A

(Nut) (Bolt)

B

General torque

specifications

Nm

1

m-kg / ft-lb

,

I

A: Distance across flats

B:

Outside thread diameter

DEFINITION OF UNITS

Unit

mm

cm

kg

N

Nm

m-kg

Pa

N/mm

L

cm3

rlmin

millimeter

centimeter

kilogram

Newton

Newton meter

Meter kilogram

Pascal

Newton per millimeter

Liter

Cubic centimeter

Rotation per minute

Read

Definition

meter

meter

lo3

gram

1 kg

x

m /sec2

Nxm

m

x

kg

~/m~

N/mm

-

-

Measure

Length

Length

Weight

Force

Torque

Torque

Pressure

Spring rate

Volume or capacity

Engine speed

Page 35

LUBRlCATlON POINTS AND LUBRICANT TYPE

LUBRICATION POINTS AND LUBRICANT TYPE

ENGINE

I

SPEC

1

pf

I

I

I

Oil seal lip

O-ring

I

Small end1Big end bearing

Bearing

Piston ring

I

Piston

Cylinder inner surface

Piston pin

I

Kick axle

Primary drivenldrive gear

Push rod

I

Push lever

PinionIWheel gears

Collar (Drive axle)

I

Guide bar (Shift fork)

Lubrication Points (Part name)

I

Lubricant Type

--.~SI

-=a&

-IQ

-IQ

-+a

A=

-4

-la

Shift shaft

Shift cam

CHASSIS

Lubrication Points (Part name)

Steering UpperlLower balls

FrontIRear wheel oil seal lip

Brake cam shaft

Speedometer gear unitloil seal

Brake pedal pivot

Rear shock absorber collar

Handlebar (Right) end

Sidestand pivot

Footrest pivot

Clutch lever

Brake lever pivot

pivotlcable end

1

1

1

-la

-a

Lubricant Type

A=

-5

I

I

-=

-?as4

-+a

I

-a

-=

-la

-IQ

-IQ

-4

Pin (Rear shock absorber)

Pivot shaft

-=

--=&

2-15

Page 36

CABLE

ROUTING

I

SPEC

/

p9

I

CABLE

a

Handlebar switch (Right) lead

@

Main switch lead

@

Clutch cable

@

Handlebar switch (Left) lead

@

Clamp

@

Throttle cable

a

Front brake hose

ROUTING

Page 37

CABLE

ROUTING

I

SPEC

I

p9

I

CABLE

@

Headlight lead

@

Spark plug lead

@

Clutch cable

@

Horn lead

@

Sidestand switch lead

@

Band

a

Cable holder

@

Speedometer cable

@

Meter light lead

ROUTING

Pass the speedometer cable through the cable

holder.

Page 38

CABLE

ROUTING

I

SPEC

1

pp

1

CABLE

Front brake hose

Clamp

Cable guide

Oil hose

@

Oil pump cable

@

Oil delivery hose

@

Fuel tank breather hose @ Taillbrake light lead

@

Wireharness

ROUTING

@

Carburetor breather hose

@

Carburetor air vent hose

0

CDl magneto lead

@

Battery breather hose

@

Rear brake switch lead

@

Band

Clamp the brake hose.

1Si]

Pass the battery breather hose through the

hole on the rear fender.

Page 39

CABLE

ROUTING

-1

CABLE

a

Clamp

a

Band

@

Throttle cable

@

Front brake hose

@

Brake switch lead

@

RectifierIRegulator @ Ignition coil hose.

a

Main switch lead

ROUTING

@

@

0

@

@

@

@

Wireharness

Clutch cable hole on the frame.

Sidestand switch lead

Handlebar switch (Left) lead

Spark plug lead

Oil tank breather hose

Oil level switch

IB]

Pass the oil tank breather hose through the

Pass the main switch and brake switch lead in-

side of the oil tank cap

Pass the sidestand lead above the Y.E.I.S.

Page 40

CABLE ROUTING

@

Band

@

Cable guide

@

Rear flasher light (Right) lead

@

Taillight lead

@

Rear flasher light (Left) lead

@

Battery negative

a

Battery positive

@

Battery

@

Flasher relay

@

CDI unit

(

-

)

lead

(

+

)

lead

CABLE

CB]

ROUTING

Pass the wireharness, flasher light lead and

battery breather hose through the guide.

Pass the flasher light lead through the guide.

-1

Page 41

lNTRODUCTlONlPERlODlC MAINTENANCE1

LUBRICATION INTERVALS

lNSP

1

I

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments.

These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and

a longer service life. The need for costly overhaul work will be greatly reduced. This information ap-

plies to vehicles already in service as well as new vehicles that are being prepared for sale. All service

technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCEILUBRICATION INTERVALS Unit: km (mi)

I

ITEM

I

Spark plug(s)

I

Air filter"

Carburetor*

Fuel line*

Wheels*

Wheel bearings*

I

Steering bearing*

Front forks*

absorber*

Drive chain

Fittings1 Fasteners*

I

Sidestand switch*

Battery*

REMARKS

Check condition. Clean or replace if

necessarv.

Clean. Replace if necessary.

Check idle speedlstarter operation.

Adjust if necessary.

Check fuel hose for cracks or damage.

Replace if necessary.

Check oil levelloil leakage.

Correct if necessary.

Replace every 12,000 (8,000) or 24 months

(Warm engine before draining.

Check operation. Correct if necessary.

Air bleeding.

Check operation/fluid IeakageISee NOTE.

Correct if necessary (front). Brake*

Check operation. Adjust if necessary (rear).

Check operation. Adiust if necessarv.

Check

Repair if necessary.

Check bearings assembly for looseness/

damage. Replace if damaged.

Check bearings assembly for looseness.

Correct if necessary.

Moderately repack every 24,000 (16,000)

or 24 months.**

Check operationloil leakage.

Repair if necessary.

Check operationloil leakage.

Repair if necessary.

Check chain slacklalignment.

Adjust if necessary. Clean and lube.

Check all chassis fittings and fasteners.

Correct if necessary.

Check operation. Repair if necessary.

Check operation.

Clean or replace if necessary.

Check specific gravity.

Check breather pipe for proper operation.

Correct if necessary.

balanceldamagelrunout.

1

BREAK-IN

1,000 (600) (2,000) or (4,000) or

REPLACE

7

1

6 months 1 12 months

EVERY 500

0

EVERY

6,000

0

(300)

It is recommended that these items be serviced by a Yamaha dealer or other qualified mechanic.

*:

**:

Medium weight wheel bearing grease. (bearing type)

3-1

Page 42

INTRODUCTION/PERIODIC MAINTENANCE1

LUBRICATION INTERVALS

NOTE:

Brake system:

1.

When disassembling the master cylinder or caliper cylinder, replace the brake fluid. Normally check

the brake fluid level and add the fluid as required.

2.

We recommend that, on the inner parts of the master cylinder and caliper cylinder, replace the

oil seals every two years.

3.

We recommend that, replace the brake hoses every four years, or if cracked or damaged.

Page 43

Page 44

"Front seat

@Side cover

everse removal ste

@

@

a

and

warm

it up.

@Engine idle speed

ut

of specification* Adjust.

@Engine idle speed

p screw

in

or out un-

Page 45

.

Install:

efore adjusting throttle ca le free play, engine

be

idle speed should

1.

Check:

@Throttle cable free

adjusted.

play

@

2.

Adjust:

@Turn the adjuster

tle cable free

pl

or out

until the cor-

1.

Remove:

Lower cowling

Page 46

e

pump

Check:

~Aiignmeni

mark

cover

a

9Tighten

P

5.

Install:

the locknut.

autol lube

@Lower cowling

pum

r

out until the

pP

ali

,

..

-

Page 47

tart

the

engine

gine the moment that the adjus

moves out to its

5.

Measure:

ut

of speci3icatioi~-~Adjus-t~

Measure ?he

between the raised boss

adjusting pulley

and

warm

the engine at idle

g

plate carefully.

limit.

gap

with the Thickness gauge

an

the adjusting plate

it

up.

@

on the pump

-

a.

@Autolube

pump

minimum

stroke

stroke

is

increase

Page 48

@Install the adjustin

locknut.

7.

Install:

.

Air

bleed:

appear.

@When air bubbles are expelled completely,

tighten the bleed screw.

damaged, replace with a new

one.

Page 49

4.

Air bleed:

ump

distributor andlor delivery

hose

:

It

is

difficult

maximum.

5.

Install:

Q

Lower

to

bleed

urnp

cowlin

-

the

stroke

--

distri

at

a

4

rn

PA

'1.

Remove:

Page 50

4.

Inspect:

@Electrode

@Insulator

Abnormal coIor-9

orrnal color

5.

Clean the spark

er or wire brus

. Measure:

sf

specification-.

ut

7.

Tighten:

efore

installing a s ark plug, clean the

gasket and

OTE:

-.....-

Finger-tighten

specifics

to

cisn.

a

is

a medium-$0-light tan color.

or Feeler Gau

auge

Wegap.

plug

surfaces.

--,

the

spark

dug(~) befcwe rorquing

--.--

-

--

N

TBMINNG

Adjustment free.

E

Olk

LEVEL

1.

Check:

@Oil

level

31

level

low-+Add

il

Tank

CHECK

CHECK

sufficient

Capacity:

oil.

Page 51

"OIL" warning

indicator

light

A

1.

Place the motorcycle on a level surface

warm

2.

Stop the engine and remove the oil filler

up

the engine for several minutes.

and

cap.

Page 52

false readings.

4.

Inspect:

il

level should

b

A

he engine for several minutes an

stop the engine.

2.

Place an oil pan under the engine.

rain the engine

oil.

Page 53

.

Install:

.

Fill:

7.

Install:

@

Loosen the locknuts

adjusters

free play is obtained.

@.

@

in or out until the

5-

14

ten the locknuts.

Page 54

~Clutcch

push

lever free play

tighten

the locknut while hoiding the

juster.

5.

Install:

@Flywheel magneto cover

"Lower cowling

6.

Adjust:

@Clutch cable free play

efer

to

@

Front seat

"Free

play adjustment" section.

ad-

Page 55

2.

Turn

the fuel cock to

"

"Fenel

4.

Remove:

tank

ir

filter cover

@

@

ever operate the

element removed.

air to enter, causin

withaut

solvent.

the filter

Clean:

@Air

filter element

nt gently, but thoroughly in

en

This

ine

with

the

will

alisw unfiltered

id

wear

will

affect cavbu-

uewt

poor perfor-

overheating.

ne

air

and

filter

possi-

Page 56

@Squeeze the excess solvent out of the element

and let dry.

r-filter oil or Vamalu

to the element.

out the excess oil.

;;

The

element should be wet

ut

not dripping.

@Air

filter case cover

4

'1.

Install:

@Fuel tank

Front seat

cSide cover

2.

Inspect:

@Carburetor joint

@

"Lower cowl

Page 57

"Lower cowl

@bower cowling

.

Install:

@lower cowling

1.

Check:

rake lever free play

ut

of specification+lnspect the brake

section.

@

Page 58

REA

1.

Check:

Out

free

edal

of

specification-AcdjuS

play

ENT

@

Adjustment

@Turn

BRAKE

1.

2.

the adjuste

fied

free

FLUID

Make

sure

by

turning

1nspecr:

oBrake

Fluid

a+~eplenisk.

Recornmewdad

play

the

fluid

lwei

st8

is

obtained.

!

the

handlebars.

level

is

under

in

or

out

r

"L

WER"

Brake

until

top

FBui

the

spsci-

is

horimontaal

level

I

i

line

I

rake

pRasPie

---

fluid

parts.

may

AGway

erode

painted

surfaces

-

or

Page 59

INSPECTIOPJ

1.

Activate the brake lever,

2.

Inspect:

r

@

2.

Inspect:

ar indicator

cator at wear limit line

brake shoes.

@

almost contacts brake

LIGHT

AICE

TE:

The

brake light switch

of

the brake pe

Proper adjustment is achieved when the

light comes on just before the brake begins to

effect.

it

that

does not rotate and turn the adjusting

Q.

nut

SbVITCH

-

is

operated

e switch body

ADJUSTMENT

--

by

movemenu

a

with your &an

bralee

-

take

1.

Inspect:

rack/ Damage/

Fluid

lea

Page 60

andlor adjust the chain slack with the rear wheel

in this "tightest"

I.

Check:

rive chain slack

ut of specification-tAdjcest.

@

is

slack

alignment.)

obtained

Page 61

eTighten the nut ( ear wheel axle)

@Insert a new cotter pin.

3-21

center rollers.

2.

To clean the

machine,

9.

Remove:

bower cowling

2.

Elevate the front wheel

chain,

dip

it

in solvent, an

under the engine.

remove 'he

by

placing a suitable

Page 62

3.

Check:

Grasp

rock

the

bottom

the

fork

assembly

seness-Adjust steerin

o$

the

back

forks

and

and

forth.

gently

oRstighten

Avoid

r

--

5.

Install:

Lower

"re

ring

nut

over-tightening.

- - -

cowling

using

-

,

the

--

Ring

Nclr

, ,

.

,

Page 63

TlRE INSPECTION

TlRE INSPECTION

Do not attempt to use tubeless tires on a

wheel designed for tube type tires only. Tire

failure and personal injury may result from

sudden deflation.

I

wheel

I

Tube type 1 Tube type only

I

Tubeless ( Tube type or tubeless

Be sure to install the correct tube when using tube type tires.

1.

Measure:

*Tire pressure

Out of specification-+Adjust.

I

lml

Tire

INSP

I

I

I

I

Tire inflation pressure should be checked and

adjusted when the temperature of the tire

equals the ambient air temperature. Tire inflation pressure must be adjusted according

to total weight of cargo, rider, passenger,

and accessories (fairing, saddlebags, etc. if

approved for this model), and vehicle speed.

Basic weight:

With oil and full

fuel tank

I

Maximum load*

I

Cold tire Dressure

Zero - Maximum 130 kPa 150 kPa

load*

*Load is the total weightof cargo, rider, and

accessories.

2.

Inspect:

*Tire surfaces

Wear/ Damage-+Replace.

/

I

1

68

kg (150 Ib)

Front

(1.3 kg/cm2, (1.5 kg/cm2,

18 psi1 21 psi)

/

Rear

I

I

I

Minimum Tire Tread Depth:

(Front and Rear)

@

Tread depth

a

Side wall

@

Wear indicator

Page 64

WHEEL INSPECTIONICABLE INSPECTION AND

LUBRICATION

WHEEL INSPECTION

1.

Inspect:

Wheels

Damage/ Bends* Replace.

NOTE:

Always balance the wheel when a tire or wheel

has been changed or replaced.

Never attempt even small repairs to the

wheel.

lNSP

AD

J

2.

Tighten:

*Valve stem locknut

Ride conservatively after installing a tire to

allow

CABLE INSPECTION AND LUBRICATION

Damaged cable sheath may cause corrosion

and interfere with the cable movement. An

unsafe condition may result so replace such

cable as soon as possible.

it

to seat itself properly on the rim.

1.

Inspect:

*Cable sheath

Damaged Replace.

Page 65

CABLE INSPECTION AND LUBRICATIONILEVER AND

PEDAL LUBRICATIONISIDESTAND LUBRICATION

2.

Check:

@Cable operation

Unsmooth operation* Lubricate.

Recommended Lubricant:

Yamaha Chain and Cable Lube

or SAE

NOTE:

Hold cable end high and apply several drops of

lubricant to cable.

10W30

Motor Oil

LEVER AND PEDAL LUBRICATION

Lubricate pivoting parts of each lever and pedal.

Recommended Lubricant:

Yamaha Chain and Cable Lube

or SAE

SIDESTAND LUBRICATION

Lubricate the sidestand at pivot points.

Recommended Lubricant:

Yamaha Chain and Cable Lube

or SAE

10W30

10W30

Motor Oil

Motor Oil

Page 66

1.

Remove:

@Front seat

@Side cover

Refer to

2.

Inspect:

Fluid level should be between upper

lower

Incorrect-. Refill.

3.

Inspect:

@Battery terminal

Dirty terminal-Clean with wire brush,

Poor connection+Correct.

:--

After cleaning the terminals, apply grease lightly

to the terminals.

"'SIDE

@

level marks.

COVER" section

a

and

--------

4.

Connect:

@Breather hose

Be sure the hose is properly attached and

routed.

@

Pass the breather hose into the

5.

Inspect:

@Breather hose

Obstruction-+ Remove.

Damage-+ Replace.

clamp.

6.

Check:

@Specific gravity

Less than 11.280-.Recharge battery.

Page 67

Replace the battery if:

Battery voltage will not rise to a specific value

or bubbles fail to rise even after many hours

of charging.

*Sulfation of one or more cells occurs, as in-

dicated by the plates turning white, or an accumulation of material exists in the bottom

of the cell.

*Specific gravity readings after a long, slow

charge indicate one cell to be lower than the

rest.

*Warpage or buckling of plates or insulators

is evident.

Always charge a new battery before using

it

to ensure maximum performance.

Battery electrolyte is dangerous;

it

contains

sulfuric acid and therefore is poisonous and

highly caustic.

Always follow these preventive measures:

*Avoid bodily contact with electrolyte as

can cause severe burns or permanent eye

injury.

*Wear protective eye gear when handling or

working near batteries.

Antidote (EXTERNAL):

*SKIN- Flush with water.

15

*EYES-Flush with water for

minutes and

get immediate medical attention.

Antidote (INTERNAL):

*Drink large quantities of water of milk. Fol-

low with milk of magnesia, beaten egg, or

vegetable oil. Get immediate medical attention.

Batteries also generate explosive hydrogen

gas, therefore you should always follow

these preventive measures:

*Charge batteries in a well-ventilated area.

*Keep batteries away from fire, sparks,

or

open flames (e.g., welding equipment,

lighted cigarettes,

etc.)

it

Page 68

inspection

@Connect the Pocket Tester to the fuse and

check

steps:

it

for continuity.

-

Set the tester selector to

"Q

x

1"

position.

elf the tester is indicated at

blown, replace

4.

Replace:

@Blown fuse

@Turn off ignition and the circuit.

a

elnstall

@If

fuse blows immediately again, check circuit

new fuse of proper amperage.

it.

3-28

a.

The fuse is

Page 69

'I.

Adjust:

@Headlight beam (Vertical)

2.

Adjust

@Headlight beam (Horizontal)

T

@Lower cowling

*Flasher lights (Left and right)

sflasher light stay

Refer to "COWLINGS" section.

2.

Remove:

@Headlight

3

Install:

@

@Headlight (New)

Install:

@Flasher light stay

@Flasher lights (Left and right)

@Lower cowling

Adjust:

@Headlight beam

Refer to "HEADLIGHT BEAM ADJUST-

MENT"

section.

Page 70

Page 71

@Autolube pump

@Transmission oil

section.

@Front seat

section.

'1.

Turn

the fuel cock to

connect the

fuel

"

hose

FF"

position and

@.

dis-

2.

Remove:

@Fuel tank

Page 72

VAL

U

@Autolube pump cover

@Autolube pump cable

@Oil

hose

a

Plug the oil hose

end

@

with a suitable screw.

Page 73

eNecatral switch leads

crankcase

oGasket (Crankcase

RBVE

cwim

Loosen:

adjuster

2.

Push

forward

drive

chain.

cover (Left)

@

a

cover

t

e

rear

-

wheel

Left)

to

loosen the

Page 74

.

Place

a

suitable

stand

under

the

engine.

Page 75

Q

Lower cowlin

0Muffler

2.

Remove:

~Gaske?

cylinder

gasket

~Intake rnanifoid

(Cylinder head)

@J

(Cylinder)

@

@

ing

into crankcase cavity.

--

pin circlip, cover crank-

Page 76

out.

CLUTCH

TE:

Bower

2,

IYsi-xve:

8

Boles

^Springs

AND

cowl

(Pressure

(Pressure

PRIMARY

-

plate)

plats)

-

.:,

--

-

Page 77

4.

Remove:

Use the Universal Clutch

the

clutch

lace a folded rag

primary drive gear and driven gear.

boss.

imary drive gear)

a

between

Holder

@

the

teeth of the

Page 78

[owing parts.

1.

Unhook the sprin

mounted, the

maintained by removing the

cable and hoses

kick

axle

and

m

kick

fol-

@Kick

axle assembly

a

Page 79

NOTE:

With

the

engine

be

mainlained by

Lower

covviiiyj

-

1.

Remove:

mounted,

removing

---

Rotor

the

the

-..--

CDB

ma

fcallo

Holder

-

a

to

-.

hold

Page 80

Use

rotor.

the

Flywheel

Puller

a

to

remove

the

loosened.

hift

cam

stopper)

ttern, loosen

them

all

after

screws

all

are

Page 81

NOTE:

sure the

"14s

front engine mounting

and

Use

only

tap

a;qd

separate

pressure

start

check

Do

-

--

hten

the

tool holdin bolts, but make

fool

body

one

screw

pressure

shift cam.

soft

on asinforced

sn

gasket mati g surface.

carsffuiiy. Make sure

over.

For

not

hammer

evenly.

of8

BB

a

remaisping

force.

is

a

plied, alternately tap

to

If

the

push

the

--

-=-

TRANSMQSSBObJ,

-

P

is parallel

may

be

backed

boss,

transmission shafts,

tap

on

the

ortiona

the

one

wad

"'hangs

screw, realign,

eases

do

case screw

SHiFTER

with

case

of

case.

Wdwk

not

---

AND

the

ease,

out

slightly

on

half. Tap

Do

s!owOy

ease

hahes

up,"

separate,

~t.

fitting.

Ef

the

not

take

and

Remove

the

transmission

assern

Page 82

Page 83

INSPECTION AND REPAIR

INSPECTION AND REPAIR

CYLINDER HEAD

1.

Eliminate:

.Carbon deposits

Use a rounded scraper.

NOTE:

Take care to avoid damaging the spark plug

threads. Do not use a sharp instrument. Avoid

scratching the aluminum.

-

--

-

2.

Measure:

.Cylinder tiead warpage

Out of

Warpage measurement and resurfacement steps:

.Attach a straight edge

gauge

.Measure the warpage.

.If the warpage is out of specification, resur-

face the cylinder head.

Place a

surface plate, and resurface the head using

a figure-eight sanding pattern.

NOTE:

Rotate the head several times to avoid remov-

ing too much material from one side.

specification-+Resurface.

Warpage Limit:

0.02

mm

(0.001

@

on the cylinder head.

400

-

600

grit wet sandpaper on the

I

ENG

-

--

in)

@

and a thickness

/

~o)(

CYLINDER AND PISTON

1.

Eliminate:

.Carbon deposits

From the piston crown and ring grooves.

2.

Eliminate:

.Score marks and lacquer deposits

From the sides of piston.

Use a

NOTE:

Sand in a crisscross pattern. Do not sand exces-

sively.

3.

Inspect:

.Piston wall

600-800

grit wet sandpaper.

Page 84

INSPECTION AND REPAIR

4.

Remove:

.Carbon deposits

Use a rounded scraper.

5. Measure:

*Piston-to-cylinder clearance

Piston-to-cylinder clearance measurement

steps:

First Step:

Measure the cylinder bore "C" with a Cylinder

Bore Gauge.

NOTE:

Measure the cylinder bore "C" in parallel to and

at

right angles to the crankshaft. Then, find the

average of the measurements.

-1

Standard Wear Limit

"C"

TaperJ1T"

)ut of Round 0.01 mm

"R"

C=

Maximum D

T= (Maximum Dl, or D2)-

(Maximum Ds or D6)

R = (Maximum Dl,

(Minimum

.If out of specification, rebore or replace

cylinder, and replace piston and piston rings

as a set.

Second Step:

@Measure the piston skirt diameter

a micrometer.

a

5

mm

edge.

(0.20

1

1

in)

-

-

D3

or D5)-

Dz

D4 or D6)

from the piston bottom

0.05 mm

/

10.0019 in)

1

10.0004 in1

"P"

with

Page 85

INSPECTION AND REPAIR

I

ENG

I

\j(

Piston size

fz

"

-

-

39.96-39.98

-

(1.573

mm

40.25

40.50

mm

--

=

Standard

Oversize 1

Oversize

*If out of specification, replace piston and

piston rings as a set.

Third Step:

*Calculate the piston-to-cylinder clearance with

following formula:

Piston-to-cylinder Clearance

Cylinder Bore "C"

Piston Skirt Diameter "P"

*If out of specification, rebore or replace

cylinder, and replace piston and piston rings

as a set.

Piston-to-cylinder Clearance:

2

P

mm

1.574 in)

(1.58 in)

(1.59 in)

(0.0012 - 0.0014

Limit:

PISTON RINGS

1.

Measure:

*Side clearance

Out of

rings.

Use a Feeler Gauge

Clearance 0.03-0.05

0.1

specification+Replace piston and/or

mm

in)

(0.004

in)

@.

0.03-0.05

(0.001 - 0.002 in)

mm

mm

Page 86

INSPECTION AND REPAIR

2.

Install:

*Piston ring

lnto the cylinder.

Push the ring with the piston

3. Measure:

*End gap

Out of

specification-+Replace r

Use a Feeler Gauge.

I

ENG

1

a-1

crown.

ings as

a

set.

0.15-0.35

14

PISTON PIN AND BEARING

1.

2.

End

Gap

Oversize Piston Ring

Oversize 1

Oversize

Lubricate:

*Piston pin (Lightly)

Install:

.Small end bearing

*Piston pin

lnto the small end of connecting rod.

1

2

:ll

1

(0.006-0.014 in1

0.15-0.35

(0.006-0.014 in)

mm

I

mrn

3.

Check:

*Free play

There should be no noticeable free play.

Free play exists+lnspect the connecting rod

for wear1Replace the pin and/or connecting rod as required.

4.

Install:

@Piston pin

lnto the piston pin hole.

Page 87

INSPECTION AND REPAIR

5.

Check:

.Free play (when the piston pin

the piston)

There should be no noticeable free play.

Free play exists-+ Replace piston pin and/or

piston.

6.

Inspect:

.Piston pin and bearing

Signs of heat discoloration-+Replace.

CLUTCH

1.

Inspect:

.Friction plate

Damage/Wear-+Replace friction plate as a

set.

2.

Measure:

.Friction plate thickness

Out of specification-+Replace friction plate

as a set.

Measure at all four points.

(

ENG

1

\jl

is

in place in

'C(

Wear

3.

Inspect:

.Clutch plate

Damage+Replace clutch plate as a set.

4.

Measure:

.Clutch plate warpage

Out of specification+Replace clutch plate

as a set.

Use

Warp

Limit: 2.7

a

surface plate and Feeler Gauge

Limit: 0.05 mm (0.002 in)

mm

(0.106 in)

a.

5. Inspect:

.Clutch damper

Wear/ Damage-+ Replace.

Page 88

INSPECTION AND REPAIR

6.

Measure:

*Clutch spring free length

Out of specification+Replace spring as a

set.

Clutch Spring Minimum Length:

26.2

mm

(1.03

7. Inspect:

*Dogs on the clutch housing

Cracks/Wear/Damage+Deburr

*Clutch housing bearing

ScoringlWear/Damage+Replace clutch

housing.

NOTE:

Scoring on the clutch housing dogs will cause

erratic operation.

[

ENG

in)

1

@

or replace.

8.

Inspect:

*Clutch boss splines

Scoring1 Wear/

boss.

NOTE:

Scoring on the clutch boss splines will cause erratic operation.

9. Check:

*Circumferential play

Free play