YAMAHA XT1200Z(Z) ASSEMBLY MANUALS

2010

ASSEMBLY MANUAL

XT1200Z(Z)

23P-28107-E0

EAA00030

FOREWORD

This Assembly Manual contains the information required for the correct assembly of this Yamaha vehicle

prior to delivery to the customer. Since some external parts of the vehicle have been removed at the

Yamaha factory for the convenience of packing, assembly by the Yamaha dealer is required. It should be

noted that the assembled vehicle should be thoroughly cleaned, checked, and adjusted prior to delivery

to the customer.

EAA00050

IMPORTANT

The service specifications given in this assembly manual are based on the model as manufactured.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will

appear in future editions of this manual where applicable.

The procedures below are described in the order that the procedures are carried out correctly and completely. Failure to do so can result in poor performance and possible harm to the vehicle and/or rider.

Particularly important information is distinguished in this manual by the following notations.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

WARNING

NOTICE

TIP

A WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

A NOTICE indicates special precautions that must be taken to avoid damage to the vehicle or other property.

A TIP provides key information to make procedures easier or clearer.

EAA00020

XT1200Z(Z)

ASSEMBLY MANUAL

©2010 by Yamaha Motor Co., Ltd.

First edition, February 2010

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Co.,Ltd.

is expressly prohibited.

EAA00060

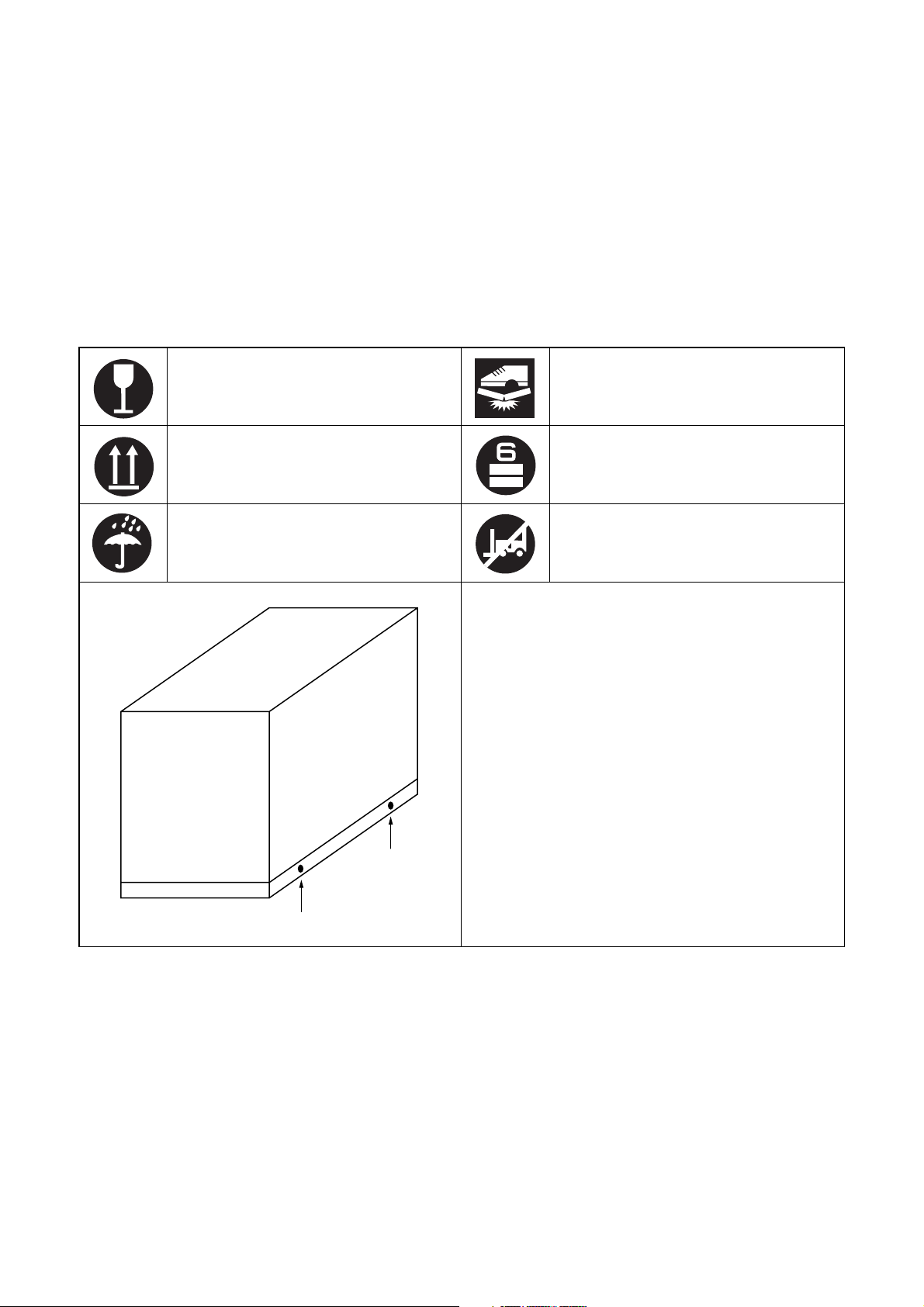

SYMBOLS USED IN THE ASSEMBLY MANUAL

In order to simplify descriptions in this assembly manual, the following symbols are used:

SYMBOL DEFINITION SYMBOL DEFINITION

Filling fluid Coat with lithium-soap-based grease.

Lubricant

Special tool Towards the front of the vehicle

Tightening torque Clearance required

T

.

R

.

Wear limit, clearance

FWD

UP

Tighten to 10 Nm.

(10 Nm = 1.0 m·kgf, 7.2 ft·lbf)

10

Install so that the arrow mark faces

upward.

Engine speed Apply motor oil.

Electrical data Made of rubber or plastics

A: Ref. No. (indicating the order of operations.)

B: Part name

C: Quantity of parts per vehicle

D: Place where parts are held

(1): Refer to “PARTS LOCATION”.

V: Stored in plastic bag

C: Stored in carton box

S: Fixed inside the steel frame and/or con-

tained in the Styrofoam tray (upper or

D

d

d

lower)

: Temporarily installed or secured

*

Example:

(1)-V

D

d

d

(1) signifies the location of the parts and V signifies that the part is stored in a plastic bag.

E: Size or material of parts

d/D: Diameter of part

: Length of part

e.g., 5 (0.20) = 5 mm (0.20 in)

EAA00070

PREPARATION

To assemble the vehicle correctly, supplies (e.g. oils, greases, and shop rags) and sufficient working

space are required.

Workshop

The workshop where the vehicle is assembled should be clean, spacious, and have a level floor.

Self-protection

Protect your eyes with suitable safety glasses or goggles when using compressed air, when grinding or

when doing any operation which may cause particles to fly off.

Protect hands and feet by wearing safety gloves and shoes.

EAA00080

SYMBOLS USED ON TRANSPORT PACKAGE COVER

Contents of the transport package

are fragile, therefore the package

must be handled with care.

Indicates correct upright position of

the transport package.

Transport package must be kept

away from rain.

Do not step anywhere on the transport package.

Up to 6 of the transport packages can

be piled up.

Insertion of the forklift arms from this

side can cause damage.

Yellow labels (1)

Lift arm insertion positions

If the forklift arms cannot be inserted under the

transport package in alignment with the two yellow labels, adjust the arms so that they are positioned evenly in relation to these marks while

taking care not to damage the package contents.

(1)

(1)

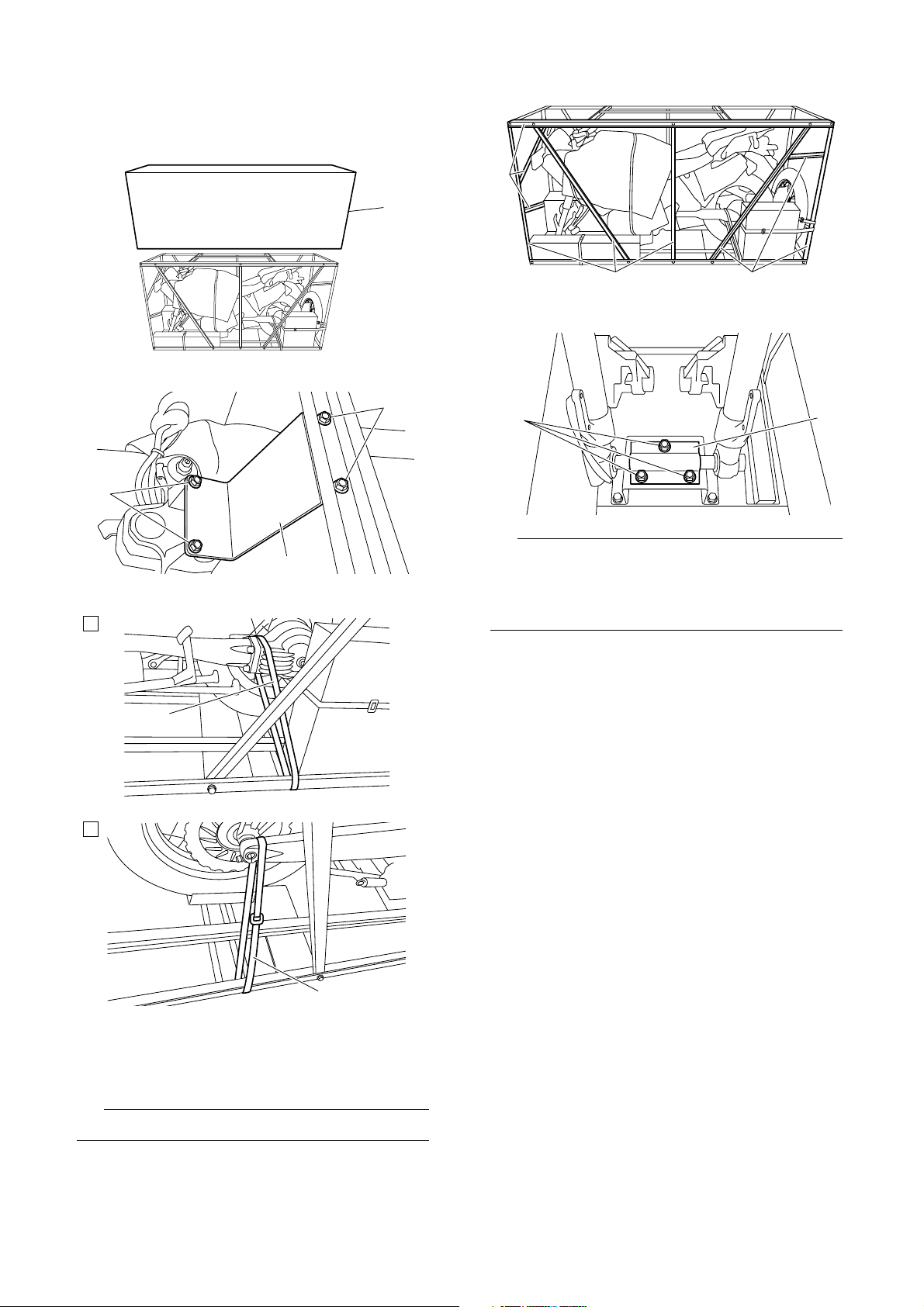

EAA00090

T

T

UNPACKING

1. Remove the frame cover “1”.

2. Remove the bolts “2” and bracket “3”.

5

1

55

5. Remove the bolts “6” and holder “7”.

2

3. Remove the bands “4”.

A

4

B

2

67

IP

Before starting the assembly, check for dam-

3

aged or missing parts. Check both the parts

contained in the carton boxes and on the vehicle for damage, scratches, and other defects.

4

A. Left side

B. Right side

4. Remove the packing frames “5”. (Lift up and

then move to the side.)

IP

Remove the bolts while holding the frame.

1

EAA00101

PARTS LOCATION

NOTICE

• Do not use a cutter, scissors, or other sharp object to open the carton boxes; otherwise, the

included parts could be damaged.

• Wear suitable protective gear such as gloves when handling and opening the carton boxes.

1,2,3,4,5

8

6

9

1. Bubble wrap pack 1

2. Bubble wrap pack 2

3. Bubble wrap pack 3

4. Bubble wrap pack 4

5. Bubble wrap pack 5

6. Plastic bag

7. Plastic bag

8. Carton box 1

9. Carton box 2

10.Carton box 3

11.Front wheel

7

11

10

2

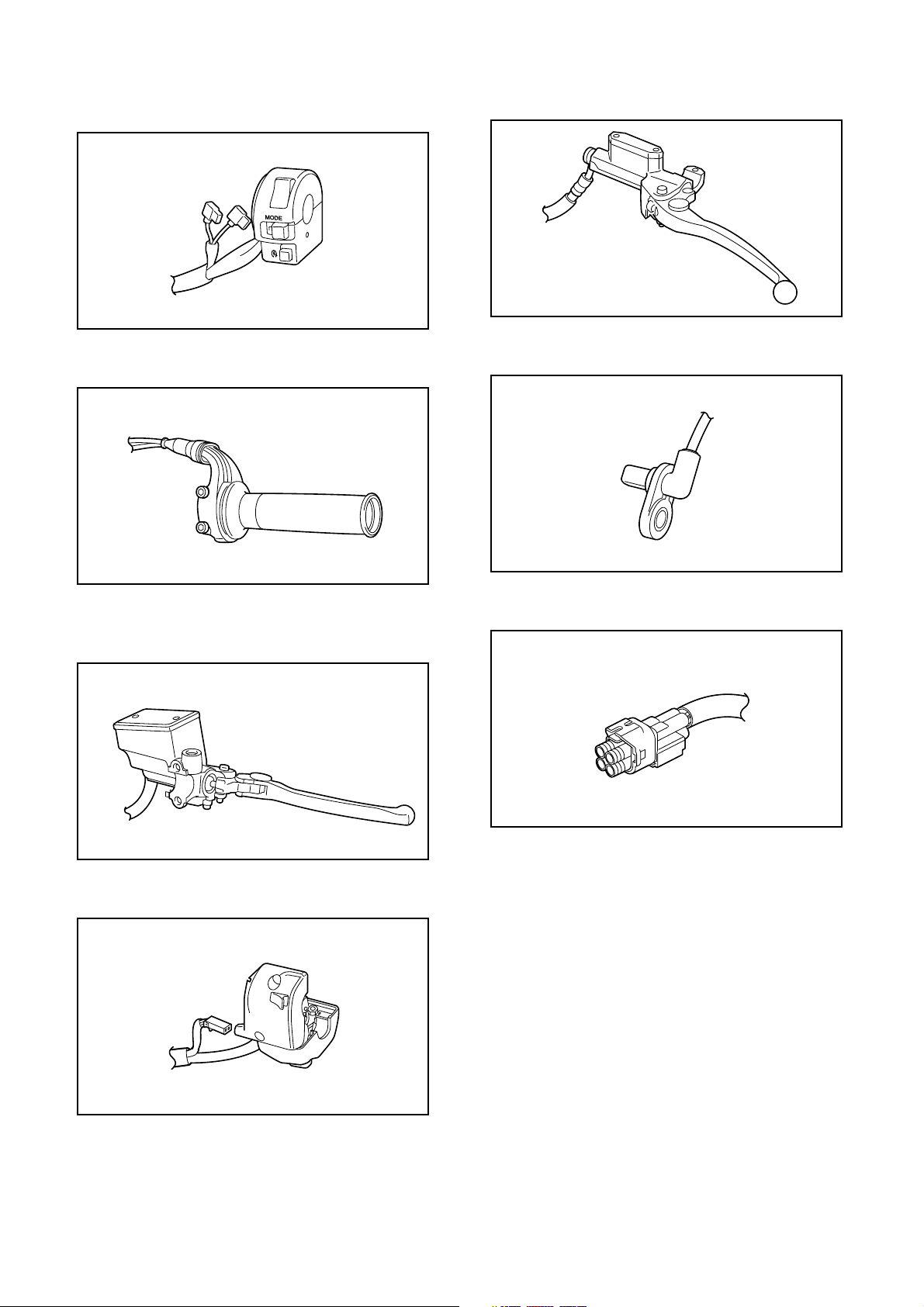

EAA00110

(1) Bubble wrap pack 1

(5) Bubble wrap pack 5

1

1. Right handlebar switch

(2) Bubble wrap pack 2

1

1. Throttle grip and throttle cable housing

assembly

1

1. Clutch master cylinder

(6) Plastic bag

1

1. Front wheel sensor

(7) Plastic bag

(3) Bubble wrap pack 3

1

1. Front brake master cylinder

(4) Bubble wrap pack 4

1

1

1. ABS test coupler

1. Left handlebar switch

3

(8) Carton box 1

7

8

12

14

13

16

19

22

1. Front fender

2. Rearview mirrors

21

43

65

11910

1715

2018

2321

3. Left hand shield

4. Right hand shield

5. Engine guard

6. Owner’s manual

7. Grip ends

8. Plastic bag

9. Windshield brackets

10.Hand shield upper brackets

11.Hand shield lower brackets

12.Plastic holder

13.Plastic locking tie

14.Plastic bag

15.Hexagon socket bolts (grip end)

[d = 8 (0.31), = 60 (2.36)]

16.Hexagon socket bolts (front fender)

[d = 6 (0.24), = 22 (0.87)]

17.Hexagon socket bolt (front fender)

[d = 6 (0.24), = 30 (1.18)]

18.Self-locking nut (front fender)

[d = 6 (0.24)]

19.Nut shields (windshield)

[d = 5 (0.20)]

20.Screws (windshield)

[d = 5 (0.20), = 20 (0.79)]

21.Hexagon socket bolts (hand shields)

[d = 5 (0.20), = 10 (0.40)]

22.Collars (hand shield upper side)

[d = 5.5 (0.22), D = 16 (0.63)]

23.Collars (hand shield lower side)

[d = 5 (0.20), D = 12 (0.47)]

24.Collars (grip end side)

[d = 8 (0.31), D = 20 (0.79)]

25.Cap nuts (engine guard)

[d = 6 (0.24)]

26.Hexagon socket bolts (engine guard)

[d = 6 (0.24), = 32 (1.26)]

27.Plastic bag

28.Reflector assembly (right side) (for AUS)

29.Flange nut (reflector) (for AUS)

[d = 6 (0.24)]

30.Reflector (for AUS)

27

25

2624

3028 29

4

(9) Carton box 2

1

2

3

7. Front brake master cylinder holder

8. Hexagon socket bolts (front brake master cylinder holder) [d = 6 (0.24), = 20 (0.79)]

9. Clutch master cylinder holder

10.Hexagon socket bolts (clutch master cylinder

holder) [d = 6 (0.24), = 22 (0.87)]

11.Screws (left handlebar switch)

[d = 5 (0.20), = 25 (0.98)]

12.Washers (left handlebar switch)

[d = 5 (0.20), D = 9 (0.35)]

13.Plastic bands

14.Front wheel sensor lead holder

15.Front wheel sensor lead guide (for EUR)

16.Hexagon socket bolt (front wheel sensor)

54

[d = 6 (0.24), = 14 (0.55)]

17.Reflector bracket (left side) (for AUS)

(10)Carton box 3

6

7

1

8

9

1110

1. Windshield

(11)Front wheel

1312

1

1514

1716

1. Front wheel

1. Handlebar

2. Front wheel sensor housing

3. Plastic bag

4. Upper handlebar holders

5. Flange bolts (upper handlebar holder)

[d = 8 (0.31), = 35 (1.38)]

6. Collar (front wheel)

[d = 22 (0.87), D = 31 (1.22)]

5

EAA00120

T

XT1200Z(Z) SETUP AND PREDELIVERY CHECKLIST

IP

Check the following items again after setup and predelivery service have been completed.

A: INSTALLATION OF THE PARTS INCLUDED IN THE CRATE

à FRONT WHEEL

à FRONT FENDER

à HANDLEBAR

à RIGHT HANDLEBAR SWITCH

à THROTTLE GRIP AND THROTTLE CABLE

HOUSING ASSEMBLY

à FRONT BRAKE MASTER CYLINDER

à LEFT HANDLEBAR SWITCH

à CLUTCH MASTER CYLINDER

à PLASTIC BANDS

B: TIGHTENING TORQUE OF EACH PART

à Front wheel axle 72 Nm (7.2 m·kgf, 52 ft·lbf)

à Front wheel axle pinch bolt 21 Nm (2.1 m·kgf, 15 ft·lbf)

à Front brake caliper bolt 40 Nm (4.0 m·kgf, 29 ft·lbf)

à Front wheel sensor bolt 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

à Reflector nut (for AUS) 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

à Front fender bolt 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

à Upper handlebar holder bolt 28 Nm (2.8 m·kgf, 20 ft·lbf)

à Right handlebar switch screw 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

à Throttle cable housing bolt 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

à Front brake master cylinder holder bolt 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

à Left handlebar switch screw 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

à Clutch master cylinder holder bolt 14 Nm (1.4 m·kgf, 10 ft·lbf)

à Grip end bolt 27 Nm (2.7 m·kgf, 20 ft·lbf)

à Rearview mirror 17 Nm (1.7 m·kgf, 12 ft·lbf)

à Clutch lever pivot nut 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

à Brake lever pivot nut 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

à Hand shield lower bolt 4.5 Nm (0.45 m·kgf, 3.3 ft·lbf)

à Hand shield upper bolt 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

à Windshield screw 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

à Engine skid plate bolt 4.5 Nm (0.45 m·kgf, 3.3 ft·lbf)

à Engine skid plate nut 4.5 Nm (0.45 m·kgf, 3.3 ft·lbf)

à LEFT REARVIEW MIRROR AND LEFT HAND

SHIELD

à RIGHT REARVIEW MIRROR AND RIGHT HAND

SHIELD

à WINDSHIELD

à RIDER SEAT AND ABS TEST COUPLER PROTEC-

TIVE CAP

à ENGINE GUARD

à BATTERY

C: ROUTING OF WIRE, CABLES, ETC.

à Front brake hose

à Front wheel sensor lead

à Throttle cable (accelerator cable)

à Throttle cable (decelerator cable)

à Right handlebar switch lead

à Left handlebar switch lead

à Clutch hose

à ABS test coupler lead

à Negative battery lead

à Positive battery lead

6

D: ADJUSTMENTS

à CHECKING AND CHARGING THE BATTERY

à MEASURING THE TIRE PRESSURE

à CHECKING THE ENGINE OIL LEVEL

à CHECKING THE FINAL GEAR OIL LEVEL

à CHECKING THE COOLANT LEVEL

à ADJUSTING THE THROTTLE CABLE FREE

PLAY

à ADJUSTING THE FRONT BRAKE

à ADJUSTING THE REAR BRAKE LIGHT SWITCH

à CHECKING THE BRAKE FLUID LEVEL

à BLEEDING THE HYDRAULIC BRAKE SYSTEM

(ABS)

à ADJUSTING THE CLUTCH LEVER

à CHECKING THE CLUTCH FLUID LEVEL

à BLEEDING THE HYDRAULIC CLUTCH SYSTEM

à ADJUSTING THE FRONT FORK LEGS

à ADJUSTING THE REAR SHOCK ABSORBER AS-

SEMBLY

à ADJUSTING THE HEADLIGHT BEAMS

E: FUNCTION AND PERFORMANCE

à Check the function of the headlight, meter light and

taillight

à Check the function of the brake light

à Check the function of the turn signals and indicator

lights

à Check the tone quality of the horn

à Check the function of the indicator on the speedom-

eter

à Check the feel of the brakes

à Check engine for irregular noise (Yes/No)

à Check for exhaust leak (Yes/No)

F: ACCESSORIES, ETC. FOR DELIVERY

à Owner’s manual à Owner’s tool kit

7

EAA00130

SETUP PROCEDURES

Perform the setup procedures in the order indicated by the numbers. Always follow the order as

shown.

13 12 2 1

1415

116810

5397 49

8

Loading...

Loading...